Patents

Literature

65results about How to "Flow loss minimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Outlet guide vanes for axial flow fans

ActiveUS20100119366A1Flow loss minimizationMaximize static pressure recoveryPump componentsStatorsGradual increaseTip clearance

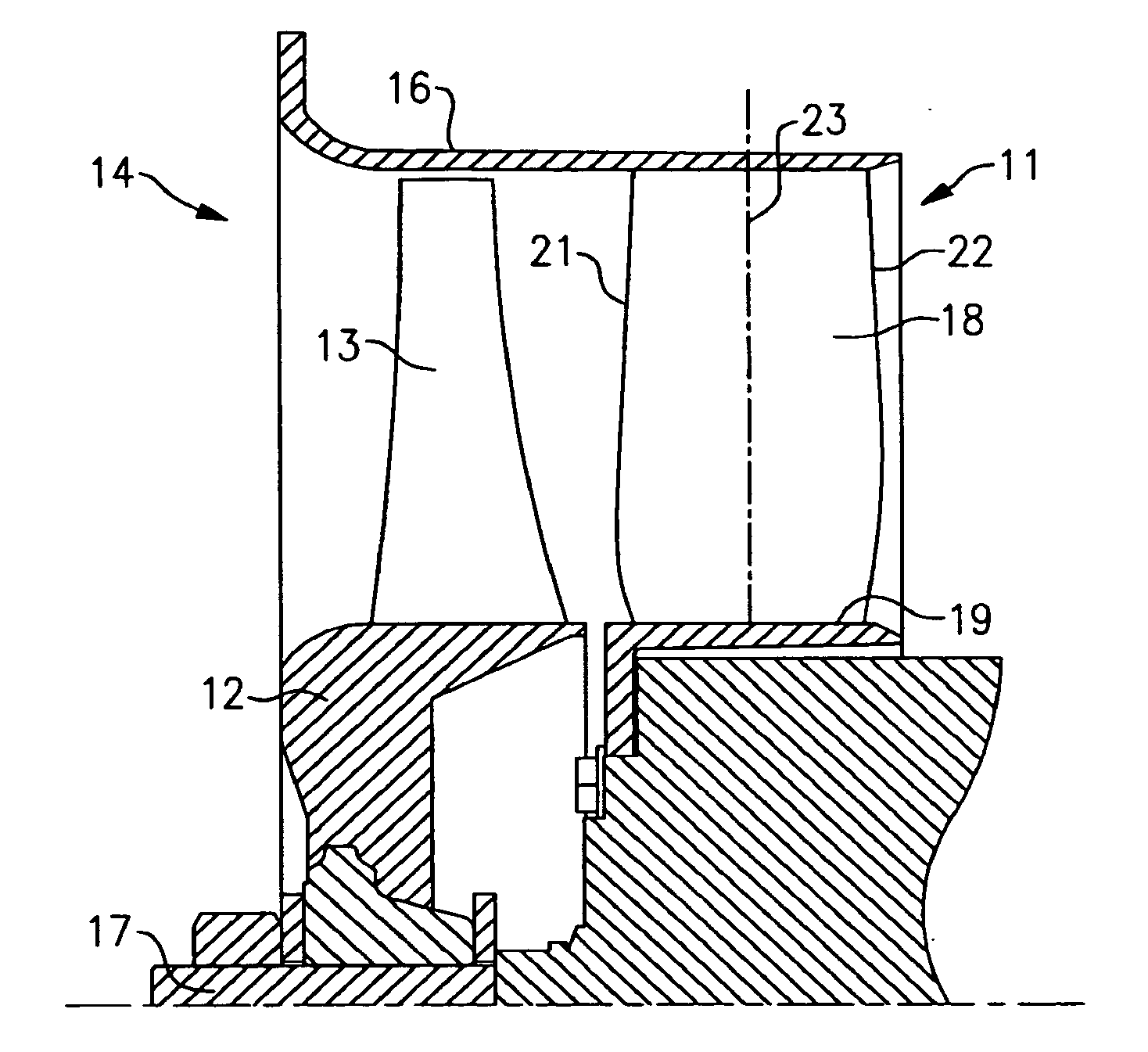

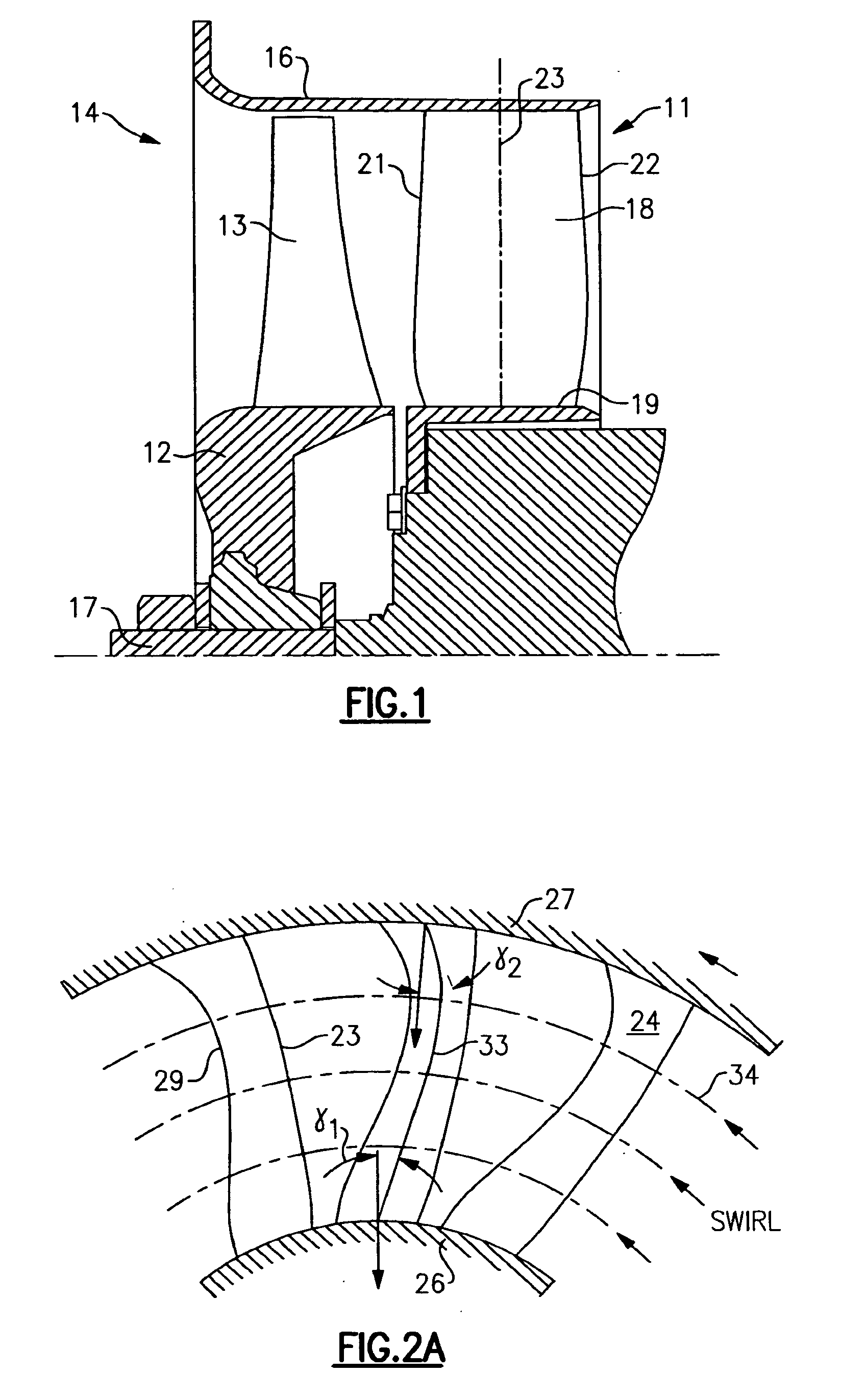

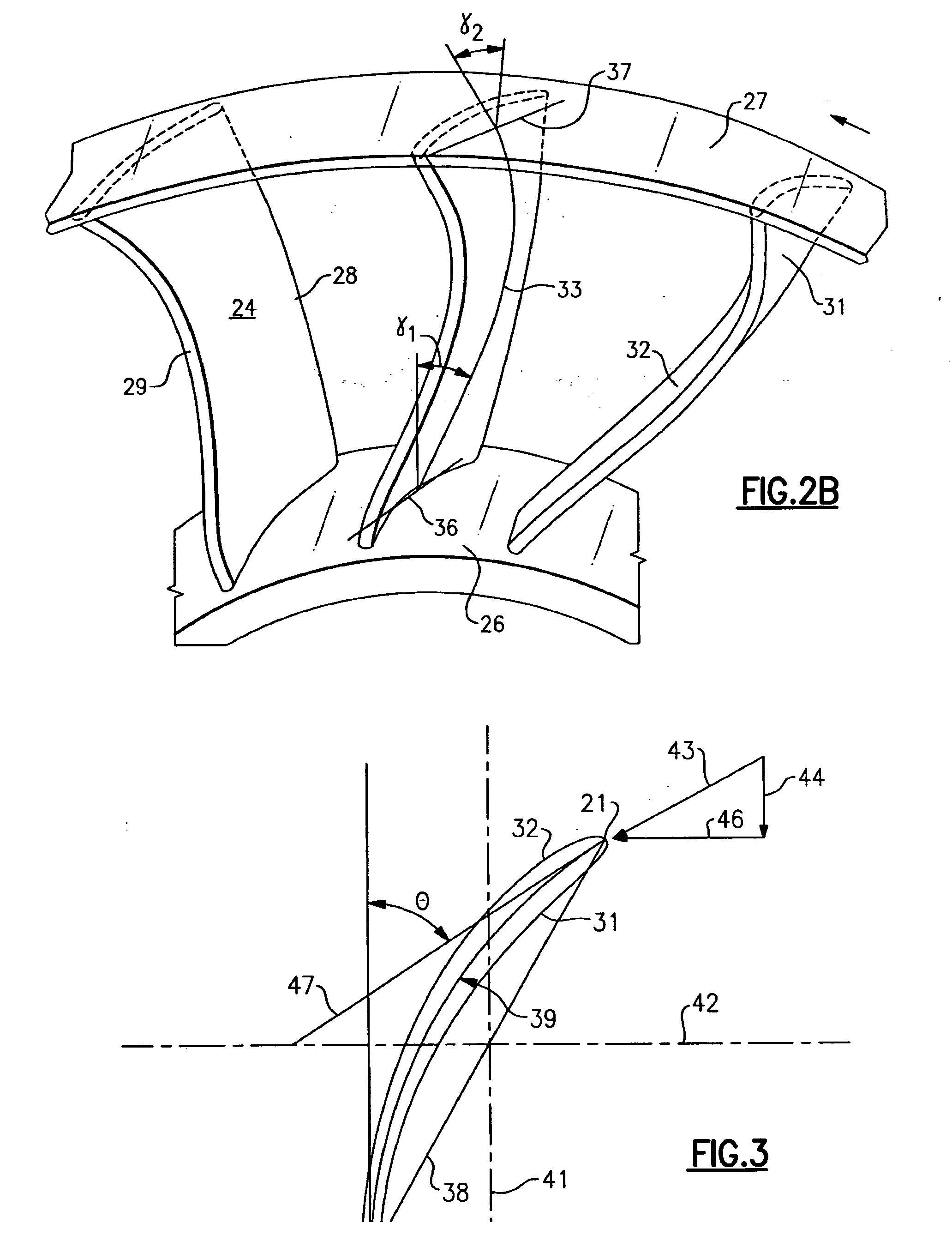

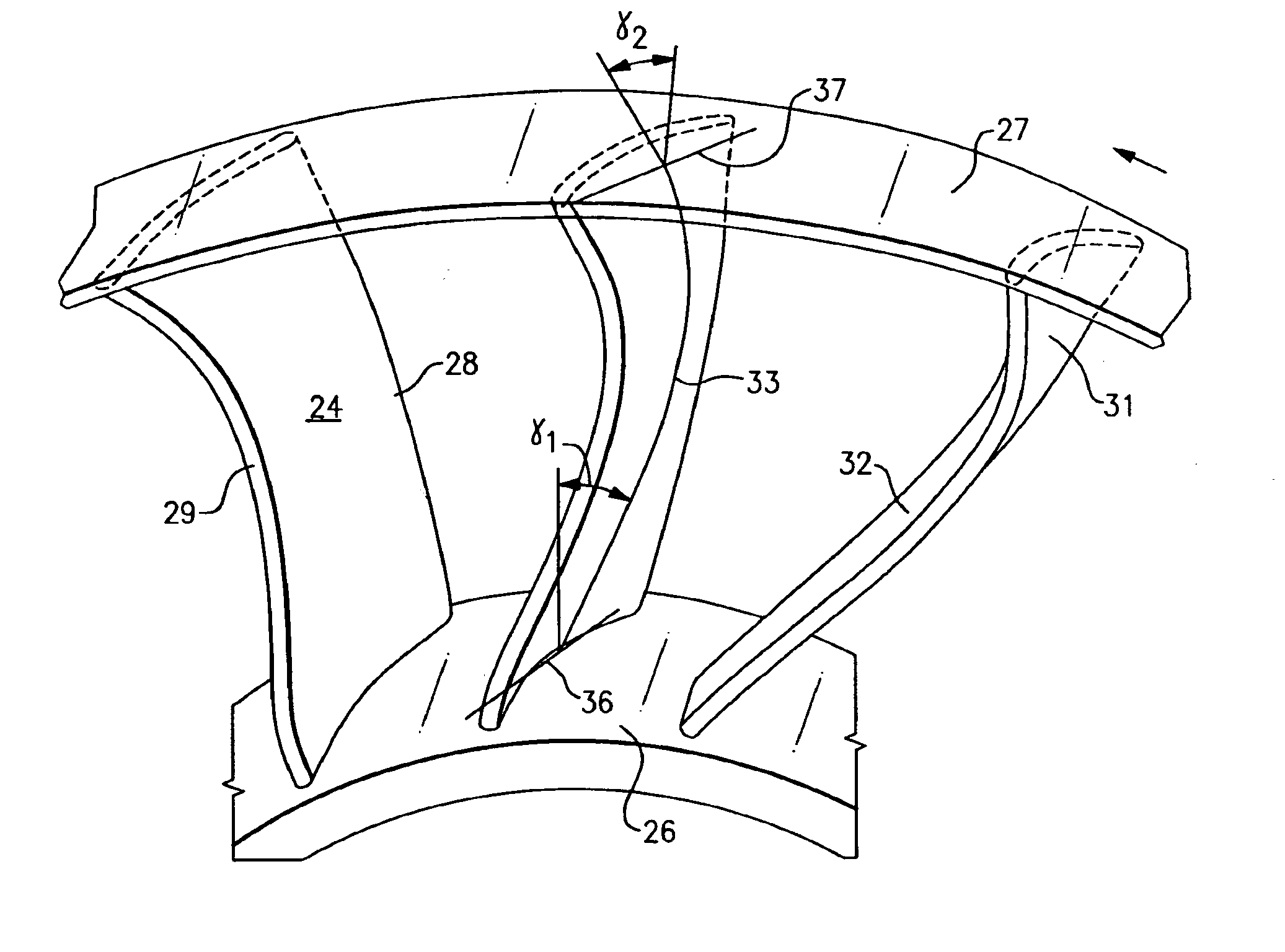

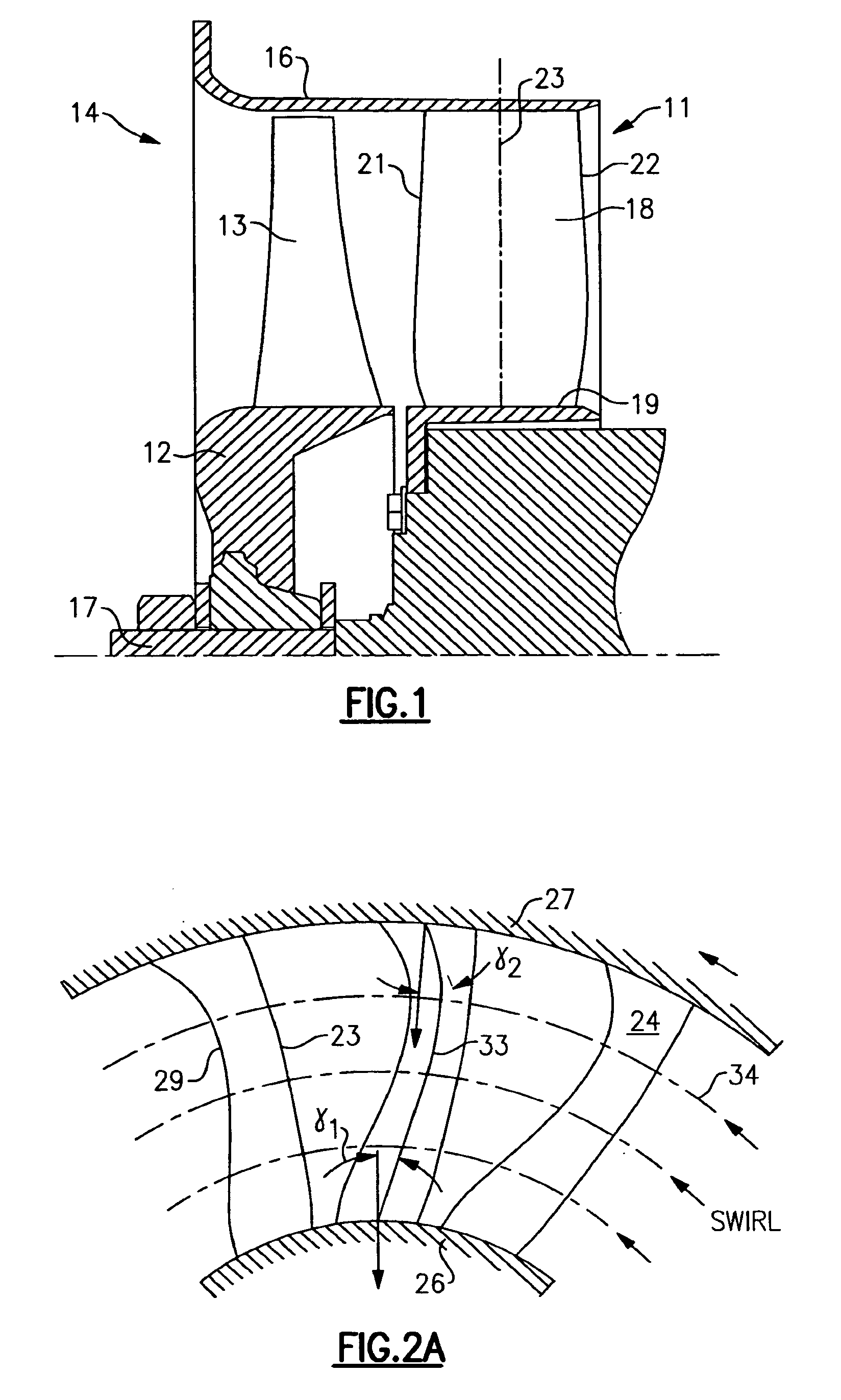

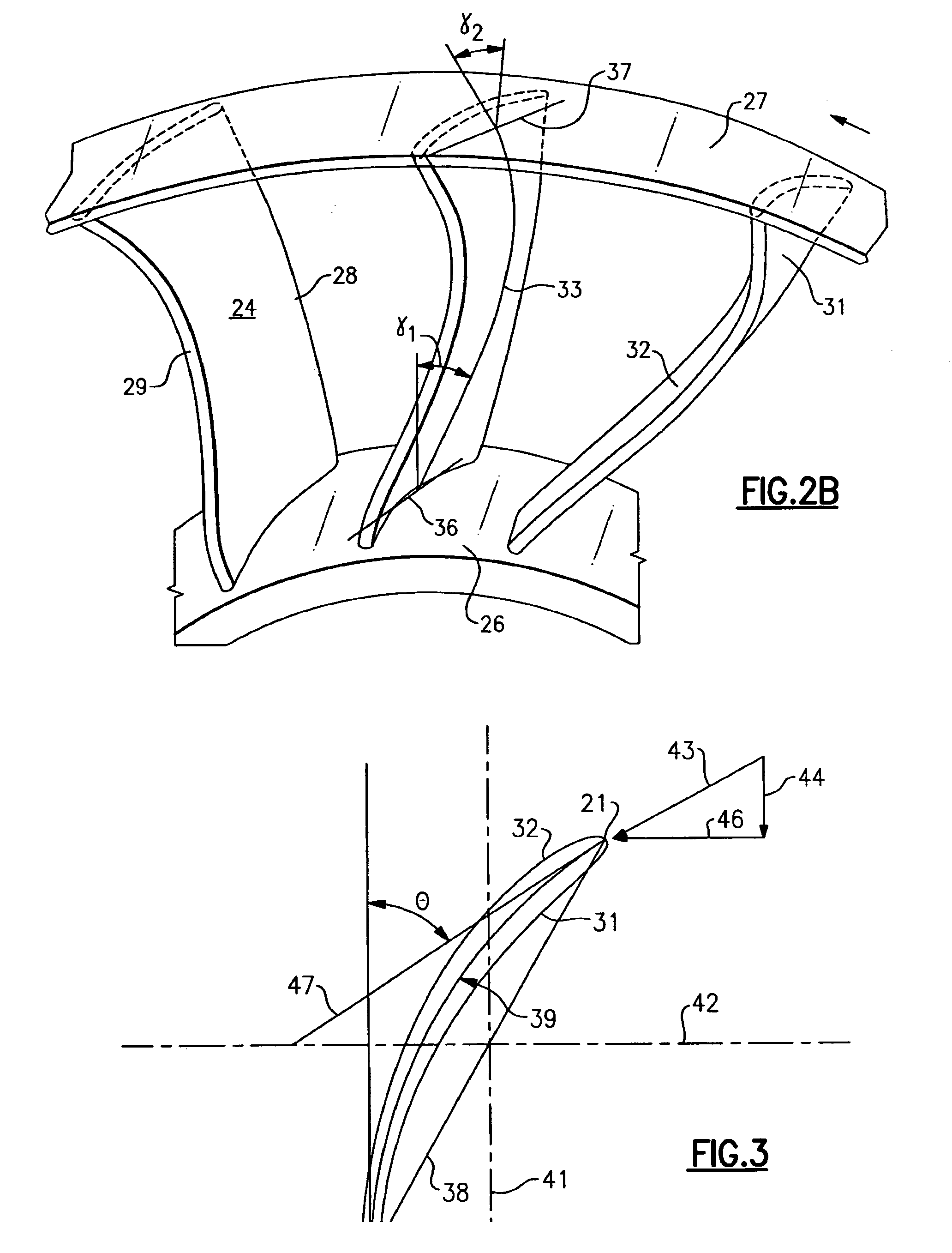

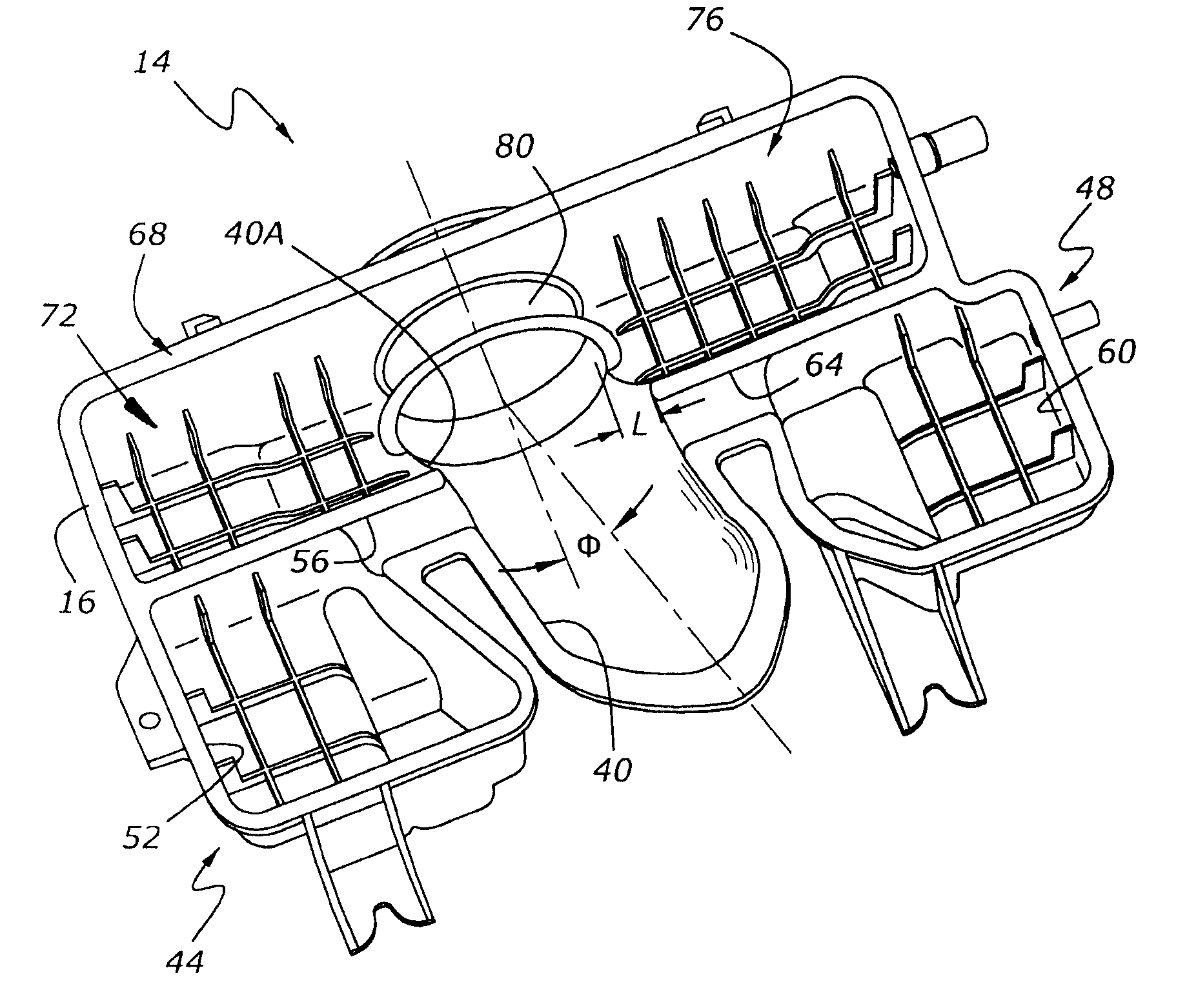

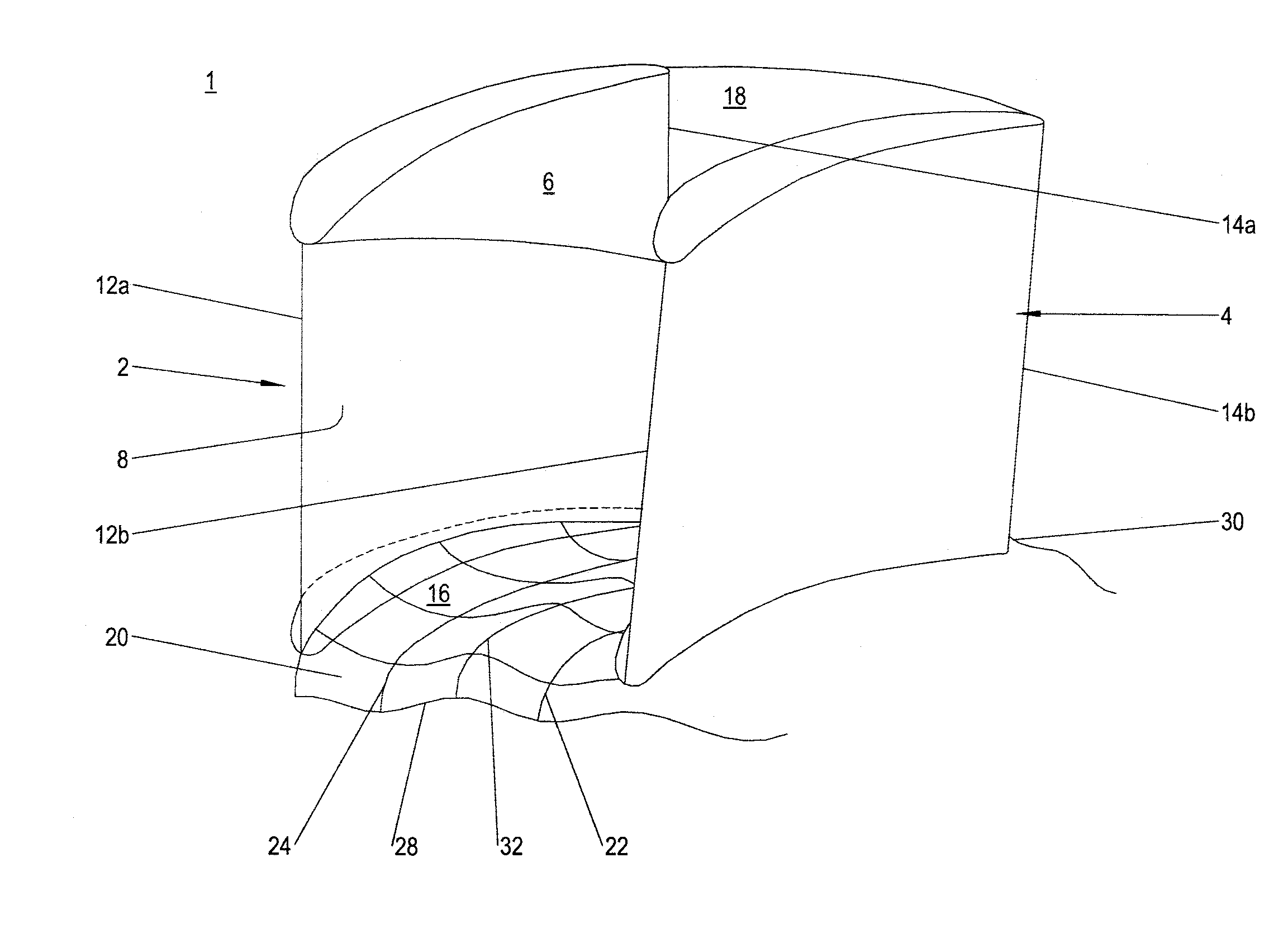

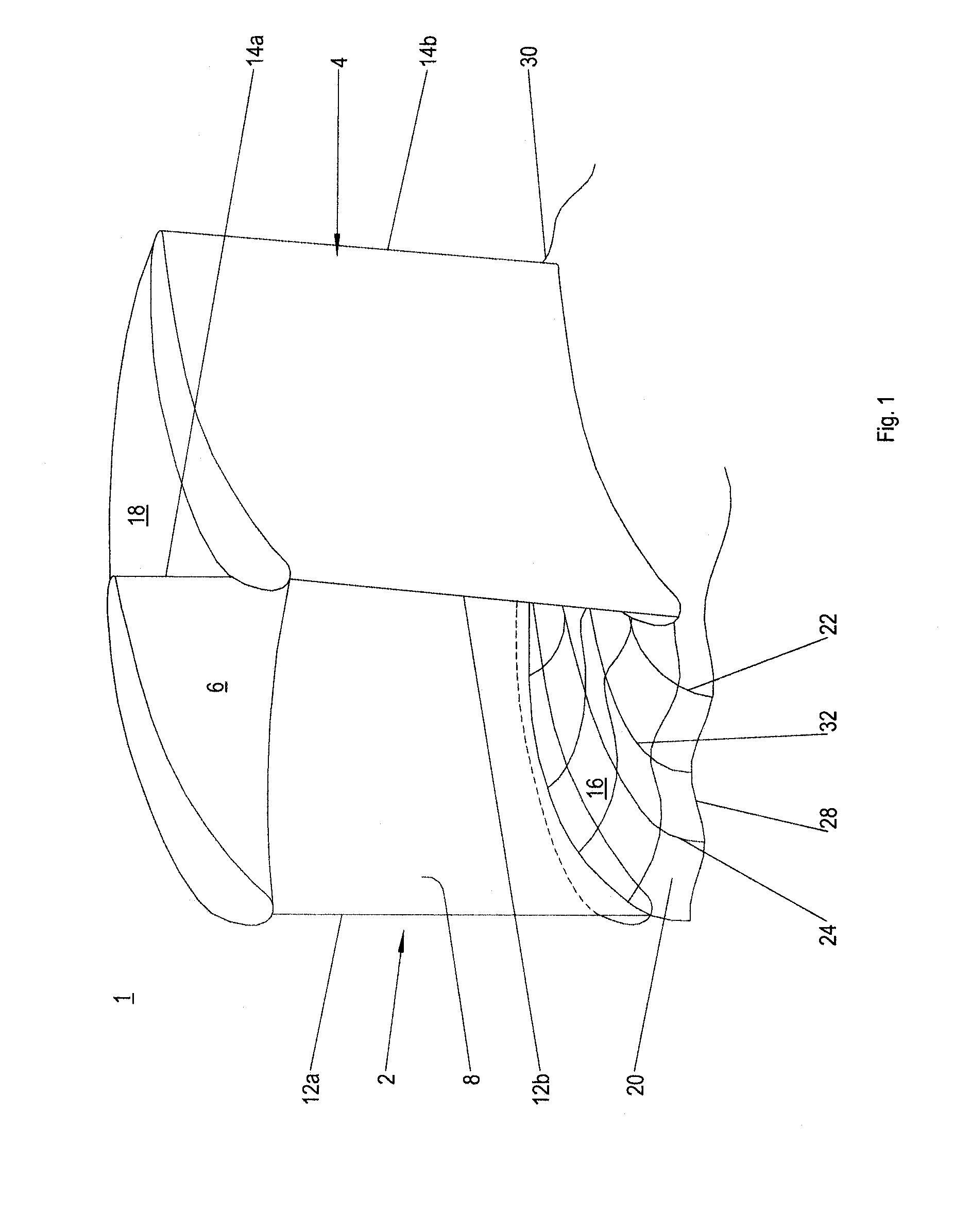

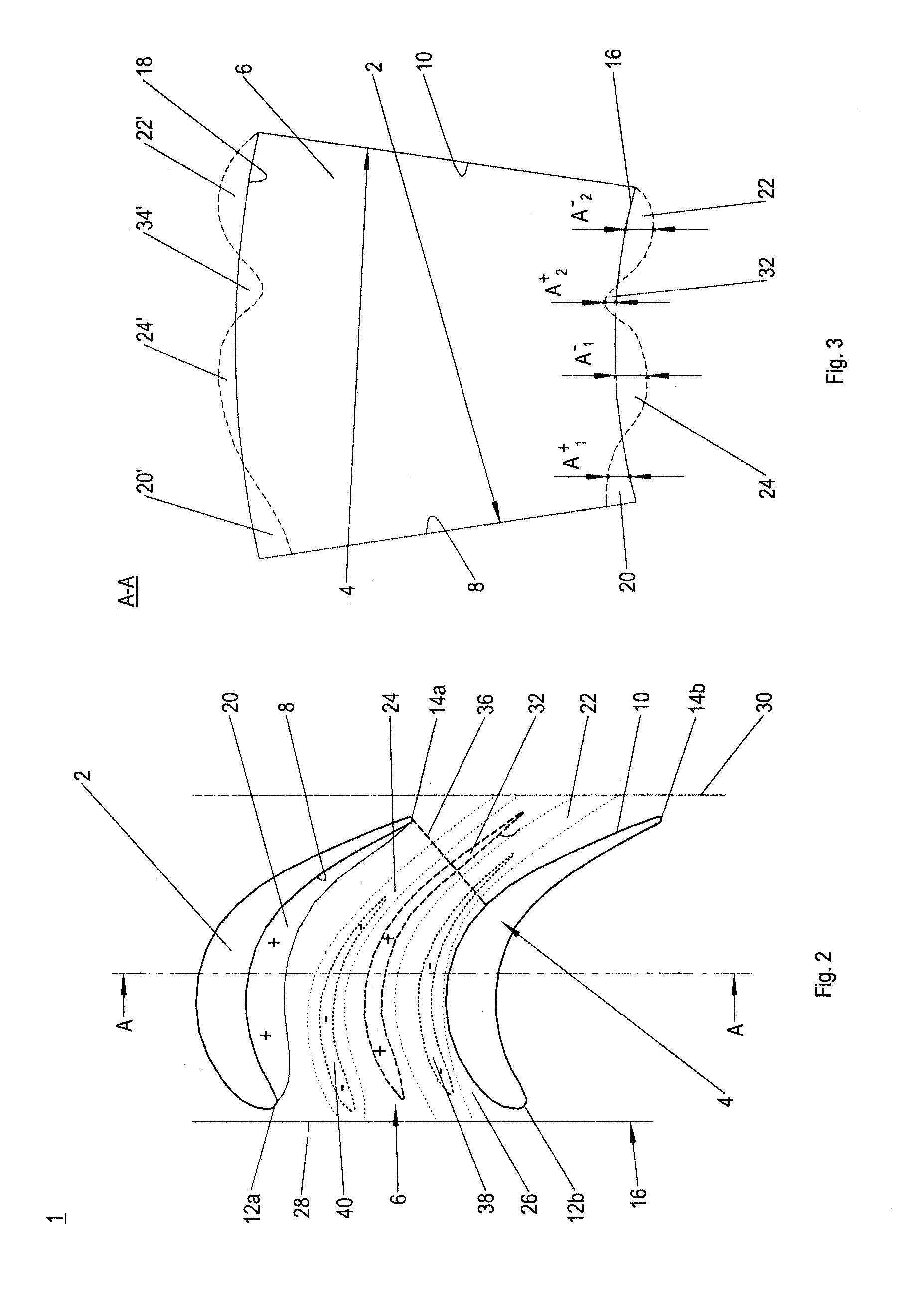

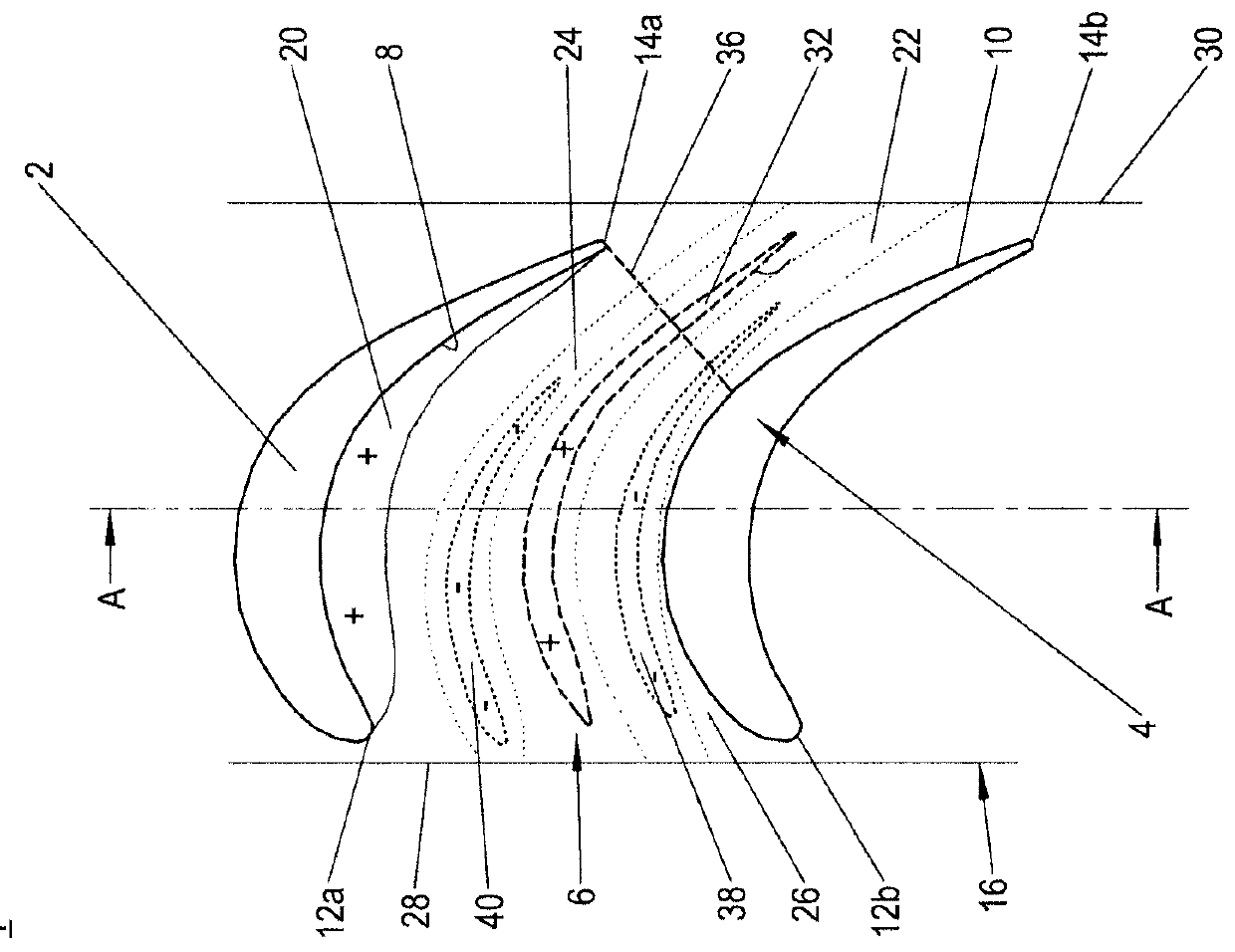

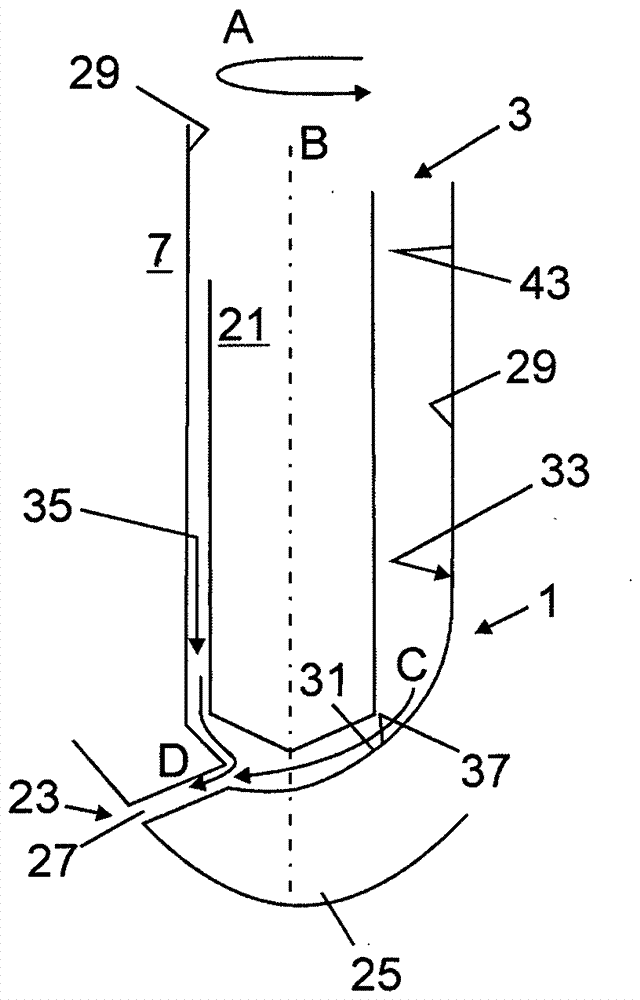

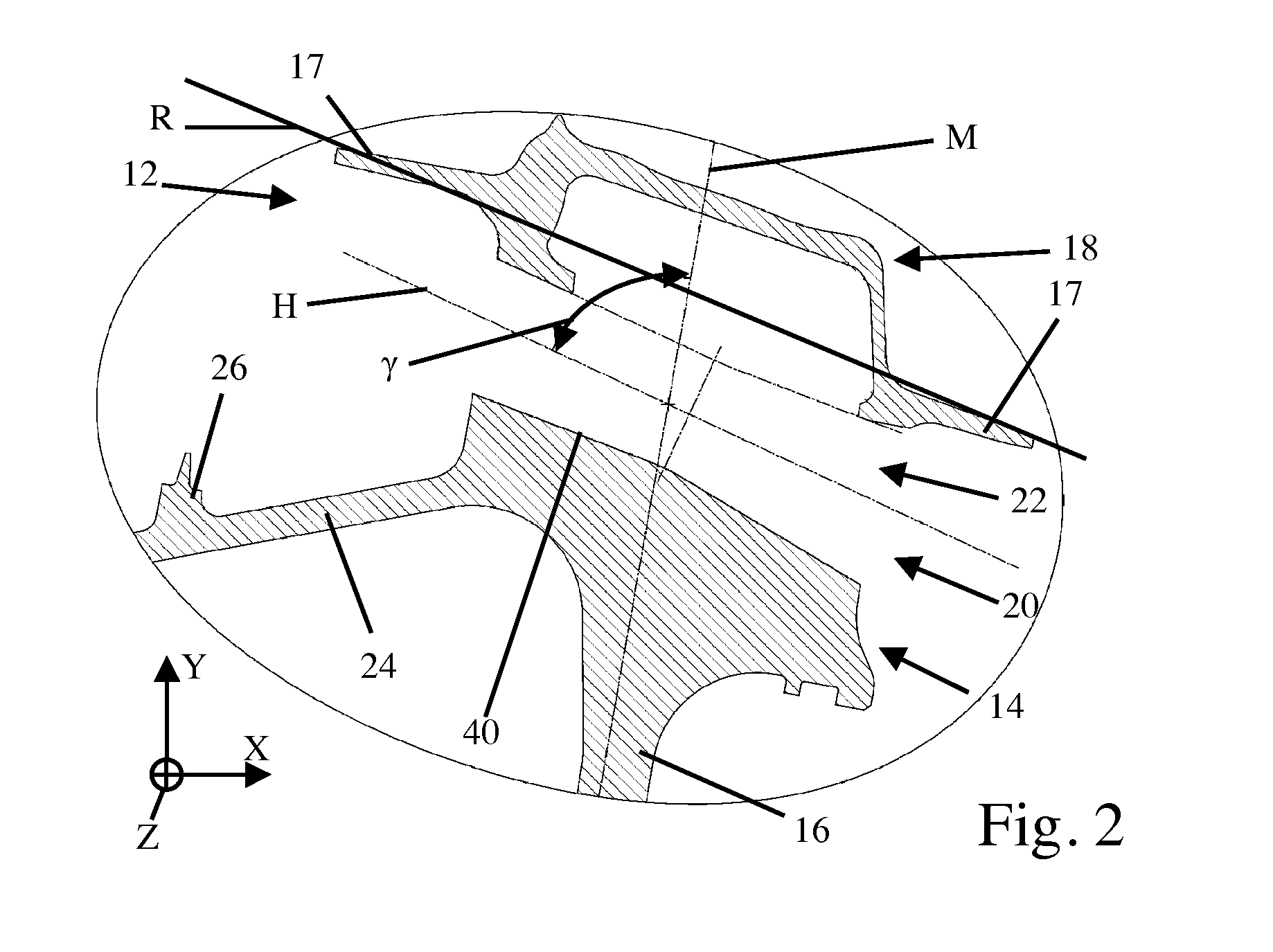

An improved outlet guide vane system is disclosed for axial flow fans. Construction details are described which reduce losses in the end wall regions of the vanes, particularly for axial flow fans operating at low flow coefficient with strong localized swirl associated with upstream rotor tip clearance flows. In the preferred embodiment, the vane spanwise airfoil stacking line is approximately straight, while leaning circumferentially toward the incoming swirl flow over the majority of the radial span. The stacking line then curves abruptly in the opposite direction over the radially outboard spanwise portion, so as to lean away from the incoming swirl at the vane tip station. The radially outboard portion of the vanes simultaneously include a gradual increase in vane stagger angle, vane camber angle and vane chord. The vane may also include an axial sweep component.

Owner:CARRIER CORP

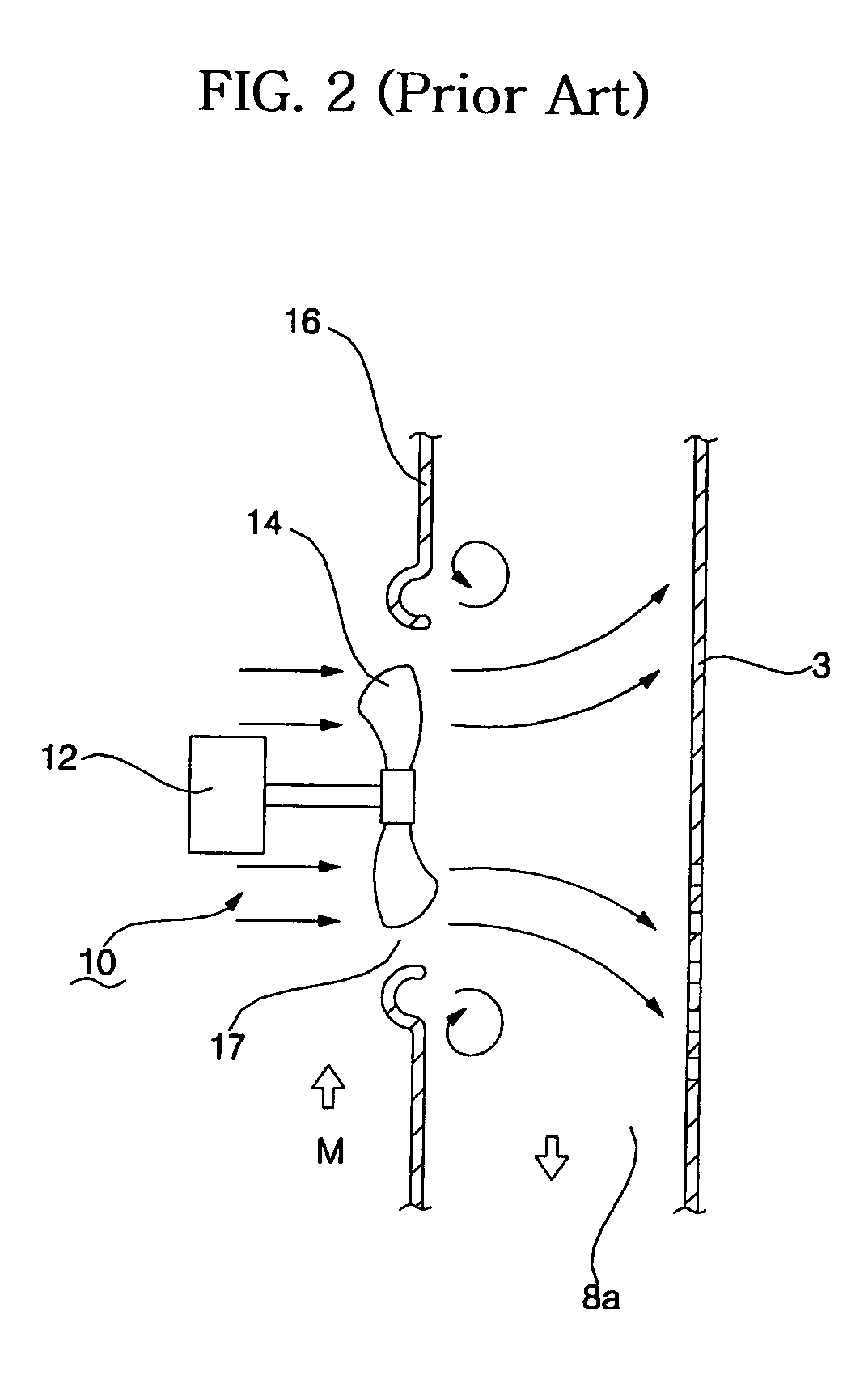

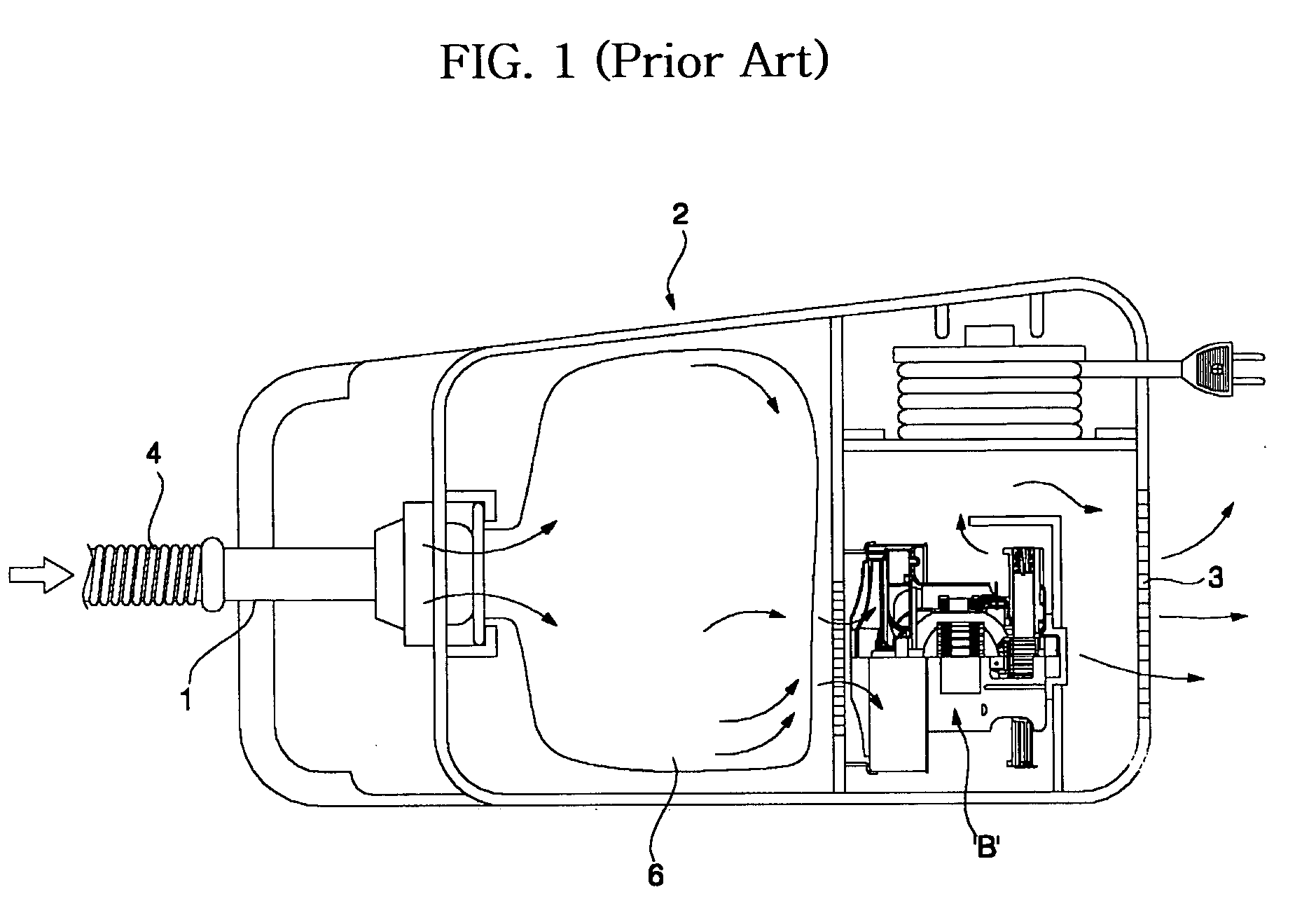

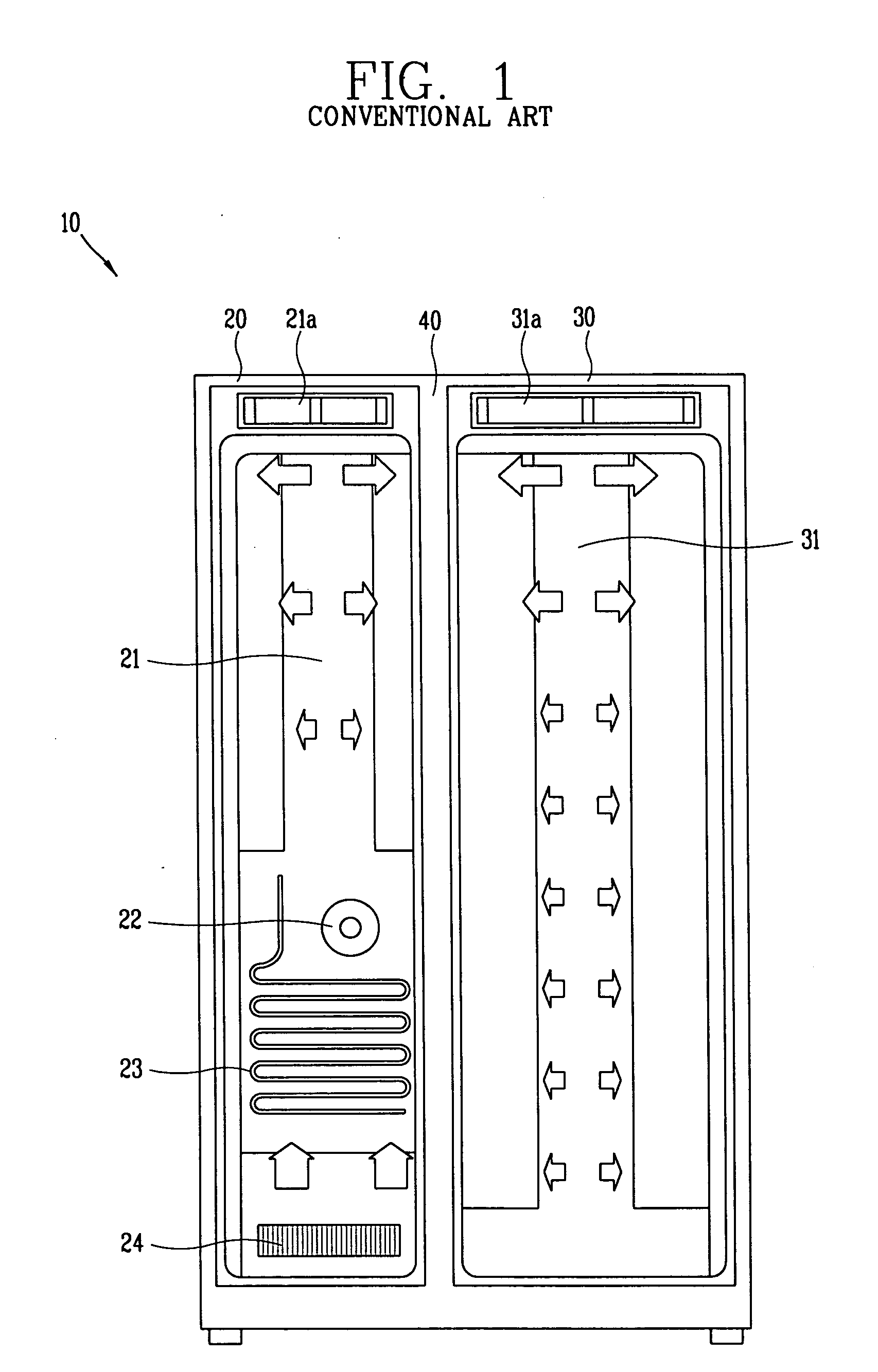

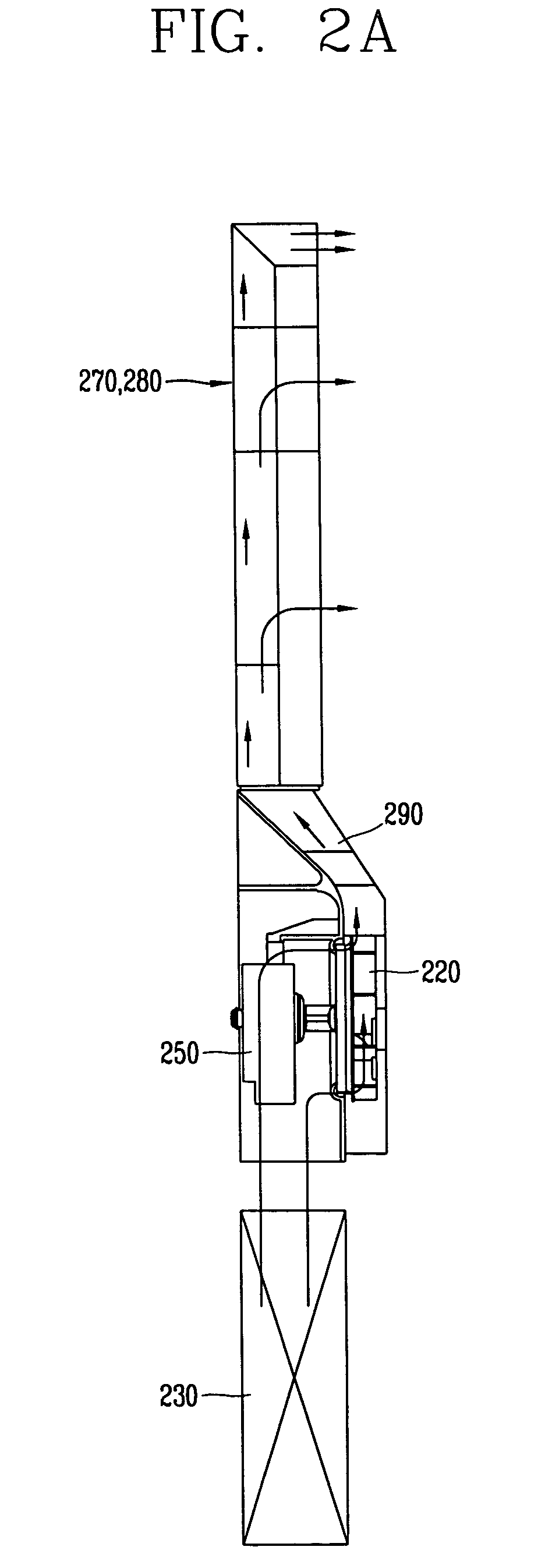

Blowing apparatus for refrigerators

