Patents

Literature

82results about How to "Efficient and clean combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

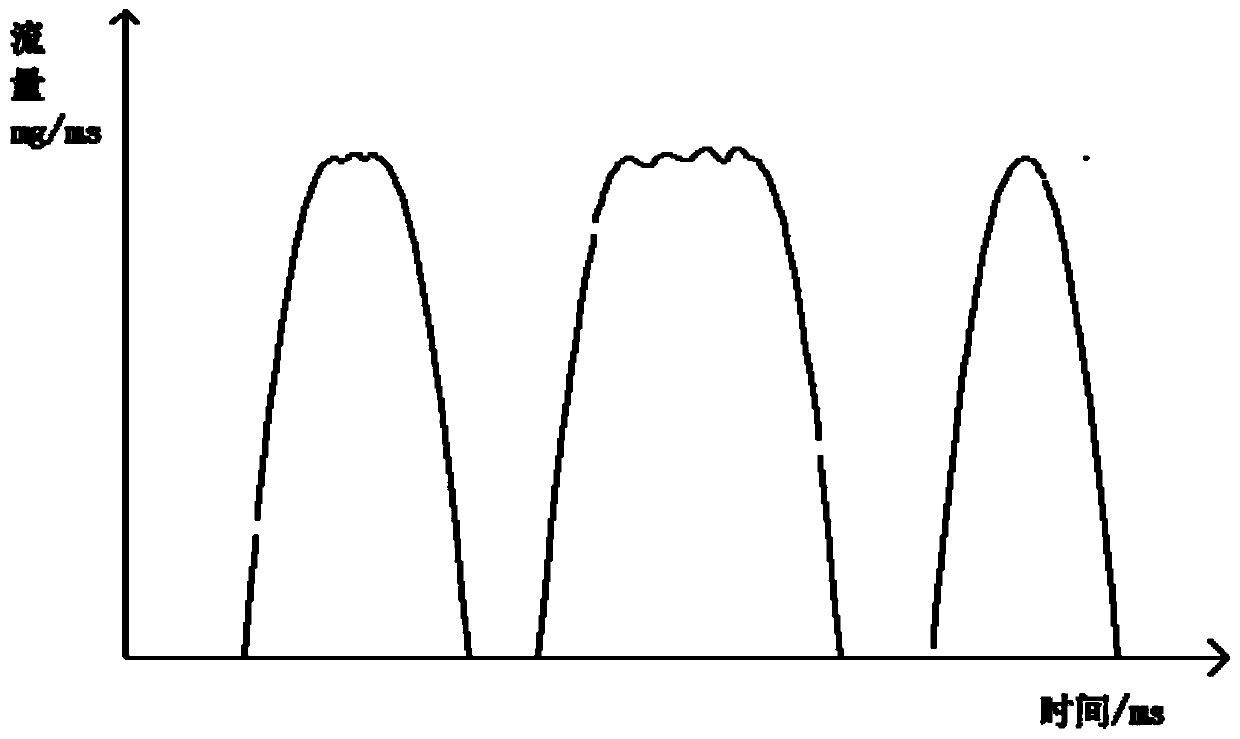

Fuel injection method for dual-fuel engine

InactiveCN106870186ANot easy to knockIncrease concentrationElectrical controlMachines/enginesExhaust valveCombustion

