Patents

Literature

170results about How to "Promote pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

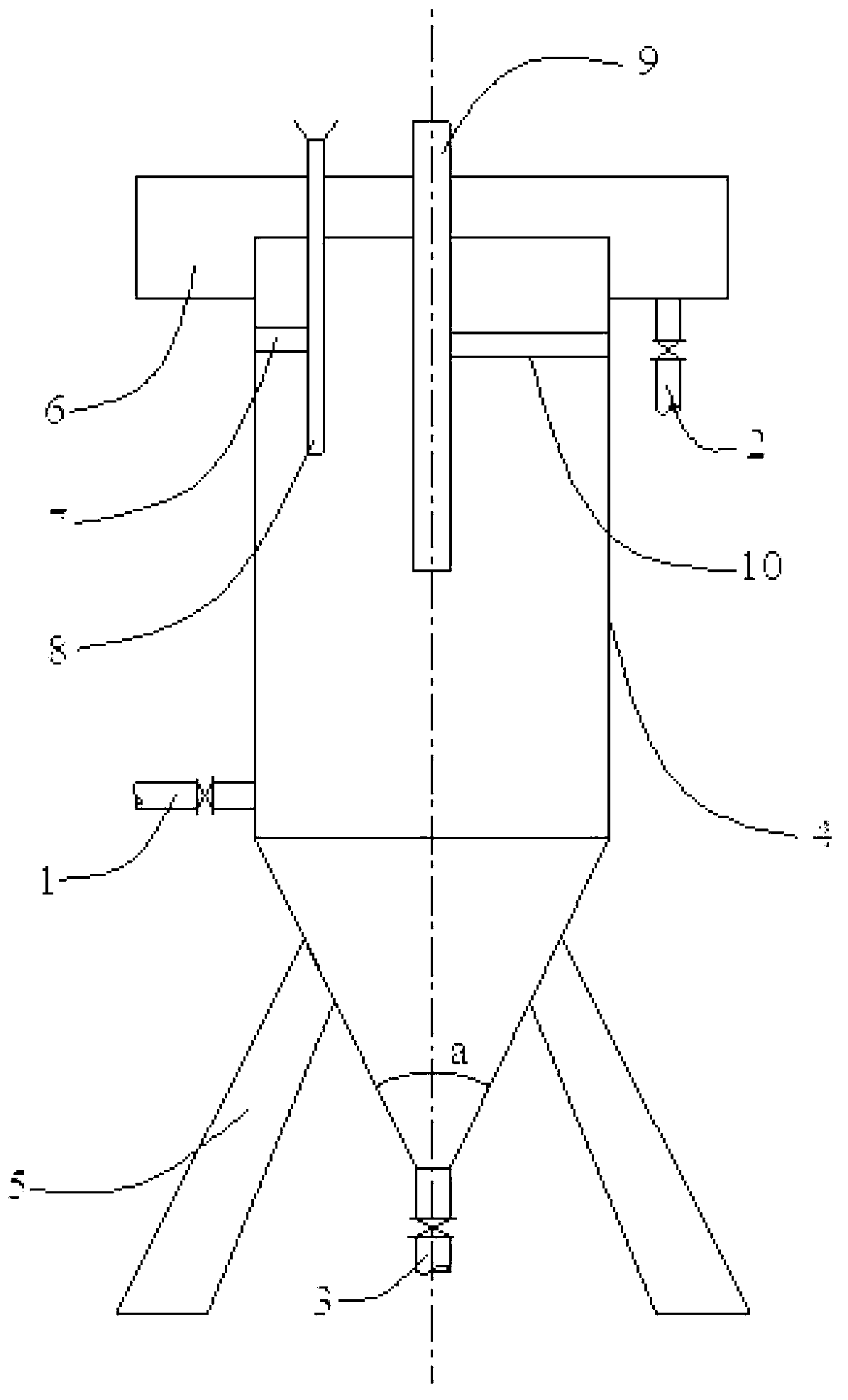

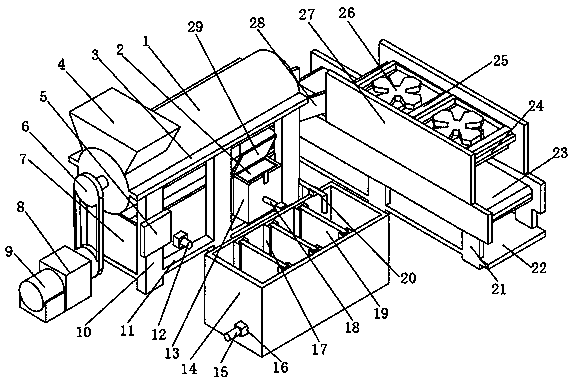

Consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as method thereof

ActiveCN104163555AGood heating selectivityRapid pyrolysisSludge treatment by pyrolysisByproduct vaporizationRadiation lossNitrogen generator

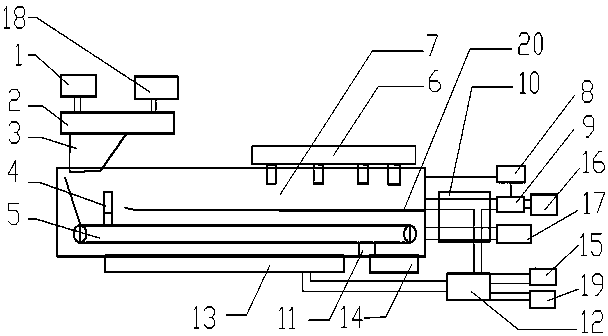

The invention discloses a consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as a method thereof. The condensation comprises a sludge warehouse, a stirrer, a hopper feeder, a sludge-shaped controller, a belt sender, a power control microwave irradiation device, a microwave pyrolysis reaction chamber, a pressure sensing controller, a blower fan, a condensation heat exchanger, a scraper plate separator, an oil-water separating device, a liquid dredging groove, a coke storage tank, a product oil tank, a product gas tank, a nitrogen generator, a coke crusher, a sludge water pot and a gas shunting plate. According to the invention, microwave material internal heating characteristic can be fully used for reducing heat radiation loss, moisture sludge is directly performed with anhydration and pyrolysis to obtain the cracking oil, combustible gas and solid coke; heat recovery of the product gas and auxiliary microwave heating characteristic of the products residue are fully used for reducing the operation cost, and sludge pyrolysis efficiency and products quality can be increased. The apparatus has the advantages of simple structure, small volume, reasonable design and convenient market popularization, and is suitable for industrial application of microwave sludge continuous pyrolysis.

Owner:ZHEJIANG UNIV

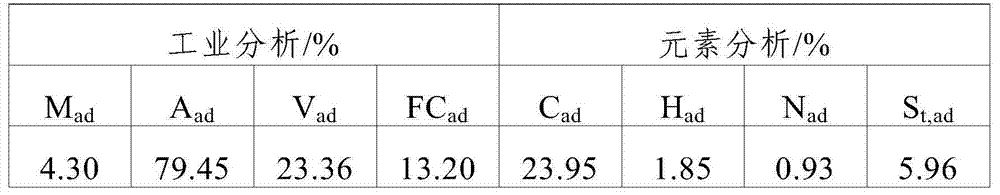

Sludge pyrolysis method adopting biomass adding

InactiveCN106433713APromote pyrolysisAchieve reductionSludge treatment by pyrolysisByproduct vaporizationMass ratioSludge

The invention relates to the technical field of sludge pyrolysis, in particular to a sludge pyrolysis method adopting biomass adding. The method comprises steps as follows: step one, firstly, biomass is crushed into powder, the biomass, sludge and a catalyst are uniformly mixed in a mass ratio being (0.25-4):1:(0.02-0.08), and a mixture is obtained; step two, the mixture is put in a reaction kettle, nitrogen is introduced to serve as protective gas, the temperature is increased to the pyrolysis temperature of 300-700 DEG C according to a certain temperature increasing procedure, and a solid-phase product, a liquid-phase product and a gas-phase product are obtained respectively. The sludge pyrolysis method adopting biomass adding not only promotes sludge pyrolysis, but also increases the product utilization value, the problem of environment pollution in the conventional sludge treatment process is solved, the reduction, stabilization, harmless and recycling targets of sludge are achieved, agricultural waste biomass is recycled, and the purpose of turning waste into wealth is achieved.

Owner:XINJIANG UNIVERSITY

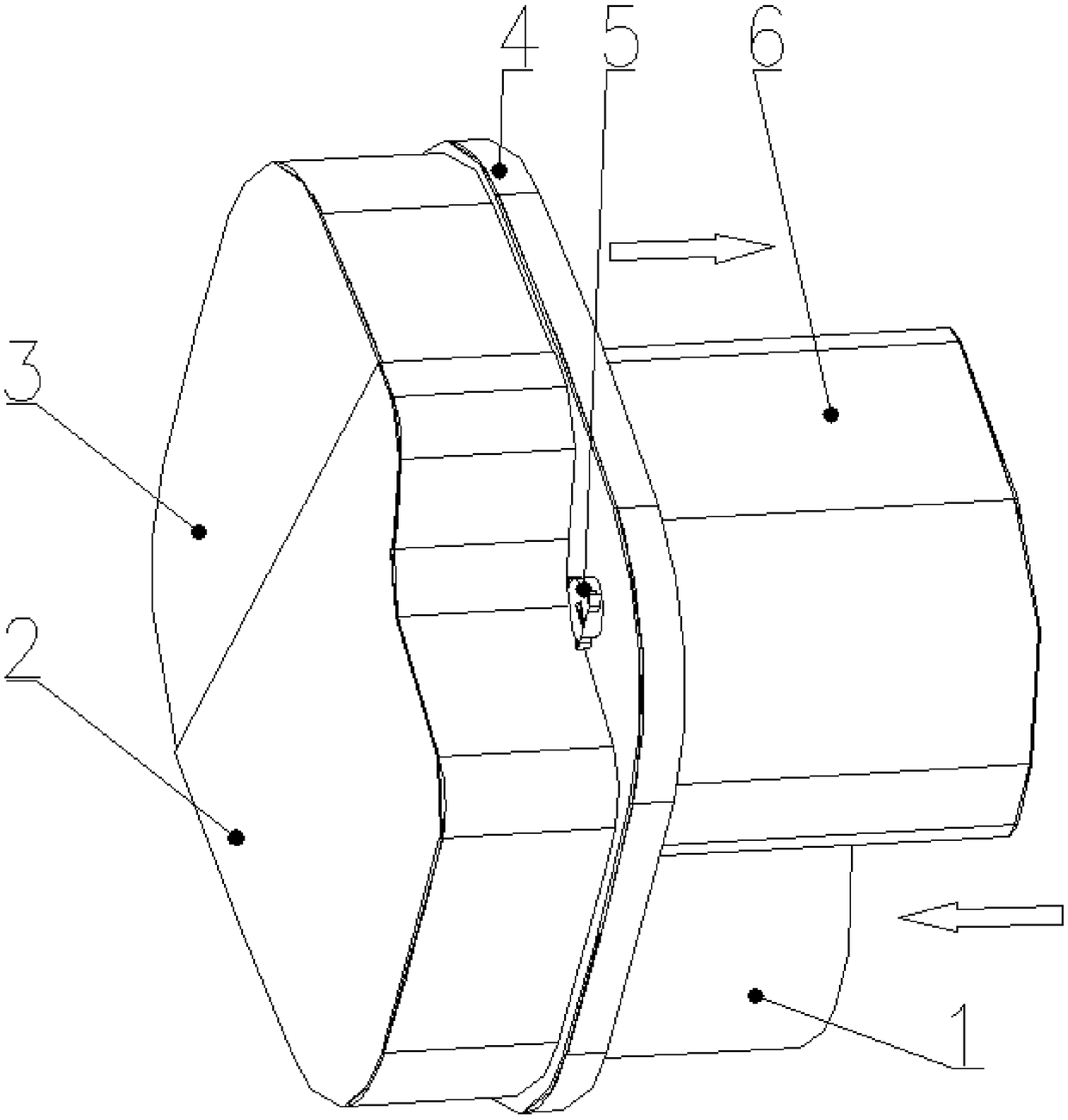

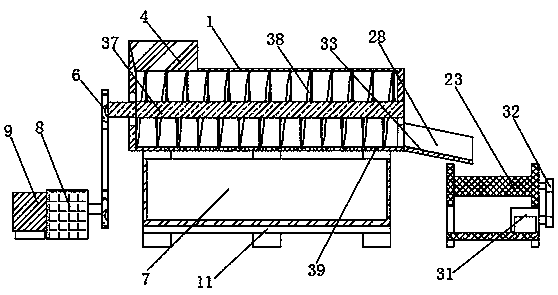

Method for producing carbonized material by means of carbonizing converter

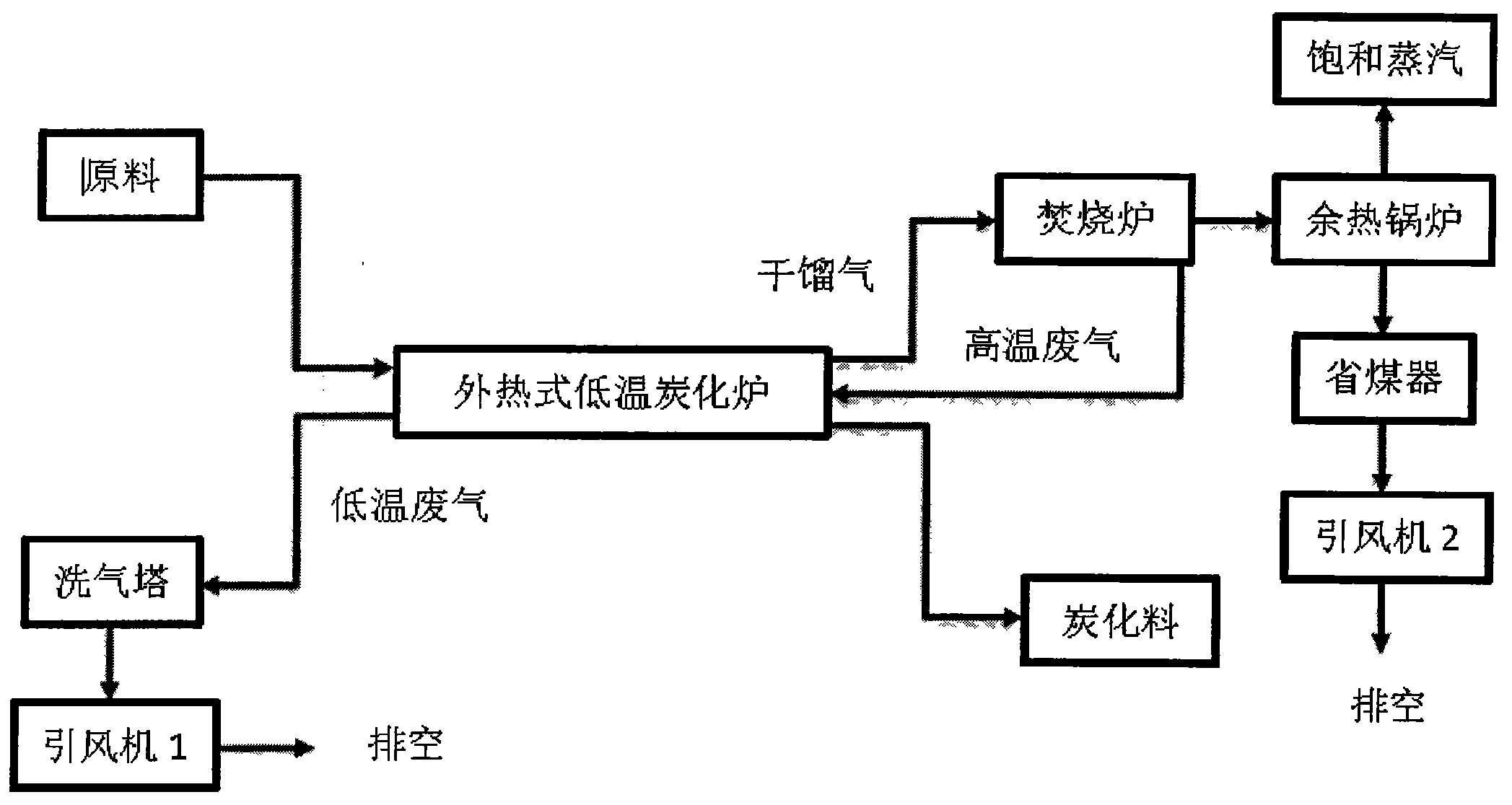

ActiveCN103865551AReduce energy consumptionEmission reductionCarbon compoundsBiofuelsExhaust gasCombustion

The invention discloses a method of producing a carbonized material by means of a carbonizing converter. The method comprises the following steps: feeding a raw material from the feed inlet of the carbonizing converter; gradually heating the raw material in a product channel of the carbonizing converter from normal temperature to 400-600 DEG C slowly; drying, pyrolysing and curing the raw material in the product channel of the carbonizing converter to produce the carbonized material and discharging the carbonized material from the discharge port of the carbonizing converter; moving the retorting gas volatilized in the drying, pyrolysing and curing process of the raw material orthokinetically with the raw material through negative pressure control; feeding the retorting gas into a combustion device through a pipeline arranged at the discharge port of the carbonizing converter; and introducing a part of high temperature gases generated by combustion to the product channel of the carbonizing converter to heat the raw material through the air inlet pipe arranged at the discharge port of the carbonizing converter. According to the method, the flow direction of the raw material is contrary to that of the high temperature exhaust gas but is orthokinetic with the retorting gas, so that not only is the quality improved, but also agglomeration is prevented. Meanwhile, fuel is not supplemented, so that the energy consumption is reduced, the emission is reduced, and the method is more energy-saving and environment-friendly.

