Biomass-coal water slurry co-fired organic working medium boiler

A coal-water slurry and biomass technology, which is applied to the fuel, combustion method, and type of combustion in the melting state, can solve the problems of small load adjustment range, high operating pressure, and high pollutant emissions, and achieves reduction of NOx emissions, The effect of good load regulation performance and simple and reliable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

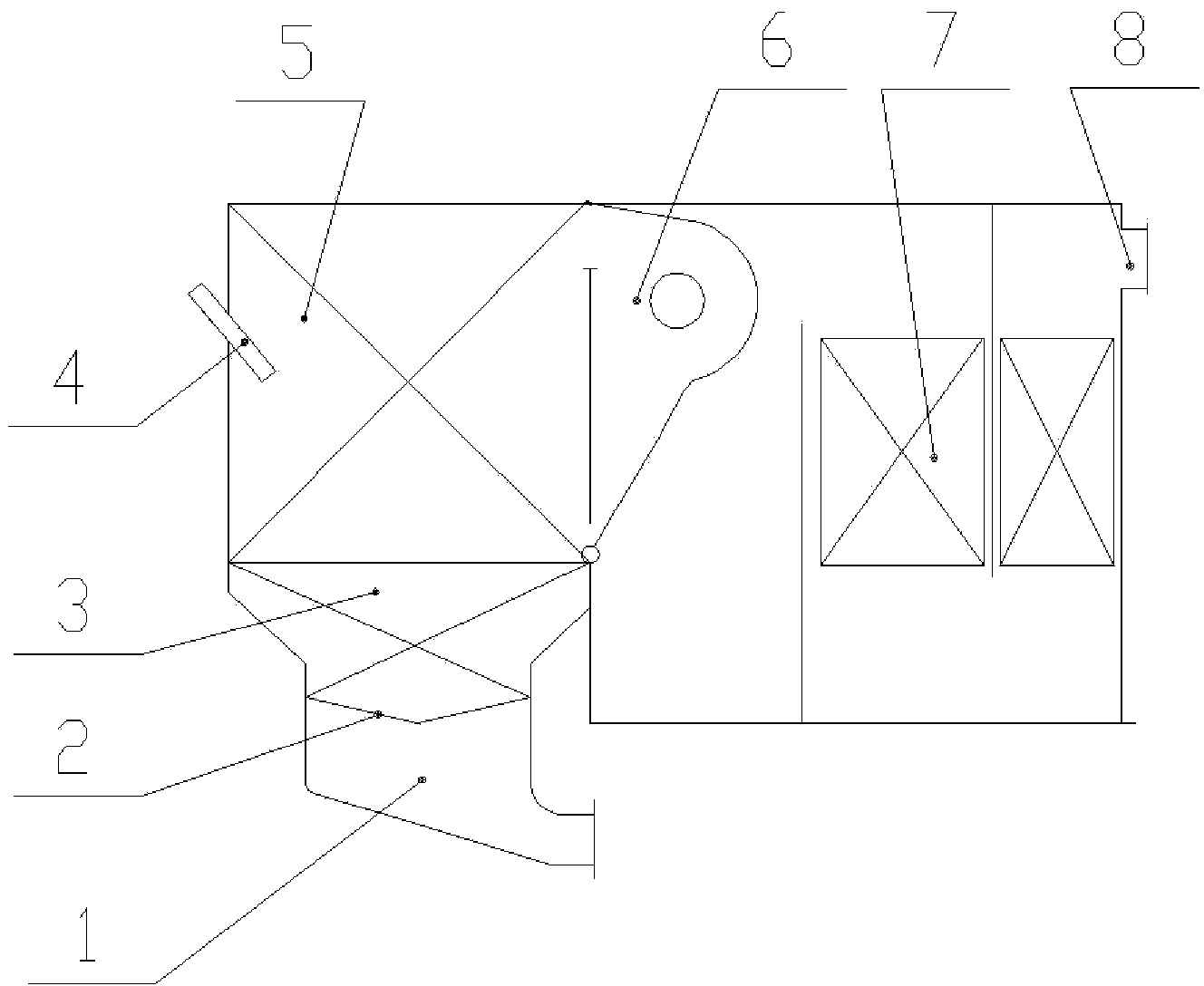

[0023] Such as figure 1 As shown, the biomass-coal water slurry mixed fuel organic working medium boiler includes: wind box 1, air distribution plate 2, dense phase area 3, fuel feeding port 4, dilute phase area 5, vortex separation burnout device 6, tail convection Heating surface component 7, outlet flue 8.

