Patents

Literature

64results about How to "Good blendability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

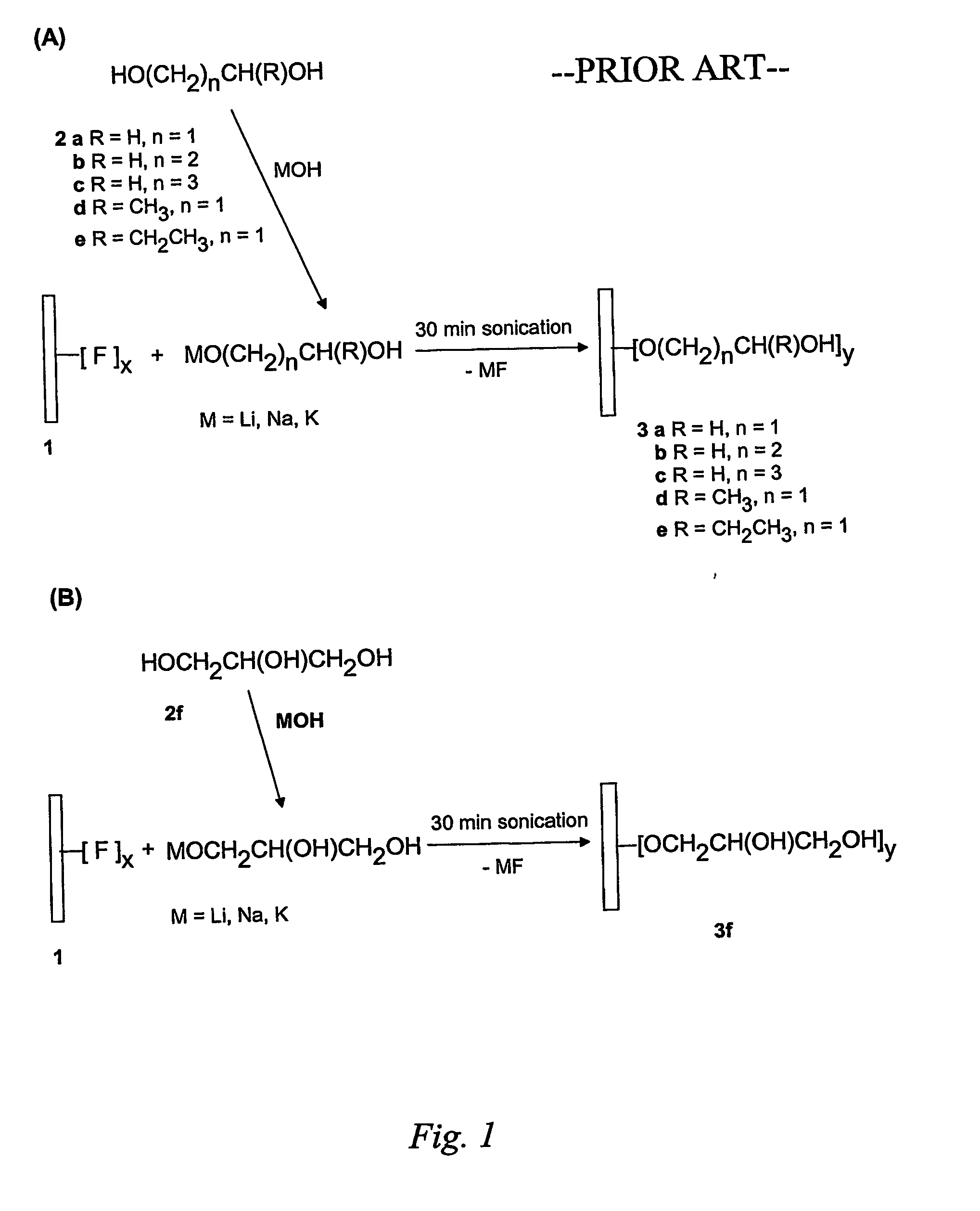

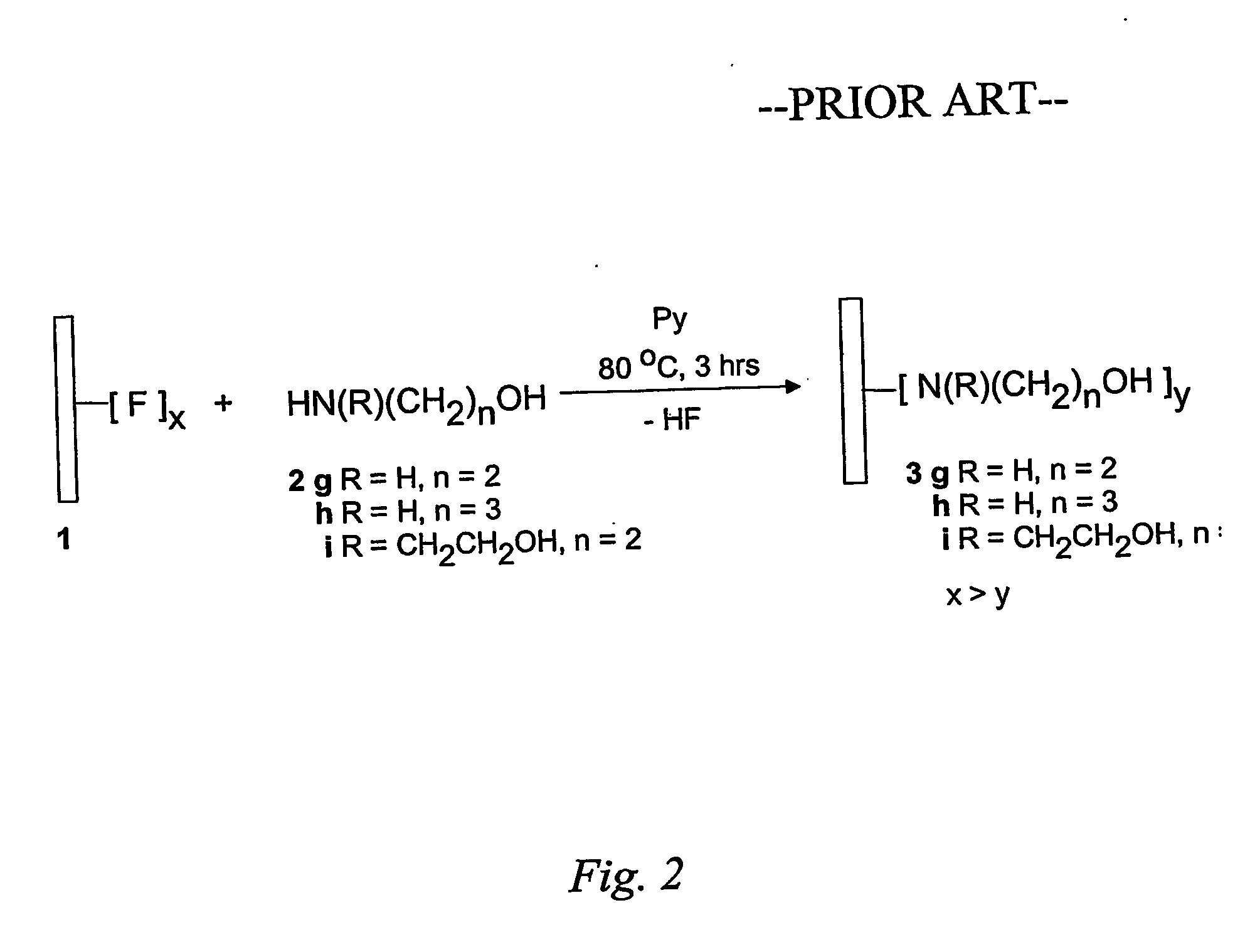

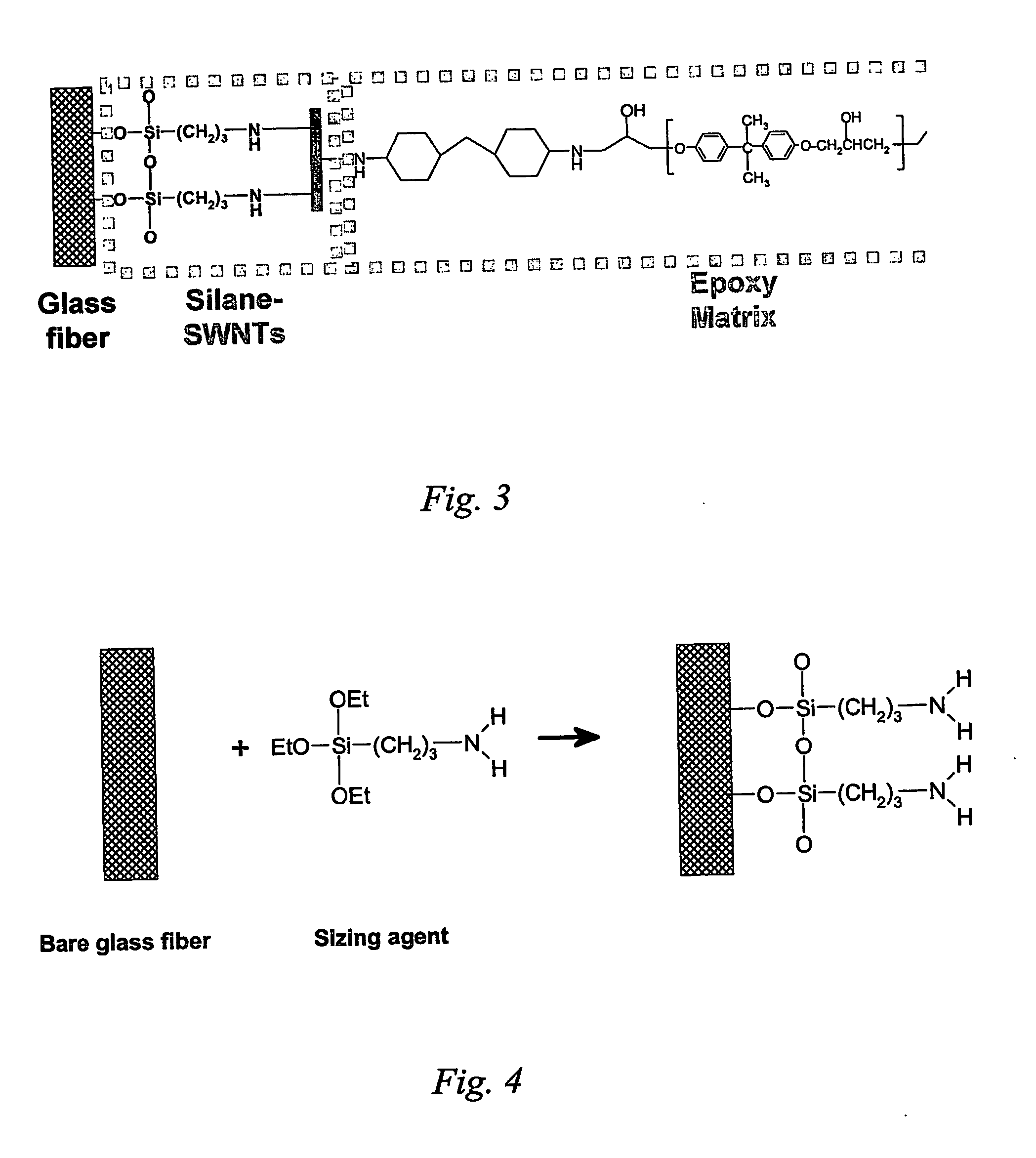

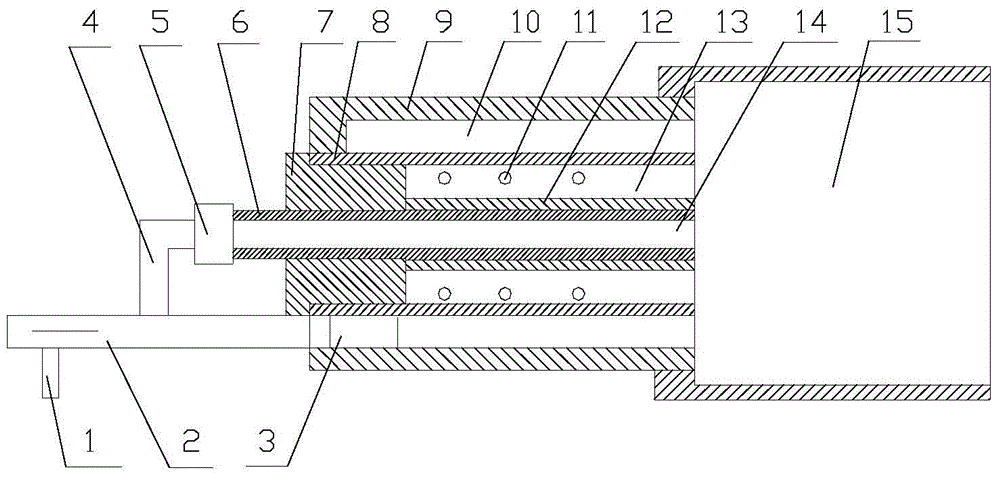

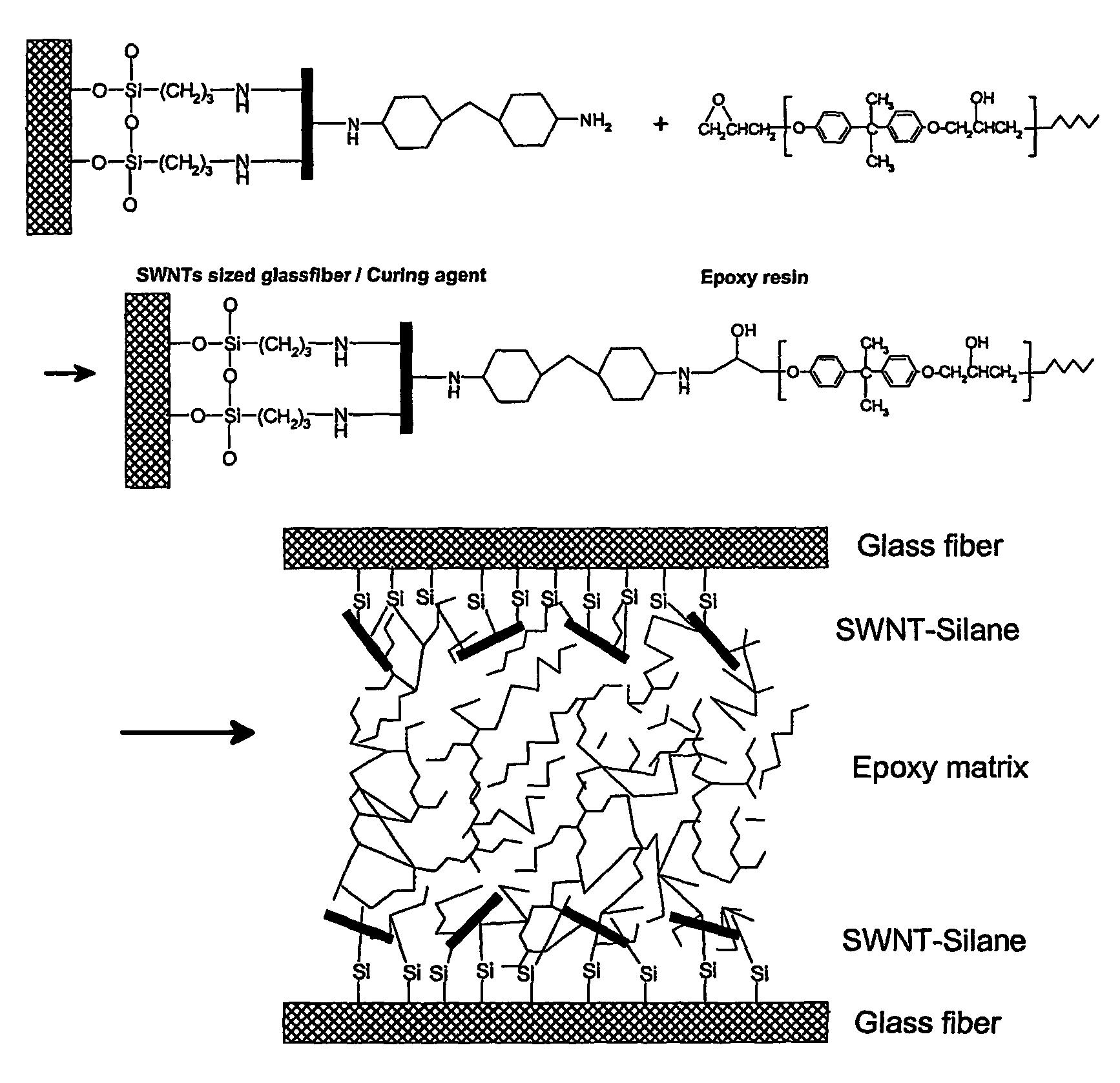

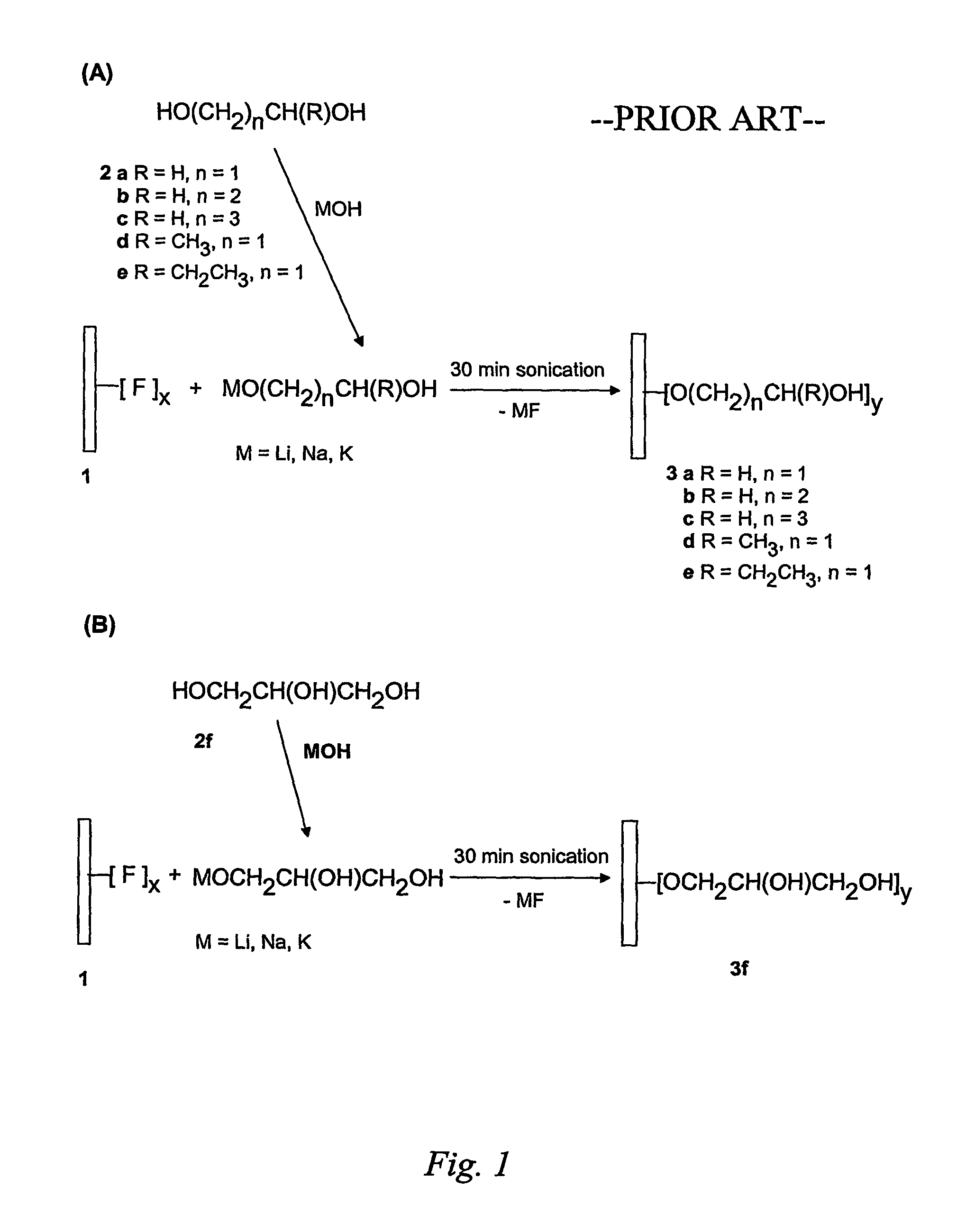

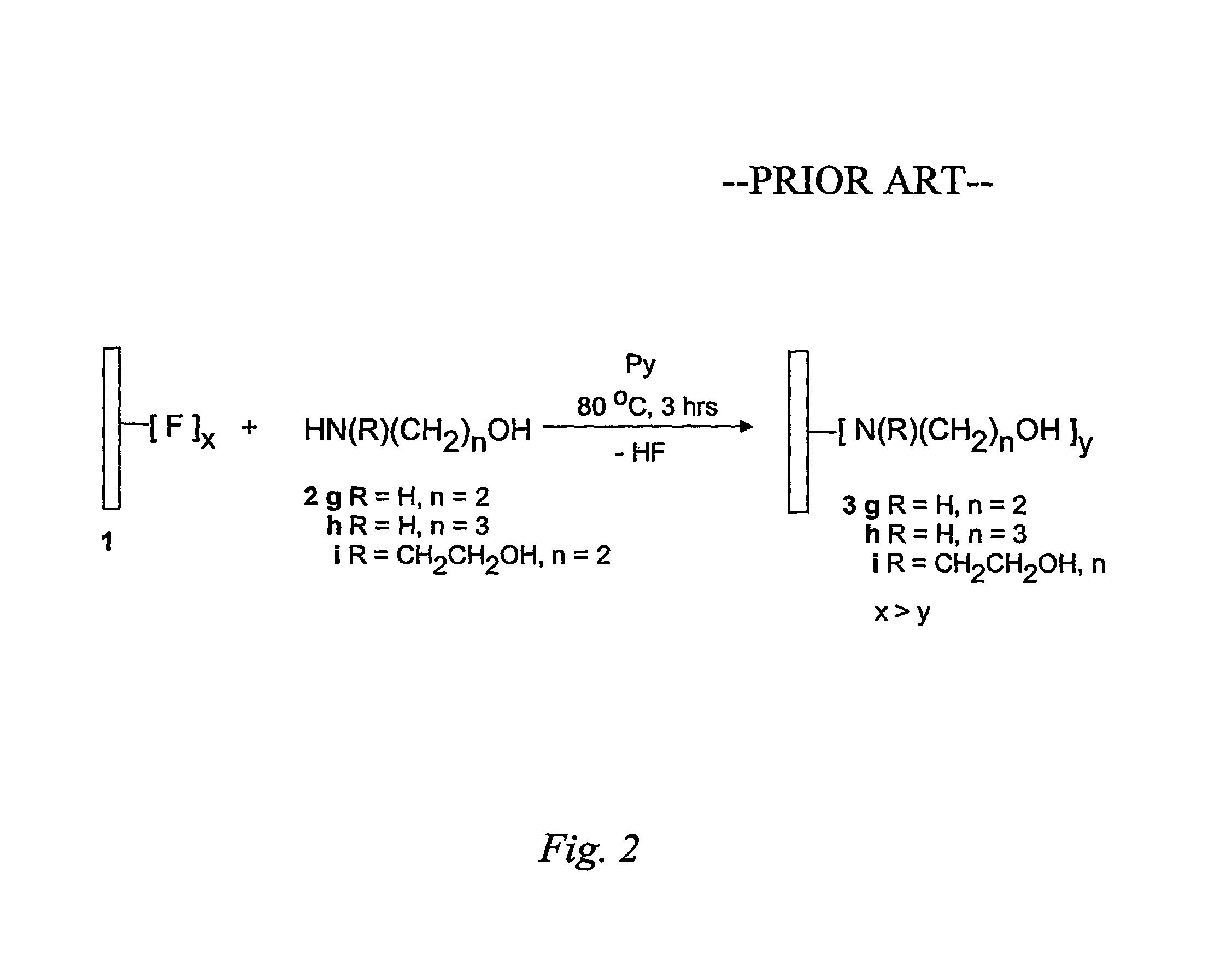

Sidewall Functionalization Of Carbon Nanotubes With Organosilanes For Polymer Composites

InactiveUS20070298669A1Improve the level ofStrong attachmentMaterial nanotechnologySilicon organic compoundsPolymer compositesPolymer chemistry

The present invention is directed to methods of functionalizing carbon nanotubes (CNTs), particularly single-wall carbon nanotubes (SWNTs), with organosilane species, wherein such functionalization enables fabrication of advanced polymer composites. The present invention is also directed toward the functionalized CNTs, advanced CNT-polymer composites made with such functionalized CNTs, and methods of making such advanced CNT-polymer composites.

