Combined combustion system of chain boiler

A technology of combustion system and chain boiler, which is applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of insufficient boiler output, excessive NOx emission, and low boiler efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and main points of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and typical embodiments.

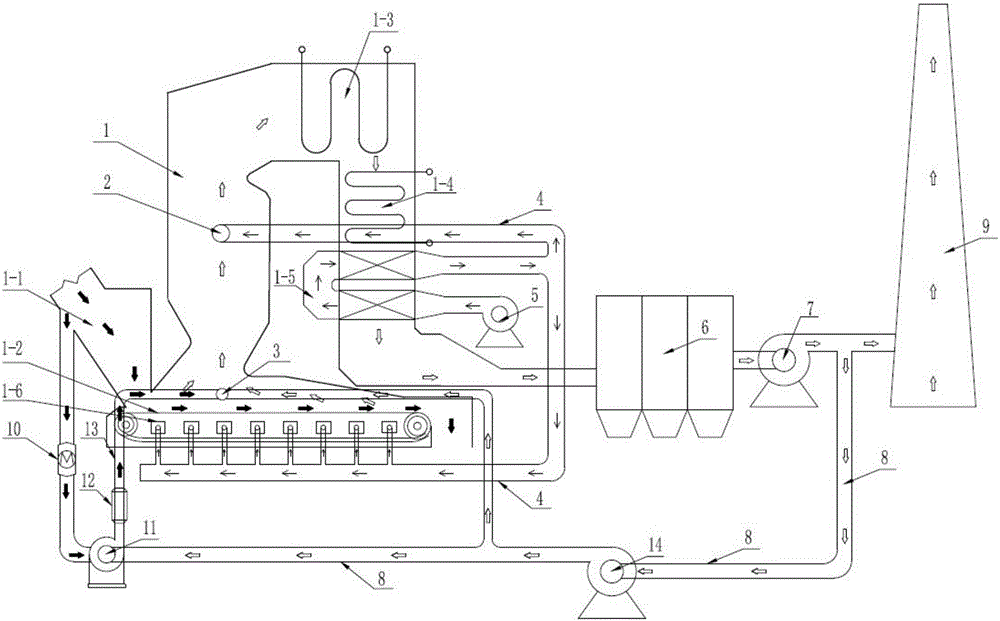

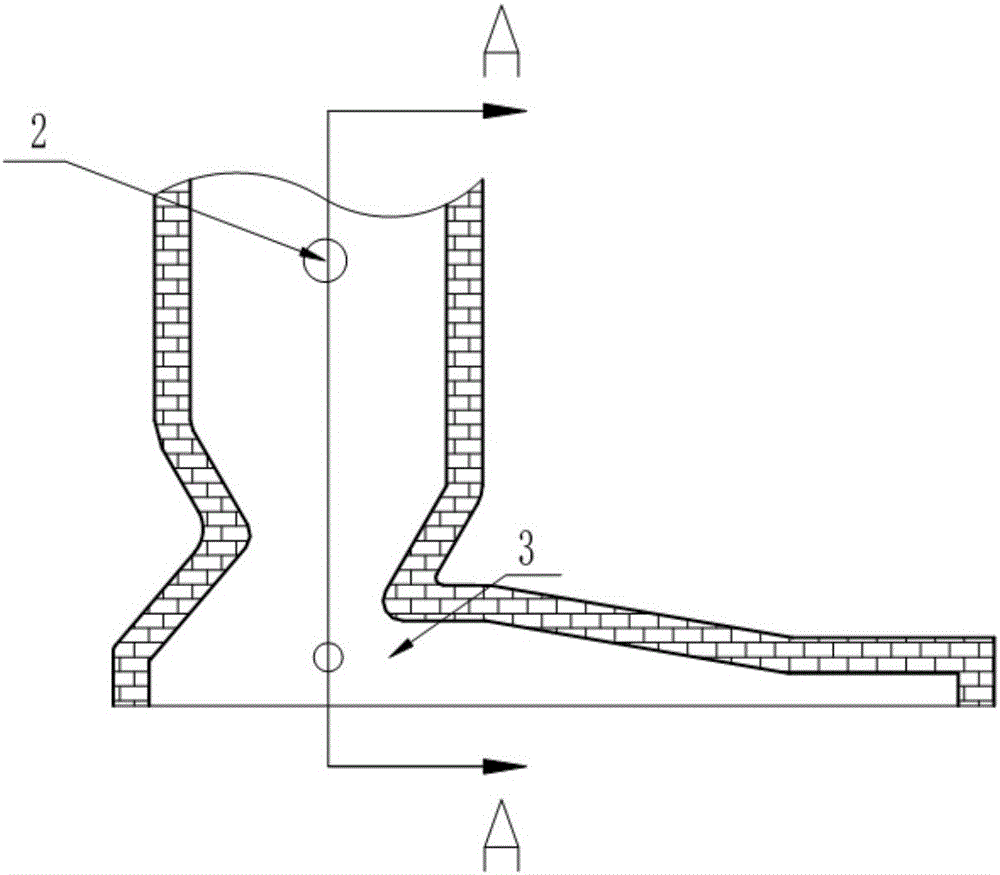

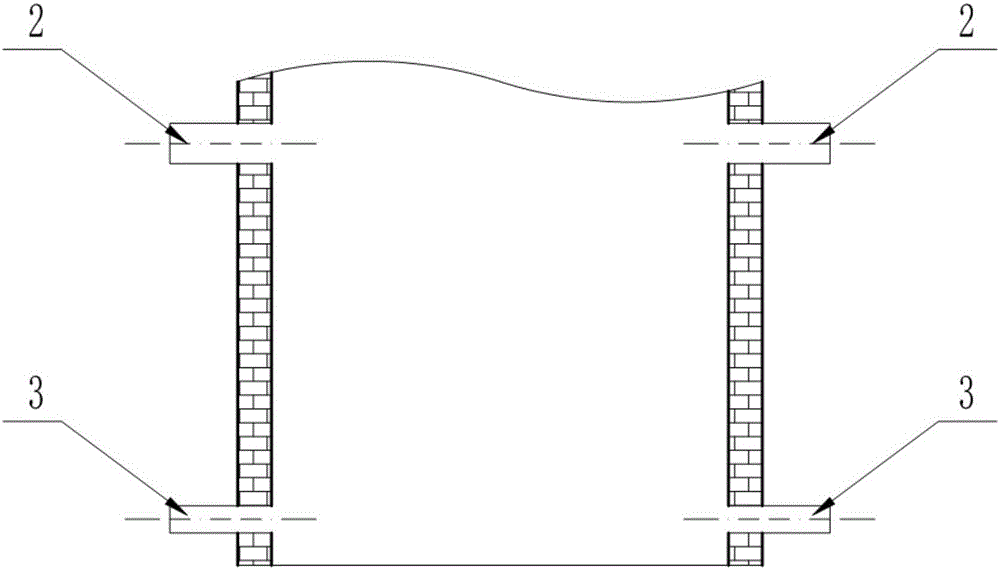

[0017] like Figure 1 to Figure 3 As shown, the chain boiler compound combustion system of the present invention is composed of a pulverizing-powder conveying system, a flue gas recirculation system, an air supply system and a combustion system.

[0018] The pulverizing-pulverizing system mainly includes a coal hopper 1-1, a coal feeder 10, a fan coal mill 11, a coarse and fine powder separator 12, a circulating fan 14, a coal conveying pipeline 13 and a smoking pipeline 8. The coal in the coal hopper 1-1 falls on the chain grate 1-2 all the way under the action of its own gravity, moves slowly with the chain grate 1-2 and burns; the other way is sent to the fan coal mill through the coal feeder 10 11. The circulating fan 14 sucks part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com