Guiding device and guiding method for diesel engine selective catalytic reduction (SCR) system for automobile

A technology of SCR system and diversion device, which is applied in the direction of mufflers, exhaust devices, mechanical equipment, etc., can solve the problem of affecting the power and economy of diesel engines, insufficient use of edge areas, and large radial temperature and pressure gradients To achieve the effect of improving the passing capacity and utilization rate of the catalyst, reducing the flow sharing rate, and weakening the flow separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

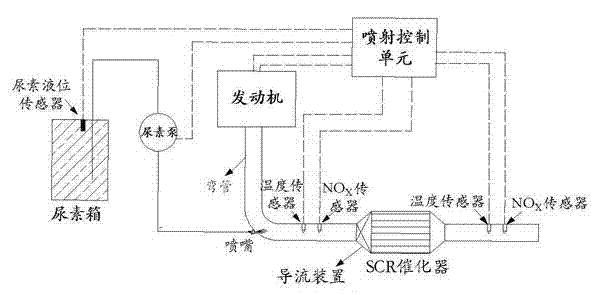

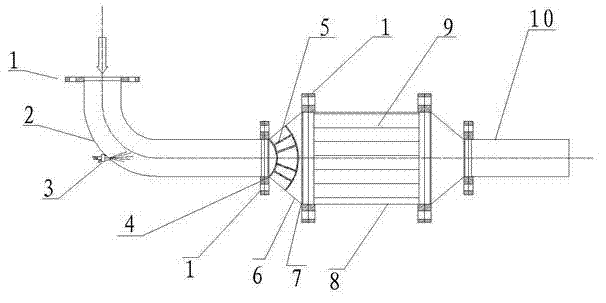

[0031] Diesel engine urea SCR system such as figure 1 with figure 2 As shown, the present invention is installed between the SCR catalytic converter 8 and the bend pipe 2, and its specific structure is as follows: Figure 3 to Figure 6 shown.

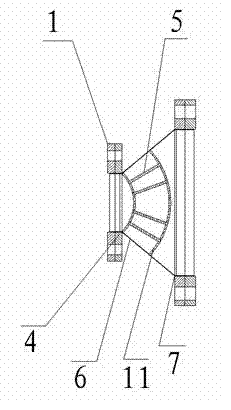

[0032] The present invention is a deflector device for the SCR system of a diesel engine for a vehicle, comprising an expansion tube 6 and at least two deflector plates 5 nested with each other. One end of the pipe 6 is the air outlet 7, the inlet end 4 of the expansion pipe 6 is connected with the elbow 2, the deflector 5 is fixedly arranged on the front end of the expansion pipe 6, and its shape is a trumpet shape without front and rear end faces. A fluid channel 12 is formed between them. The quantity of deflector plate 5 is preferably 2 to 4 pieces, and the length of deflector plate 5 is preferably 1 / 3 to 2 / 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com