Patents

Literature

49results about How to "Pressure resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

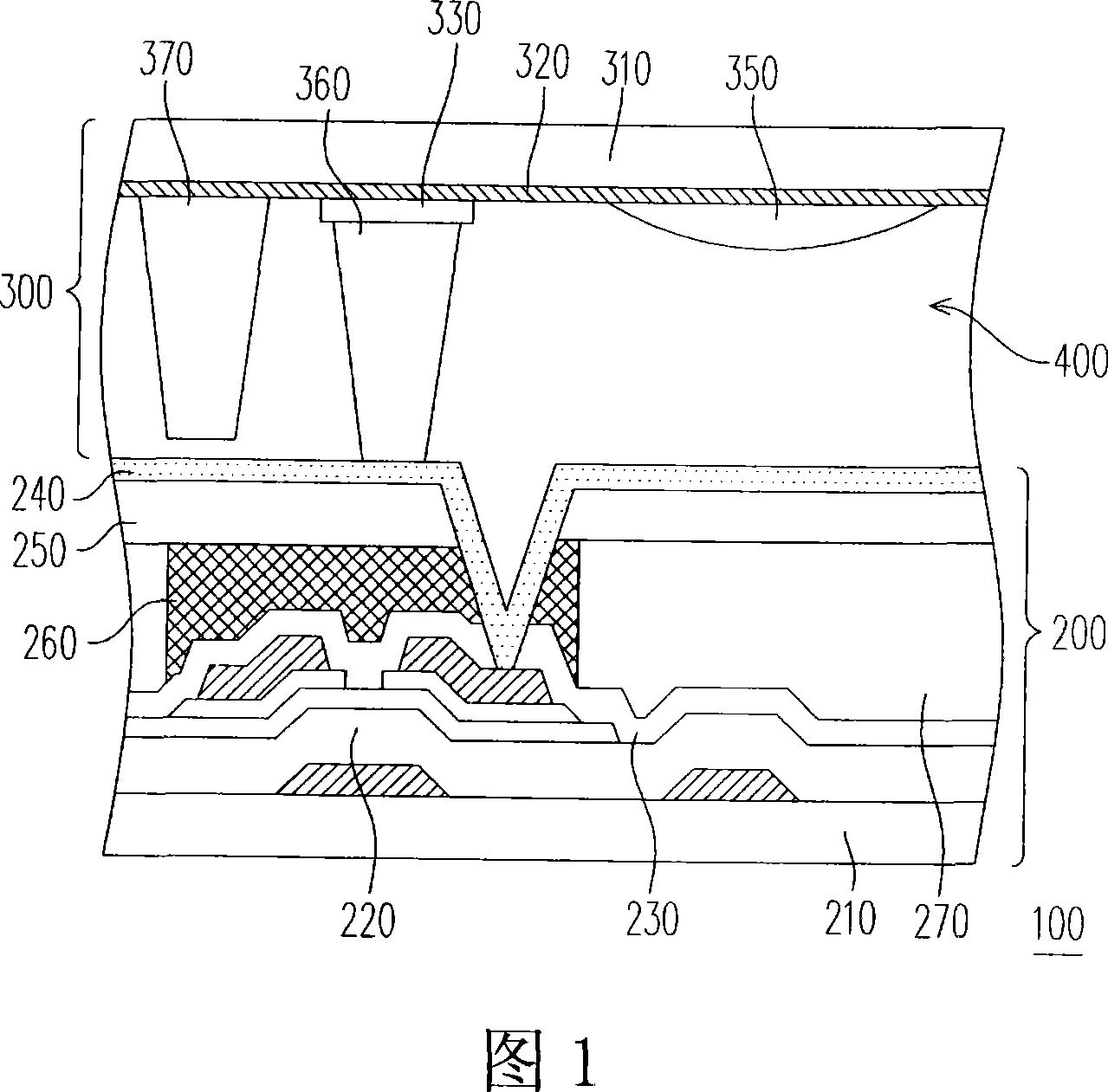

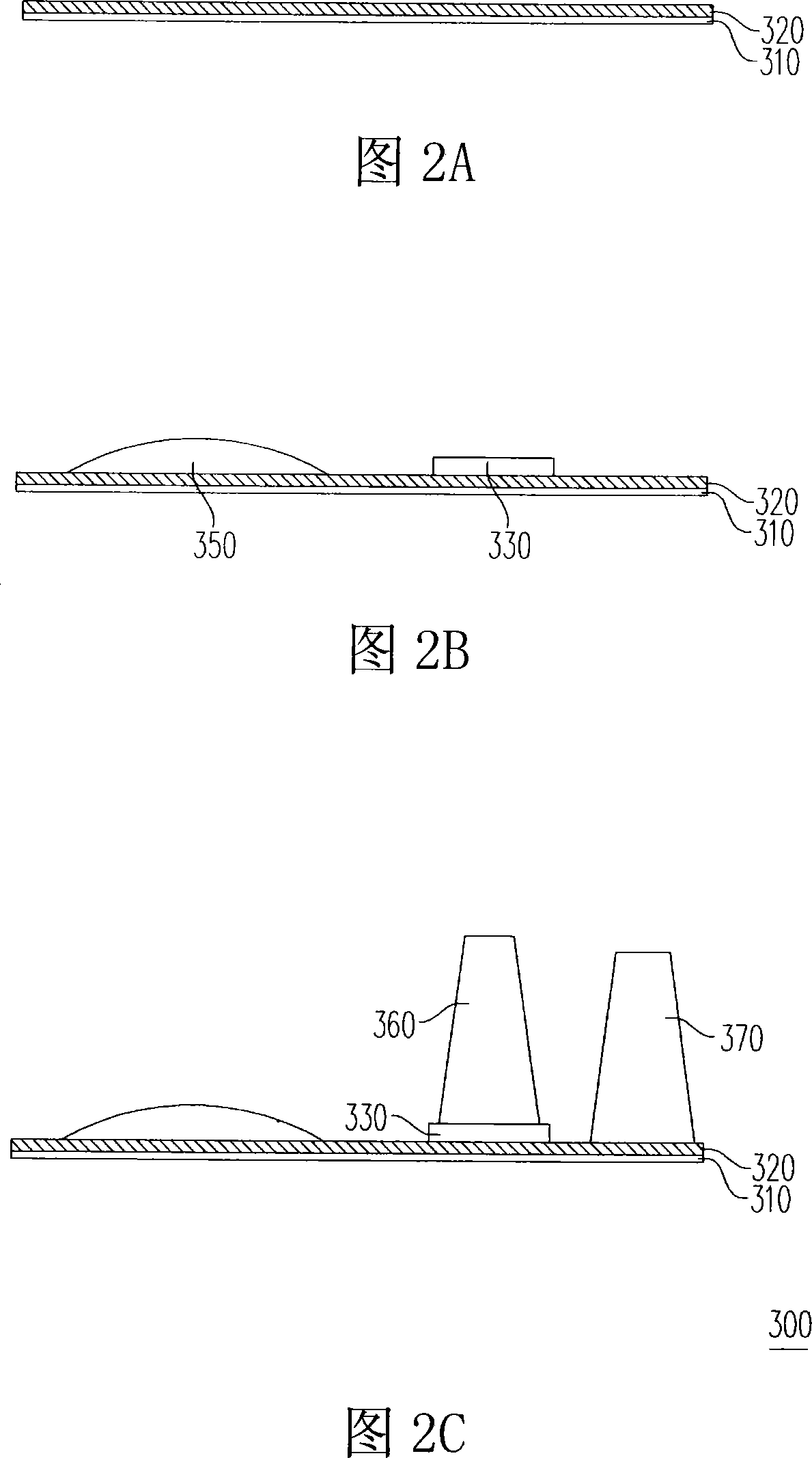

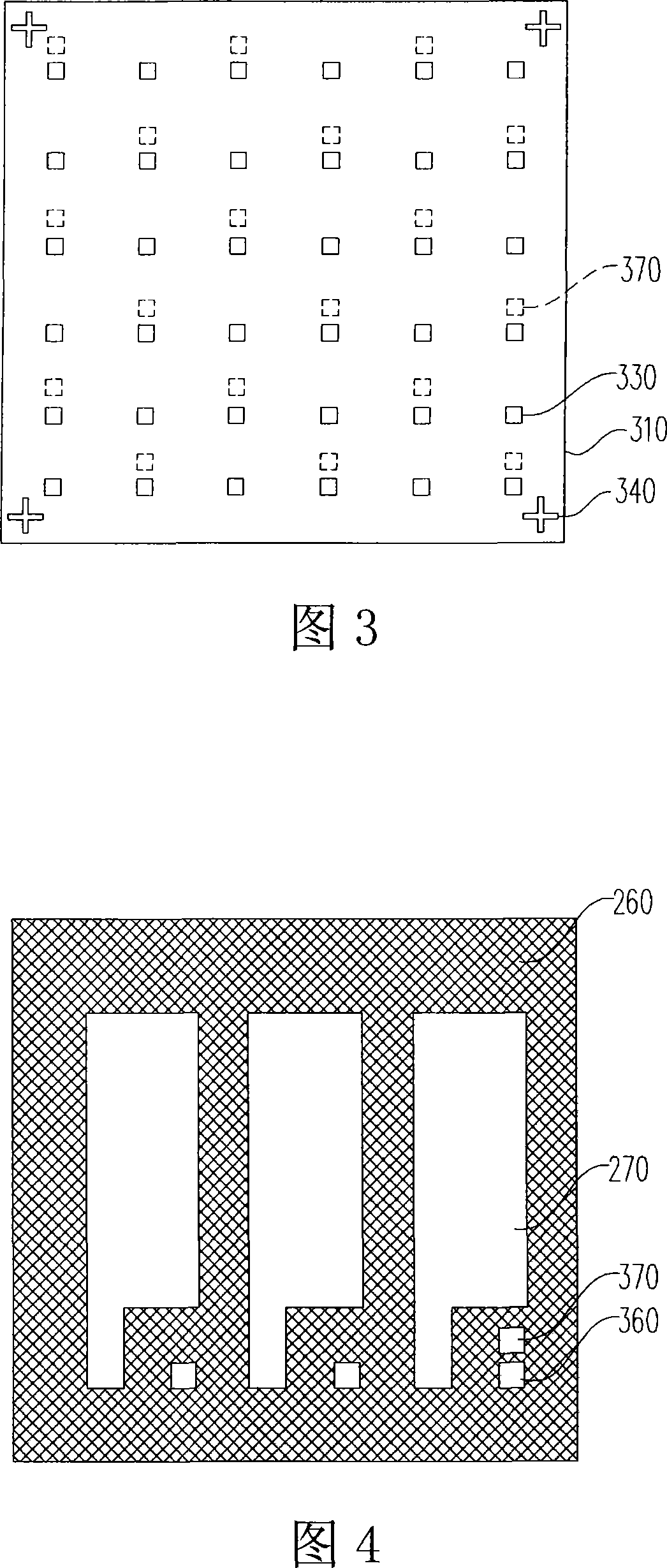

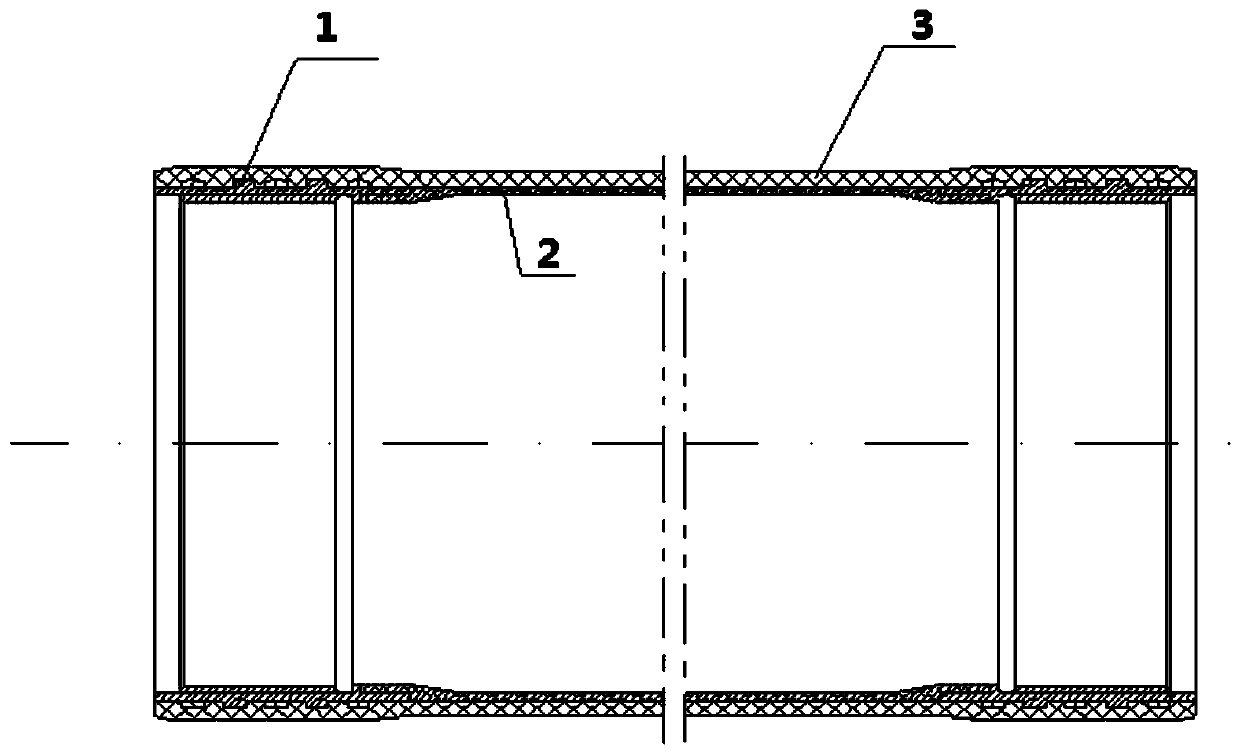

Liquid crystal display board and method for manufacturing facing direction substrates thereof

ActiveCN101162338APressure resistantEasy to maintain pressure resistanceSemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayEngineering

The invention discloses a liquid crystal display panel and a manufacturing method of an opposite base plate. The liquid crystal display panel comprises a thin film transistor array base plate with a colorful filter layer, the opposite base plate and a liquid crystal layer. The opposite base plate is provided with a common electrode, a plurality of main gap objects arranged on the common electrode, a plurality of gap object seats which are arranged on the common electrode and bulge toward the thin film transistor array base plate with the colorful filter layer, and a plurality of sub gap objects arranged on the common electrode. The main gap objects are arranged on the gap object seats for maintaining gaps between the thin film transistor array base plate with the colorful filter layer and the opposite base plate. The liquid crystal layer is also arranged between the thin film transistor array base plate with the colorful filter layer and the opposite base plate. Due to the main gap objects and the sub gap objects, the liquid crystal display panel of the invention forms a liquid crystal display panel with mixed type gap objects.

