Patents

Literature

171results about How to "Improve fan efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

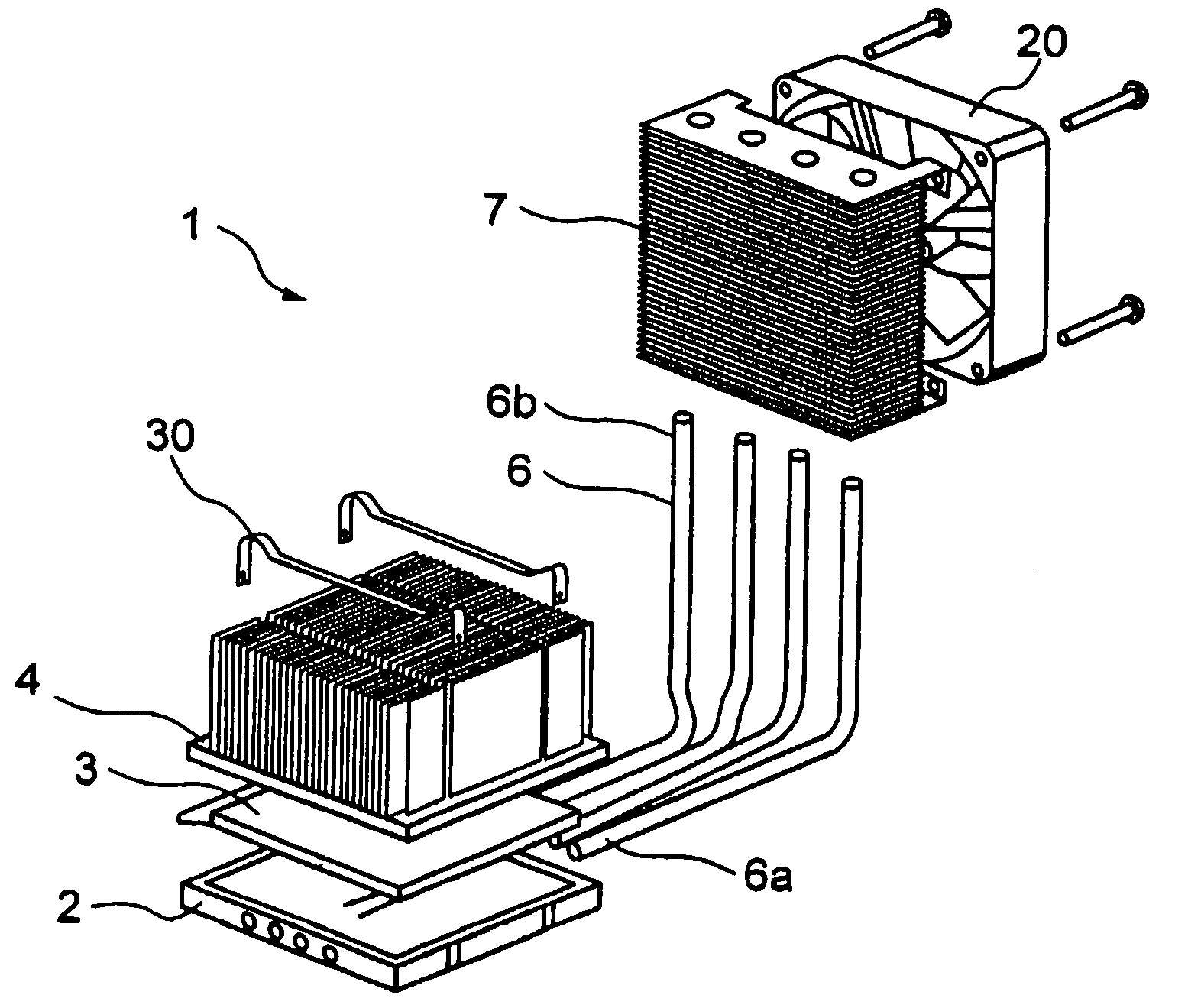

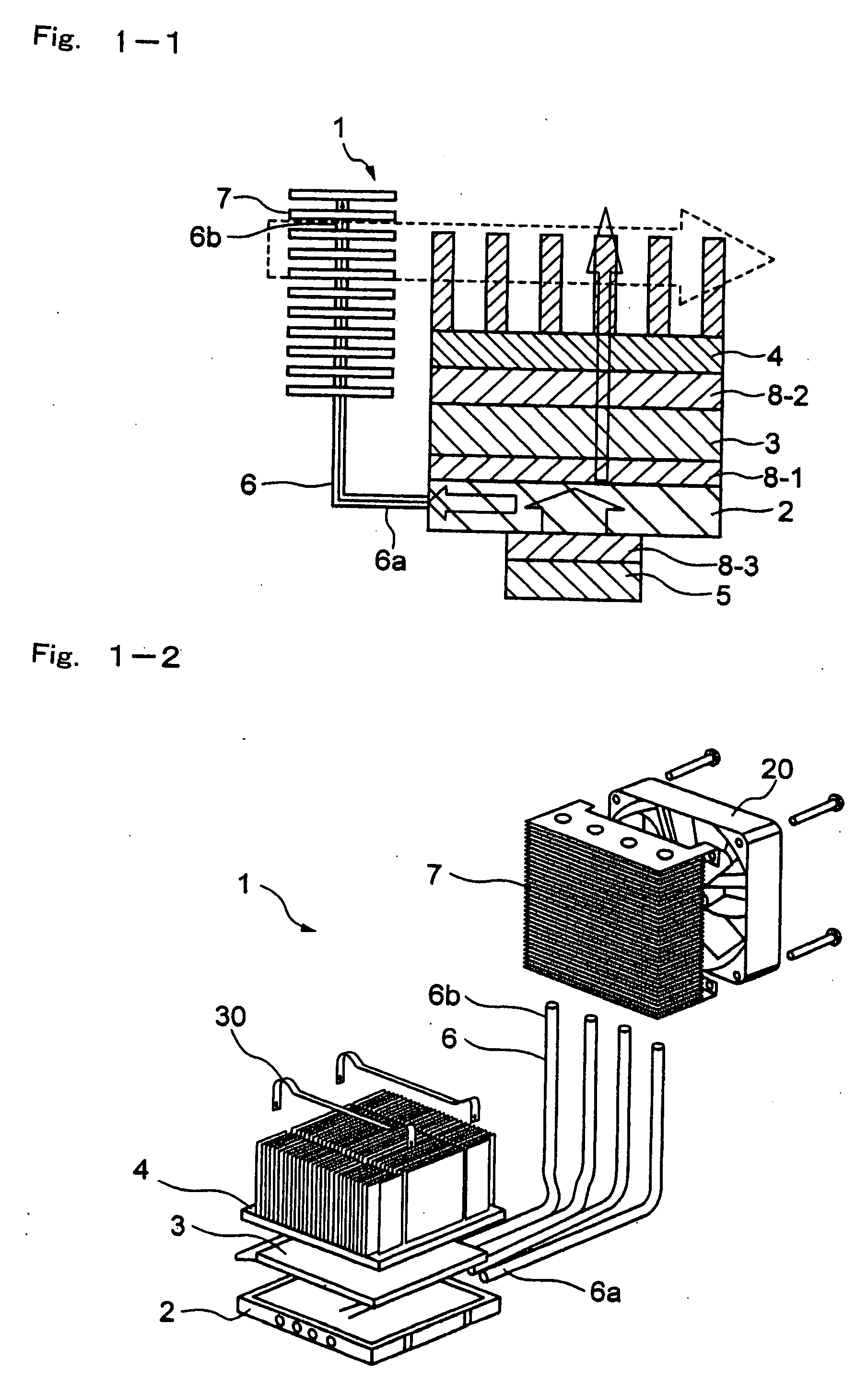

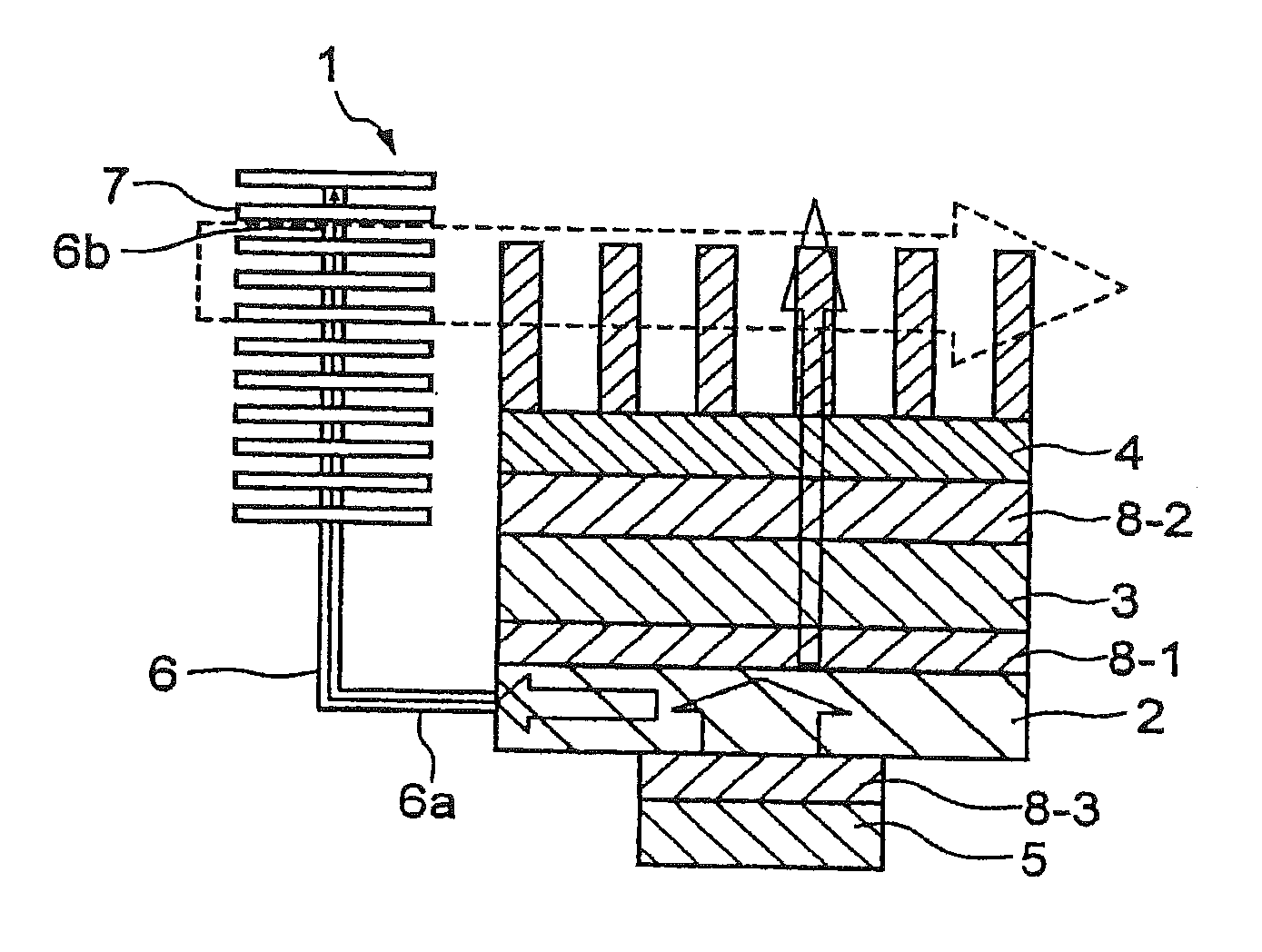

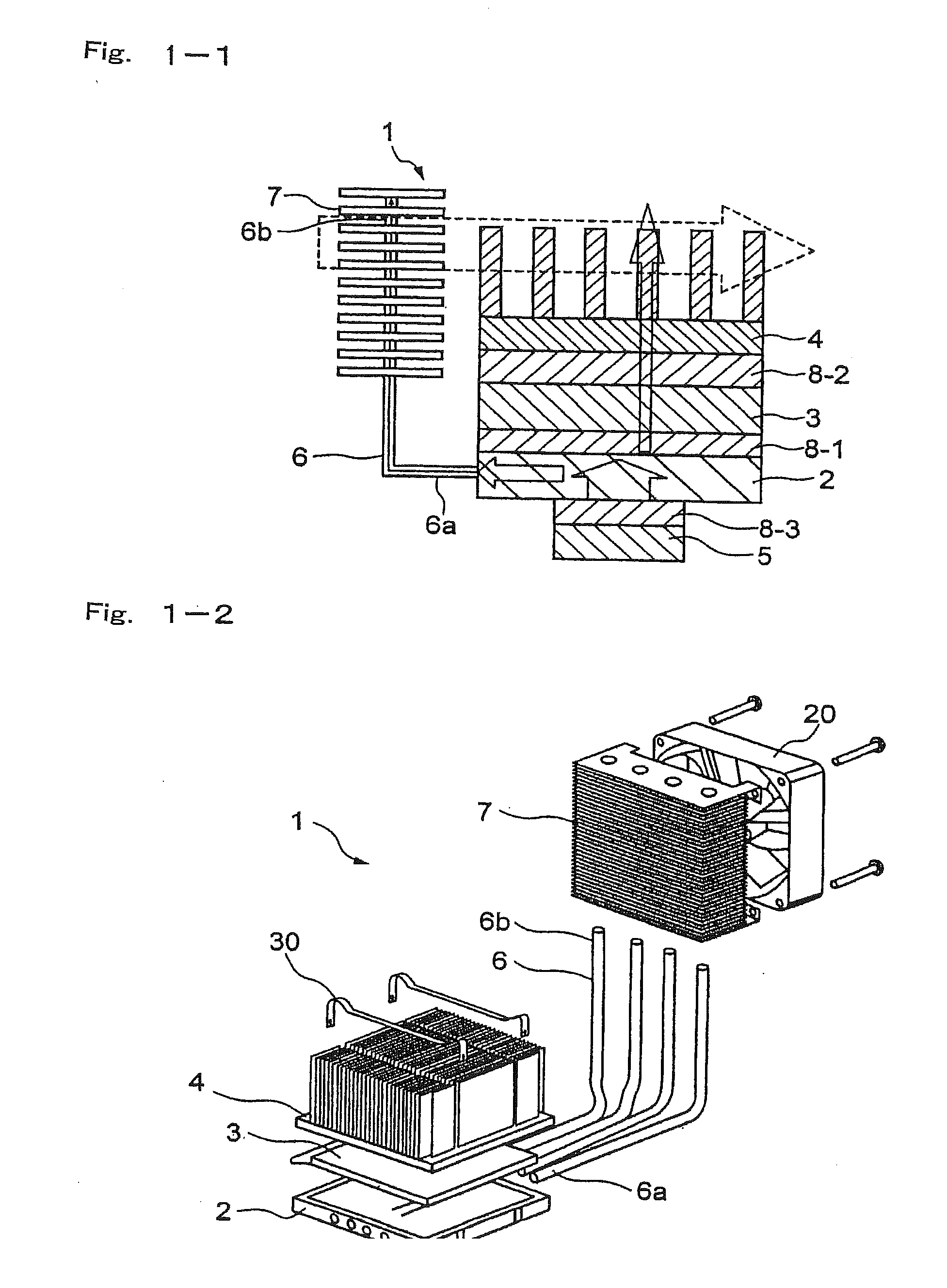

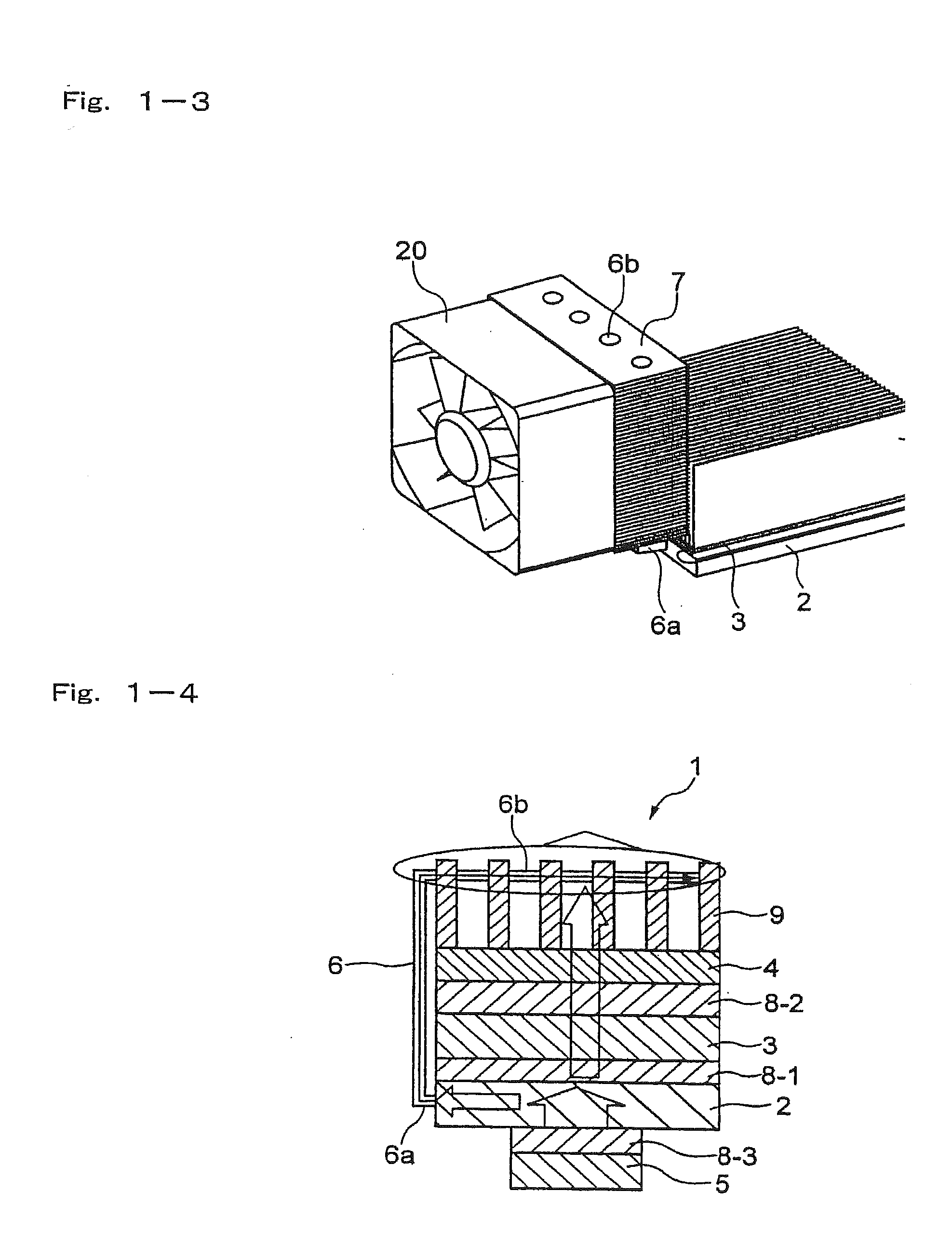

Module for cooling semiconductor device

InactiveUS20050257532A1Improve cooling efficiencyReduce heat gainDomestic cooling apparatusIndirect heat exchangersThermoelectric coolingDevice material

A module for cooling a heat generating element comprising a heat receiving plate thermally connected to at least one heat generating element; a heat transfer device one end portion of which is thermally connected to the heat receiving plate and other end portion of which is thermally connected to a heat dissipating plate; a thermoelectric cooler one face of which is thermally connected to one face of the heat dissipating plate; a first heat sink thermally connected to other face of the heat dissipating plate; and a second heat sink thermally connected to other face of said thermoelectric cooler.