InactiveUS7281898B2Quieter operationFlow loss minimizationPropellersRotary propellersEngineeringCentrifugal fan

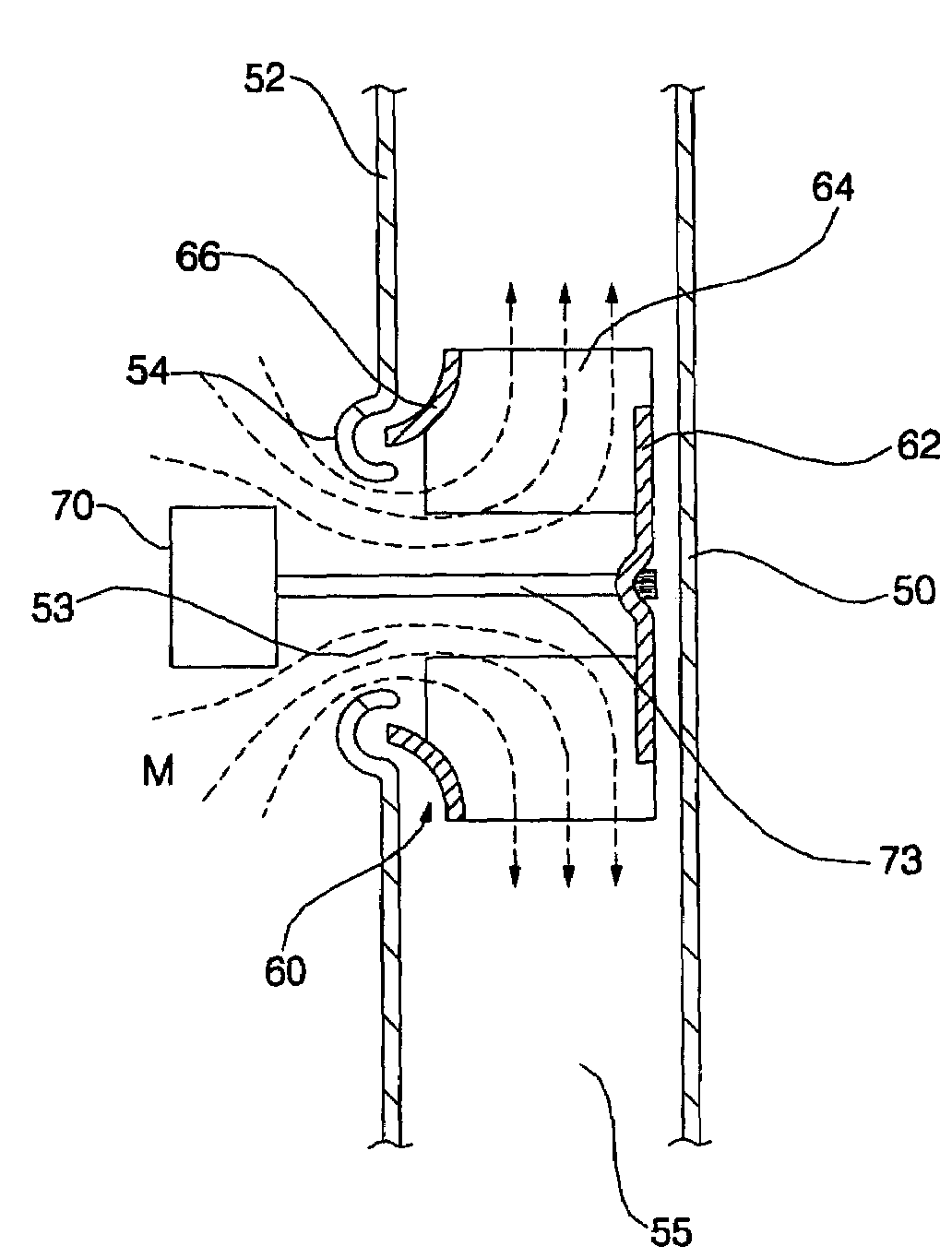

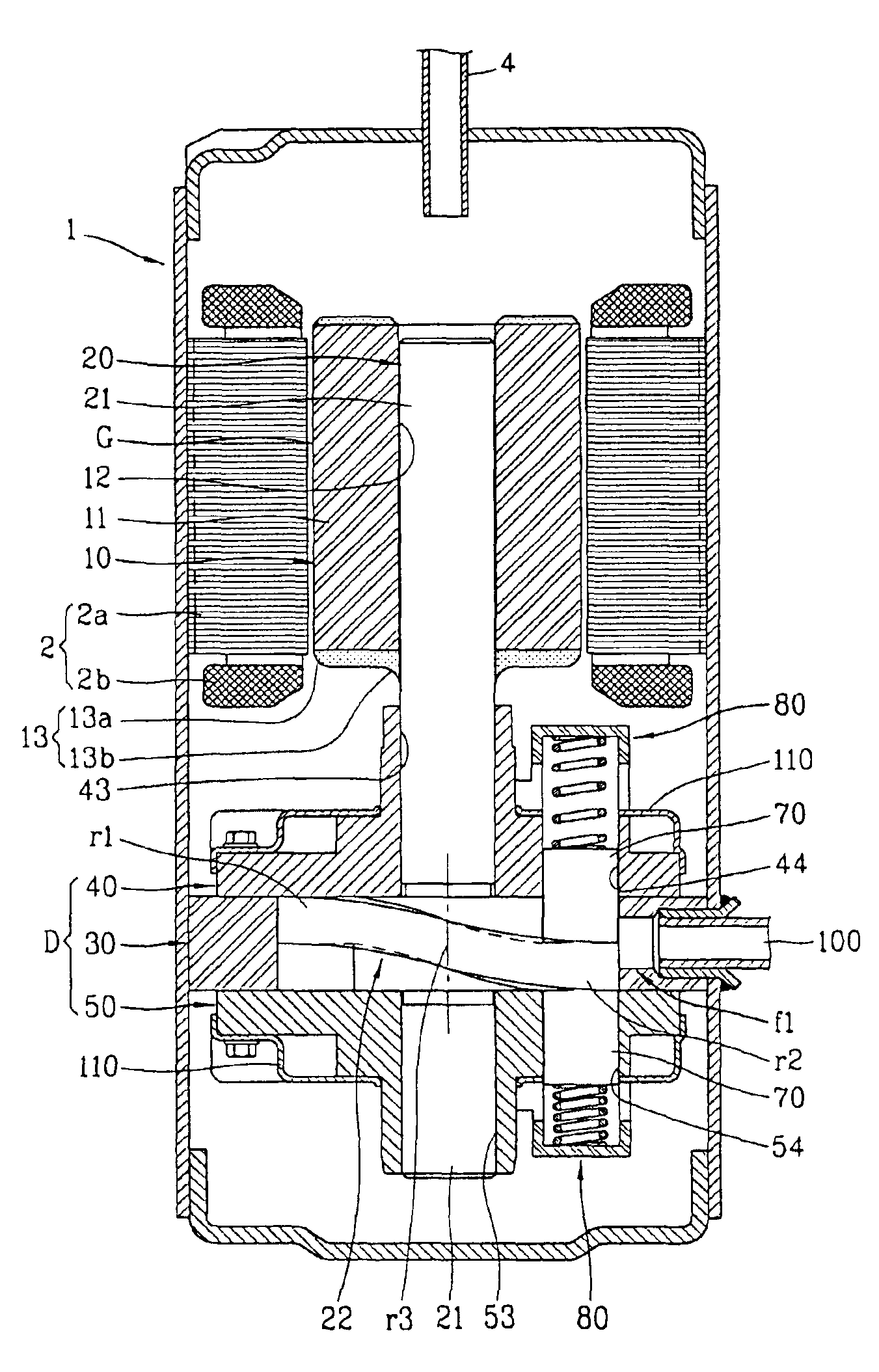

Disclosed herein is a blowing apparatus for refrigerators. The blowing apparatus includes a centrifugal fan. The centrifugal fan comprises a hub plate connected to a shaft of the motor, a plurality of blades attached to the hub plate in the radial direction of the hub plate for forcing cool air to flow, and a ring-shaped shroud connected to ends of the blades. The ratio of the inner diameter of the centrifugal fan, formed through connection of the inner ends of the blades, to the outer diameter of the centrifugal fan, formed through connection of the outer ends of the blades, is 0.63±0.01. With the blowing apparatus for refrigerators according to the present invention, flow loss is minimized. Consequently, the present invention has the effect that energy consumption is reduced, noise is decreased, and thus the refrigerator is quietly operated.

Owner:LG ELECTRONICS INC

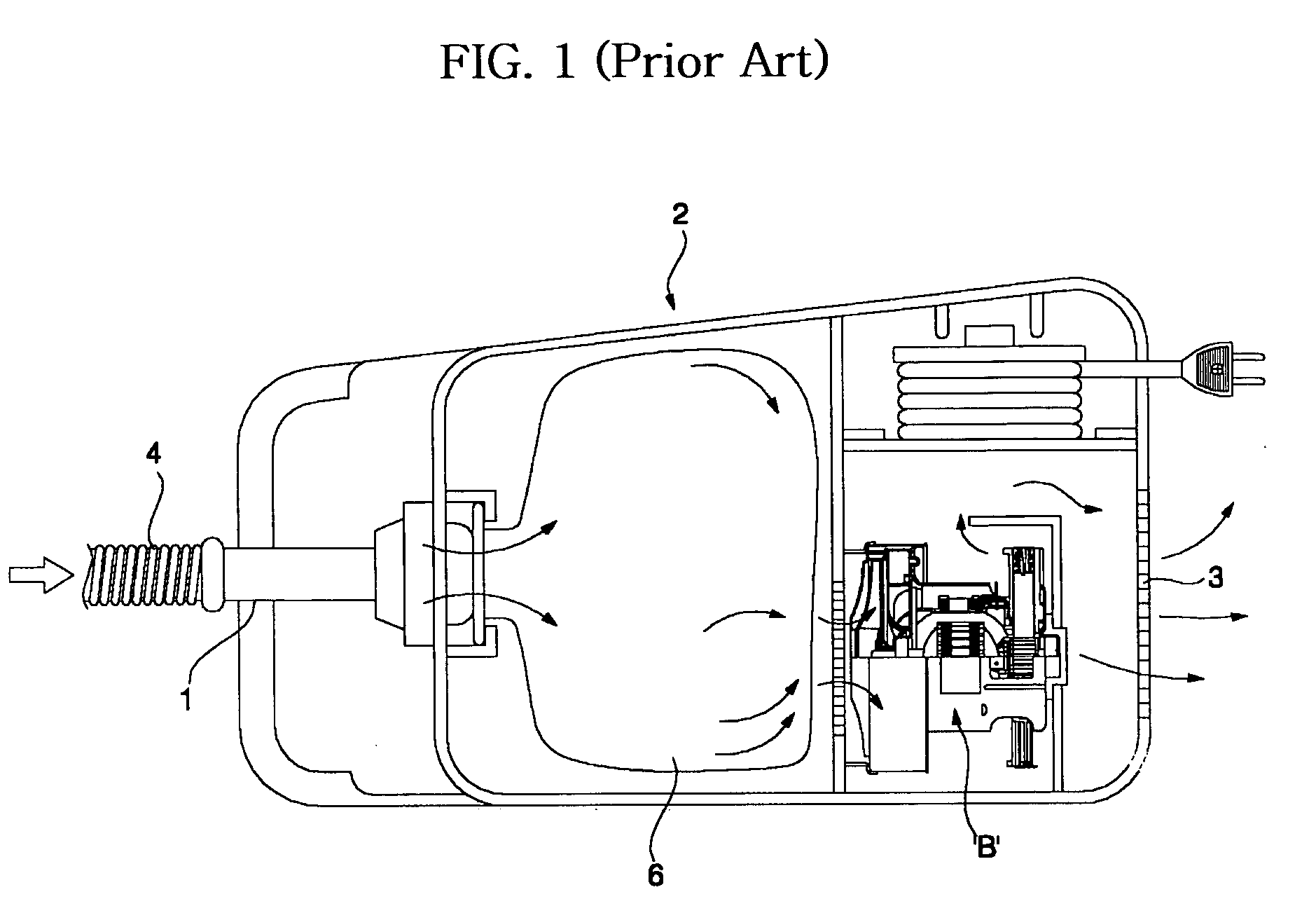

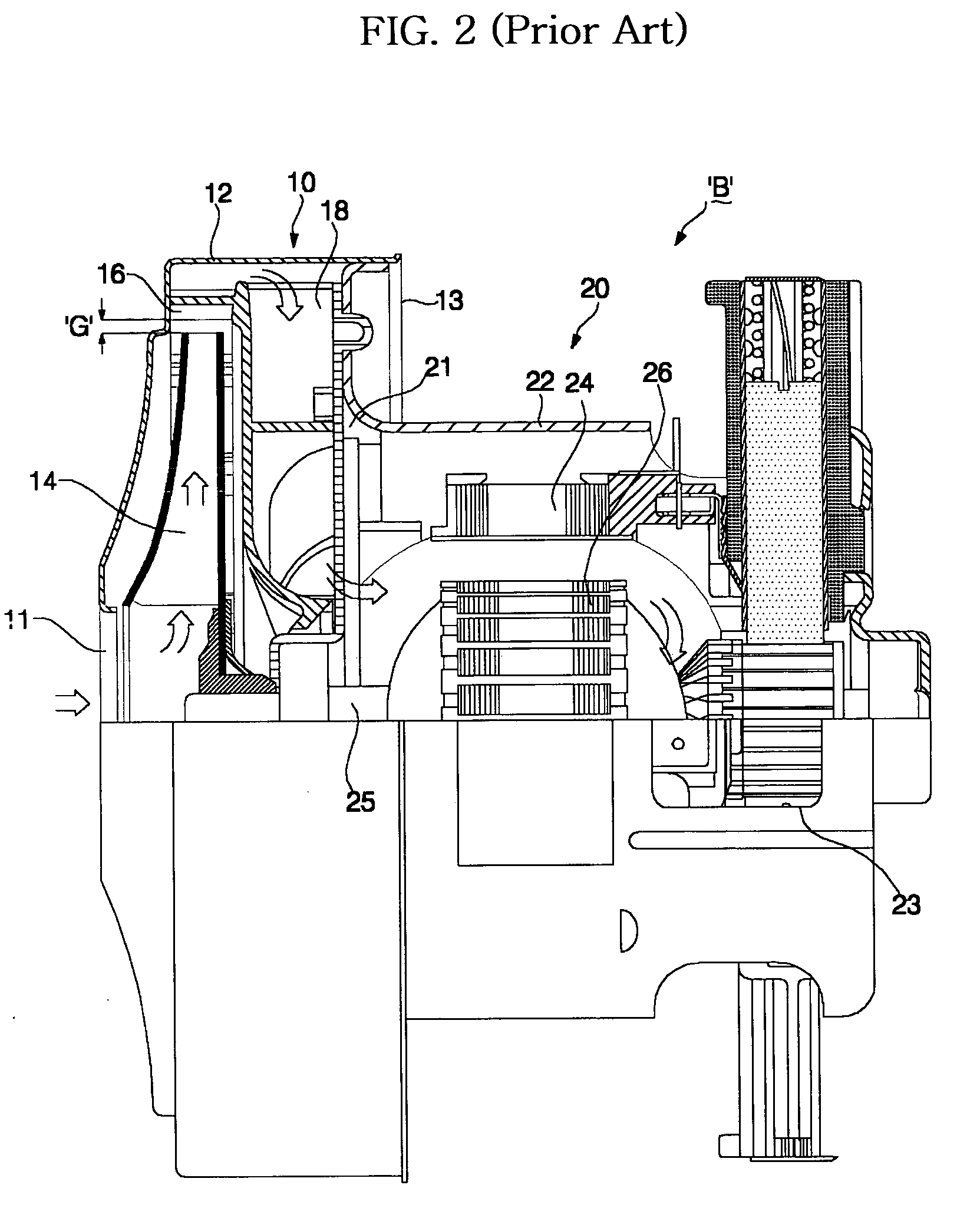

Air-blowing apparatus of cleaner

InactiveUS20050169750A1Reduce noiseFlow loss minimizationEngine manufacturePump componentsPhysicsMechanical engineering

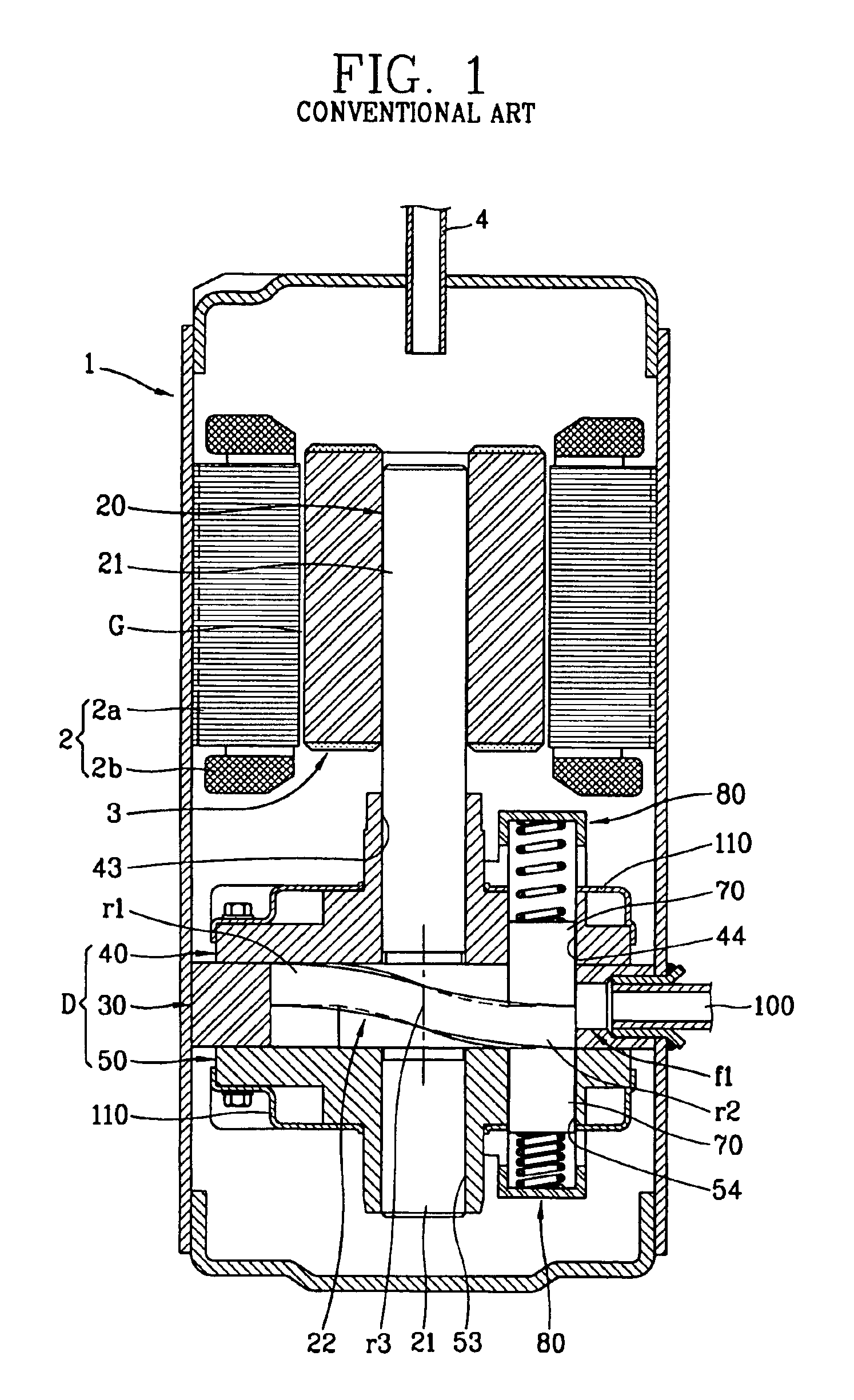

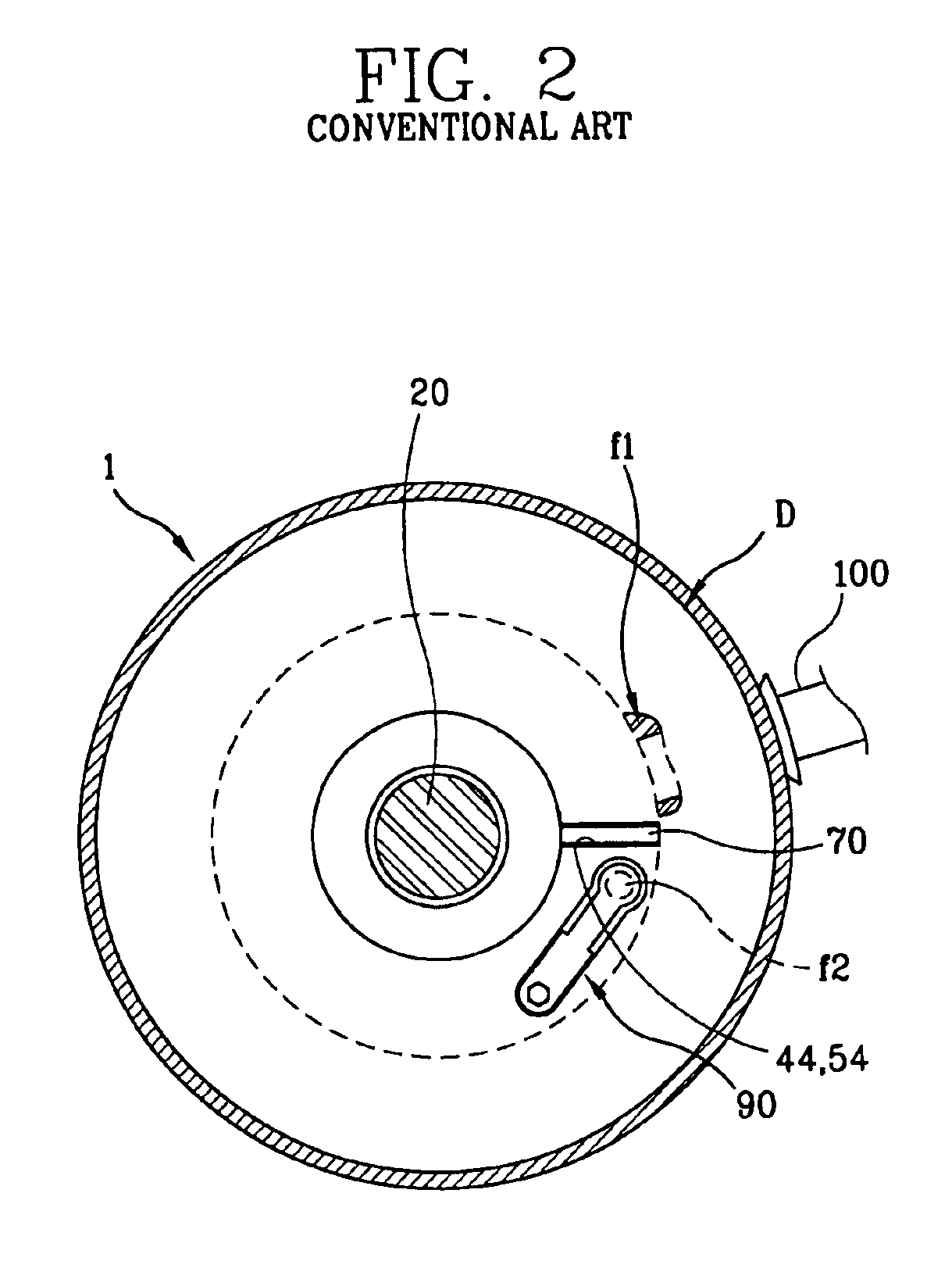

Disclosed herein is an air-blowing apparatus of a cleaner. The air-blowing apparatus comprises a fan having a plurality of blades spaced apart from each other in the circumferential direction of the fan for generating a blowing force in the centrifugal direction thereof, and a diffuser disposed outside the fan in the radial direction of the fan for diffusing air blown from the fan. Each blade is formed such that at least a part of the blade is shorter than the other part of the blade extending to the outer diameter of the fan, whereby noise is reduced while blowing efficiency is not affected.