Owner:RICE UNIV

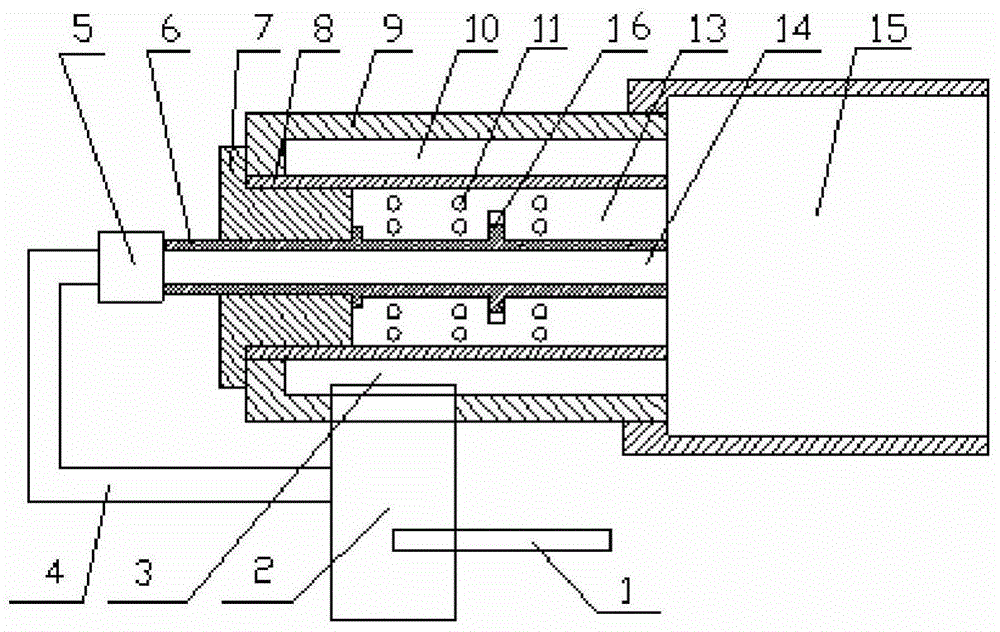

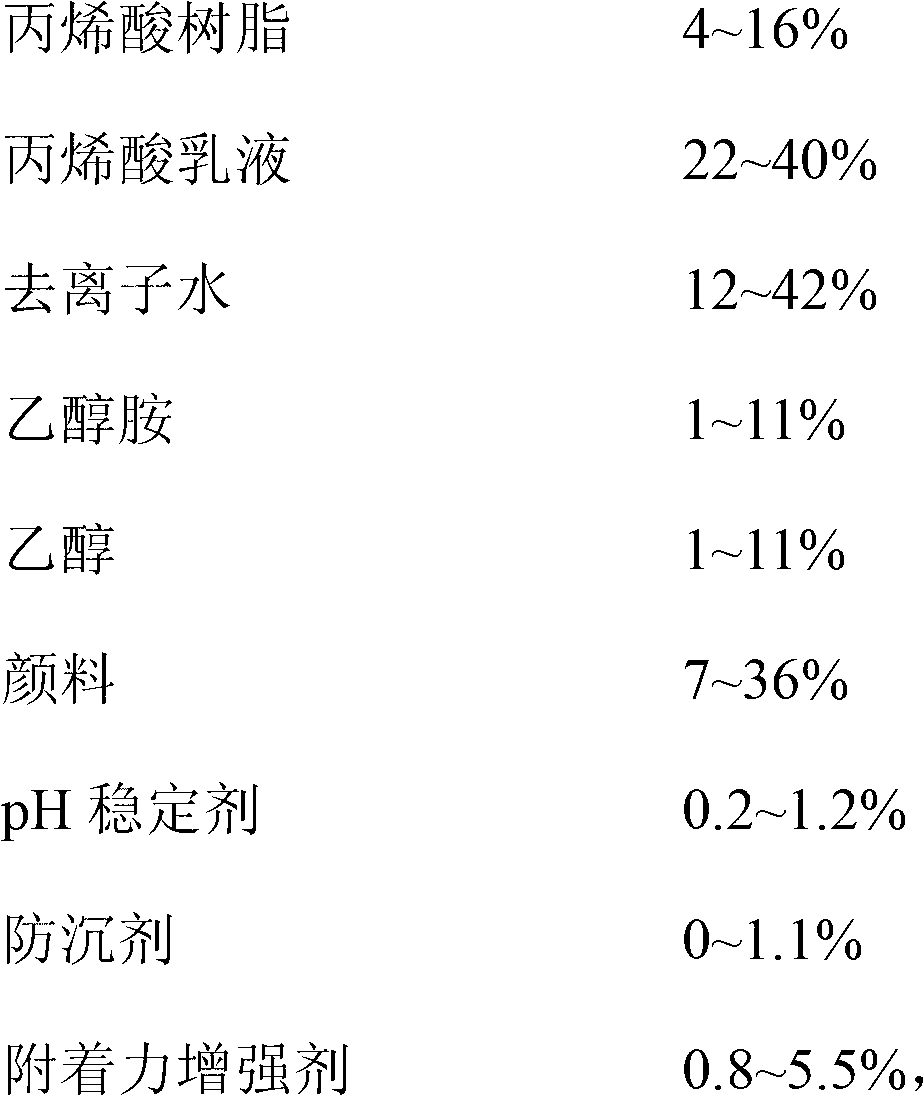

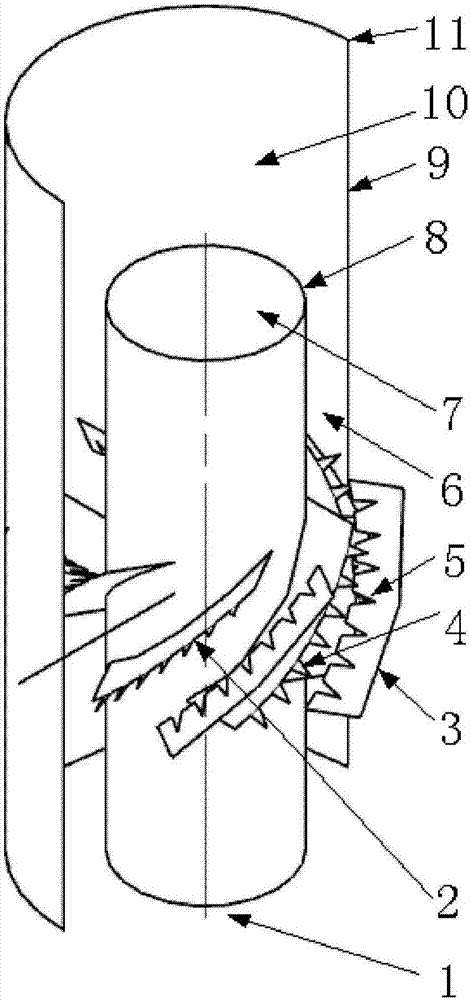

Multichannel plasma area igniting burner

ActiveCN104879780AAct as ignition sourceFlame stabilityGas turbine plantsCombustion ignitionCombustion chamberLow speed

The invention discloses a multichannel plasma area igniting burner. The igniting burner comprises a plasma power supply, a nozzle, an air inlet fish nozzle, a tangential air hole, an air pipe, a hollow insulator, a high-voltage electrode, an insulation piece, a low-voltage electrode, a housing, a swirl chamber, air vents, barrier mediums, a low-speed area, center jet flow and a flame stabilization chamber. Fuel oil is atomized by the use of a splash plate disposed inside the air inlet pipe, mixed gas composed of high-speed rotation air-flow and direct current jet flow is disposed inside the igniting burner, and the two flows cool the igniting burner. The space between the high-voltage electrode and the low-voltage electrode is filled with the inflammable mixed gas flowing at a low speed, so that multi-point discharge and ignition can be carried out in a low-speed mixed gas area inside the igniting burner; and an on-duty high-temperature combustion thermonuclear area and the flame stabilization chamber have ignition source and flame stabilization functions and form a miniature high-speed combustion chamber, so that the combustion chamber can efficiently and reliably ignite and keep flames stable under poor conditions such as high-speed, low-temperature, low-pressure, coal firing and the like.

Owner:PEKING UNIV

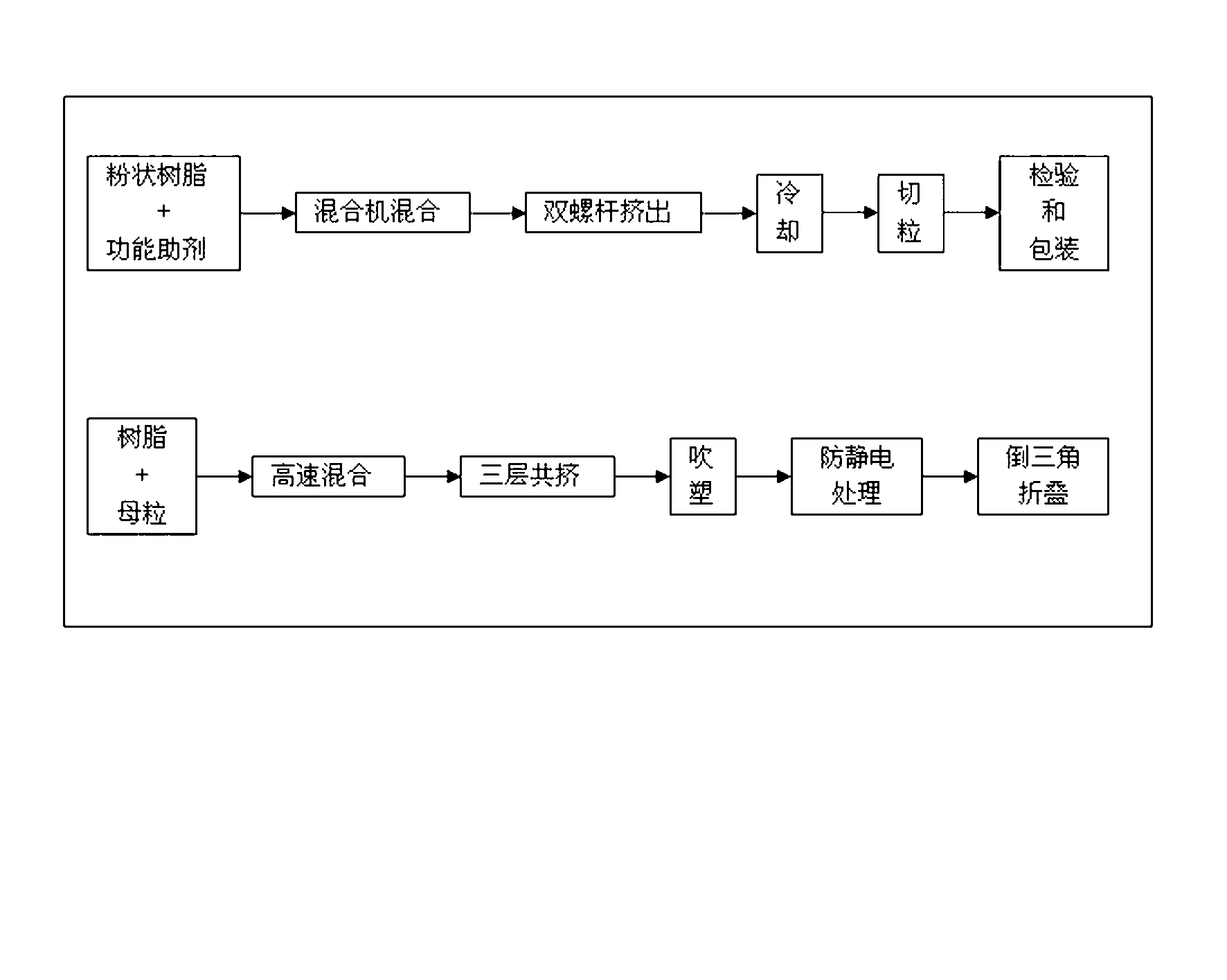

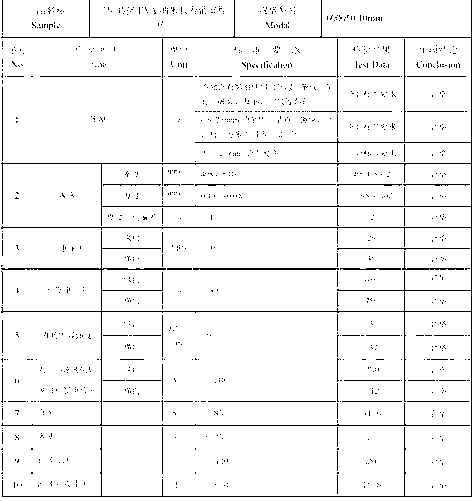

Three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film

ActiveCN103264563AGood colorEasy to processClimate change adaptationSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a nano fog-dissipation multifunctional greenhouse agricultural film, and in particular relates to a three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film, belonging to the field of agricultural mulching films. The raw material formula of an outer layer comprises the following components in percentage by weight: 20-50% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE), 10-20% of metallocene polyethylene (mPE) and 5-10% of double-prevention masterbatch; the raw material formula of a middle layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 20-40% of linear low-density polyethylene (LLDPE), 20-40% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; the raw material formula of an inner layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 10-20% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; and the formulas of the outer layer, the middle layer and the inner layer are uniformly mixed respectively, master batches are prepared by using a double-head thread screw double-screw extruding machine, a three-layer film is formed through a co-extrusion die head and is extruded out to prepare the multifunctional agricultural greenhouse film. Every quality technical index of the film reaches or exceeds a national standard, and a small part of the indexes is more than 2 times better than the national standard, so that the film is excellent in antiaging performance and cannot generate fog drops, and the service life of the film reaches more than 3 years.