Owner:AU OPTRONICS CORP

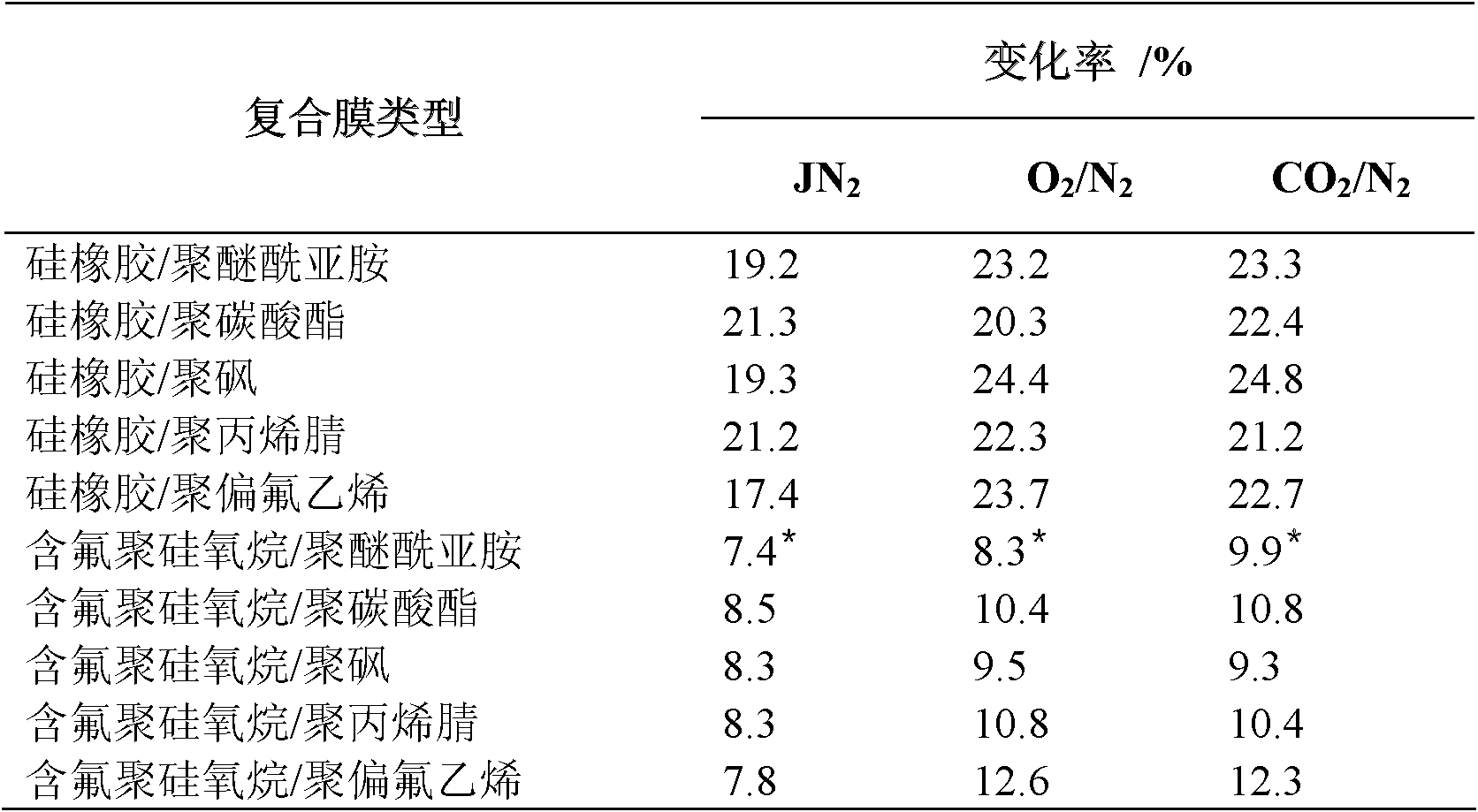

Fluorine-containing polysiloxane rubber state composite gas separation membrane, preparation method and application thereof

ActiveCN102327747AMild preparation conditionsResistant to swellingSemi-permeable membranesDispersed particle separationCross-linkProduct gas

The invention discloses a fluorine-containing polysiloxane rubber state composite gas separation membrane, a preparation method and an application thereof. A porous polymer material is used as a support membrane, and a fluorine-containing polysiloxane material is coated on the surface of the support membrane. The preparation method of the fluorine-containing polysiloxane rubber state composite gas separation membrane comprises the following steps of: dissolving fluorine-containing polysiloxane into a solvent to prepare coating liquid; adding a cross-linking agent and a catalyst into the obtained solution; uniformly stirring, standing and de-foaming; coating the coating liquid on the porous support membrane; and heating, curing and cross-linking until the porous support membrane is dried to obtain the fluorine-containing polysiloxane rubber state composite gas separation membrane. The composite gas separation membrane provided by the invention can be applied to separations of oxygen gas from nitrogen gas, carbon dioxide from nitrogen gas, and organic vapors, and has the characteristics of swelling resistance, resistance to pressure, weather fastness, and the like.

Owner:DALIAN UNIV OF TECH

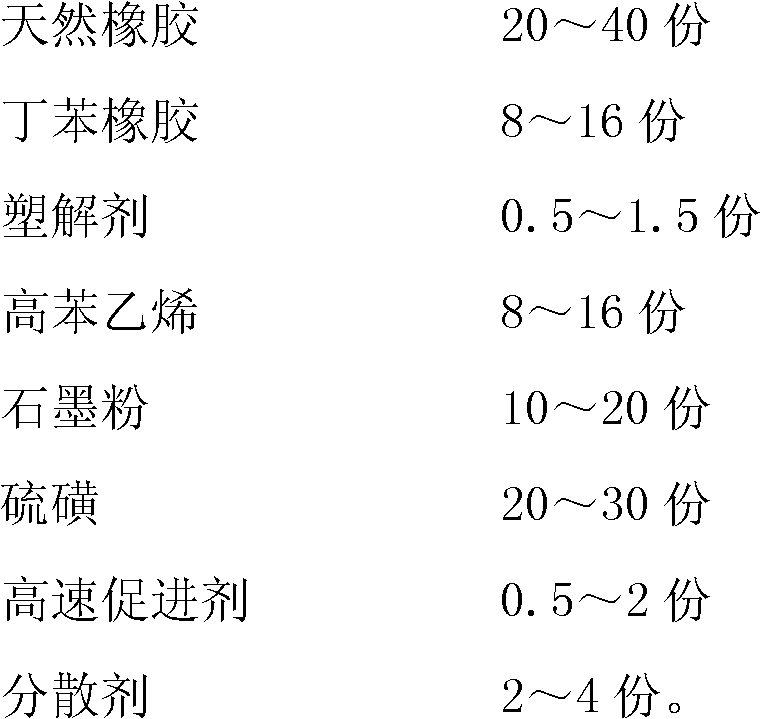

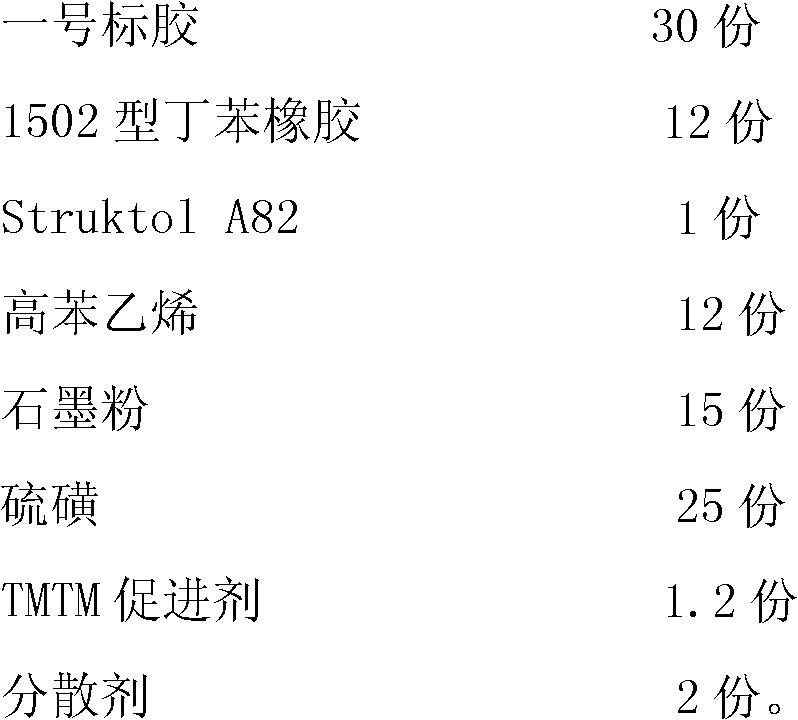

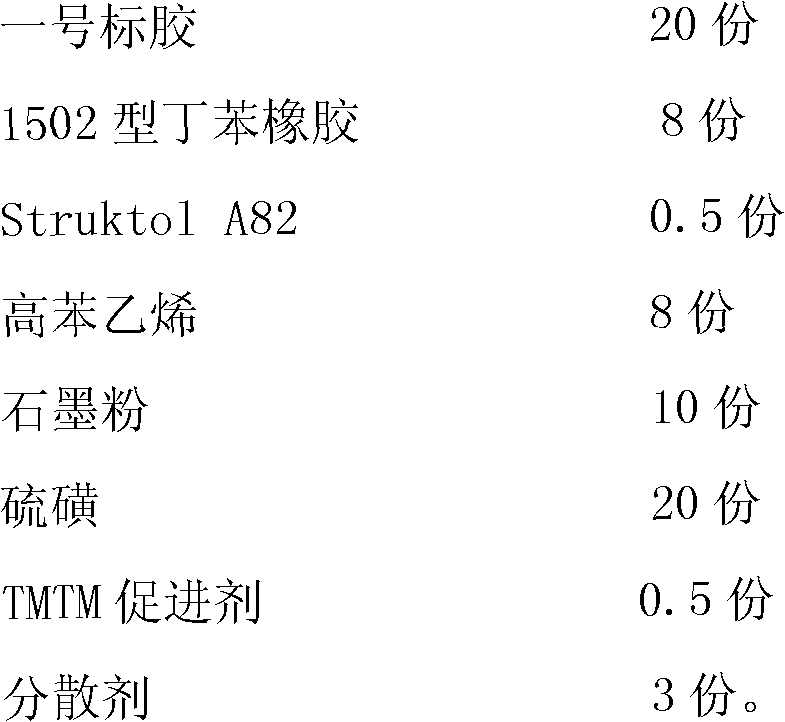

Antiseptic rubber lining and preparation method thereof

InactiveCN102134337ASolve the problem of anti-corrosion performanceExtend effective lifePolymer scienceVulcanization

The invention discloses an antiseptic rubber lining which comprises 20-40 parts of nature rubber, 8-16 parts of butadiene styrene rubber, 0.5-1.5 parts of peptizer, 8-16 parts of high styrene, 10-20 parts of graphite powder, 20-30 parts of sulfur, 0.5-2 parts of high-speed accelerator and 2-4 parts of dispersing agent. The invention also discloses a preparation method of the antiseptic rubber lining. The antiseptic rubber lining disclosed by the invention has excellent corrosion resisting property on various acid and alkali media; and the problem of the corrosion resisting property of a steelmaterial is solved, so that the effective service life of a steel member can be prolonged by 10 to 20 years; and the lining is applied to a smoke absorption column in a waste incineration factory, a kettle operating at a high temperature, a storage tank and other steel members, and has the characteristics of excellent combination property, high hardness, high-temperature resistance, pressure resistance, wearing resistance, tension stress, good ductility and the like. The preparation process is simple, can be used in a workshop or in site operation, and the hot water or steam is used for vulcanization, thereby being easy to realize.