Owner:FURUKAWA ELECTRIC CO LTD

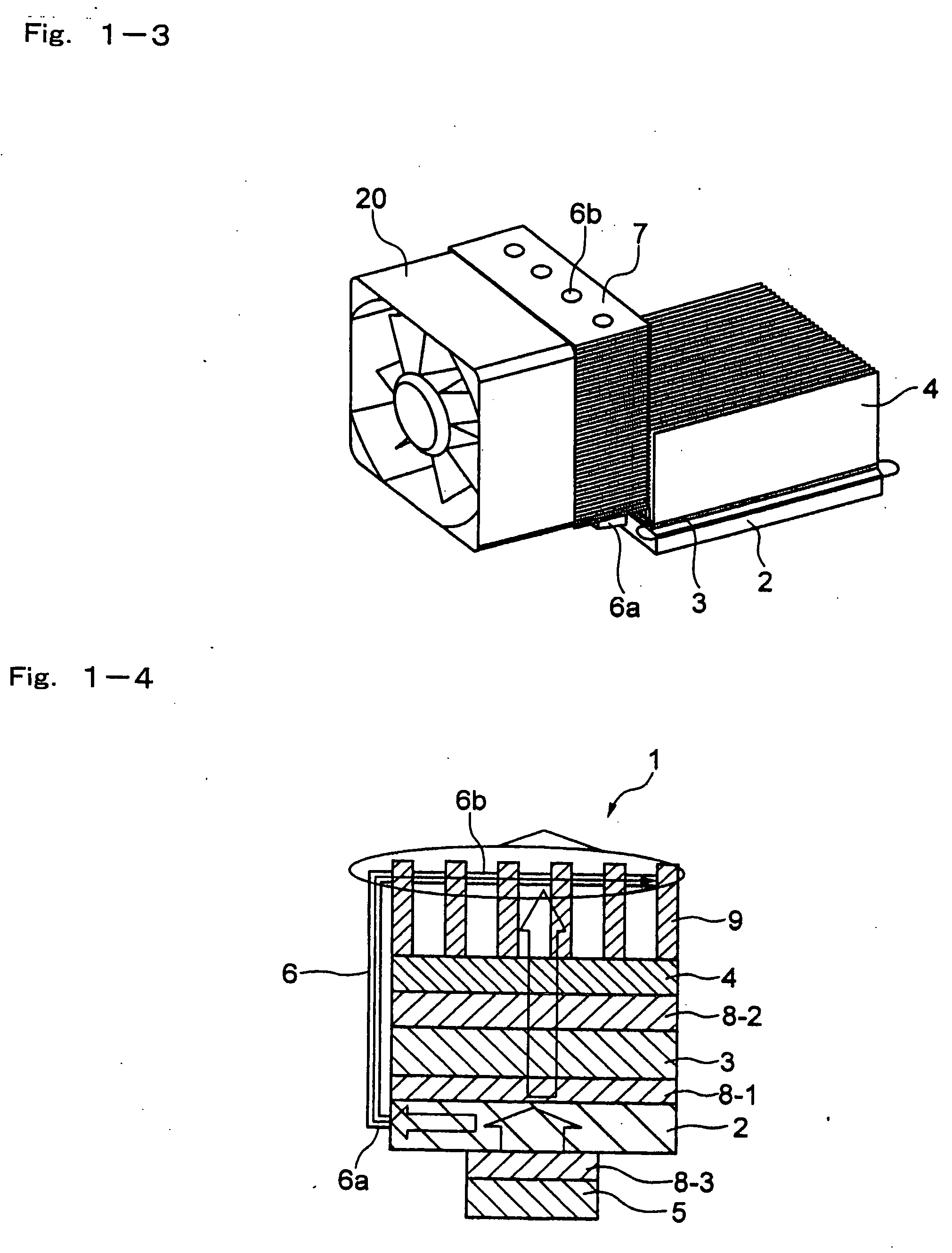

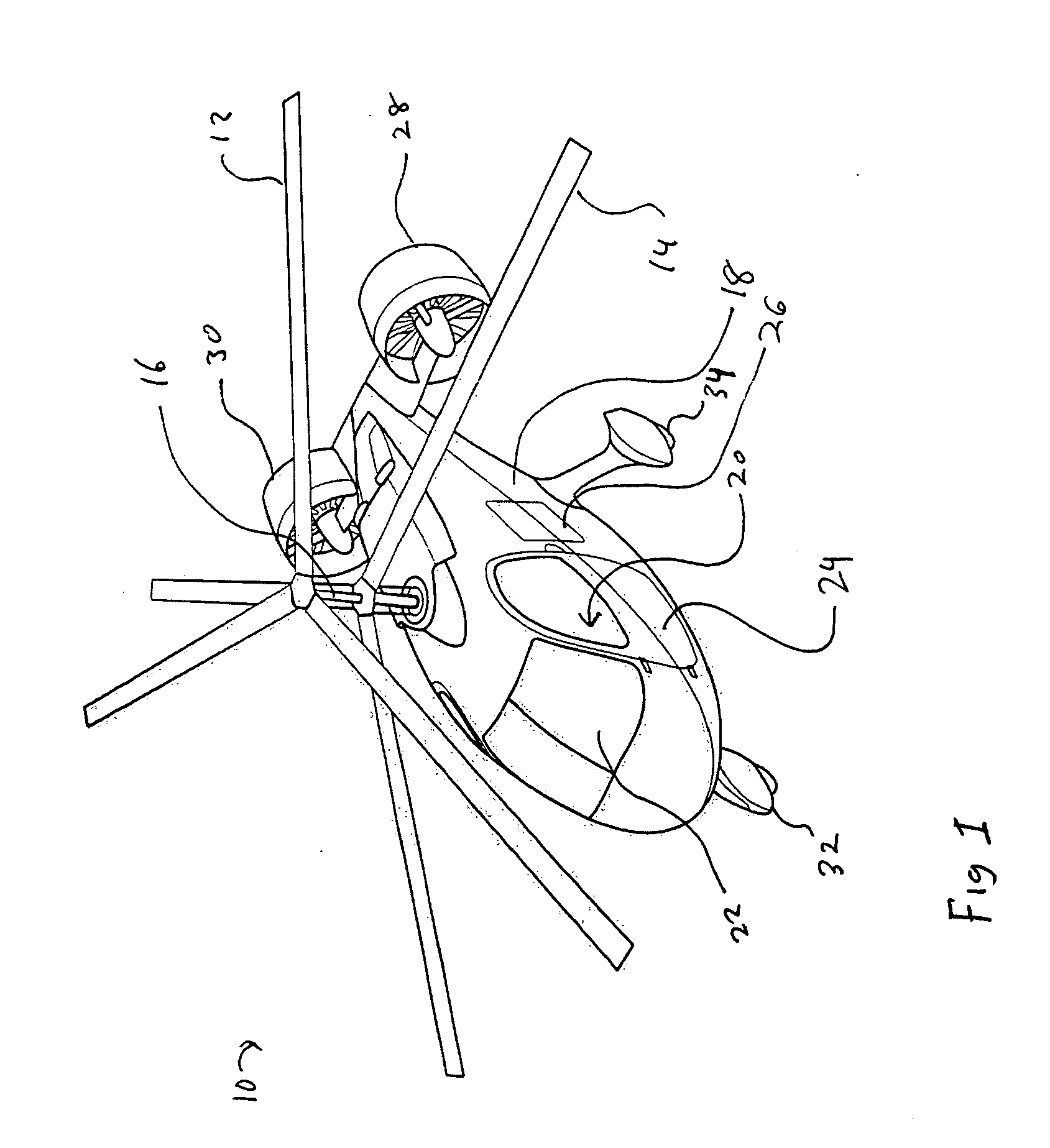

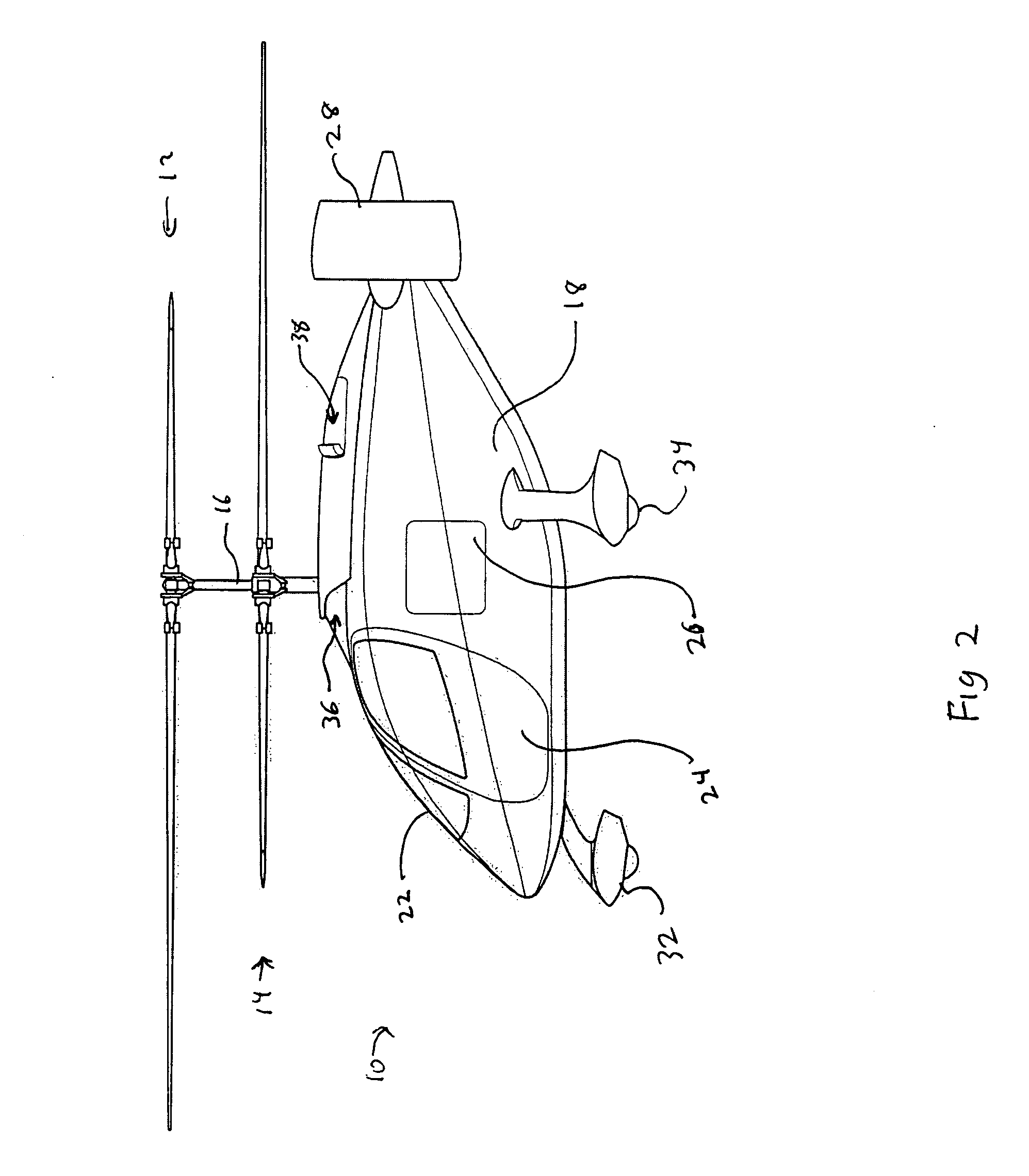

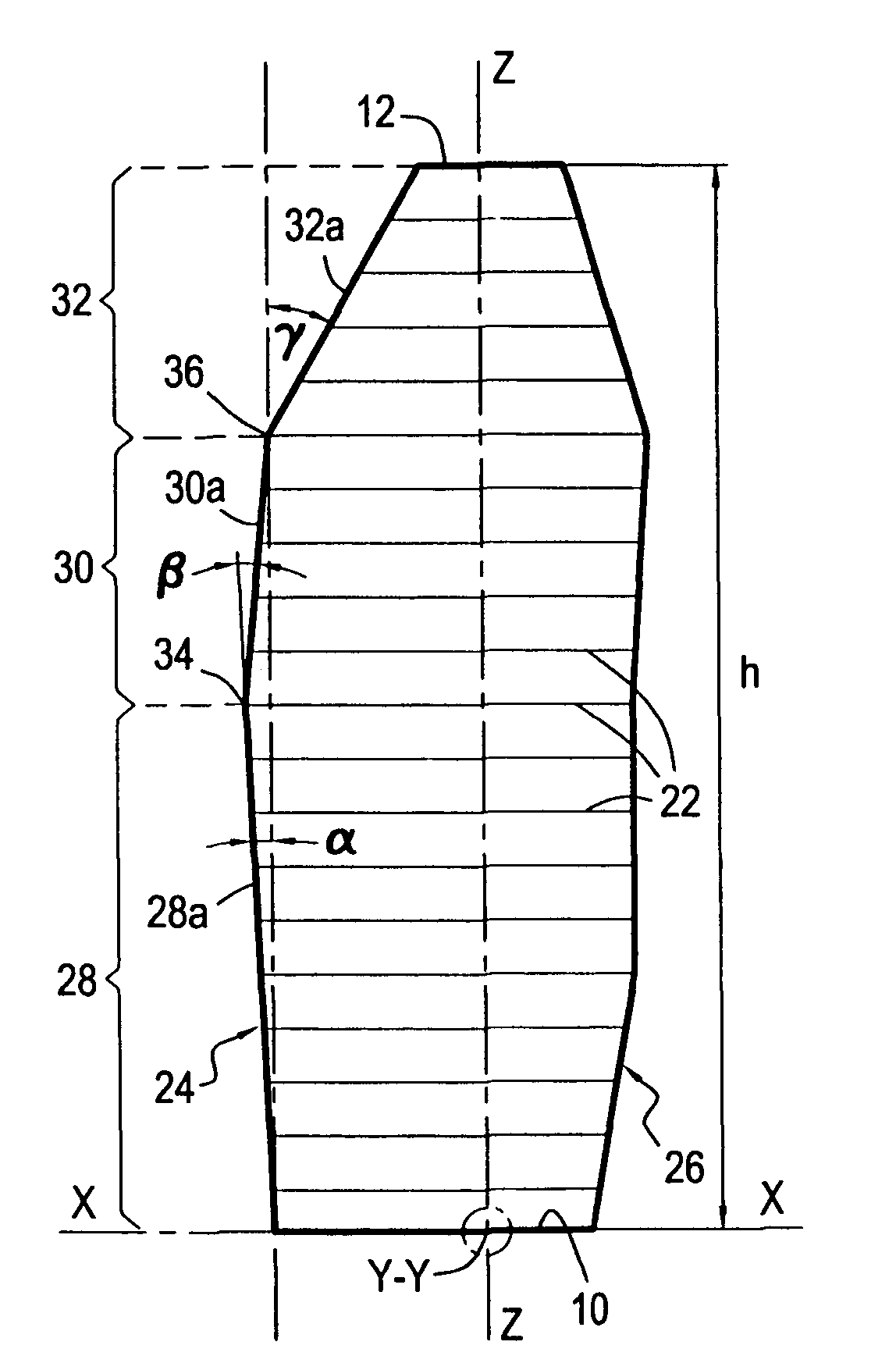

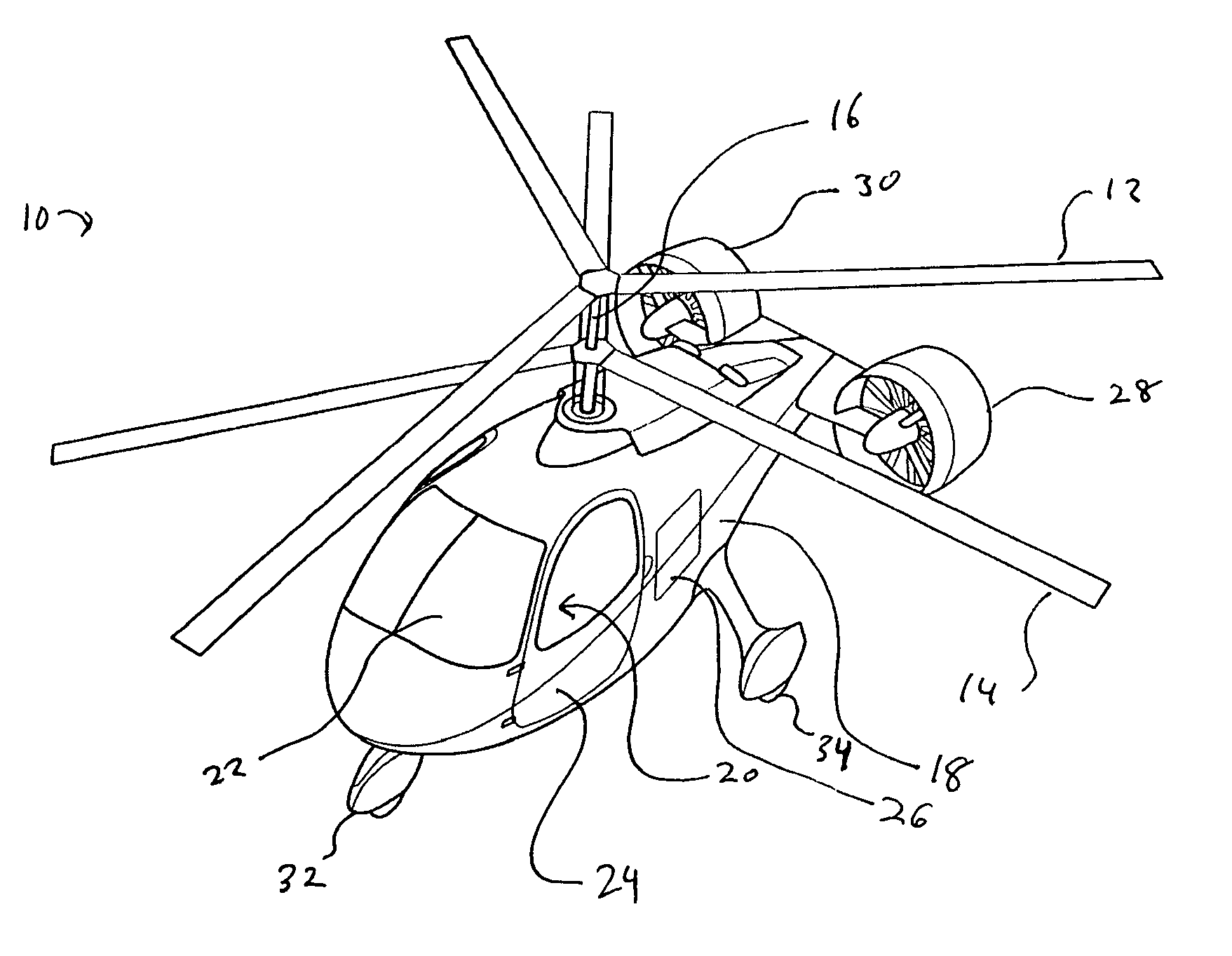

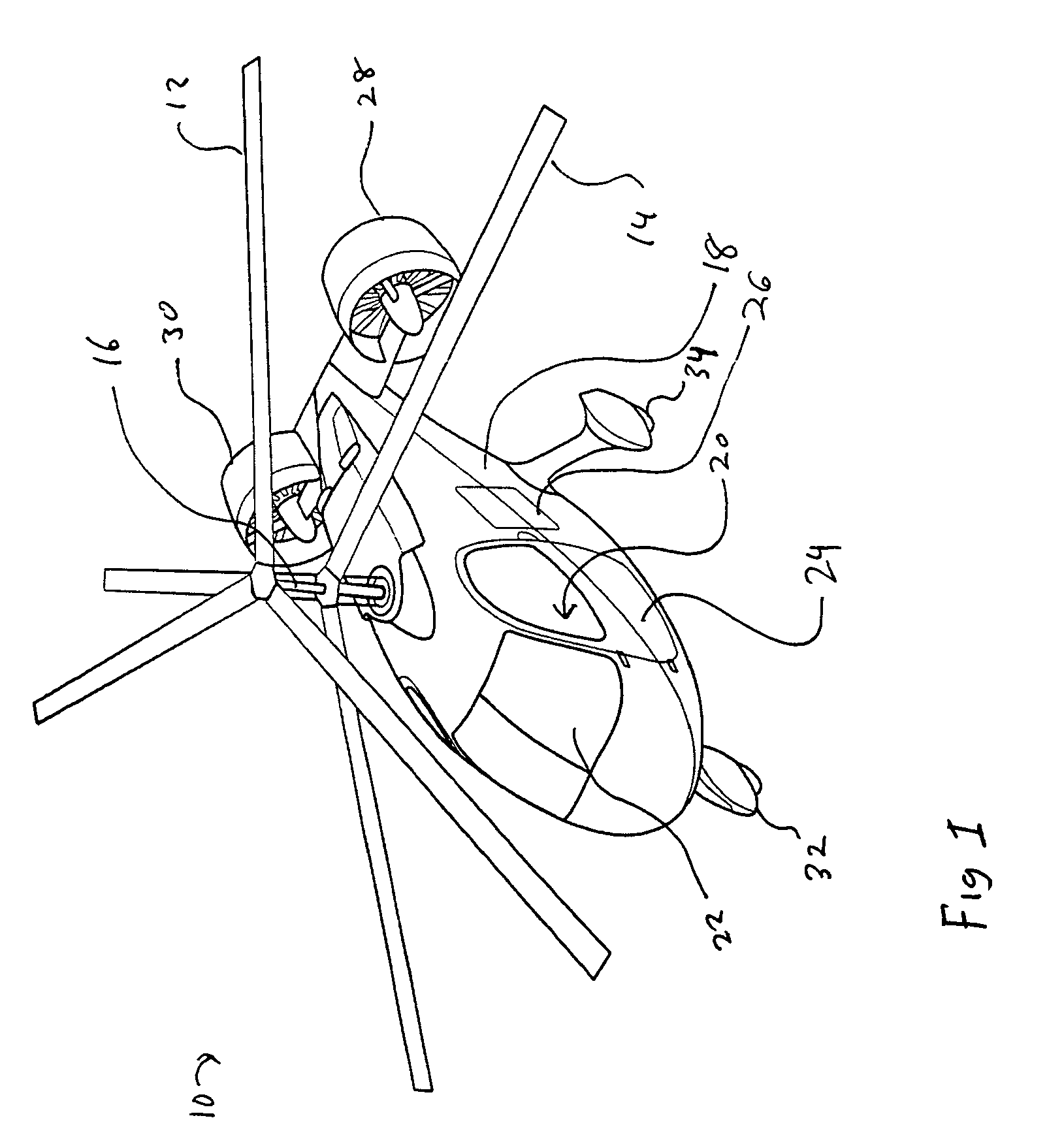

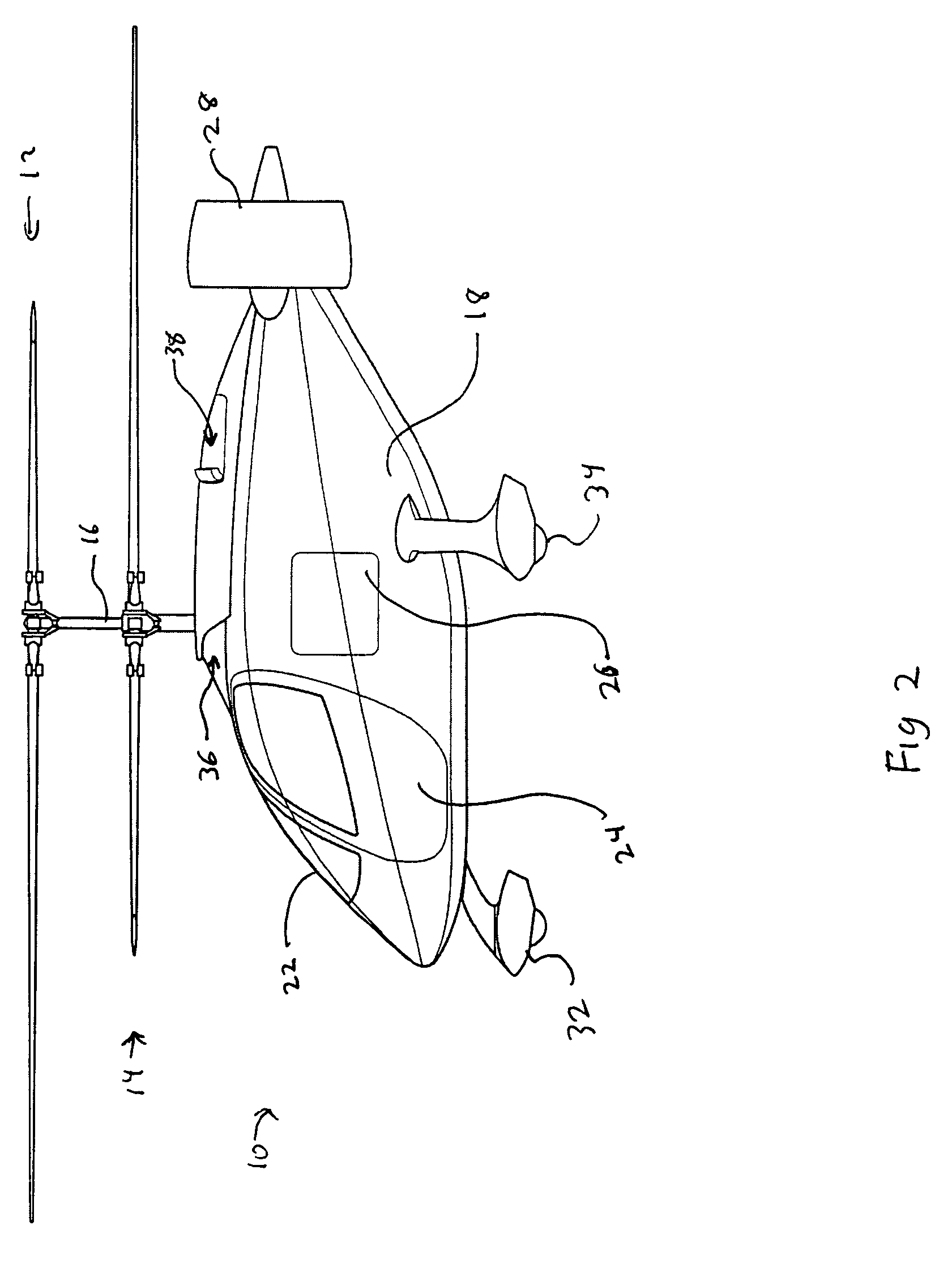

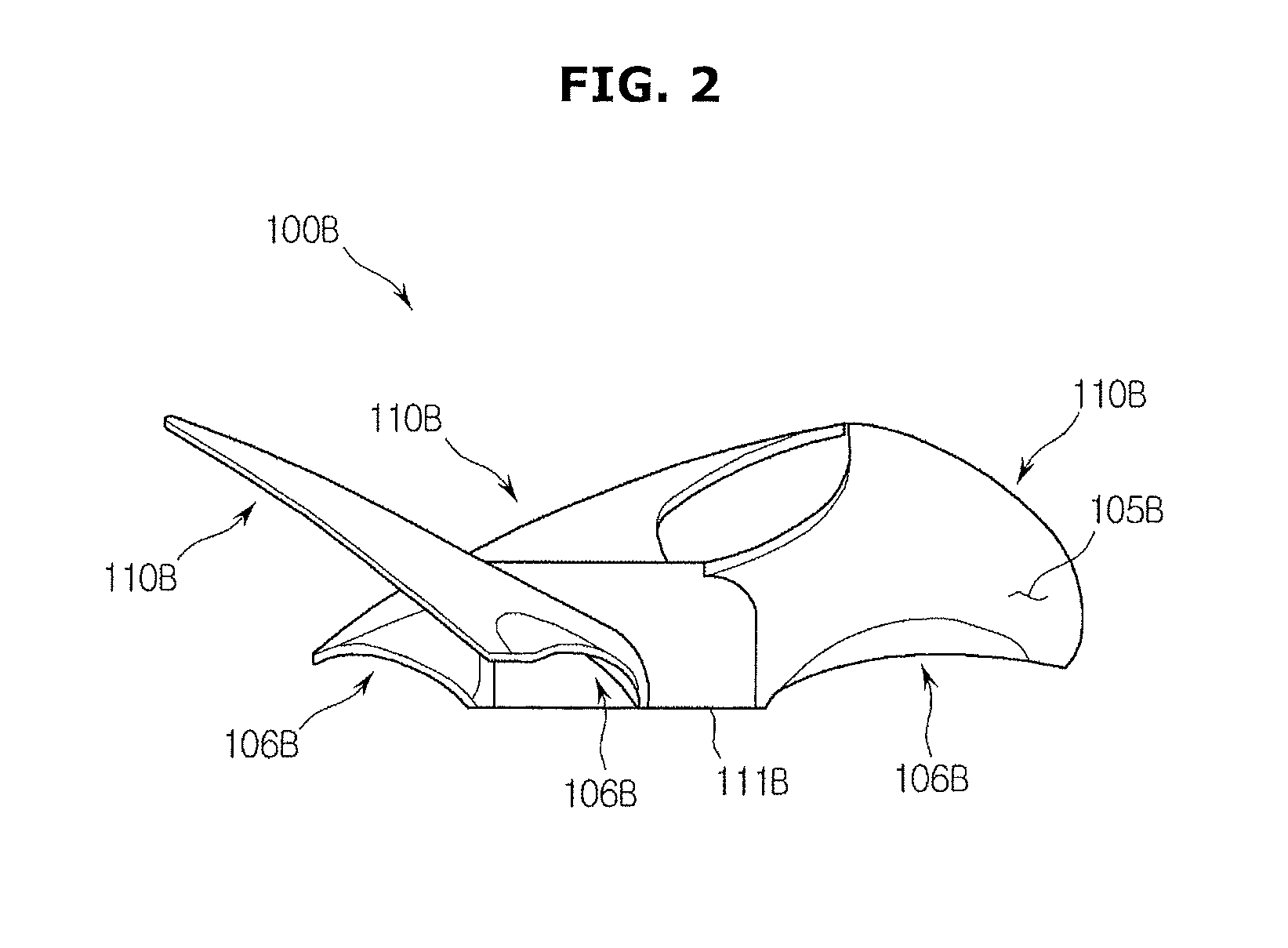

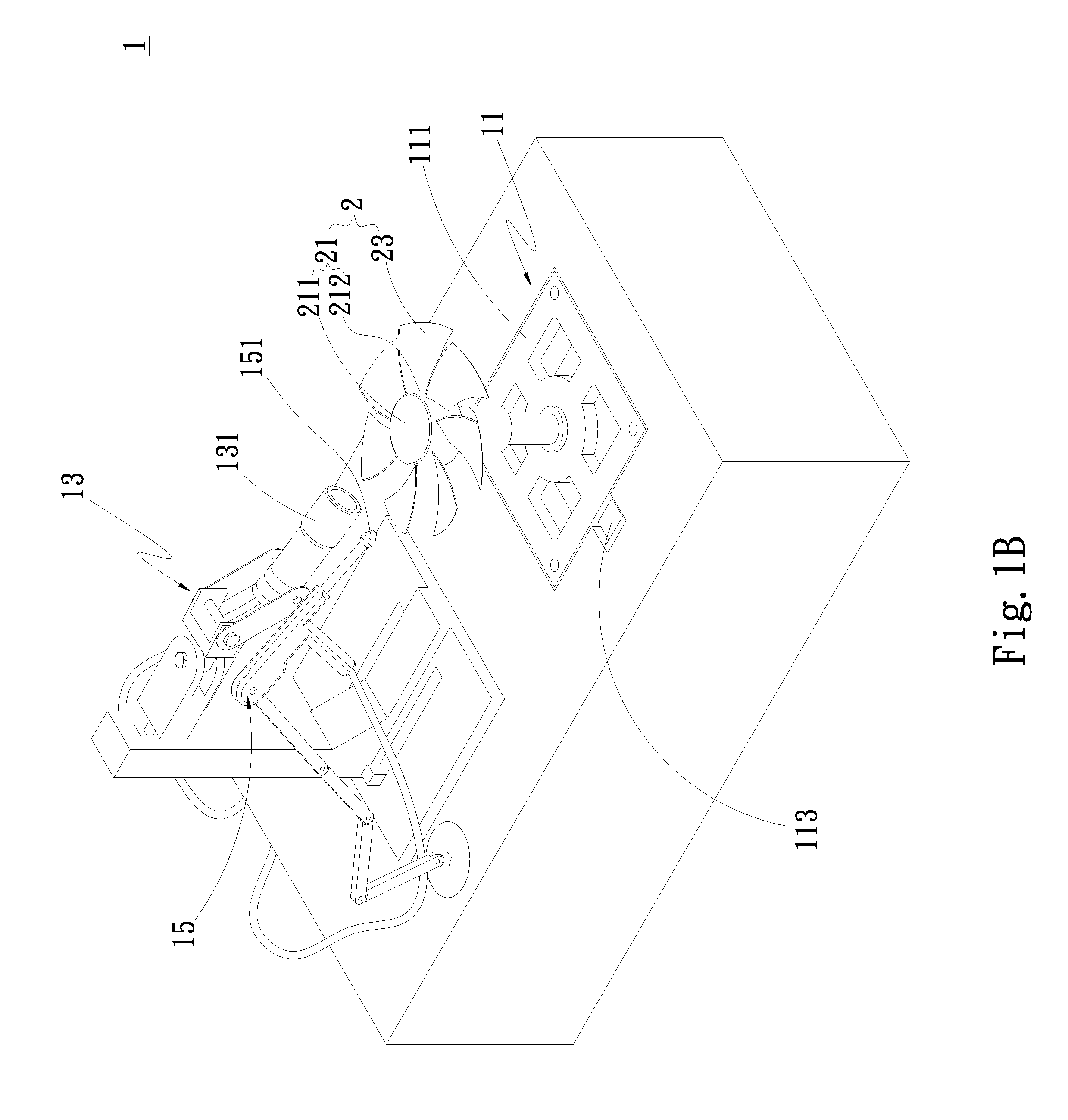

Coaxial rotor aircraft

ActiveUS20090159740A1Easy to flySimplified Control RequirementsDepending on number of propellersRotocraftCruise speedHorizontal and vertical

A dual, coaxial rotor helicopter is provided that is relatively easy to fly. Thrust is provided by two ducted fans that are mounted at the rear of the aircraft and spaced apart laterally. Differential thrust generated by the fans provides yaw control for the aircraft, and forward thrust is provided by the fans working in combination. The coaxial rotors are preferably utilized primarily for lift, and not for forward thrust, which simplifies the control requirements. The coaxial rotor with ducted fan configuration also results in lower vibratory loads being imposed on the helicopter, thereby increasing its speed capability. The fan ducts serve to protect the fans, augment the fan thrust at low airspeeds, increase the efficiency of the fans at cruise speeds, and provide horizontal and vertical stabilizing surfaces to ensure aircraft flight stability.

Owner:AVX AIRCRAFT

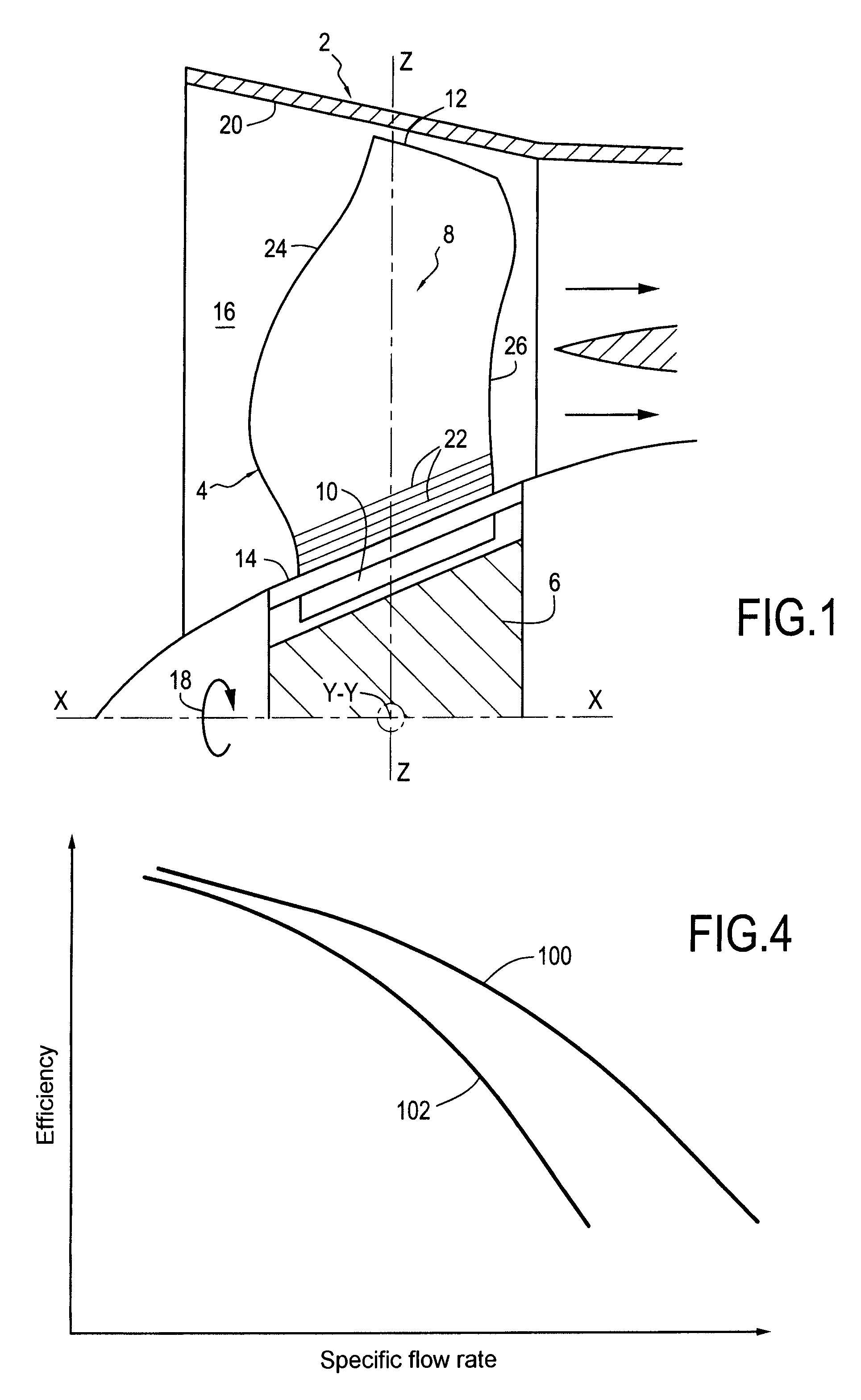

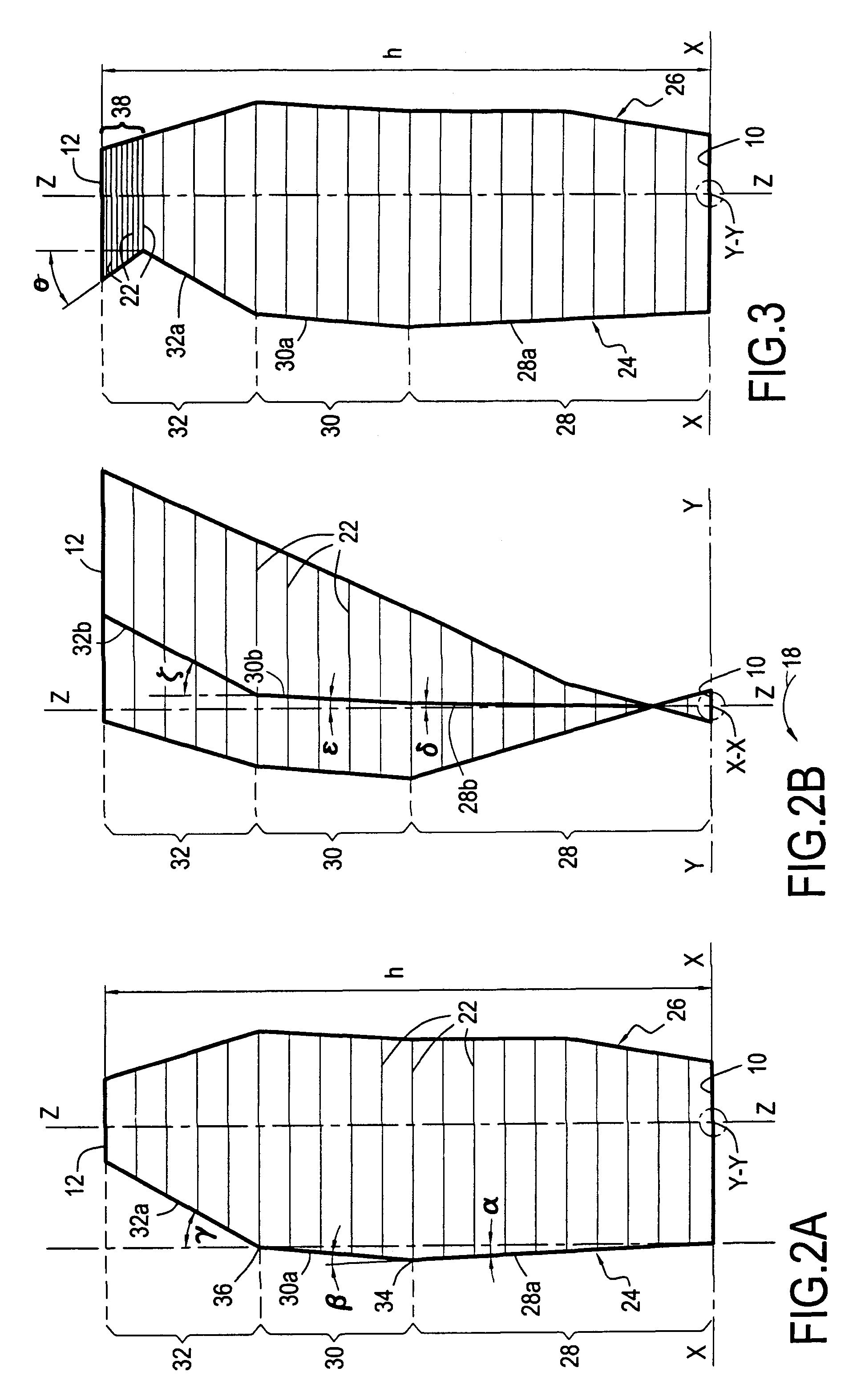

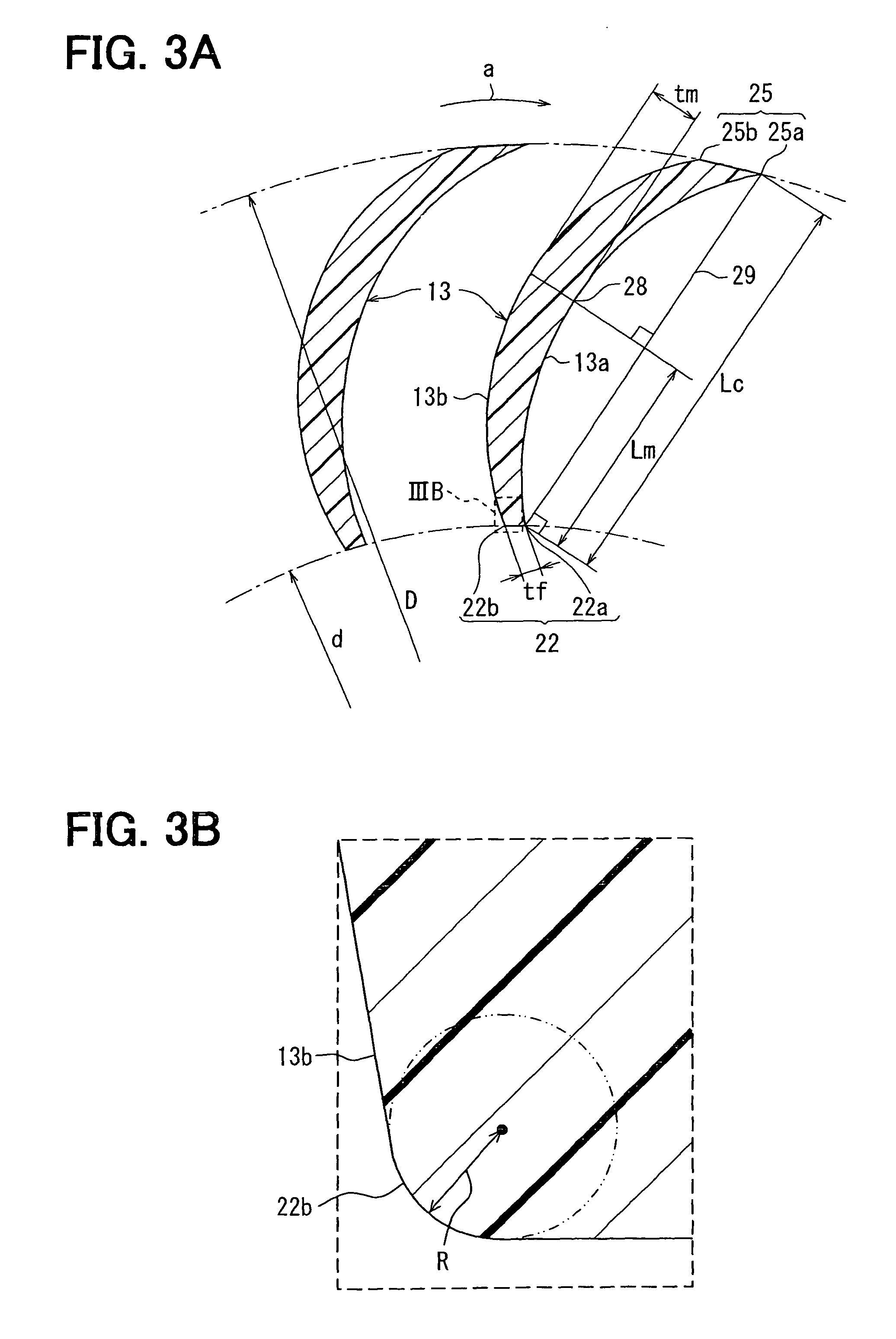

Swept turbomachine blade

ActiveUS20080107538A1Mitigate such drawbackEasy to operateEngine manufacturePump componentsLeading edgeEngineering

The invention relates to a turbomachine blade comprising a plurality of blade sections stacked along a radial axis, and in which the projection of a line interconnecting the leading edges of the blade sections of the bottom stack onto a mid-plane presents a first longitudinal angle of inclination towards the leading edge that lies in the range 10° to 25°, the projection of a line interconnecting the leading edges of the blade sections of the intermediate stack presents a second longitudinal angle of inclination towards the trailing edge lying in the range 10° to 25°, the projection of a line interconnecting the leading edges of the blade sections of the top stack presents a third longitudinal angle of inclination towards the trailing edge lying in the range 20° to 50°, and the bottom limit of the intermediate stack of the blade sections lies in the range 30% to 40% of the total radial height of the stack of blade sections.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Air cleaner having vanes with a winglike cross-section between a shroud and baseplate for rotation within a housing

InactiveUS6156090AEfficiency of fanReduce energy lossCombination devicesPropellersImpellerAir filter

An air cleaner includes a housing having an upper wall and side walls, an air filter mounted with respect to the housing, a fan including a vane-wheel having a plurality of vanes, a supporting plate extending substantially between at least two side walls for supporting the fan. An air flow directional member directs an air flow output from the fan. The vane is formed to have a winglike cross-section, and the vane-wheel includes not more than four vanes. The vane-wheel has a base plate and a shroud. Each of the base plate and the shroud is formed to have a reinforcement portion on its circumference. A U-shaped balance weight is attached to a flattened portion formed on the curled portion. The air cleaner of the present invention can reduce noise and vibration and improve efficiency of the fan.

Owner:HITACHI LTD +1

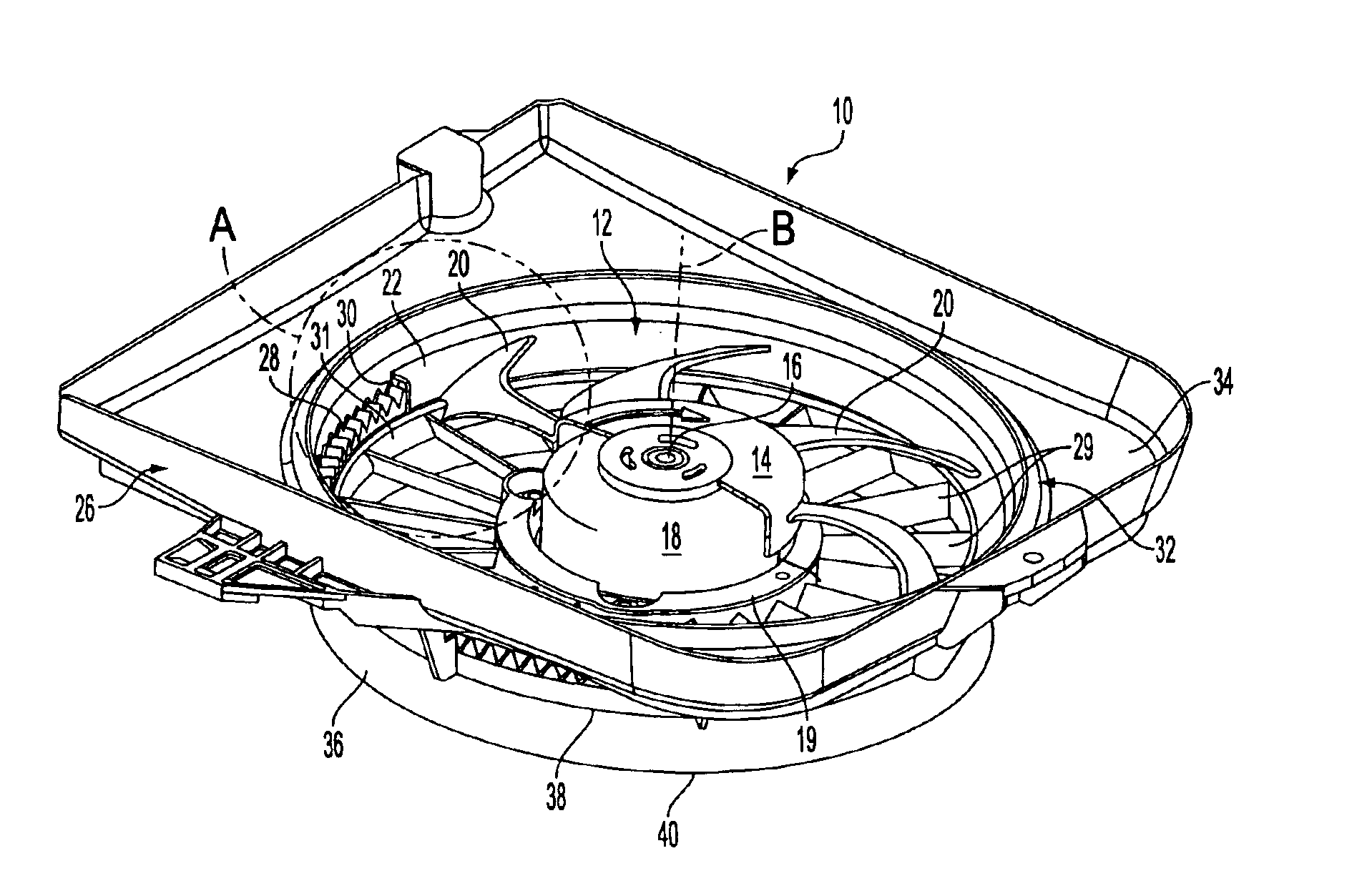

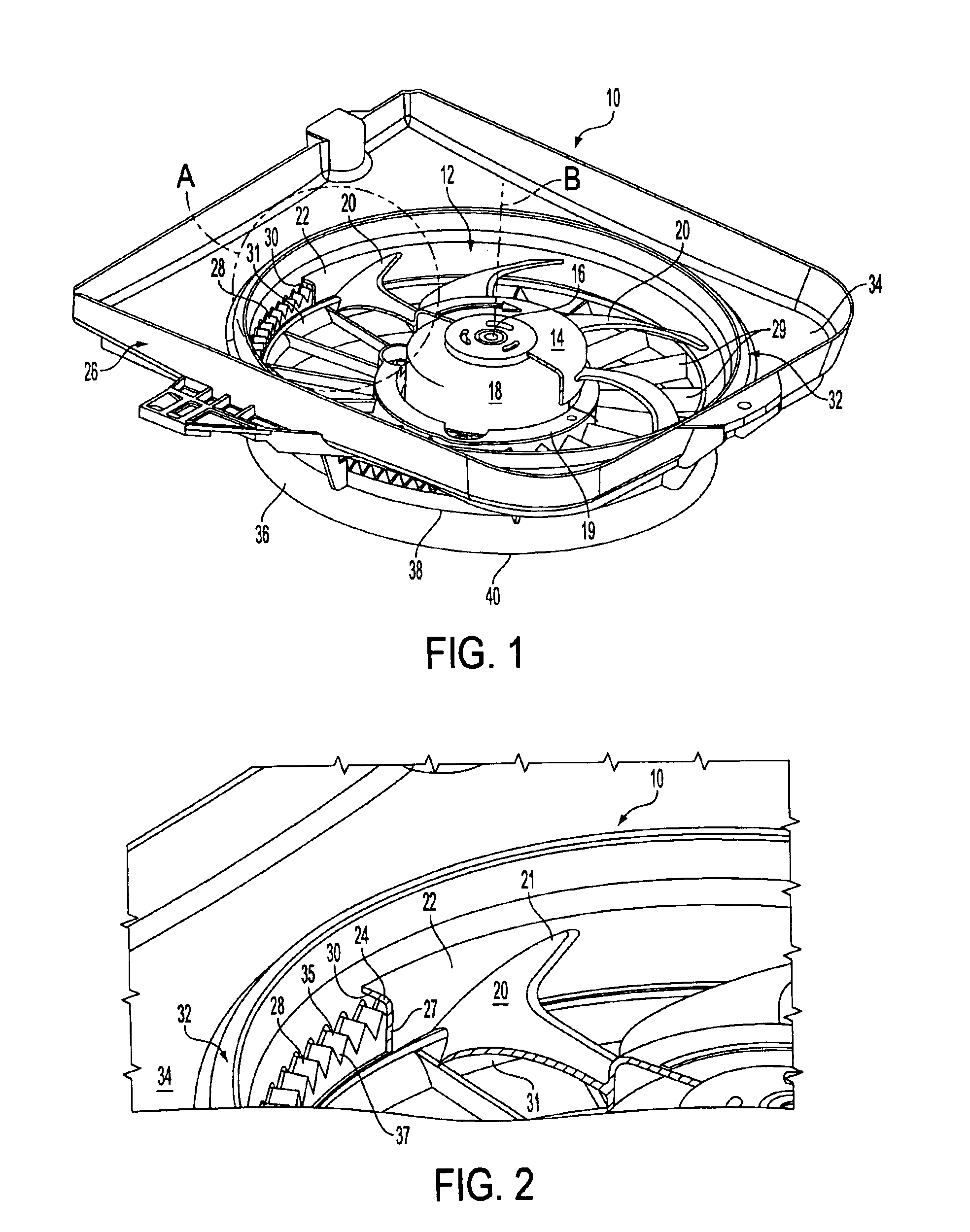

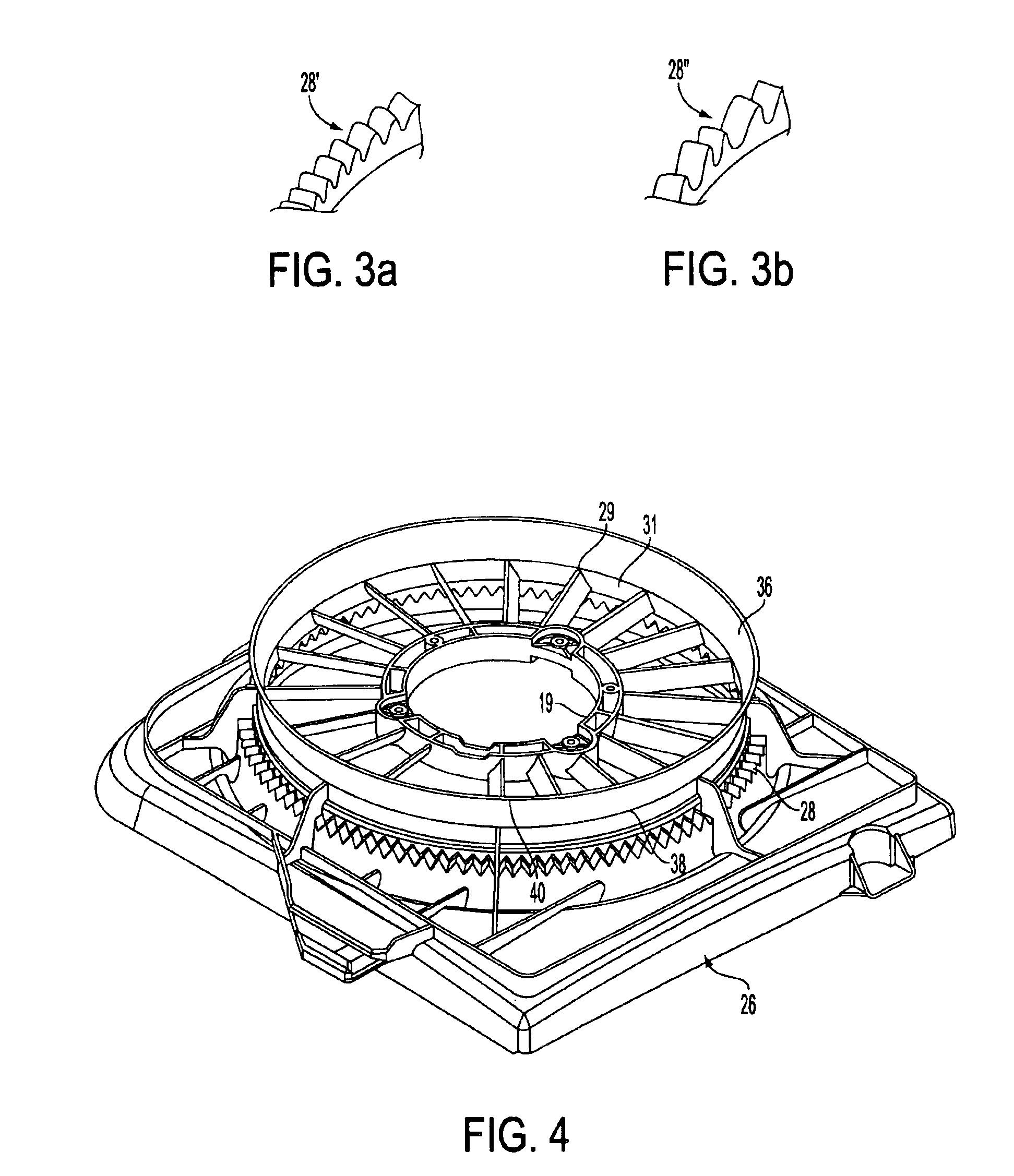

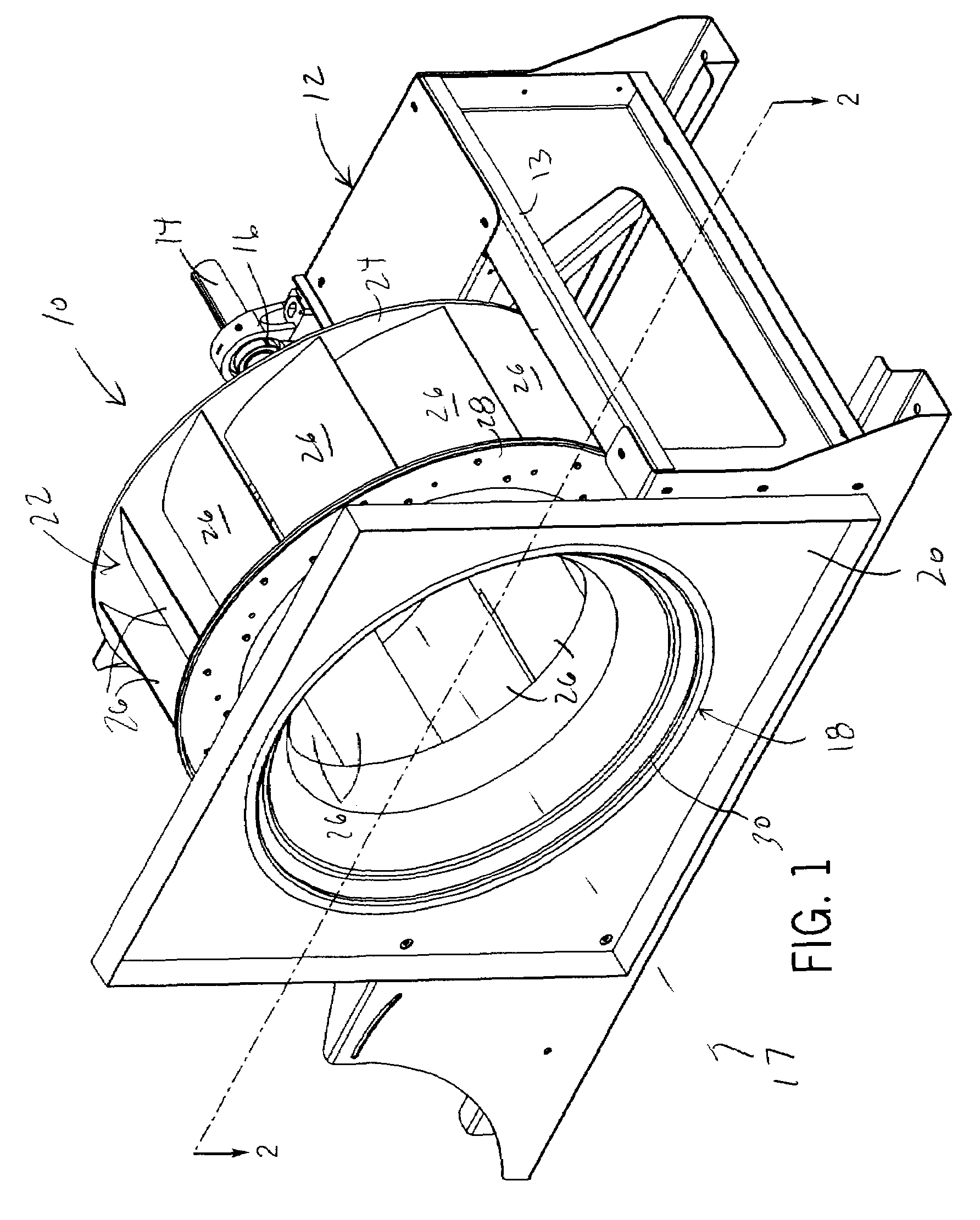

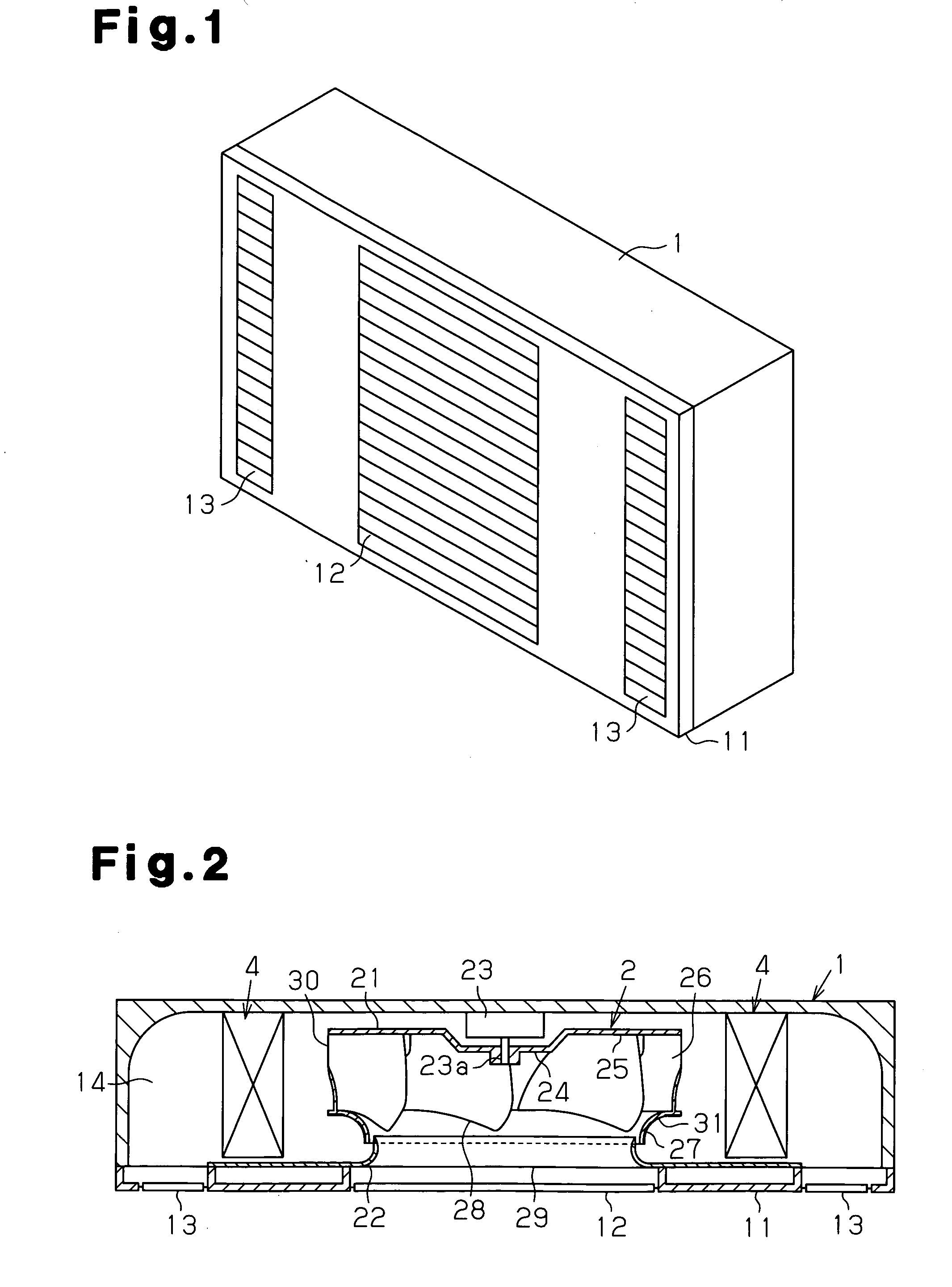

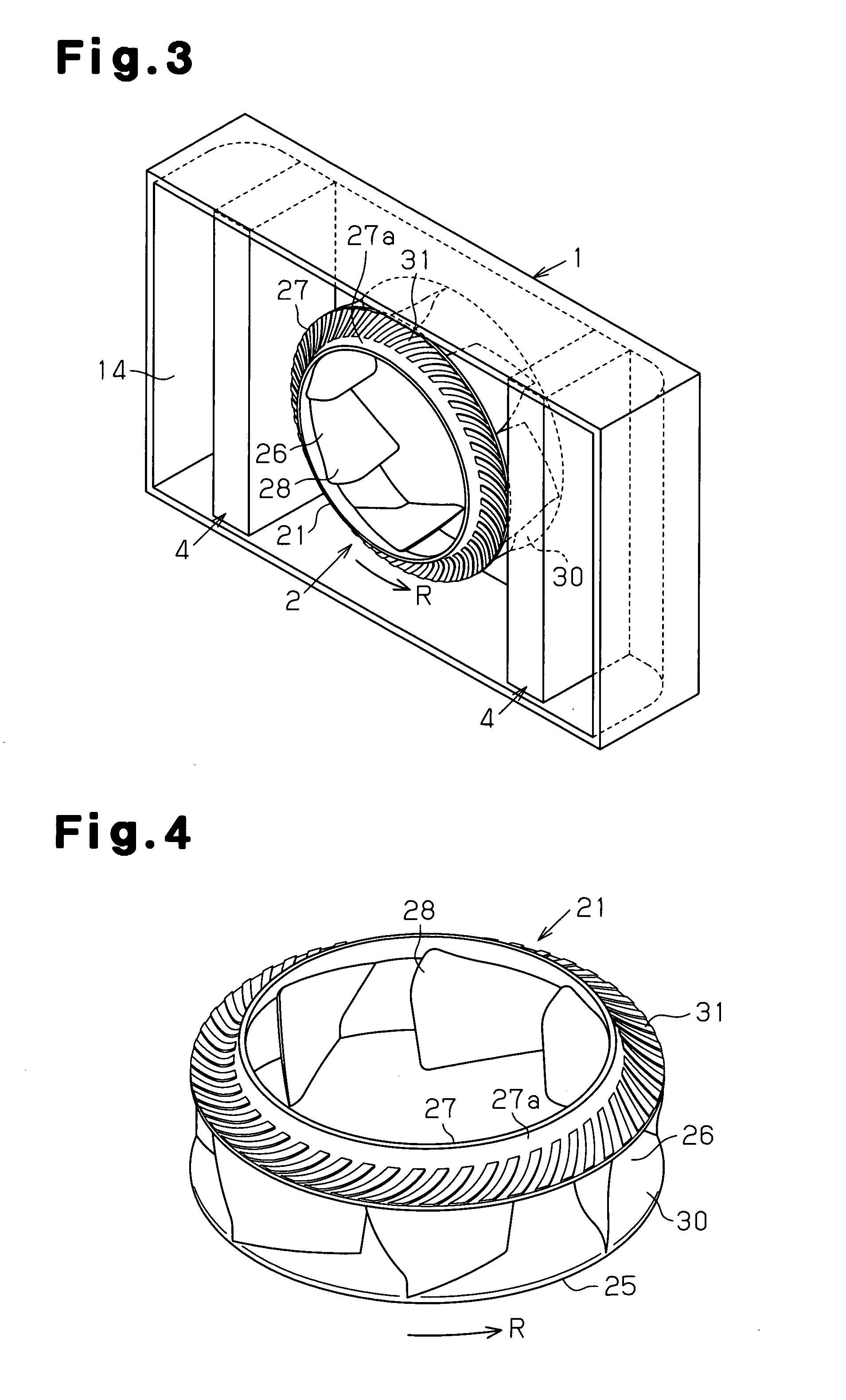

Integral tip seal in a fan-shroud structure

InactiveUS6874990B2Reduce noiseImprove fan efficiencyPropellersPump componentsEngineeringMechanical engineering

