Lithium ion battery and combination method of pole pieces thereof

A lithium-ion battery and pole piece technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfavorable mass production, expansion, and high equipment requirements, and achieve good rate discharge performance, simple operation, and good safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

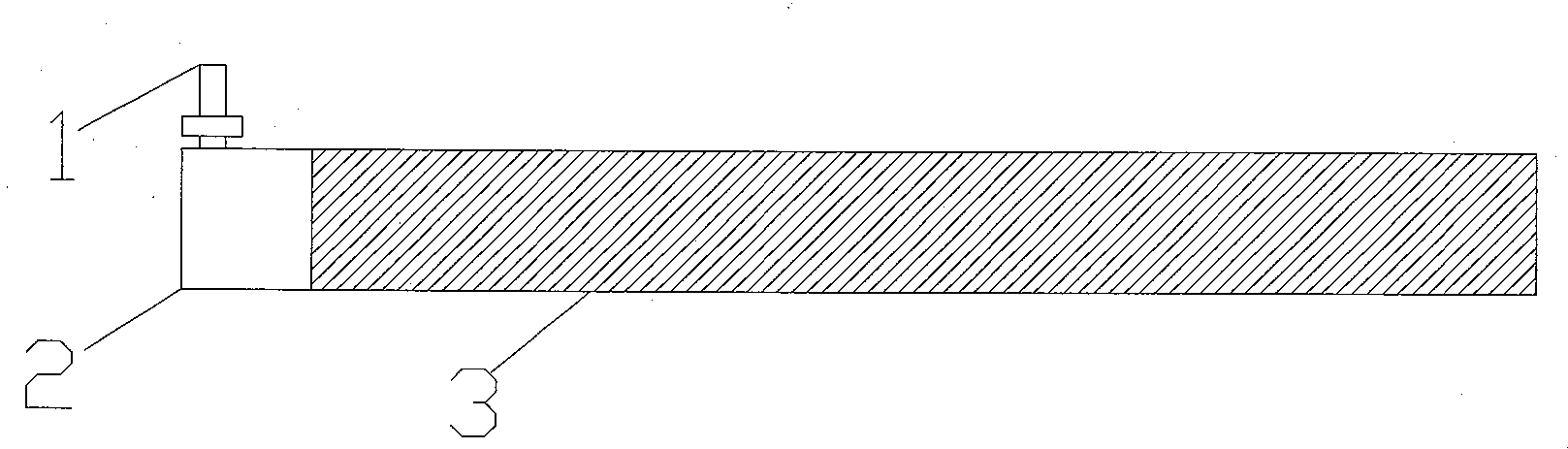

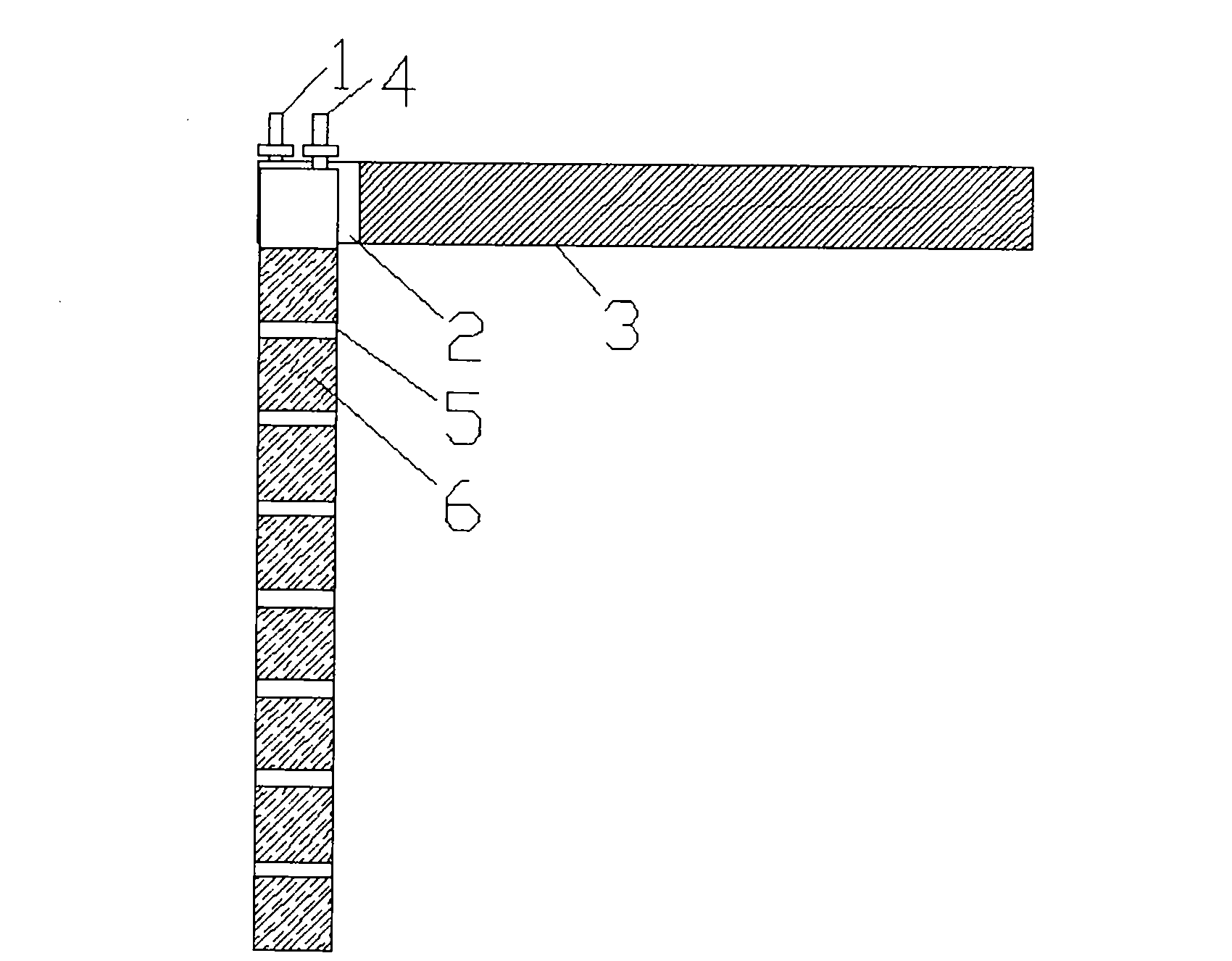

[0047]Taking the prismatic lithium-ion battery of model 656790 (the thickness of the finished battery is 6.5mm, the width is 67mm, and the length is 90mm) as an example, the design capacity of the battery is 4Ah. Graphite is used as the negative electrode active material, and the negative electrode active material and the conductive agent, the binder and the thickener are made into a negative electrode slurry in a mass ratio of 94:2:2:2, coated on the negative electrode current collector 2, and subjected to cold pressing , slitting, and welding the negative electrode lug 1 on the head of the pole piece to prepare a negative pole piece; use LiCoO 2 As the positive electrode active material, the positive electrode active material, the conductive agent, and the binder are made into a positive electrode slurry in a mass ratio of 96:2:2, coated on the positive electrode current collector 5, and subjected to processes such as cold pressing, slitting, and welding. It is prepared as a...