Owner:HENAN YINFENG PLASTIC

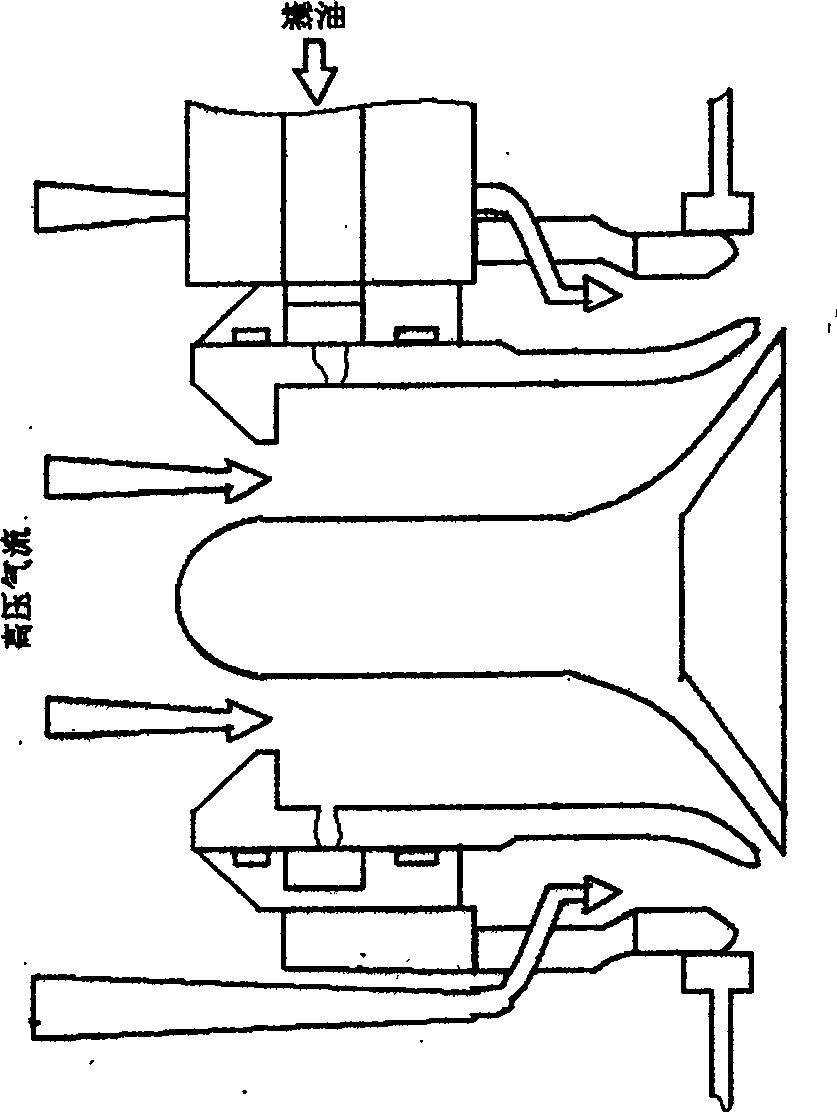

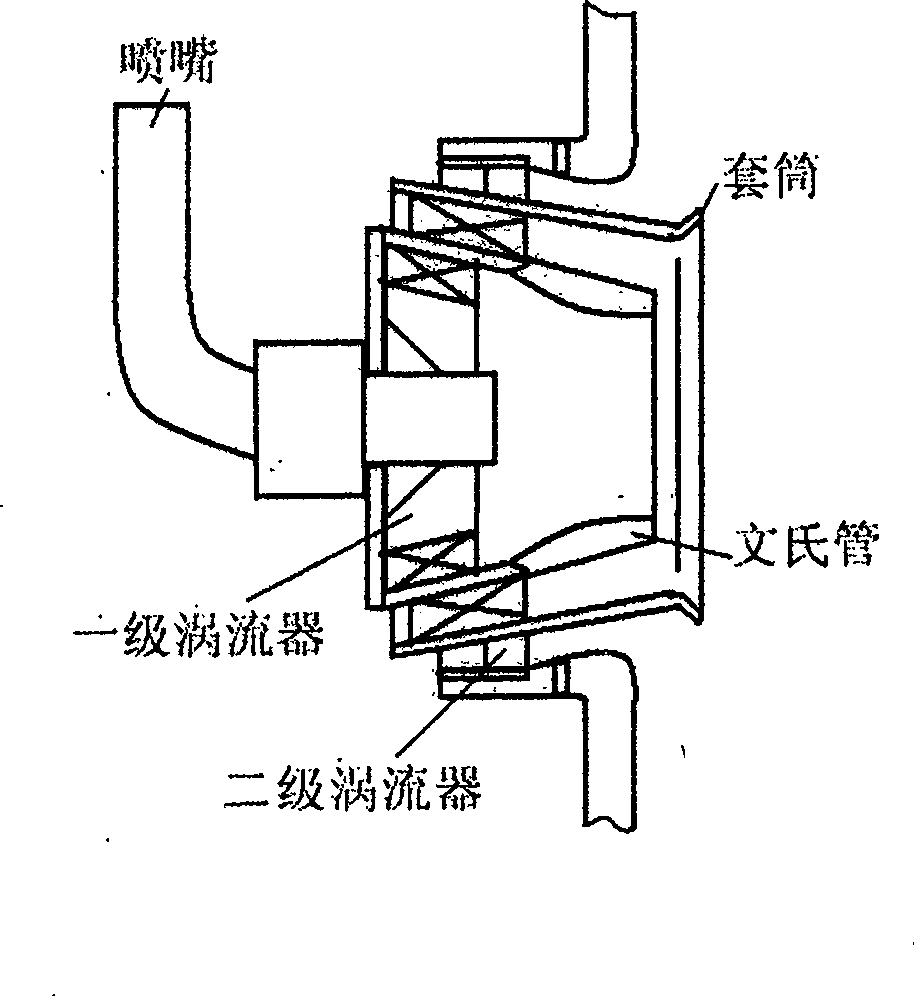

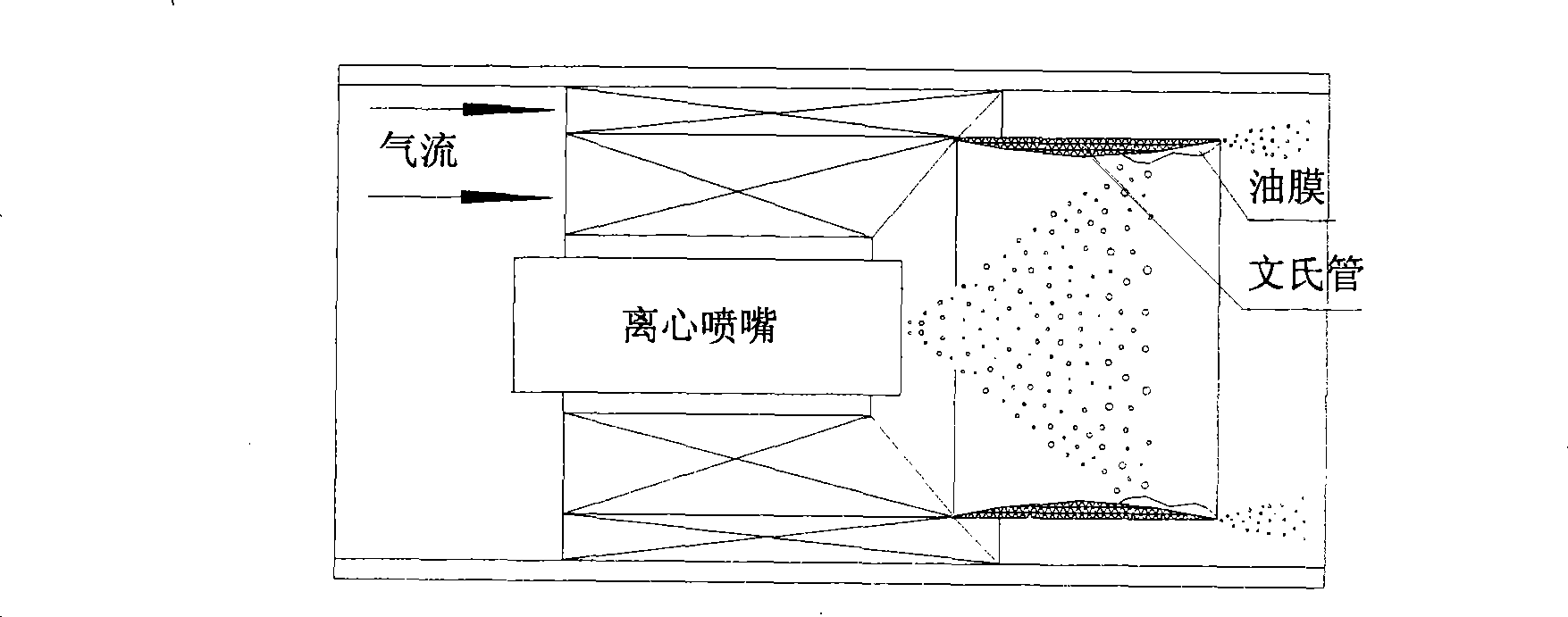

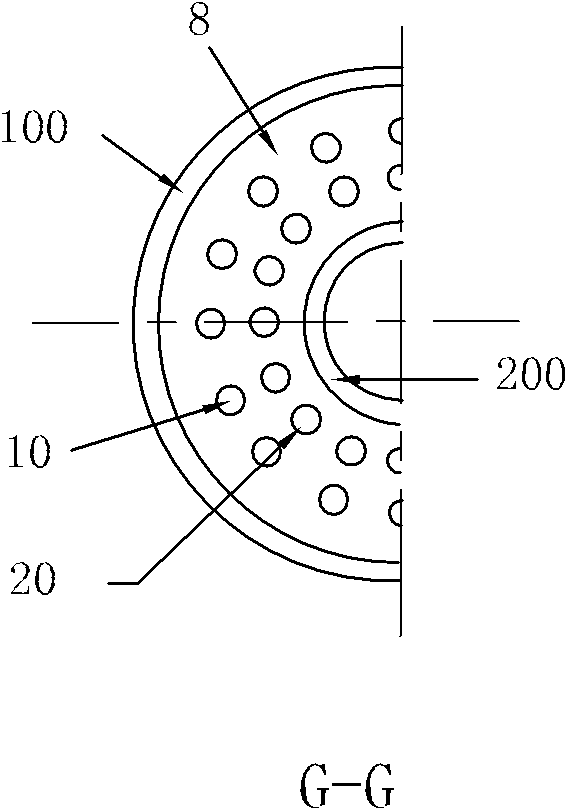

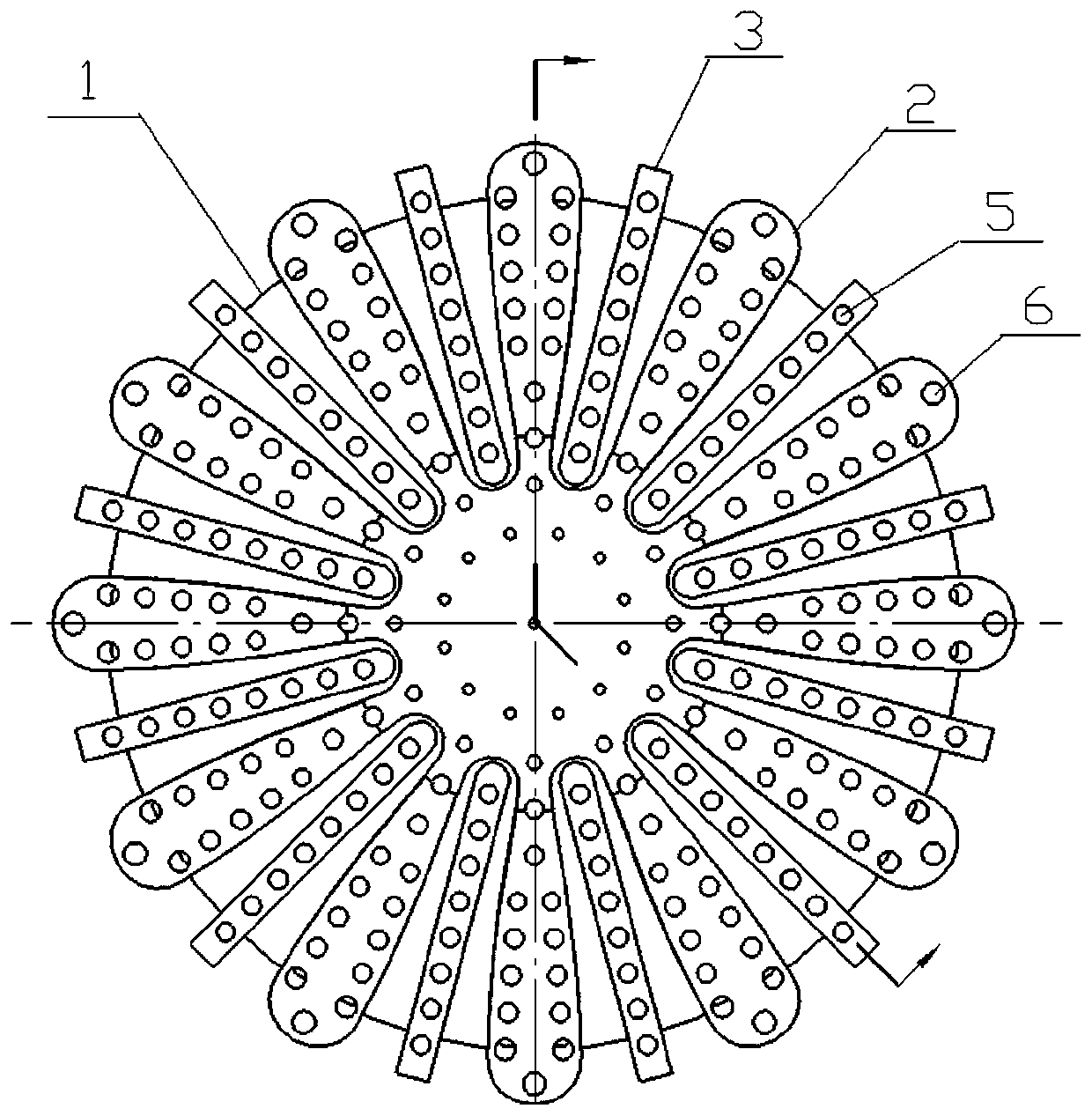

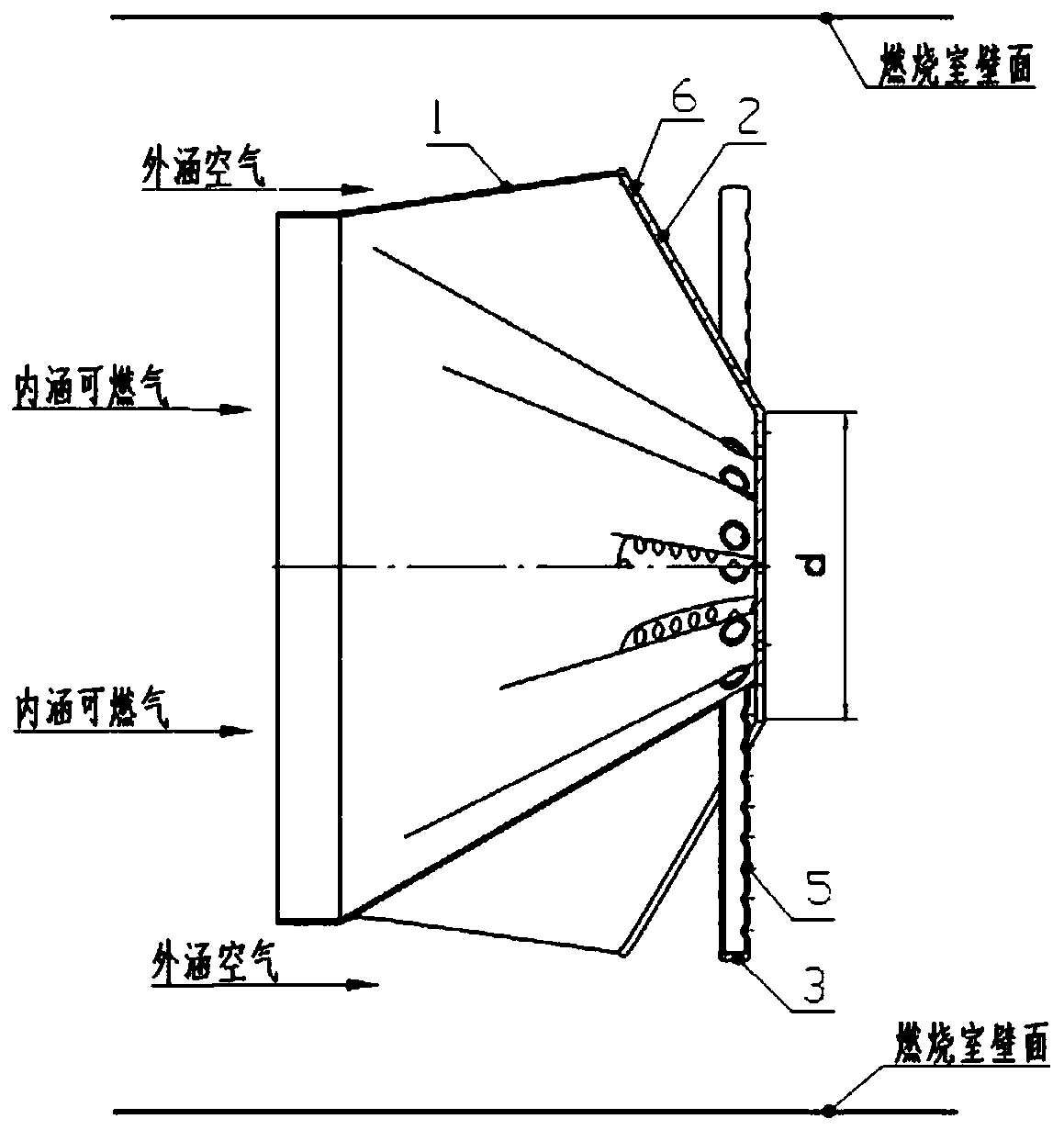

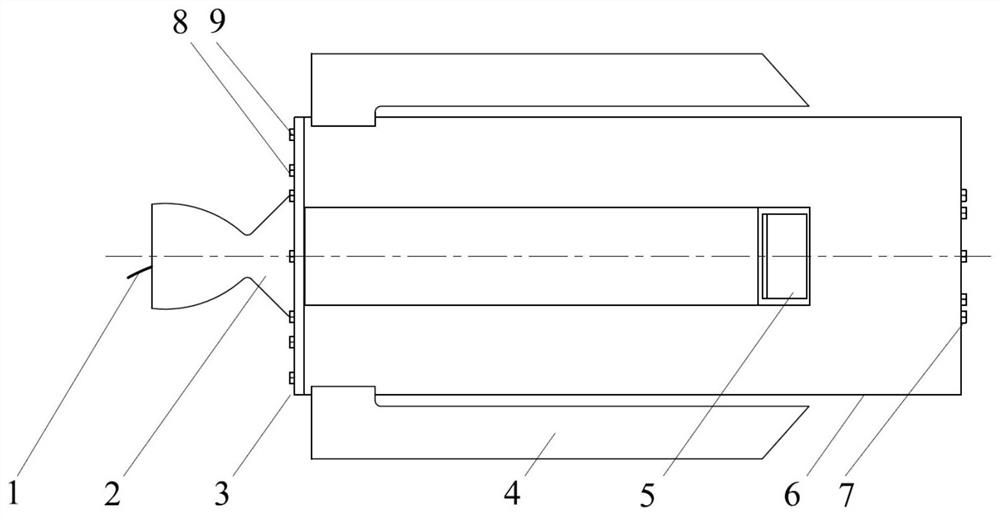

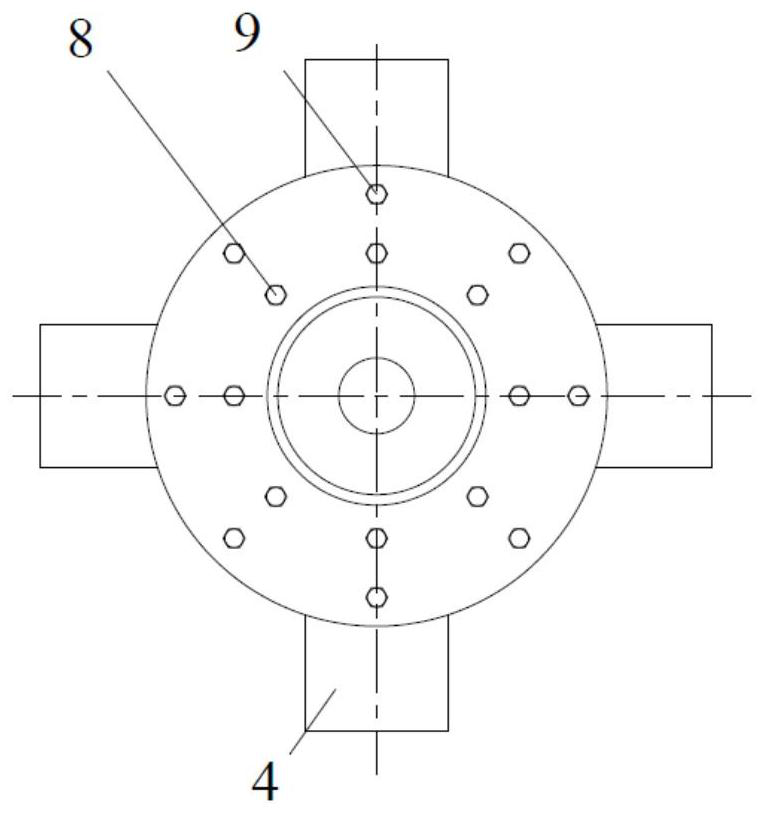

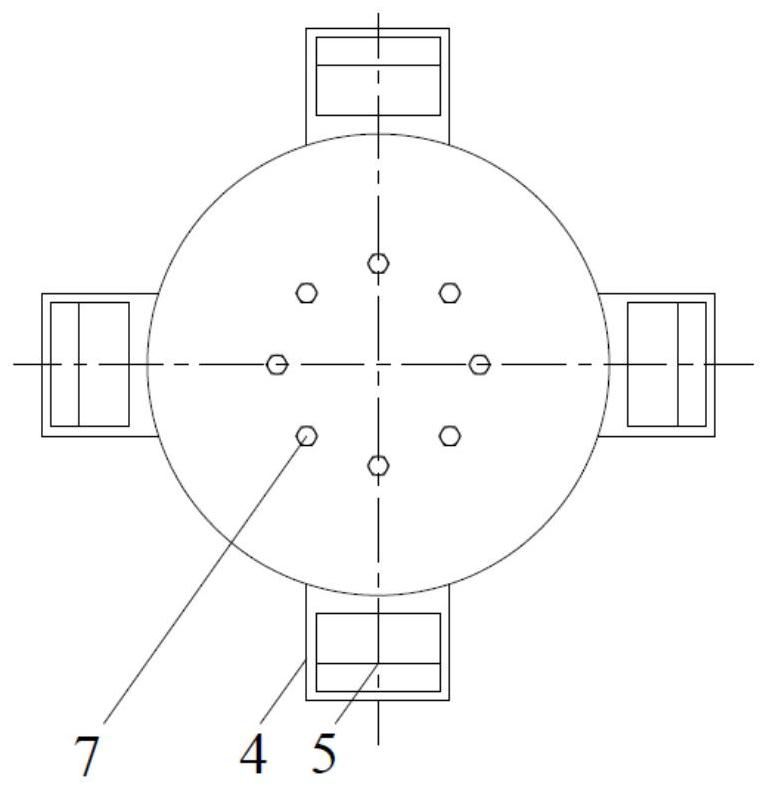

Gas turbine combined type fuel evaporating and atomizing combustion apparatus

InactiveCN101435585AIncrease the pre-mixed pre-evaporation processImprove atomization and evaporationContinuous combustion chamberAviationCyclone

The invention provides a combined fuel oil atomizing, evaporating and combusting device for a gas turbine, relates to an air inlet device of the gas turbine, a fuel oil atomizing, evaporating and blending device, and core technology of organized combustion and stable flame, and belongs to the power field of an aeronautic power propulsion system and a ground gas turbine. A nozzle 1 is arranged at a central position of an inlet of a premixing chamber 2; an evaporator 3 is fixed in an inner cavity of the premixing chamber 2; double cyclones 4 are arranged at the inside of the outlet end of the premixing chamber 2 and connected hermetically; a centrifugal nozzle 5 is arranged at a central position of the double cyclones 4; a venturi 6 is welded at a transition position of an outlet of internal and external cyclones of the double cyclones 4; a sleeve 7 is hermetically welded with the outside of an outlet of the premixing chamber 2; and the head of a combustion chamber 8 is hermetically welded with the sleeve 7. Compared with the prior fuel oil combined nozzle, the device has the advantages of improving properties of fuel oil atomizing, evaporating and blending and evenness of oil-gas space distribution, improving combustion performance, shortening flame length and reducing discharge of pollutant, and is a comparatively ideal combined fuel oil atomizing and combusting device for a high-performance gas turbine.

Owner:PEKING UNIV

Jet pump

InactiveCN102654145ANovel structureUnique structureJet pumpsMachines/enginesSuction forceEngineering

The invention provides a jet pump, and relates to a mixed flow jet apparatus. The jet pump is composed of a current distributing assembly, an inner pipe assembly and an outer sleeve assembly which have a same shaft core, wherein the current distributing assembly and the inner pipe assembly are fixedly connected in series, thereby forming a blind top centre cavity and a centre mixing tube; the outer sleeve assembly is sleeved outside the current distributing assembly and the inner pipe assembly, thereby forming an annular mixing chamber, an annular mixing pipe, a total mixing chamber and a total mixing output pipe; an internal ring nozzle and an external ring nozzle are arranged between the current distributing assembly and the inner pipe assembly, a mainstream body sprayed by the internal ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the centre mixing tube, and the secondary fluid is mixed in the centre mixing tube so as to output a centre mixed flow; a mainstream body sprayed by the external ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the annular mixing pipe, and the secondary fluid is mixed in the annular mixing pipe so as to output an annular mixed flow; and the two mixed flows are mutually injected to enter the total mixing chamber and the total mixing output pipe so as to further output in an isotrope voltage-sharing manner. The jet pump provided by the invention has the advantages of smaller weight and axial direction size, high injection rate, great suction force and good property in large flow.

Owner:韩铁夫

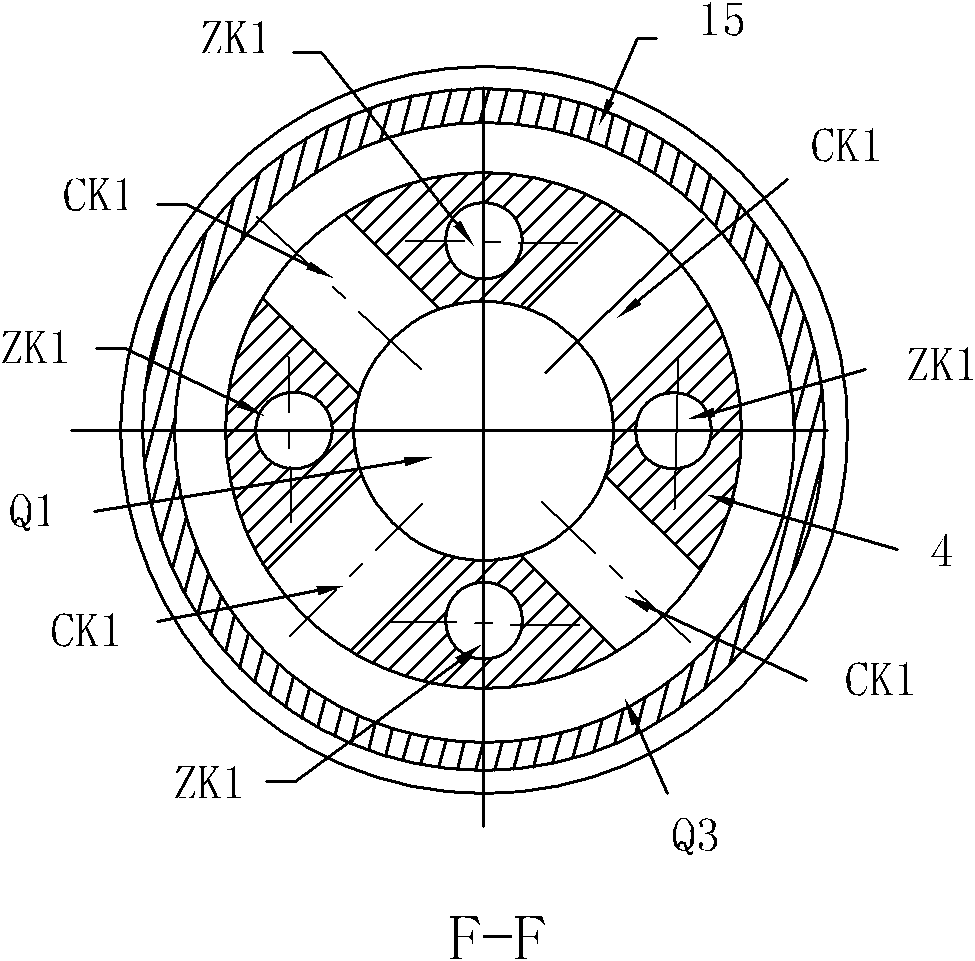

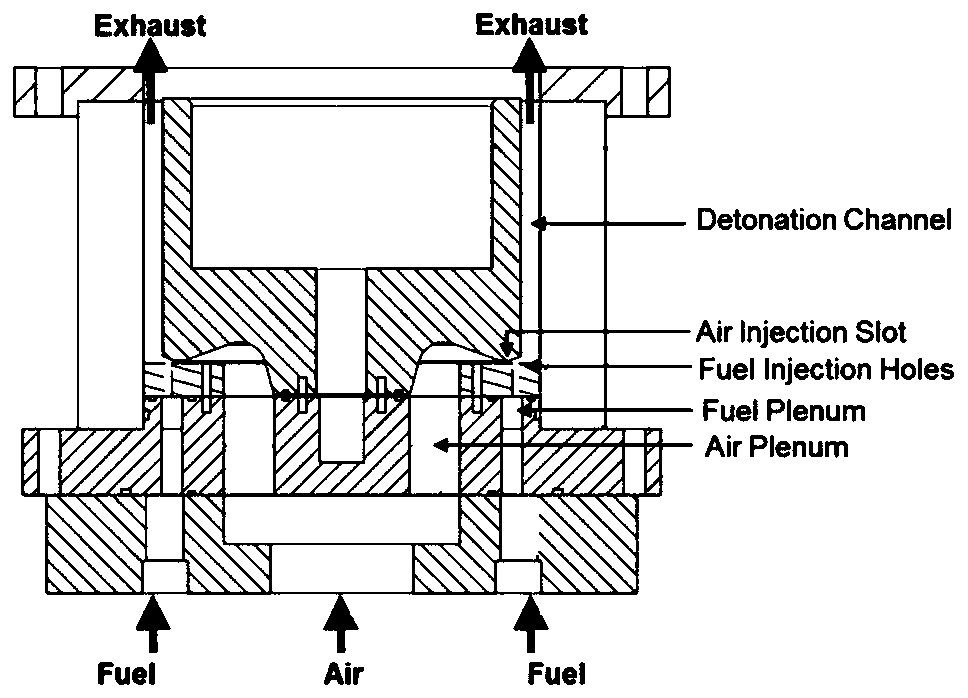

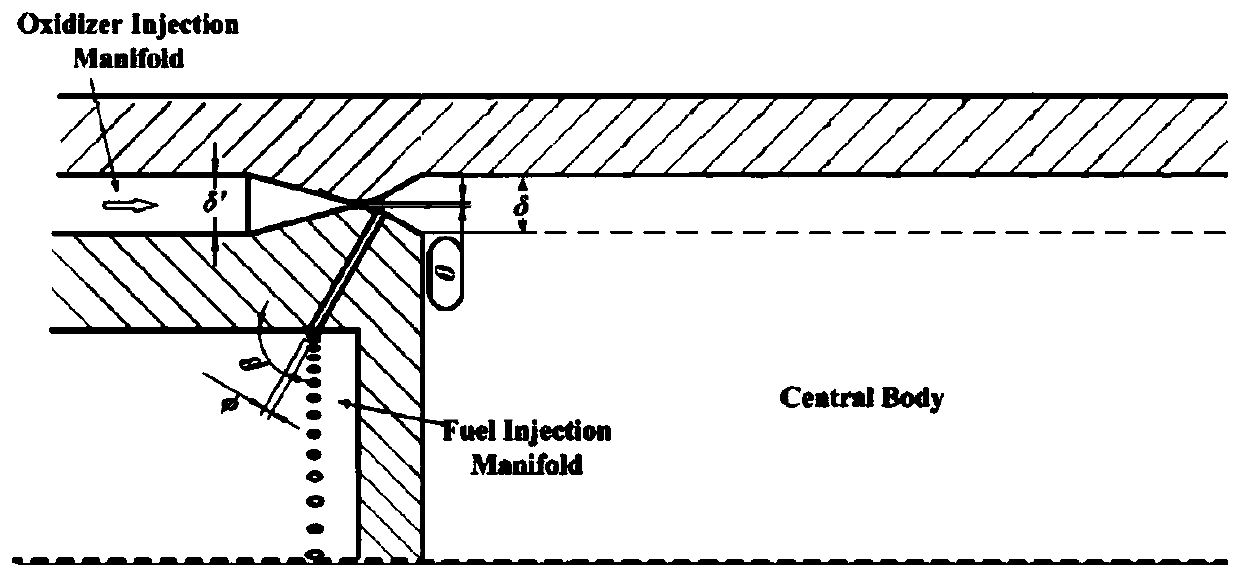

Ring cavity rotational flow opposite spraying structure based on RDE combustion chamber

The invention provides a ring cavity rotational flow opposite spraying structure based on an RDE combustion chamber. An axial symmetry hook face circular seam is adopted in a circular seam of an RDE,an included angle of the obtuse angle is formed between the transverse jet flow and the main jet flow direction of RDE, single-row annular cavity array cylindrical fuel spraying holes are evenly distributed in the inner and outer wall faces of the head of the RDE combustion chamber, and on the basis of the two-dimensional deflection, circumferential deflection is added on the fuel spraying holes.The structure has the advantages that non-linear circular seam configuration is adopted, pressure losses are reduced, and the outlet flow field is more stable. The upstream area of the transverse jetflow is decelerated, the sufficient fuel penetrating and mixing can be achieved, and the mixing efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