Owner:淮北中清环保科技有限公司

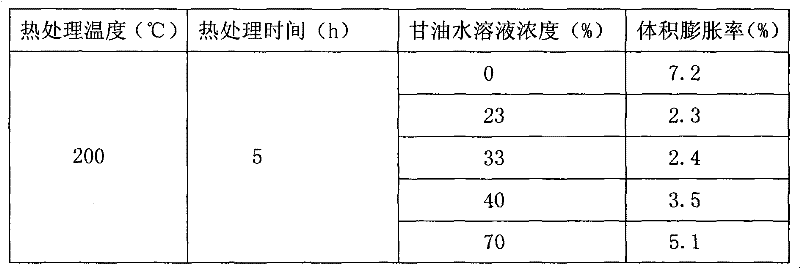

Pretreatment method for improving dimension stability of timber

InactiveCN102241032AImprove hydrophilicityGood dimensional stabilityPressure impregnationWood impregnation detailsPretreatment methodWater vapor

The invention discloses a pretreatment method for improving dimension stability of timber. The method comprises the following steps: pretreating timber with glycerin and then carrying out air seasoning on the timber so as to enable the water content of the timber to decline to less than 15%; putting the timber into a heat treatment box, turning on a vapor switch, allowing the temperature of the heat treatment box to rapidly rise to 140 DEG C at a rate of 10 to 20 DEG C / h, keeping the temperature for 30 to 60 min, and drying the timber at a high temperature so as to enable the water content of the timber to decline to 0; allowing the temperature to rise to 160 DEG C to 200 DEG C and maintaining heat treatment for 2 to 5 h; turning off the vapor switch, allowing the temperature of the heat treatment box to decline, turning on the vapor switch when the temperature of the heat treatment box declines to 80 DEG C, adjusting the water content of the timber to be 7% to 10%, and moving the timber out. According to the invention, pretreatment of the timber with an aqueous solution of glycerin enables pyrolysis of chemical components in the timber to be accelerated, molecular chains of the timber to break and to form new crosslinked bond, and dimension stability and corrosion resistance of the timber to be effectively improved.

Owner:NORTHWEST A & F UNIV

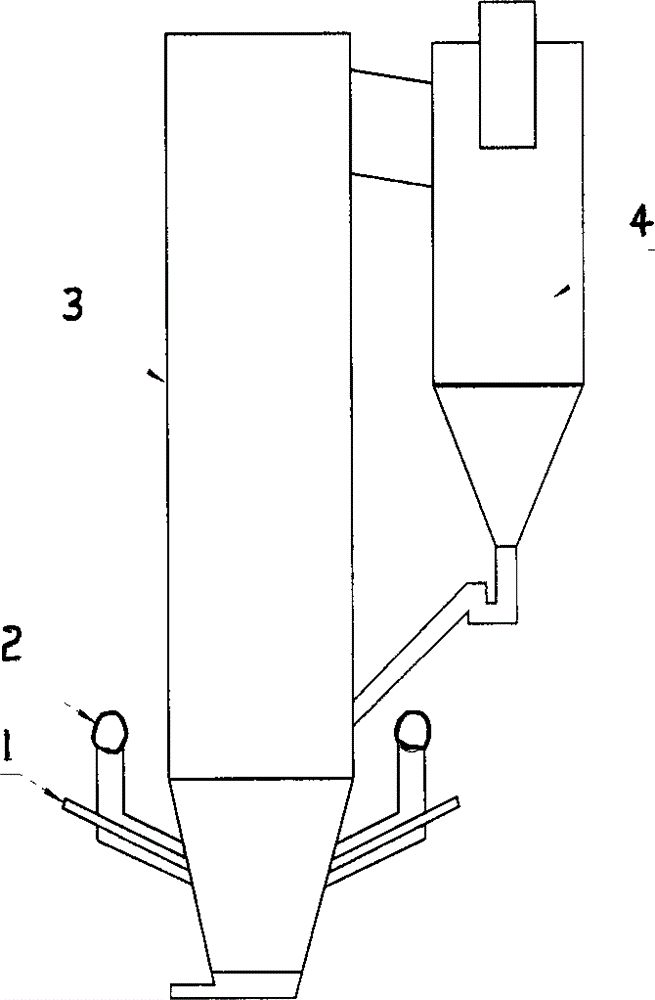

Multi-jet composite fluidized bed coal and biomass gasifier

InactiveCN1974733ARealize gasificationGood fluidization effectCombined combustion mitigationGranular/pulverulent flues gasificationFluidized bedWater vapor

The multi-jet composite fluidized bed coal and biomass gasifier consists of a fluidized bed, a synthesized gas outlet, a water vapor inlet and jet pipes. The fluidized bed consists of three parts, including the lower conic bed body, the middle expanding section and the upper expanding section, and has one cyclonic separator inside the upper expanding section. The synthesized gas outlet is in the top of the cyclonic separator. The jet pipes in the lower bed body include radial auxiliary material feeding jet pipes in two layers and main material feeding jet pipes in the center of bed body. The bed body has cinder outlet in the conic bottom and water vapor inlet beside the cinder outlet and the fluidized bed has outside heat insulating layer. The present invention has the advantages of simple structure, low cost and easy operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for in-situ synthesizing silicate/carbon composite cathode material by taking rice husk carbon as silicon source

ActiveCN103346300ARealize resource utilizationIn situ synthesisCell electrodesCarbon compositesSilicon dioxide

A disclosed method for in-situ synthesizing a silicate / carbon composite cathode material by taking rice husk carbon as a silicon source comprises the following preparation steps: (1) primary smashing of rice husks; (2) purification of the rice husks; (3) pyrolyzing the rice husks under catalysis of metal elements to obtain a SiMO / C mixture; (4) smashing the SiMO / C mixture to D50=1-2 [mu]m by an jet mill; (5) adding a lithium source, ball milling and mixing; and (6) sintering under gas protection to obtain Li2MSiO4 / C. According to the method, cheap biological silica is used to prepare the silicate cathode material, resource utilization of agriculture wastes is realized, and high added-value products are produced; at the same time, the rice husk carbon is obtained by the middle-temperature pyrolysis method, the residual carbon of the rice husk carbon is taken as a carbon source, and the synthesis process of the silicate cathode material does not need extra carbon, and the in-situ synthesis of the Li2MSiO4 material is realized synchronously.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

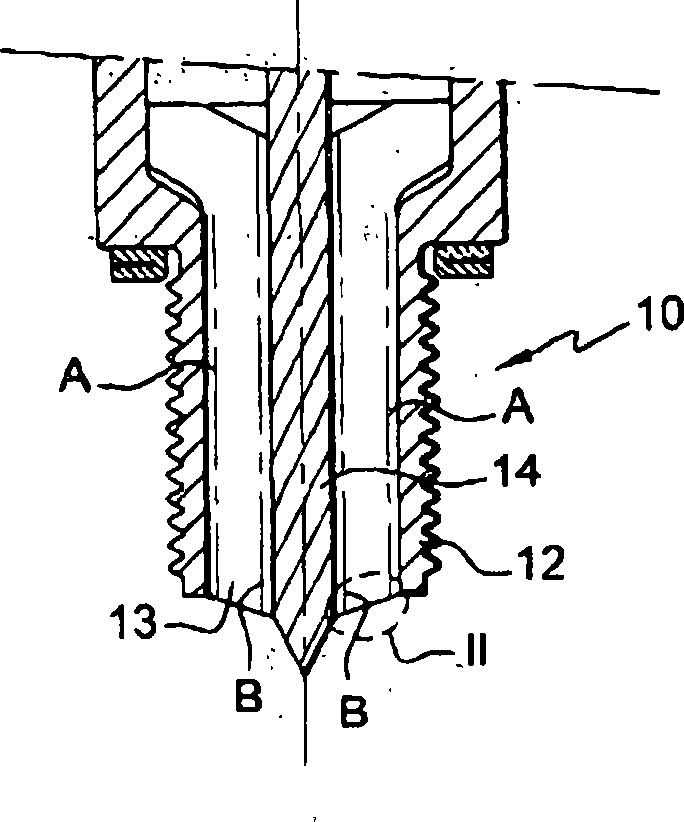

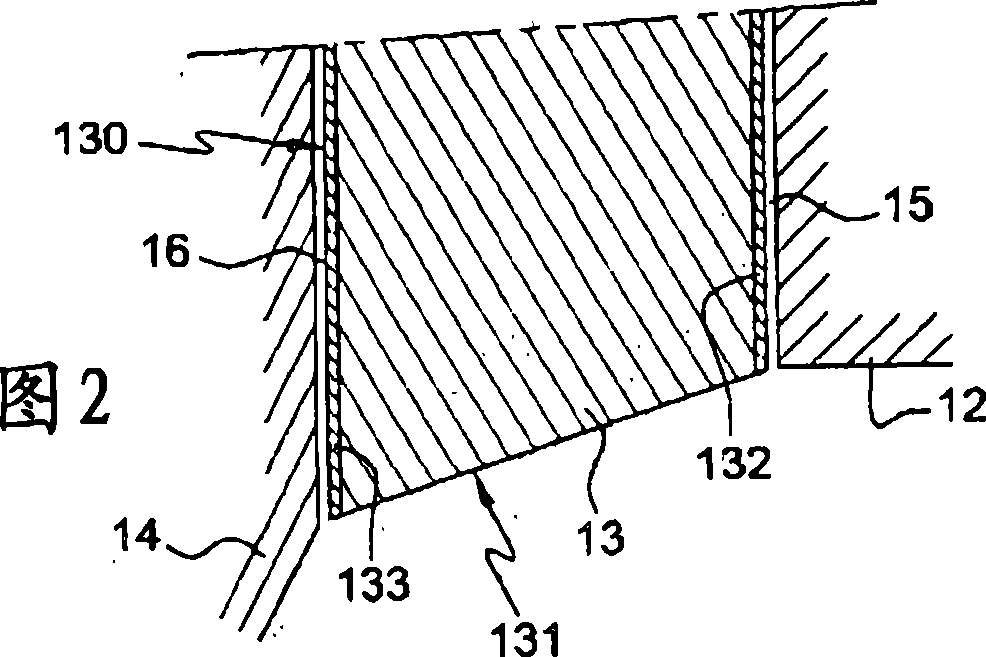

Plasma-generating plug

ActiveCN101366154APromote pyrolysisAvoid temperature homogeneitySparking plugsMetallic electrodeEngineering

The invention relates to a plasma-generating spark plug which undergoes excitation in the radio frequency domain. The invention comprises at least one first metallic electrode (12, 14), an insulator (13), one of which is equipped with a housing (130) in which the other element (13, 14) is mounted with a gap (15, 16) therebetween. The surface of the insulator (13) opposite the first electrode (12,14) is metallised.

Owner:RENAULT SA

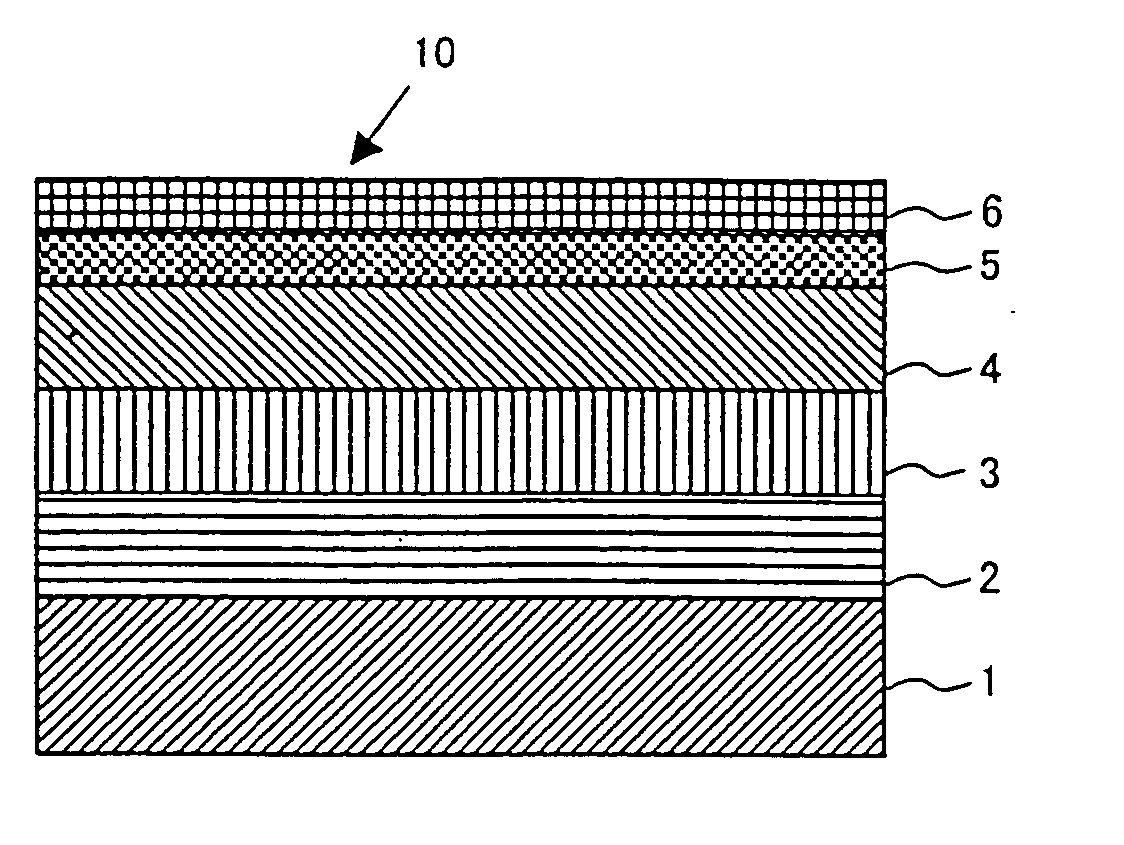

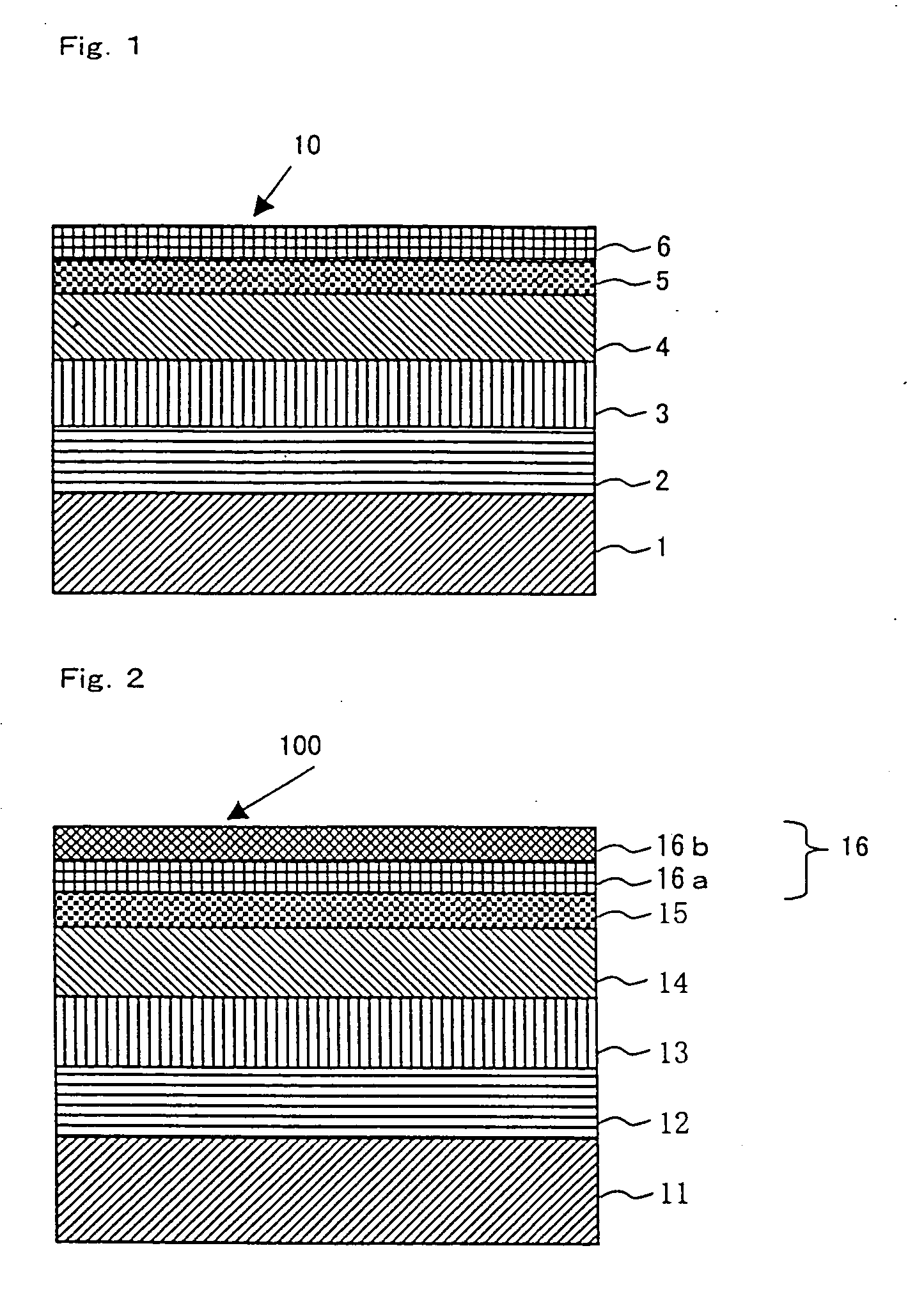

Magnetic recording disk and process for manufacture thereof

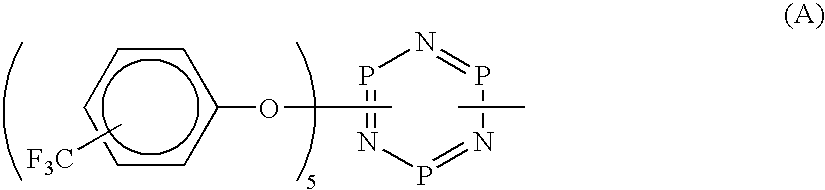

InactiveUS20050170136A1Promote pyrolysisImprove liquidityProtective coatings for layersMagnetic materials for record carriersPerfluoropolyetherPhotochemistry

A magnetic recording disk having a substrate, a magnetic layer formed on the substrate, a protective layer formed on the magnetic layer and a lubricant layer formed on the protective layer, the lubricant layer containing a perfluoropolyether compound having an end moiety containing a phosphazene ring and a perfluoropolyether compound having an end moiety containing a hydroxyl group, or the lubricant layer containing a perfluoropolyether compound having an end moiety containing a hydroxyl group on the protective layer side and a perfluoropolyether compound having an end moiety containing a phosphazene ring on the other surface side, and a process for manufacturing each of these magnetic recording disks.