Owner:TAICANG KUBO ANTI CORROSION MATERIAL

Method for preparing black monodisperse polymer microspheres

The invention provides a method for preparing black monodisperse polymer microspheres. The method comprises the following steps: by taking polymer seed microspheres as raw materials and oil-soluble aniline black as a black dye, dyeing the polymer seed microspheres by using a seed swelling polymerization method, thereby preparing polymer microspheres; and activating black dyes adsorbed by the black polymer microspheres through a chemical reaction so as to form an activated reaction intermediate, realizing chemical bond connection between the black dye and the polymer microspheres, thereby obtaining the black monodisperse polymer microspheres. The black monodisperse polymer microspheres prepared by the method are different from common dyed microspheres and have certain resistance to pressure, namely excellent mechanical property. Moreover, the black microspheres are smooth in surface without agglomeration, uniform in particle size and narrow in particle size distribution range and have high dispersity, and the CV value of the black microspheres is less than 3 percent.

Owner:镇江爱邦电子科技有限公司

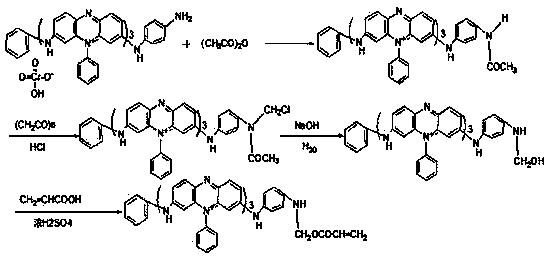

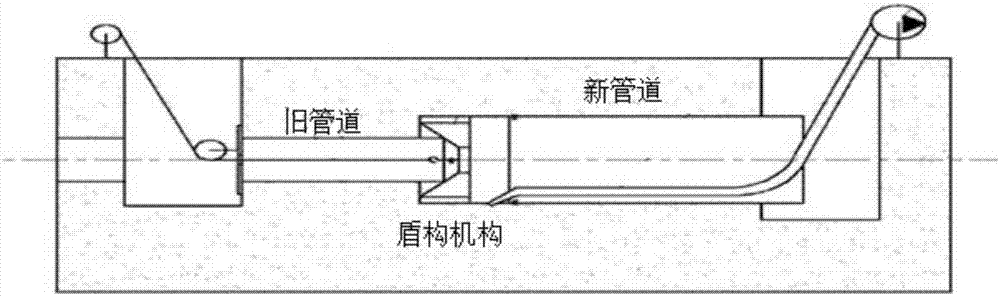

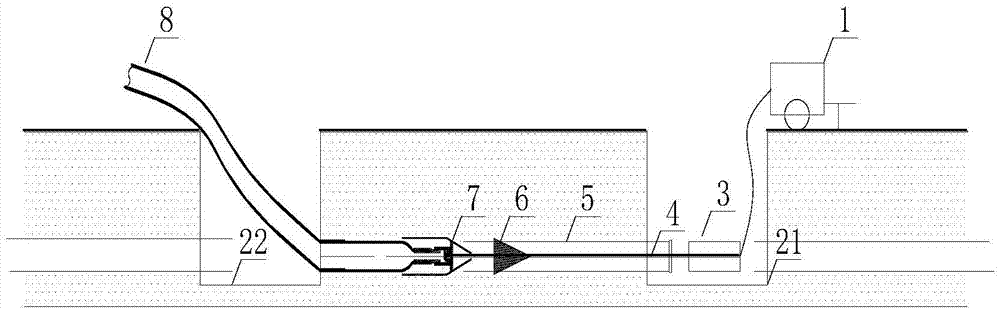

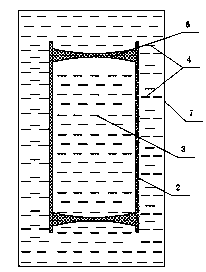

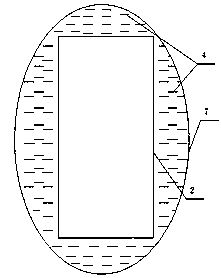

Device and method for replacing non-excavation underground pressure-bearing pipeline

InactiveCN107366781AAchieve replacementPressure-resistantPipe laying and repairEngineeringUnderground pipeline

The invention discloses a device and a method for replacing a non-excavation underground pressure-bearing pipeline, and the device and the method are used for replacing an old underground pipeline. The device disclosed by the invention comprises a drill rod collecting and placing device arranged at one end of the old pipeline, an anti-slip drill rod, an oil pipeline cutting knife and a flexible composite tube, wherein one end of the anti-slip drill rod is connected with the drill rod collecting and placing device, the other end of the anti-slip drill rod pushes the anti-slip drill rod to pass through the interior of the old pipeline to arrive at the other end of the old pipeline by virtue of the drill rod collecting and placing device; the old pipeline cutting knife is used for cutting the old pipeline, is located at the other end of the old pipeline and is connected with the anti-slip drill rod passing through the old pipeline; the flexible composite tube is connected with the old pipeline cutting knife by virtue of a tube expansion head, the drill rod collecting and placing device drives the old pipeline cutting knife to cut the old pipeline by virtue of the anti-slip drill rod, the old pipeline is expanded by virtue of the tube expansion head, and the flexible composite tube is linked and enters a new underground channel, so that pipeline replacement is realized. The device and the method which are disclosed by the invention have the advantage that non-excavation replacement of the old pipeline is realized under the conditions that an underground pressure-bearing old pipeline is restricted by buildings and water areas and excavation replacement construction is difficult.

Owner:CHINA PETROLEUM & CHEM CORP

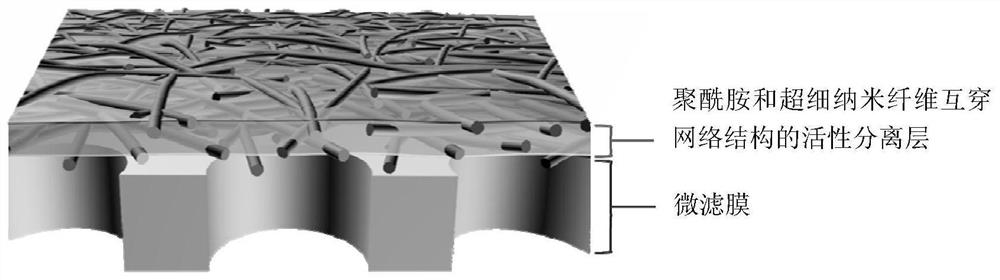

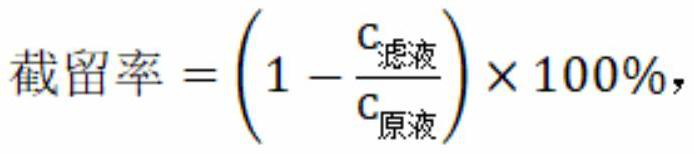

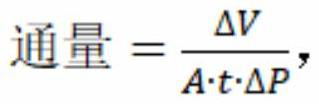

Nanofiltration membrane, preparation method and application thereof

InactiveCN111659270APressure resistantFilter stableMembranesGeneral water supply conservationFiberWater softening

The invention discloses a nanofiltration membrane, a preparation method and application thereof. The nanofiltration membrane comprises a support bottom membrane and an active separation layer arrangedon the support bottom membrane, wherein the active separation layer has an interpenetrating network structure, and the interpenetrating network structure is mainly formed by interpenetrating polyamide formed by an interfacial polycondensation reaction of a polyethyleneimine monomer and an acyl chloride monomer with ultrafine nanofibers. The preparation method comprises the following steps: arranging an ultrafine nano-fiber layer on a micro-filtration membrane to prepare an ultrafine nano-fiber / micro-filtration membrane composite substrate; and carrying out an interfacial polycondensation reaction on a polyethyleneimine monomer and an acyl chloride monomer on the surface of the superfine nanofiber / micro-filtration membrane composite substrate, and carrying out heat treatment to obtain thenano-filtration membrane. The preparation method of the nanofiltration membrane is simple, and the obtained nanofiltration membrane has high flux and high salt rejection performance, so that the desalination energy consumption cost is reduced, and the nanofiltration membrane has a wide application prospect in the aspects of seawater desalination pretreatment, water softening and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

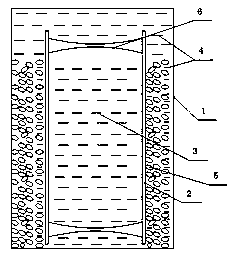

Polymeric composite and preparation process and application thereof

InactiveCN1560126AFine foamUniform foamingWatering devicesCultivating equipmentsFoaming agentPolymer science

The invention discloses a microporous leaking polycompound and its preparing method, as well as its application in preparing microporous leaking pipes, and its technical project includes: polyvinylchloride (PVC) 40-60%, nitrile rubber 15-30%, heat stabilizer 6-10%, plasticizer 16-24% and foaming agent 1-4% (all in weight percent). It can be prepared by physical or chemical foaming method. The product pipe walls are formed with irregular micropores, suitable for preparing common used microporous leaking pipes in irrigation. At no pressure, the micropores close, and at a certain external pressure, open, and as the pressure in the pipes is reduced or does not exist, automatically close, thus effectively preventing substances outside the pipe walls flowing into the pipes, solving the disadvantage that the micropores in existing techniques are easy to stop. It can be widely applied to water-saving irrigation, fertilizing with pipelines, applying drugs, oxygen leaking with pipelines, and many agricultural, forest, fish culture works.

Owner:谢志伟

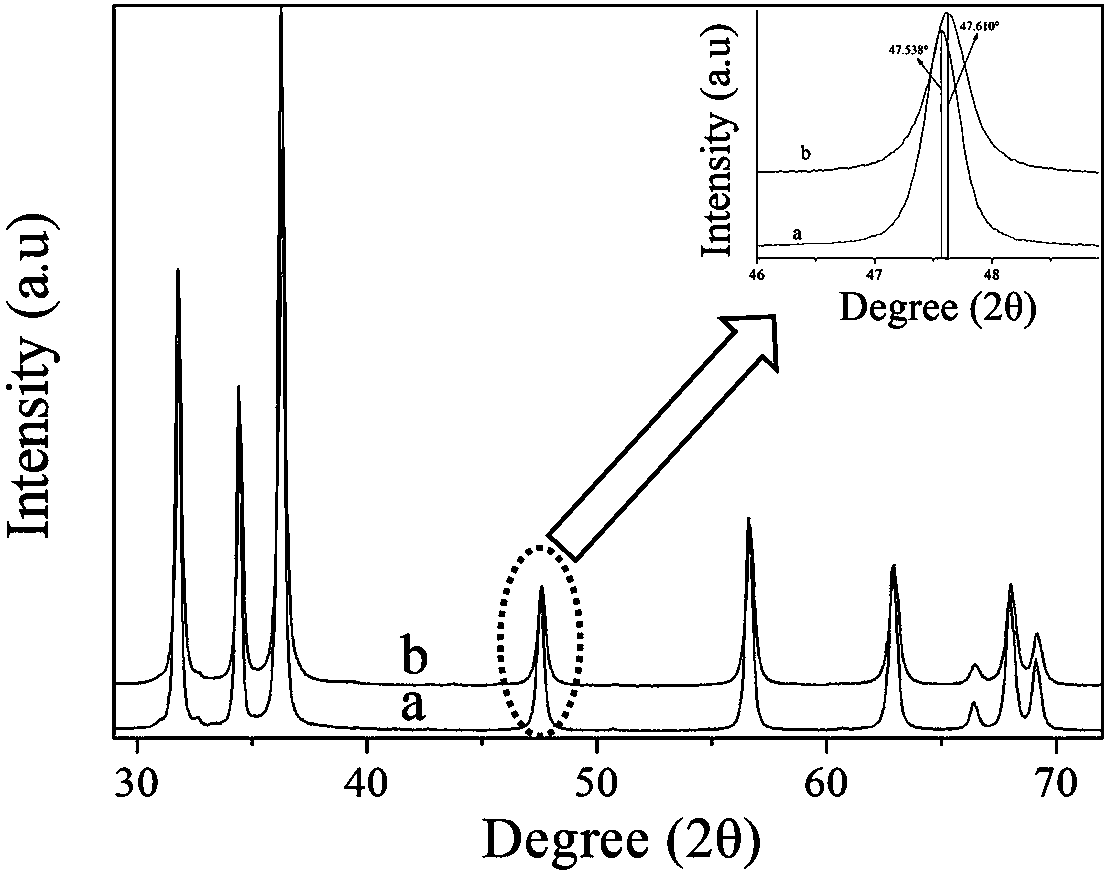

Method for simply and quickly preparing carbon-doped zinc oxide nanosheet

InactiveCN107552034AEasy transferLarge specific surface areaMaterial nanotechnologyCatalyst activation/preparationRoom temperatureFree cooling

The invention provides a method for simply and quickly preparing a carbon-doped zinc oxide nanosheet. The method comprises the following steps: firstly, respectively weighing basic zinc carbonate andlow molecular weight organic matters with certain mass, grinding and enabling the two substances to be fully and uniformly mixed; secondly, putting basic zinc carbonate and the low molecular weight organic matters which are uniformly mixed in the first step in an air-free vacuum environment, carrying out calcining treatment and then carrying out natural cooling to room temperature; and thirdly, grinding the powder obtained in the second step by calcining, wherein the powder obtained by grinding is the carbon-doped zinc oxide nanosheet. The zinc oxide nanosheet prepared by the invention has a laminar structure with the size of about 1 micron and the thickness of 20 to 30 nanometers; in addition, in the photocatalytic process, the nanosheet has higher specific surface area and higher adsorption ability; besides, the operation and technological method is simple, quick and, high in repeatability and facilitates industrialized production.