A fan-shroud structure 10 includes a fan 12 mounted for rotation about an axis B. The fan has a plurality of blades 20 with tips of the blades being coupled to an annular band 22. A shroud 26, including an annular labyrinth seal 28, is disposed generally adjacent to the annular band thereby defining a gap 30 between the annular band and the seal. The seal has a corrugated profile and is constructed and arranged to provide resistance to air flow as air swirls and flows back into the gap and to minimize air leakage across the gap.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Coaxial rotor aircraft

A dual, coaxial rotor helicopter is provided that is relatively easy to fly. Thrust is provided by two ducted fans that are mounted at the rear of the aircraft and spaced apart laterally. Differential thrust generated by the fans provides yaw control for the aircraft, and forward thrust is provided by the fans working in combination. The coaxial rotors are preferably utilized primarily for lift, and not for forward thrust, which simplifies the control requirements. The coaxial rotor with ducted fan configuration also results in lower vibratory loads being imposed on the helicopter, thereby increasing its speed capability. The fan ducts serve to protect the fans, augment the fan thrust at low airspeeds, increase the efficiency of the fans at cruise speeds, and provide horizontal and vertical stabilizing surfaces to ensure aircraft flight stability.

Owner:AVX AIRCRAFT

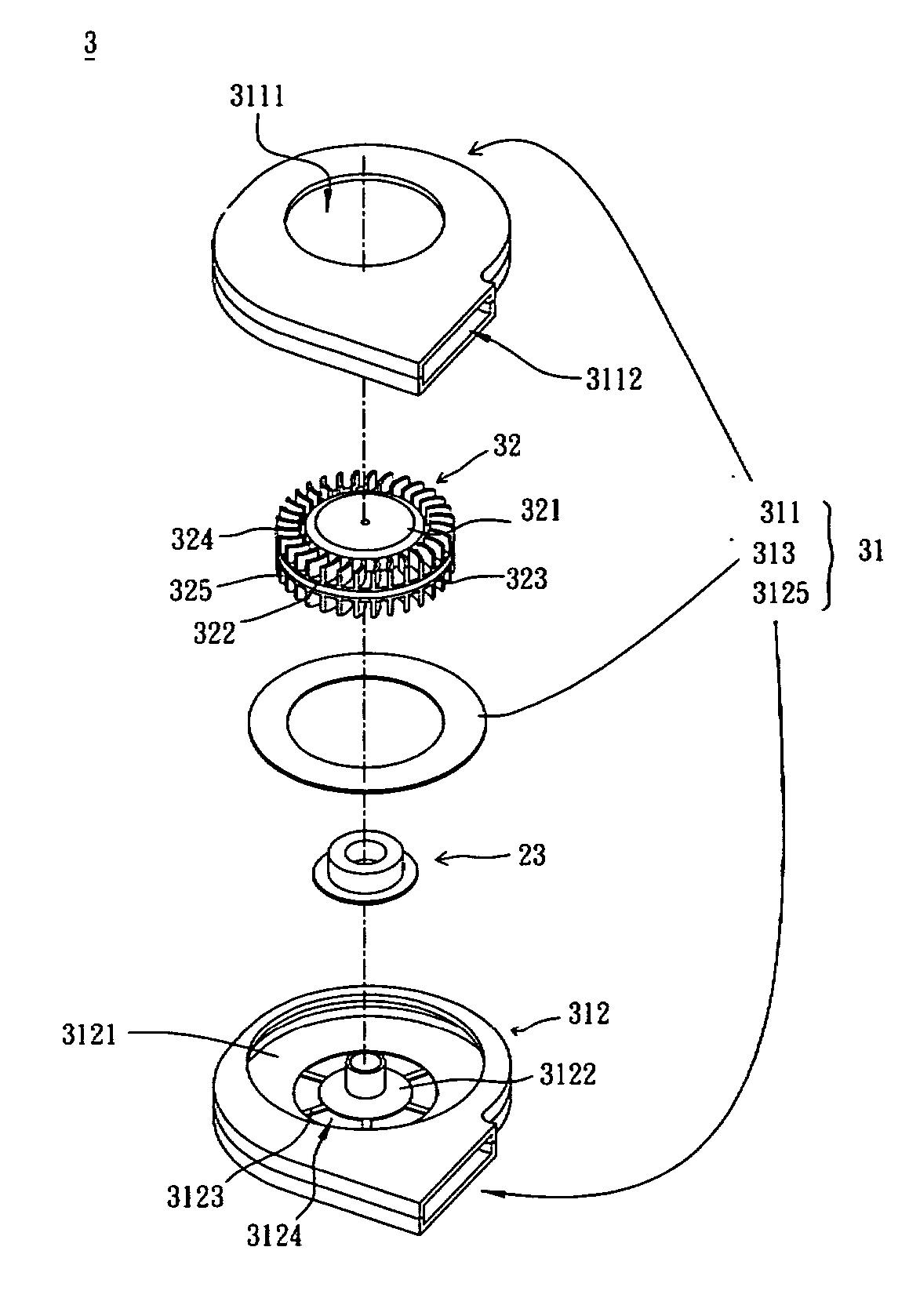

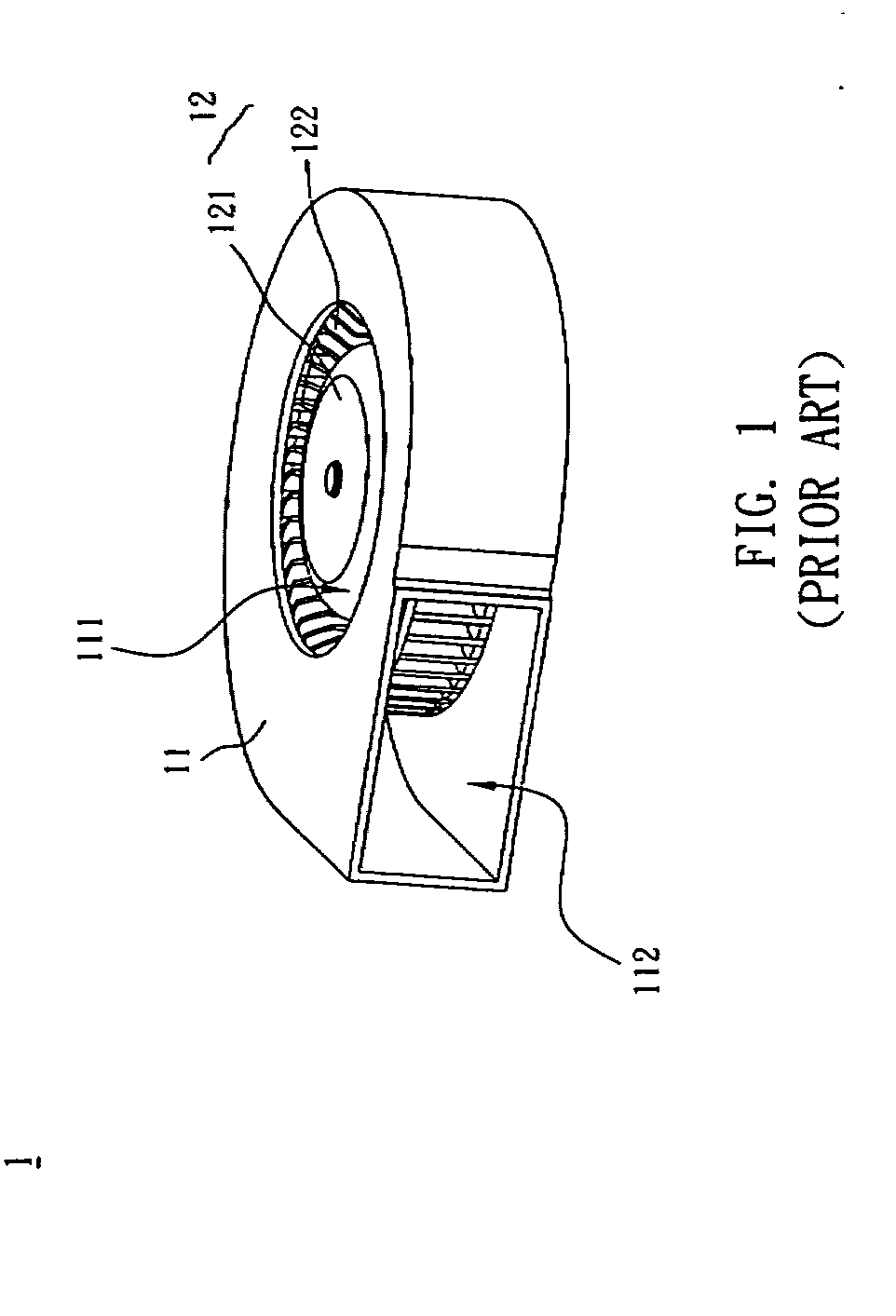

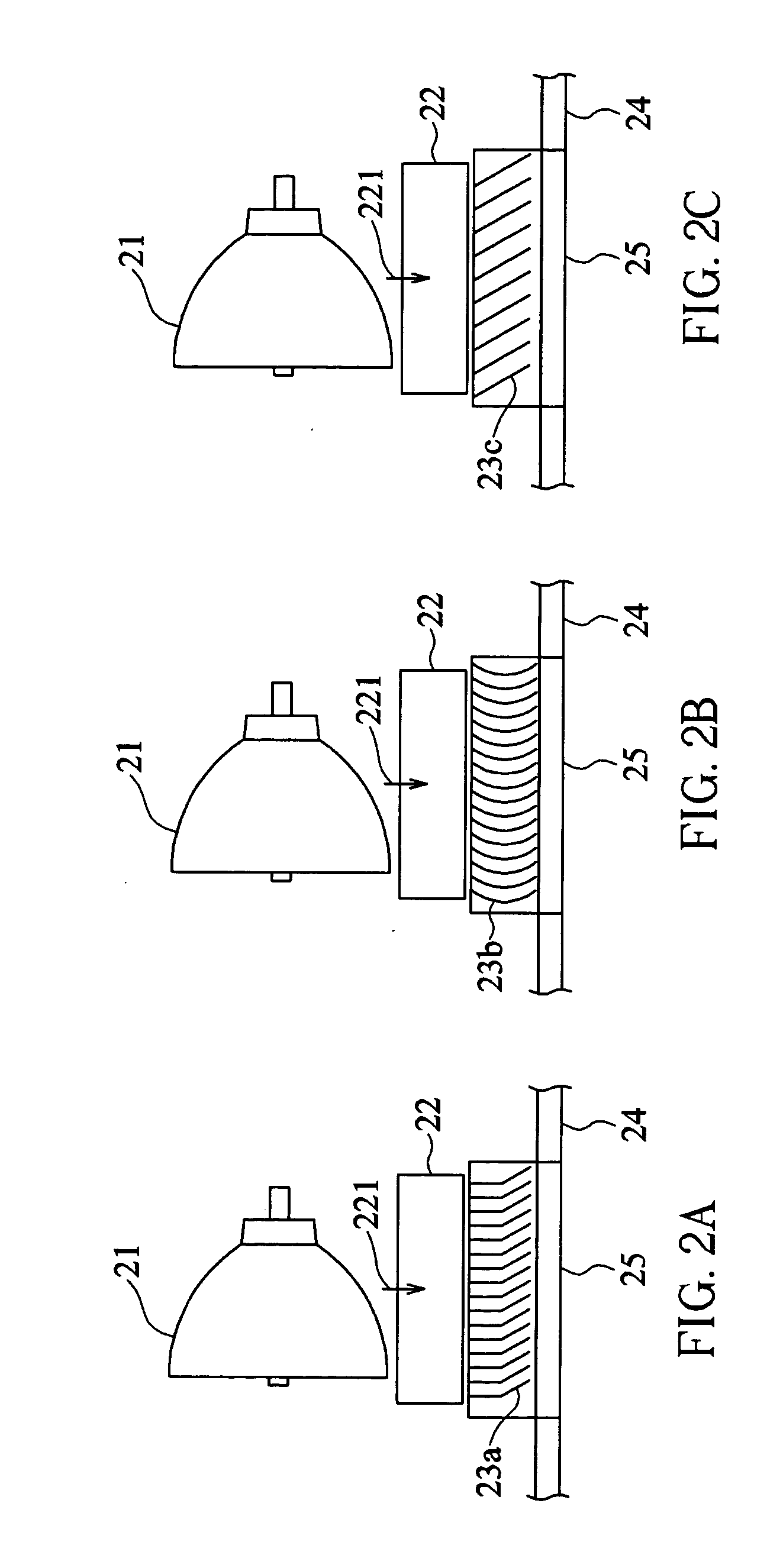

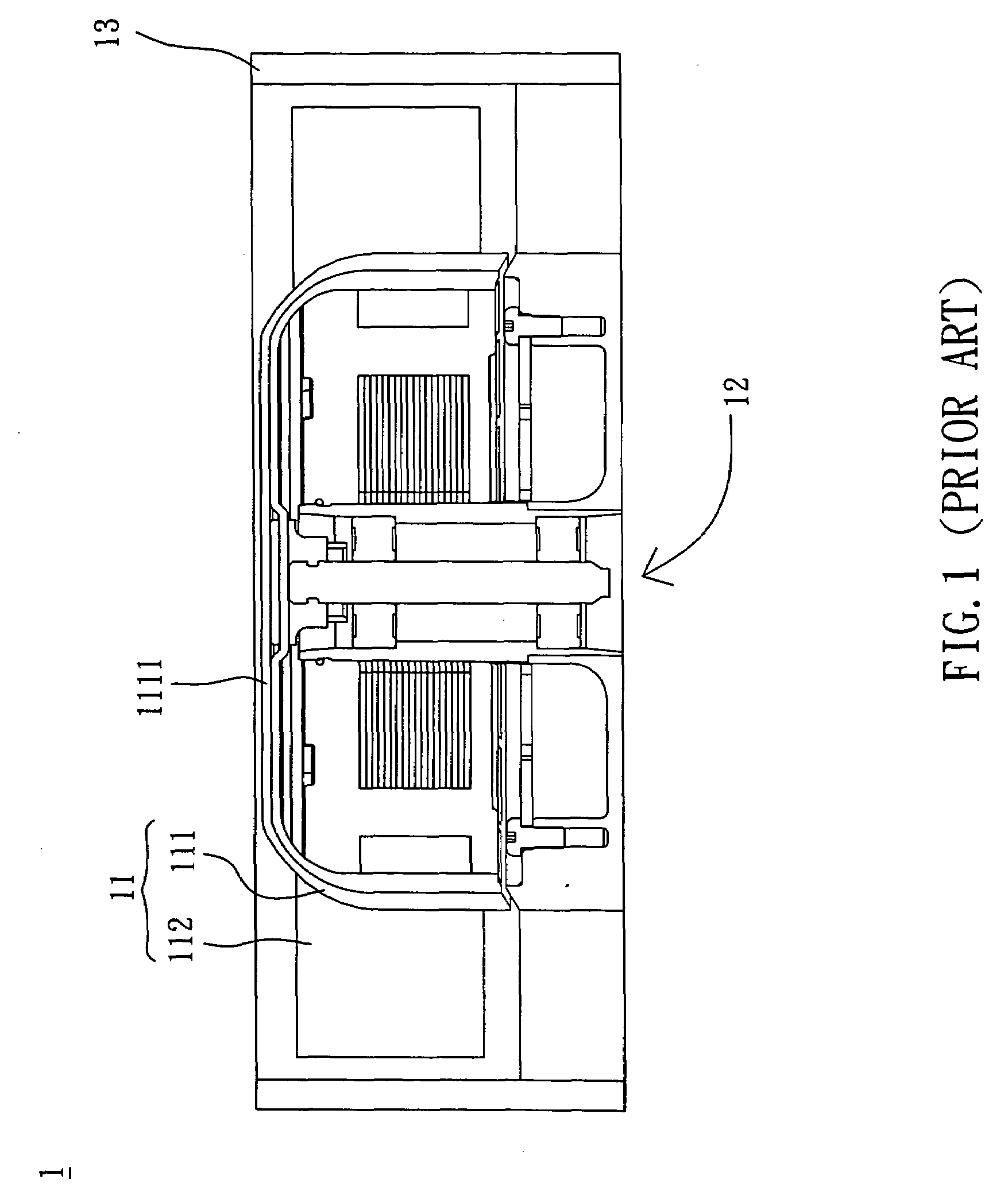

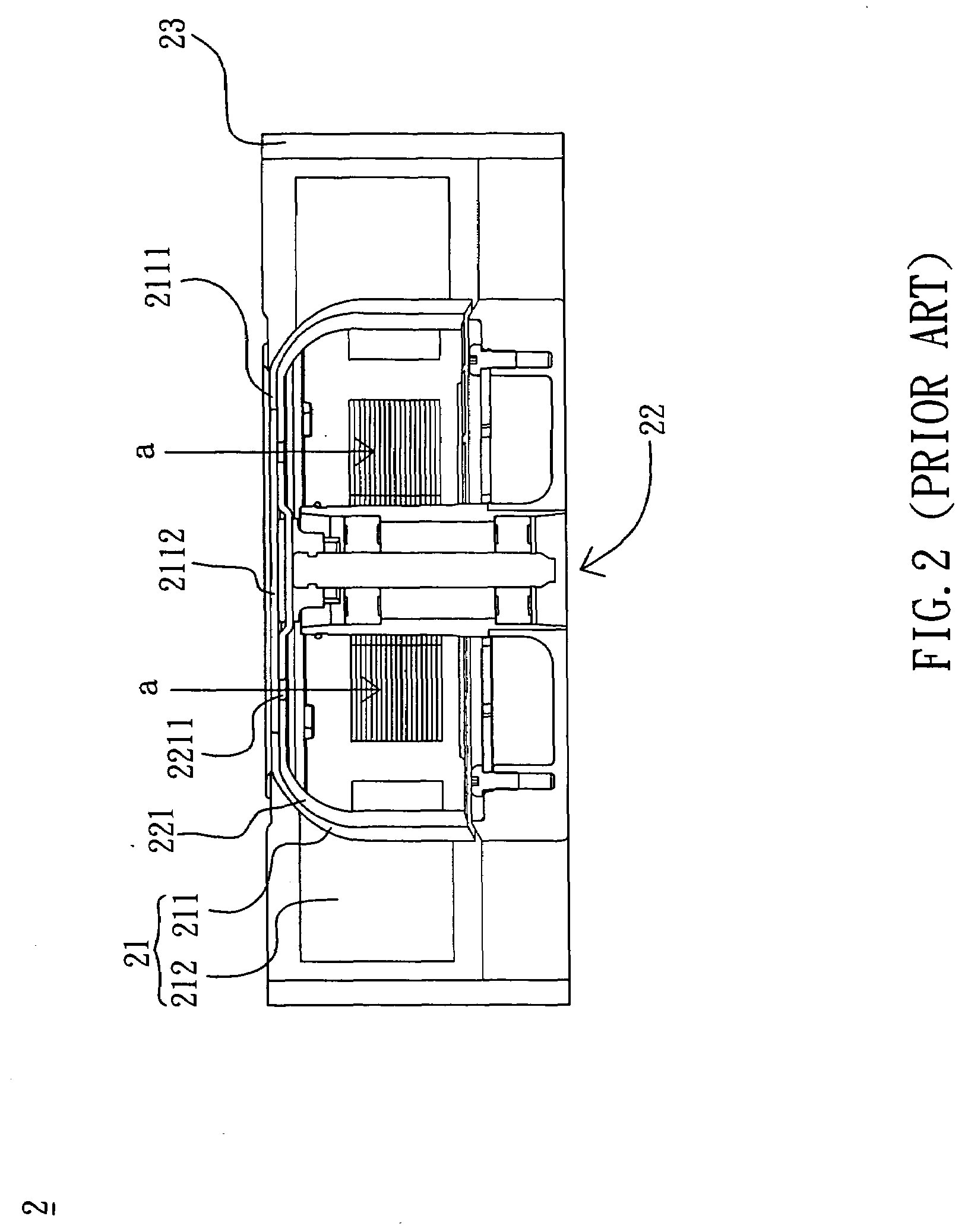

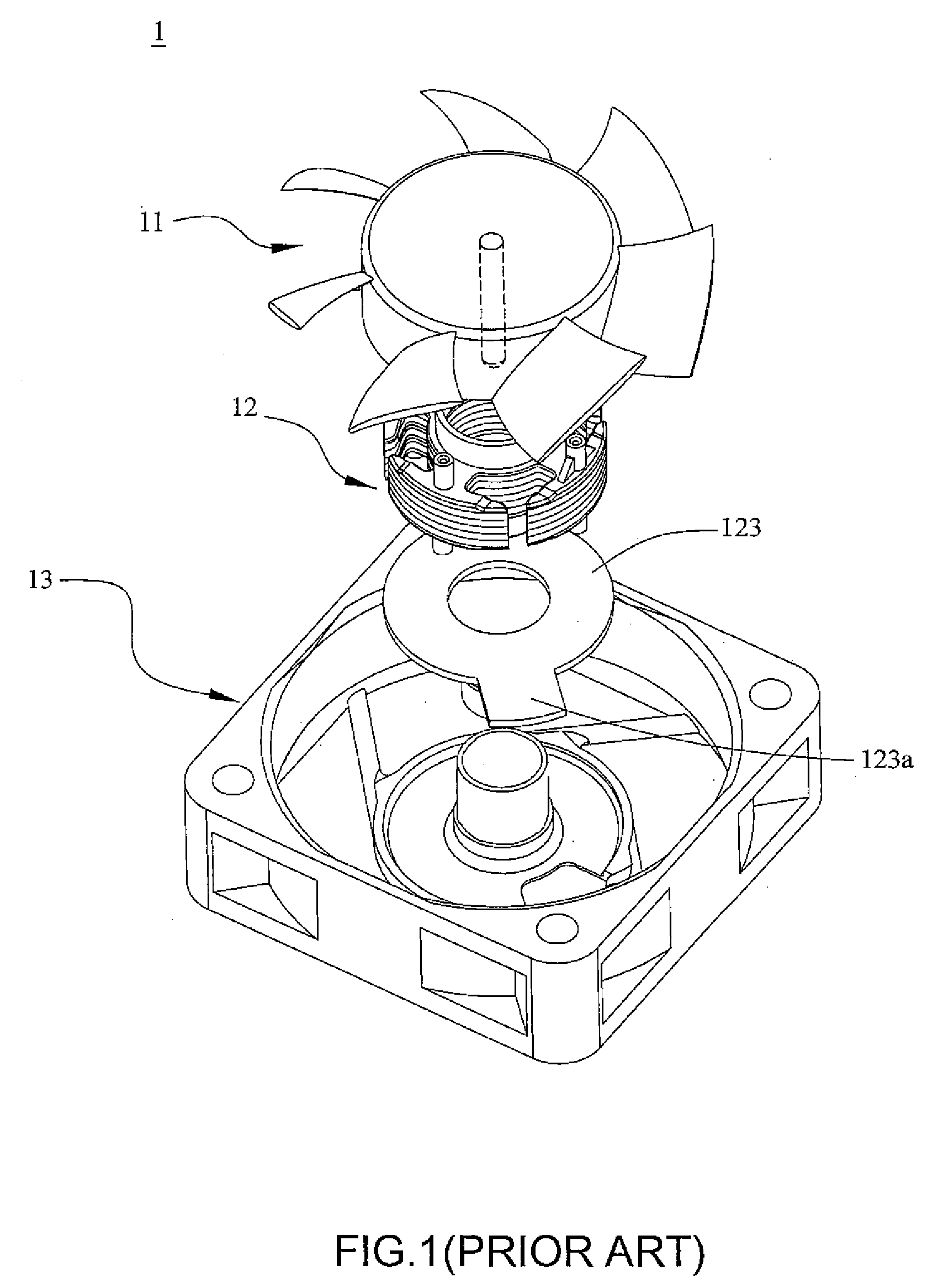

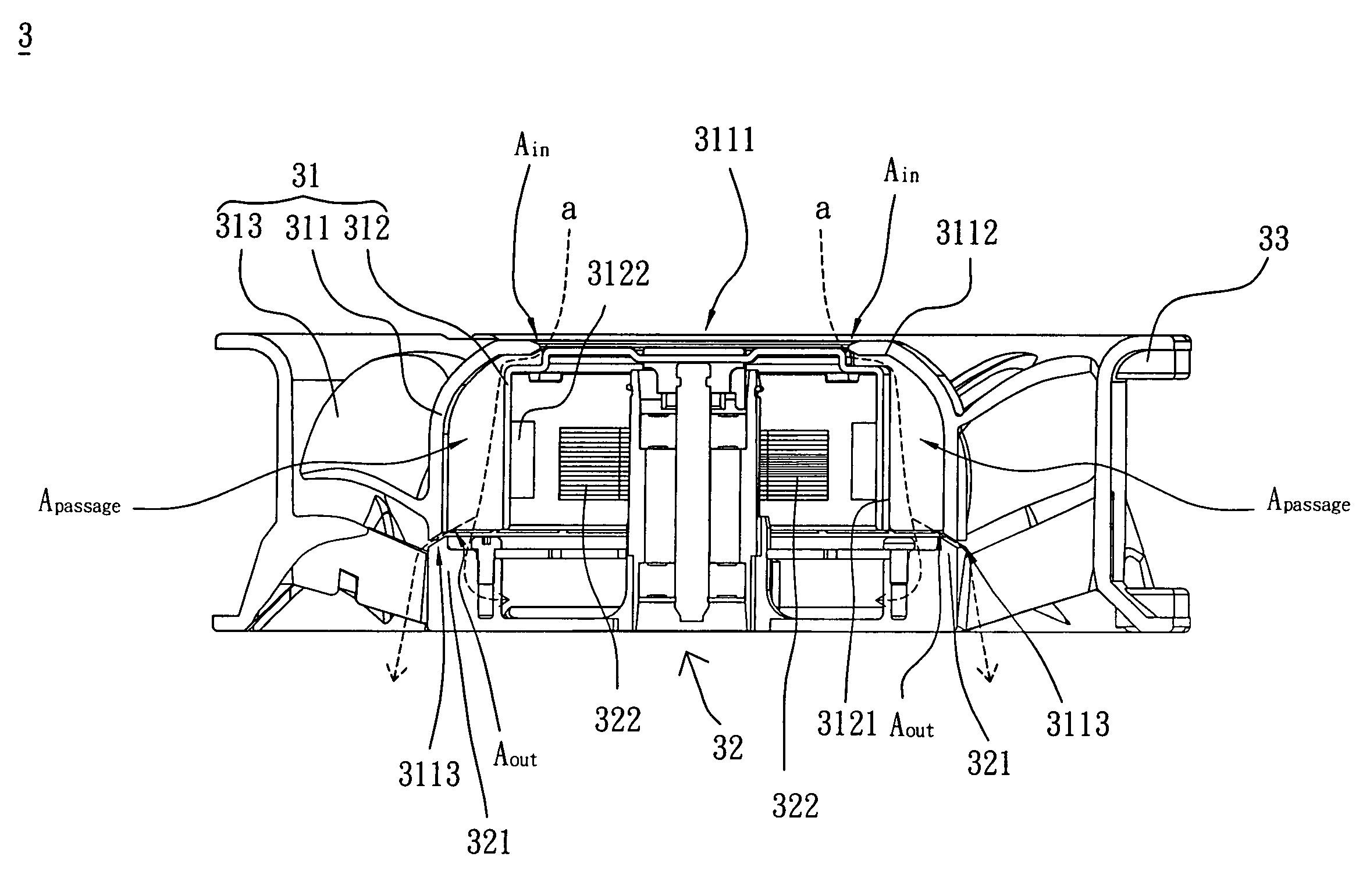

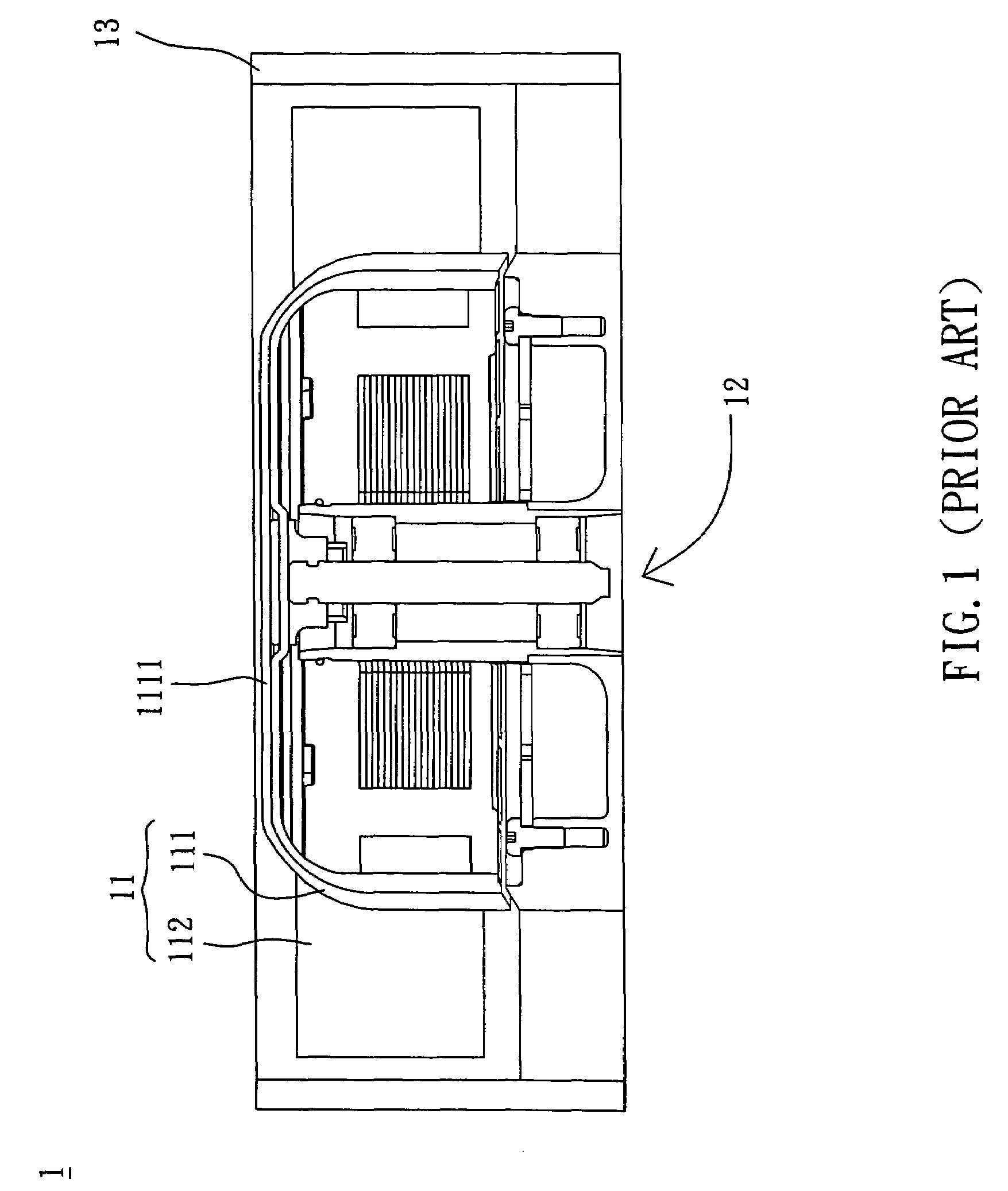

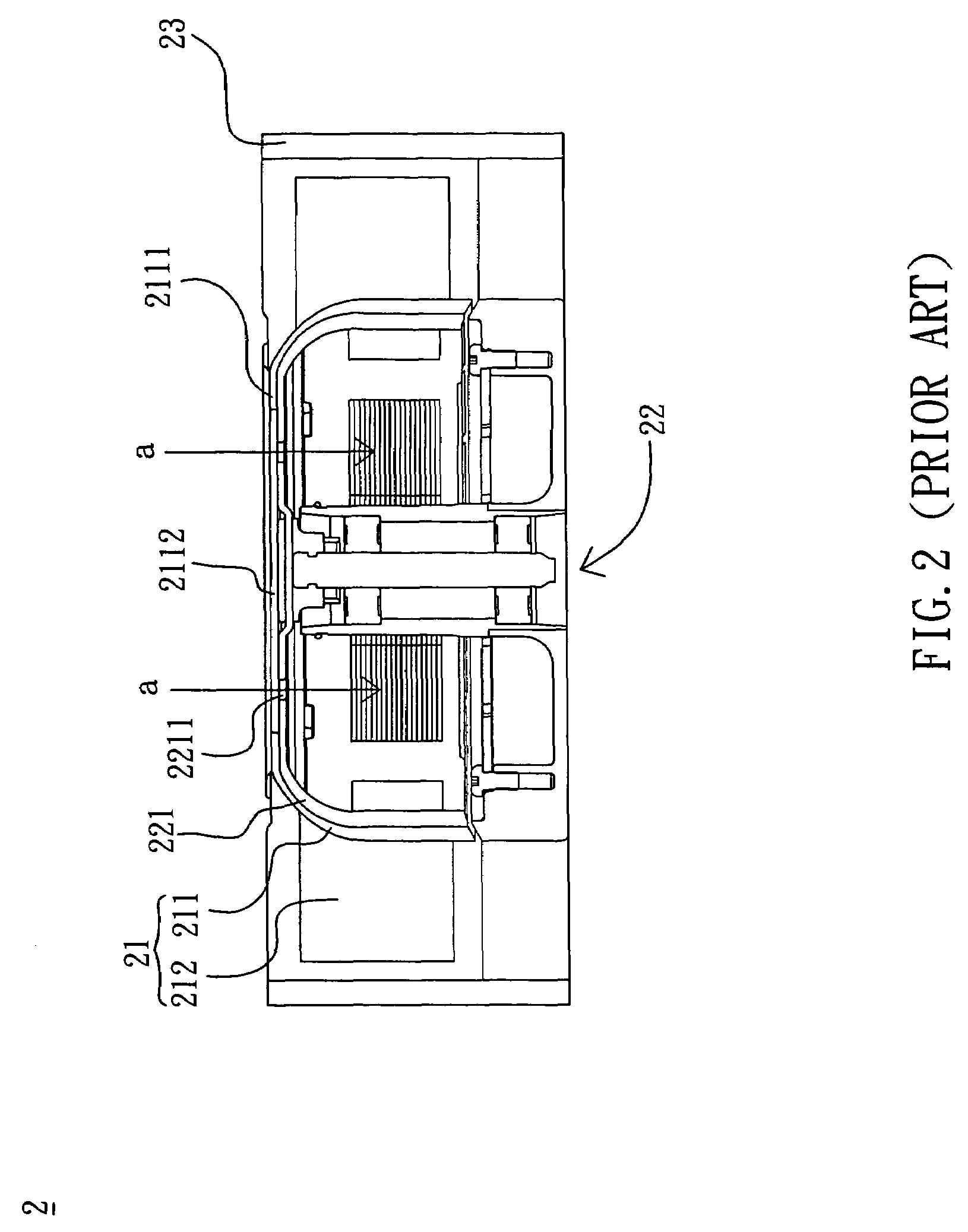

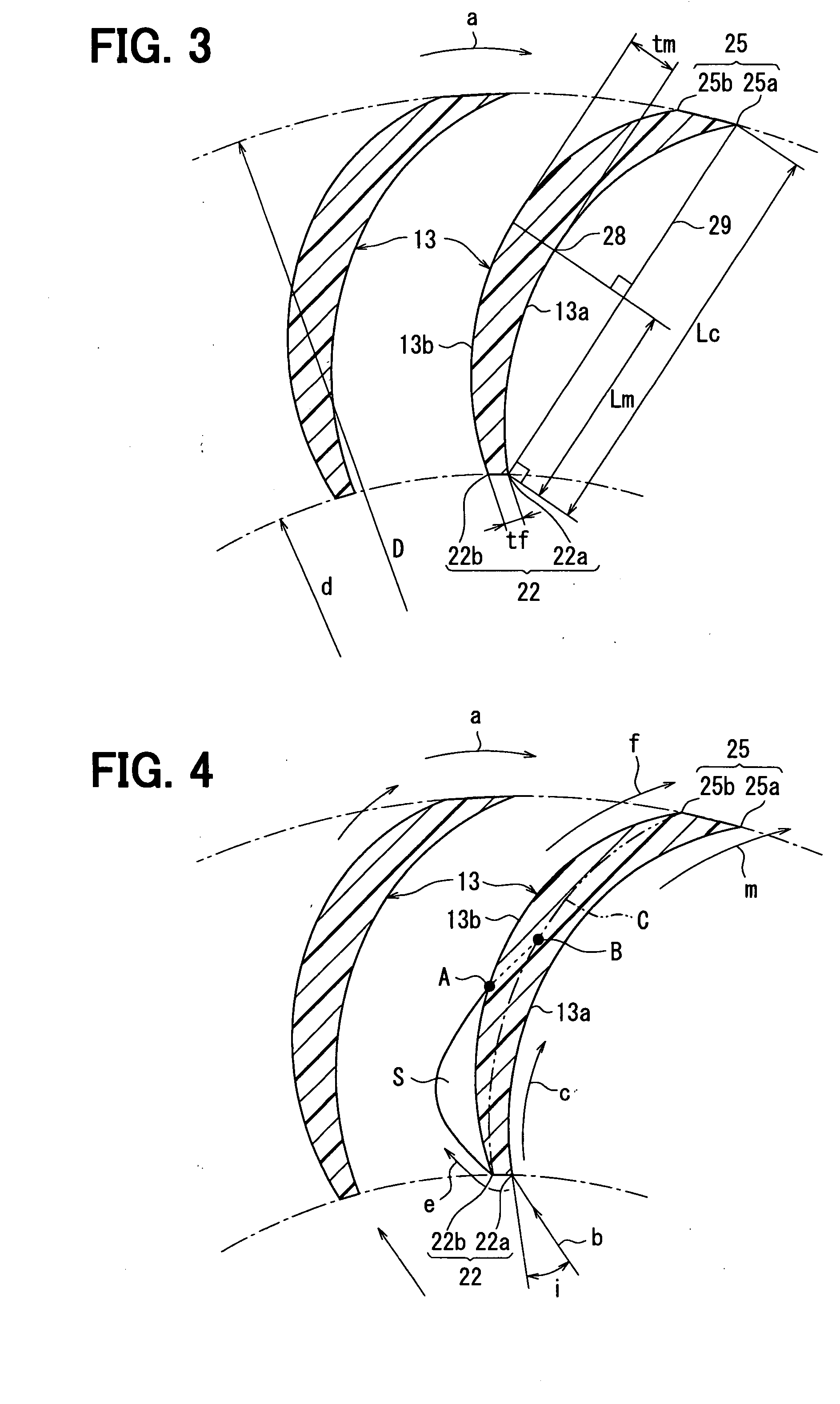

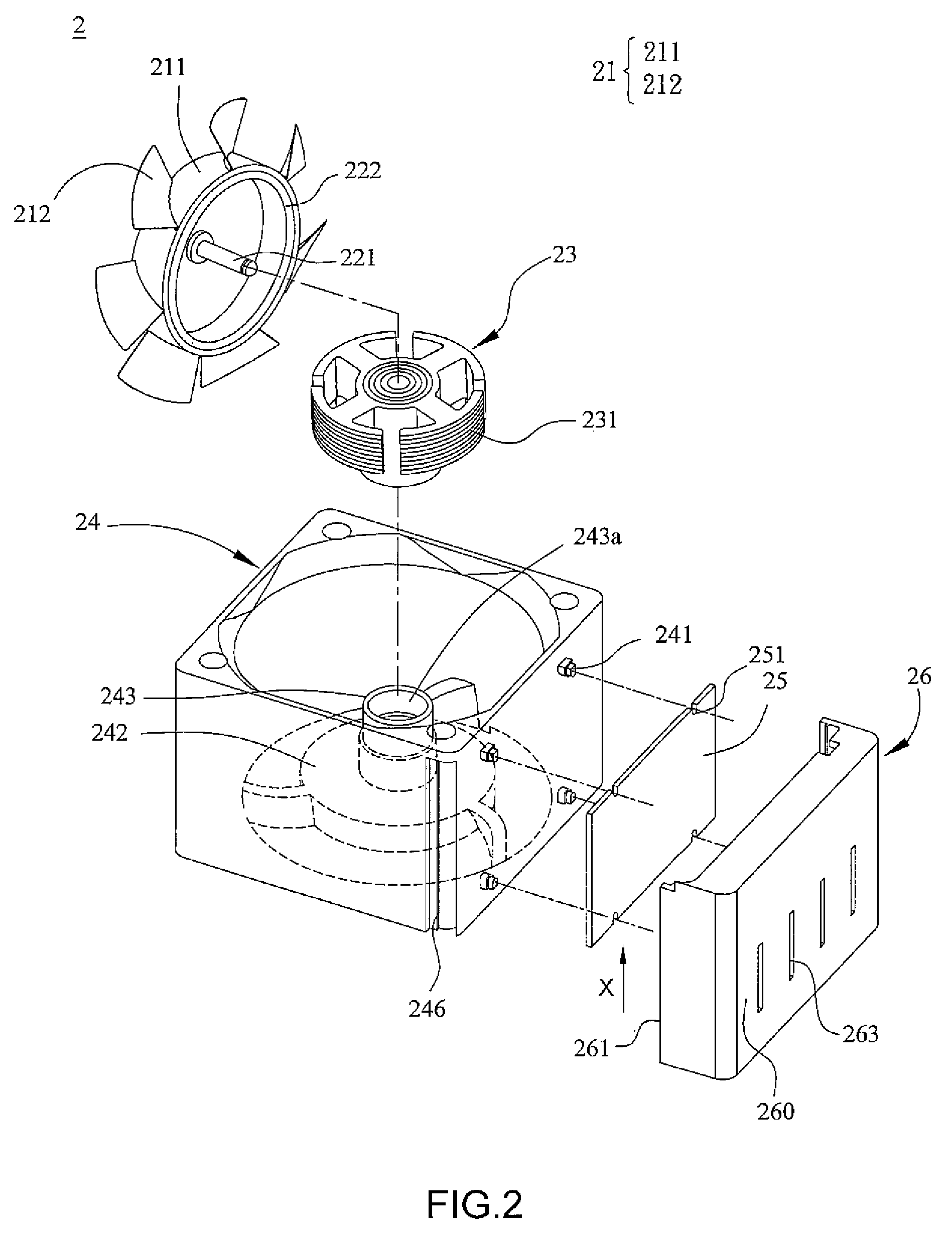

