Solid fuel burning stove

A solid fuel and stove technology, applied in the field of clean combustion of solid fuel, can solve the problems of difficult supervision, emission pollution, poor compatibility, etc., and achieve the effect of avoiding black smoke and clean and efficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

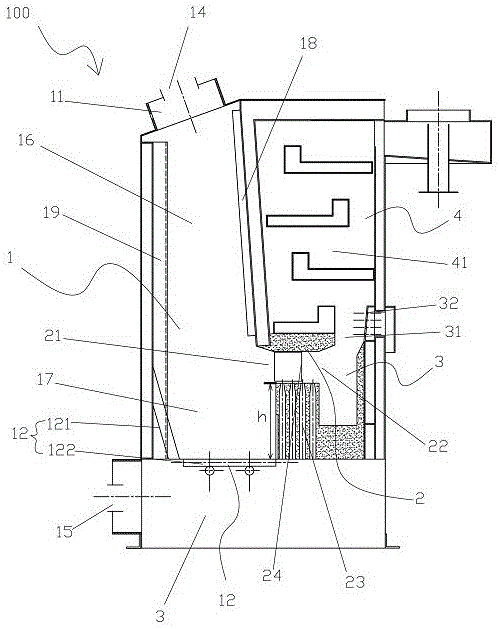

[0035] like figure 1As shown, the present invention provides a solid fuel burning stove 100 . The stove includes a solid sequential combustion chamber 1 , a gas combustion chamber 3 and a heat storage channel 2 connected between the solid sequential combustion chamber 1 and the gas combustion chamber 3 . Among them, the upper part of the solid-state sequential combustion chamber 1 is formed with a feed inlet 11, and the bottom is provided with a grate 12 and an ash chamber 13 below the grate 12, and an upper air inlet 14 is arranged at the upper part, and a lower air inlet 15 is arranged at the bottom. . The heat storage channel inlet 21 is formed at a position higher than the grate 12 on the lower side of the solid-state sequential combustion chamber 1, so that the upper part of the thermal storage channel inlet 21 of the solid-state sequential combustion chamber 1 is used for drying and dry distillation. The reverse combustion zone 16 for solid fuel, the part below the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com