Owner:WD MEDIA SINGAPORE PTE

Wastewater treatment method by ultrasonic reinforcement micron-scale iron-copper bimetallic particle

ActiveCN102795690AImprove processing efficiencyClose contactWater/sewage treatment with mechanical oscillationsMicron scaleCavitation

The present invention relates to a wastewater treatment method by ultrasonic reinforcement micron-scale iron-copper bimetallic particles, and belongs to the field of refractory wastewater treatment. The method includes the following process steps: adding the micron-scale iron-copper bimetallic particles to a reactor, then feeding wastewater to-be-treated continuously to the reactor and starting an ultrasonic probe, treating the wastewater by the micron-scale iron-copper bimetallic particles which are in a fluidized state with the action of ultrasonic, and continuously discharging the wastewater processed by the micron-scale iron-copper bimetallic particles from the reactor, wherein the retention time of the wastewater in the reactor is 0.2-1.0 h. The method not only improves the efficiency of wastewater treatment, but also can prevent the ultrasonic probe from cavitation corrosion and packing passivation compaction, and broadens the range of pH for the wastewater treatment.

Owner:成都柏溪环境科技有限公司

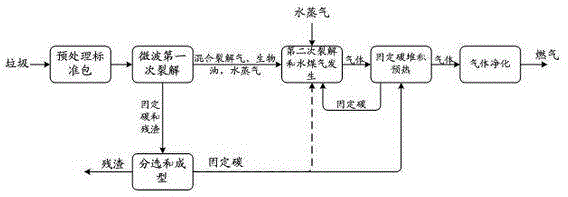

Process for preparing gas by microwave carbon pyrolysis of municipal solid waste

ActiveCN102719279ALarge amount of gasPromote lysisSolid waste disposalSpecial form destructive distillationWater vaporMaterials science

The invention relates to a process for preparing gas by the microwave carbon pyrolysis of municipal solid waste and belongs to the technical field of environmental protection. The process comprises the following steps of: removing dust from municipal solid waste which is accumulated for a certain time, press-packing, and feeding into microwave heating equipment for pyrolysis; separating fixed carbon and residue which are generated by the pyrolysis, and making the fixed carbon into a shape which is loose and through which gas can conveniently pass; continuously heating the fixed carbon, and fully cracking incomplete pyrolysis gas and biological oil to generate combustible gas; reacting water vapor and thermofixed carbon to generate water gas; and performing purification treatment such as desulfurization and dephosphorization on the gas to obtain harmless combustible gas. By the process, the yield of the gas is high, the calorific value is high, the energy is equal to or higher than the energy consumed by the process, and the operation cost is low; and toxic and substances with peculiar smell such as dioxin are eradicated while a large amount of harmless combustible gas is obtained, so that the environment is effectively protected.

Owner:SICHUAN HOPE MICROWAVE SCI & TECH

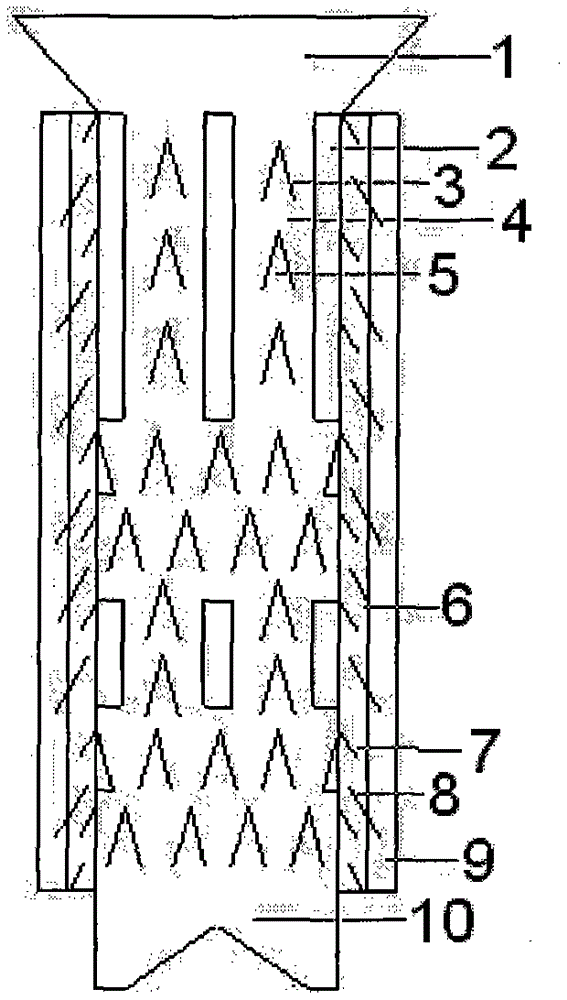

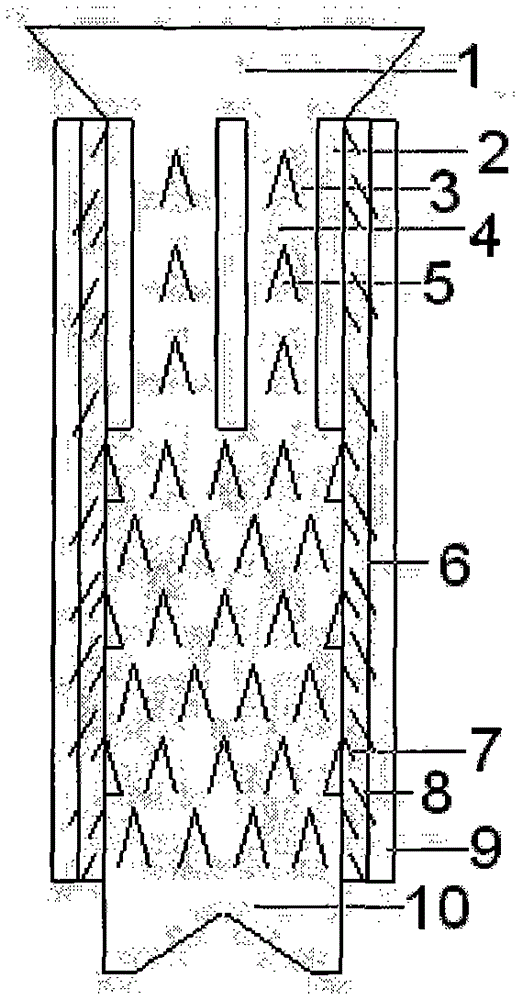

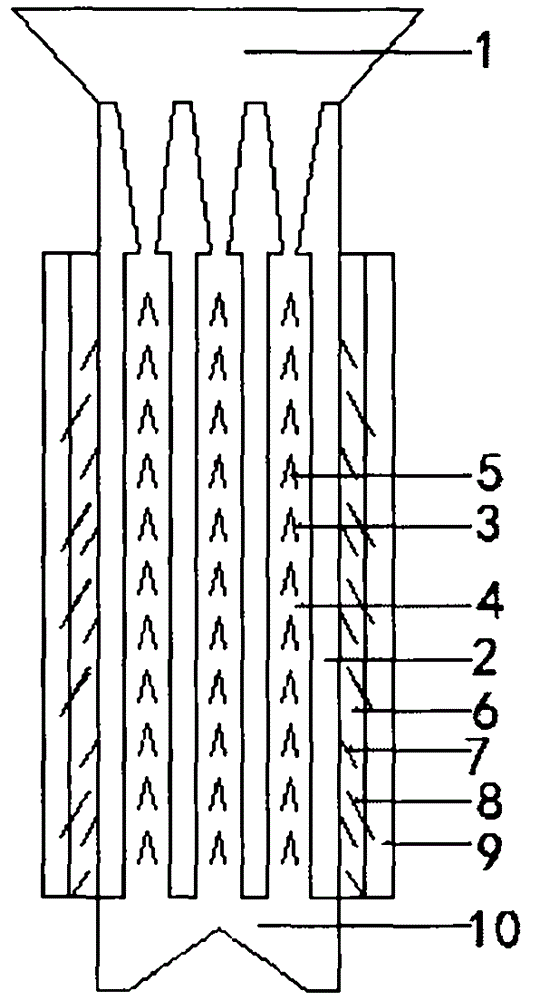

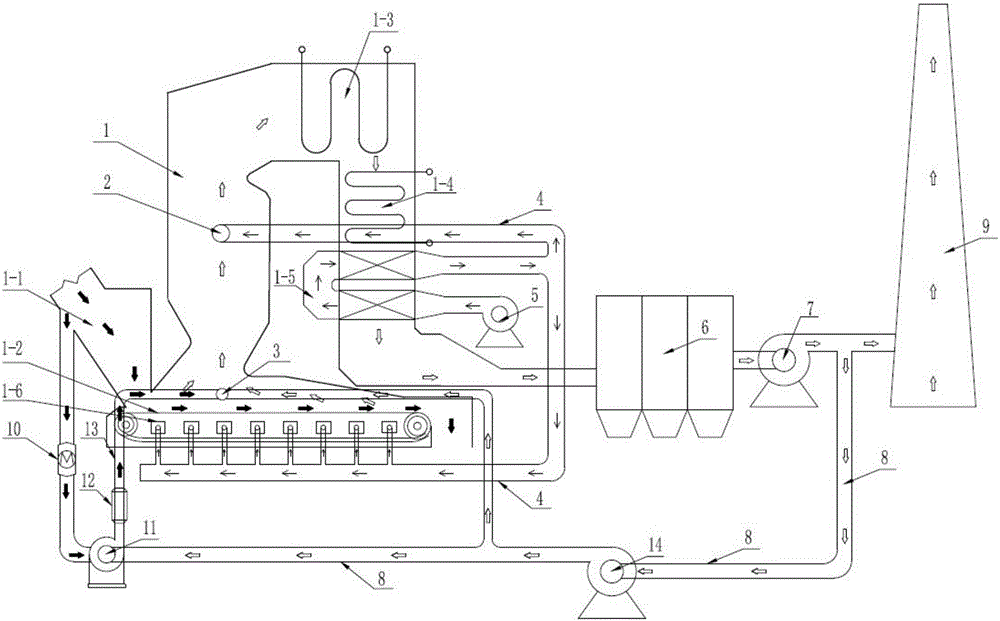

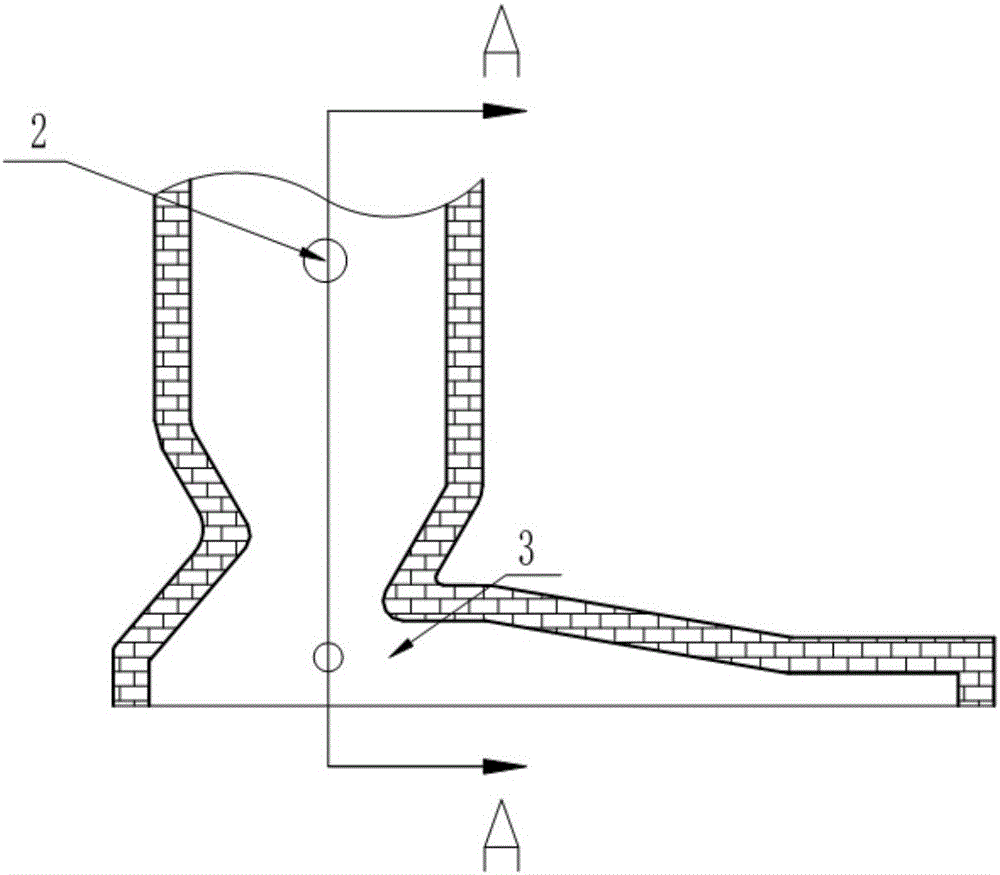

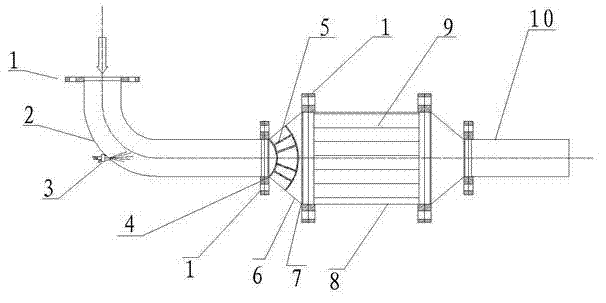

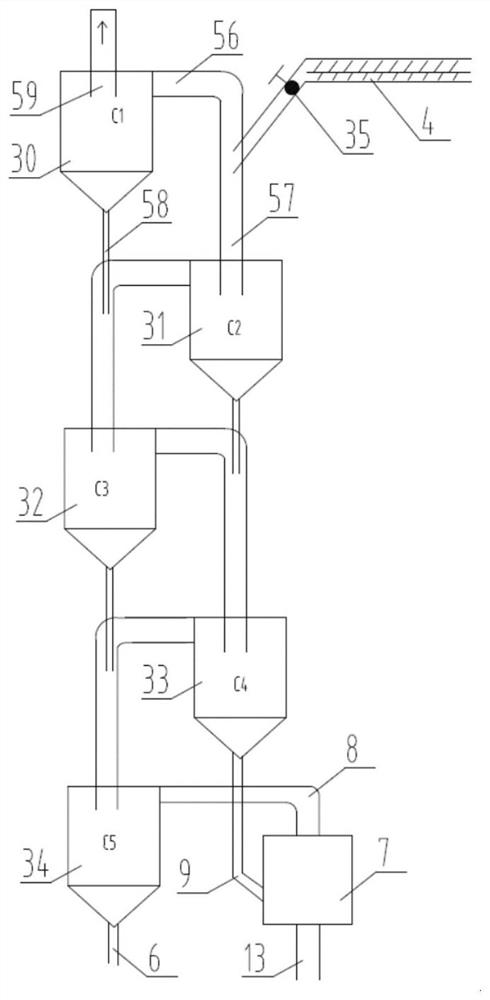

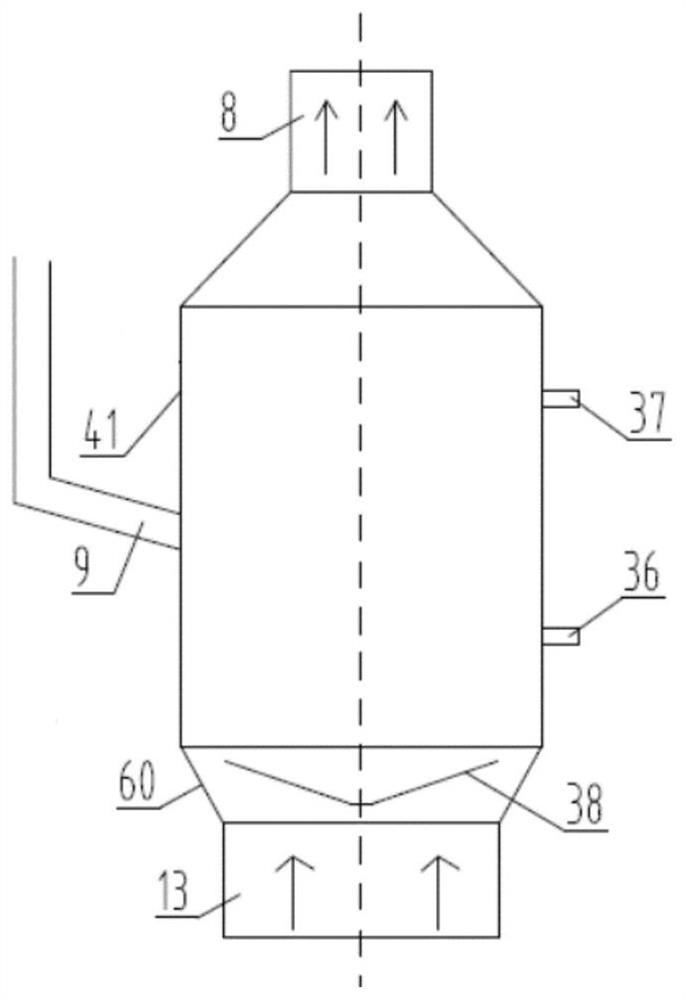

Low-temperature pyrolysis method for pulverized coal and oil shale powder and external heating vertical type descending low-temperature pyrolysis furnace