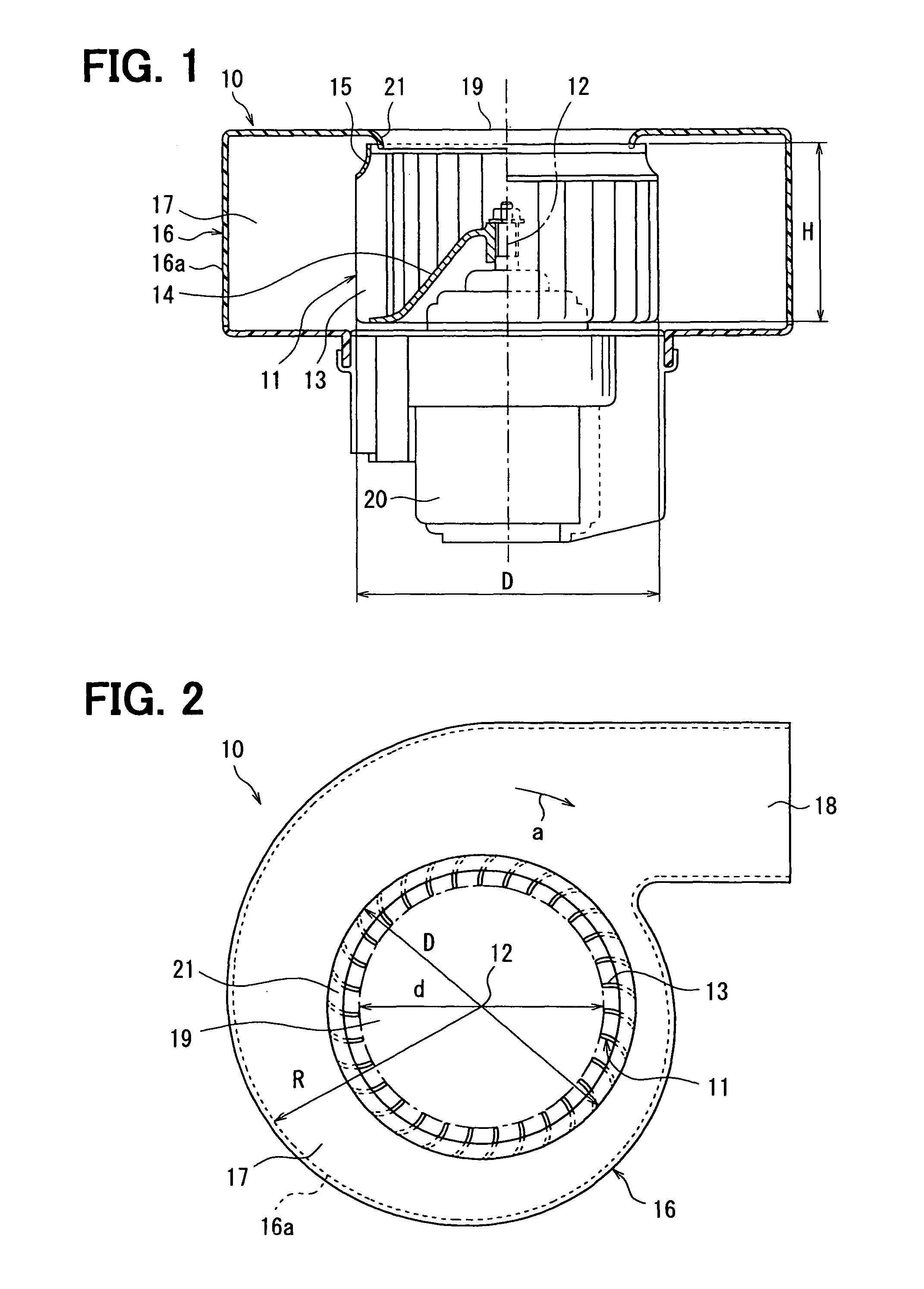

Centrifugal fan and fan frame thereof

InactiveUS20070160462A1Improve fan efficiencyIncrease airflowPump componentsCombination enginesEngineeringCentrifugal fan

A fan frame includes a first housing and a second housing. The first housing has at least one first inlet, and the second housing has at least one second inlet. The combination of the first housing and the second housing forms two independent airflow passages, at least one first outlet and at least one second outlet. A centrifugal fan including the fan frame is also disclosed.

Owner:DELTA ELECTRONICS INC

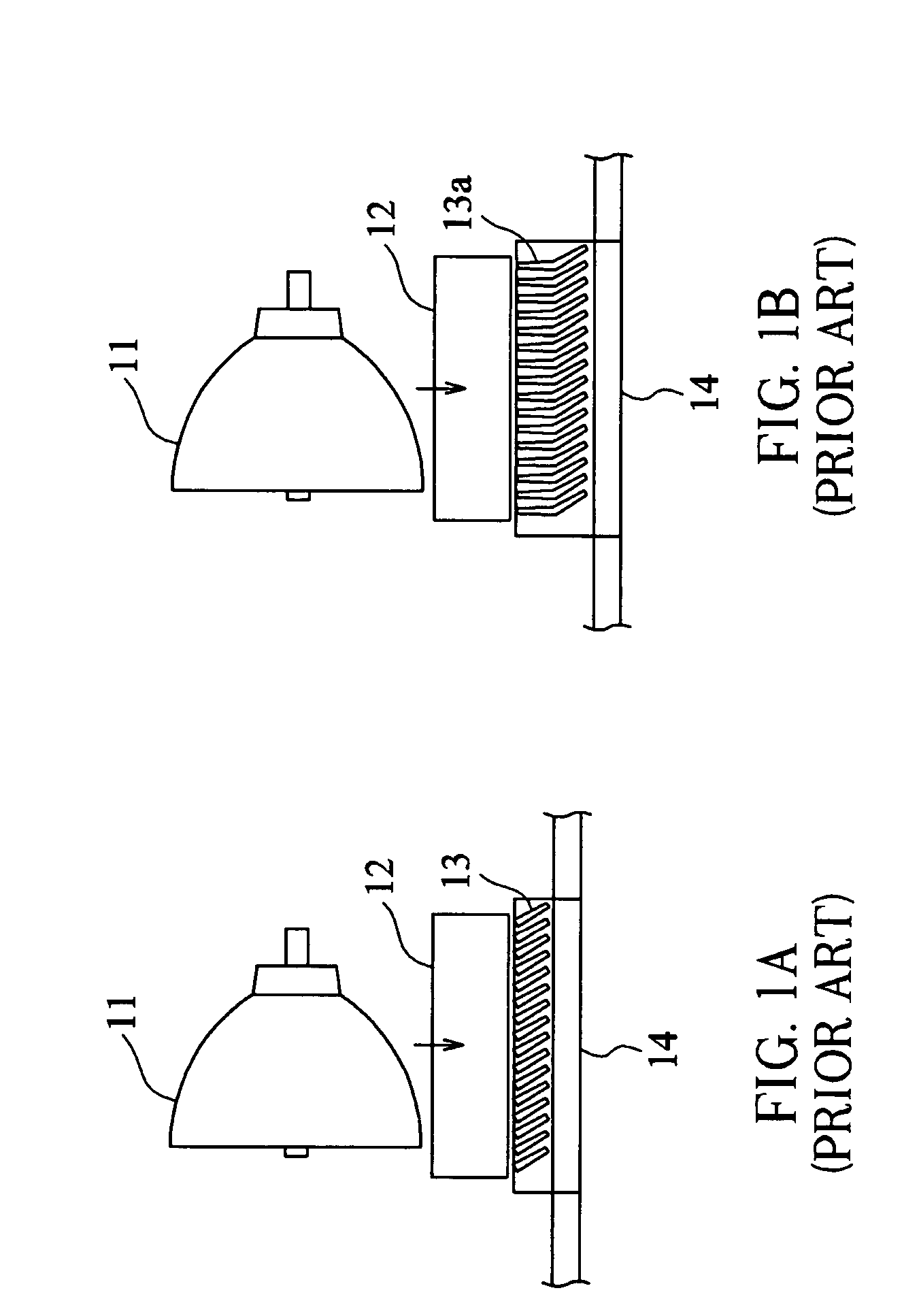

Projector and light-shielding heat-dissipating mask for the same

InactiveUS20050073658A1Improve thermal conductivityReduce the temperatureProjectorsOptoelectronicsMetal sheet

The present invention discloses a light-shielding heat-dissipating mask for a projector. The projector has a light source, a fan, and an air vent. The light-shielding heat-dissipating mask comprises a plurality of metal sheets which are positioned at the air vent for dissipating the heat generated by the light source and decreasing the possibility of the light emitted form the light source escaping out of the air vent.

Owner:DELTA ELECTRONICS INC

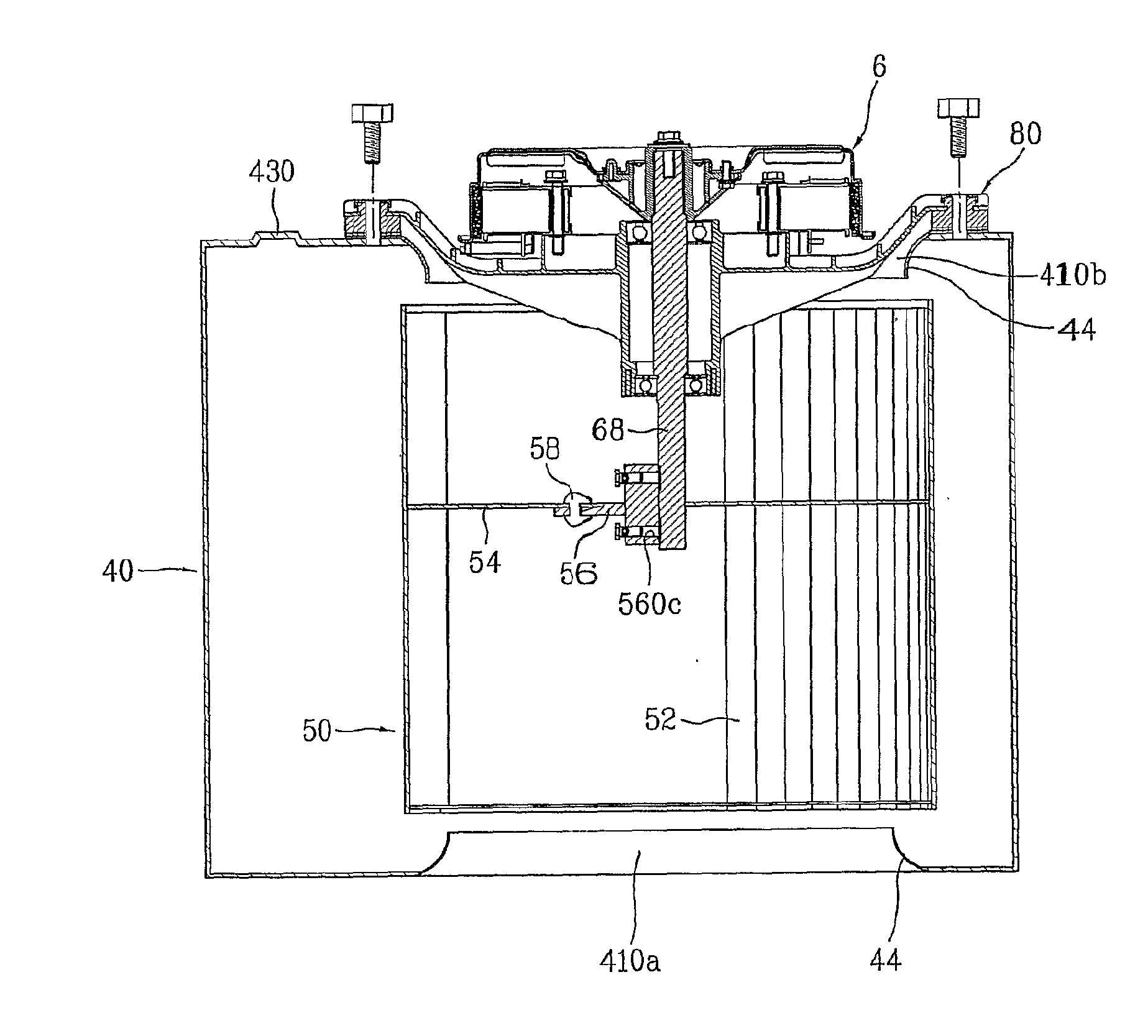

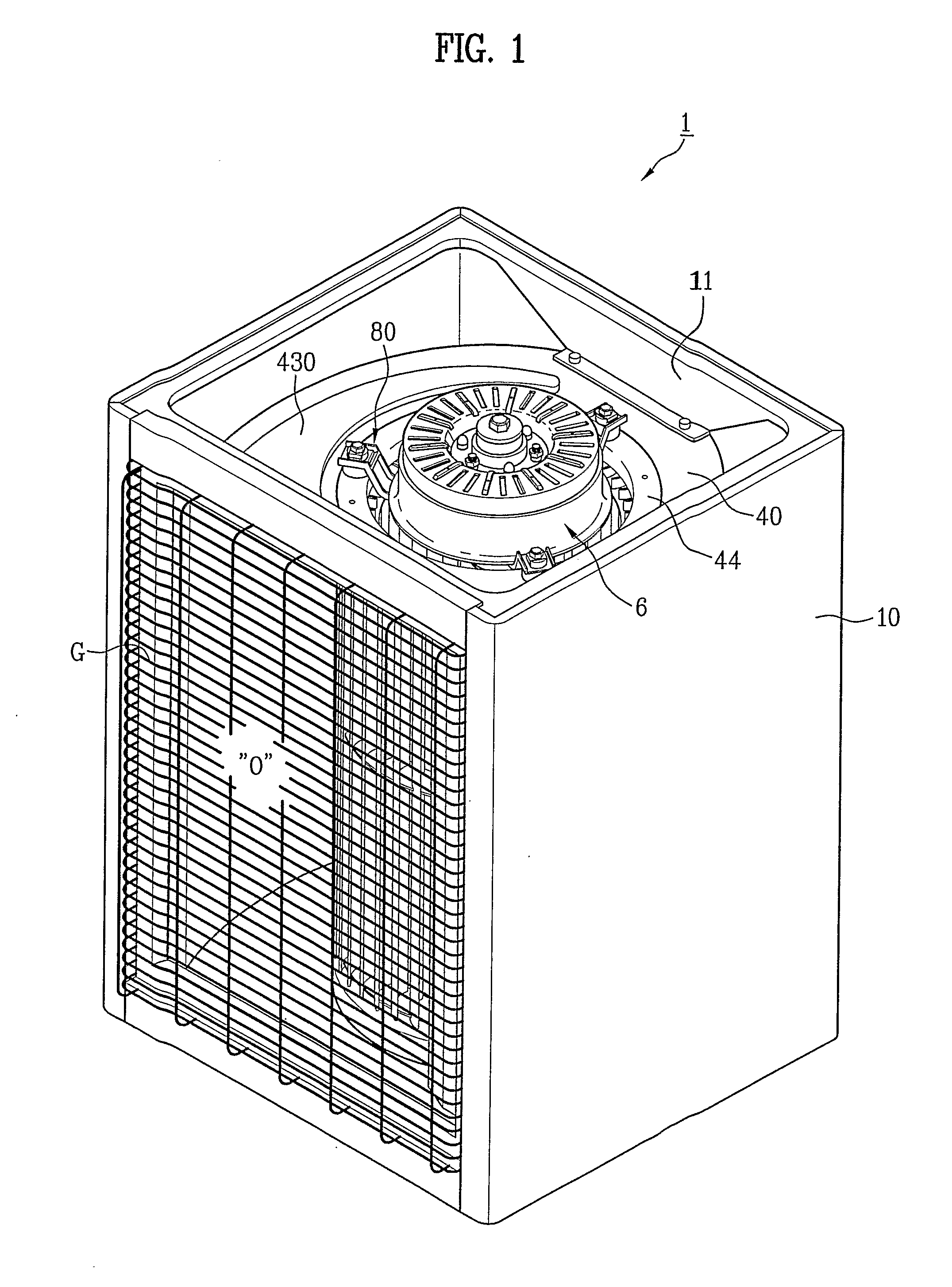

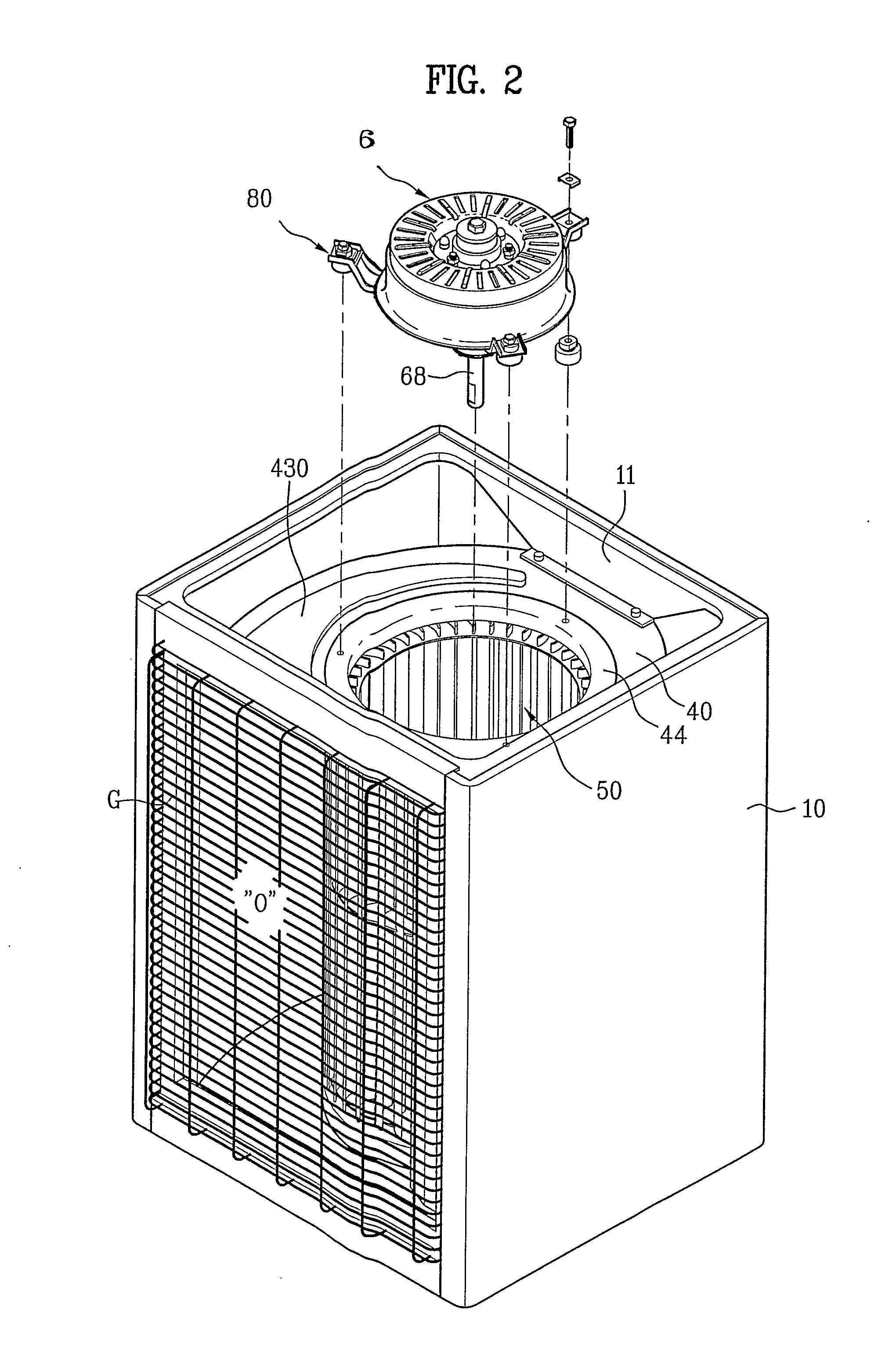

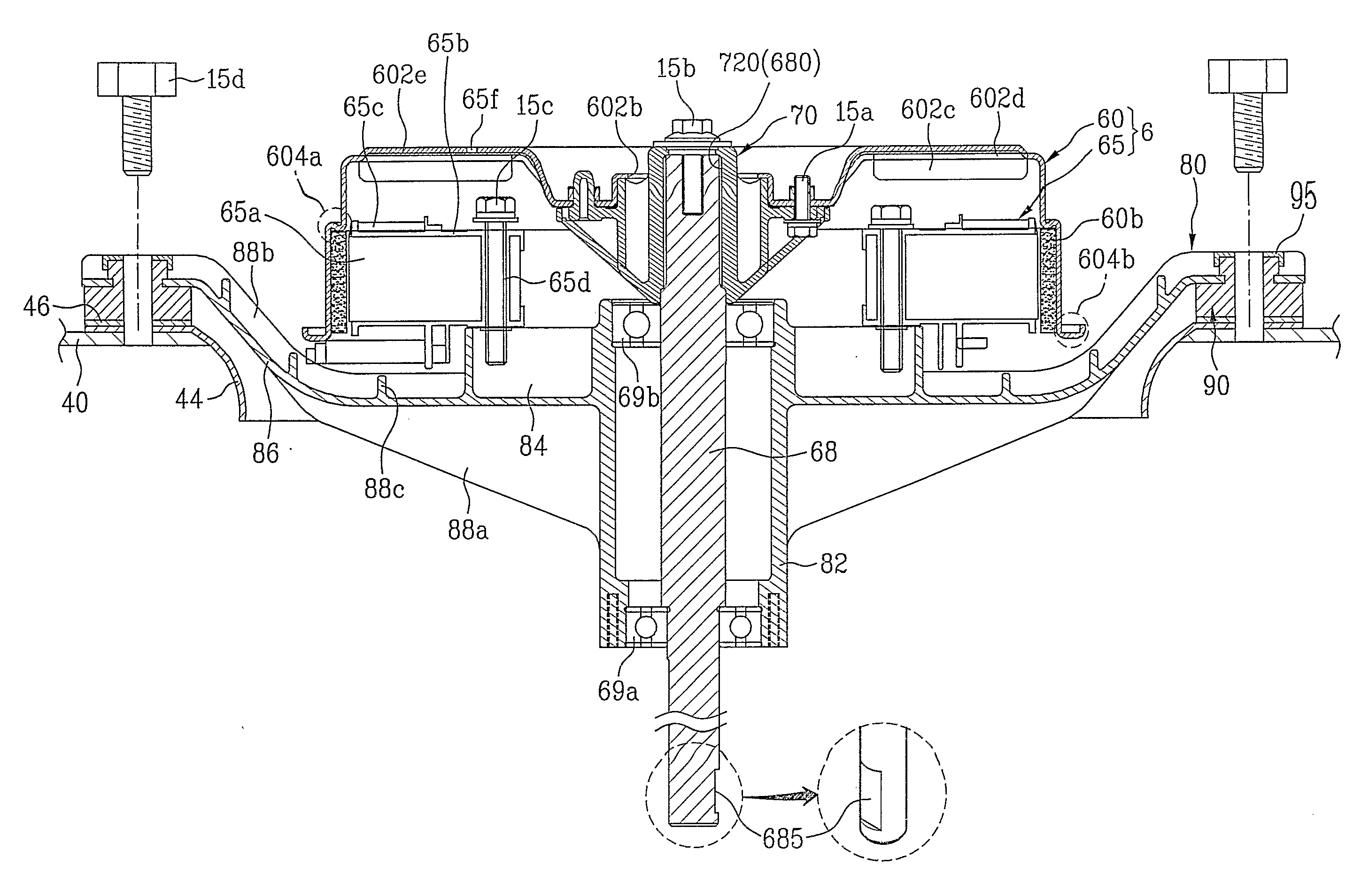

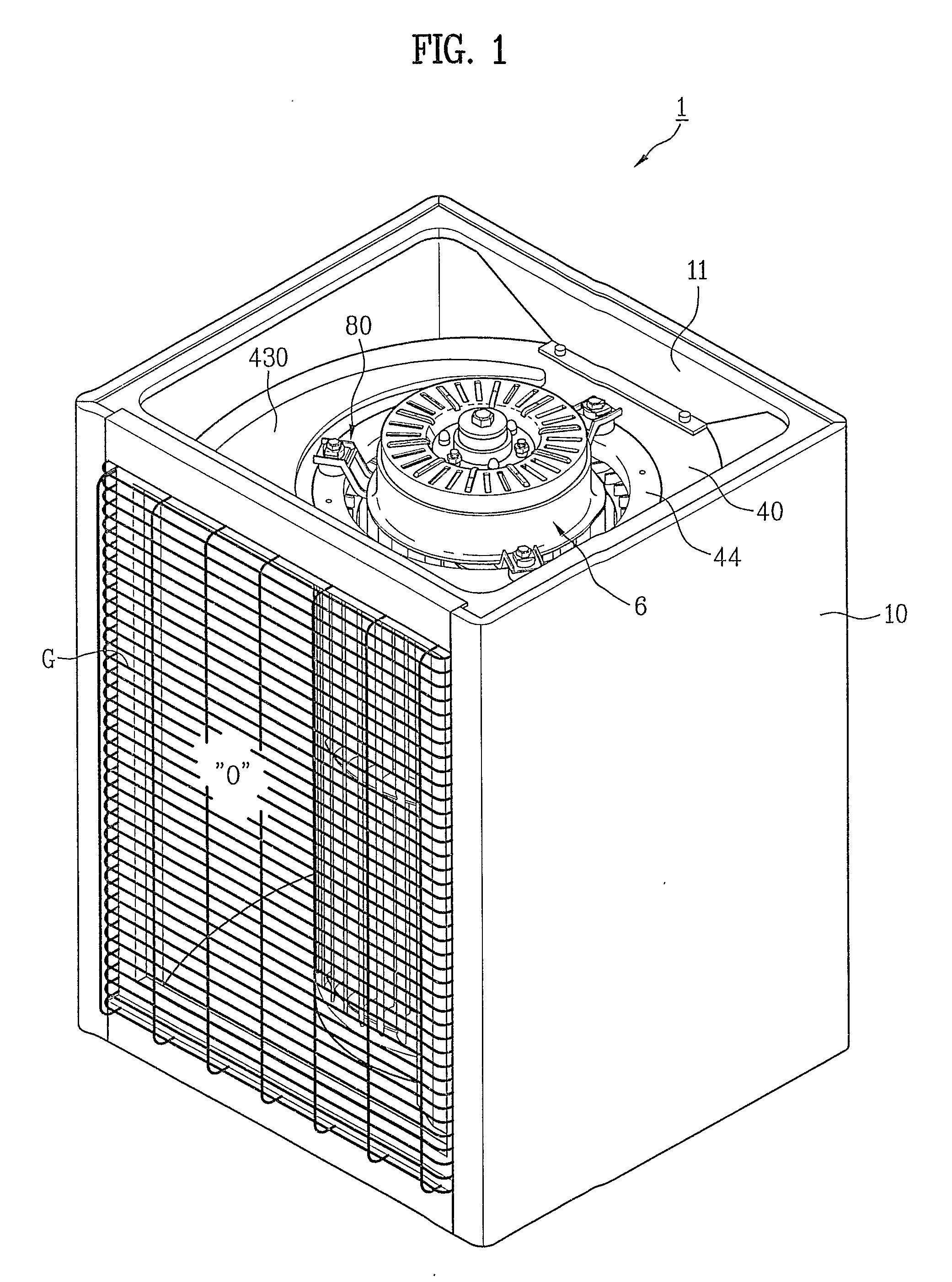

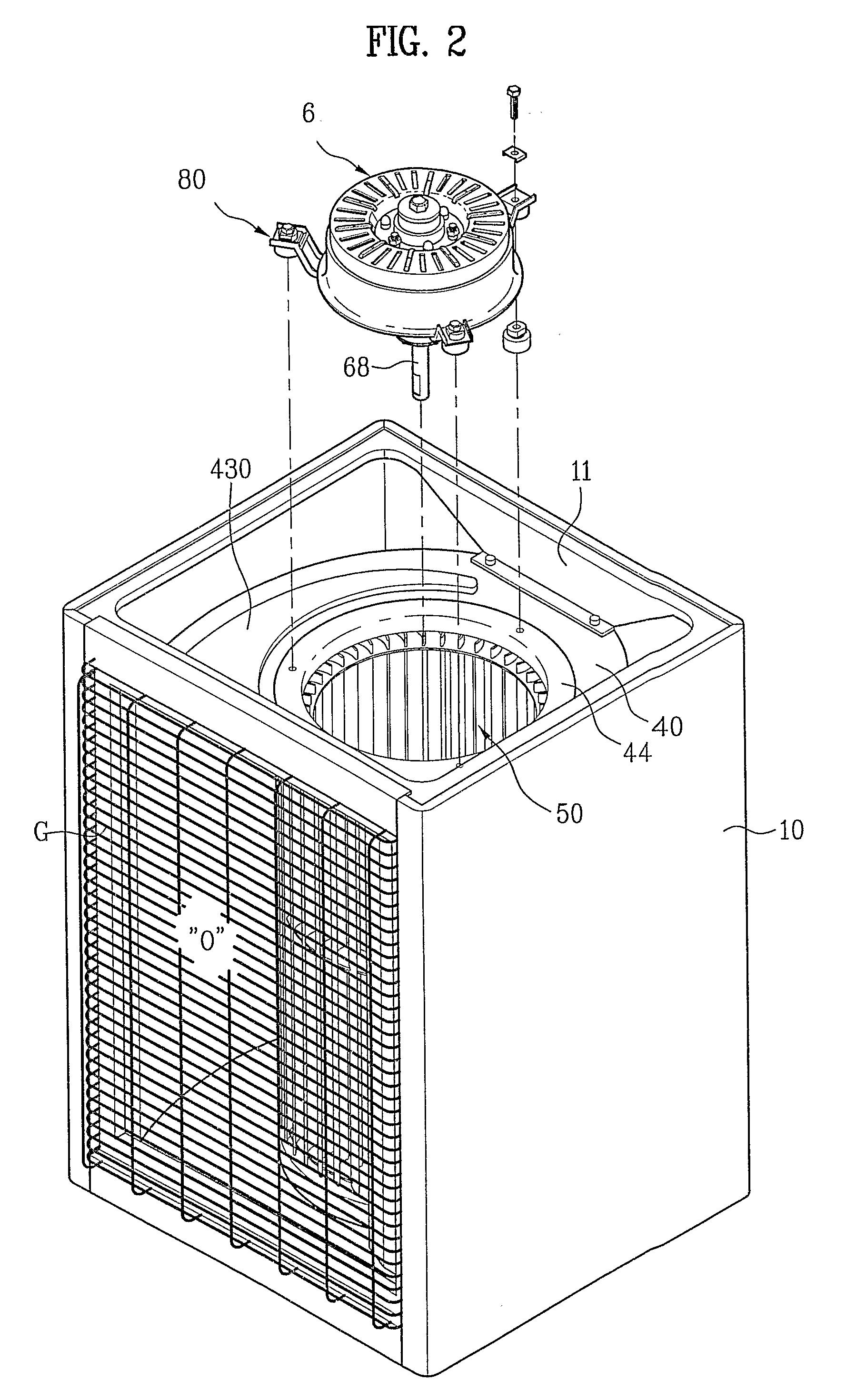

Fan for air conditioner

Fan apparatus for an air conditioner including a fan (50), a shaft (68) coupled to the fan (50), a rotor (60) for transmission of driving force to the shaft (68) for rotating the fan (50), a stator (65) on an inside of the rotor (60) to form a BLDC motor together with the rotor (60), and a fan housing (40) for enclosing the fan (50), thereby reducing noise and enhancing fan (50) efficiency.