Owner:DALIAN UNIV OF TECH

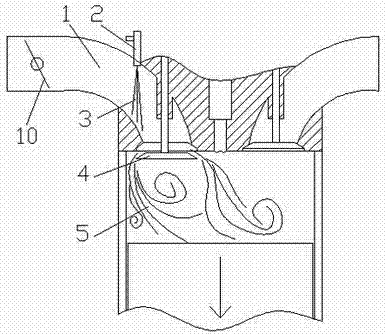

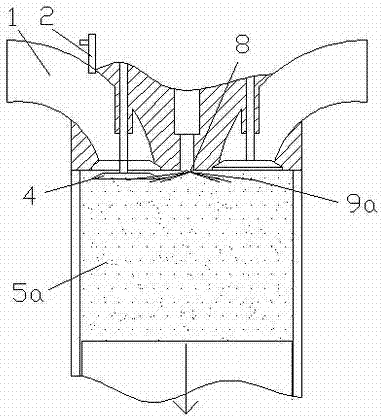

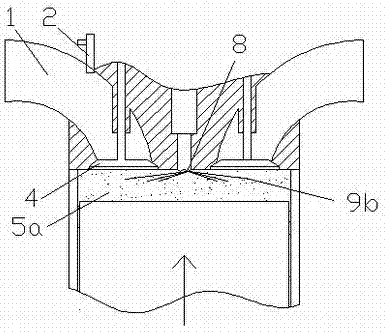

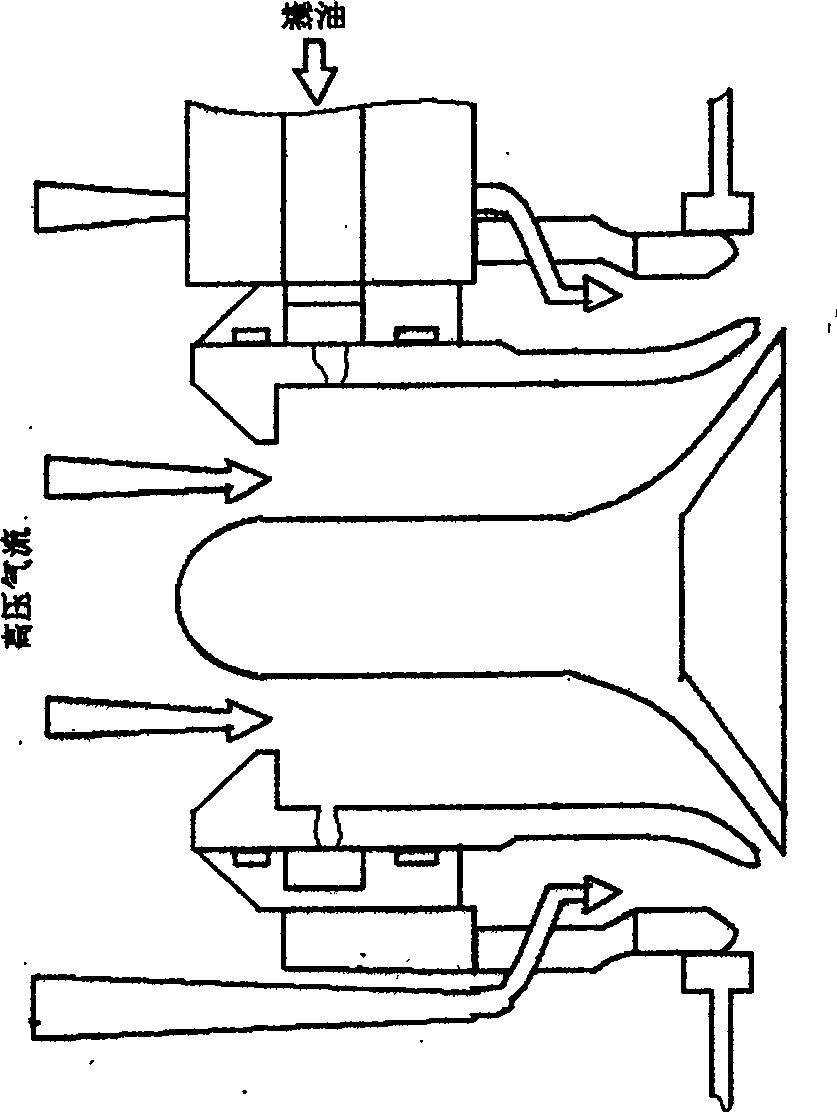

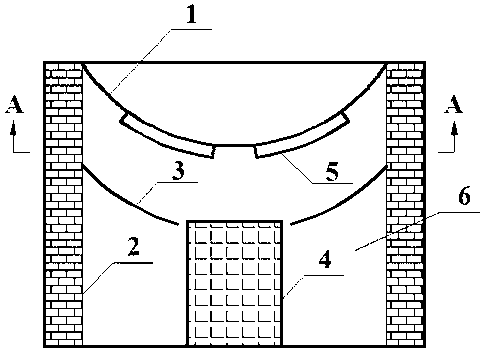

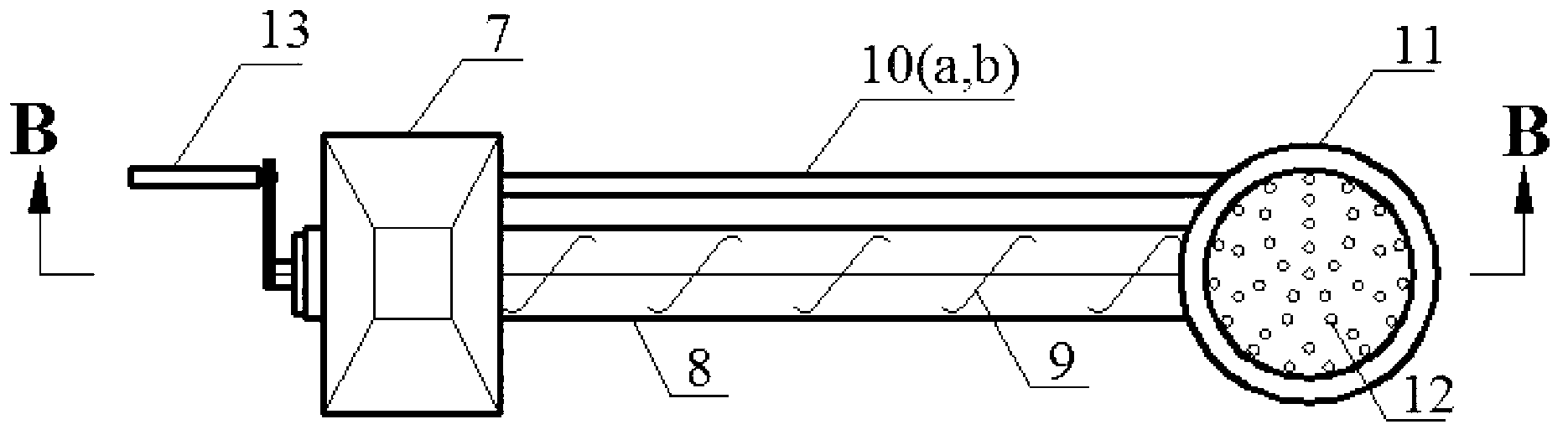

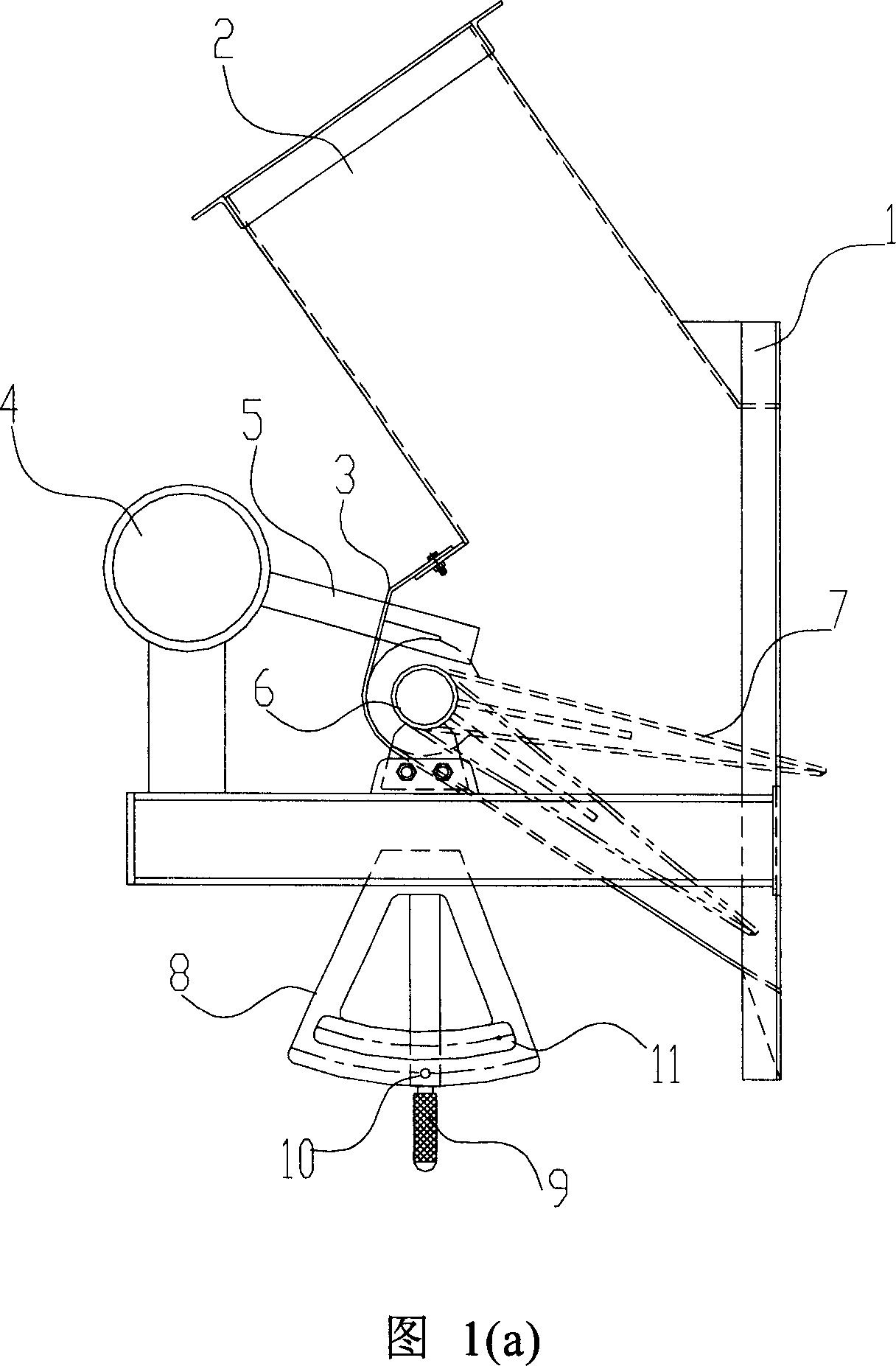

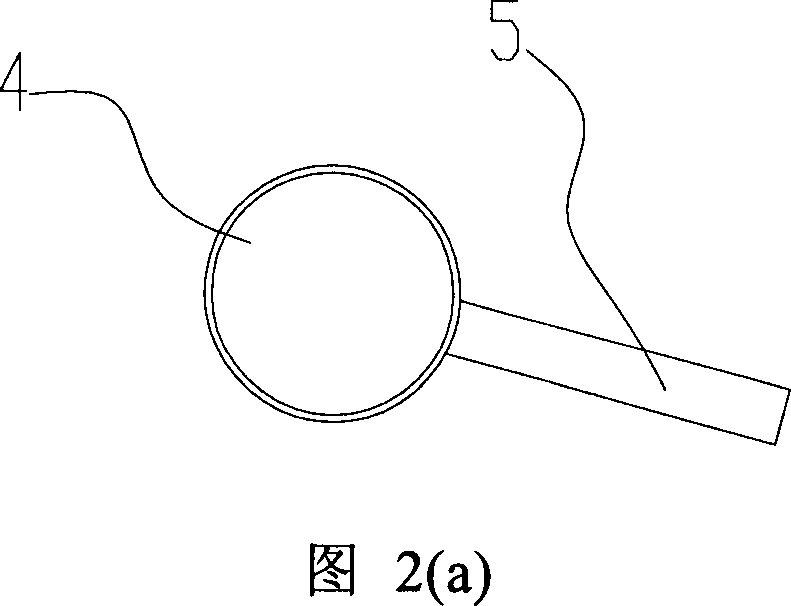

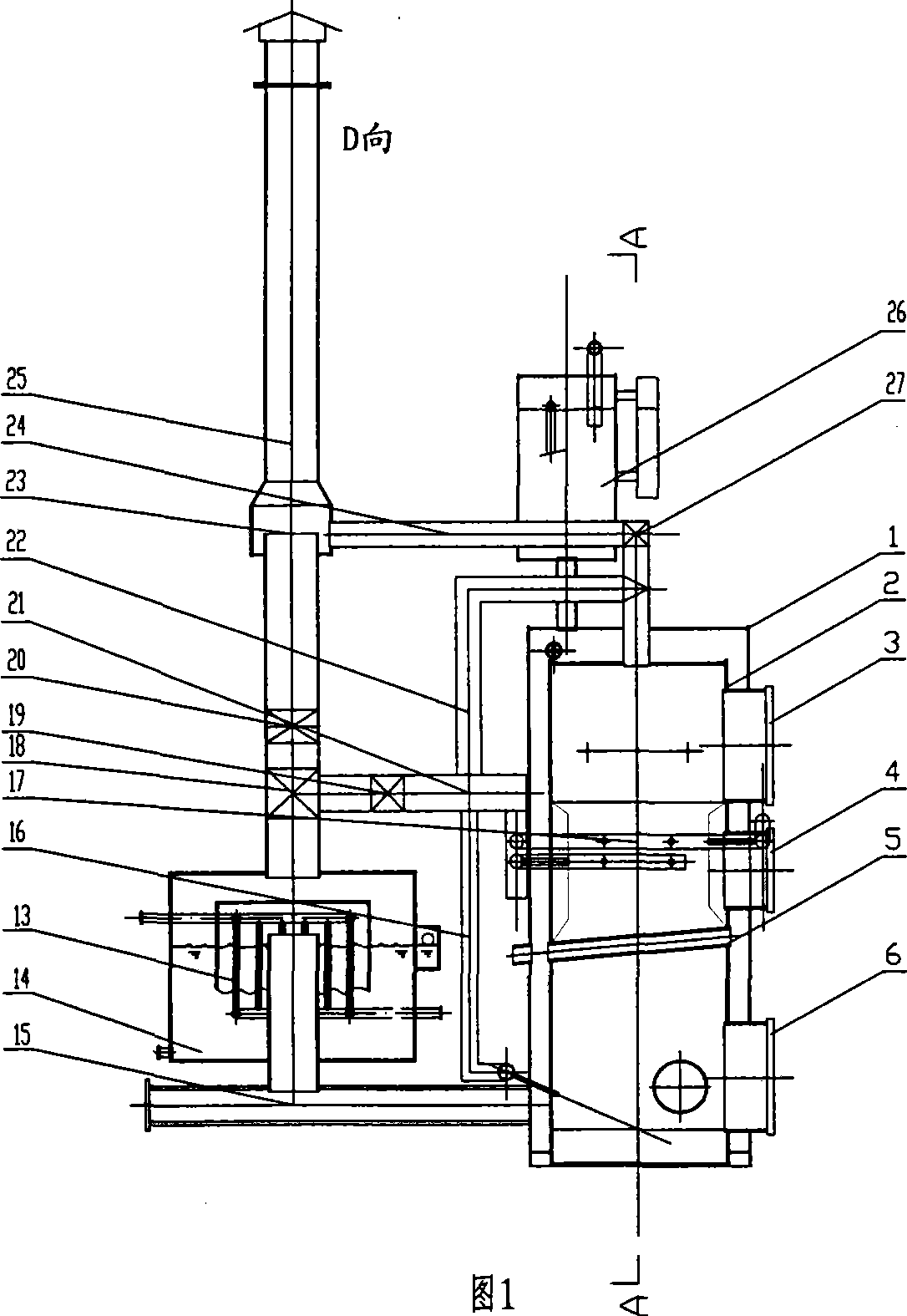

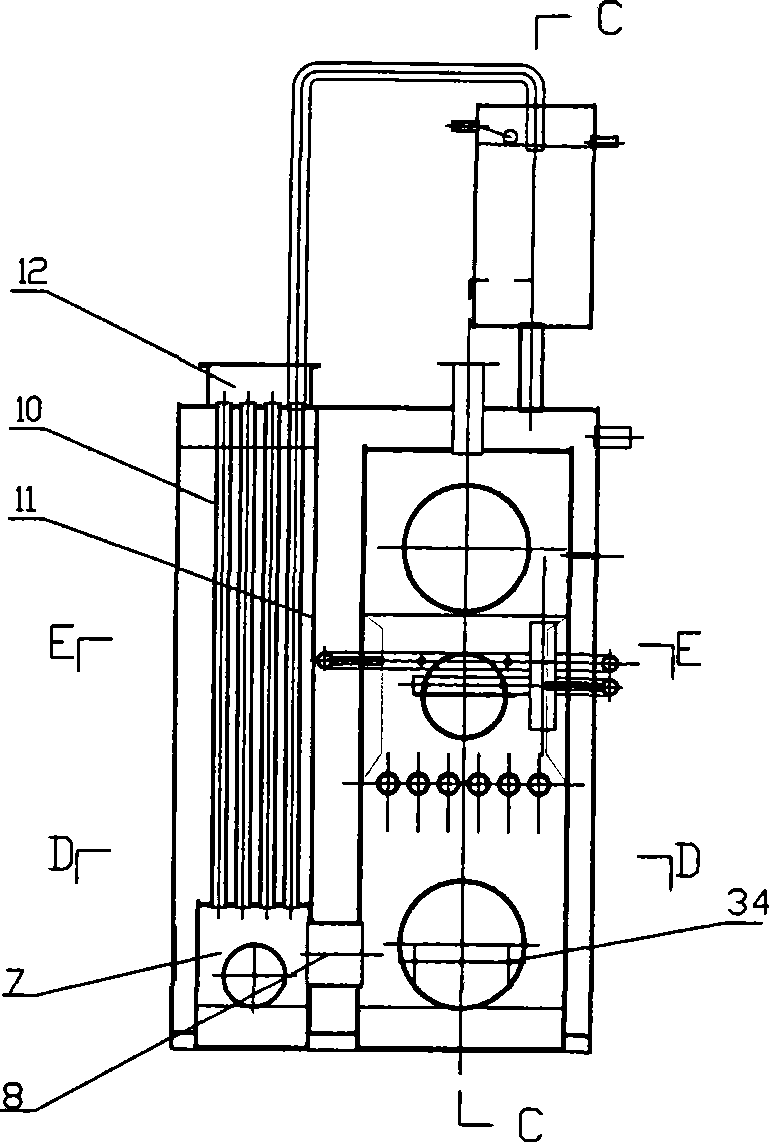

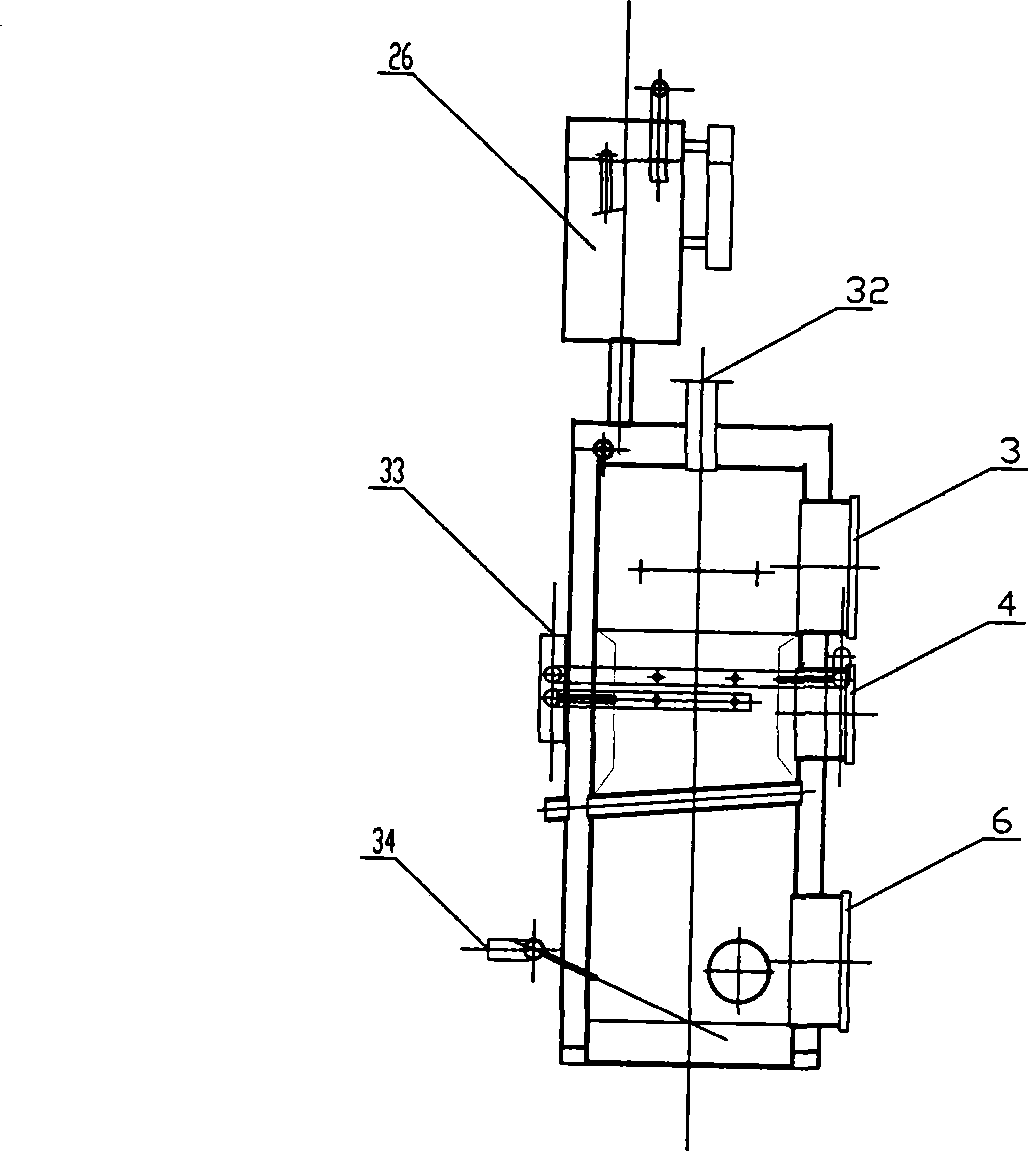

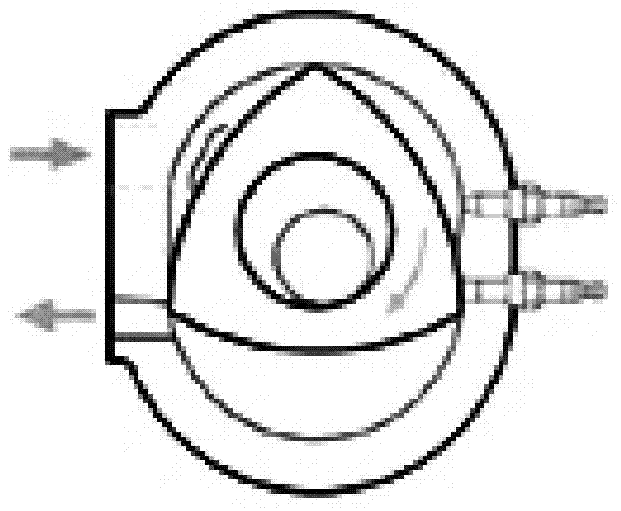

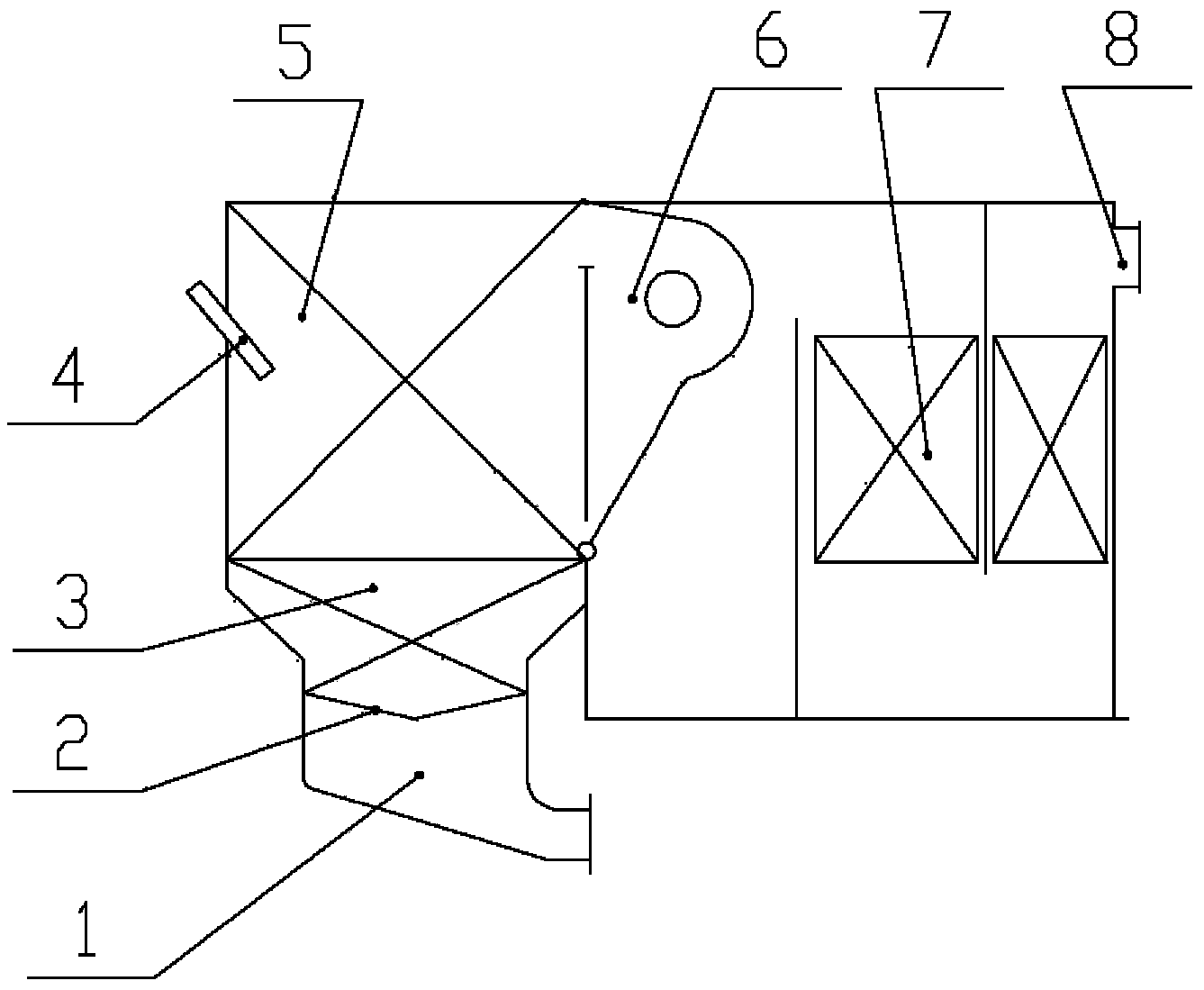

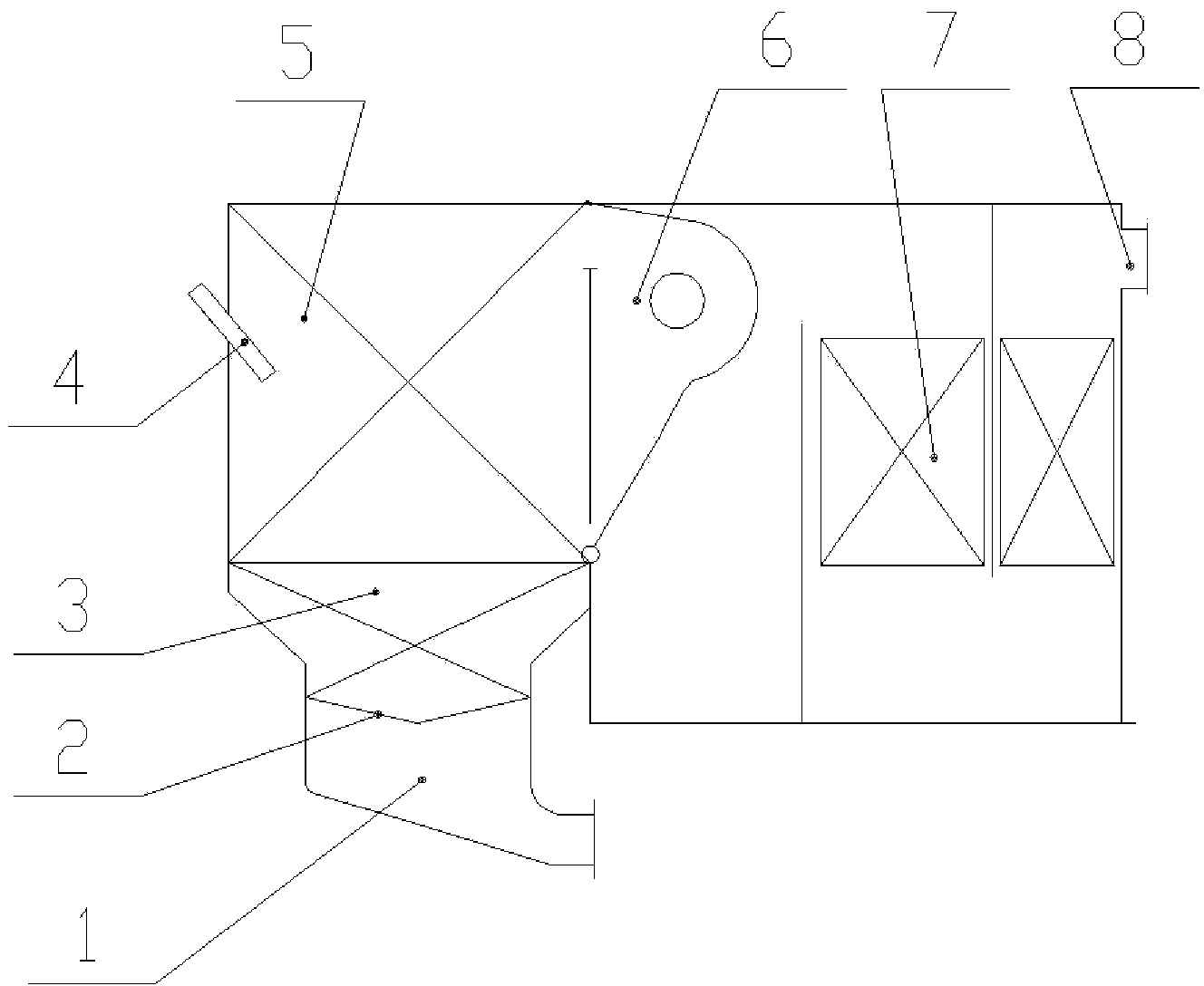

Gas turbine combined type fuel evaporating and atomizing combustion apparatus

InactiveCN101435585AIncrease the pre-mixed pre-evaporation processImprove atomization and evaporationContinuous combustion chamberAviationCyclone

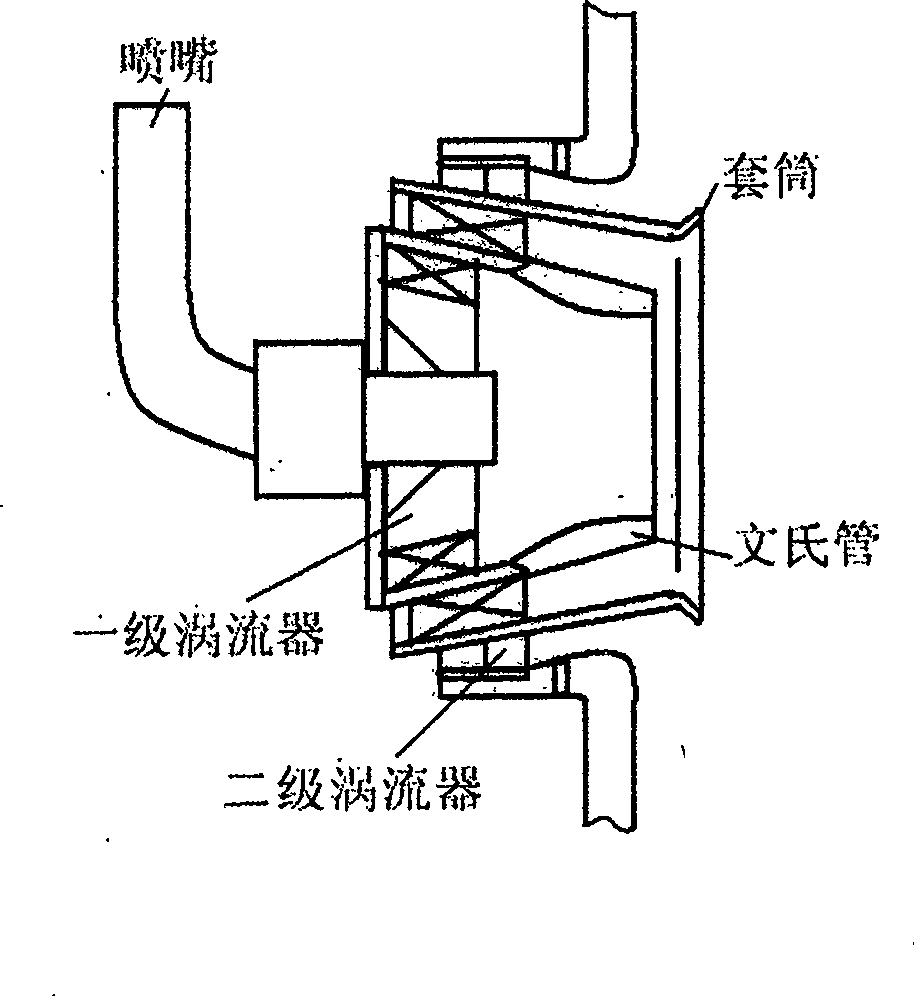

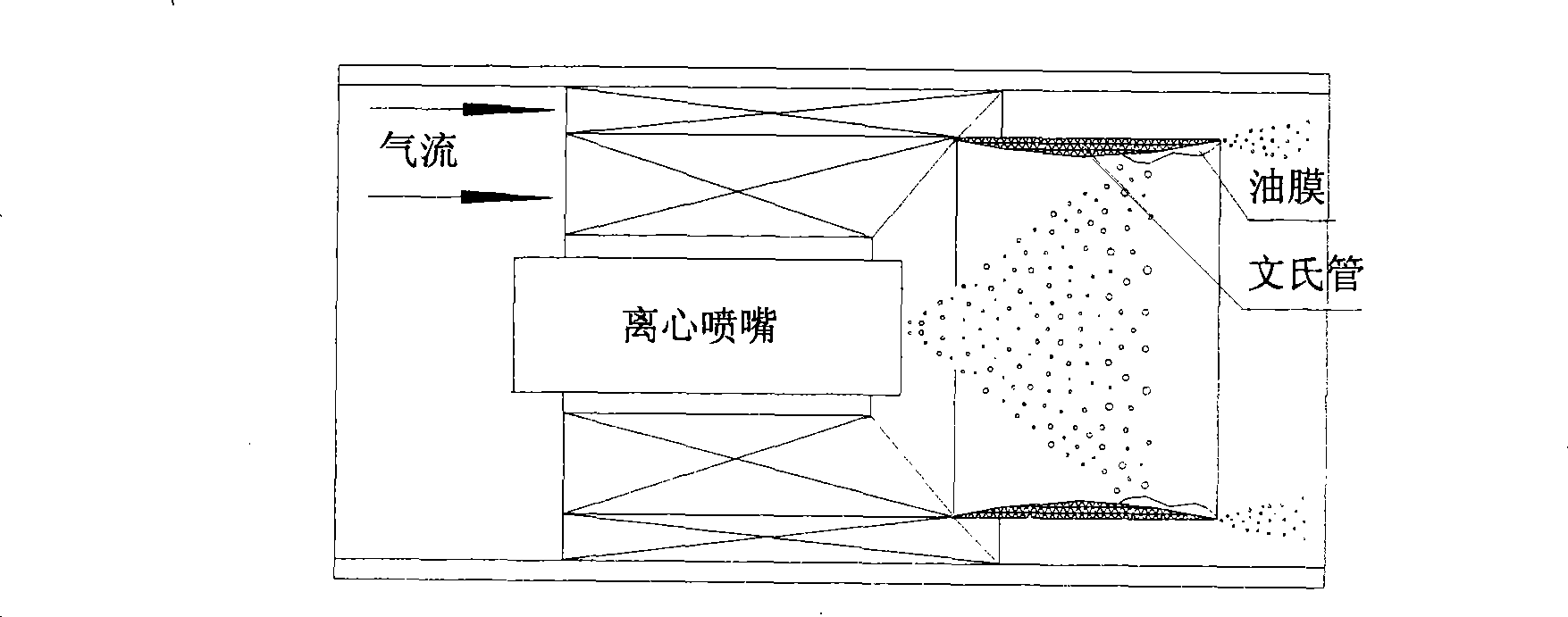

The invention provides a combined fuel oil atomizing, evaporating and combusting device for a gas turbine, relates to an air inlet device of the gas turbine, a fuel oil atomizing, evaporating and blending device, and core technology of organized combustion and stable flame, and belongs to the power field of an aeronautic power propulsion system and a ground gas turbine. A nozzle 1 is arranged at a central position of an inlet of a premixing chamber 2; an evaporator 3 is fixed in an inner cavity of the premixing chamber 2; double cyclones 4 are arranged at the inside of the outlet end of the premixing chamber 2 and connected hermetically; a centrifugal nozzle 5 is arranged at a central position of the double cyclones 4; a venturi 6 is welded at a transition position of an outlet of internal and external cyclones of the double cyclones 4; a sleeve 7 is hermetically welded with the outside of an outlet of the premixing chamber 2; and the head of a combustion chamber 8 is hermetically welded with the sleeve 7. Compared with the prior fuel oil combined nozzle, the device has the advantages of improving properties of fuel oil atomizing, evaporating and blending and evenness of oil-gas space distribution, improving combustion performance, shortening flame length and reducing discharge of pollutant, and is a comparatively ideal combined fuel oil atomizing and combusting device for a high-performance gas turbine.

Owner:PEKING UNIV

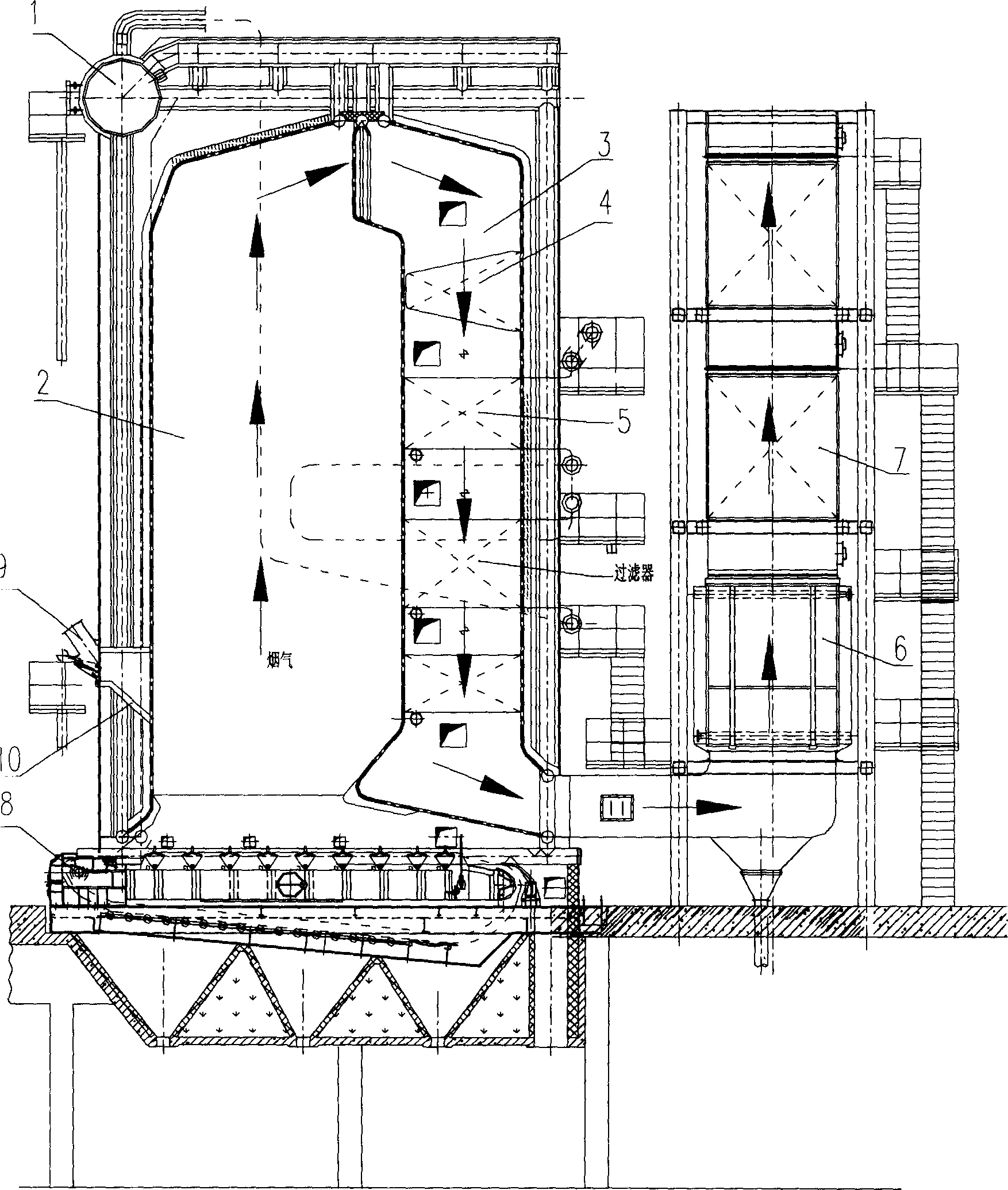

Biological mass-energy fuel boiler and its burning method

InactiveCN1900589AEfficient and clean combustionRealize comprehensive utilizationDamper arrangementSolid fuel combustionFlue gasEngineering

Characters of the invention are that suspension burning plus grate firing carry out in boiler; first, through conveying facilities, biomass energy fuel in sheet, granular or powder is fed equably through feed inlets with adjustable angles; next, secondary air under feed inlets sends fuel to fire box, and suspension burning is carried out in fire box under cooperation of primary air; then, based on burning properties and state to adjust primary / secondary air in order to guarantee high temperature in burning area, and prolong residence time of combustible and flue gas in high temperature; finally, in suspension burning, bigger fuel granules drop to fire grate to carry out grate firing, and adjusting angles of feed inlets and secondary air to make thickness of fuel layer even on fire grate, and adjusting primary air to ensure full burning. The invention strengthens burning and guarantees firing in time and full burning so as to realize clean burning biomass energy fuel.

Owner:上海四方锅炉厂

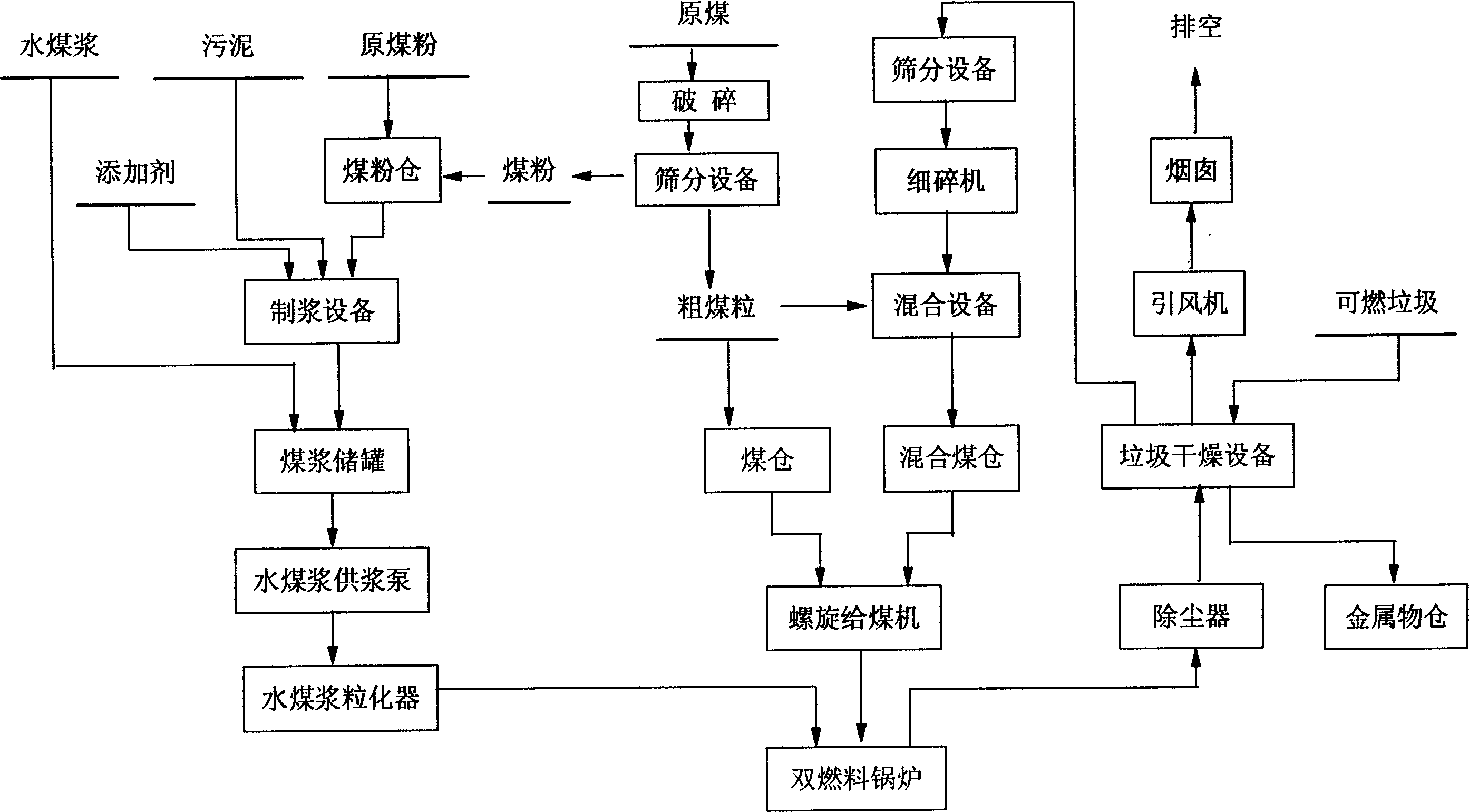

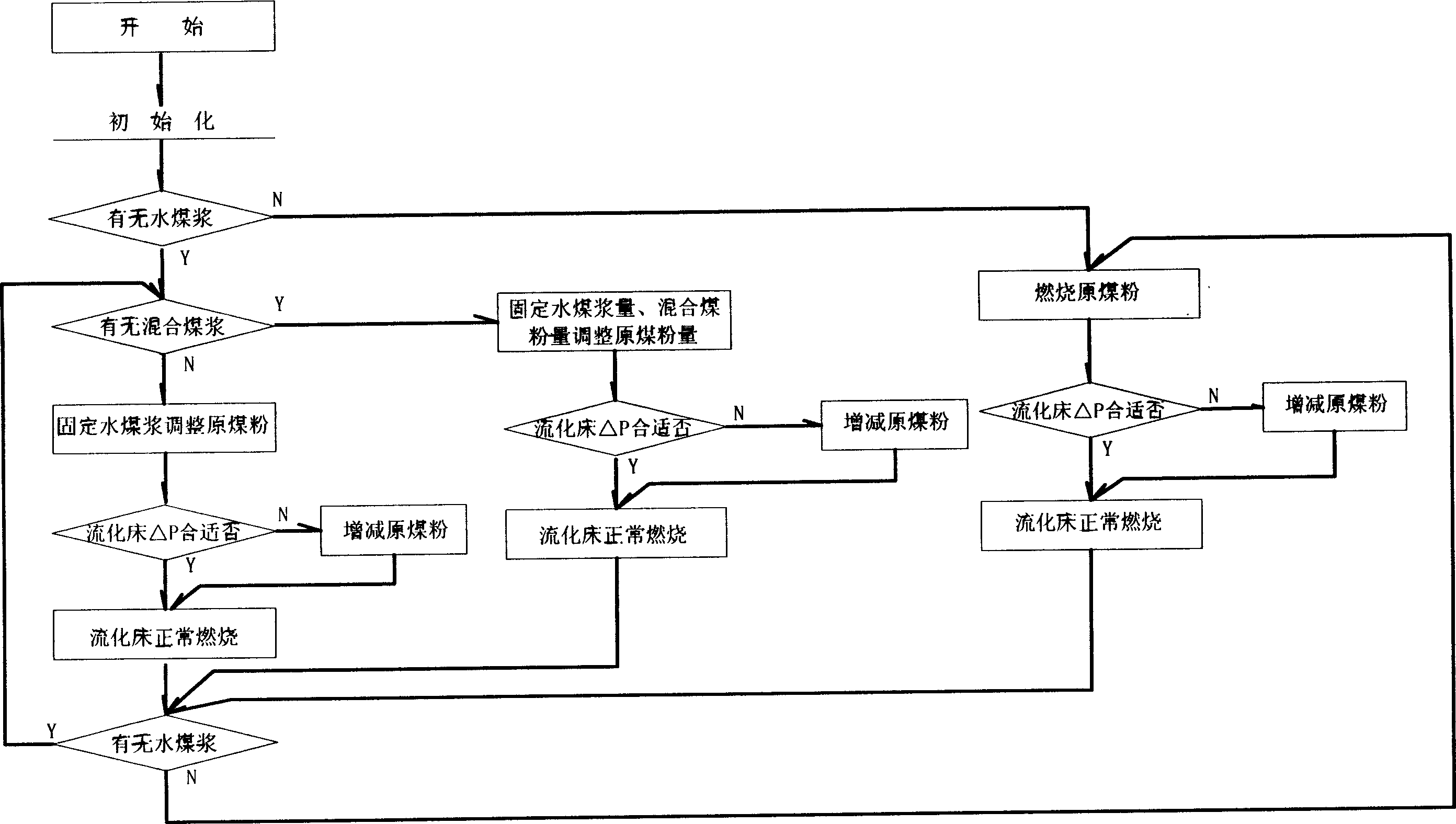

Method for using solid/liquid coal double fuel for circulation fluidized bed boiler