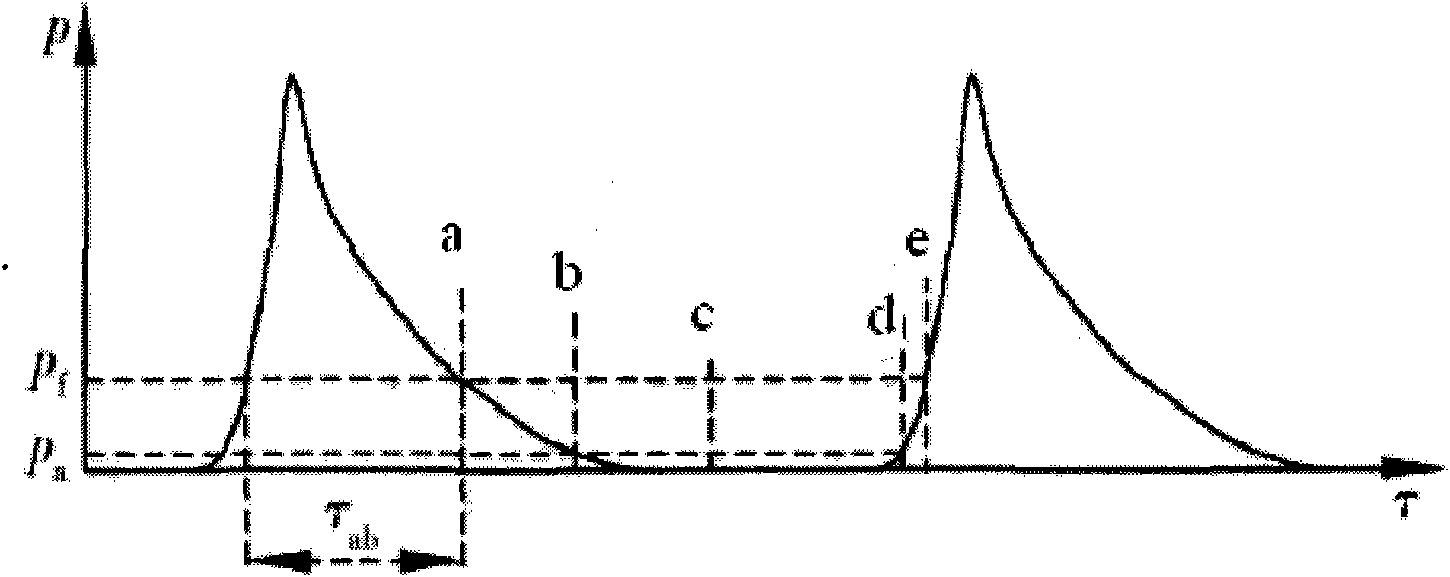

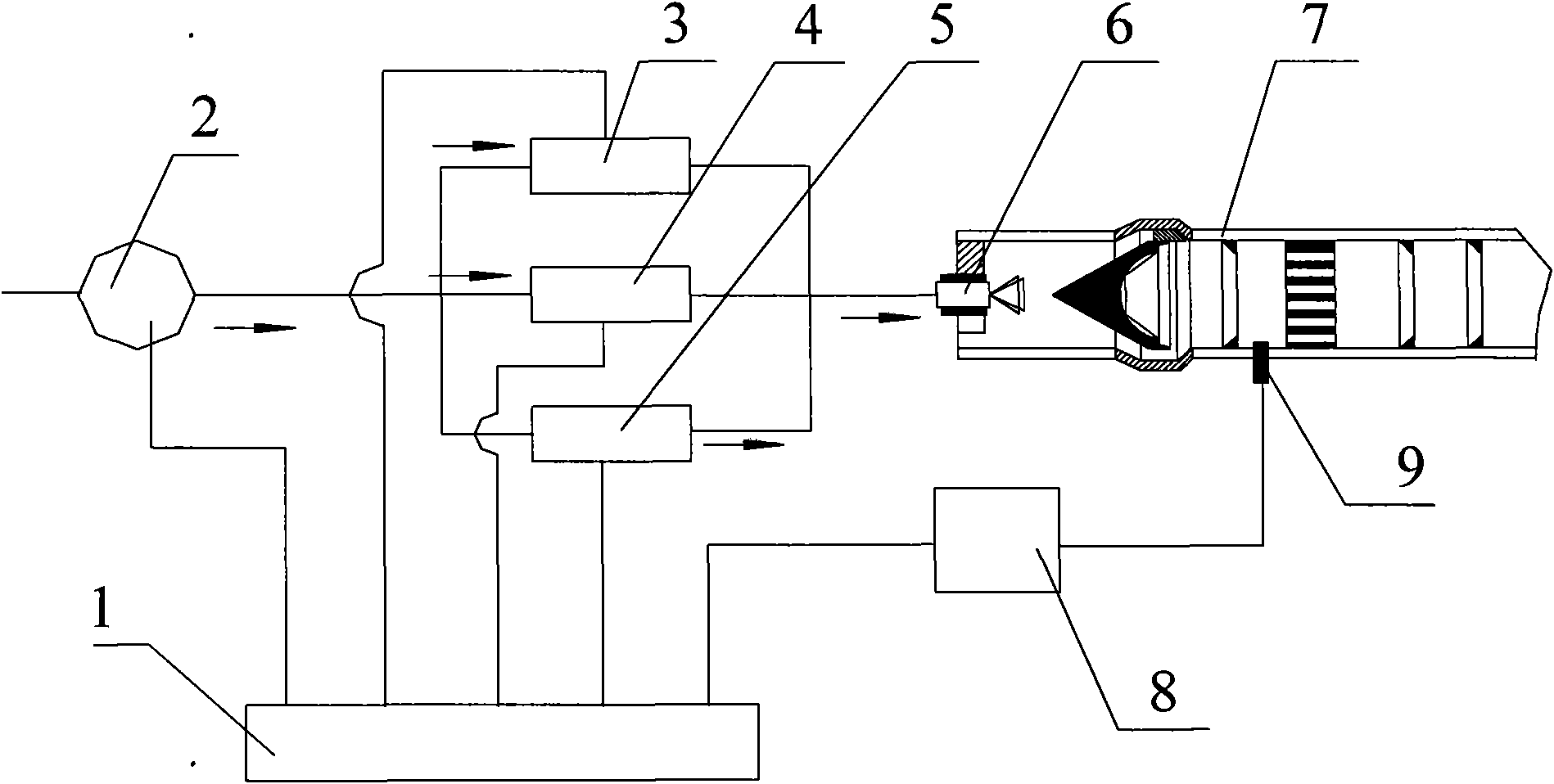

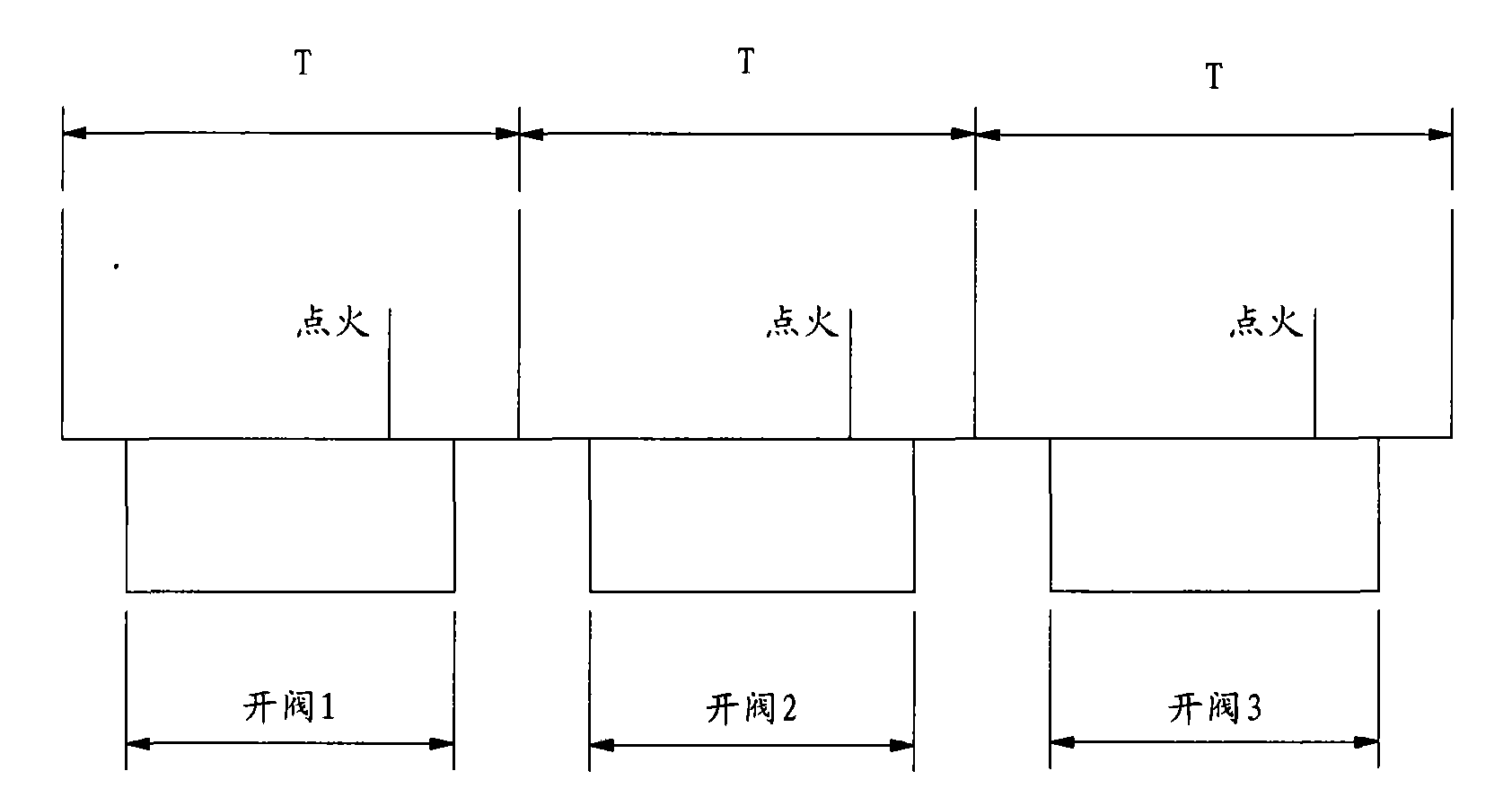

Pulse detonation engine (PDE) magnetic valve high frequency oil supply and ignition system

The invention discloses a pulse detonation engine (PDE) magnetic valve high frequency oil supply and ignition system, comprising a controller, an oil pump, a plurality of magnetic valve branches connected in parallel, a pulse detonation engine (PDE), a nozzle and a spark plug arranged at the head part of the PDE, an ignition power supply connected with the spark plug via a wire, wherein the controller is respectively connected with the oil pump, the multiple magnetic valve branches connected in parallel and the ignition power supply via wires; and the upstream of the multiple magnetic valve branches connected in parallel is connected with the oil pump through an oil pipe, and the downstream thereof is connected with the nozzle via an oil pipe. The invention can enhance oil supply and ignition frequency, control intermittent supply of fuel oil actively, improve fuel oil atomization evaporation and mixing properties, shorten DDT distance and time, reduce oil consumption, increase thrust-weight ratio, and is adaptable to urgent development demands of the PDE.

Owner:PEKING UNIV

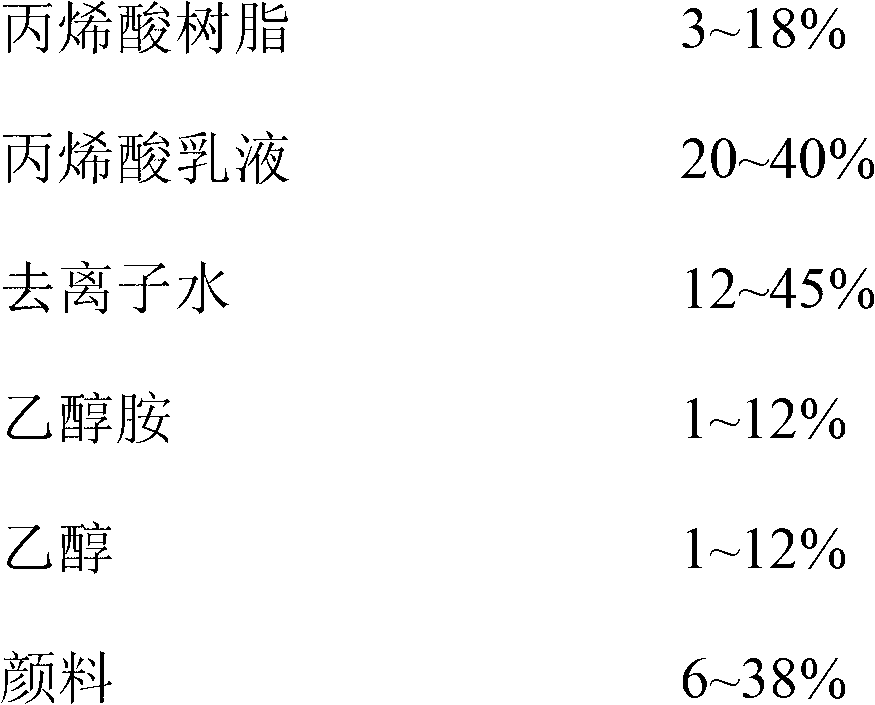

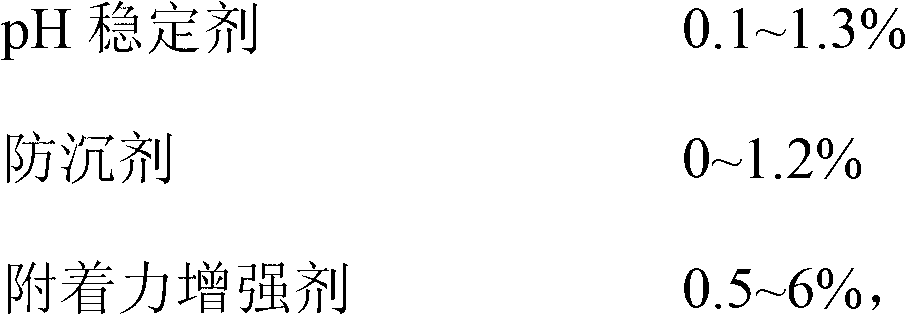

Water-soluble environmental-protection composite printing ink and preparation method thereof

InactiveCN102838899AComply with food hygiene and safety requirementsAvoid pollutionInksEnvironmental resistanceAcrylic resin

The invention relates to water-soluble environmental-protection composite printing ink which comprises the following components by weight: 3-18% of acrylic resin, 20-40% of acrylic emulsion, 12-45% of deionized water, 1-12% of ethanol amine, 1-12% of ethanol, 6-38% of pigment, 0.1-1.3% of pH stabilizer, 0-1.2% of anti-settling agent and 0.5-6% of adhesion enhancer. The sum of components of the composite printing ink is 100%. The invention further discloses a preparation method of the composite printing ink. The composite printing ink does not contain organic solvents such as benzene and ketone and the like, is free of solvent residues, environment-friendly and non-toxic, completely meets environmental-protection and national food hygiene safety requirements, can be used for high-grade package printing such as food packaging, medicine packaging and packaging of articles of everyday use, and is particularly suitable to oriented polypropylene (OPP) film composition (treatment degree achieves 38 dynes or higher).

Owner:东莞市锐达涂料有限公司

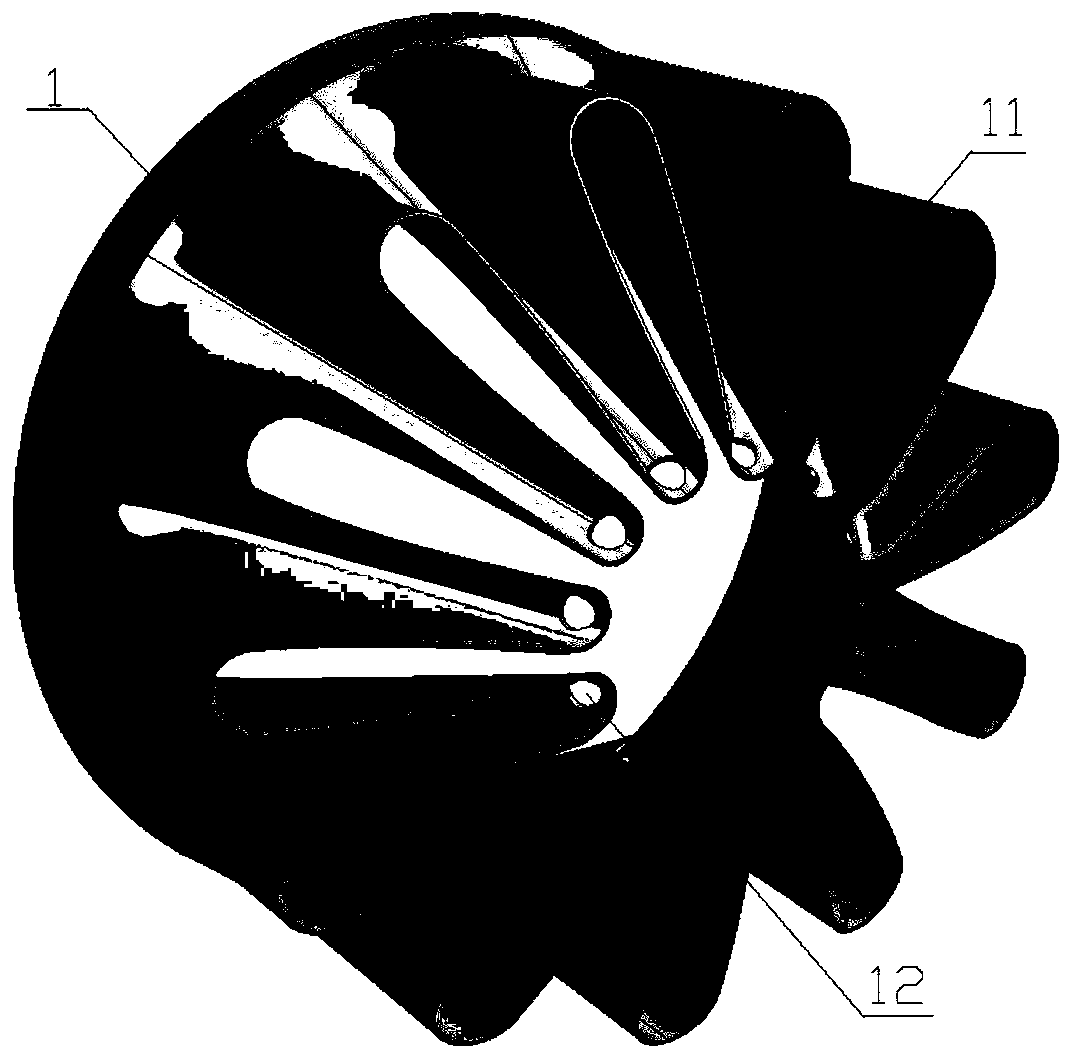

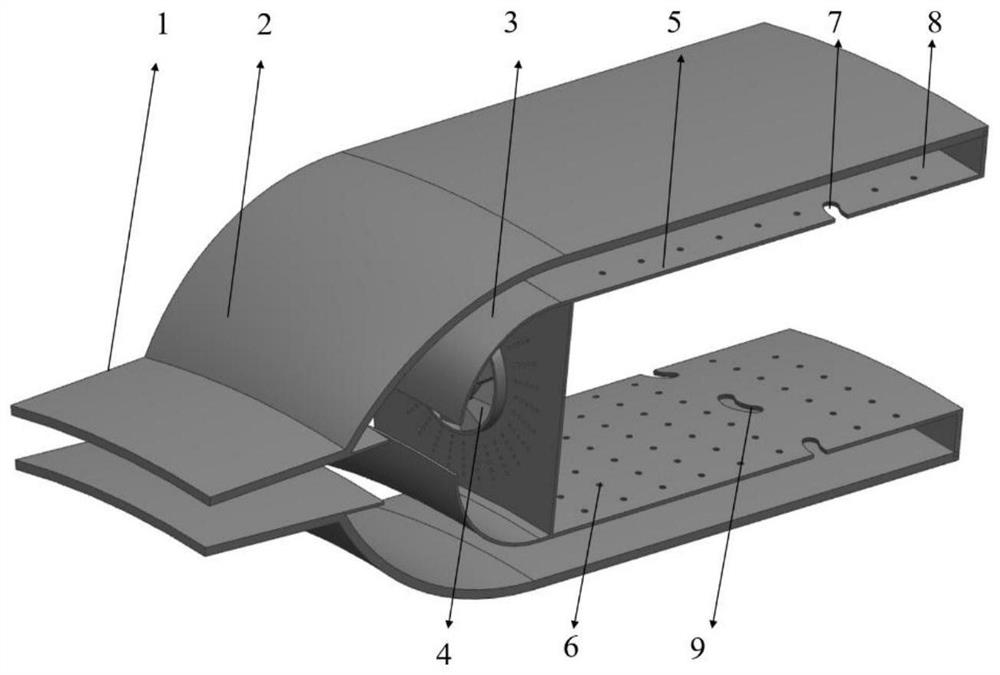

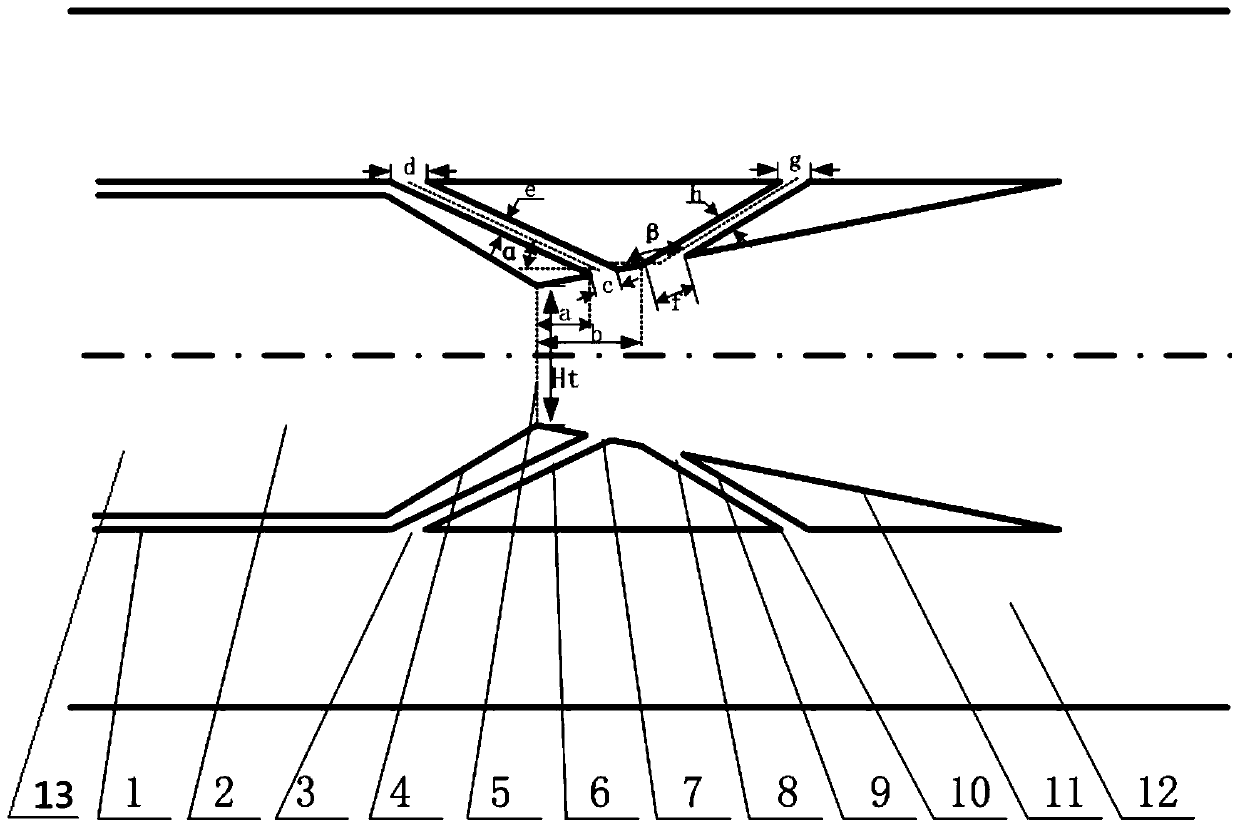

Mixing flame stabilizing device

PendingCN110939530AShorten the mixing distanceEfficient mixingContinuous combustion chamberRocket engine plantsCombustion chamberCombustible gas

The invention relates to the technical field of engines, and discloses a mixing flame stabilizing device. The mixing flame stabilizing device comprises a lobe mixer, a cover plate and turbulent flow columns, wherein a gas collecting cavity is formed between the cover plate and the lobe mixer; the turbulent flow columns are arranged at the position of an outer culvert air flow outlet of the lobe mixer; inner cavities of the turbulent flow columns communicate with the gas collecting cavity; the side walls of the turbulent flow columns and the cover plate are provided with spraying holes a and spraying holes b correspondingly; combustible gas is subjected to secondary flow dividing through the spraying holes a and the spraying holes b and then enters a combustion chamber to be mixed with air,the spraying pressure of the combustible gas is increased, accordingly, the penetrating capacity of the combustible gas in the gaseous environment is improved, and accordingly efficient mixing of twoair flows is achieved; and the turbulent flow columns are arranged at the position of the outer culvert air flow outlet of the lobe mixer, a large-scale radial vortex can be formed on the downstreamportion of the turbulent flow columns, outer culvert air is forced to flow in the circumferential direction of the turbulent flow columns at an outlet of the mixer, the mixing distance of the outer culvert air and inner culvert combustible gas is shortened, the mass exchange rate of the air and the combustible gas at an inner culvert outlet of the mixer is increased, and the mixing effect is improved.