Owner:XINYANG NORMAL UNIVERSITY

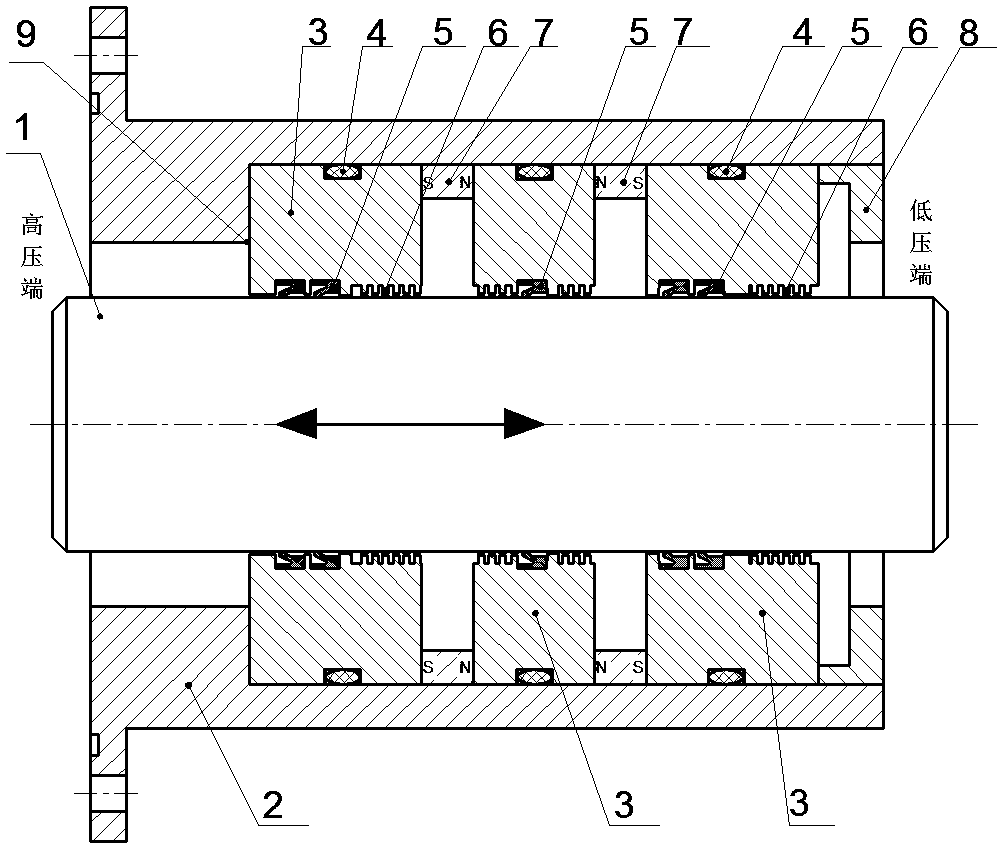

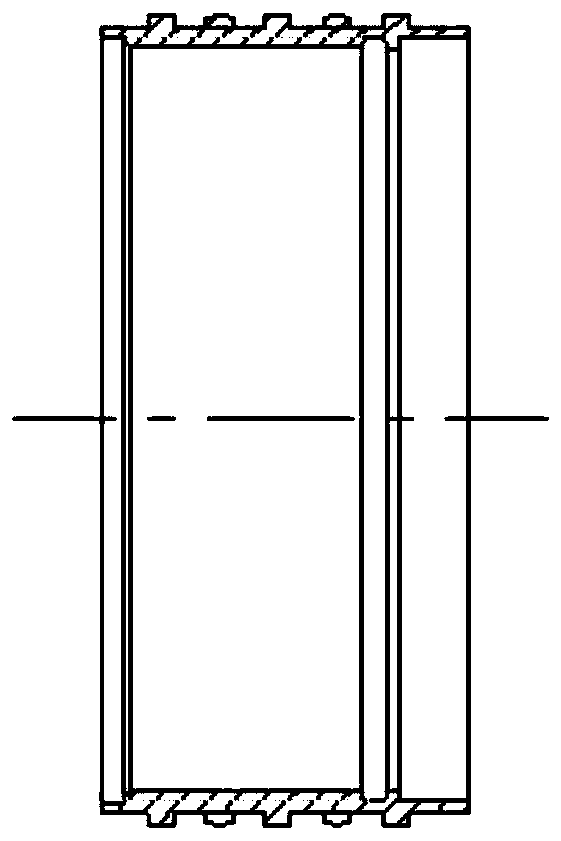

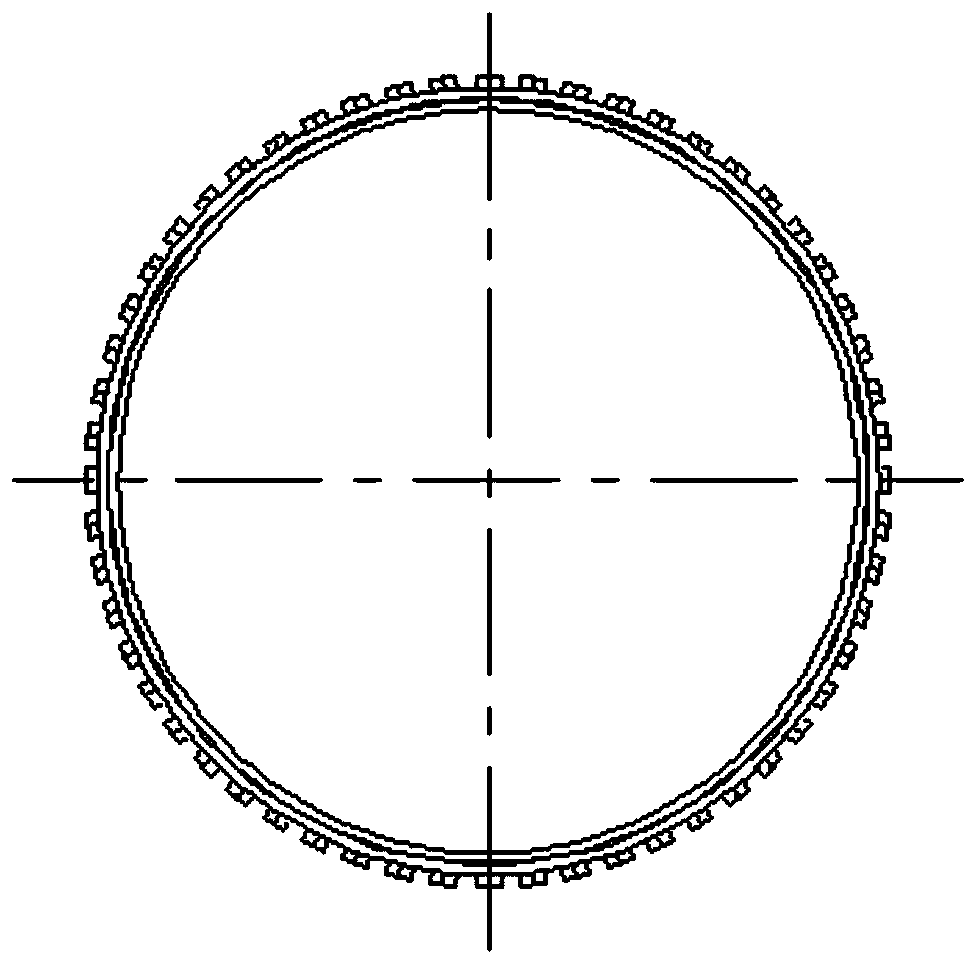

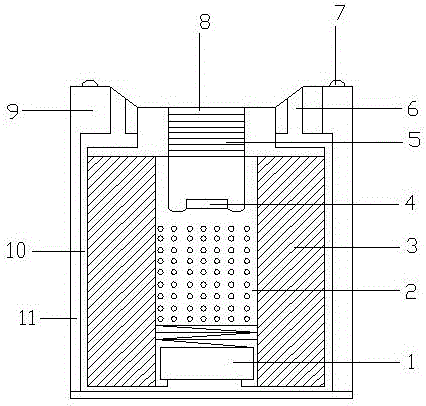

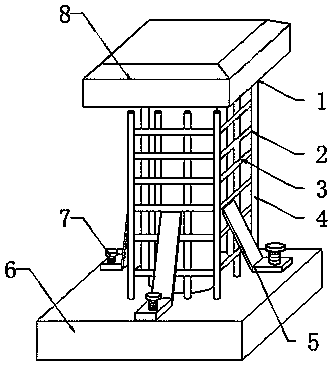

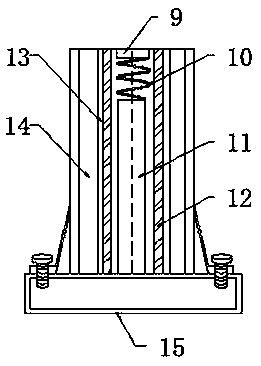

Magnetic fluid sealing structure for reciprocating motion

InactiveCN107893854AReduce pollutionExtended service lifeEngine sealsReciprocating motionEngineering

The invention discloses a magnetic fluid sealing structure for the reciprocating motion. The magnetic fluid sealing structure comprises a hollow shell, a reciprocating shaft arranged in an inner cavity of the shell and at least one permanent magnet. Pole shoes are arranged on the two sides of each permanent magnet. At least one groove is formed around the inner circle face of each pole shoe, and aY-shaped sealing ring is arranged in each groove. Pole teeth are arranged on the inner circle faces of the pole shoes, gaps exist between the pole teeth and the outer surface of the reciprocating shaft, and magnetic fluid is injected into the gap positions. Through combined usage of the magnetic fluid and the Y-shaped sealing rings, a sealing structure excellent in pressure resisting performanceand sealing performance is formed. Accordingly, due to the fact that the magnetic fluid seal has a dustproof function, pollution to the Y-shaped sealing rings from outside impurities is reduced, purity of sealed media is improved, the service life of the sealing ring is prolonged to the maximum degree, and the requirements for zero leakage and long service life are met.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Full-sintered ceramic filter element

InactiveCN102643076AImprove filter adsorption effectHas acid and alkali resistanceFiltration separationCeramicwareMicrometerFlue gas

The invention discloses a full-sintered filter element which is formed by mixing 5-10 percent of green dry stone powder, 65-75 percent of alumina powder, 10-20 percent of kaolin and 2-8 percent of evaporating agent counted in percentage by weight and sintering the mixture at the temperature of 1000-1200DEG C. The outer surface of the full-sintered filter element disclosed by the invention is coated by a layer of alumina, so that the absolute filtering precision reaches 0.3-1 micrometer. The full-sintered filter element disclosed by the invention has the advantages of acid and alkali resistance and high temperature and high pressure resistance and is suitable for filtering flue gas in the chemical production process of which the temperature range is within 500DEG C and the pH value is in a range of 1 to 13.

Owner:苏州市东方净水器厂

Bamboo spirit

InactiveCN103666991AKeep the traditional styleEnvironmentally friendlyAlcoholic beverage preparationAlcoholAdditive ingredient

The invention discloses Cengcengfu bamboo spirit. The Cengcengfu bamboo spirit comprises a container and a bamboo joint tube filled with bamboo joint spirit, wherein the bamboo joint spirit is white spirit or Kaoliang spirit filled in a bamboo joint inner cavity and the white spirit or Kaoliang spirit in the bamboo joint inner cavity is hermetically preserved via bamboo joints. The Cengcengfu bamboo spirit is structurally characterized in that the bamboo joint tube filled with bamboo joint spirit is put in the container and the container is packaged hermetically; the white spirit or Kaoliang spirit with alcohol strength more than 30 degrees is filled between the bamboo joint tube filled with the bamboo joint spirit and the container; pebbles are filled between the bamboo joint tube filled with the bamboo joint spirit and the container. The pebbles can isolate the bamboo joint tube from the container, so that the bamboo joint tube and the container are not easy to collide. The nutritional ingredients of the pebbles can be dissolved in the white spirit or Kaoliang spirit in which the pebbles are soaked. The bamboo joint spirit is the spirit naturally and healthily growing in the animate bamboo cavity for about three years, has perfect style and ingredients and not only can maintain the traditional intrinsic style of the white spirit or Kaoliang spirit but also has many additional substances that traditional spirit cannot naturally contain in any case and are beneficial to human bodies.