InactiveCN1563792AGuaranteed uptimeBurn instantFluidized bed combustionApparatus for fluidised bed combustionCentrifugal pumpCoal water

The present invention is the technological process of simultaneously burning solid and liquid fuel in circular fluidized bed boiler. In the boiler, are installed simultaneously granulator for feeding coal water slurry, spiral coal feeder for feeding coal powder, coal gangue powder or coal powder mixture with inflammable garbage, and auxiliary double-fuel feeder. The technological parameters includes coal water slurry pressure of 0.2-0.4 MPa, certain solid / liquid fuel ratio, fluidized bed expansion ratio of 1.5-2.1, operation gas speed of 3-7 m / s, circulation multiplying factor of 6-8, boiling pressure difference of 4500-6000 Pa, and burning temperature of 800-950 deg.c. The burning technological process includes three different cases including that with coal water slurry, that without coal water slurry and that with coal powder mixture; and coal powder adding amount is regulated based on the bed layer height and the furnace temperature mainly.

Owner:SHENYANG DAVID ENVIRONMENTAL PROTECTION & ENERGY SAVING EQUIP

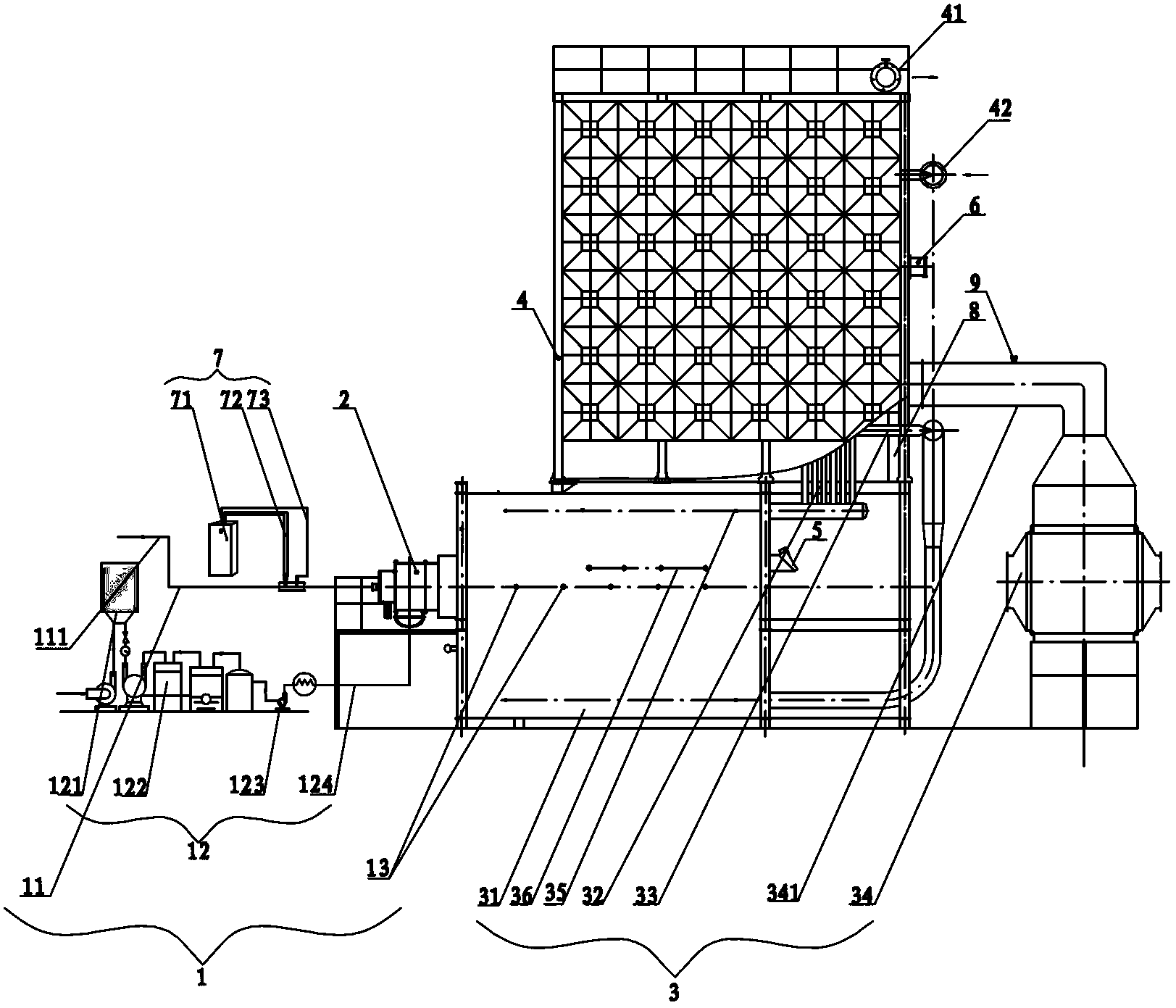

Combined combustion system of chain boiler

InactiveCN105864748AEfficient and clean combustionPromote pyrolysisStaged combustionFluegas recirculationCombustion systemCoal

The invention relates to a combined combustion system of a chain boiler. The combined combustion system comprises a pulverized coal making-pulverized coal conveying system, a smoke recirculating system, an air supply system and a combusting system; and a discharging opening of a coal hopper is divided into two paths, one path is connected with a chain fire grate, the other path feeds coal in the coal hopper into a fan coal mill through a coal feeder, a circulating fan is connected with an induced draft fan through a smoke pumping pipeline, the circulating fan pumps part of smoke from a flue of an induced draft fan outlet via the smoke pumping pipeline to serve as a drying agent of pulverized coal in the fan coal mill, and a coarse and fine pulverized coal separator is connected with a pulverized coal combustor through a pulverized coal conveying pipeline. The system is organically combined with the traditional combined combustion technology, the fuel grading combustion technology and the smoke recirculation technology, the problems that an existing chain boiler is poor in coal type adaptation, low in boiler combustion efficiency, insufficient in performance and slightly high in NOx emission are solved, and the clean, efficient and safe combustion manner is provided for the chain boiler.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

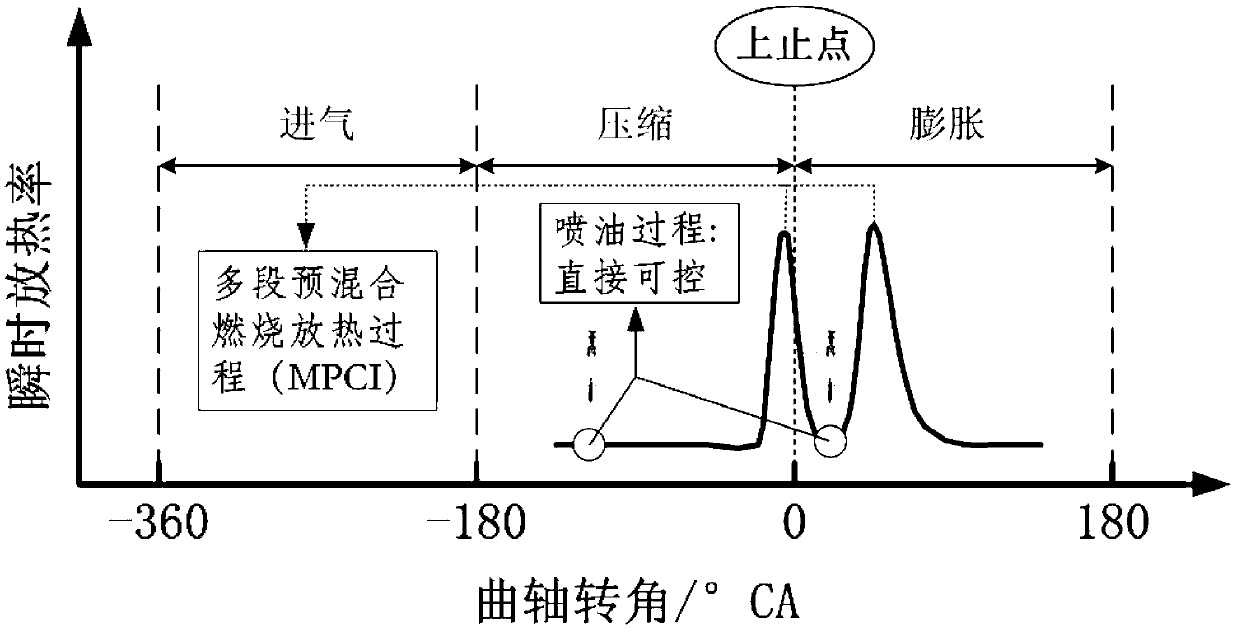

Multi-stage premixed compression ignition method for gasoline fuels with low octane value

ActiveCN102900555ALow high isovolumicGuaranteed high volumeElectrical controlMachines/enginesPressure riseGasoline fuel

The invention provides a multi-stage premixed compression ignition method for gasoline fuels with low octane values. When an engine runs, a multi-stage oil spraying and multi-stage premixed compression ignition combined mode is adopted in a range from a front 160 degree crank angle (CA) at a compression top dead point to a rear 40 degree CA at the compression top dead point, premixed compression ignition is performed each time when oil is sprayed; and oil spraying and combustion can be repeated for 1 to 3 times. According to the multi-stage premixed compression ignition method, multi-stage premixed ignition is performed, so that the problem that pressure rising rate is overhigh during large-load in a gasoline compression ignition mode is solved, and soft controllable slight-pollution combustion is performed. Due to relatively high premixed compression ignition speed, high content in the combustion and heat release processes is guaranteed, the heat efficiency is relatively high, and the fuel consumption is relatively low; the gasoline fuels with the low octane values are adopted, so that production cost of gasoline can be reduced, the using amount of anti-block additives harmful to the environment is reduced, and high-efficiency clean ignition of an internal combustion engine.

Owner:TSINGHUA UNIV

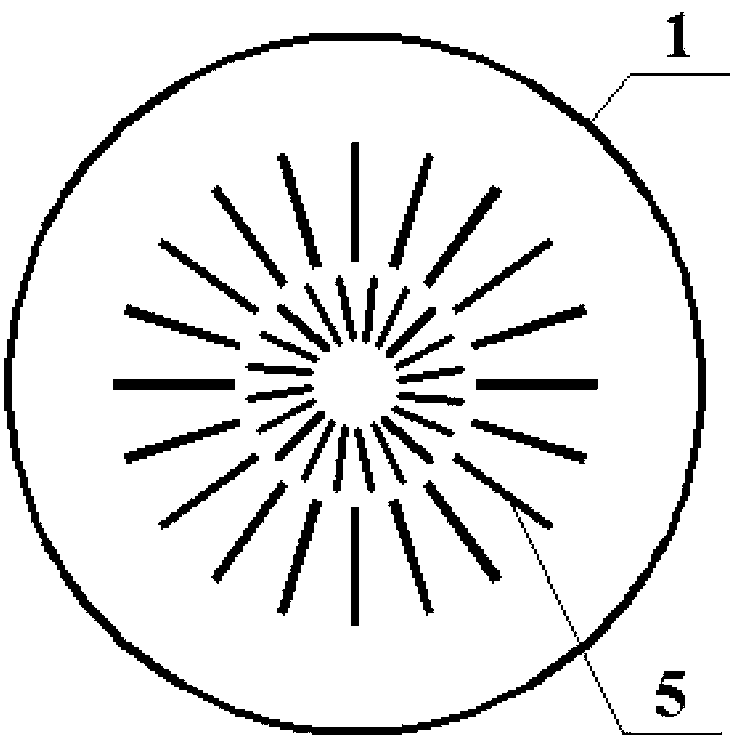

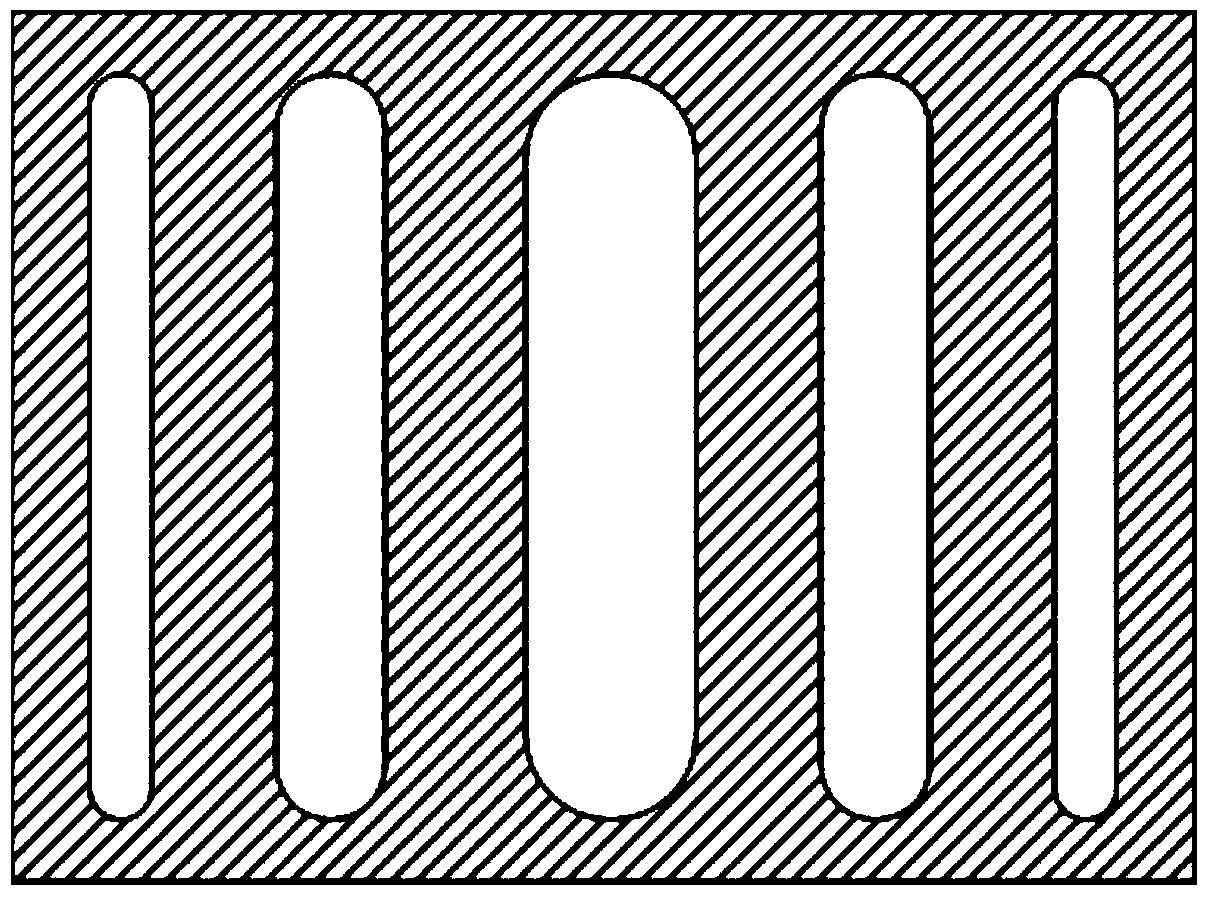

Wood stove capable of burning biomass pellet fuel

ActiveCN103292362AEfficient and clean combustionReduce Radiation Heat DissipationDomestic stoves or rangesLighting and heating apparatusEngineeringHearth

The invention discloses a wood stove capable of burning biomass pellet fuel and belongs to the technical field of biomass pellet fuel equipment. The wood stove capable of burning the biomass pellet fuel mainly comprises cookware and a stove chamber, wherein a plurality of fins are distributed on the lower bottom surface of the cookware, a biomass pellet burner is arranged inside a stove wall so as to replace an original grate, a metal reflective surface which is smooth on the surface is installed on the periphery of the top of the biomass pellet burner, the reflective surface is arc-shaped and parallel to the lower bottom surface of the cookware, and the fins arranged at the bottom of the cookware are arranged in a radial mode. The wood stove capable of burning the biomass pellet fuel has the advantages of being simple in structure, easy to construct, convenient to use, and capable of achieving efficient cleaning burning of the biomass fuel, reducing pollution emission, effectively avoiding heat radiation of flames on the stove wall and the ground, improving the utilization rate of flame radiant heat, increasing the heat-absorption surface area of the cookware, improving the rate of utilization of smoke flow heat by the flames and finally enabling heat efficiency of a normal wood stove to reach over 40%.

