Rotary compressor and refrigeration cycle device

A technology of a rotary compressor and a compression mechanism, applied to a rotary piston type/oscillating piston type pump component, a rotary piston type/oscillating piston type pump combination for an elastic fluid, and a component of a pumping device for an elastic fluid Equal direction, to achieve the effect of strong interchangeability, stable angular velocity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

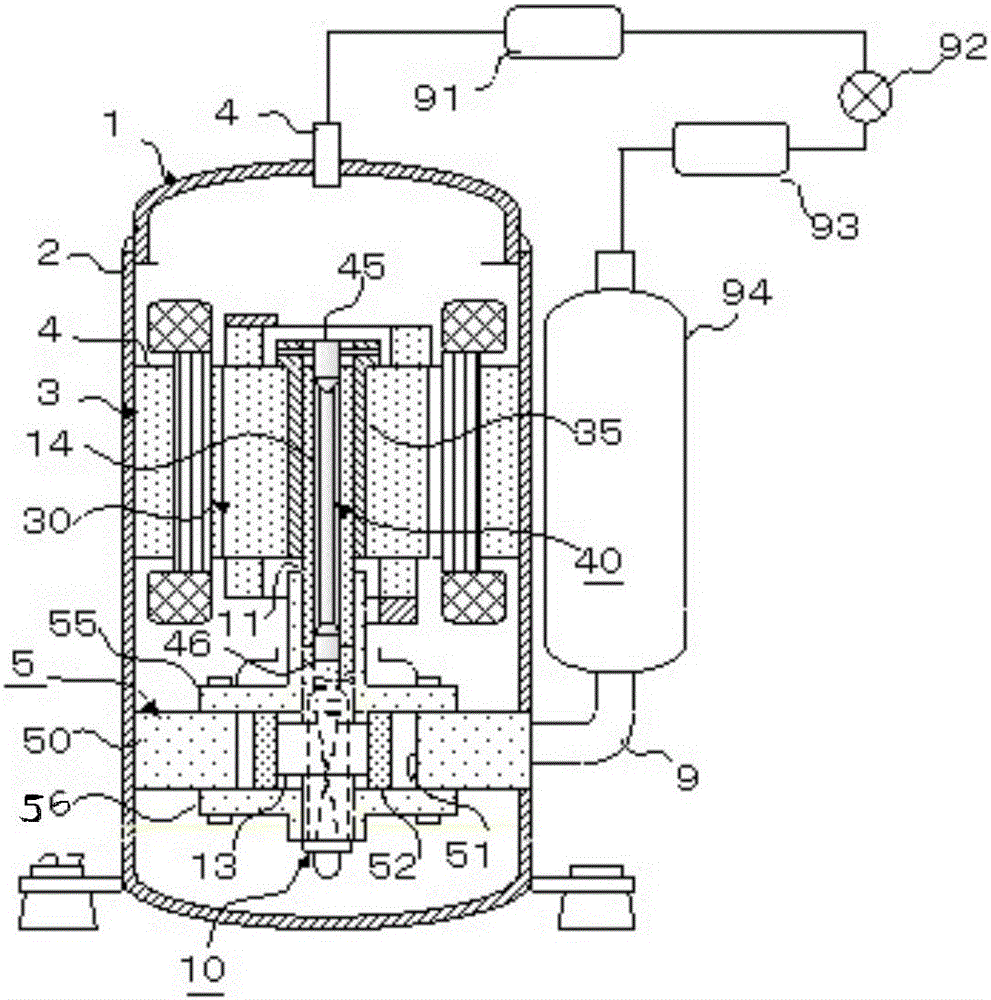

[0057] This embodiment is an application example of a single-cylinder rotary compressor using a single-phase induction motor. figure 1 The configurations of the rotary compressor 1 and the refrigeration cycle are shown.

[0058] The rotary compressor 1 is composed of a compression mechanism 5 fixed on a sealed cylindrical casing 2 , a motor 3 arranged on top of it, and a stator 4 fixed on the casing 2 . Therefore, the compression mechanism 5 is driven by the rotational moment of the rotor 30 generated between the stator 4 and the stator 4 . In addition, lubricating oil (not shown) is stored in the bottom of the casing 2 .