Owner:张国天

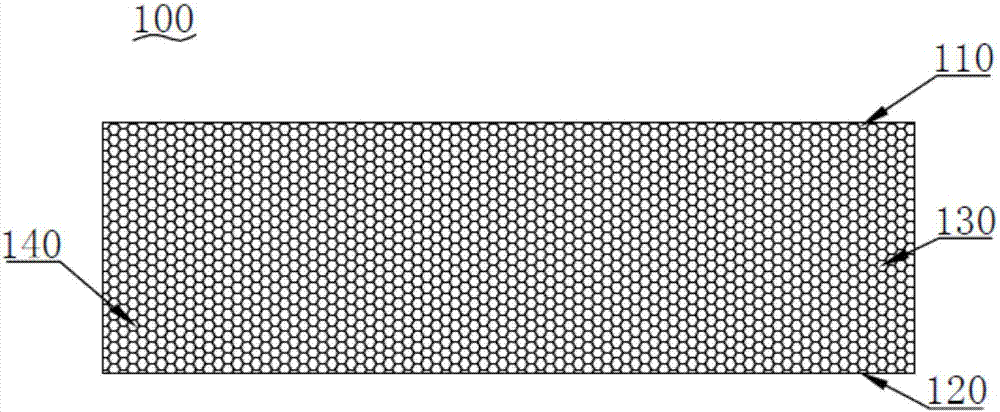

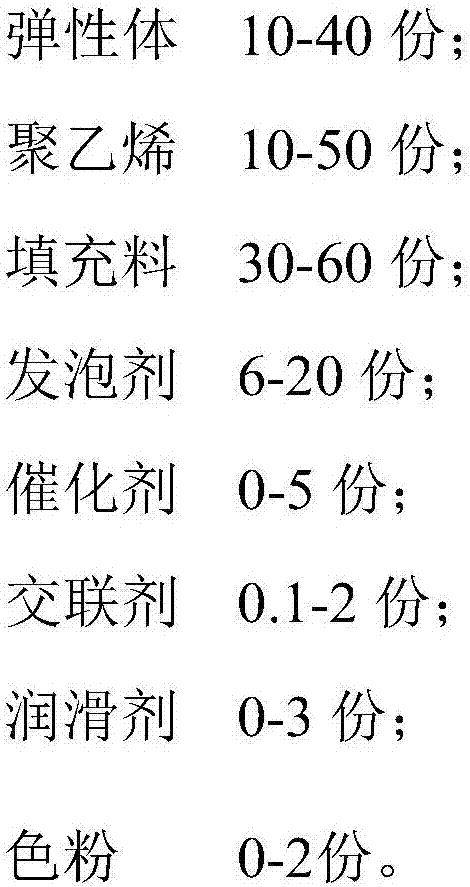

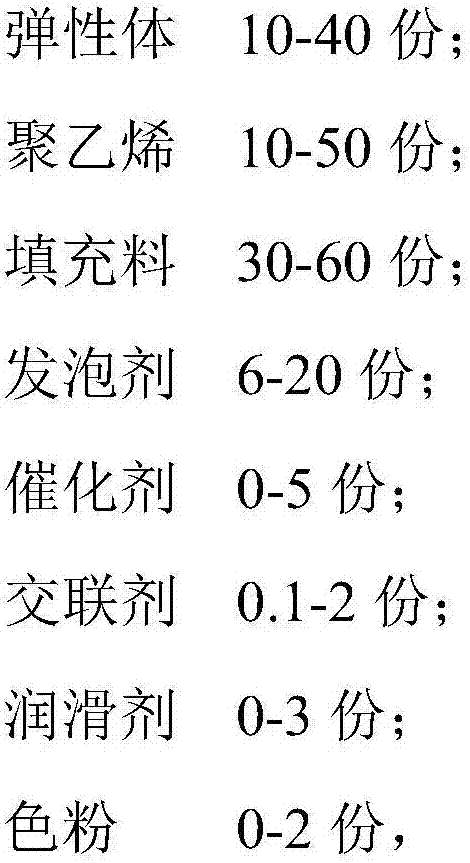

Closed-cell foaming material as well as manufacturing formula and manufacturing method thereof

PendingCN107379695AIncrease foam densityLow costSynthetic resin layered productsElastomerPolymer science

The invention relates to the technical field of foaming materials, and in particular relates to a closed-cell foaming material as well as a manufacturing formula and a manufacturing method thereof. The closed-cell foaming material comprises a body, wherein the body is integrally molded through continuous foaming; the body comprises an upper surface skin, a middle core layer and a lower surface skin; the upper surface skin, the middle core layer and the lower surface skin are integrally molded through continuous closed-cell foaming; a formula of the foaming material comprises 10 to 40 parts of elastomers (including EVA (Ethylene-vinyl Acetate copolymer), POE (Polyolefin Elastomer), TPE (Thermoplastic Elastomer), TPR (Thermoplastic Rubber) and MPP (Modified Polypropylene)), 10 to 50 parts of polyethylene, 30 to 60 parts of a filling material, 6 to 20 parts of a foaming agent, 0 to 5 parts of a catalyst, 0.1 to 2 parts of a cross-linking agent, 0 to 3 parts of a lubricant and 0 to 2 parts of toner; the manufacturing method of the foaming material comprises the following steps: mixing; extruding; calendering to form a master batch; carrying out primary cooling and winding; adding the master batch into a continuous foaming tunnel furnace and carrying out closed-cell cross-linking foaming under normal pressure; carrying out secondary cooling; printing to obtain a finished product and winding. The method provided by the invention completely meets European Union standards and user requirements especially in the aspect of formamide; the closed-cell foaming material provided by the invention can be used for continuously carrying out chemical cross-linking closed-cell foaming without electron irradiation crosslinking and mould pressing.

Owner:广东富利时实业有限公司

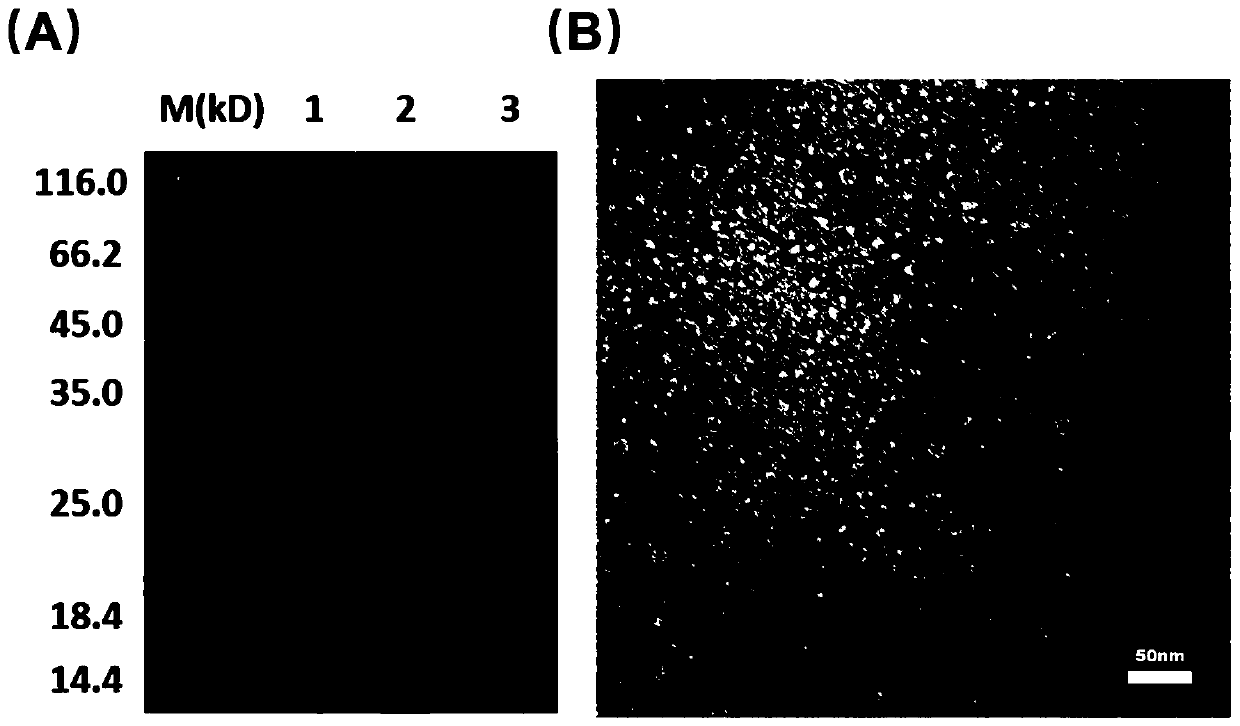

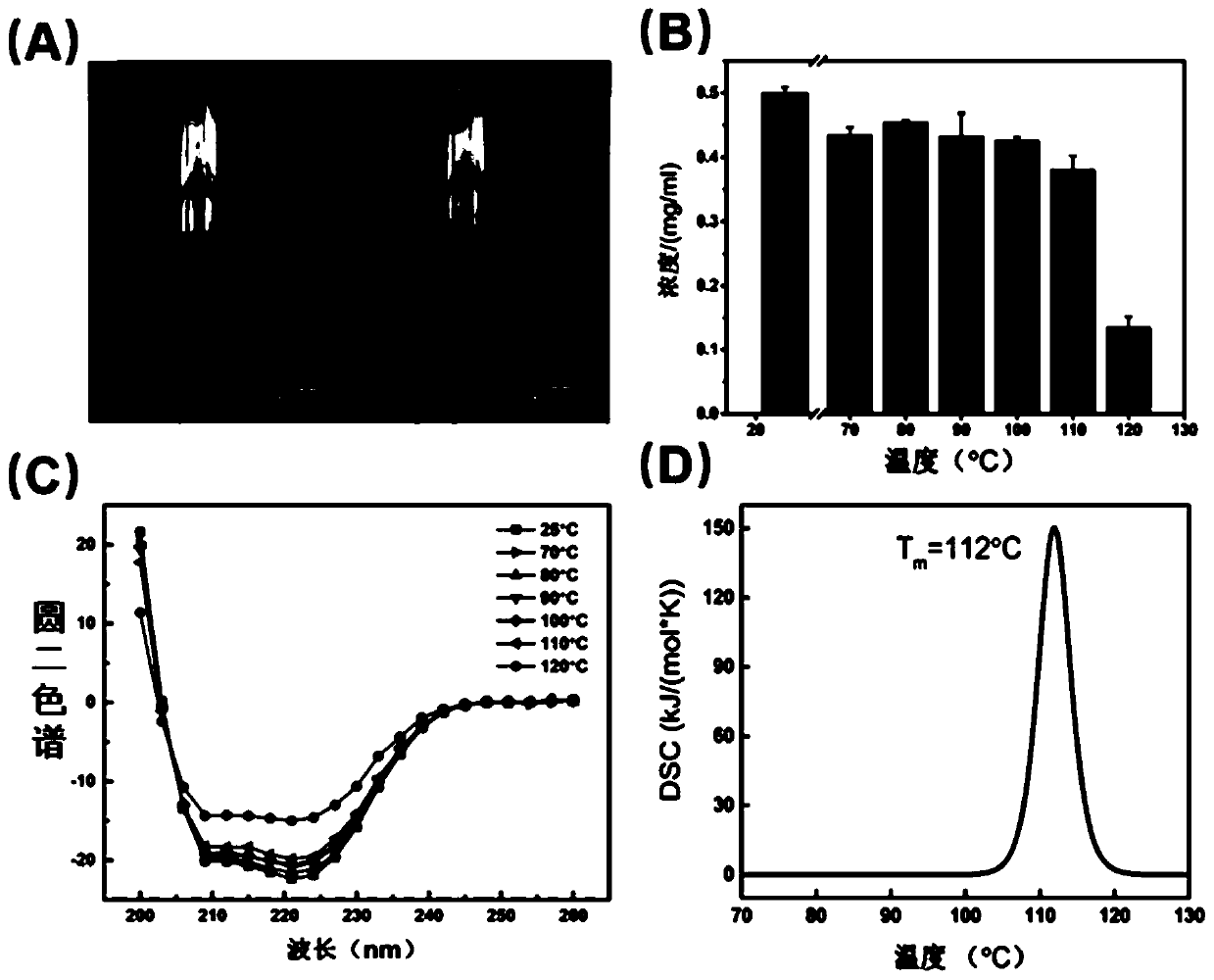

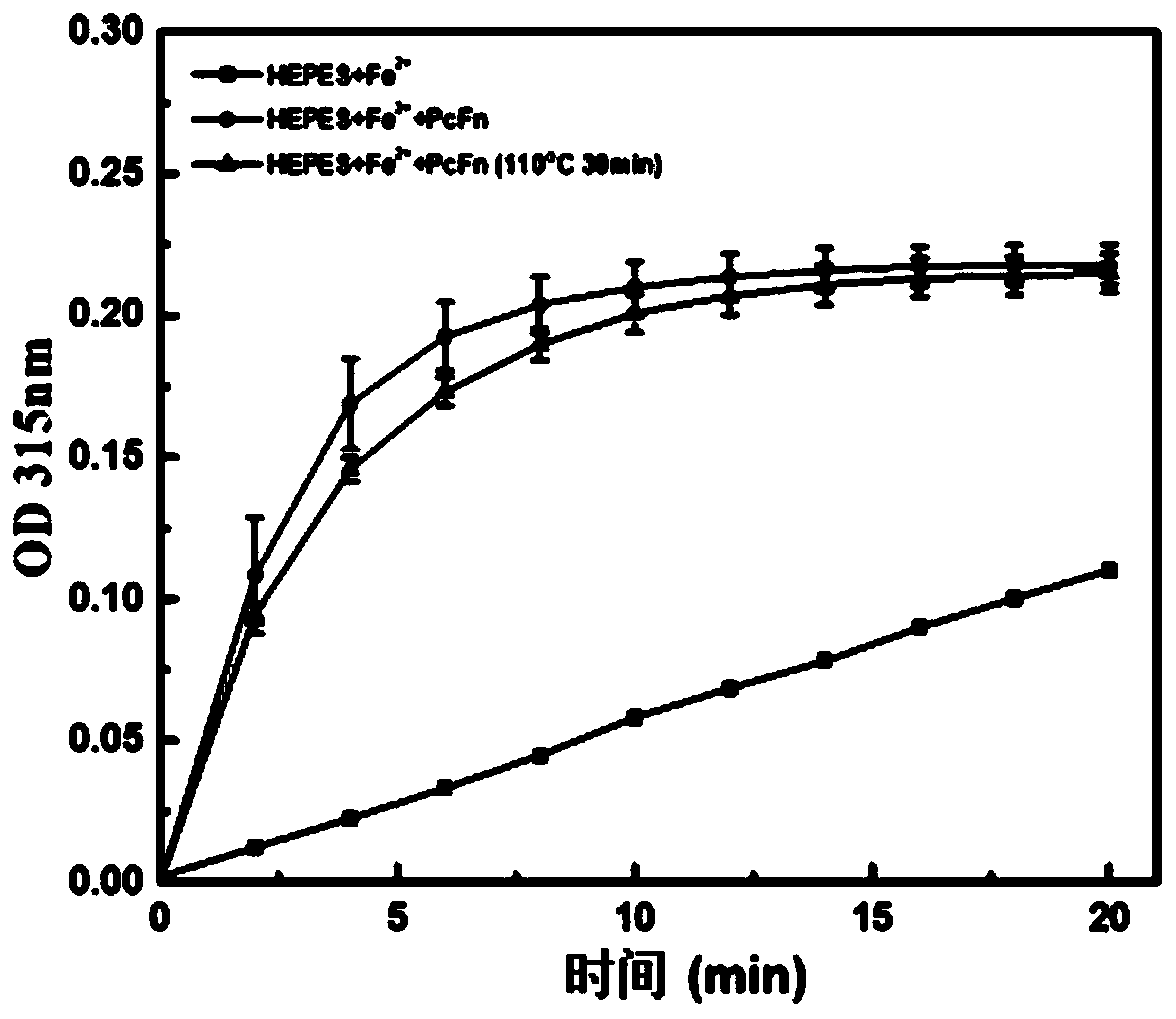

Preparation method and application of heat-resistant ferritin

InactiveCN110819651APressure resistantImprove thermal stabilityPeptide preparation methodsBacteria peptidesProtein engineeringGenetic engineering

