Shockproof relay

A technology of relays and shrapnel, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of reduced working life of relays, inconvenient automatic assembly, and reduced work stability, so as to achieve a clean and environmentally friendly production environment and easy automatic assembly , the effect of simple structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the anti-shock relay provided by the embodiment of the present invention, the yoke 1 or the armature 2 will not move in series even under the condition of vibration, and the edge of the yoke 1 and the edge of the armature 2 are always in contact with each other. The assembly is convenient, the product consistency is high, and it is easy to realize automatic assembly.

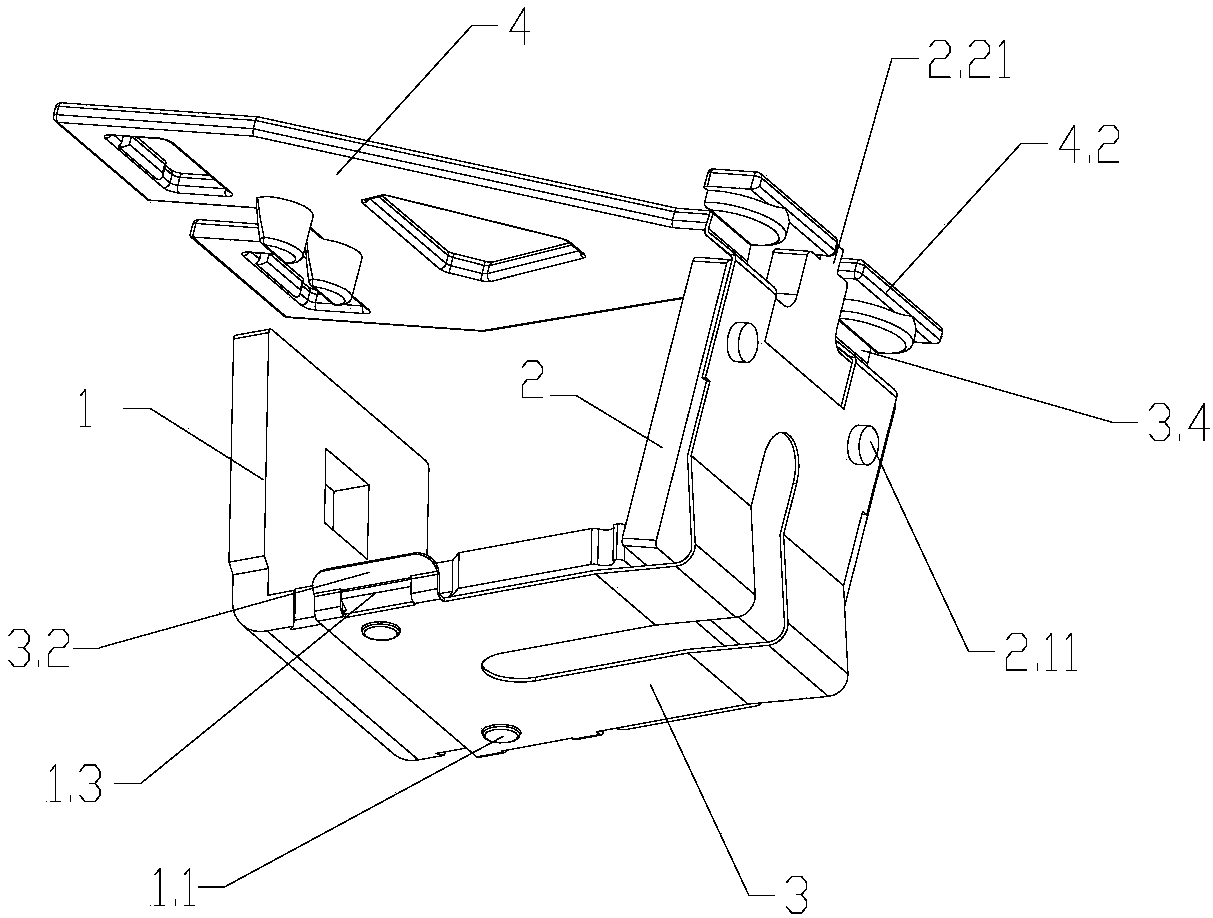

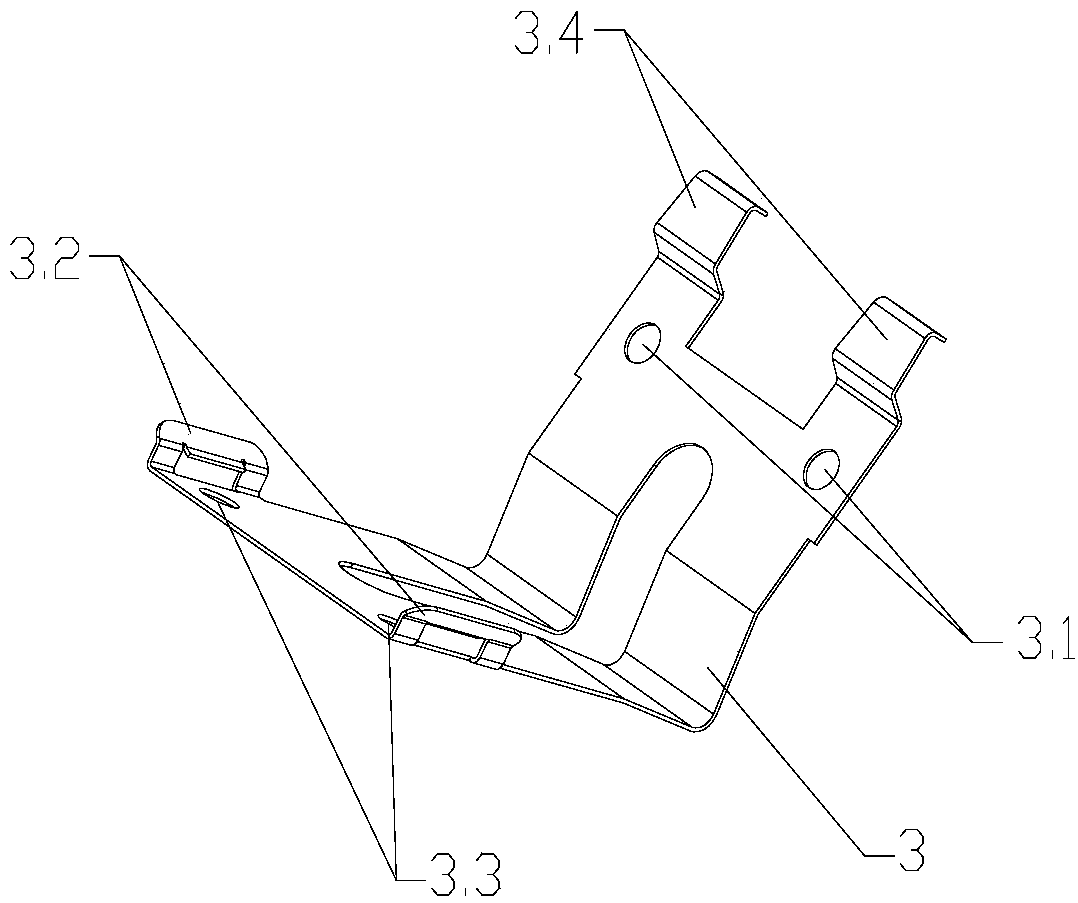

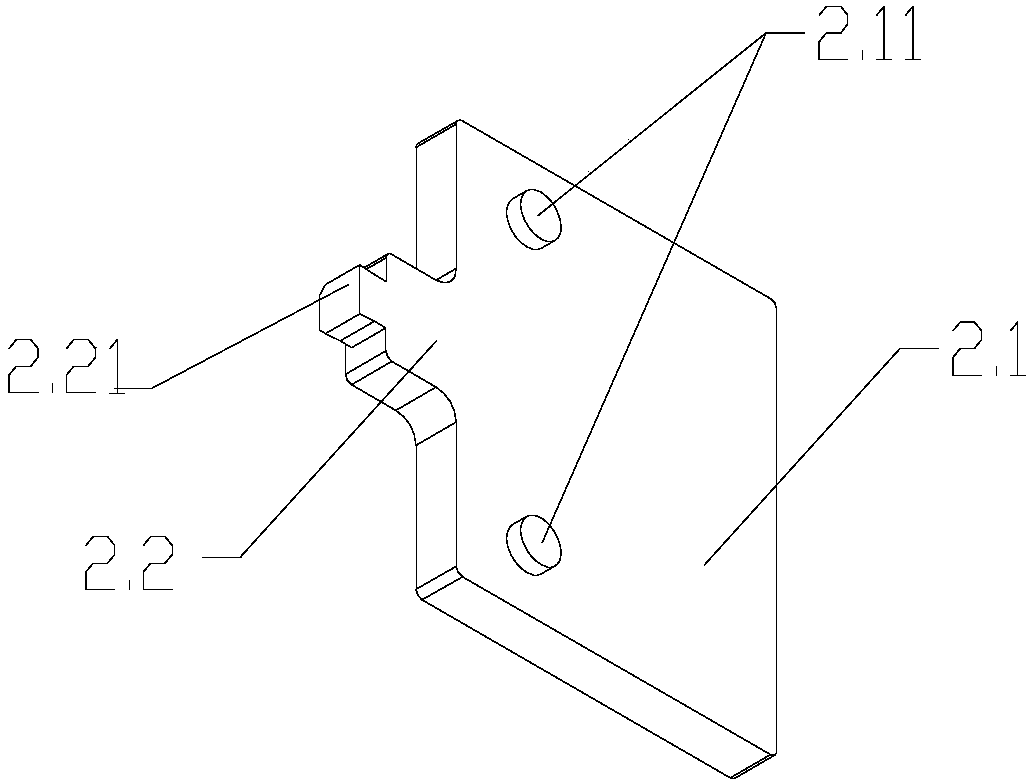

[0021] Such as figure 1 As shown, the anti-shock relay provided in this embodiment includes a yoke 1, an armature 2, a shrapnel 3 and a push rod 4. The shrapnel 3 is an "inverted L-shaped" integrated front and rear symmetrical structure, in which the two armature holes in the vertical section are riveted 3.1 Riveted with the two protruding shrapnel riveting terminals 2.11 on the outer wall of the armature 2, the two trapezoidal bending structure stoppers 3.4 on both sides of the tail of the vertical section are pushed against the retaining groove 4.22 of the shrapnel connection end 4.2 of the push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com