Multistage-welding-chamber extrusion mould used for producing aluminium sections and production technology of the aluminium sections

A technology of extrusion die and welding chamber, which is applied in the field of aluminum extrusion product manufacturing, can solve the problems of high scrap rate of extrusion die, slow temperature distribution, low product yield rate, etc. The effect of uniform velocity distribution and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

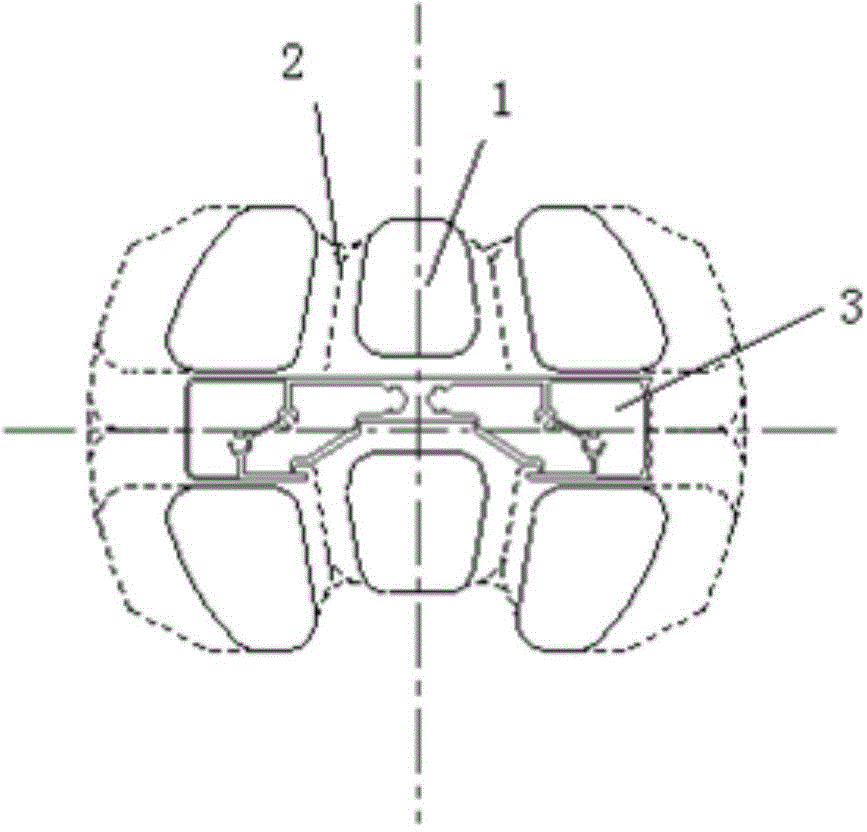

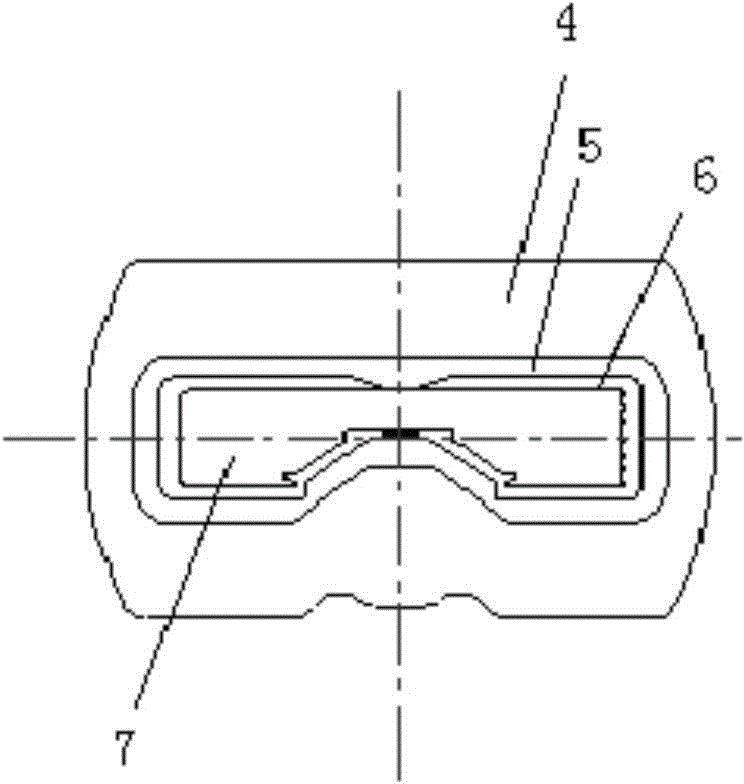

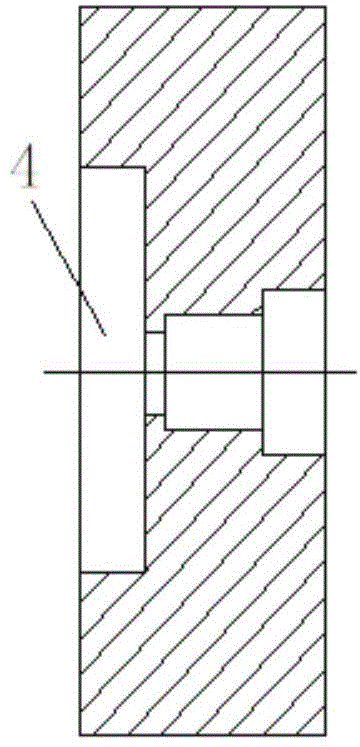

[0034] Example: see Figure 1~5 The multi-stage welding chamber extrusion die for producing aluminum profiles provided in this embodiment includes an upper die and a lower die, the upper die includes a deflector, and the deflector is provided with a plurality of shunt bridges 2, so A plurality of shunt holes are formed between the plurality of shunt bridges 2, and the junction of the shunt bridges 2 is lower than the surrounding feed surface to form a concave surface, and the shunt bridge 2 on the feed surface and the concave surface are transitioned by a slope to form the first The decompression angle, the feed port of the diversion hole at the concave surface forms the second decompression angle, and the third decompression angle is formed on both sides of the diversion bridge 2; chamber, the multi-stage welding chamber is located in the lower mold.

[0035] The multi-level welding room is a three-level welding room, and the three-level welding room is divided into a first-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com