Owner:LG ELECTRONICS INC

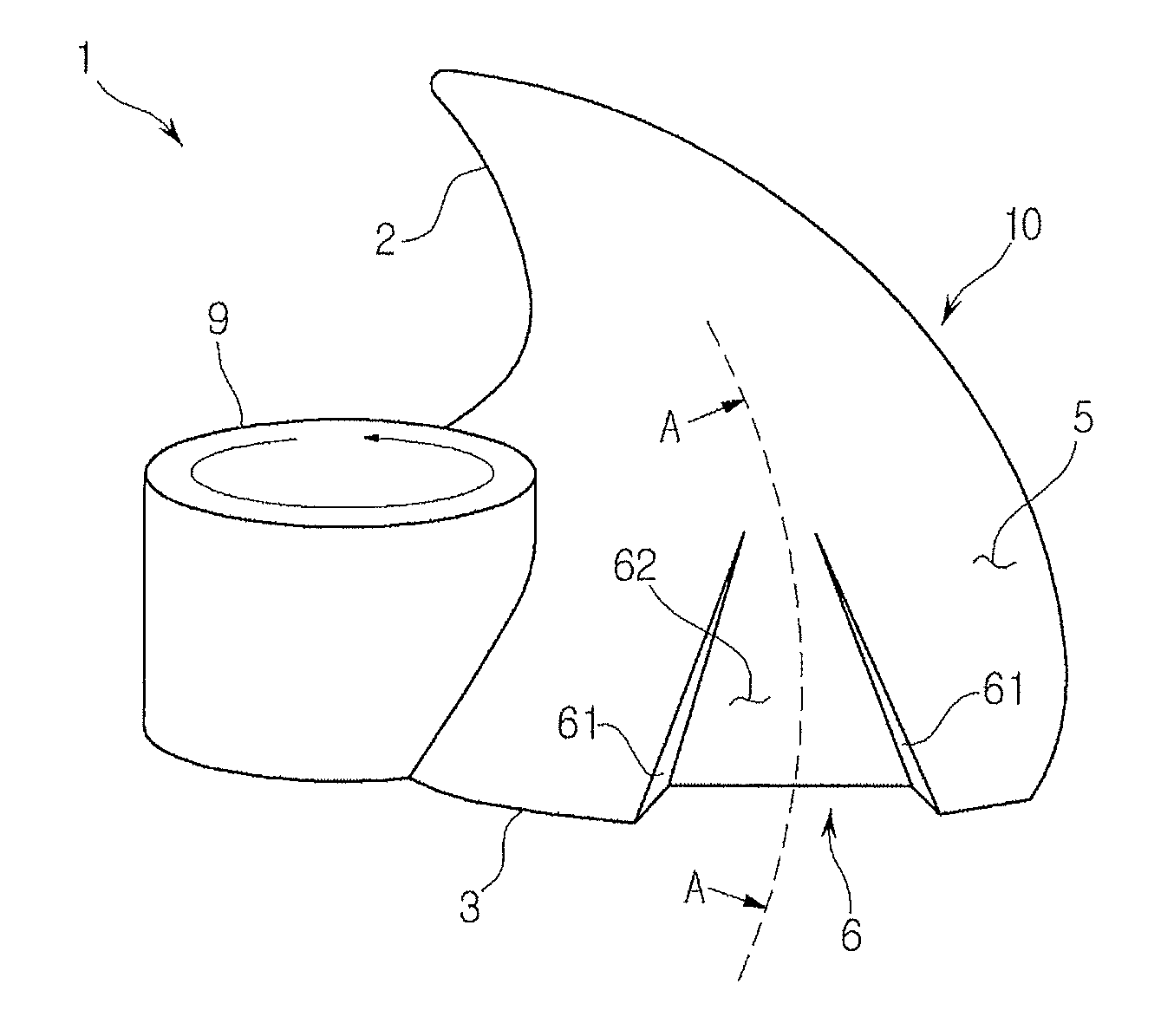

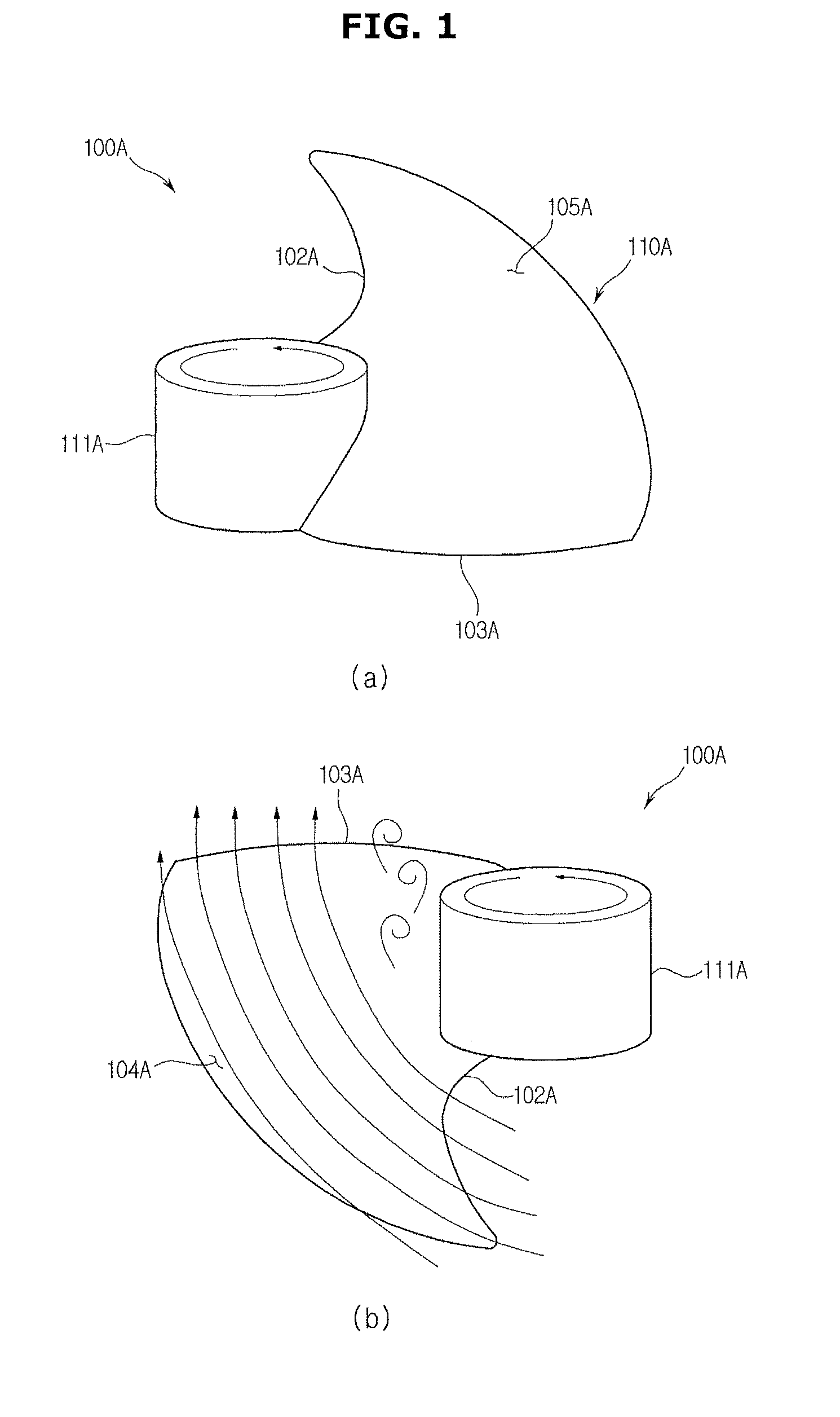

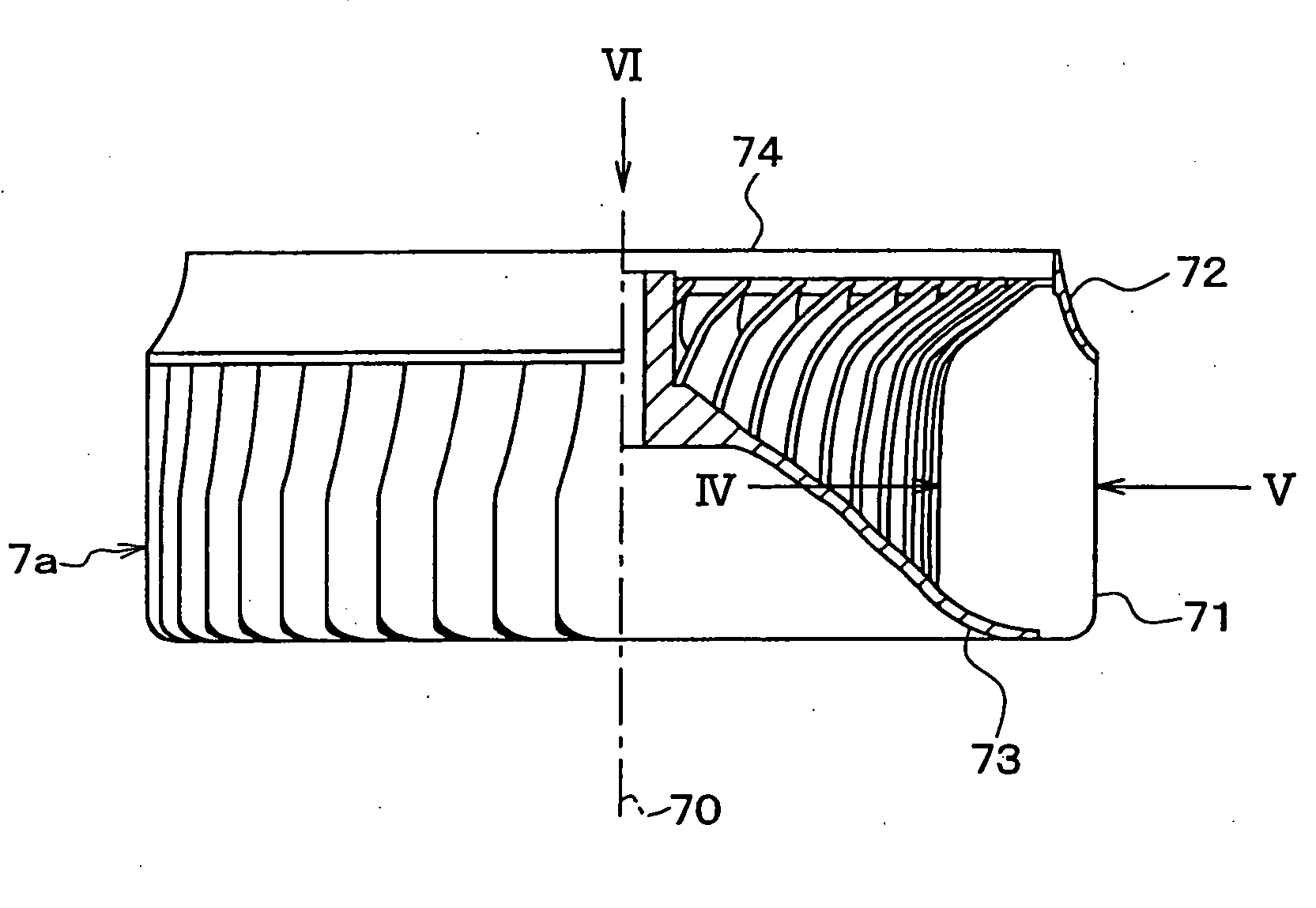

Propeller fan

ActiveUS20140086754A1Propulsive power can be enhancedIncrease heightPropellersRotary propellersLeading edgeSuction stress

A propeller fan may strongly draw the flow toward the inner circumferential side and greatly improve the pressure efficiency by degrading the tendency of the flow near the pressure surface to be inclined toward the outer circumferential side at the trailing edge of the blade. The blade is provided with a recessed portion raised toward a suction surface at a central portion of a trailing edge of the blade in a radial direction such that the recessed portion is open at least on a pressure surface of the blade, the recessed portion extending from the trailing edge toward a leading edge of the blade, and a cross section of the recessed portion taken in a radial direction is provided with a pair of lateral portions rising at a predetermined angle with respect to the suction surface and facing each other. The span-wise width of the recessed portion between the lateral portions increases as the recessed portion extends from an upstream side to a downstream side.

Owner:SAMSUNG ELECTRONICS CO LTD

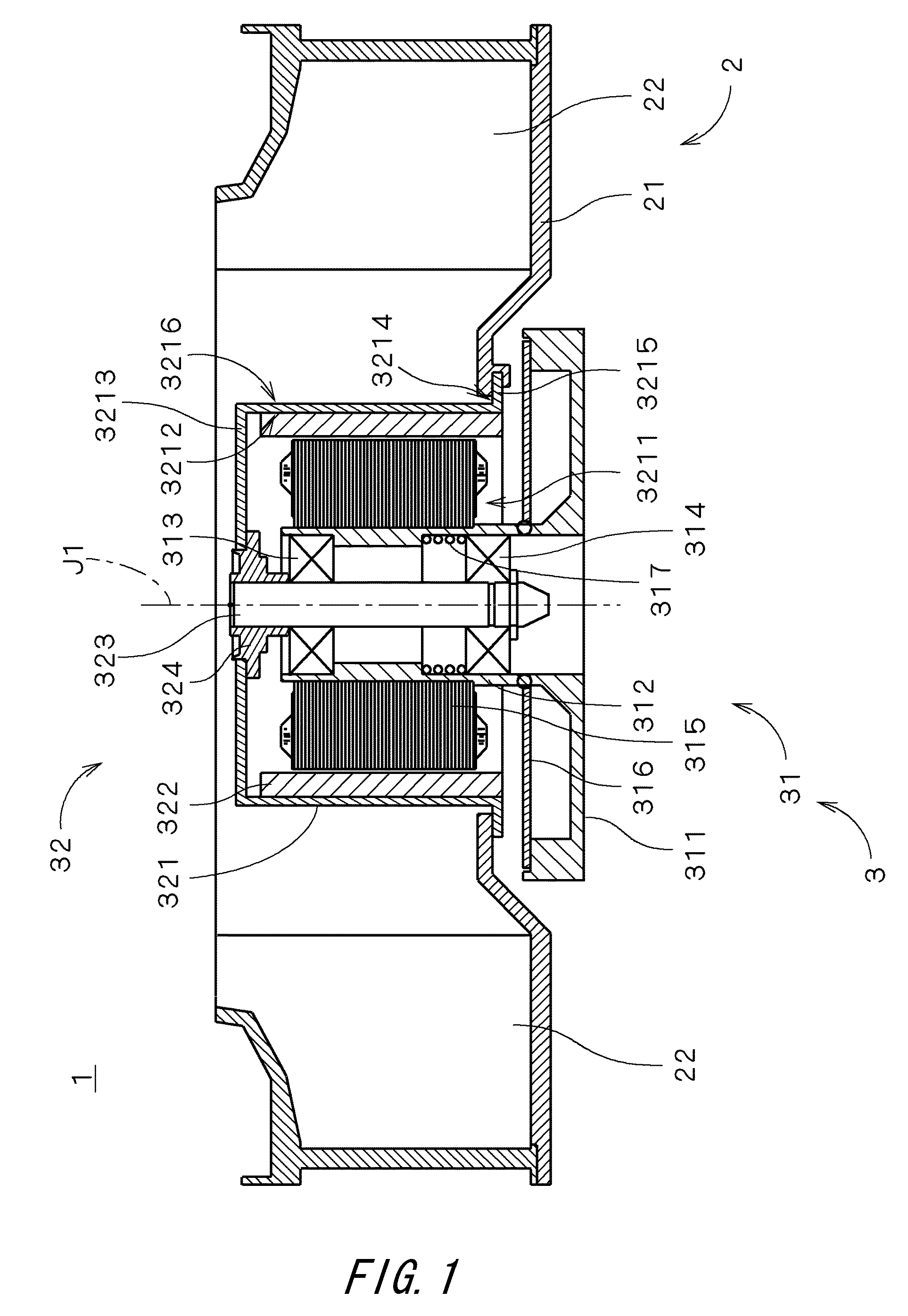

Fan assembly

InactiveUS20070014675A1Improve fan efficiencyPrevent thermal deformationPump componentsPiston pumpsImpellerEngineering

A fan assembly includes an impeller portion generating an air flow and a motor that rotates the impeller portion about a center axis. The impeller portion is attached to a yoke of a rotor portion of the motor and is rotated with the yoke. A circular portion of the impeller is attached to a bottom opening of the yoke having a cylindrical shape whose top is covered by insert molding. Therefore, the impeller and the yoke may be securely fixed to each other. In addition, an outer side surface of the yoke is exposed to outside air such that the space arranged inward from the plurality of blades may be enlarged.

Owner:NIDEC CORP

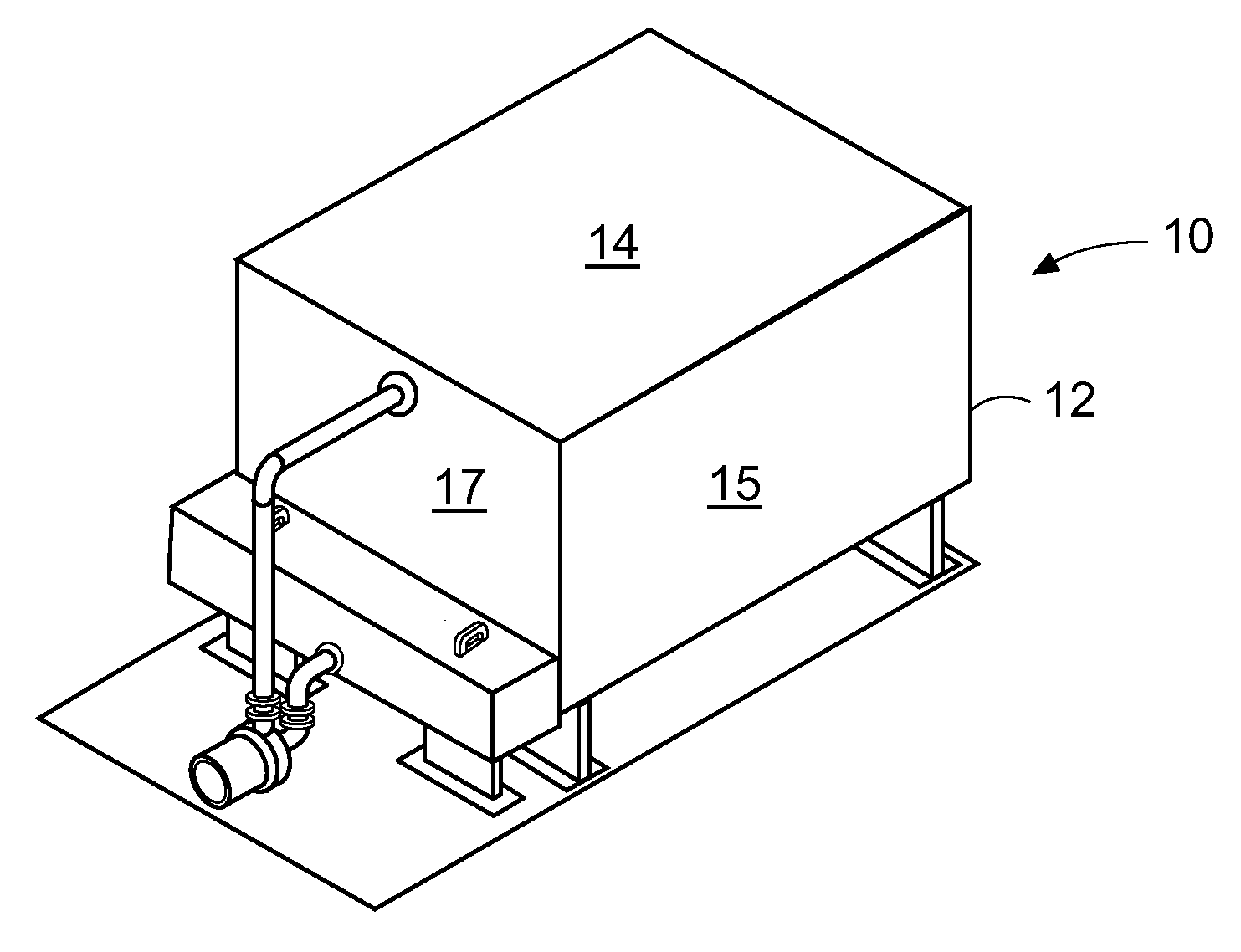

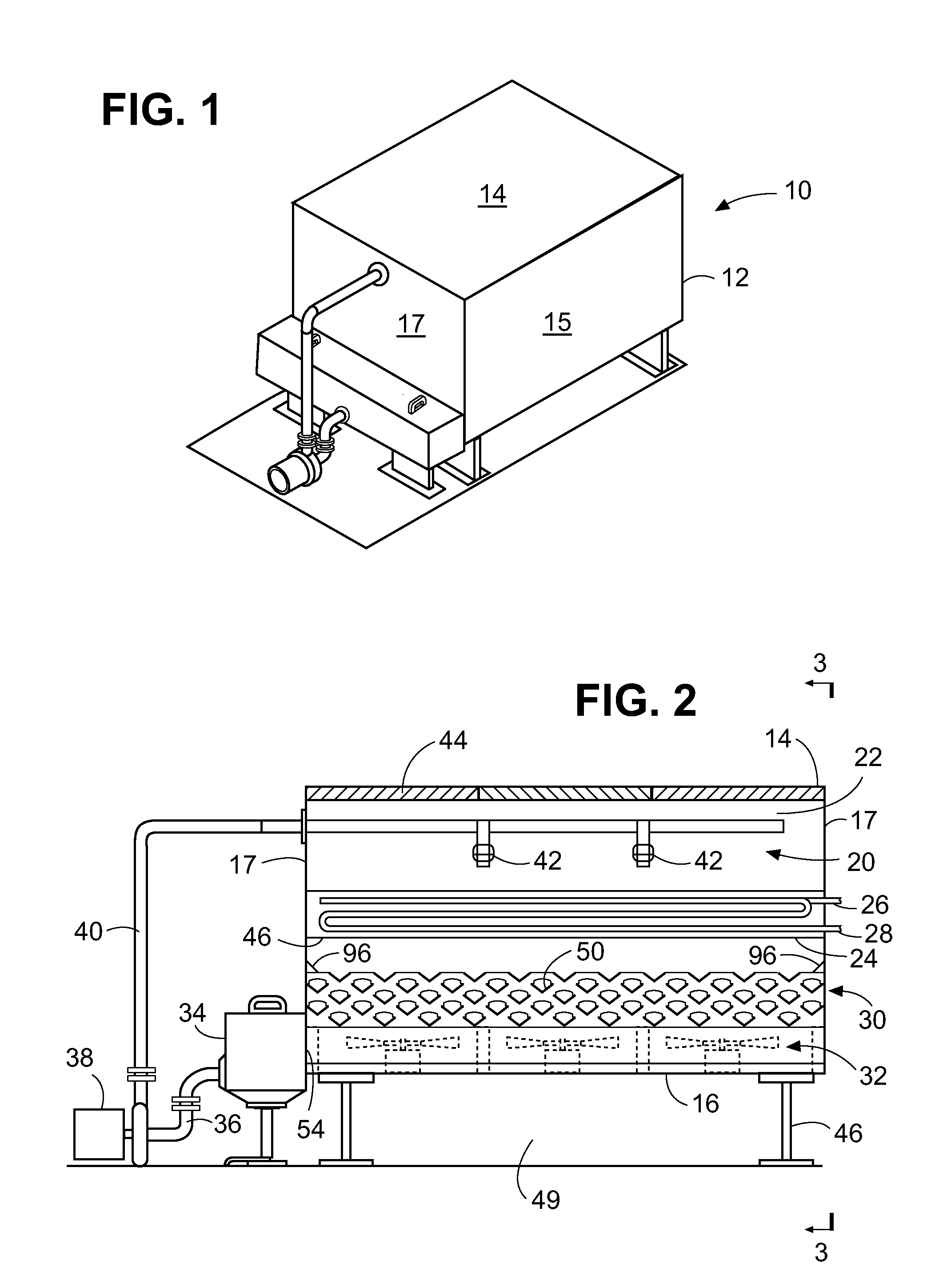

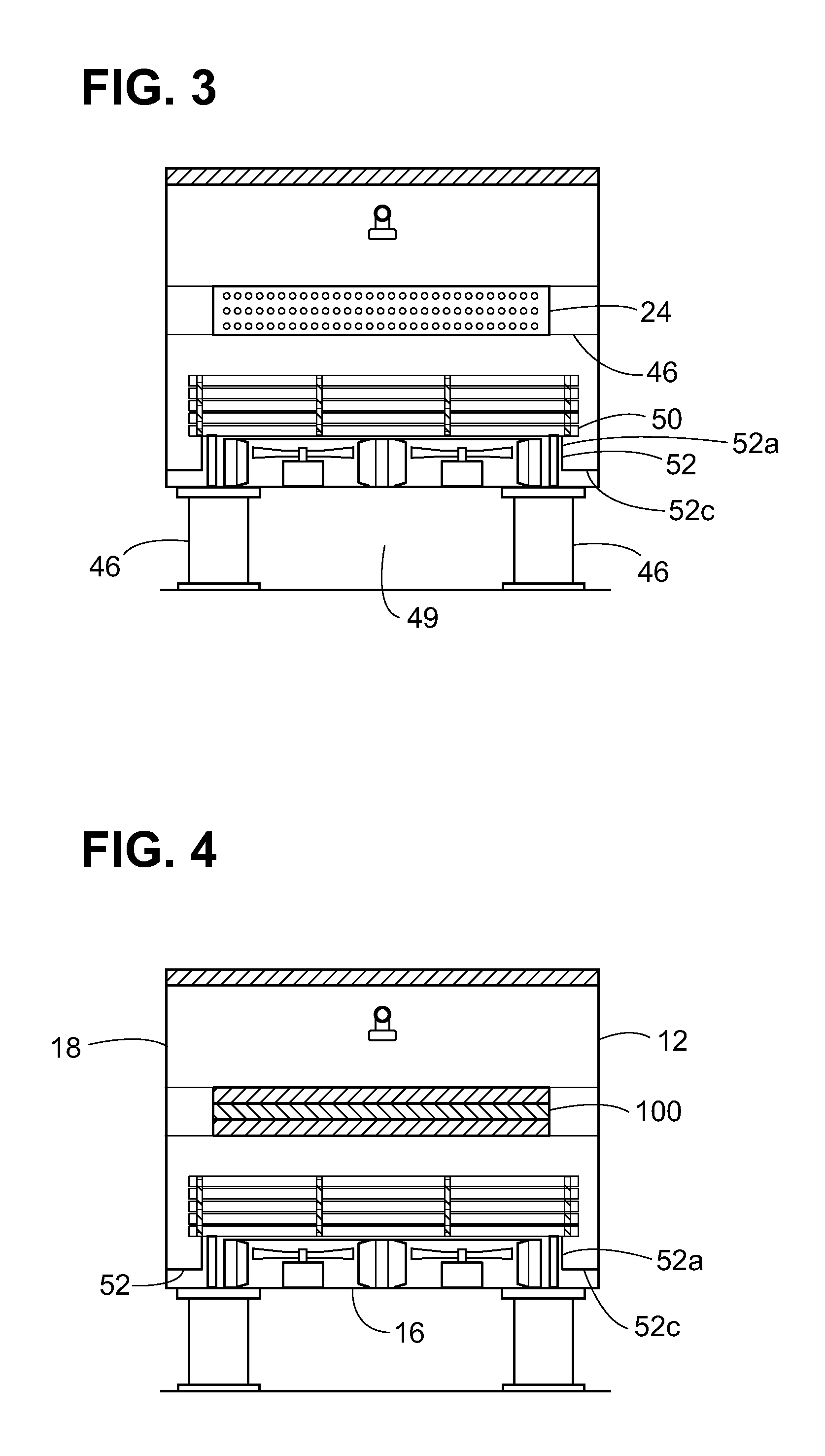

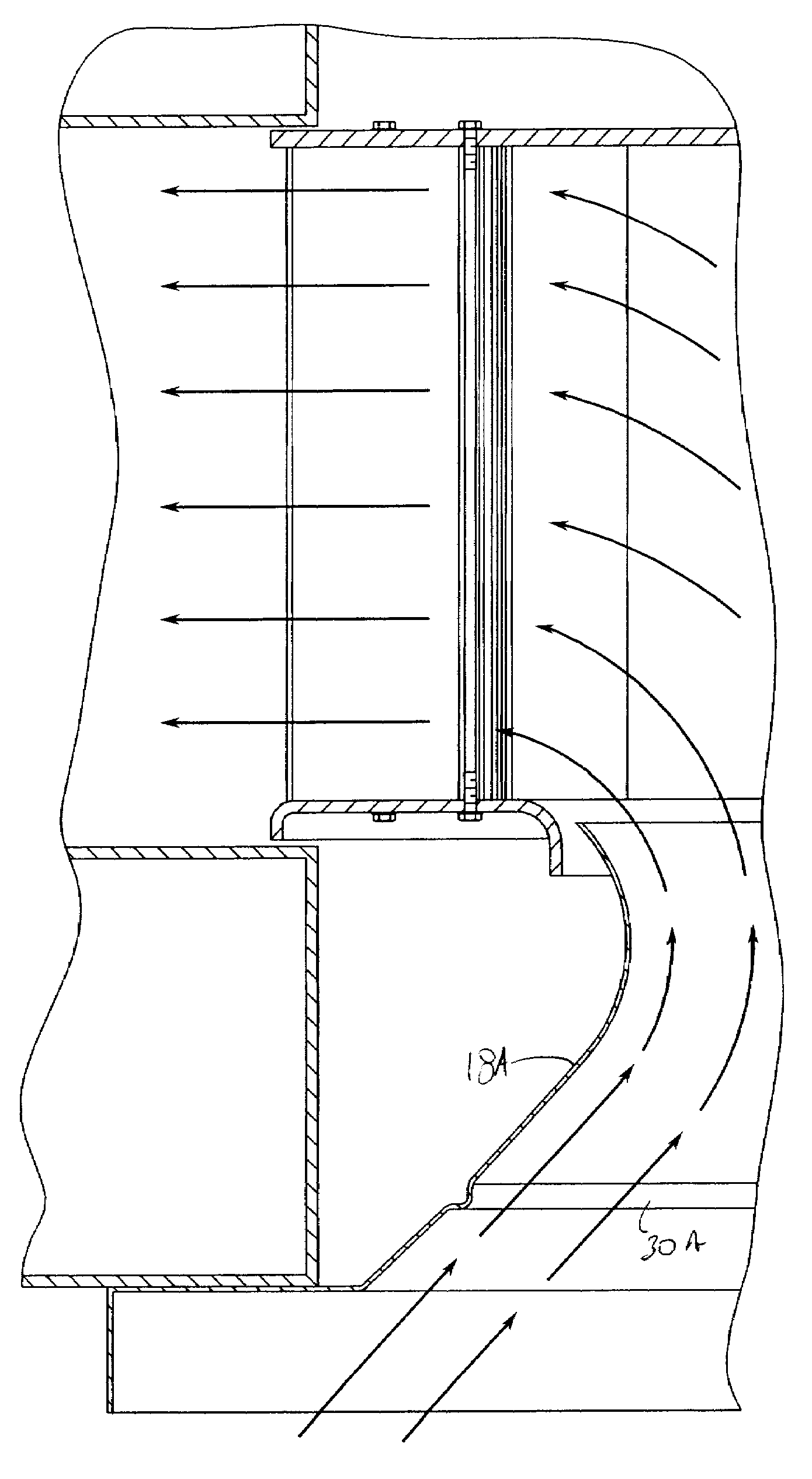

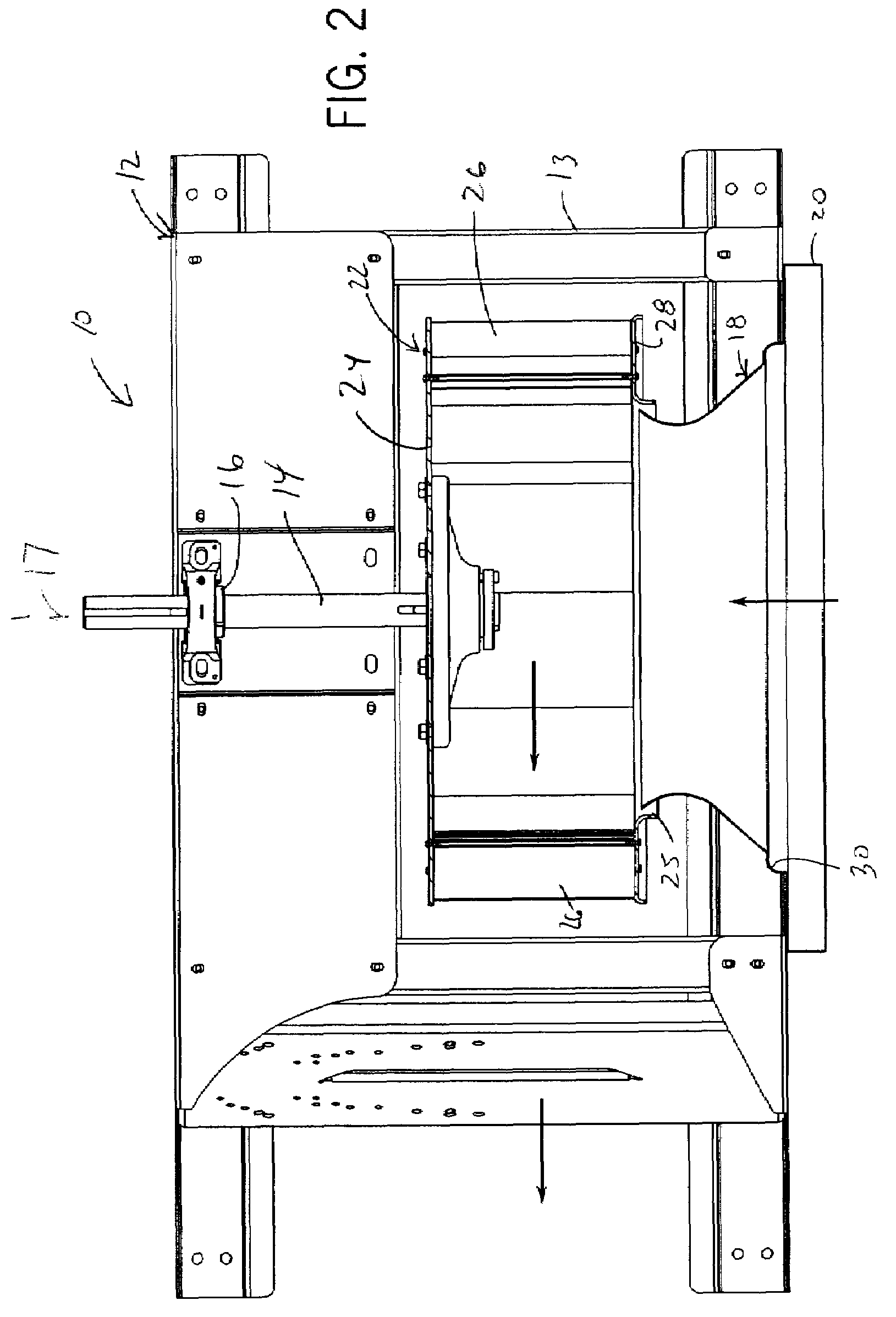

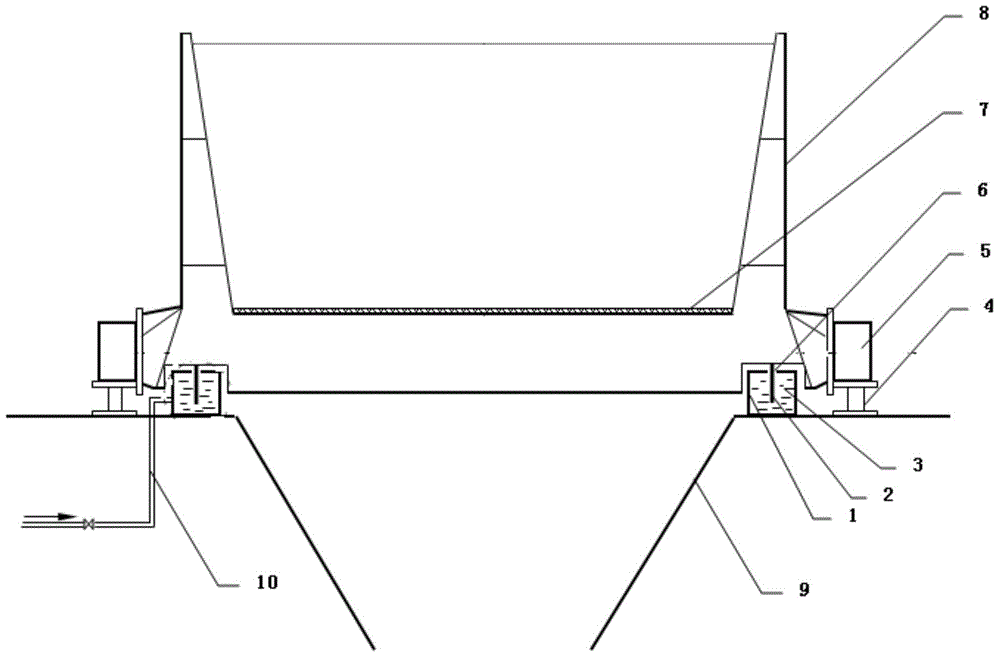

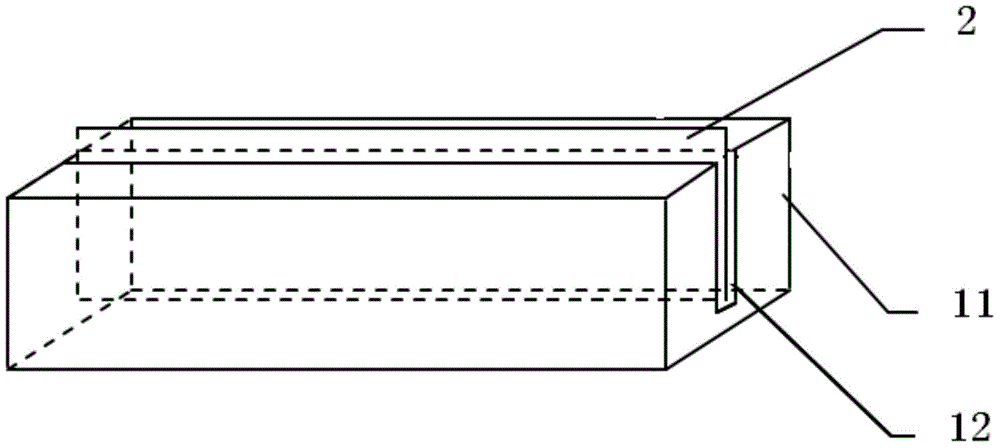

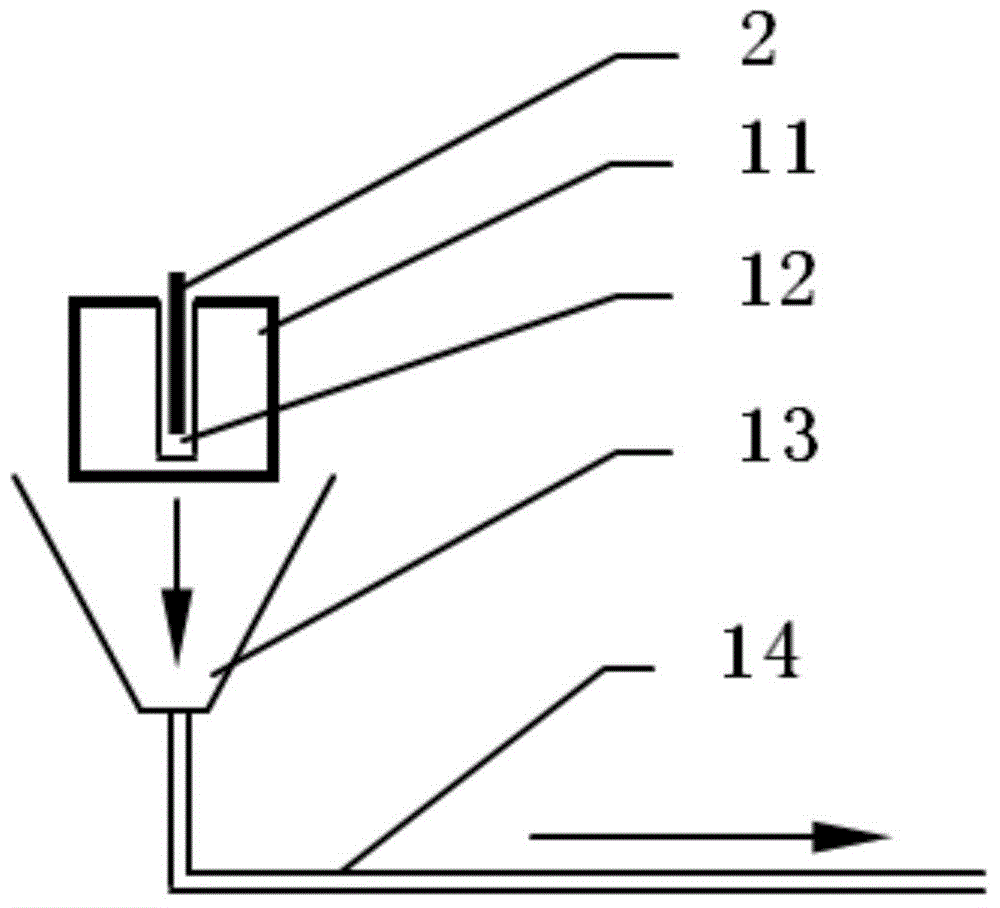

Direct forced draft fluid cooler/cooling tower and liquid collector therefor

InactiveUS20110315350A1Reduced initial construction costHeight of structurePipe supportsServomotor componentsCooling towerClosed loop

Direct forced draft fluid cooler / closed loop cooling towers and cooling towers are provided with fans at the bottom of the unit, and a plurality of layers of water collection troughs or channels above the fans to capture water droplets sprayed downwardly from the top of the device through a heat exchanger or fill media above the collection troughs. In one embodiment the collection troughs supply the collected water to one or more gutters inside the housing which lead the water to an external collection tank from which the water is recirculated through the system.