The invention provides a preparation method of a high-heat-resistant ferritin cage structure and a method for preparing heat-resistant magnetic ferritin by using the high-heat-resistant ferritin cagestructure. Specifically, the protein is expressed and purified by genetic engineering and protein engineering technologies, and the protein can be self-assembled to form the high-heat-resistant ferritin cage structure with an inner diameter of about 8 nm and an outer diameter of about 12 nm. The ferritin cage structure and the magnetic ferritin prepared by the method can endure high-temperature conditions of 110 DEG C or above for more than 30 minutes and have good pressure resistance.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

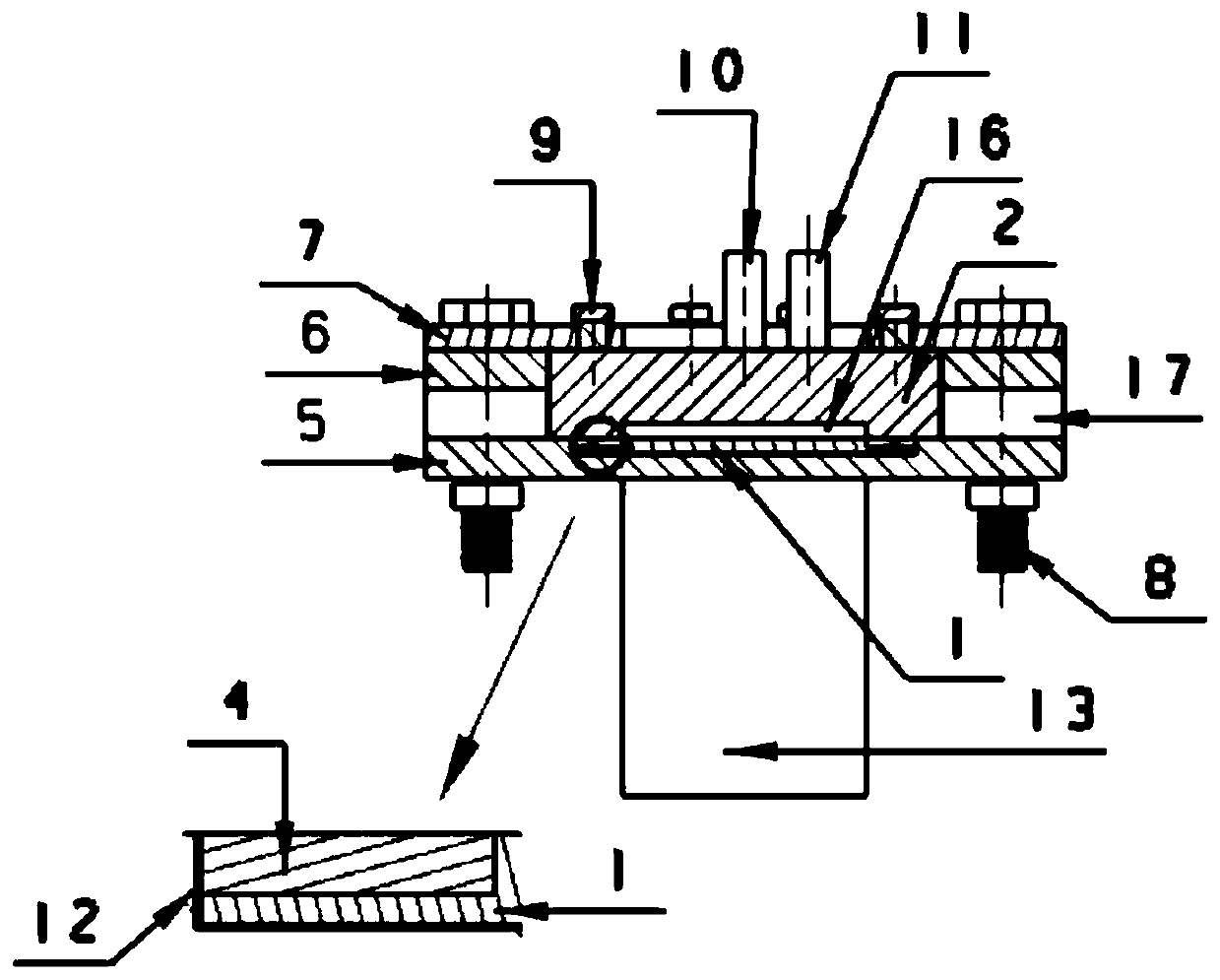

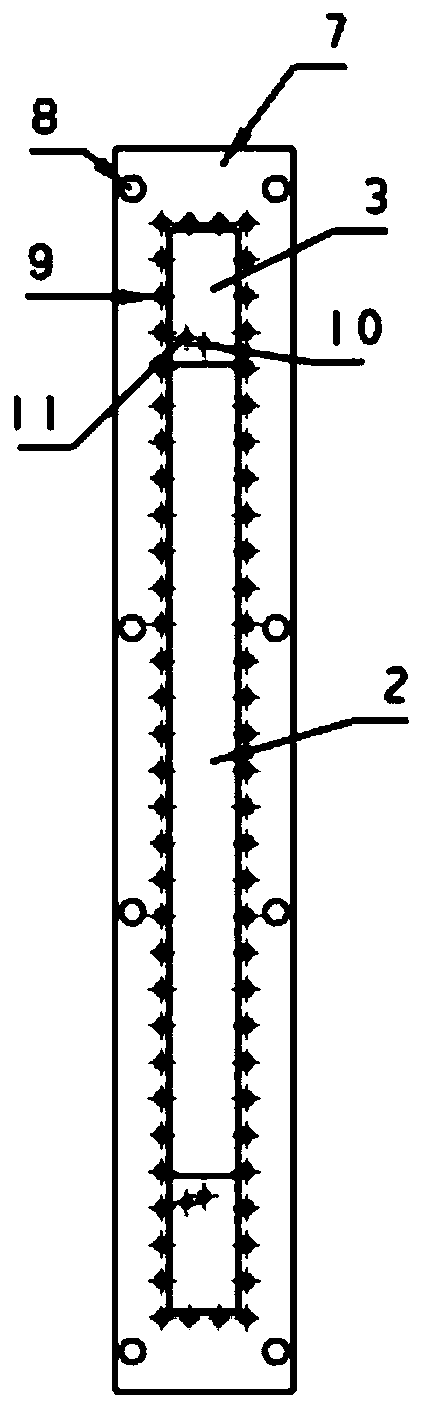

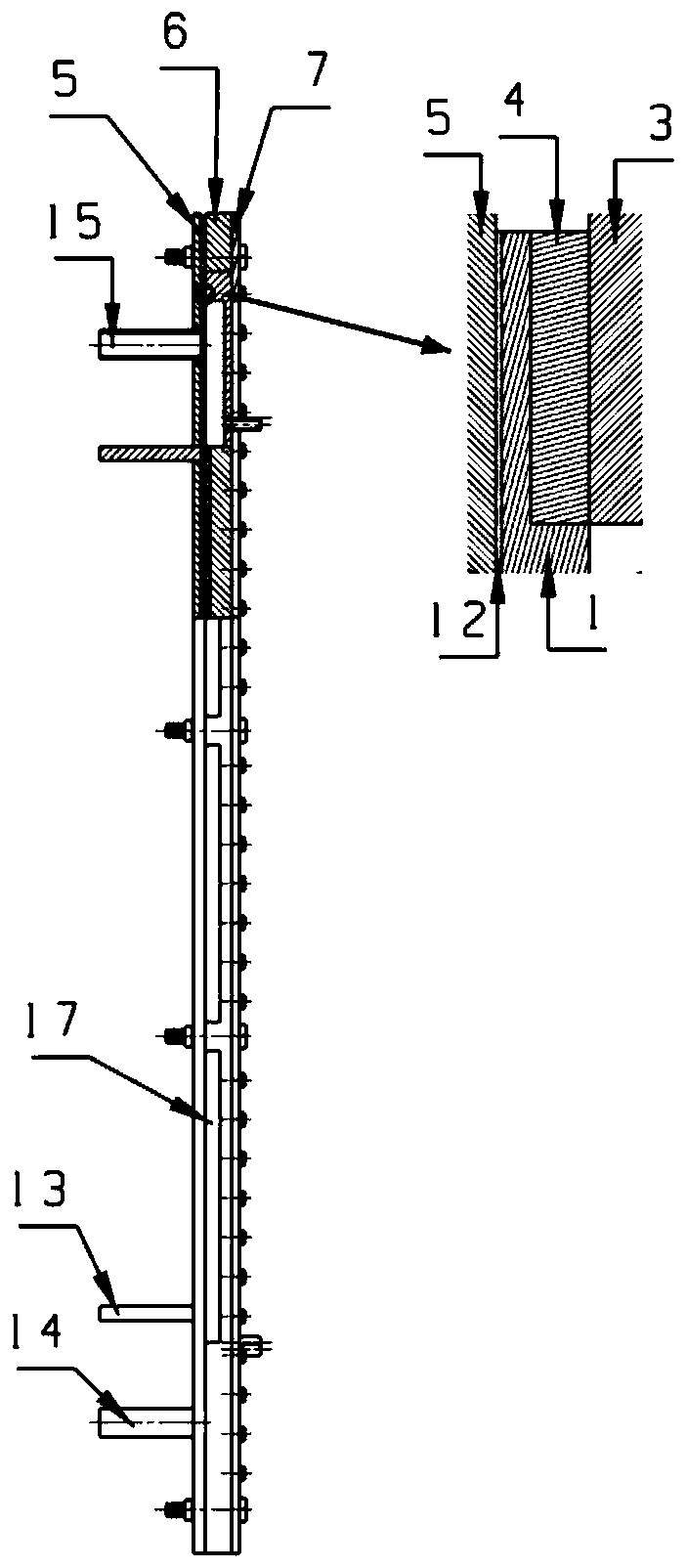

Flow field-temperature field synchronous measurement system under narrow rectangular channel blocking condition

PendingCN110058048AGuaranteed synchronicityDoes not affect exposureNuclear energy generationNuclear monitoringSilica gelIrradiation

The invention provides a flow field-temperature field synchronous measurement system under a narrow rectangular channel blocking condition, which comprises a 1-3 mm narrow rectangular channel formed by a heating plate and a visual PC endurance plate, a buffer chamber, an upper bearing plate, a middle bearing plate and a lower bearing plate of the fixed narrow rectangular channel, a laser incidentwindow, a spectroscope, an optical filter, a laser, a high-speed camera, a synchronizer, an acquisition system and the like, wherein blocking objects with different sizes and shapes are arranged at different positions of the narrow rectangular channel through silica gel, so that the blocking working condition in a reactor is simulated. A Particle Image Velocimetry (PIV) technology and a Laser Induced Fluorescence (LIF) technology are adopted to measure a flow field and a temperature field, three laser incident windows are arranged on two sides of the middle bearing plate for laser irradiation,the synchronizer is used for controlling two high-speed cameras, a visualization section is divided into three areas under the action of the spectroscope and the optical filter to carry out synchronous shooting of the flow field and the temperature field, and the acquisition system records experimental data of the flow field and the temperature field in real time. The flow field-temperature fieldsynchronous measurement system under the narrow rectangular channel blocking condition is simple and feasible, and has low cost and wide range of research working conditions.

