Patents

Literature

183results about How to "Uniform velocity distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

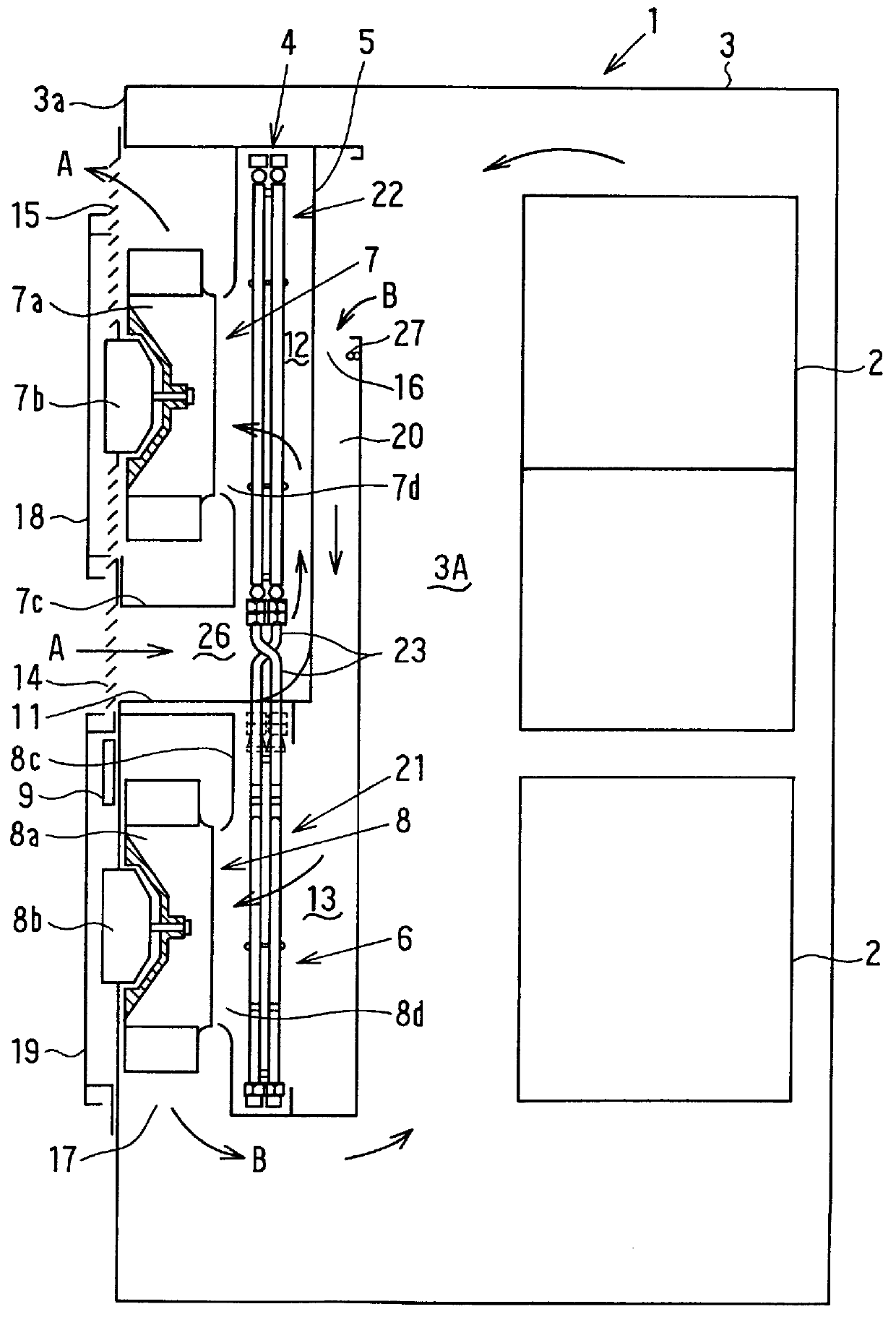

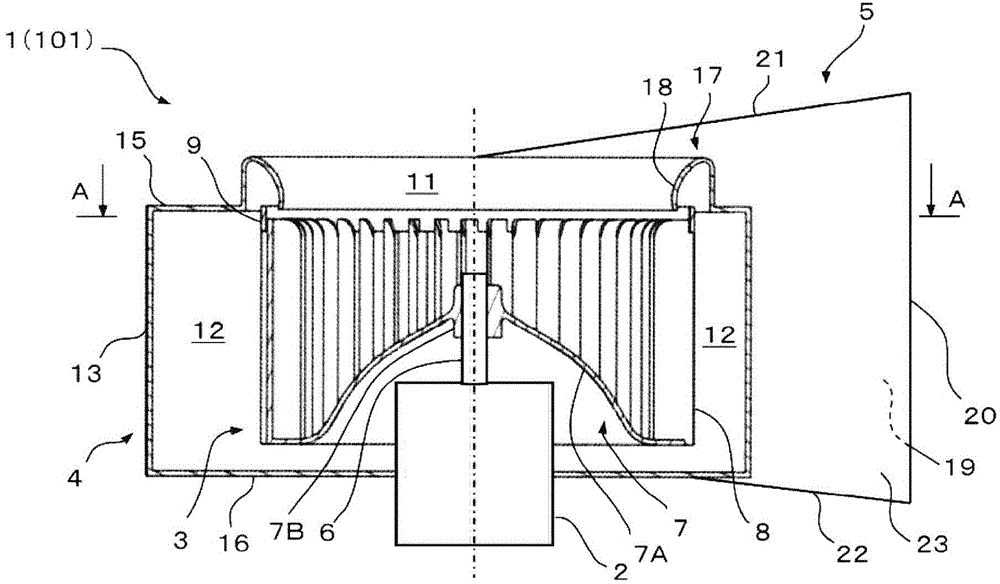

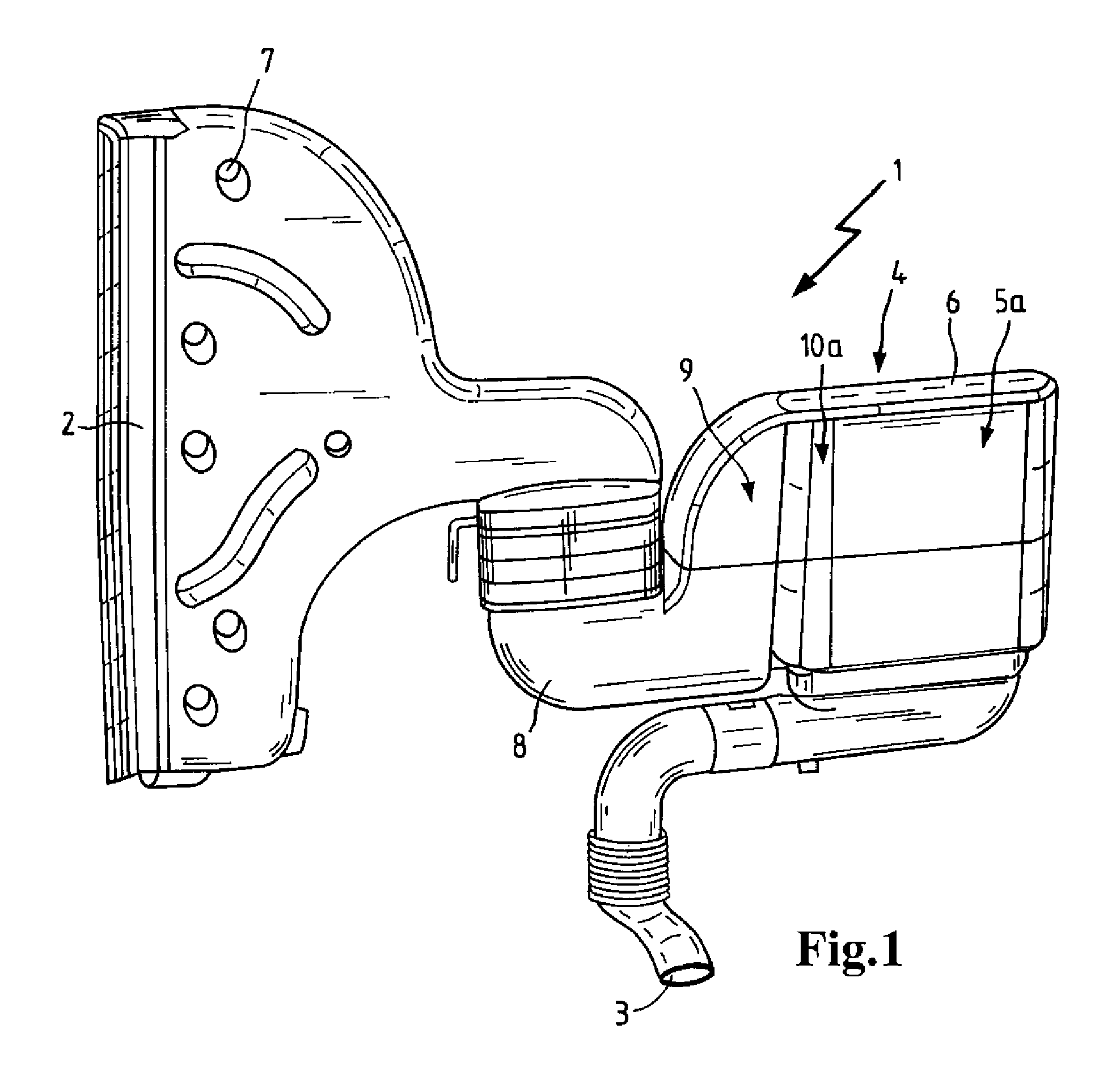

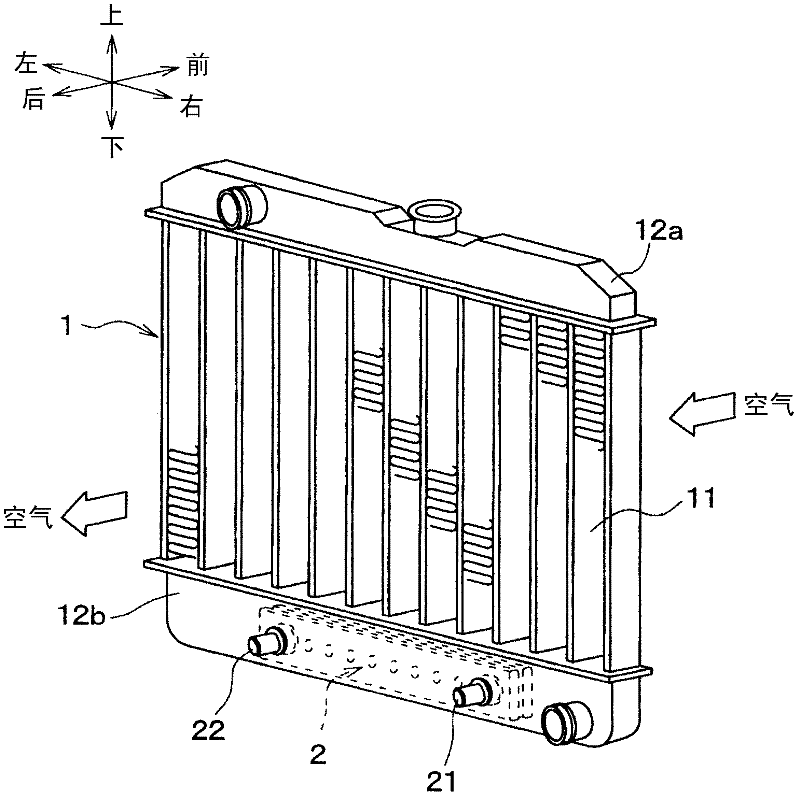

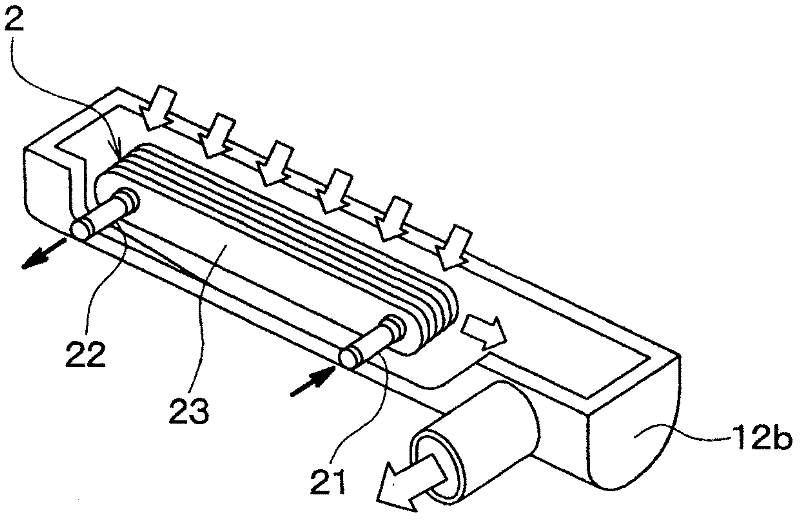

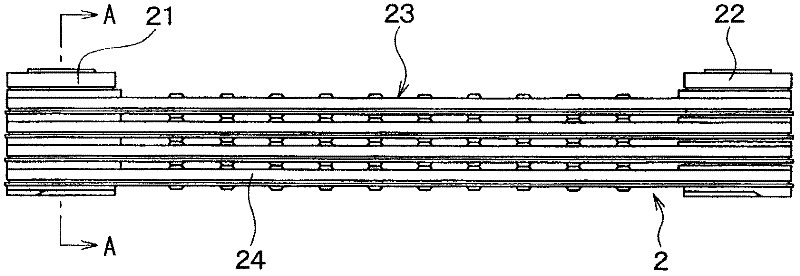

Cooling device boiling and condensing refrigerant

A cooling device includes: a partition plate for partitioning an interior of a case into a first fluid passage through which first fluid having a high temperature flows and a second fluid passage through which second fluid having a low temperature flows; a heat receiving portion disposed in the first fluid passage; a heat radiating portion disposed in the second fluid passage; and a connection pipe for communicating the heat receiving portion and the heat radiating portion. The heat radiating portion is disposed at an upper side of the heat receiving portion in such a manner that the second fluid from a front side of the heat radiating portion flows into a rear side of the heat radiating portion through a pipe space between the heat radiating portion and the heat receiving portion, and further passes through the heat radiating portion from the rear side toward the front side of the heat radiating portion. Thus, the cooling device has a small size while improving the cooling capacity of the cooling device.

Owner:DENSO CORP

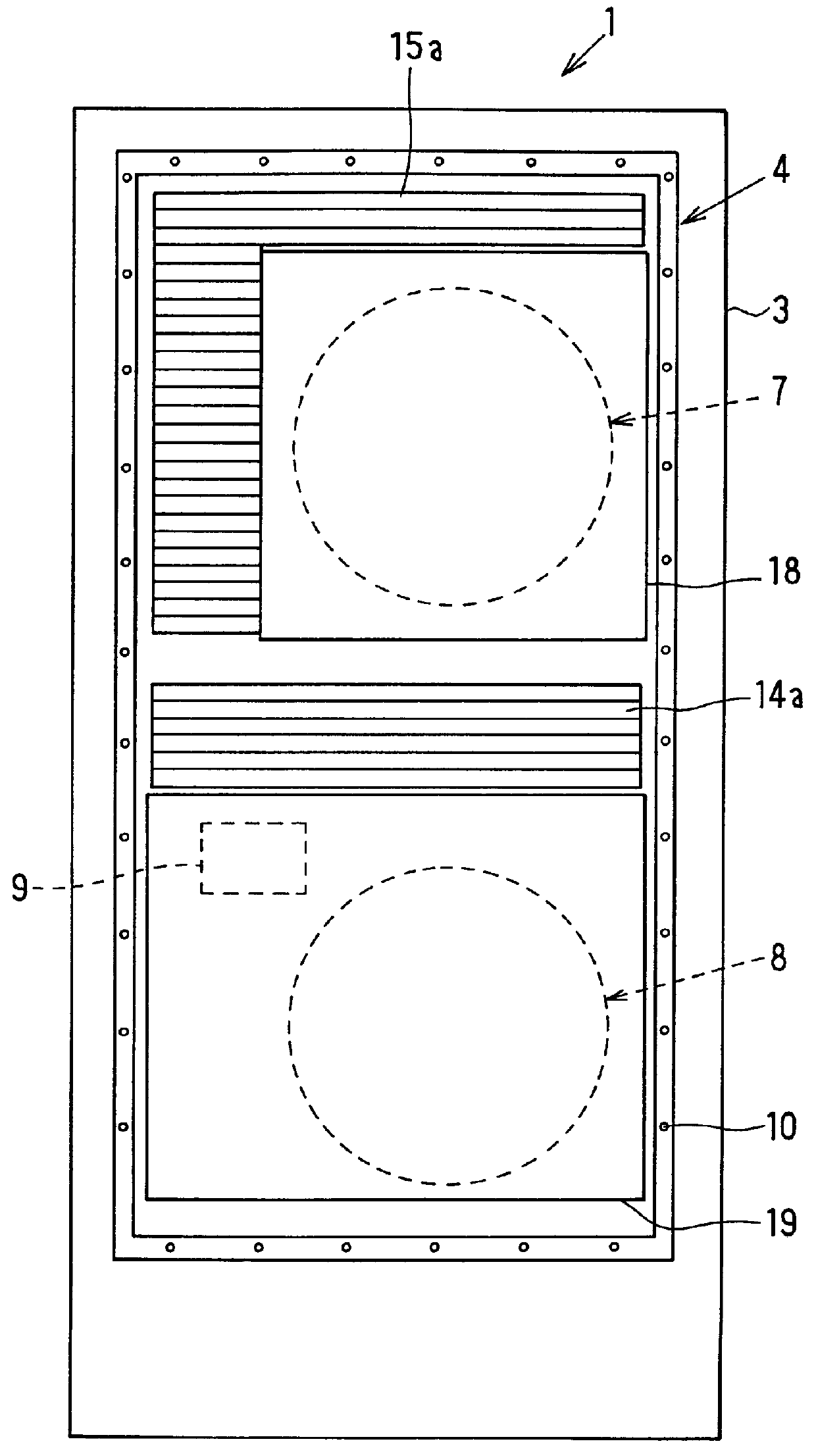

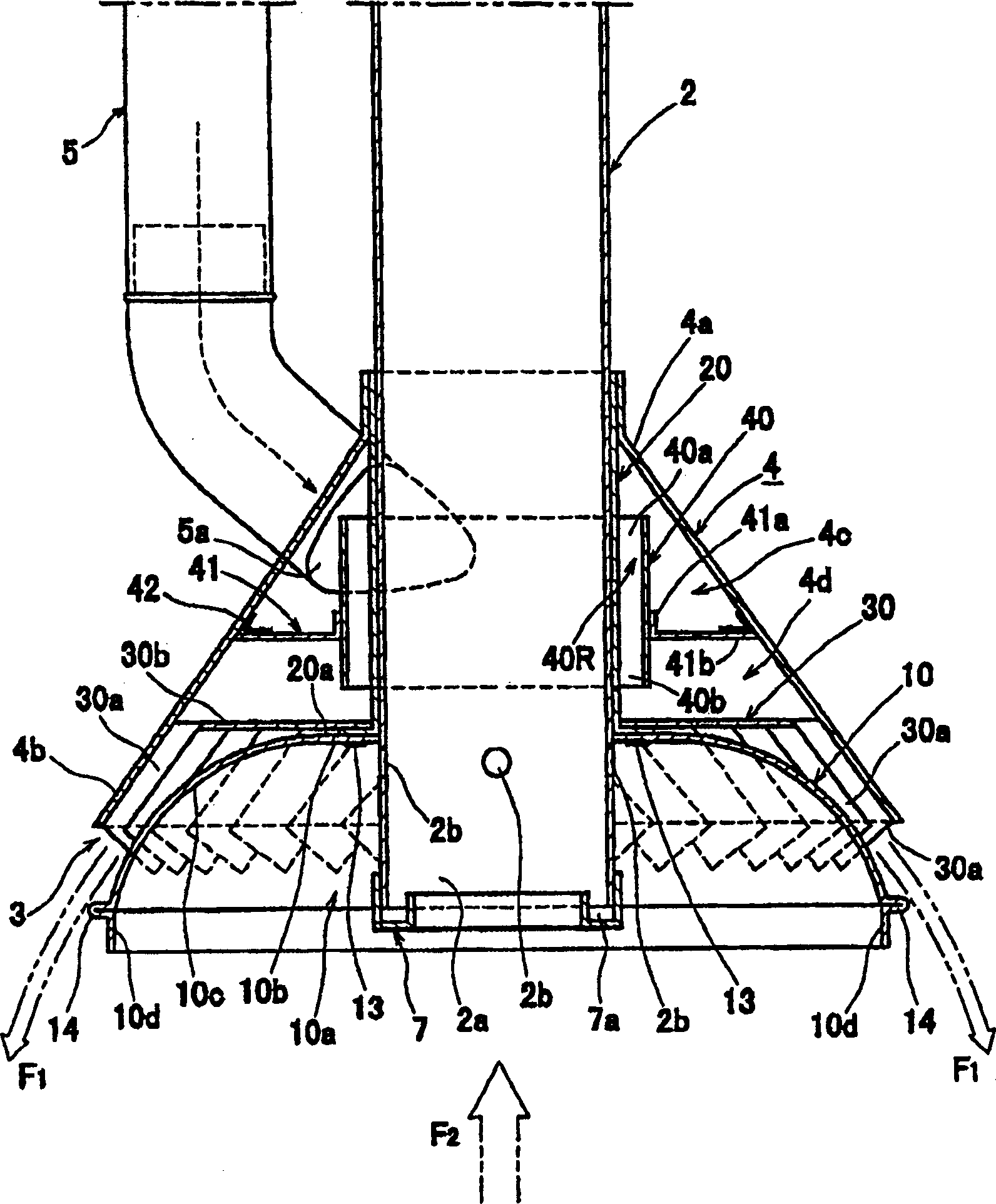

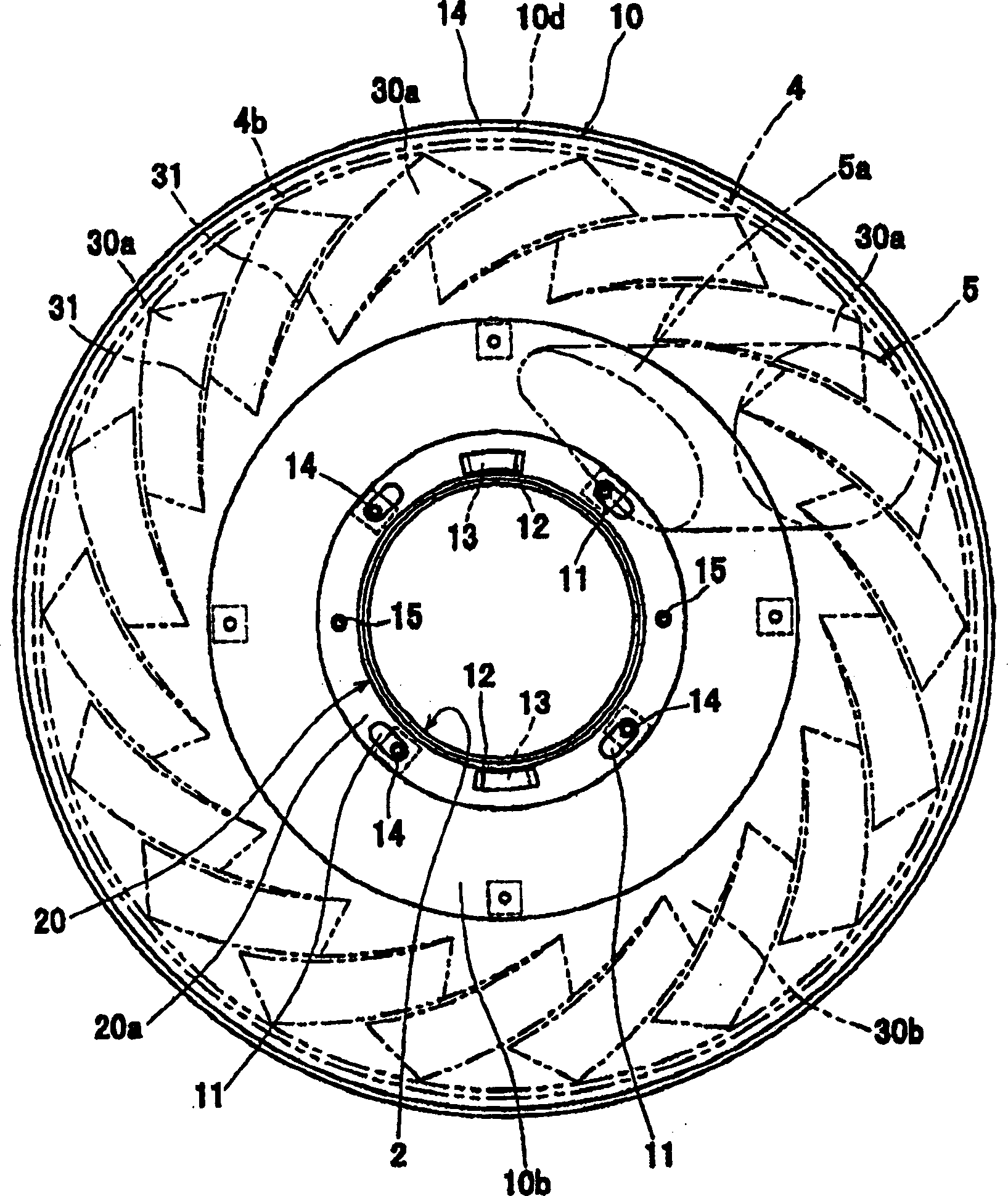

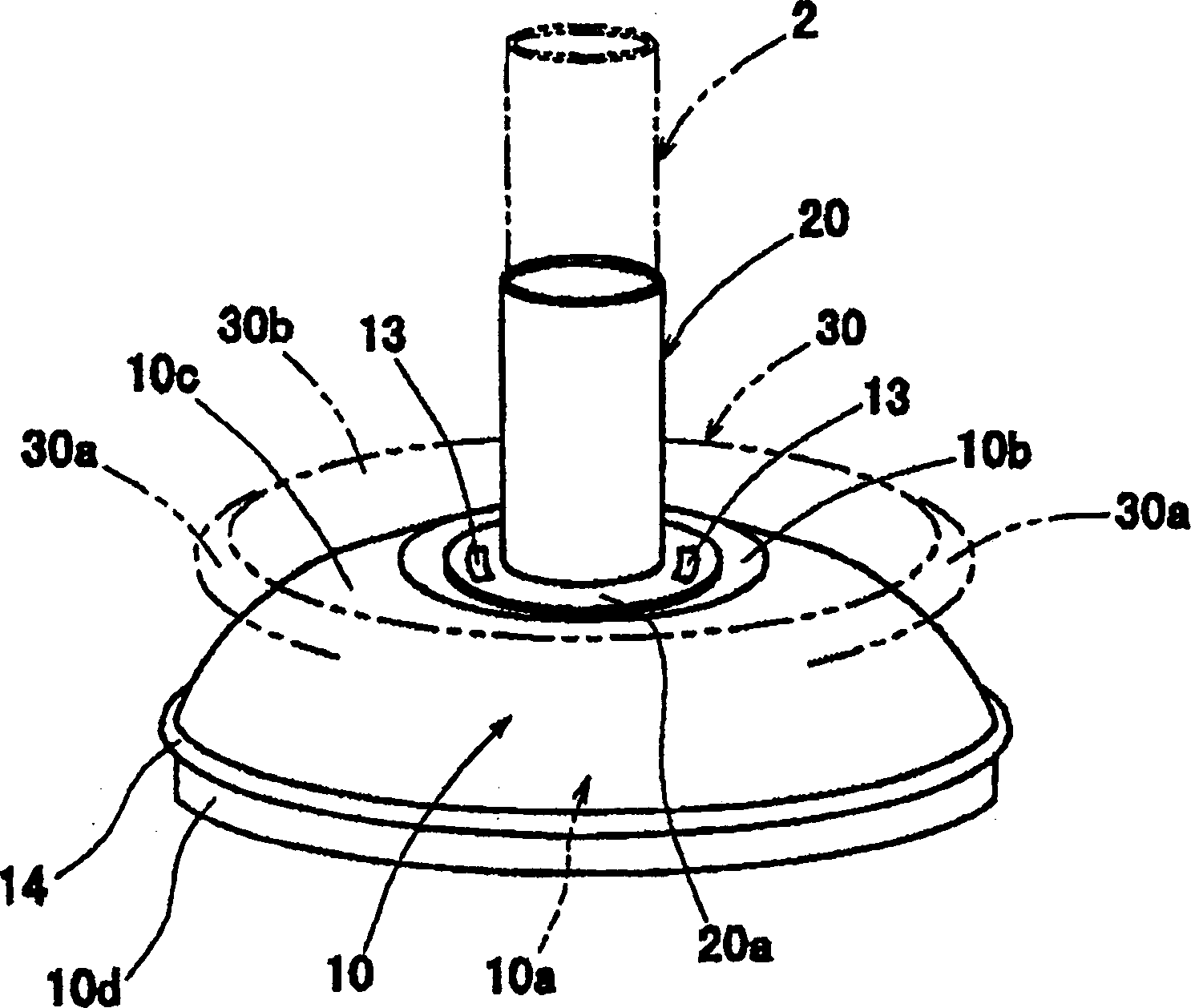

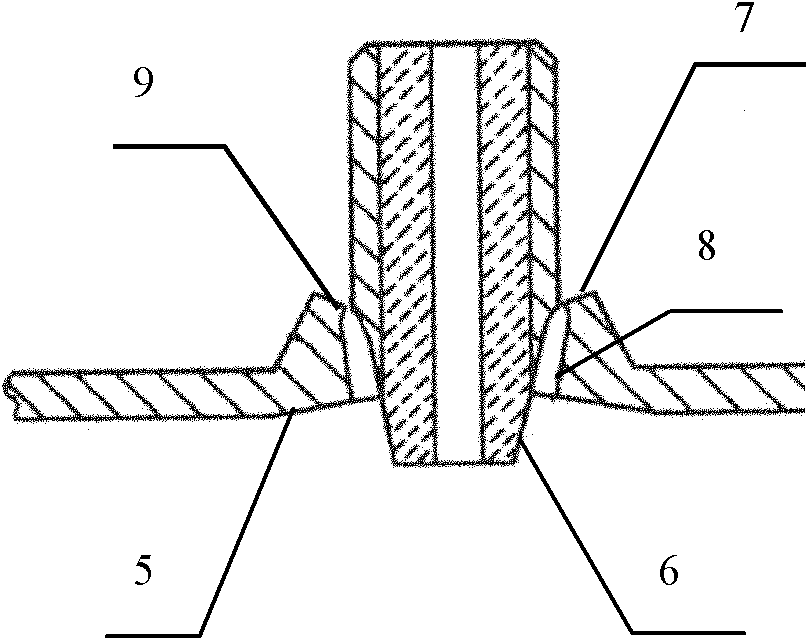

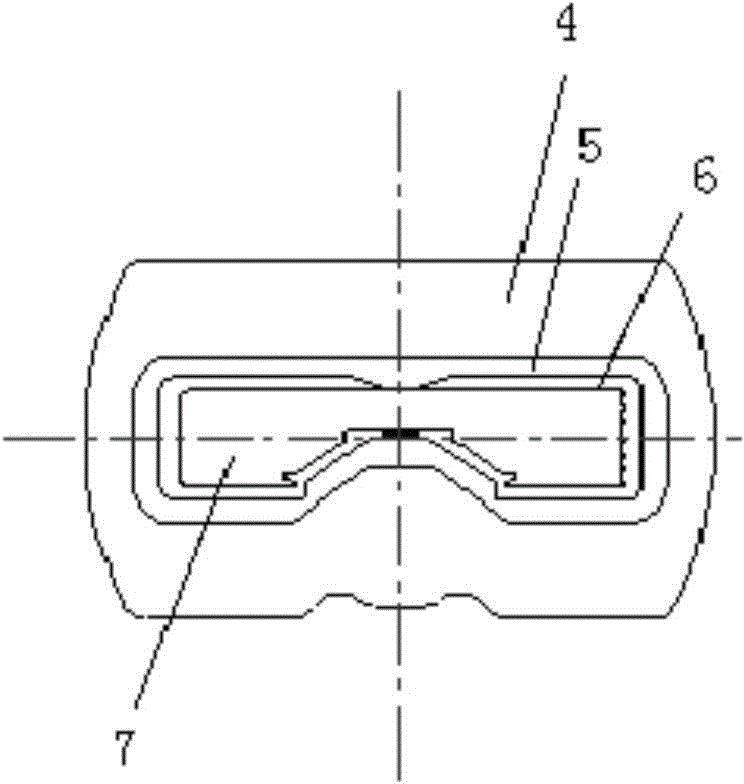

Suction and exhaust device

InactiveCN1384909AUniform velocity distributionRealize the exhaust effectDucting arrangementsDomestic stoves or rangesEngineeringWaste management

An air supply and exhaust device, which uses the air blowing outlet 3 on the lower side of the circumferential opening to introduce the air above the predetermined air supply space from the air supply pipe 5 with a predetermined air supply pressure as an air curtain flow outside the predetermined local area. Blow out, and suck the air in the above-mentioned predetermined local area surrounded by the air curtain flow through the air suction port 2a inside the air blowing port 3, and discharge it to the upper part of the air suction pipe 2, and the air suction pipe 2 runs through the air blowing direction The central part of the reverse air supply space extends to the outside. The above-mentioned air blowing space is divided by the partition plate 41 into upper and lower first air blowing spaces 4c where the air from the air blowing pipe 5 is introduced and a second air blowing space 4d that expands in the direction of the air blowing port 3. The first and second air blowing spaces 4c, 4d are communicated with each other through annular rectifying passages 40R, 50R with small passage diameters extending vertically around the outer periphery of the suction pipe 2 . Therefore, the velocity distribution of the airflow blown out from the air outlet is made uniform, and a stable air curtain flow can be formed.