Owner:XIAN AEROSPACE PROPULSION INST

Sidewall functionalization of carbon nanotubes with organosilanes for polymer composites

InactiveUS8541322B2Improve the level ofStrong attachmentPigmenting treatmentSilicon organic compoundsCarbon nanotubePolymer composites

Owner:RICE UNIV

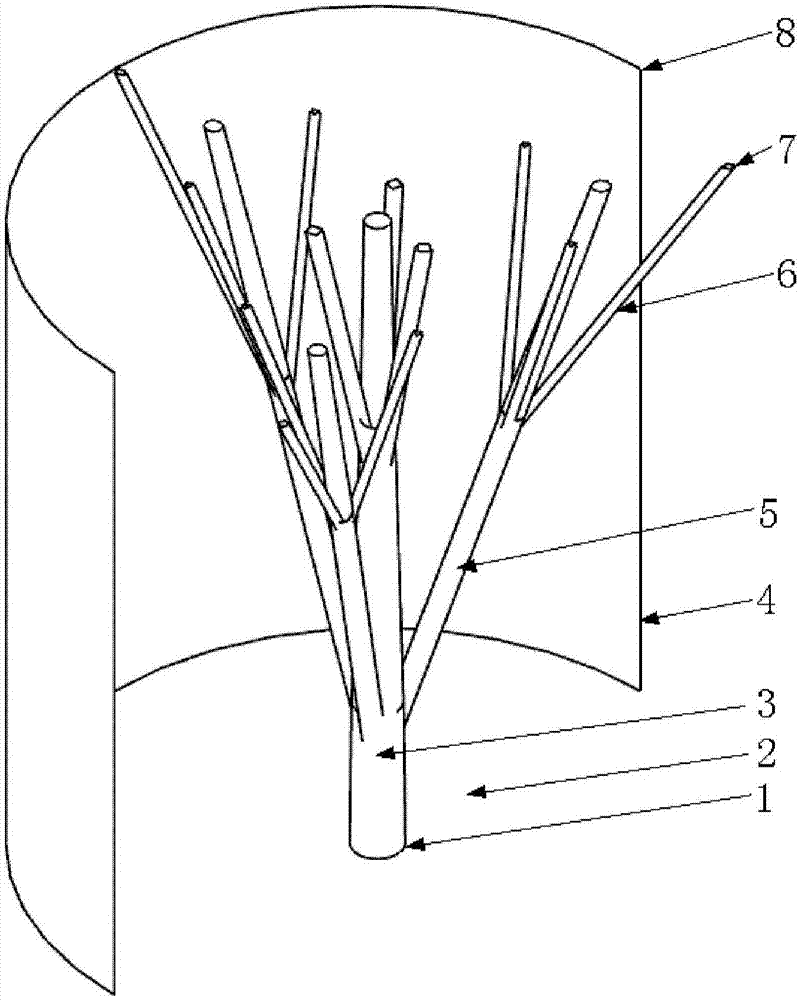

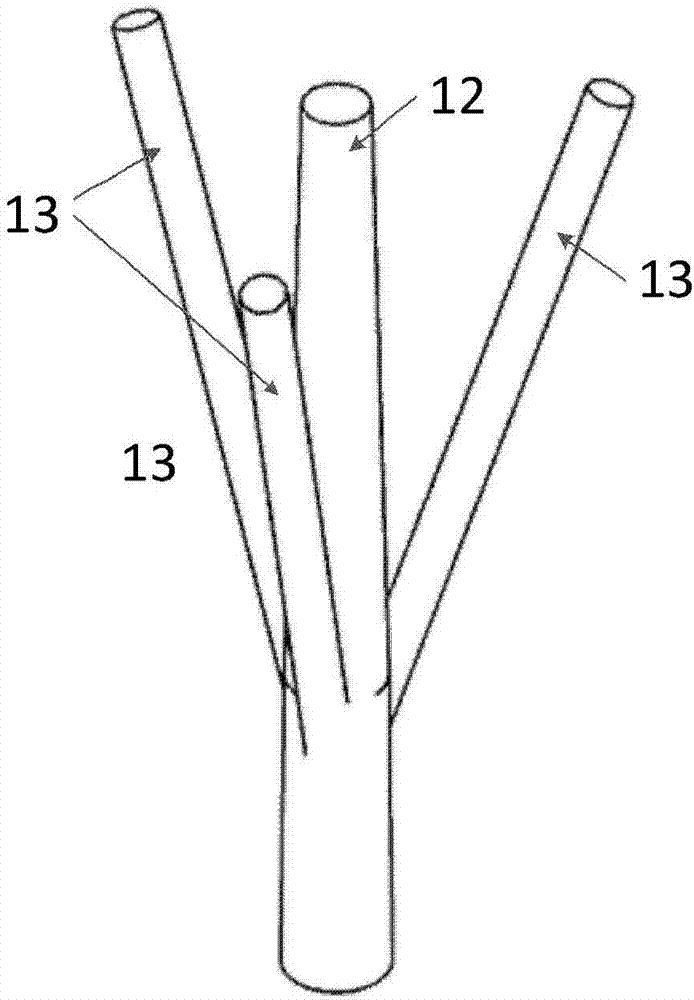

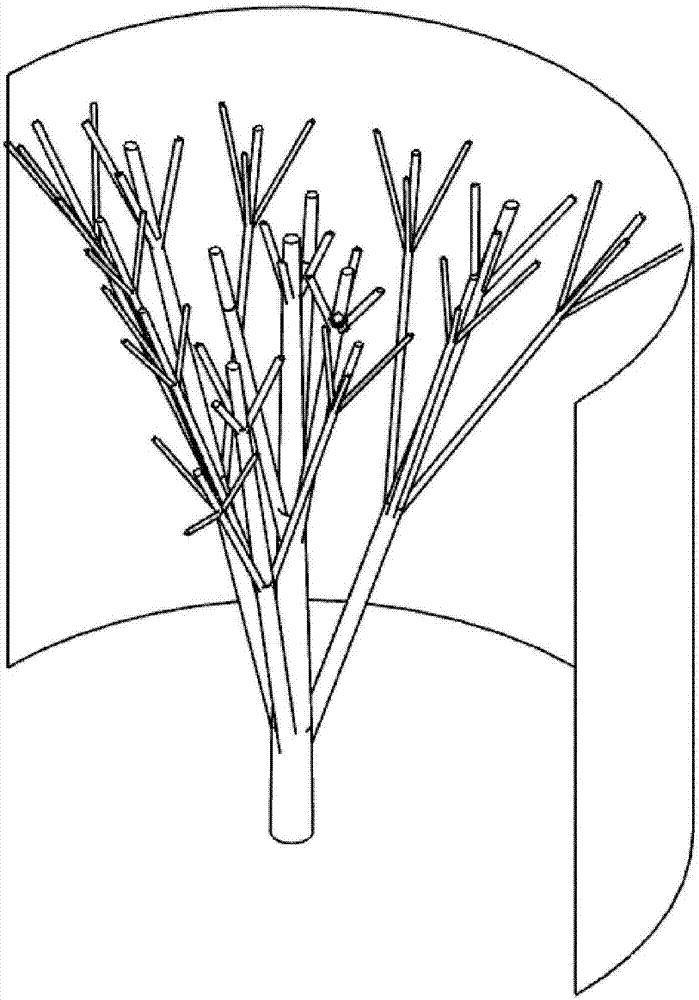

Double-fuel nozzle with fractal structured fuel pipe, nozzle array and combustor

InactiveCN106907710AReduce flow lossSmall flow blockageGaseous fuel burnerCombustorPollutant emissions

The invention provides a dual fuel nozzle with a fractal structure fuel pipe, comprising the outer wall of the nozzle and a fractal structure fuel pipe, the fractal structure fuel pipe is a multi-stage fractal structure, including a main pipe and a multi-stage fractal branch pipe, and each stage of the fractal branch pipe includes multiple Branches, each branch of the upper level fractal branch branches out the next level of fractal branch. The nozzle adopting the fractal structure fuel pipe has small flow loss, small flow blockage, good mixing effect, good combustion stability and low pollutant emission.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

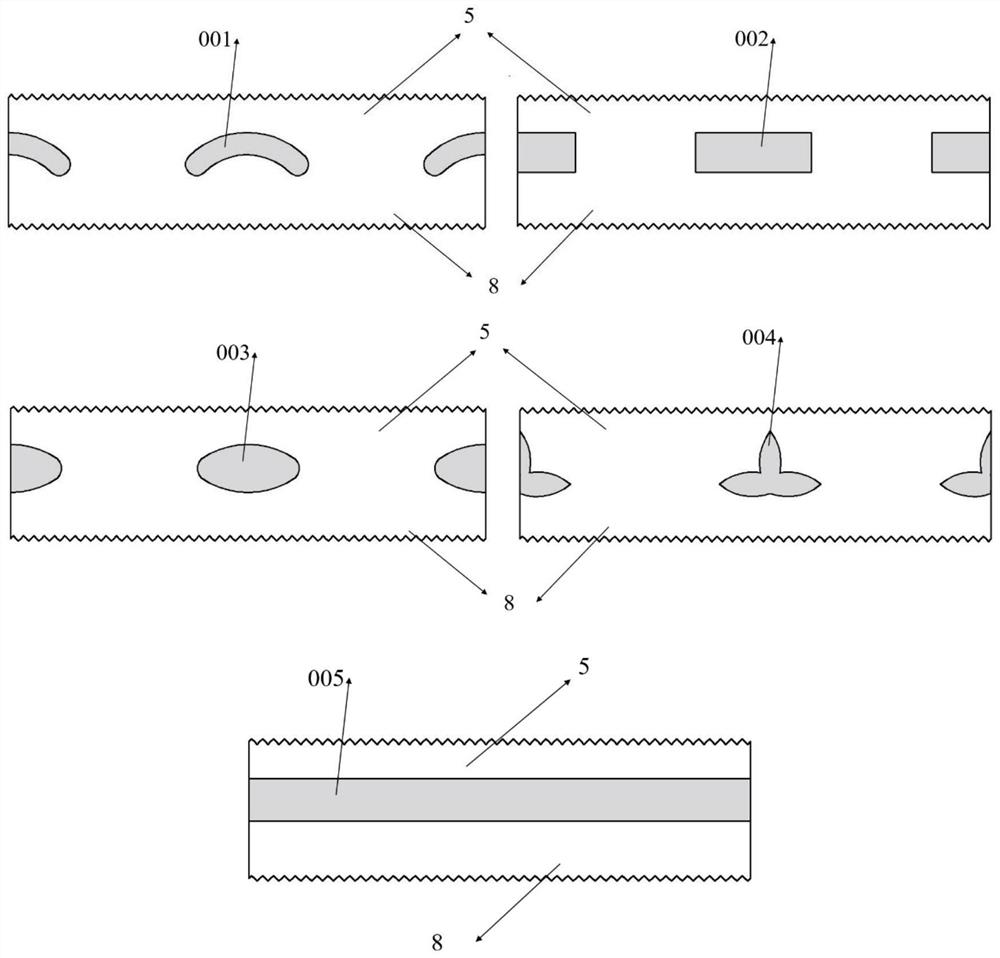

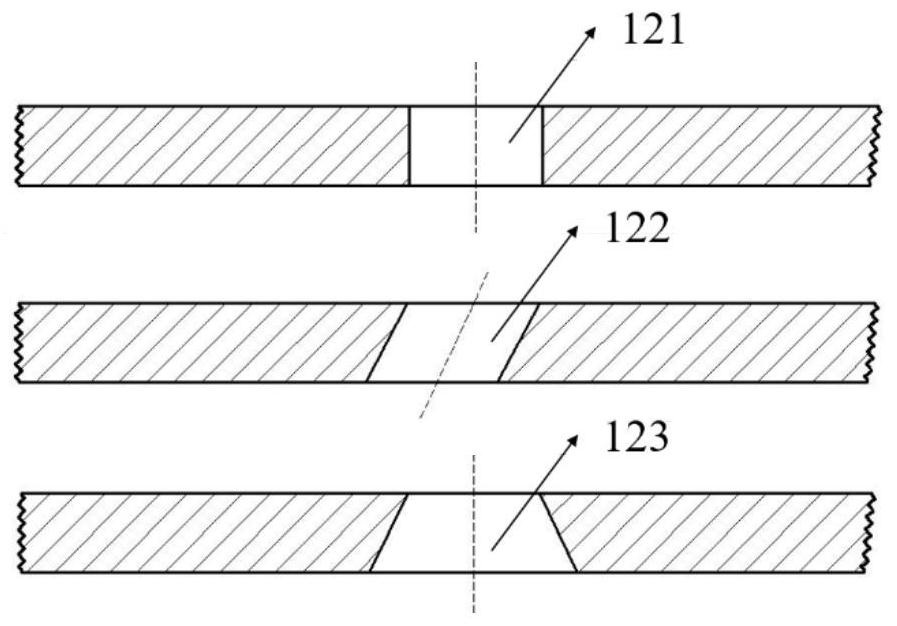

Specially-shaped mixing holes for adjusting outlet temperature distribution of combustion chamber

ActiveCN112146127AIncrease the divergence angleExpand space coverageContinuous combustion chamberCombustion chamberEngineering

The invention discloses specially-shaped mixing holes for adjusting outlet temperature distribution of a combustion chamber, and belongs to the field of combustion of gas turbines. The specially-shaped mixing holes are formed in the inner ring wall surface and the outer ring wall surface of a flame tube of the combustion chamber correspondingly; the specially-shaped mixing holes divide the wall surface of the flame tube into a flame tube front section and a flame tube back section; the specially-shaped mixing holes are evenly distributed in the circumferential direction of the wall surface ofthe flame tube to form mixing jet flows evenly distributed in the circumferential direction, the penetration depth of the mixing jet flows is increased, the contact area of mixing cold air and high-temperature main stream gas is increased, the mixing effect is improved, and the outlet temperature distribution quality of the combustion chamber is improved; the effect of adjusting outlet temperaturedistribution of the combustion chamber is achieved by changing the jet flow penetration depths, the jet flow circumferential expansion angles and the jet flow directions of the mixing holes; and outlet temperature distribution of the combustion chamber is adjusted, so that the temperature quality of an inlet of a turbine is improved, the service life of the turbine is prolonged, and the heat-proof design difficulty of the turbine is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

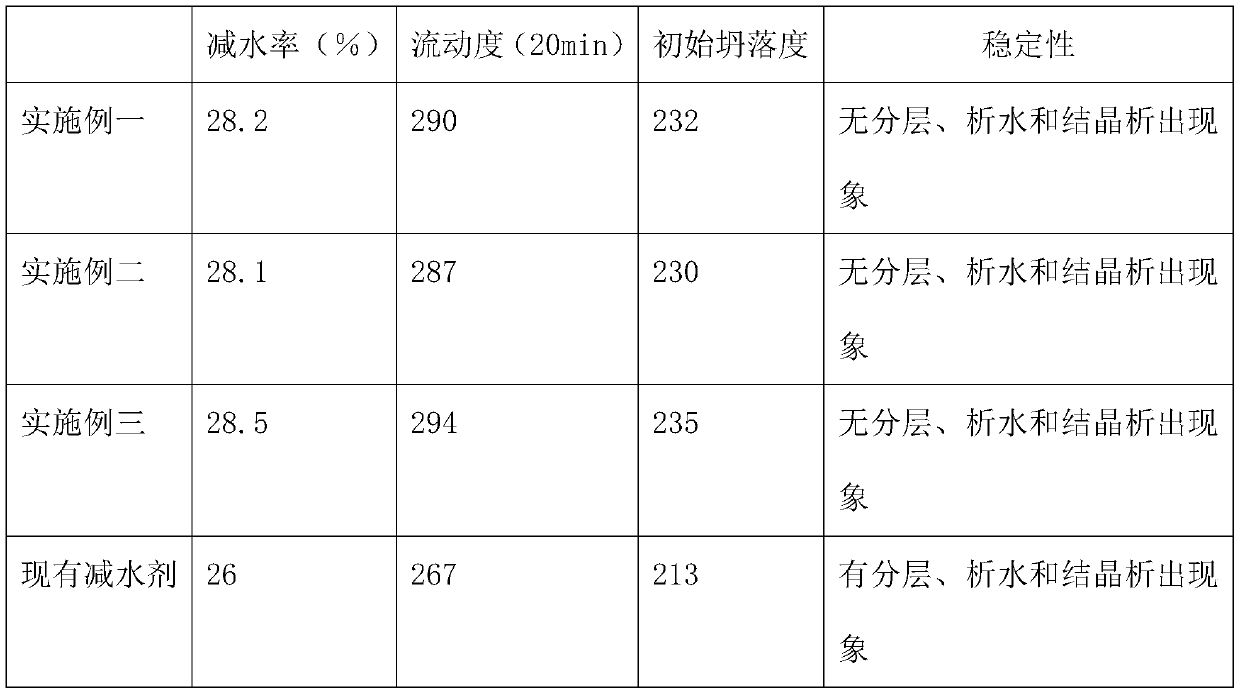

Modification water reduction agent for concrete

The invention discloses a modification water reduction agent for concrete and relates to the technical field of water reduction agent. The modification water reduction agent comprises the following components in parts by mass: 30-50 parts of methyl allyl polyoxyethylene ether, 25-40 parts of a sodium beta-naphthalenesulfonate wastewater mixed liquid, 10-20 parts of sulfite, 4-8 parts of a modifier, 0.75-2 parts of polyvinylpyrrolidone, 0.65-1.4 parts of dodecylpyridinium bromide, 3-4 parts of 30% hydrogen peroxide, 5-8 parts of a viscosity adjustment agent, 8-11 parts of an air entraining agent and 7-10 parts of an early-strength agent. By adopting the modification water reduction agent for concrete, the blending performance of the water reduction agent can be improved, the strength and the hardness of the concrete can be improved in application, and the viscosity of the water reduction agent can be adjusted in the use process through the viscosity adjusting agent, the air entraining agent and the early-strength agent, so that the concrete can be well laid, the curing time of the concrete can be shortened, and the modification water reduction agent for concrete has good effects inimproving the corrosion resistance of the concrete, increasing the water reduction rate and prolonging the service life of an engineering structure.

Owner:江苏博思通新材料有限公司

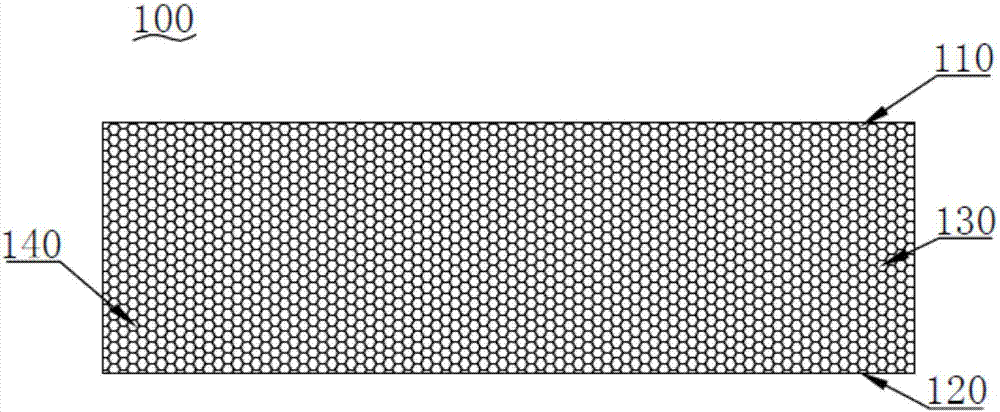

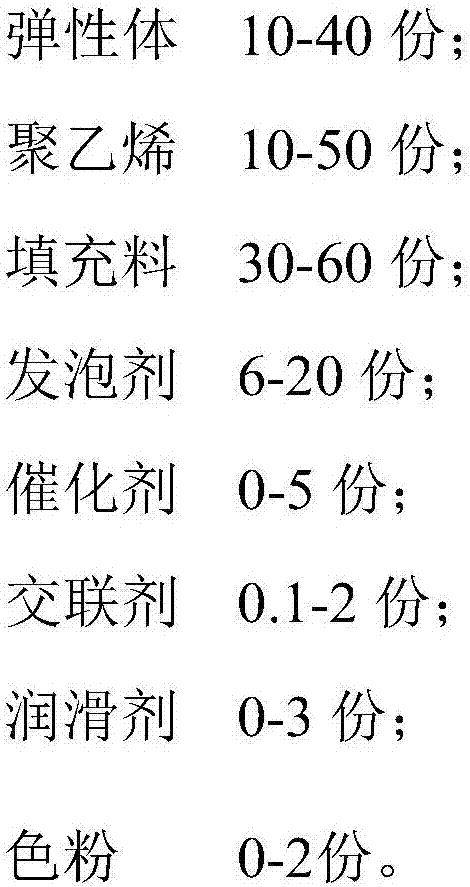

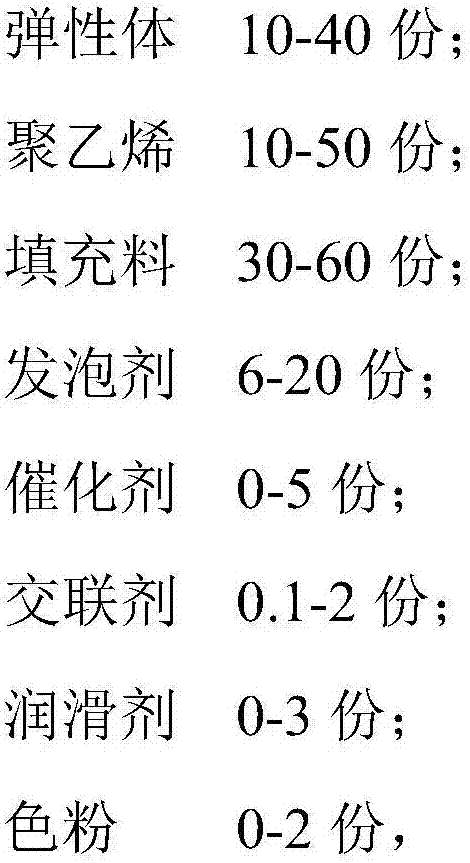

Closed-cell foaming material as well as manufacturing formula and manufacturing method thereof

PendingCN107379695AIncrease foam densityLow costSynthetic resin layered productsElastomerPolymer science

The invention relates to the technical field of foaming materials, and in particular relates to a closed-cell foaming material as well as a manufacturing formula and a manufacturing method thereof. The closed-cell foaming material comprises a body, wherein the body is integrally molded through continuous foaming; the body comprises an upper surface skin, a middle core layer and a lower surface skin; the upper surface skin, the middle core layer and the lower surface skin are integrally molded through continuous closed-cell foaming; a formula of the foaming material comprises 10 to 40 parts of elastomers (including EVA (Ethylene-vinyl Acetate copolymer), POE (Polyolefin Elastomer), TPE (Thermoplastic Elastomer), TPR (Thermoplastic Rubber) and MPP (Modified Polypropylene)), 10 to 50 parts of polyethylene, 30 to 60 parts of a filling material, 6 to 20 parts of a foaming agent, 0 to 5 parts of a catalyst, 0.1 to 2 parts of a cross-linking agent, 0 to 3 parts of a lubricant and 0 to 2 parts of toner; the manufacturing method of the foaming material comprises the following steps: mixing; extruding; calendering to form a master batch; carrying out primary cooling and winding; adding the master batch into a continuous foaming tunnel furnace and carrying out closed-cell cross-linking foaming under normal pressure; carrying out secondary cooling; printing to obtain a finished product and winding. The method provided by the invention completely meets European Union standards and user requirements especially in the aspect of formamide; the closed-cell foaming material provided by the invention can be used for continuously carrying out chemical cross-linking closed-cell foaming without electron irradiation crosslinking and mould pressing.

Owner:广东富利时实业有限公司

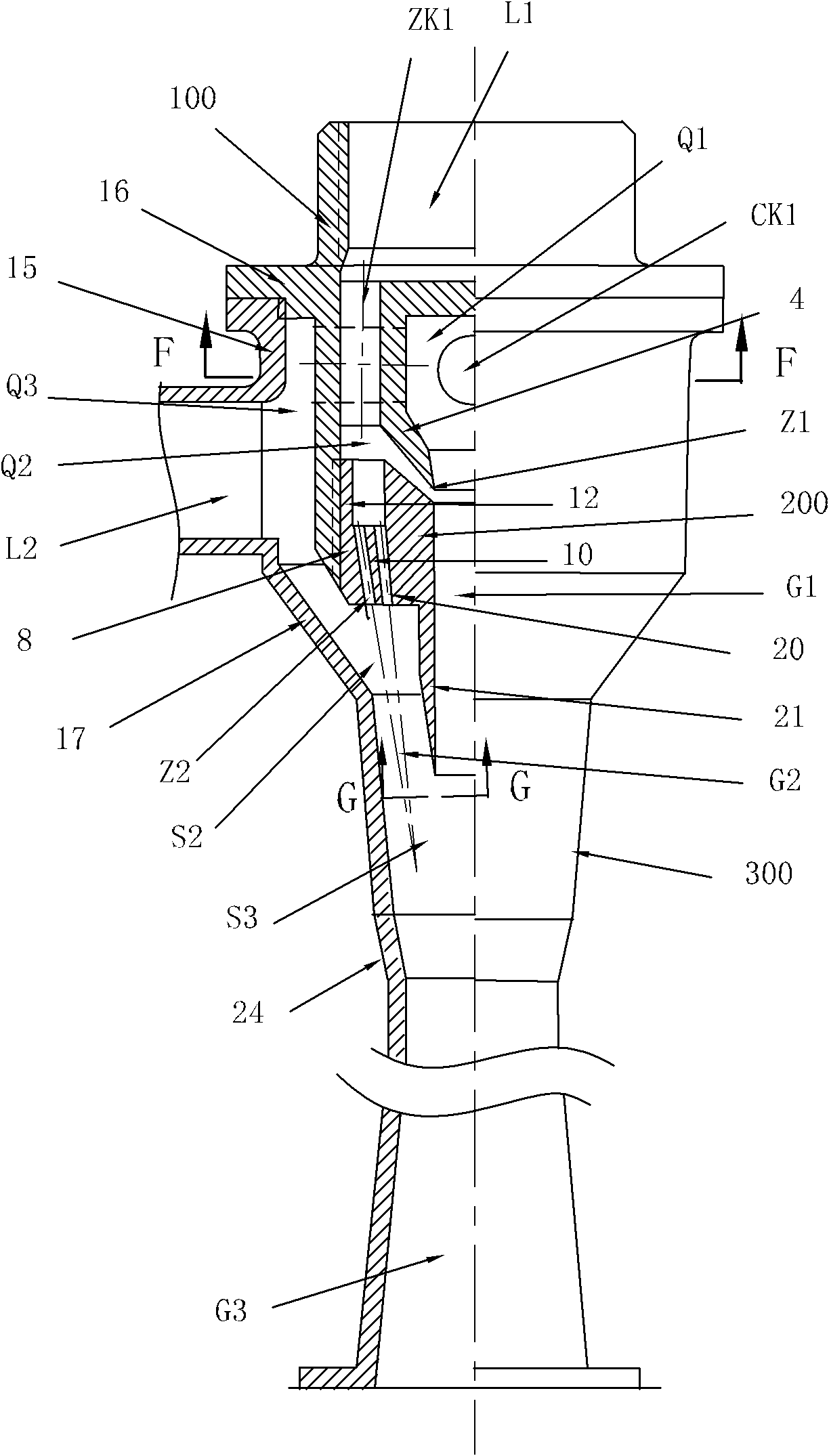

Nozzle with adjustable swirling number and turbulence level, nozzle array and combustor

The invention provides a nozzle with the adjustable swirling number and the turbulence level, a nozzle array and a combustor. The relative position between an inner-circle blade and an outer-circle blade of a cyclone is adjusted by rotating a middle cylinder or an outer-layer cylinder, and the purpose of adjusting the swirling number and the turbulence strength can be adjusted. The work range of the nozzle is wide, the swirling number and the turbulence of a flow field can be flexibly adjusted, the mixing effect is good, safety is good, pollutant emission is low, the fuel application range is wide, and good combustion stability is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