Owner:LG ELECTRONICS INC

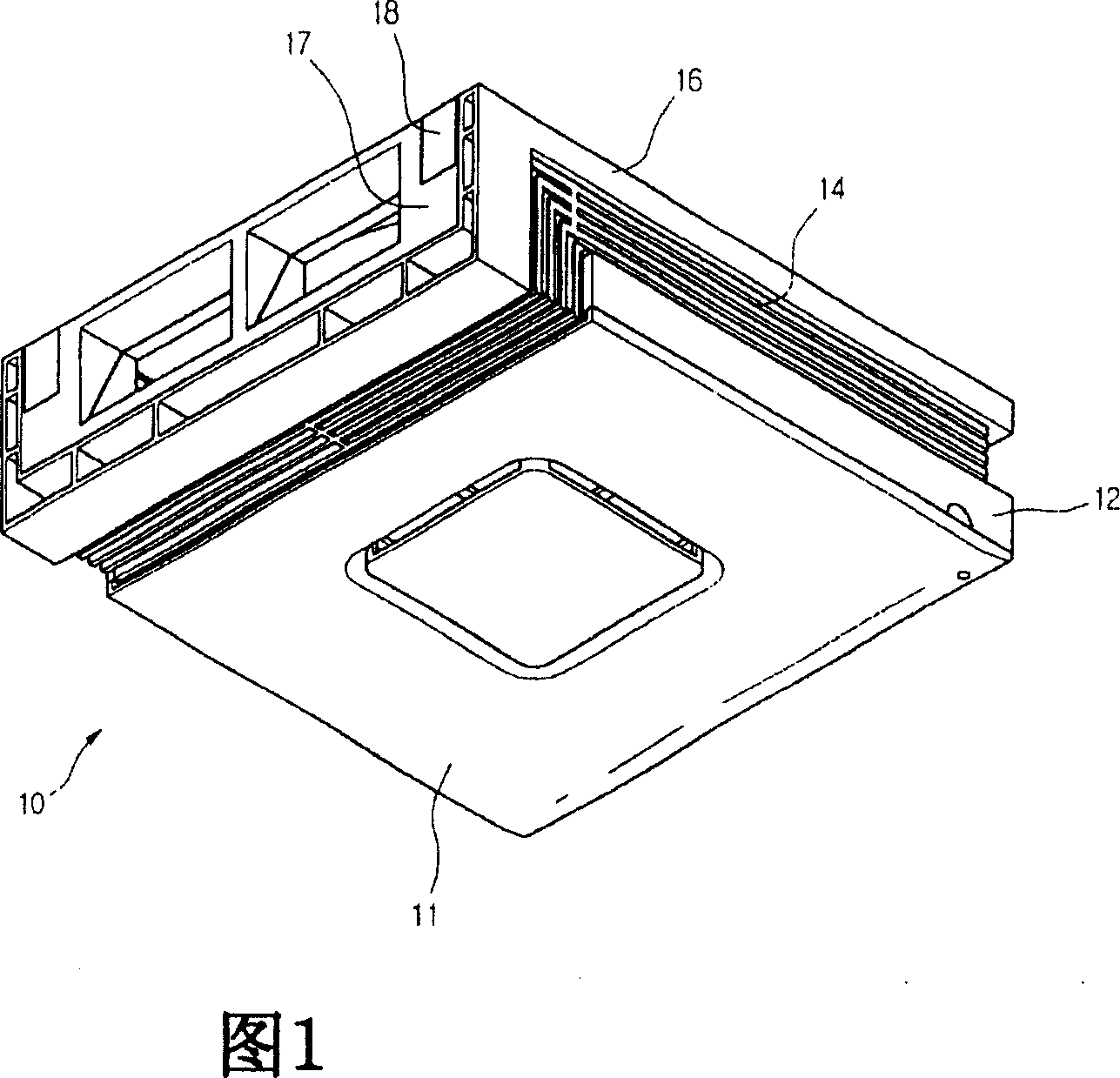

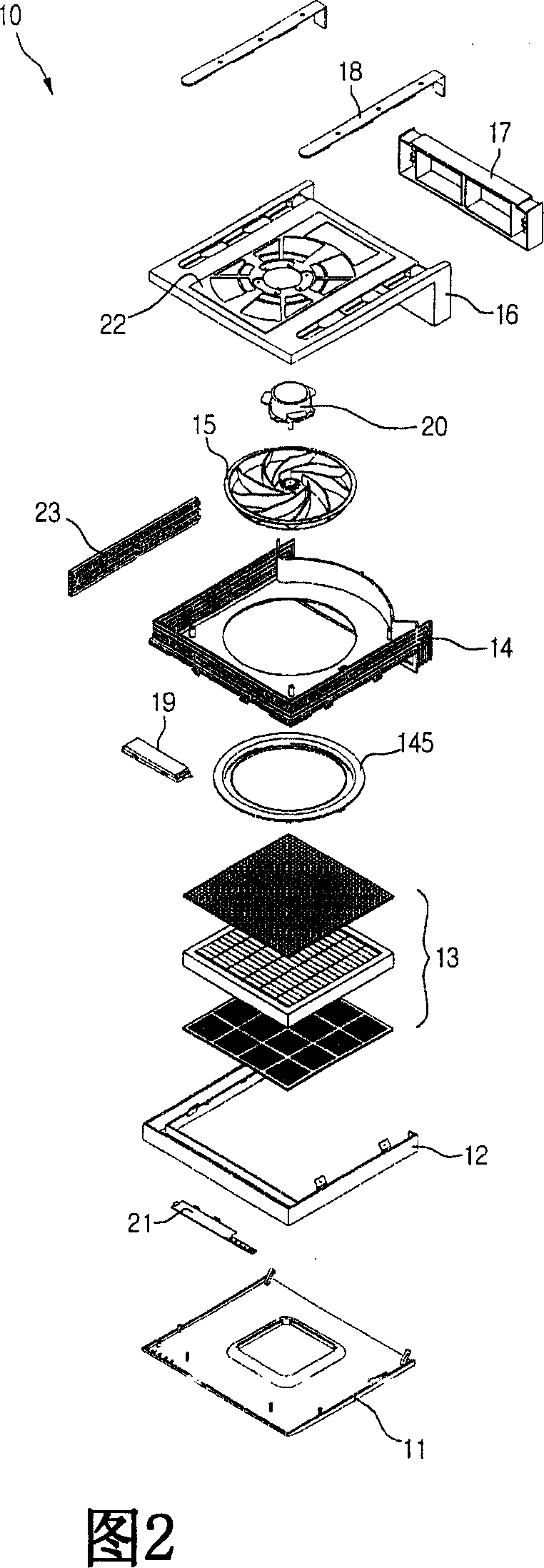

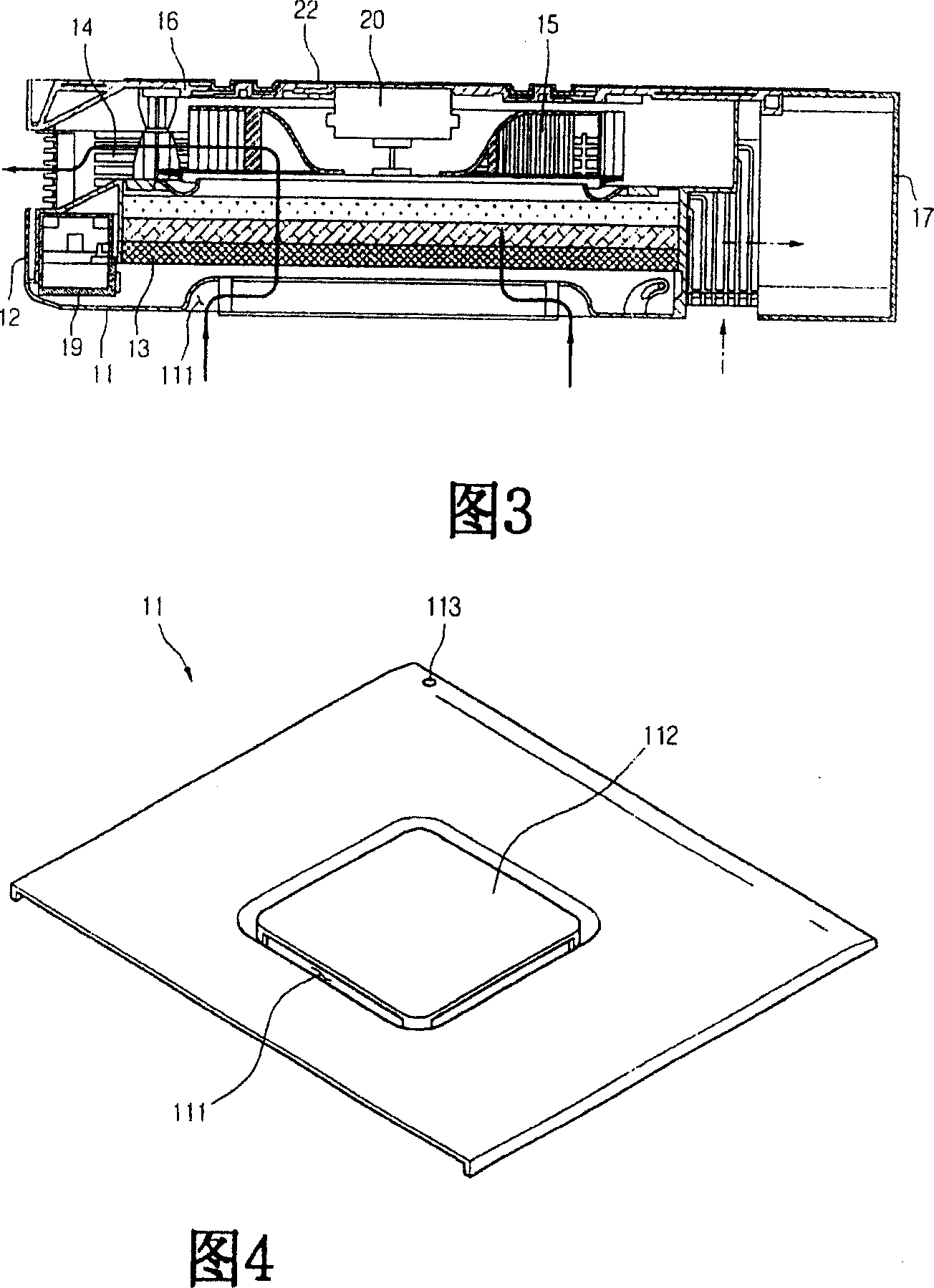

Air conditioning apparatus

InactiveCN1936439AEfficient removalStop fallingLighting and heating apparatusAir conditioning systemsOutdoor areaAir conditioning

An air conditioning apparatus is provided. The air conditioning apparatus includes a cover assembly having an indoor air suction hole, a filter assembly cleaning indoor air sucked through the indoor air suction hole, and a grill. The grill includes a discharge grill formed on a side for discharging the indoor air cleaned by the filter assembly to an indoor area, and an exhaust grill for discharging indoor air to an outdoor area. A fan assembly draws indoor or outdoor air toward the grill. A rear panel is coupled to the grill. The rear panel includes a suction hole formed in one side for introducing outdoor air and an exhaust hole formed beside the suction hole for discharging indoor air to the outdoor area.

Owner:LG ELECTRONICS INC

Outlet guide vanes for axial flow fans

ActiveUS8333559B2Flow loss minimizationMaximize recoveryPump componentsStatorsCamber angleGradual increase

An outlet guide vane system is disclosed for axial flow fans. Construction details are described which reduce losses in the end wall regions of the vanes, particularly for axial flow fans operating at low flow coefficient with strong localized swirl associated with upstream rotor tip clearance flows. In the preferred embodiment, the vane spanwise airfoil stacking line is approximately straight, while leaning circumferentially toward the incoming swirl flow over the majority of the radial span. The stacking line then curves abruptly in the opposite direction over the radially outboard spanwise portion, so as to lean away from the incoming swirl at the vane tip station. The radially outboard portion of the vanes simultaneously include a gradual increase in vane stagger angle, vane camber angle and vane chord. The vane may also include an axial sweep component.

Owner:CARRIER CORP

Air induction sound modification system for internal combustion engine

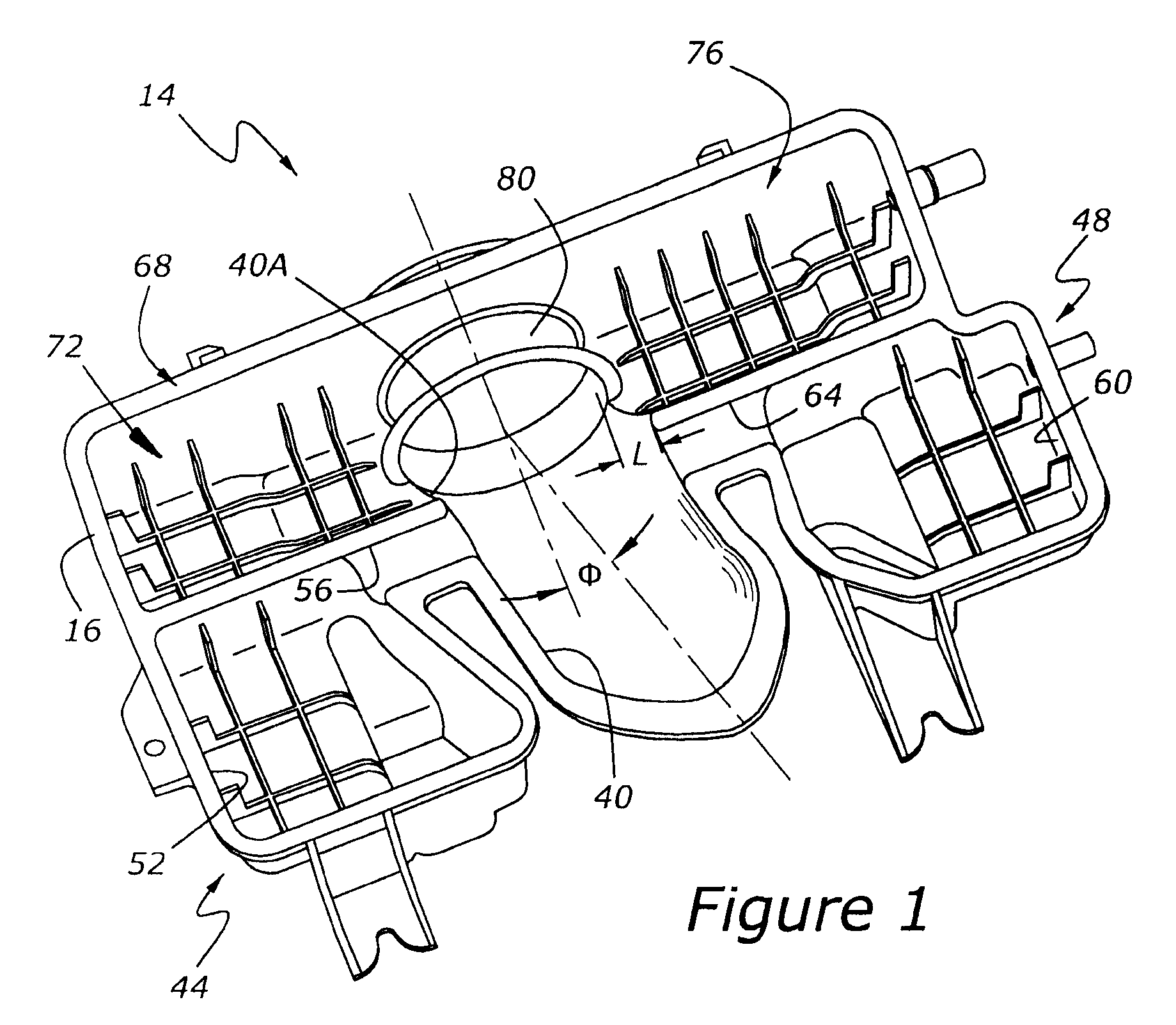

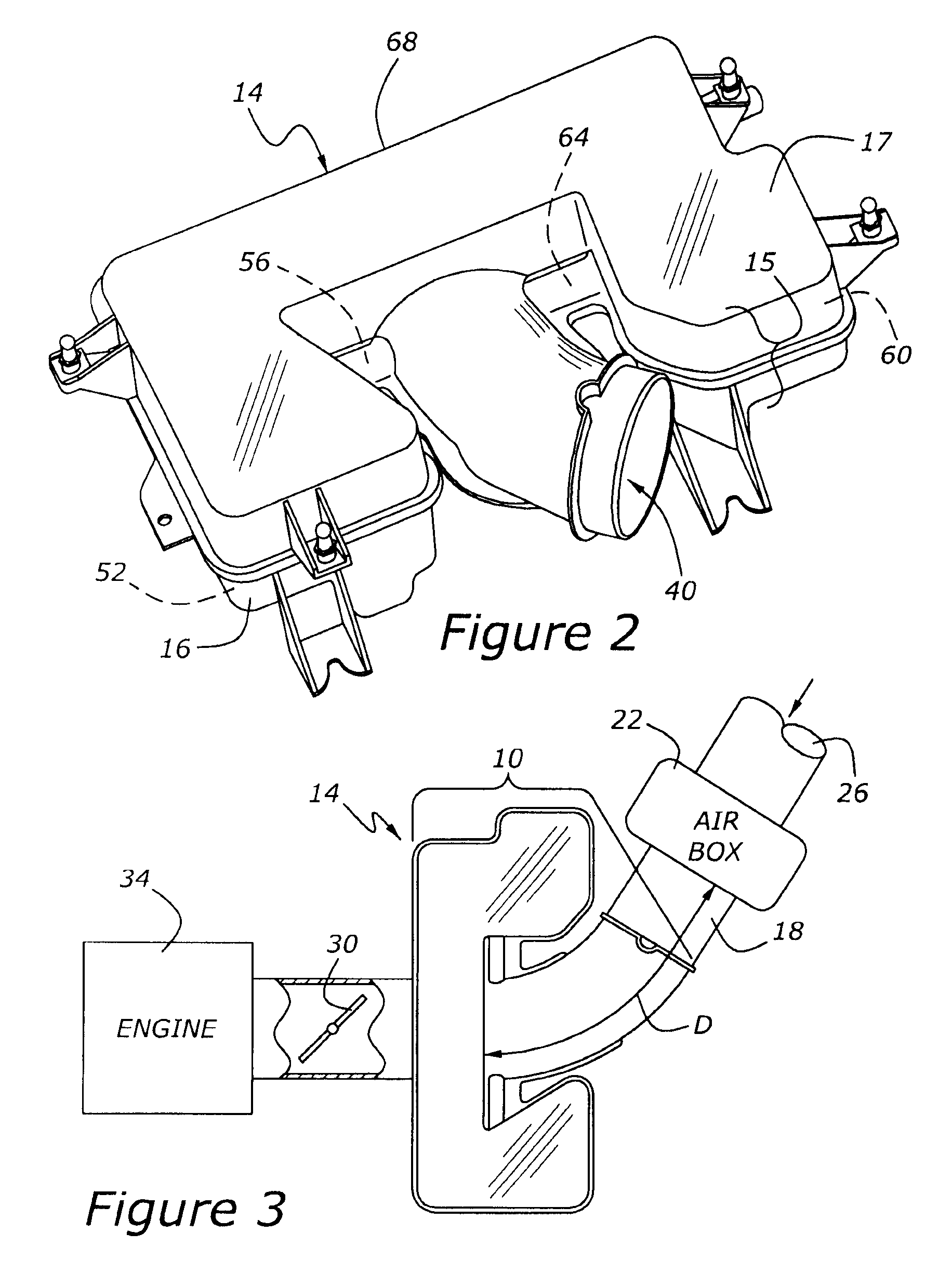

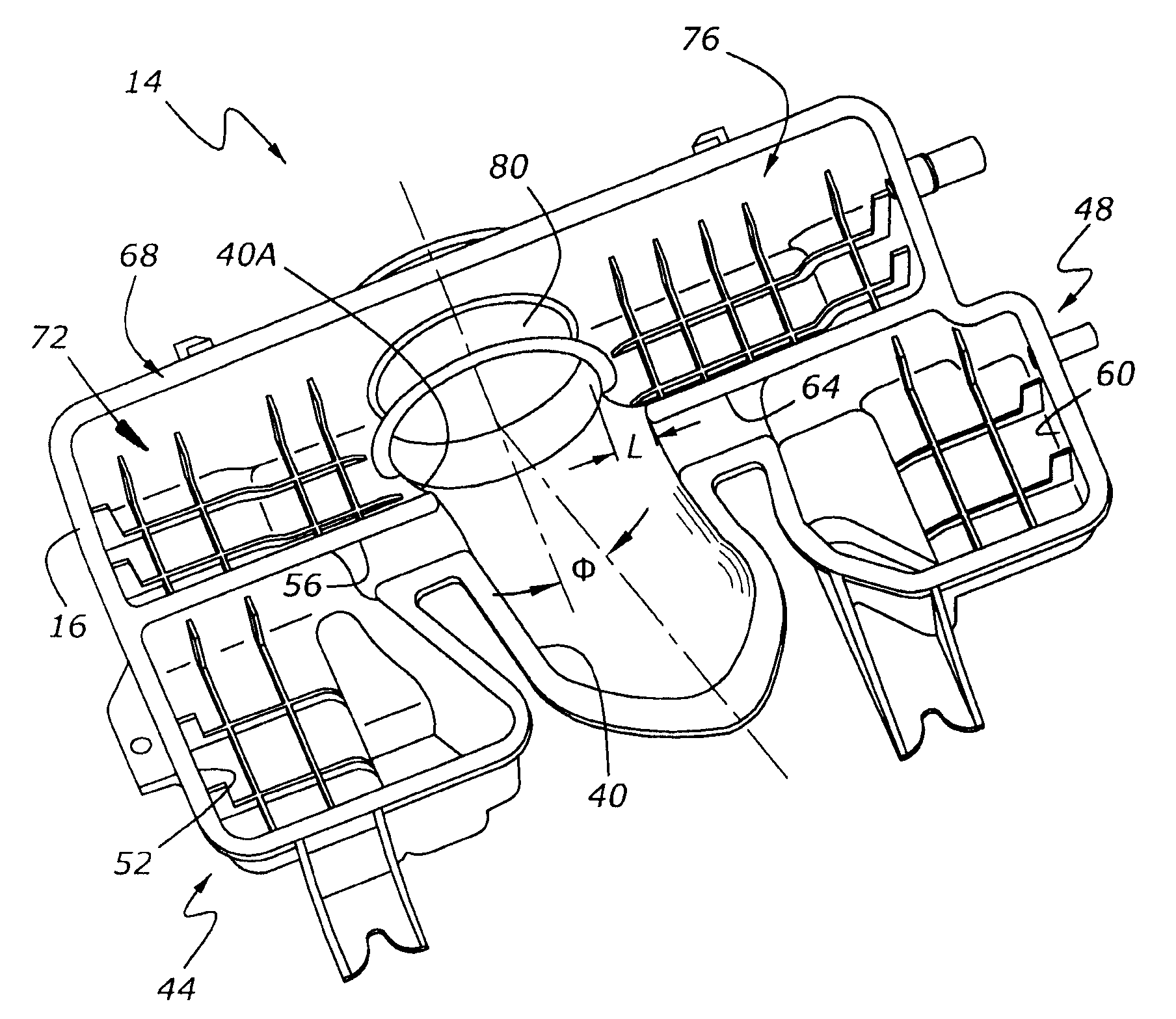

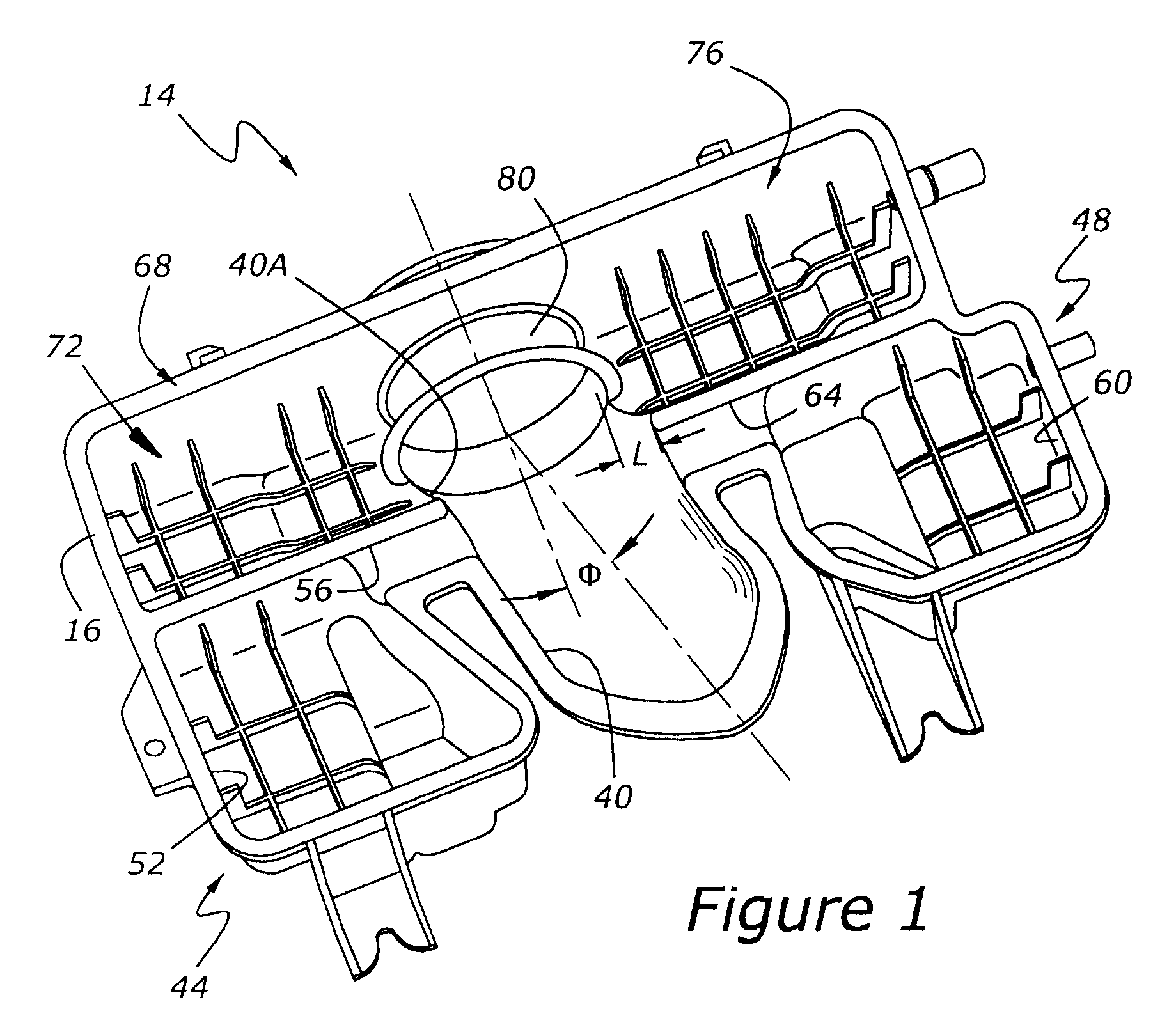

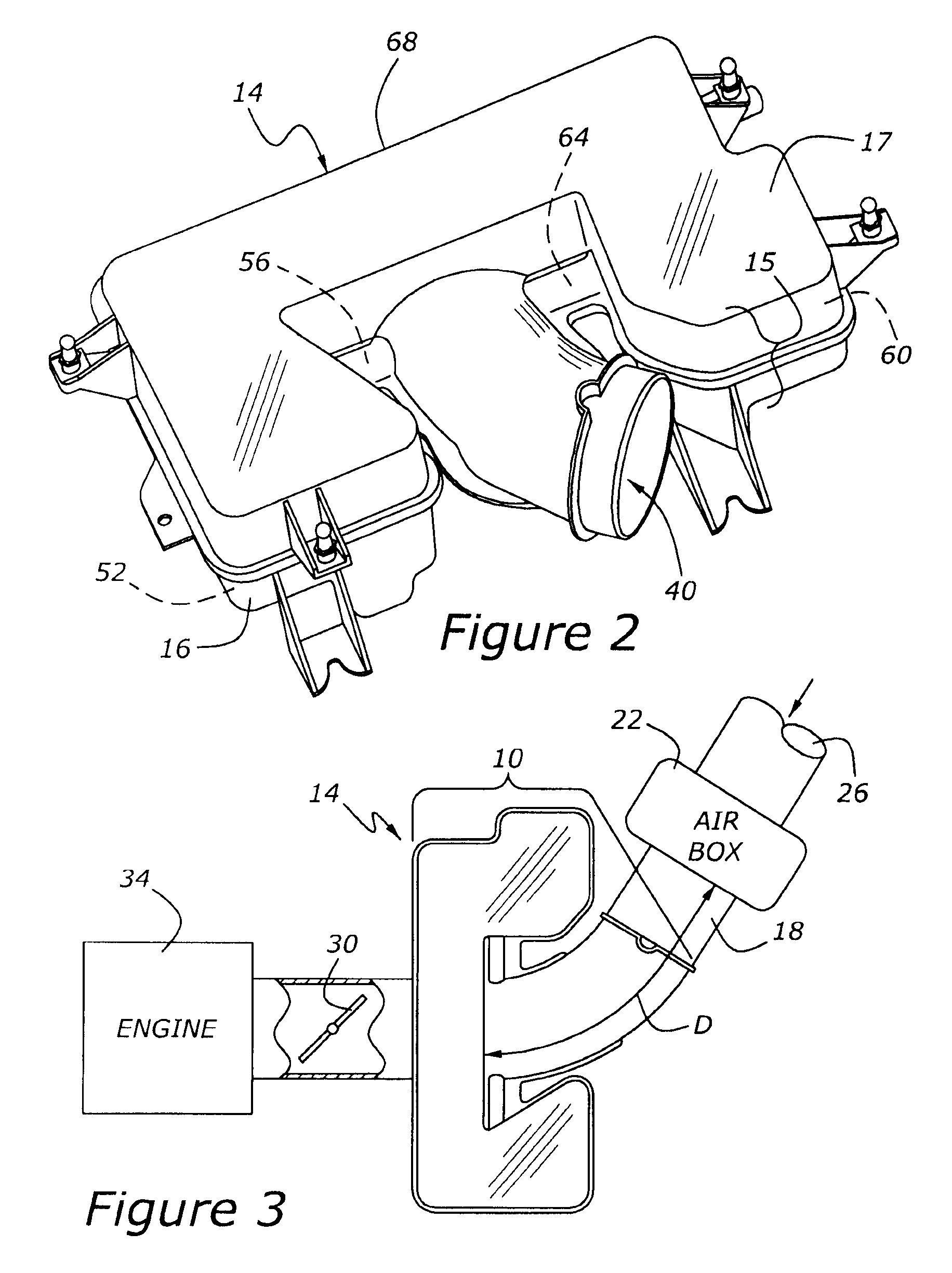

ActiveUS7967106B2Minimize impingementFlow loss minimizationExhaust apparatusSilencing apparatusExternal combustion engineHelmholtz resonator

An air induction sound modification system for an internal combustion engine includes a multi-frequency sound suppression unit having Helmholtz resonators and a multi-component expansion chamber. A sound generator, which functions to radiate sound at a desirable, tuned frequency, extends between the multi-function sound suppression unit and a second expansion chamber, such as an air cleaner box.

Owner:FORD GLOBAL TECH LLC

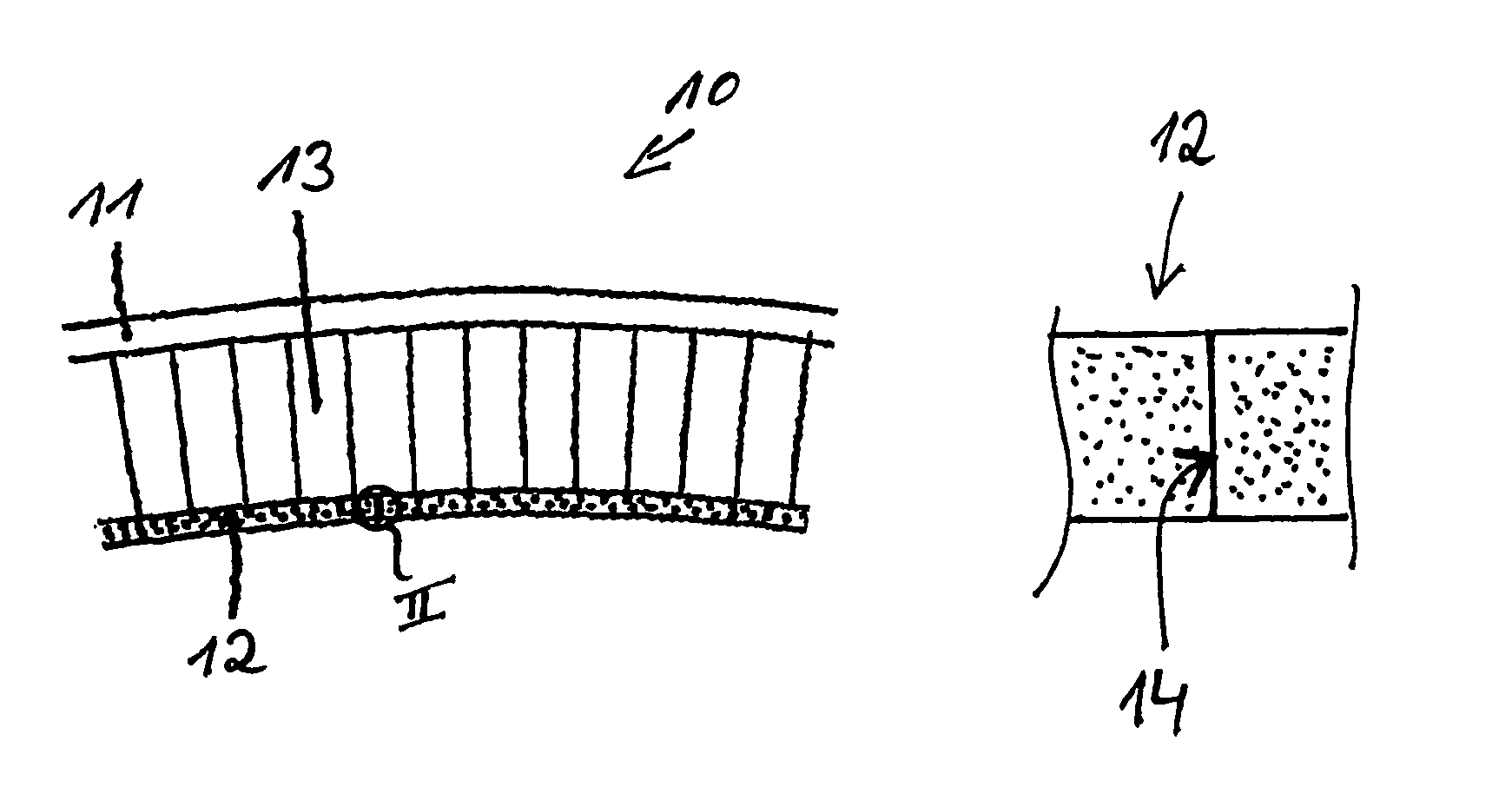

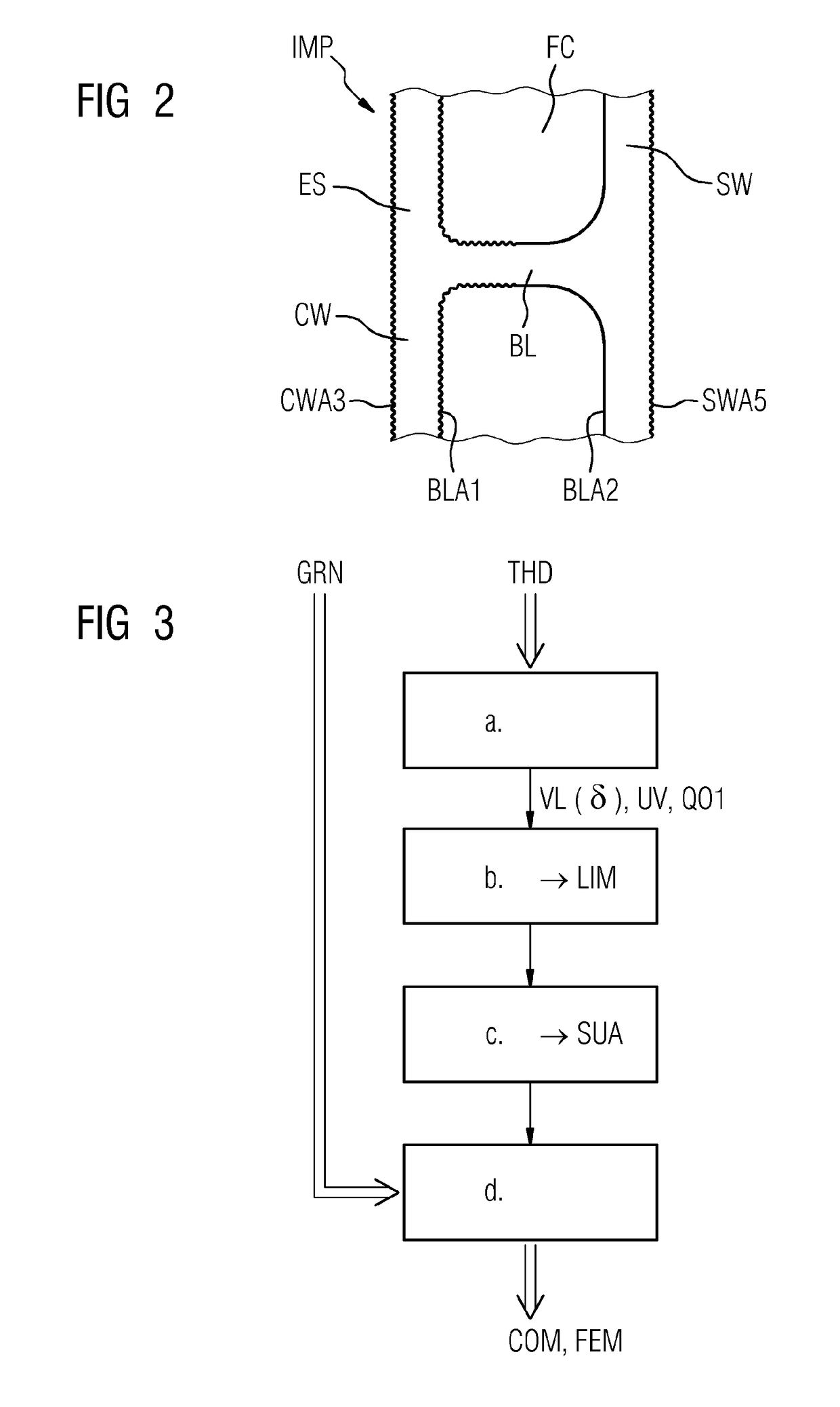

Blade cascade and turbomachine

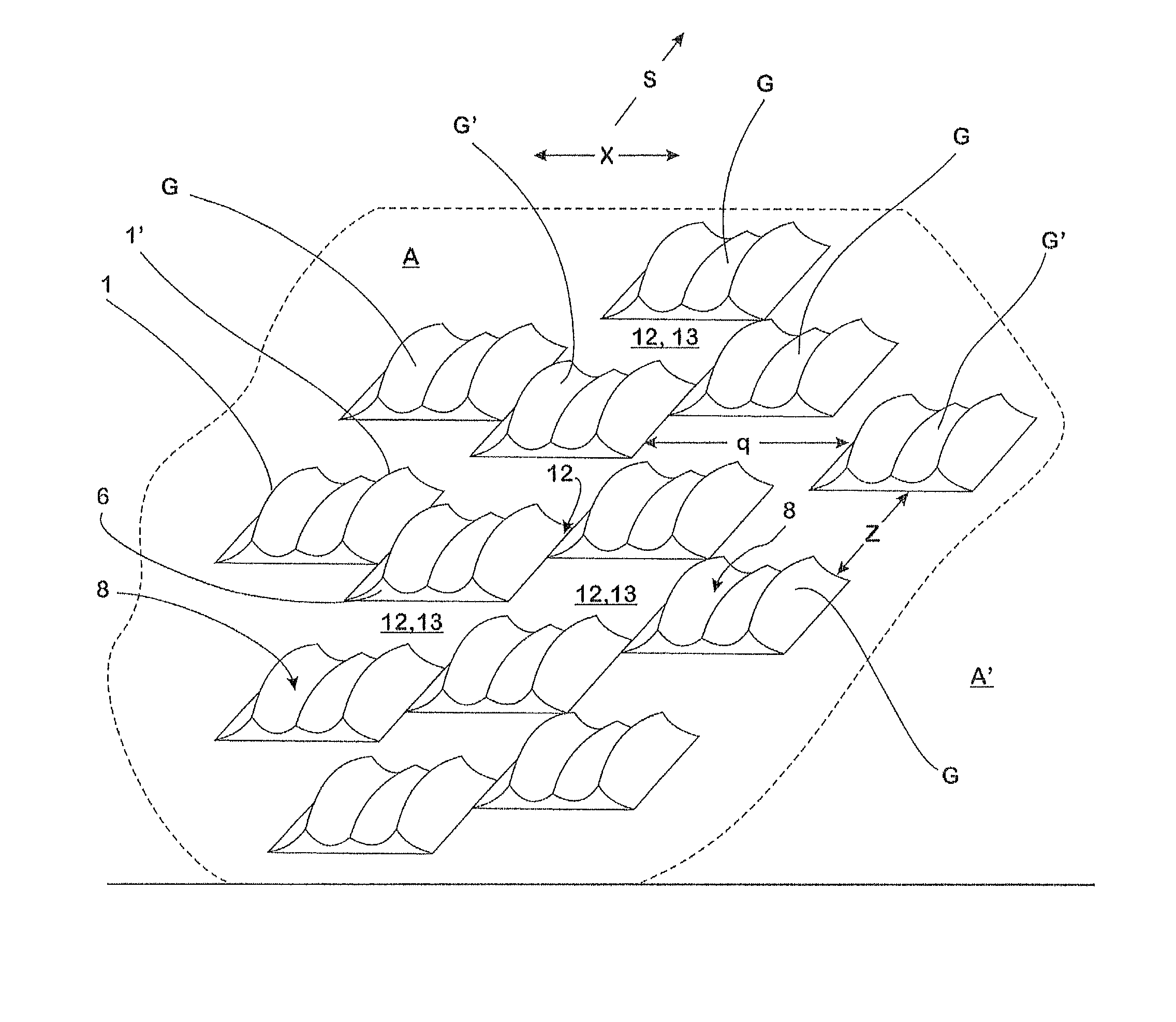

ActiveUS20150044038A1Reduce secondary flowEnhanced efficiencyEngine manufacturePump componentsMechanical engineering