Owner:DAIKIN IND LTD

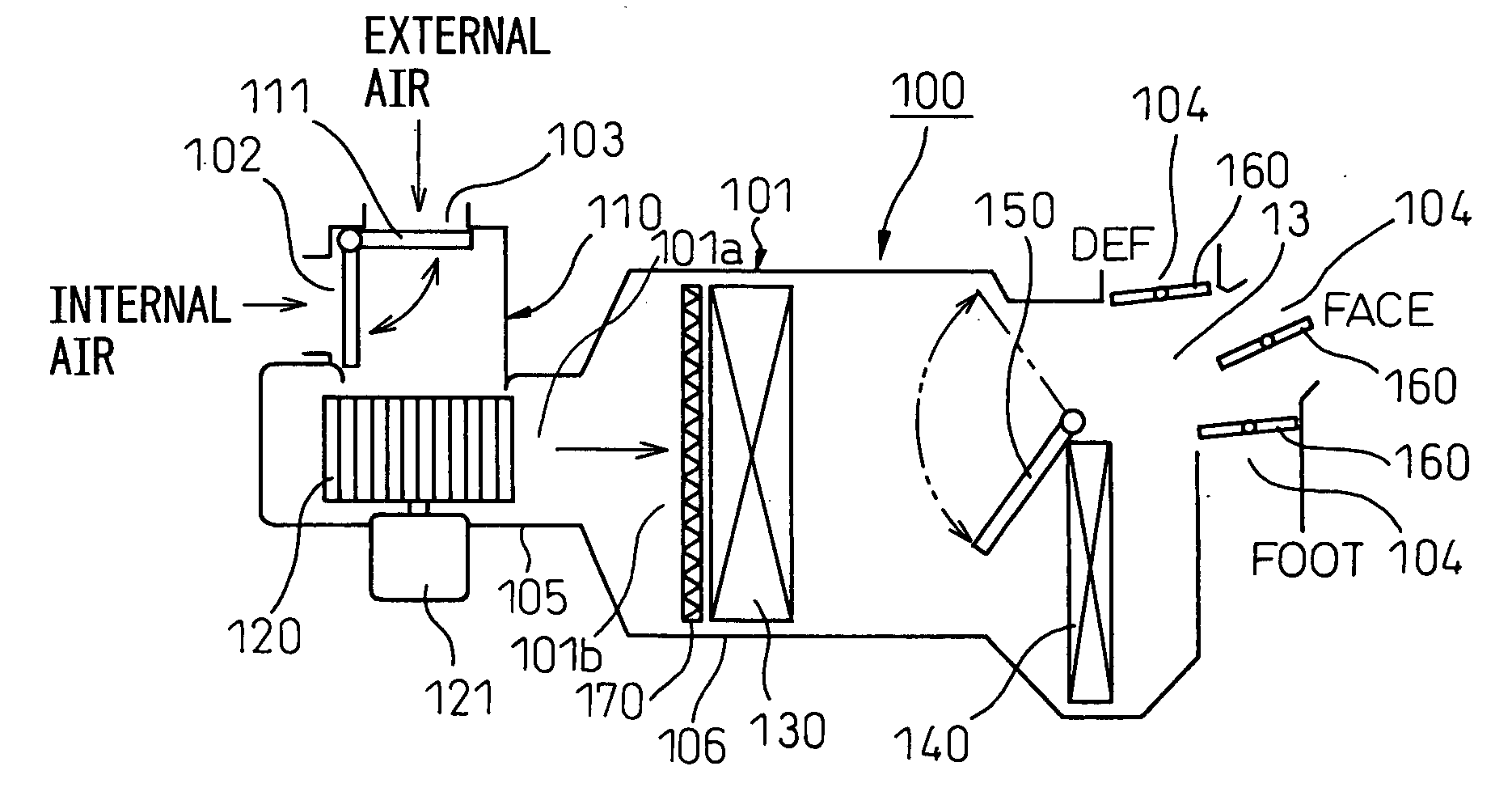

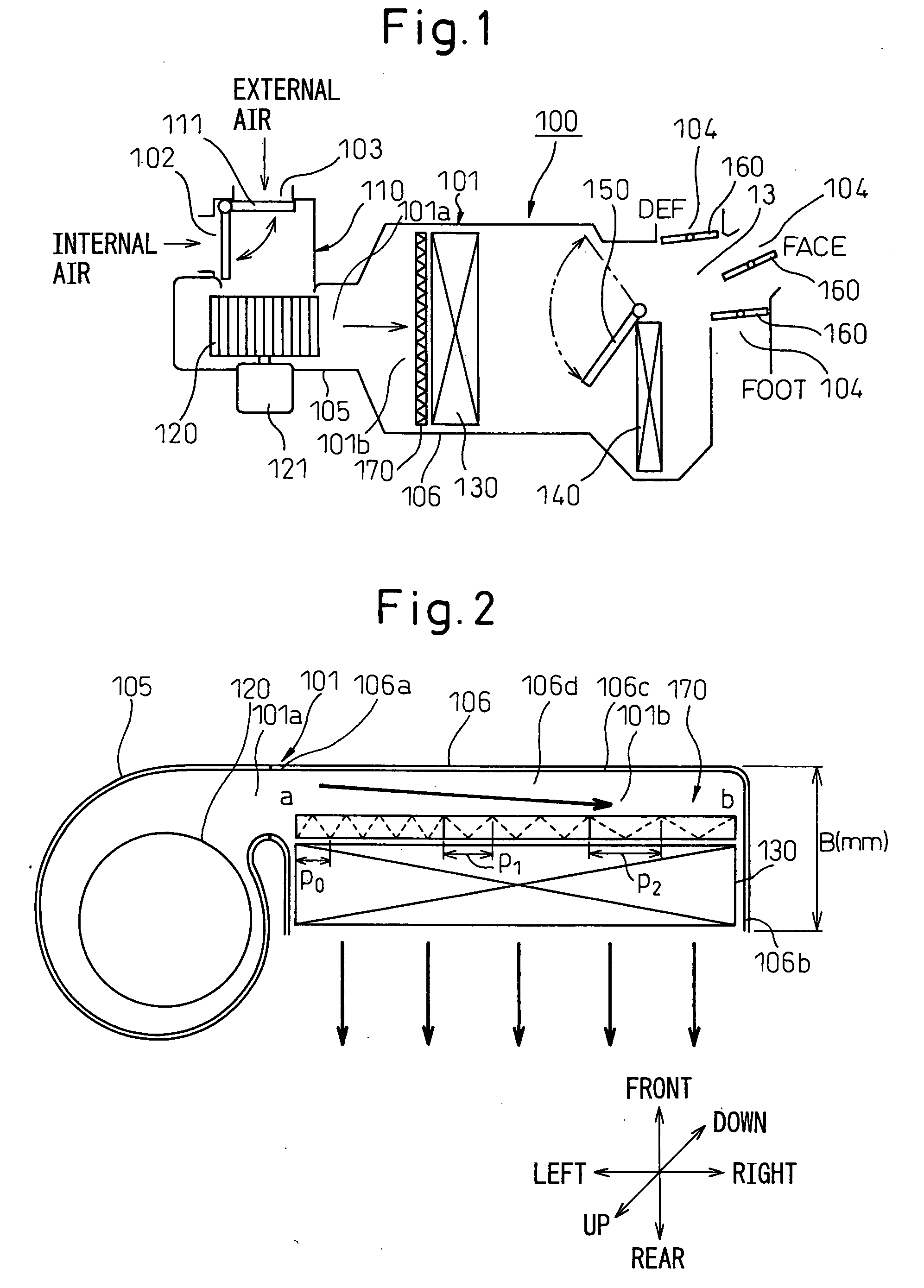

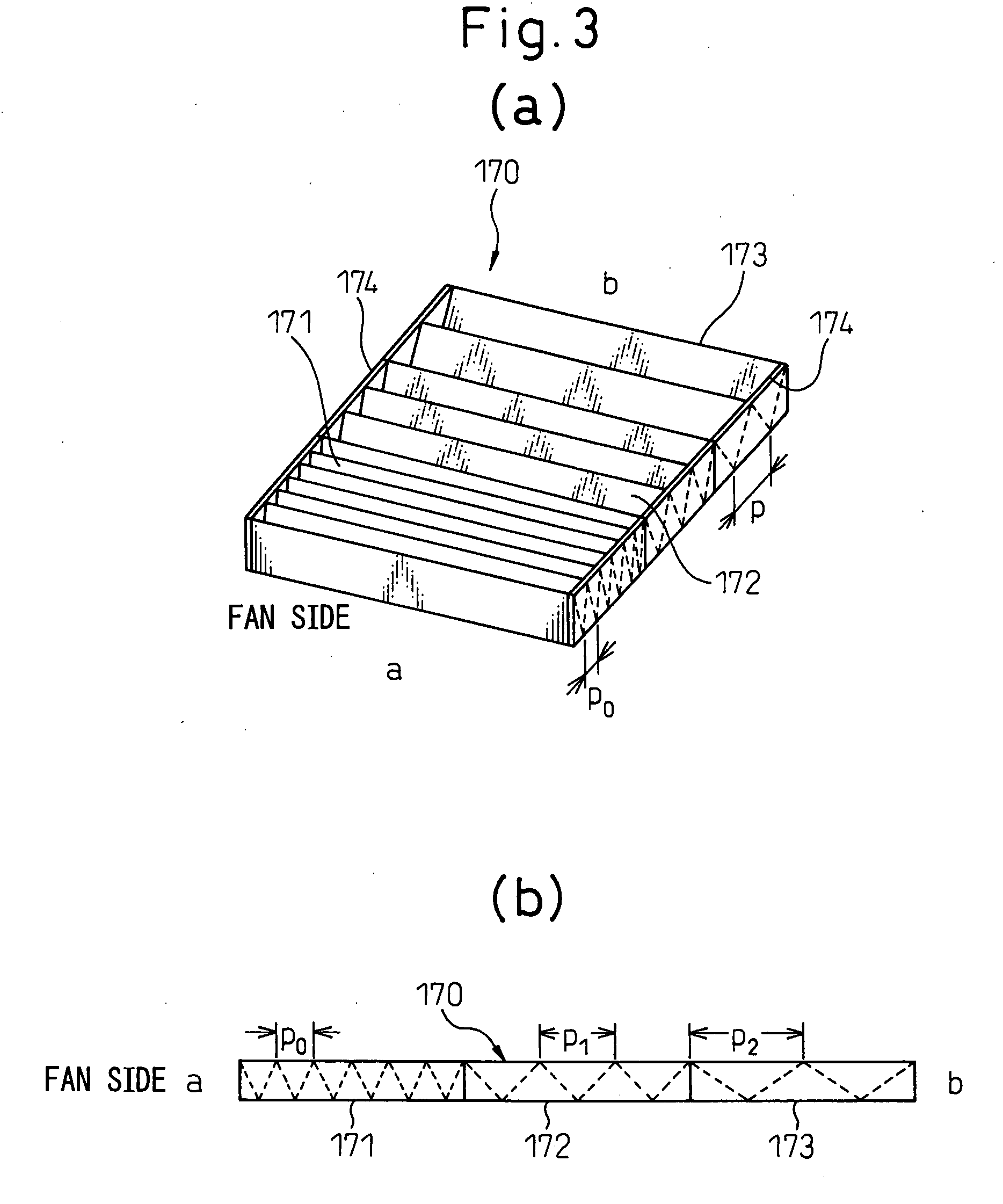

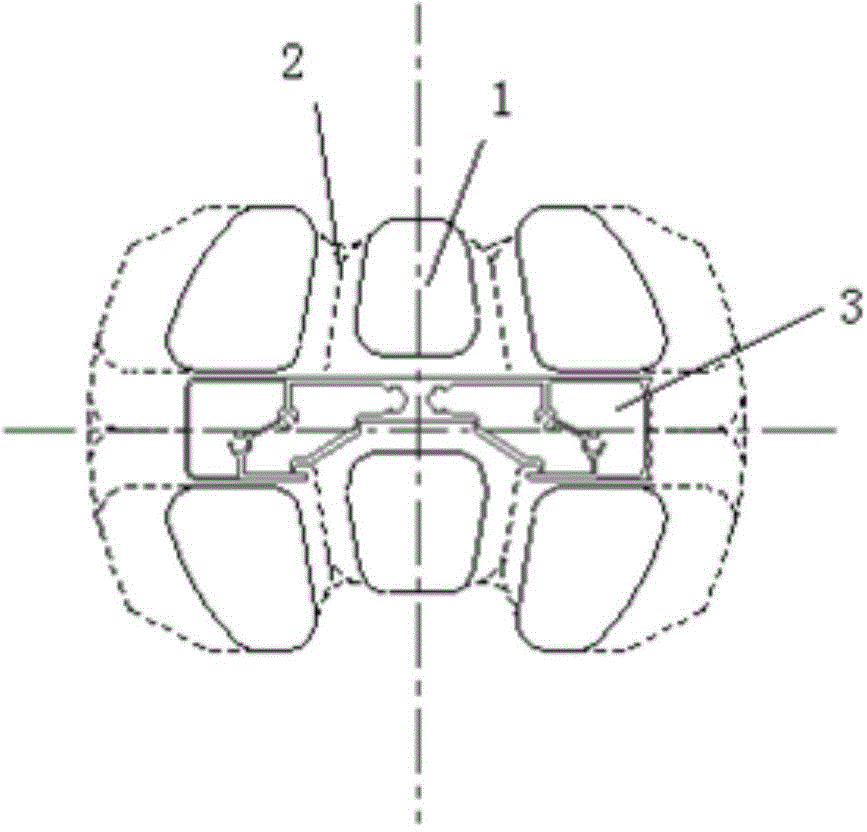

Car air conditioner

InactiveUS20070270095A1Decrease lengthReduce pressure lossGas treatmentAir-treating devicesAirflowEngineering

A construction of a filter 170 that allows air stream from a blower fan 120 to pass through a heat exchanger 130 arranged adjacent to the blower fan 120 after its flowing direction is changed by about 90 degrees. The filter 170 is disposed on the front surface of the heat exchanger on the upstream side of the air flow and has a construction such that airflow resistance of the filter gradually changes with respect to the flow velocity of air passing through the filter and in this way, flow velocity distribution of air passing through the heat exchanger becomes uniform. In this case, a fold pitch P of folds of the filter that is folded or a peak height h of the folds is changed in a plurality of steps or without any steps.

Owner:DENSO CORP

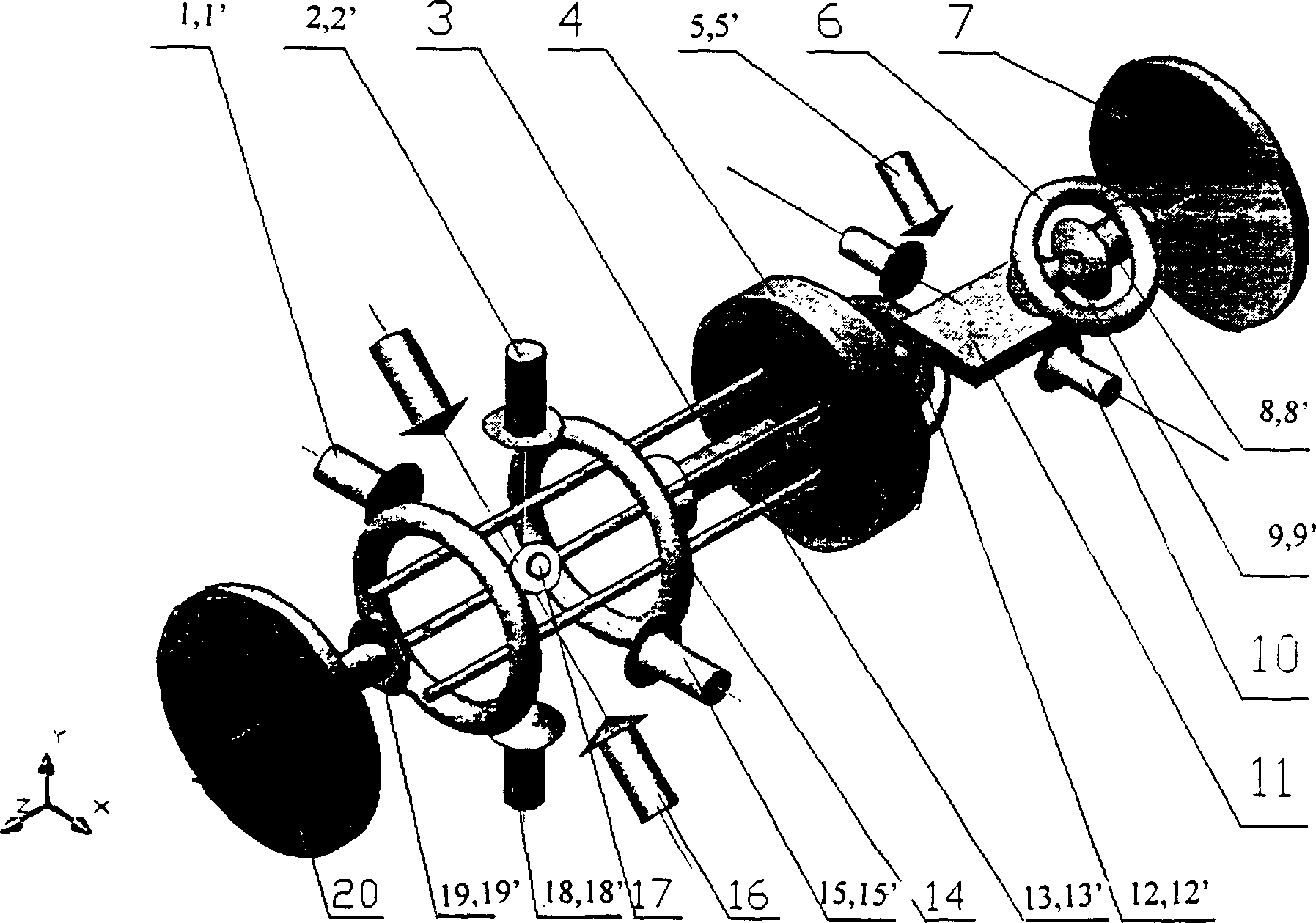

Atomic beam generation method and apparatus for atomic chipset

The invention relates to a method for generating the atom bean used in atom chip and relative device, wherein, the device comprises a vacuum room, an atom source, a two-dimensional micro adjusting platform, a magnetic iron and inner and outer light paths. The inner and outer light paths comprise a main laser and a re-pump laser; the vacuum room is mounted with a 1 / 4 wave plate reflector group with a hole in center and a direct-guide group; the magnetic light well uses the optical pump laser and the re-pump laser to prepare the atom into optimized weak field scanning state. The invention has small volume and simple structure, while it can supply the optimized weak field scanning state to the atom chip with the atom beam whose longitudinal speed is lower and uniform, transverse speed is nearly zero and density is high. The invention can be used in the guide, wave-division, interference and the Bose-Einstein Coagulation (BEC).

Owner:TSINGHUA UNIV

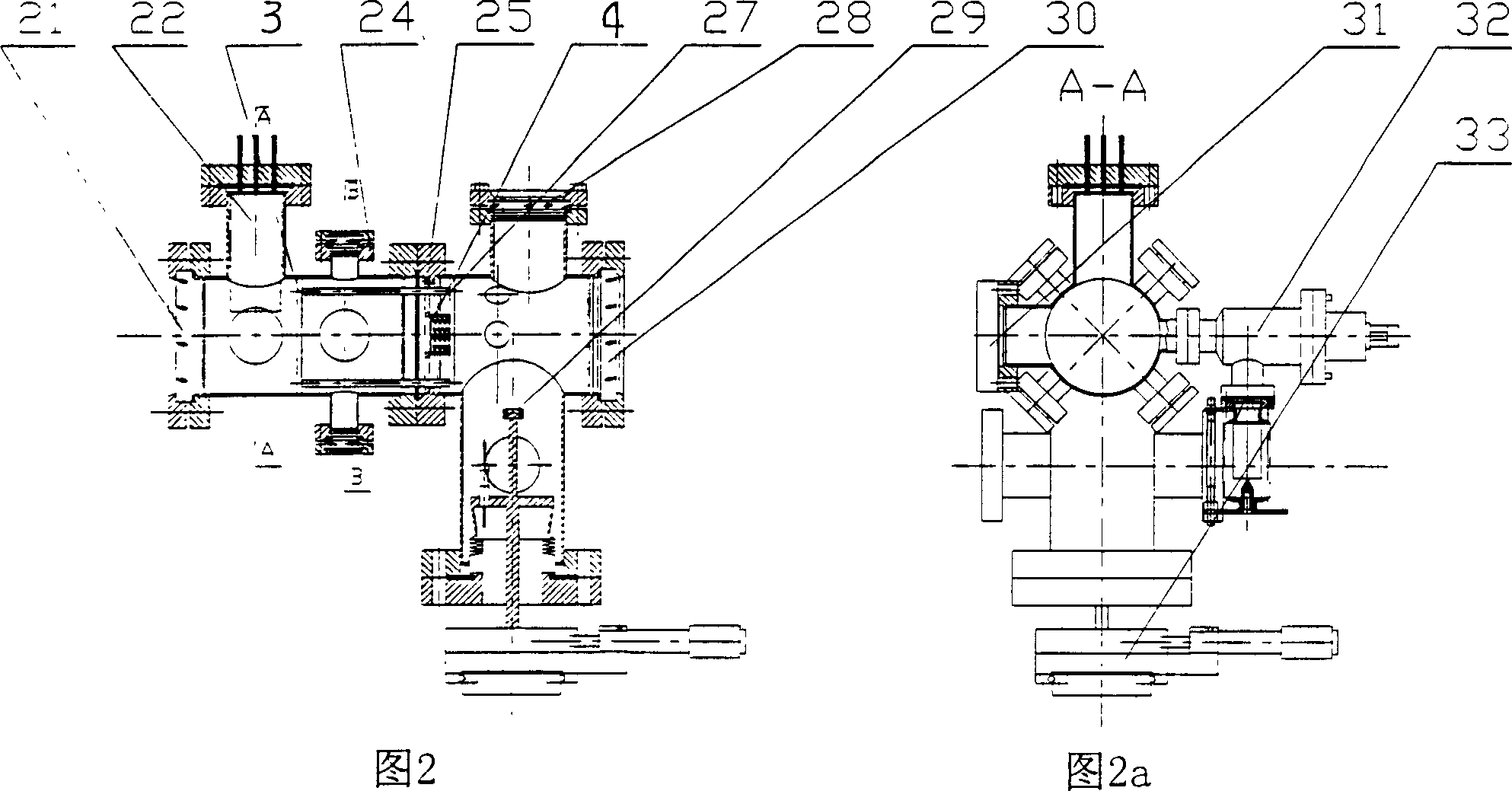

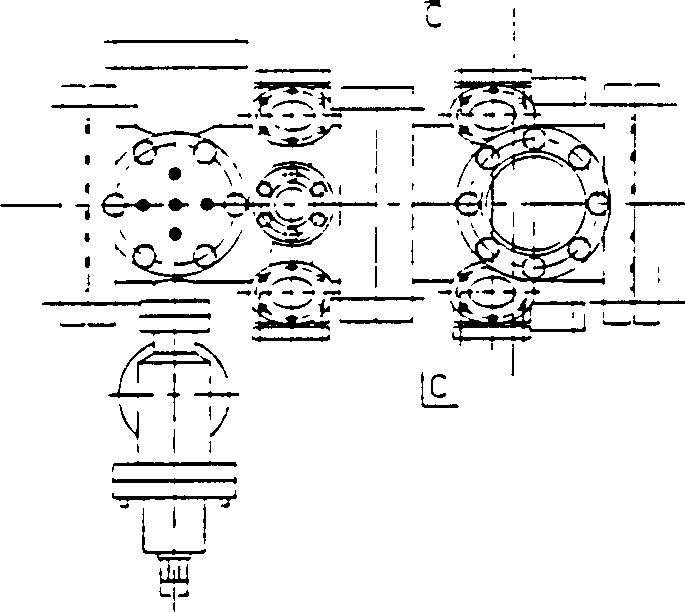

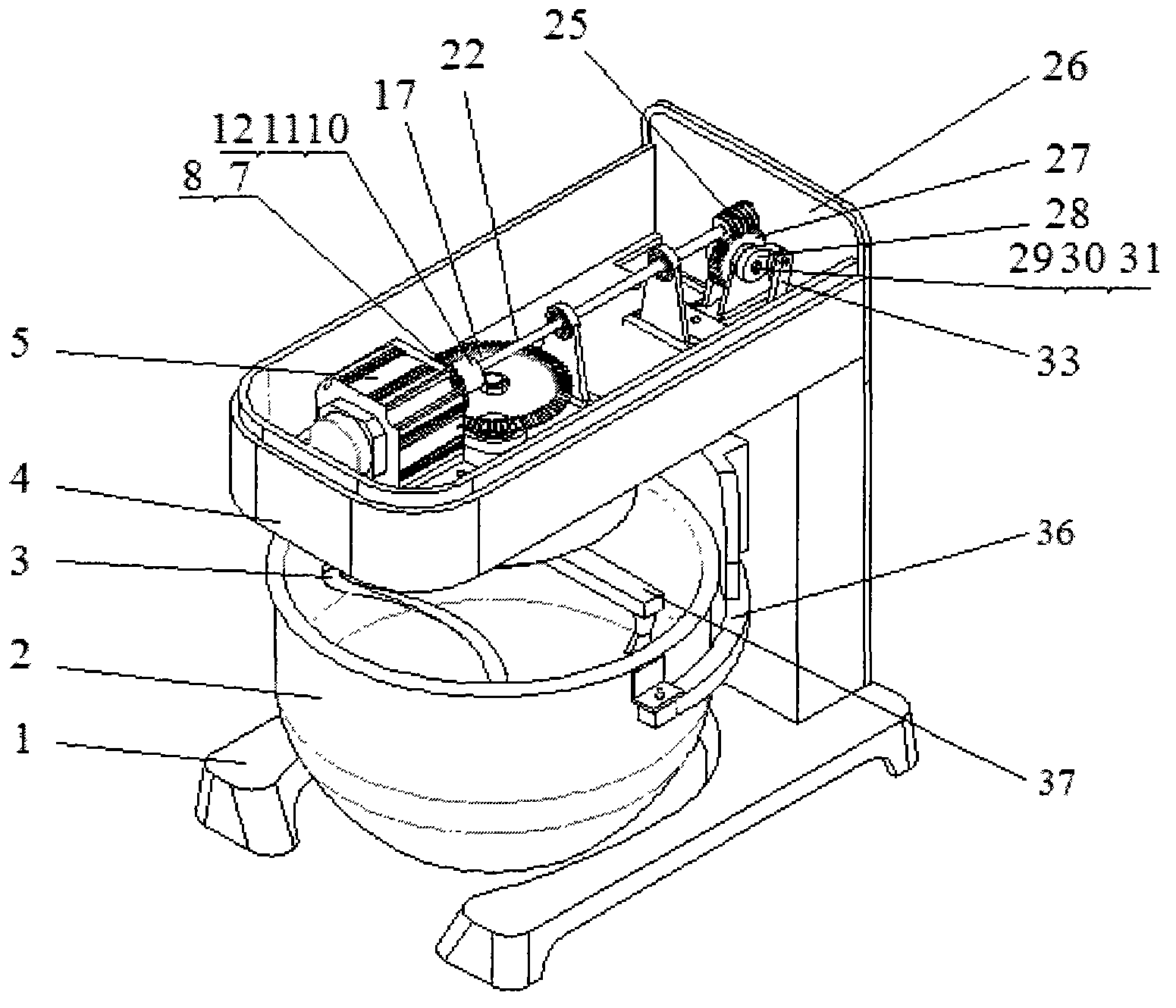

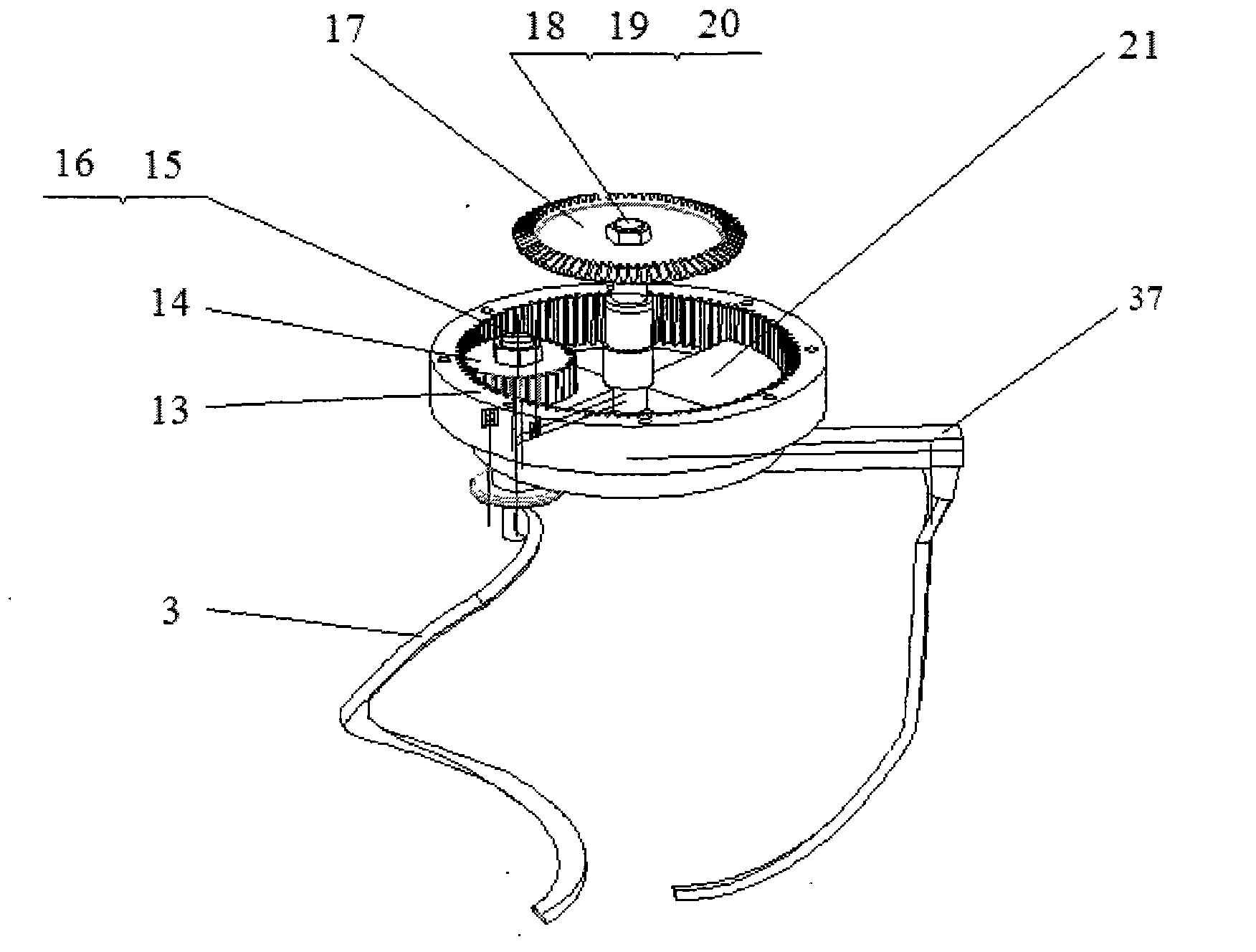

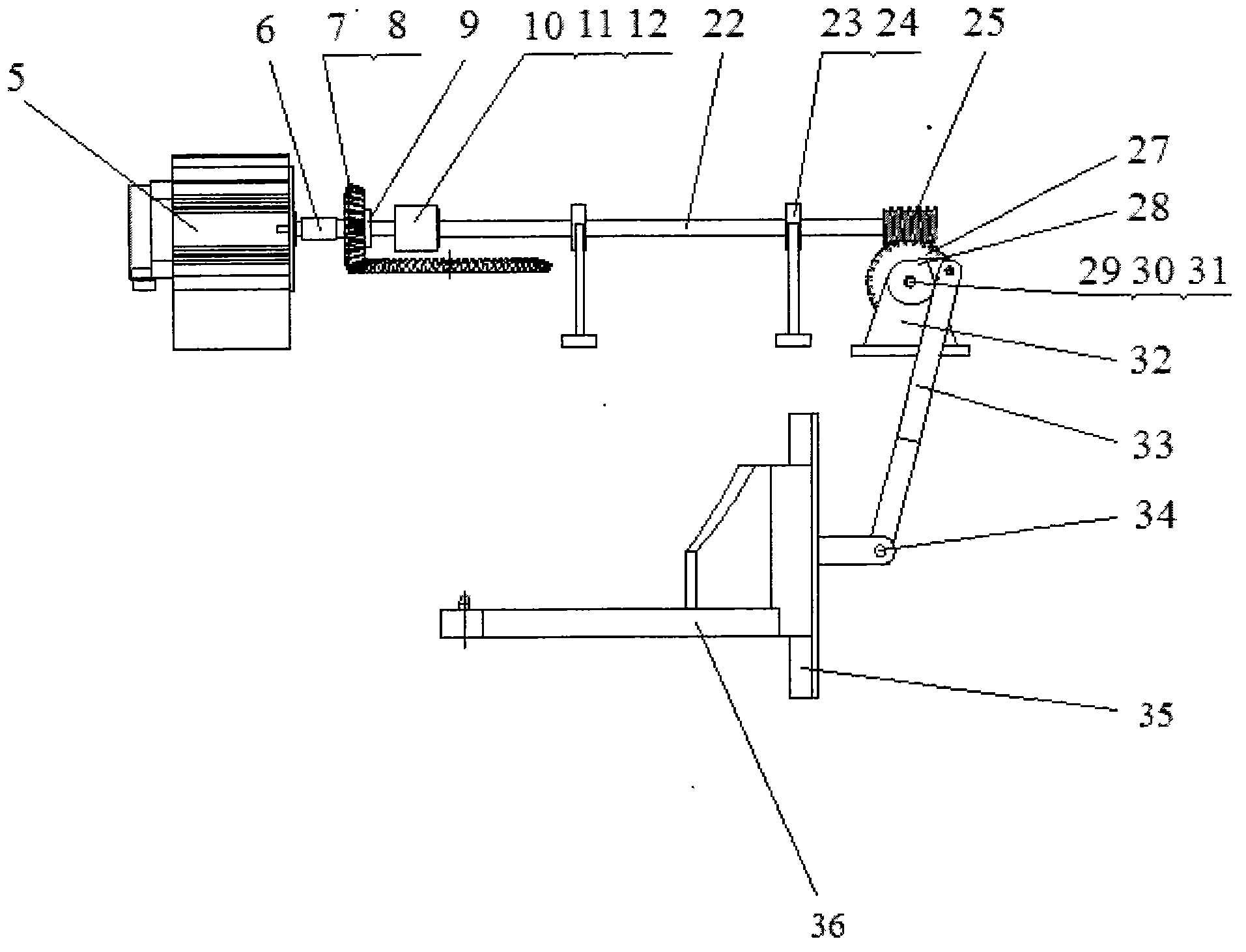

Movement separation spiral multifunctional food mixing machine

InactiveCN103210966AReduce manufacturing costImprove structural performanceMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsMixing effectMechanical engineering

The invention designs a movement separation spiral multifunctional food mixing machine. The movement separation spiral multifunctional food mixing machine comprises a spiral mixer, a mixing tank, a movement separation mechanism, a lifting device and a dough scraping device, wherein the movement separation mechanism can meet the power demand of all movements in the mixing machine by one motor; when the motor rotates forwards, materials are mixed by the mixer at different speeds, and when the motor rotates reversely, the mixing tank ascends or descends; due to the spiral and rodless designs of the spiral mixer, the spiral mixer can be used for mixing in a wide range, overcomes the phenomenon of automatic material climbing, and improves the structural performance of the mixer; and the dough scraping device can accelerate the rolling of the materials in the mixing tank so as to improve the mixing effect. The multifunctional food mixing machine overcomes the shortcomings of a conventional mixing machine that a plurality of power sources are needed and the mixing efficiency is low, thus being very beneficial to the production and generalization of the mixing machine. According to the mixing machine, the production cost is reduced, the mixing is more sufficient, and the mixing time is greatly shortened.