Owner:CURTIS HAROLD +1

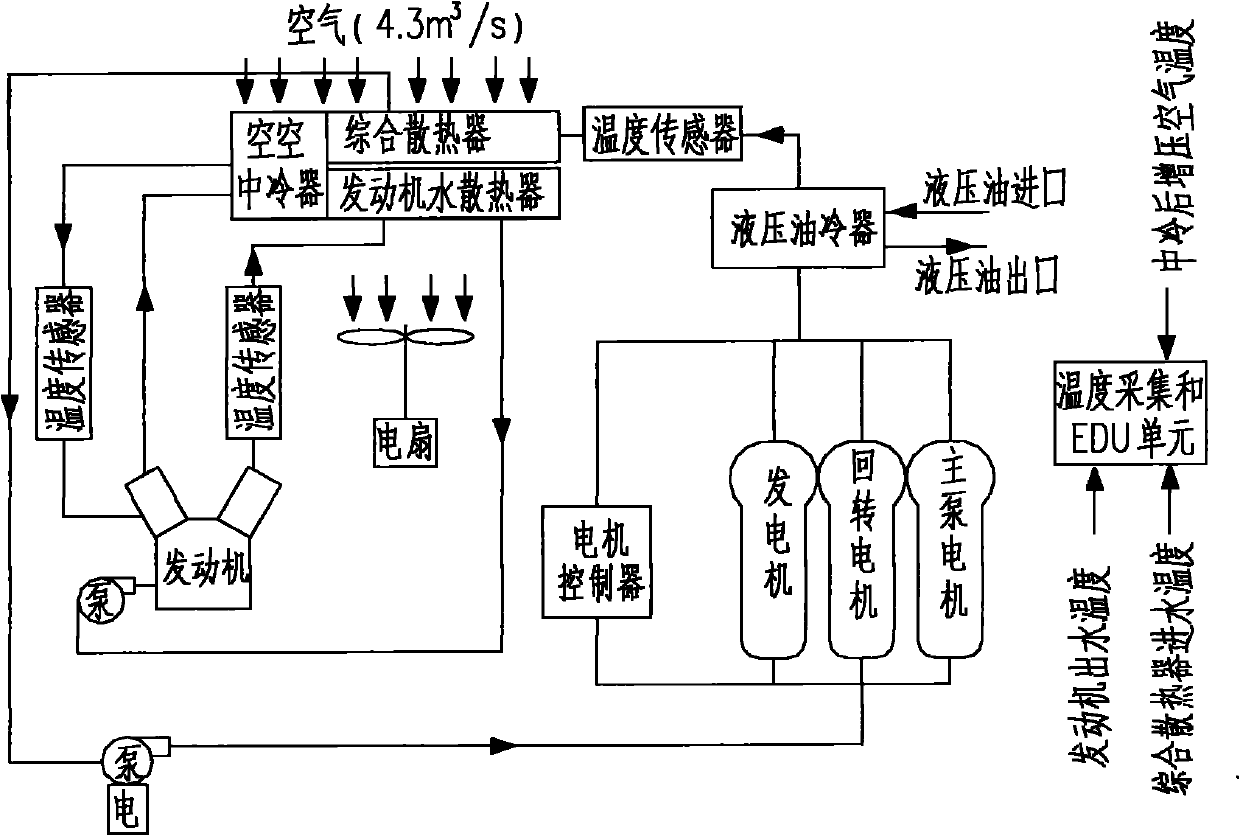

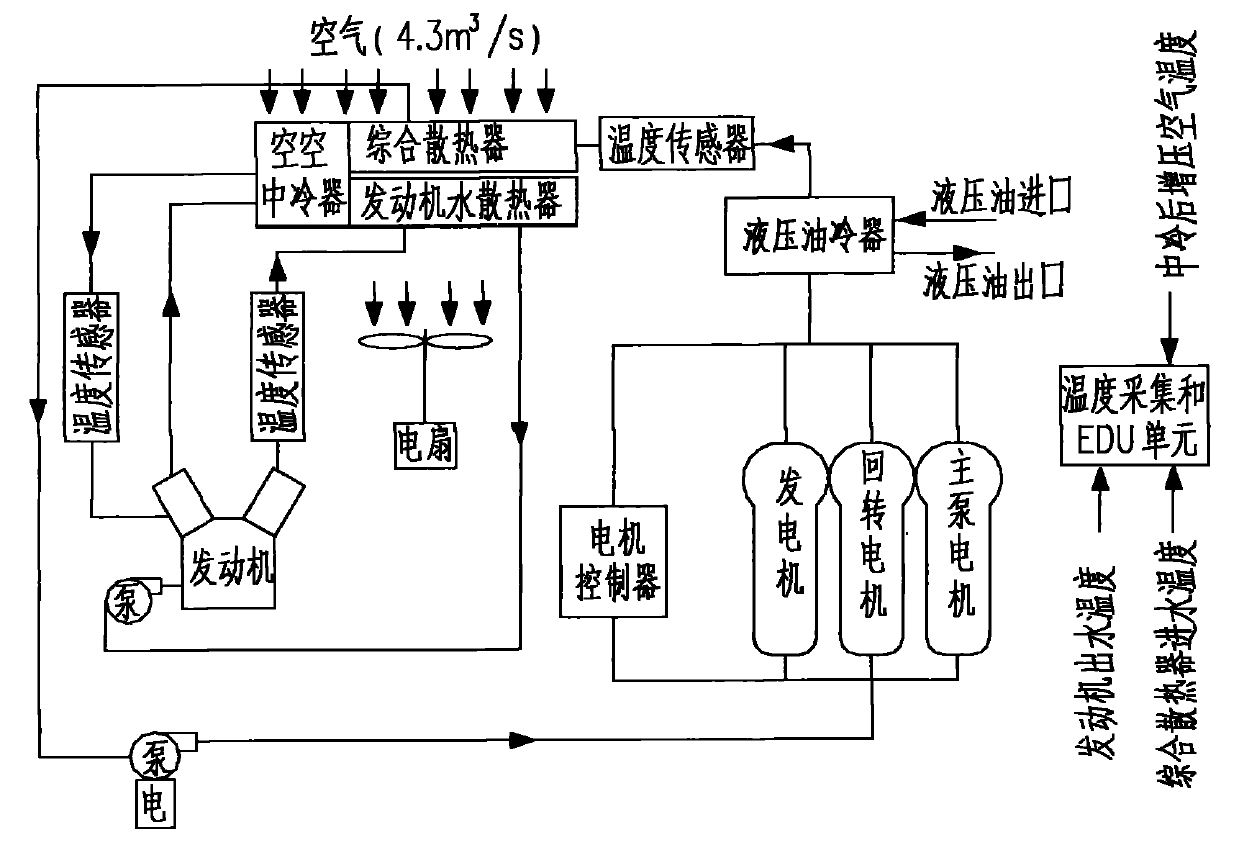

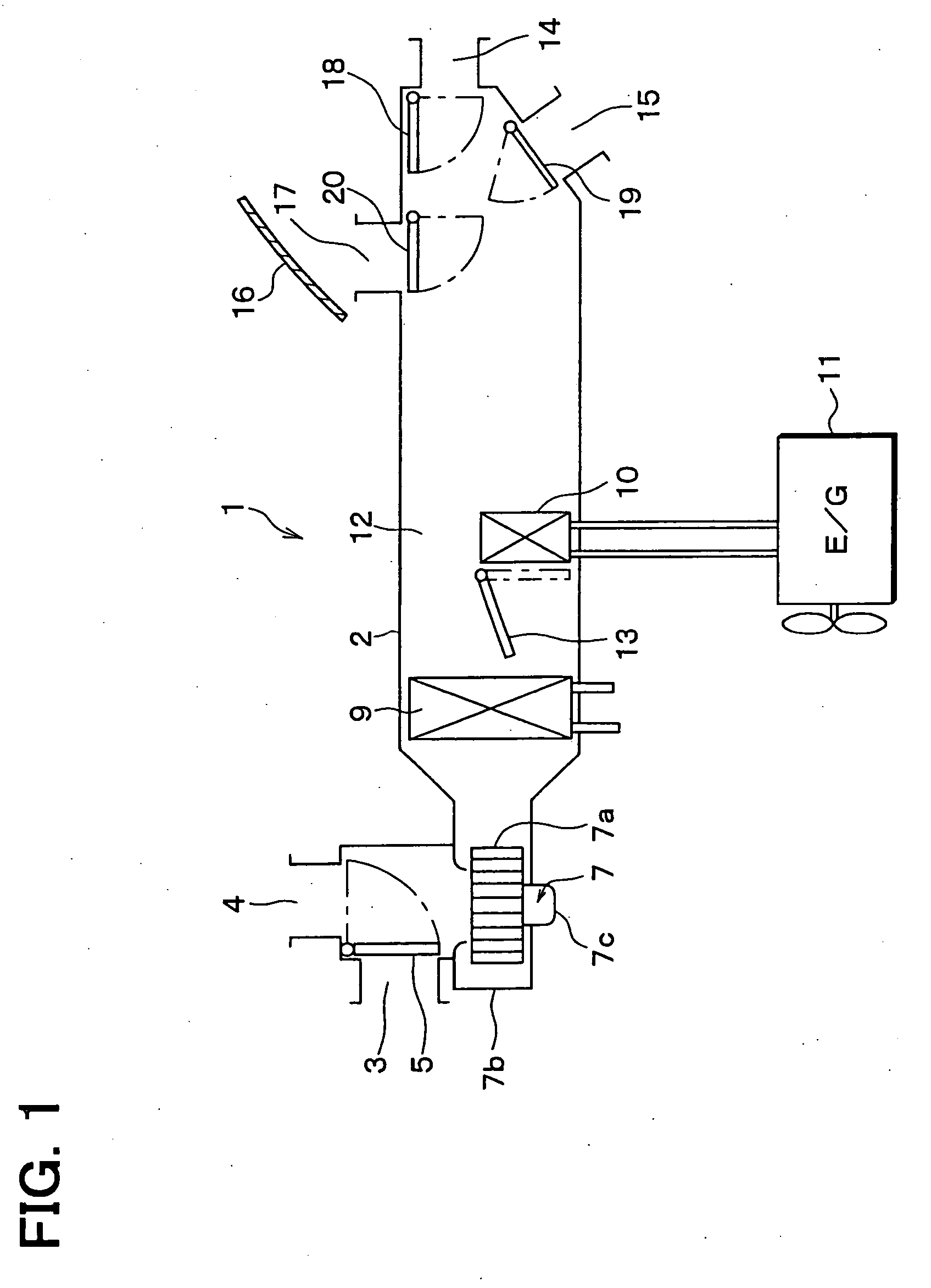

Integrative cooling system of hybrid power excavating machine

InactiveCN101907015AImprove cooling effectImprove fan efficiencyCoolant flow controlInternal combustion piston enginesCooling effectWorking temperature

The invention relates to a novel cooling system of a hybrid power excavating machine. In the invention, a water radiator, an integrative radiator and an air-to-air intercooler are designed as an independent circulation loop respectively, thus ensuring respective working temperature thereof within respective permission scope. The integrative radiator and the water radiator are successively arranged from outside to inside, and are welded with the air-to-air intercooler respectively, thus effectively solving the problems of poor sealing, ventilation leakage and the like between the radiators, improving the cooling effect of the cooling system, and reducing space arrangement. In addition, the complete machine system is simple, reliable and practical.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

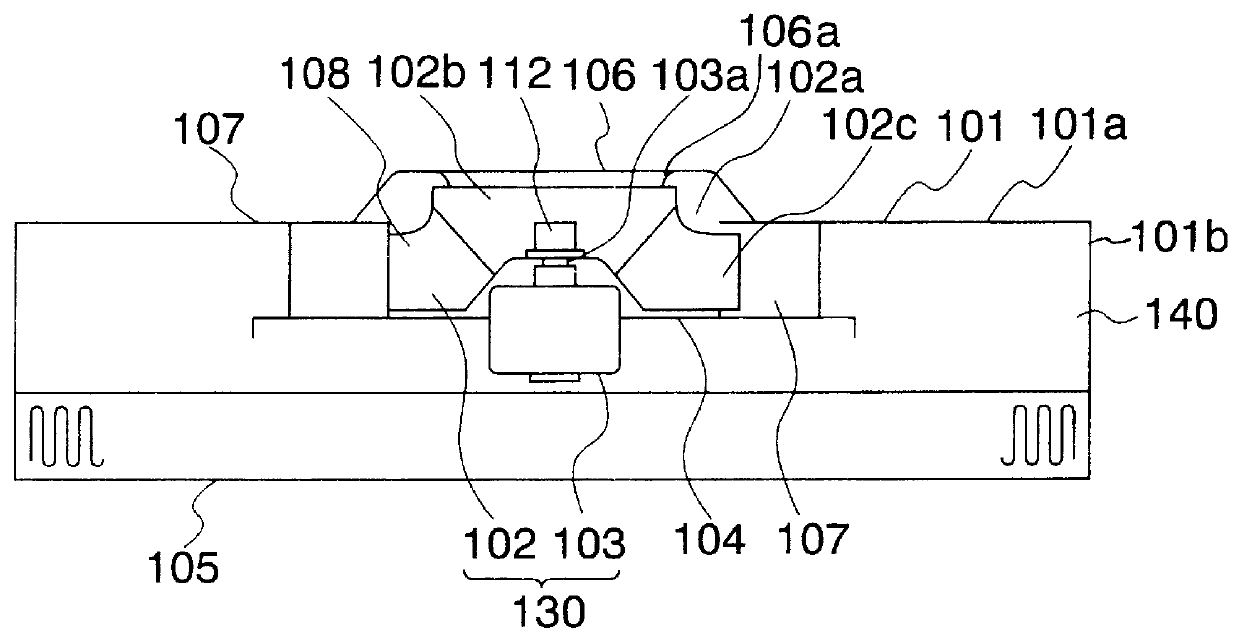

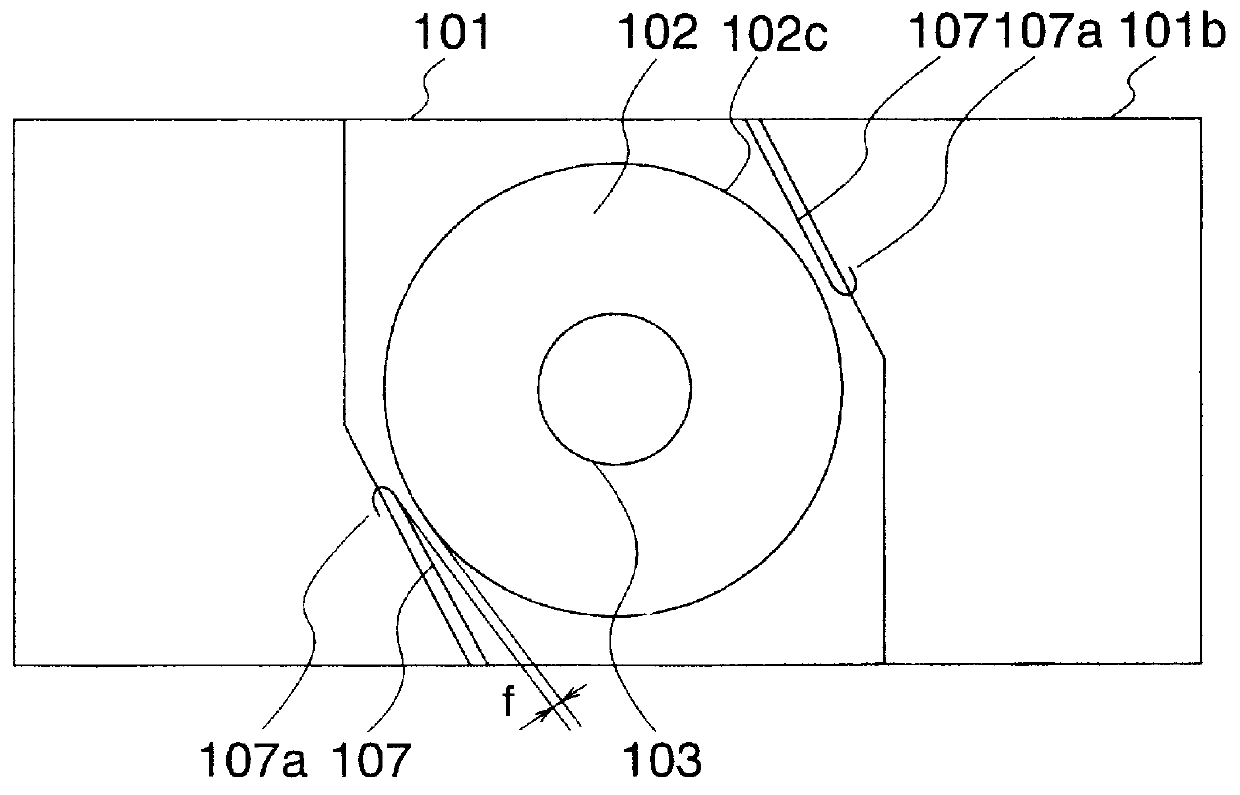

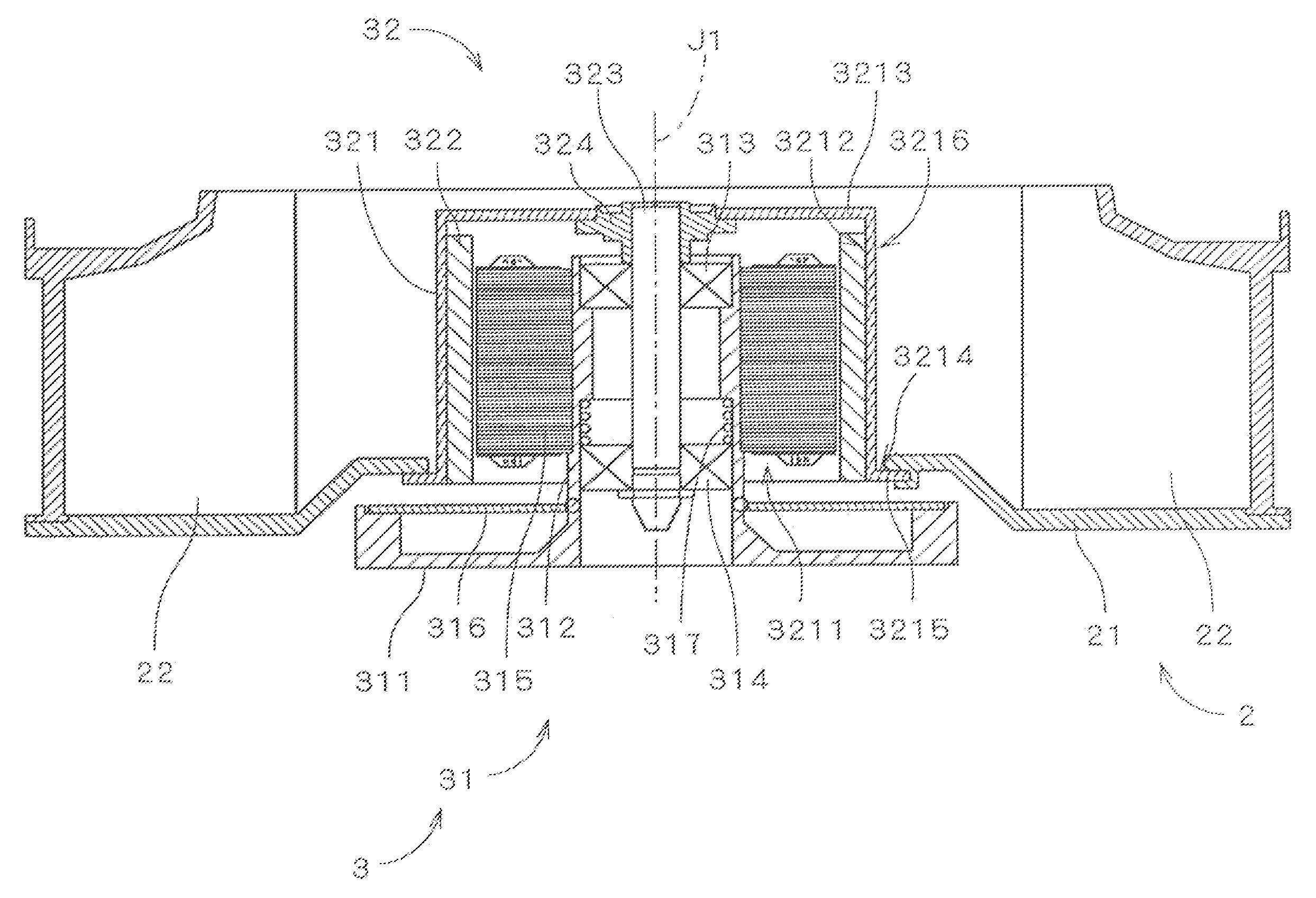

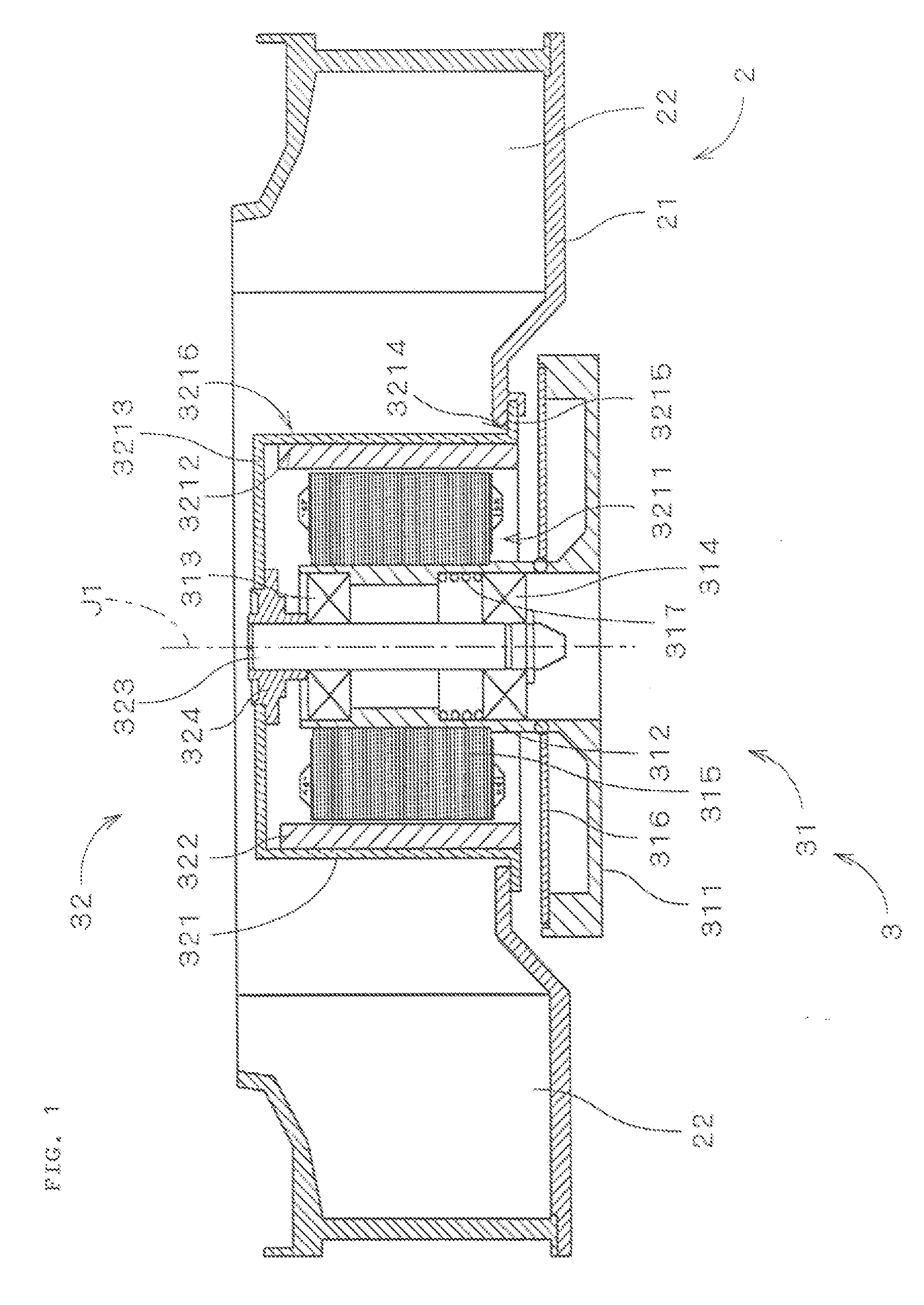

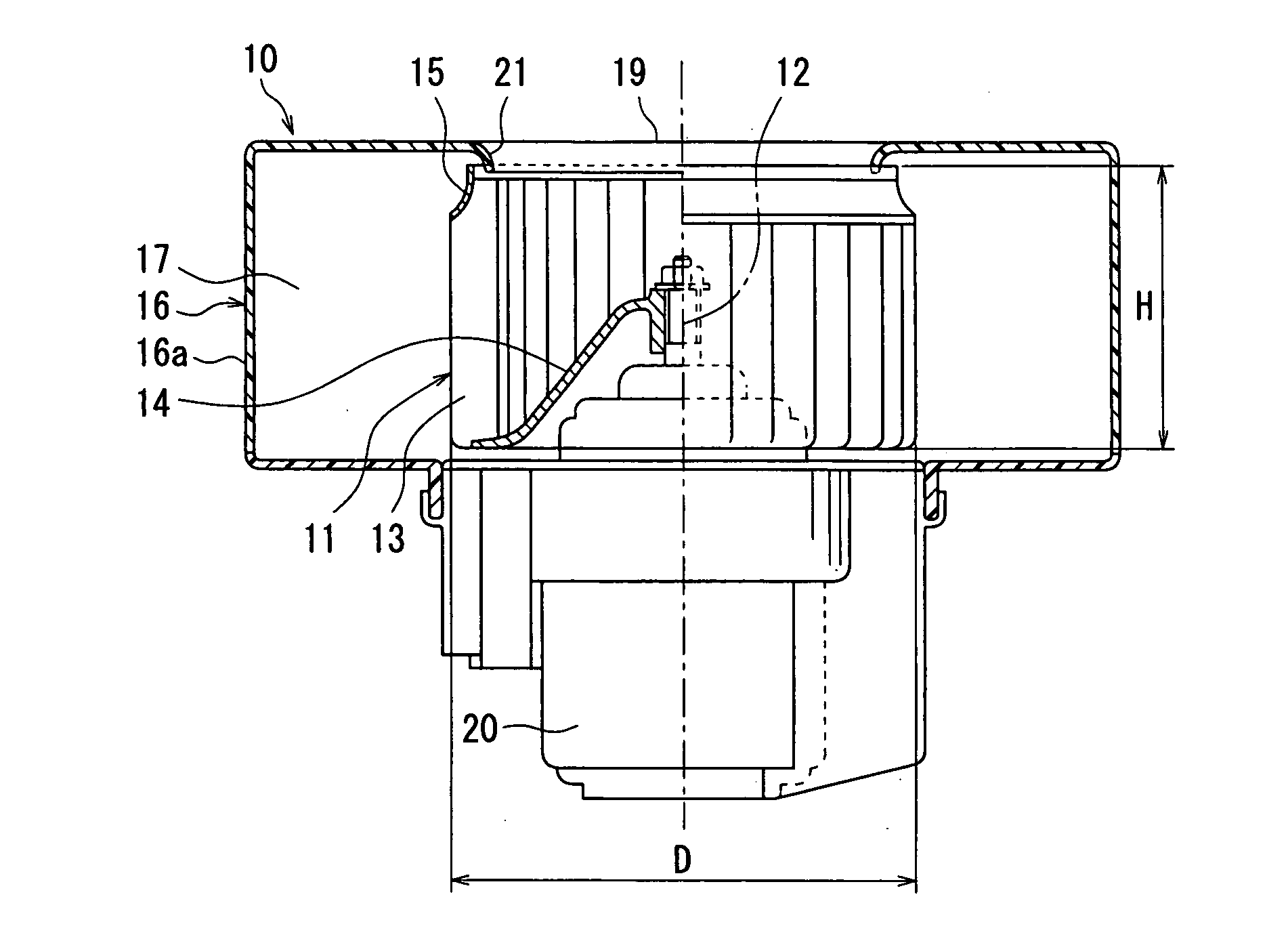

Module for cooling semiconductor device

InactiveUS20100269517A1Improve cooling efficiencyReduce heat gainDomestic cooling apparatusIndirect heat exchangersThermoelectric coolingEngineering

A module for cooling a heat generating element comprising a heat receiving plate thermally connected to at least one heat generating element; a heat transfer device one end portion of which is thermally connected to the heat receiving plate and other end portion of which is thermally connected to a heat dissipating plate; a thermoelectric cooler one face of which is thermally connected to one face of the heat dissipating plate; a first heat sink thermally connected to other face of the heat dissipating plate; and a second heat sink thermally connected to other face of said thermoelectric cooler.

Owner:FURUKAWA ELECTRIC CO LTD

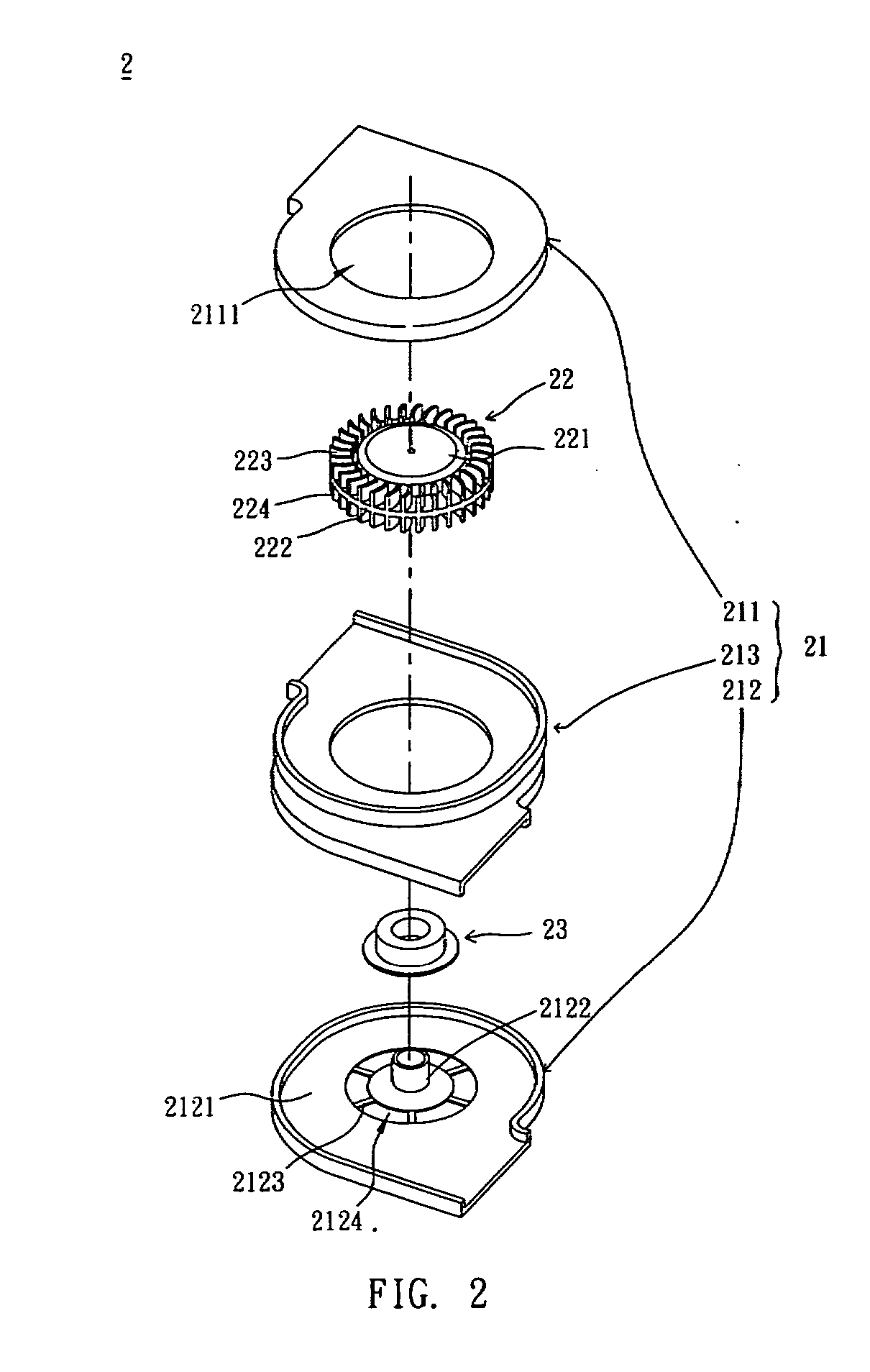

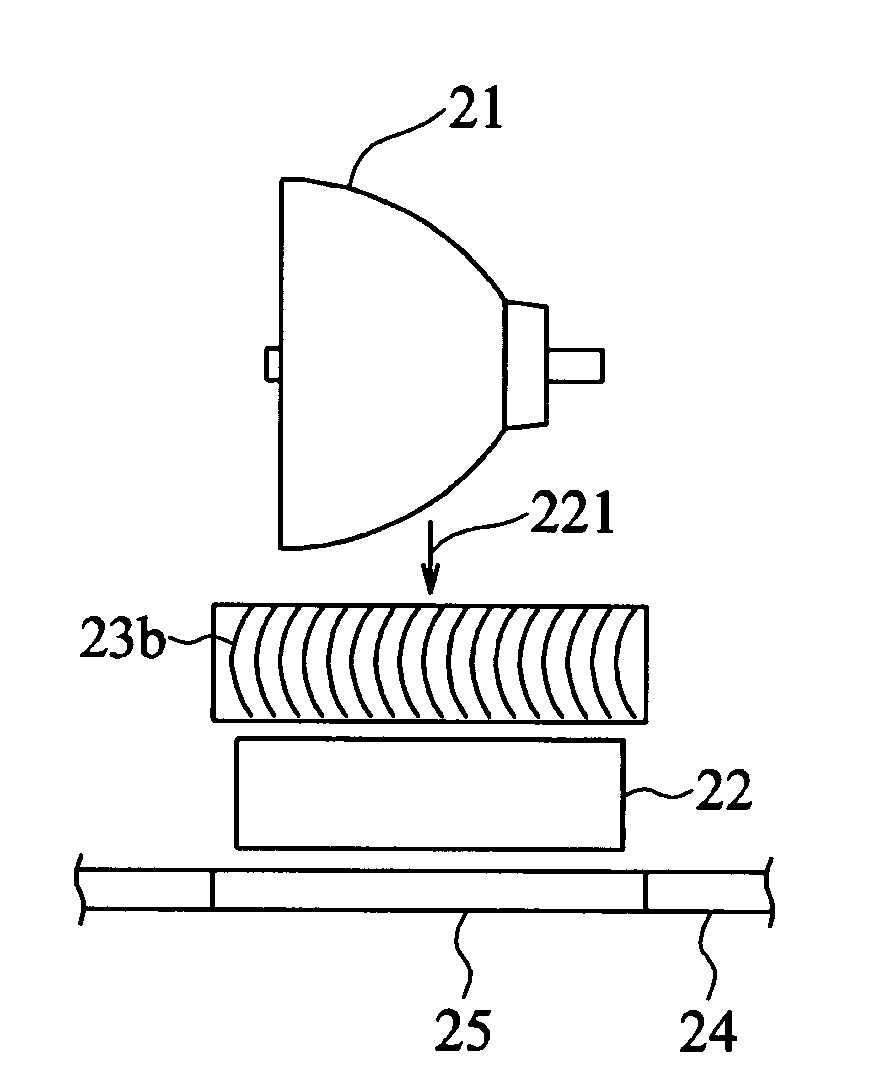

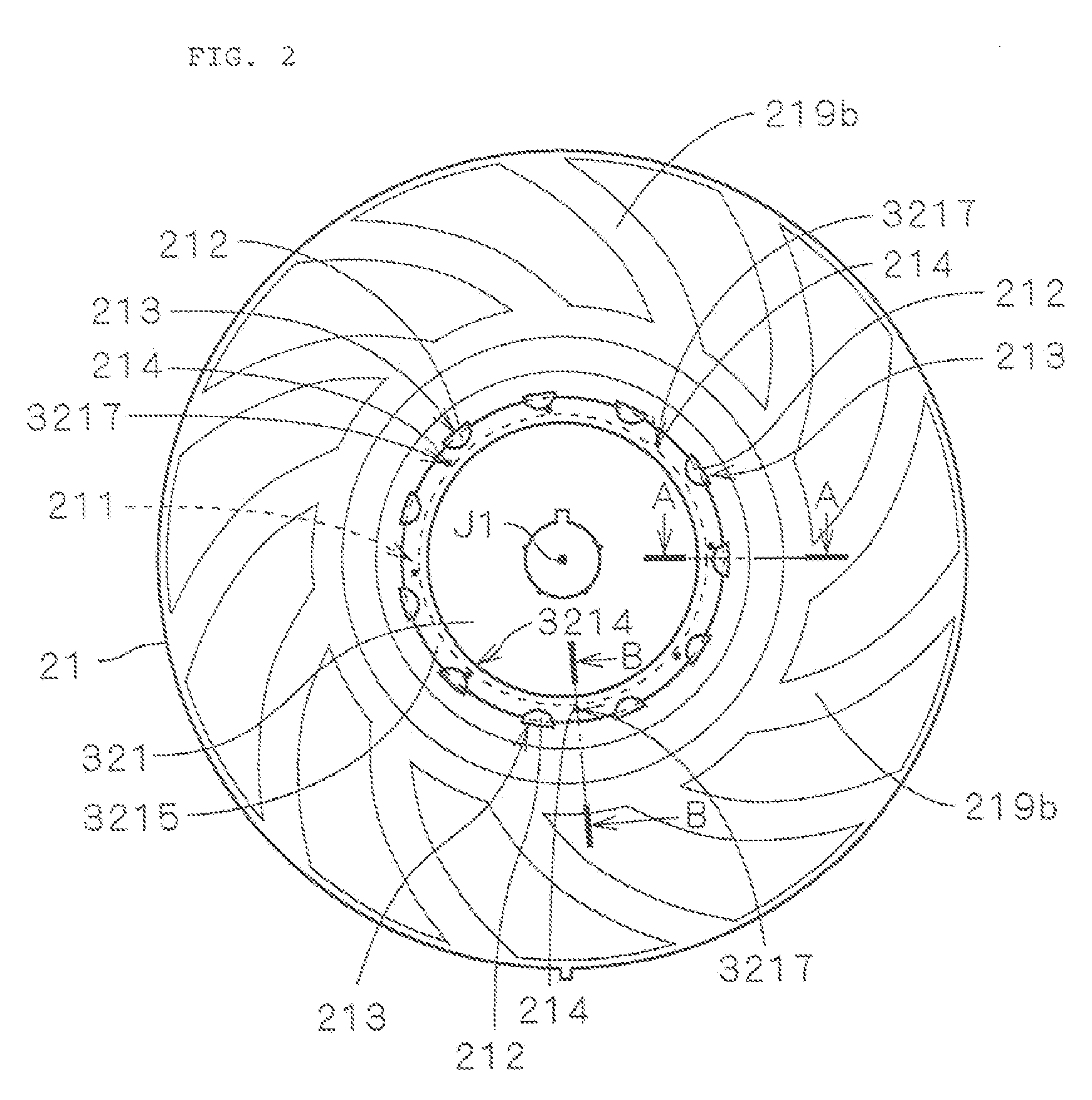

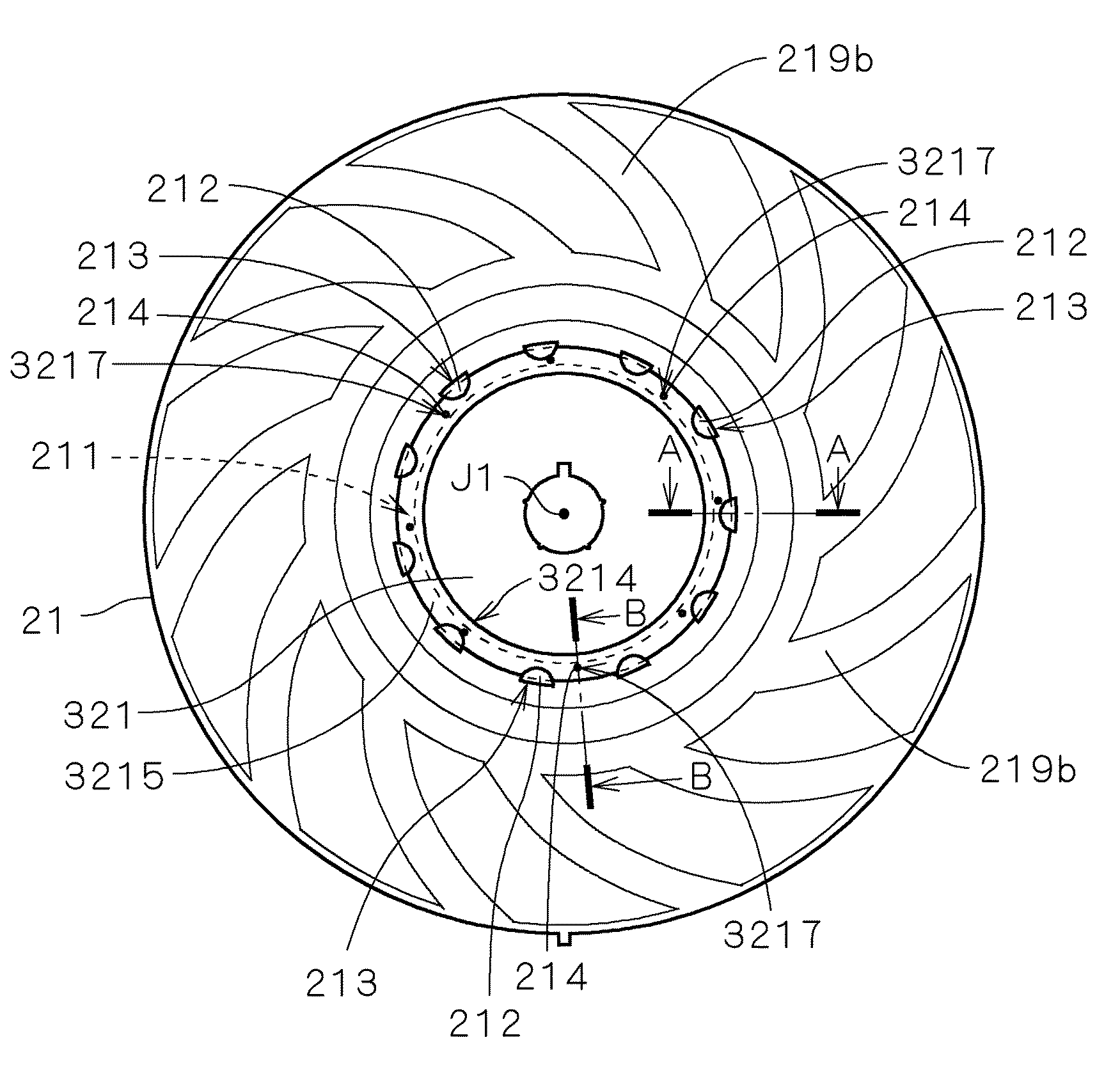

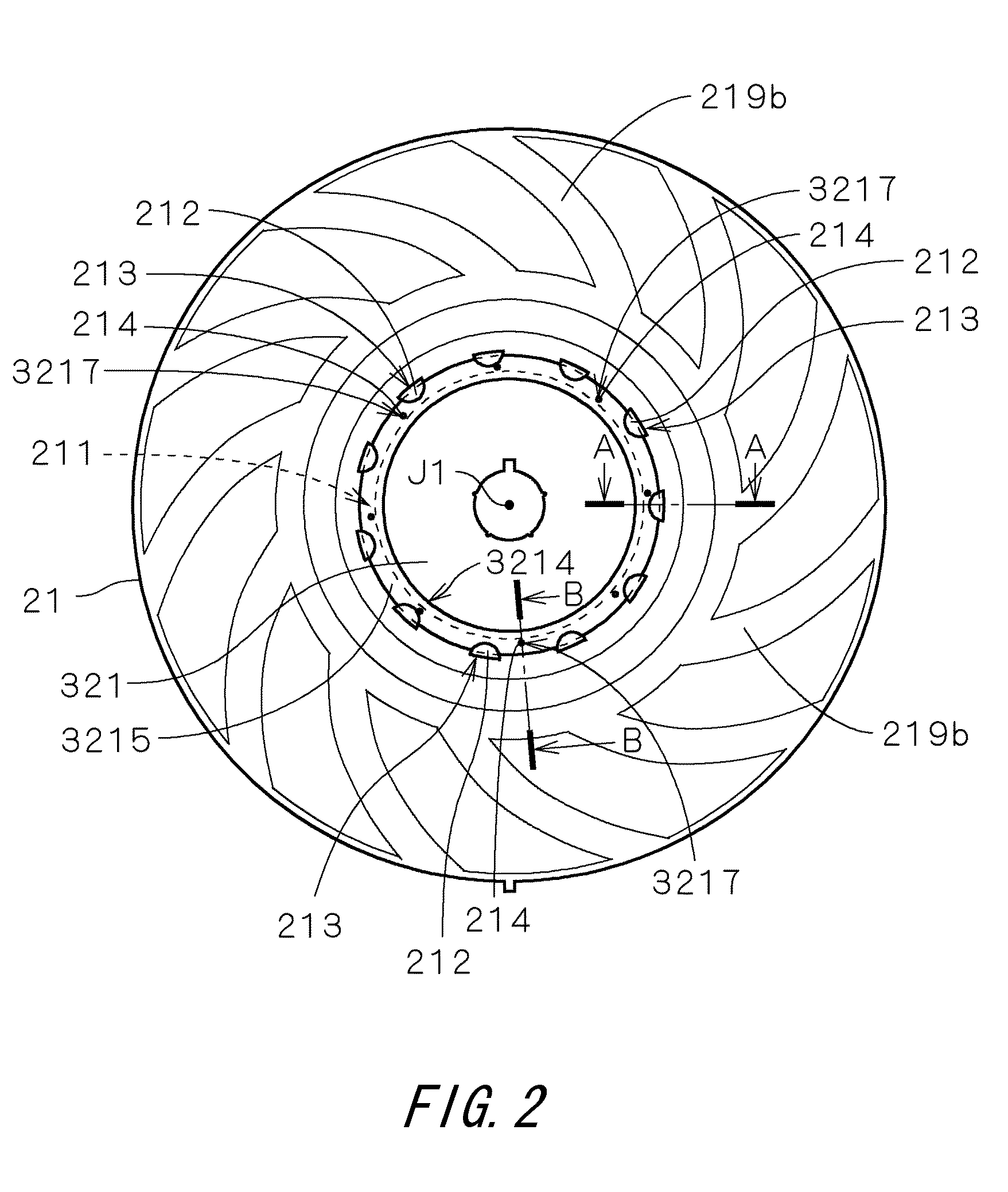

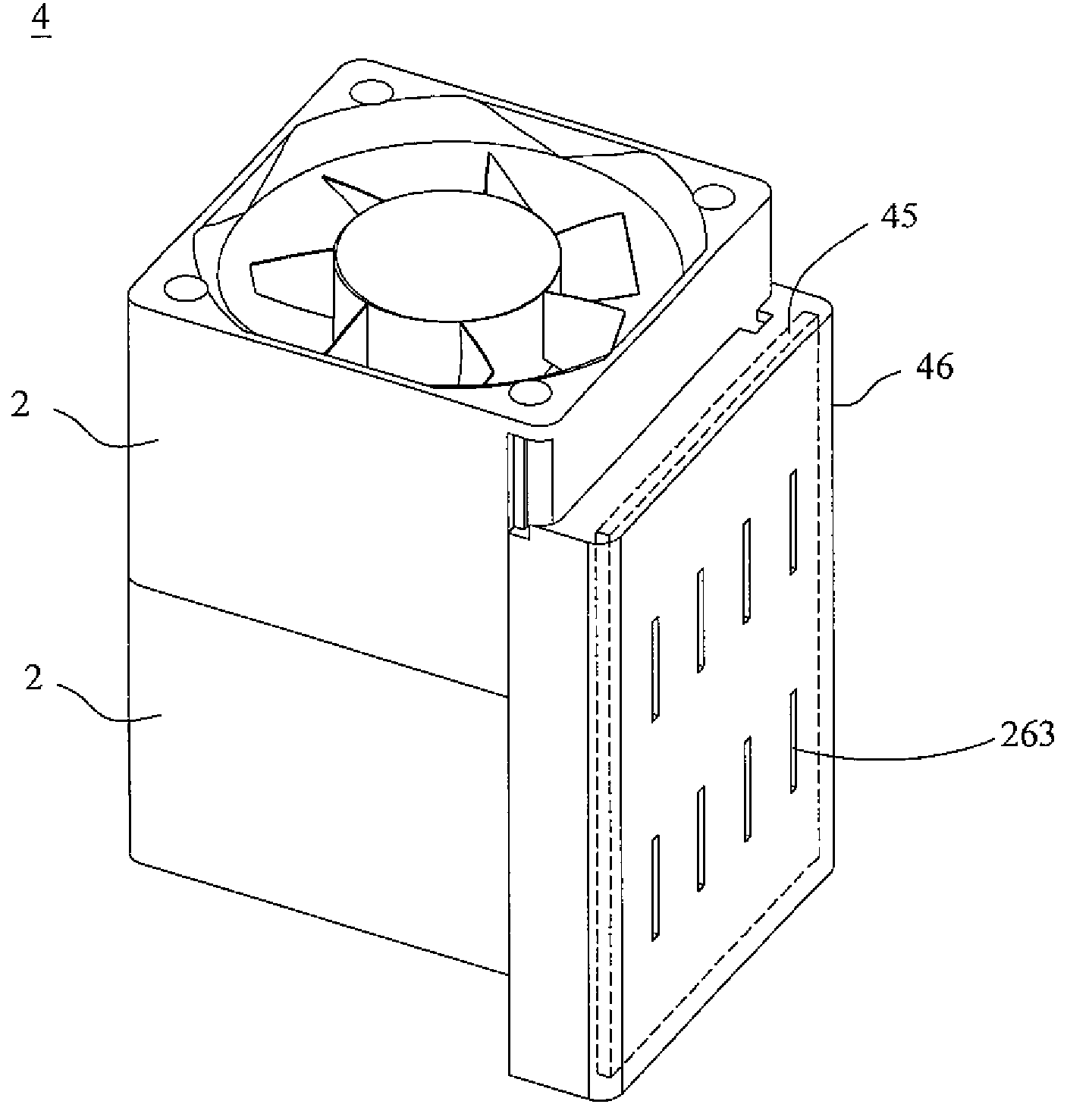

Fan, motor and impeller thereof

ActiveUS20070205676A1Easy to operateHeat dissipationMagnetic circuit rotating partsPump componentsImpellerEngineering

An impeller, which is driven by a stator, includes a conducting shell, a hub and a plurality of blades. The conducting shell covers at least one side of the stator. The hub covers the conducting shell. At least one air gap is formed between the hub and the stator. A top portion of the hub has an opening to partially expose a top portion of the conducting shell. At least one airflow passage is formed between an inner wall of the hub and an outer surface of the conducting shell. The airflow passage has at least one inlet connected with the opening and at least one outlet connected with the air gap. The blades are disposed around the circumferences of the hub.

