Separate flow path type of gas-air mixing device

A mixing device and gas technology, applied in the direction of gas and gas/steam mixing, burners, combustion methods, etc., can solve the problems of up and down vibration of the separation membrane, increase of gas supply pressure, unstable operation, etc., to minimize flow loss, Effect of reducing flow noise and simplifying the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Preferred embodiments of the present invention will be described in more detail with reference to the following drawings. In the drawings, similar or identical technical features are indicated by similar or identical reference signs.

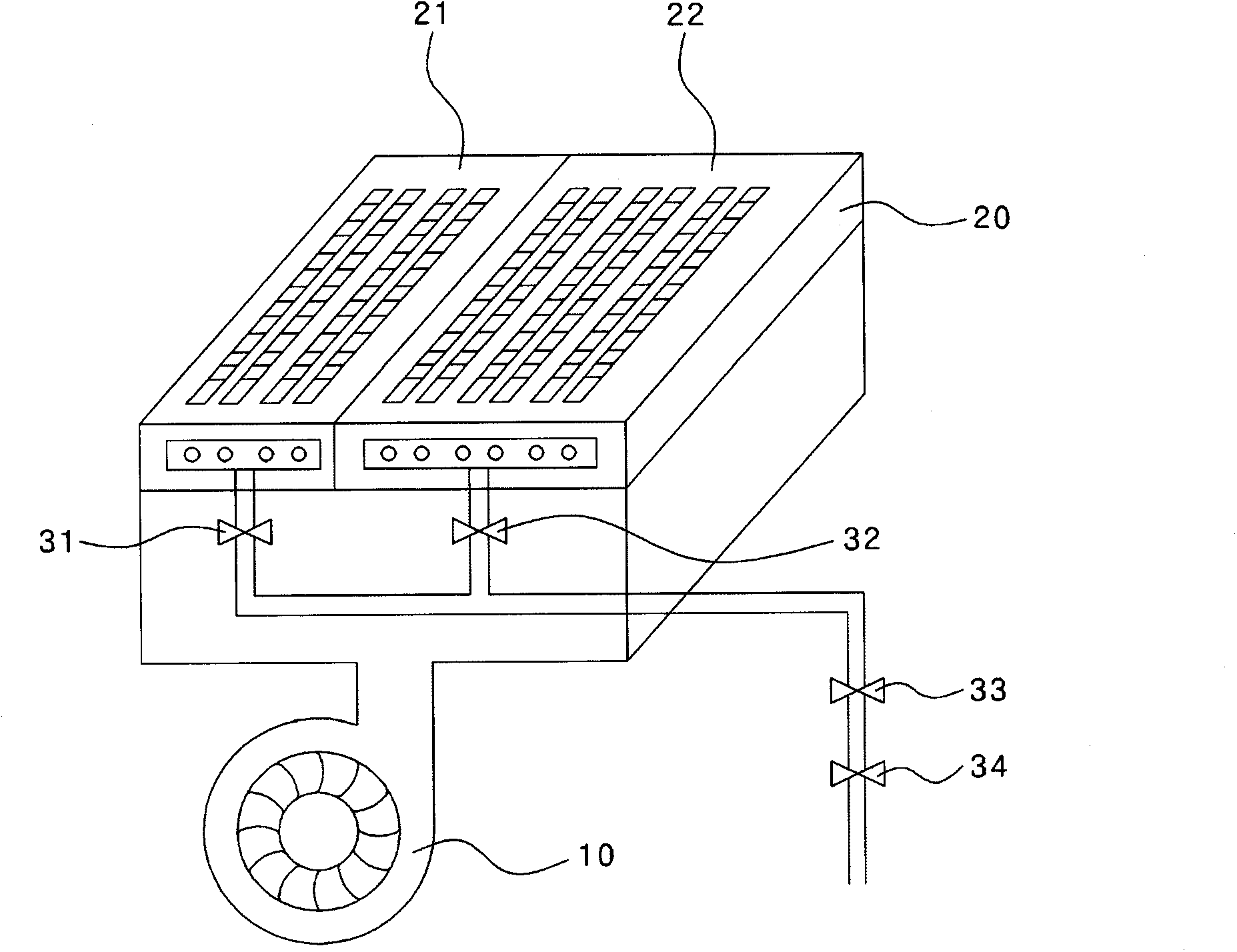

[0055] refer to Figure 5 and Image 6 , an exemplary embodiment of a channel-separated gas-air mixing device according to an embodiment of the present invention will be described.

[0056] As far as the flow path separation type gas-air mixing device of the present invention is concerned, the gas supply pipe 112 of the fuel gas is branched into a plurality of gas flow paths, for example, two gas flow paths 115, 16 are branched; the air supply pipe 113 is branched into The plurality of air flow paths are, for example, branched into two air flow paths 117 and 118 .

[0057] Image 6 Schematically shows the state of the flow path separation type gas-air mixing device of the present invention in the high output power mode. refer to Im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com