Owner:吴玉国 +6

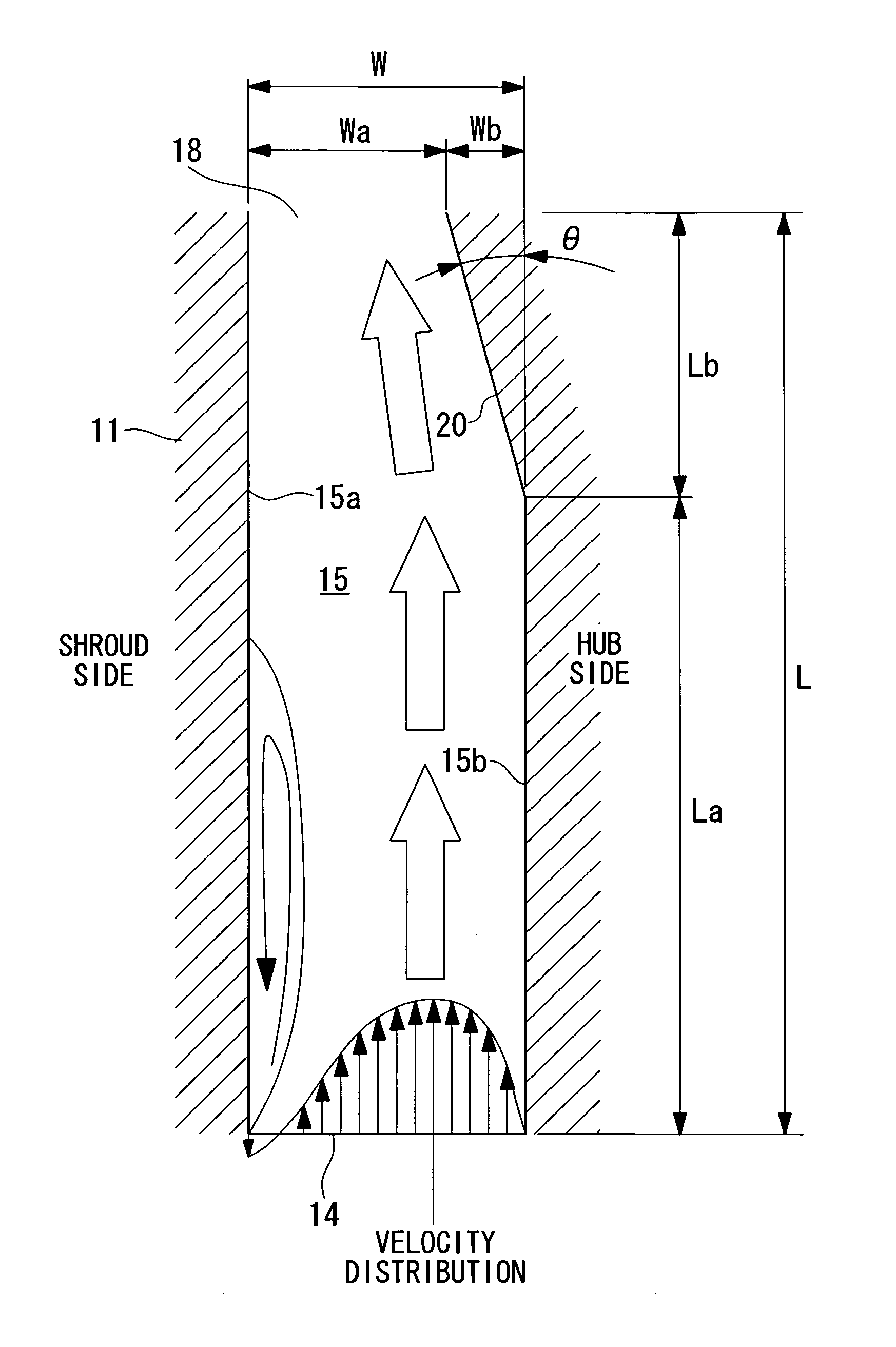

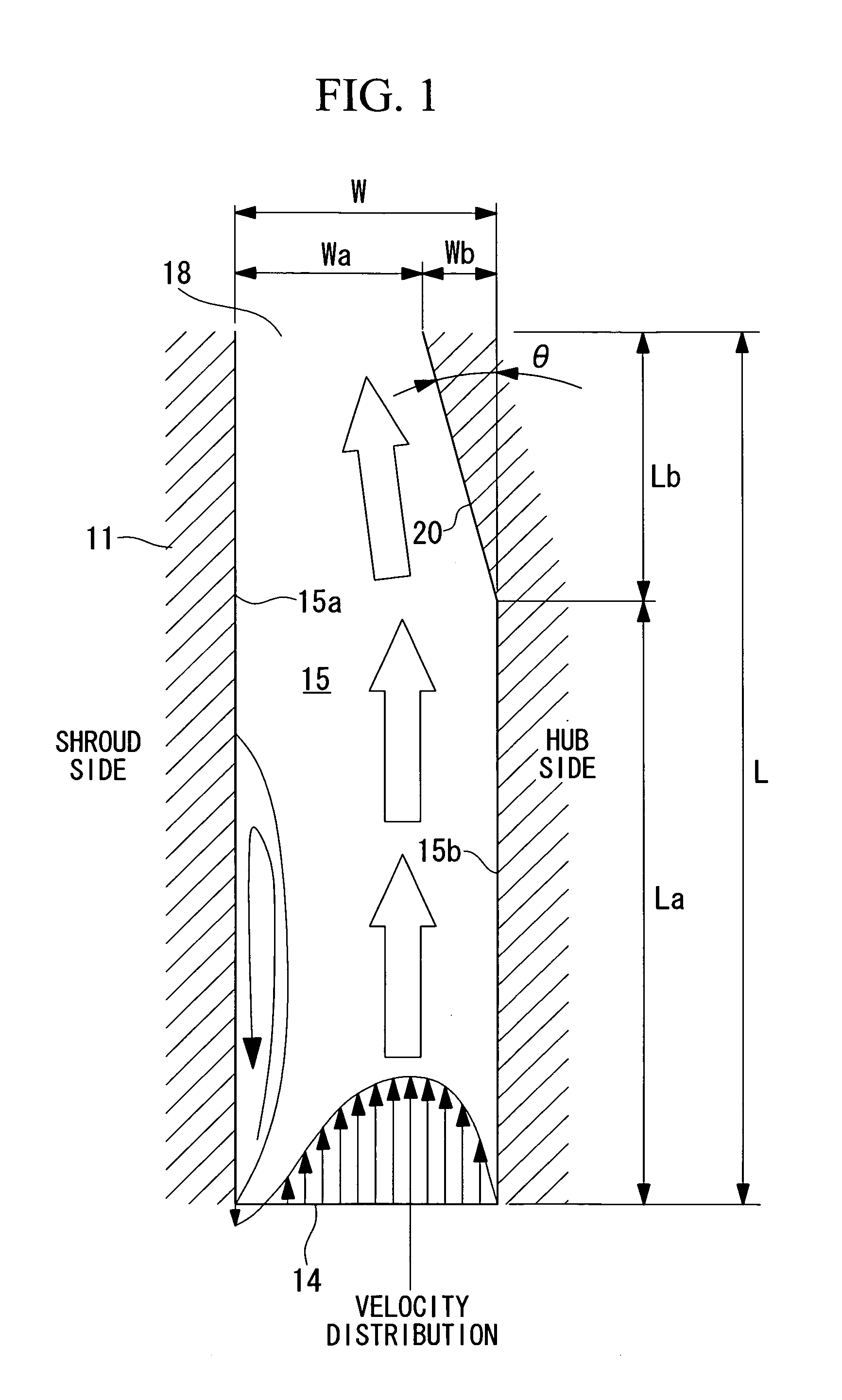

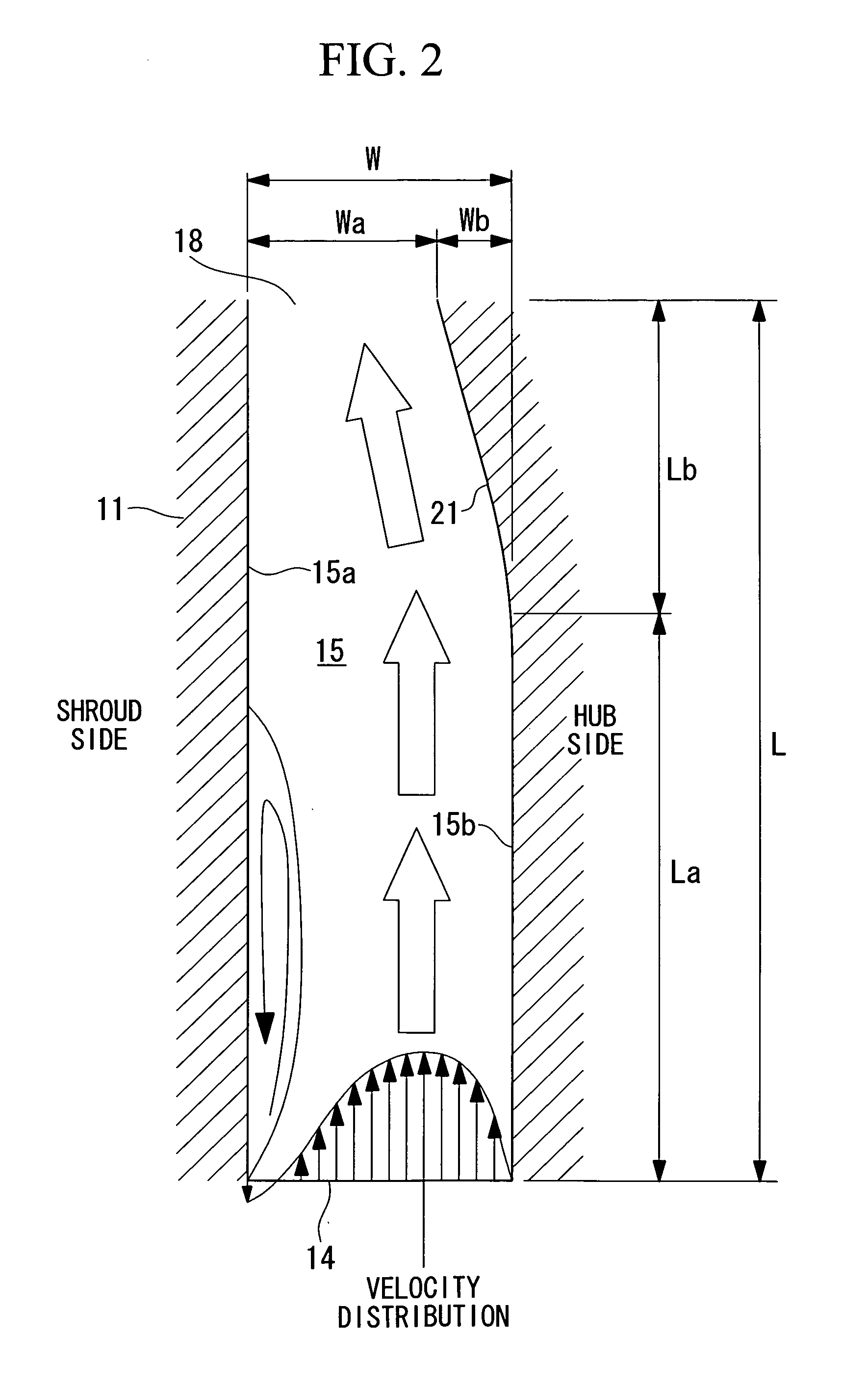

Centrifugal Compressor

InactiveUS20100129209A1Reduce flow rateExpand the scope of operationEngine manufacturePump componentsCentrifugal compressorAirflow

There is provided a centrifugal compressor having a diffuser structure in which airflow is unlikely to separate from a hub side wall surface on a hub side wall surface downstream side within a diffuser passage. In a centrifugal compressor provided with a diffuser passage 15 for recovering static pressure by slowing down discharged air from an outer circumferential end of an impeller that rotates within a housing 11, a hub side wall surface 15b of the diffuser passage 15 is provided with an inclined plane 20 that approaches toward a shroud side, in a position on a downstream side of a portion parallel with a normal line direction of a section surface of an impeller exit.

Owner:MITSUBISHI HEAVY IND LTD

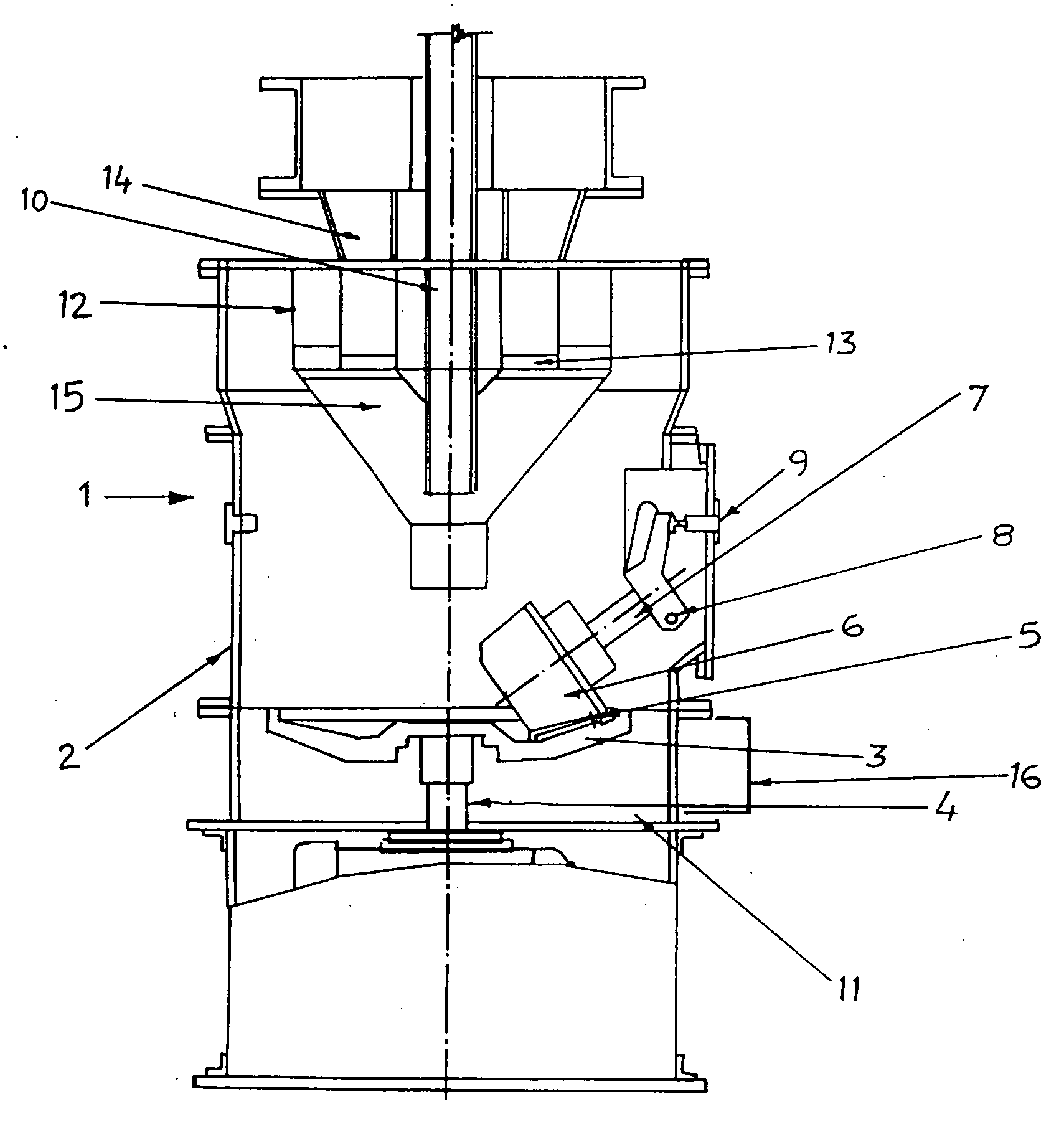

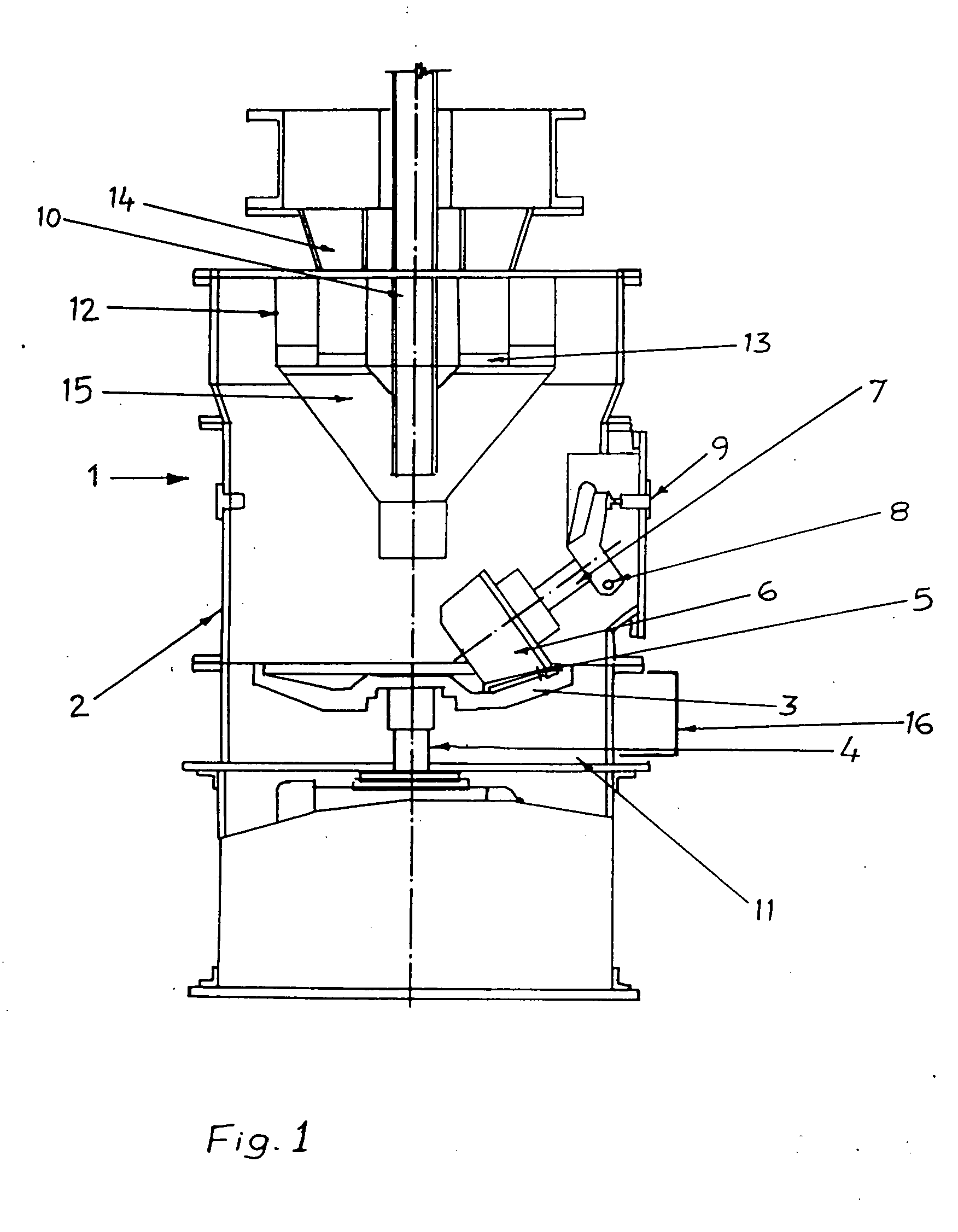

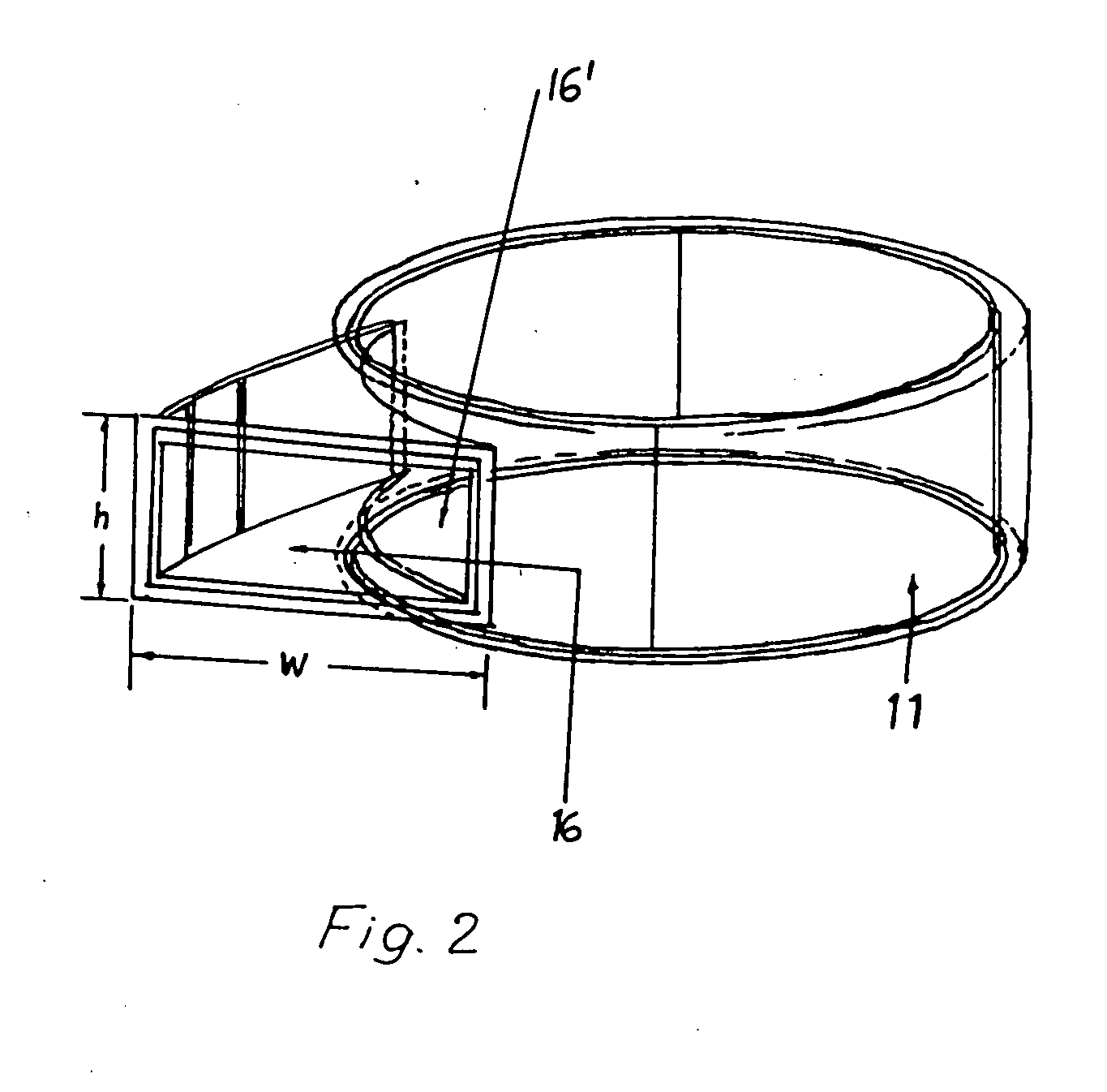

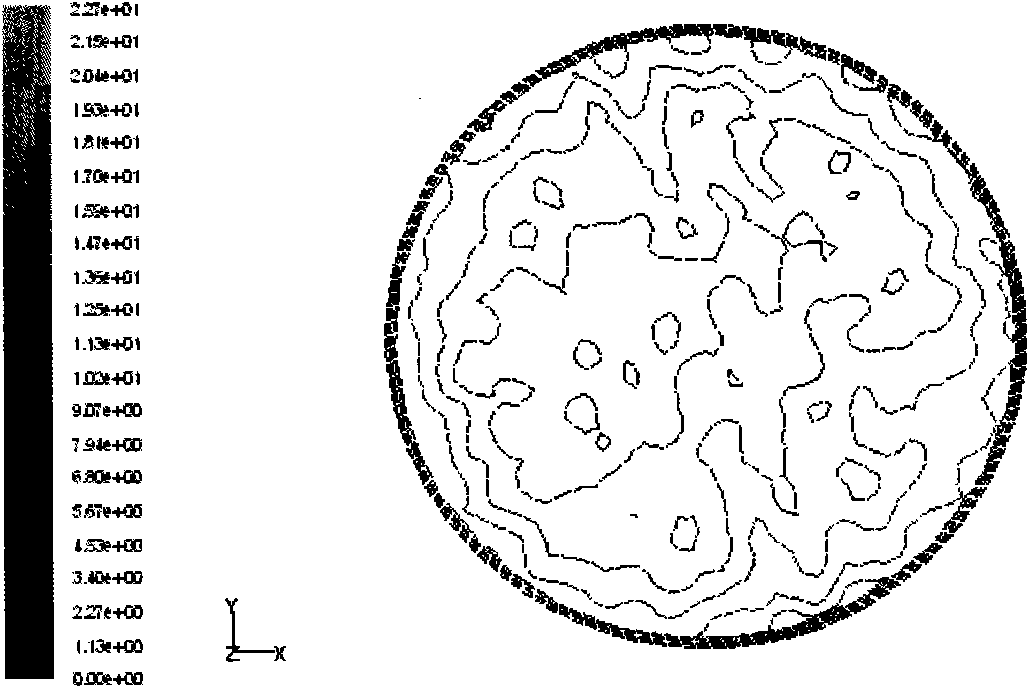

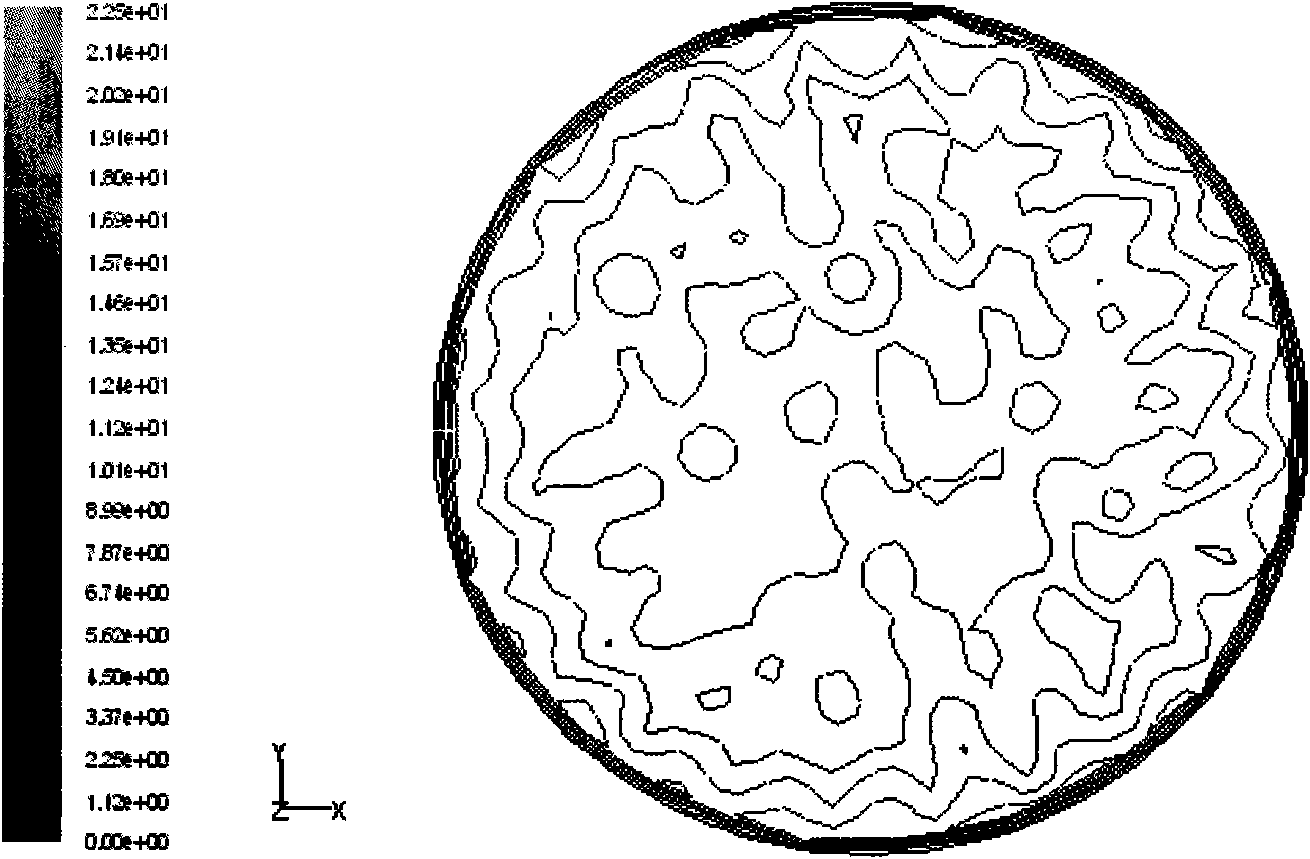

Bowl mill for a coal pulverizer with an air mill for primary entry of air

A bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body (2) having a central axis; and a bowl-like grinding table (3) mounted on a shaft (4) rotatable about said central axis, cooperating with a plurality of grinding rolls (6). The airmill is provided with multiple entry openings (17', 17''; 18', 18''; 21, 25) on the outer wall of the air mill for multiple entry of hot primary air from the inlets, resulting in better uniformity in air flow around the air mill section and for minimizing formation of eddies and vortices As a variation of the multiple entry double entry openings can be arranged for entry of hot primary air.