Owner:DELTA ELECTRONICS INC

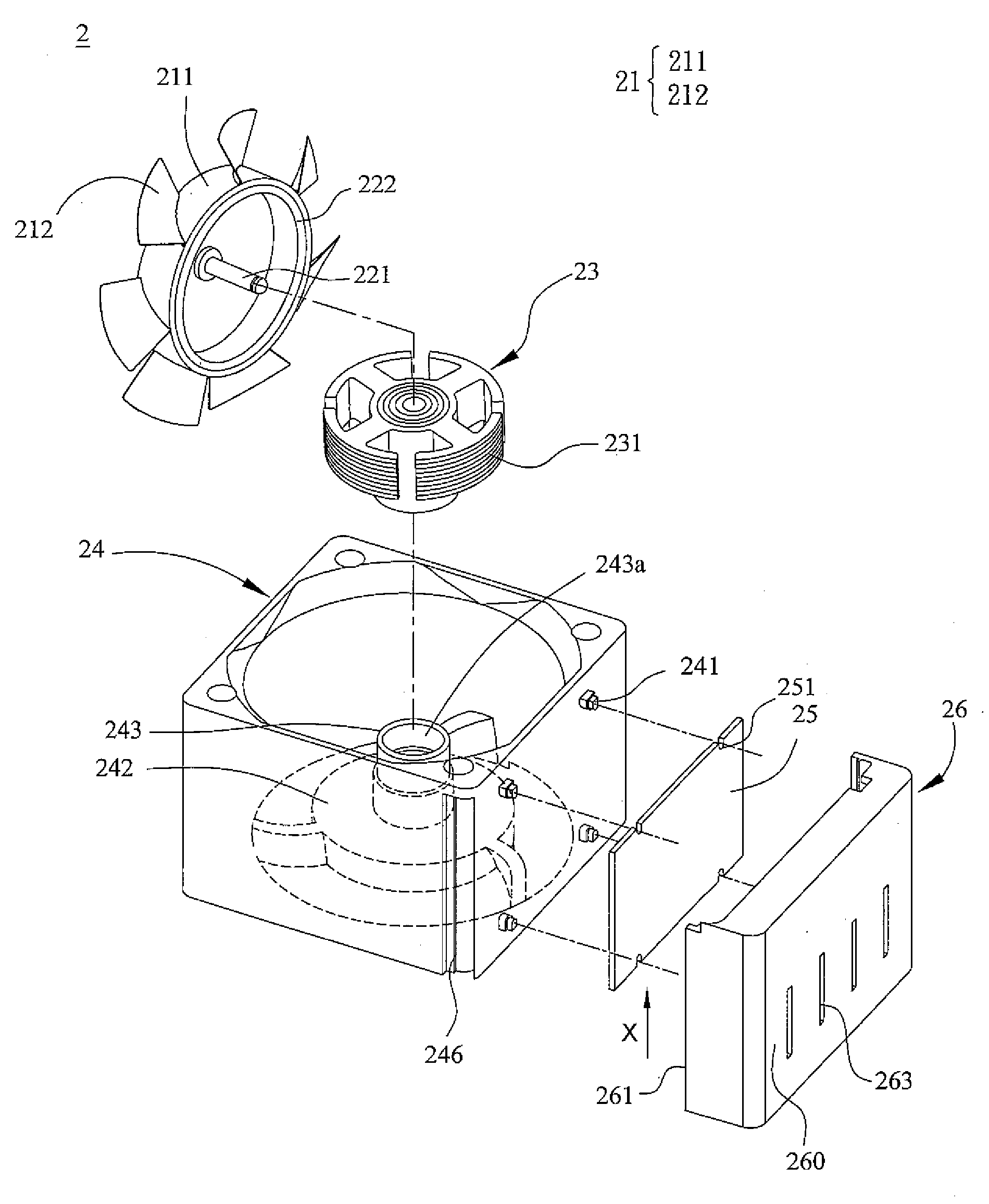

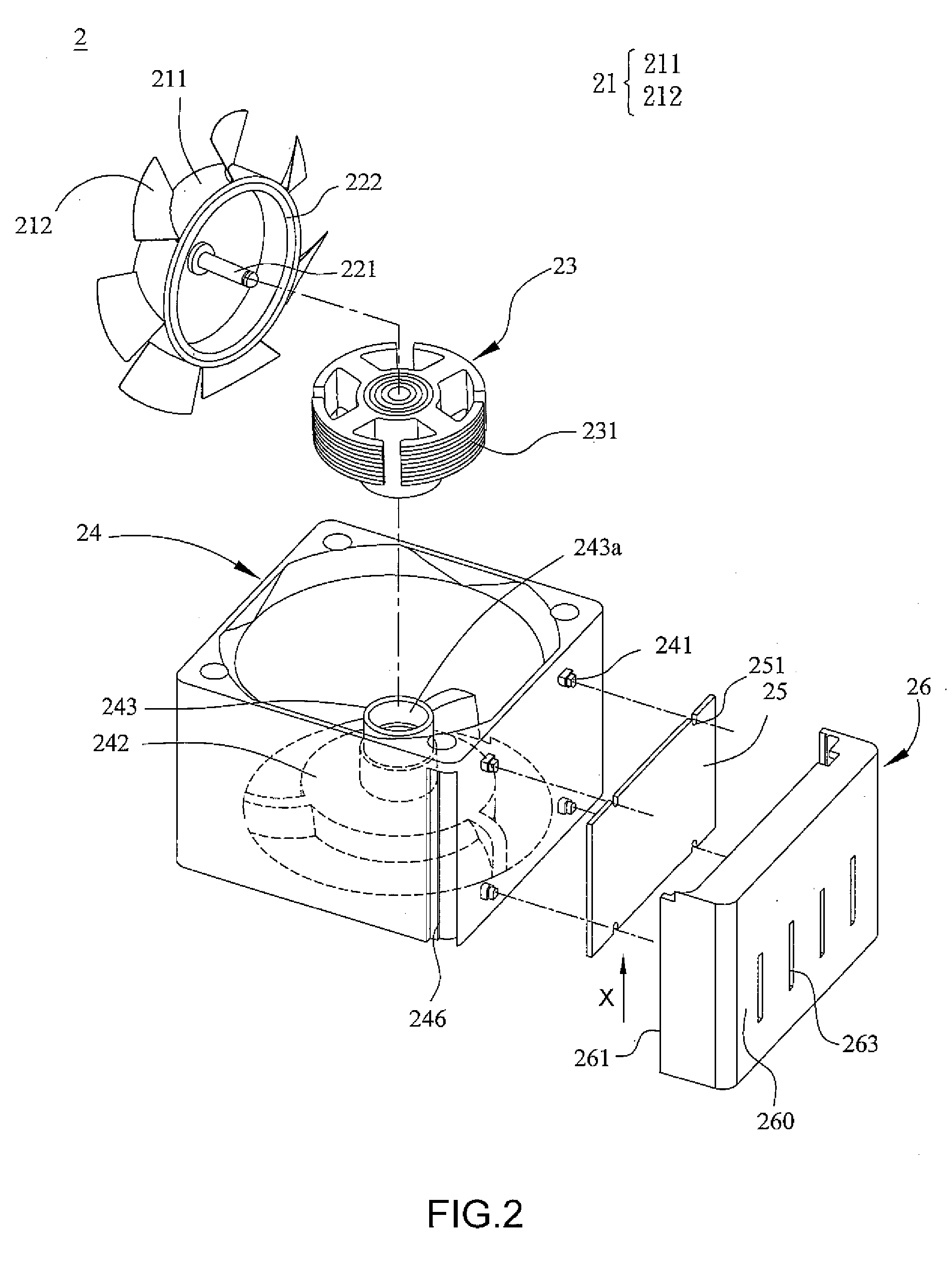

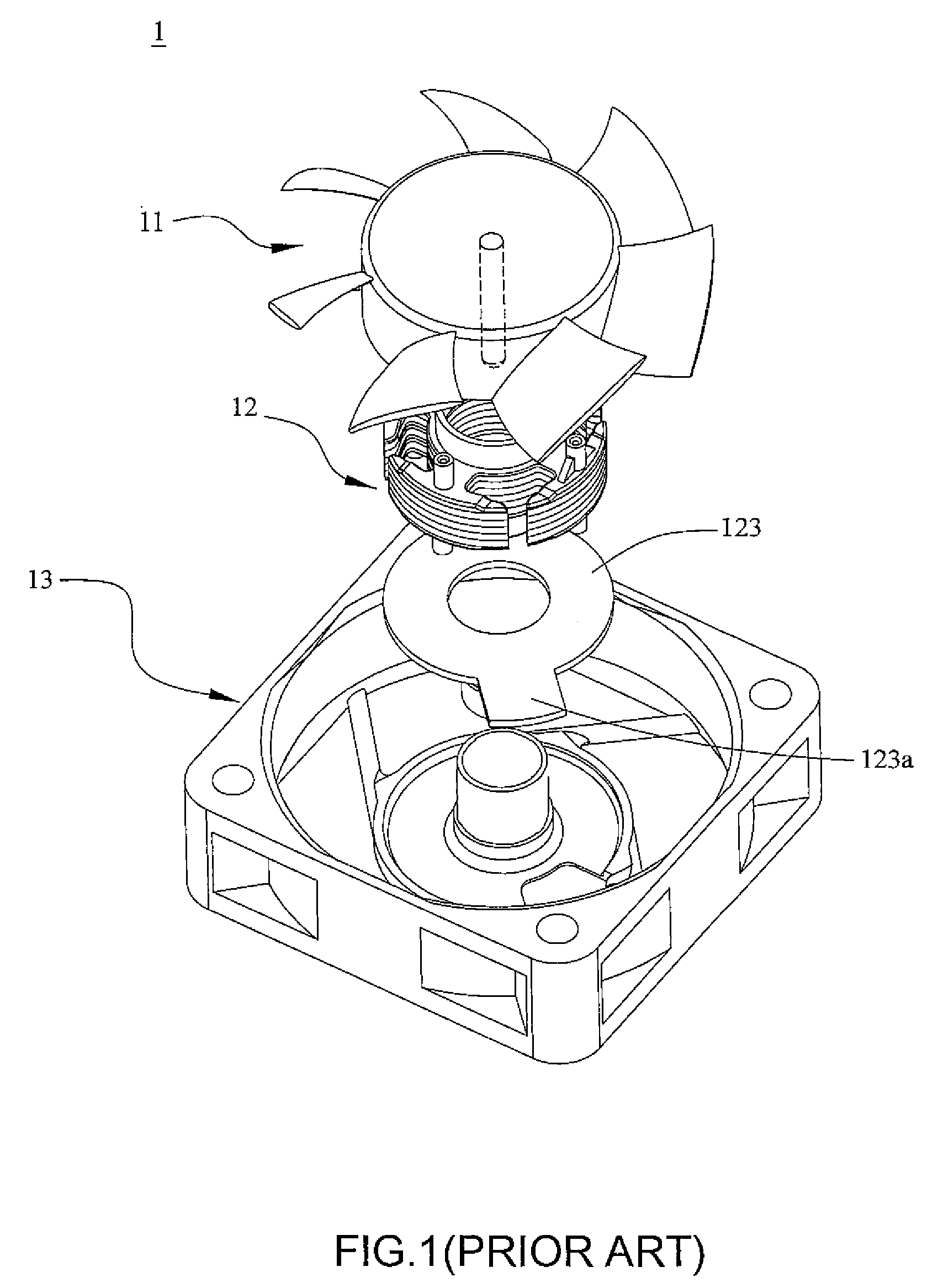

Fan and fan assembly

ActiveUS20080279694A1Improve fan efficiencyImproved circuit arrangementPump componentsRotary propellersImpellerControl theory

A fan includes an impeller, a motor, a circuit board, a fan frame and a connecting member. The motor is used to drive the impeller to rotate. The circuit board is electrically connected to the motor. The impeller and the motor are accommodated in the fan frame. The connecting member is disposed at one side of the fan frame. The circuit board is disposed between the connecting member and the fan frame. Also, a fan assembly including such two fans is also disclosed.

Owner:DELTA ELECTRONICS INC

Centrifugal fan with turbulence inducing inlet bell

ActiveUS7758305B2Improve output efficiencyReduce noiseEngine manufacturePump componentsImpellerEngineering

A centrifugal fan has an inlet bell that induces turbulence in the intake air stream so as to better distribute air across the rotating radial fan blades and thereby increase fan efficiency. The “turbulator” feature is one or more preferably arcuate surfaces integrally formed in the inlet bell to either project into or away from the intake air stream. The turbulator disrupts smooth air flow across the inside surface of the inlet bell has the effect of randomizing the air at the boundary layer to reduce separation of the air from the inlet bell as it leaves the inlet bell and enters the impeller. The air can thus follow the contour of the inlet bell more closely to make a tighter radius turn as it enters the impeller. In so doing, air is delivered across more of the fan blades so that output air flow is increased.

Owner:GREENHECK FAN

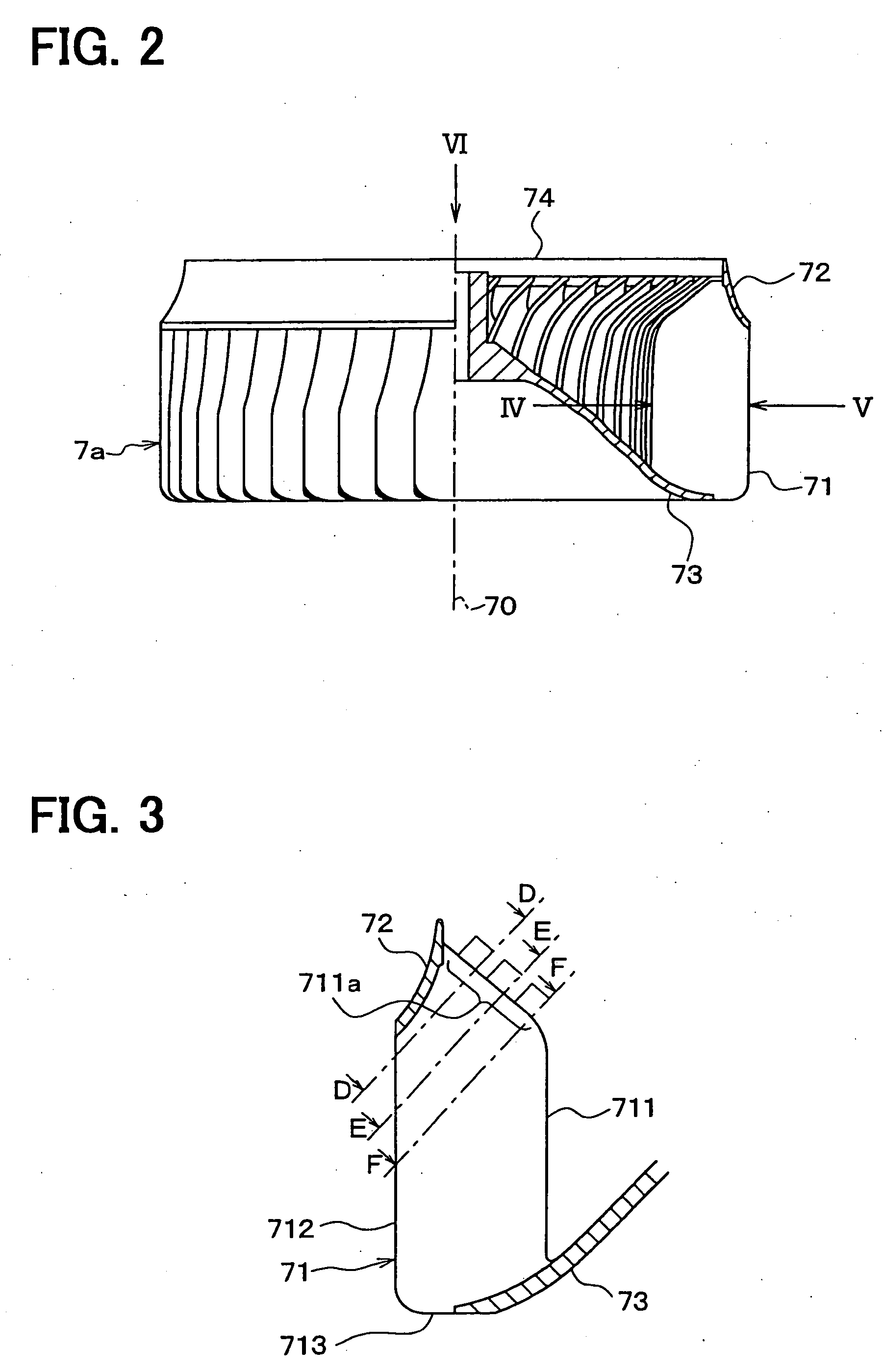

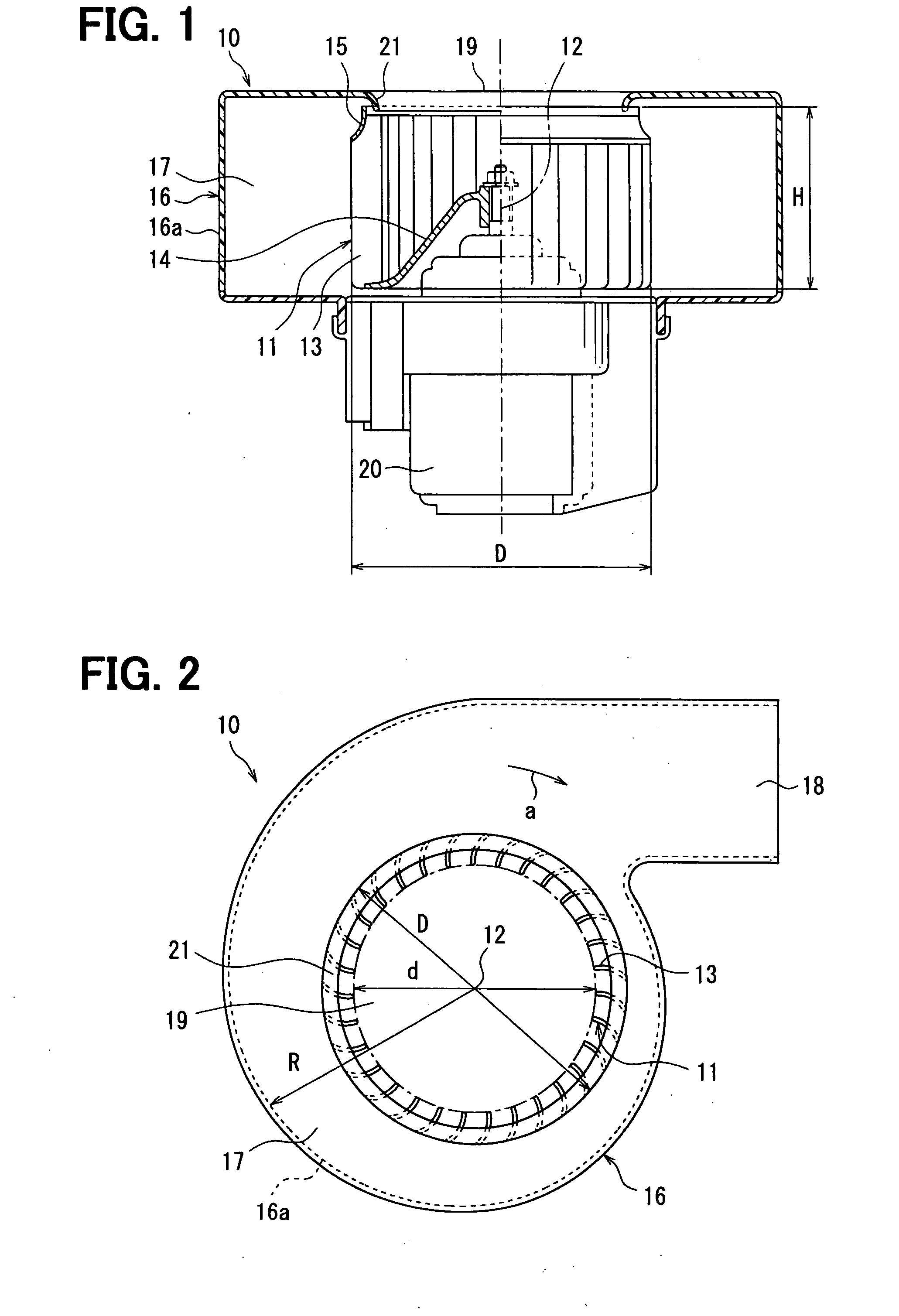

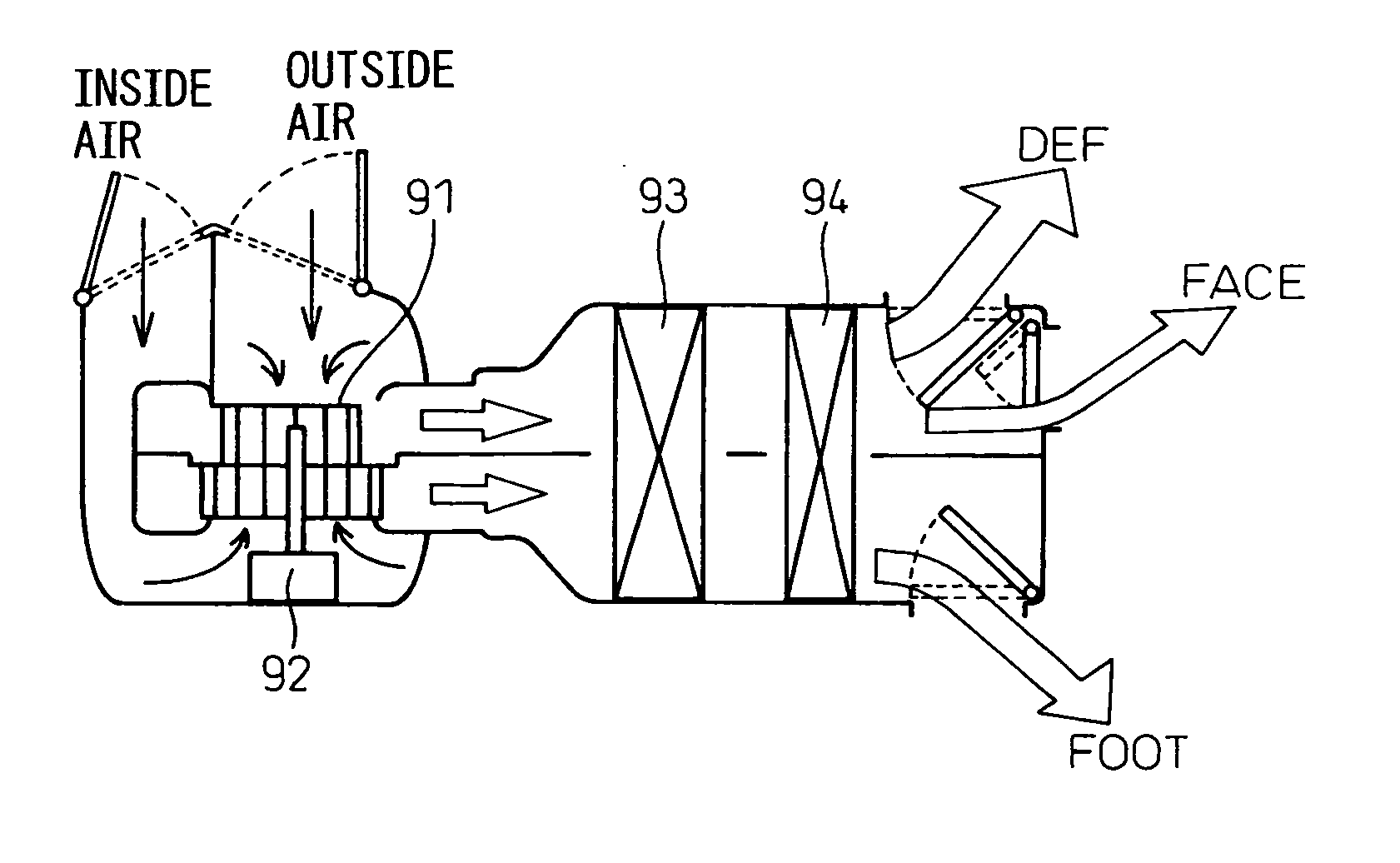

Multi-blade centrifugal blower

InactiveUS20060140758A1Improve work performanceImprove work efficiencyPropellersRotary propellersImpellerEngineering

Each of blades of a multi-blade centrifugal blower is provided with a taper portion, which is arranged at an inside periphery at least at the side of one rotation-shaft-direction end of the blade and tapers from the side of other rotation-shaft-direction end of the blade toward the side of the one rotation-shaft-direction end. The taper portion is positioned at a rotation-direction front side with respect to a back portion disposed at the side of the other rotation-shaft-direction end of the blade. Each of inlet angles throughout the taper portion is set in a range from 55° to 74°. Therefore, air flowing speed at an outlet of an impeller wheel is uniformed throughout the blade width. Work capacity and efficiency of the impeller wheel are increased, while noise is reduced.

Owner:DENSO CORP +1

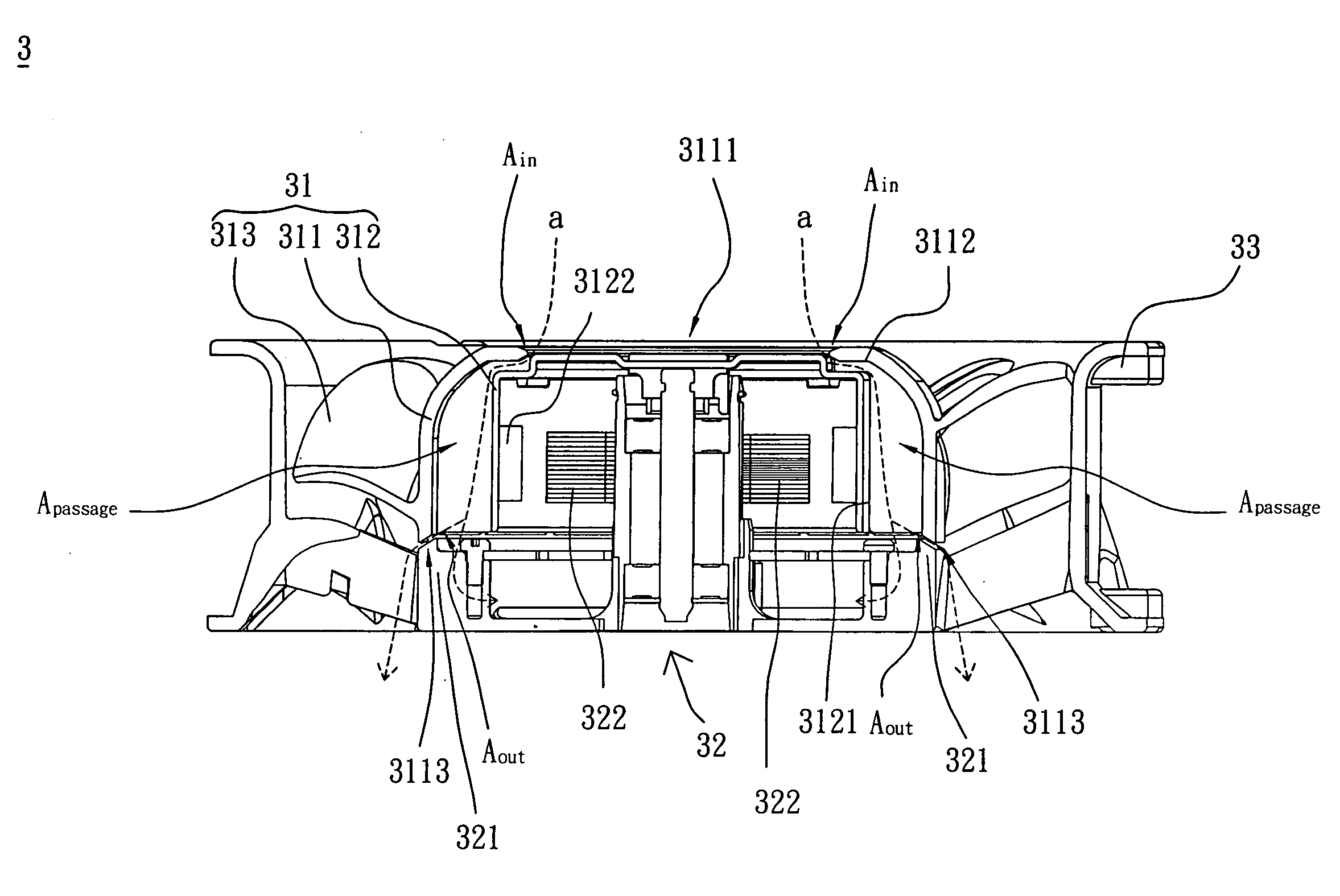

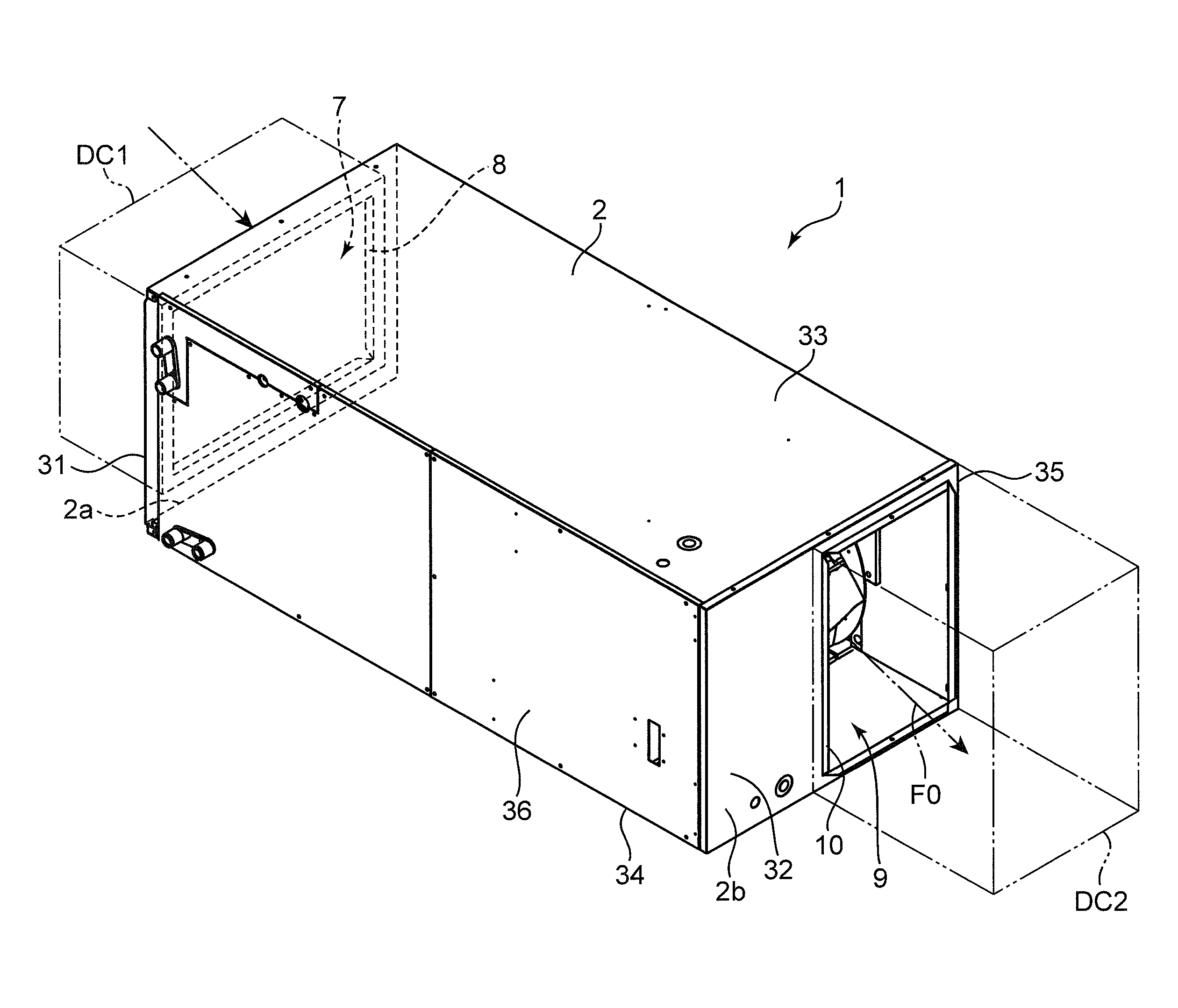

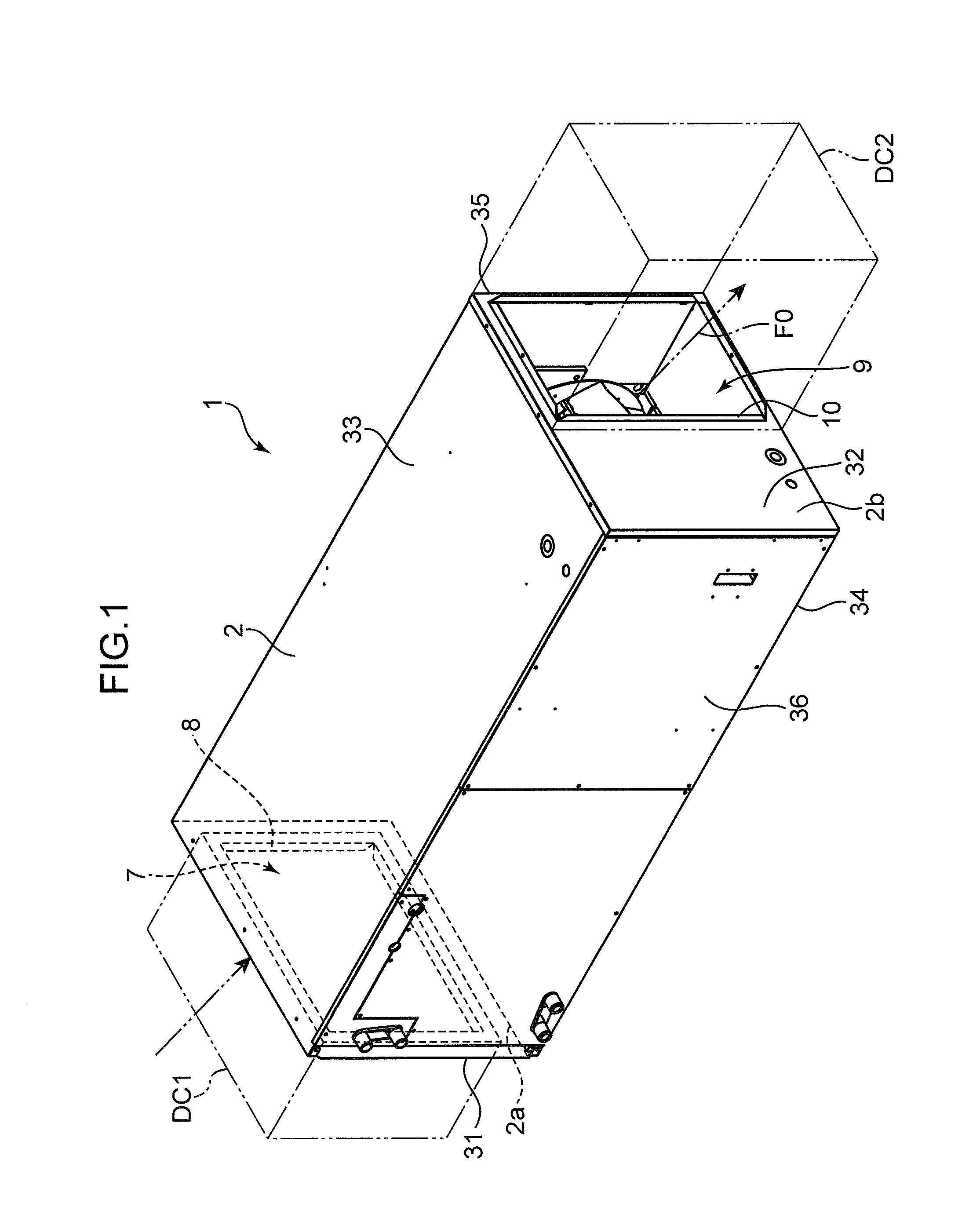

Duct-type indoor unit of air conditioner

ActiveUS20150068711A1Reduce in quantityImprove fan efficiencyHeating and ventilation casings/coversSemiconductor/solid-state device detailsImpellerEngineering

The duct-type indoor unit of an air conditioner includes: a casing including a first surface and a second surface opposing each other, an inlet duct connection part which is formed in the first surface and to which an inlet duct is connected, and an outlet duct connection part which is formed in the second surface and to which an outlet duct is connected; a partition member partitioning interior of the casing into a first space on an inlet side and a second space on an outlet side, the partitioning member having an opening communicating the first space with the second space; a heat exchanger arranged inside the first space; and a centrifugal fan having an impeller with backward curved blades, the impeller being positioned inside the second space to suck in air in the first space through the opening. The impeller has a rotating shaft parallel to the first surface.