Owner:北京未来蓝天技术有限公司

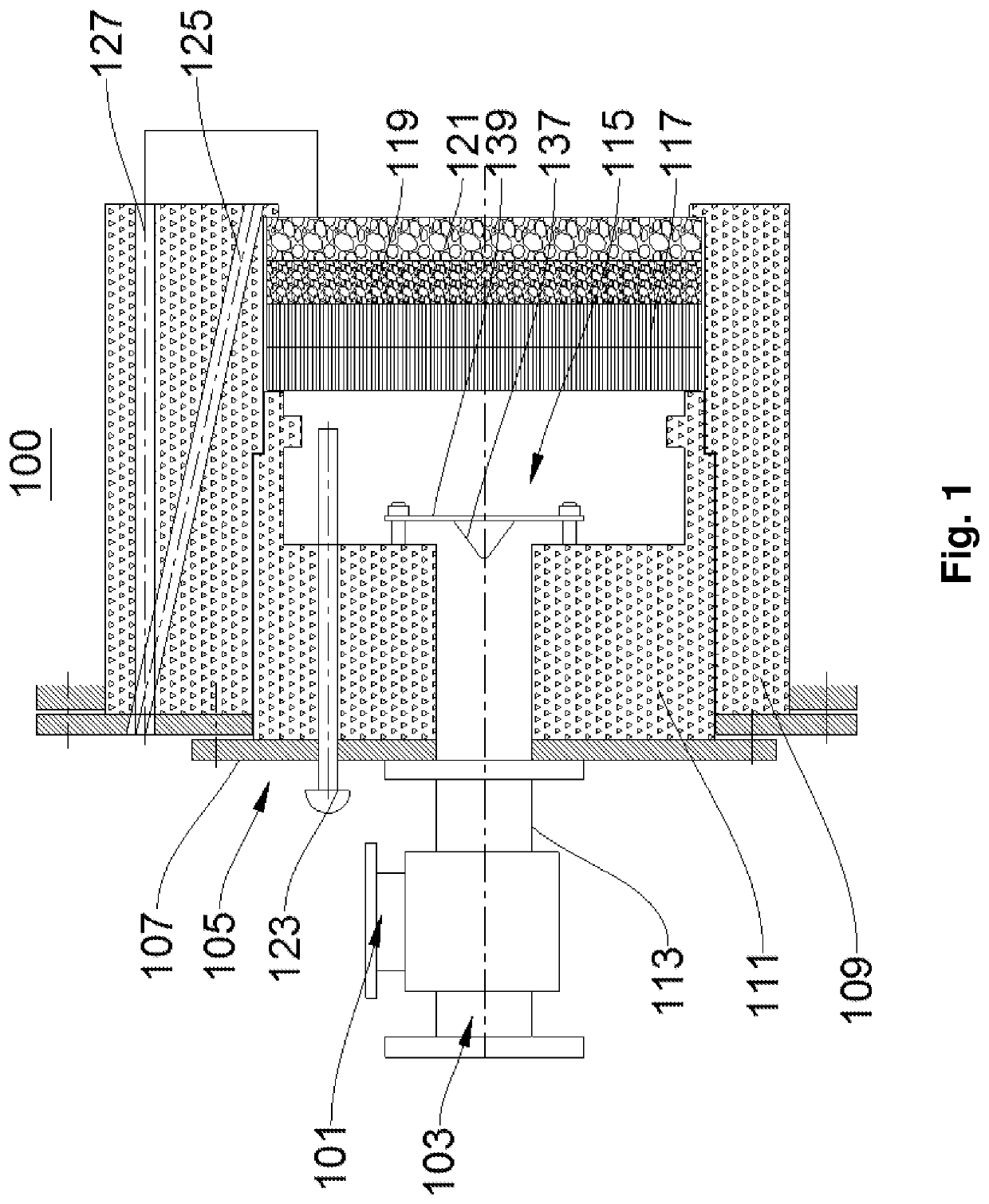

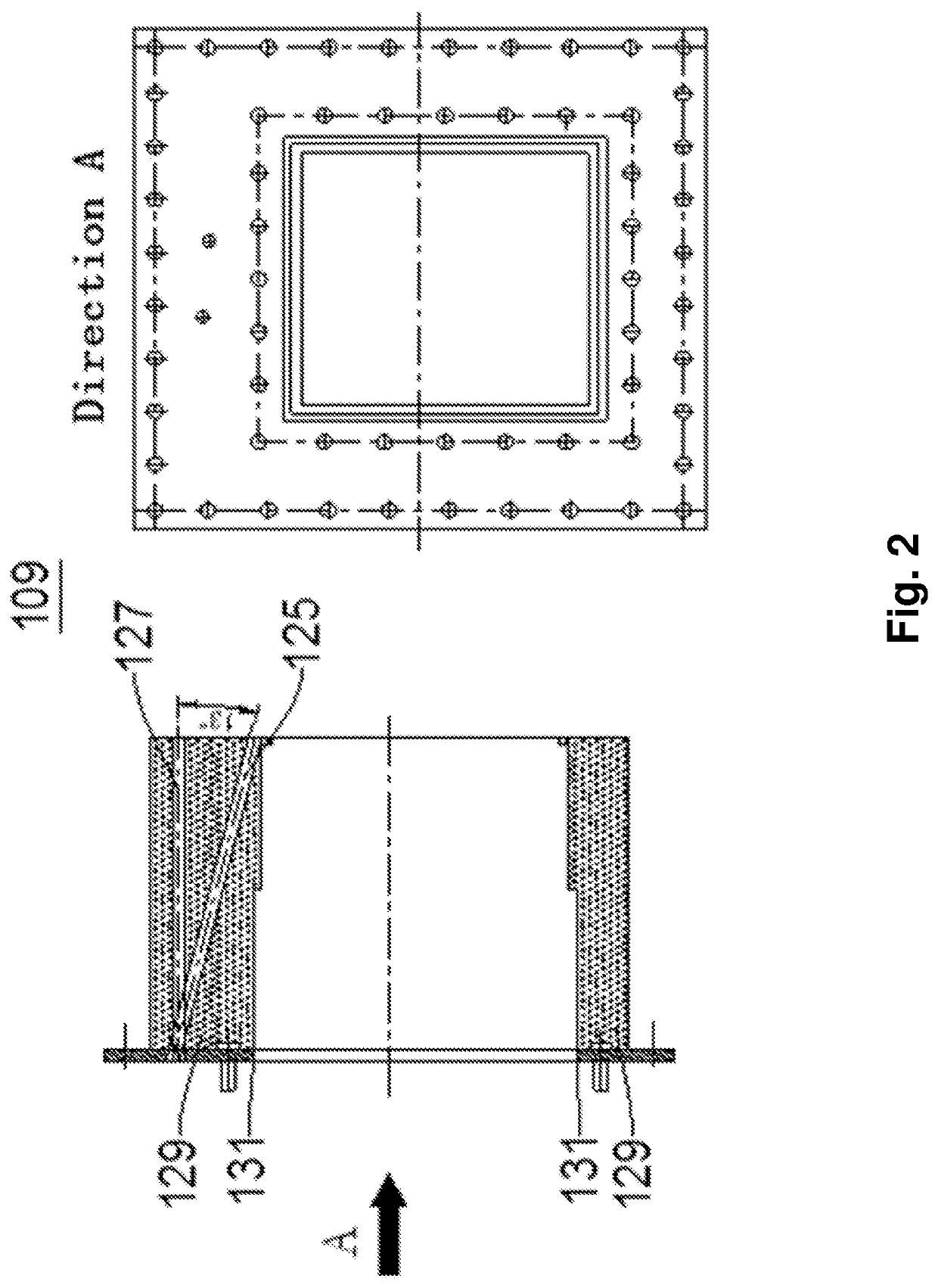

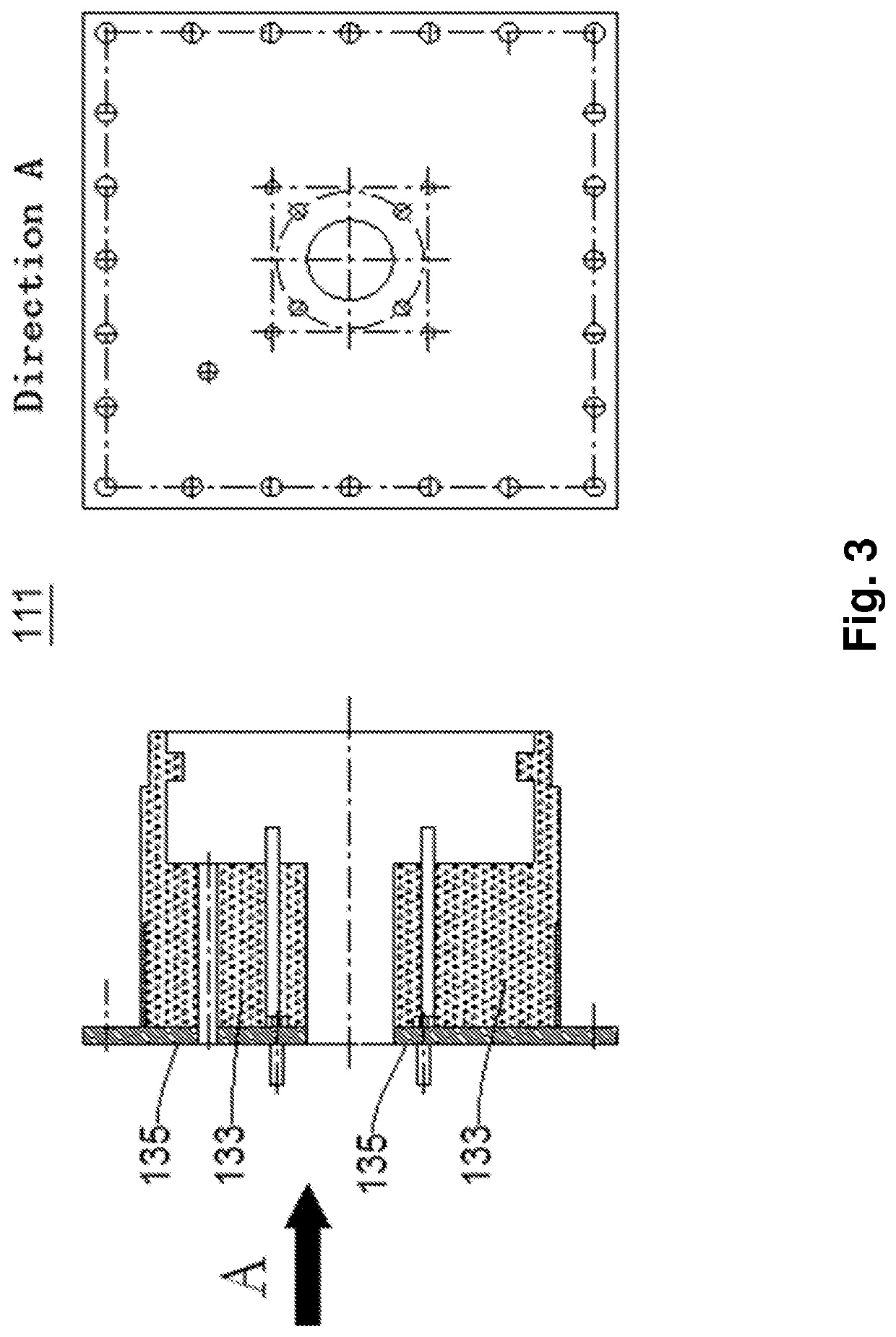

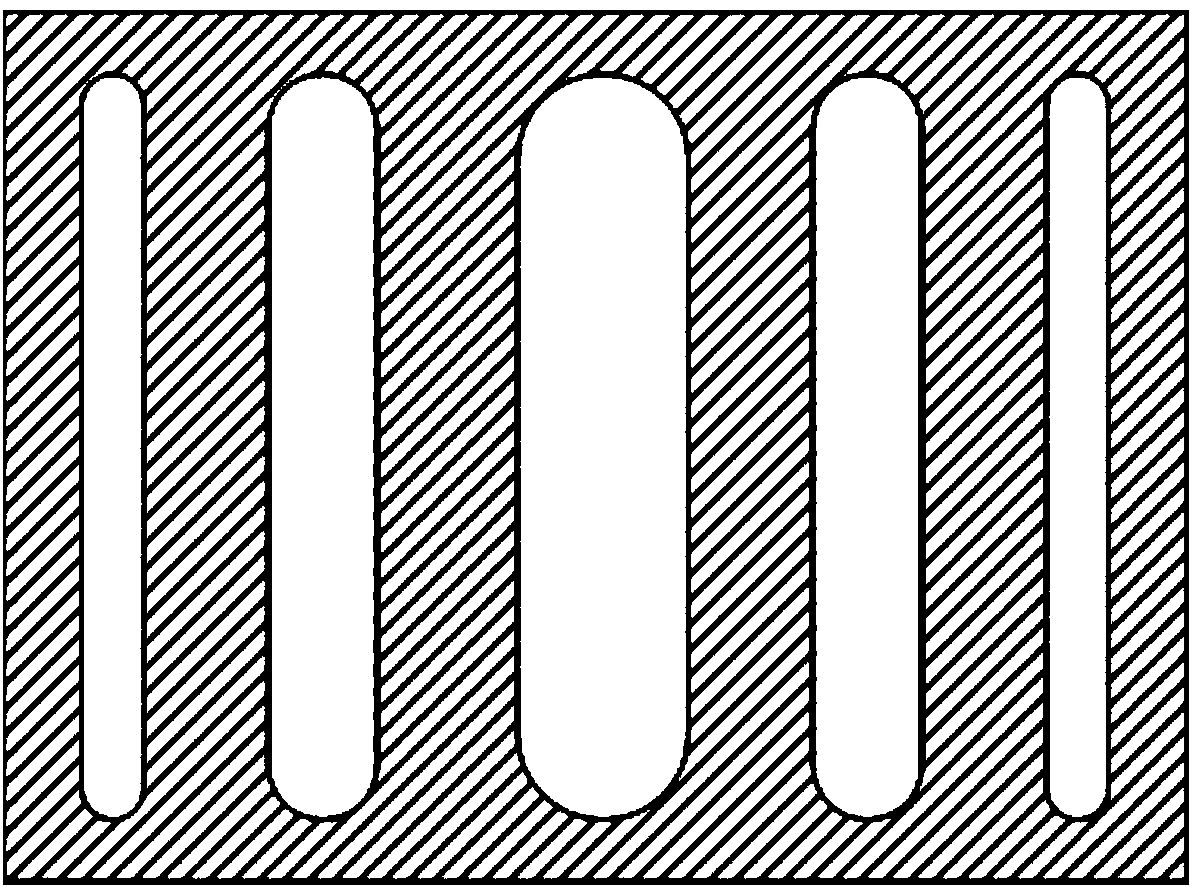

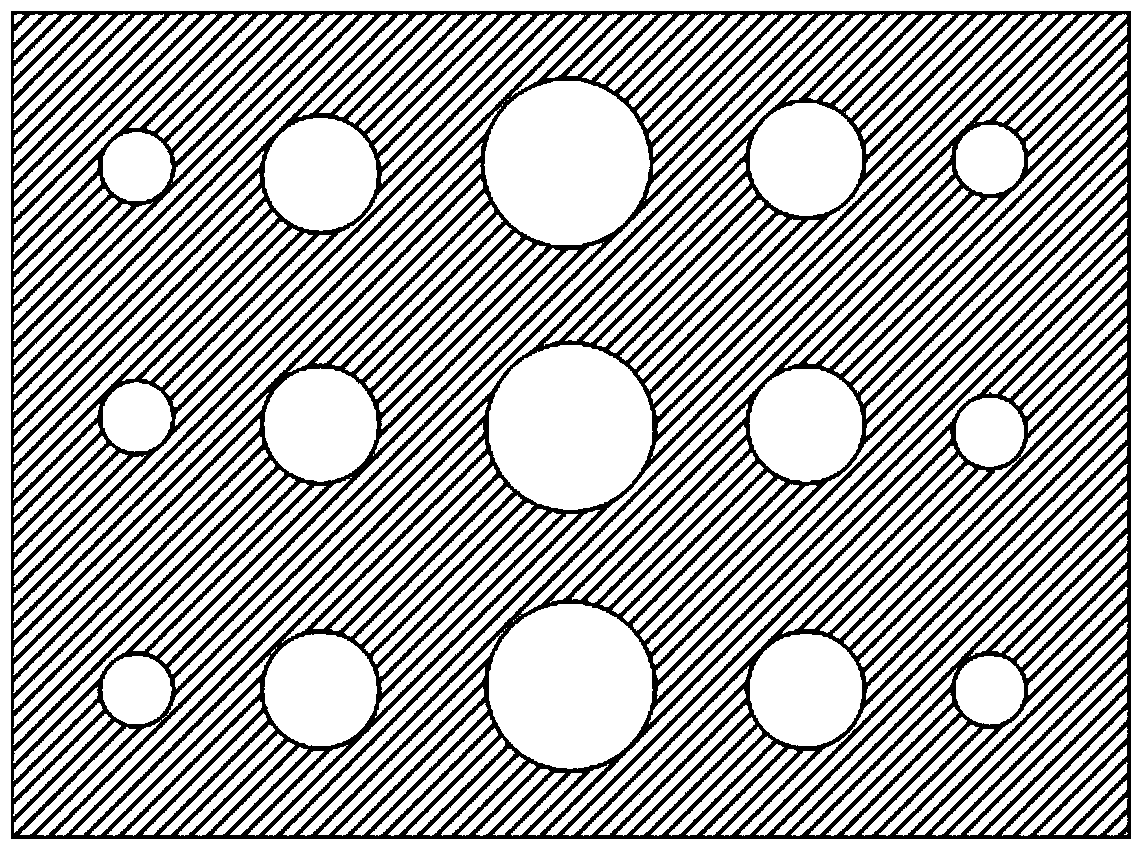

Porous Medium Premixing Combustor

ActiveUS20190353346A1Effectively avoid occurrenceAvoid it happening againFlow mixersTransportation and packagingCombustorPorous medium

A porous-medium premixing combustor is provided, which includes: an air-fuel gas mixer, a combustor body, a thermocouple, an ignition electrode, and a detecting electrode. The combustor body includes a casing connected to the air-fuel gas mixer; an outer and an inner burner-block, wherein the outer burner-block and the casing are connected, forming a square chamber, and the inner burner-block is provided inside the square chamber, with a via hole communicating with a pipe; and a mixed gas distributing plate, an ordered porous plate, a small-pore foamed ceramic plate, and a big-pore foamed-ceramic plate sequentially provided along an axis direction of the via hole of the inner burner-block. The thermocouple is provided at the casing and extends into the square chamber. The ignition electrode is provided close to an end of the big-pore foamed-ceramic plate. The detecting electrode is provided close to an exit end of the big-pore foamed-ceramic plate.

Owner:WUHAN UNIV OF SCI & TECH

Lean burn engine and automobile

ActiveCN111379634AEfficient and clean combustionLower combustion temperatureElectrical controlNon-fuel substance addition to fuelLean combustionWater pipe

The invention belongs to the technical field of engines, and relates to a lean burn engine and an automobile. The lean burn engine comprises a water spraying system and an electric control unit, wherein the water spraying system comprises air flue water sprayers, pressure sensors and a water supply device; the air flue water sprayers are connected with the water supply device through water pipes;the pressure sensors are used for detecting the pressure values of the water pipes and sending the pressure values to the electric control unit; the air flue water sprayers are arranged on air inlet channels of air cylinders of the engine and spray water to the air inlet channels; the electric control unit is in signal connection with the air flue water sprayers and the pressure sensors; and whenthe engine is in different work conditions, the pressure values of the water pipes change, the pressure sensors send corresponding signals to the electric control unit according to the different pressure values of the water pipes, and the electric control unit controls the air flue water sprayers to adjust the water spraying amount. According to the lean burn engine, the electric control unit controls the air flue water sprayers to adjust the water spraying amount according to different engine work conditions (loads), and efficient clean combustion of the engine is achieved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

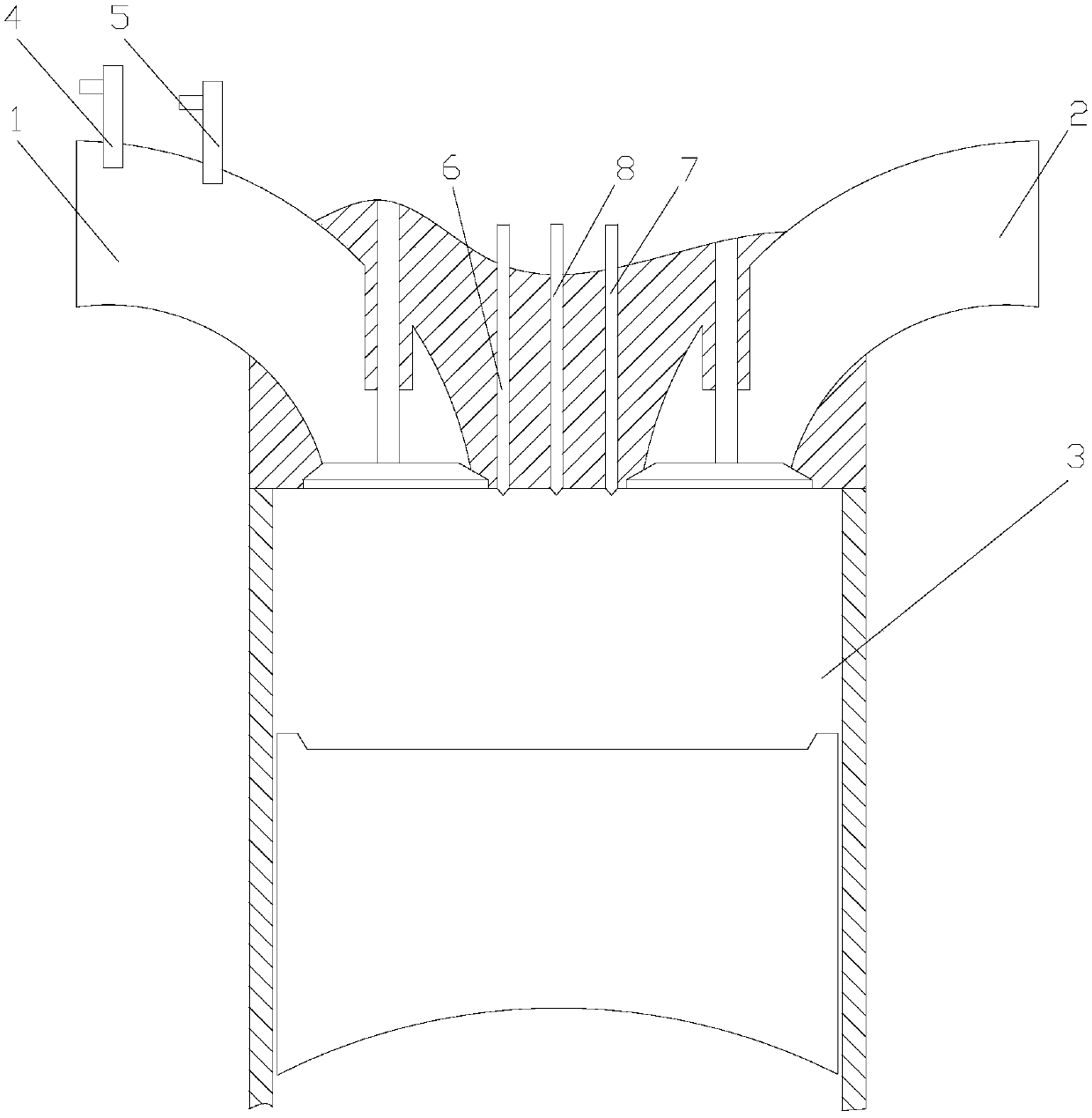

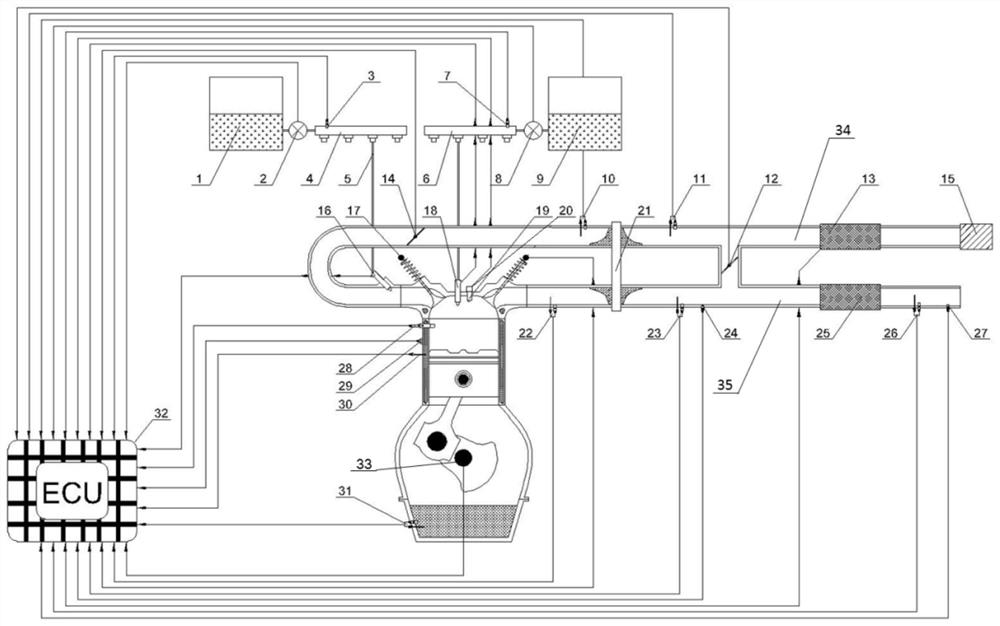

Dual-fuel pressure combustion type four-stroke engine based on reformed gas and combustion control method

ActiveCN110821661AEfficient thermal managementSimple structureInternal combustion piston enginesCylinder headsFour-stroke engineSpray nozzle

The invention provides a dual-fuel pressure combustion type four-stroke engine based on reformed gas and a combustion control method, and belongs to the field of combustion in an internal combustion engine. A direct-injection first fuel spray nozzle is arranged on a cylinder cover and / or a gas inlet channel first fuel spray nozzle is arranged on a gas inlet channel, a direct-injection second fuelspray nozzle is arranged on the cylinder cover, and a direct-injection reformed gas spray nozzle is arranged on the cylinder cover and / or a gas inlet channel reformed gas spray nozzle are / is arrangedon the gas inlet channel. In the state that all categories of spray nozzles are arranged, first fuel and second fuel are supplied through the direct-injection spray nozzles at low load, and heat efficiency is increased; the fuel is supplied through the gas inlet channel first fuel spray nozzle and the direct-injection second fuel spray nozzle at middle load, and production of NOx is reduced; all spray nozzles of the first fuel and the second fuel all perform fuel supply at high load, and detonation is controlled. Efficient clean combustion in all work condition ranges is realized, and the energy structure is optimized.

Owner:DALIAN UNIV OF TECH

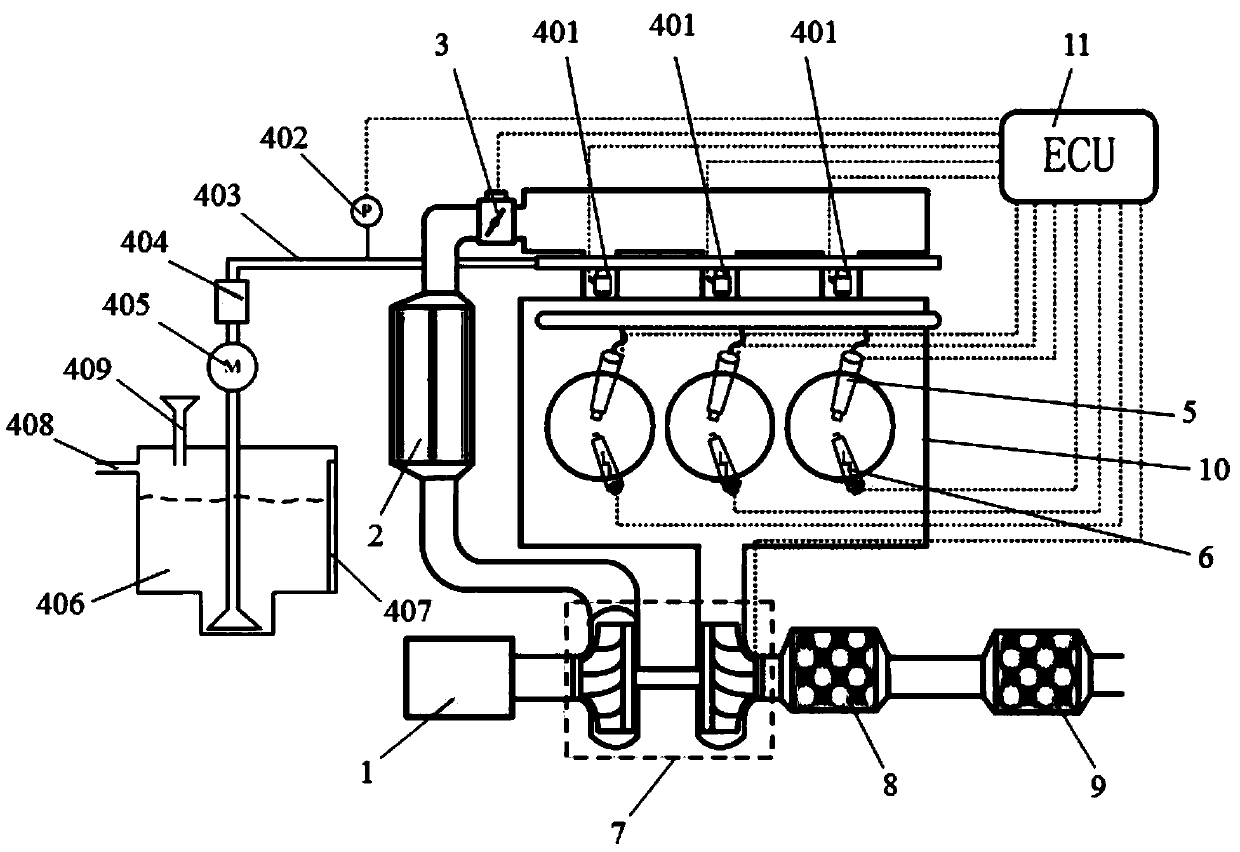

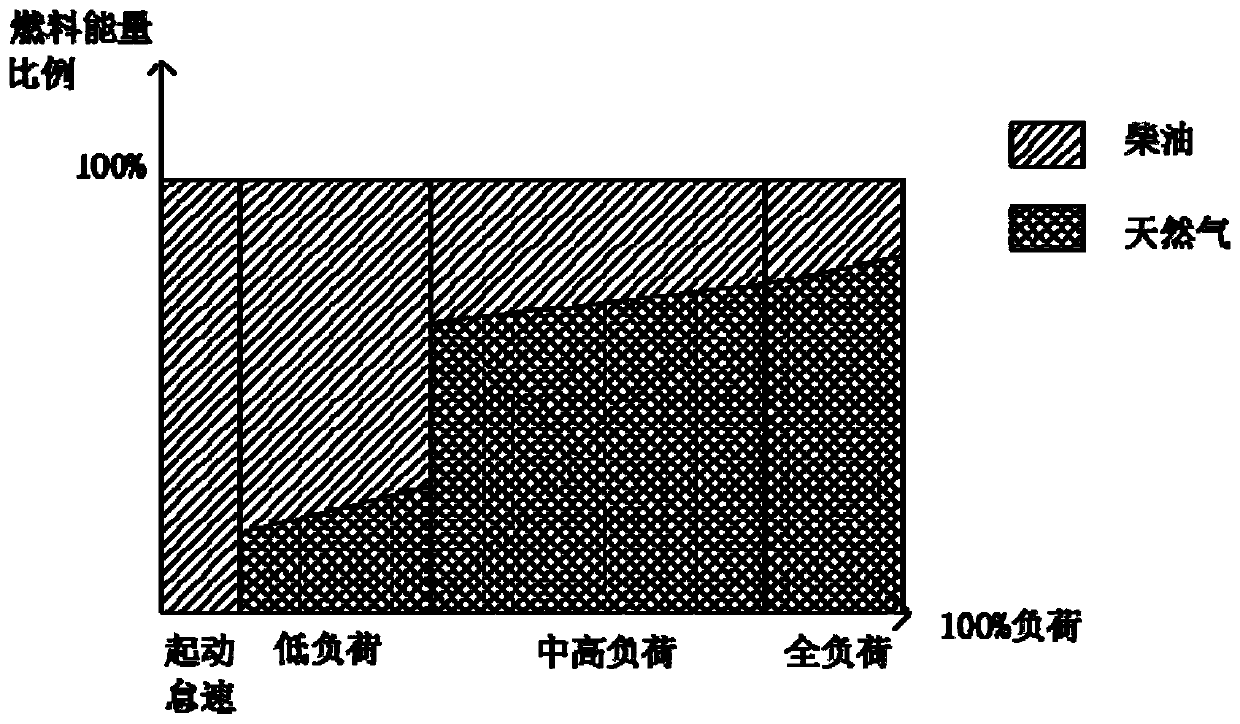

Multi-mode combustion organization method of natural gas/diesel oil dual-fuel engine

ActiveCN110318891AShortened afterburn periodEmission reductionElectrical controlInternal combustion piston enginesCombustionInlet channel

The invention aims to provide a multi-mode combustion organization method of a natural gas / diesel oil dual-fuel engine. Natural gas used as a low-reaction-activity fuel is injected into a gas channelby a natural gas low-pressure injection system, is preliminarily mixed with air in a gas inlet channel and enters a gas cylinder through a gas inlet valve; diesel oil used as a high-reaction-activityfuel is directly injected into the gas cylinder by a high-pressure common-rail fuel injection system; after the diesel is spontaneously combusted, the mixed gas with the natural gas and the air is ignited so as to supply power to the engine. According to the multi-mode combustion organization method of the natural gas / diesel oil dual-fuel engine, through independent or collaborative control of thehigh-pressure common-rail fuel injection system and the natural gas low-pressure injection system, multi-mode combustion of the natural gas / diesel oil dual-fuel engine can be achieved under differentconditions, so that the engine can operate more flexibly; the problems of difficult cold starting, high emission of low-load THC and high-load knocking can be avoided; and reliable operation and efficient and clean combustion of the engine can be achieved.