Owner:BHARAT HEAVY ELECTRICALS LIMITED

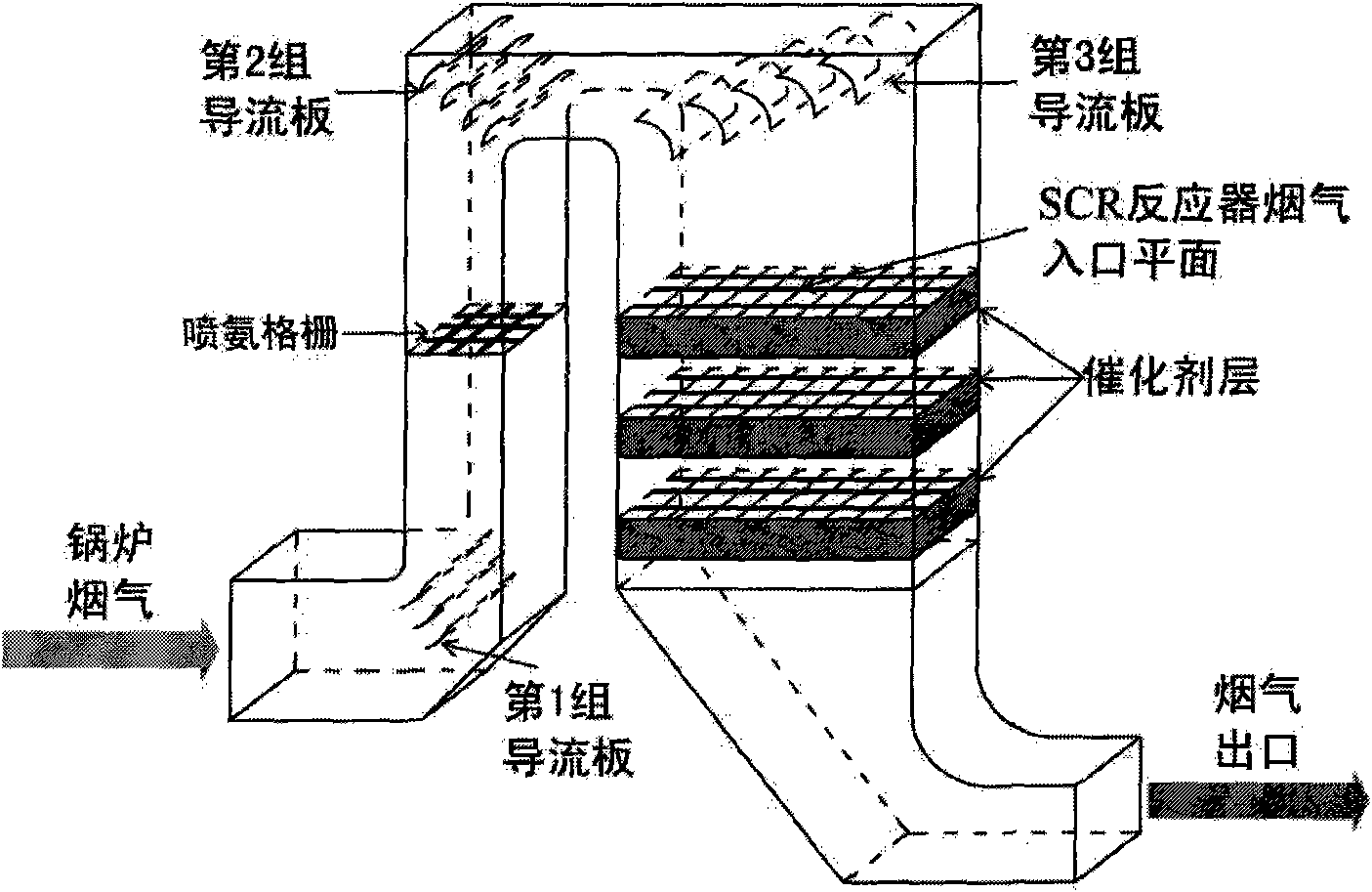

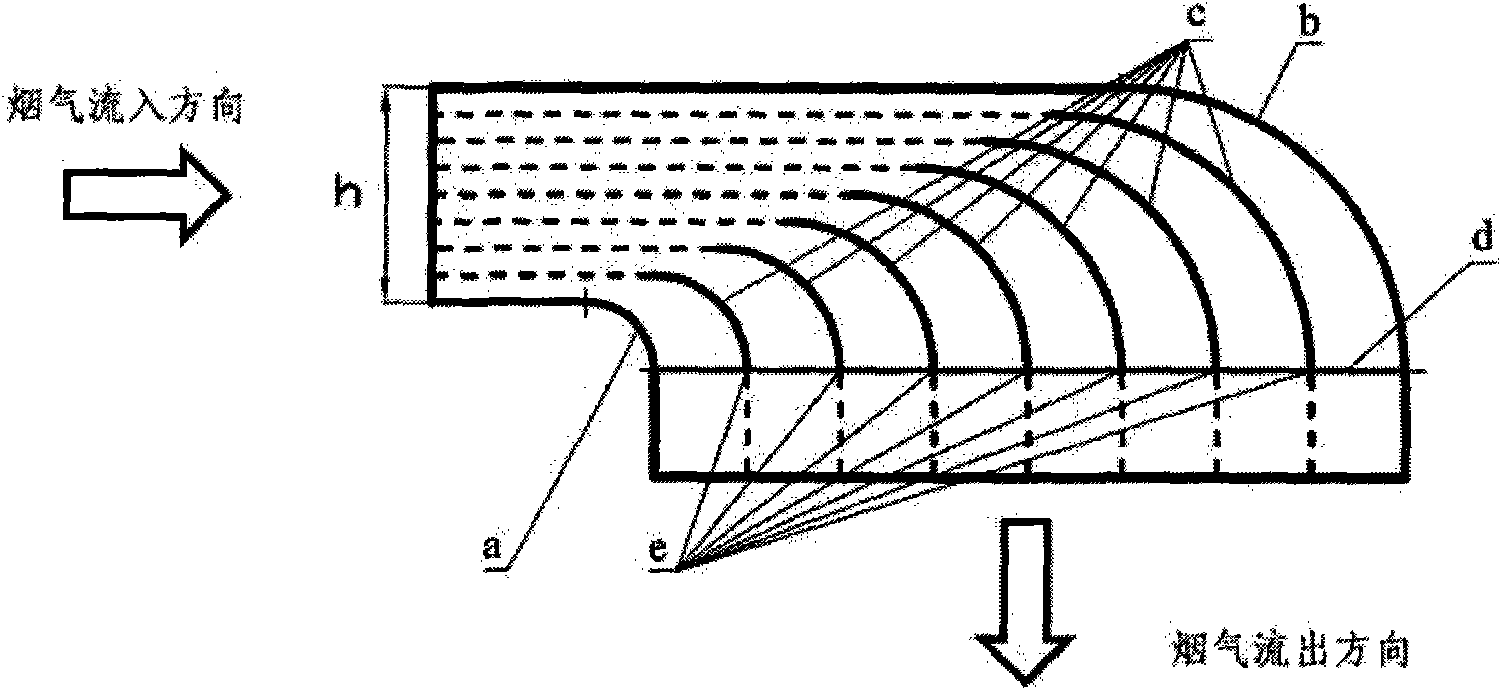

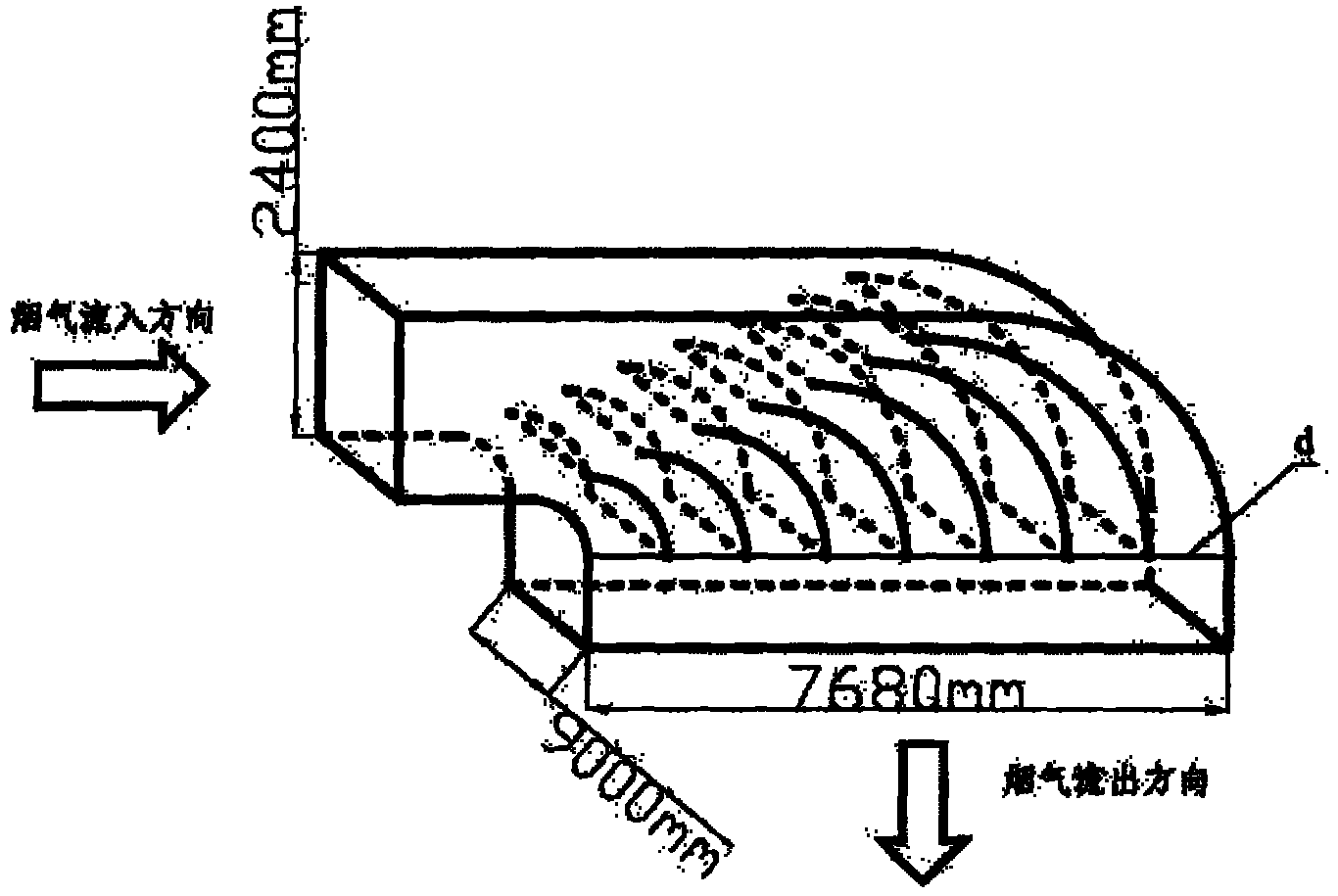

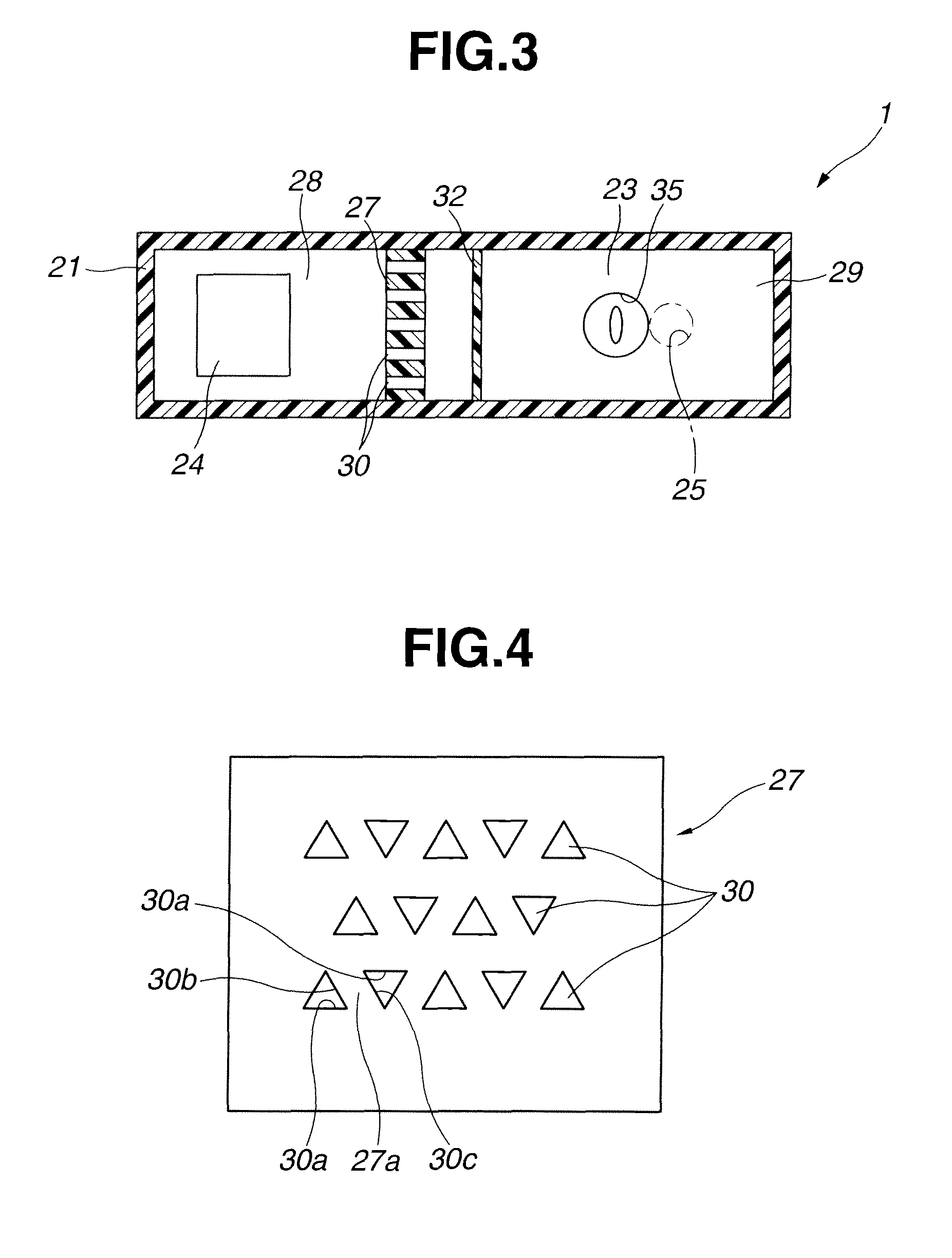

Flue gas flow equalizing and guiding assembly of selective catalyctic reduction (SCR) denitration reactor inlet

ActiveCN101766950AReduce kinetic energy lossArea of reduced vortexDispersed particle separationFlue gasProcess engineering

The invention relates to a flue gas flow equalizing and guiding assembly of a selective catalyctic reduction (SCR) denitration reactor inlet, belonging to the technical field of flue gas denitration of heat power stations. The inlet flue gas flow equalizing and guiding assembly comprises a bend, two straight flue ducts and flow guide plates, wherein the two straight flue ducts are used as connection arcs of the inner and the outer pipe walls of the bend; and a plurality of the flow guide plates are connected with arcs of pipelines positioned at the inner side and the outer side of the bend and sequentially arranged on the internal bend of a gas flow denitration pipeline from inside to outside in a mutually parallel way. The invention can solve the problem of the flue gas flow equalizing and guiding of the bend with great sectional area change by adopting the arc-shaped flow guide plates with different radiuses, optimizes the speed distribution of the SCR denitration reactor inlet and enhances the catalyst utility ratio and the denitration efficiency.

Owner:上海电气电站环保工程有限公司 +1

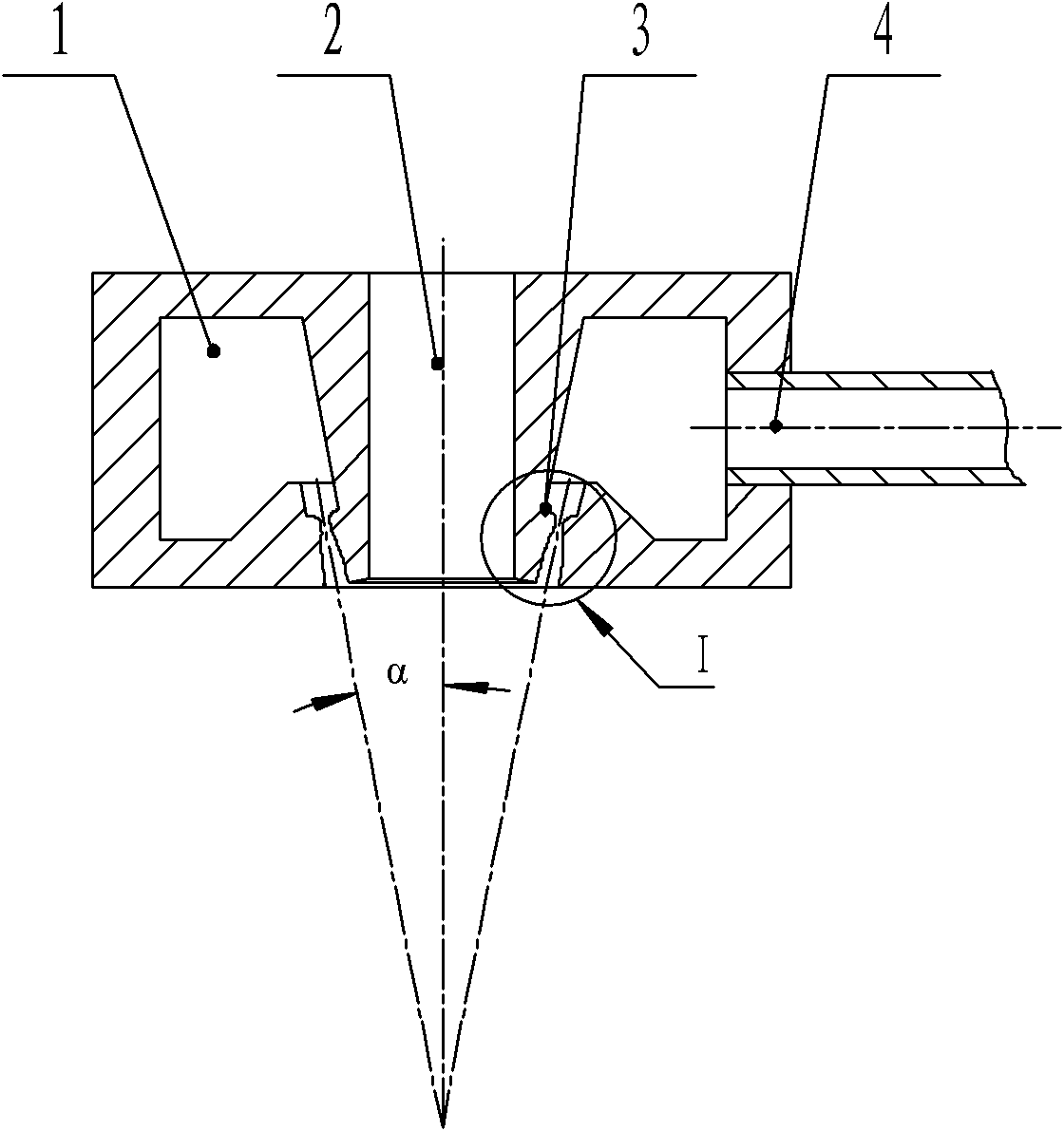

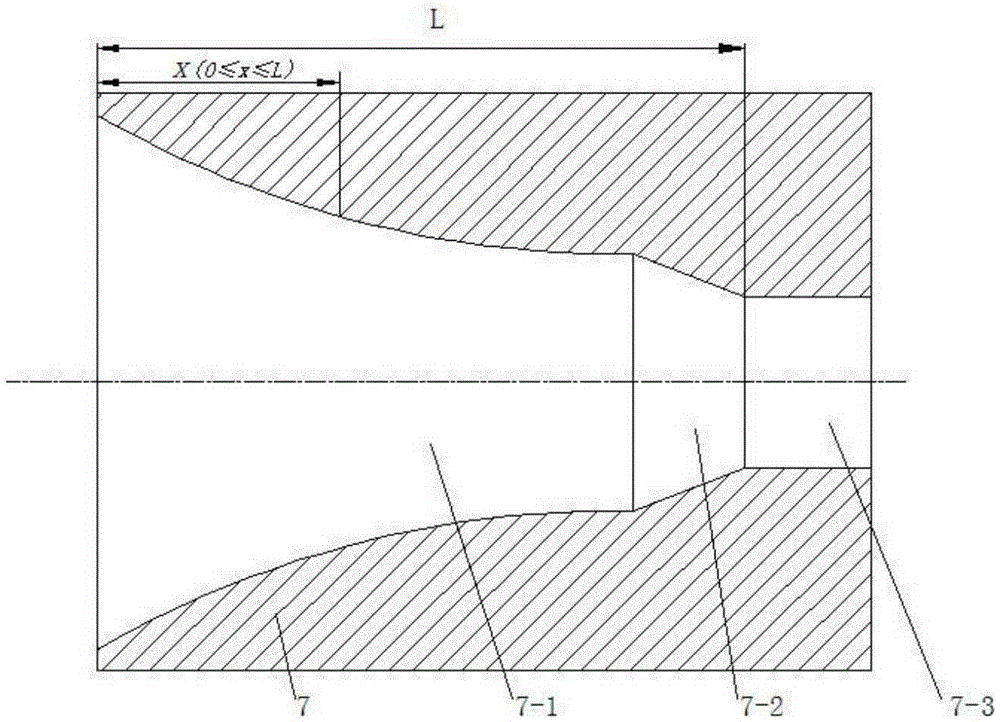

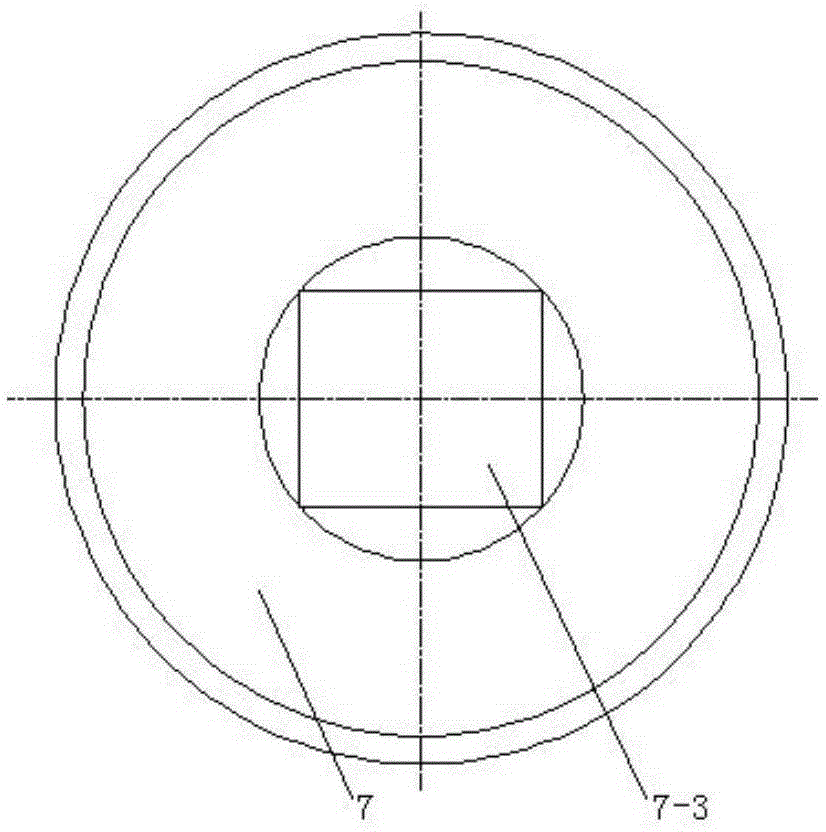

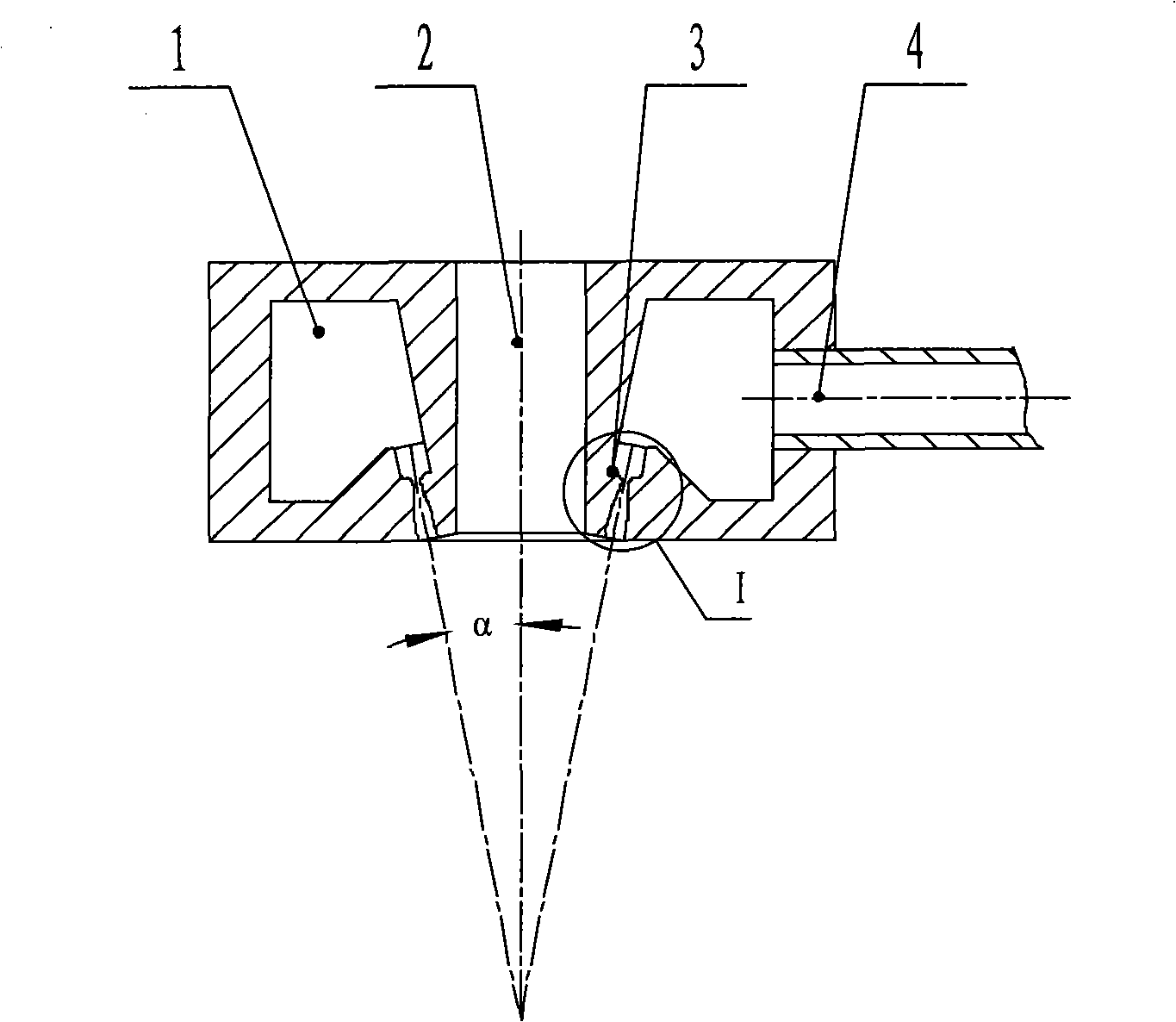

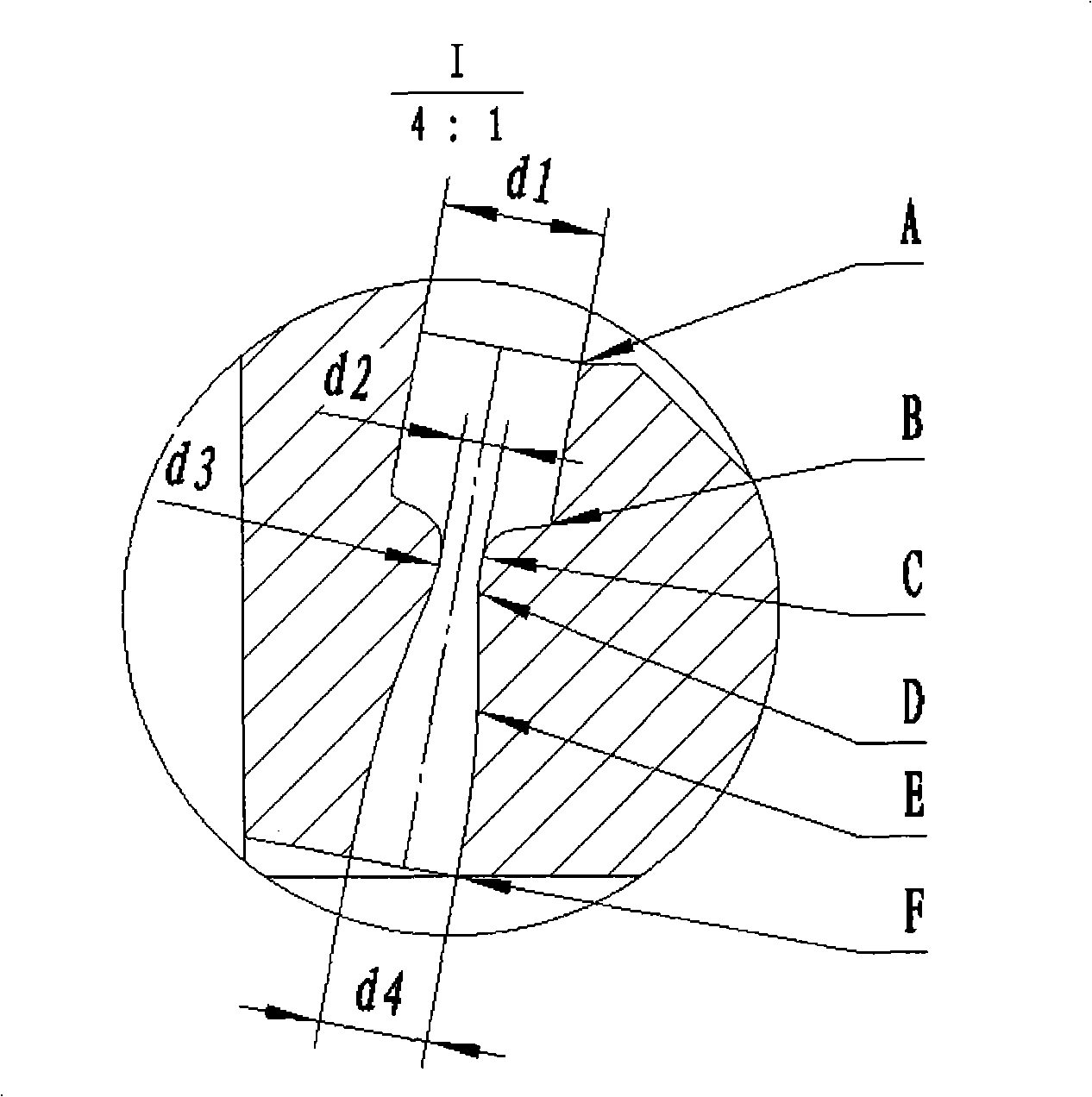

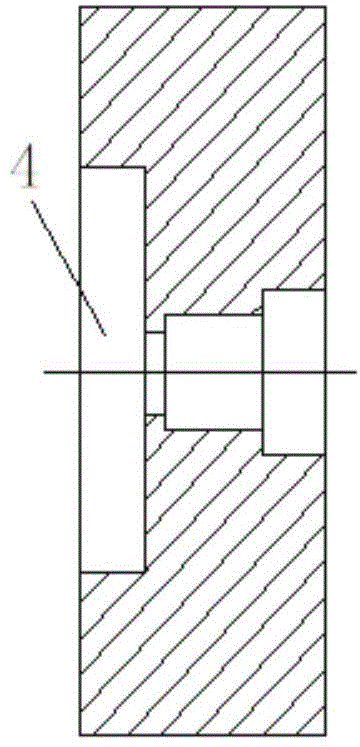

Circumferential seam type supersonic nozzle for metal gas atomization

ActiveCN102581291AUniform velocity distributionReduce turbulenceLiquid spraying apparatusShock waveGas cylinder

A circumferential seam type supersonic nozzle for metal gas atomization comprises a gas inlet pipe (4) connected with an external gas bottle. The gas inlet pipe is connected with an annular gas chamber (1) of the nozzle, the center of the nozzle is provided with a central hole (2), a supersonic gas spray pipe (3) of a circumferential seam structure is formed on the inner chamber wall and the outer chamber wall below the gas chamber and comprises stabilizing sections, contracting sections, throats and diffusion sections, a seam profile consists of symmetric curves, the profile of the whole spray pipe is the seam profile formed by the curves AB, BC and CD to take the axis of central hole (2) as the symmetry axis, the profile rotates by 360 degrees around the axis of the central hole (2) so that a curved surface is obtained, and an included angle alpha ranging from 0 degree to 6 degrees but not equal to 0 degree is formed by an extension line of a central line of each seam passage and the axis of the central hole of the nozzle in the profile of the gas spray pipe (3) passing through the axis of the central hole of the nozzle. The supersonic nozzle for gas atomization has the advantages that gas flow is uniform, turbulence level is low, and shock waves are absent in a flow field.