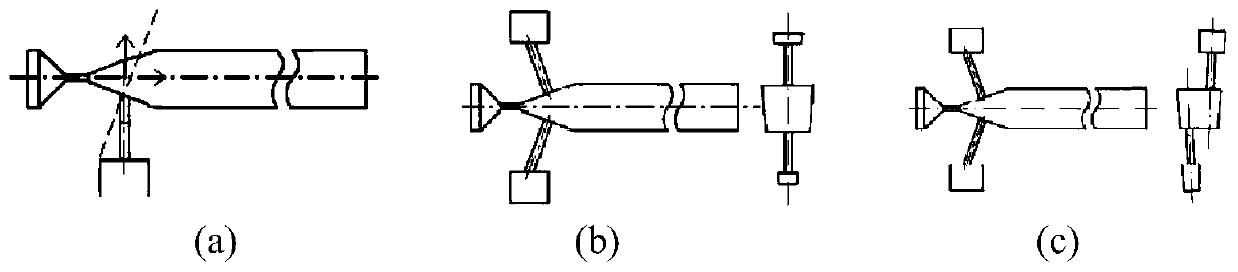

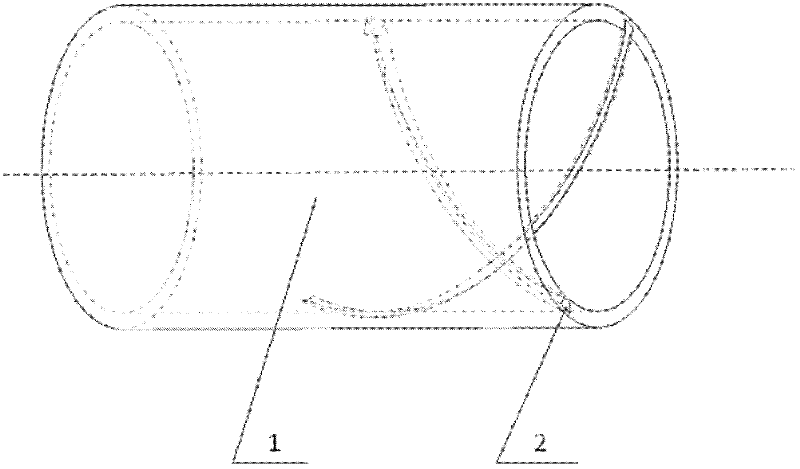

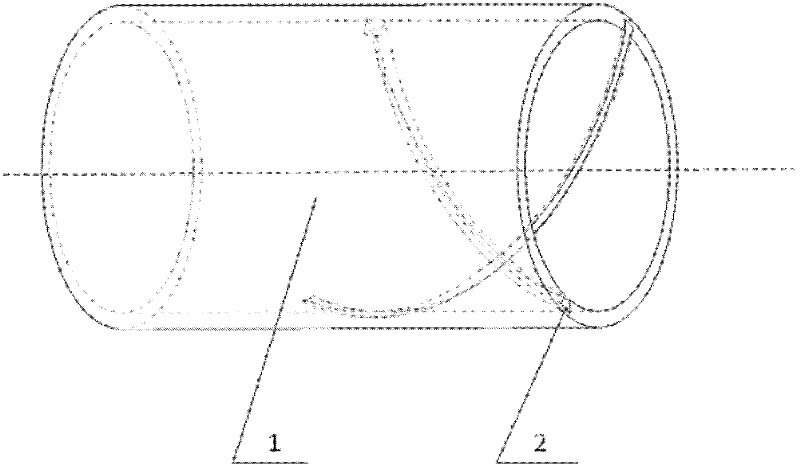

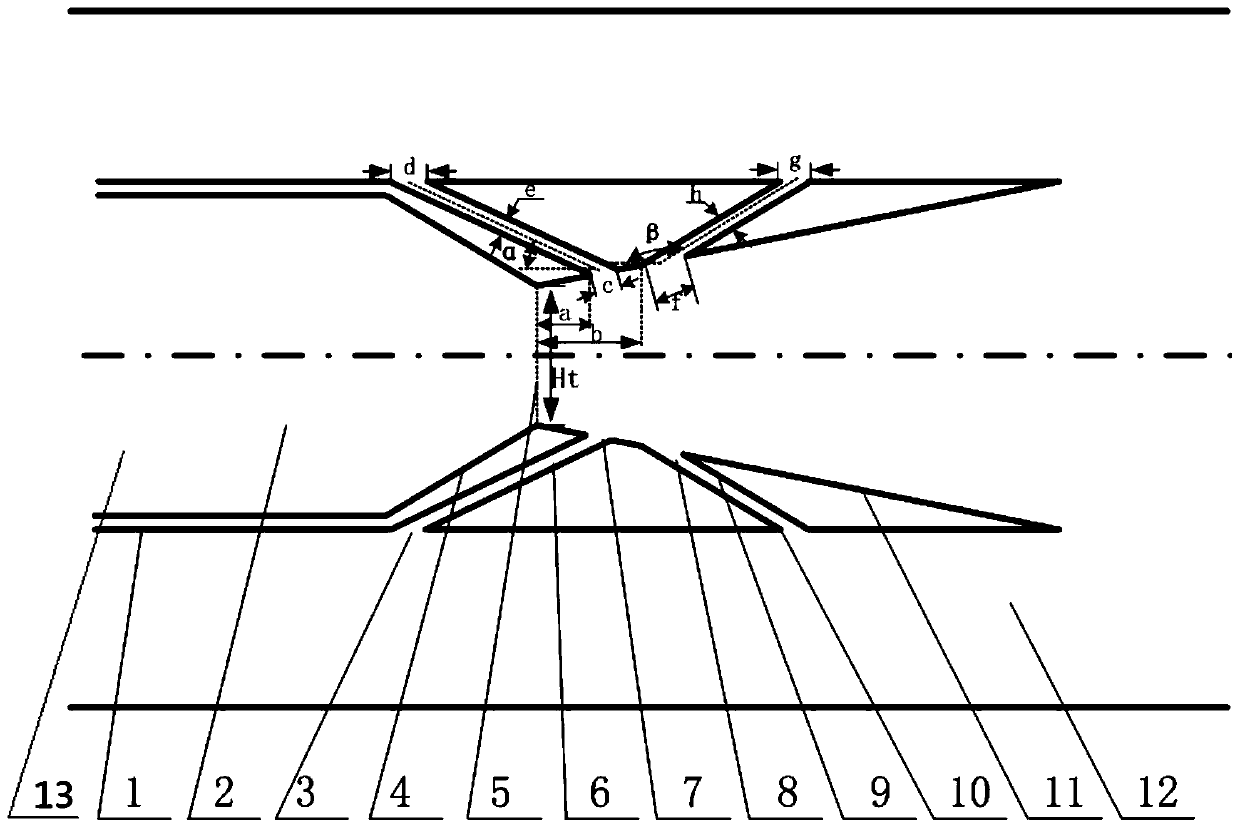

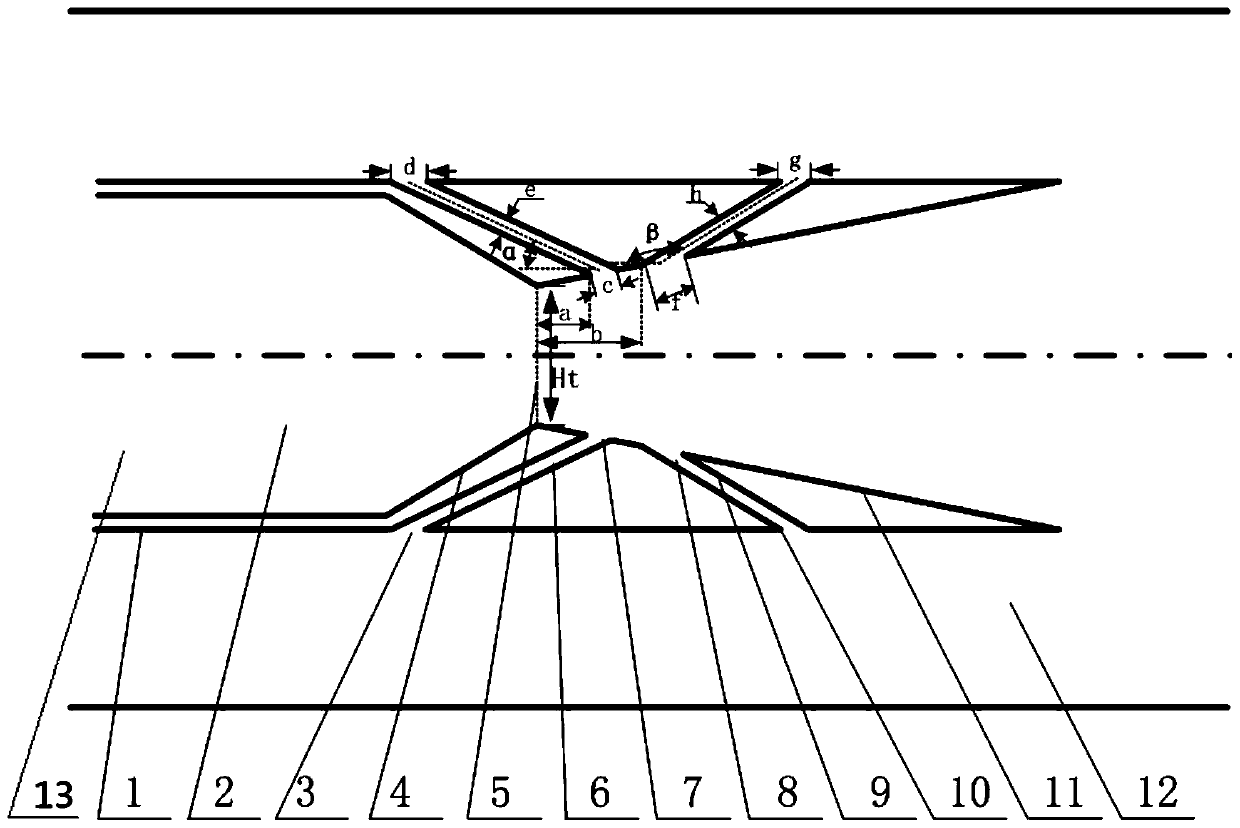

Exhaust mixing method of refiling pneumatic ribbed jet pipe and device thereof

InactiveCN102444499AImprove entrainment capacityImprove blending effectJet propulsion plantsJet flowEngineering

The invention discloses an exhaust mixing method of a refiling pneumatic ribbed pipe and a device thereof. The exhaust mixing method is that refiling cylindrical jet flow jetted to a main flow area of a main jet pipe of the engine is led into the position close to an outlet of the main jet pipe of the engine to lead air flow in the main flow area of the main jet pipe of the engine to generate peripheral rotating component velocity and accelerate the mixing effect of the air flow in the main flow area and air flow of the outside. Therefore, the exhaust mixing method of the refiling pneumatic ribbed jet pipe and the device of the exhaust mixing method narrows the range of the potential flow core area of the outlet of the jet pipe and enhances entrainment capacity of the main air flow so as to improve the mixing effect of the air flow at the outlet of the main jet pipe of the engine and the air flow of the outside.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

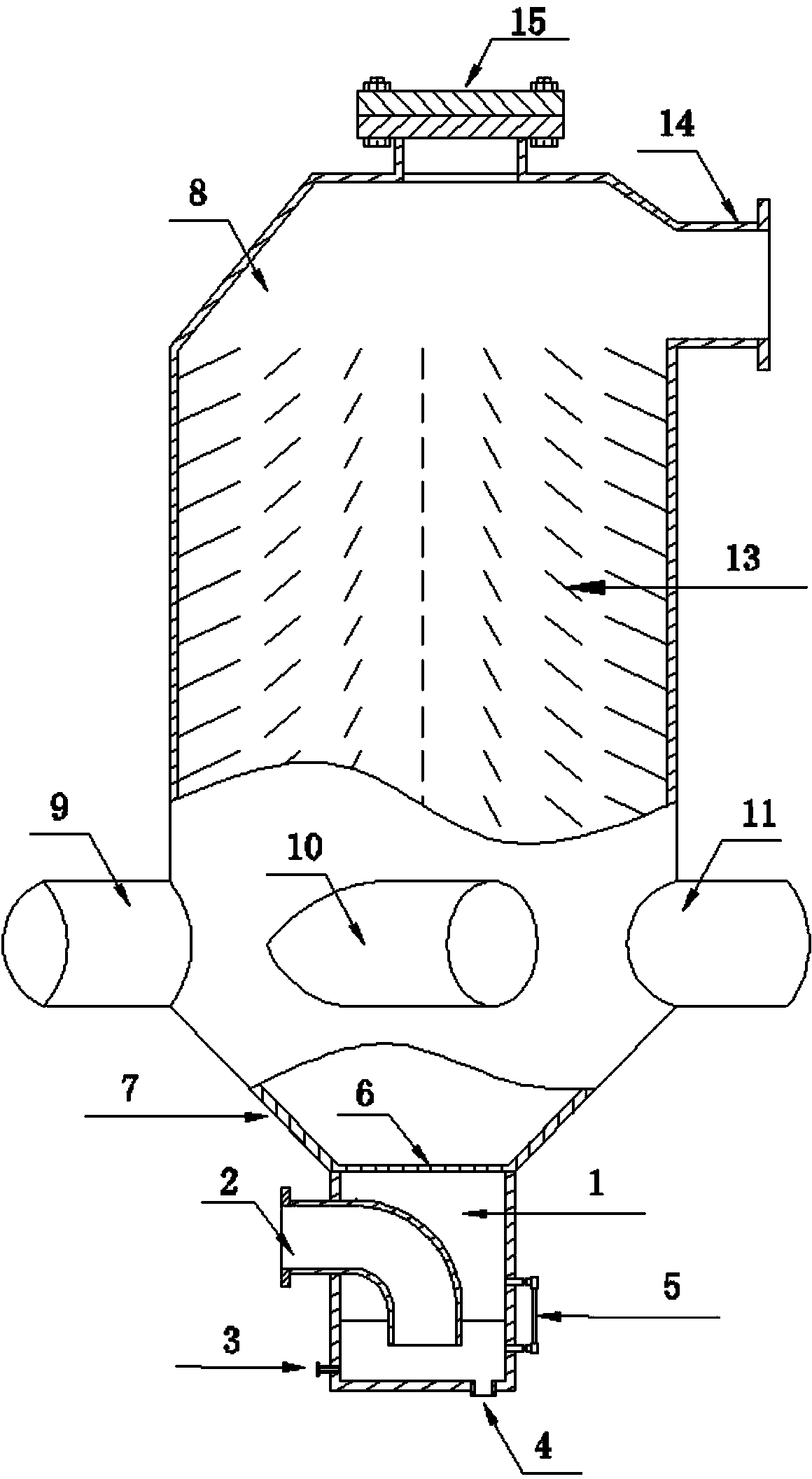

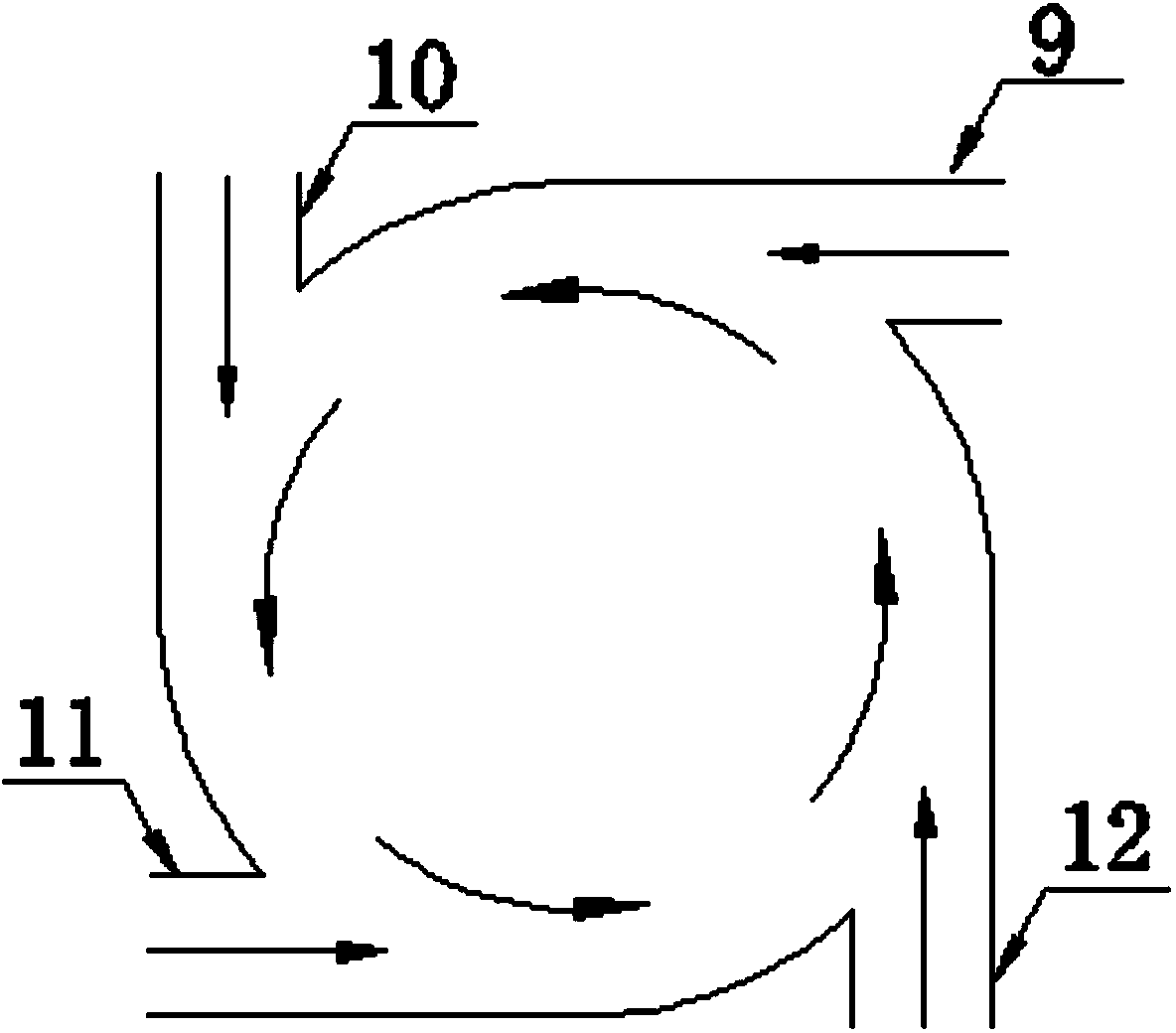

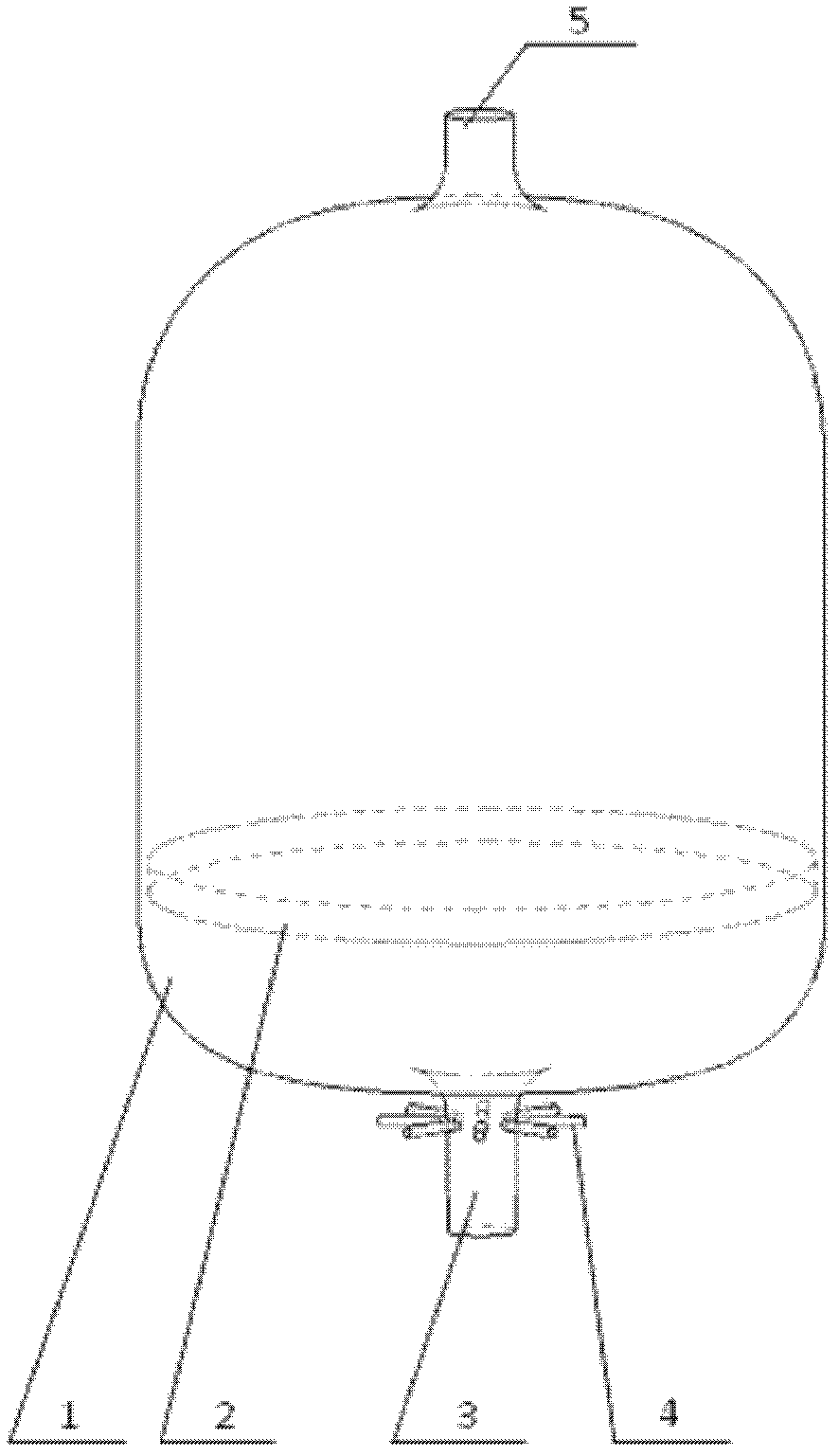

Water-fire resistant ventilation air methane mixing device

ActiveCN103801205AImprove securityEvenly distributedFlow mixersMixing gases with gases/vapoursEngineeringMixing effect

The invention discloses a water-fire resistant ventilation air methane mixing device, comprising a water storage barrel and a mixing barrel connected with the water storage barrel, wherein the water storage barrel is arranged at the bottom of the mixing barrel; a low-concentration gas intake pipe is arranged on the water storage barrel; a pipe orifice of the intake pipe is merged below the liquid level; at least two ventilation air intake pipes are arranged at the lower part of the mixing barrel; an escape pipe is arranged on the upper wall surface of the mixing barrel; ventilation air entering the mixing barrel forms a circumferential rotational flow by the at least two ventilation air intake pipes. The invention provides the mixing device which is good in mixing effect, high in safety performance and small in fluid pressure loss, and has dewatering and dust removing functions. The device is applicable to mixing of low-concentration gas with ventilation air or air as well as flammable and explosive gas and air.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Phase change type paraffin-containing fuel ramjet engine

ActiveCN112814807APhase transition helpsIncrease temperatureContinuous combustion chamberTurbine/propulsion fuel heatingRamjetCombustion chamber

The invention discloses a phase change type paraffin-containing fuel ramjet engine, which adopts an integrated design of a combustion chamber and a gasification chamber, and is compact in structure and high in energy utilization rate. A shell is heated by a large amount of heat released by combustion reaction in the combustion chamber, the surface of paraffin-containing fuel can be preheated under the action of radiation and heat convection, and meanwhile, ram air is heated, so that the surface of the fuel has higher temperature, and phase change of the fuel is facilitated. Mode conversion is easy to achieve, and automatic switching between a boosting section and a ramming section can be completed through change of pressure intensity. The head of the combustion chamber is provided with a conical hole with a certain inclination, so that the rotational flow of gas can be realized, and higher combustion efficiency can be further obtained. When the boosting section and the ramming section are switched, a mixture of a phase change product and air generates rotational flow under the action of the conical hole when flowing into the combustion chamber, so that the mixing effect is good. The engine is adjustable in size, wide in application range, and suitable for power systems of supersonic aircrafts.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

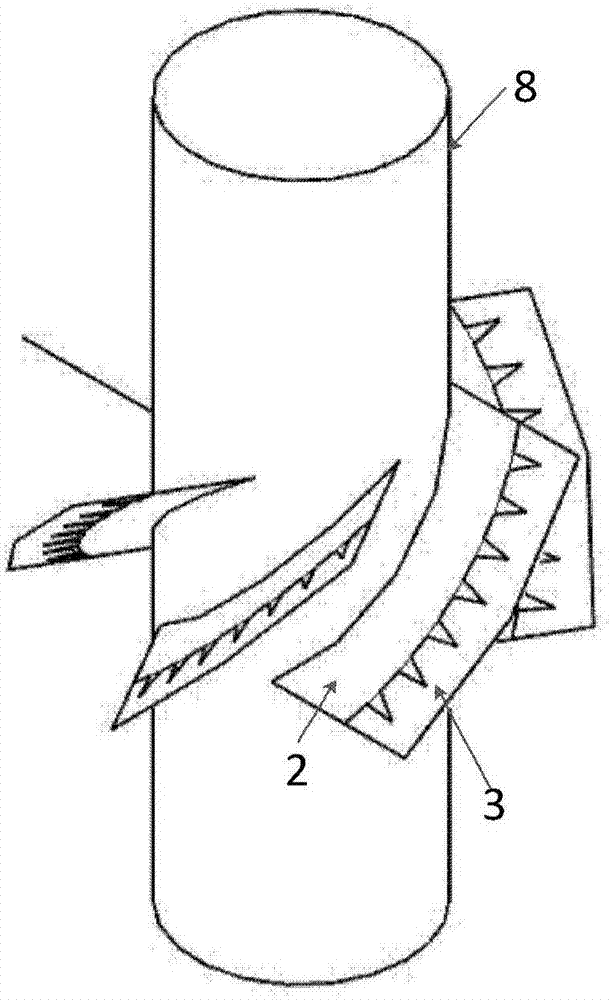

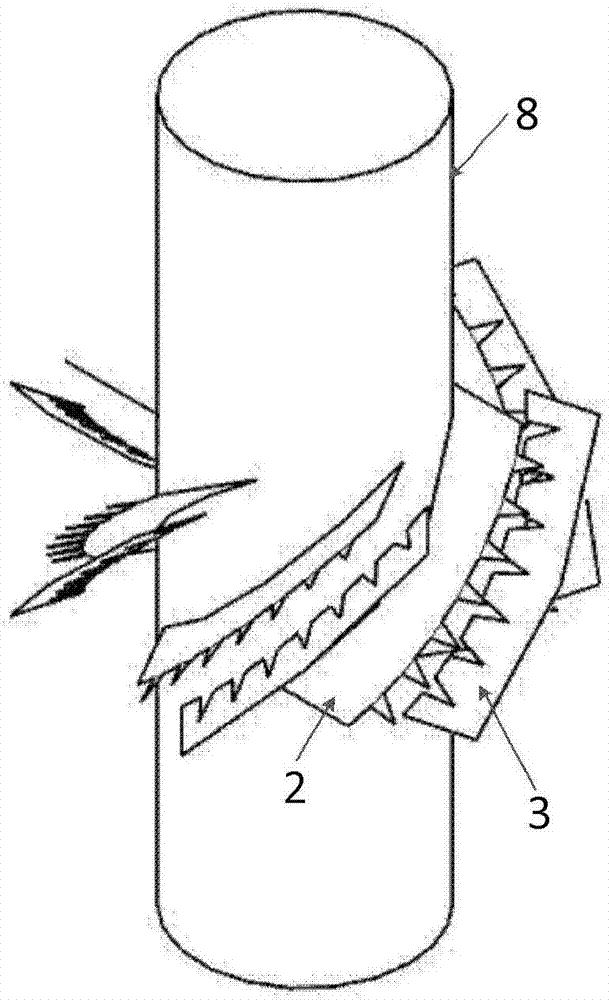

Self-adaptive rocket spray tube applied to rocket based combined circulating engine

ActiveCN109915282AReduce overexpansionReduce bottom resistanceRocket engine plantsSelf adaptiveJet flow

The invention discloses a self-adaptive rocket spray tube applied to a rocket based combined circulating engine. The self-adaptive rocket spray tube comprises a spray tube body, wherein a flow-supplementing sucking channel and a pneumatic tab channel are arranged on the spray tube body; when the rocket based combined circulating engine works in an ejector mode, the rocket engine sprays high-speedgas flow to the outer side of the spray tube body along a pneumatic tab channel, and high-speed gas flow mutually acts with gas flow on the outer part of the spray tube body to form streamwise vortex,so that mixing between rocket jet flow and outer gas flow is strengthened; and moreover, along with different working conditions of the rocket engine, penetrating depth of a pneumatic tab generates changes. When the rocket based combined circulating engine is in a sub-combustion or super-combustion mode, the rocket engine is switched off; and gas flow on the outer part of the spray tube body automatically flows into the spray tube body from the outer side of the spray tube body along the flow-supplementing sucking channel as a result of internal and external pressure difference, so that bottom resistance generated by the spray tube is reduced. The self-adaptive rocket spray tube has certain self-adaptive regulating ability, and facilitates integral pneumatic performance.