Owner:DAIKIN IND LTD

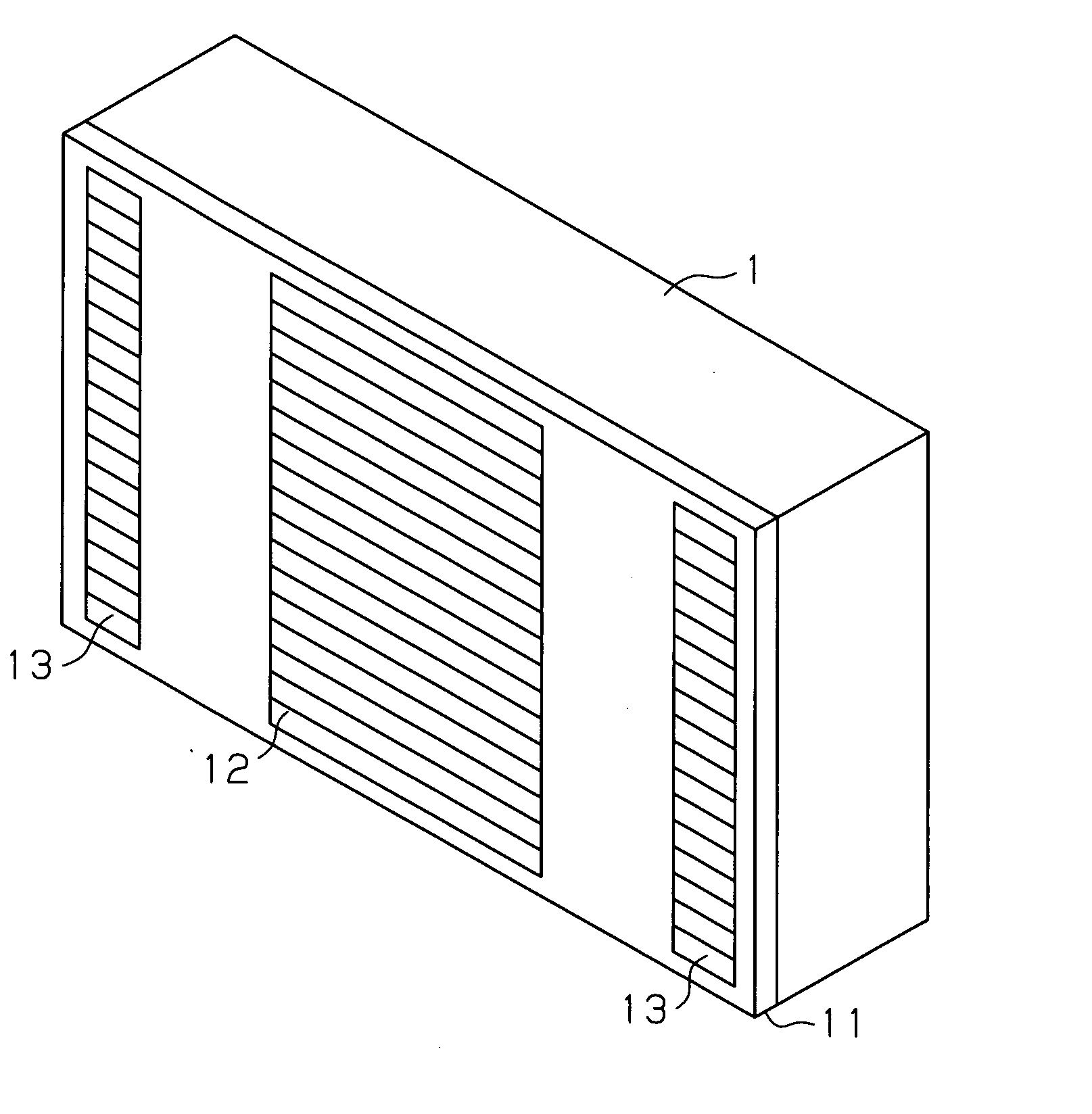

Sintering machine trolley bottom two-side sealing structure

ActiveCN104457257AReduce power consumptionReduce solid fuel consumptionEngine sealsFurnace typesMaterials scienceLeakage rate

The invention relates to the field of sintering machine flexible liquid sealing devices, in particular to a sintering machine trolley bottom two-side sealing structure. The sintering machine trolley bottom two-side sealing structure effectively achieves sealing of a sintering system through water seal formation. The sintering machine trolley bottom two-side sealing structure comprises a trolley and a sintering machine air box arranged below the trolley. Trolley wheels are arranged at the bottoms of the two sides of the trolley. The trolley wheels are arranged on trolley tracks in a slidable mode. The sintering machine trolley bottom two-side sealing structure further comprises sealing plates and sealing water tanks, wherein the sealing plates are fixedly arranged on the two sides of the bottom of the trolley in pairs and extend downwards in the vertical direction, and the sealing water tanks are arranged below the corresponding sealing plates. The sealing plates are inserted into the sealing water tanks through walking grooves in the upper portions of the sealing water tanks, and therefore the sintering machine air box is sealed. Due to the fact that the sealing plates are inserted into the sealing water tanks through the walking grooves in the upper portions of the sealing water tanks, the sintering machine air box is sealed relative to the exterior, the air leakage rate is lowered, and the sintering machine trolley bottom two-side sealing structure is particularly applicable to a sintering machine with the higher sealing requirement.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

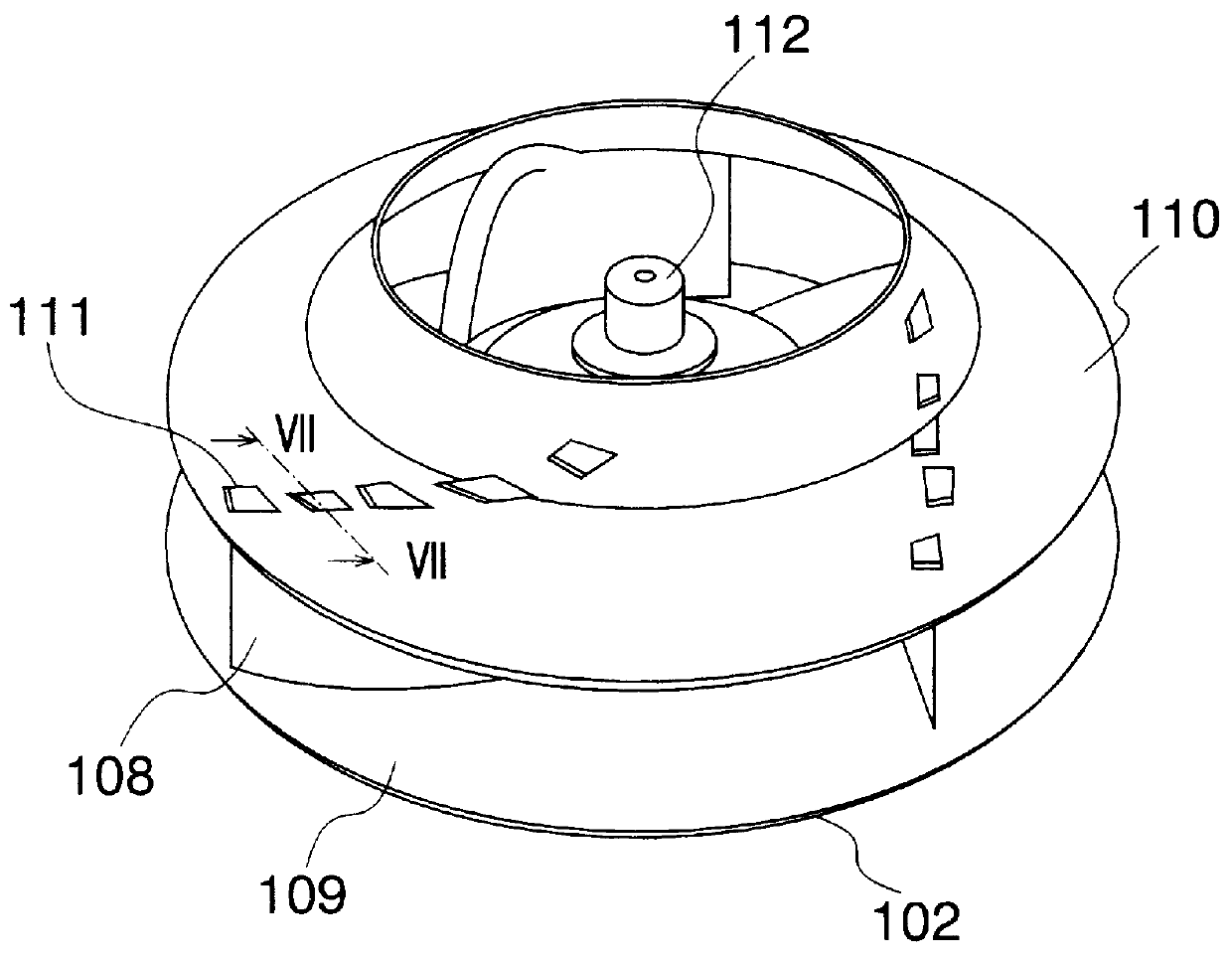

Centrifugal Fan and Air Conditioner Using the Same

InactiveUS20090255654A1Reduce running noiseUniform velocity distributionPropellersPump componentsImpellerAir velocity

The present invention provides a centrifugal fan by which air velocity distribution in the height direction of impellers at a fan blow-out port is made uniform and running noise is reduced, and an air conditioner whose running noise is reduced by applying the centrifugal fan thereto. The centrifugal fan is provided with a hub for fixing the rotary shaft of a motor, a main plate formed on the outer circumference of the hub, a shroud disposed to be opposed to the main plate, which forms an air passage, a plurality of impellers disposed between the main plate and the shroud, and a bellmouth disposed at the suction side of the shroud. Projections or recesses are formed on the surface of the shroud facing the bellmouth, which projections or recesses form air streams flowing from the center of the shroud toward the outer circumference thereof along the surface when running a fan. The air conditioner has a thus constructed centrifugal fan mounted therein.

Owner:DAIKIN IND LTD

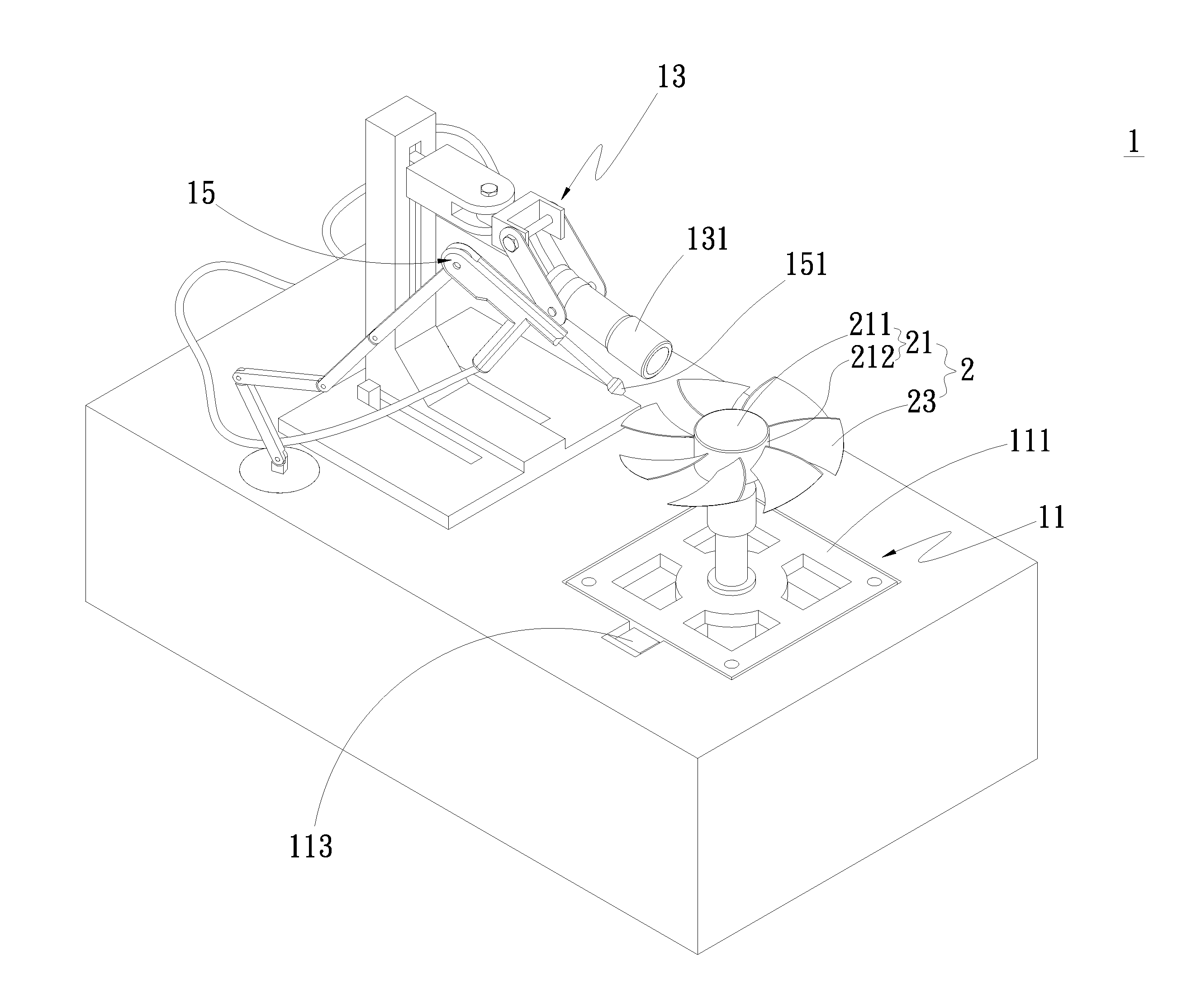

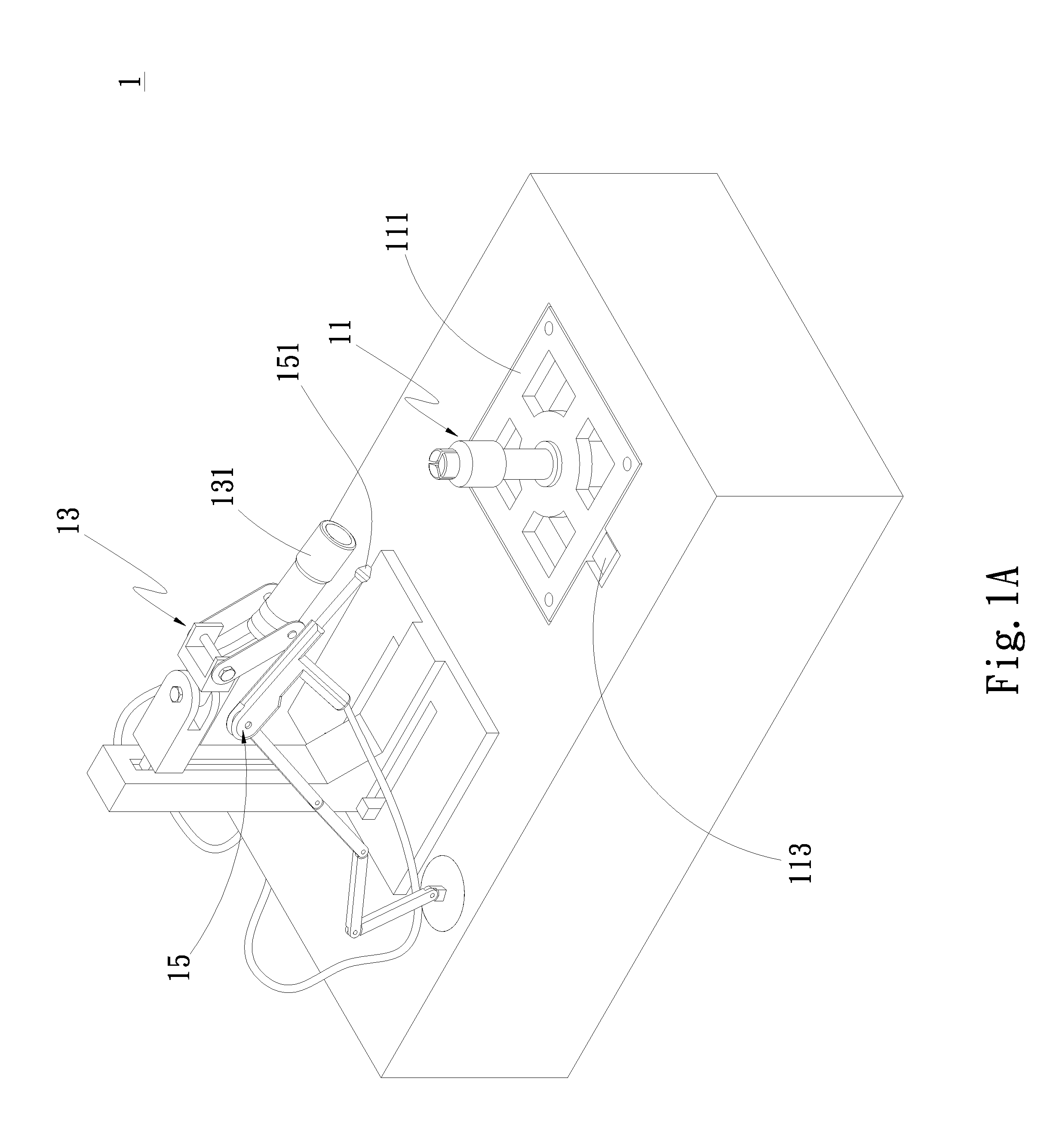

Rotor balance device for laser removal and method thereof

InactiveUS20130334184A1Improve degree of balanceWork hour be reducePump componentsStatic/dynamic balance measurementEngineeringLaser beams

The present invention provides a rotor balance device and a method thereof. The device includes a balance measurement unit and at least one laser unit. The balance measurement unit has a correcting platen for supporting the rotor and at least one sensor. The laser unit receives a sensing signal outputted by the sensor to identify at least one position to be removed on the rotor and controls a laser beam to illuminate the position to be removed. By the inventive device and method, an improved degree of balance and reduced working hours can be obtained.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Fan

ActiveUS20080112810A1Improve fan efficiencyPrevent thermal deformationPropellersPump componentsImpellerAirflow

Owner:NIDEC CORP

Fan, motor and impeller thereof

ActiveUS7701097B2Heat dissipationImprove fan efficiencyMagnetic circuit rotating partsPump componentsImpellerEngineering

An impeller, which is driven by a stator, includes a conducting shell, a hub and a plurality of blades. The conducting shell covers at least one side of the stator. The hub covers the conducting shell. At least one air gap is formed between the hub and the stator. A top portion of the hub has an opening to partially expose a top portion of the conducting shell. At least one airflow passage is formed between an inner wall of the hub and an outer surface of the conducting shell. The airflow passage has at least one inlet connected with the opening and at least one outlet connected with the air gap. The blades are disposed around the circumferences of the hub.

Owner:DELTA ELECTRONICS INC

Centrifugal multiblade fan

ActiveUS20070217908A1Increase distanceImprove efficiencyPropellersRotary propellersTrailing edgeLeading-edge slats

A centrifugal multiblade fan according to the present invention sucks air from one end side of an axial direction of a rotation axis to a radial inside, and blows the air to a radial outside. The centrifugal multiblade fan includes a plurality of blades located around the rotation axis. Each blade has a leading edge positioned at the radial inside, and a trailing edge positioned at a radial outside. The leading edge of each blade has an edge shape with a radius of curvature of 0.2 mm or less, for example.

Owner:DENSO CORP

Fan and fan assembly

ActiveUS7985056B2Improve fan efficiencyImproved circuit arrangementPump componentsPiston pumpsImpellerEngineering

A fan includes an impeller, a motor, a circuit board, a fan frame and a connecting member. The motor is used to drive the impeller to rotate. The circuit board is electrically connected to the motor. The impeller and the motor are accommodated in the fan frame. The connecting member is disposed at one side of the fan frame. The circuit board is disposed between the connecting member and the fan frame. Also, a fan assembly including such two fans is also disclosed.

Owner:DELTA ELECTRONICS INC

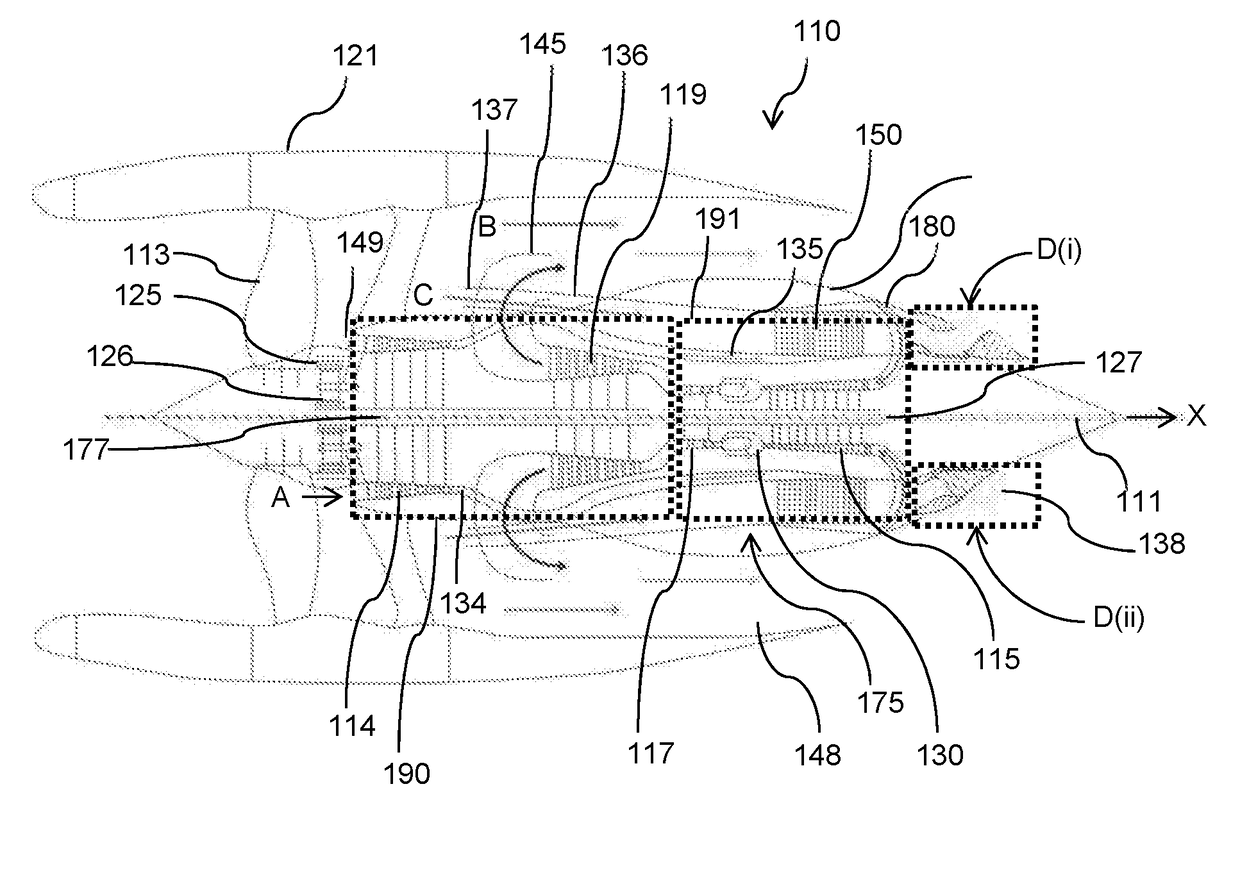

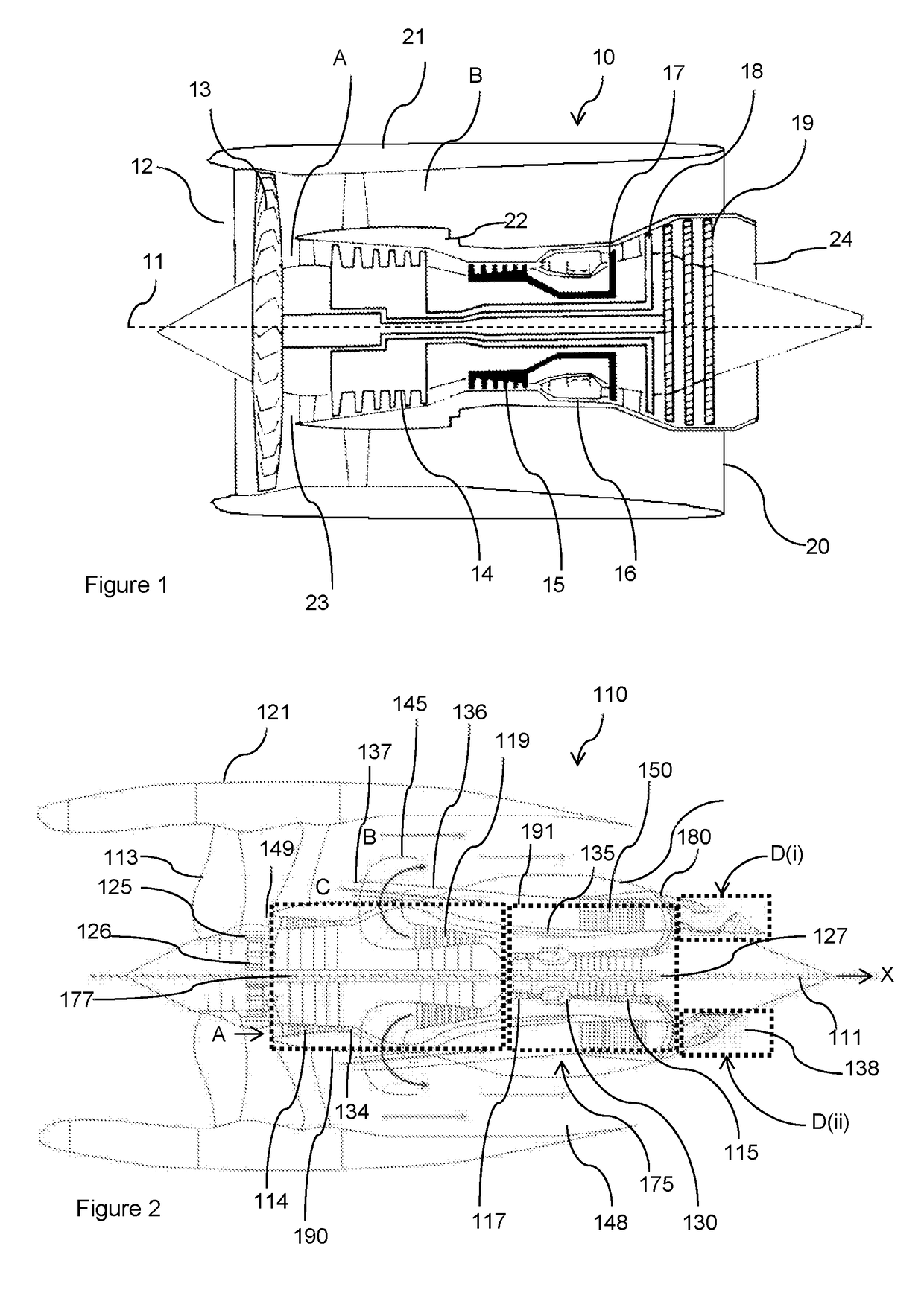

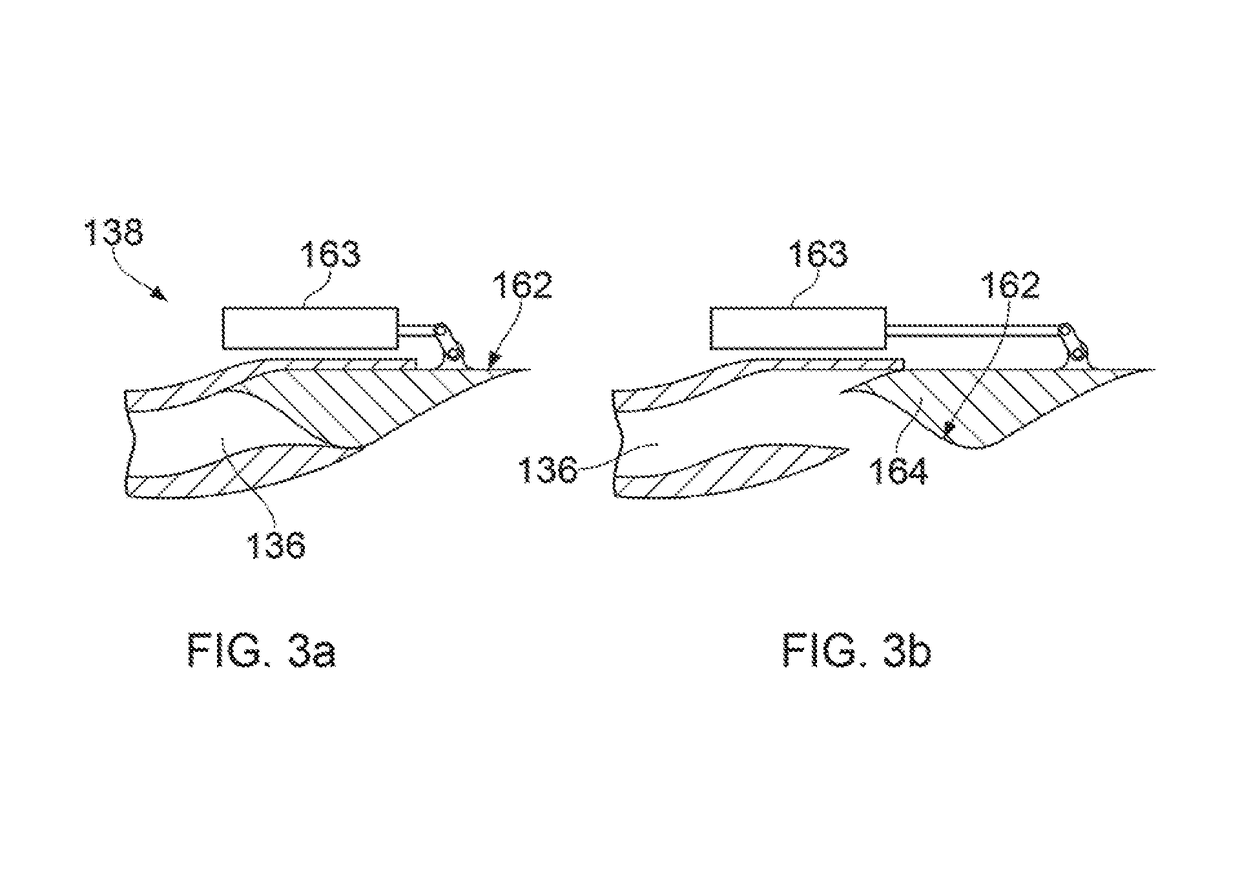

Gas turbine engine

InactiveUS20170370290A1Improve turbine efficiencyReduce in quantityTurbine/propulsion engine coolingEngine fuctionsIntercoolerTurbine

An aircraft gas turbine engine includes a fan arranged to be driven by a gas turbine engine core. The core includes a first core module including a first compressor and a fan drive turbine interconnected by a first shaft, and a second core module including a second compressor and a second turbine interconnected by a second shaft, the first and second core modules being axially spaced. The gas turbine engine further includes an intercooler arrangement configured to cool core airflow between the first and second compressors, the intercooler arrangement including a cooling air duct provided in heat exchange relationship with a compressor duct provided between the first and second compressors, the cooling air duct including a fan air inlet configured to ingest fan air downstream of the fan, wherein the cooling air duct includes a flow modulation valve configured to modulate air mass flow through the fan air inlet.

Owner:ROLLS ROYCE PLC

Fan for Air Conditioner

InactiveUS20080131274A1Drive stabilityReduce noiseWindingsPump componentsMechanical engineeringStator

Fan apparatus including a fan, a shaft coupled to the fan for transmission of driving force from a motor to the fan, a rotor bushing of an insulating material joined to a rear end portion of the shaft, a rotor joined to the rotor bushing for transmission of the driving force to the shaft through the rotor bushing, and a stator mounted so as to be positioned on an inside of the rotor to form a BLDC motor together with the rotor, thereby reducing noise and enhancing fan efficiency by employing the BLDG motor which can make stable operation of the fan and increase an air flow rate.

Owner:LG ELECTRONICS INC

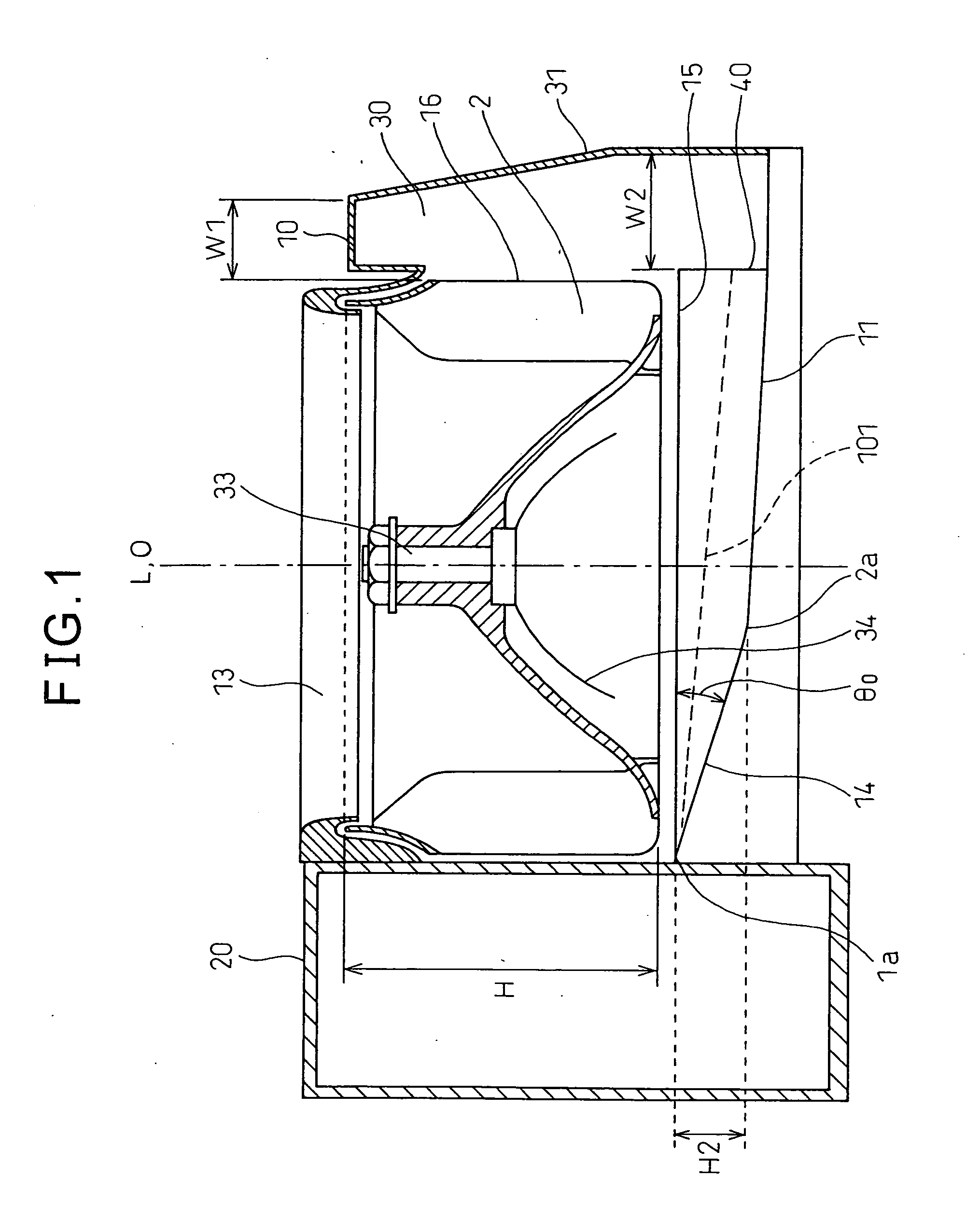

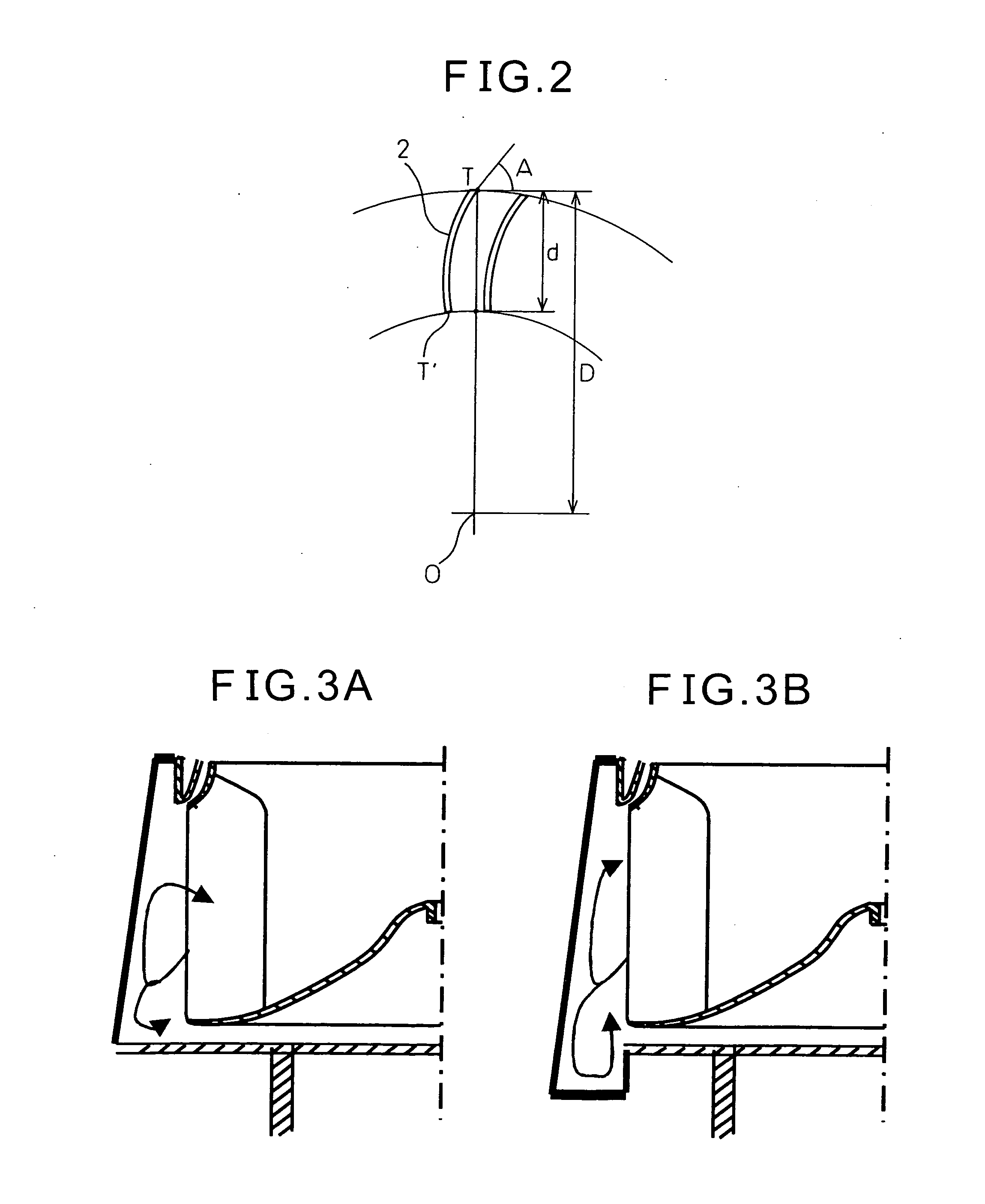

Centrifugal blower

ActiveUS20120057971A1Reduce noise levelEfficient reductionPump componentsStatorsSlant angleEngineering

A centrifugal blower provided with a spiral shaped scroll chamber where a bottom part of the scroll chamber gradually expands downward in the axial direction of the fan well along with expansion of the spiral and where a flow area gradually expands toward an air outlet from a spiral start part of the casing, the centrifugal blower having an initial slant angle θ0 at the spiral start part of the bottom part of the scroll chamber of a range of angle of 5.2° to 27.5° or setting a backflow prevention rib at the fan outlet.

Owner:NIPPON SOKEN +1

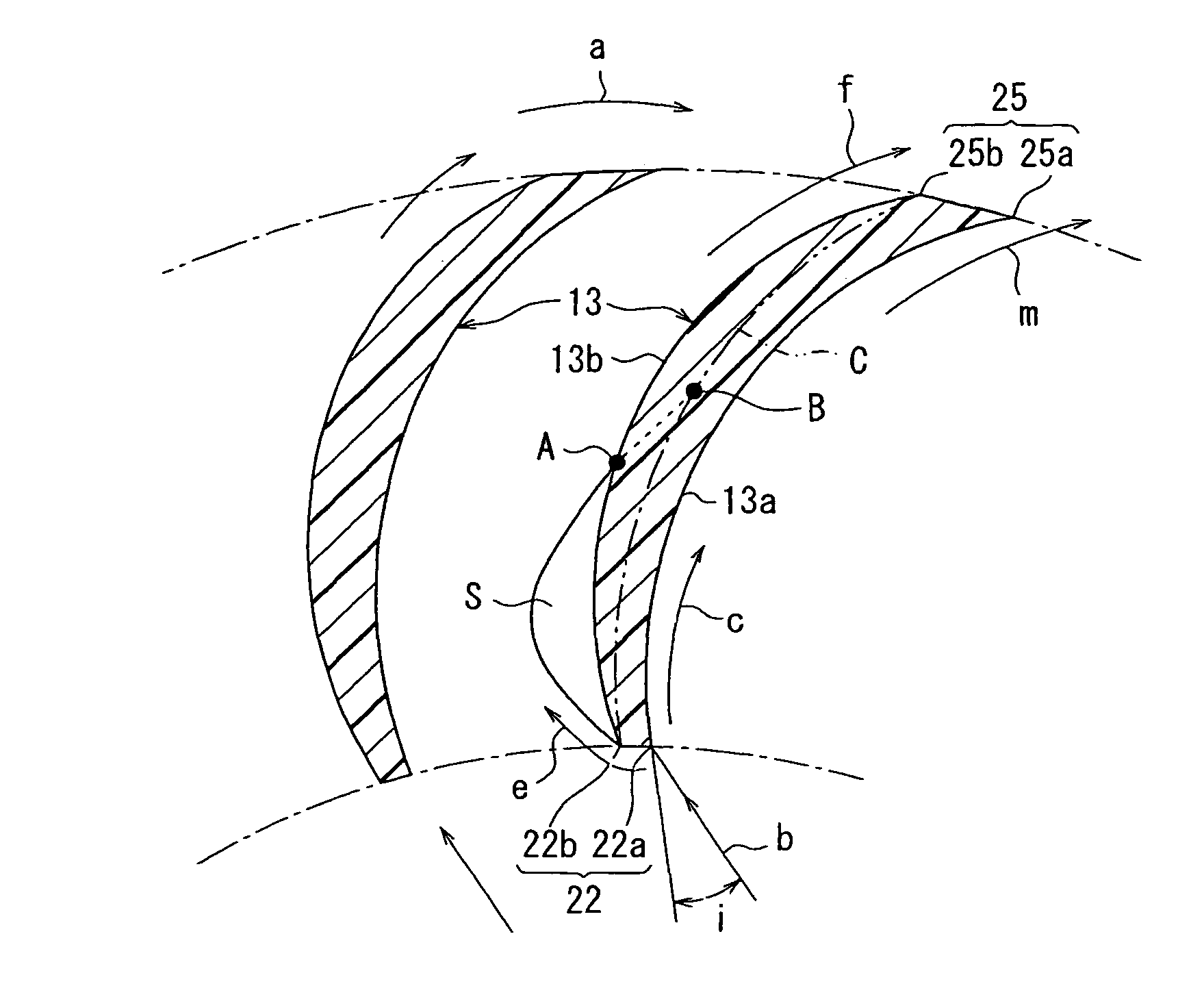

Centrifugal multiblade fan

ActiveUS8011891B2Improve fan efficiencyReduce noisePropellersPump componentsLeading edgeTrailing edge

A centrifugal multiblade fan according to the present invention sucks air from one end side of an axial direction of a rotation axis to a radial inside, and blows the air to a radial outside. The centrifugal multiblade fan includes a plurality of blades located around the rotation axis. Each blade has a leading edge positioned at the radial inside, and a trailing edge positioned at a radial outside. The leading edge of each blade has an edge shape with a radius of curvature of 0.2 mm or less, for example.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com