Owner:有研增材技术有限公司

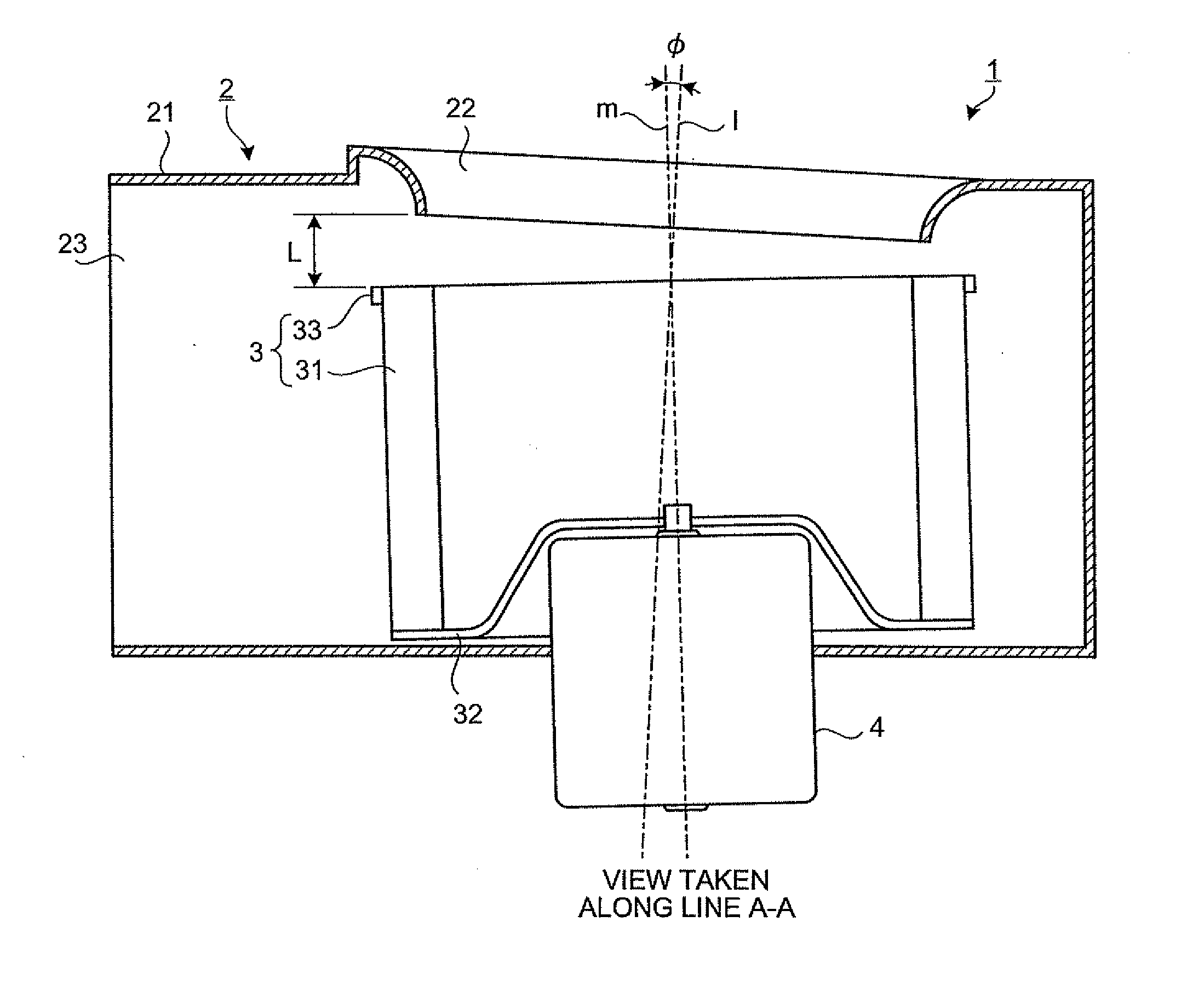

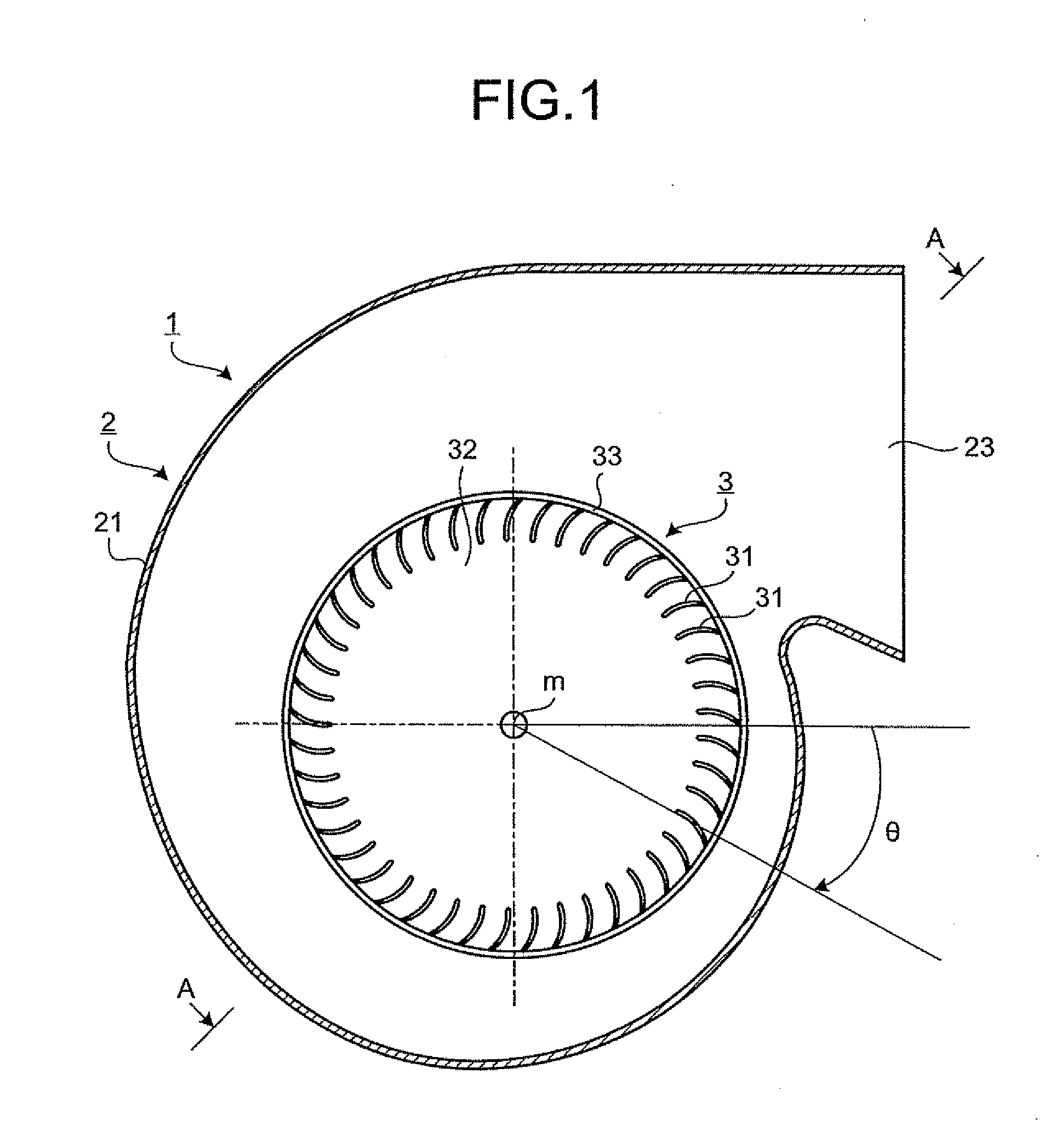

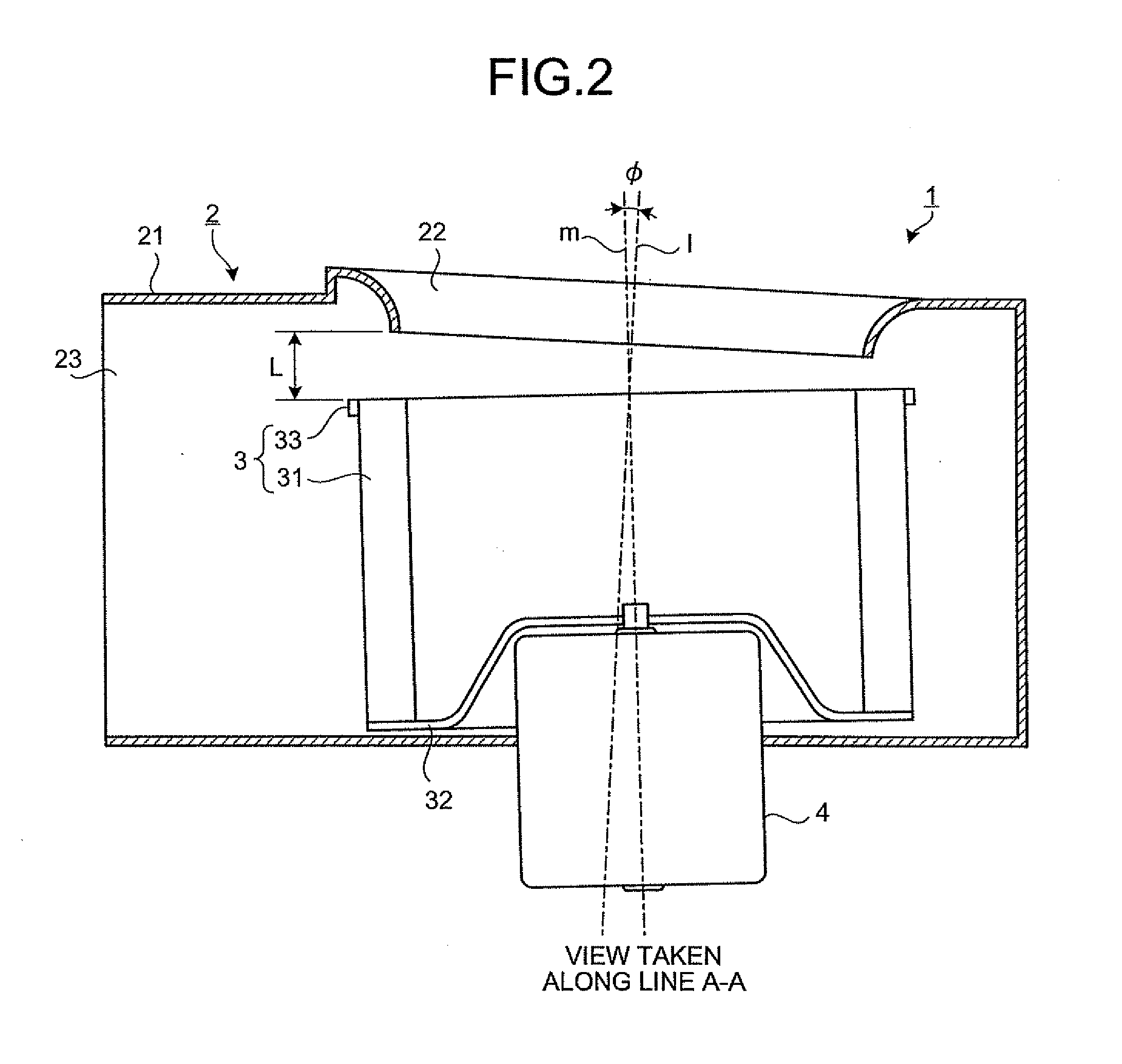

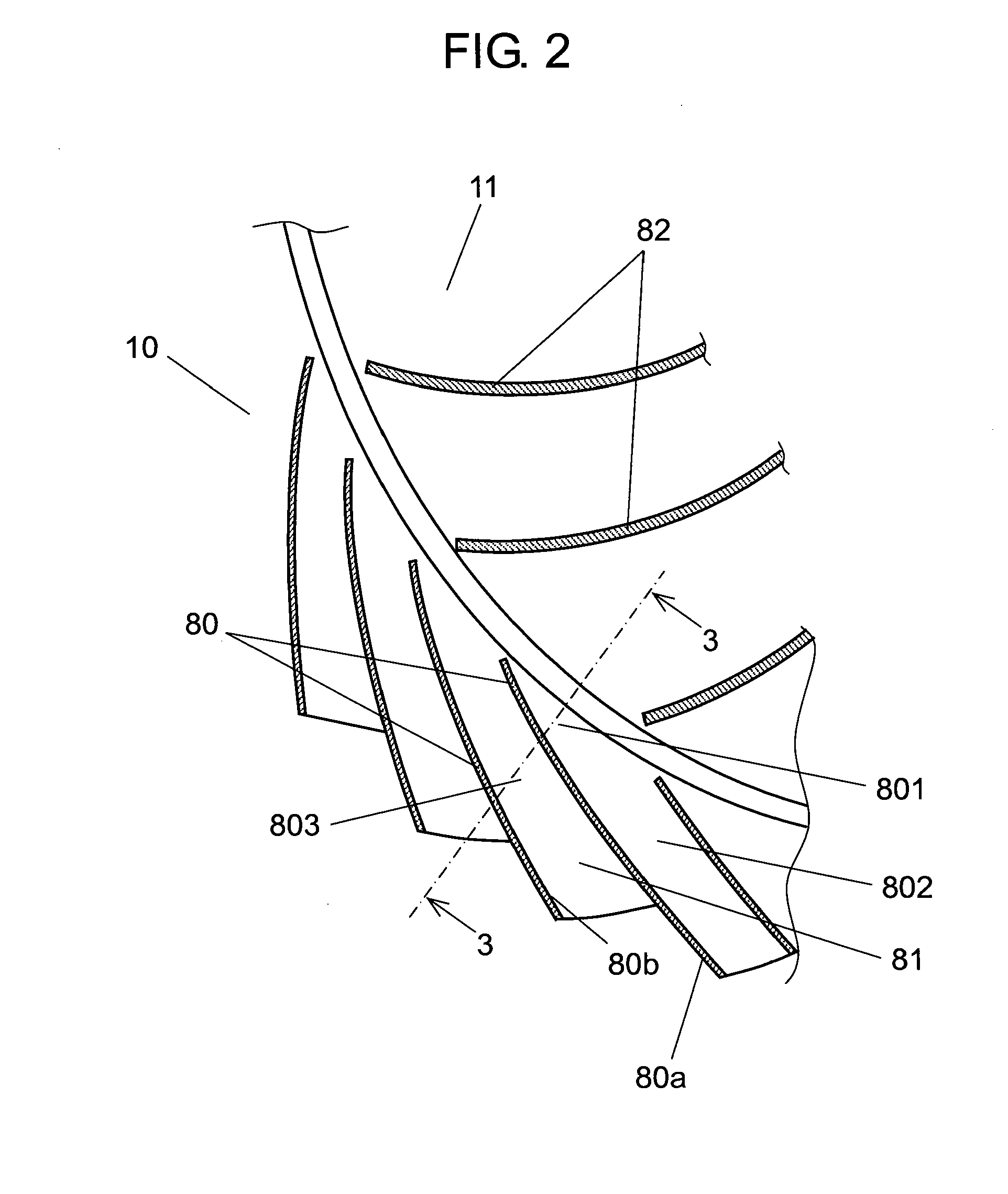

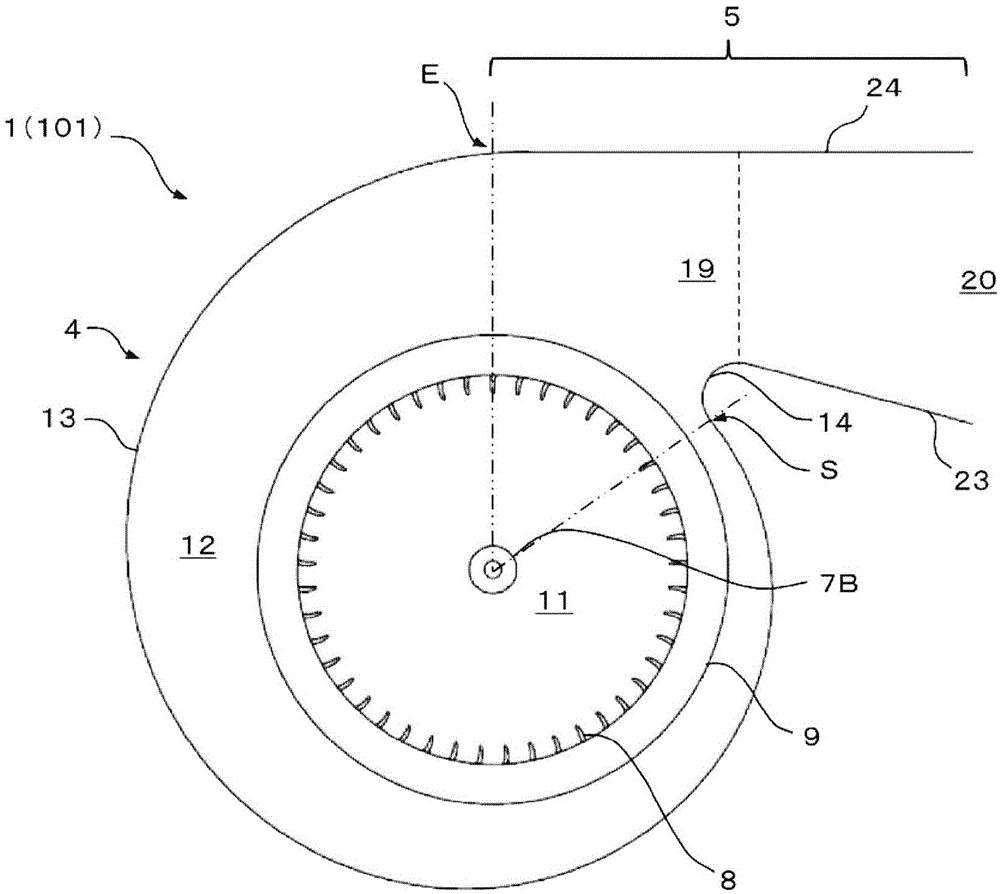

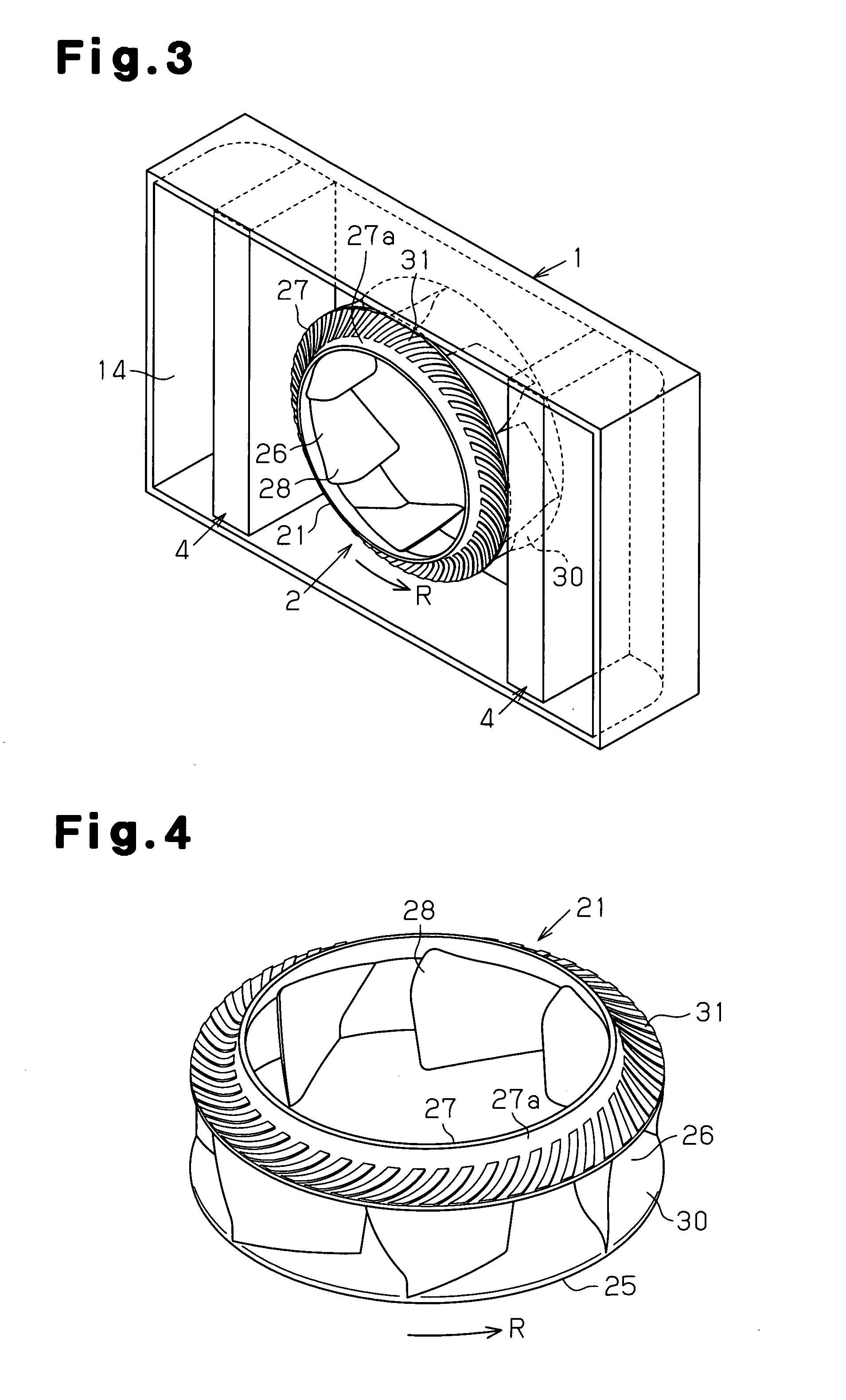

Multiblade fan

InactiveUS20120009059A1Blow performance be advantageously improveNoise characteristicEngine manufactureCircumferential flow pumpsImpellerBell mouth

To provide a multiblade fan that enables an improvement in noise characteristics or blowing performance. The multiblade fan includes a scroll type casing that has a bell-mouthed inlet and an impeller housed in the casing. The impeller includes a plurality of blades and a rotation axis m oriented toward the inlet of the casing. The blades are annularly arranged. In the multiblade fan, a center axis of the inlet and the rotation axis of the impeller are arranged at a tilt angle to each other and in any one of an intersecting positional relationship and a skew-lines positional relationship so that a space between the inlet and the impeller increases from the rotation axis of the impeller toward an outlet of the casing.

Owner:MITSUBISHI ELECTRIC CORP

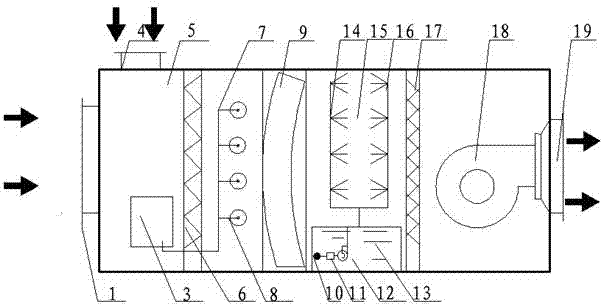

High pressure air injection-fluid power type water spraying chamber composite evaporative cooling air-conditioning unit

InactiveCN102230651AIncrease jet expansion entrainmentIncrease expansion entrainmentLighting and heating apparatusEnergy industryCooling effectHigh pressure

The invention relates to a high pressure air injection-fluid power type water spraying chamber composite evaporative cooling air-conditioning unit which is characterized in that the side wall opposite to the shell of the unit is respectively provided with an air inlet and an air supply outlet; the shell of the unit is internally provided with a primarily efficient filter, a high pressure air injection cooling air device, a rotation type air flow equalization plate, a fluid power type water spraying device, a weir plate and an air feeder in turn in an air inlet direction; a novel air returningmixed section is arranged between the air inlet and the primarily efficient filter; and the side wall of the unit shell on the novel air returning mixed section is provided with an air returning port. According to the invention, high pressure air injection and fluid power type water spraying chambers are organically combined, and two direct evaporative cooling sections are used, thus the unit hasan obvious cooling effect on places in which indoor air needs to be cooled in quantity, such as industrial factory buildings and workshops based on high sensible heat, especially, mines.