Owner:NAT UNIV OF DEFENSE TECH

Rubber composition, and tire using the same

PendingUS20210292519A1Improve wet skid resistanceGreat tractionSpecial tyresTyre tread bands/patternsElastomerPolymer science

Disclosed is a rubber composition and a tire using the same. The rubber composition comprises a rubber matrix and a compounding component. In parts by weight, every 100 parts by weight of said rubber matrix comprises 5-95 parts by weight of a branched polyethylene, 5-90 parts by weight of a highly unsaturated diene elastomer and 0-30 parts by weight of a low unsaturated diene elastomer; and said compounding component comprises a vulcanization system and a filler. The rubber composition has good aging resistance and mechanical properties, and can be applied for products such as tires, rubber hoses, rubber tapes and so on, in which the traditional, easily aging diene rubber was commonly used.

Owner:HANGZHOU XINGLU TECH CO LTD +1

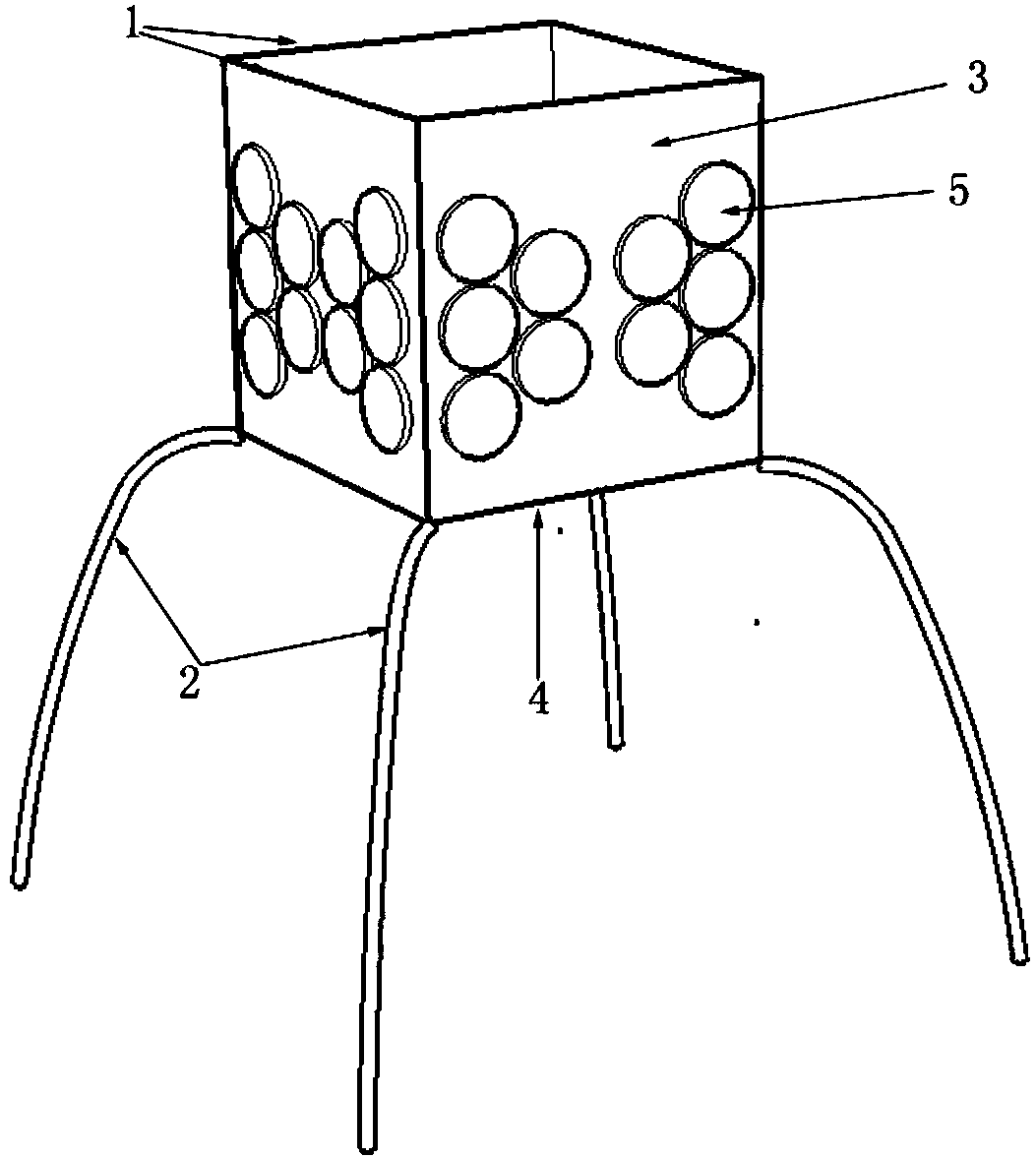

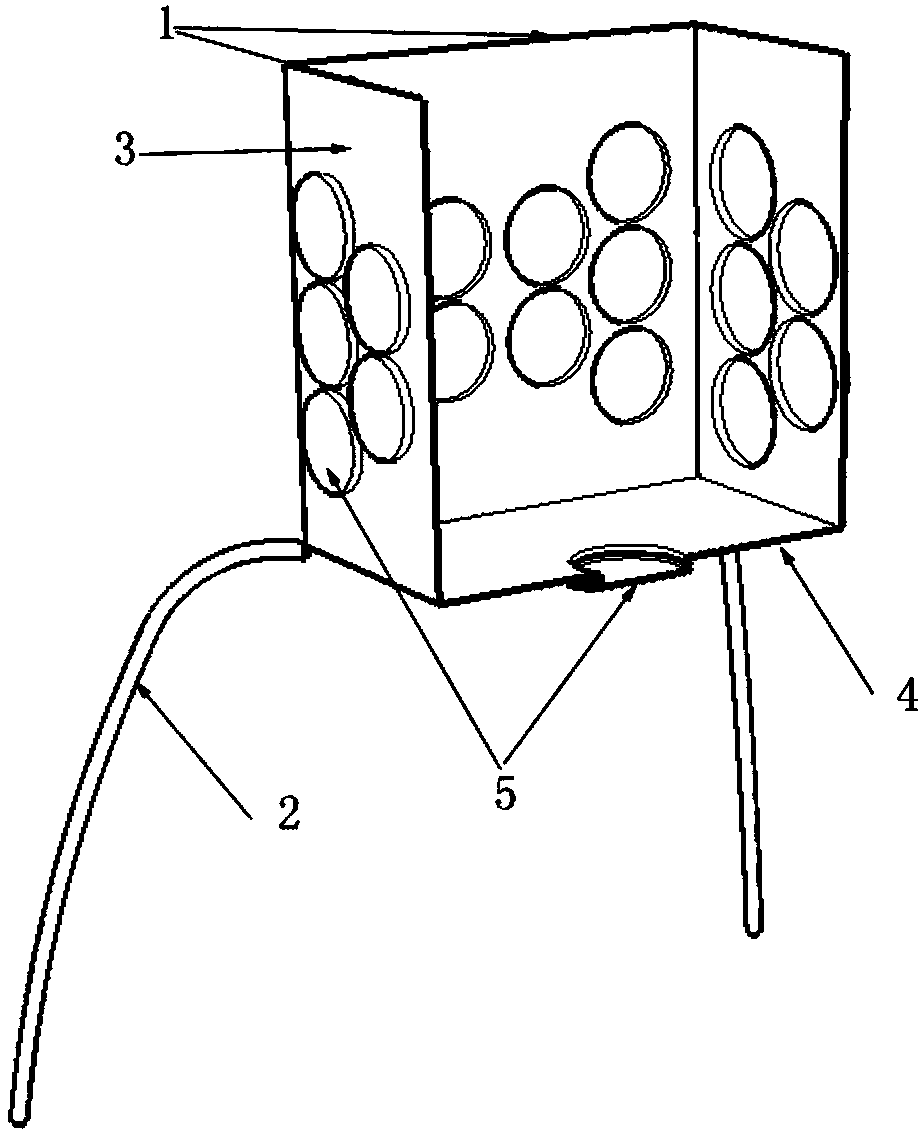

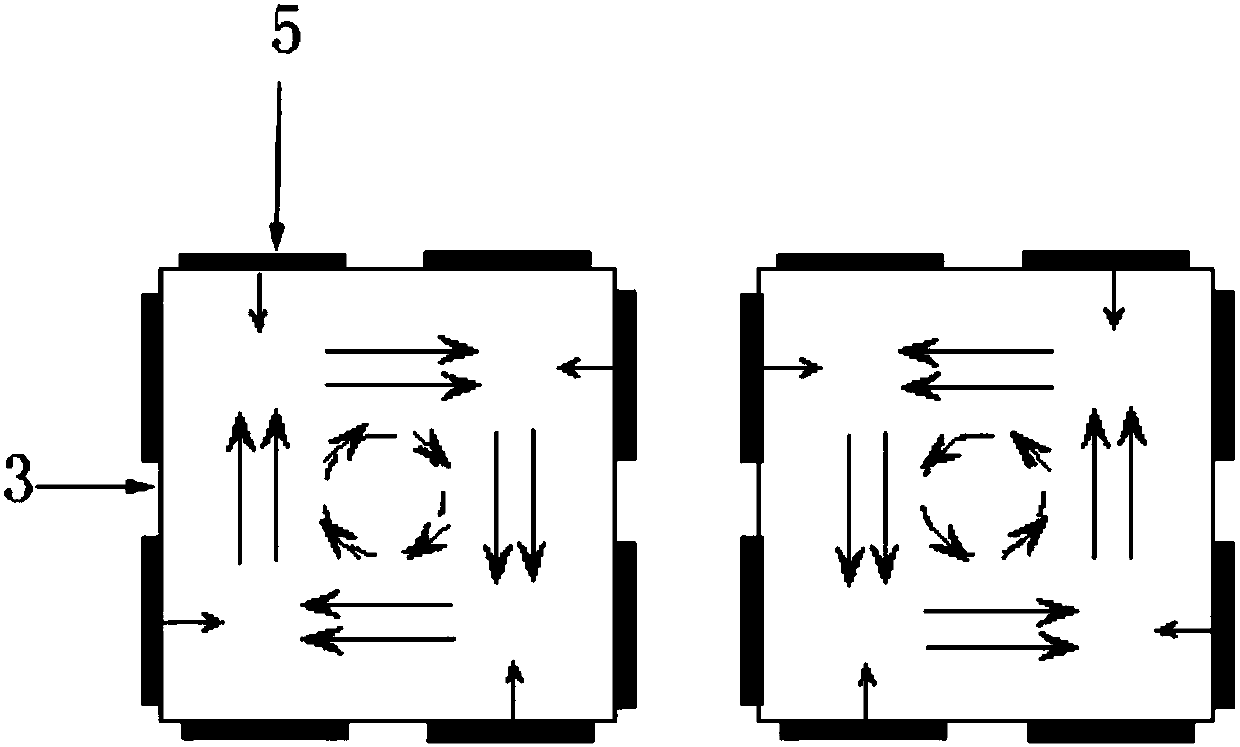

Multi-scale blender and multi-scale blending method

PendingCN107551920AMulti-scale blending implementationGood blendabilityShaking/oscillating/vibrating mixersUltrasonic vibrationMechanical engineering

The present invention provides a multi-scale blender, which comprises a housing and support legs for supporting the housing, wherein a plurality of piezoelectric sheets are attached to the housing, and ultrasonic waves generated by the plurality of the piezoelectric sheets drive a fluid to rotate so as to produce various scales of vortexes. According to the present invention, the multi-scale blender combines fluid motion and ultrasonic vibration, such that the multi-scale blending from the large scale to the microscopic scale is achieved, and the blending effect is improved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

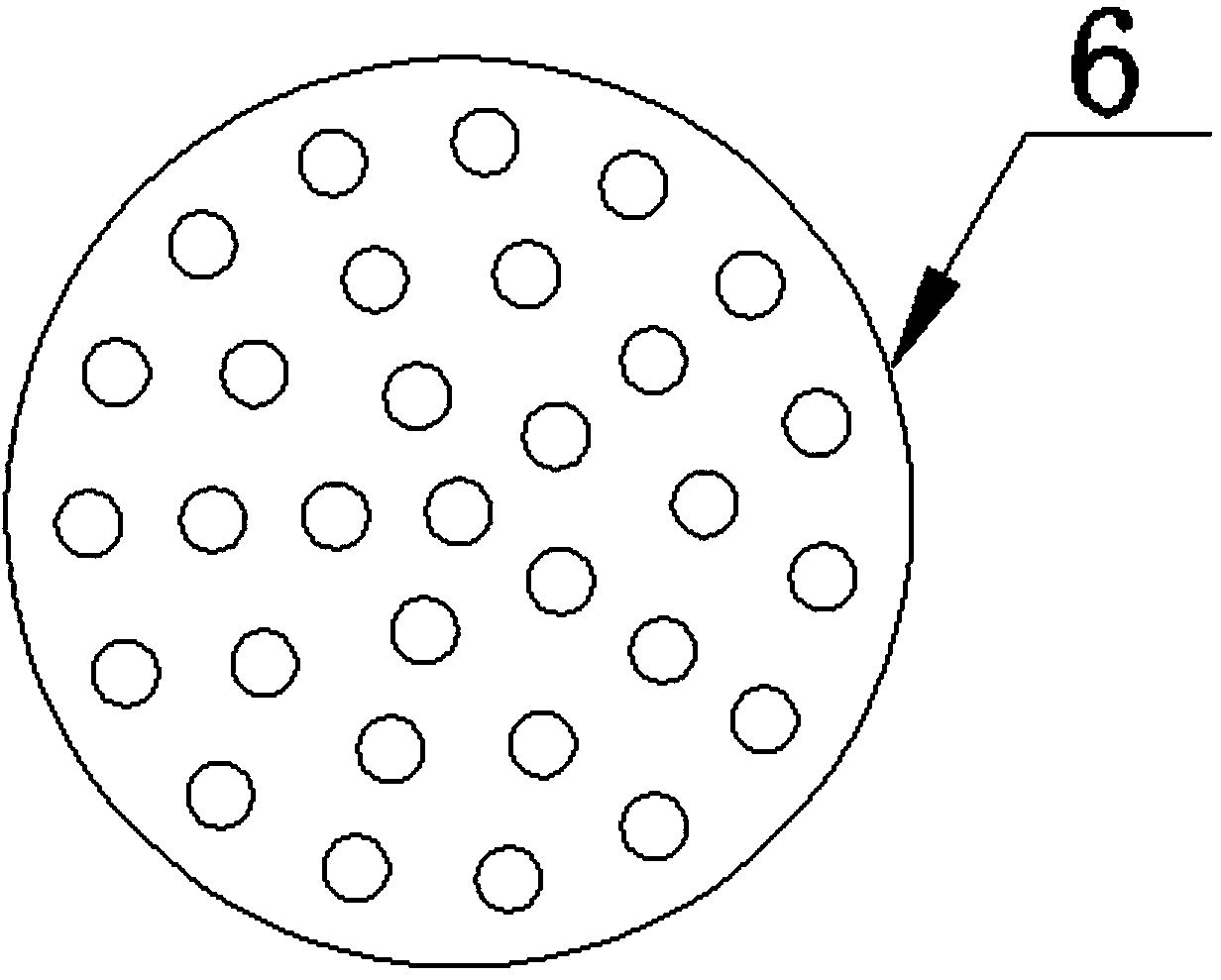

Particle image velocimetry (PIV) experimental particle mixing device based on pneumatic lug technology

InactiveCN102513012BShorten the core area of potential flowWell mixedAerodynamic testingTransportation and packagingEngineeringMixing effect

The invention discloses a particle image velocimetry (PIV) experimental particle mixing device based on a pneumatic lug technology, which comprises a mixing tank and a filtering element disk for containing PIV trace particles; the filtering element disk is arranged in the mixing tank; moreover, the mixing tank is respectively provided with an air-inlet main pipe and an air outlet pipe, the circumferential direction nearby the position of an outlet of the air-inlet main pipe is evenly distributed with pneumatic lugs, the pneumatic lugs comprise the jetting pipes of the pneumatic lugs and flow-jetting control mechanisms for controlling the jetting flow rate of the jetting pipes of the pneumatic lugs, and the jetting ports of the jetting pipes of the pneumatic lugs are arranged in a way of facing to a main flow area of the air-inlet main pipe; furthermore, the air inlets of the jetting pipes of the pneumatic lugs are communicated with bypass airflow; and moreover, the total pressure of airflow jetted by the jetting pipes of the pneumatic lugs is higher than the total pressure of airflow in the air-inlet main pipe. Therefore, flowing vortex is formed at the positions of the outlets of the jetting pipes by arranging the pneumatic lugs on the air-inlet main pipe according to the PIV experimental particle mixing device based on the pneumatic lug technology, so that the mixing effect of PIV particles in a particle mixer is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

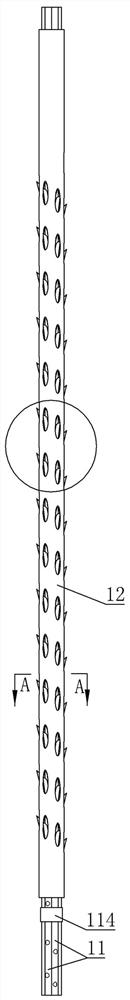

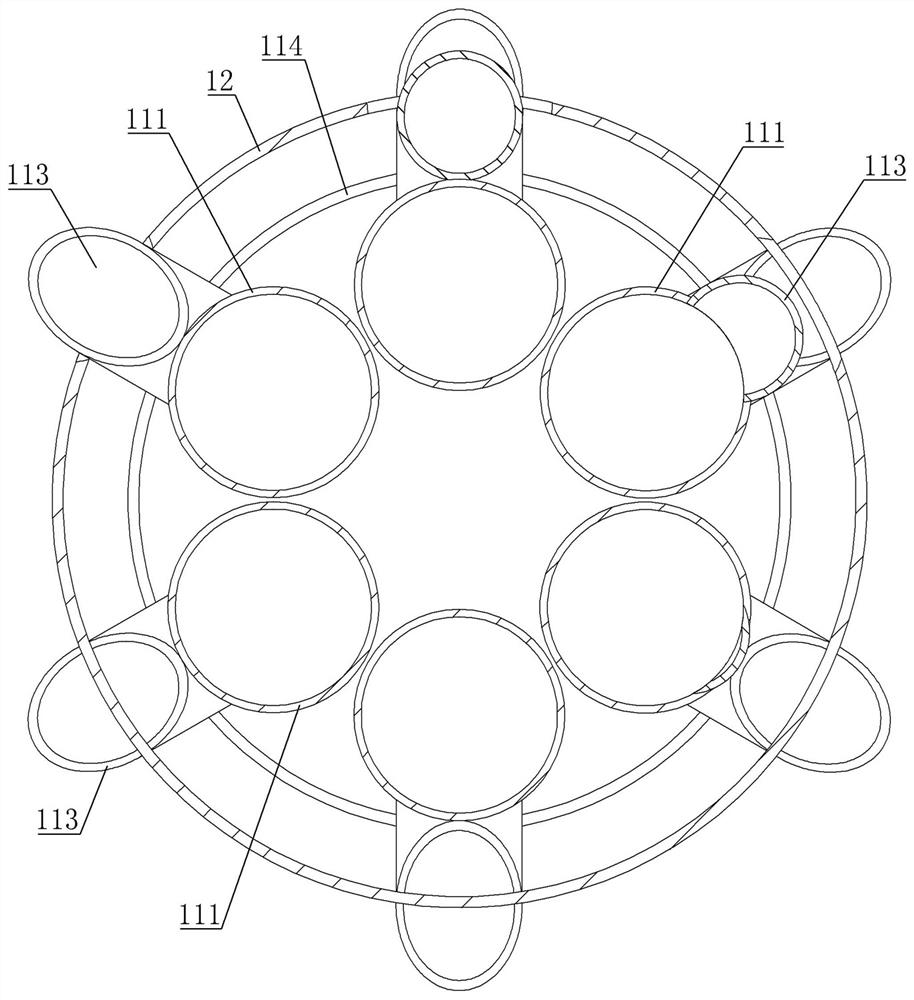

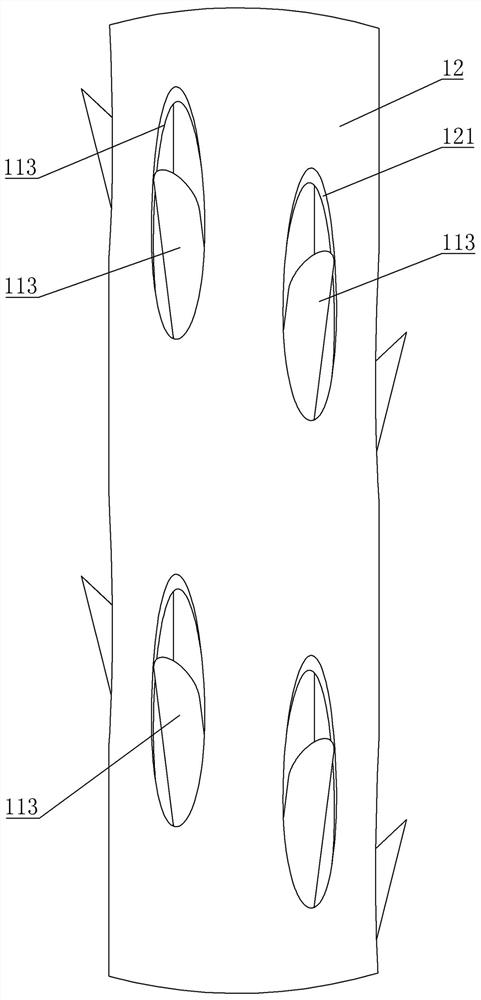

Double-layer mixing pipe and residue-free mixing bin

PendingCN114452872AWell mixedImprove product qualityShaking/oscillating/vibrating mixersTransportation and packagingVertical vibrationPipe

According to the double-layer mixing pipe and the residue-free mixing bin, a mixing pipe in the bin is the double-layer mixing pipe, a mixing pipe bundle in the double-layer mixing pipe is fixedly connected with a vibration supporting plate arranged on an end cover, an outer sleeve is fixedly connected with a barrel-shaped support arranged on the end cover, an oval hole is formed in the outer sleeve, and the outer sleeve is fixedly connected with the barrel-shaped support. The feeding hole of the mixing pipe is provided with the inclined feeding duckbilled pipe extending out of the oval hole, the oval hole reserves a vibration space for the feeding duckbilled pipe, interference of the inner pipe and the outer pipe is avoided, and when the mixing pipe bundle vibrates to discharge materials, the outer sleeve bears the pressure of materials in the stock bin, so that the mixing effect is good. The problem of different vertical vibration amplitudes caused by different pressures of materials at the upper part and the lower part of the internal mixing tube bundle is solved, the flows of the materials at the upper part and the lower part entering the mixing tube are the same, and the materials are mixed more uniformly; in addition, each mixing tube bundle transmits vibration force to the auxiliary mixing tube in the conical bin bottom through the cross-shaped support, materials in different batches in the conical bin bottom can be mixed and discharged, and the whole mixing is more uniform.

