Glass rod sintering furnace used for making optical fiber preform

A technology for optical fiber prefabricated rods and glass rods, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of consuming cold furnace downtime and maintenance downtime, damaging glass rods, glass tube workpieces, and affecting production progress, etc., to achieve It is easy to manufacture and maintain, improve the service life, and have the effect of reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

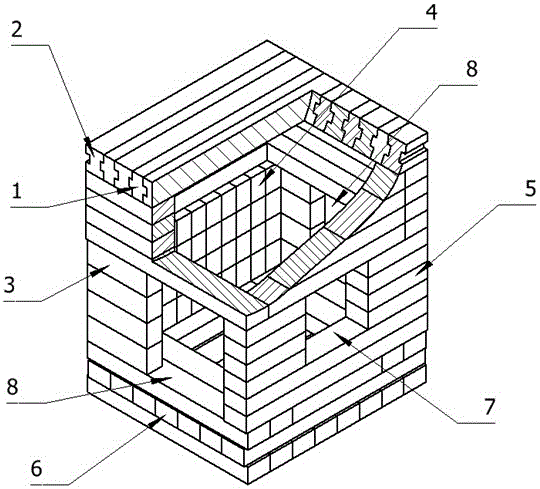

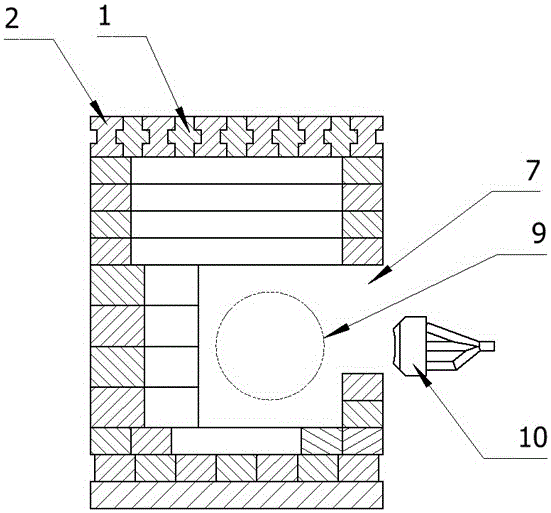

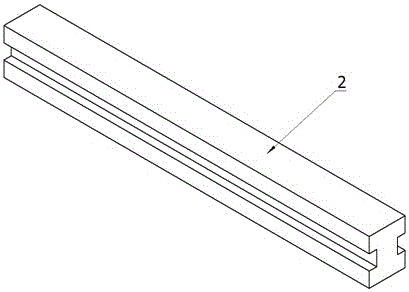

[0017] It includes a box-shaped furnace body. The furnace body includes two sides 3, front and rear sides 5, 4, bottom surface 6 and top surface. The two sides are correspondingly provided with a rod-threading window 8. The rod-threading window is a square, which is convenient for glass preforms. 9, a gas torch window 7 is provided in front of the body of furnace to install the gas torch 10. The two sides, the front, the back and the bottom surface are all spliced by quartz glass strips and quartz glass blocks. The cross section is rectangular; the top surface is constructed by splicing and inlaying quartz glass strip-shaped top bricks with tenons and grooves on the sides, and the strip-shaped top bricks include convex strips with longitudinal tenons symmetrically arranged on both sides. The top brick 1 and the concave strip top brick 2 with longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com