Gas turbine combined type fuel evaporating and atomizing combustion apparatus

A fuel atomization and combustion device technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of no fuel primary atomization premixing pre-evaporation process, poor fuel atomization of direct injection nozzles, easy coke accumulation, etc. , to achieve the effect of improving fuel atomization evaporation and blending performance, improving the uniformity of oil-gas spatial distribution, and increasing the gas-phase oil-gas ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

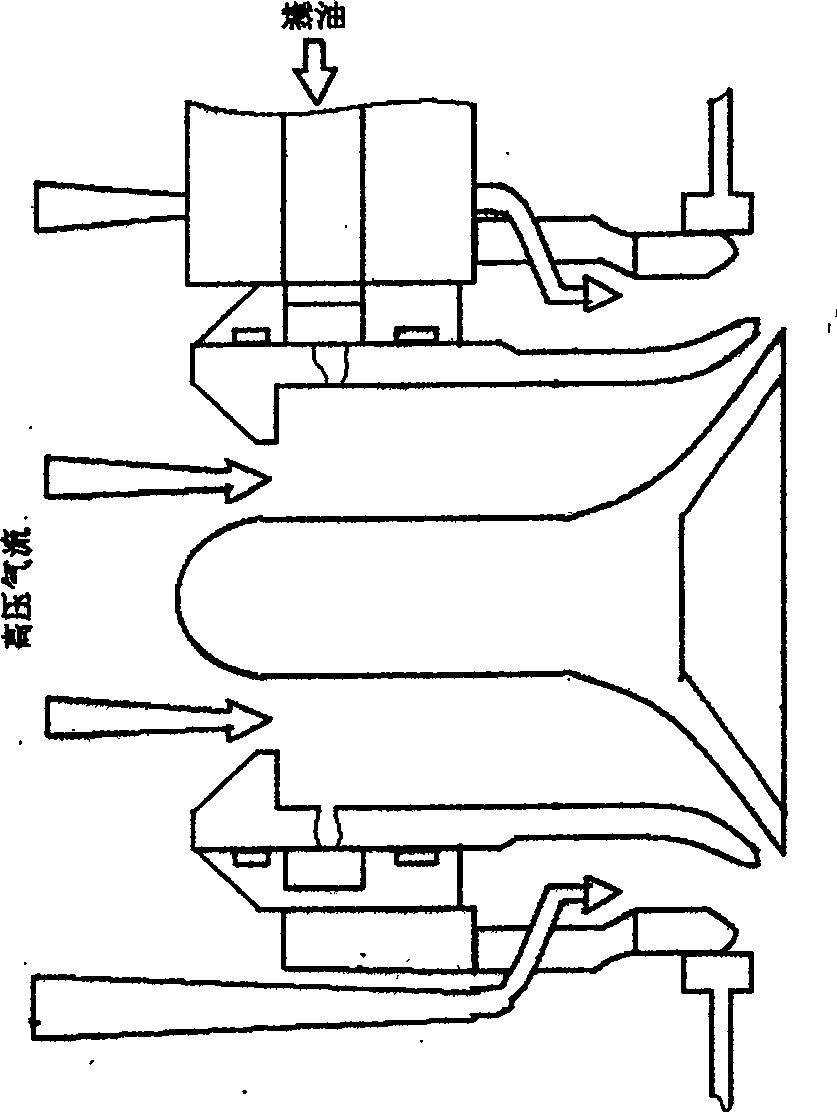

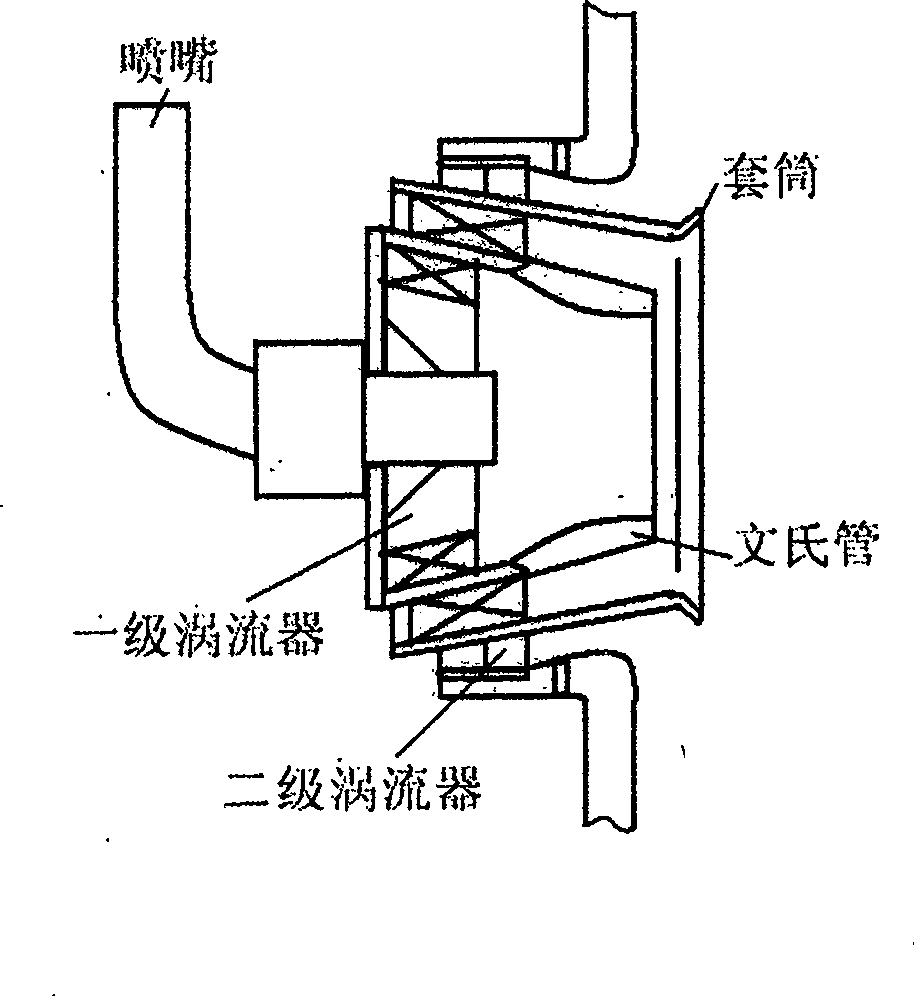

[0057] A combined fuel atomization device for a gas turbine, comprising a nozzle 1, a premixing chamber 2, an evaporator 3, a double swirler 4, a centrifugal nozzle 5, a venturi tube 6, a sleeve 7 and a combustion chamber 8.

[0058] The nozzle 1 refers to the fuel centrifugal spray group or other nozzles (such as atomizing tank nozzles), which are installed at the center of the inlet of the premix chamber 2; A straight pipe with the same diameter, it is in the upstream of the double cyclone 4, and is sealed with the outer end of the double cyclone 4; the evaporator 3 refers to a plurality of thin steel pipes welded in parallel (or a plurality of round pipes set or blunt body, etc.), installed inside the premixing chamber 2, a certain distance upstream is the nozzle, and a certain distance downstream is the double cyclone 4; Composed of cyclones, each cyclone has multiple blades, the inlet and outlet are straight sections, and the middle is connected by an arc. It is installed...

Embodiment 2

[0061] A gas turbine combined fuel atomization evaporation combustion device, including a nozzle 1, a premixing chamber 2, an evaporator 3, an axial swirler 12, a centrifugal nozzle 5, a venturi tube 6, a fixed seat 7, and a radial swirler 8. It is composed of connecting plate 9, sleeve 10 and combustion chamber 11.

[0062] The nozzle 1 refers to the fuel centrifugal spray group or other nozzles (such as atomization tank nozzles), which are installed at the center of the inlet of the premix chamber 2; the premix chamber 2 refers to the 4 straight pipes with the same outer diameter, which are in the upstream of the axial swirler 12 and sealed with the inlet outer end of the axial swirler 12; the evaporator 3 refers to double blunt bodies (or spiral bodies or multiple Thin steel pipes are welded side by side or a plurality of round pipes are set), installed inside the premixing chamber 2, a certain distance upstream is the nozzle, and a certain distance downstream is the axial ...

