Integrative cooling system of hybrid power excavating machine

A technology of hybrid power and cooling system, which is applied in the direction of engine cooling, engine components, combustion engine, etc. It can solve the problems of poor sealing of radiators and air leakage, and achieve the effect of simple cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

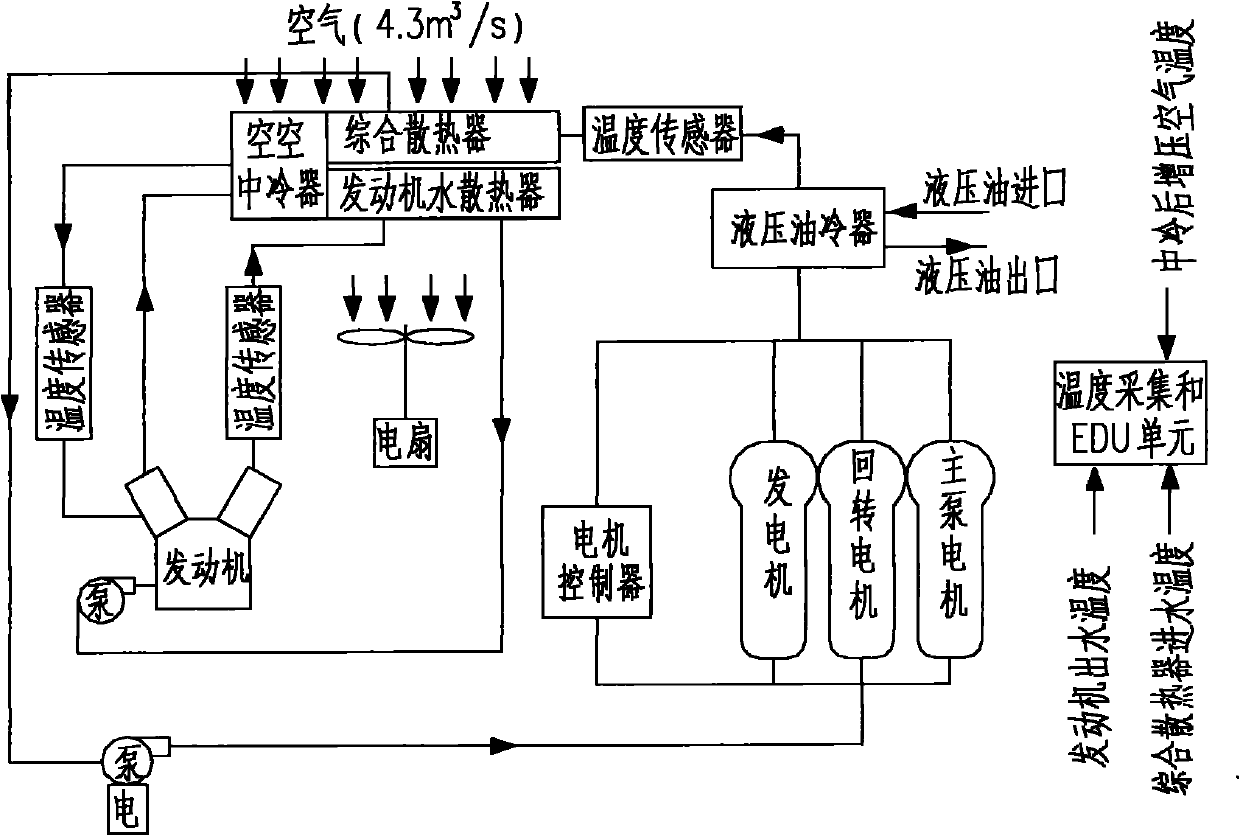

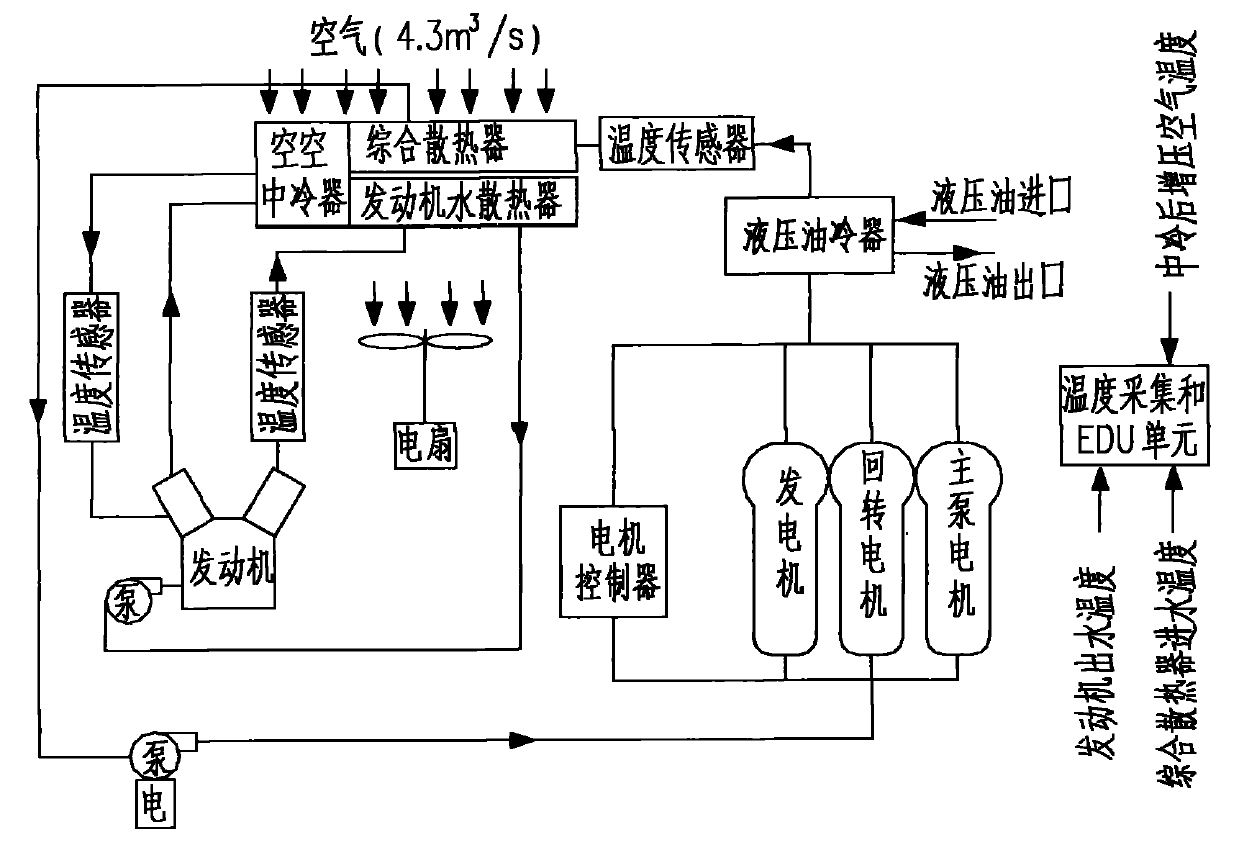

[0008] see figure 1 , The engine water radiator, integrated radiator, and air-to-air intercooler are each an independent circulation loop. The overall dimensions of the radiator and the size of the fan are determined by performing thermal balance calculation, wind resistance calculation, air volume calculation and the optimal design inside the radiator. The engine water radiator is connected with the engine's own water pump through the pipeline, and then the heat generated by the engine is taken away by the cooling fan to form a high-temperature circulation loop; the heat generated by the hydraulic oil is exchanged between the oil and water of the hydraulic oil cooler Transfer the heat to the integrated radiator, connect the hydraulic oil cooler, motor controller, generator, rotary motor, main pump motor, electric water pump, etc. It is taken away by the cooling fan to form a low-temperature circulation loop; the hot air after the engine is supercharged is sent to the air-to-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com