Owner:HARBIN ENG UNIV

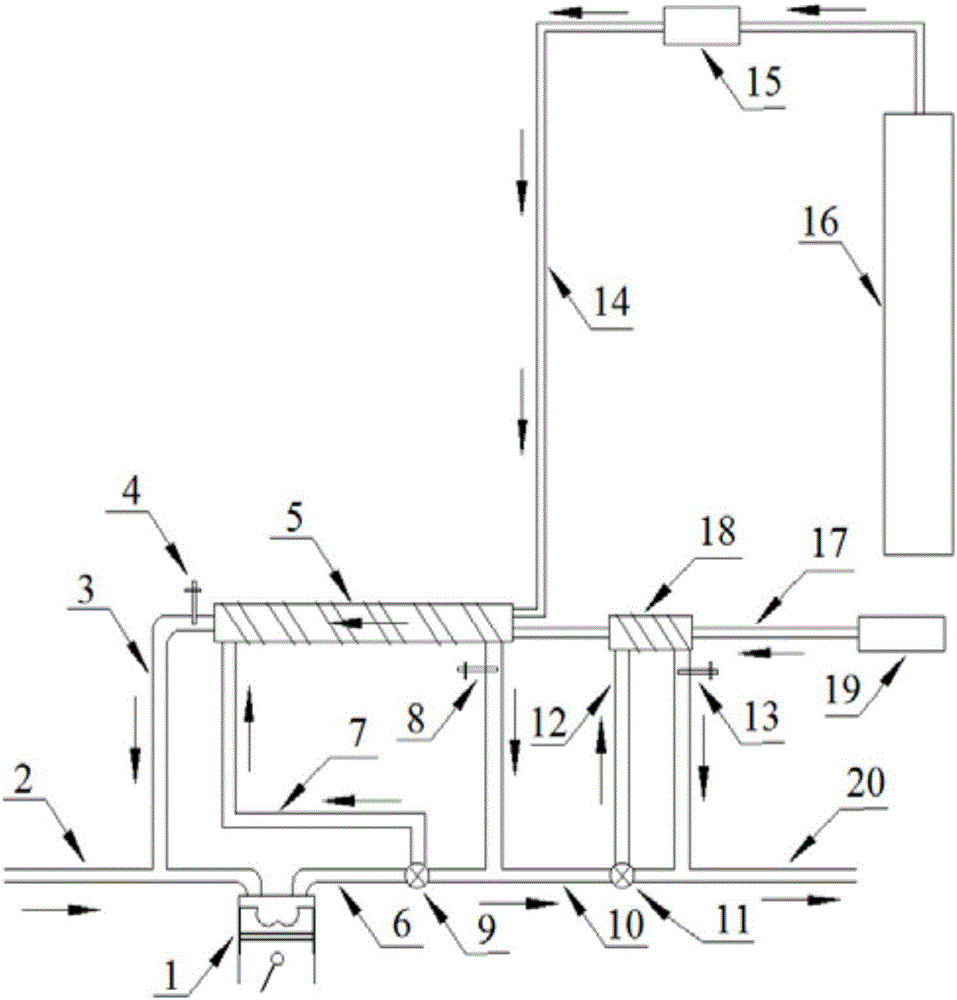

Device for reforming fuel at low temperature through exhaust gas residual heat of engine

InactiveCN106704048AAchieve efficient and clean combustionBroaden the range of efficient and clean combustionInternal combustion piston enginesExhaust apparatusCryogenic fuelFuel injection

The invention discloses a device for reforming fuel at low temperature through exhaust gas residual heat of an engine. The device comprises an engine cylinder and an externally-arranged low-temperature fuel reformer, an air inlet pipe and a fuel sample injection pipe are connected to an inlet of the externally-arranged low-temperature fuel reformer, and the air inlet pipe is provided with a gas flowermeter; a fuel injection pump and a fuel vaporization tank are connected to the fuel sample injection pipe, and an outlet of the externally-arranged low-temperature fuel reformer is provided with a thermocouple and connected with an engine gas inlet pipe through a reforming gas pipe. According to the device, full utilization of the exhaust gas residual heat of the engine is achieved by winding an engine exhaust gas pipe around the externally-arranged low-temperature fuel reformer and the fuel vaporization tank; a low-temperature product obtained after reforming enters the engine gas inlet pipe through the reforming gas pipe and is mixed with fresh air again to form uniform mixed gas, the uniform mixed gas is introduced into the engine cylinder and burnt with fuel directly sprayed in the cylinder in a mixed mode, mixed gas activity and concentration layering is achieved, and due to the fact that a catalyst does not need to be added in the process, the engine can run more efficiently in a better energy-saving mode.

Owner:TIANJIN UNIV

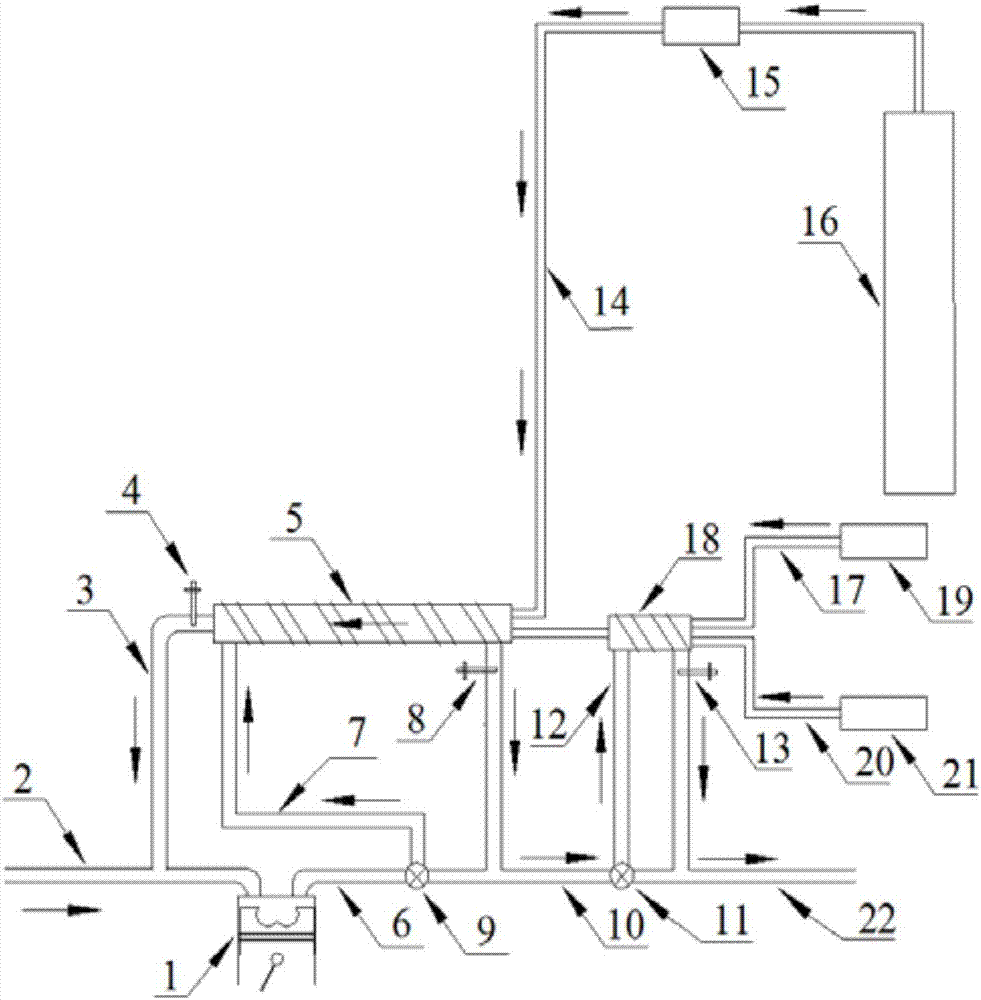

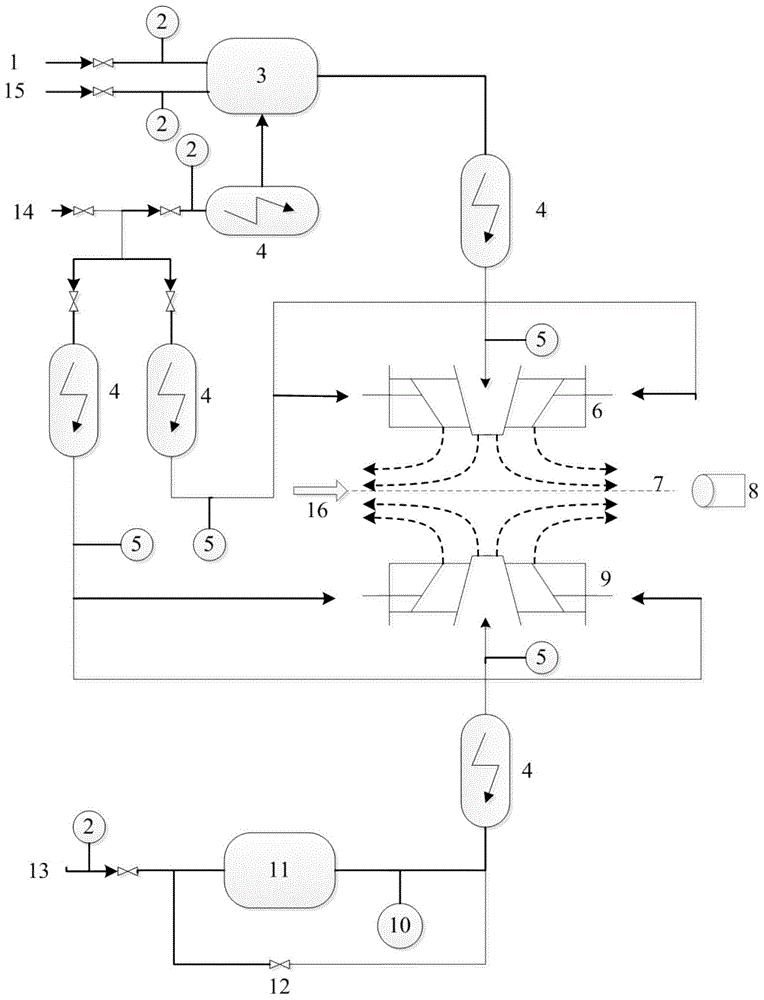

Device for reforming fuel through engine waste gas waste heat in catalyst-free low-temperature water adding manner

InactiveCN106968845ALower combustion temperatureEmission reductionInternal combustion piston enginesExhaust apparatusEvaporationFuel injection

The invention discloses a device for reforming fuel through engine waste gas waste heat in a catalyst-free low-temperature water adding manner. The device comprises an engine air cylinder and an external low-temperature water adding reformer. An inlet of the external low-temperature water adding reformer is connected with an air inlet pipe and a fuel sample inlet pipe. The fuel sample inlet pipe is connected with a fuel injection pump and an evaporation tank. An inlet of the evaporation tank is connected with a water sample inlet pipe. A waste gas pipe passes through the external low-temperature water adding reformer and the evaporation tank through an engine in a wound manner, and engine waste gas waste heat is fully utilized. In the external low-temperature water adding reformer, fresh air and mixed gas of evaporated fuel and water are subjected to low-temperature reforming, a low-temperature product obtained after reforming passes through a reforming gas pipe to enter an engine gas inlet pipe and is mixed with the fresh air again to form even mixed gas to be guided into the engine air cylinder, and the even mixed gas and fuel directly injected in the cylinder are mixed and combusted to achieve mixed gas activity and concentration layering. Due to the fact that a catalyst does not need to be added in the process, the engine operates more efficiently by saving more energy.

Owner:TIANJIN UNIV

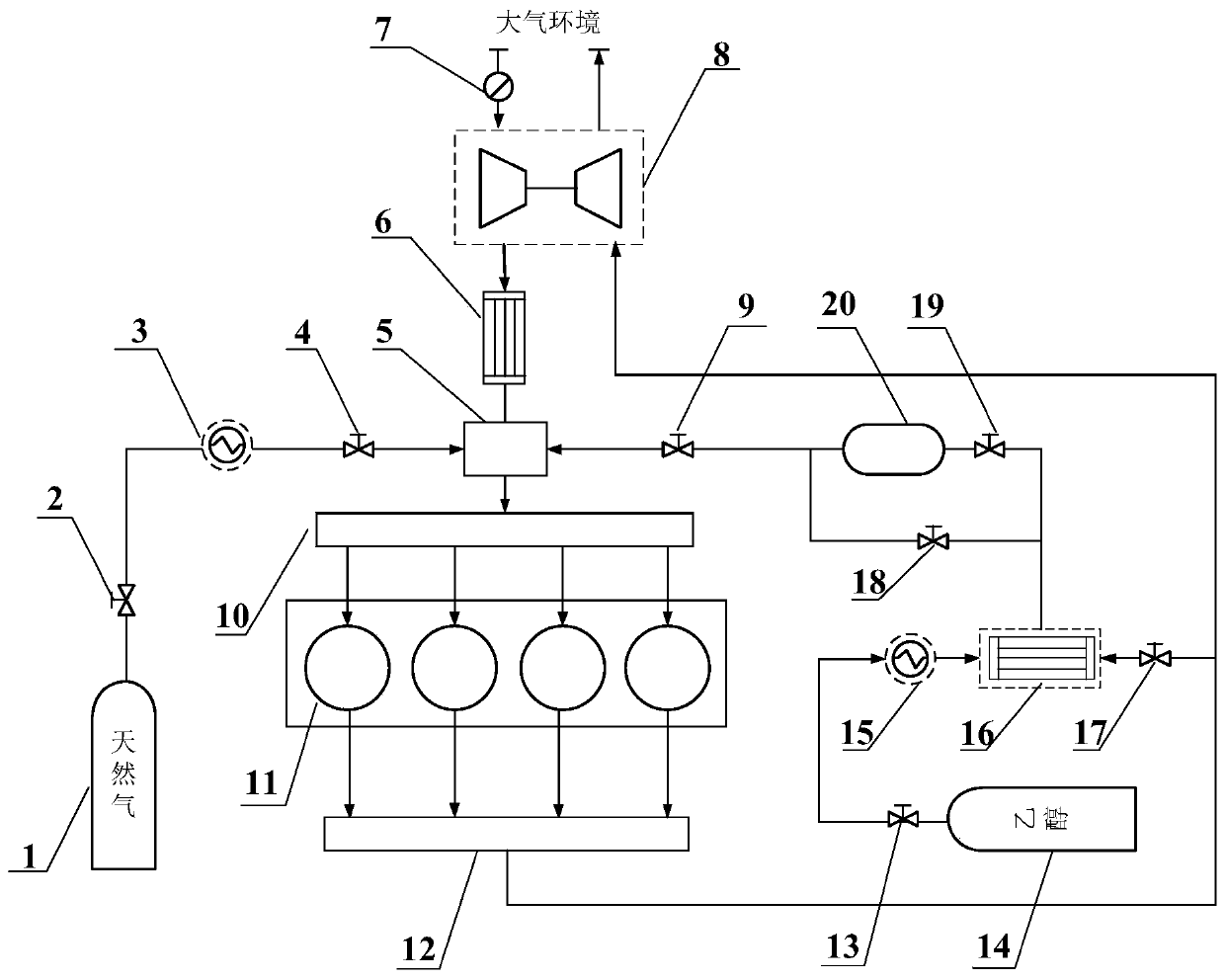

Ethyl alcohol reforming system and control method for improving dynamic performance of natural gas engine

ActiveCN110360026AKnock suppressionEfficient and clean combustionInternal combustion piston enginesFuel supply apparatusAlcoholCombustion

The invention aims at providing an ethyl alcohol reforming system and an ethyl alcohol reforming control method for improving dynamic performance of a natural gas engine. The ethyl alcohol reforming system for improving the dynamic performance of the natural gas engine comprises an LNG (liquefied natural gas) storage tank, an LNG vaporizer, a mixer, a turbine supercharger, an ethyl alcohol storagetank, an ethyl alcohol vaporizer and an ethyl alcohol reformer, wherein a gas compressor in the turbine supercharger is connected with the mixer through an intercooler, the LNG storage tank is connected with the LNG vaporizer through a liquified natural gas flow valve, the LNG vaporizer is connected with the mixer through a gaseous natural gas flow valve, the mixer is connected with a gas inlet pipe, the gas inlet pipe is connected with a turbine of the turbine supercharger, a gas discharge pipe is connected with the ethyl alcohol reformer through a waste gas bypass pipe, a waste gas bypass valve is connected onto the waste gas bypass pipe, the ethyl alcohol storage tank is connected with the ethyl alcohol vaporizer through a liquified ethyl alcohol flow valve, the ethyl alcohol vaporizeris connected with the ethyl alcohol reformer, the ethyl alcohol reformer is connected with the mixer through a reforming pipeline, and a reformed gas flow valve is installed on the reforming pipeline. The ethyl alcohol reforming system and the ethyl alcohol reforming control method for improving the dynamic performance of the natural gas engine can effectively inhibit engine knocking and accidentfire phenomena of the natural gas engine, and also can achieve efficient combustion under cold start and low load work conditions and loading work conditions.

Owner:HARBIN ENG UNIV

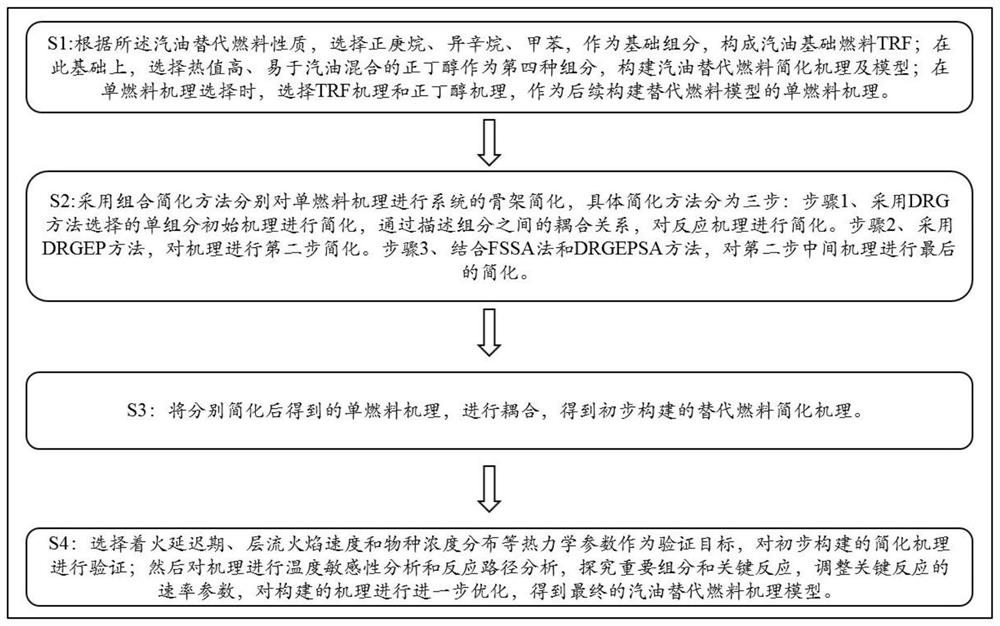

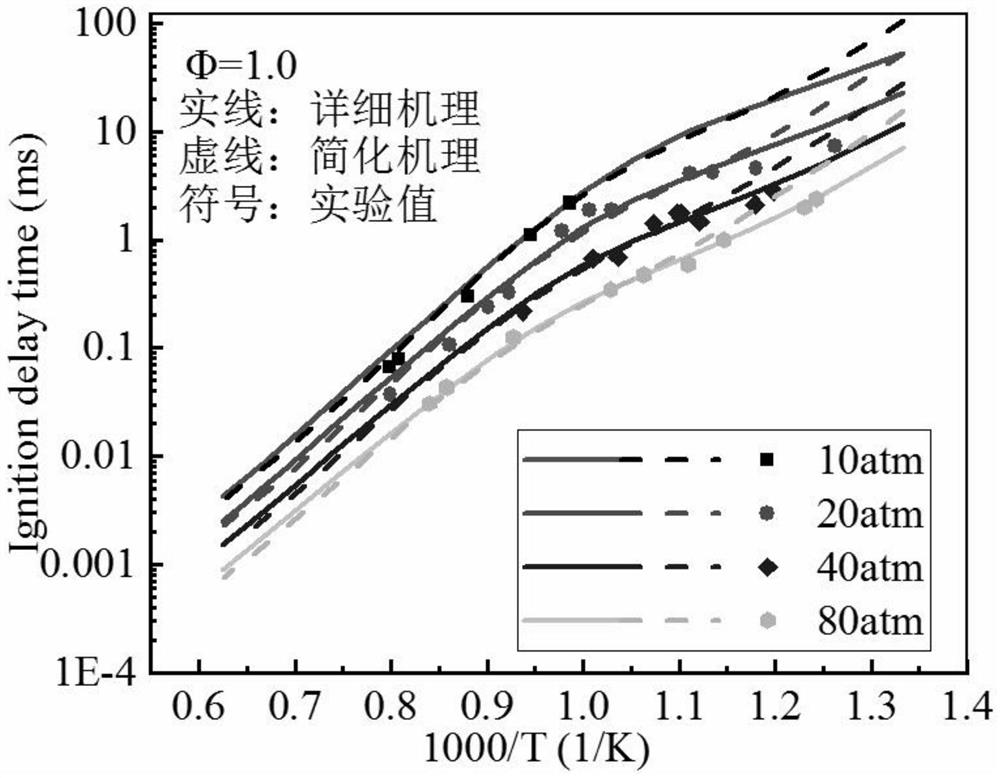

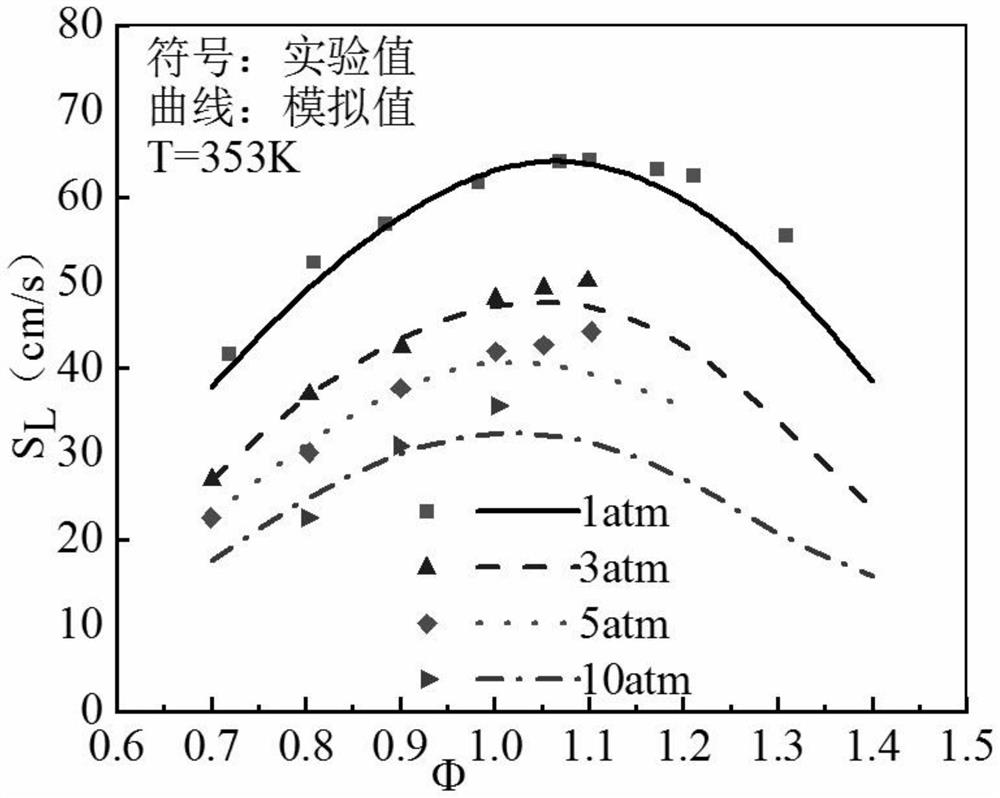

Method for constructing gasoline alternative fuel model and simplifying mechanism

ActiveCN111849567AHigh calorific valueEasy to transportLiquid carbonaceous fuelsComputational theoretical chemistryRelation graphAlternative fuels

The invention discloses a method for constructing a gasoline alternative fuel model and simplifying a mechanism. The method comprises the following steps: determining key components and an adaptationmechanism of a gasoline alternative fuel; systematically simplifying the framework of the single fuel mechanism from the perspective of framework simplification by adopting a directed relation graph (DRG) method, a directed relation graph (DRGEP) method based on error propagation, and a directed relation graph (DRGEPSA) method based on a full substance sensitivity analysis (FSSA) method and coupling error transfer and sensitivity analysis; coupling single fuel mechanisms obtained after respective simplification to obtain a constructed alternative fuel simplification mechanism; and selectingthermodynamic parameters, and comparing and verifying a constructed simplified mechanism model by utilizing comparison of experiments and numerical simulation. The method greatly reduces the sizeof the detailed mechanism, and can achieve efficient and accurate calculation.