Owner:MTU AERO ENGINES GMBH

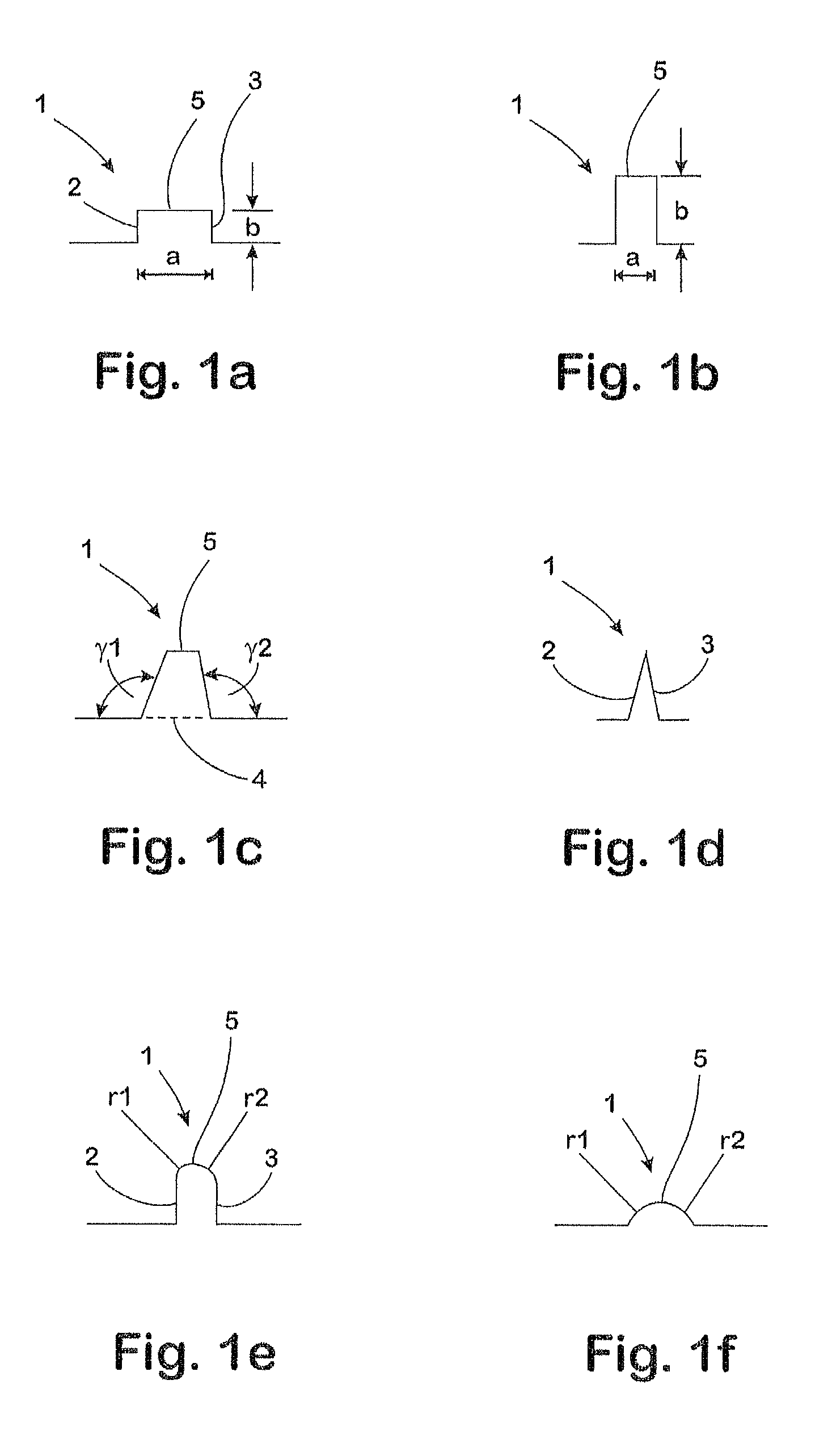

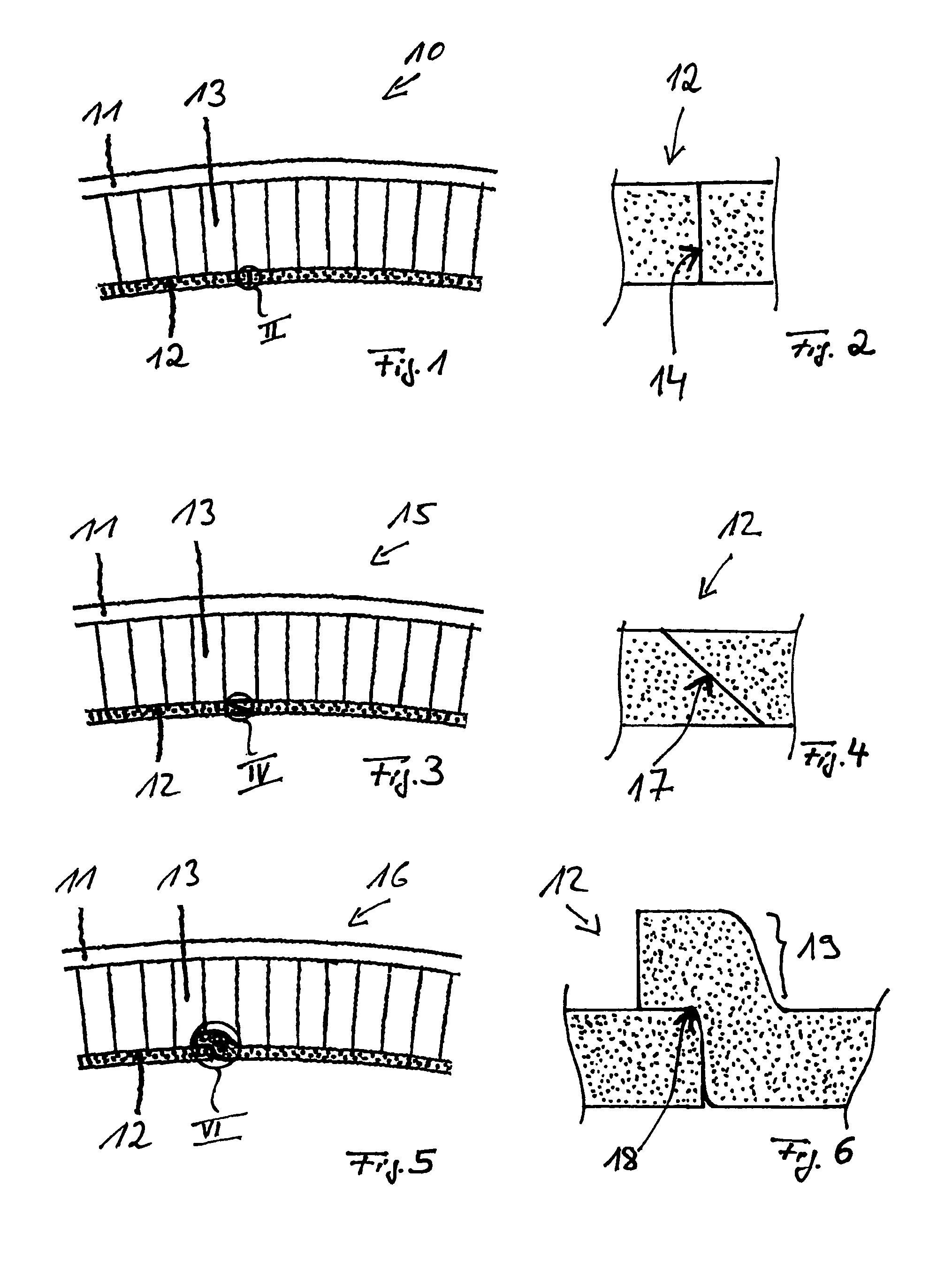

Product for fluidic applications, method for its production and use of such a product

ActiveUS9188287B2Avoid it happening againManufactured reproduciblyEnergy industryFluid dynamicsEngineeringMethods of production

Owner:OUTOKUMPU NIROSTA

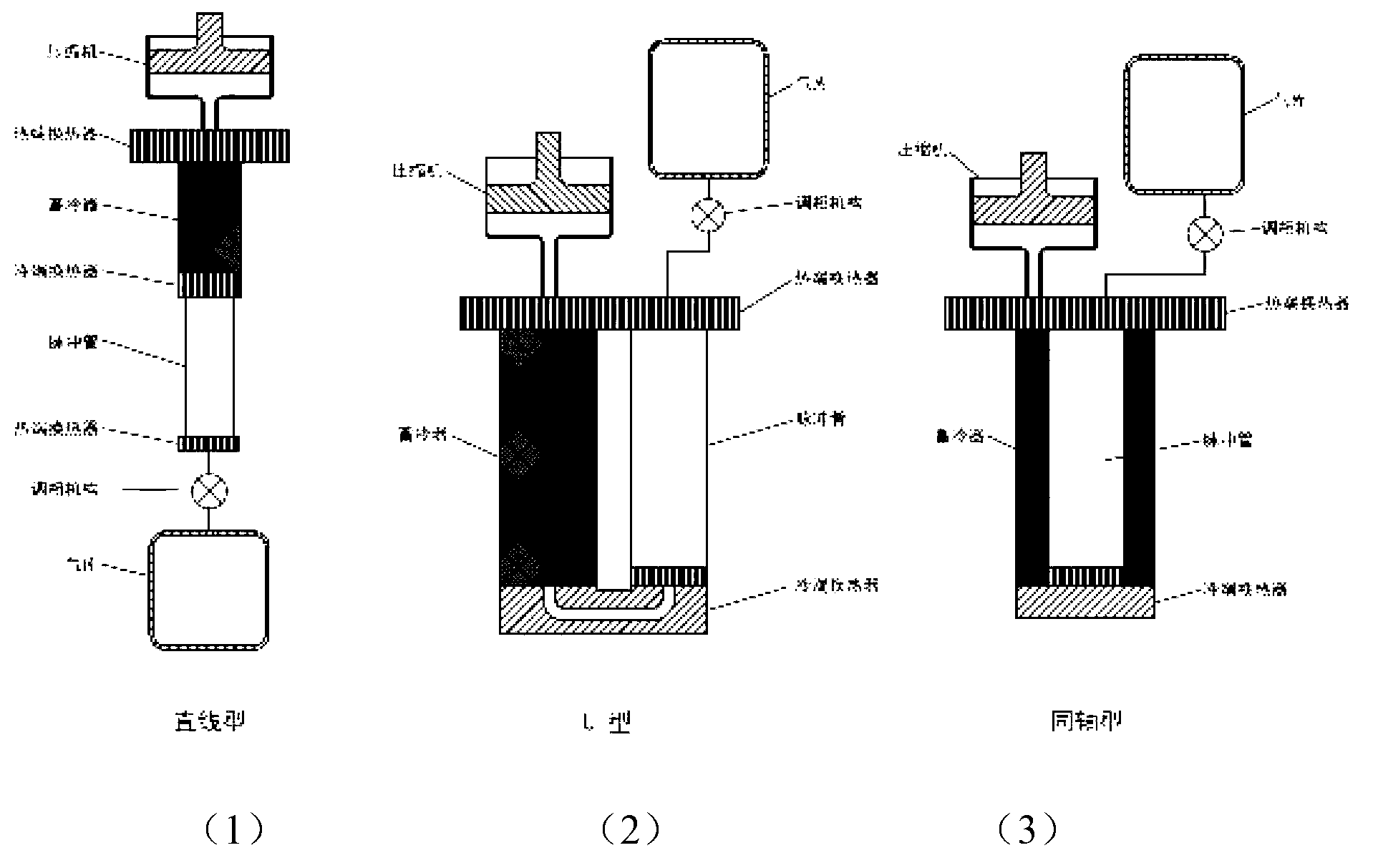

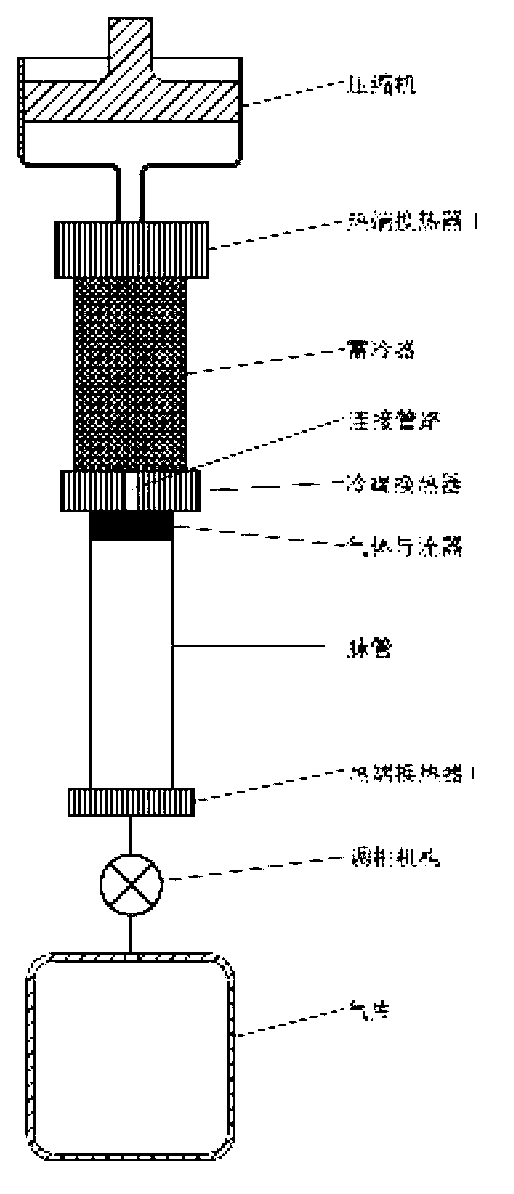

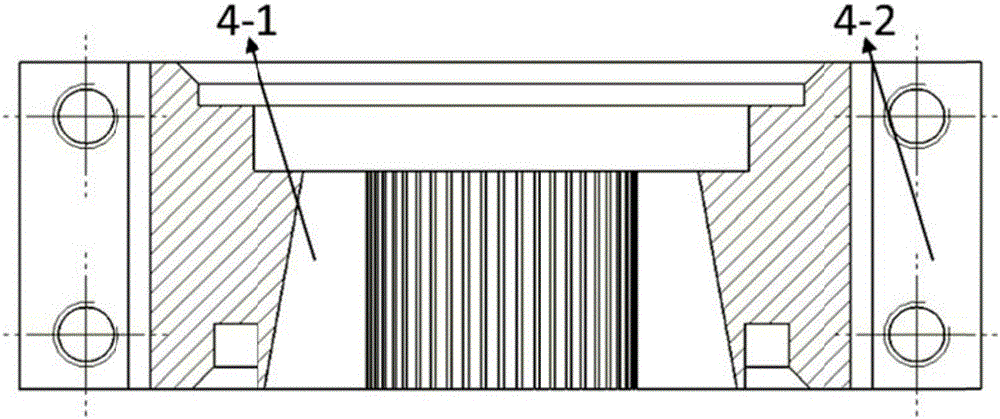

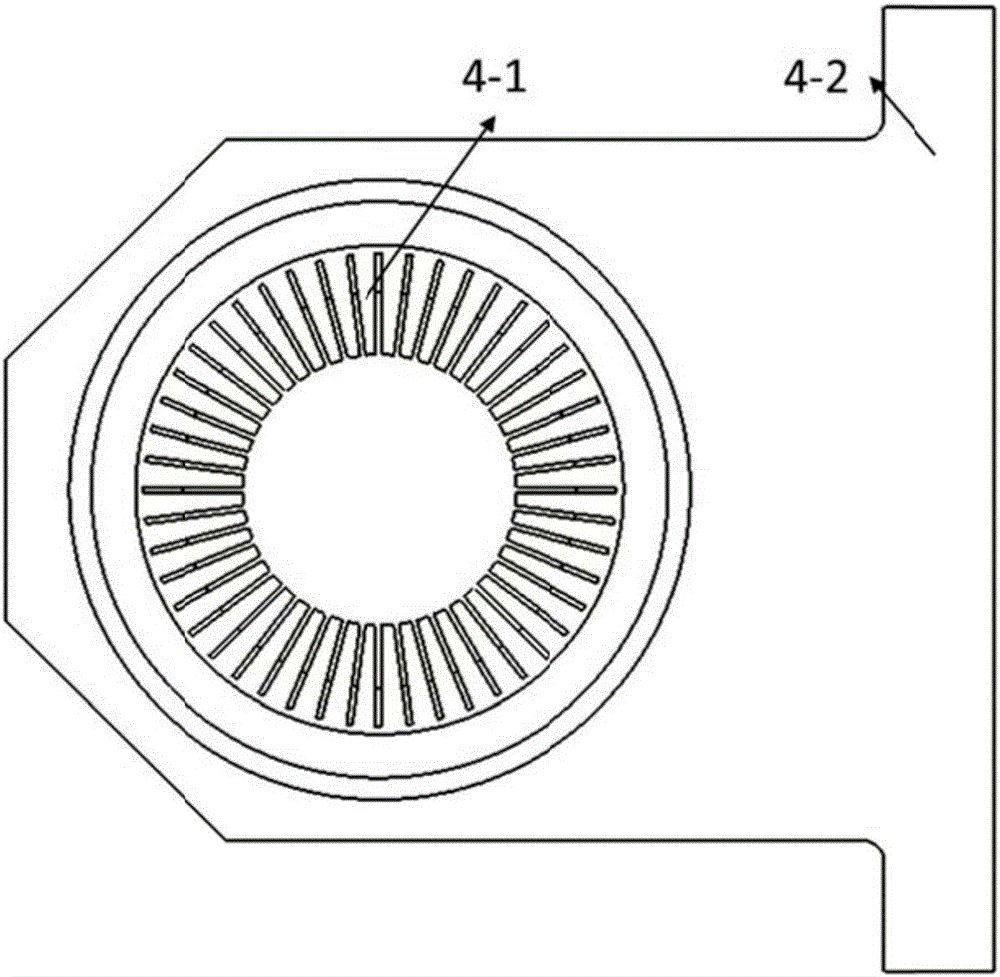

Integrated tapered slit cold-end heat exchanger of linear pulse tube refrigerator and manufacturing method

ActiveCN103017394AGuaranteed heat exchange effectAvoid dead volumeCompression machinesGas cycle refrigeration machinesLow speedWire cutting

The invention discloses an integrated tapered cold-end heat exchanger for a linear pulse tube refrigerator and a manufacturing method. The heat exchanger mainly comprises a shell, a tapered slit body and a T-shaped guide core column, wherein the shell is a main heat-dispersing surface and a coupled interface, protects the tapered slit body and the T-shaped guide core column and is connected with a regenerator and a pulse tube; the tapered slit body is cut inside the shell by a low-speed wire cutting technology; the T-shaped guide core column is arranged in the center; and a core column slit is cut on the guide core column. According to the heat exchanger, the heat exchanging area is maximized within a limited volume by uniformly cutting the tapered slit in unequal diameters; the cutting way makes a natural transition from a large diameter end to a small diameter end; the thermal resistance and flow loss are minimized; and the gas in the pulse tube is laminarized without an additional gas director. The heat exchanger greatly improves the performance of the whole linear pulse tube refrigerator and is very significant to the practicality of the linear pulse tube refrigerator, aerospace application and other aspects.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Blade cascade and turbomachine

ActiveUS10041353B2Reduce flowImprove efficiencyEngine manufactureBlade accessoriesEngineeringMechanical engineering

Owner:MTU AERO ENGINES GMBH

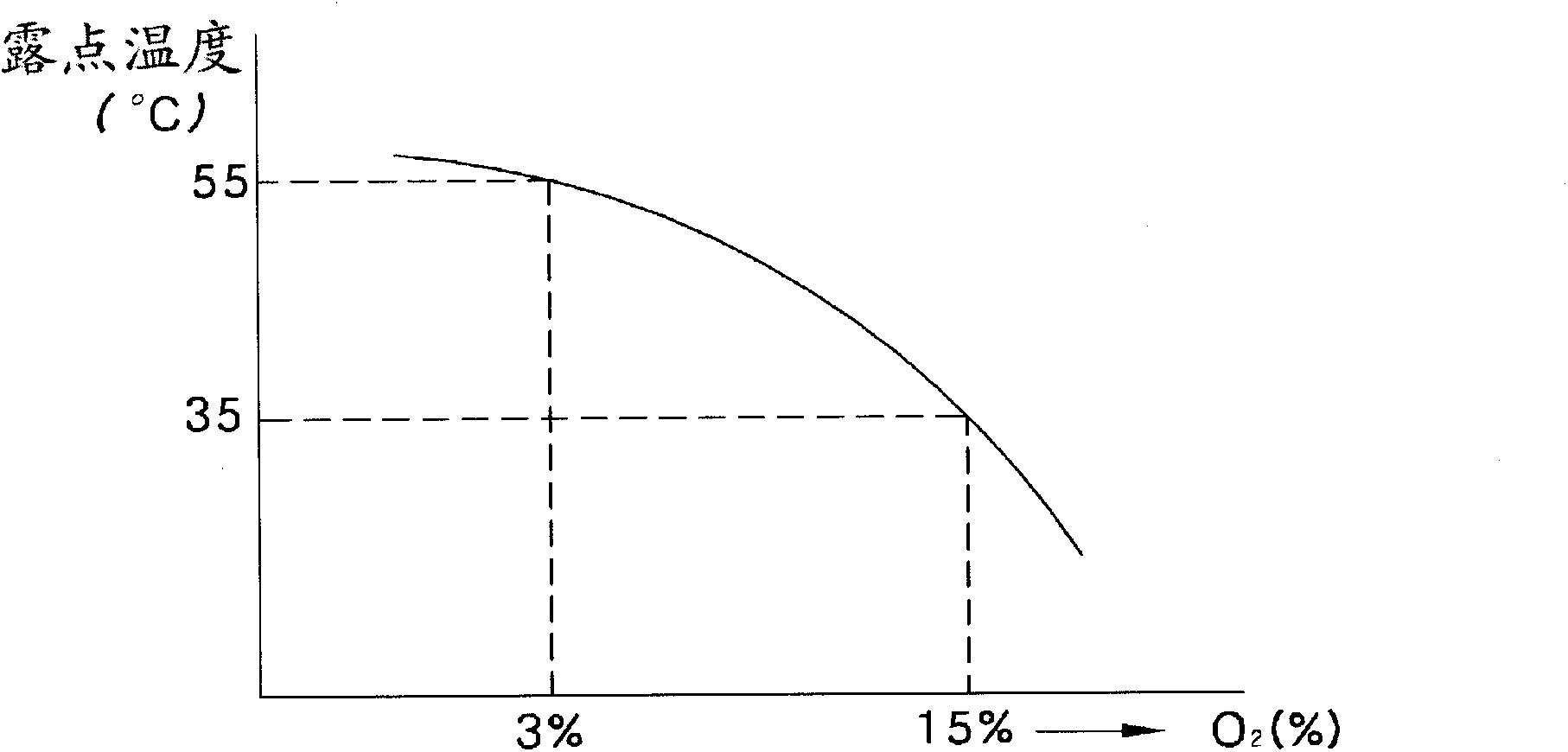

Separate flow path type of gas-air mixing device

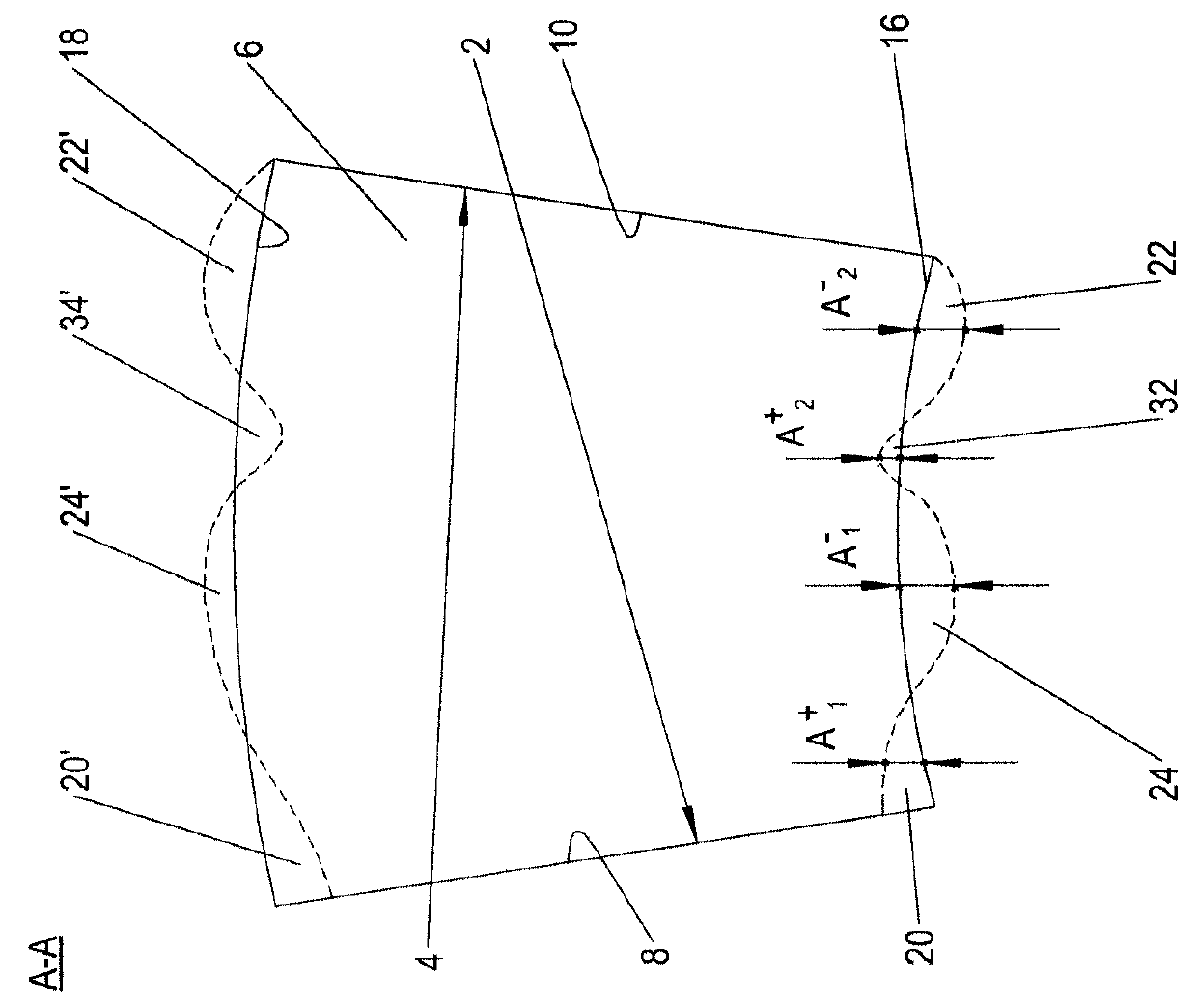

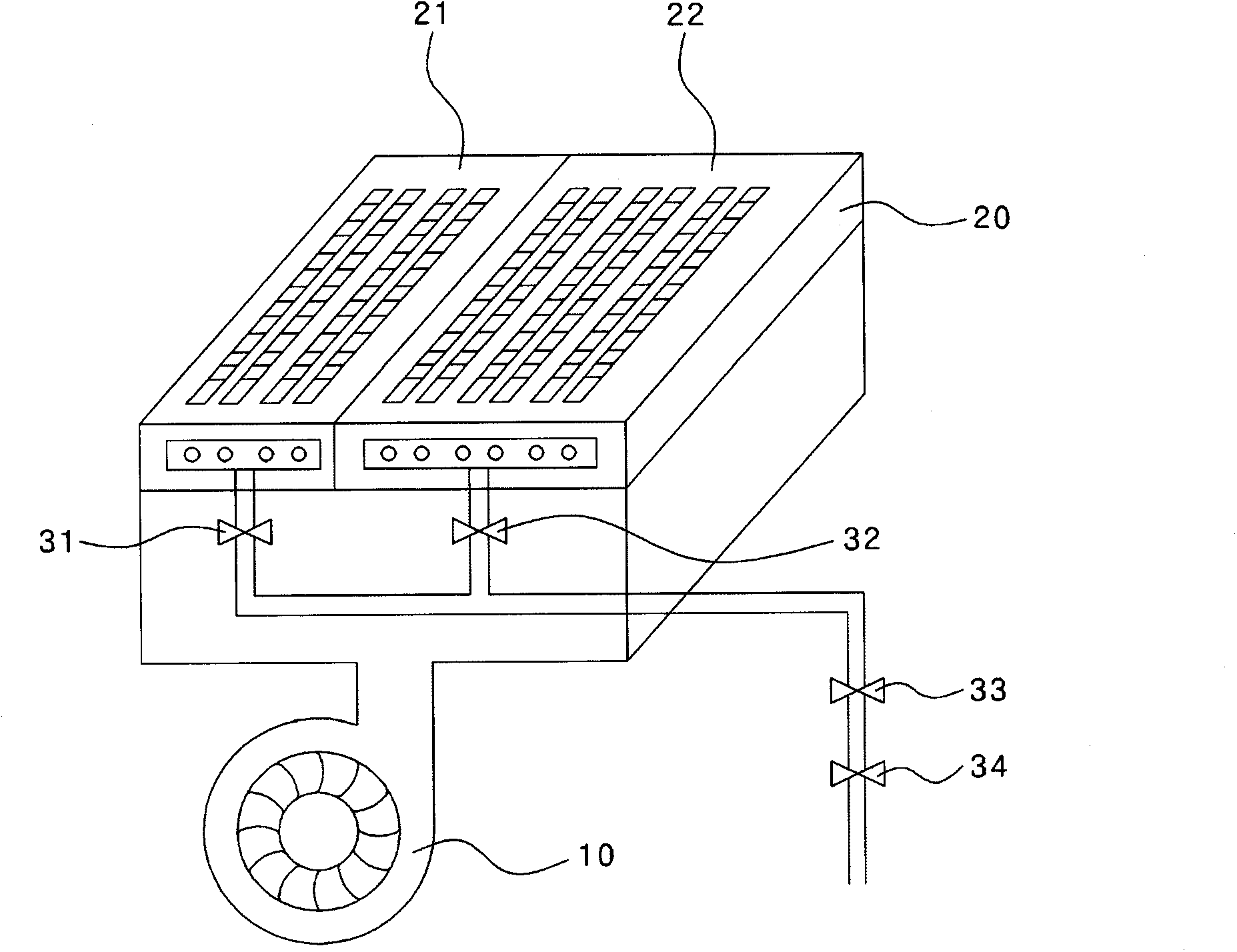

ActiveCN103328889AThere will be no problem of loss of efficiencyReduce flow noiseFuel supply regulationTransportation and packagingEngineeringGas supply

According to the present invention, a gas-air mixing device used in a gas boiler comprises: a gas supply tube branched into a first gas flow path and a second gas flow path; an air supply tube branched into a first air flow path and a second air flow path by means of an air-flow-path branching apparatus; a pressure valve which is connected to the inlet port side of the gas supply tube in order to adjust the supply rate of gas being supplied to the gas supply tube; and a drive unit in which two valve bodies are connected to a rod that moves vertically up and down due to the magnetic force of an electromagnet; and the air-flow-path branching apparatus is formed so as to have a slot that can link through to either the first air flow path or the second air flow path, and so as to have a joining part which the rod can pass through in a position corresponding to the slot.

