Closed-cell foaming material as well as manufacturing formula and manufacturing method thereof

A foaming material and closed-cell technology, applied in the field of foaming materials, can solve the problems of XPE foaming holes are large and not dense, the density of foaming materials is high, and the scope of use is limited, so as to achieve high foaming density and increase foaming density , to create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

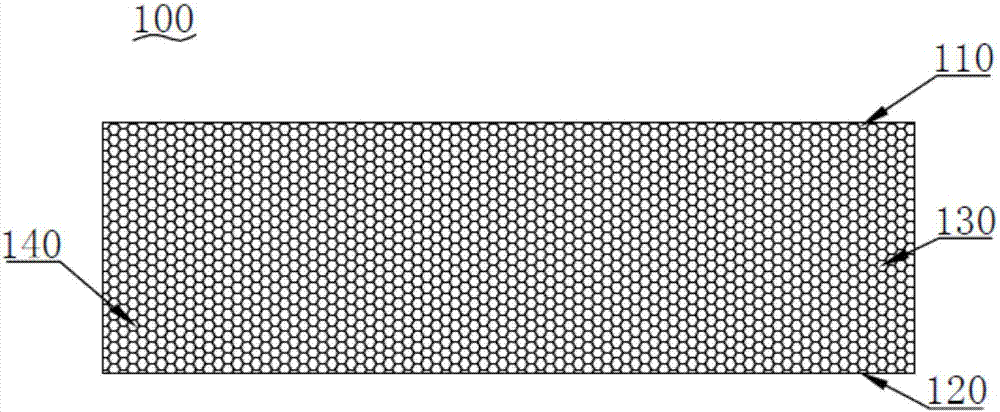

[0040] Such as figure 1 Shown is a schematic diagram of the present invention.

[0041] A closed-cell foam material, comprising a body 100, the body 100 is integrally formed by continuous foaming, the body 100 includes an upper skin 110, a central core layer 120 and a lower skin 130, the upper skin 110, the central core layer 120 and the lower skin 130 are integrally formed by continuous closed-cell foaming, the upper skin 110 and the lower skin 130 are smooth surfaces, and the core layer 120 is provided with a porous body 140 .

[0042] The continuous closed-cell foaming of the present invention is integrally molded, and the appearance of the foamed product is the same as that of IXPE and EVA molded foaming. No need to invest in high cost of equipment; molded foaming cannot be produced continuously, resulting in high labor costs and energy consumption; specifically,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com