Air-controlled valve

A technology of controlling cavity and valve chamber, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as large dead zone, and achieve the effect of simple control and small control force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

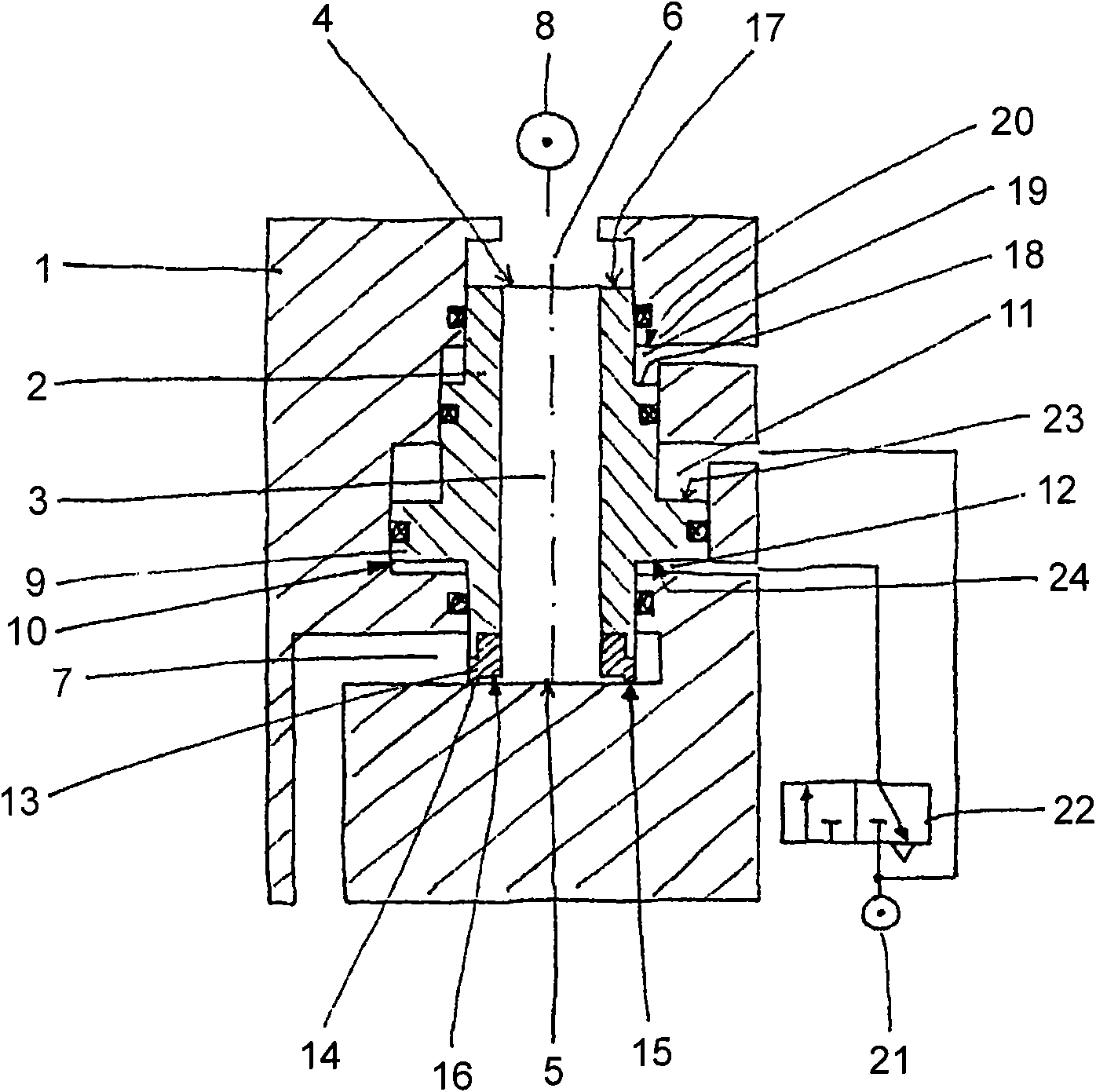

[0045] exist figure 1 A longitudinal section through the valve according to the invention is shown purely schematically. A piston 2 is embodied longitudinally displaceable in the housing 1 as an annular piston and has a centrally arranged channel 3 extending between the two end faces 4 and 5 of the piston 2 .

[0046] The upper end face 4 of the piston 2 opens into a first valve chamber 6 which is likewise formed in the housing 1 and is connected to an external pressure source 8 , for example via a pressure line 7 .

[0047] The lower end face 5 of the piston 2 opens into a second valve chamber 7 , which is connected, for example, via a connecting channel 8 also arranged in the housing 1 to a compressed air-controlled device, such as a blowing cylinder of a hollow body blower. (not shown) connection.

[0048] Furthermore, the piston 2 has in its central region a radially outwardly protruding piston ring 9 which opens into an annular chamber 10 of the housing and divides this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com