Owner:KYUNGDONG NAVIEN

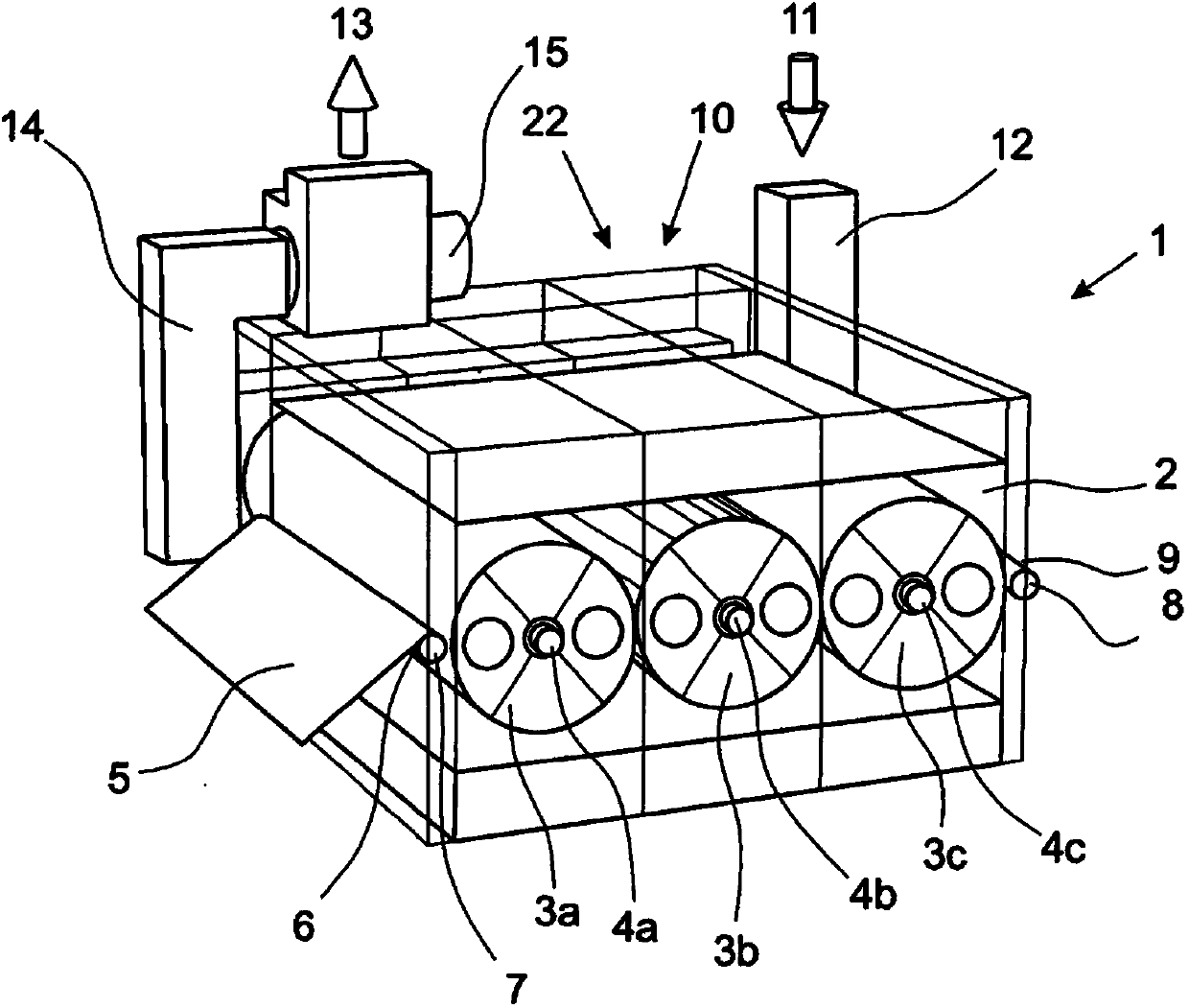

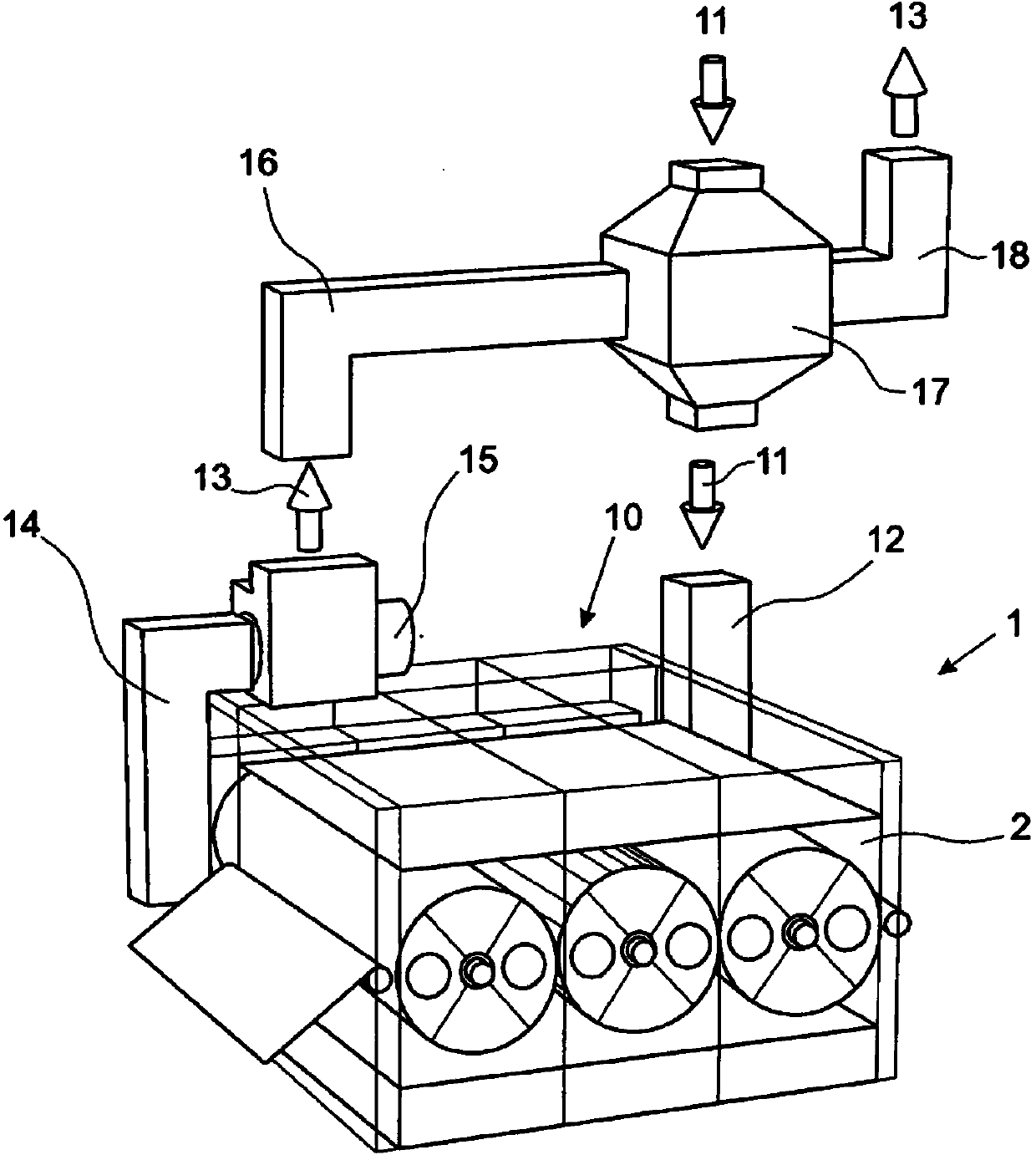

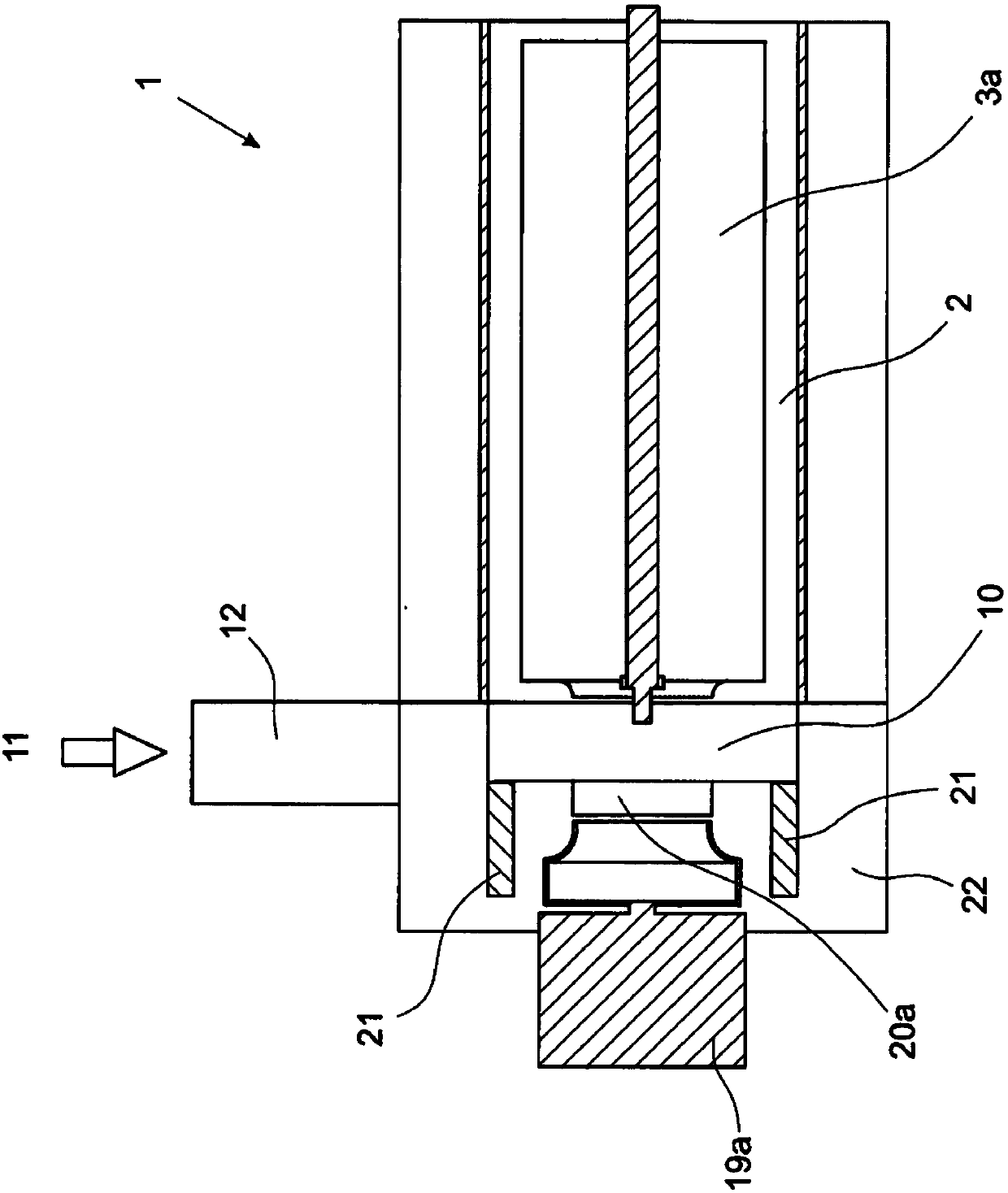

Dryer for a textile product web

ActiveCN104136871AFree to learnReduce flow rateDrying gas arrangementsDrying machines with progressive movementsMechanical engineeringEngineering

The invention relates to a dryer for a textile product web, comprising a dryer chamber (2) and having at least one drum (3a), which is arranged in the dryer chamber (2) and around which the product web (5) wraps at least partly, wherein heated drying air flows through the product web (5) and is led away via an interior of the drum (3a), and the dryer (1) has a separate additional chamber (10), via which fresh air (11) is led in and exhaust air (13) is led away.

Owner:TRUETZSCHLER GRP SE

Air induction sound modification system for internal combustion engine

ActiveUS20090236172A1Minimize impingementFlow loss minimizationExhaust apparatusSilencing apparatusExternal combustion engineHelmholtz resonator

An air induction sound modification system for an internal combustion engine includes a multi-frequency sound suppression unit having Helmholtz resonators and a multi-component expansion chamber. A sound generator, which functions to radiate sound at a desirable, tuned frequency, extends between the multi-function sound suppression unit and a second expansion chamber, such as an air cleaner box.

Owner:FORD GLOBAL TECH LLC

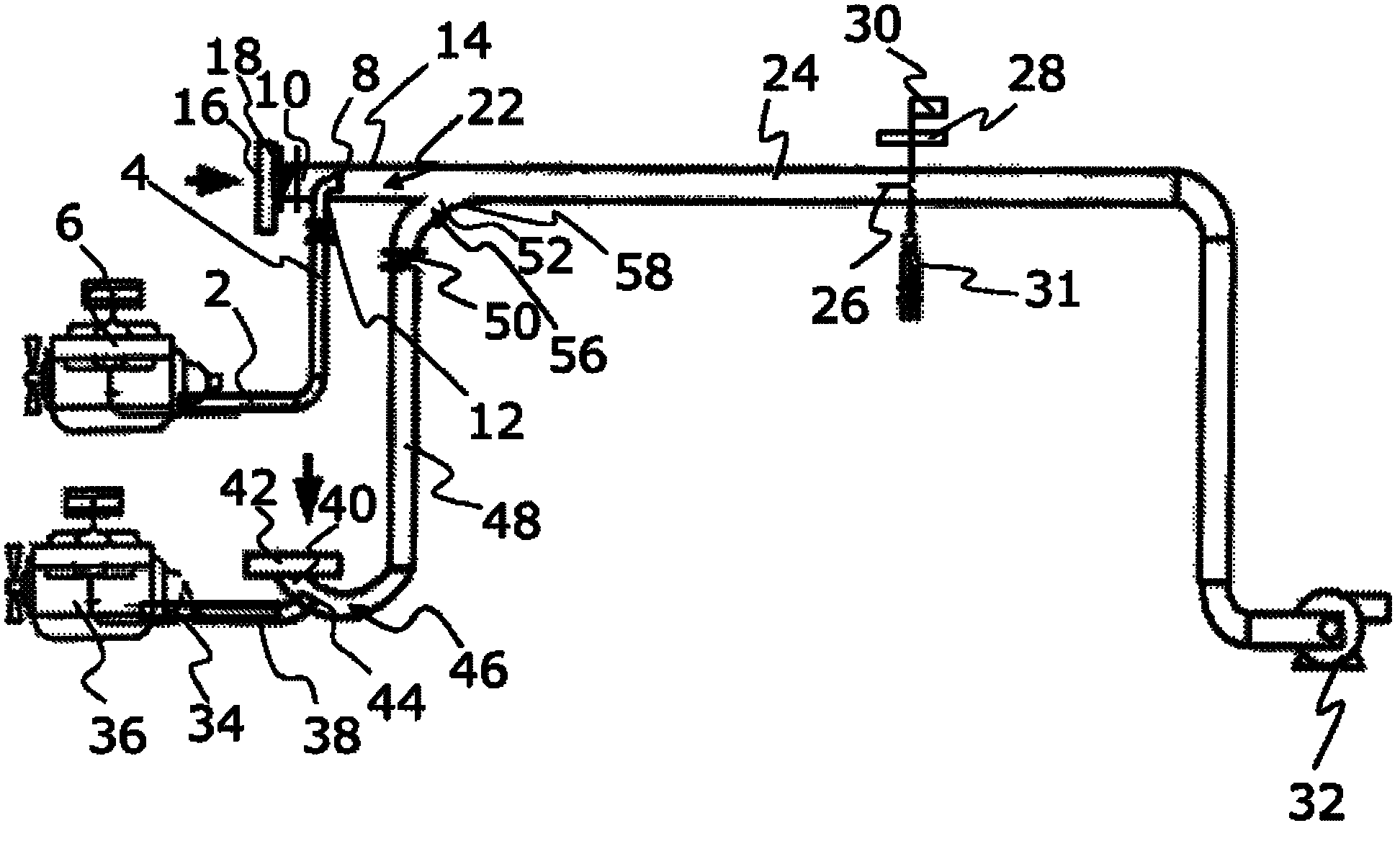

System for taking exhaust gas samples from internal combustion engines

ActiveCN102378906AHigh speedWell mixedInternal-combustion engine testingSamplingExternal combustion engineAir filter

Systems for taking exhaust gas samples are known. Use is normally made of CVS systems in which an exhaust gas channel (4) is fluidically connected to an exhaust gas source (6) via an exhaust gas inlet (2) and an air channel (10), into which ambient air is sucked via an air filter (16), opens in a first mixing zone (22) which merges into a dilution tunnel (24) from which the samples are taken. The invention now proposes that the system have a second exhaust gas channel (38) which is fluidically connected to a second exhaust gas source (36) via a second exhaust gas inlet (34) and has a second mixing zone (46), wherein the diluted exhaust gas / air mass flows flow either from the first exhaust gas source (6) or from the second exhaust gas source (36) into the one dilution tunnel (23) and to the sampling probe (26). A particularly advantageous embodiment is described in this respect. The system is suitable for the connection of diesel and spark ignition engines, the exhaust gas of which can thereby be removed and analysed for the first time via only one sampling point and using only one dilution tunnel and one pump in a common system.

Owner:AVL EMISSION TEST SYST GMBH

Air-blowing apparatus of cleaner

InactiveUS7179053B2Flow loss minimizationReduce noiseEngine manufacturePump componentsEngineeringMechanical engineering

Disclosed herein is an air-blowing apparatus of a cleaner. The air-blowing apparatus comprises a fan having a plurality of blades spaced apart from each other in the circumferential direction of the fan for generating a blowing force in the centrifugal direction thereof, and a diffuser disposed outside the fan in the radial direction of the fan for diffusing air blown from the fan. Each blade is formed such that at least a part of the blade is shorter than the other part of the blade extending to the outer diameter of the fan, whereby noise is reduced while blowing efficiency is not affected.

Owner:LG ELECTRONICS INC

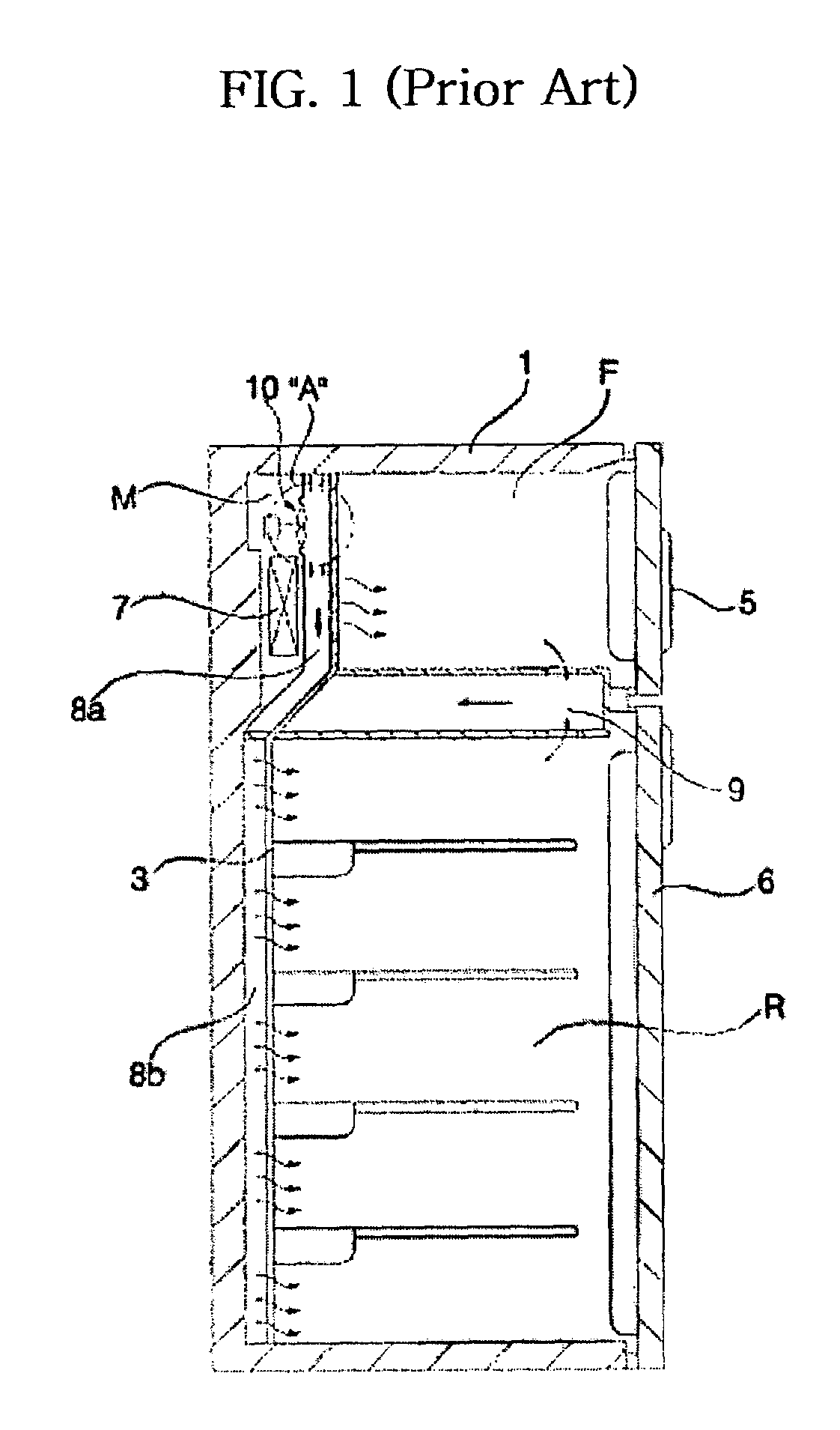

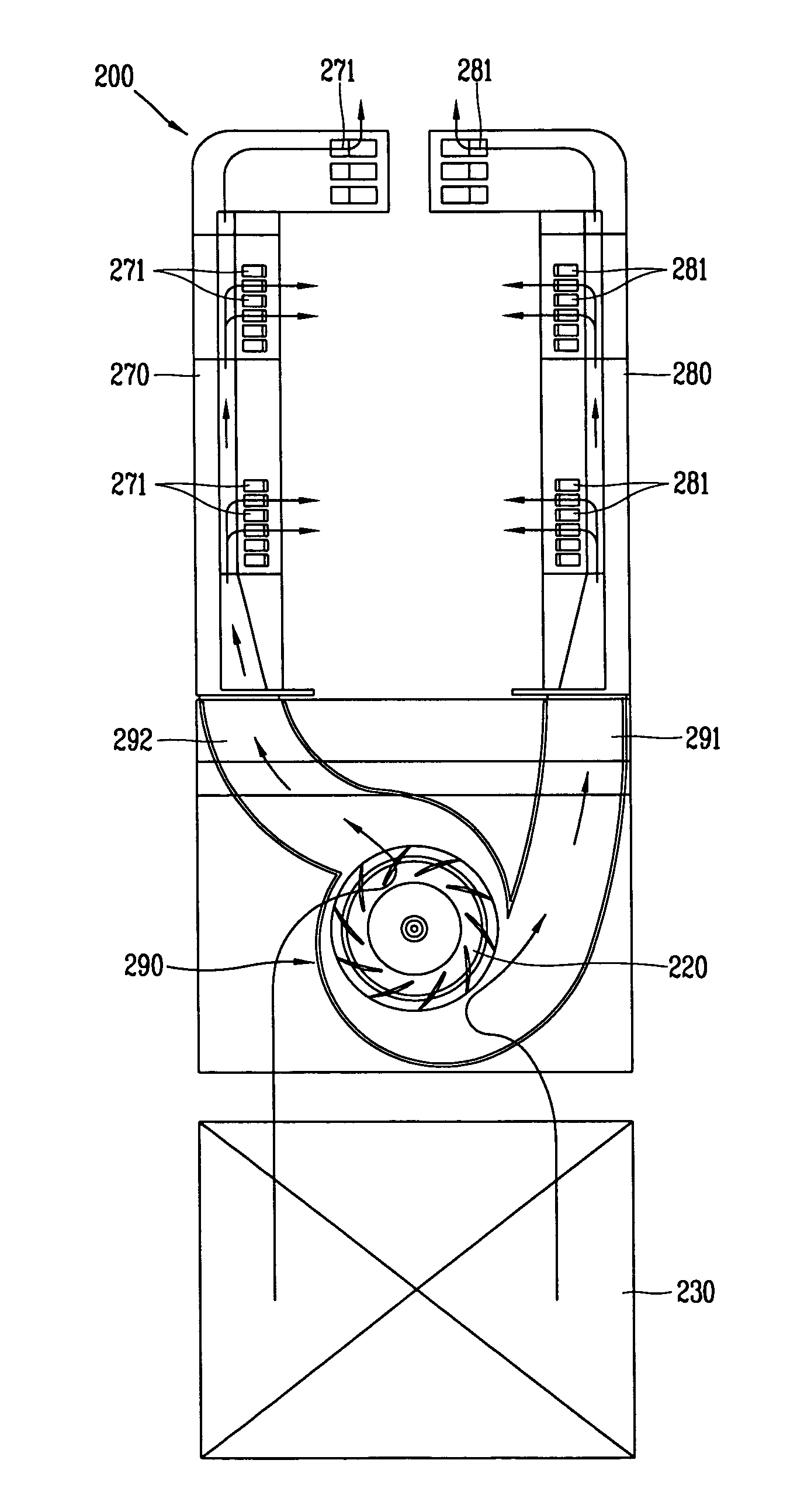

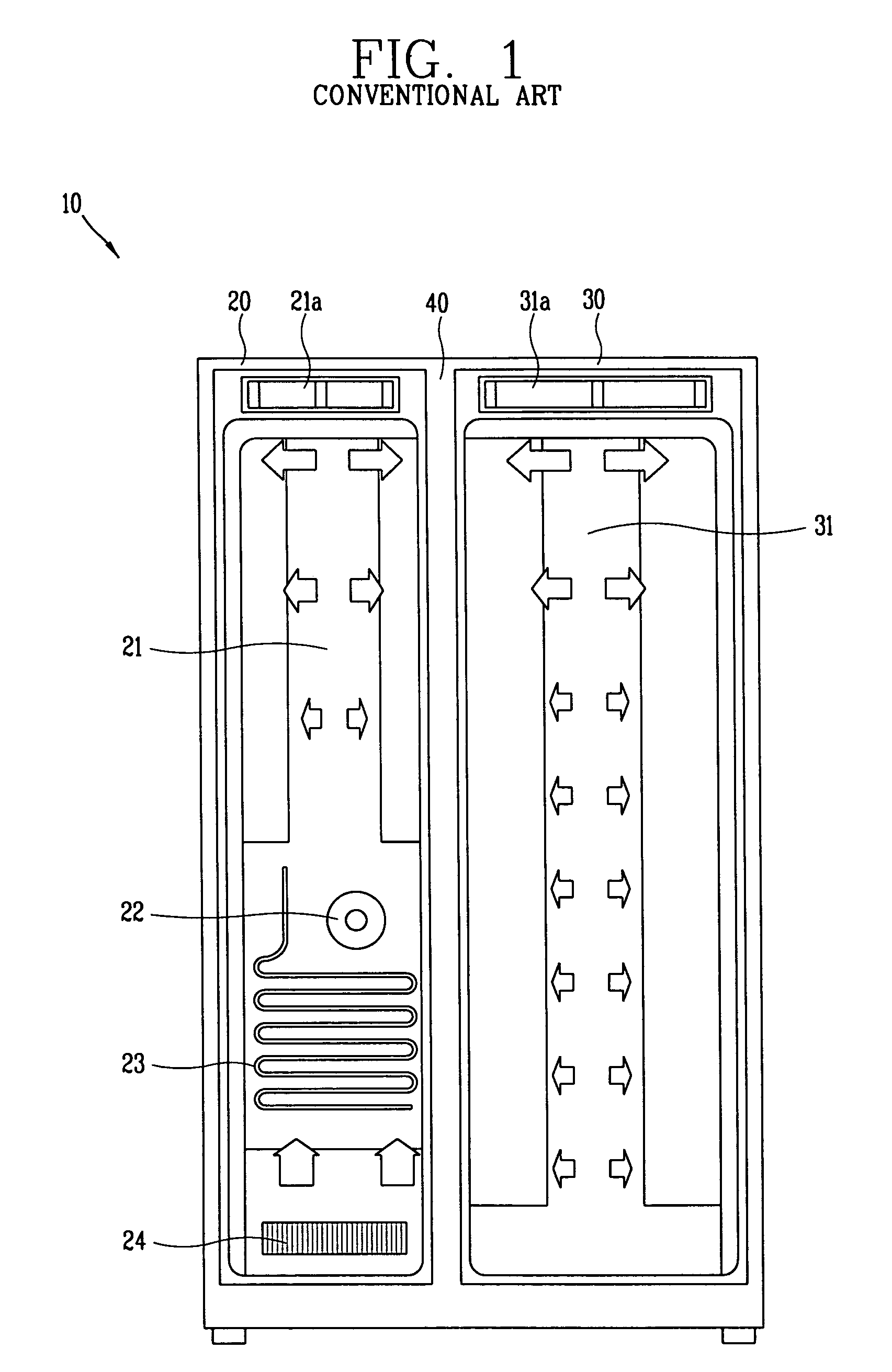

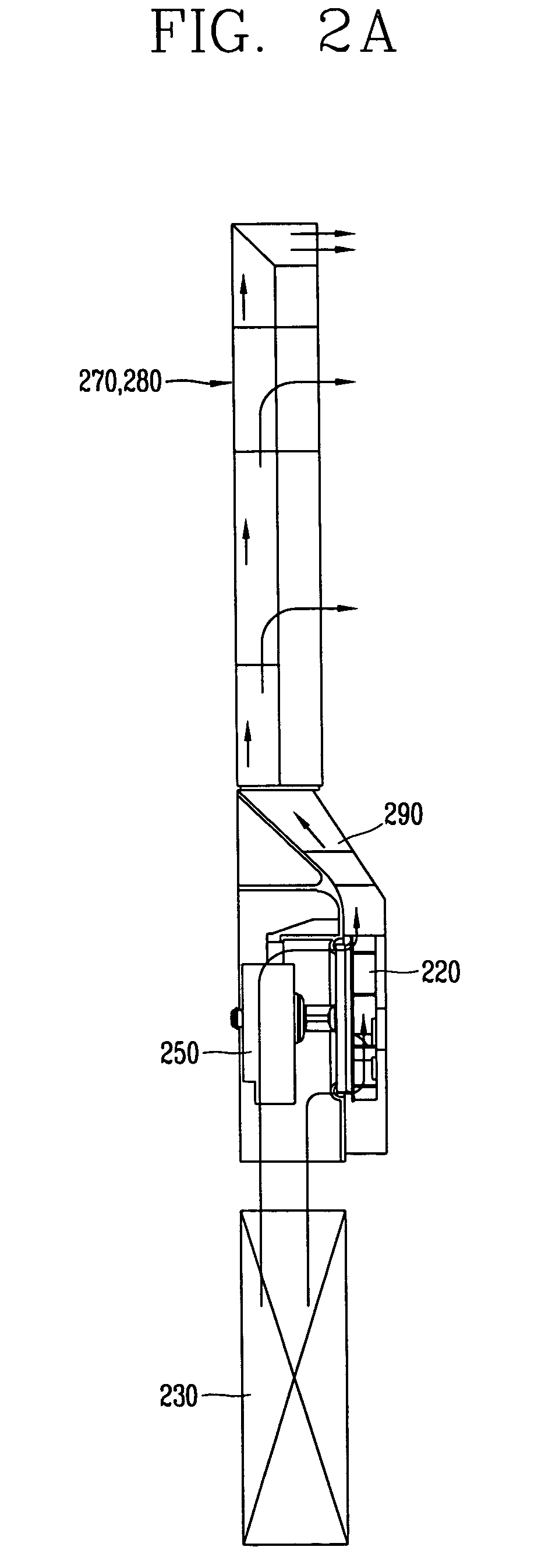

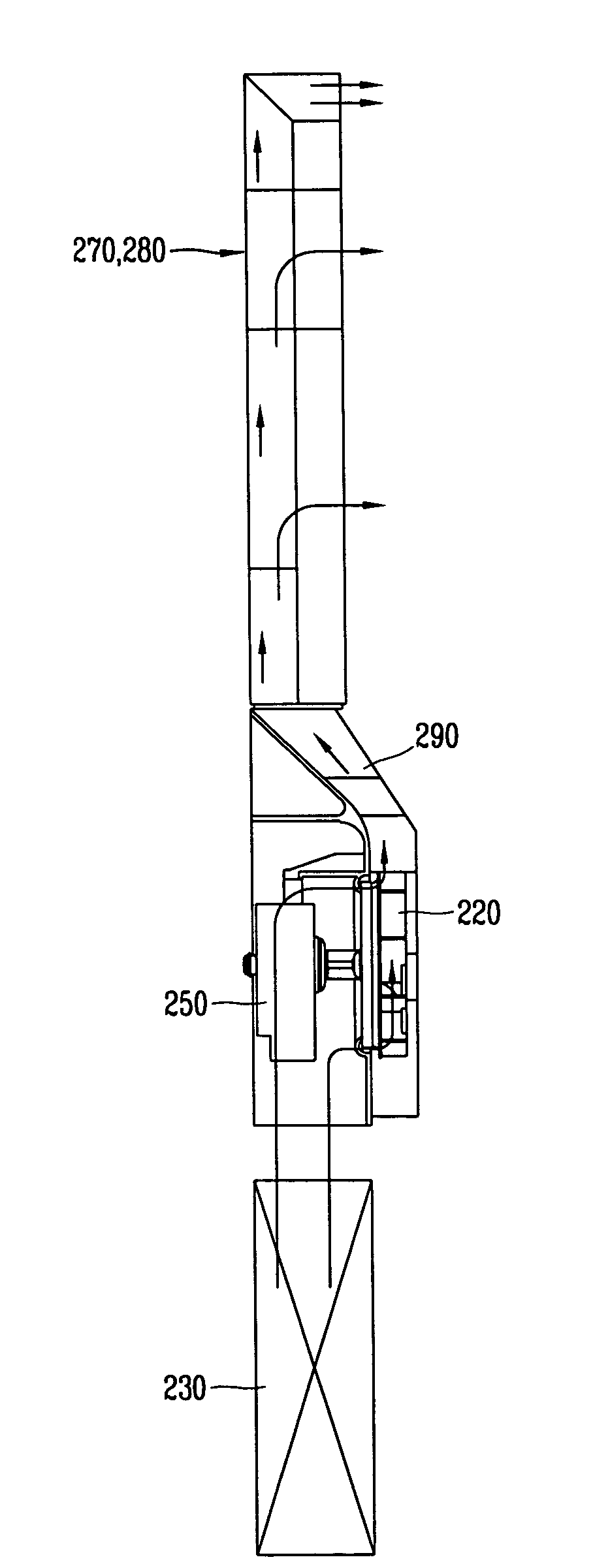

Refrigerator

ActiveUS7762100B2Flow loss minimizationImprove fan efficiencyPump componentsLighting and heating apparatusEngineeringCold store

A refrigerator is provided that includes a fan that blows cool air generated by an evaporator to a freezing chamber or a refrigerating chamber; a scroll guide that discharges cool air discharged from the fan in two directions; a guide pipeline formed at the scroll guide in two directions, that guides cool air discharged from the scroll guide; and a cool air duct connected to the guide pipeline, that supplies cool air to the freezing chamber or the refrigerating chamber. An optimum scroll guide that can be applicable even when a plurality of cool air ducts are implemented is provided, thereby reducing a flow loss of cool air discharged from the fan and decreasing power consumption.

Owner:LG ELECTRONICS INC

Refrigerator

ActiveUS20070266728A1Flow loss minimizationImprove fan efficiencyPump componentsLighting and heating apparatusCold storeRefrigerated temperature

A refrigerator comprises: a fan for blowing cool air generated by an evaporator to a freezing chamber or a refrigerating chamber; a scroll guide for discharging cool air discharged from the fan in two directions; a guide pipeline formed at the scroll guide in two directions for guiding cool air discharged from the scroll guide; and a cool air duct connected to the guide pipeline for supplying cool air to the freezing chamber or the refrigerating chamber. An optimum scroll guide that can be applicable even when a plurality of cool air ducts are implemented is provided, thereby reducing a flow loss of cool air discharged from the fan and decreasing consumption power.

Owner:LG ELECTRONICS INC

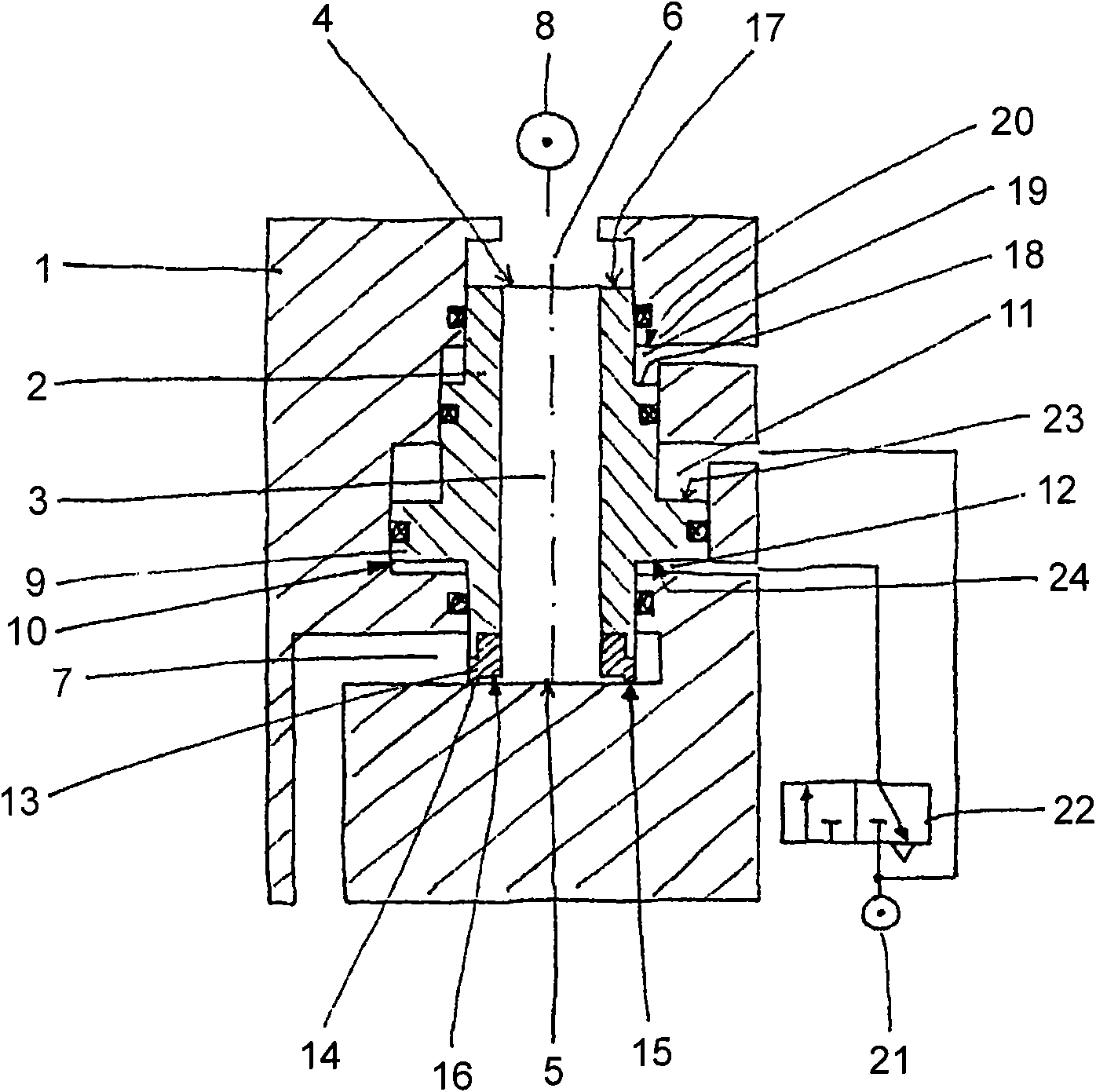

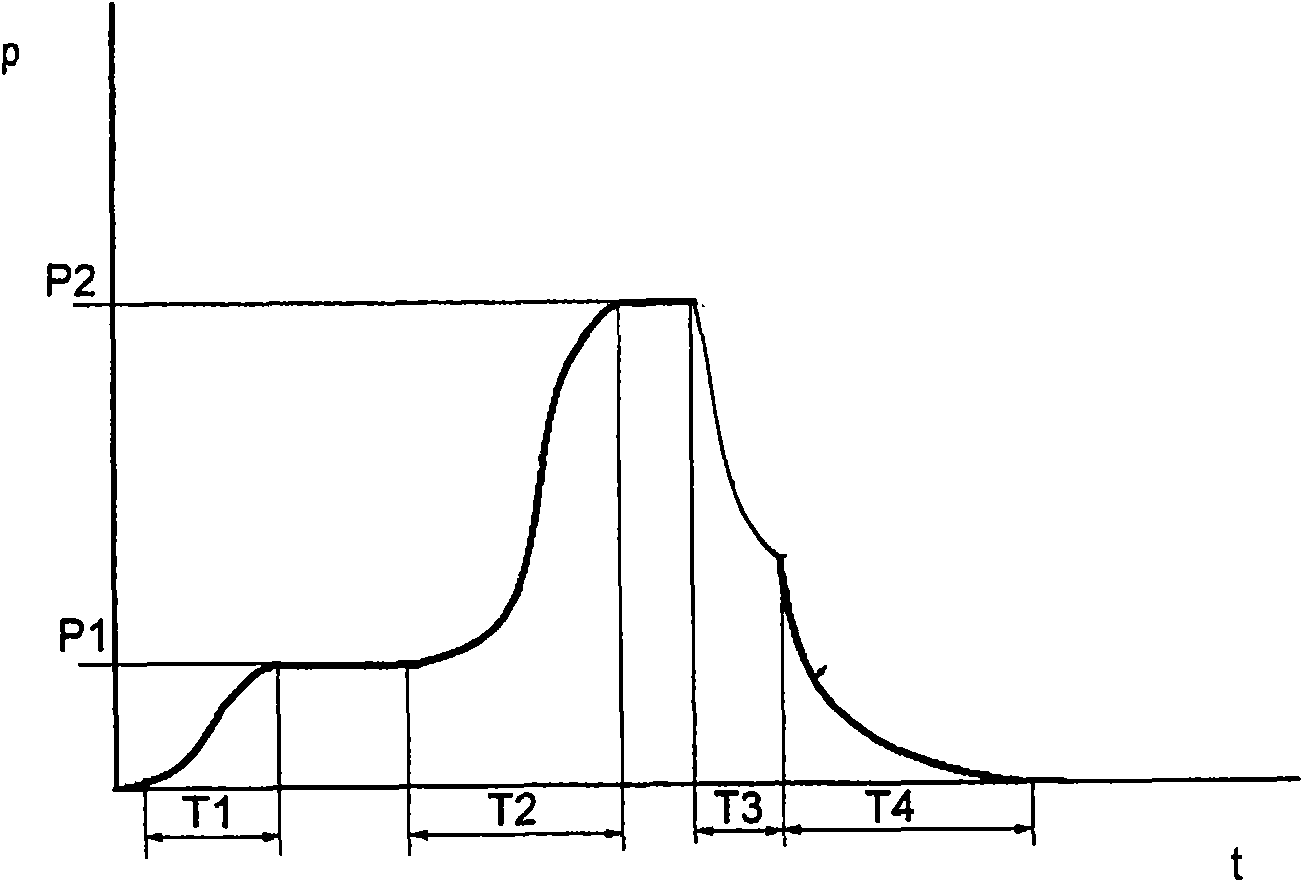

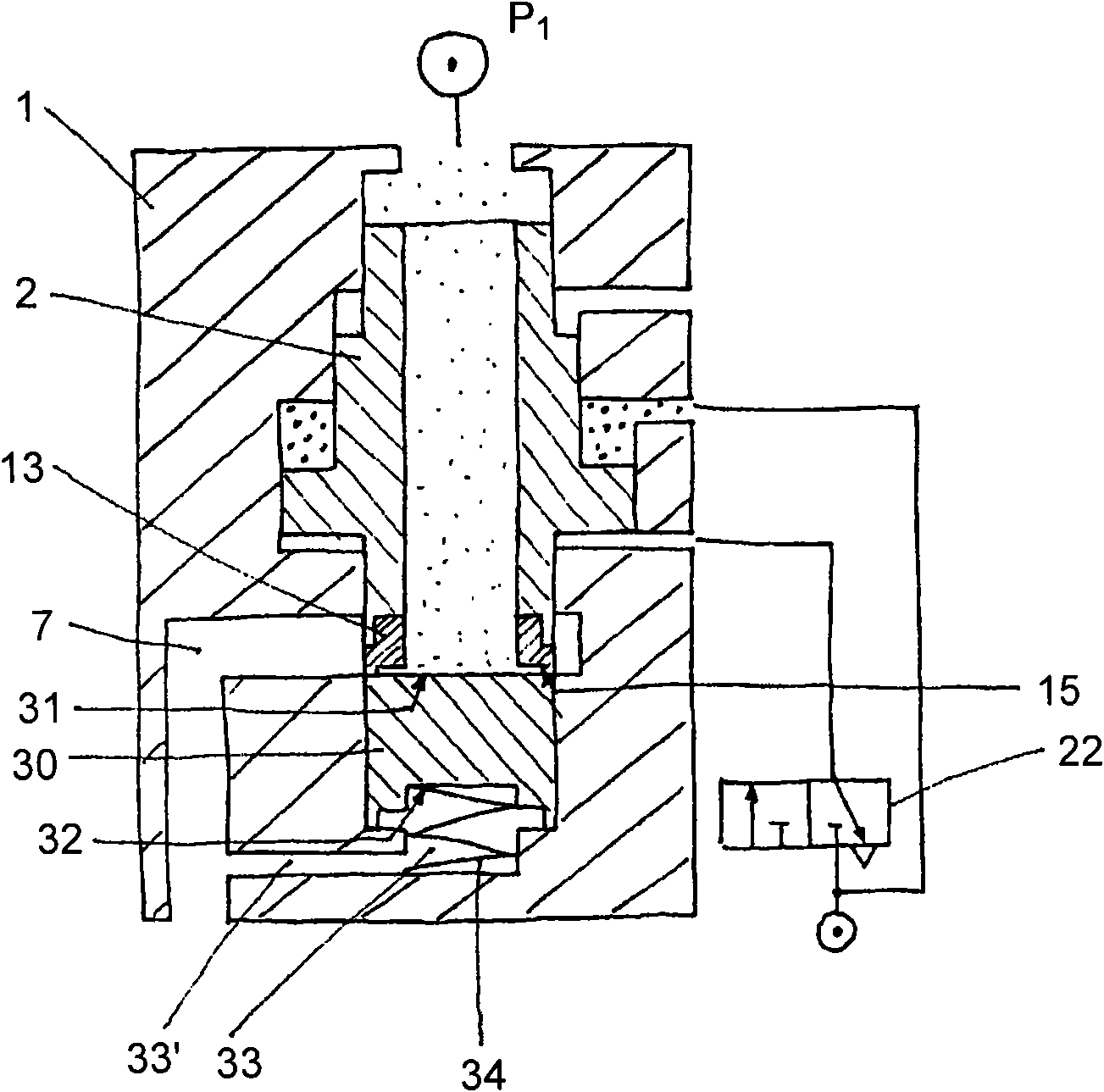

Air-controlled valve

ActiveCN101663524AEasy to controlSmall sizeOperating means/releasing devices for valvesPiston ringControl valves

The present invention relates to a valve with a housing (1) and a piston (2), wherein the piston (2) has a channel (3) connecting the two end faces (4; 5) and a piston ring (9) which protrudes radially outward and which is arranged on the outside of the piston (2) and is disposed between the two end faces of the piston (2). A ring-shaped, axially aligned valve seal (13), the end surface (14) of which forms the closing surface (15) of the piston, is disposed on one of the two end faces (5) and, in the closed state of the piston (2), is in contact with a seating surface (15) of the correspondingvalve space (7). Furthermore, the piston (2) and the valve seal (13) are dimensioned and disposed in such a way that the active areas (16; 17) thereof are practically equalized in the open state of the piston (2) and, in the closed state, the active area (16) of the end face (5) in the region of the valve seal (13) is smaller than that of the opposite end face (4).