ActiveCN105018118AHigh yieldHigh recovery rateIndirect heating destructive distillationSpecial form destructive distillationProduction rateBusiness efficiency

The invention relates to a low-temperature pyrolysis method for pulverized coal and oil shale powder and an external heating vertical type descending low-temperature pyrolysis furnace so as to solve the problem that pyrolysis can not be carried out on powder in the prior art. The furnace is composed of a drying system, a heating pyrolysis system, a dust removing system, an oil-gas separating system and a coke quenching system; at first, the drying system is utilized for drying and preheating the pulverized coal or the oil shale powder with the diameter smaller than 0.6 cm to the temperature of 200 DEG C; the heating pyrolysis system with clean coal gas as fuel is utilized for indirectly heating the dried and preheated pulverized coal or oil shale powder to the temperature of 550 DEG C-600 DEG C to dissolve and separate semi-coke, oil gas and heating gas out; the dust removing system is utilized for removing dust in the oil gas and the heating gas; the oil-gas separating system is utilized for separating the clean coal gas and coal tar; finally, inert gas generated by the drying system and the coke quenching system are utilized for carrying out coke quenching on the semi-coke produced by the heating pyrolysis system. The furnace has the advantages that the pulverized coal and the oil shale powder can be fully utilized, safety performance is high, the energy efficiency ratio is high, the gas production rate is large, the gas production quality is good, the production capacity of the single furnace is high, and the production cost is low.

Owner:肖自江 +5

Combined combustion system of chain boiler

InactiveCN105864748AEfficient and clean combustionPromote pyrolysisStaged combustionFluegas recirculationCombustion systemCoal

The invention relates to a combined combustion system of a chain boiler. The combined combustion system comprises a pulverized coal making-pulverized coal conveying system, a smoke recirculating system, an air supply system and a combusting system; and a discharging opening of a coal hopper is divided into two paths, one path is connected with a chain fire grate, the other path feeds coal in the coal hopper into a fan coal mill through a coal feeder, a circulating fan is connected with an induced draft fan through a smoke pumping pipeline, the circulating fan pumps part of smoke from a flue of an induced draft fan outlet via the smoke pumping pipeline to serve as a drying agent of pulverized coal in the fan coal mill, and a coarse and fine pulverized coal separator is connected with a pulverized coal combustor through a pulverized coal conveying pipeline. The system is organically combined with the traditional combined combustion technology, the fuel grading combustion technology and the smoke recirculation technology, the problems that an existing chain boiler is poor in coal type adaptation, low in boiler combustion efficiency, insufficient in performance and slightly high in NOx emission are solved, and the clean, efficient and safe combustion manner is provided for the chain boiler.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Catalyst for pyrolysis of oil shale as well as preparation method and use method of catalyst

InactiveCN103878031AIncrease lytic activityHigh cracking rateOrganic-compounds/hydrides/coordination-complexes catalystsSpecial form destructive distillationCatalytic pyrolysisMetallic sulfide

The invention discloses a catalyst for pyrolysis of oil shale. The catalyst is prepared from the following raw materials by weight percentage: 2-8% of a molecular sieve, 1-5% of activated clay, 10-60% of organic cobaltate, 5-20% of metal sulfide, 8-30% of glycerate, and 15-35% of paraffin; the organic cobaltate is one or more of cobalt acetate, cobalt oxalate, cobalt naphthenate and cobalt neocaprate; the metal sulfide is molybdenum sulfide and / or nickel sulfide. The invention further discloses a preparation method of the catalyst and a use method of the catalyst. According to the catalyst disclosed by the invention, the pyrolysis efficiency of the oil shale can be improved, the distribution of pyrolysis products of the oil shale is improved, more light products are produced, and components of gasoline and diesel oil can be separated through rectification. According to the preparation method and use method of the catalyst, which are disclosed by the invention, the catalytic pyrolysis and microwave heating are combined, so that the utilization efficiency of energy source can be improved, the composition and process performance of liquid fuel are improved, and the following processing difficulty is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

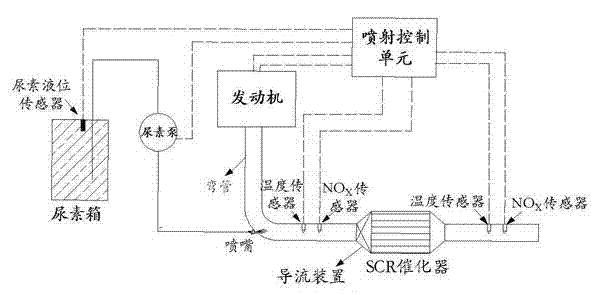

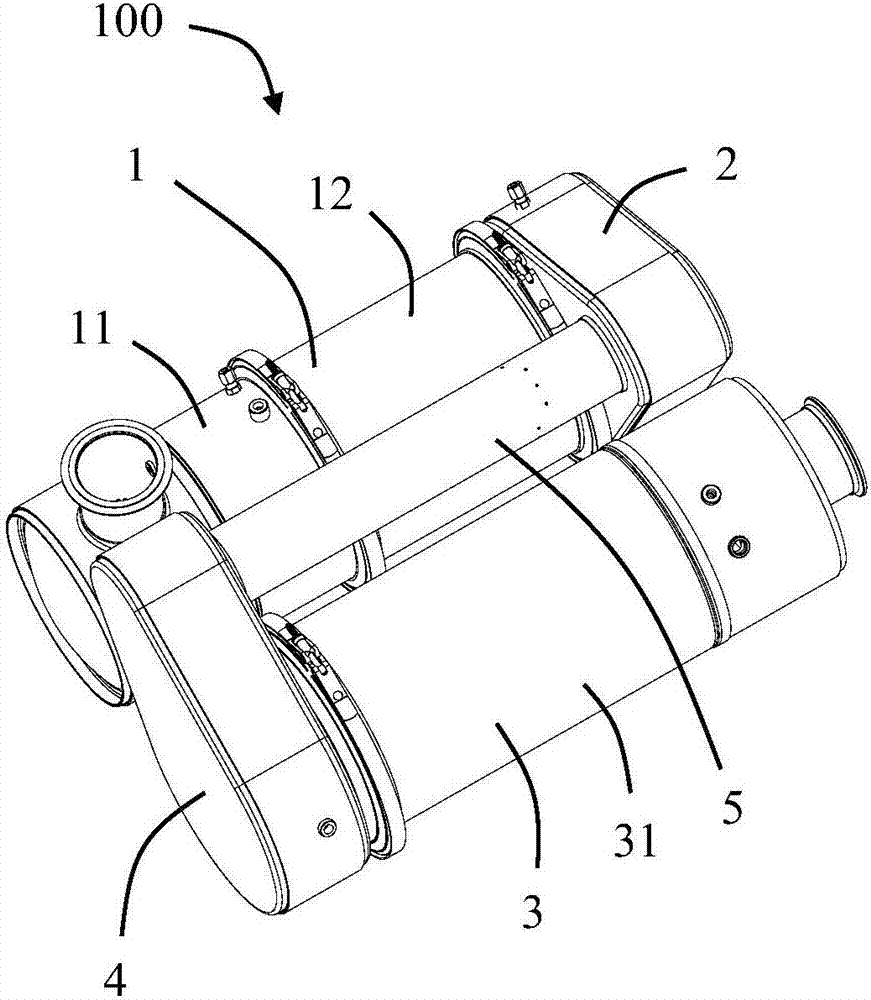

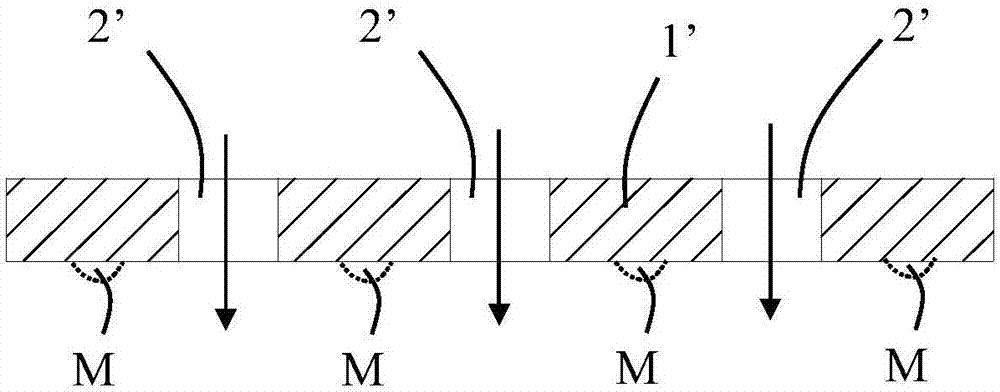

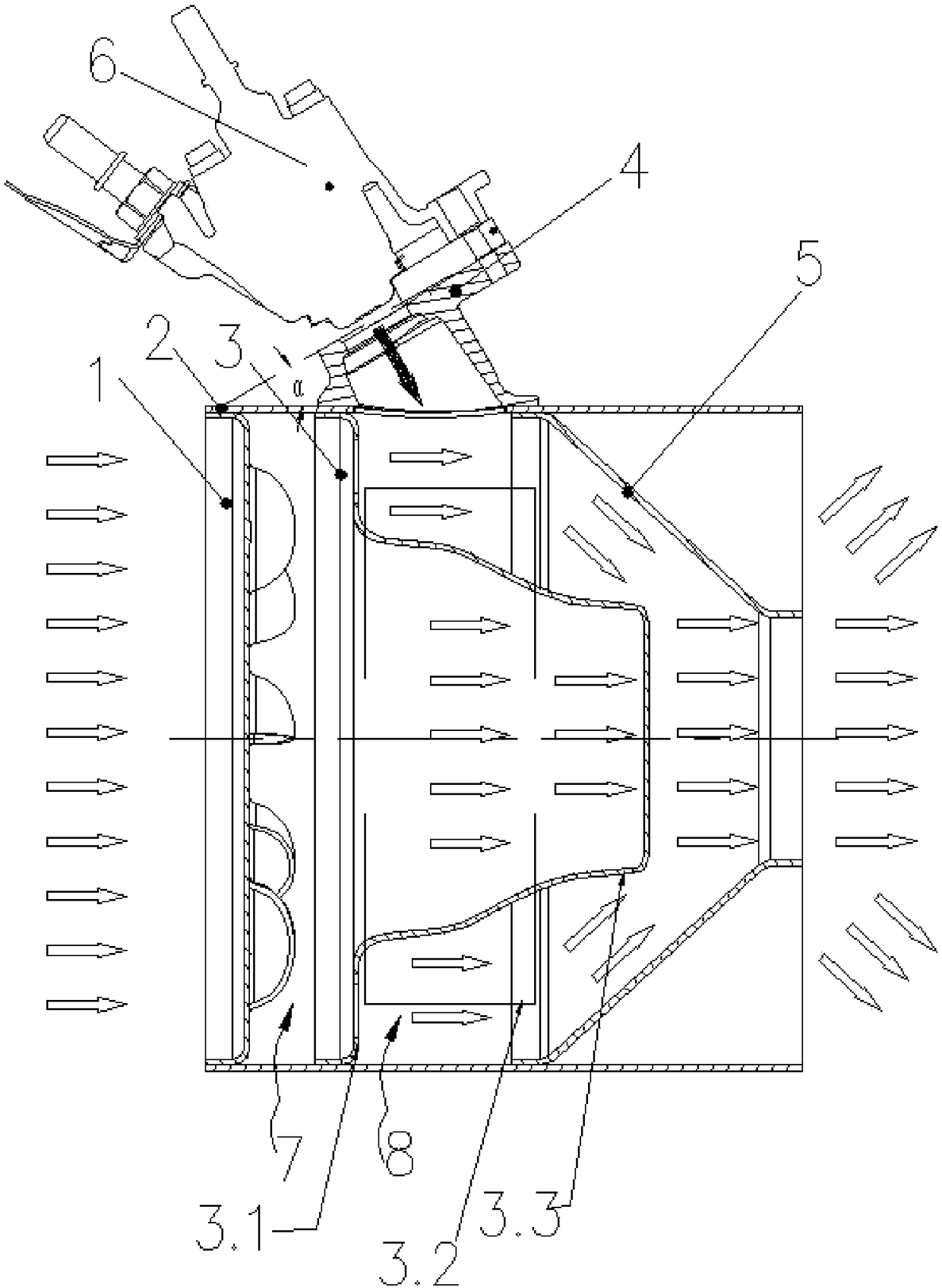

Guiding device and guiding method for diesel engine selective catalytic reduction (SCR) system for automobile

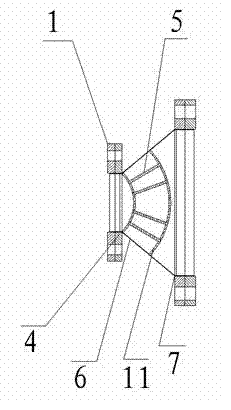

InactiveCN103089383ASimple structureLow costInternal combustion piston enginesExhaust apparatusEngineeringNitric oxide

The invention relates to a guiding device and a guiding method for a diesel engine selective catalytic reduction (SCR) system for an automobile. The guiding device comprises an expansion pipe and at least two guiding plates arranged in a mutually embedding mode. The end where gas flows to the expansion pipe is a gas inlet end and the end where the gas flows out of the expansion pipe is a gas output end. The guiding plates at fixedly arranged on the gas inlet end of the expansion pipe and each guiding plate is in a trumpet shape without a front end face and a rear end face. A fluid channel is formed among the guiding plates. The guiding device is simple in structure, low in manufacturing cost and easy to install. According to the guiding device and the guiding method, due to backflow generated in the portion of an elbow pipe, exhaust of the automobile and urea sprayed from a nozzle can mix well so that generation of crystal on a wall is reduced. Due to the guiding device in the expansion pipe portion, mixed gas is converted from turbulent flow to laminar flow so that velocity distribution is even, radial pressure difference and temperature difference inside a catalytic agent are reduced, conversion efficiency of nitric oxides is improved, through capacity of a catalytic agent carrier is improved and service life of a catalyst is prolonged.

Owner:JIANGSU UNIV

Method for synthesizing P zeolite molecular sieve from rice husk

InactiveCN106379913APromote pyrolysisDamage structureCrystalline aluminosilicate zeolitesHigh pressureMuffle furnace

The invention discloses a method for synthesizing a P zeolite molecular sieve from rice husk. The method includes: subjecting crushed rice husk to pretreatment with sulfuric acid, conducting washing and drying, then putting the dried rice husk into a muffle furnace for pyrolysis, collecting combusted rice husk ash, putting the combusted rice husk ash and a sodium hydroxide aqueous solution in a high pressure kettle to conduct hydrothermal activation for 2-4h under a temperature of 180-230DEG C, and performing cooling to obtain an activated alkali solution, adding an aluminum source into the activated alkali solution, then adding a P zeolite molecular sieve crystal, and carrying out aging, heating crystallization, filtering, washing and drying, thus obtaining a finished product. The method realizes waste recycling, and has the advantages of simple process, short production period, easy operation, and the obtained product has the characteristics of high quality and low cost, etc.