Owner:NANJING XIANGRUI INTELLIGENT EQUIP TECH CO LTD +2

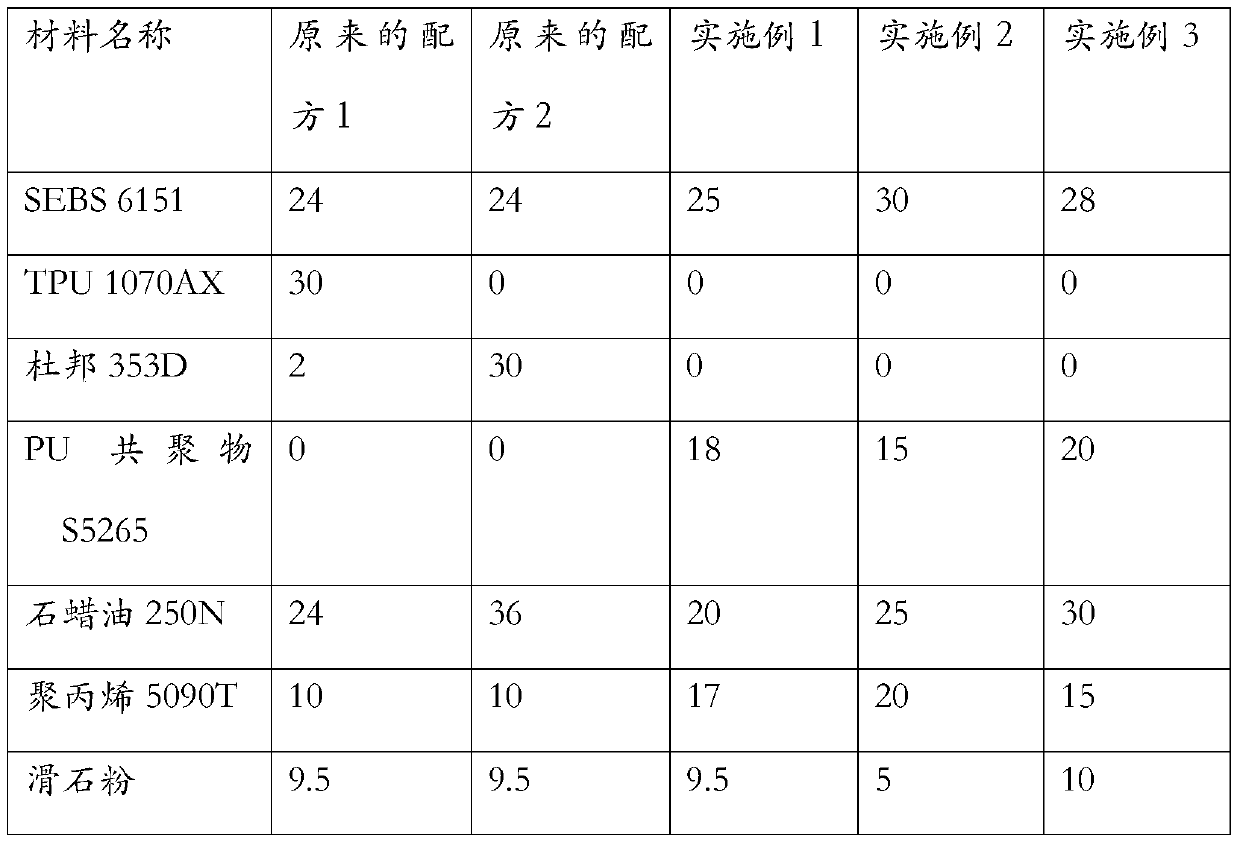

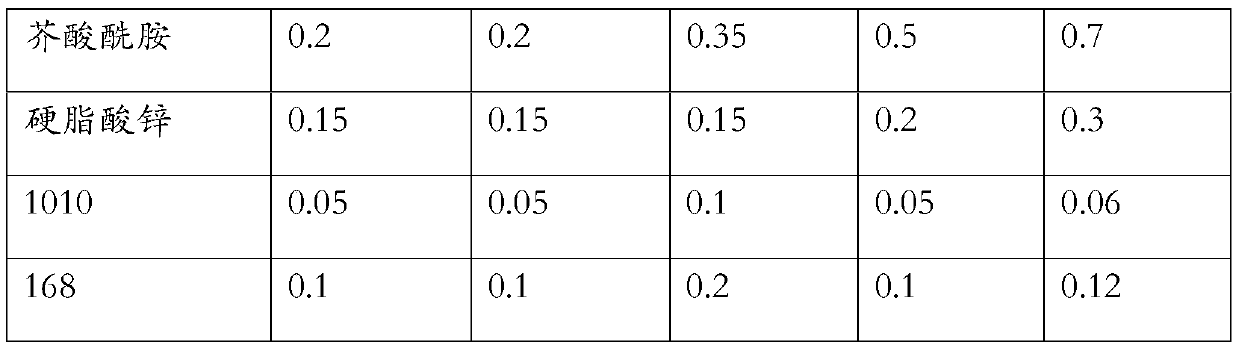

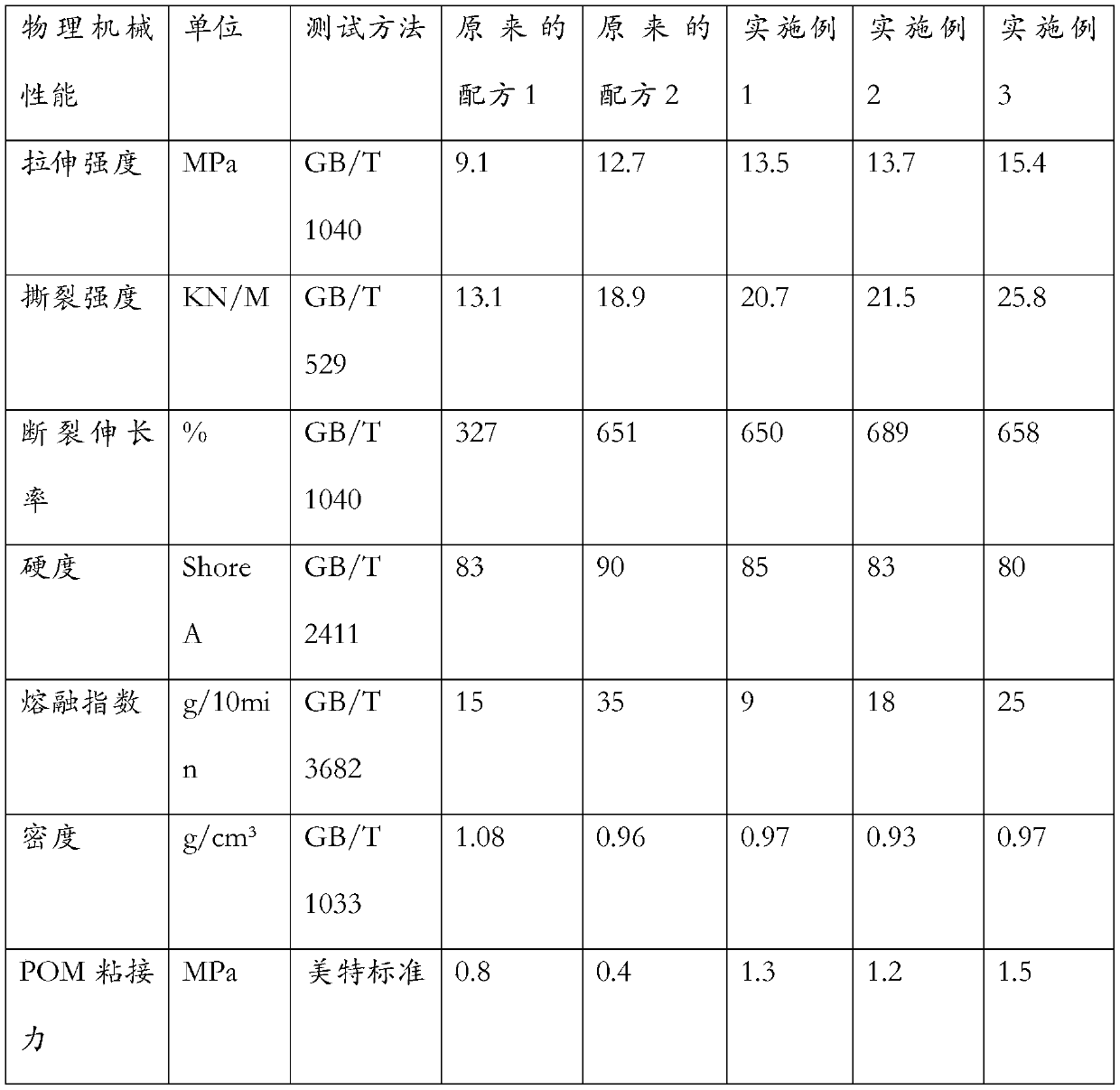

TPE material for bonding polyformaldehyde (POM) and preparation method of TPE material

ActiveCN110746915AGood stability and aging resistanceImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolypropyleneDouble bond

The invention discloses a TPE material for bonding polyformaldehyde (POM). The TPE material is prepared from the following raw materials in parts by weight: 25-30 parts of styrene-ethylene-butane-styrene (SEBS) block copolymer, 15-20 parts of polypropylene, 20-30 parts of mineral oil, 15-20 parts of a PU copolymer, 5-10 parts of talcum powder, 0.5-1 part of a lubricant and 0.15-0.3 part of an antioxidant. SEBS in the TPE material components contains unsaturated double bonds and has good stability and aging resistance, heat resistance of the SEBS is significantly improved compared with heat resistance of SBS, and good wear resistance and flexibility are achieved; compatibility between the polypropylene and a PS segment in the SEBS is good, double continuous phases can be formed, and thus the tensile strength of TPE is improved; compatibility between the PU copolymer and the SEBS is good, double continuous phases can be formed, and the overall mechanical properties are improved; and thePU copolymer contains a PU polar segment, thus material polarity is high, and bonding force is increased.

Owner:张家港市美特高分子材料有限公司

High-property mine modified cable sheath material

InactiveCN104610685AGood chemical stabilityNo toxicityPlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxideDi-tert-butyl peroxide

The invention discloses a high-property mine modified cable sheath material. The sheath material is prepared from the following raw materials in parts by weight: 40-50 parts of polyvinyl chloride resin, 30-40 parts of EVA (ethylene-vinyl acetate copolymer) resin, 1-2 parts of triethanolamine, 10-15 parts of modified aluminium hydroxide, 20-30 parts of magnesium hydroxide, 1-2 parts of zinc oxide, 0.5-0.8 part of accelerator TAC, 0.5-1 part of accelerator HVA-2, 1-1.5 parts of triallyl isocyanurate, 0.4-0.6 part of di-tert-butyl peroxide, 1-1.6 parts of light magnesium oxide, 1-3 parts of anti-aging agent A, 0.5-1.5 parts of anti-aging agent 4010NA, 20-30 parts of carbon black N990, 12-16 parts of diatomite and 30-45 parts of calcined clay. The sheath material has good processability, good mechanical properties and excellent flame retardance.

Owner:ANHUI WANTAI CABLE

Agrochemical composition and dispersal method therefor

ActiveUS20180352813A1Good blendabilityImprove the mixing effectAircraft componentsBiocidePesticideChemistry

Provided are an agrochemical composition containing pyribencarb which has good blendability with an agrochemical composition containing etofenprox, and a method for spraying the composition. The agrochemical composition which contains pyribencarb (A) and a surfactant (B), characterized in that as the surfactant (B), a lignin sulfonic acid salt having purity of 85% by mass or more, wherein the content of reducing sugars is less than 5% by mass and the content of sugar sulfonic acids is less than 6% by mass (B1), and a monoalkylarylsulfonic acid salt formalin condensate and / or a polycarboxylic acid salt having mass average molecular weight of 5,000 to 50,000 (B2) are exclusively included; and the method for spraying the composition.

Owner:KUMIAI CHEM IND CO LTD

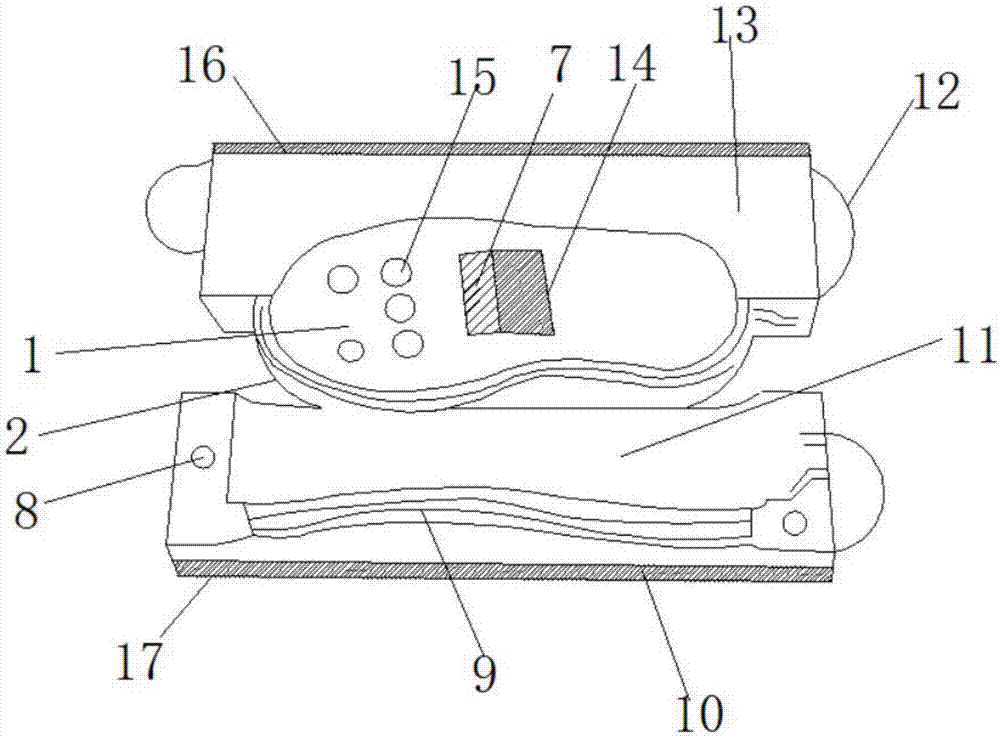

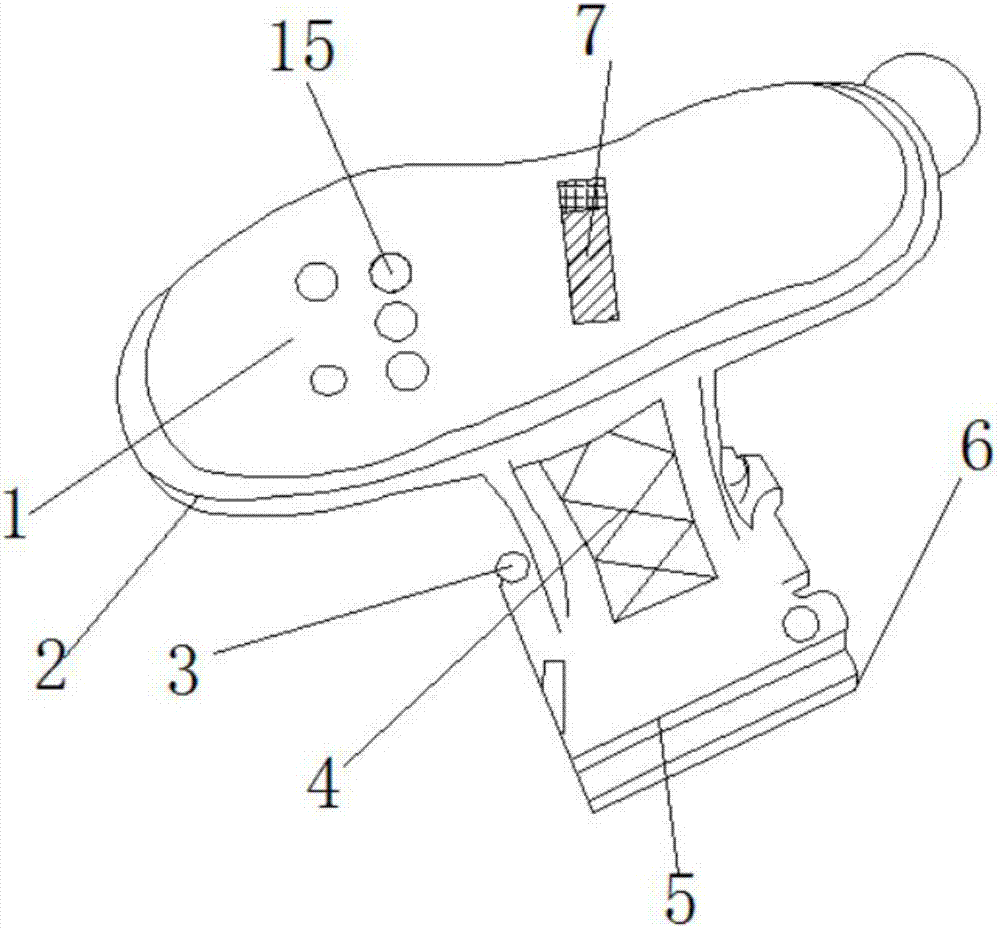

Injection mould shoe insole for manufacturing bottom face anti-sliding protruding points and manufacturing method of injection mould shoe insole

InactiveCN107053724AEasy to disassembleGood flexibilitySolesDomestic footwearEngineeringNail structure

The invention discloses an injection mould shoe insole for manufacturing bottom face anti-sliding protruding points and a manufacturing method of the injection mould shoe insole. The injection mould shoe insole comprises a base and a lower die, a shock pad is fixedly installed at the upper end of the base, and the upper portion of the shock pad is provided with a fixing hole, a first horizontal working table, a second horizontal working table and a radiating guide sheet; a protruding nail structure is arranged on one side of a protruding groove, and the other side of the protruding groove is provided with a protruding groove and a rectangular groove; the bottom of the lower die is provided with an upper base, a lower base and a screw, a connecting plate is arranged at the upper end of the upper base, and the upper base is fixedly connected with the lower die through the connecting plate; and a lamp strip is fixedly installed on the upper surface of the second horizontal working table. By means of the injection mould shoe insole for manufacturing the bottom face anti-sliding protruding points and the manufacturing method of the injection mould shoe insole, the shock pad and the lamp strip are arranged, and therefore equipment operation convenience can be guaranteed, night operation can be carried out, skid resistance of the shoe insole is effectively achieved, the injection mould shoe insole is suitable for different working conditions, and the better using prospect is achieved.

Owner:东莞市鹏翼自动化科技有限公司

Adaptive rocket nozzle for rocket-based combined cycle engines

ActiveCN109915282BImprove performancePerformance impactRocket engine plantsClassical mechanicsSelf adaptive

The invention discloses a self-adaptive rocket spray tube applied to a rocket based combined circulating engine. The self-adaptive rocket spray tube comprises a spray tube body, wherein a flow-supplementing sucking channel and a pneumatic tab channel are arranged on the spray tube body; when the rocket based combined circulating engine works in an ejector mode, the rocket engine sprays high-speedgas flow to the outer side of the spray tube body along a pneumatic tab channel, and high-speed gas flow mutually acts with gas flow on the outer part of the spray tube body to form streamwise vortex,so that mixing between rocket jet flow and outer gas flow is strengthened; and moreover, along with different working conditions of the rocket engine, penetrating depth of a pneumatic tab generates changes. When the rocket based combined circulating engine is in a sub-combustion or super-combustion mode, the rocket engine is switched off; and gas flow on the outer part of the spray tube body automatically flows into the spray tube body from the outer side of the spray tube body along the flow-supplementing sucking channel as a result of internal and external pressure difference, so that bottom resistance generated by the spray tube is reduced. The self-adaptive rocket spray tube has certain self-adaptive regulating ability, and facilitates integral pneumatic performance.

Owner:NAT UNIV OF DEFENSE TECH

Flame-retardant environment-friendly foamed plastic

The invention discloses a flame-retardant environment-friendly foamed plastic which comprises the following raw materials in parts by weight: 32-37 parts of ethylene-vinyl acetate (EVA) resin, 68-72 parts of polycaprolactone (PCL), 2.8-3.2 parts of soybean meal, 2.7-3.6 parts of wood fibers, 1.2-1.7 parts of a titanate coupling agent NDZ-TTS, 3-3.6 parts of sodium lactate, 13-17 parts of a foaming agent ADC, 8-12 parts of zinc oxide, 9-10 parts of citric acid, 11-14 parts of sodium hydrogen carbonate, 1.6-1.9 parts of diisononyl phthalate (DINP), 2.2-2.7 parts of epoxy octyl stearate, 23-28 parts of barite powder, 15-18 parts of augite powder, 7-11 parts of white carbon black, 5-9 parts of mica powder, 3-6 parts of ammonium polyphosphate, 5-8 parts of melamine sodium polyphosphate, 1.5-1.8 parts of 2,6-di-tert-butyl-4-methylphenol (BHT) and 1.3-1.6 parts of an antioxidant BLE.

Owner:NINGGUO NINGSHENG RUBBER PROD

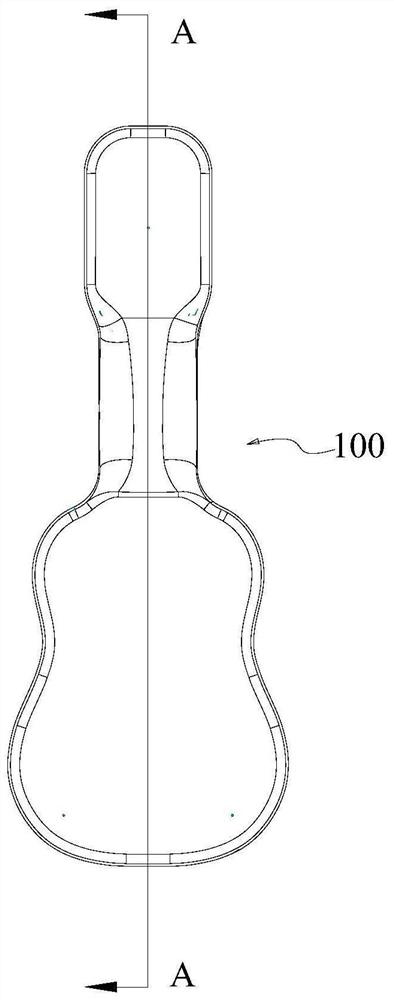

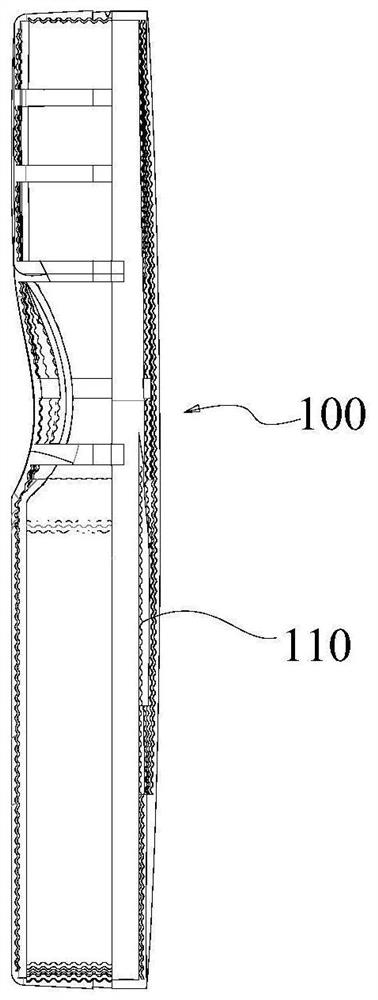

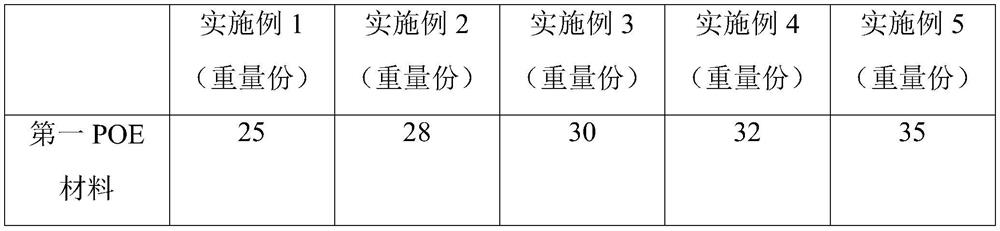

Foaming material applied to musical instrument box and preparation method thereof

The invention belongs to the technical field of musical instrument box manufacturing materials, and particularly relates to a foaming material applied to a musical instrument box and a preparation method thereof. According to the foaming material applied to the musical instrument box, the inner wall surface of the musical instrument box is filled with the foaming material, the Shore C hardness of the foaming material is 10-80 degrees, and the rebound rate of the foaming material is 25-65%. The inner wall surface of the musical instrument box is filled with the foaming material with the Shore C hardness of 10-80 degrees and the rebound rate of 25%-65%, so that the musical instrument box has an excellent protection effect, and the musical instrument in the musical instrument box is still intact after being impacted violently. The foaming material is a thermoplastic POE foaming material, and the thermoplastic POE foaming material is prepared from the following raw materials in parts by weight: 25 to 35 parts of a first POE material, 20 to 30 parts of a second POE material, 20 to 30 parts of a third POE material, 7 to 13 parts of talcum powder, 3 to 8 parts of zinc oxide, 0.5 to 1.5 parts of a lubricating agent, 0.5 to 1.5 parts of zinc stearate, 0.5 to 1.5 parts of a wear-resistant agent, 0.5 to 1.5 parts by weight of a bridging agent; and 0.5 to 1.5 parts by weight of a foaming agent.

Owner:DONGGUAN HUAJIN GIFTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com