Owner:XI'AN POLYTECHNIC UNIVERSITY

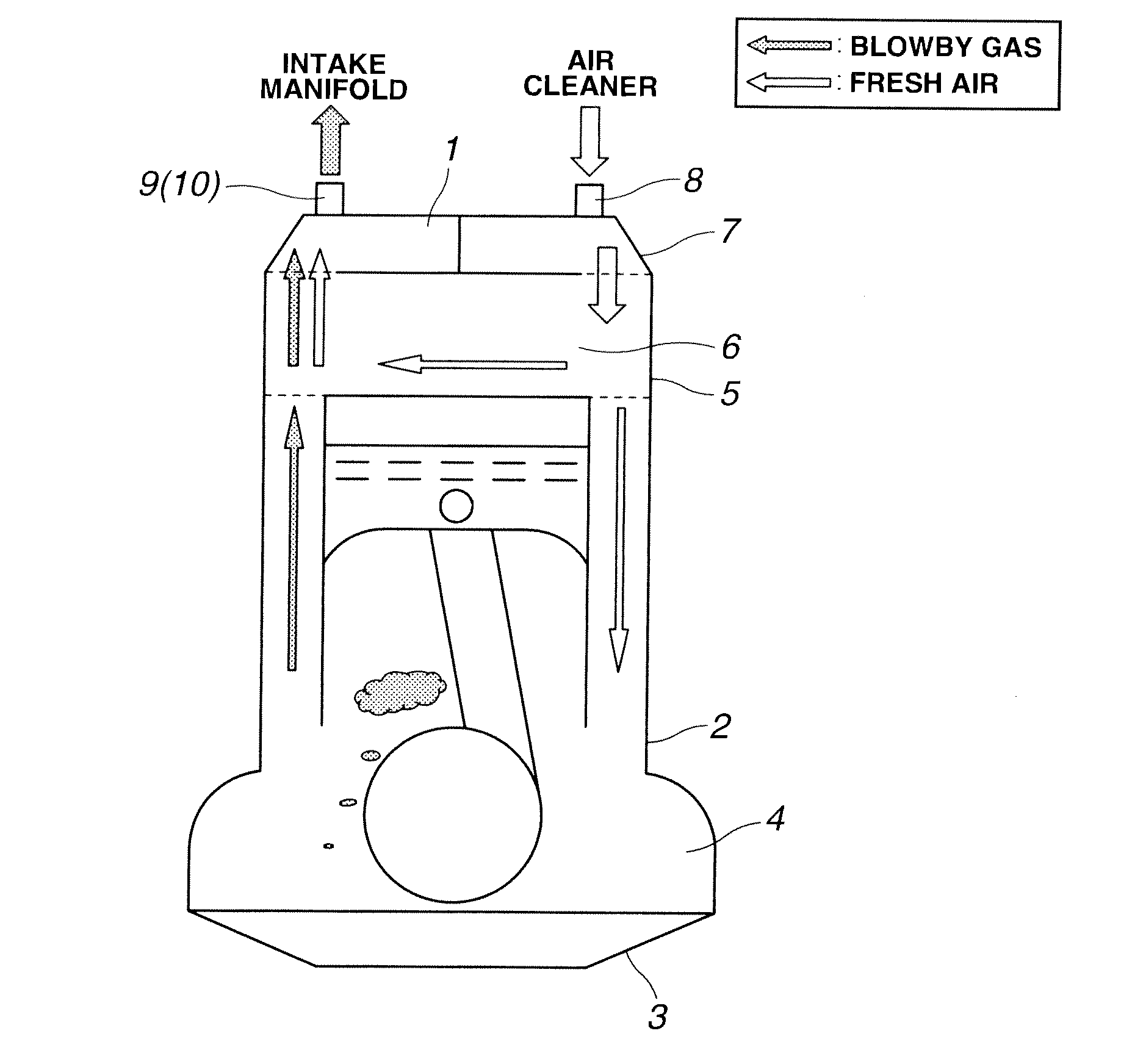

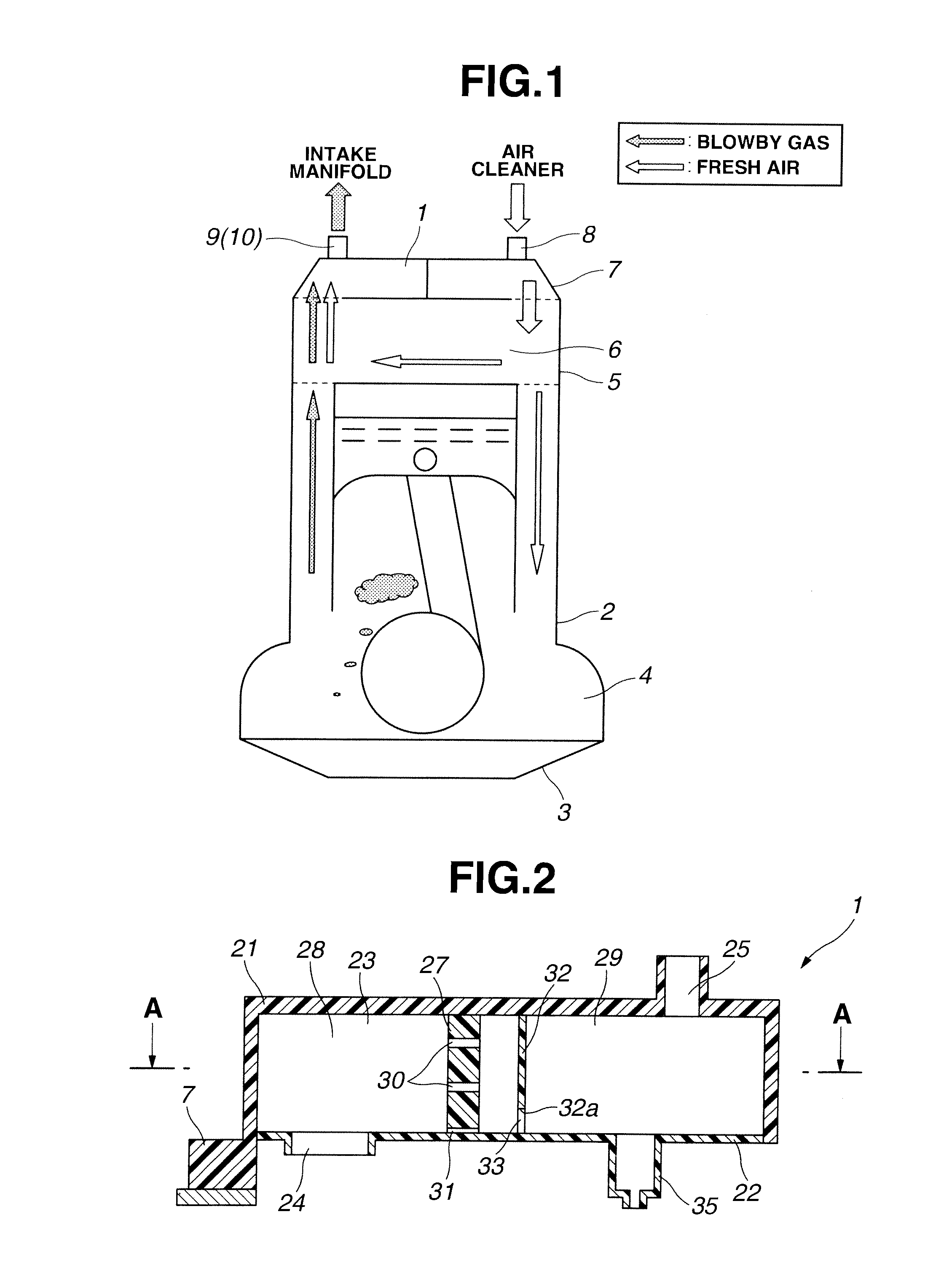

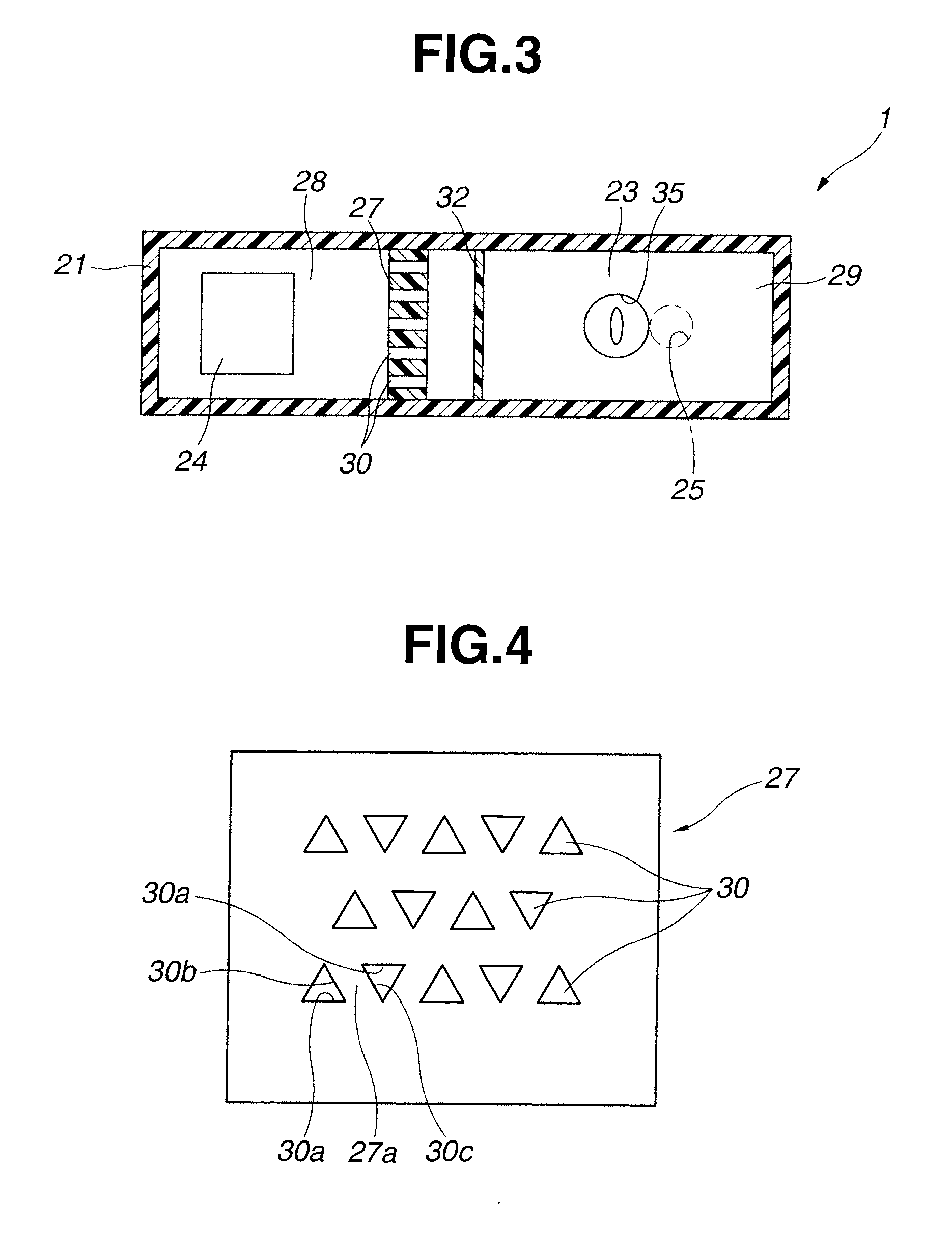

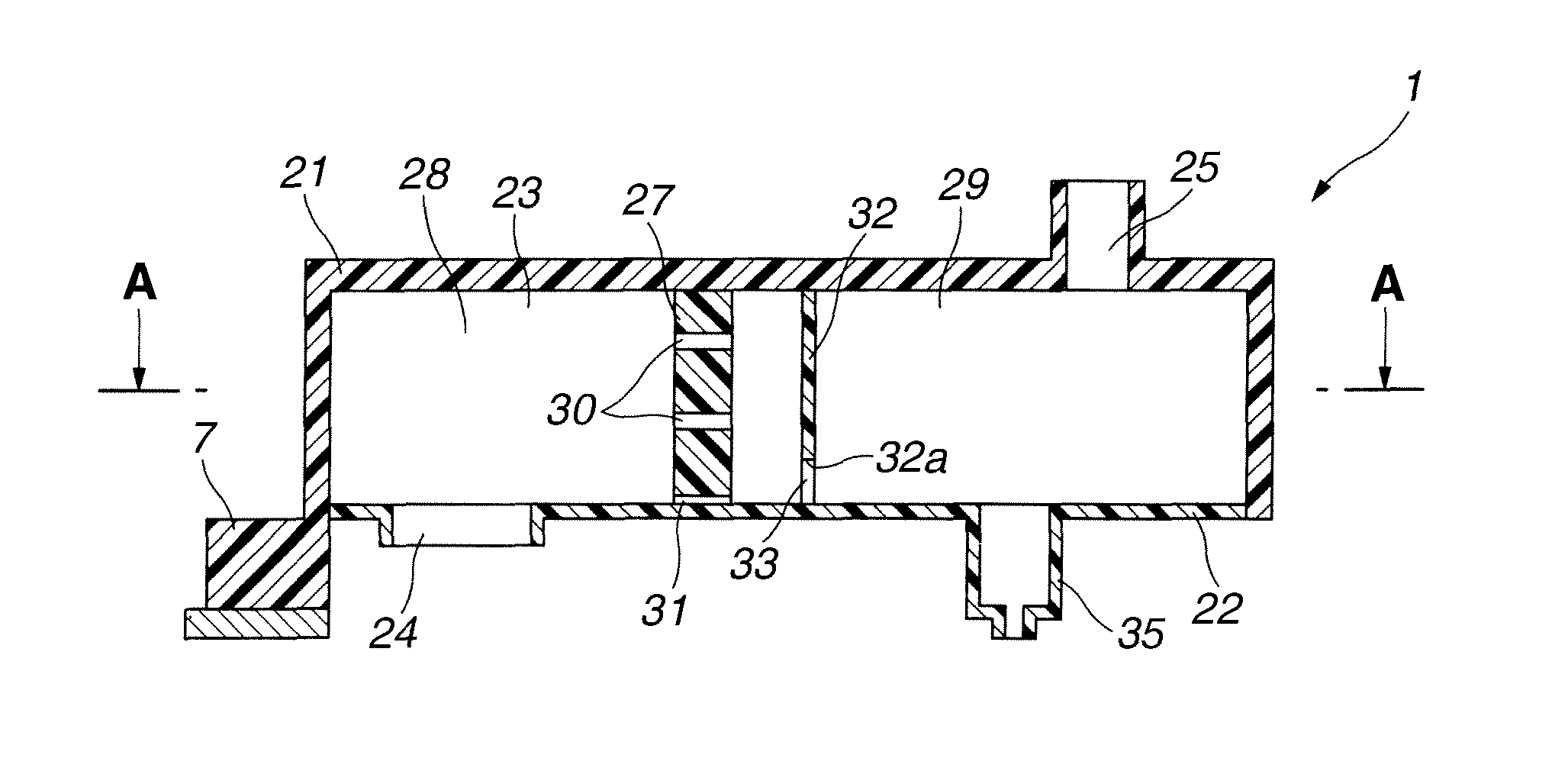

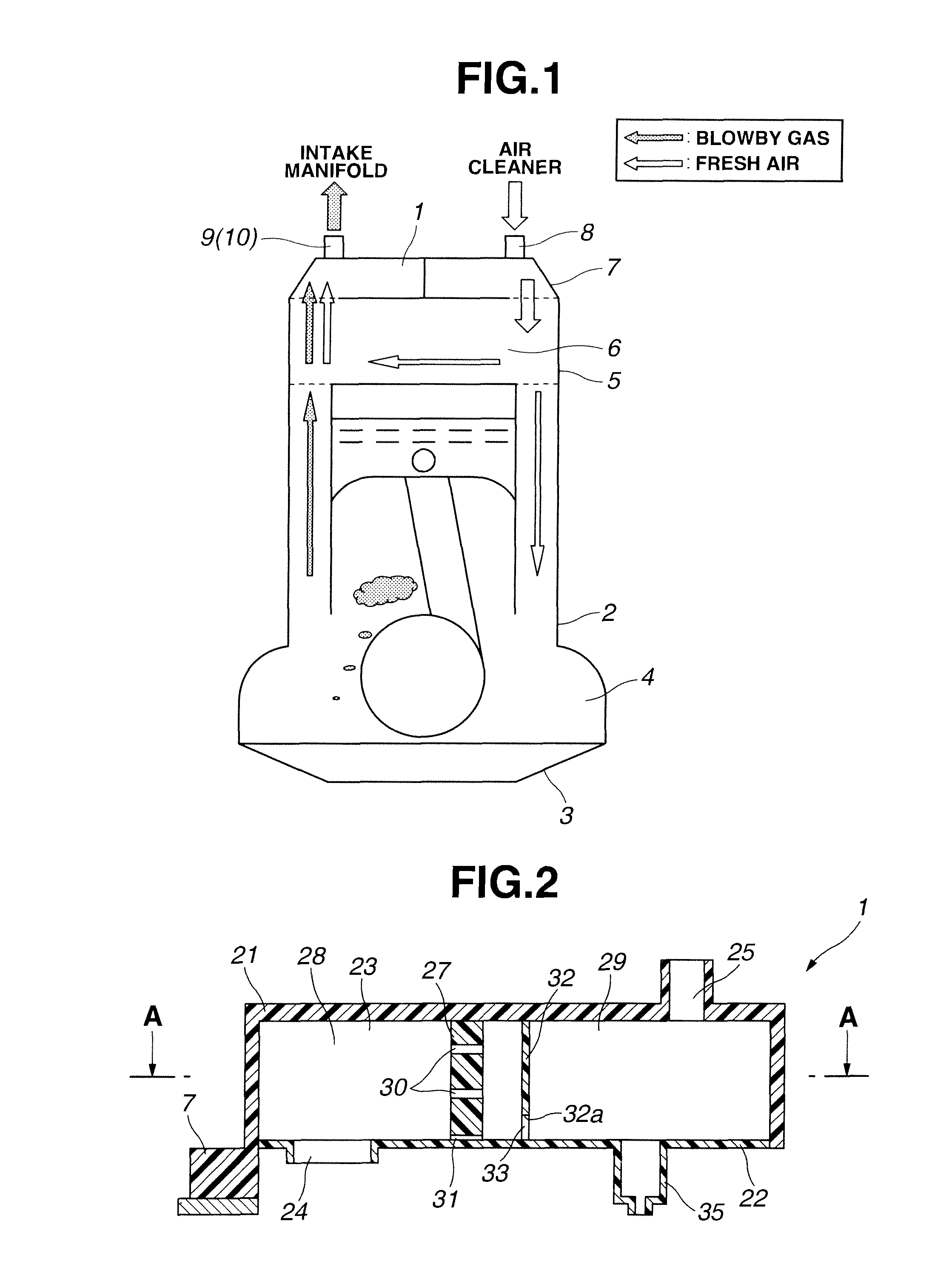

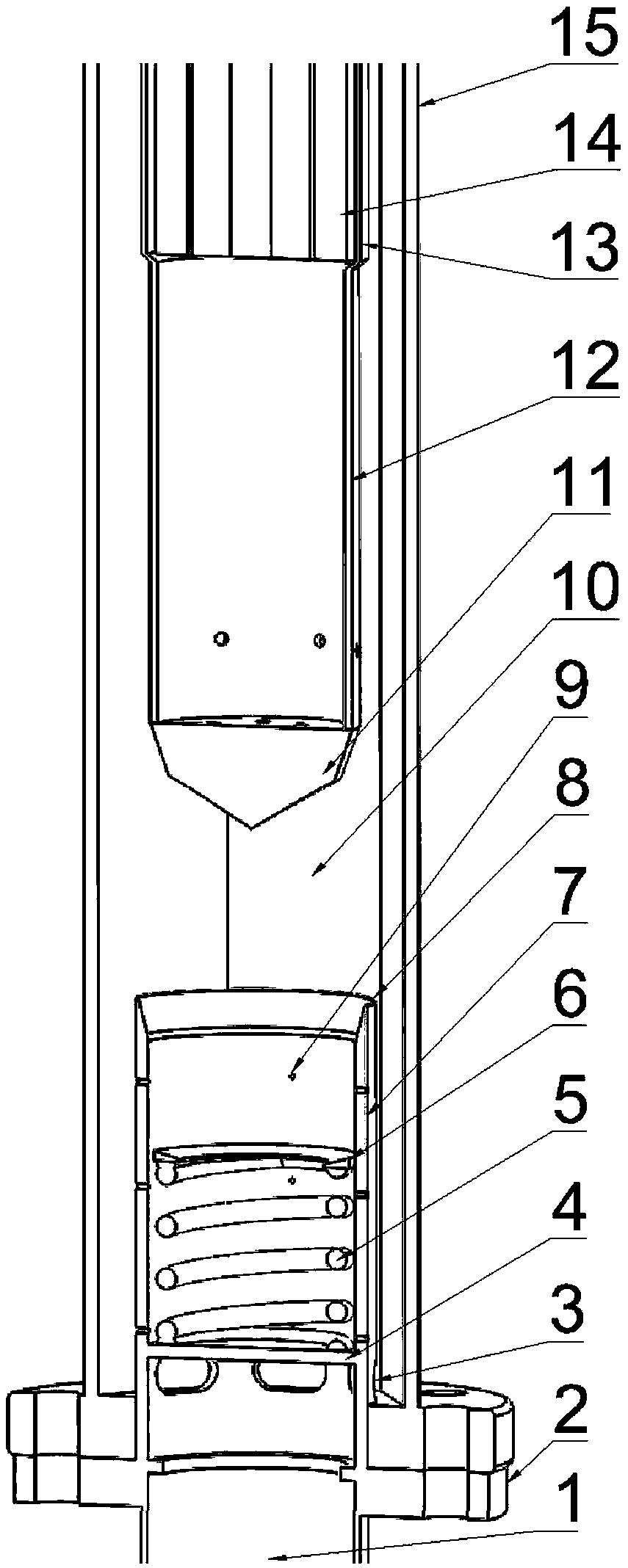

Oil separator for internal combustion engine

InactiveUS20130125865A1Facilitate flow velocityReduce the cross-sectional areaCombustion enginesCrankcase ventillationCylinder headExternal combustion engine

An oil separator disposed inside a cylinder head cover of an internal combustion engine. The oil separator includes a body section defining an elongate separator chamber and having a blowby gas inlet and a blowby gas outlet. A partition wall is disposed to divide the separator chamber into an inlet chamber at side of the blowby gas inlet and an outlet chamber at side of the blowby gas outlet. The partition wall is formed with a plurality of passage holes each of which is triangular in cross-section. A collision plate is disposed inside the outlet chamber and located opposite to the passage holes of the partition wall. A slit-like opening is defined by a lower section of the collision plate and communicated with a drain section for discharging oil separated from blowby gas into a valve operating chamber.

Owner:MAHLE FILTER SYST JAPAN CORP

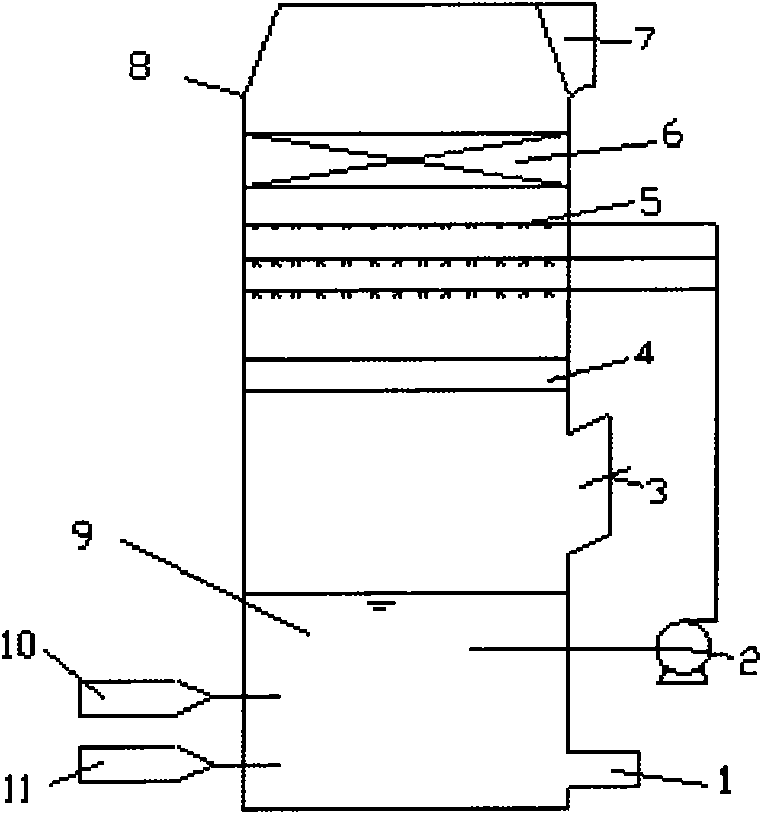

Tower for flue gas desulfurization in homogeneous air-humidifying method

InactiveCN101844037AUniform distribution of flow fieldReduce dosageCalcium/strontium/barium sulfatesDispersed particle separationFlue gasSlurry

The invention discloses a tower for flue gas desulfurization in a homogeneous air-humidifying method. In the technical scheme, the top of the desulfurization tower is provided with a flue gas outlet, the bottom thereof is provided with a desulfurizer slurry tank, a flue gas inlet, a venturi draft tube zone, a slurry spray zone and a mist eliminator zone which are inclined downwards are arranged between the desulfurizer slurry tank and the top flue gas outlet in sequence from bottom to top, and the desulfurizer slurry tank is connected with the slurry spray zone through an external slurry circulating pump and is also connected with an external limestone slurry supply device and an oxidation air system. The flue gas forms a uniform upward turbulent flow through the venturi draft tube after flowing into the desulfurization tower, then passes through the slurry spray zone arranged in a staggered way so that SO2 in the flue gas can be transformed into CaSO3, and is finally oxidized into gypsum after being dropped into the slurry tank below the tower along with absorption slurry droplets. Compared with the conventional desulfurization tower, the gas-liquid mass transfer efficiency can reach 20-30 percent, the desulfurization efficiency is up to more than 97 percent, the liquid-gas ratio can be reduced by 3-5L / m2, the structure is simple, and the cost is low.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

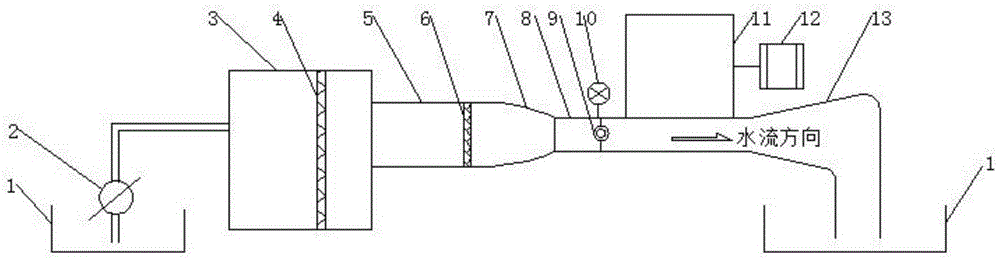

Testing apparatus for fluid resistance performance of flat plate surface

InactiveCN105387993ANo separationAvoid distortionHydrodynamic testingProgrammable logic controllerFrequency conversion

The invention discloses a testing apparatus for a fluid resistance performance of a flat plate surface. The testing apparatus is characterized in that a water tank, a frequency conversion pump, a settling chamber, a diffusion section, a contraction section, a working section and a spreading section are communicated successively to form a water circulation system. A test box is arranged above the working section and a lower opening is communicated with an upper pipe wall of the working section; and a bottom of a horizontal testing flat plate suspended inside the test box is flush with the inner wall of the upper pipe wall of the working section to form a constituent part of a flowing channel and the part is located above the flow of the working section. A pressure contact of a pressure sensor is in movable contact with a suspension rod of the testing flat plate along a horizontal direction; and the pressure sensor and a programmable logic controller arranged outside the test box are connected electrically. Therefore, a drag reduction effect of the flat plate surface after texturing or reducing material coating can be measured accurately; the stable flow is obtained based on the precise structure design of the water circulation system; and the interference like friction between the frame of the pipe wall and the flow is eliminated by suspending the testing flat plate. Moreover, the testing method is simple and is easy to operate; and the testing is accurate.

Owner:WUHAN UNIV OF TECH

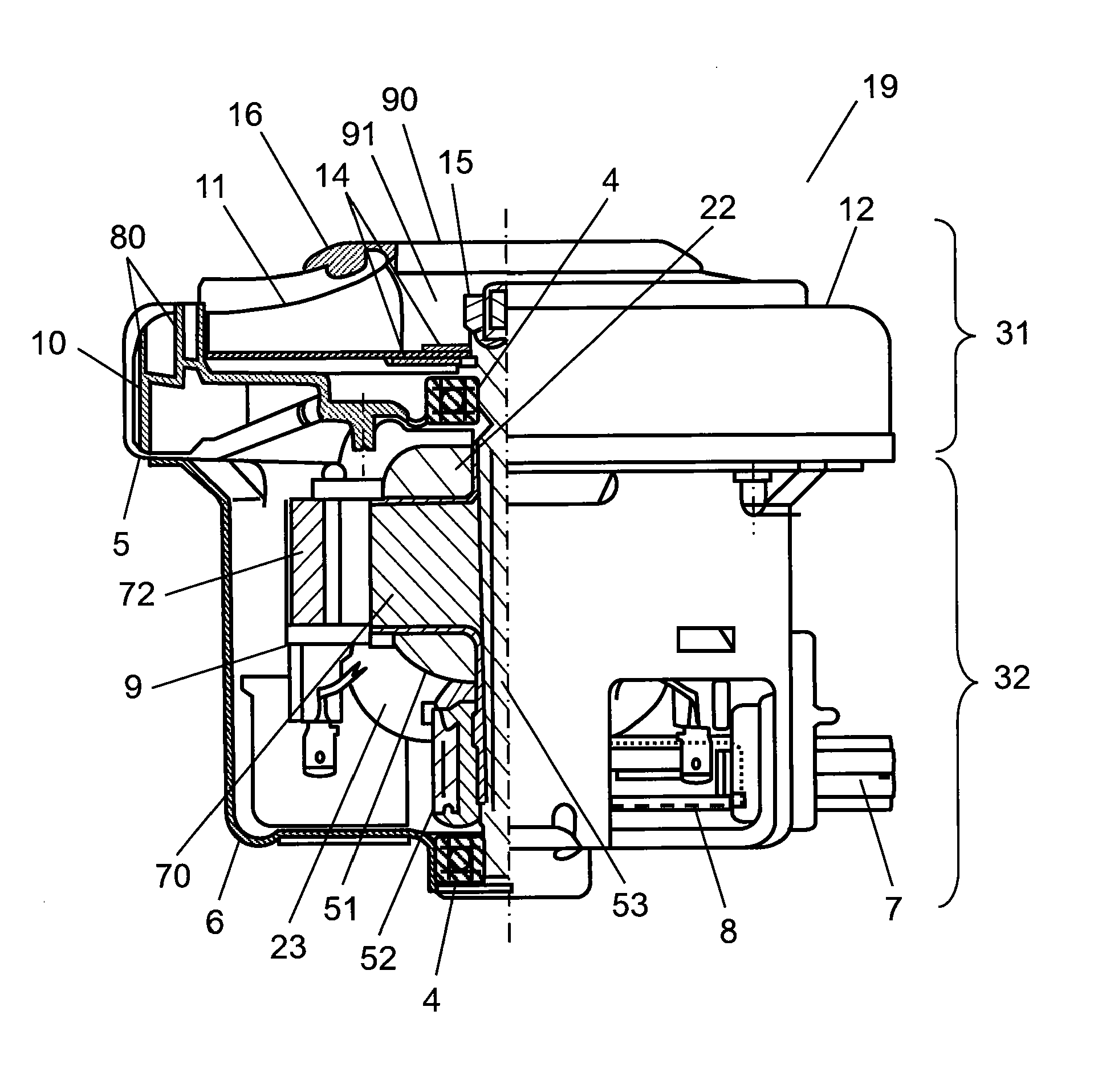

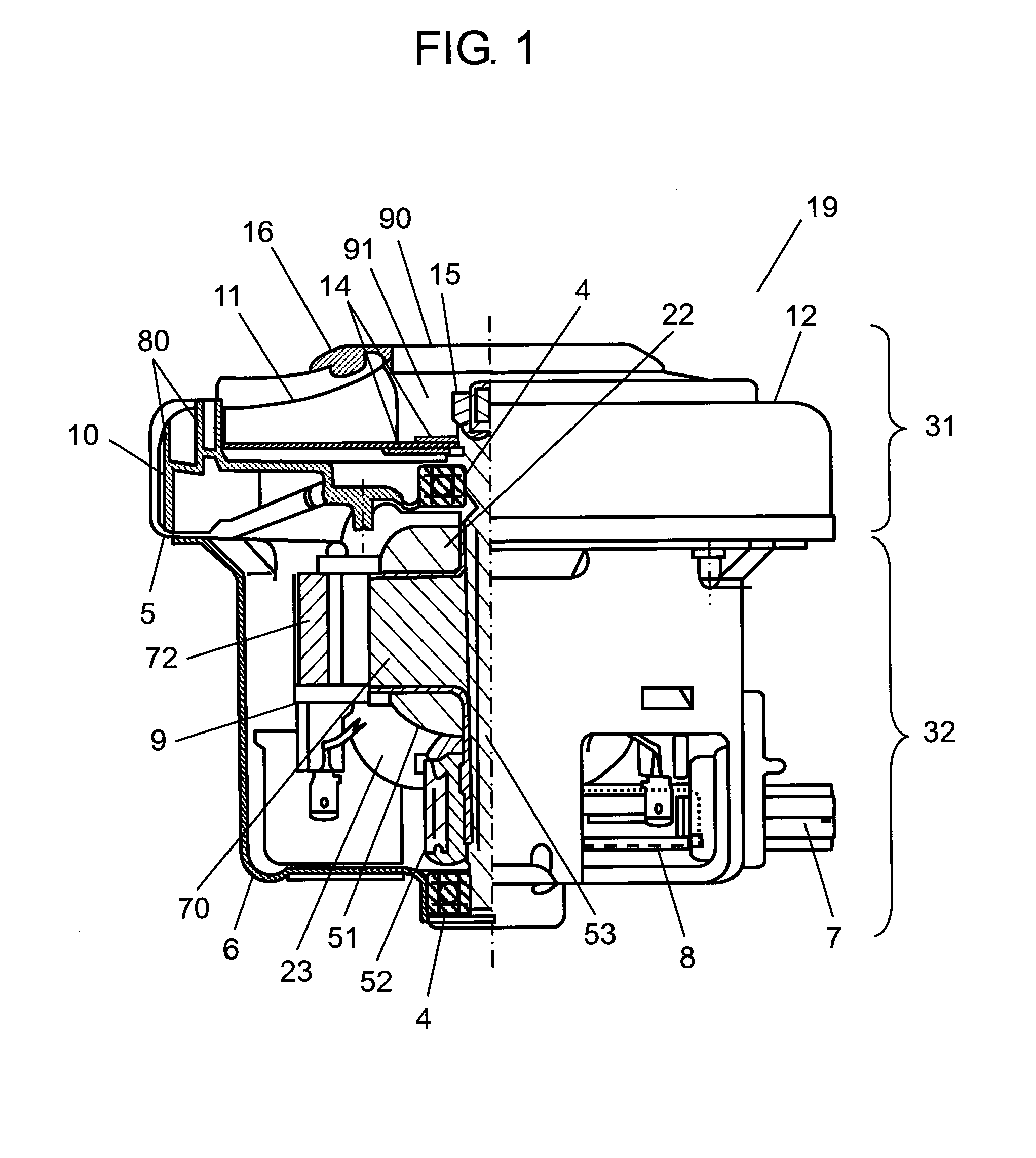

Electric blower and electric vacuum cleaner utilizing the same

InactiveUS20110277267A1High suction performanceReduce lossMechanical cleaningPressure cleaningImpellerEngineering

Air guide (10) that rectifies air blown out from an impeller includes a plurality of guide vanes (80) having a circular arc shape. In a cross-sectional shape of each one of flow passages (81) of air guide (10), length B of a straight-line portion in a shaft direction of an inner wall-surface formed by one of guide vanes (80) on an outer peripheral side is small compared with length A of a straight-line portion in a shaft direction of an inner wall-surface formed by one of guide vanes (80) on an inner peripheral side. This provides a uniformed flow velocity distribution inside flow passages (81), resulting in a reduced loss caused by differences in flow velocity.

Owner:PANASONIC CORP

Oil separator for internal combustion engine

InactiveUS8726876B2Velocity increasesReduce the cross-sectional areaCombustion enginesPressure lubricationCylinder headExternal combustion engine

An oil separator disposed inside a cylinder head cover of an internal combustion engine. The oil separator includes a body section defining an elongate separator chamber and having a blowby gas inlet and a blowby gas outlet. A partition wall is disposed to divide the separator chamber into an inlet chamber at side of the blowby gas inlet and an outlet chamber at side of the blowby gas outlet. The partition wall is formed with a plurality of passage holes each of which is triangular in cross-section. A collision plate is disposed inside the outlet chamber and located opposite to the passage holes of the partition wall. A slit-like opening is defined by a lower section of the collision plate and communicated with a drain section for discharging oil separated from blowby gas into a valve operating chamber.

Owner:MAHLE FILTER SYST JAPAN CORP

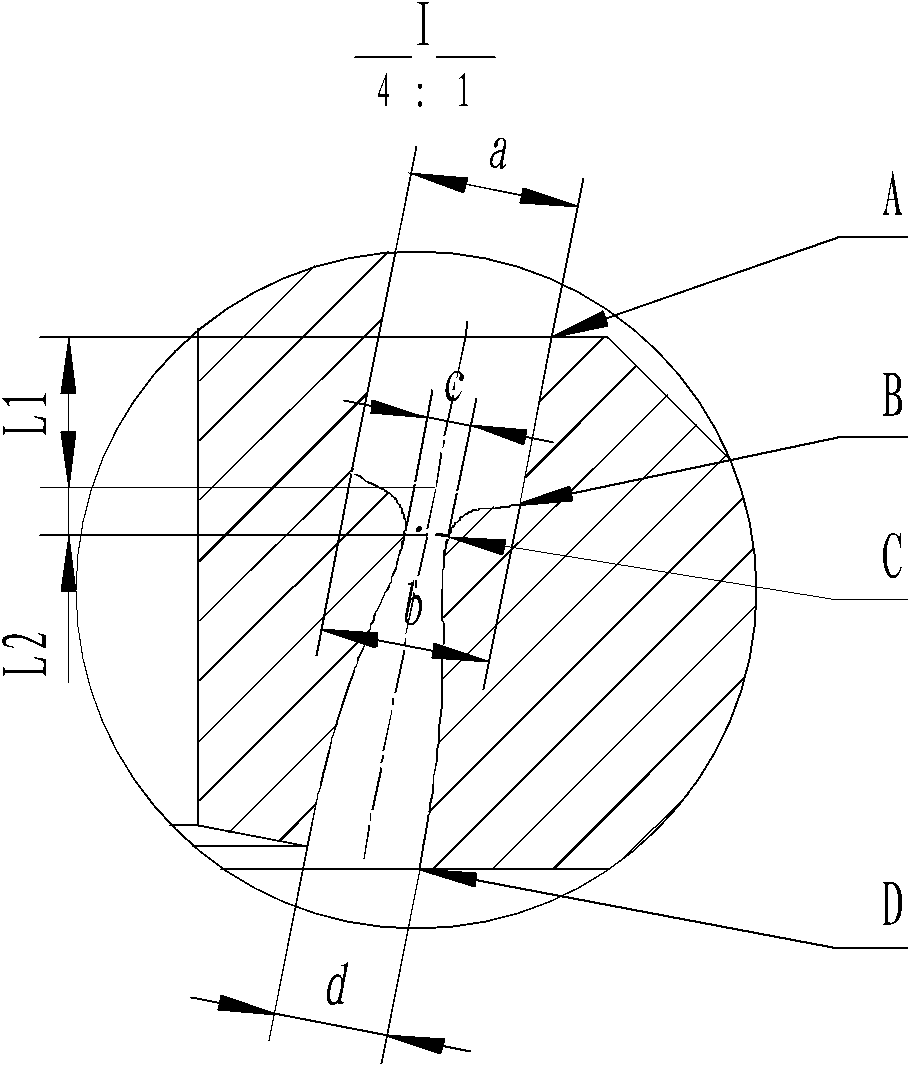

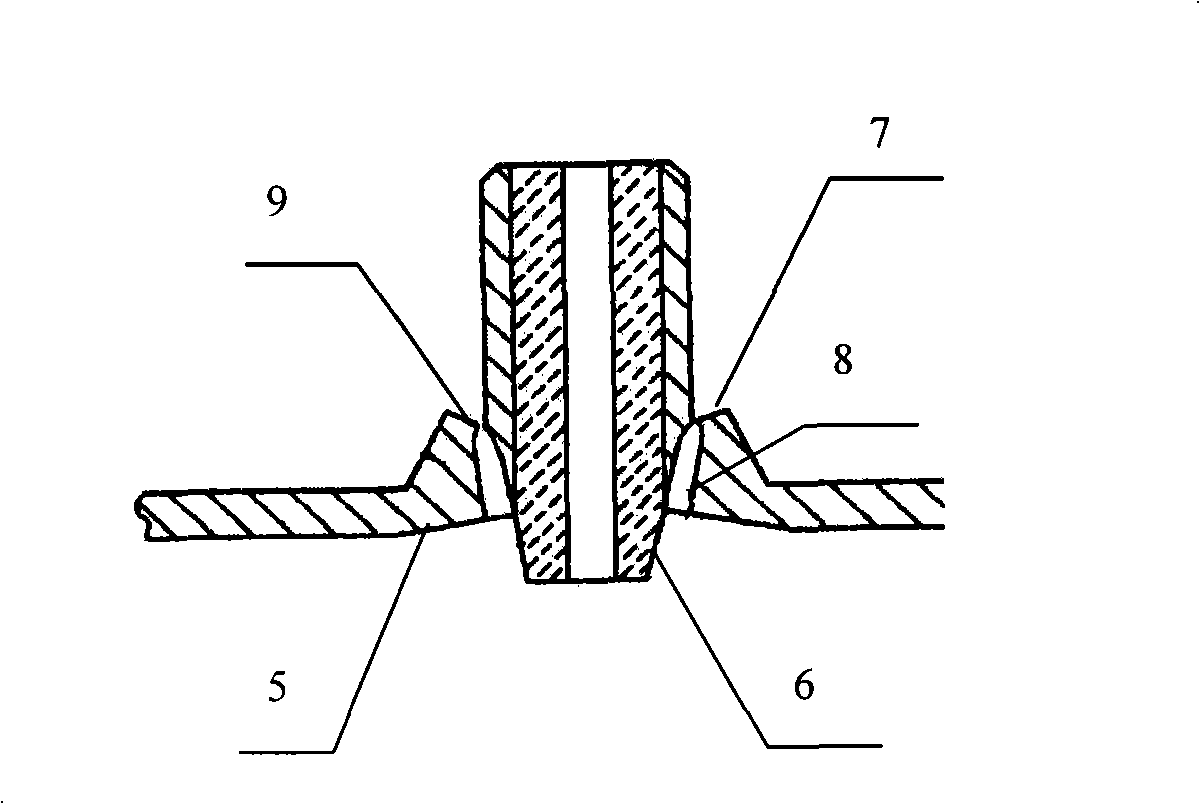

Loop type supersonic nozzle device for atomizing metal gas

InactiveCN101406862AUniform accelerationReduced characteristicsSpray nozzlesLiquid spraying apparatusShock waveGas cylinder

The invention provides an annular ring type supersonic nozzle device used for metal gas atomization, which comprises an inlet pipe (4) connecting an external gas cylinder, wherein the inlet pipe is connected with a nozzle annular air-chamber (1); the center of a nozzle is provided with a central hole (2); a plurality of supersonic gas nozzles (3) are evenly distributed on the chamber wall under the air chamber; each supersonic gas nozzle comprises a stable section, a contraction section, a throat part and a diffusion section; and an extension line of the central line of the gas nozzle and an axial line of the central hole form an included angle alpha. A line segment AB of the stable section is a straight line parallel to the axial line of the nozzle; contraction section BC of the nozzle is a contraction type curve; the throat part CD of the nozzle is a section of circular arc; a segment type line of the extension section DEF consists of a straight line DE and a curve EF; the section of the whole nozzle is a circle; and the profile of the nozzle is a streamline curved surface produced by rotating ABCDEF curves in the nozzle around the axial line of the nozzle. The device has the advantages that the supersonic atomization nozzle with even and uniform air flow and small turbulence scale without compression wave in a flow field can fulfill the technical requirement of quickly solidifying metal atomization; and the prepared metal powder achieves the aim of small granularity and narrow distribution of grain diameter.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

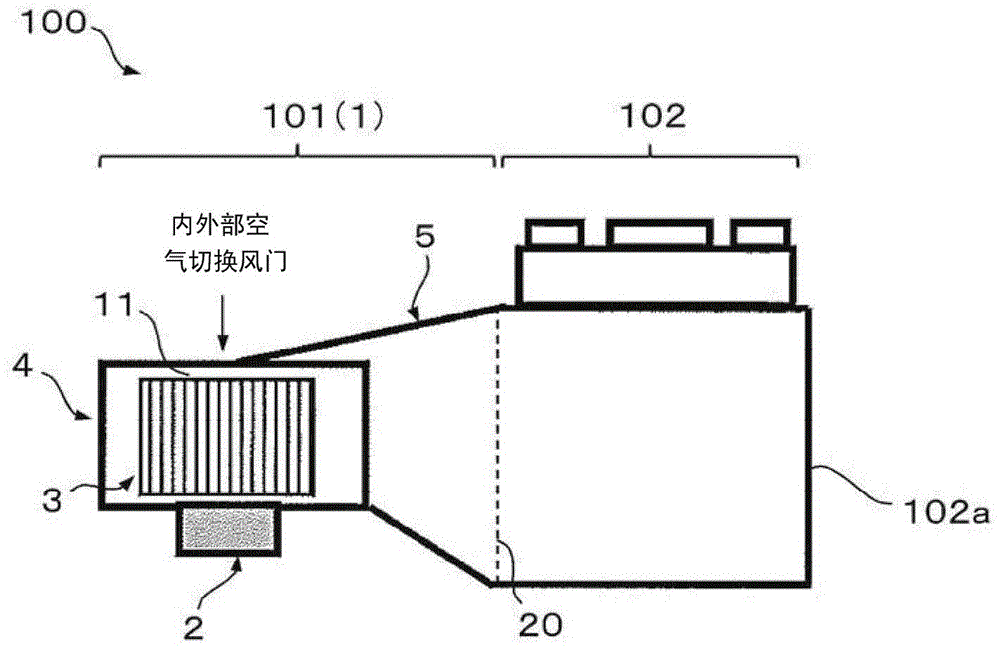

Centrifugal air blower and vehicle-mounting air-conditioning apparatus comprising same

ActiveCN104343727AUniform velocity distributionReduce flow ratePump componentsPumpsCentrifugal fanAir blower

A centrifugal air blower and vehicle-mounting air-conditioning apparatus capable of improving air flow amount. The centrifugal blower (1) comprises: a multifin centrifugal fan (3), having a plurality of blades (8) arranged around a rotating shaft (6); a scroll-shaped casing (4) accommodating the centrifugal fan (3) and having an air suction inlet (11) and a flow passage vortex-shaped flow path (12) as a flow path for air from multiple fins centrifugal fan exhaust air; and a diffuser portion (5), which has a expanded stream path (19) and an outlet (20), wherein the downstream end of the vortex-shaped flow path (12) is communiated with the expanded stream path (19), and changes the height of the flow path in a manner of the cross-sectional area increasing with downstream side of the air flow. The outlet is opened at the downstream of the expanded stream path. The centrifugal blower is provided with multiple fins from centrifugal fan exhaust air flow rate uniform distribution of the upstream distribution equalizing element (18), wherein the upper side wall (21) of the diffuser portion of the inclined starting position than the lower side wall disposed in the diffuser portion (22) is inclined starting position closer to the air flow position side.