Owner:曹蕊

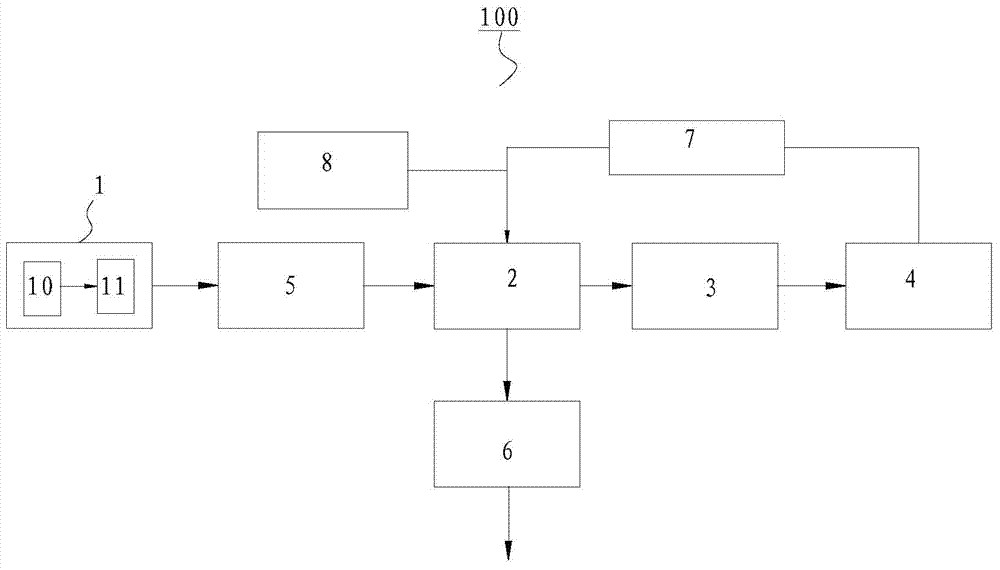

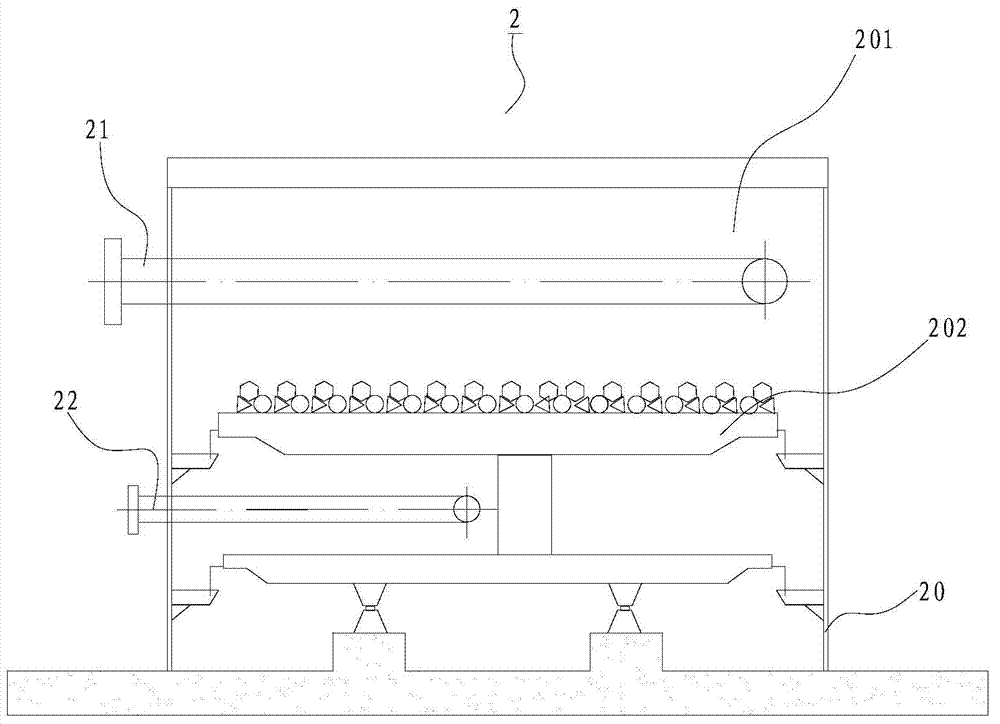

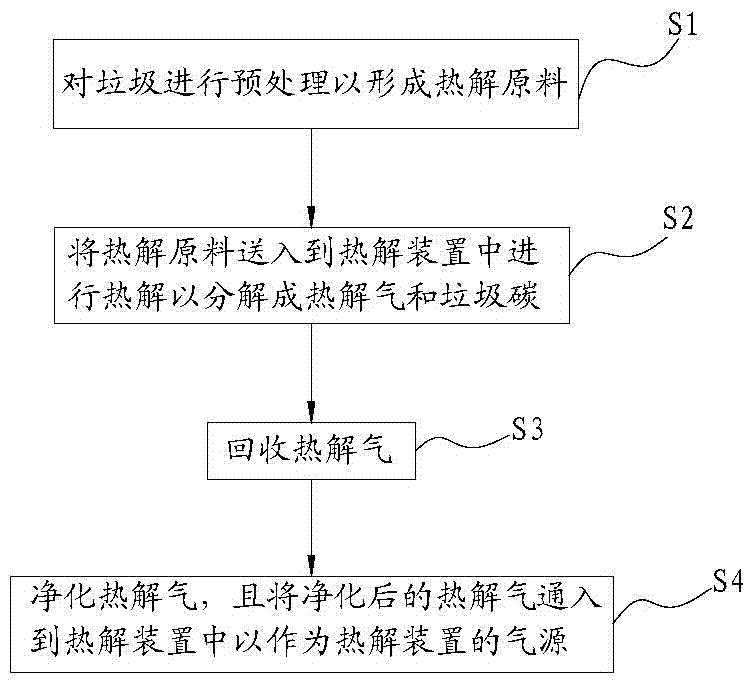

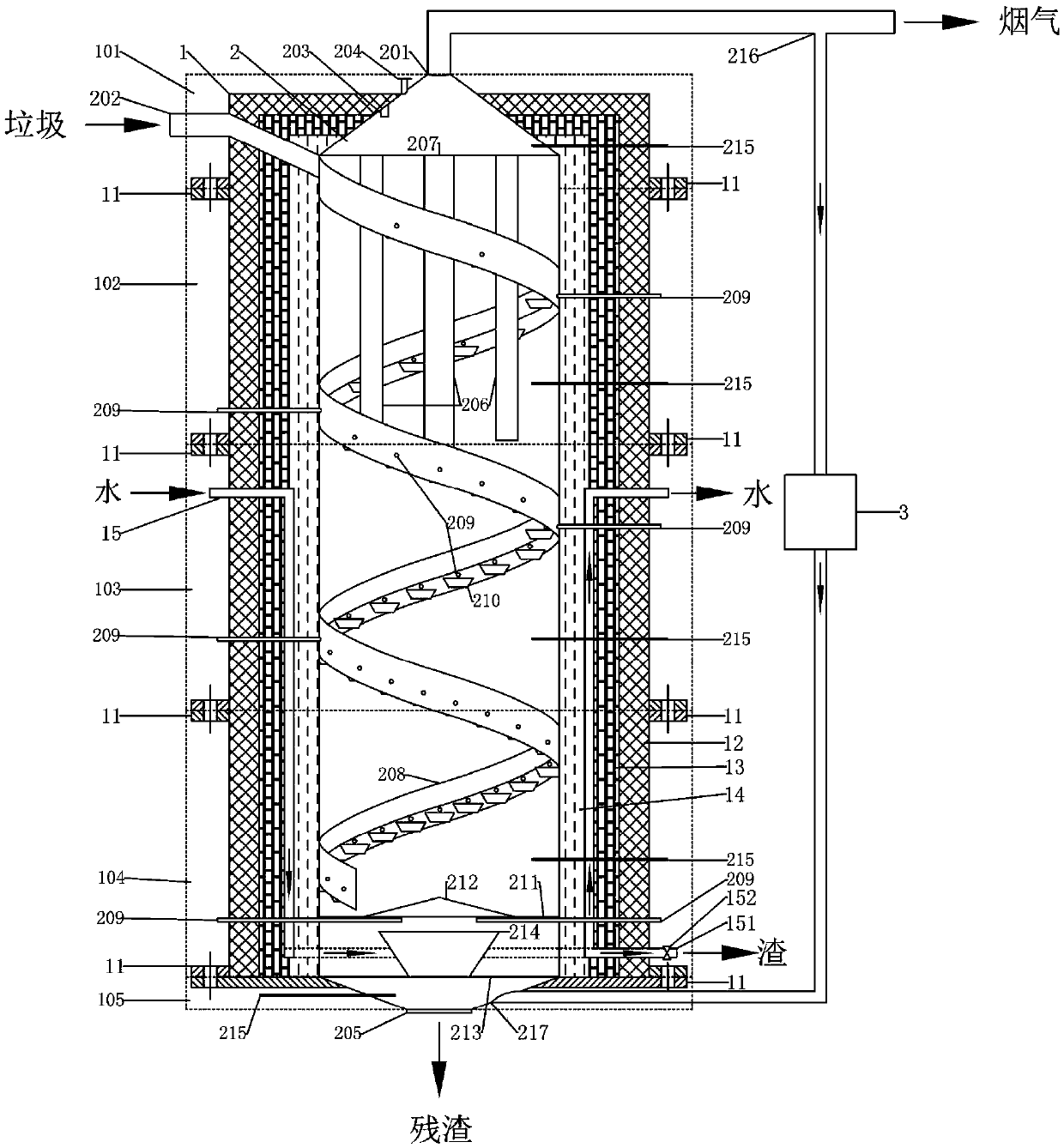

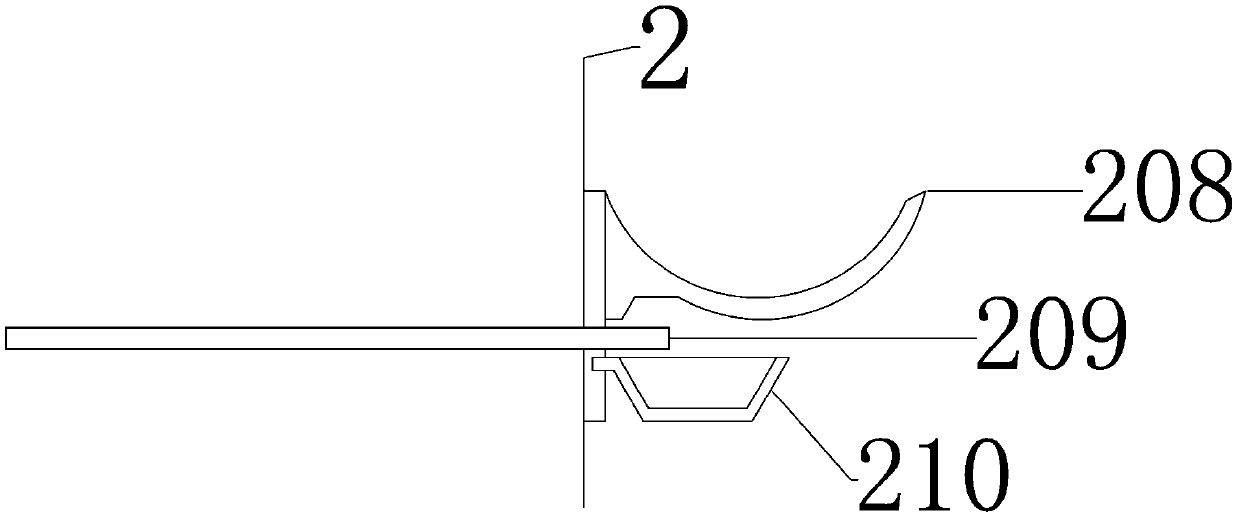

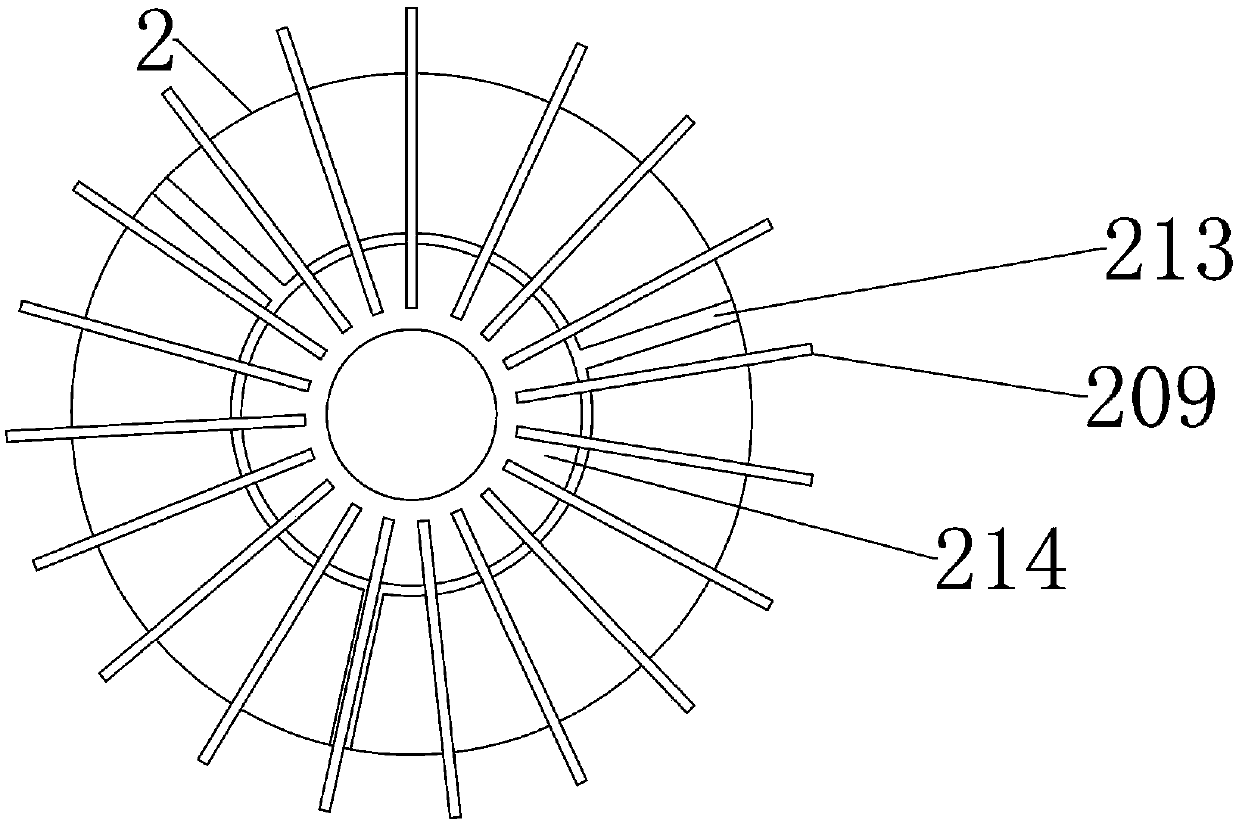

Garbage treatment system and method

ActiveCN103672907ALow running costReduce energy consumptionIncinerator apparatusLitter decompositionEnergy consumption

The invention discloses a garbage treatment system and method. The garbage treatment system comprises pretreatment equipment, a pyrolyzation device, a purification device and an gas storage tank, wherein the pretreatment equipment conducts pretreatment on garbage so that pyrolyzation raw materials can be formed, the pyrolyzation device is connected with the pretreatment equipment and is used for receiving the pyrolyzation raw materials and decomposing the pyrolyzation raw materials into pyrolysis gas and garbage carbon, the purification device is connected with the pyrolyzation device and is used for receiving the pyrolysis gas and cooling and purifying the pyrolysis gas, the gas storage tank is connected with the purification device and is used for receiving the purified pyrolysis gas, and the gas storage tank is also connected with the pyrolyzation device to provide a gas source for the pyrolyzation device. According to the garbage treatment system, the garbage is decomposed into the pyrolysis gas and the garbage carbon, the pyrolysis gas of the garbage is used as fuel gas, as a result, the utilization rate of the pyrolysis products is improved, and the problems caused by pyrolytic oil treatment and operation are avoided; meanwhile, the operation cost of the garbage treatment system is reduced, energy consumption is low, and the recycling level is high.

Owner:北京节净环保科技有限公司

Brown's gas-burning solid organic waste pyrolyzing furnace

ActiveCN109681884ALow costInhibitionSpecial form destructive distillationIncinerator apparatusHeat conductingCrucible

The invention relates to the field of solid waste pyrolyzing devices, and discloses a Brown's gas-burning solid organic waste pyrolyzing furnace which comprises a housing and a cavity positioned inside the housing, wherein the housing is equipped with a main gas exhaust port, a pressure detector, an overpressure relief valve, an inductive ash-discharging electric valve and a feeding port; the cavity is equipped with smoke-guiding gas columns, a guiding chute, Brown's gas burning guns, wall-hanging crucibles, a heat conducting plate and a crucible basin; the wall-hanging crucibles and the crucible basin are filled with a metal material; and through an external fan of the Brown's gas-burning solid organic waste pyrolyzing furnace, part of burnable gas generated from the pyrolyzing process can flow back to the Brown's gas-burning solid organic waste pyrolyzing furnace. A kind of clean burning energy, namely Brown's gas, is utilized for the Brown's gas-burning solid organic waste pyrolyzing furnace; and the Brown's gas-burning solid organic waste pyrolyzing furnace has the advantages that the environment-friendly property is achieved, the cost is low, the occupied area is small, and solid organic waste can be efficiently, continuously and massively treated.