Embodiment 3

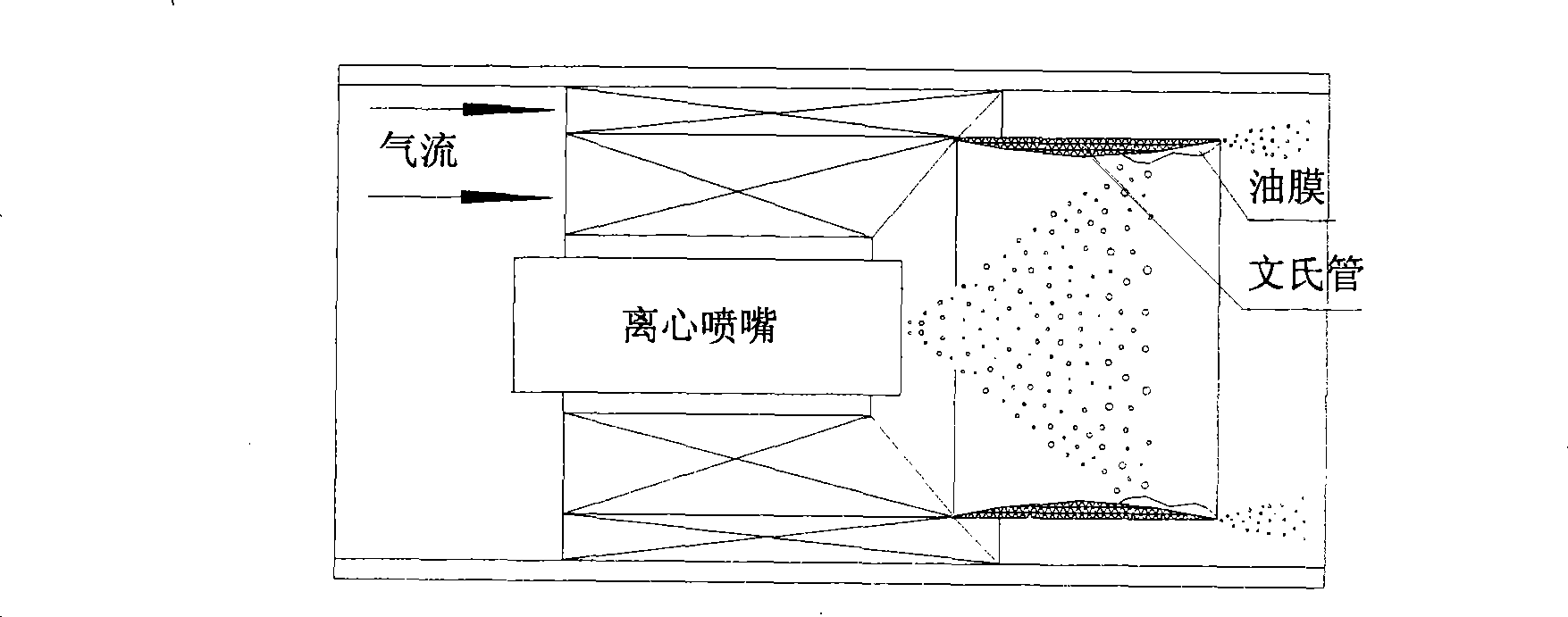

[0064] Embodiment 3: as Figure 5 Shown is a structural schematic diagram of the first scheme of the gas turbine combined fuel atomization evaporation combustion device. It consists of a nozzle 1, a premix chamber 2, an evaporator 3, a double swirler 4, a centrifugal nozzle 5, a venturi tube 6, a sleeve 7 and a combustion chamber 8. The nozzle 1 is installed at the center of the inlet of the pre-mixing chamber 2; Sealed connection; the evaporator 3 is installed inside the premixing chamber 2, the nozzle is a certain distance upstream, and the double cyclone 4 is a certain distance downstream; the double cyclone 4 is installed inside the outlet end of the premixing chamber 2, and is connected with the premixing The chamber 2 is tightly connected, and the centrifugal nozzle 5 is installed at the center of the double swirler 4; the venturi tube 6 is welded at the outlet of the inner and outer swirlers of the double swirler 4, upstream of the combustion chamber 8; the inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com