Owner:오이겐자이츠아게

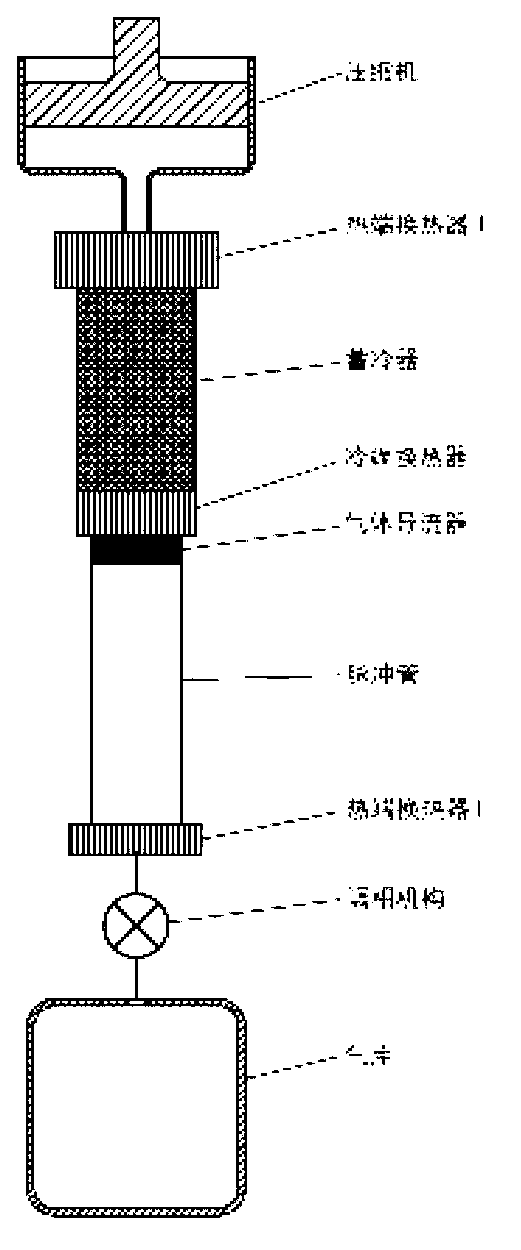

Secondary intermediate heat exchanger for thermal coupling coaxial two-stage pulse pipe refrigerator and design method

InactiveCN106642822AMinimizeGuaranteed heat exchange effectEvaporators/condensersPlate heat exchangerIntermediate heat exchanger

The invention discloses a secondary intermediate heat exchanger for a thermal coupling coaxial two-stage pulse pipe refrigerator and a design method. The heat exchanger is of a structure which is machined through a hollow high-heat-conductivity material and is approximate to a column shape, and conical slit bodies are arranged in the middle. The slit bodies are of trapezoidal fin structures arranged on the circumference uniformly. The inner hole diameter of each slit body is equal to the diameter of a pulse pipe, the outer diameter of the upper end of each slit body is equal to the inner diameter of a regenerator of the low-temperature section, and the outer diameter of the lower end of each slit body is equal to the inner diameter of a regenerator of the high-temperature section. According to the secondary intermediate heat exchanger, conical slits are uniformly machined in the portions of unequal diameters, maximization of the heat exchange area in the limit size is achieved, the machining manner transits naturally from the large-diameter end to the small-diameter end, and the flow loss is minimized. The secondary intermediate heat exchanger can effectively improve the overall performance of the thermal coupling coaxial two-stage pulse pipe refrigerator.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

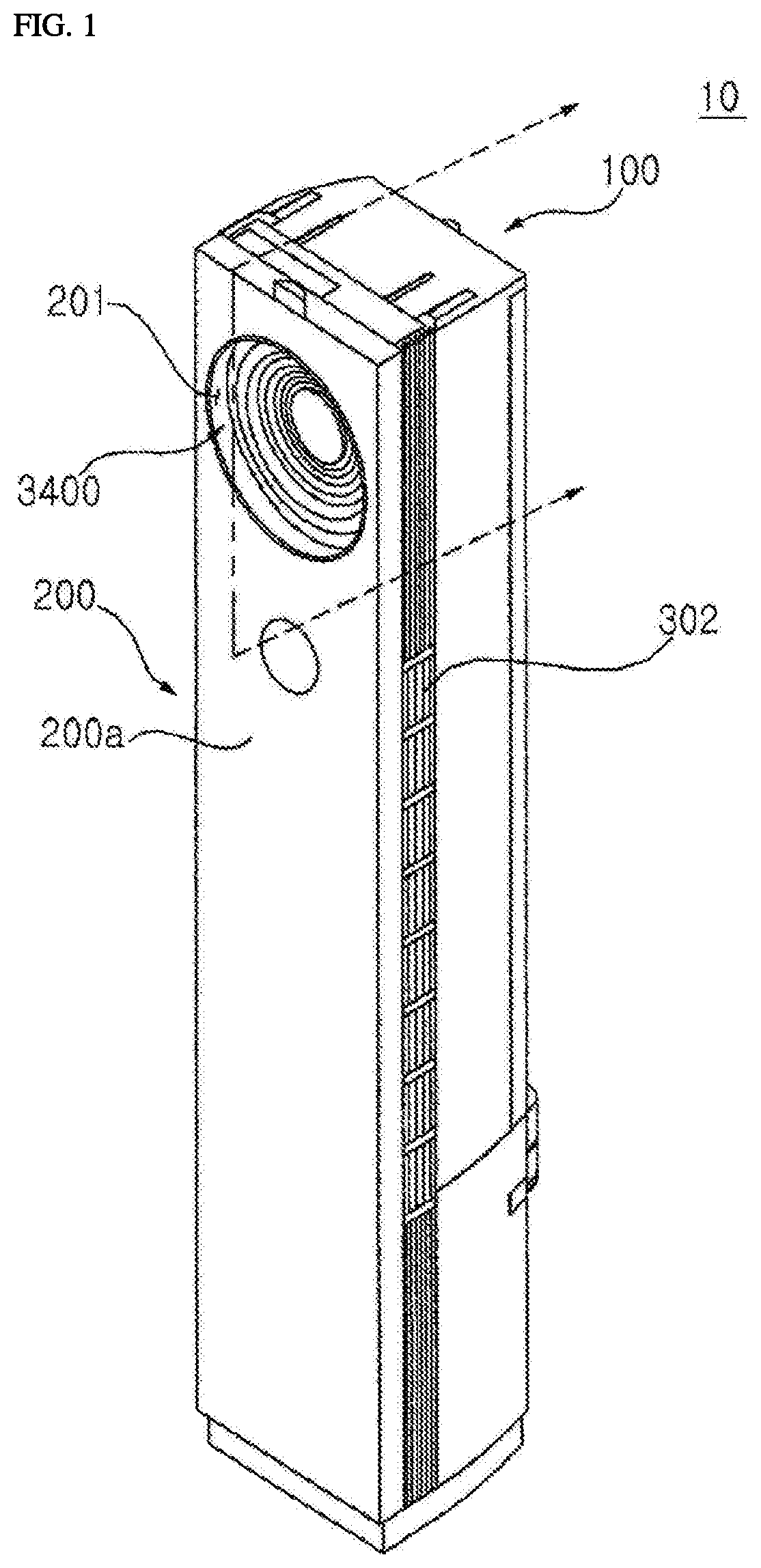

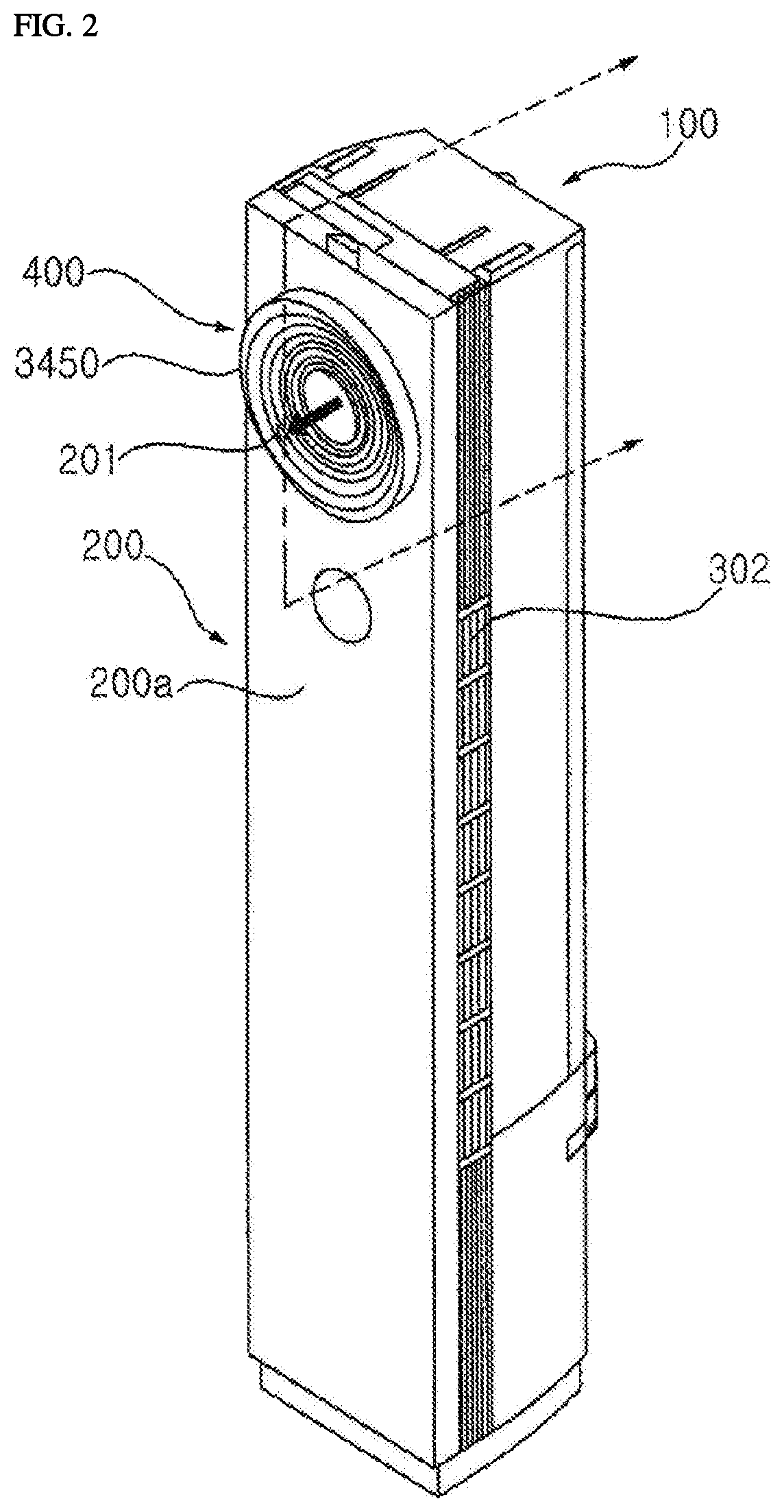

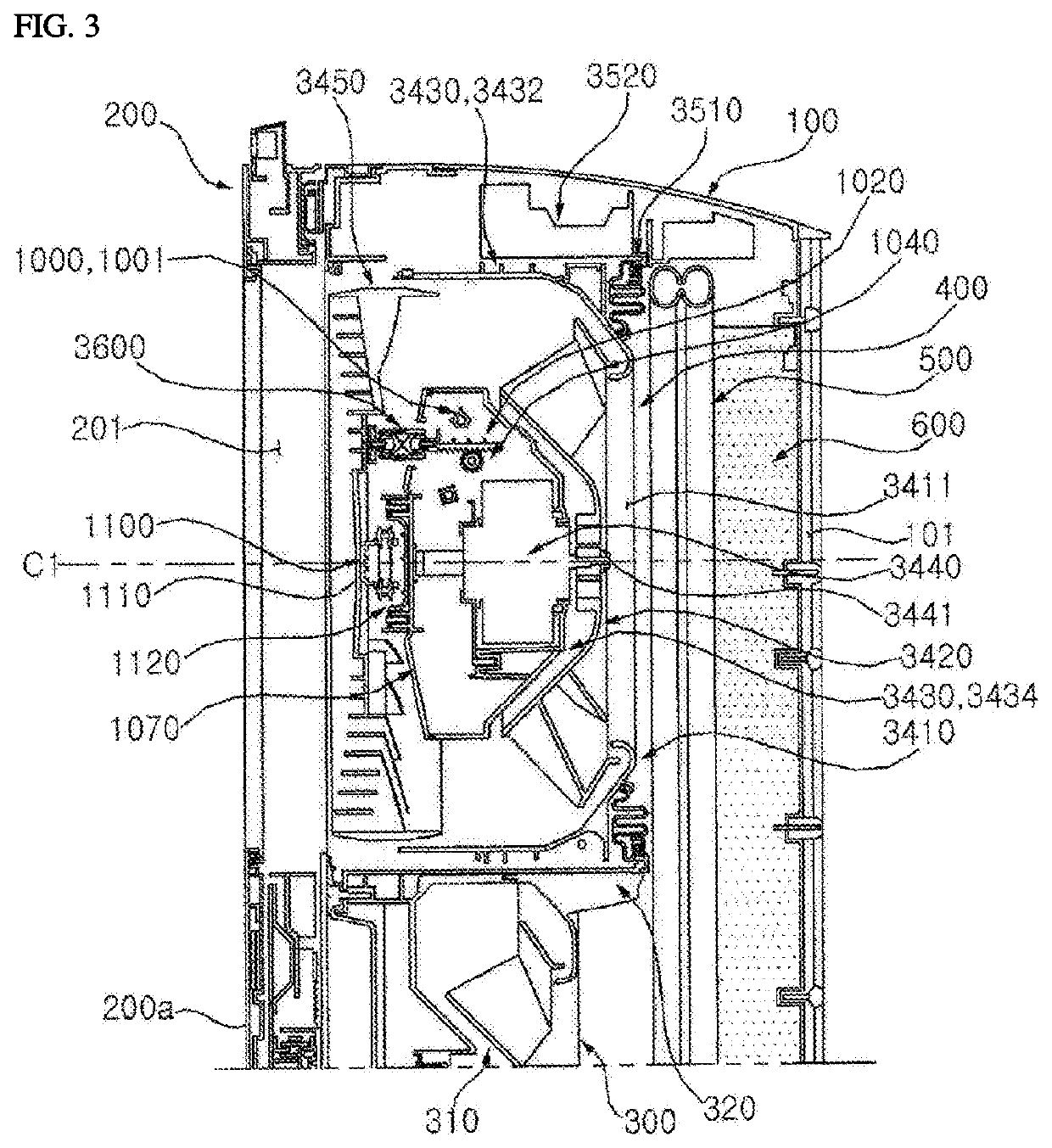

Indoor unit of an air conditioner

PendingUS20210025601A1Flow loss minimizationLess formationMechanical apparatusLighting and heating apparatusStructural engineeringActuator

An air conditioner may provide a a fan housing assembly that moves in the front-rear direction by the operation of an actuator, and the fan housing assembly moves so as to pass through a front outlet arranged on a door assembly to be in a projected state, and the front end of the fan housing assembly protrudes further to the front than the front surface of the door assembly; and through the projected state, may provide conditioned air by a direct air flow to a long-distance target region. The configuration may enable the minimization of interference between the discharged air and the door assembly, and the minimization of flow loss of the discharged air since, when the fan housing assembly is in the projected state, a steering grill is in a state of protruding to the outside of the door assembly by passing through the front outlet.

Owner:LG ELECTRONICS INC

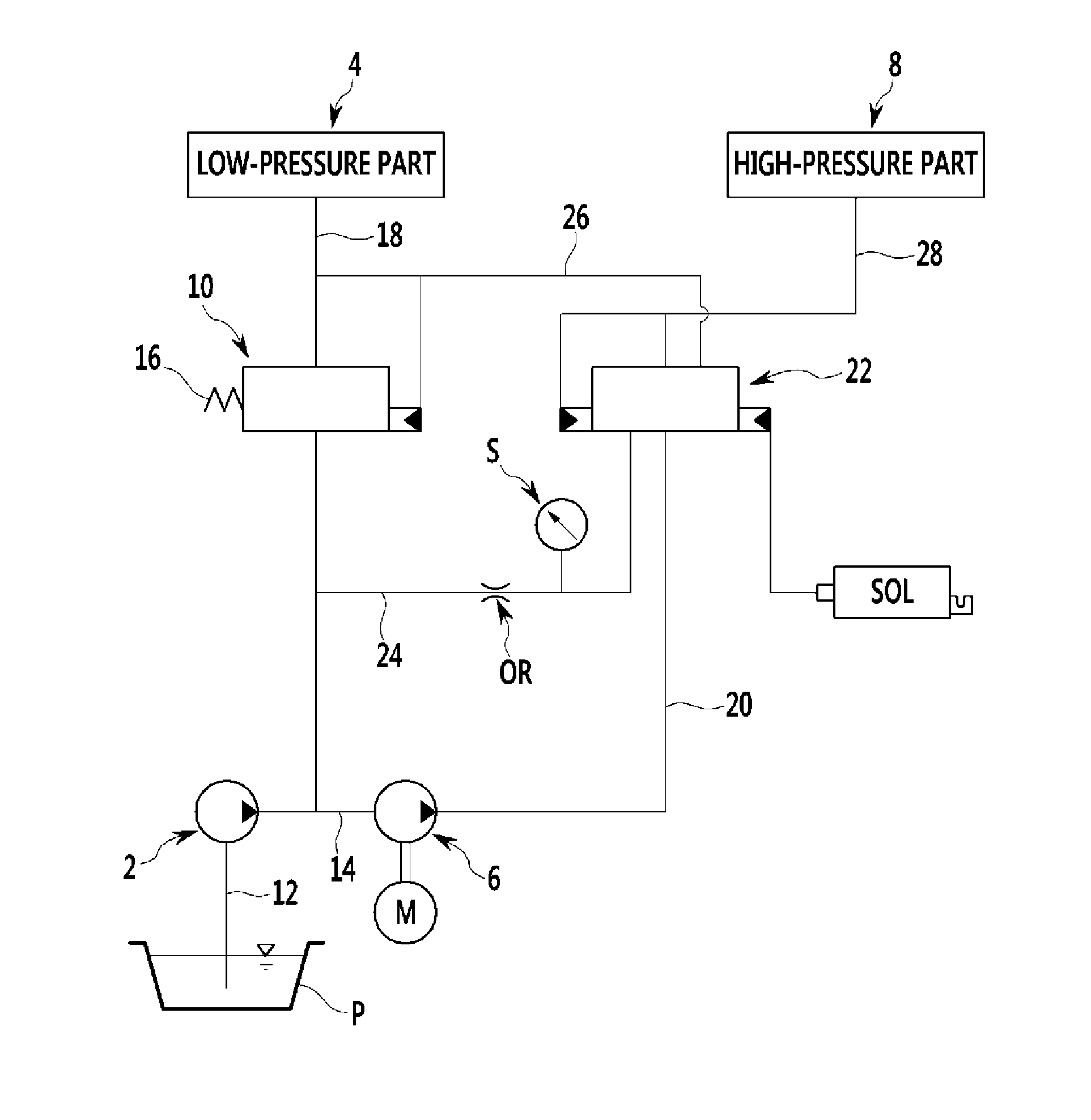

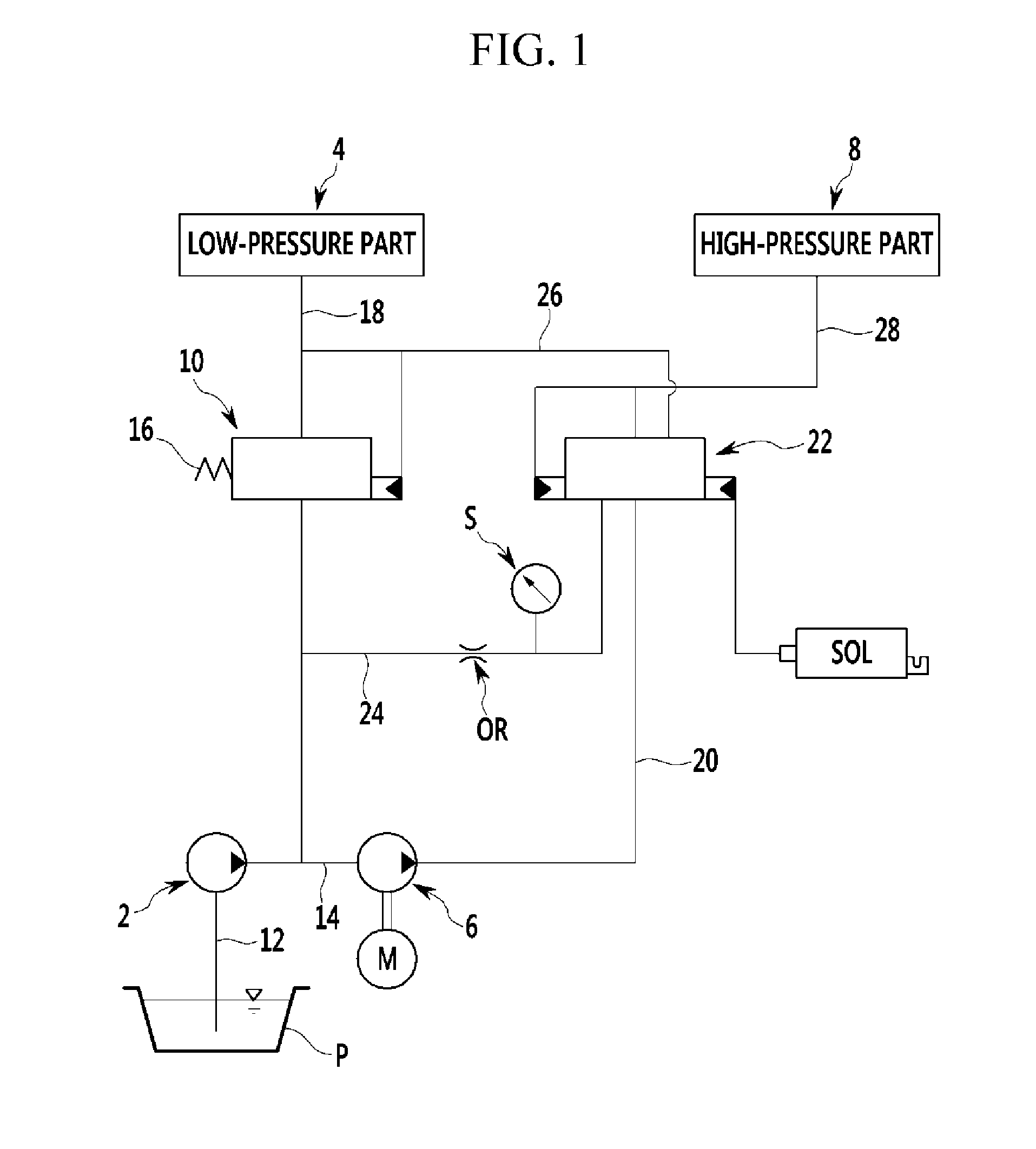

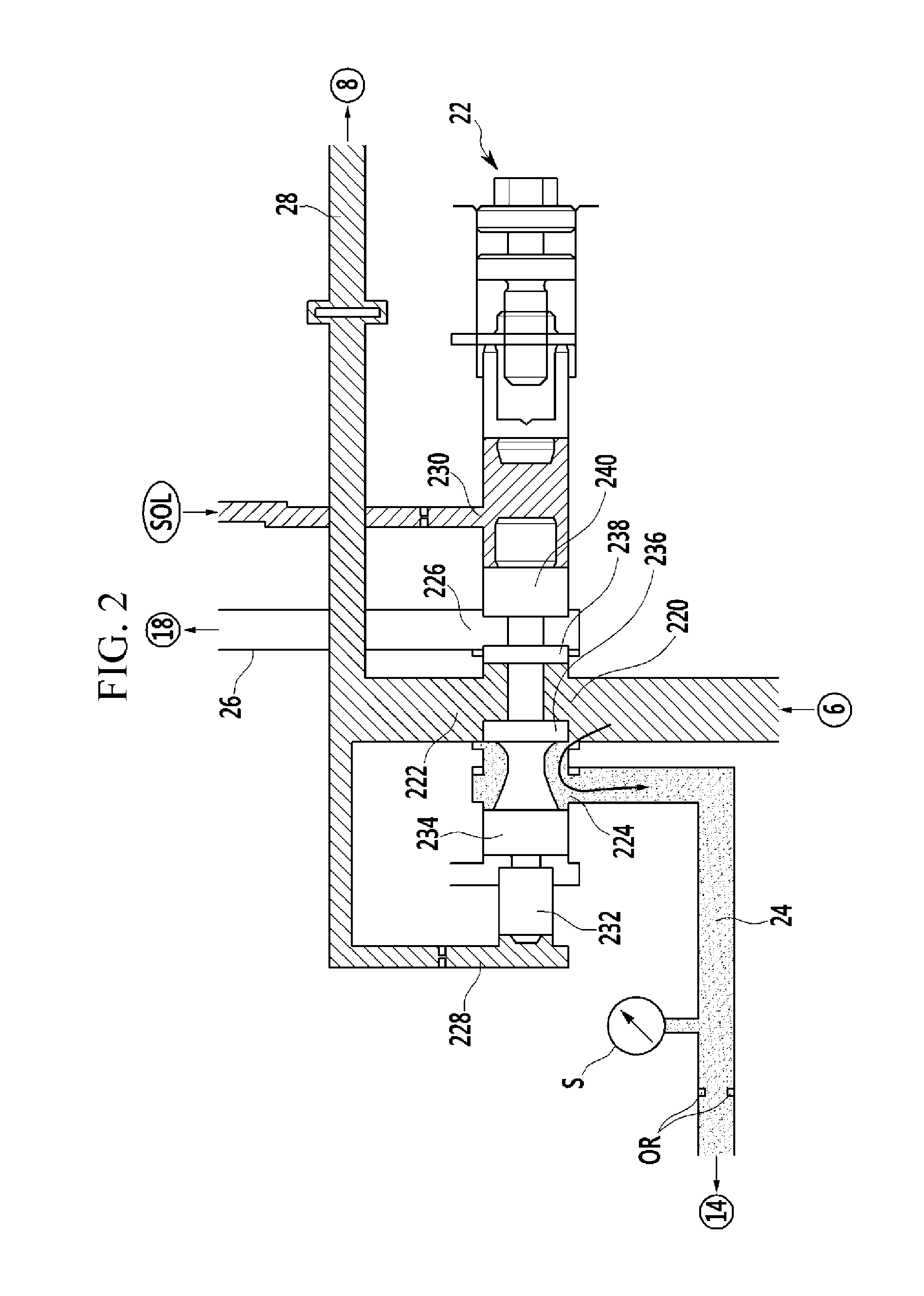

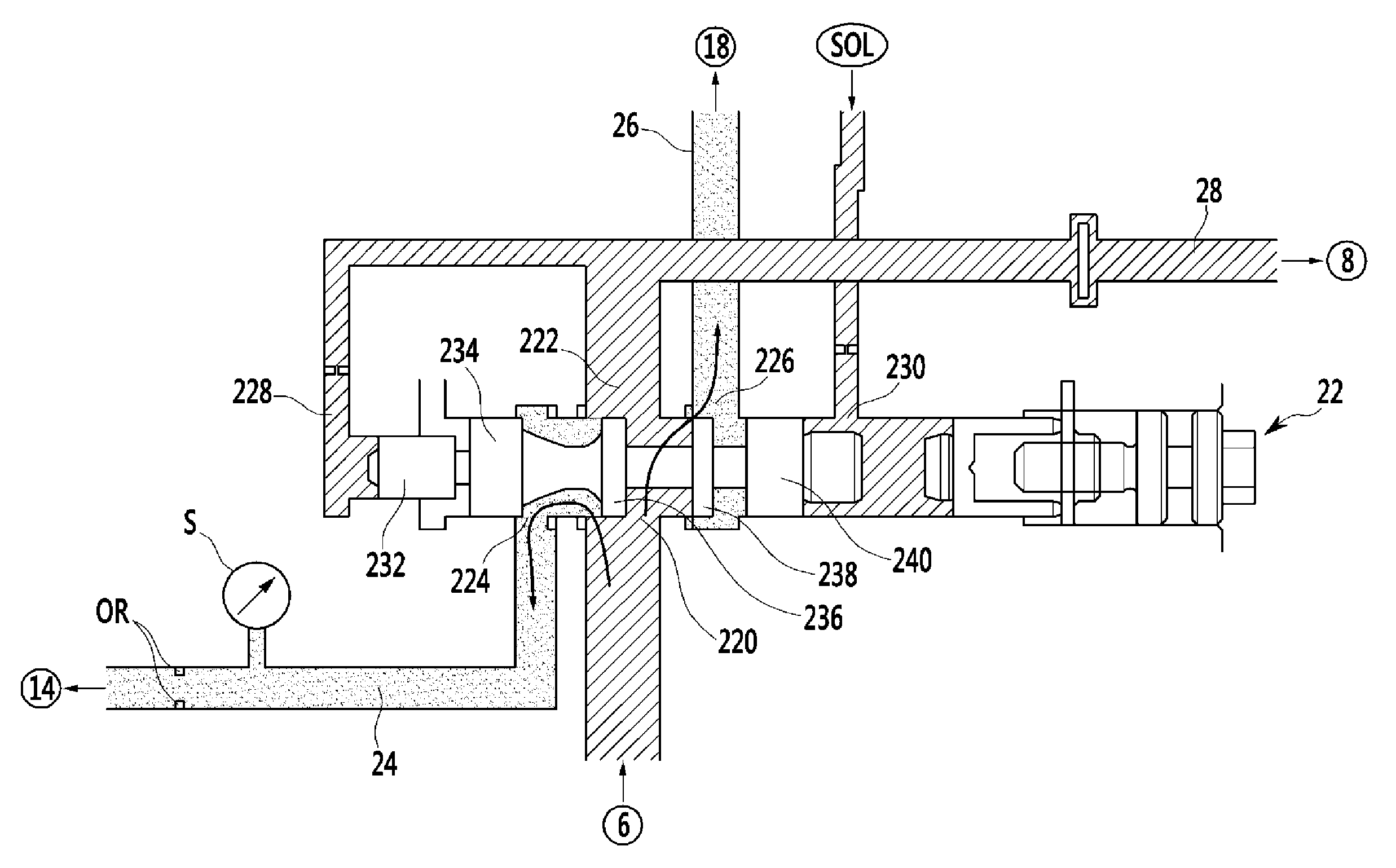

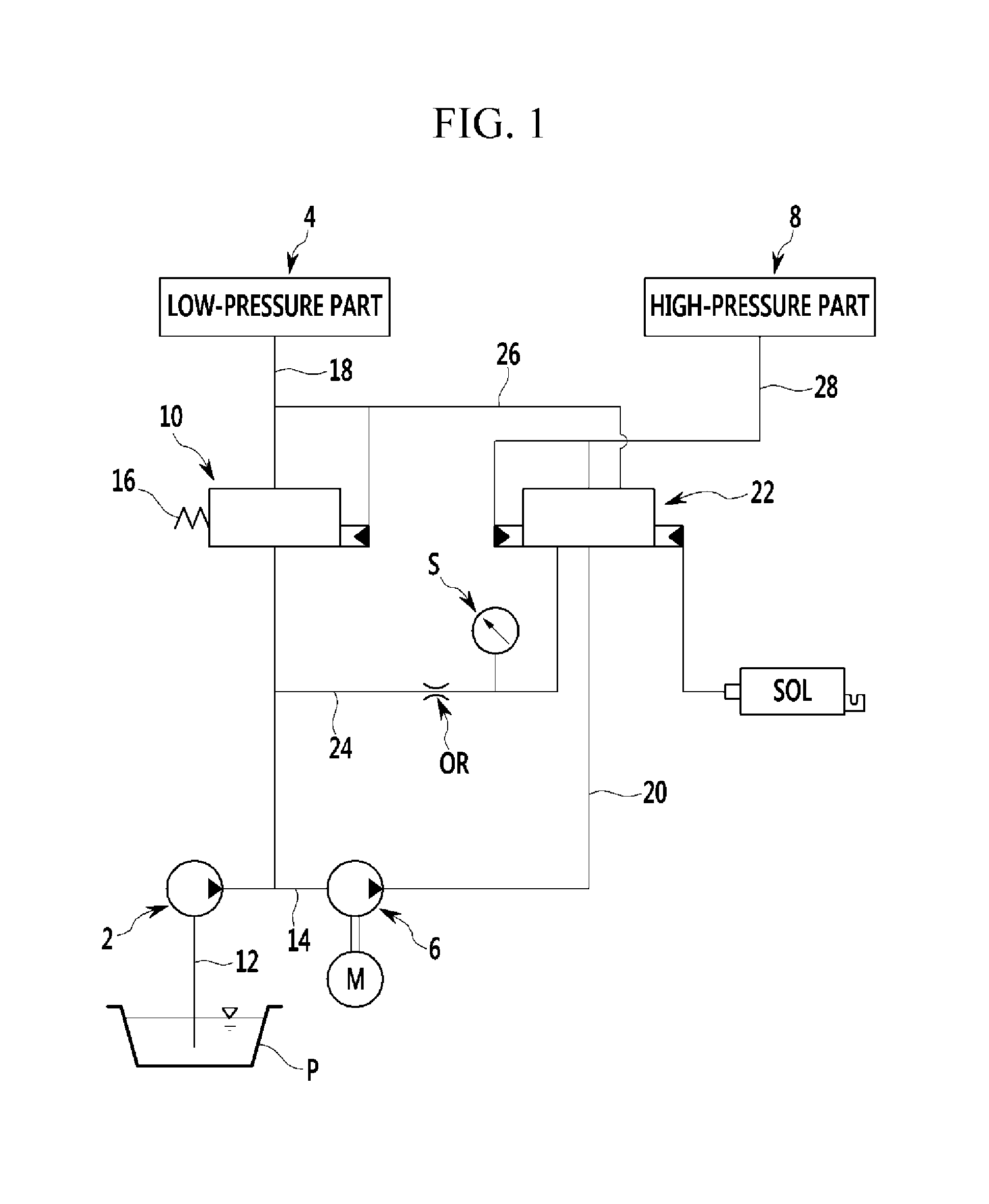

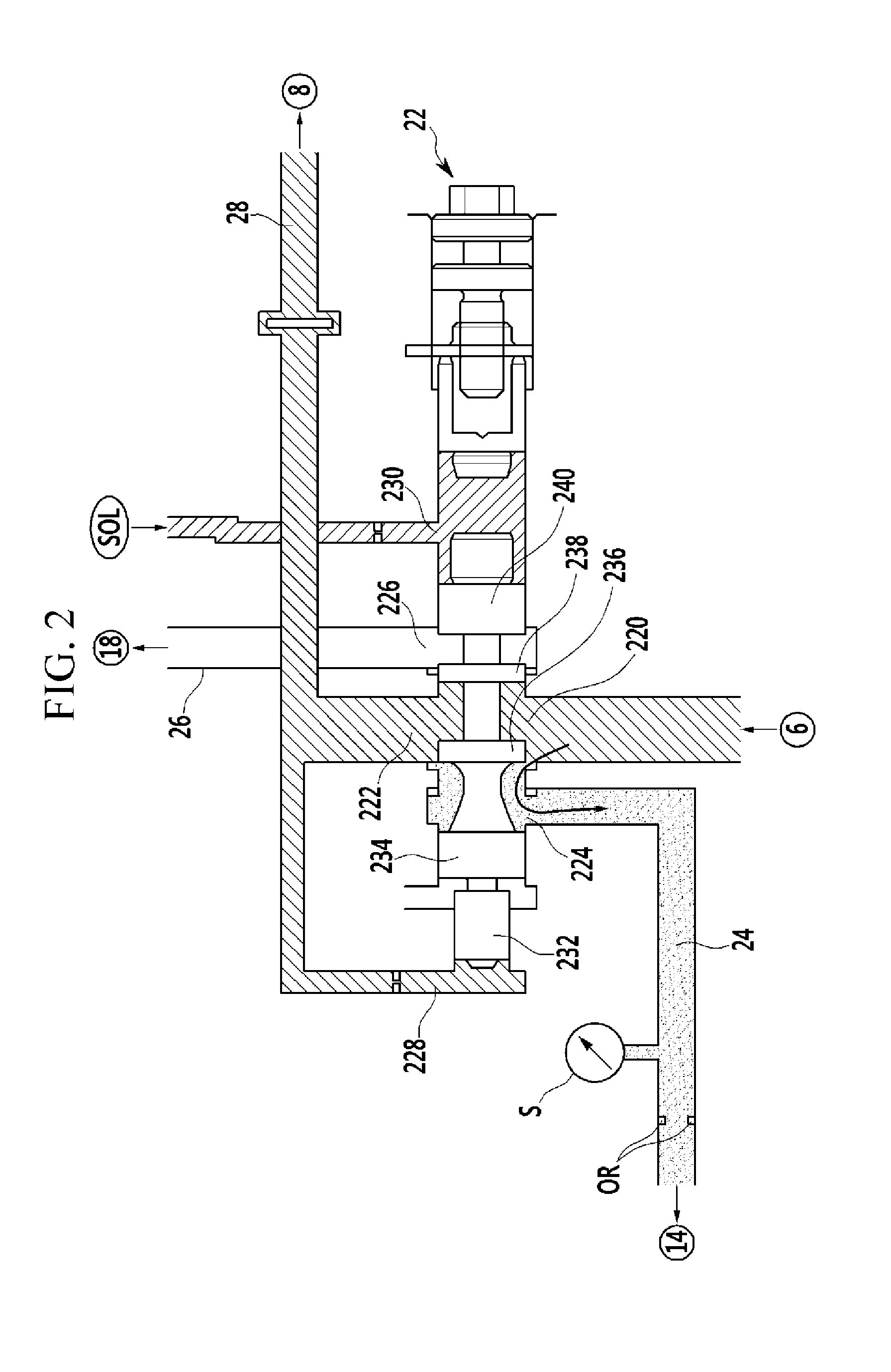

Hydraulic Pressure Supply System of Automatic Transmission

ActiveUS20160003348A1Simple processFlow loss minimizationGearing controlMultiple way valvesAutomatic transmissionEngineering

A hydraulic pressure supply system of an automatic transmission may include a low-pressure oil pump generating low hydraulic pressure while being driven by an engine to exhaust the low hydraulic pressure to a first low-pressure channel, a high-pressure oil pump raising a portion of the hydraulic pressure in the first low-pressure channel to a high pressure while being driven by an electric motor to exhaust the hydraulic pressure to a first high-pressure channel, a low-pressure regulator valve controlling the hydraulic pressure while exhausting a portion of the hydraulic pressure to supply the controlled hydraulic pressure to a low-pressure part through a second low-pressure channel, and a high-pressure regulator valve controlling the hydraulic pressure while re-circulating a portion of the hydraulic pressure to the low-pressure part through single or two re-circulation channels according to the pressure to supply the controlled hydraulic pressure to a high-pressure part through the second high-pressure channel.