Owner:广东蓝新氢能源科技有限公司

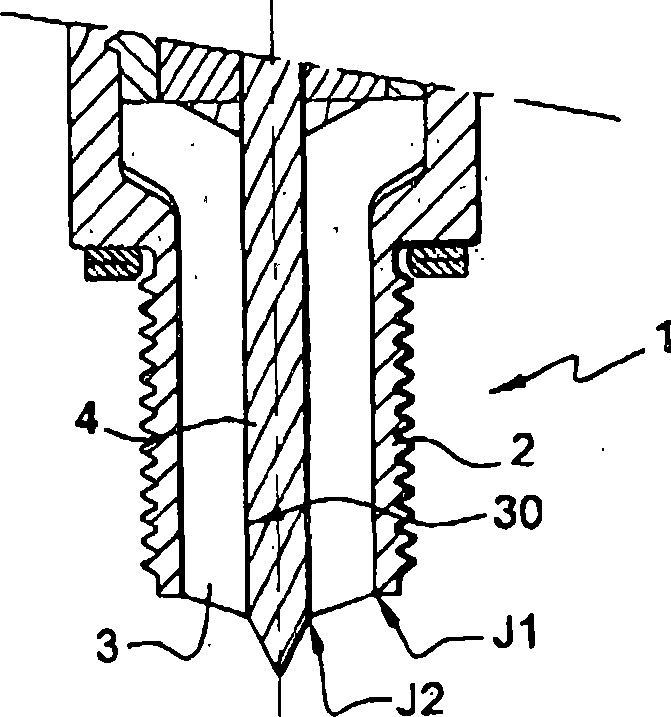

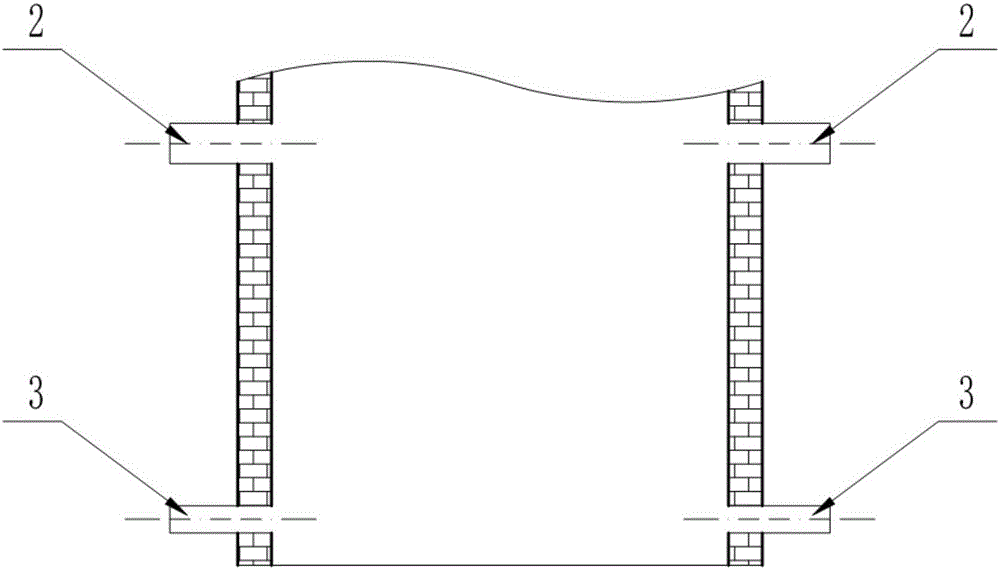

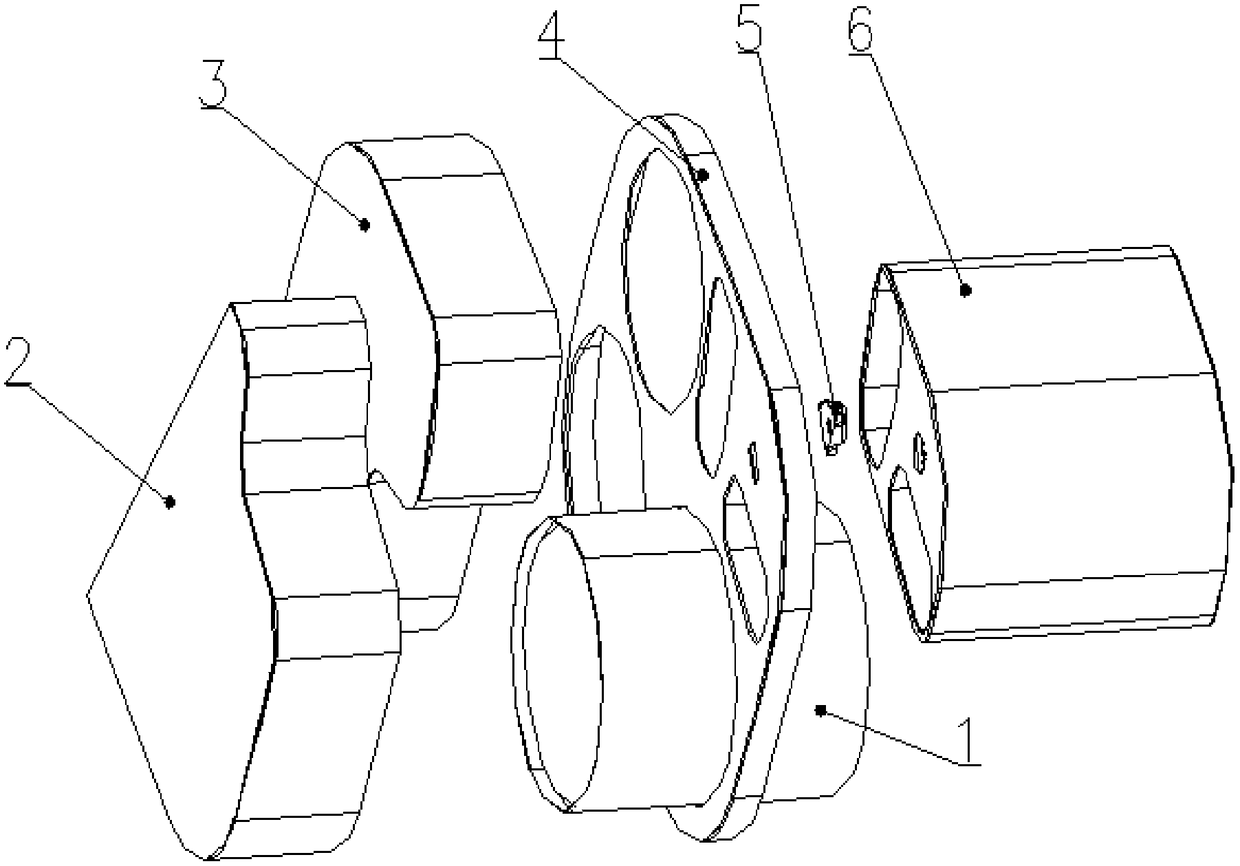

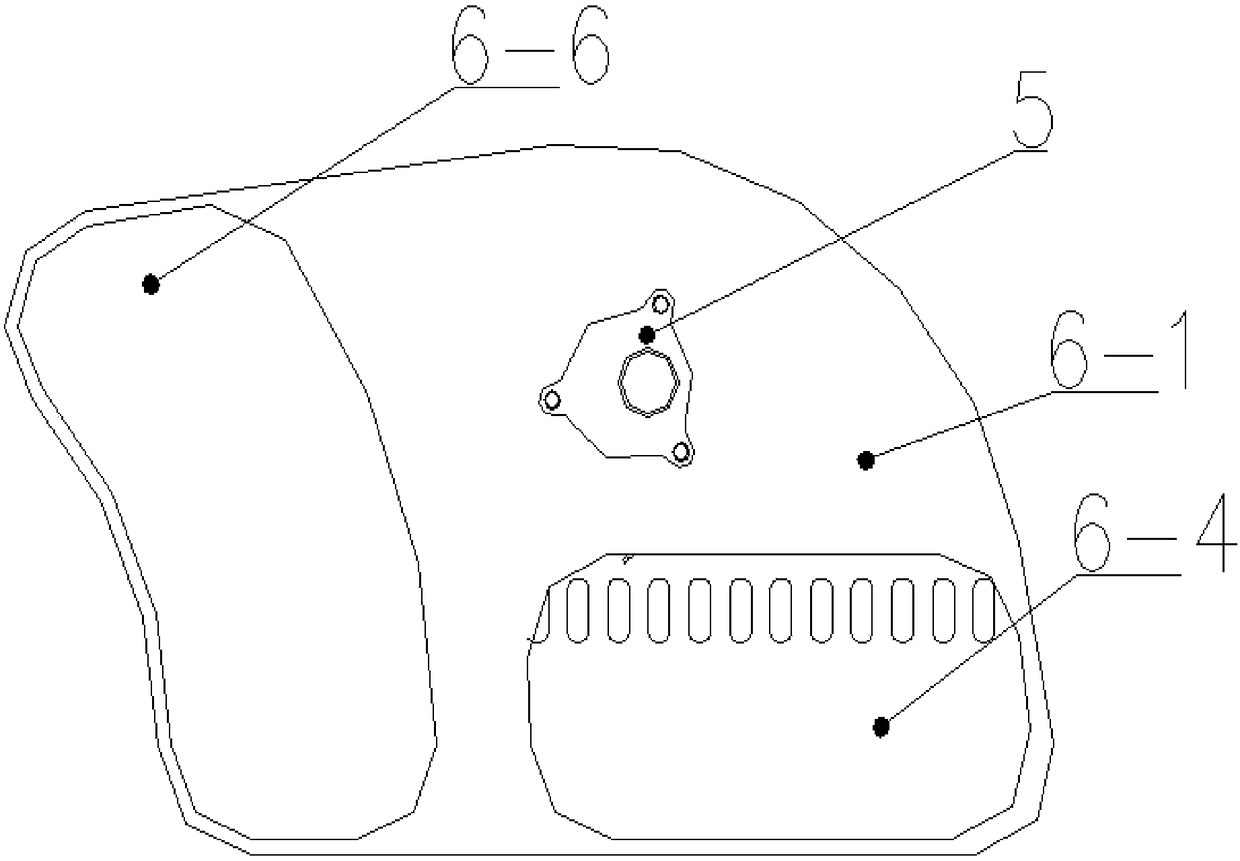

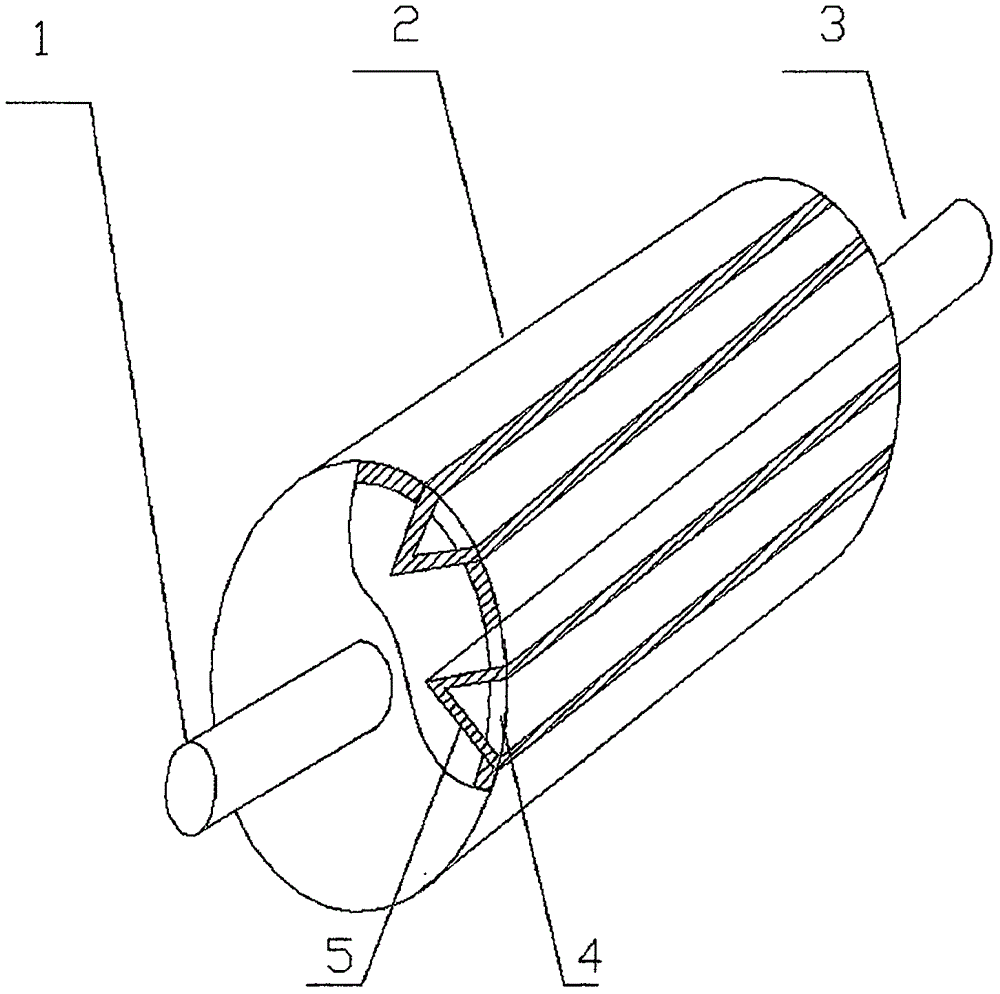

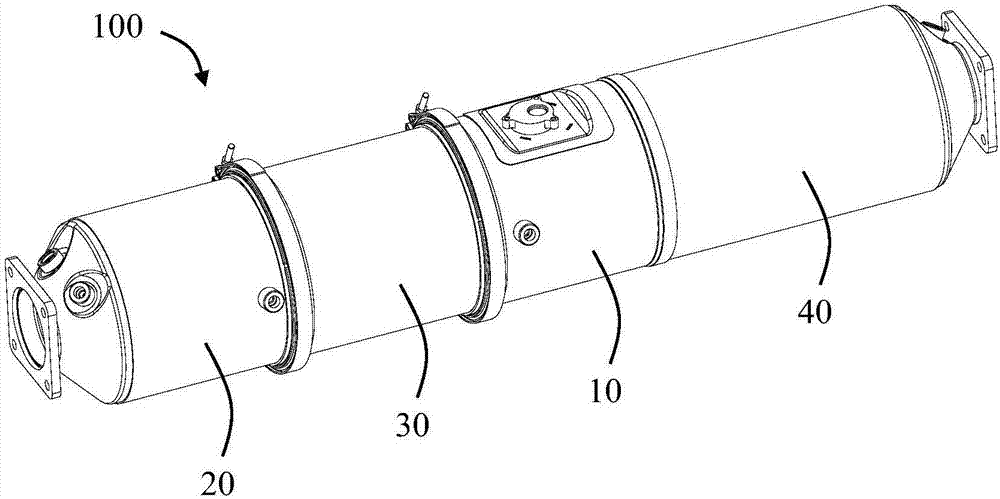

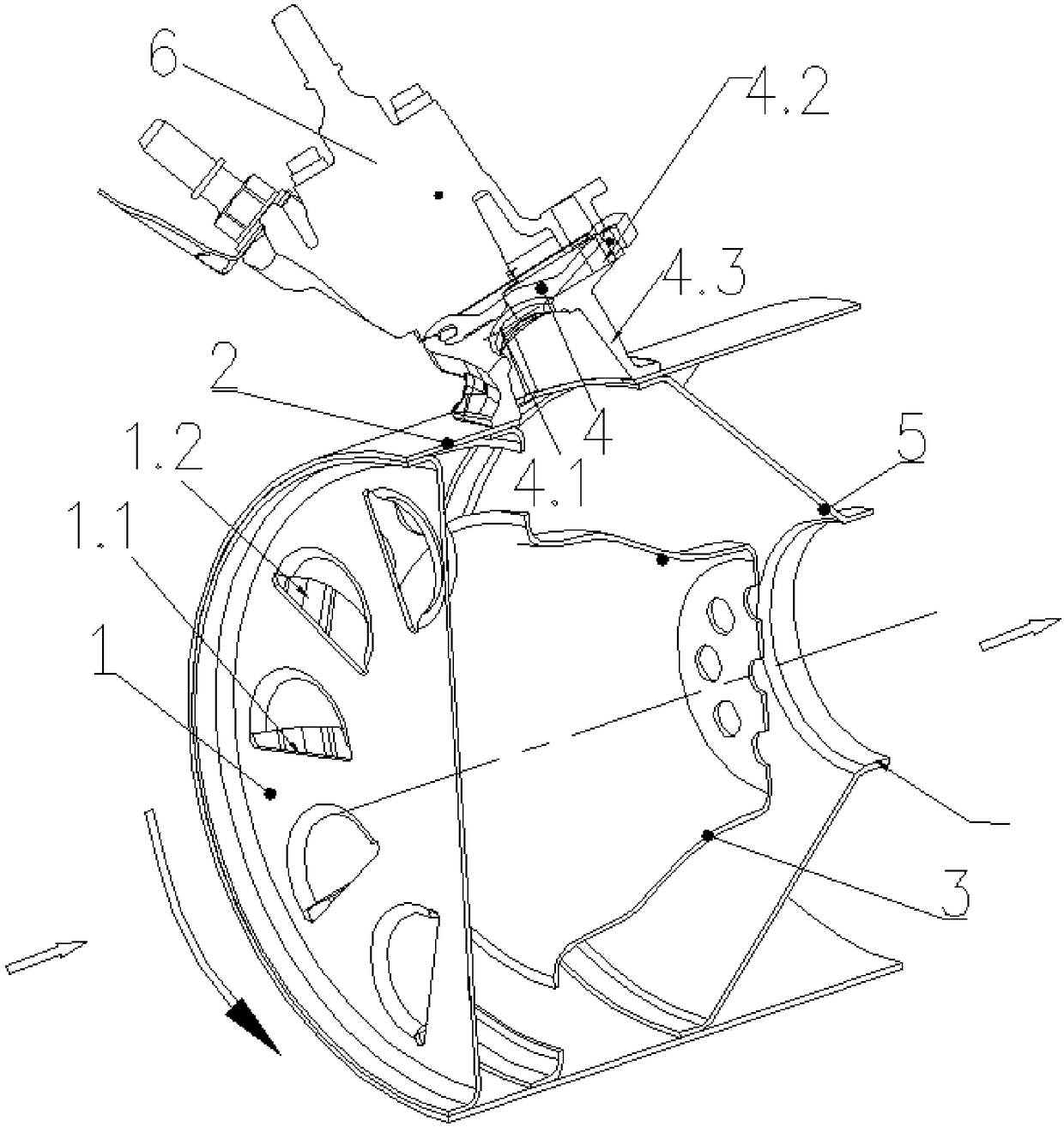

U-shaped mixer device used for square box structure

ActiveCN108194176AAccelerated pyrolysis/hydrolysisWell mixedInternal combustion piston enginesExhaust apparatusAfter treatmentEngineering

