Sintering machine trolley bottom two-side sealing structure

A technology of sealing structure and trolley, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of high air leakage rate, increased air leakage rate, failure, etc., to improve the effective air volume and fan efficiency, increase production The effect of energy saving, cost reduction and solid fuel consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

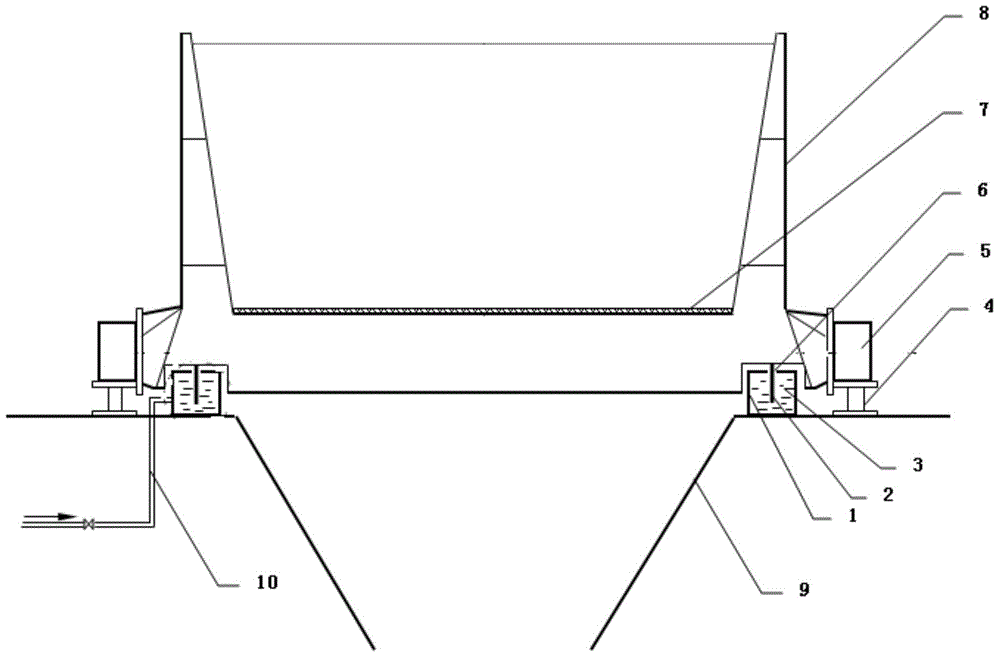

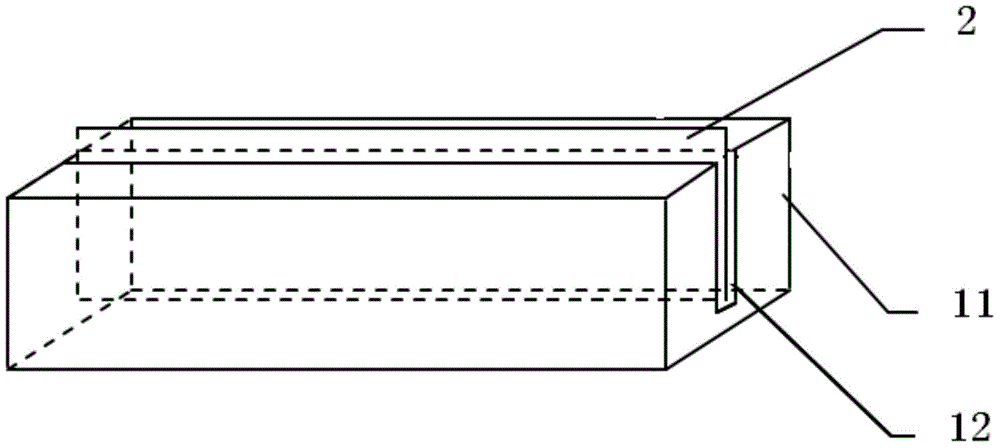

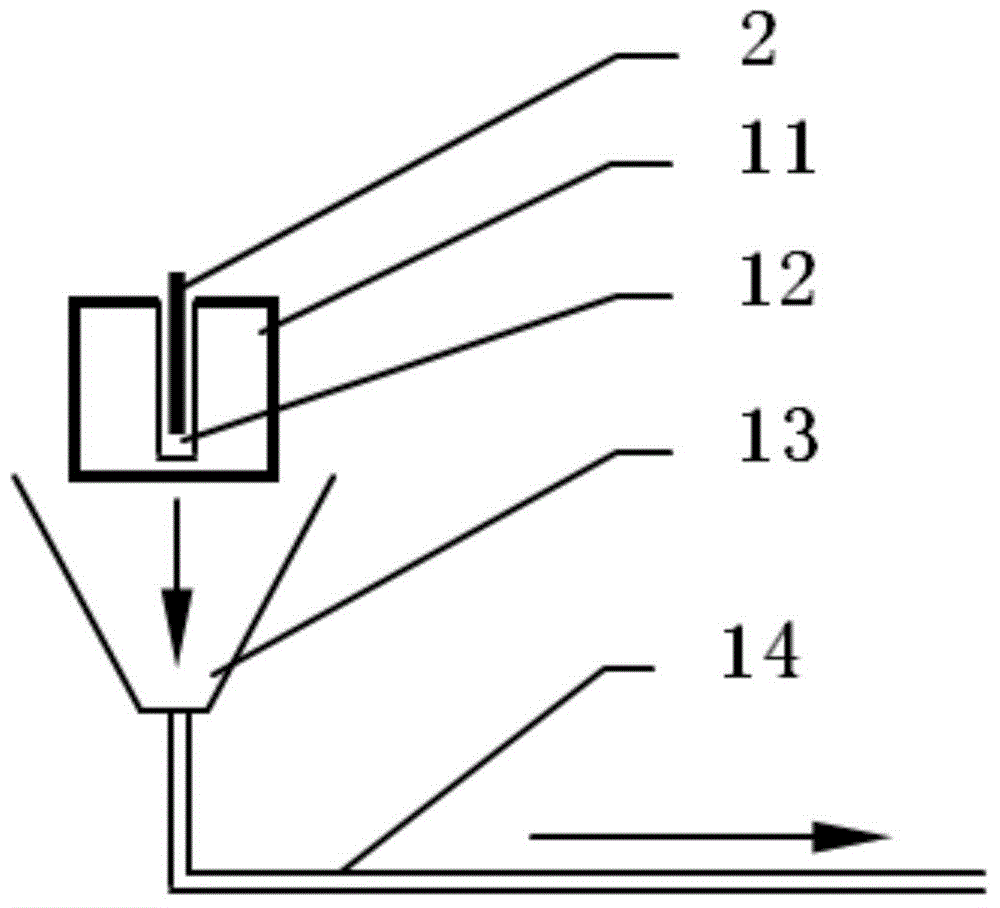

[0018] Such as figure 1 , figure 2 , image 3 The shown sealing structure on both sides of the bottom of the sintering machine trolley includes a trolley 8 and a sintering machine bellows 9 arranged under the trolley 8. The bottom of the trolley 8 on both sides is provided with a trolley wheel 5, and the trolley wheel 5 It can be slidably arranged on the trolley track 4, and also includes a pair of sealing plates 2 fixedly arranged on both sides of the bottom of the trolley 8 and extending downward in the vertical direction and a sealing water tank 1 arranged below the corresponding sealing plate 2. The sealing plate 2 is inserted into the sealing water tank 1 through the upper groove 6 of the sealing water tank to seal the bellows 9 of the sintering machine.

[0019] In view of the high air leakage rate of iron ore sintering in my country, part of the total air vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com