Owner:HARBIN ENG UNIV

Preparation method for seal head-free fiber reinforced resin-based composite material combustion chamber shell of rocket projectile

ActiveCN110978558AIncrease burst pressureImprove insulation performanceDomestic articlesCoatingsYarnCombustion chamber

The invention discloses a preparation method for a seal head-free fiber reinforced resin-based composite material combustion chamber shell of a rocket projectile and belongs to the field of preparation methods of polymer-based composite materials. The preparation method aims to solve the technical problem that the combustion chamber shell prepared by an existing method is poor in heat isolating property, low in bursting strength and heavy in weight. The preparation method comprises the following steps of I, milling the outer side of a metal ring to obtain a metal wire hanging ring; II, assembling an assembling part; III, impregnating fiber yarns and then winding the surface of the assembling part; and IV, carrying out heating and curing and natural cooling and then drawing a mandrel to demould. An inside liner which has good properties can meet airtightness and ablation resistance in a combustion chamber grain combustion process. The demand on pressure resistance and rigidity is met bymeans of a wound and formed structural layer. The fiber yarns fall between wire hanging tables of the metal wire hanging ring in accordance with a rule, so that the connecting strength of a compositematerial and a metal and the bursting pressure of the shell are improved. The preparation method is used for preparing the seal head-free fiber reinforced resin-based composite material combustion chamber shell of the rocket projectile.

Owner:HARBIN FRP INST

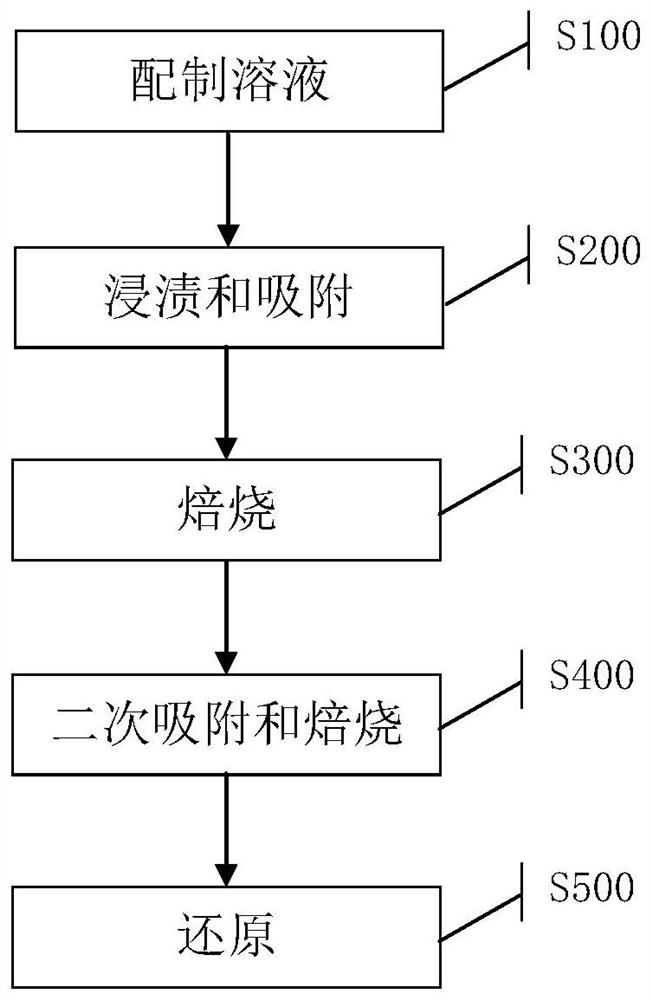

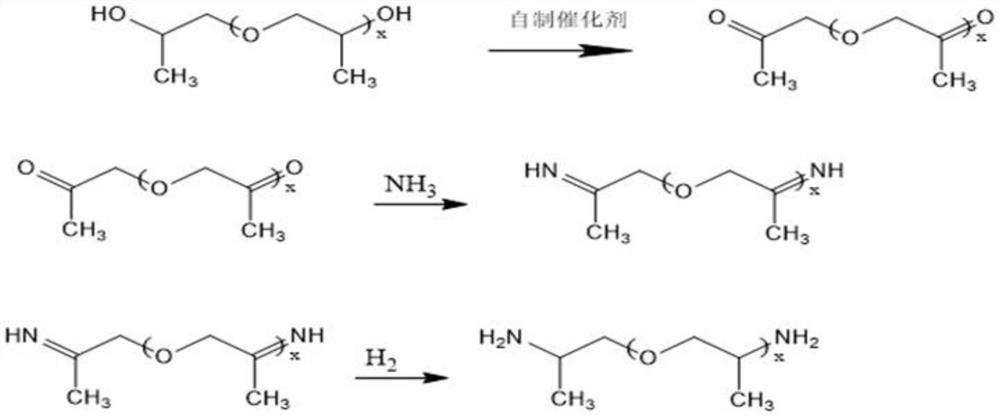

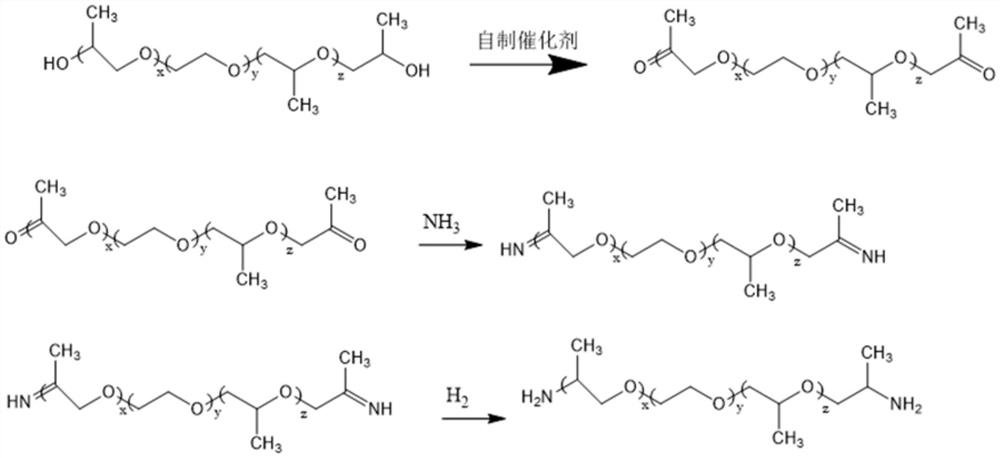

Preparation method of polyether amine catalyst and polyether amine

PendingCN114669302AEasy to decomposeSave cost and processMetal/metal-oxides/metal-hydroxide catalystsHeterogenous catalyst chemical elementsExhaust fumesBASIC CUPRIC CARBONATE

The polyether amine catalyst is a supported metal catalyst, gamma-Al2O3 is used as a carrier, basic cupric carbonate, basic nickel carbonate and basic cobalt carbonate are used as precursors of supported metal, and the supported metal catalyst is prepared by a hydrothermal method. And the polyether amine catalyst is prepared by two times of adsorption roasting and one time of reduction through an equivalent-volume impregnation method. By using the basic carbonate, decomposition is easier, only water and carbon dioxide are generated, the waste gas treatment process and cost are saved, meanwhile, the prepared polyether amine catalyst is high in activity and selectivity, long in service life and wide in application range, the conversion rate and the primary amine selectivity can be improved when the polyether amine catalyst is used for preparing polyether amine, and the product color is reduced; therefore, the obtained polyether amine has higher activity and wider application range.

Owner:ZHEJIANG HUANGMA TECH +3

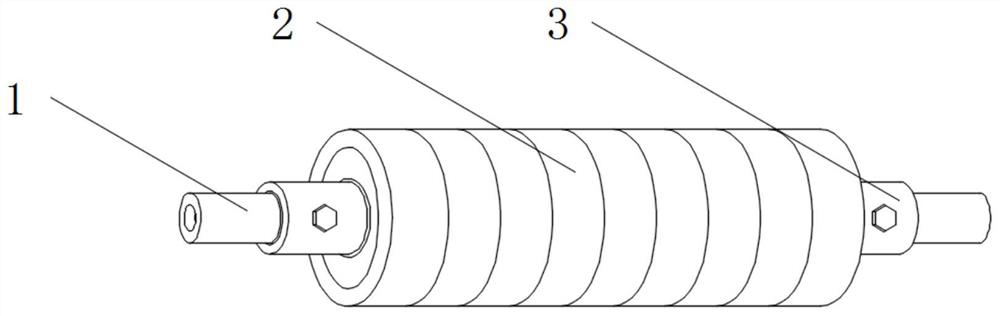

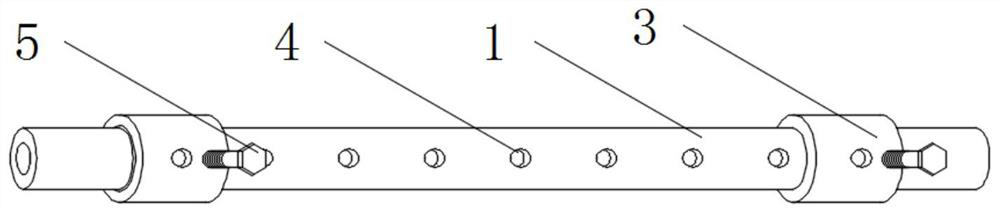

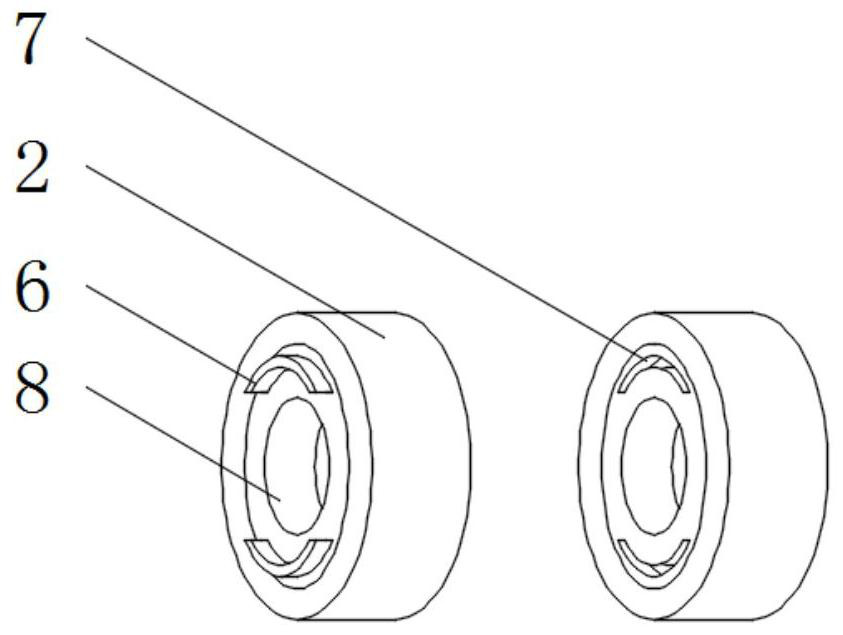

High-temperature-resistant rubber roller for offset printing

InactiveCN111823709AReduce in quantityPressure resistantInking apparatusLayered productsProduction lineEngineering

The invention relates to the field of production lines, and discloses a high-temperature-resistant rubber roller for offset printing. The high-temperature-resistant rubber roller comprises a rubber roller body, wherein roller wheels are arranged on the outer surface of the upper end of the rubber roller body; fixing sleeves are arranged on the two sides, close to the roller wheels, of the outer surface of the rubber roller body; fixing holes are formed in the outer surfaces of the fixing sleeves and the outer surface of the rubber roller body; hexagonal bolts are arranged on the outer surfacesof the fixing sleeves; connecting blocks are arranged on the outer surfaces of one sides of the roller wheels; and connecting grooves are formed in the other sides of the roller wheels. According tothe high-temperature-resistant rubber roller for offset printing, the rubber roller body can be split into a plurality of groups of roller wheels, the roller wheels can be well connected, so that thesize of the rubber roller body can be conveniently replaced and used, the rubber roller can be conveniently suitable for machines with different widths, the step of replacing the rubber roller by personnel is omitted, and the working efficiency is improved; a heat-resistant layer and an anti-skid layer are arranged, so that the rubber roller body can be used in a high-temperature environment, andthe service life of the rubber roller body is prolonged; and a detection cabinet is arranged, so that the balance performance of the rubber roller body can be conveniently detected.