Owner:HYUNDAI MOTOR CO LTD

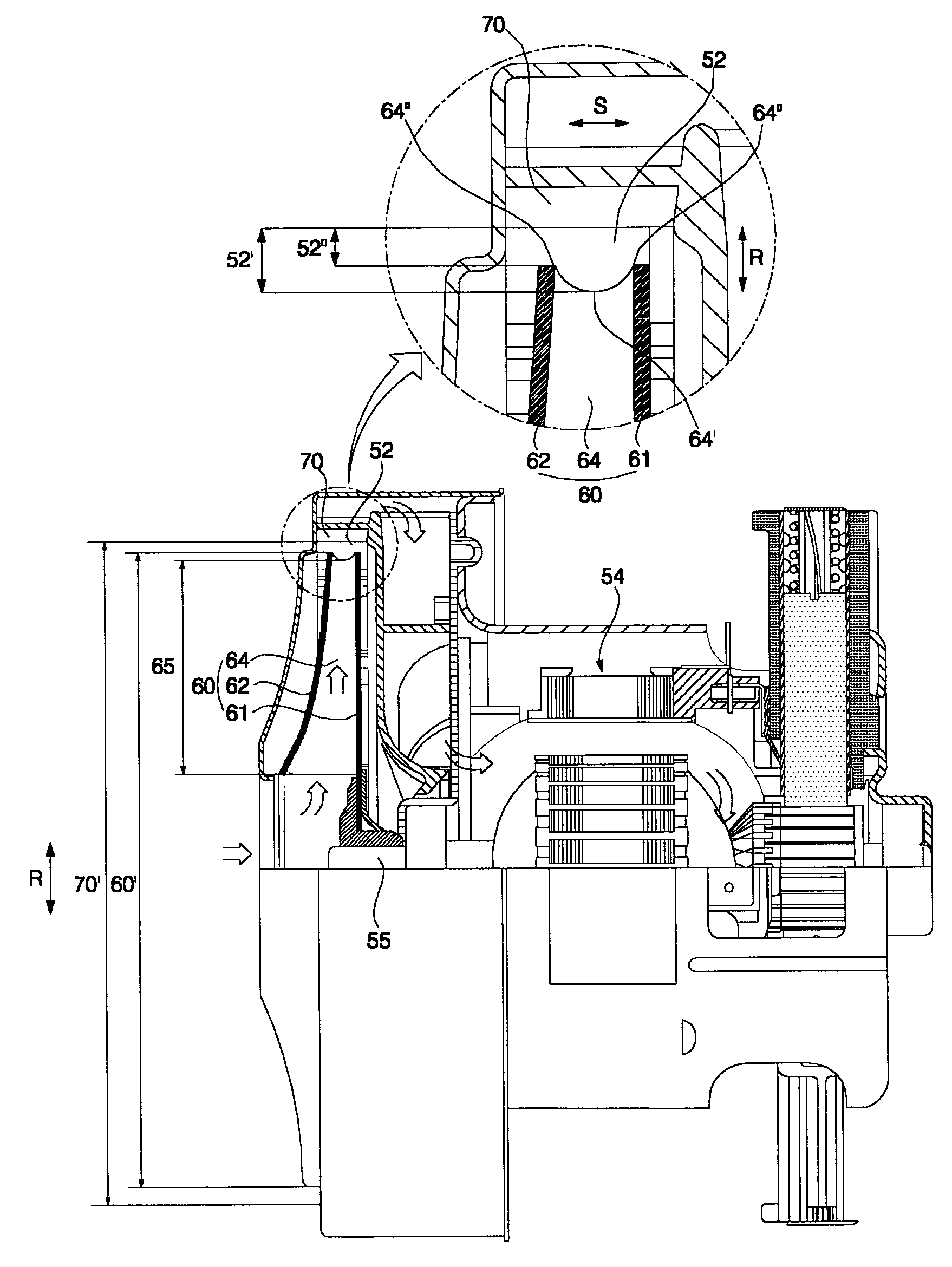

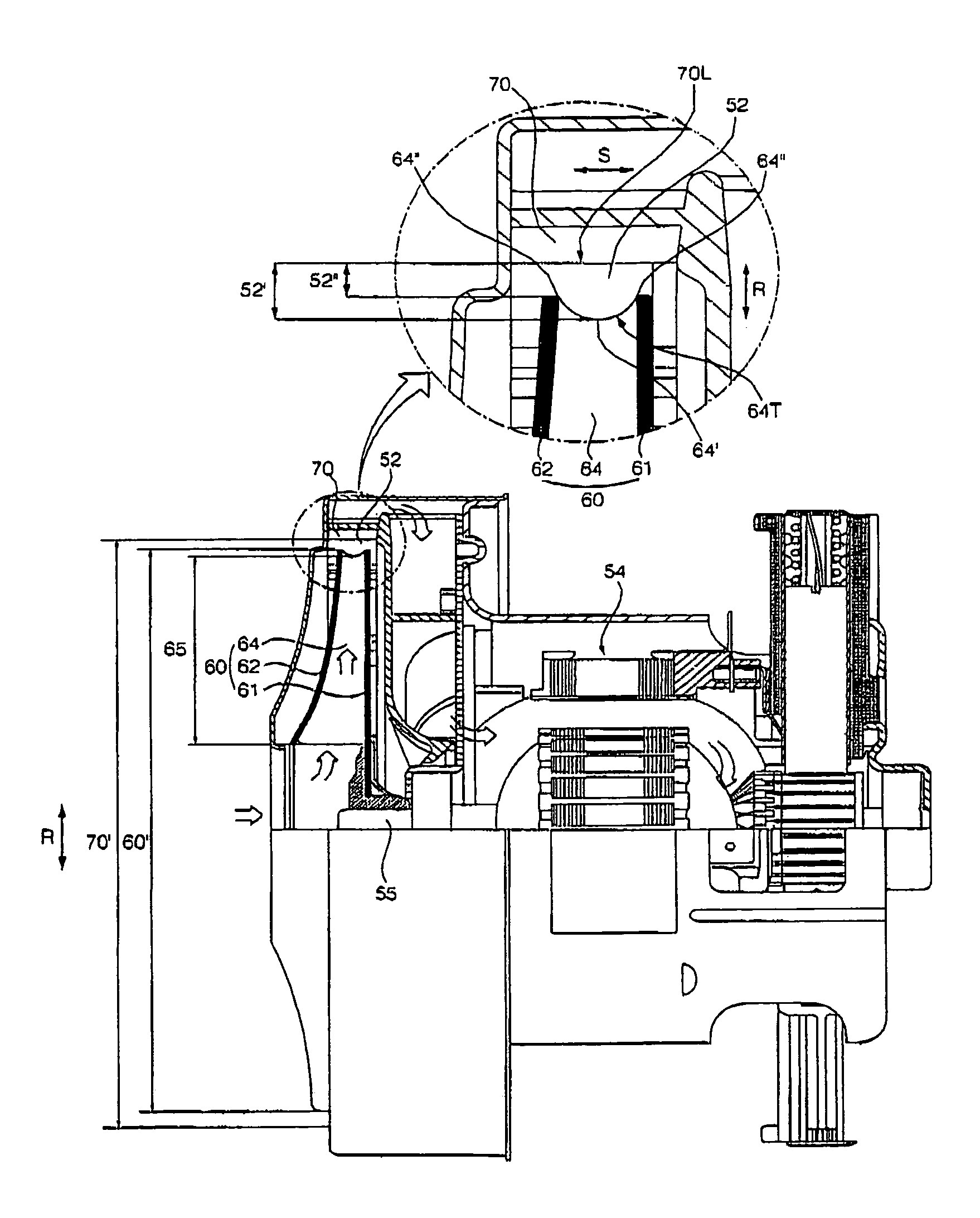

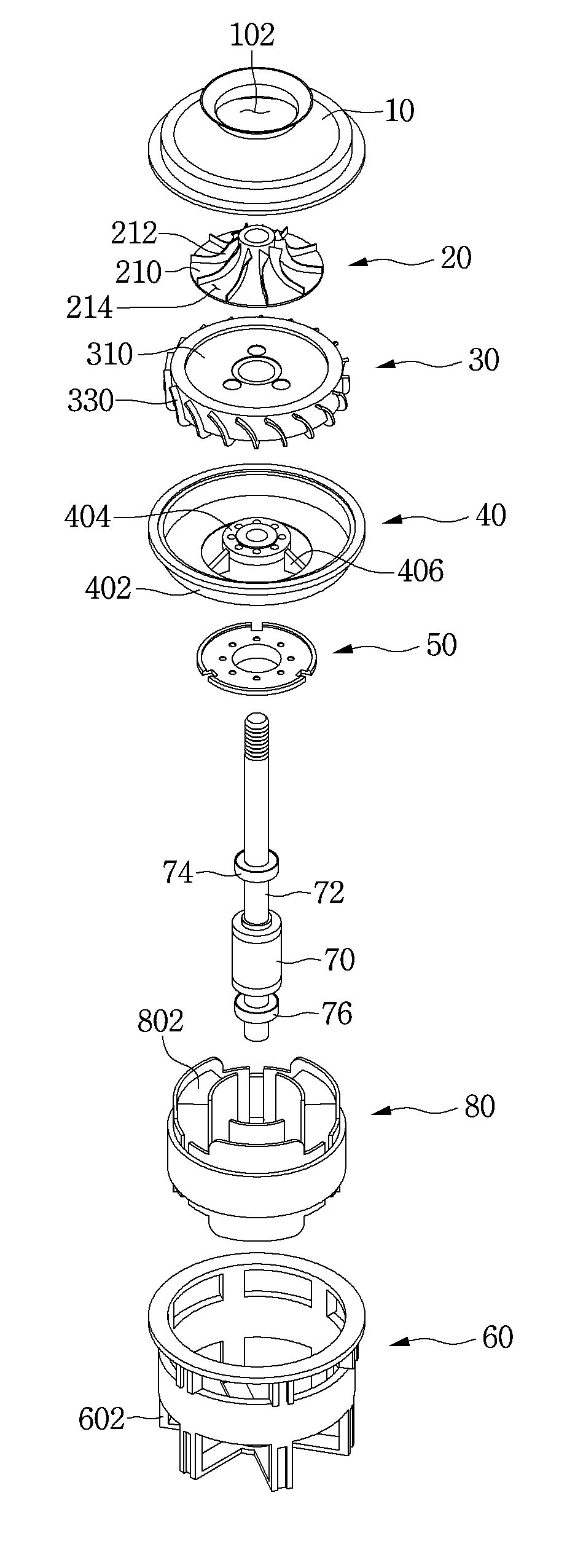

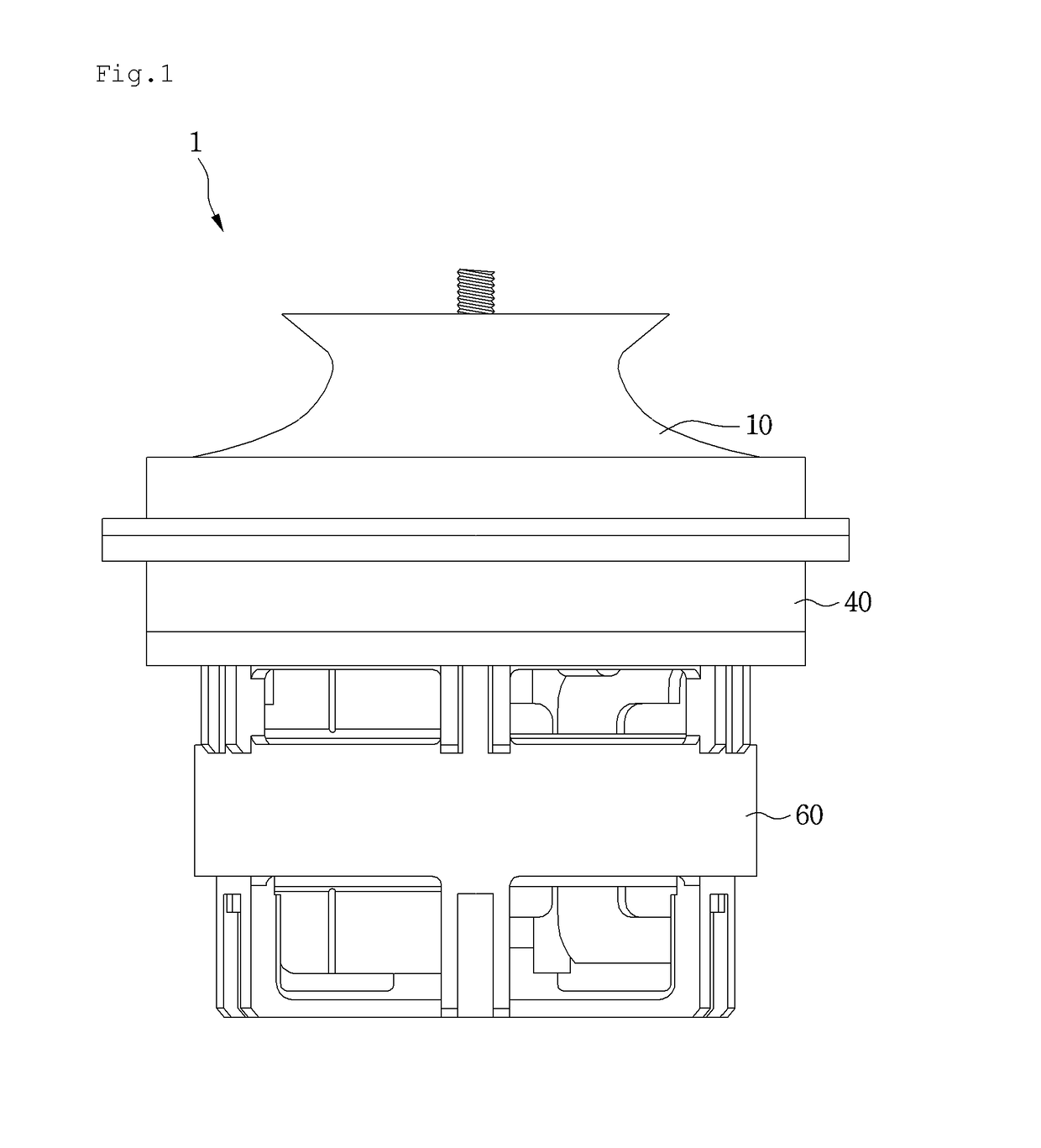

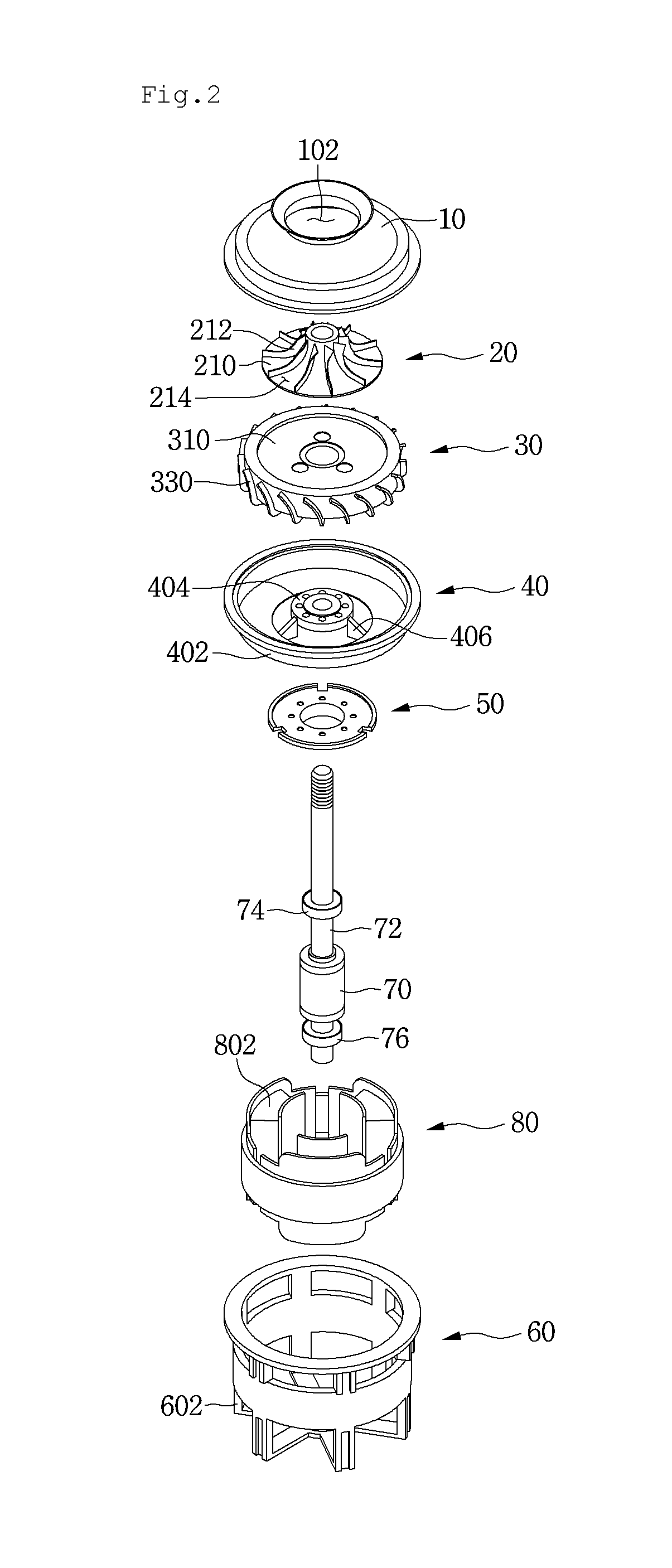

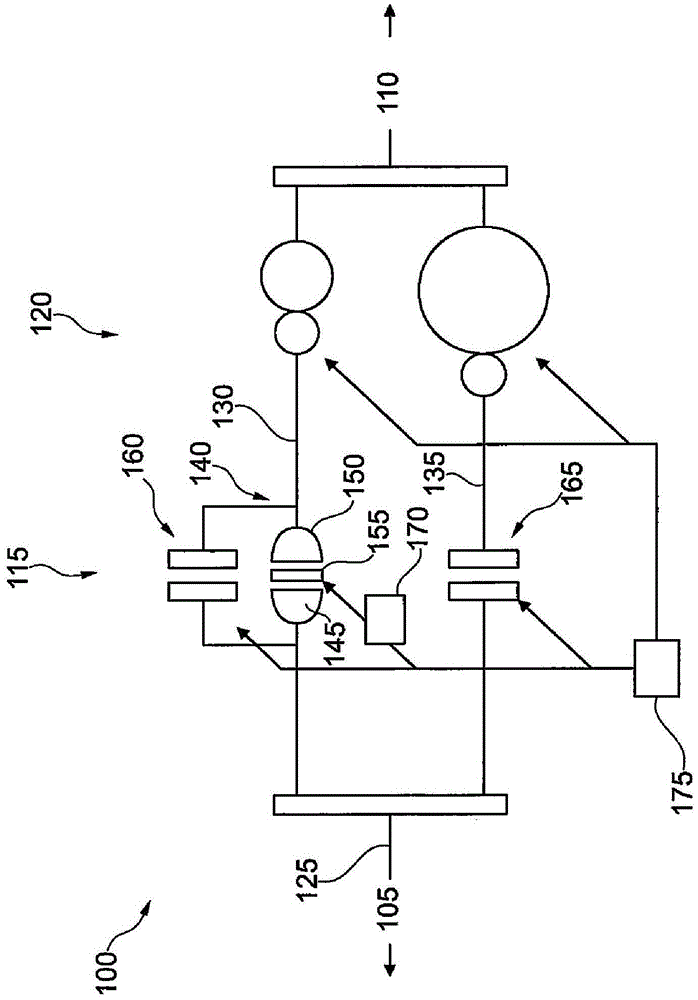

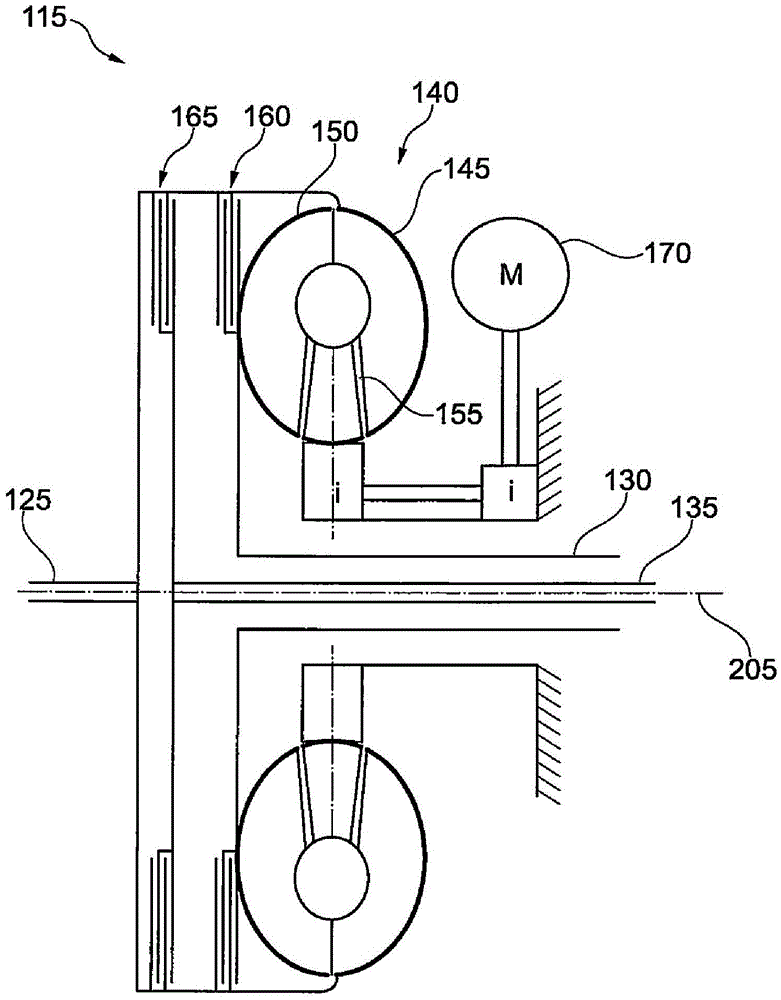

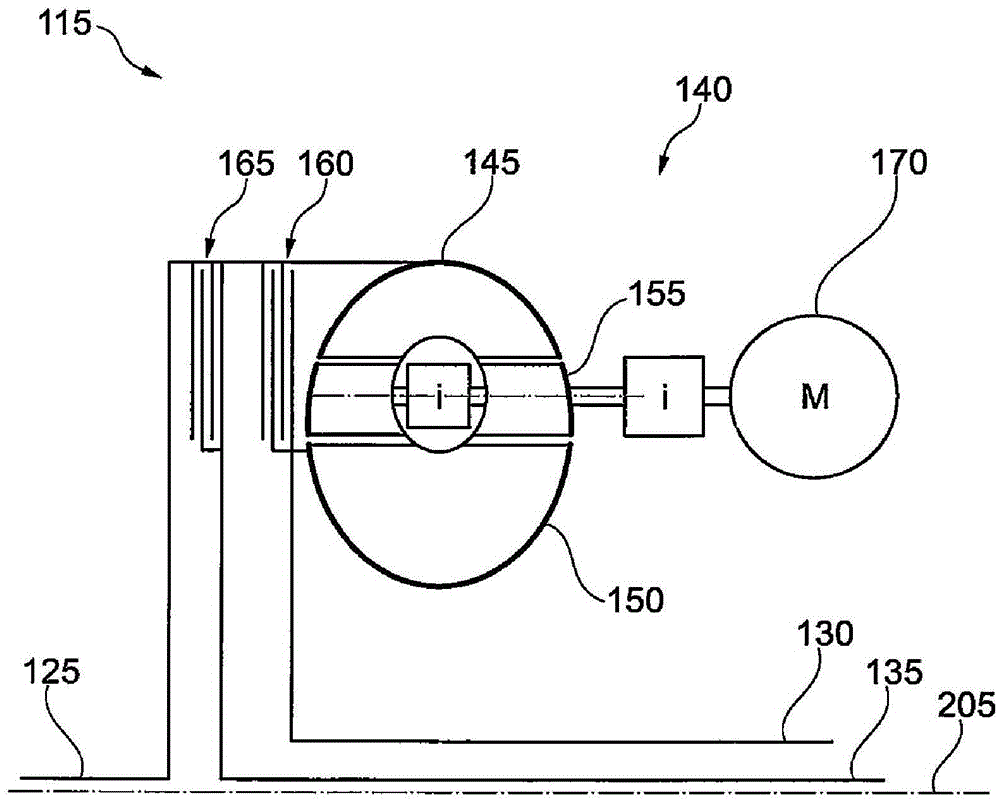

Vacuum suctioning unit

ActiveUS20180064302A1Maximize efficiencyMinimize flow lossEngine manufacturePump componentsImpellerEngineering

The vacuum suctioning unit of the present invention includes: a cover provided with an air entrance; an impeller for circulating air that enters the air entrance; a motor provided with a shaft connected to the impeller; a guide device for guiding the flow of air that exits an exit of the impeller; and a motor housing that houses the motor and is provided with an air exit. The guide device includes: a guide body disposed below the impeller; a first guide vane formed on a side surface of the guide body and guiding air discharged from the impeller; and a second guide vane formed on the bottom surface of the guide body and connected to the first guide vane to guide air that is moved by the first guide vane. The entrance angle of the first guide vane is within the range of 10 to 27 degrees.

Owner:LG ELECTRONICS INC

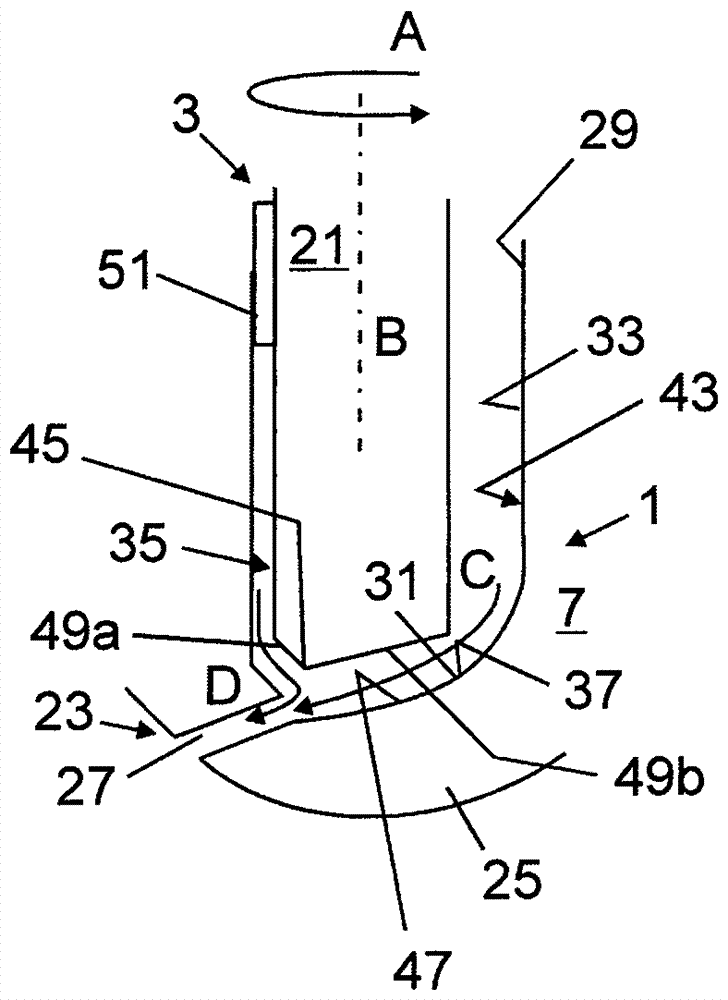

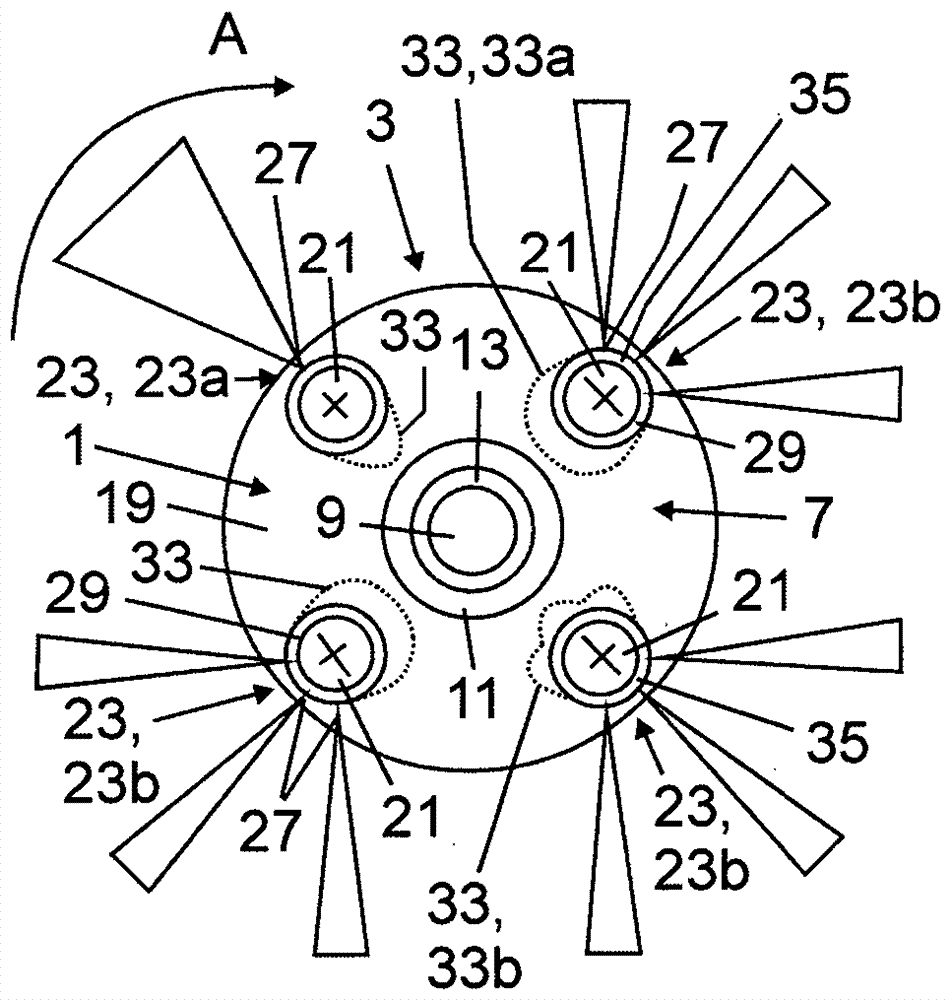

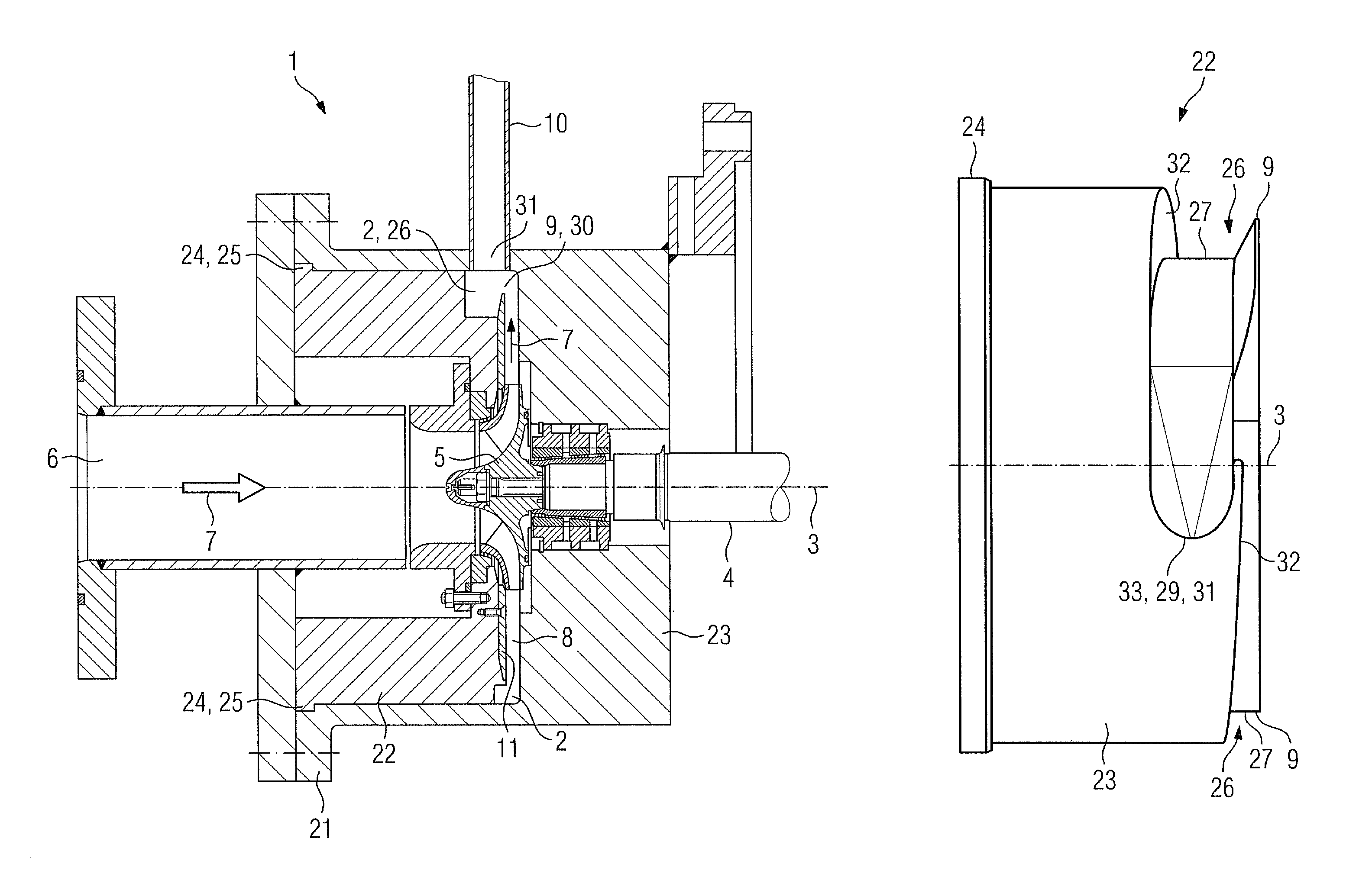

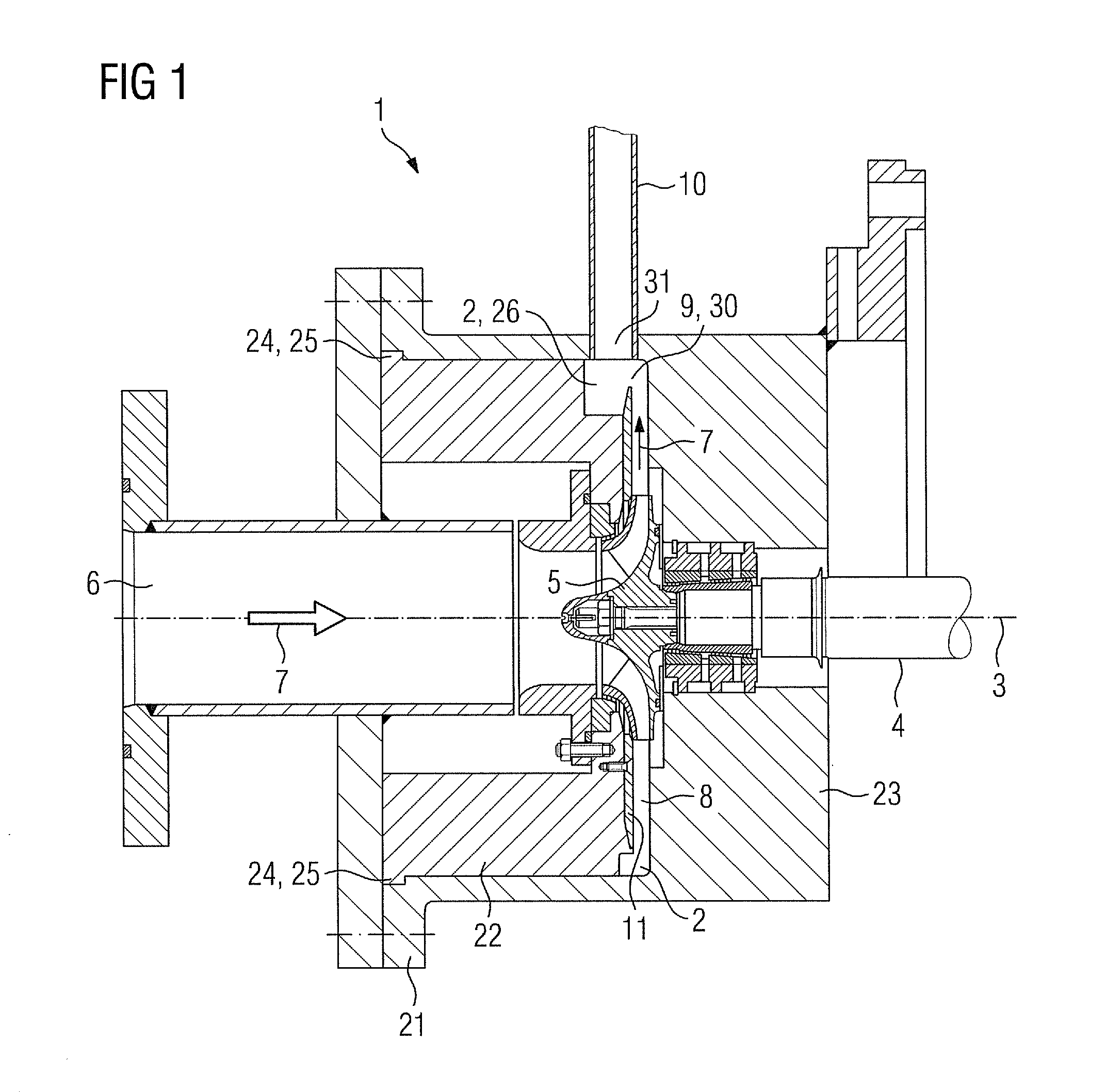

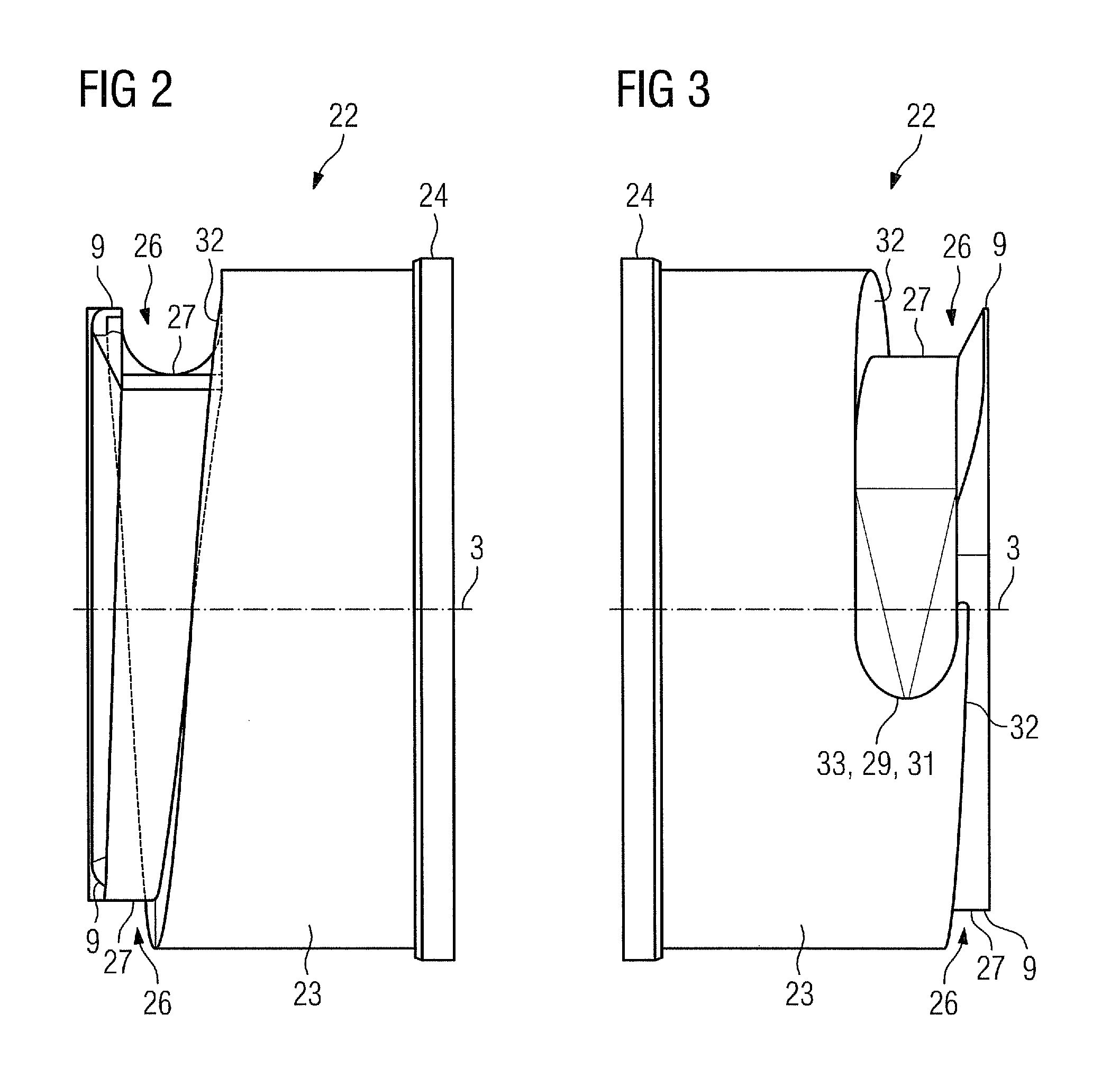

Fuel injector for operation with combustible gas

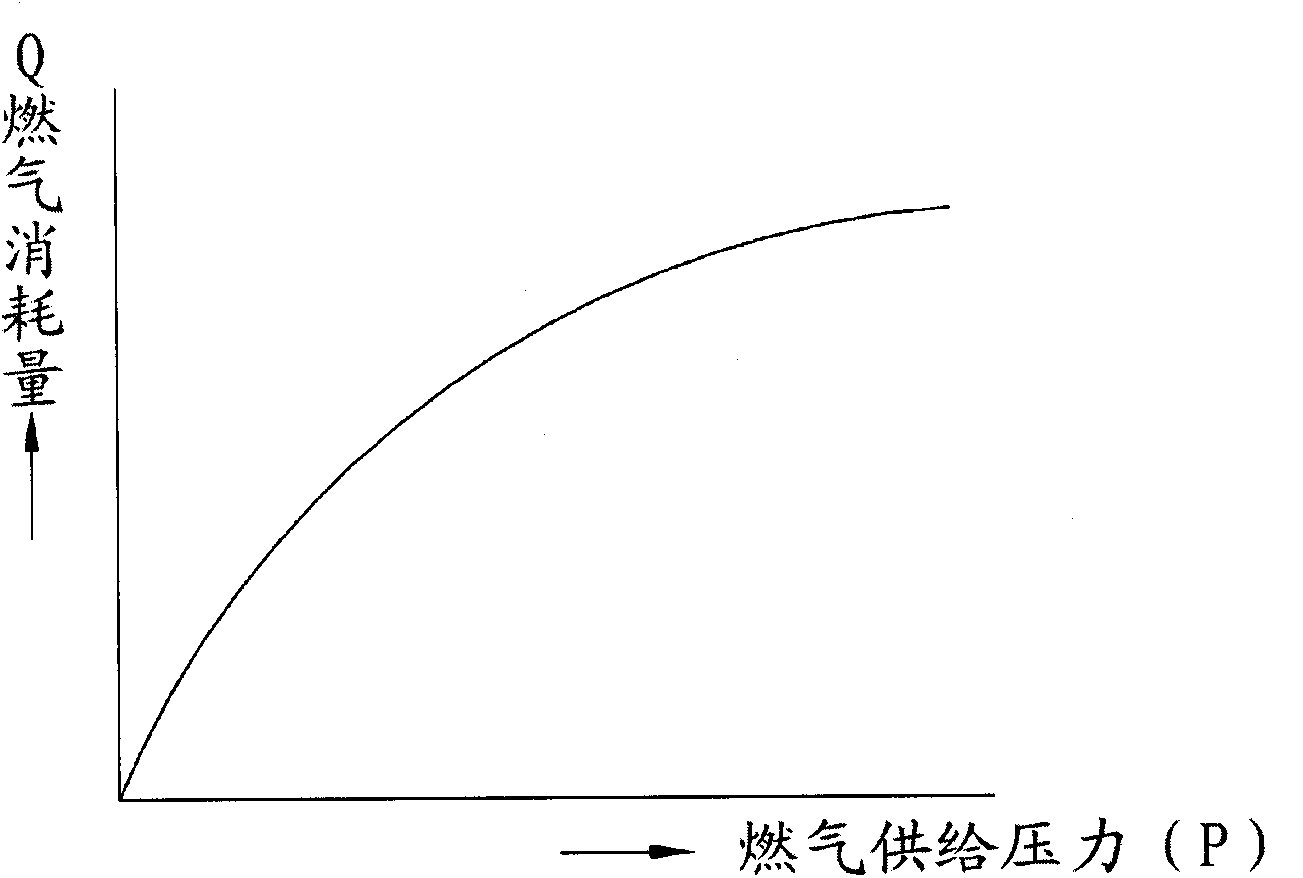

ActiveCN107208583AFlow loss minimizationReduce flow lossInternal combustion piston enginesFuel supply apparatusCombustible gasEngineering