The invention relates to the field of diesel engine exhaust gas after-treatment, and provides a U-shaped mixer device used for a square box structure. The device comprises a DPF particle complementingunit, a mixer air inlet end cover, a mixer air outlet end cover, a square box platform partition board, a urea injection base and a mixer device body; the urea injection base is arranged on the square box platform partition board, the DPF particle complementing unit and the mixer device body are arranged on the other side of the square box platform partition board at an interval, one end of a mixer supporting plate and the lower portion of a mixer partition board are arranged in a crossed manner, the other end of the mixer supporting plate is fixed to the inner wall of a mixer cylinder. Exhaust fluid flows through rotational flow blades of a mixer rotational flow pipe, higher rotation air flow is formed, pyrolysis / hydrolysis of urea water solutions can be accelerated, the mixing effect isgood, the fluid flows to an SCR through a U-shaped structure, and compared with the existing technology, the mixing distance is lengthened, pyrolysis of the urea water solution can be benefited, thebackpressure effect of the whole mixing device is reduced, the structure is compact, and mounting is convenient.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Desulphurization method for circulating fluidized bed boiler with superfine desulfurizing agent granules

InactiveCN106178907ALarge particlesIncrease particle diameterDispersed particle separationEngineeringPetroleum coke

The invention discloses a desulphurization method in a circulating fluidized bed boiler, and belongs to the technical field of desulphurization of the fluidized bed boiler burning solid fuel such as coal, petroleum coke and biomass. The method is mainly used for solving the problem that the desulfurization efficiency in the circulating fluidized bed boiler is low. The desulphurization method is characterized by comprising the following steps of selecting limestone or magnesium oxide powder of which the diameter is 50-75[mu]m as a desulfurizing agent, conveying desulfurizing agent powder by using compressed air of which the flow rate is 45-55m / s, spraying the desulfurizing agent into a furnace chamber by using a secondary air nozzle of the circulating fluidized bed boiler, inserting a conveying pipeline into each secondary air duct of the boiler, and maintaining the desulfurizing agent conveying pipe and the secondary air nozzle concentric, wherein the calcium sulfur ratio is 1.8-2.5, and the temperature of the furnace chamber is 800-950 DEG C. According to the method, the desulfurization efficiency can reach 90% or above.

Owner:周建强

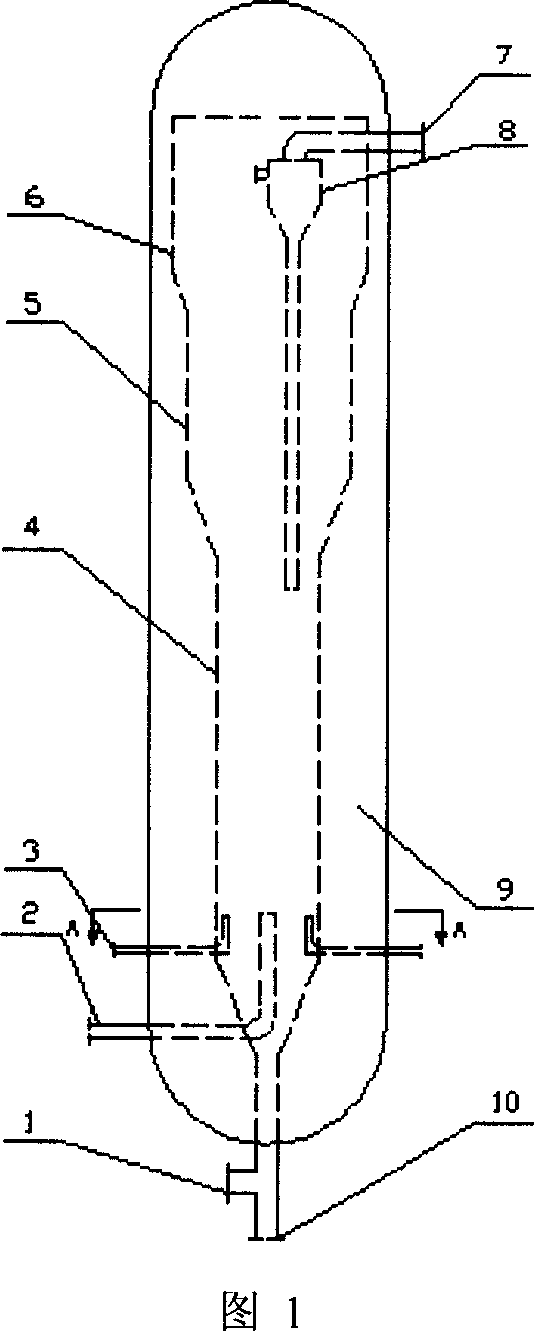

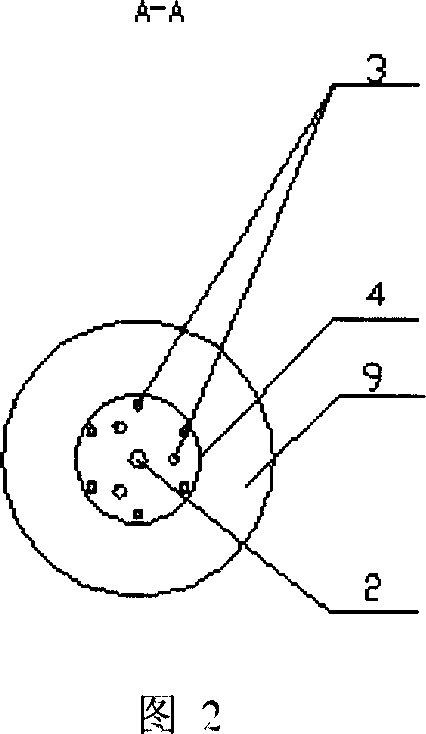

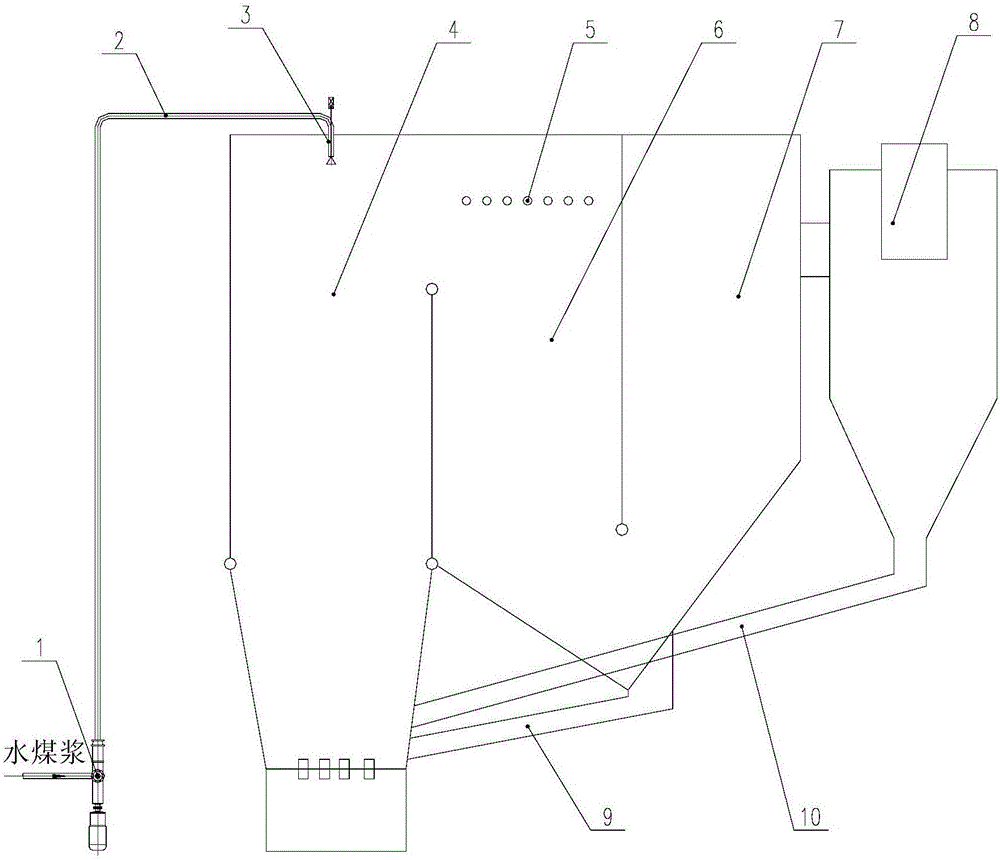

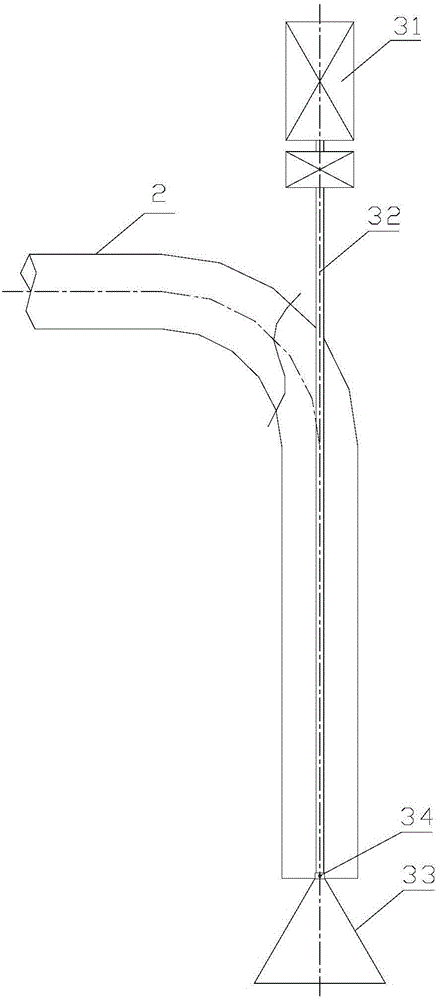

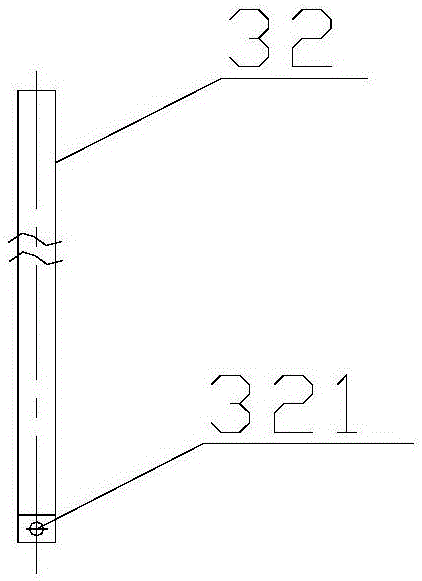

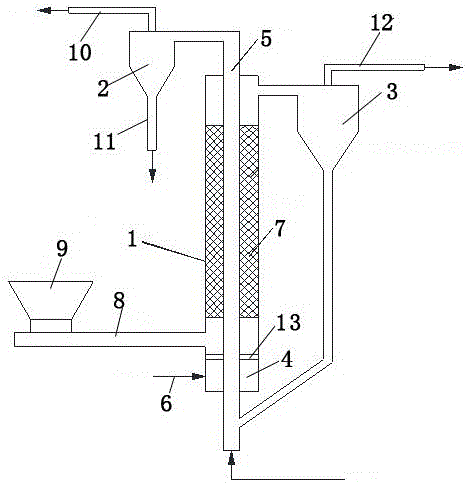

Coal water slurry feeding device for multi-flow circulating fluidized bed boiler and boiler

ActiveCN106838893AHelp volatilizationEvenly distributedFluidized bed combustionFuel feeding arrangementsCoal waterCombustion chamber

The invention relates to a coal water slurry feeding device for a multi-flow circulating fluidized bed boiler and the boiler. The coal water slurry feeding device comprises a slurry supply pump (1), a slurry supply pipe (2), a coal water slurry granulator (3) and secondary air ports (5), wherein the slurry supply pipe (2) is communicated with the slurry supply pump (1), and the other end of the slurry supply pipe (2) is communicated with the coal water slurry granulator (3) distributed at the top of a main combustion chamber (4); the secondary air ports (5) are distributed in positions close to tops of side walls of an auxiliary combustion chamber (6); a sprayer (33) of the coal water slurry granulator (3) is arranged in the hearth of the main combustion chamber (4), fixed at the lower end of a movable part (32) and can rotate along with the movable part (32); coal water slurry can be sprayed in a slurry droplet form under the centrifugal force of the sprayer (33). The coal water slurry feeding device has the advantages that coal water slurry droplets can be easily decomposed and pyrolyzed, the coal water slurry droplets can be evenly distributed, low-temperature combustion is facilitated, raw material requirements on coal quality can be lowered greatly, and cost is saved; uncombusted coal water slurry particles can be combusted sufficiently favorably, and combustion efficiency is increased.

Owner:BEIJING NOWVA ENERGY TECH CO LTD

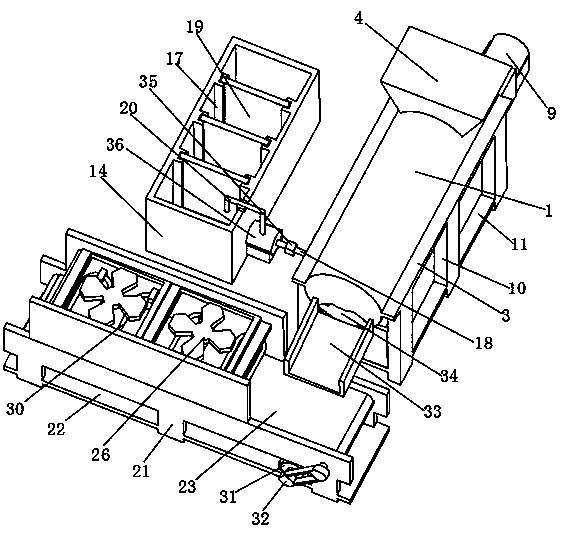

Pyrolysis and biomass gas catalytic reforming reactor and application thereof

ActiveCN106367119APromote pyrolysisImprove gas qualityGas treatmentCombustible gas catalytic treatmentCatalytic reformingCyclone

The invention discloses a pyrolysis and biomass gas catalytic reforming reactor and application thereof. The reactor comprises a pyrolysis gasifier, a smoke cyclone separator, a pyrolysis gas cyclone separator and a feeder. The pyrolysis gasifier with novel characteristics can meet the pyrolysis gasifying treatment requirement for waste with complex physical properties well. A direct-fired type inner heating pipe and metal filler connected with the direct-fired type inner heating pipe are adopted and arranged in the pyrolysis gasifier, controllable temperature field reasonable in distribution can be set up in the pyrolysis gasifier, and beneficial reaction temperature conditions are set up for material pyrolysis in the pyrolysis gasifier. Meanwhile, the metal filler is coated with a catalyst in a segmented mode, pyrolysis of organic matter and reforming and detarring treatment on pyrolysis gas can be promoted, therefore, the pyrolysis gasifying conversion rate is overall increased, and the fuel gas quality of biomass gas serving as the pyrolysis product is overall improved.

Owner:NANJING UNIV

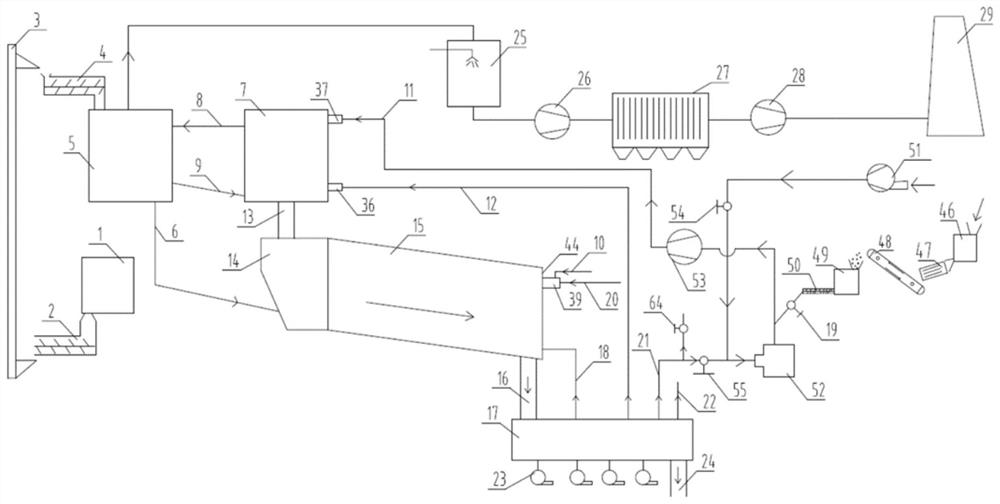

System for treating waste fan blades in decomposing furnace and working method of system

The invention discloses a system for treating waste fan blades in a decomposing furnace and a working method of the system, and belongs to the technical field of resource recovery. The system comprises a blade crushing system, a raw material feeding system, a flue gas treatment system, a suspension preheater, a decomposing furnace, a rotary kiln, a clinker cooling device and a fan coal mill. Crushed waste fan blade particles are merged into a pneumatic conveying pipeline at the downstream of the fan coal mill and are conveyed into the decomposing furnace together for pyrolysis and combustion, heat released by combustion of organic composite materials of the waste blade particles and heat released by combustion of pulverized coal provide energy for dehydration and decomposition of raw materials together, and the potential heat value of fan blades is effectively utilized. Glass fibers in the blade particles, combusted pulverized coal and ash residues formed by combustion of the pulverized coal are mixed into the raw material together, enter a downstream suspension preheater, are finally separated and are returned to the rotary kiln to participate in clinker firing. Harmless and resourceful treatment of the waste fan blades is achieved, and good environmental protection benefits and economic benefits are achieved.