Embodiment 2

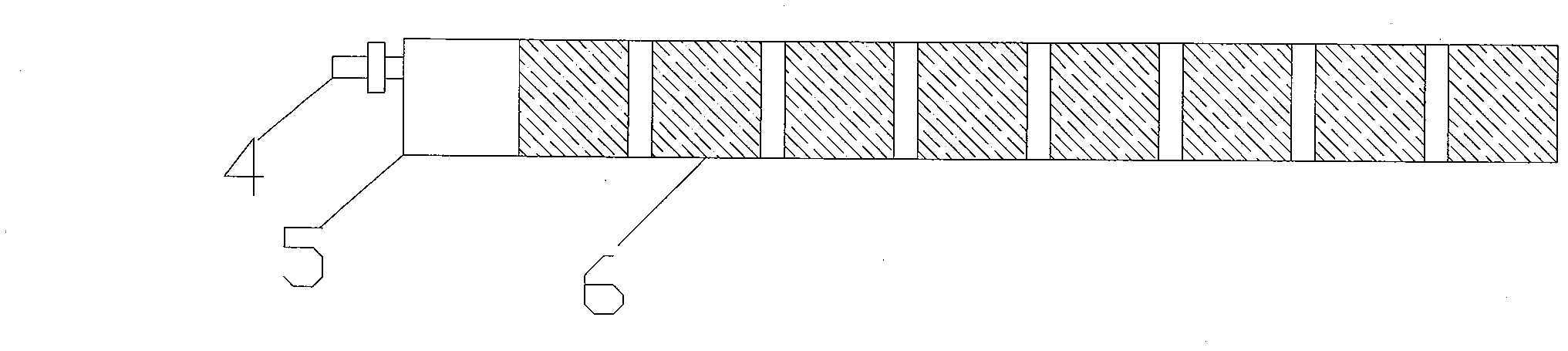

[0064] Taking the prismatic lithium-ion battery of model 486789 (the thickness of the finished battery is 4.8mm, the width is 67mm, and the length is 89mm) as an example, the design capacity of the battery is 3Ah. Graphite is used as the negative electrode active material, and the negative electrode active material and the conductive agent, the binder and the thickener are made into a negative electrode slurry in a mass ratio of 94:2:2:2, coated on the negative electrode current collector 2, and subjected to cold pressing , slitting, welding and other processes to prepare a negative electrode sheet, wherein the negative electrode sheet includes four negative electrode tabs 1 evenly distributed on the negative electrode sheet (see Figure 6 ); using LiCoO 2 As the positive electrode active material, the positive electrode active material, the conductive agent, and the binder are made into a positive electrode slurry in a mass ratio of 96:2:2, coated on the positive electrode cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com