Owner:JIANGSU UNIV

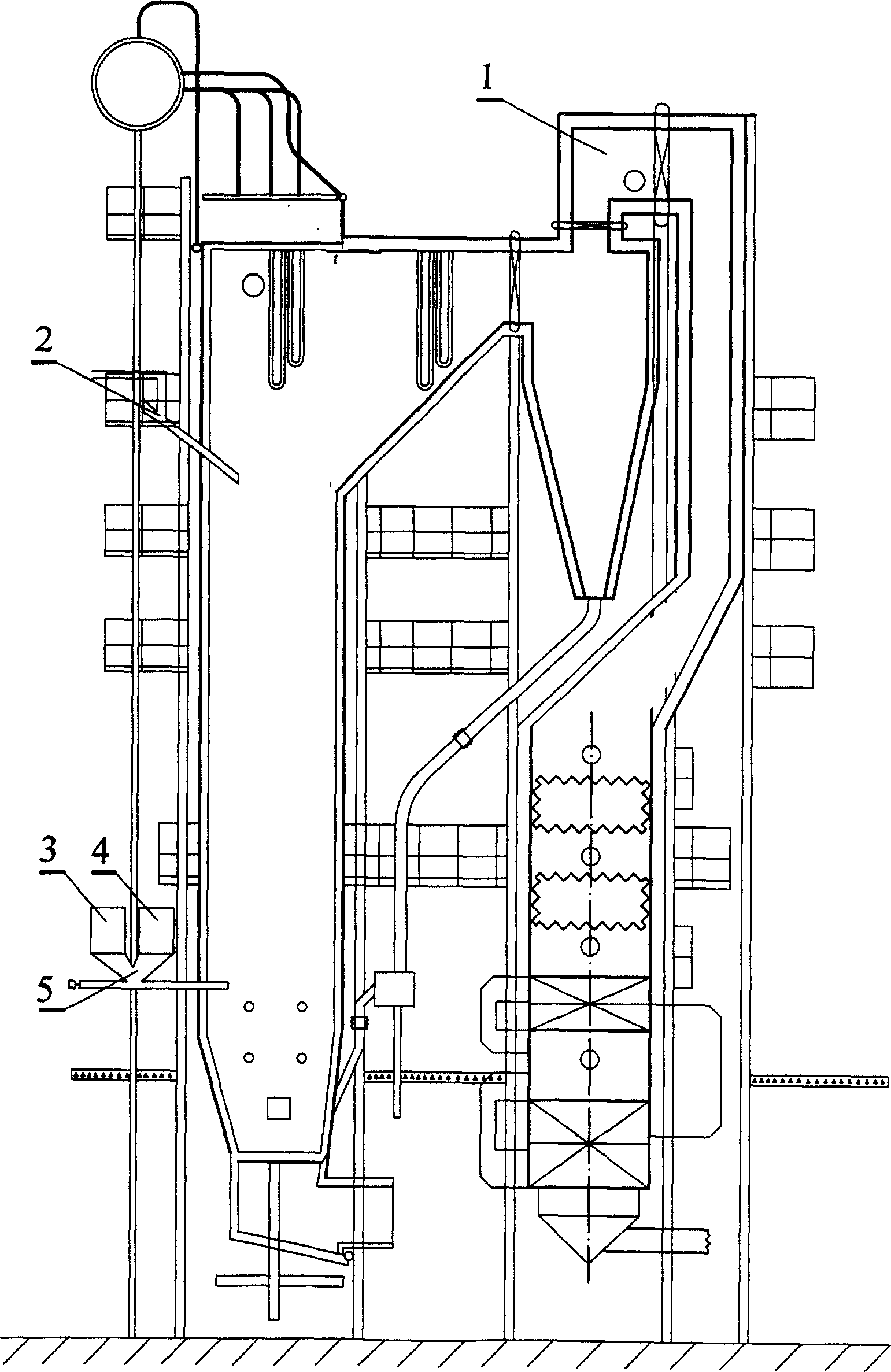

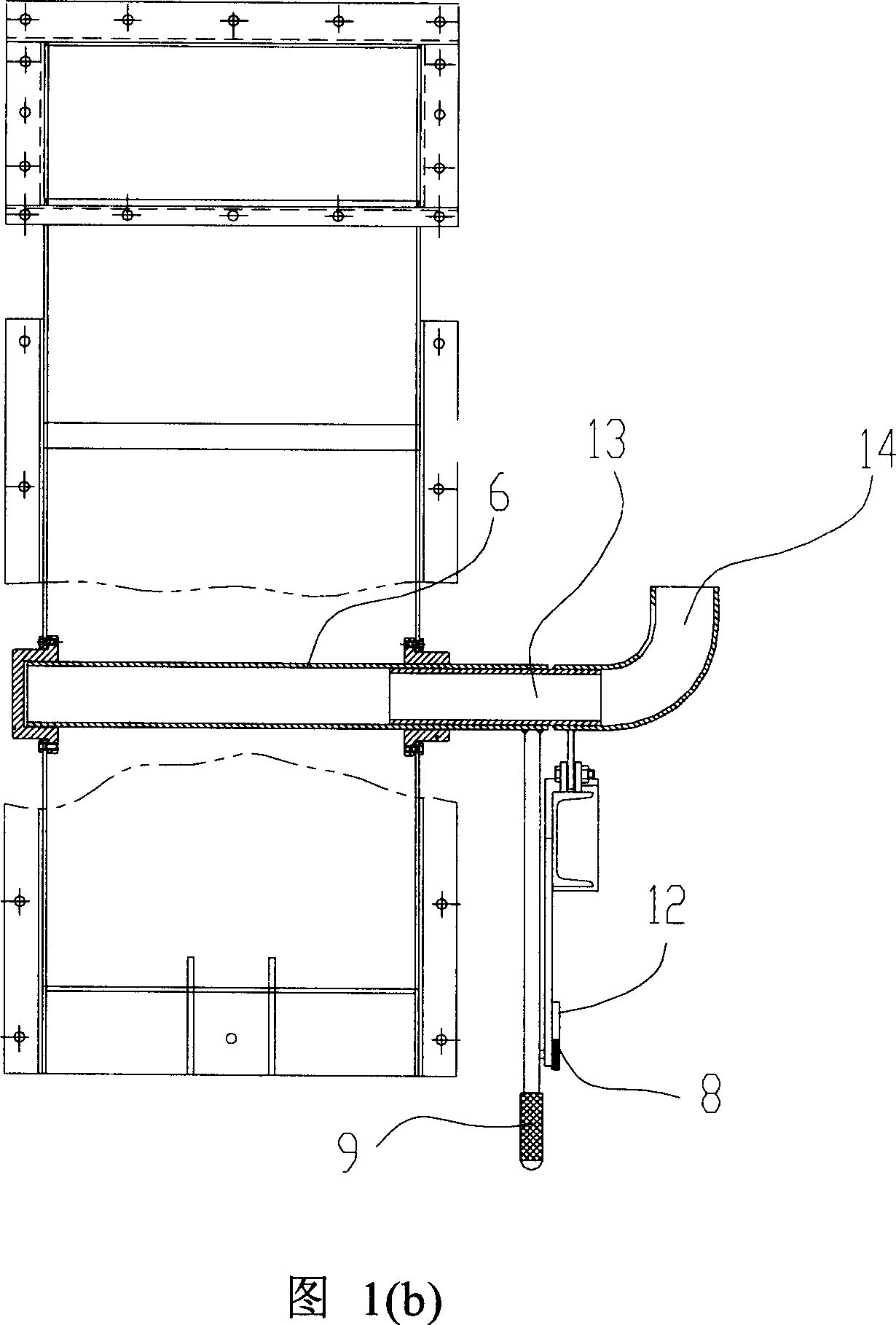

Feeding inlet structure for biomass energy fuel boiler

InactiveCN1945122AEvenly distributedEfficient and clean combustionDamper arrangementIncinerator apparatusBiomassNozzle

The feed inlet structure for biomass fuel boiler includes one upper inclined fuel feeding structure comprising one fuel feeding pipe in certain angle to the front hearth wall and one outwards widening part below the fuel feeding pipe; one lower secondary air pipe structure comprising one secondary air pipe and several secondary air nozzles inserted into the outwards widening part and fixed to the secondary air pipe; and one regulating mechanism comprising one cooling air pipe, one regulating baffle and one regulator to control the rotation of the baffle. The feed inlet structure feeds fuel into the boiler homogeneously, cools the feed inlet and realizes the efficient clean burning of the biomass fuel.

Owner:SHANGHAI INDAL BOILER RES INST

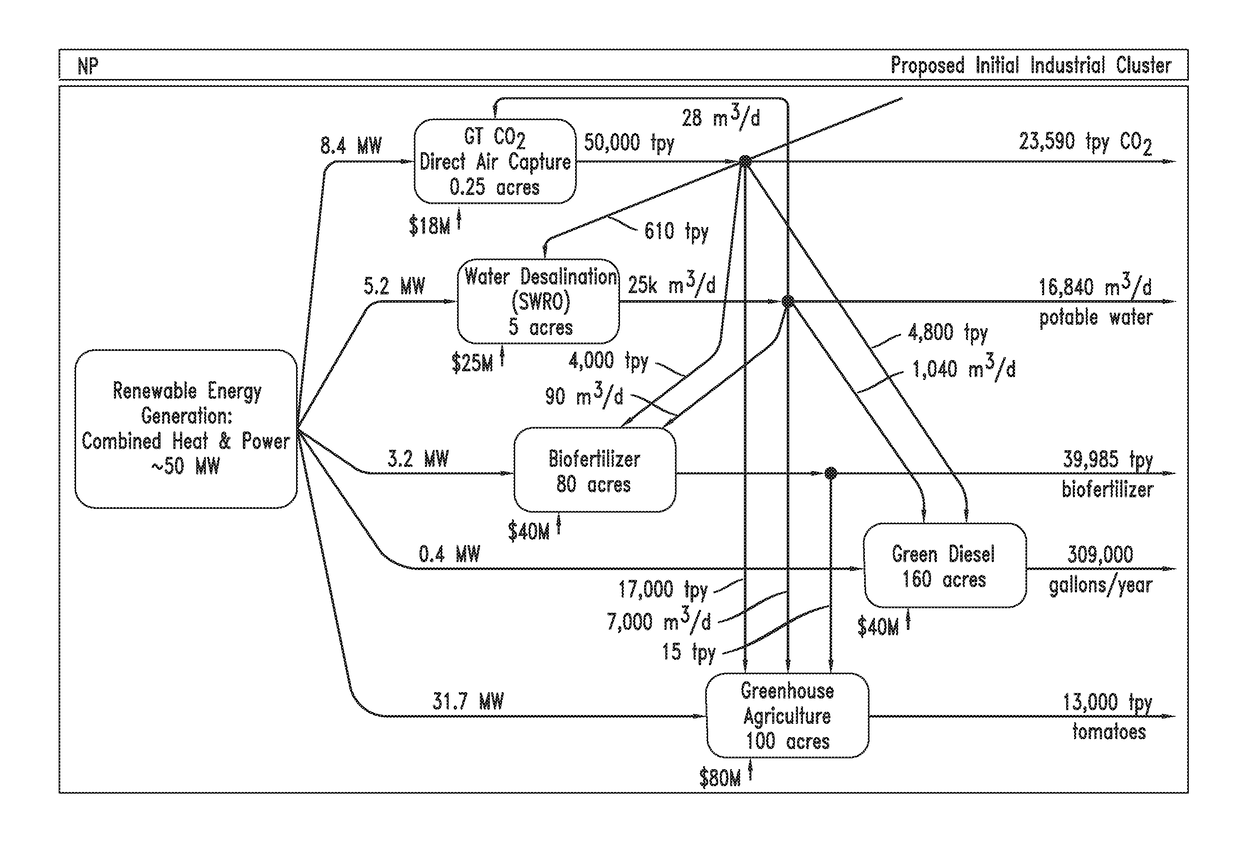

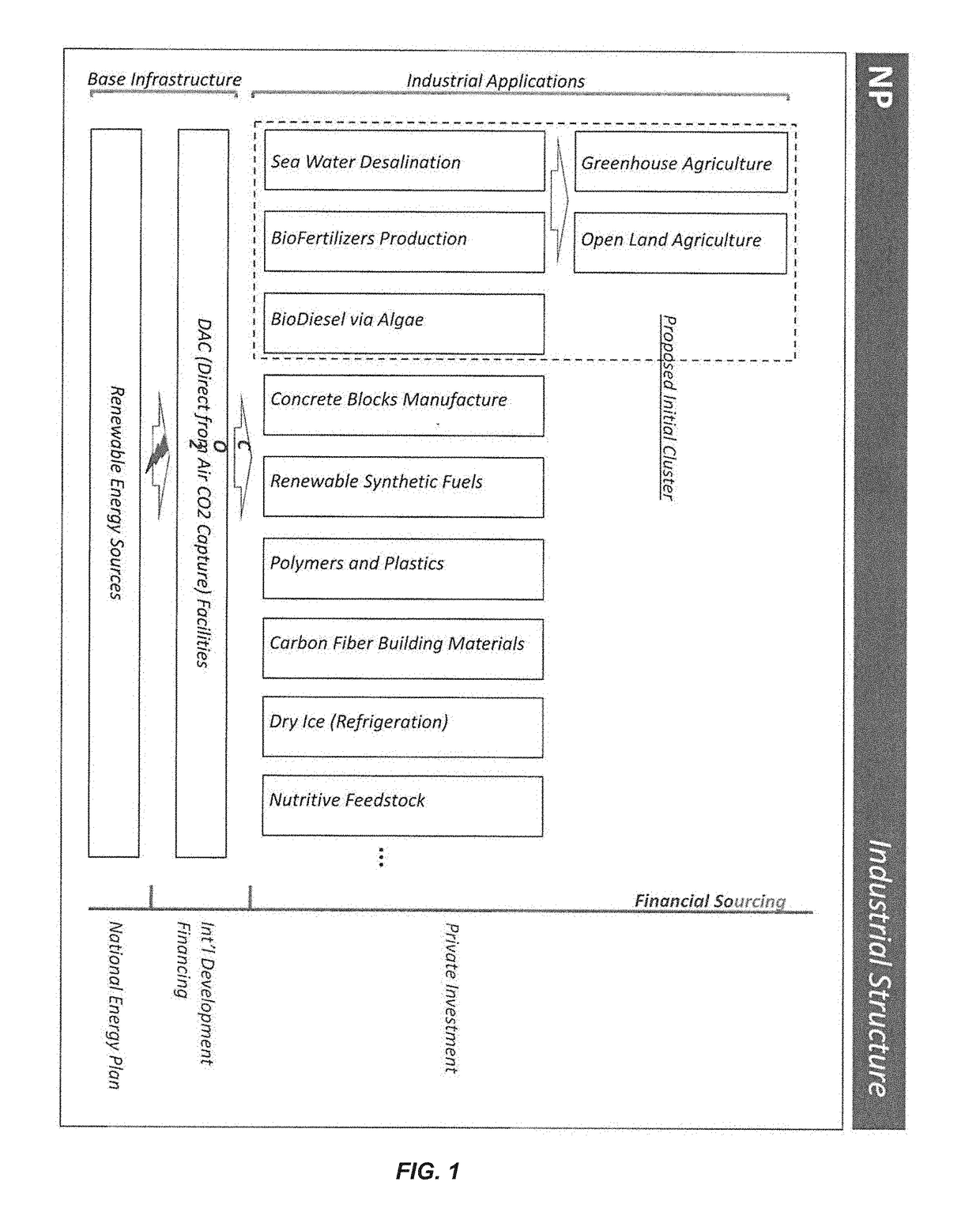

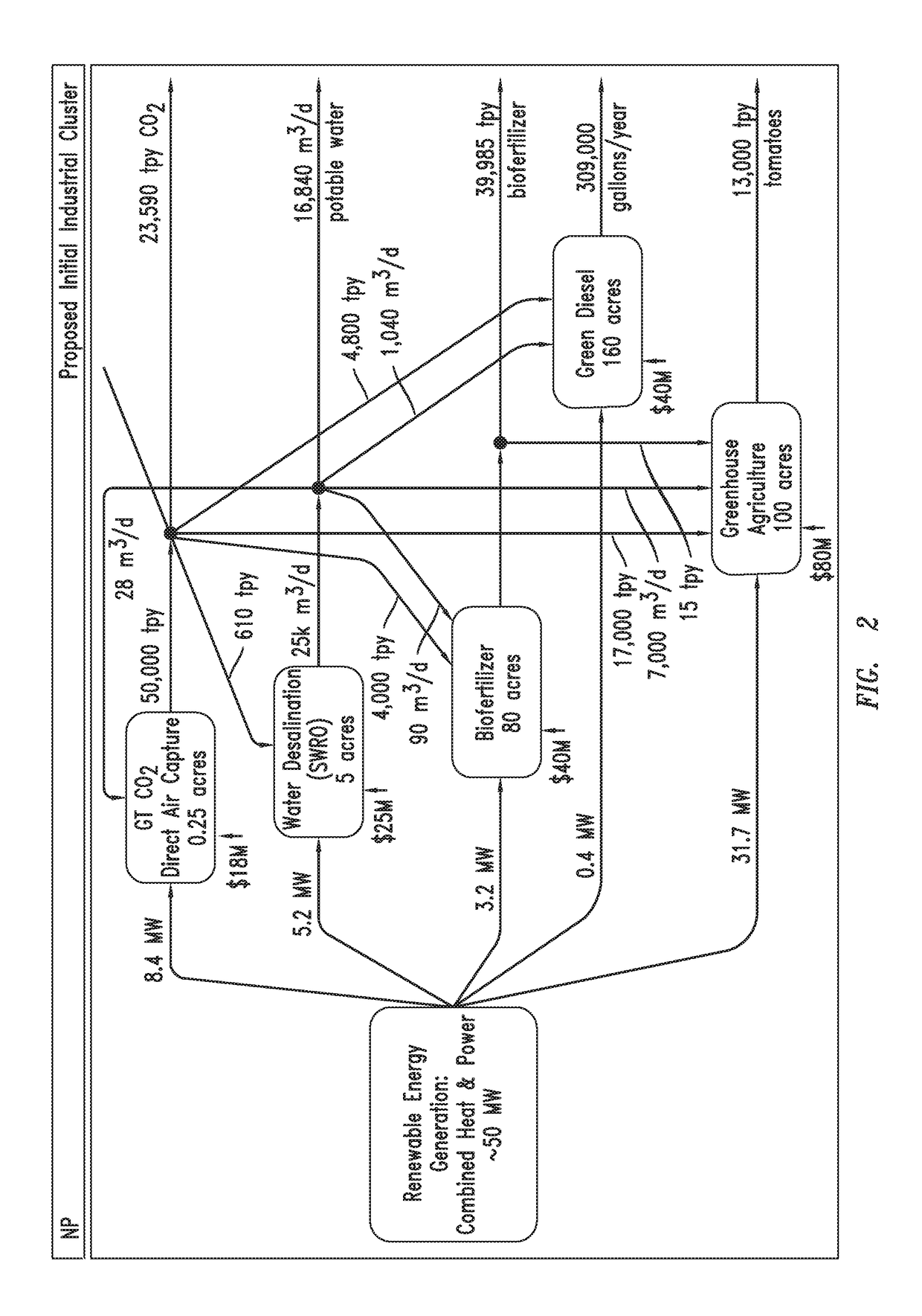

Renewable energy-driven carbon cycle economic and ecological operating systems

InactiveUS20170321656A1Efficient and clean combustionImproving economic well-beingElectrolysis componentsGeneral water supply conservationElectrolysisAtmospheric air

An integrated system for exploiting renewable energy sources based upon carbon dioxide captured from the atmosphere is provided, the system comprising: a solar energy collector; apparatus for capturing CO2 from the atmosphere; a wind power driven electrical generator; water power driven electrical generator; electric power distribution control means from the renewable energy sources; energy storage systems; water desalinating means and water electrolysis means powered by the renewably generated electricity; hydrocarbon fuel preparation means utilizing the hydrogen and the carbon dioxide generated by this system; and a body of saline water adjacent the land on which the integrated system is built.

Owner:GLOBAL THERMOSTAT OPERATIONS LLC

Coal gasification boiler by reverse coal combustion

InactiveCN101382294AEfficient and clean combustionBurn fullyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAutomatic controlBoiler furnace

The invention discloses a novel gasification counter-heating water boiler, which comprises a boiler shell, a boiler furnace, a fire grate, a coal door, a poke door, an ash door, a smoke channel, a chimney and an automatic control device, and is characterized in that: the coal door, the poke door and the ash door are all visible sealed furnace doors with micro positive pressure, and the novel gasification counter-heating water boiler further comprises a circumferential multipoint air distributing device, a wet desulfurizing dust remover of a built-in pipe burying afterheat recycling device, and a smoke gas afterheat recycling air heater. The novel gasification counter-heating water boiler has the advantages of less equipment investment, low running cost, automated operation, 85 percent of the boiler thermal efficiency, low pollutant discharge and boiler modularization, and can be widely used in places needing small-scale heat supply such as residential houses, bath centers, factories, hotels, government agencies and the like.