Owner:HUANENG CLEAN ENERGY RES INST

Refrigerating oil composition

InactiveCN1364189AGood compatibilityEasy to operateHeat-exchange elementsAdditivesChemical compositionAliphatic alcohol

A refrigerating machine oil composition which comprises an alicyclic dicarboxylic ester compound having an alicyclic ring and two ester groups which are represented by the following general formula (1): -COOR<1> (1) (wherein R<1> represents C1-18 alkyl) and are bonded respectively to carbon atoms adjacent to each other on the ring, wherein the ester compound is one obtained from, as alcohol ingredients, (a) a C1-5 aliphatic alcohol and (b) a C6-18 aliphatic alcohol.

Owner:MITSUBISHI OIL CO LTD

Post-treatment package of engine exhaust and application

InactiveCN107255043AAccelerate evaporationPromote pyrolysisExhaust apparatusSilencing apparatusFiberEvaporation

Disclosed is a post-treatment package of engine exhaust. The post-treatment package comprises a first post-treatment assembly, a first mixing cavity assembly and a mixing pipe communicated with the first mixing cavity assembly, wherein the mixing pipe comprises a swirling flow pipe which is at least partially located in the first mixing cavity assembly. The swirling flow pipe comprises a hollow inner cavity and a plurality of fins distributed around the periphery of the inner cavity in the circumferential direction. The first mixing cavity assembly comprises an installation base for installing a urea nozzle, and the urea nozzle is used for spraying atomized urea droplets into the mixing pipe. The post-treatment package of the engine exhaust further comprises a fine fiber element located in the mixing pipe, the fine fiber element is used for the exhaust and the urea droplets to pass through to further improve crushing and evaporation of the urea droplets. In this way, the post-treatment package of the engine exhaust has a high crystallization resistance capability. The invention further relates to application of the fine fiber element in the post-treatment package of the engine exhaust.

Owner:TENNECO SUZHOU EMISSION SYST

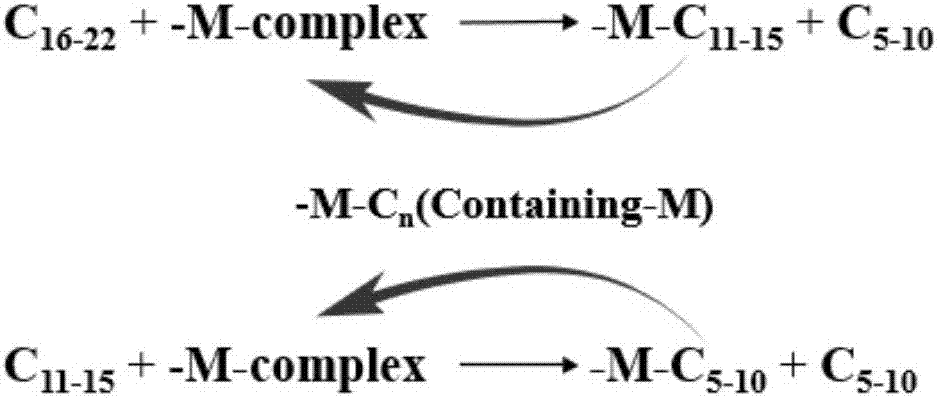

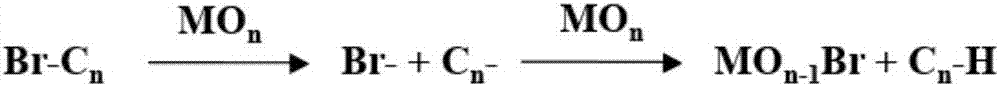

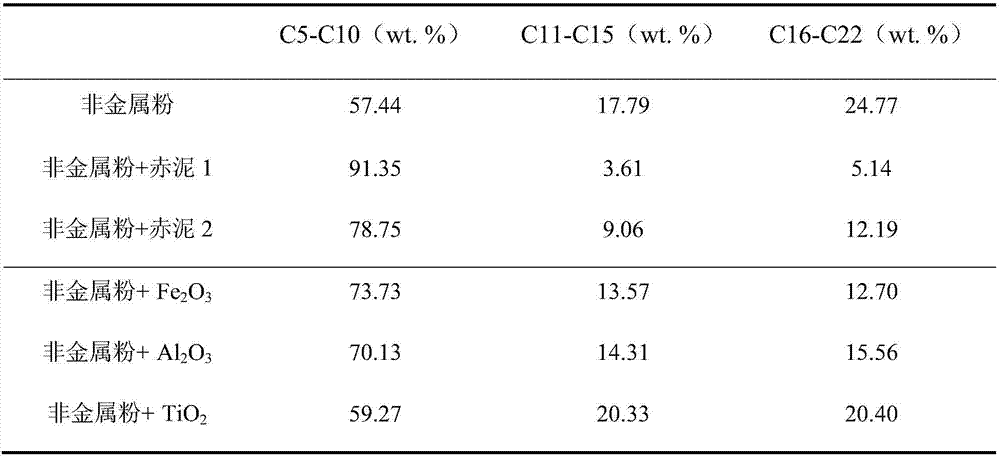

Method for catalytic pyrolysis of residual nonmetallic powder generated by crushing, separation and recycling of copper from waste circuit board

ActiveCN107457246ALightweightAvoid it happening againSolid waste disposalTransportation and packagingCatalytic pyrolysisCarbon number

The invention discloses a treatment method for catalytic pyrolysis of residual nonmetallic powder generated by crushing, separation and recycling of copper from a waste circuit board. The method comprises the steps that alkaline waste residues are added into the nonmetallic powder to be mixed evenly to obtain a mixture, then the mixture is subjected to pyrolysis, and accordingly co-pyrolysis of the nonmetallic powder and the alkaline water residues is achieved; and the alkaline water residues contain metallic oxide so as to promote catalysis of pyrolysis products, so that the bromine content in pyrolysis gas in the obtained pyrolysis products is decreased, the content of bromine fixed in pyrolysis residues is increased, and the proportion of light oil with the carbon number being 5-10 in pyrolysis tar is increased. By improving the reaction parameters and conditions of a key co-pyrolysis reaction, a microcosmic displacement mechanism corresponding to the reaction and the like, compared with the prior art, the method can effectively solve the problems that the pyrolysis tar in the pyrolysis products is mainly the heavy tar, and quality is low; and co-processing of the alkaline waste residues and the nonmetallic powder is achieved, and the problem of solid bromine is solved at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of high-conductivity lithium iron phosphate cathode material

InactiveCN103247801AEvenly dopedImproved internal lattice conductivityCell electrodesPhosphorus compoundsHigh rateLithium iron phosphate

The invention provides a preparation method of a high-conductivity lithium iron phosphate cathode material. The preparation method comprises the steps of: adding a doping compound into phosphoric acid and trivalent ferric salt solution, separately adding a pyrolytic carbon source and a carbonization accelerator in two manners, adding alkaline solution, controlling the pH of the system to be within 1-4, reacting for a period of time, washing and drying so as to obtain a ferric phosphate precursor; and mixing a lithium source, the precursor, the pyrolytic carbon source and the carbonization accelerator, stirring (or ball milling), drying in vacuum, thermally treating and grinding so as to prepare the doped carbon-wrapping lithium iron phosphate. The doping compound, the pyrolytic carbon source and the carbonization accelerator are added when the ferric phosphate precursor is prepared, the electric conductivity of lithium iron phosphate intracells and the electric conductivity among particles are improved, and the electrochemical performance of the lithium iron phosphate intracells is obviously improved at a high rate; and moreover, ferrous iron at high price is not used any more, so that the production cost is greatly lowered.

Owner:HUNAN UNIV

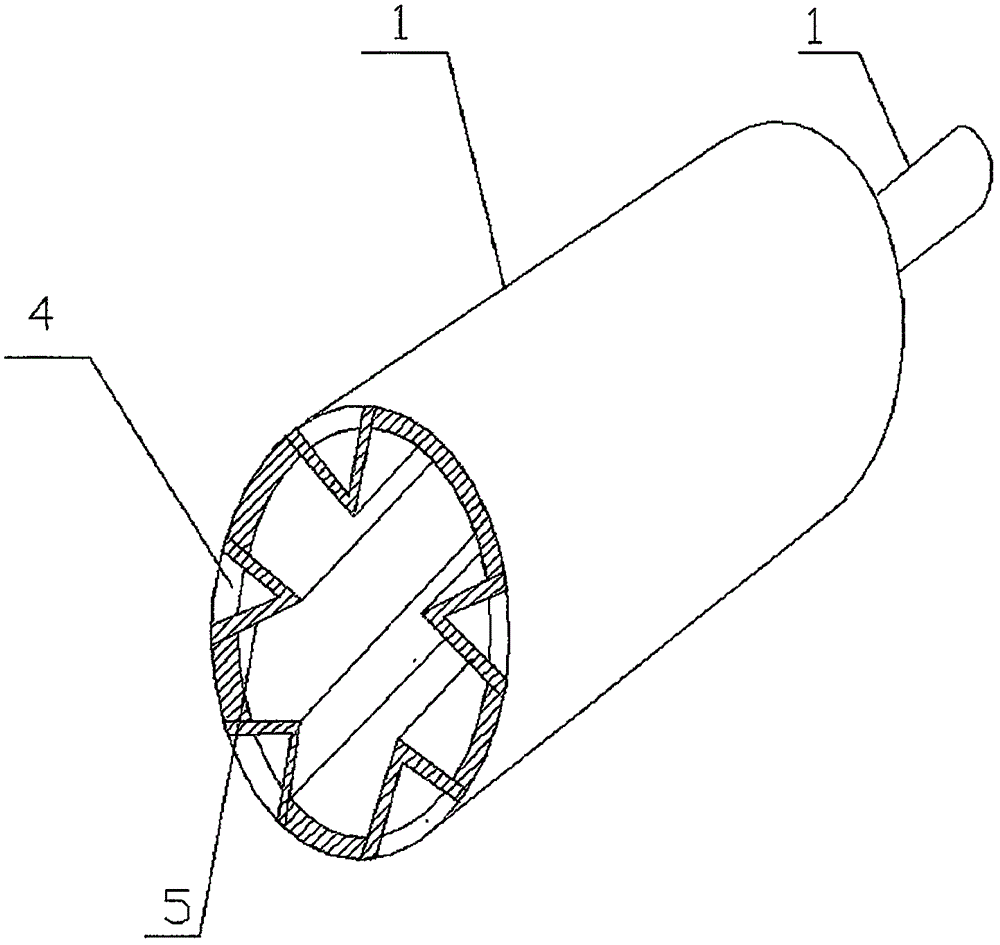

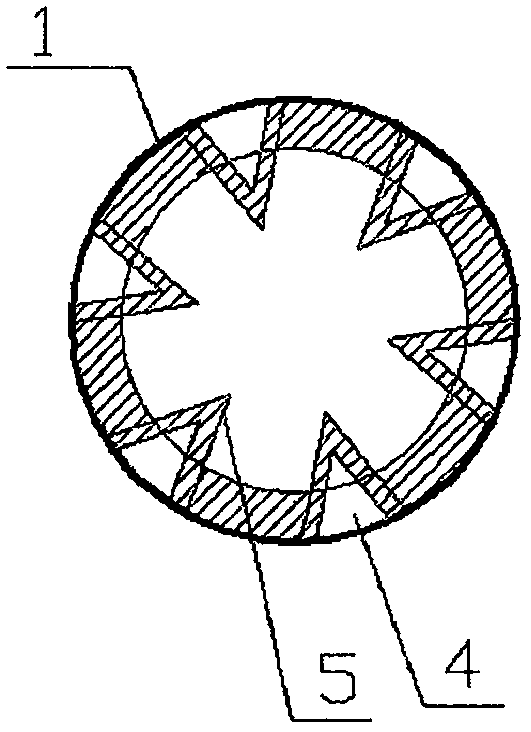

Concave internal and external dual-heating efficient reaction kettle for pyrolysis of waste tyre, waste plastics and domestic electronic waste

InactiveCN107434977AIncrease the heating areaPromote pyrolysisProductsReagentsControl engineeringHeating furnace

A concave internal and external dual-heating efficient reaction kettle for pyrolysis of waste tyre, waste plastics and domestic electronic waste is composed of a feed pipe, a reaction kettle body, an outgassing and deslagging pipe, a reaction kettle opening, a concave clamping plate, a first support roller, a heating furnace and a second support roller, wherein there are more than two openings on the periphery of the reaction kettle body; vertex angle of the concave clamping plate extends into the reaction kettle body; two opened sides and the reaction kettle opening are firmly welded; the feed pipe is welded on a baffle plate at one end of the reaction kettle body; the outgassing and deslagging pipe is welded on a baffle plate at the other end of the reaction kettle body; the first support roller is arranged at one end of the reaction kettle body; the second support roller is disposed at the other end of the reaction kettle body; and the reaction kettle body is arranged inside the heating furnace. The reaction kettle of the invention has a novel structure. As the concave clamping plate extends (is embedded) into the reaction kettle body, heating area is increased, especially when the reaction kettle body rotates, more uniform large-area heating will be achieved. Thus, the reaction kettle of the invention has remarkable practicality.

Owner:李艺 +3

Engine exhausted gas post-treatment mixing device and post-treatment device and application thereof

InactiveCN107084028AAccelerate evaporationPromote pyrolysisExhaust apparatusSilencing apparatusFiberSpray nozzle

An engine exhausted gas post-treatment mixing device comprises an installation base and a mixing element, wherein the installation base is used for installing a urea spray nozzle, and the mixing element is located on the downstream portion of the installation base. The mixing element is used for mixing urea drops with exhausted gas. The engine exhausted gas post-treatment mixing device further comprises a fine fiber element which is located on the downstream portion of the installation base in the exhausted gas flow direction, and the urea drops are further crushed and evaporated. Through the arrangement, the engine exhausted gas post-treatment mixing device has high crystallization resistance. The invention further relates to application of a fine fiber element in the engine exhausted gas post-treatment mixing device and an engine exhausted gas post-treatment device provided with the mixing device.

Owner:TENNECO SUZHOU EMISSION SYST

Solid-liquid separation device for household garbage pyrolysis treatment

InactiveCN108941158APromote pyrolysisImprove separation efficiencySolid waste disposalTransportation and packagingFiltrationSingle chip

The invention discloses a solid-liquid separation device for household garbage pyrolysis treatment. The device comprises a cylinder; two symmetrical fixed bars are arranged on the side surface of thecylinder; first brackets are arranged on the lower surfaces of the fixed bars; first support plates are arranged at the middle parts of the first brackets; first liquid holding boxes are arranged on the upper surfaces of the first support plates, and are arranged at the middle parts of the first brackets; and a feed hopper is arranged on the left side of the side surface of the cylinder. The solid-liquid separation device for household garbage pyrolysis treatment is firm in structure, stable and durable, is more thorough in solid-liquid separation through extrusion, drying and filtration to achieve the use convenience, is high in automation degree through control by a single-chip microcomputer to improve the solid-liquid separation efficiency and to reduce garbage in separated liquid, andcan blow hot air near a heating pipe to the garbage through a fan without wetting the separated garbage anymore to facilitate pyrolysis of household garbage.

Owner:贵州德科科技有限公司

Radial injecting mixer for mixing exhaust gas and reducing agent fluid

ActiveCN108194178AAccelerated pyrolysis/hydrolysisWell mixedExhaust apparatusSilencing apparatusNitrogen oxidesPollutant emissions

The invention provides a radial injecting mixer for mixing exhaust gas and reducing agent fluid. The radial injecting mixer comprises a cylindrical barrel body, a reducing agent injecting base is arranged on the outer wall of the cylinder body; a first rotational flow partition plate is arranged at an air inlet end of the cylinder body; a plurality of semi-circular through holes are formed in thefirst rotational flow partition plate, the lower end of each through hole is provided with a hemispherical wall plate on the inner wall of the first rotational flow partition plate; a second rotational flow partition plate is arranged along the inner wall of the cylinder body at the rear end of the rotational flow partition plate; expanding partition plates are arranged along the inner wall of thecylinder body; and the reducing agent injecting base comprises a supporting plate and a supporting column, the supporting plate is of a generally triangular structure, and a nozzle is arranged on thesupporting plate, an injecting hole is formed in the center of the supporting plate, and the supporting column is arranged at the lower end of the supporting plate. According to the radial injectingmixer for the mixing exhaust gas and the reducing agent fluid, the radial injecting mixer is fully mixed with the radially injected reducing agent fluid, so that the uniformity of the reducing agent is improved, the sufficient reaction of the nitrogen oxide is realized, and the pollutant emission of the automobile is reduced.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com