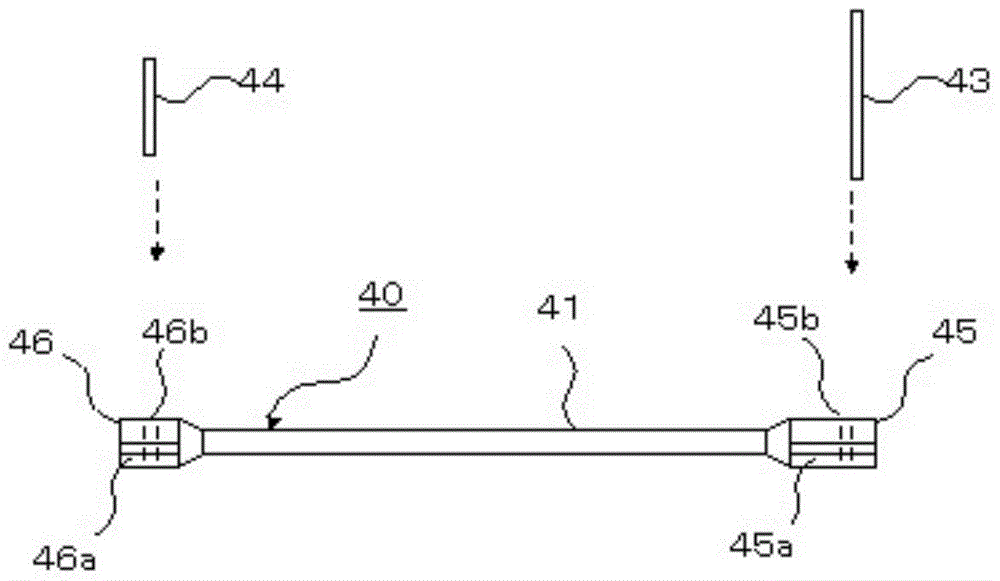

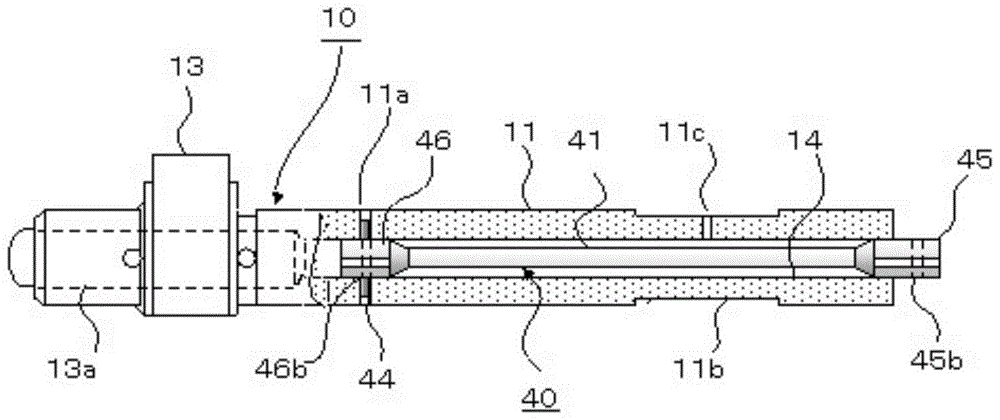

[0059] The characteristic of this embodiment is that the torsion bar spring 40 is equipped in the shaft center hole 14 provided in the main shaft 11 of the eccentric shaft 10, and the C action end 46 and the R action end 45 equipped at both ends are respectively connected to the eccentric shaft 10 and the rotor. 30, and the rotor 30 provided with the main...

Embodiment 2

[0088] The maximum value of the phase angle θ3 fluctuates greatly due to different operating conditions. In the case of a rotary compressor installed in an air conditioner, generally, θ3 becomes larger in proportion to the difference between the high-pressure side pressure and the low-pressure side pressure. Generally speaking, during cooling operation, θ3 will increase during the day when the air conditioning load is high, and will decrease at night when the air conditioning load is low. However, the reverse is true during heating operation. In addition, in the model equipped with an inverter motor with variable rotation speed, not only the air conditioning load, but also the inertial mass of the rotor is considered.

[0089] As mentioned above, if θ3 is too large during fluctuations in conditions such as operating load, the synchronous speed of the stator and rotor cannot be maintained, that is, a step-out phenomenon may occur, and the motor may stop suddenly. The present ...

Embodiment 3

[0101] Embodiment 1 is a manufacturing method in which the compression mechanism 5 and the rotor 30 are integrated and fixed in the inner diameter of the casing. In contrast to this method, after fixing the compression mechanism 5 and the stator 4 to the inner diameter of the housing 2, the method of inserting the rotor 30 into the main shaft 11 and assembling is also popularized. This embodiment corresponds to the latter method.

[0102] exist Figure 12 and Figure 13 In the center of the R action end 45 and the round pipe end 36, there is a rod groove 45c ( Figure 13 ) and round pipe groove 36c. After the rotor 30 is inserted into the main shaft 11, the two grooves are made in the same direction, and the R moment bars 43 are inserted into these grooves. Thereafter, the flat washer 47 is inserted into the outer periphery of the R-action end 45, and the C-stop ring 48 is inserted into the circumferential groove provided in the R-action end 45, so that the rotor 30 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com