Owner:QINHUANGDAO JIEMEI BOILERS MFG

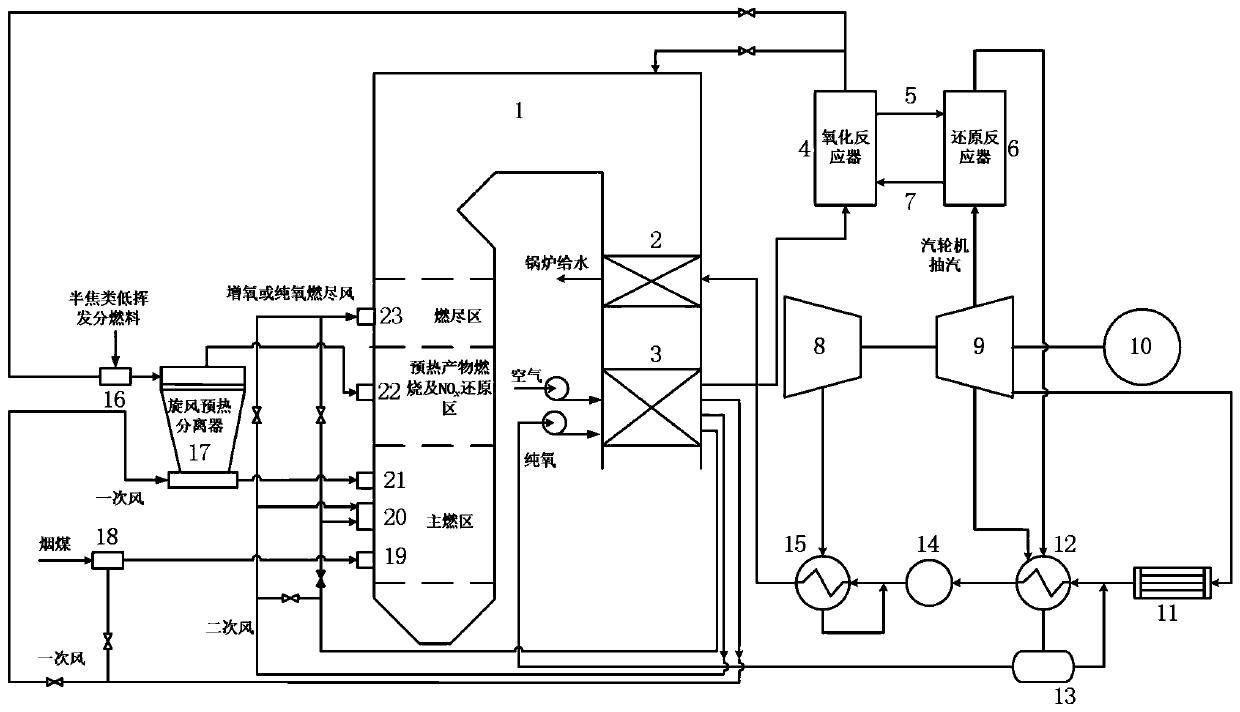

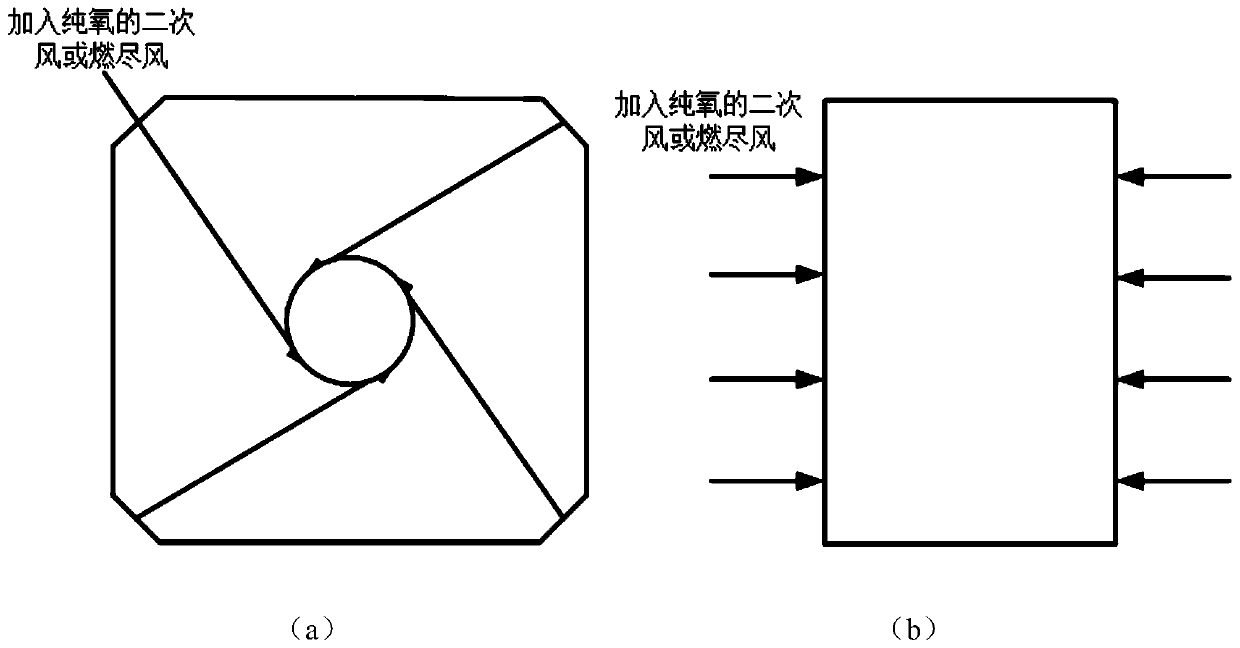

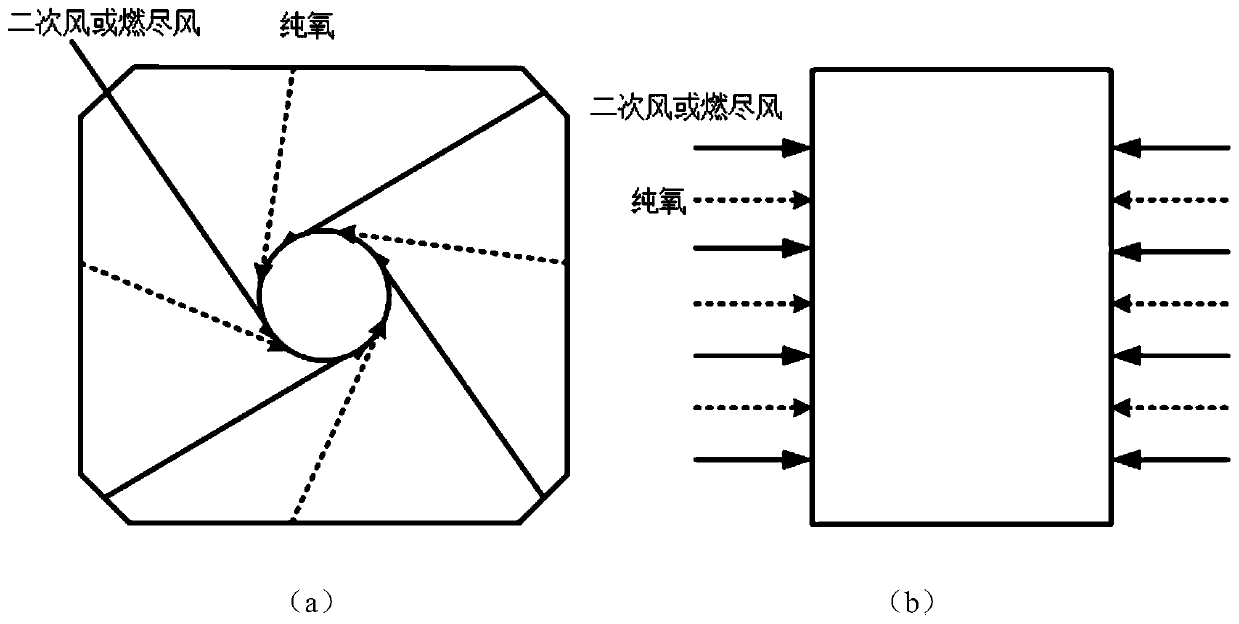

Power station system and method for realizing semi-coke low NOx blended combustion through chemical chain air separation

ActiveCN110360589AExtend NOx reduction lengthImprove combustion efficiencyCombustion using gaseous and pulverulent fuelLiquid fuel feeder/distributionInlet temperatureHigh oxygen

The invention discloses a power station system and method for realizing semi-coke low NOx blended combustion through chemical chain air separation. Oxygenation high-temperature reductive combustion, chemical chain air separation and semi-coke preheating system are mainly included, large proportion, low NOx and high-efficiency mixed combustion of a semi-coke low-volatile fuel with coal in a power station boiler can be realized, and the economic and environmental benefits of a power plant are remarkably improved. An optimized metal oxygen carrier is selected, pure oxygen prepared by a chemical chain air separation principle is fed into a hearth through secondary air or a wall type air nozzle, it is guaranteed that excess oxygen coefficient of a main combustion area is lower than 0.8, and a reductive high-temperature oxygenation area is created; a chemical chain air separation device is utilized to obtain high-temperature oxygen-poor air to preheat the semi-coke fuel, the furnace inlet temperature is increased, and the problem of difficult combustion is solved; combustion air adopts high oxygen concentration air or pure oxygen to improve the combustion efficiency of the fuel; and oxygen generated by a reduction reactor is carried by the extraction steam of a steam turbine and is condensed and separated by a low-pressure heater of the power plant, so that the energy consumption ofan air separation system is greatly reduced.

Owner:XI AN JIAOTONG UNIV

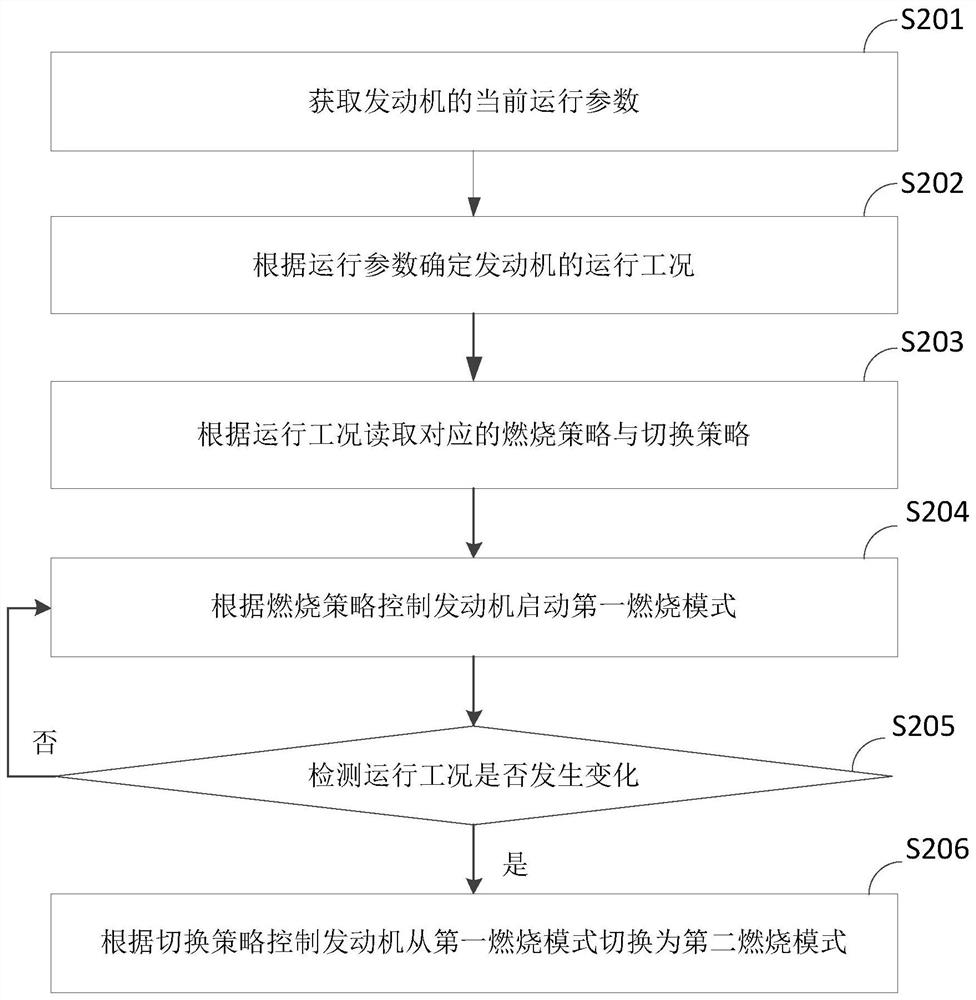

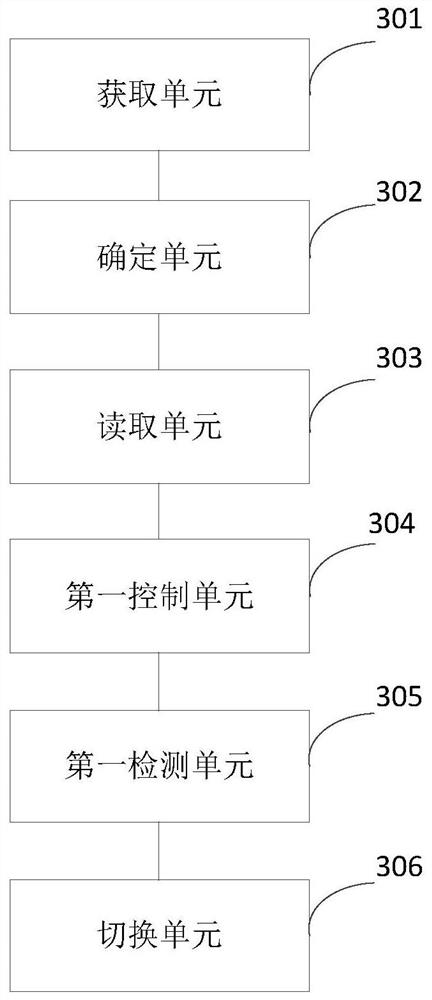

Engine control method and device

PendingCN111980817AEfficient and clean combustionIncrease flexibilityElectrical controlMachines/enginesControl theoryMechanical engineering

The embodiment of the invention discloses an engine control method and an engine. The engine control method specifically comprises the steps that firstly, current operation parameters of the engine are obtained, an operation condition is determined according to the operation parameters, and a corresponding combustion strategy and a switching strategy are read according to the operation condition;and the engine is controlled to start a first combustion mode according to the combustion strategy. Meanwhile, whether the operation condition of the engine changes or not is detected in real time, and if yes, the engine is controlled to be switched from the first combustion mode to a second combustion mode according to the switching strategy. Obviously, when the operation condition of the enginechanges, stable switching of the combustion modes can be achieved according to the pre-configured switching strategy, so that efficient and clean combustion in the full-condition range is achieved, and the flexibility of combustion process control is improved.

Owner:SAIC MOTOR

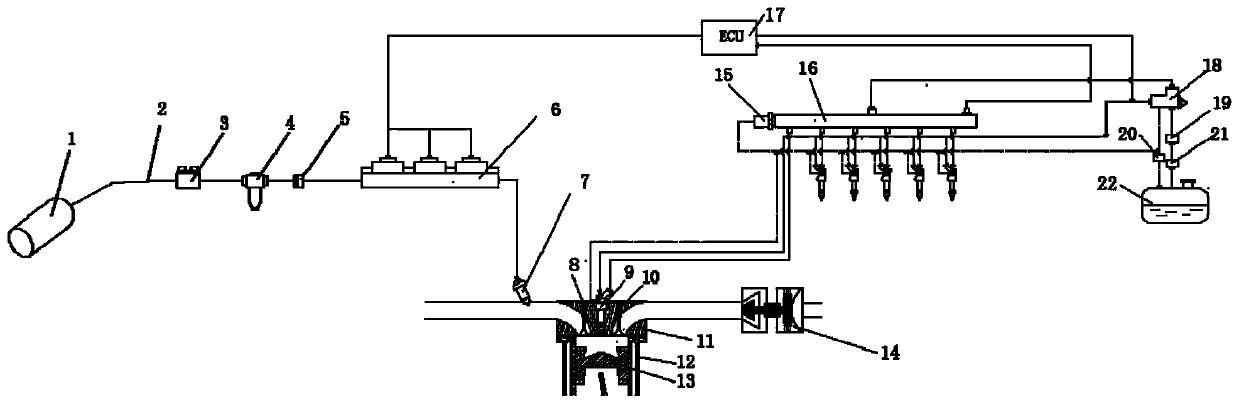

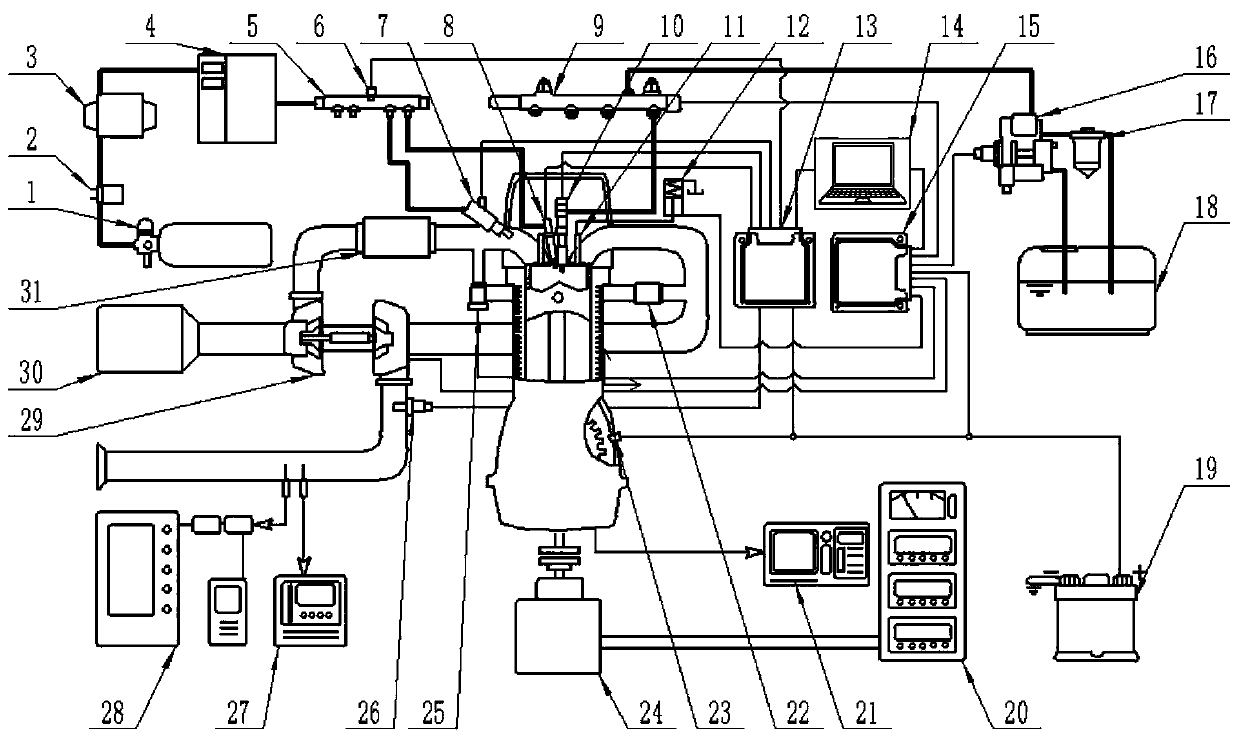

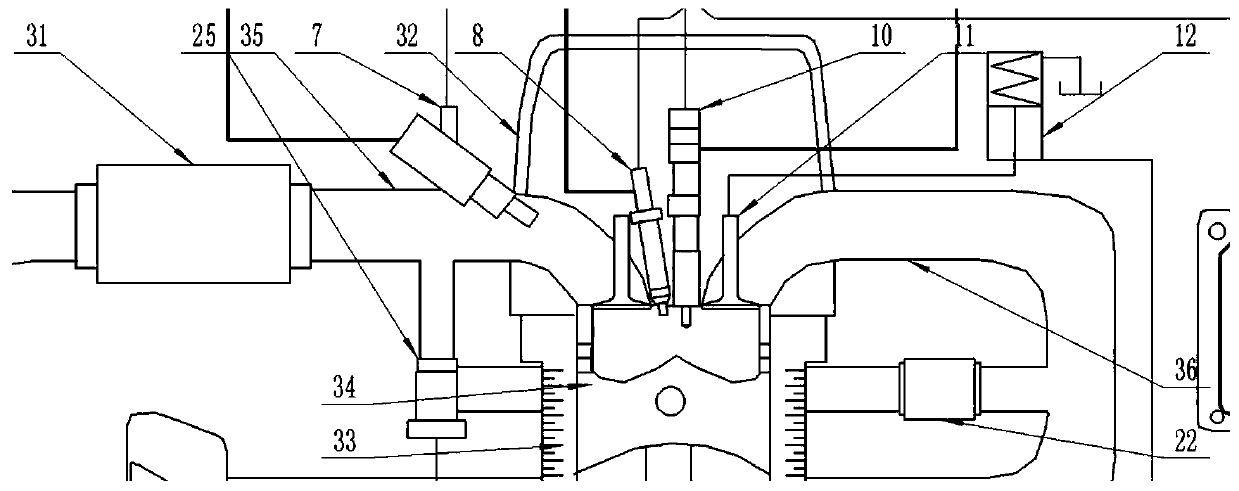

Diesel oil ignition natural gas engine combustion system and control method thereof

PendingCN111472891ARealize regulationFlexible regulationElectrical controlInternal combustion piston enginesTurbochargerIntercooler

The invention relates to a diesel oil ignition natural gas engine combustion system and a control method thereof. The diesel oil ignition natural gas engine combustion system comprises an engine body,a diesel oil inlet system, a natural gas inlet system, a variable cross-section turbocharger VGT, an exhaust gas recirculation system EGR, a variable valve regulator VVT, a dual-fuel ECU, a comprehensive ECU, a computer and a power source, wherein the exhaust gas recirculation system EGR comprises an EGR intercooler and an EGR valve. According to the system, according to different operation conditions of an engine, accurate control over the fuel gas amount is achieved through strategies of adjusting a gas channel and gas injection of a gas injection valve in a cylinder, mixed gas with different filling amounts and layering states is formed in the cylinder, thermodynamic state control is coupled on the basis, through combined control of the variable valve regulator VVT and the exhaust gasrecirculation system EGR and cooperation of different equivalent ratios, stable ignition and controllable stratified combustion under various working conditions are achieved, the natural gas replacement ratio of a dual-fuel engine is further increased, and efficient and clean combustion within a wider working condition operation range is achieved.

Owner:KUNMING UNIV OF SCI & TECH

Treatment process of agricultural and forest waste

InactiveCN109022092AAbundant resourcesSimple methodBiofuelsSolid fuelsMaterial resourcesEnergy conservation

The invention discloses a treatment process of agricultural and forest waste. The process comprises the following steps of S1, performing coarse crushing on agricultural and forest waste; crushing theagricultural and forest waste to the particle diameter being below 2mm; S3, soaking the materials crushed to the state with the particle diameter being smaller than 2mm into hot water being 60 to 70DEG C for 10 to 12h; performing press filtering by a plate-and-frame filter press; putting the materials into a fermentation pool; S3, adding biomass carbon powder into materials subjected to anaerobic fermentation treatment in the step S2; after the uniform stirring, isolating the air for continuous fermentation for 10 to 20 days; performing deodorization and drying to obtain a mixture A; S4, adding additives, bentonite and anti-coking additives into the mixture A; then, performing uniform mixing to obtain a mixture B; ensuring the water content of the mixture B to be within 15 percent; performing extrusion shaping by using an extrusion shaping machine; performing drying to obtain biomass fuel. The agricultural and forest waste is a resource capable of being regenerated and utilized; theraw material resources are rich; the energy source saving is facilitated by using the agricultural and forest waste solid type regeneration clean fuel; the problem of energy source shortage is solved.

Owner:滁州三丰科技有限公司

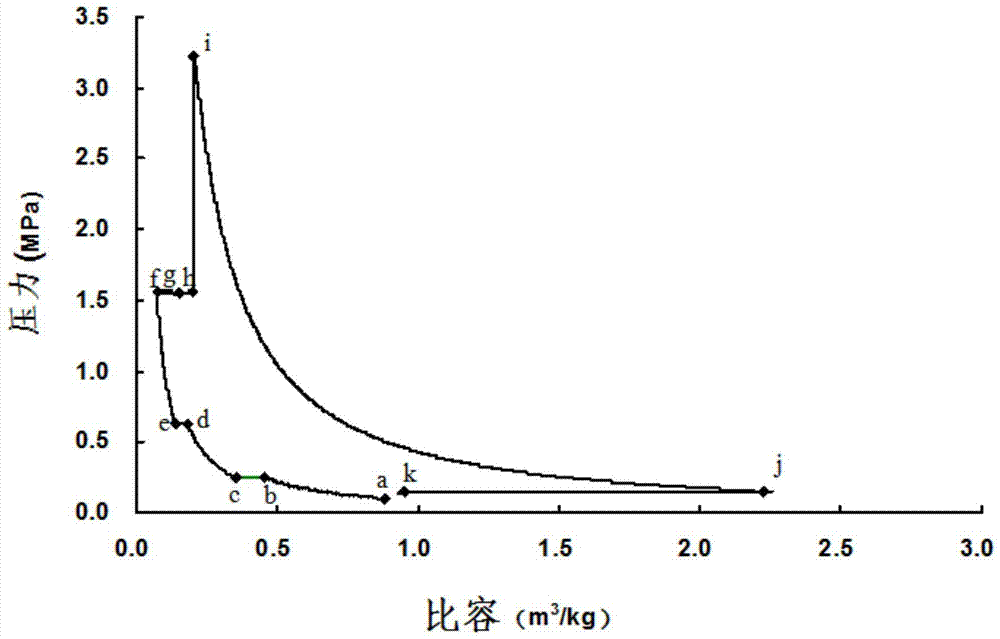

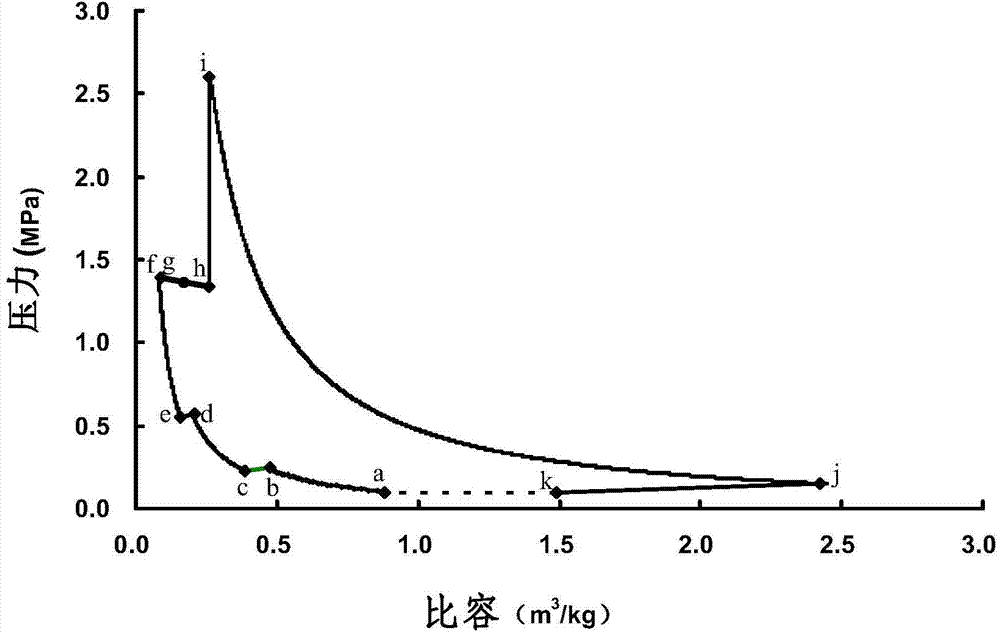

Thermodynamic cycle method for prime mover on basis of correct timing constant volume combustion mode

ActiveCN103939229AImprove thermal efficiencyReduce heat loadInternal combustion piston enginesRotary piston enginesThermal energyMechanical energy

The invention provides a thermodynamic cycle method for a prime mover on the basis of a correct timing constant volume combustion mode. In thermodynamic cycle, a multistage compression interstage cooling process, a countercurrent flow heat exchange process, a correct timing constant volume combustion process and an adiabatic expansion process are included, and thermal energy is converted into mechanical energy in the thermodynamic cycle. Compression power consumption is reduced through the multistage compression interstage cooling process; through the countercurrent flow heat exchange process, enthalpy of working media to be exhausted to the external environment originally is recycled and used for the thermodynamic cycle, and the utilization rate of the thermal energy is improved; through the correct timing constant volume combustion process, long-time uniform low-temperature constant volume combustion is achieved, generation of harmful pollutants such as HC, CO, PM and NOx is effectively suppressed, and meanwhile combustion efficiency is improved; through the adiabatic expansion process, pressure after expansion is approximate to ambient pressure, and work is fully done in an expanding mode. The method provides orientation for design of efficient low pollutant emission and high-performance prime movers in future.