Owner:三电株式会社

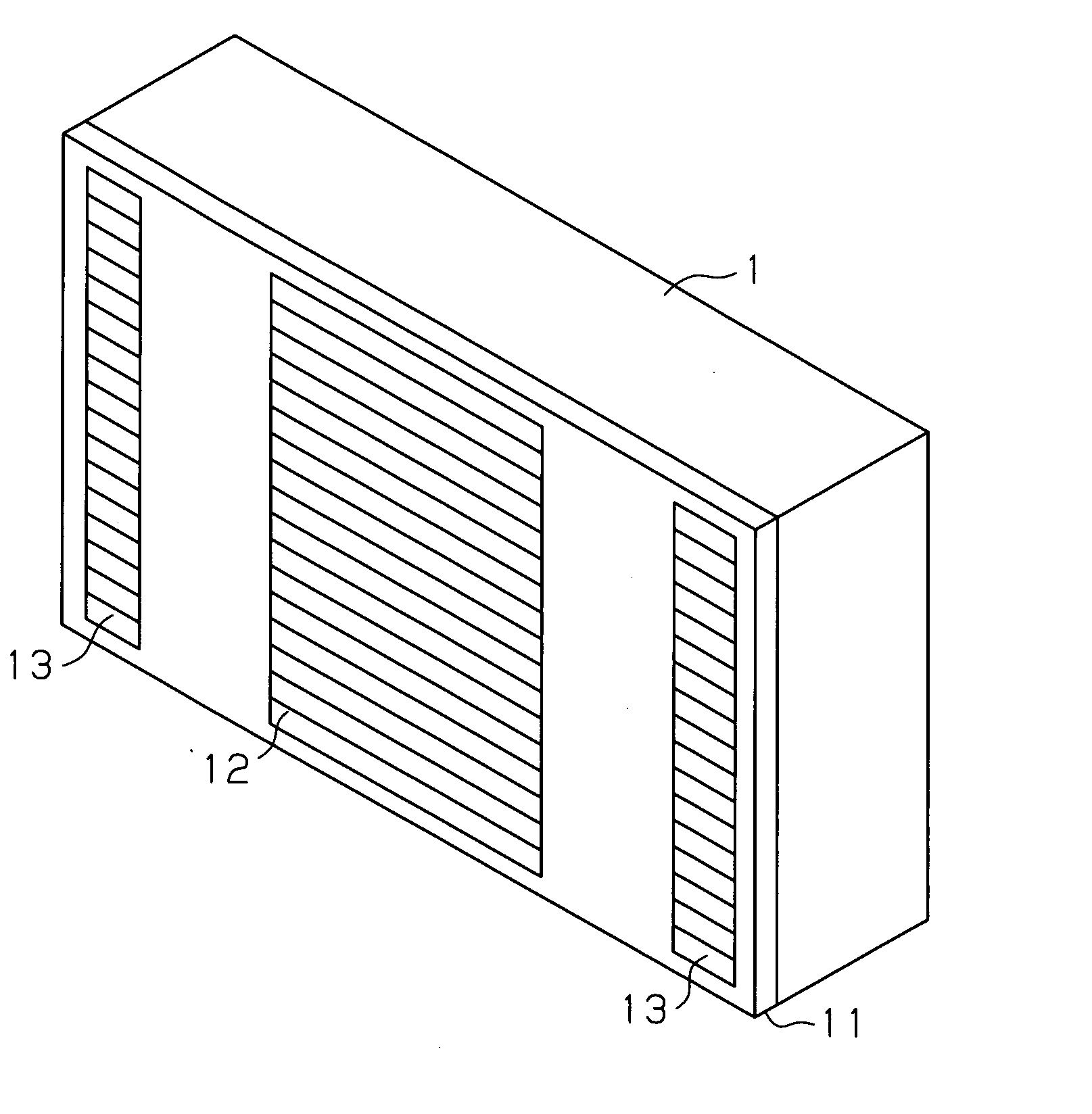

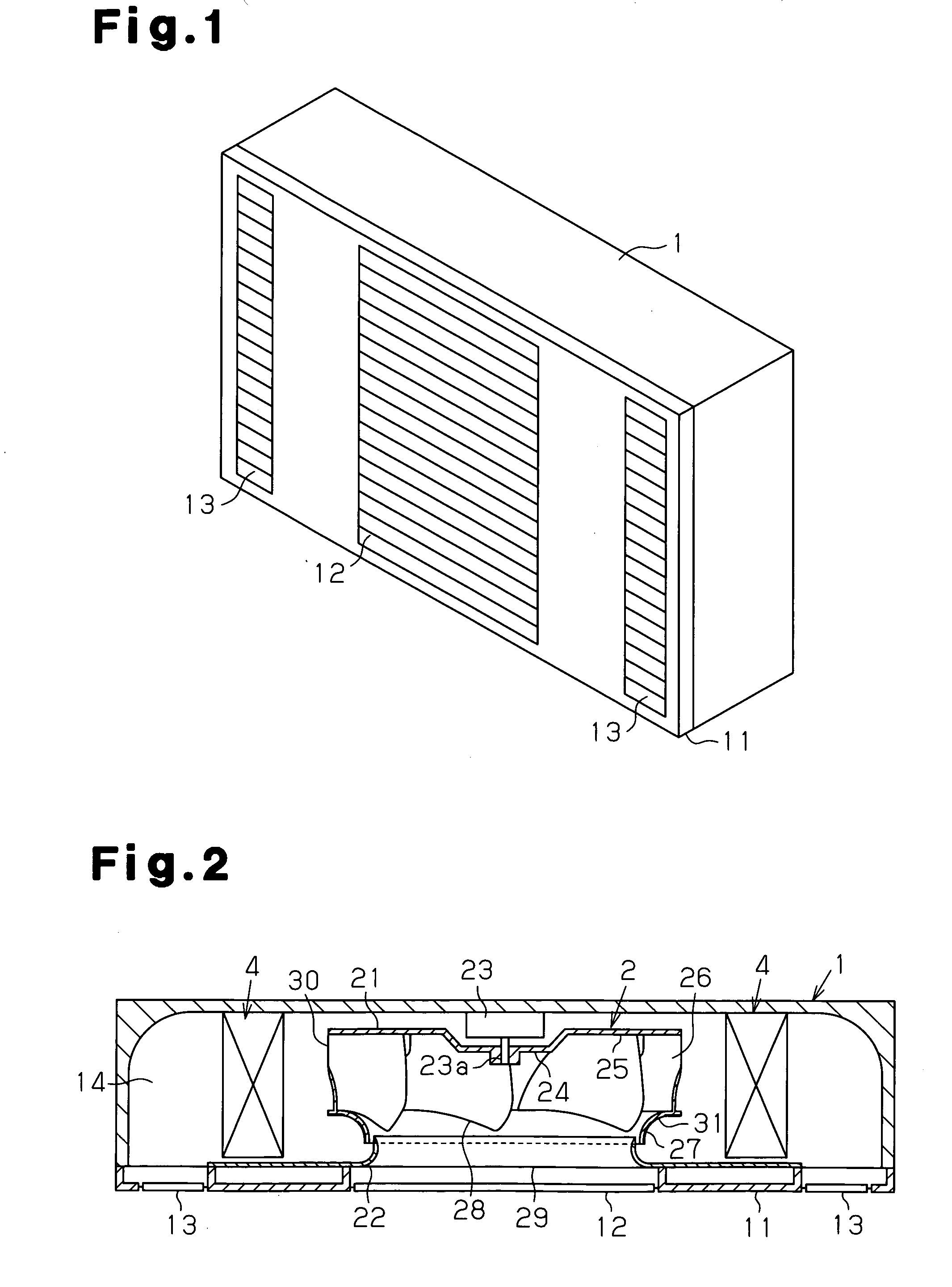

Centrifugal Fan and Air Conditioner Using the Same

InactiveUS20090255654A1Reduce running noiseUniform velocity distributionPropellersPump componentsImpellerAir velocity

The present invention provides a centrifugal fan by which air velocity distribution in the height direction of impellers at a fan blow-out port is made uniform and running noise is reduced, and an air conditioner whose running noise is reduced by applying the centrifugal fan thereto. The centrifugal fan is provided with a hub for fixing the rotary shaft of a motor, a main plate formed on the outer circumference of the hub, a shroud disposed to be opposed to the main plate, which forms an air passage, a plurality of impellers disposed between the main plate and the shroud, and a bellmouth disposed at the suction side of the shroud. Projections or recesses are formed on the surface of the shroud facing the bellmouth, which projections or recesses form air streams flowing from the center of the shroud toward the outer circumference thereof along the surface when running a fan. The air conditioner has a thus constructed centrifugal fan mounted therein.

Owner:DAIKIN IND LTD

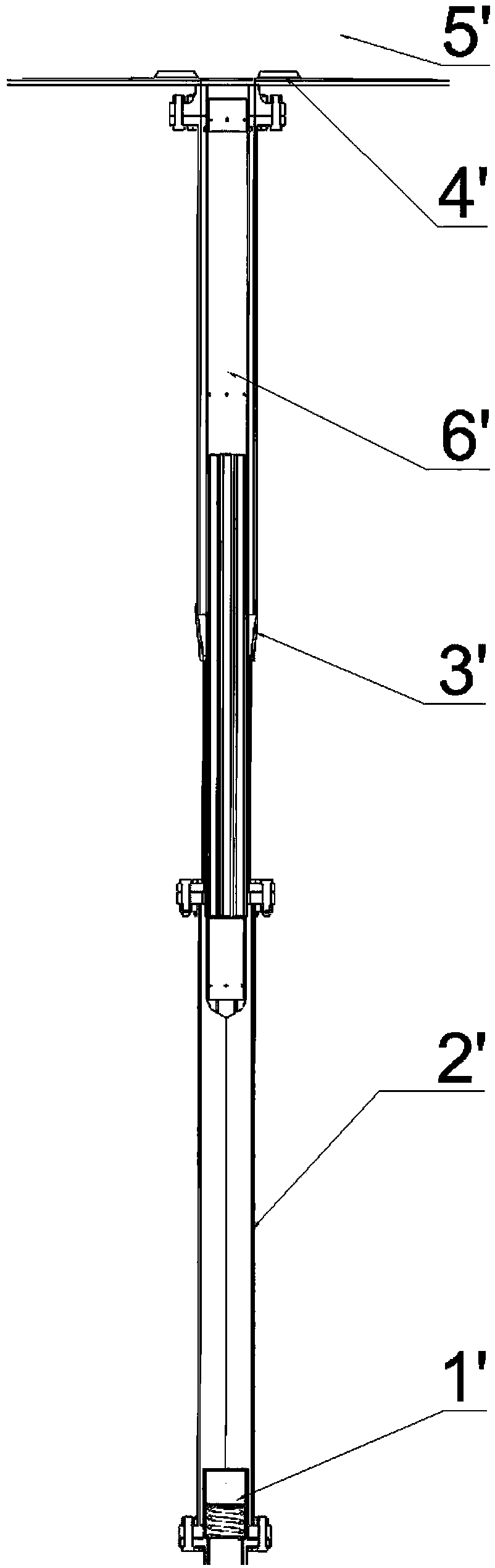

Hydraulic buffer structure for hydraulic suspension passive shutdown experimental device

ActiveCN108695004AReduce stick drop timeEffective rod drop deceleration bufferNuclear energy generationNuclear reaction controlHydraulic cylinderFlange

The invention discloses a hydraulic buffer structure for a hydraulic suspension passive shutdown experimental device. The hydraulic buffer structure comprises a hydraulic buffer cylinder mounted on aninlet pipe flange, a compression spring and a base baffle thereof, a visual casing pipe and a passive shutdown rod lower end plug structure. The hydraulic buffer cylinder is divided into an upper part and a lower part through the compression spring base baffle. The lower part is provided with a group of water inlet holes arranged at equal intervals along the circumferential direction. The upper part is provided with three groups of pressure relief holes equally spaced in the circumferential direction. The tail of the upper part is processed to form a tapered through hole. The passive shutdownrod lower end plug structure comprises a damping block and a conical lower end cover. The damping block is provided with a group of through holes at equal intervals along the circumferential direction. The upper part of the damping block is connected to a passive shutdown rod middle casing pipe. Through combination of the necking transition design and the compression spring, the total rod fallingtime of the passive shutdown rod is significantly reduced. The annular gap water inlet design realizes uniform coolant velocity distribution and improves the suspension stability of the passive shutdown rod.

Owner:XI AN JIAOTONG UNIV

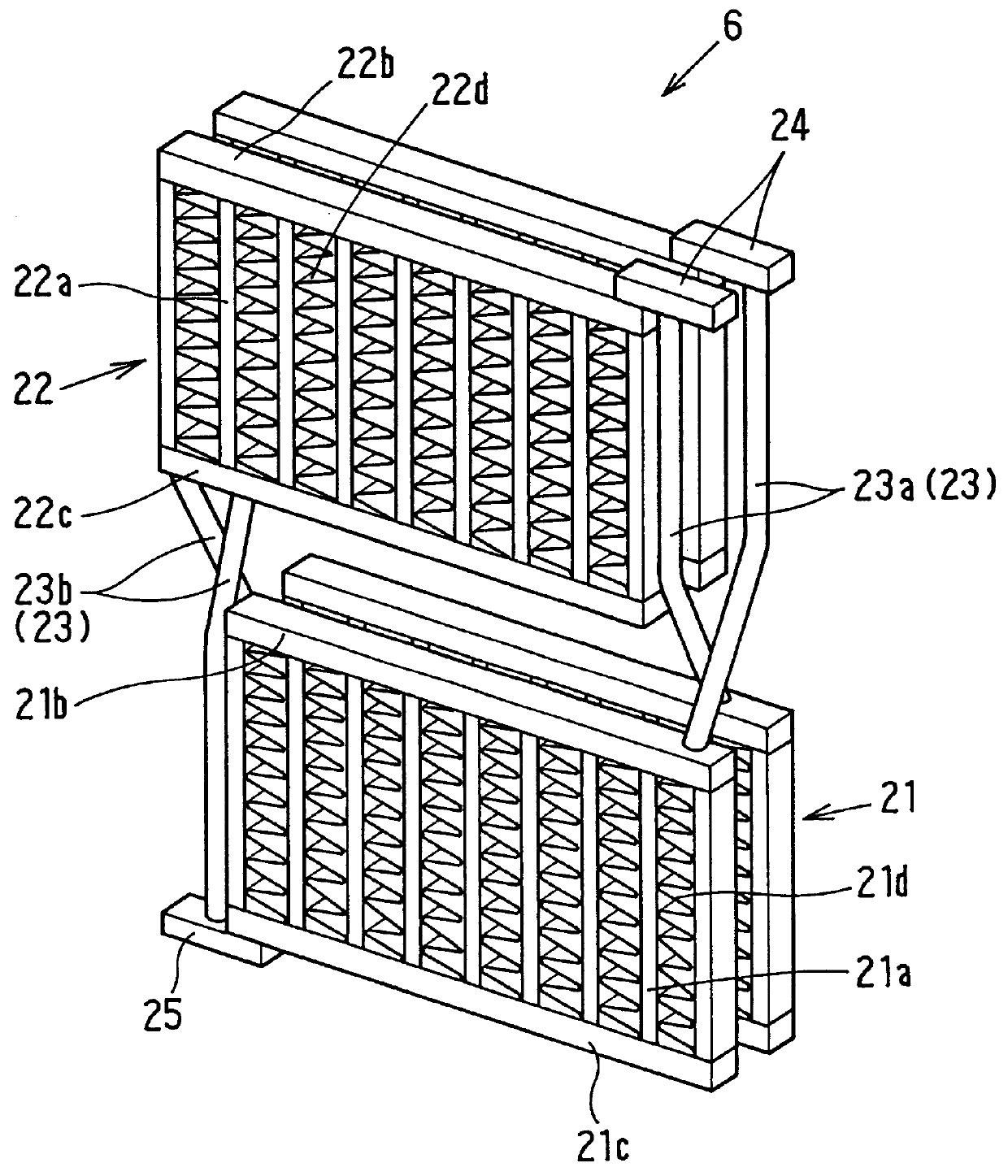

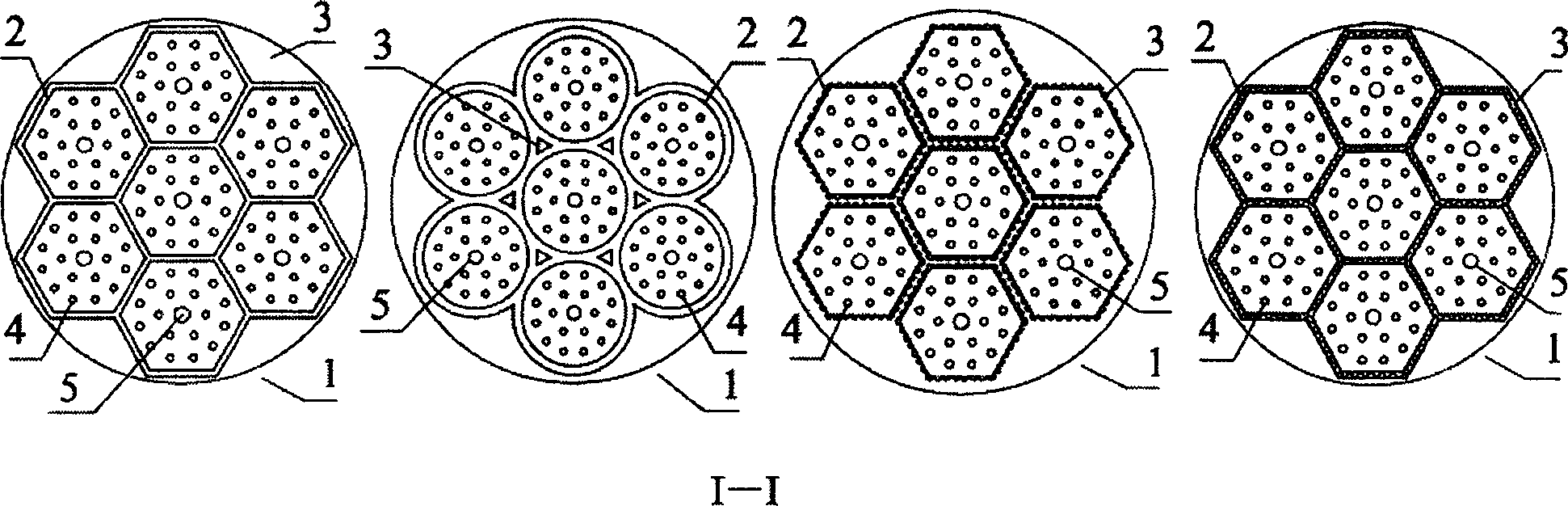

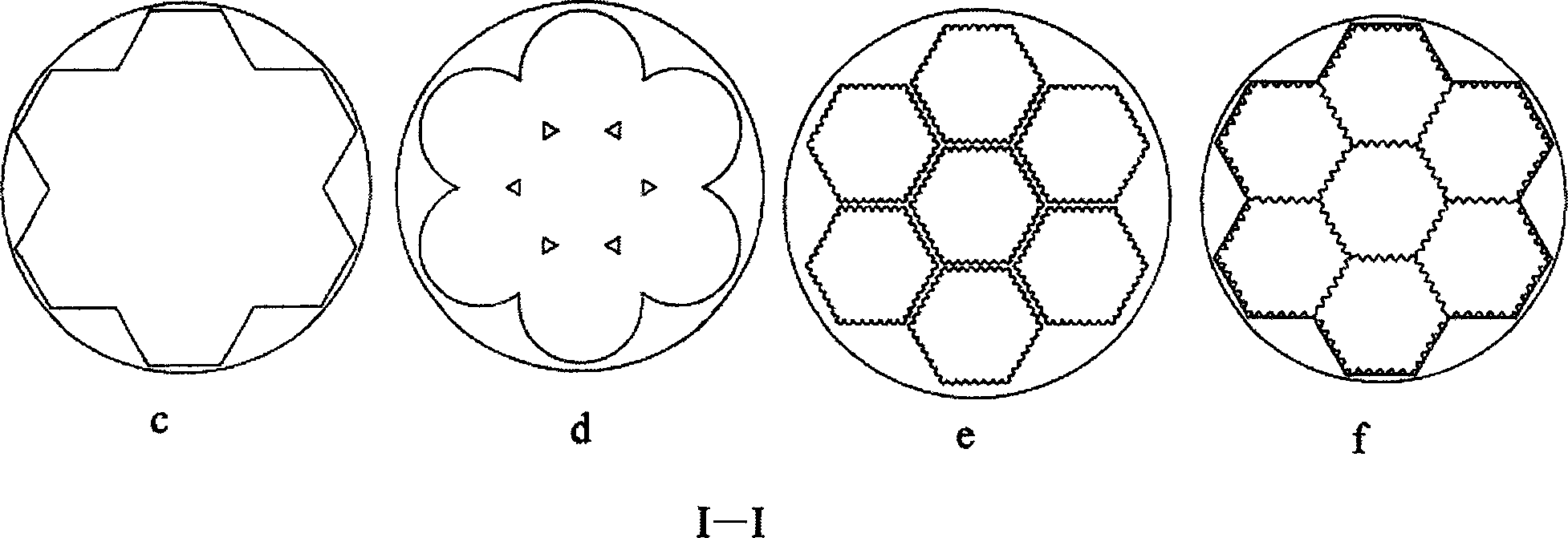

Immersion type membrane module and membrane filtering device

InactiveCN1883777ASimple structureEasy maintenanceSemi-permeable membranesSustainable biological treatmentAeration systemCross-flow filtration

The present invention relates to an immersion membrane component and airlift membrane filtration apparatus using the same. The said immersion membrane component uses a membrane pipe leading out from inner passage of a filtration solution as a membrane component, making the raw materials liquid uniformly distributed in the membrane components arrays through array arrangement and auxiliary array arrangement apparatus. The said airlift membrane filtration apparatus comprises the immersion membrane component, raw materials pool, aeration system and osmosis liquid negative pressure pumping system. Vertically dipping the component into the raw materials pool with aeration system in the bottom makes the airlift liquid move axially along membrane pipe and the osmosis liquid penetrate radically from membrane pipe, realizing cross-flow filtration and the osmosis liquid capable of being lead out by negative pressure pumping system.

Owner:JIANGSU JIUWU HITECH

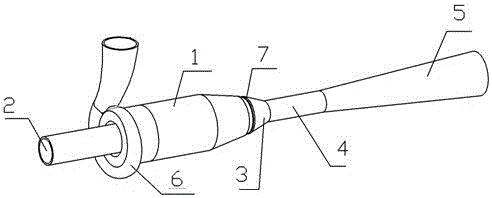

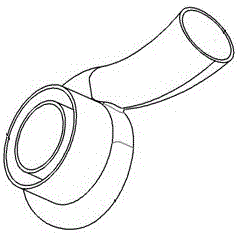

Jet pump with volute type flume

InactiveCN106224302AImprove flow statusJet pump efficiency improvementJet pumpsMachines/enginesStraight tubeWater flow

The invention provides a jet pump with a volute type flume. The jet pump comprises a fluid pipeline B, a fluid pipeline A arranged outside the fluid pipeline B in a sleeving mode, a constricted tube, a throat tube and an expansion tube, wherein the constricted tube, the throat tube and the expansion tube are sequentially connected with the water outlet end of the fluid pipeline A. The volute type flume arranged outside the fluid pipeline B in a sleeving mode is arranged at the inlet end of the fluid pipeline A. The diameter of the water outlet end of the fluid pipeline A is decreased gradually in the water flowing direction. The constricted tube is a round tube with the diameter being decreased gradually. The throat tube is a straight tube. The expansion tube is a round tube with the diameter being increased gradually. The jet pump is easy to manufacture and install, the symmetry of internal flow of the jet pump is good, flowing is more stable, and hydraulic performance is improved; the flow losses are reduced, mixing of two fluids is promoted, and the efficiency is improved advantageously; the frictional hydraulic losses are reduced; and the jet pump is suitable for an annular jet pump as well as a central jet pump.

Owner:WUHAN UNIV

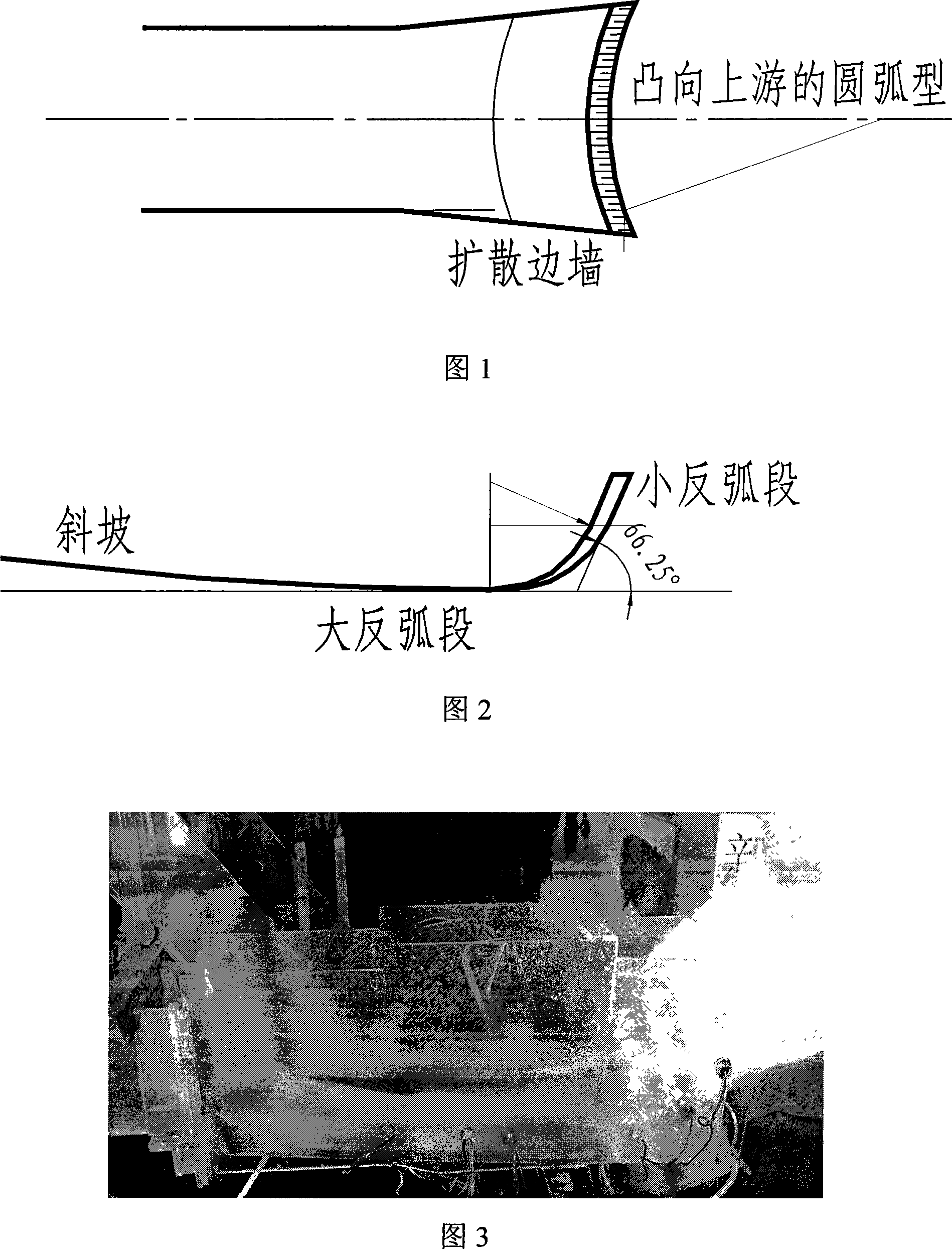

Diffusion type curve trajectory bucket

InactiveCN101100849AImprove hydraulic propertiesReduce washoutBarrages/weirsEngineeringCavitation erosion

This is a novel outstretch curve bucket lip for drain hole. A reverse arc curve of bigger diameter is connected to the slop of a pressure drain hole with the slop tangent to the curve. Another reverse arc curve of smaller diameter is then tangent to the previous curve. Drained water is heaved up after the curves of an angle 66.25 deg.. The traditional bucket lip is of a rectangle outlet, while the novel one is of an outstretching angle o f6-8 deg. at 5-8 meters from the outlet. With the novel design, water diffusion is enhanced as well as avoiding cavitation erosion and decreasing drained water speed.

Owner:DALIAN UNIV OF TECH

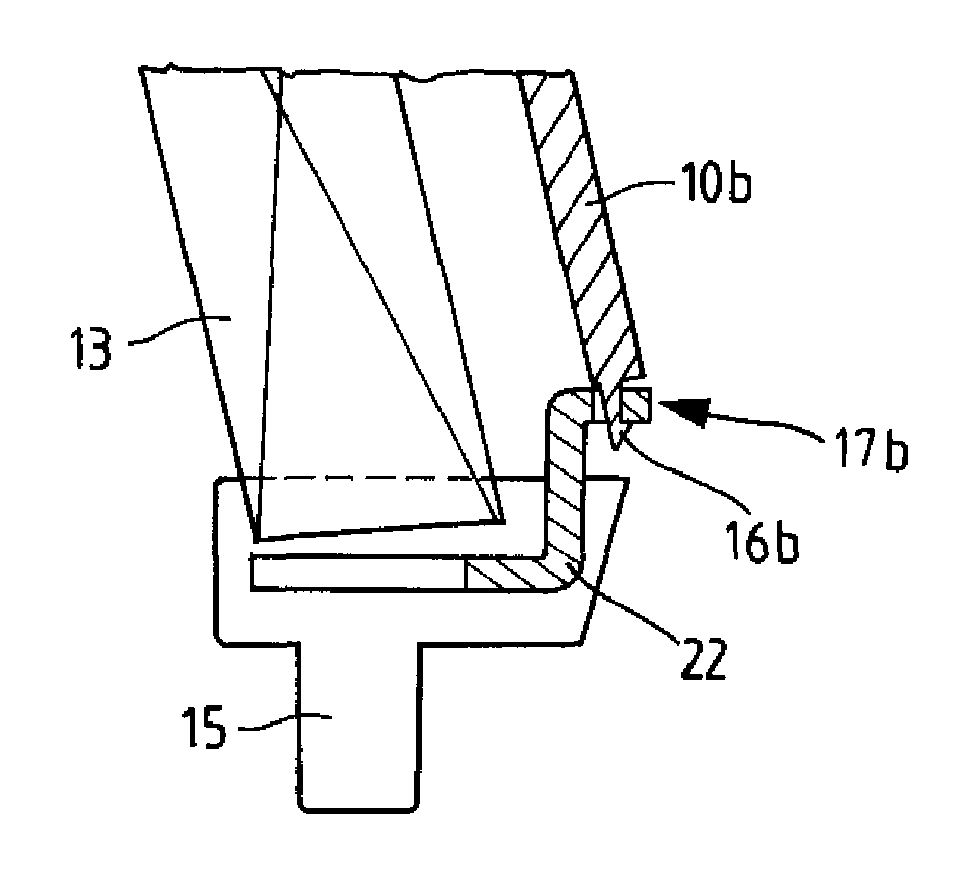

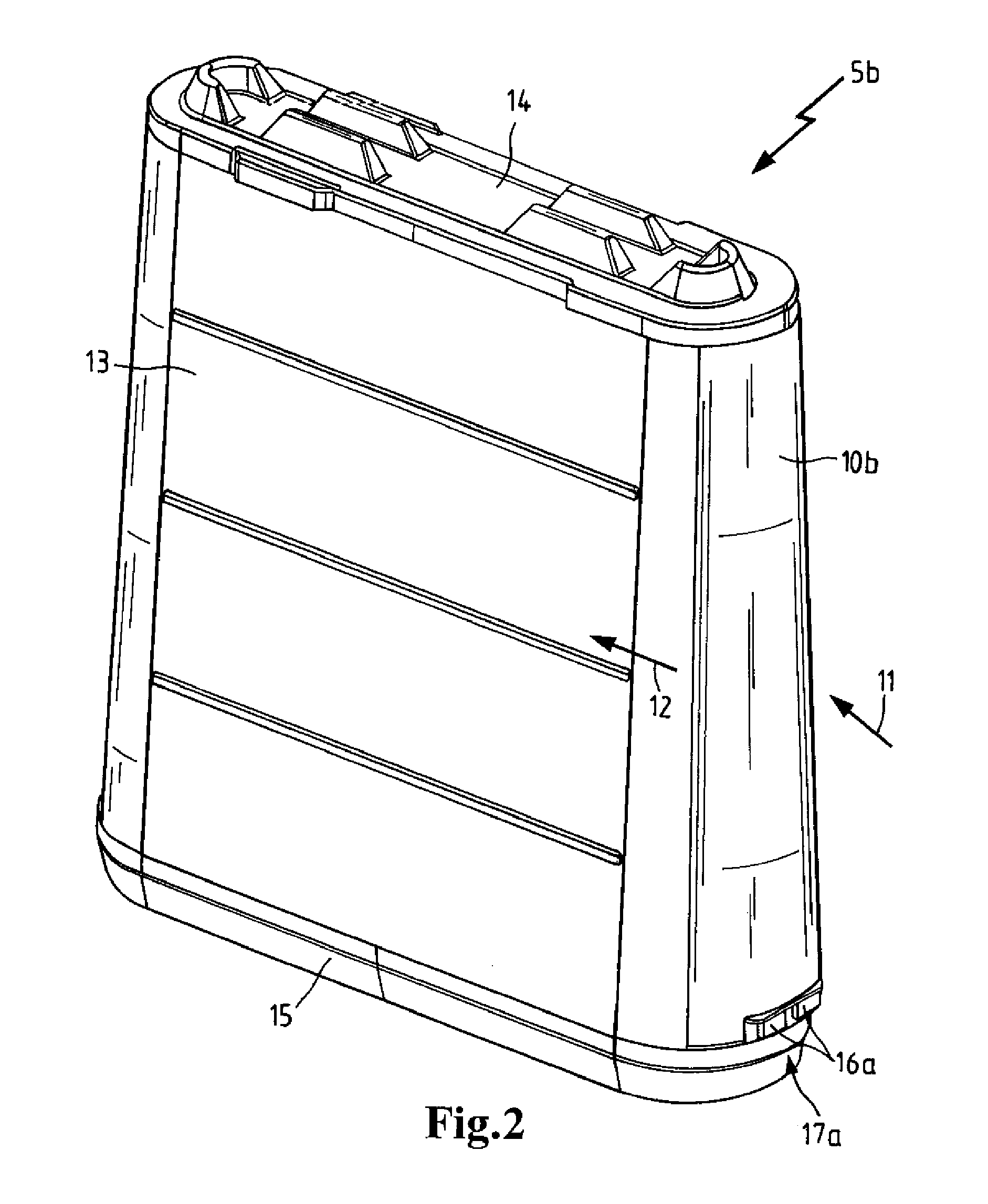

Filter element for an air inlet system

ActiveUS9132371B2Uniform velocity distributionAvoid damageCombination devicesAuxillary pretreatmentFilter mediaFilter element

Owner:MANN HUMMEL GMBH

Multistage-welding-chamber extrusion mould used for producing aluminium sections and production technology of the aluminium sections

InactiveCN103599956AUniform velocity distributionImprove mold strengthExtrusion diesWeld seamAluminium

The invention discloses a multistage-welding-chamber extrusion mould used for producing aluminium sections. The extrusion mould comprises an upper mould and a lower mould. The upper mould comprises a guide plate. The guide palate is provided with a plurality of flow distribution bridges. A plurality of flow distribution holes are formed among the plurality of the flow distribution bridges. The extrusion mould is characterized in that intersections of the flow distribution bridges are lower than a material feeding surface around to form recessed surfaces; slopes are disposed between the flow distribution bridges and the recessed surfaces on the material feeding surface for transition to form first pressure-relief angles; flow distribution hole and feeding openings in the recessed surfaces form second pressure-relief angles; two sides of the flow distribution bridges form third pressure-relief angles; the lower end of the guide plate is provided with multistage welding chambers communicated with the flow distribution holes; and the multistage welding chambers are disposed below the material feeding surface of the lower mould. The invention also discloses an extrusion technology for producing the aluminium sections by the extrusion mould. The multistage-welding-chamber extrusion mould can effectively control metal flow, and therefore the speed distribution in the section of the aluminium sections is uniform, the thickness of the mould is increased relatively, the mould intensity is enhanced, the stage of the welding chambers is increased, the welding pressure increases gradually, and the quality and the surface of the welding seams are improved.

