Fuel injector for operation with combustible gas

A fuel injector and gas nozzle technology, which is applied to fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as flow loss of combustible gas, and achieve the effect of high engine power and reduced flow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following description and drawings, the same reference numerals correspond to functionally identical or similar elements.

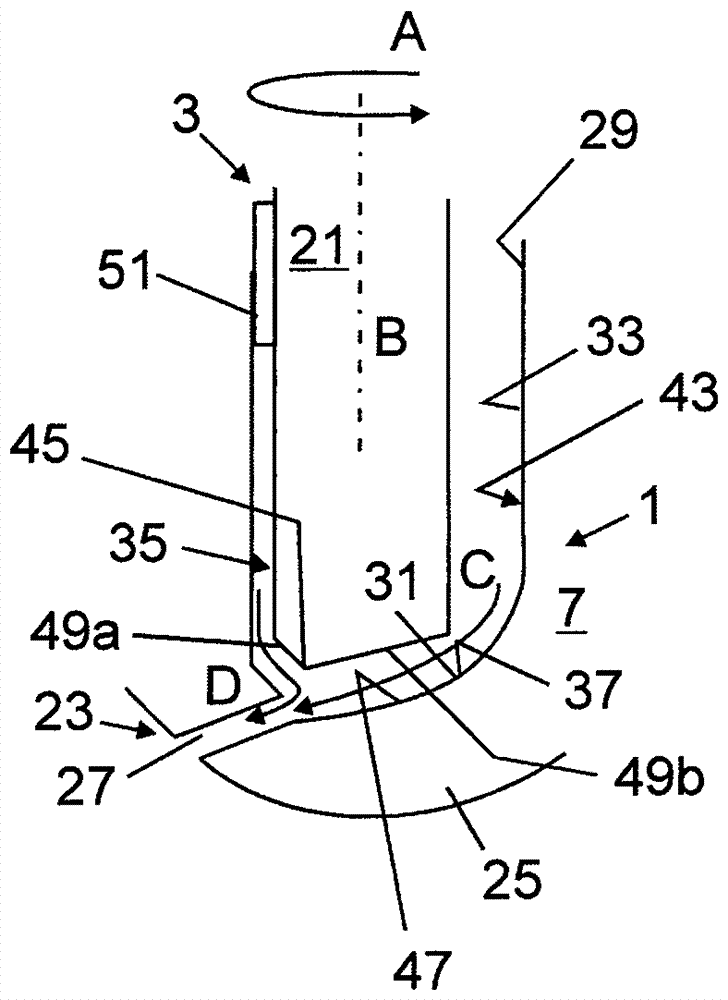

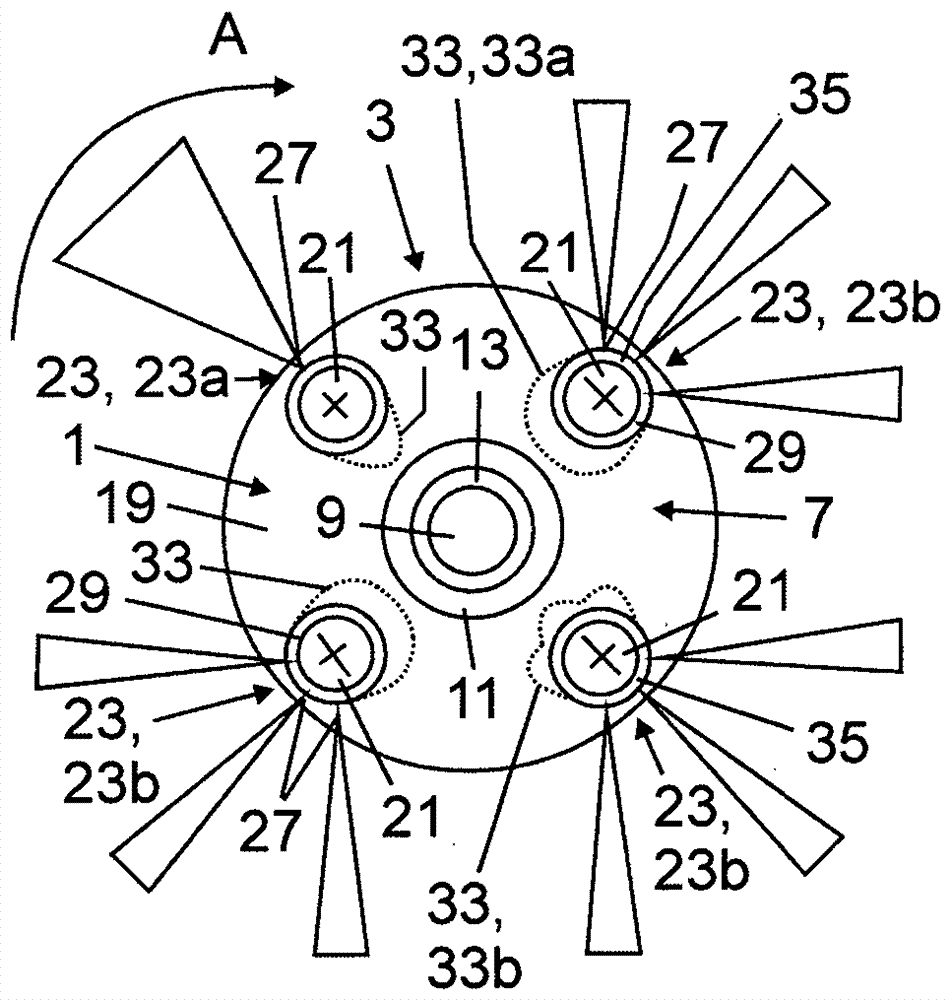

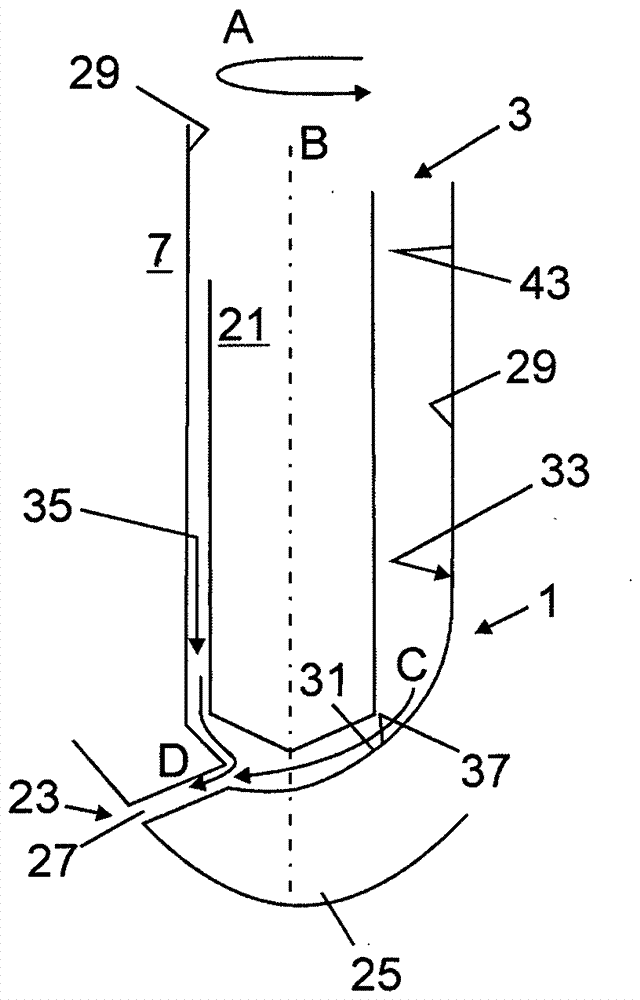

[0030] figure 1 The nozzle-side end section 1 of a fuel injector 3 according to the invention for operation with a combustible gas is shown in an exemplary and schematic manner, the fuel injector 3 shown as dual fuel-fuel injection The device is provided, that is to say not only for operation with liquid fuels but also for operation with combustible gases. As a liquid fuel for use with the fuel injector 3, diesel fuel, bio-oil, heavy oil or a liquid fuel different from these can be provided, as a combustible gas for use with the fuel injector 3, in particular natural gas can be provided , Also such as biogas, soil waste gas, etc. In addition to, for example, pure liquid fuel operation, the fuel injector 3 provided in this way is especially designed for combustion jet operation.

[0031] The fuel injector 3 has an injector housing 5 which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com