Owner:GREEN ENERGY HIGH TECH GRP +5

Method for obtaining stale cold flame through adding O3 and CH3OH

InactiveCN105114974AEfficient and clean combustionAvoid knockingCombustion using multiple fuelsIndirect carbon-dioxide mitigationEngineeringCombustion process

The invention provides a method for obtaining stale cold flame through adding O3 and CH3OH, and aim to provide a method for stabilizing cold flame having fuel applicability, provide conditions of measurement on the structure of cold flame, temperature and concentrations of components, and establish base to research on rules of generation, end and fluctuation of cold flame. The combustion can be controlled through adjusting the proportions of O3 and CH3OH.

Owner:CHONGQING UNIV

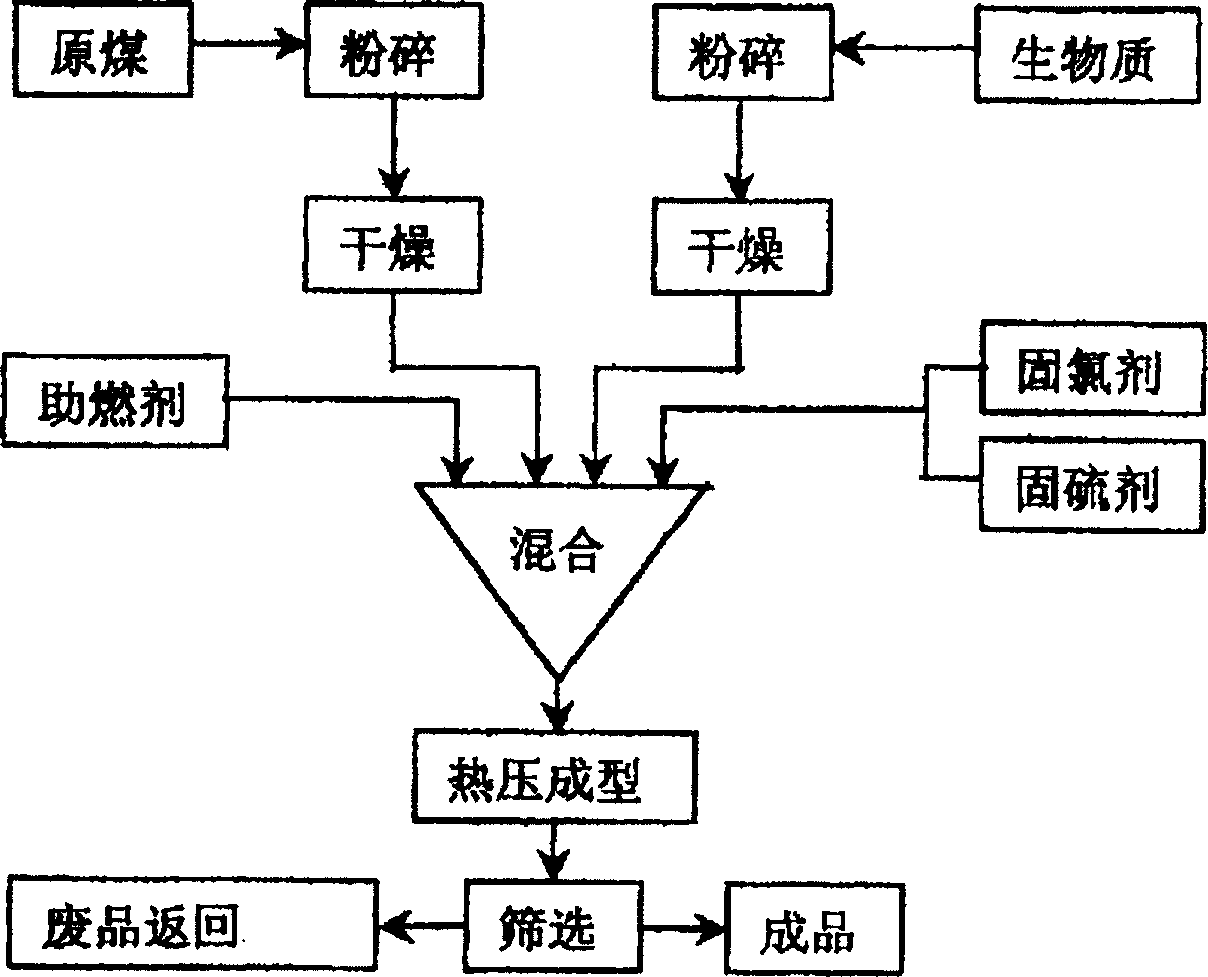

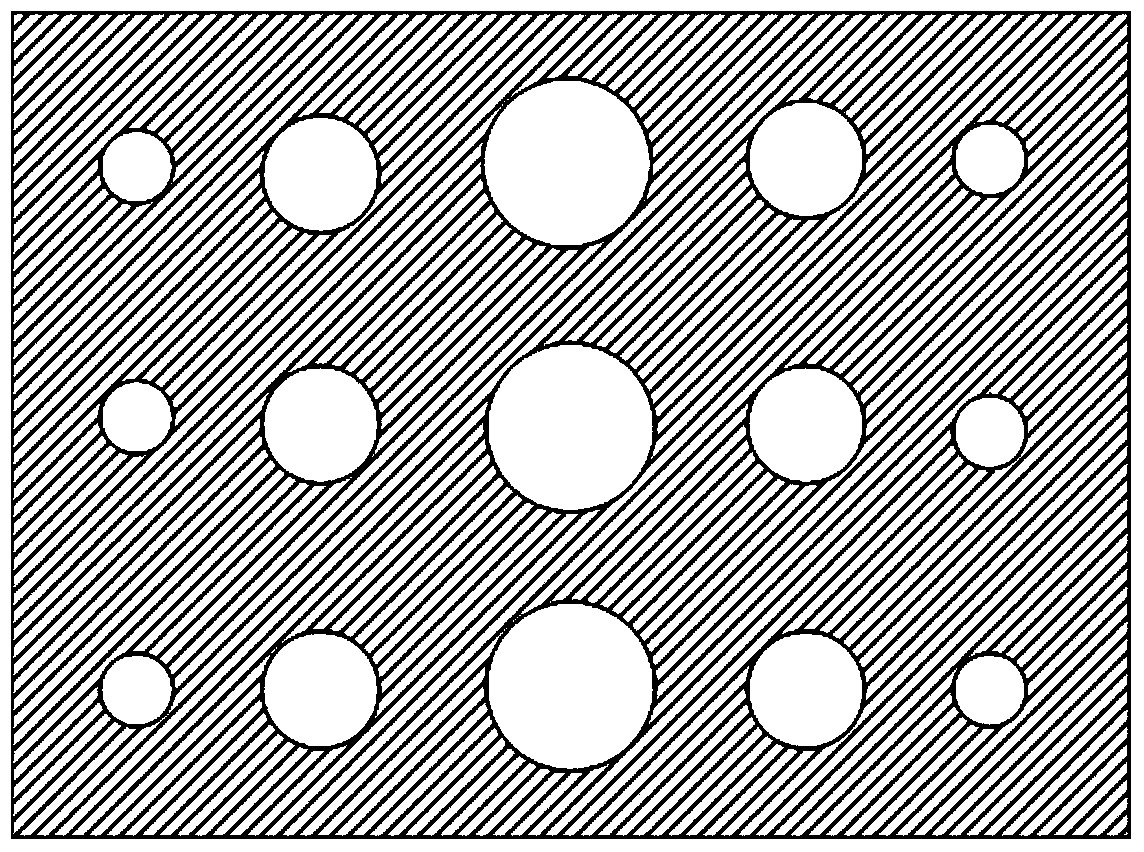

Process for preparing composite biomass briquettes

InactiveCN1236027CHigh compressive strengthSuitable for long distance transportationBiofuelsSolid fuelsForest industryCombustion

A composite biomass briquette is made up of biomass including stalk or straw, wood leftover, city household garbage and raw coal through crushing, mixing with chlorine fixating agent, sulfur fixating agent and combustion promoter, and hot die pressing. Its advnatages are high compression strength, low combustion point, high combustion efficiency and less environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

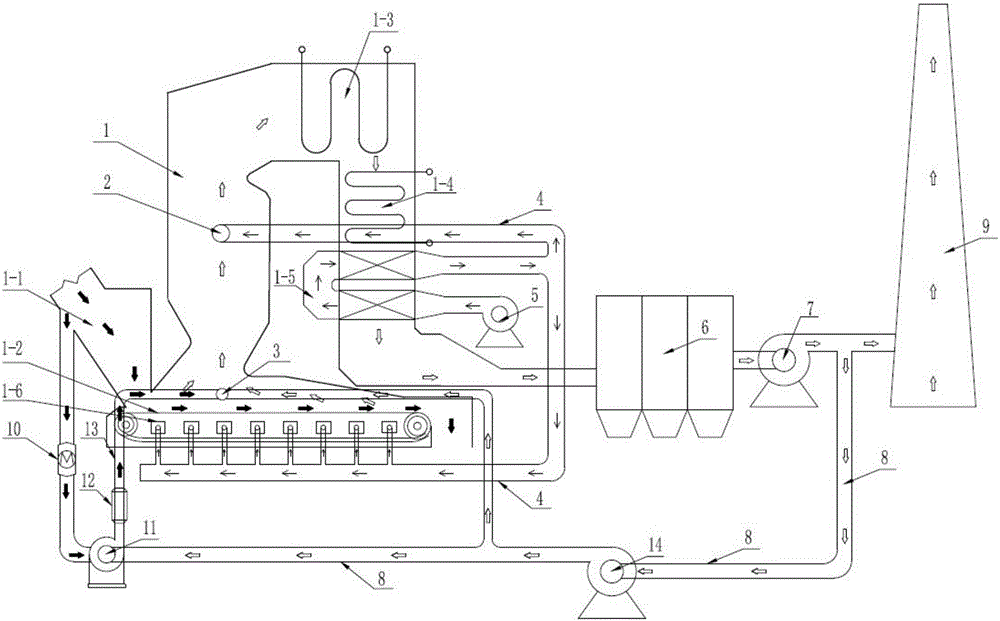

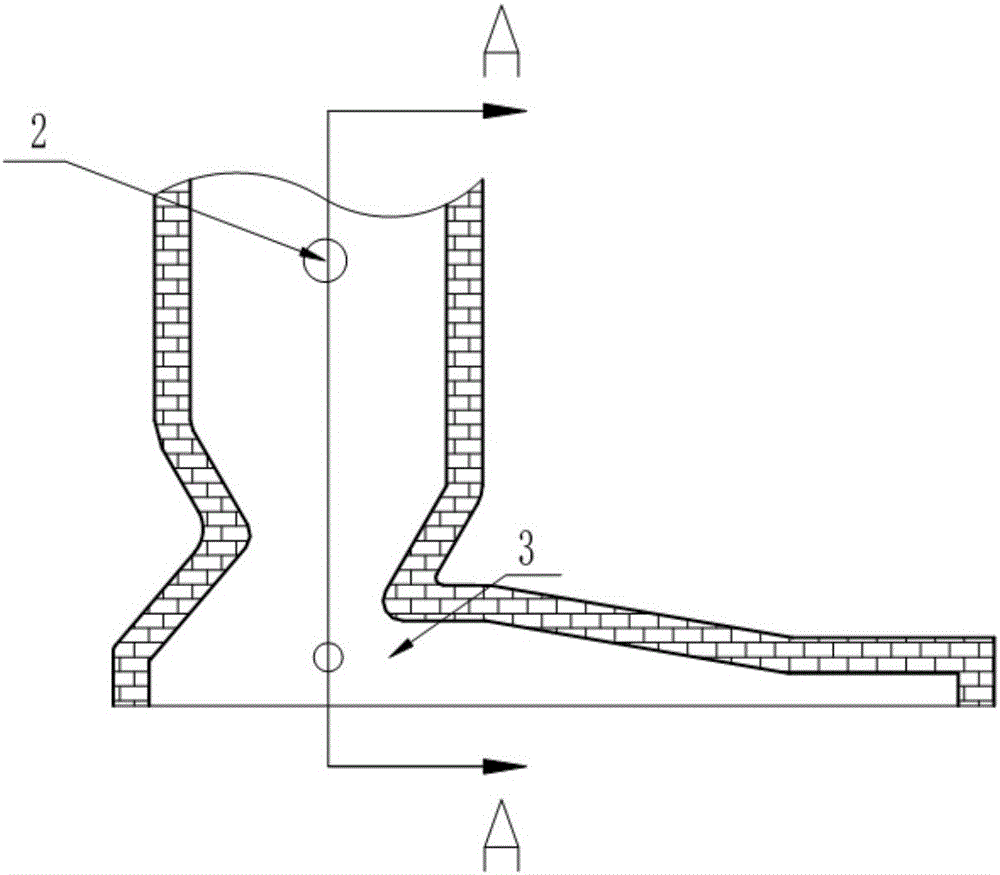

Municipal sludge-coal water slurry co-fired organic working medium boiler

InactiveCN103528054AEmission reductionEfficient and clean combustionFluidized bed combustionIncinerator apparatusCoal waterCombustion chamber

The invention discloses a municipal sludge-coal water slurry co-fired organic working medium boiler which comprises an air distribution device, a combustion chamber, a vortex separation burnout device and a tail convection heating surface component, wherein the combustion chamber is divided into a dense-phase zone and a dilute-phase zone; the air distribution device is provided with an air distribution plate; vent holes are formed in the air distribution plate; the vent holes are sequentially arranged from the middle to the edge of the air distribution plate, and the areas of the vent holes are gradually reduced; the dense-phase zone is of an inverted landing-shaped structure, and a buried pipe is arranged in a return flow zone of the dense-phase zone; water cooling walls are arranged around the dilute-phase zone; the vortex separation burnout device is arranged at the upper part of the dilute-phase zone; the tail convection heating surface component is arranged at the rear part of the vortex separation burnout device; the organic working medium boiler adopts the municipal sludge-coal water slurry mixed fuel. According to the municipal sludge-coal water slurry co-fired organic working medium boiler disclosed by the invention, the application range of the municipal sludge is widened, and the use cost of the organic working medium boiler is lowered.

Owner:SHANGHAI JIAO TONG UNIV

Efficient oxygen-enriched-combustion multiple-unit-powder heat transfer oil boiler system

InactiveCN103225881AFast ignitionIncrease temperatureFuel supply regulationStorage heatersCombustion chamberCombustor

The invention relates to an efficient oxygen-enriched-combustion multiple-unit-powder heat transfer oil boiler system, and belongs to the technical field of heat transfer oil equipment. The efficient oxygen-enriched-combustion multiple-unit-powder heat transfer oil boiler system comprises an air inlet system, a burner and a boiler body, wherein the boiler body comprises a combustion chamber as well as a radiation heat-exchange surface and a convection heat-exchange surface, which adopt exhaust pipe structures, and are arranged in series on the outer wall of the combustion chamber; the burner is communicated with the combustion chamber; the air inlet system comprises a primary air inlet device, a secondary air inlet device and a tertiary air inlet device; the primary air inlet device and the secondary air inlet device are both connected to the burner; the primary air inlet device is put in from the middle part of the burner; the secondary air inlet device is put in from bottom of the burner; and the tertiary air inlet device is arranged in the middle of the side wall of the combustion chamber and used for directly supplying wind for the combustion chamber. The efficient oxygen-enriched-combustion multiple-unit-powder heat transfer oil boiler provided by the invention has the advantages of high automatic degree, high heat efficiency and the like.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Biomass-coal water slurry co-fired organic working medium boiler

InactiveCN103528049AEfficient and clean combustionGood load regulation performanceFluidized bed combustionApparatus for fluidised bed combustionCoal waterMixed fuel

The invention discloses a biomass-coal water slurry co-fired organic working medium boiler which comprises an air distribution device, a combustion chamber, a vortex separation burnout device and a tail convection heating surface component, wherein the combustion chamber is divided into a dense-phase zone and a dilute-phase zone; the air distribution device is provided with an air distribution plate; the air distribution plate is of a V shape; vent holes are formed in the air distribution plate; the vent holes are sequentially arranged from the middle to the edge of the air distribution plate, and the areas of the vent holes are gradually reduced; the dense-phase zone is of an inverted landing-shaped structure, and a buried pipe is arranged in a return flow zone of the dense-phase zone; water cooling walls are arranged around the dilute-phase zone; the vortex separation burnout device is arranged at the upper part of the dilute-phase zone; the tail convection heating surface component is arranged at the rear part of the vortex separation burnout device; the organic working medium boiler adopts the biomass-coal water slurry mixed fuel. According to the biomass-coal water slurry co-fired organic working medium boiler disclosed by the invention, the application range of the biomass fuel is widened, and the use cost of the organic working medium boiler is lowered.

Owner:SHANGHAI JIAO TONG UNIV

Solid fuel burning stove

InactiveCN106524132AEfficient and clean combustionAvoid black smokeSolid fuel combustionCombustion apparatusCombustion chamberSolid fuel

The invention provides a solid fuel burning stove which comprises a solid sequential burning chamber (1), a heat storage channel (2) and a gas state burning chamber (3). A heat storage channel inlet (21) is formed in the position, higher than a grate (12), of one side of the lower portion of the solid sequential burning chamber, and therefore a reversal-burning area (16) is formed above the heat storage channel inlet (21) of the fuel solid sequential burning chamber, a burning area (17) is formed below the heat storage channel inlet (21) of the solid sequential burning chamber, and a solid-gas separation area is formed at the heat storage channel inlet (21). Air inlet holes (23) are formed in the peripheral wall of the heat storage channel. By adoption of the solid fuel burning stove, cleaning and efficient burning of all kinds of solid fuels can be achieved.

Owner:杨德山

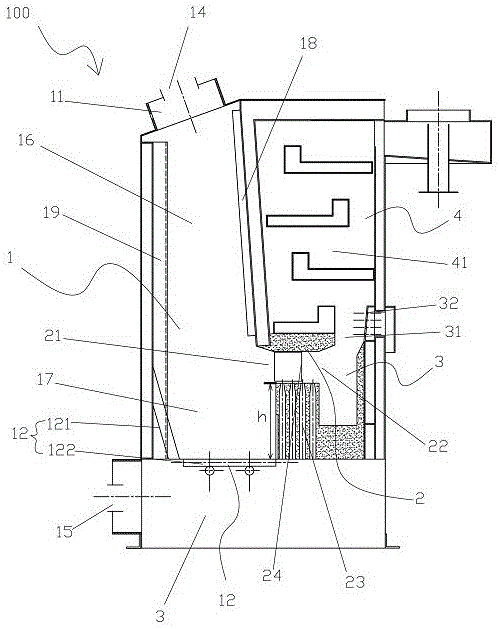

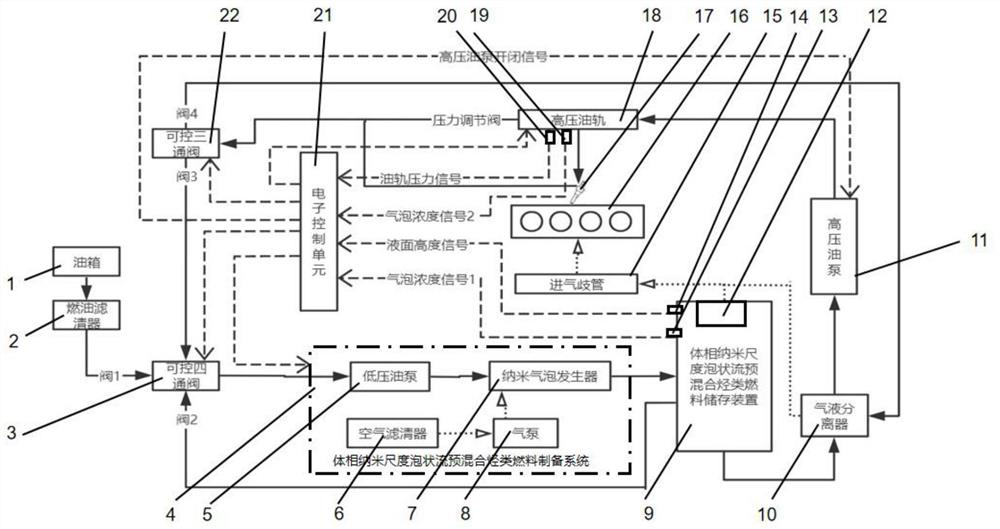

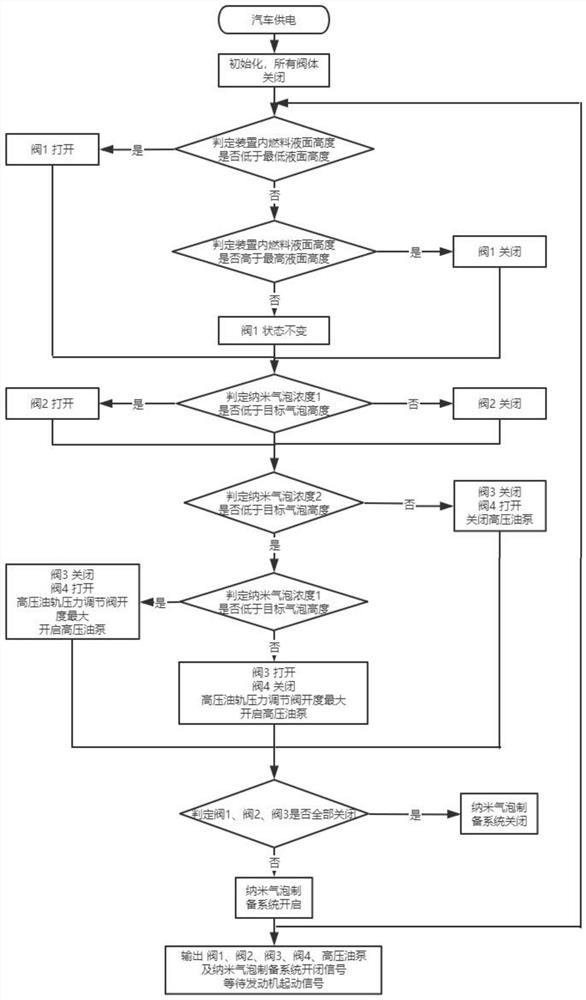

Bubble flow premixed hydrocarbon fuel preparation and supply system and control method thereof

PendingCN113153585AGuaranteed uptimeEfficient and clean combustionElectrical controlNon-fuel substance addition to fuelRail pressureFour-way valve

The invention belongs to the technical field of engine fuel pretreatment and particularly relates to a bubble flow premixed hydrocarbon fuel preparation and supply system and a control method thereof. The bubble flow premixed hydrocarbon fuel preparation and supply system comprises a fuel tank, a fuel filter, a controllable four-way valve, a bulk phase nano-scale bubble flow premixed hydrocarbon fuel preparation system, a bulk phase nano-scale bubble flow premixed hydrocarbon fuel storage device, a second gas-liquid separator, a high-pressure fuel pump, a high-pressure fuel rail, a fuel sprayer, a controllable three-way valve, an electronic control unit, a first bubble concentration sensor, a liquid level height sensor, a second bubble concentration sensor and a fuel rail pressure sensor, wherein an outlet of the fuel tank is connected with an inlet of the fuel filter; the impurities of liquid fuel are filtered; a fuel supply system is prevented from being blocked; the structure is reasonable; the hydrocarbon fuel can be pretreated; the mixing uniformity of the fuel with the air is improved; and the engine fuel combustion process is improved.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com