Power station system and method for realizing semi-coke low NOx blended combustion through chemical chain air separation

A chemical chain and semi-coke technology, applied in chemical instruments and methods, combustion methods, inorganic chemistry, etc., can solve problems such as poor combustion stability and burnout performance, high emissions, and ignition, so as to improve combustion efficiency and reduce NOx generation , Improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

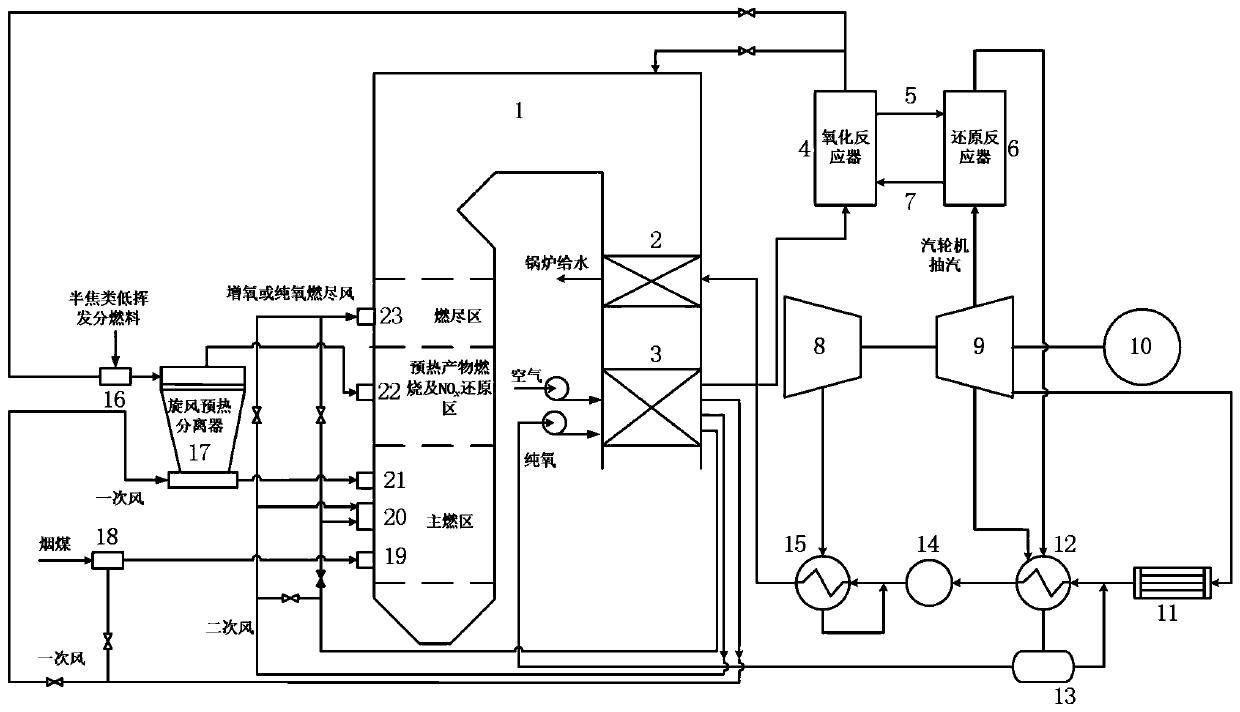

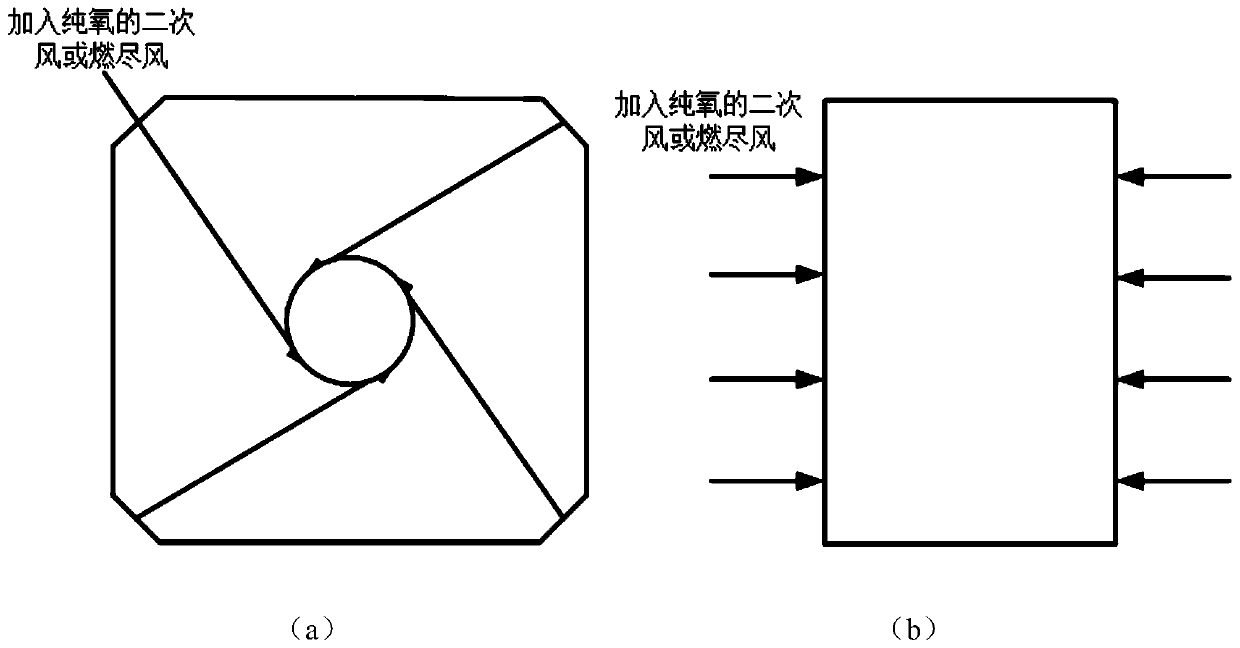

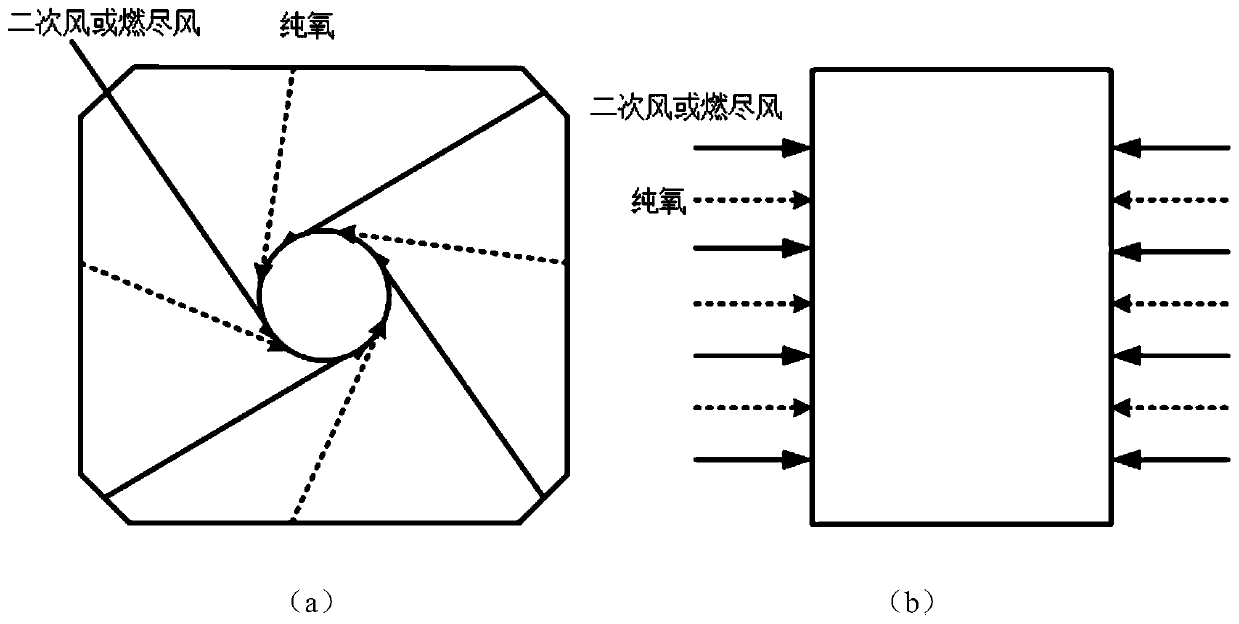

[0035] The purpose of the present invention is to provide a method that can achieve a large proportion of mixed burning semi-coke in power plant boilers, obtain high-temperature oxygen-poor air and high-purity oxygen through chemical chain air separation technology, use high-temperature oxygen-poor air to preheat semi-coke fuel, and convert high-temperature Purity oxygen is injected into the main combustion zone, and under the condition that the excess oxygen coefficient of the main combustion zone is controlled to be lower than 0.8, an oxygen-increasing, high-temperature and strong reducing atmosphere is created, and at the same time, the NO produced during the combustion of semi-coke fuel is solved x High emissions and poor ignition, stable combustion and burnout performance, etc., to achieve large-scale, efficient and clean combustion of semi-coke low-volatile fuels.

[0036] In order to make the purpose, features and advantages of the present invention more obvious and unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com