The invention relates to a fuel injector (3) for operation with combustible gas, wherein the fuel injector (3) has, at a nozzle end (25), a gas nozzle assembly (23) having at least one gas nozzle opening (27); wherein the fuel injector (3) has at least one gas nozzle needle (21), which is associated with the gas nozzle assembly (23) and is accommodated in an axial holder (29) in such a way that the stroke of the at least one gas nozzle needle can be controlled, wherein each gas nozzle opening (27) leads out of the holder (29) having a radial direction component at the nozzle end (25); wherein the fuel injector (3) has, in the holder (29), a needle seat (31) upstream of the particular nozzle opening (27), which needle seat is provided for selectively blocking a combustible-gas flow path to the associated gas nozzle opening (27) in interaction with the gas nozzle needle (21); wherein the one or more gas nozzle openings (27) are distributed merely over part of the circumference in the circumferential direction (A) of the gas nozzle needle (21), wherein the holder (29), adjoining the needle seat (31) and extending away therefrom axially in the upstream direction, is asymmetric with respect to an axial center axis (B) through the gas nozzle needle (21), wherein the asymmetry results from a cross-section expansion (33) of the holder (29) on a side of the holder (29) that lies radially opposite the at least one gas nozzle opening (27), such that a greater mass flow rate of combustible gas can be conducted in the holder (29) by means of the cross-section expansion (33) than on the gas nozzle opening side (35) opposite thereto; wherein the holder (29) is also shaped to apply a flow direction oriented toward the radially opposite at least one gas nozzle opening (27), already upstream of the needle seat (31) and by means of the cross-section expansion (33), to a combustible-gas flow (C) guided to the needle seat (31) by the cross-section expansion (33).

Owner:L'ORANGE GMBH

Ring structure of metal construction having a run-in lining

InactiveUS8061965B2Flow loss minimizationSimple designEngine manufacturePump componentsEngineeringSoldering

A ring structure with a metal design for a moving blade of axially flowed through compressor and turbine stages, particularly in gas turbine engines is provided. The ring structure includes a circular ring-shaped outer wall, a circular ring-shaped inner wall, which is located at a short radial distance from the moving blade tips, and includes a joining structure provided in the form of hollow chamber structure between the outer wall and the inner wall. The outer wall is provided in the form of a closed, mechanically stable housing wall of the compressor or turbine stage, and the joining structure provided in the form of hollow chamber structure is joined in a fixed manner to the outer wall and to the inner wall, for example, by soldering, diffusion welding or other joining techniques. The inner wall is provided in the form of a closed, mechanically stable structure, which serves as a run-in lining for the moving blade tips and which is made of a metal woven fabric and / or of a metal felt.

Owner:MTU AERO ENGINES GMBH

Collecting chamber and production process

InactiveUS8105025B2Firmly connectedEasy to movePump componentsMilling machinesMechanical engineeringLoss minimization

A collecting chamber of a flow machine which expands in the direction of circumference, including at least one outer shell part and a contour insert is provided. The contour insert is provided with a groove which extends in the circumferential direction and is preferably configured as a helical spiral. The contour insert, is cut from a whole unit and is delimited at one end in the circumferential direction by a bent edge so that the flow losses are minimized during the passage from the collecting chamber into a subsequent diffuser.

Owner:SIEMENS AG

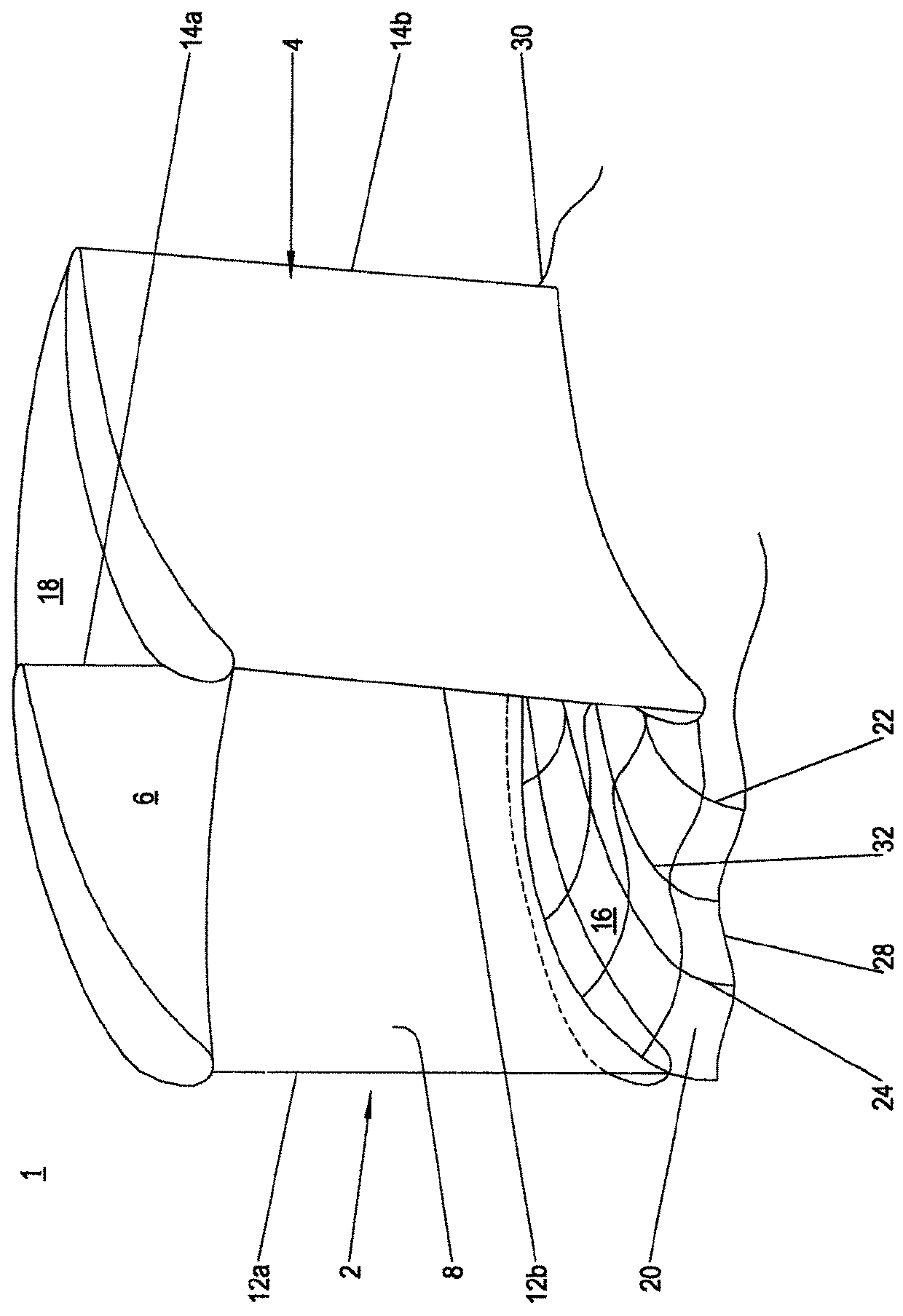

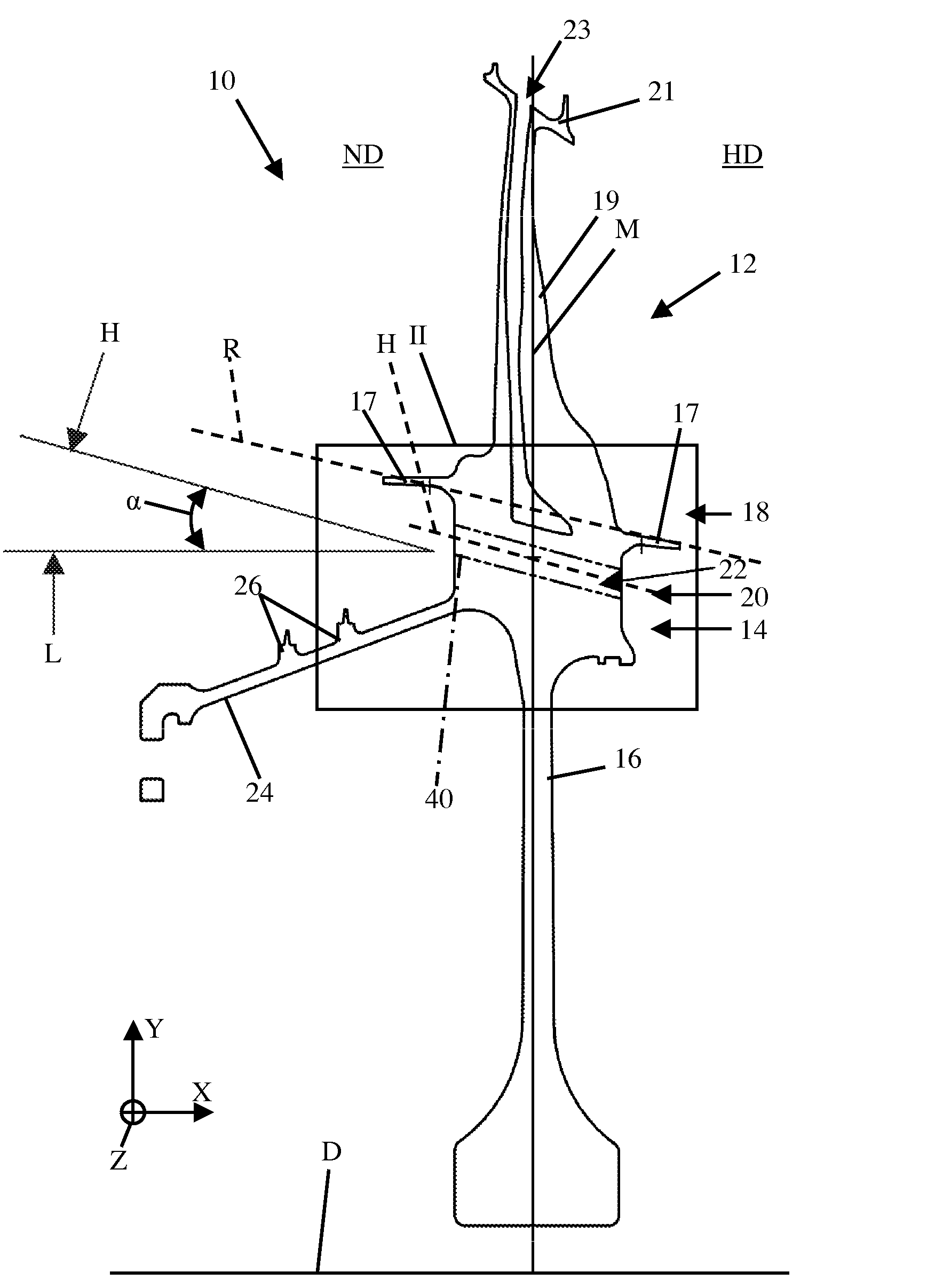

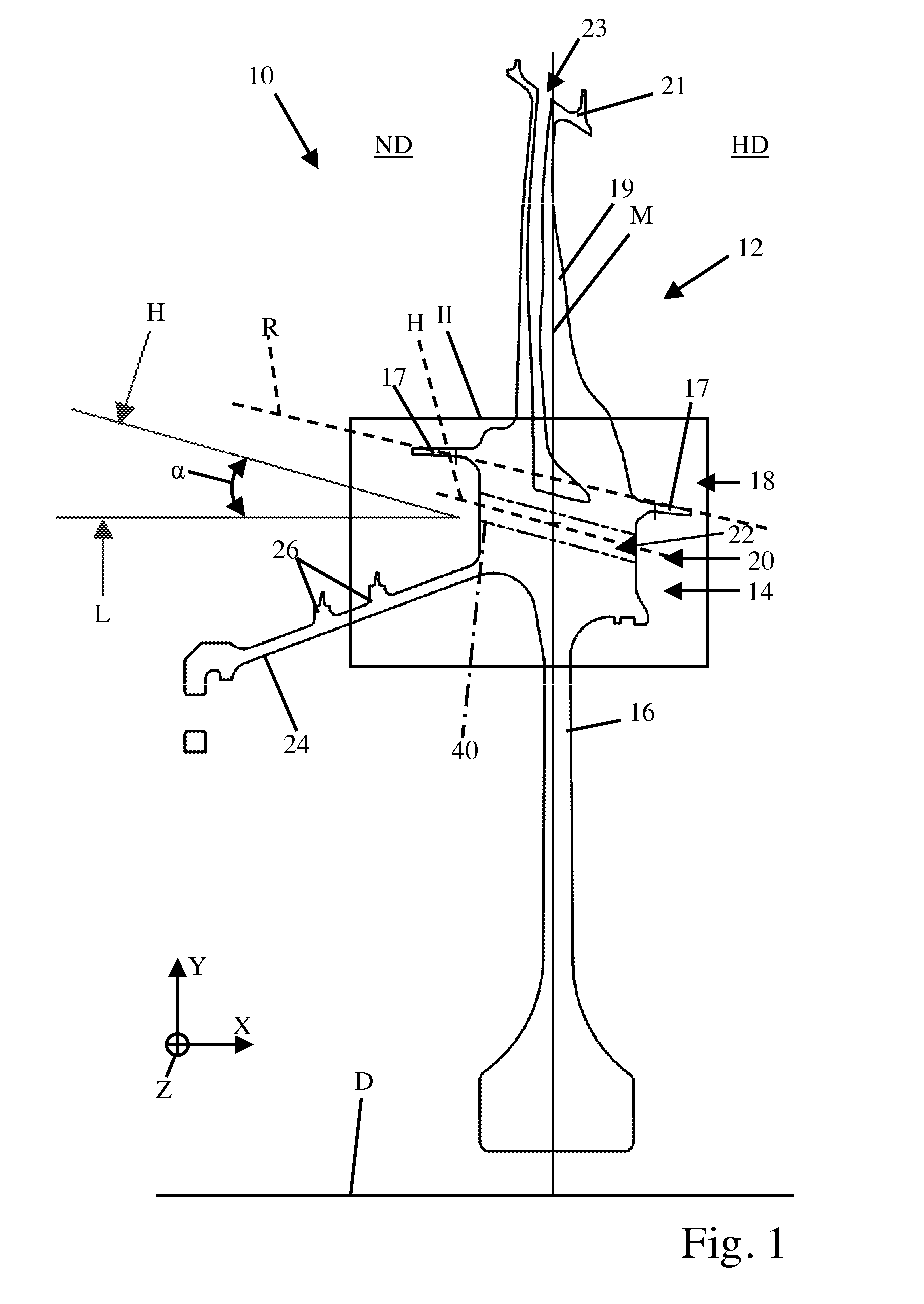

Rotor for a turbo machine

InactiveUS20120121435A1Good introductionHigh strain reliefPump componentsBlade accessoriesHigh pressureTurbine

The invention relates to a rotor (10) for a turbo machine, in particular for an aircraft turbine, with rotating blades (12) that are joined to a basic rotor body (16), whereby at least one channel (22) extending between the high-pressure side (HD) and the low-pressure side (ND) of rotor (10) radially underneath a blade platform (18) of at least one rotating blade (12) is provided, whereby a slope of a principal axis of extension (H) of channel (22) relative to an axis of rotation (D) of rotor (10) has the same sign as a slope of a principal axis of extension (R) of a radially inner boundary of the flow channel of rotor 10. In addition, the invention relates to a turbo machine having a rotor (10) as well as to a method for manufacturing a rotor (10) for a turbo machine.

Owner:MTU AERO ENGINES GMBH

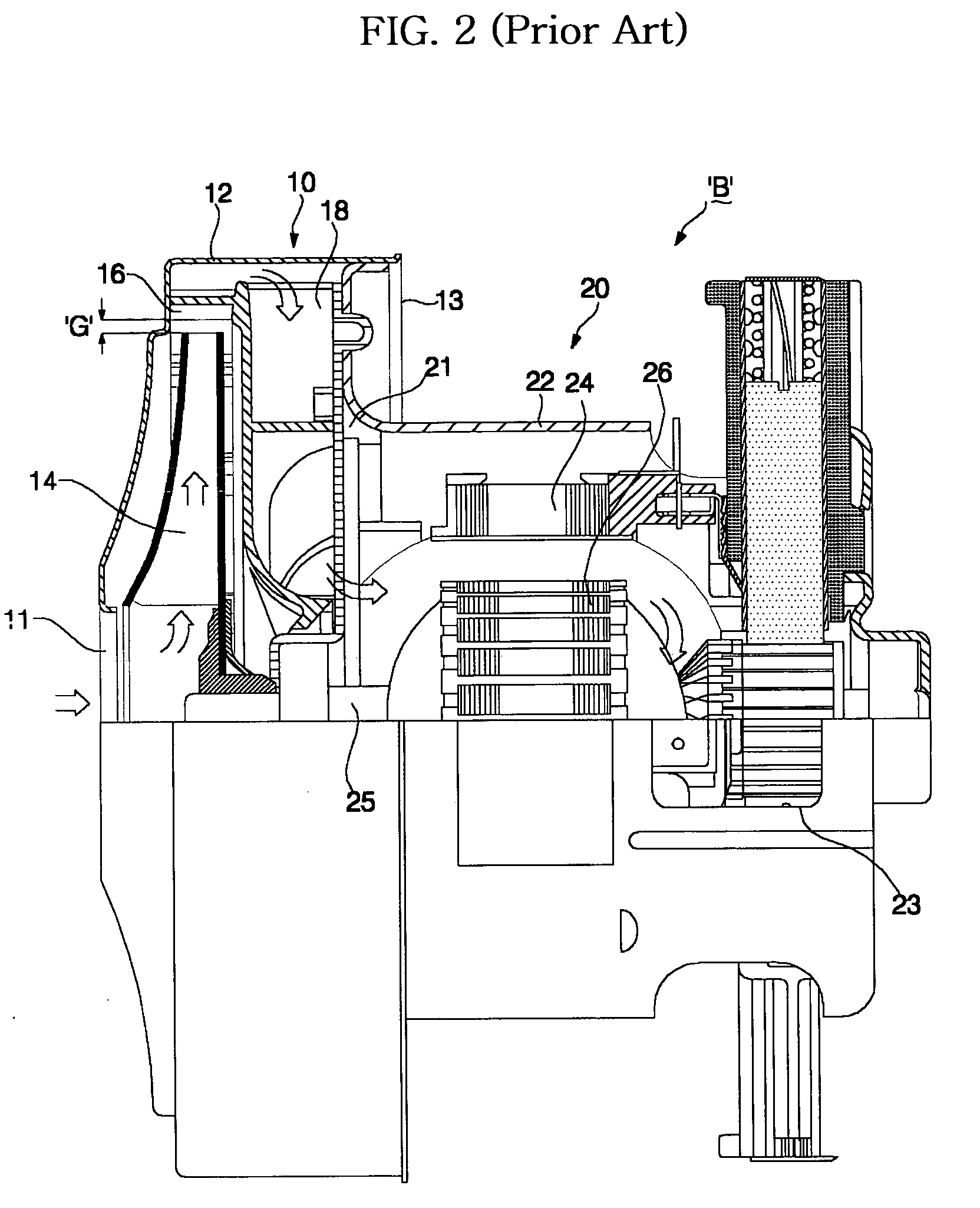

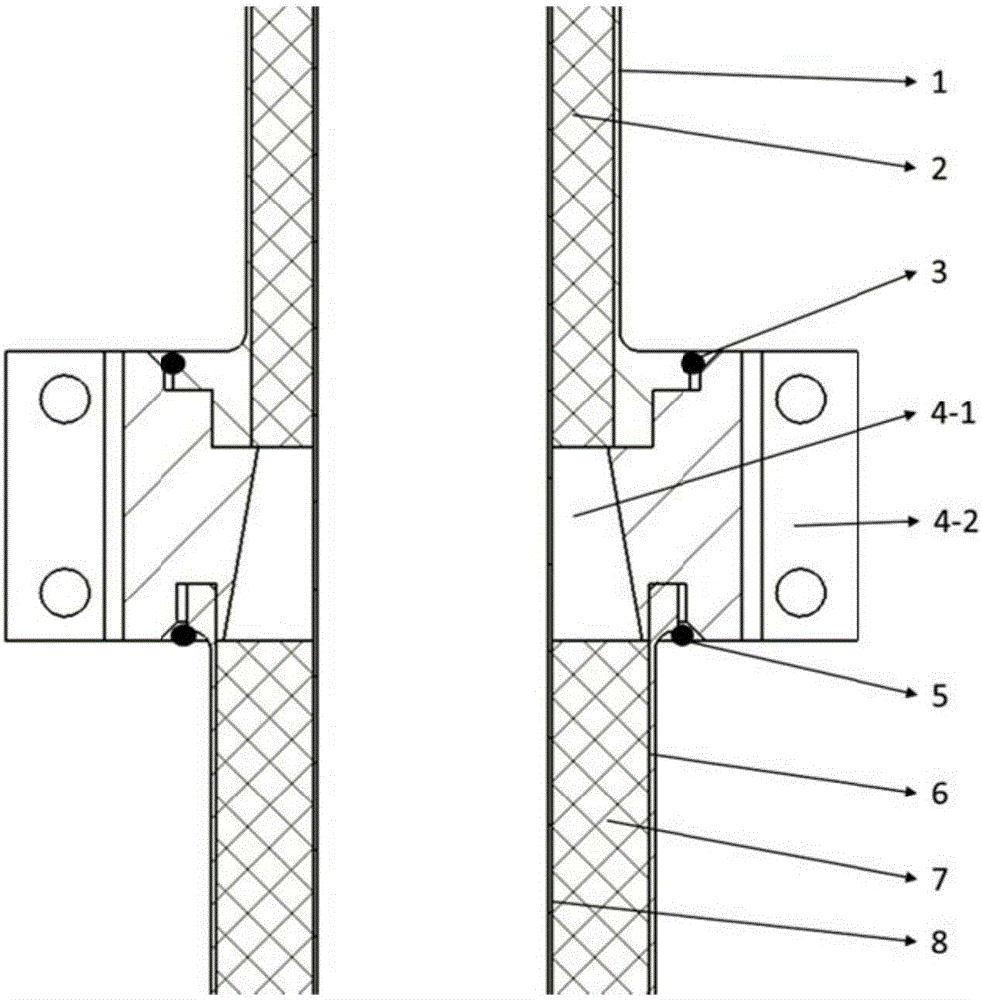

Structure for reducing refrigerant flow loss in compressor

InactiveUS6912871B2Refrigerant flow lossFlow loss minimizationRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsNoise generationEngineering

A structure for reducing a refrigerant flow loss in a compressor includes a refrigerant flow resistance reducing unit to reduce a refrigerant channel resistance at a lower surface of a rotor facing a compression mechanism unit. When the high temperature and high pressure refrigerant gas discharged from the compression mechanism unit flows to the discharge pipe through the refrigerant passage including the gap between the rotor and the stator of the electric mechanism unit, the flow resistance of the refrigerant gas is reduced. Therefore, since the refrigerant can flow smoothly, a flow loss of the refrigerant can be reduced and, as a noise generation is reduced, a reliability can be heightened.

Owner:LG ELECTRONICS INC

Hydraulic pressure supply system of automatic transmission

ActiveUS9494231B2Simple processFlow loss minimizationControlling ratio of multiple fluid flowsGearing controlAutomatic transmissionHigh pressure

A hydraulic pressure supply system of an automatic transmission may include a low-pressure oil pump generating low hydraulic pressure while being driven by an engine to exhaust the low hydraulic pressure to a first low-pressure channel, a high-pressure oil pump raising a portion of the hydraulic pressure in the first low-pressure channel to a high pressure while being driven by an electric motor to exhaust the hydraulic pressure to a first high-pressure channel, a low-pressure regulator valve controlling the hydraulic pressure while exhausting a portion of the hydraulic pressure to supply the controlled hydraulic pressure to a low-pressure part through a second low-pressure channel, and a high-pressure regulator valve controlling the hydraulic pressure while re-circulating a portion of the hydraulic pressure to the low-pressure part through single or two re-circulation channels according to the pressure to supply the controlled hydraulic pressure to a high-pressure part through the second high-pressure channel.

Owner:HYUNDAI MOTOR CO LTD

Clutch device

ActiveCN105587854ALittle energy lossReduce slippage problemsGearing controlFluid gearingsCouplingDrive motor

The invention discloses a clutch device used for a transmission system of a vehicle. The clutch device comprises an input side connected with a driving motor; a first output side and a second output side, which are respectively used for connection with an input shaft of a transmission. The clutch device comprises a torque converter connected between the input side and the first output side. The coupling of the torque converter is adjusted, and then the improving of the positive or negative rotating speed of the input side with respect to the first output side can be adjusted.

Owner:SCHAEFFLER TECH AG & CO KG

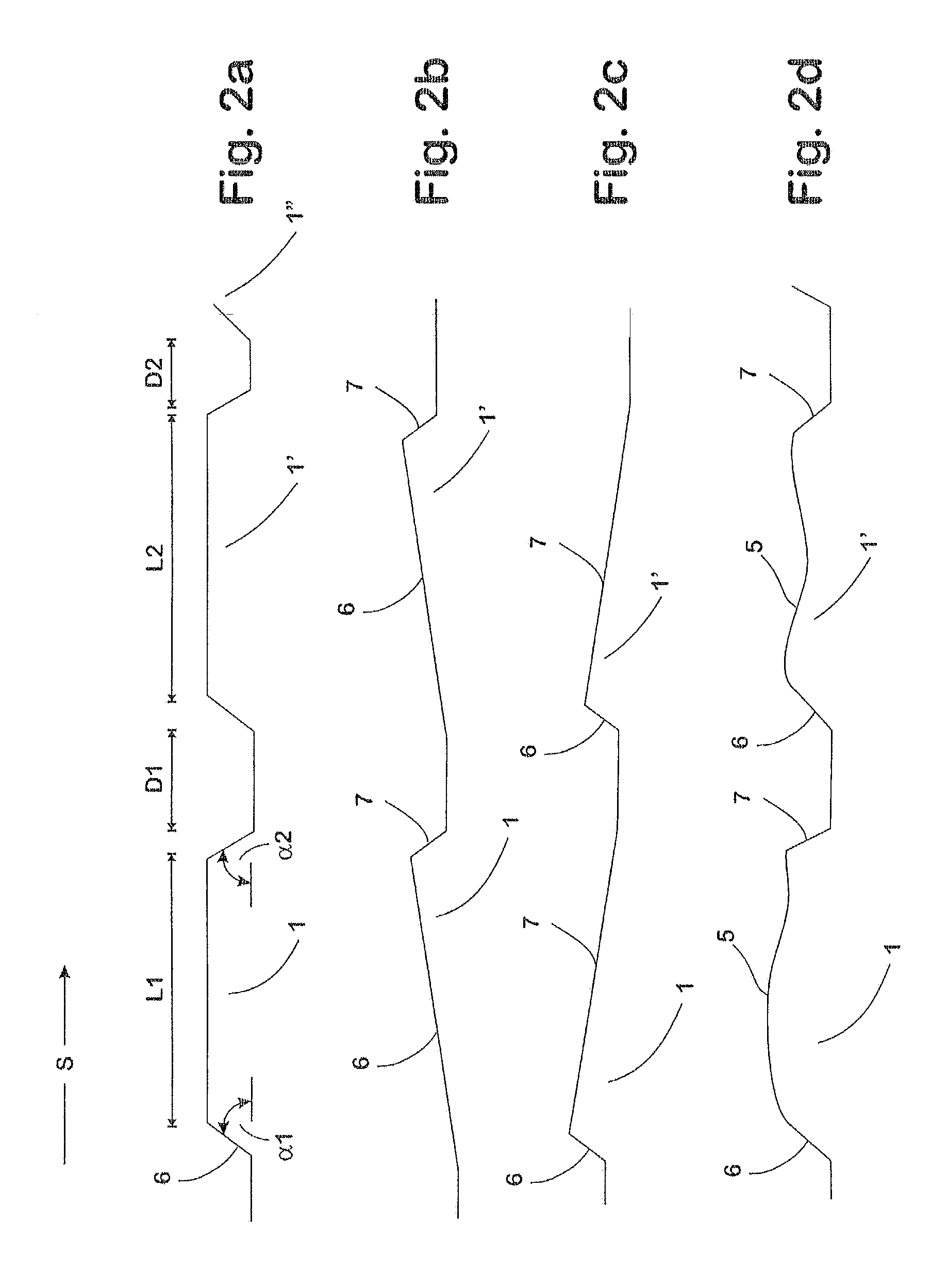

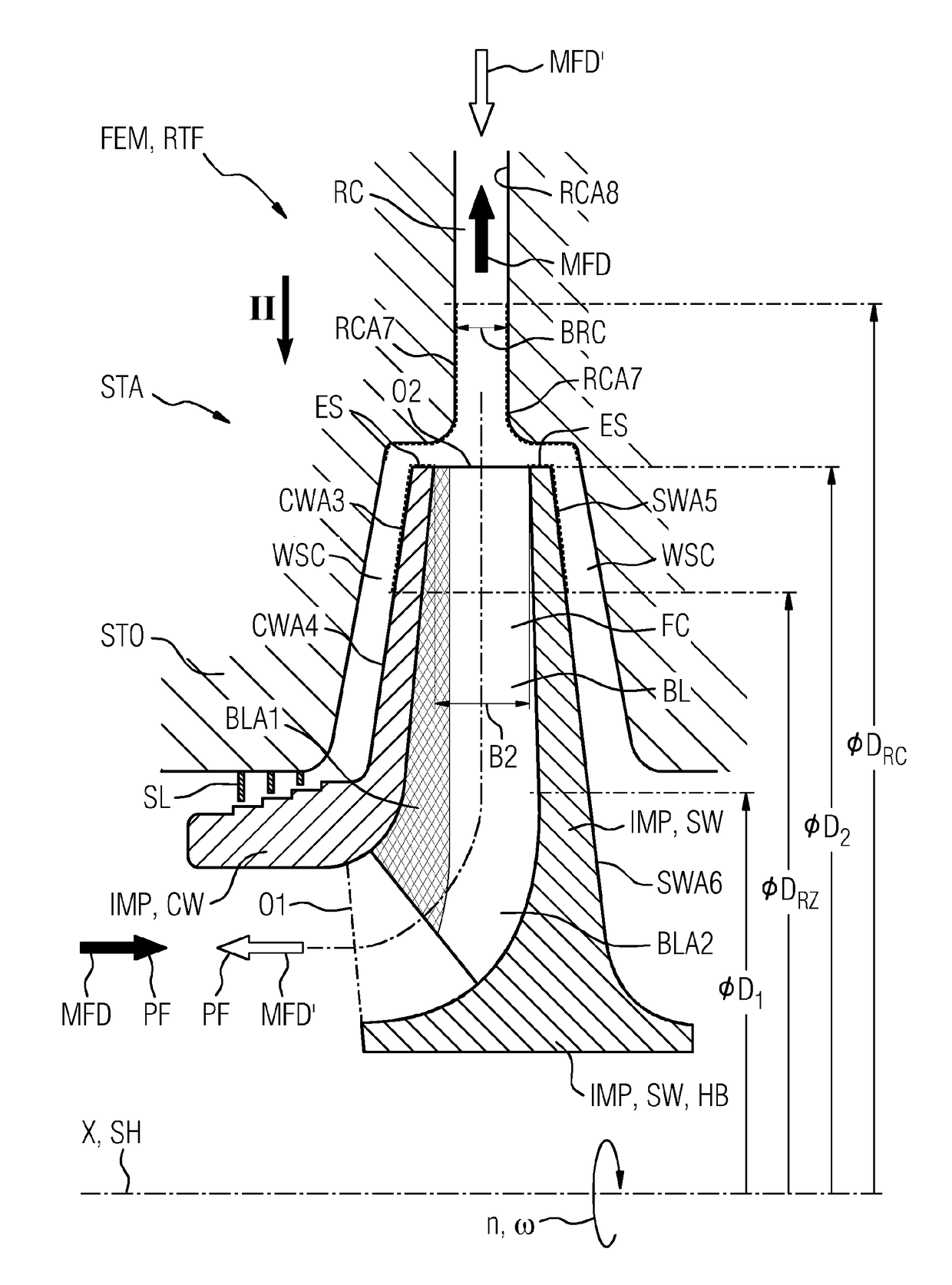

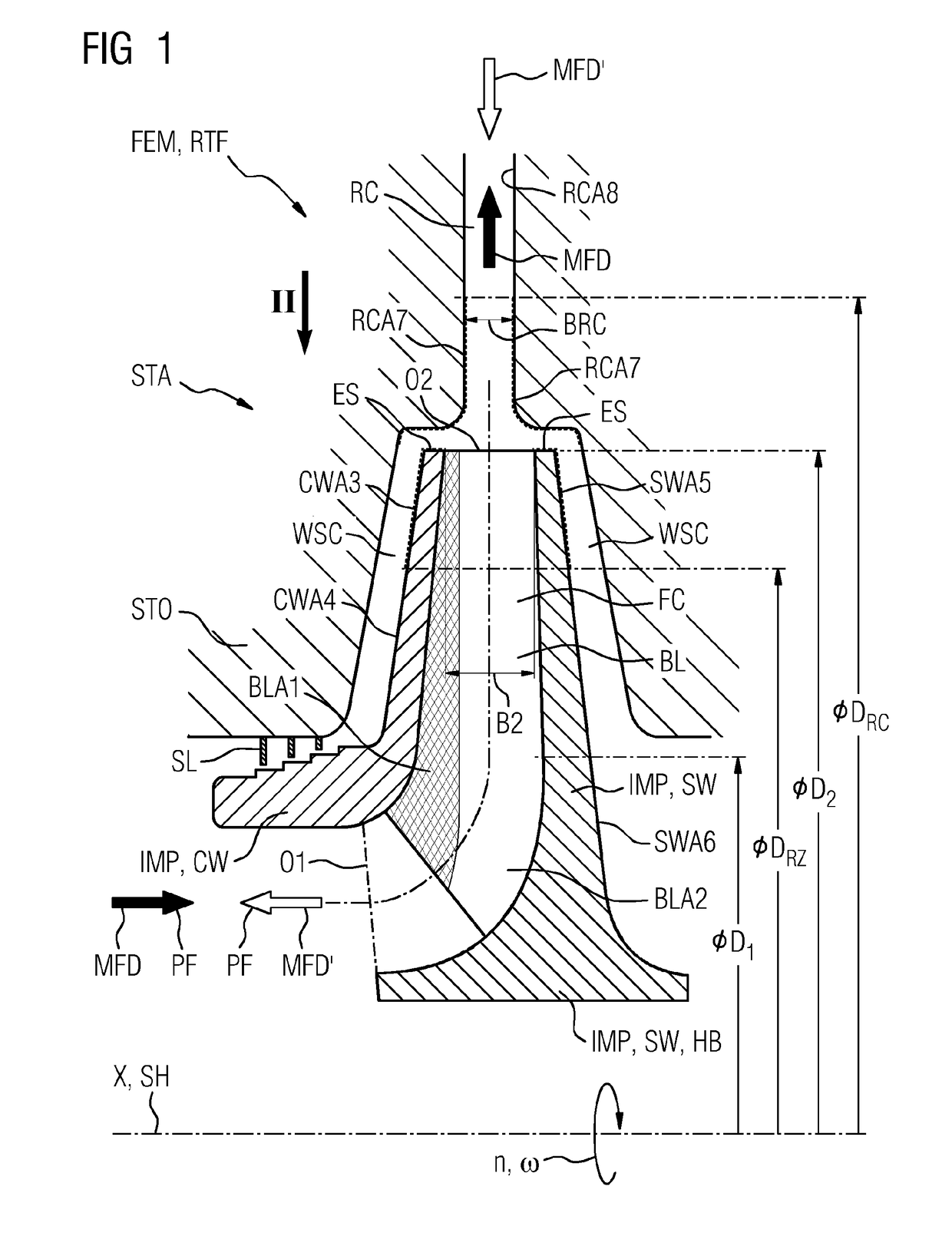

Method for creating an impeller of a radial turbo fluid energy machine, and stage

InactiveUS20170314576A1Reduce surface roughnessImprove surface roughnessPump componentsBlade accessoriesImpellerEnergy analysis

A method for creating an impeller and an impeller of a radial turbo fluid energy machine includes a wheel disc, cover disc, blades, and hub. The hub is mounted on a shaft which extends along an axis, the wheel disc extends substantially radially from the hub, and the cover disc is connected to the wheel disc by the blades such that flow channels separated from one another in the circumferential direction are defined by the blades. The impeller has a first flow passage in a substantially axial direction in the radial proximity of the hub, and the impeller has a second flow passage in a substantially radial direction radially farther away from the hub than the first flow path passage. The cover disc surface facing the wheel disc has a lower degree of roughness at least in some regions than the wheel disc surface facing the cover disc.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com