Engine control method and device

A control method and engine technology, applied in engine control, machine/engine, electrical control, etc., can solve the problems of poor combustion phase control, fuel injection control combustion process, and smooth switching between compression ignition mode and ignition mode, etc., to achieve high efficiency Clean combustion, improved flexibility, and smooth switching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the above objects, features and advantages of the present application more obvious and understandable, the embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

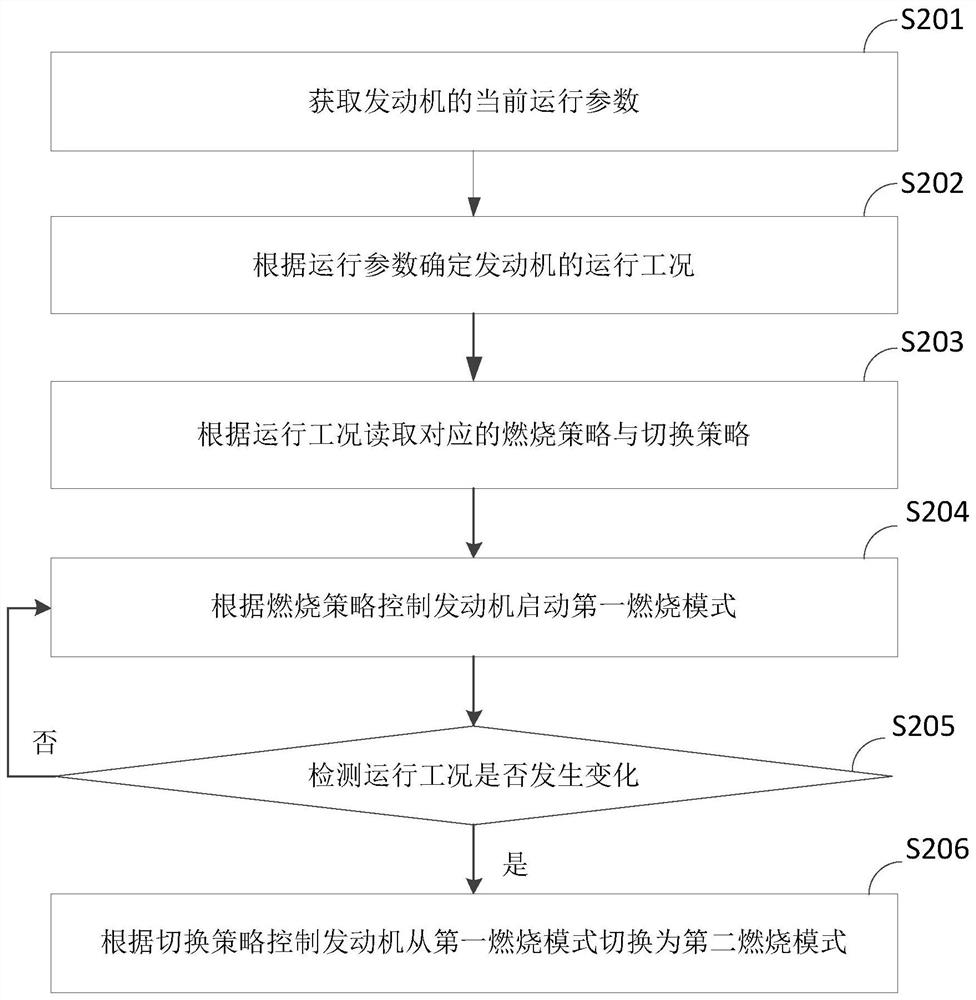

[0062] The inventor found in the research on the traditional control combustion mode switching method that the traditional switching method achieves switching by changing the ratio of two different fuel injections in the intake port, and the response speed of this method is faster. However, since the two nozzles are located in the intake port, the formed mixture is completely homogeneous when inhaled into the cylinder, and the control of the combustion phase is poor.

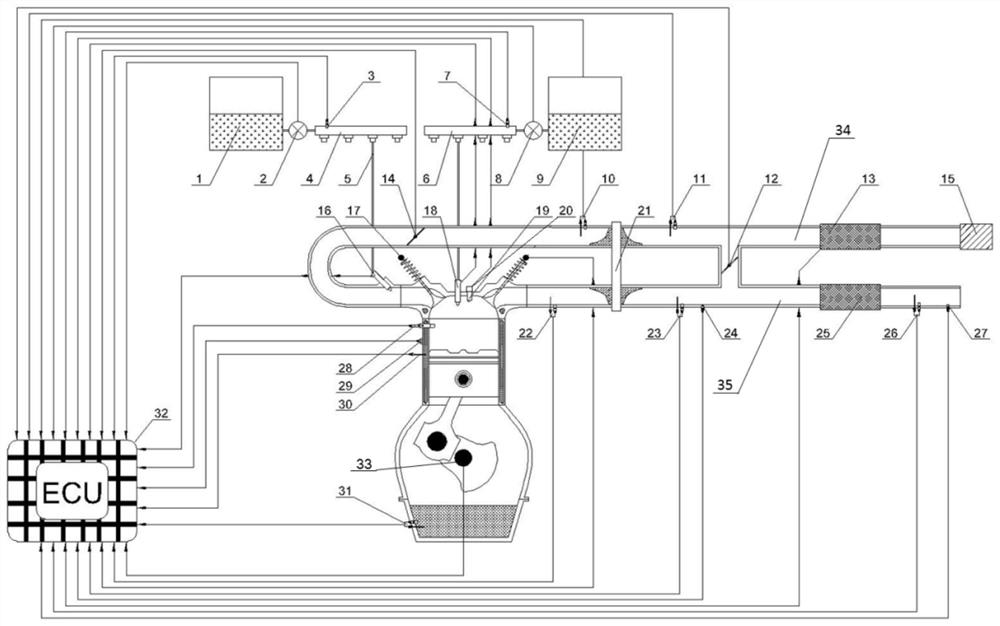

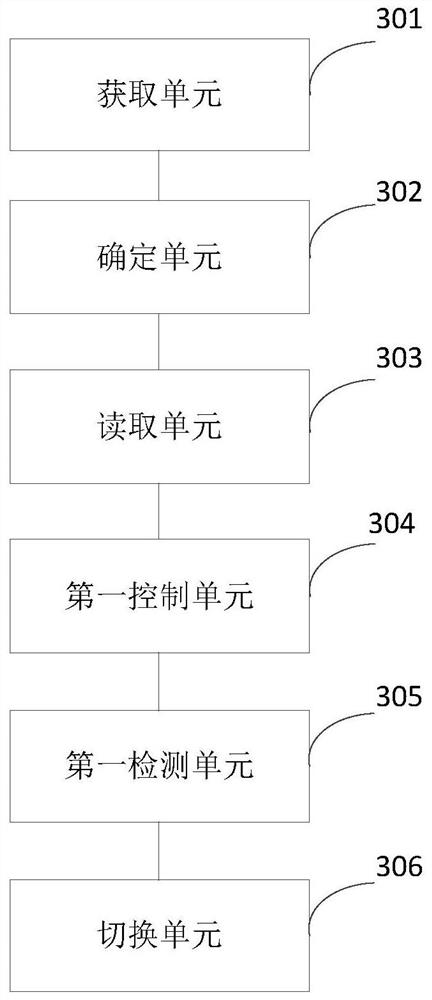

[0063] Based on this, embodiments of the present application provide an engine and a method for controlling the engine. The engine includes components such as an intake port injection system, an in-cylinder direct injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com