Owner:东莞市东联铝业有限公司

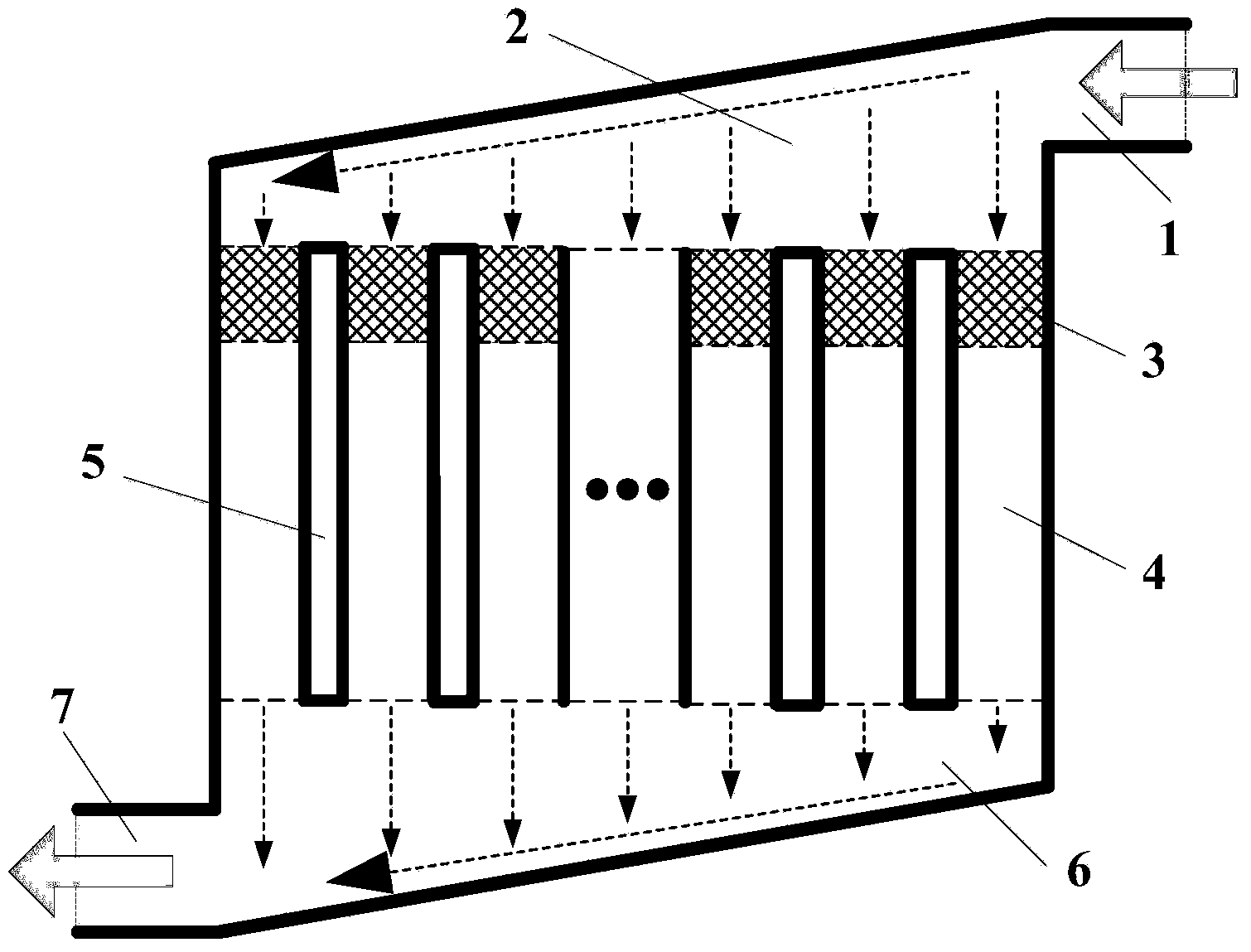

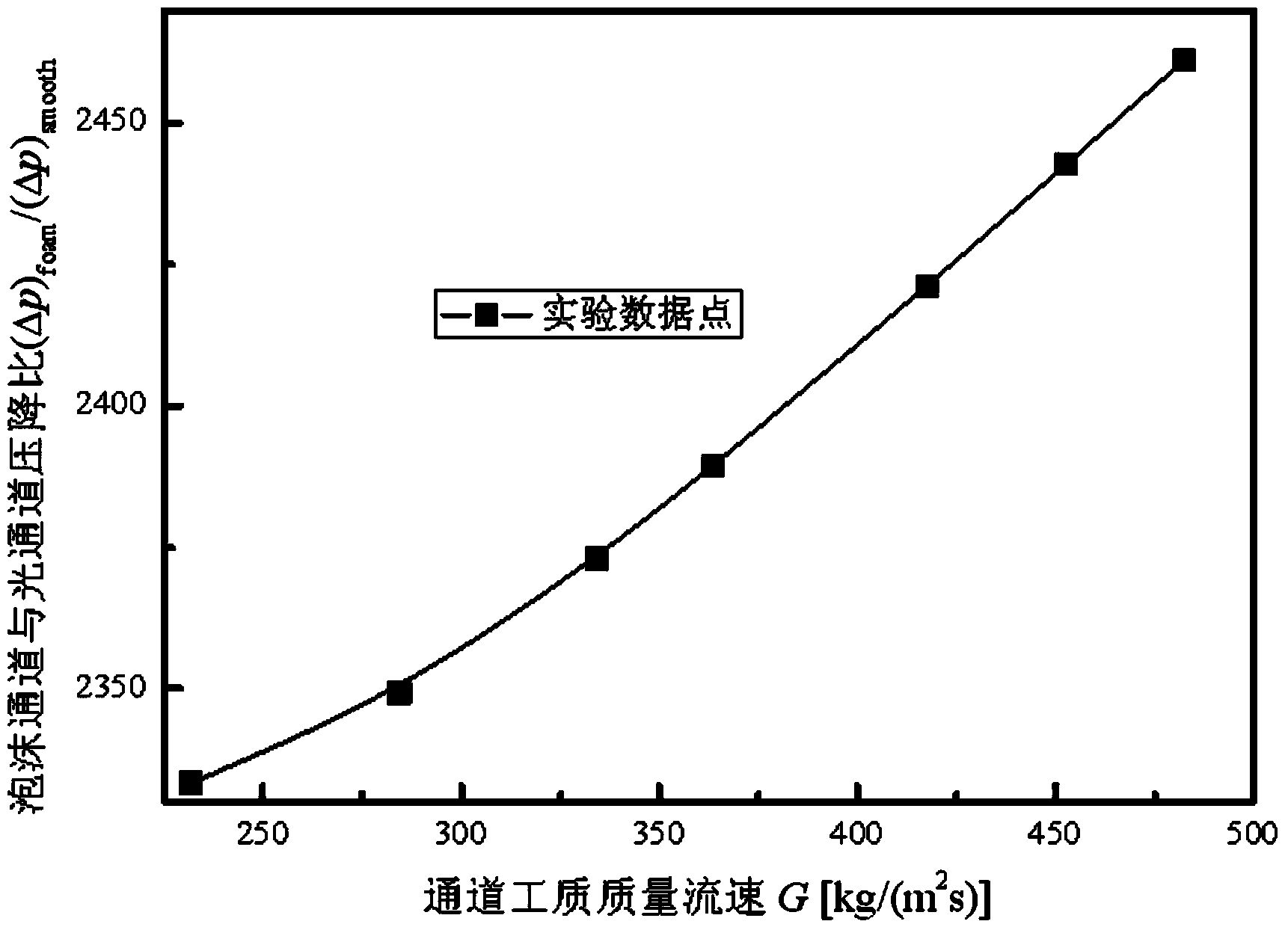

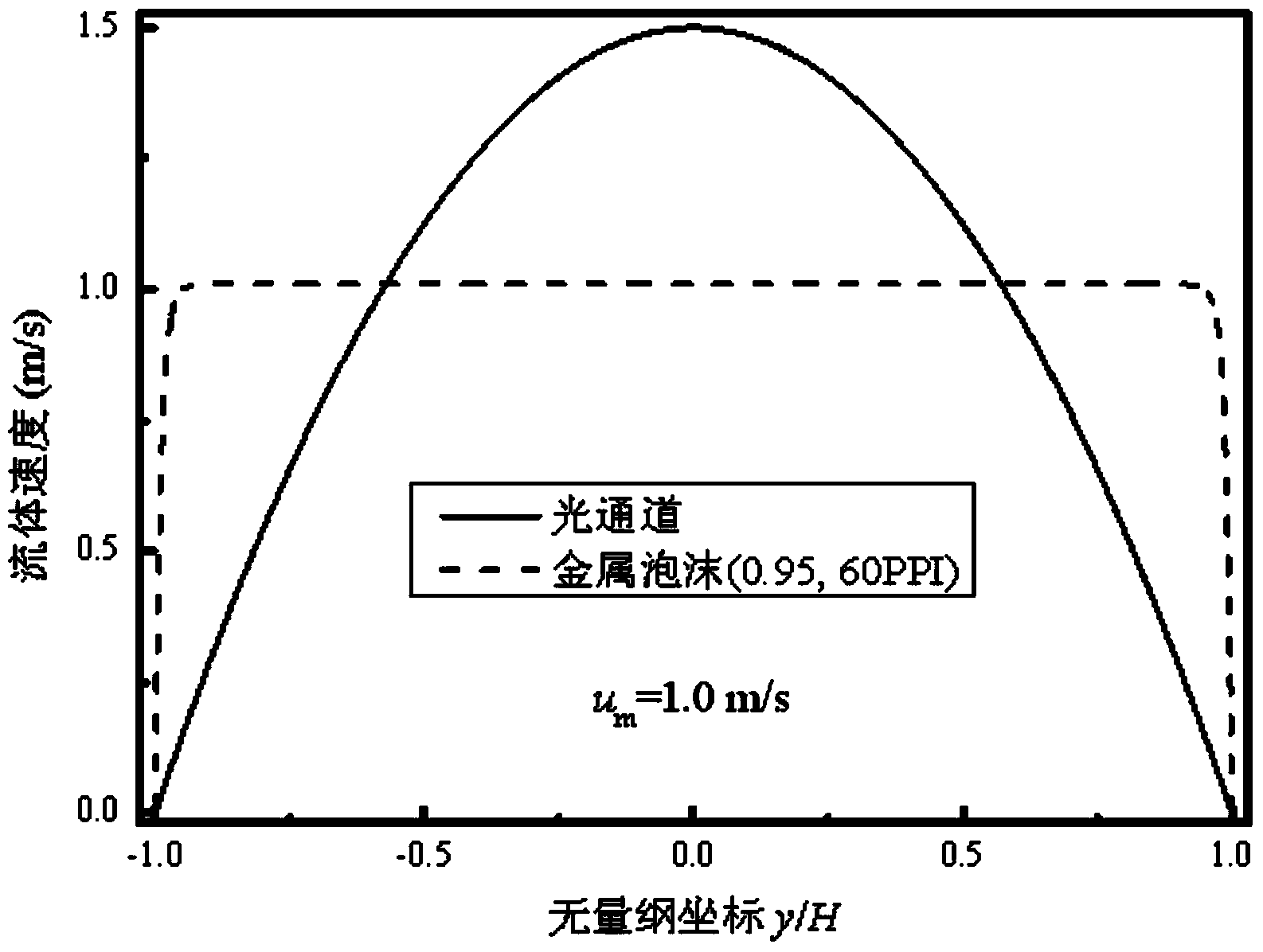

Multichannel structure using metal foam to uniformly distribute fluid flow

InactiveCN104266531ASolve the problem of uneven distribution of fluid flowGreat application potentialHeat exchanger casingsMain channelEngineering

The invention discloses a multichannel structure using metal foam to uniformly distribute fluid flow and relates to a multi-channel structure for a heat exchanger. The multichannel structure using the metal foam to uniformly distribute the fluid flow aims at solving the problem that the flowing between multiple channels is not uniform in the existing heat exchanger. The multichannel structure using the metal foam to uniformly distribute the fluid flow comprises a flow channel inlet, a distribution end, a main channel, a convergence end and a flow channel outlet which are sequentially communicated; a plurality of channel intervals are arranged inside the main channel to separate the main channel into a plurality of sub-channels; the front end of every sub-channel is full of metal foam section which is formed by metal foam; the sub-channel portions which are not full of metal foam are defined to be foam-free sections. The multichannel structure using the metal foam to uniformly distribute the fluid flow is applied to the multichannel heat exchanger in the fields such as the electronic device cooling, the refrigeration low temperature technology, air separation and petrochemical engineering and guarantees the fluid flowing uniformity.

Owner:SHANGHAI JIAO TONG UNIV +1

Oil cooler

ActiveCN102384674AUniform velocity distributionEfficient heat transferMachines/enginesStationary conduit assembliesFin heightMechanical engineering

An oil cooler comprises an inner fin 3, an offset fin, having a wavy cross-section that is perpendicular to an oil flowing direction, and has a louver 32 that is partially cut and bent in a direction parallel with the oil flowing direction. The wavy cross-section is defined by alternately placing first-side convex parts 31 and second-side convex parts. A fin height fh is defined by a distance from the first-side convex part 31 to the second-side convex part 31 in the cross-section. An area C surrounded by the inner fin 3, a tube 24, and the first-side or second-side convex parts 31 located adjacent with each other on the same side in the cross-section is converted into a corresponding circle having a diameter de. When a relationship of X=de / fh0.3 is defined, the diameter of the corresponding circle and the fin height respectively have dimensions that satisfy a relationship of 0.5<=X<=1.0.

Owner:DENSO CORP

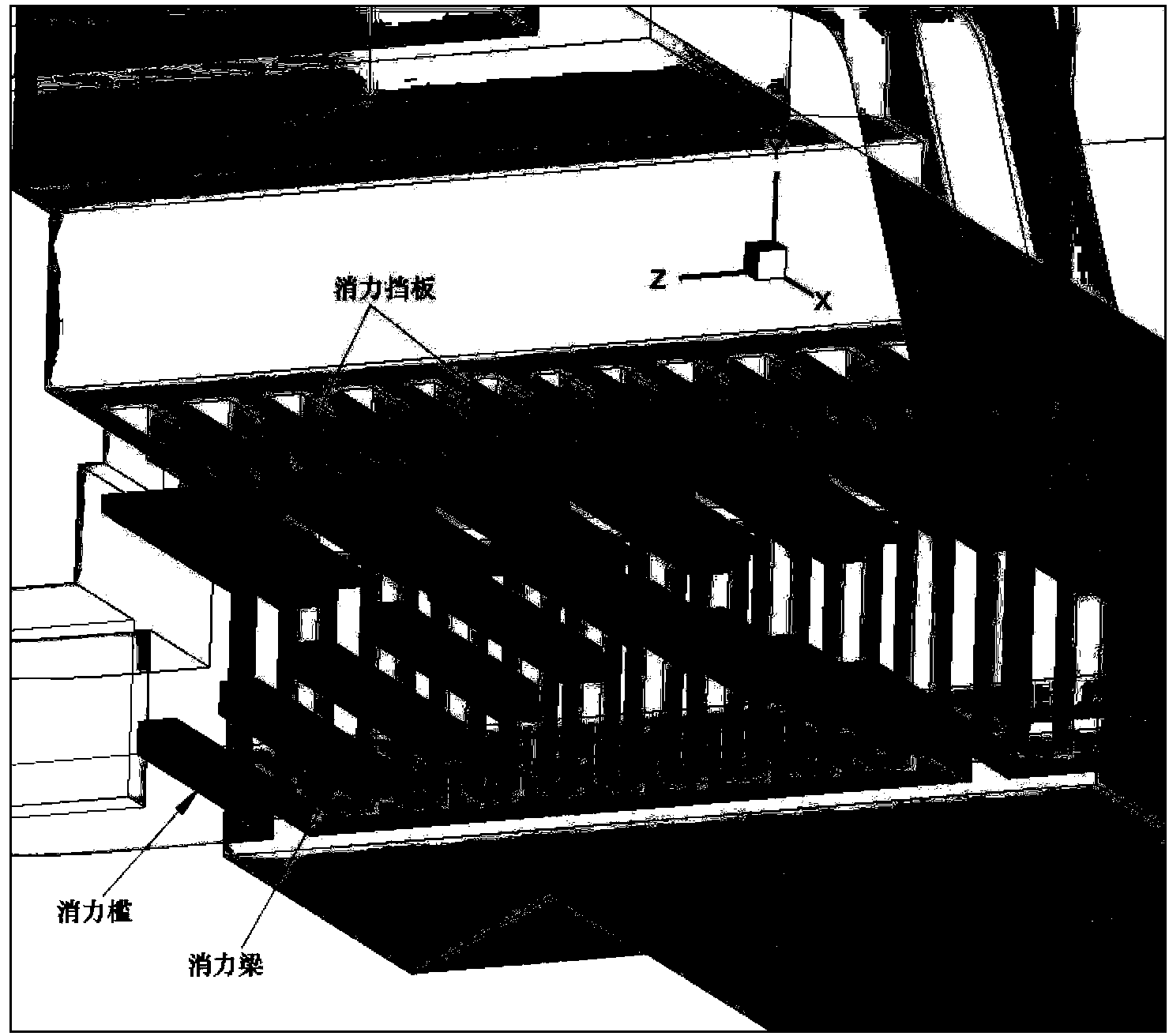

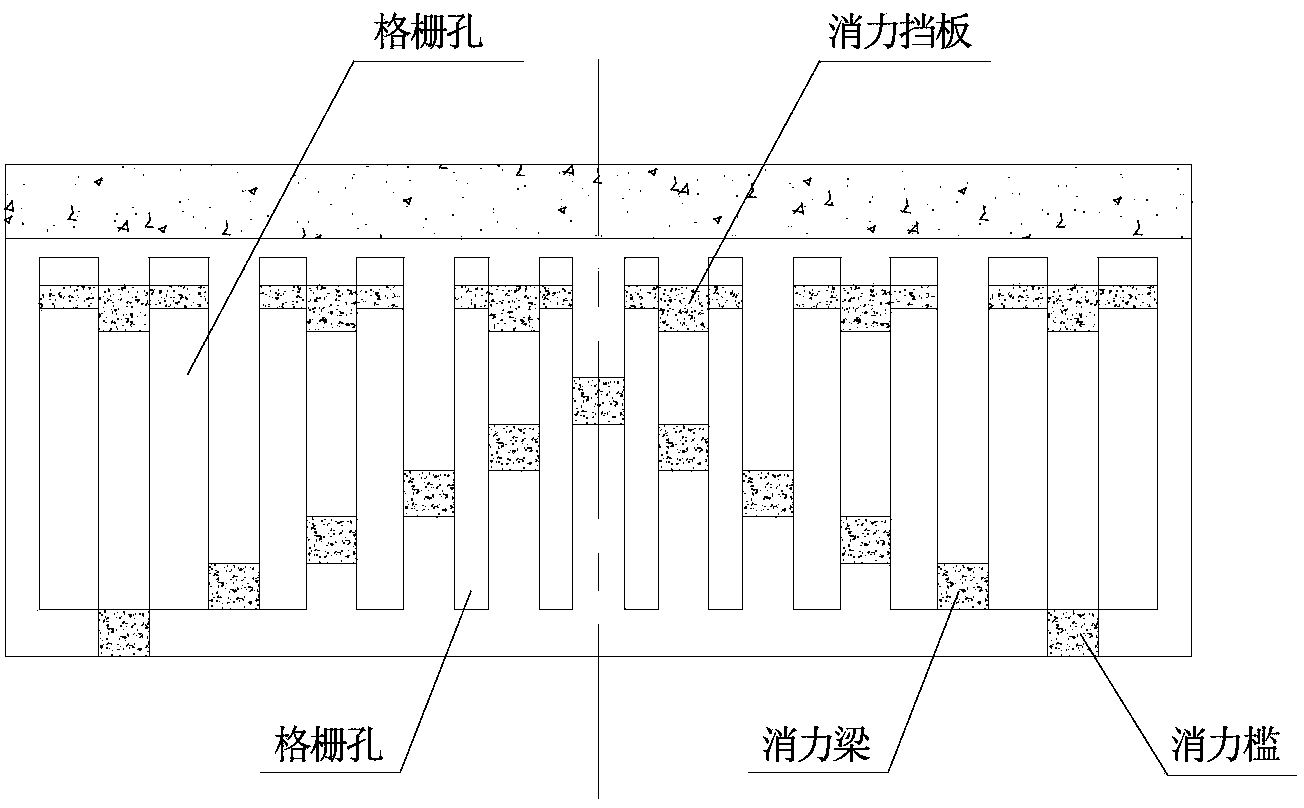

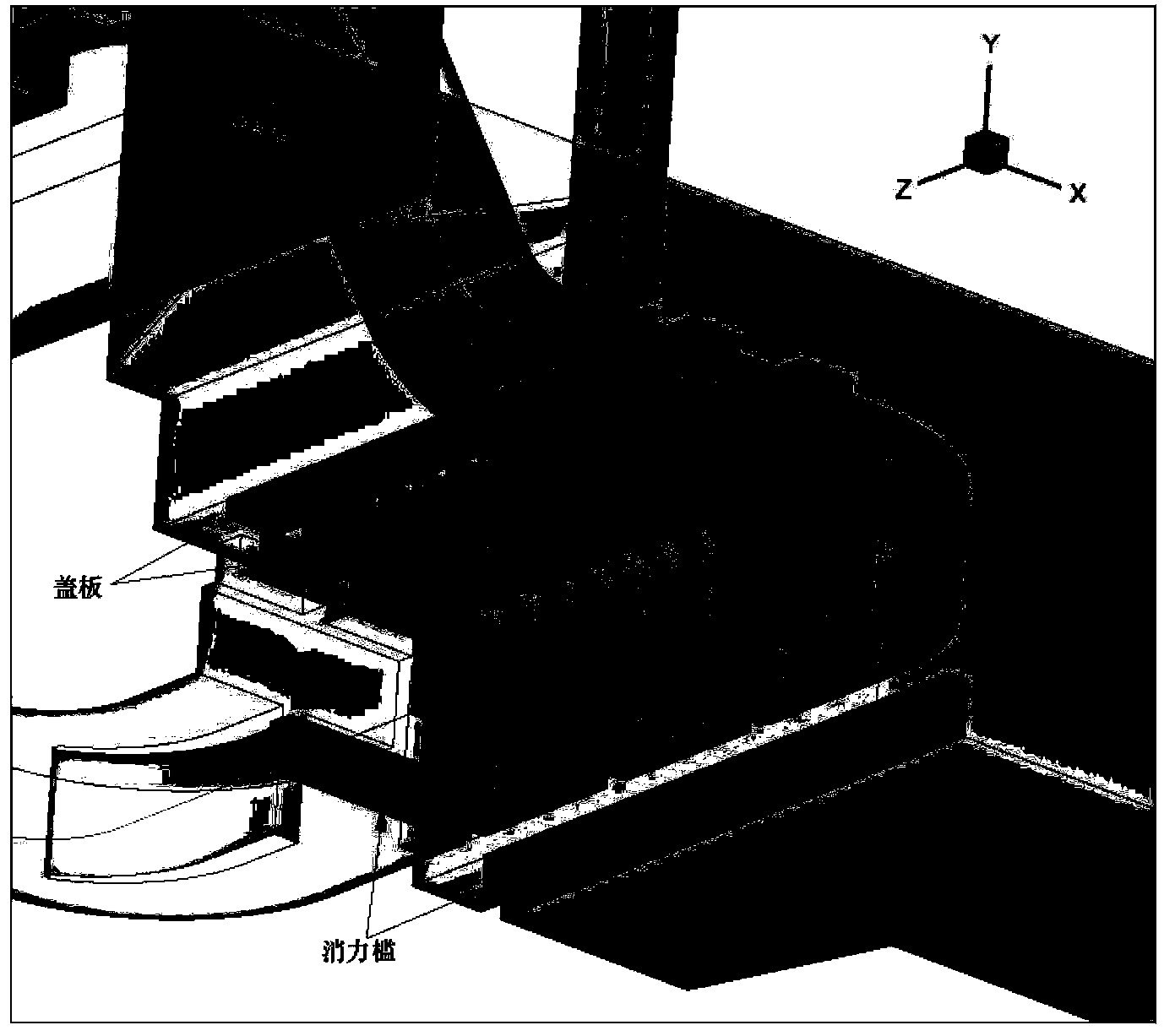

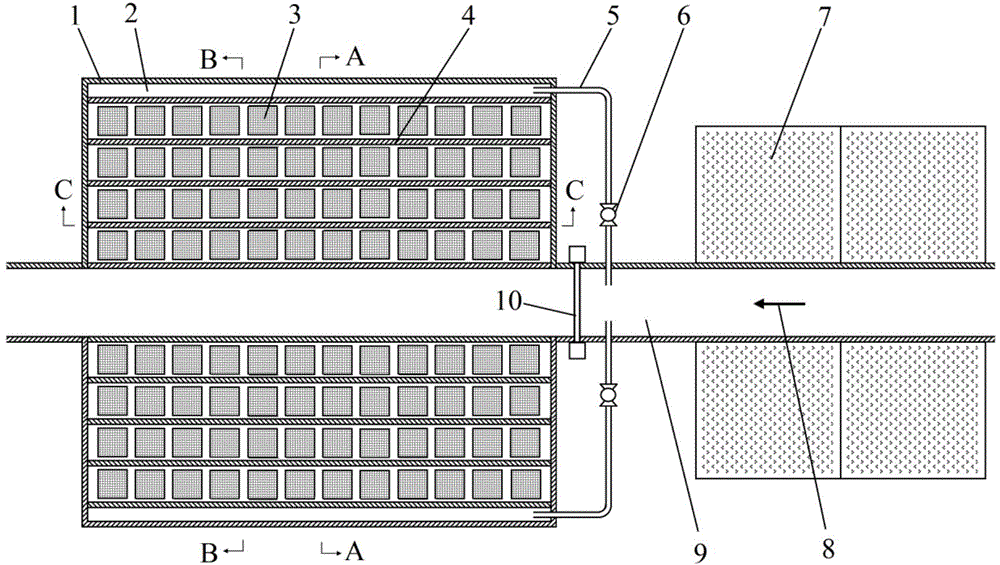

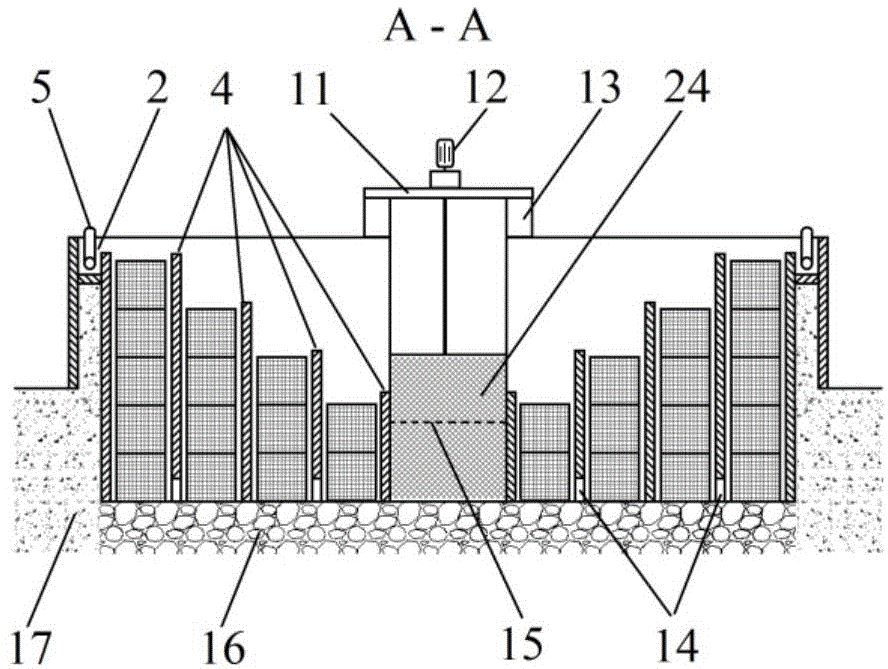

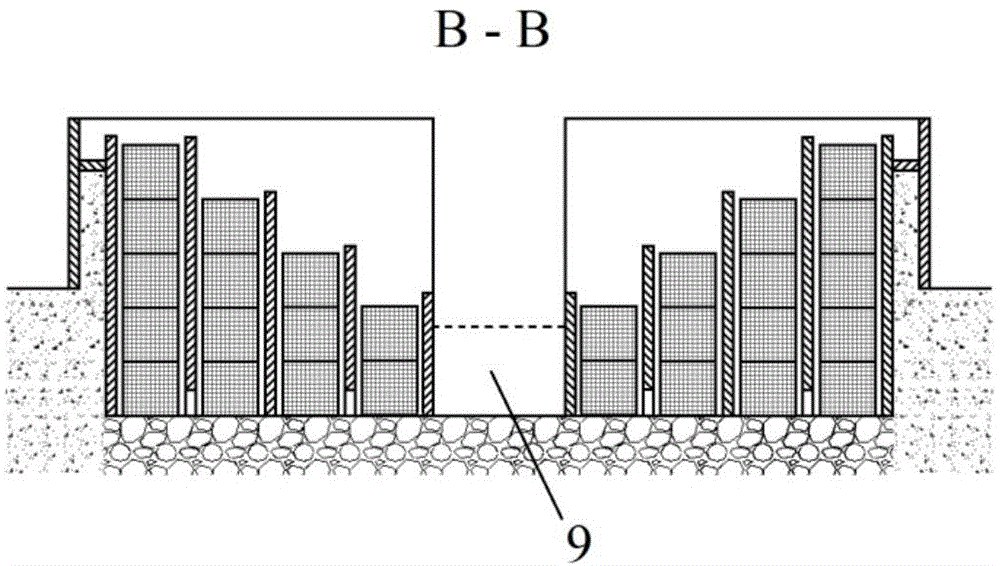

Inverted K-shaped energy dissipater of concentrated water conveyance system of ship lock and layout method thereof

InactiveCN103397624AUniform velocity distributionIncreased velocity distribution uniformityDry-docksEngineering

The invention discloses an inverted K-shaped energy dissipater of a concentrated water conveyance system of a ship lock and a layout method thereof, belonging to the technical field of the hydraulics of the water conveyance system of the ship lock. The whole energy dissipater is arranged in a grille energy dissipating chamber of a ship-lock short-corridor water conveyance system with the grille energy dissipating chamber and is composed of baffle sills, baffle beams and baffle dampers. The two longitudinal baffle sills are symmetrically arranged in front of a left corridor water outlet and a right corridor water outlet of the water conveyance system, a plurality of longitudinal baffle beams are symmetrically arranged in the energy dissipating chamber according to stepped separated holes, and a plurality of longitudinal baffle dampers are arranged under each top-surface grille hole of the energy dissipating chamber; the baffle sills, the baffle beams and the baffle dampers form the inverted K-shaped energy dissipater on the cross section of a lock chamber. The energy dissipater can significantly increase the uniformity coefficient of velocity distribution of the section of the lock chamber and reduce the turbulent fluctuation of water of the lock chamber so as to effectively improve the mooring condition of lock-chamber ships.

Owner:CHONGQING JIAOTONG UNIVERSITY

Multilayer overflowing type ecological cleaning pond applicable to farmland drainage ditch

InactiveCN104310572AIncrease floor area ratioIncrease usageBiological treatment apparatusRunoff/storm water treatmentSmall footprintSewage

The invention discloses a multiplayer overflowing type ecological cleaning pond applicable to a farmland drainage ditch. The multiplayer overflowing type ecological cleaning pond comprises a purifying pool body, two water inlet troughs, purification grooves, water separation walls, purification boxes, a gate, water pumps and water inlet pipes, wherein the purifying pool body is communicated with the farmland drainage ditch and is separated into the two water inlet troughs and a plurality of purification grooves with different depths through the water separation walls, and the purification boxes are arranged in the purification grooves. The purification grooves have a graded cascade structure, agricultural wastewater enters the water inlet trough after passing through the water pumps and the water inlet pipes and then flows through the purification grooves step by step under the action of a pressure head, and purified water finally flows back into the farmland drainage ditch. The efficient volume fraction of the cleaning pond can be improved, the hydraulic retention time of sewage in the pond is prolonged, the content of eutrophic substances in farmland drainage can be effectively lowered, and non-point source pollution in farmland is prevented from expanding to the outside. The multiplayer overflowing type ecological cleaning pond has the advantages of small floor space, high purification efficiency, simplicity in manufacture and convenience in maintenance, and an original water-logging drainage function of the farmland drainage ditch is not influenced.

Owner:HOHAI UNIV CHANGZHOU

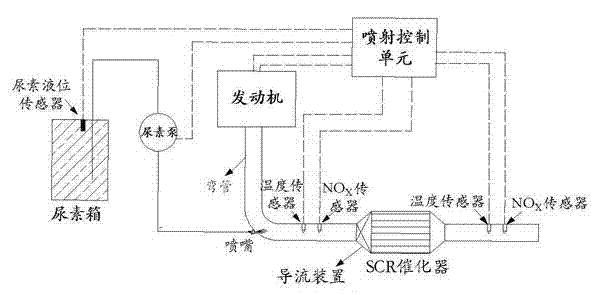

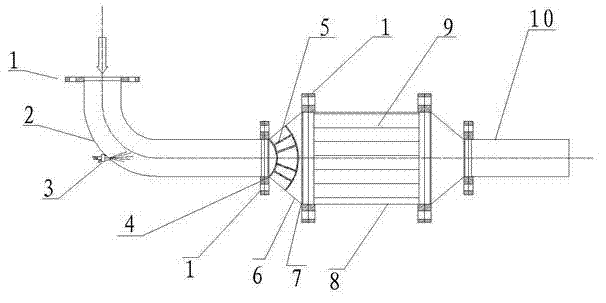

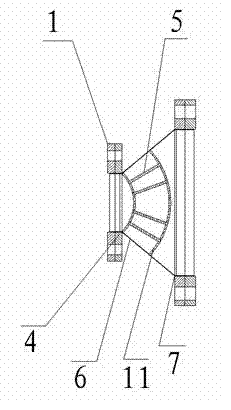

Guiding device and guiding method for diesel engine selective catalytic reduction (SCR) system for automobile

InactiveCN103089383ASimple structureLow costInternal combustion piston enginesExhaust apparatusEngineeringNitric oxide

The invention relates to a guiding device and a guiding method for a diesel engine selective catalytic reduction (SCR) system for an automobile. The guiding device comprises an expansion pipe and at least two guiding plates arranged in a mutually embedding mode. The end where gas flows to the expansion pipe is a gas inlet end and the end where the gas flows out of the expansion pipe is a gas output end. The guiding plates at fixedly arranged on the gas inlet end of the expansion pipe and each guiding plate is in a trumpet shape without a front end face and a rear end face. A fluid channel is formed among the guiding plates. The guiding device is simple in structure, low in manufacturing cost and easy to install. According to the guiding device and the guiding method, due to backflow generated in the portion of an elbow pipe, exhaust of the automobile and urea sprayed from a nozzle can mix well so that generation of crystal on a wall is reduced. Due to the guiding device in the expansion pipe portion, mixed gas is converted from turbulent flow to laminar flow so that velocity distribution is even, radial pressure difference and temperature difference inside a catalytic agent are reduced, conversion efficiency of nitric oxides is improved, through capacity of a catalytic agent carrier is improved and service life of a catalyst is prolonged.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com