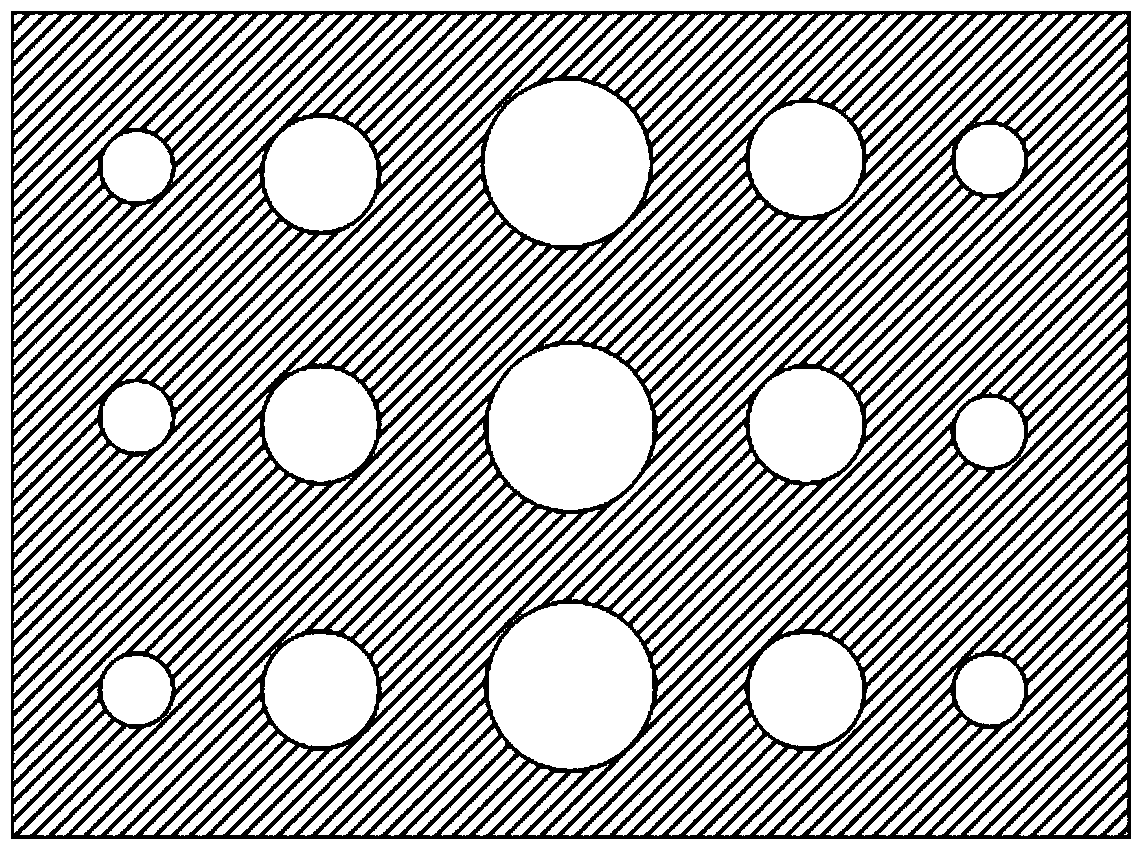

[0024] Biomass fuel usually has a water content below 10%. Firstly, the biomass fuel and coal are crushed into powder with a particle size of less than 1mm. After being fully mixed, it becomes a biomass-coal mixed fuel. By weight, 7 parts of this biomass-coal mixed fuel, plus 3 parts of water, plus an appropriate amount of additives, are fully stirred evenly, and then the biomass-coal water slurry mixed fuel is prepared. In the actual production process, biomass fuel and coal powder are usually mixed at a ratio of 1:1, and the use of biomass fuel to partially replace coal greatly reduces the cost of use.

[0025] Such as figure 1 As shown, the blower blows air into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com