Owner:江苏永辉橡胶有限公司

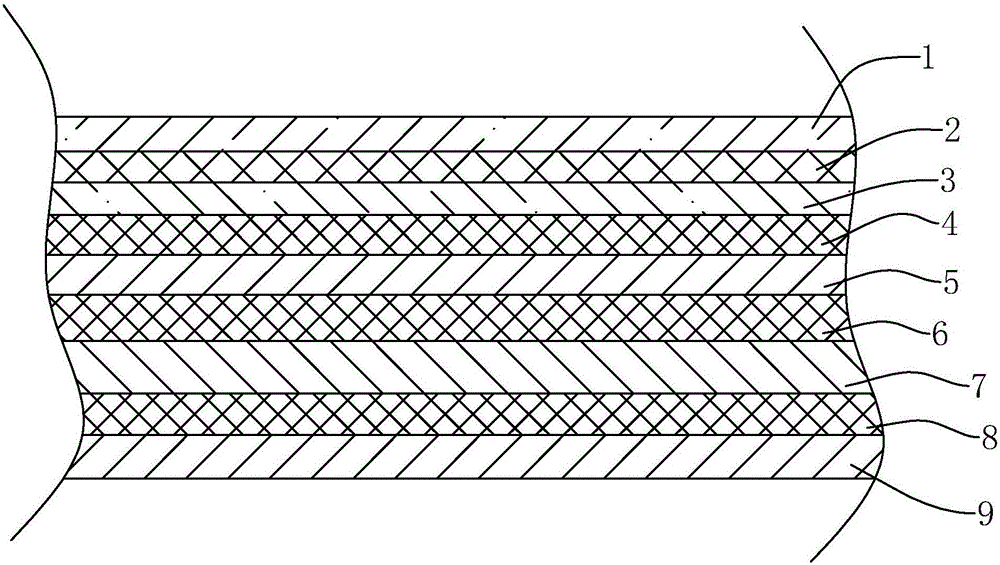

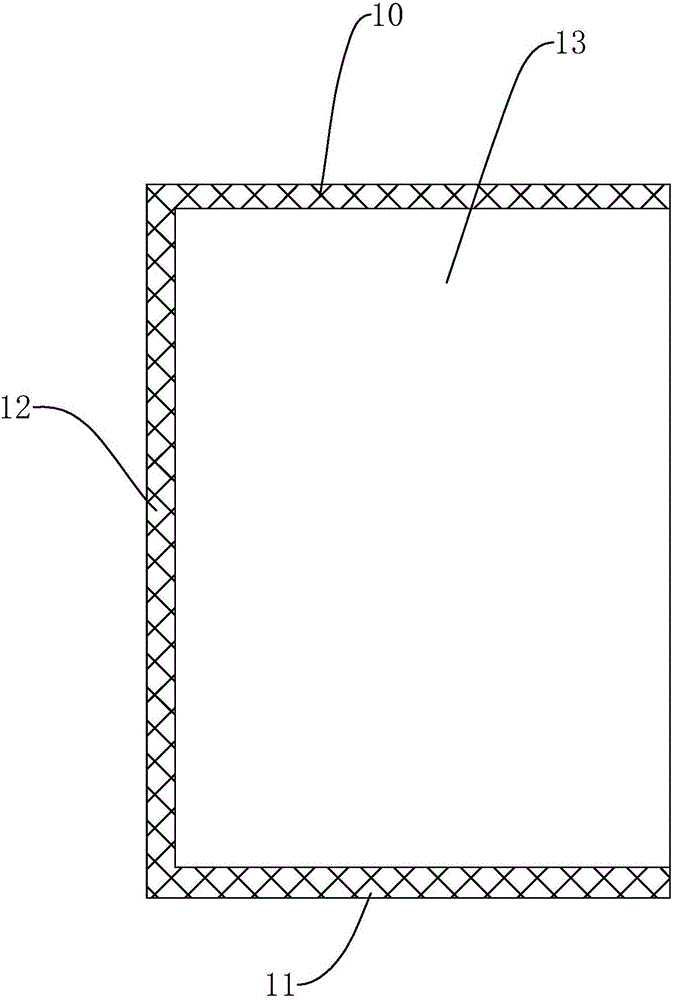

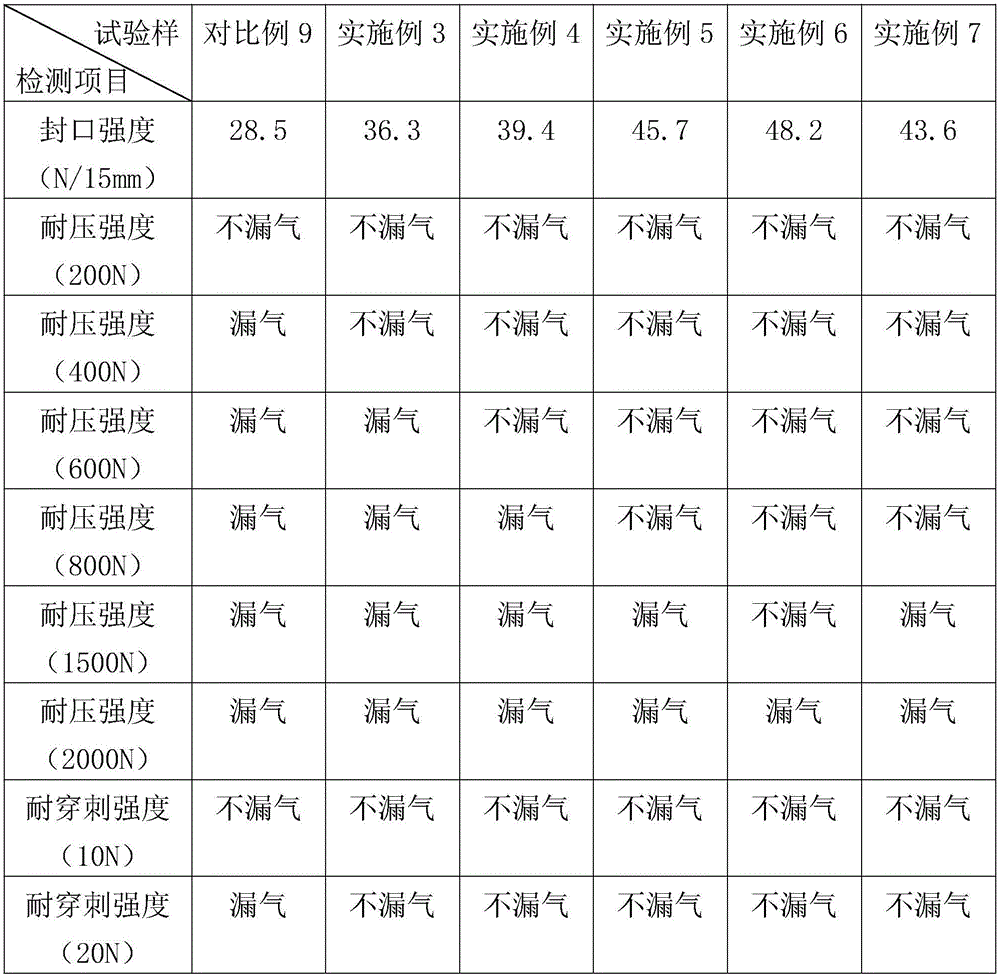

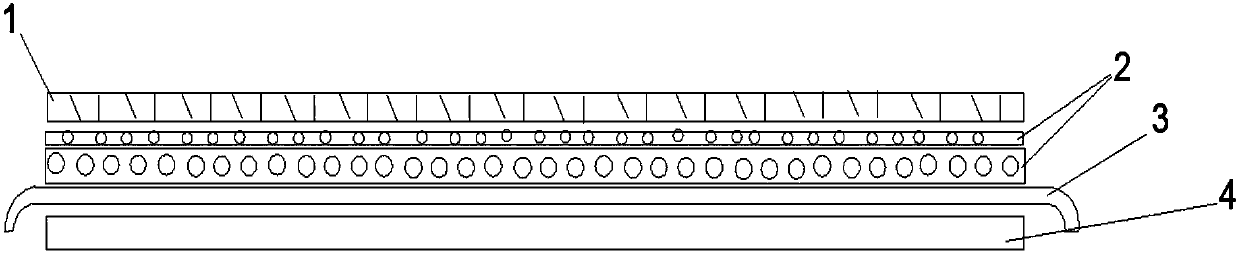

Glass-fiber membrane and glass-fiber vacuum bag

ActiveCN107175861AImprove connection stabilityImprove stabilityFlexible coversWrappersGlass fiberPuncture resistance

The invention discloses a glass-fiber membrane and a glass-fiber vacuum bag. According to the technical scheme, the glass-fiber membrane is characterized by comprising a glass-fiber cloth layer, a flame-retardant adhesive layer, a PET layer, a first adhesive layer, an aluminum-foil layer, a second adhesive layer, a PA layer, a third adhesive layer and an SPE layer which are sequentially connected from bottom to top. The glass-fiber membrane is prepared into the corresponding glass-fiber vacuum bag through a corresponding process, the prepared glass-fiber vacuum bag is good in sealing strength, compression strength and puncture resistance, and the sealing structural strength and usability of the glass-fiber vacuum bag are improved.

Owner:安徽科能新材料环保科技有限公司

Novel reflecting film

The invention discloses a novel reflecting film. The novel reflecting film sequentially comprises an anti-scraping layer, a foaming layer, a periphery layer and a bottom plate layer from top to bottom. First trapezoid reinforcing particles and second trapezoid reinforcing particles are clamped mutually in the anti-scraping layer and are mutually matched. The foaming layer comprises a micro foaminglayer and a high foaming layer. An integral structure is formed by the foaming layer and the periphery layer through hot pressing. The periphery layer is provided with a peripheral arc edge through high-temperature shaping. The novel reflecting film has the advantages that the first trapezoid reinforcing particles and the second trapezoid reinforcing particles, matched mutually, are clamped mutually in the anti-scraping layer, so that reflectivity of the reflecting film is enhanced; the foaming layer comprises the micro foaming layer and the high foaming layer, so that both reflectivity and deflection of the reflecting film are enhanced; the periphery layer is provided with the peripheral arc edge through high-temperature shaping, so that the film has high adhesion, and a coating edge isnot easy to upwarp during use.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

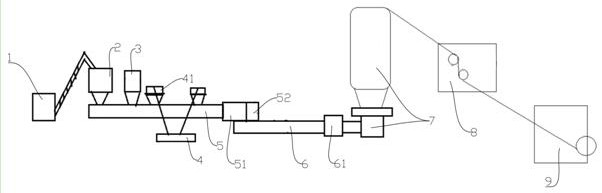

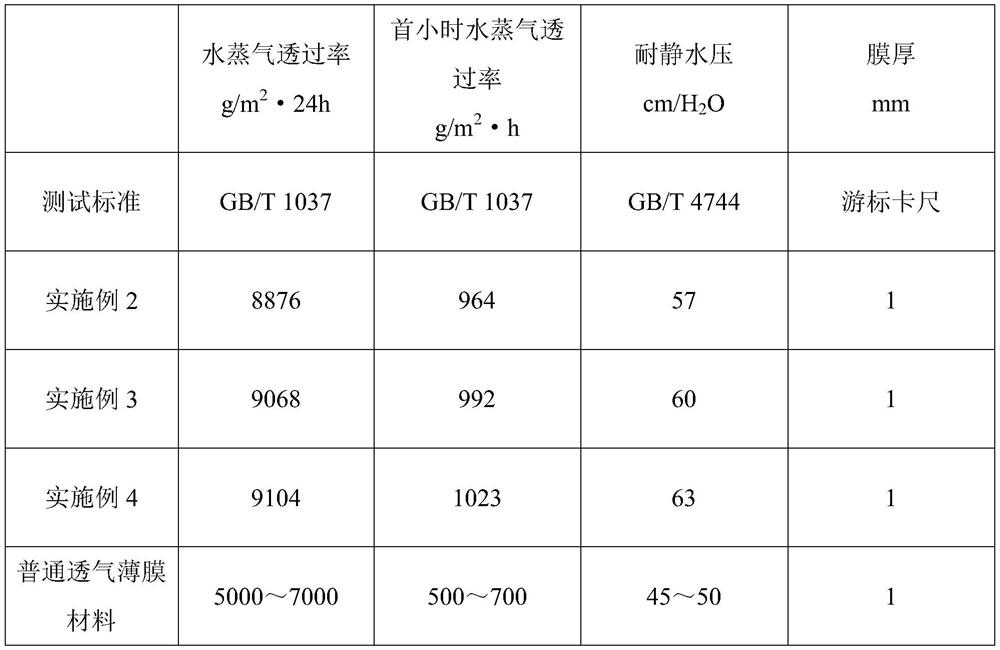

One-step breathable film and preparation method thereof

The invention discloses a one-step breathable film and a preparation method thereof. The one-step breathable film is prepared by one-step film blowing equipment, and the preparation method comprises the following steps: A, inorganic powder is activated to prepare active inorganic powder; B, mixed breathable film plastic particles and the active inorganic powder form a mixed melt in a double-screwextruder, and the mixed melt sequentially passes through a first metering pump and a melt pressure buffer area, then enters a feeding port of a single-screw extruder, and then enters a film blow molding machine through a second metering pump to be subjected to extrusion blow molding to prepare a primary film; then, longitudinal stretching is performed; and thickness measurement control, corona treatment, film deviation rectification, thick edge cutting and rolling are carried out to prepare the one-step breathable film. The one-step breathable film is high in water vapor transmission rate, good in breathability, high in first-hour water vapor transmission rate and high in water vapor transmission efficiency; the one-step breathable film is high in static water pressure resistance and doesnot leak liquid water during use; and the one-step breathable film is degradable and does not cause any pollution to the environment.

Owner:福建琦峰科技有限公司

Lead-acid battery with good waterproof effect

InactiveCN110797485AImprove waterproof performanceImprove structural strengthFinal product manufactureBattery isolationEngineeringFan blade

Owner:FUJIAN HUAXIANG POWER TECH

Magnetic oil filter for automobile blockage prevention

InactiveCN106050355AAvoid cloggingEasy to wearLubricant mounting/connectionPressure lubricationFilter paperImpurity

The invention discloses a magnetic oil filter for automobile blockage prevention. The magnetic oil filter comprises a body. A center pipe is arranged in the body. A backflow restraining valve and a bypass valve are arranged in the center pipe. A clean oil outlet is formed in the upper end of the backflow restraining valve and provided with a thread connector. Dirty oil inlets are formed in the periphery of the clean oil outlet. The bypass valve is arranged at the bottom of the body, and filter paper is arranged on the periphery of the center pipe. A metal shell is arranged at the outer portion of the body. A dirty oil cavity is formed between the filter paper and the metal shell and communicates with the dirty oil inlets. The magnetic oil filter has the beneficial effects of being resistant to the high temperature, corrosion and pressure, magnets are arranged on the inner wall of the metal shell and can attract scrap iron in oil to the inner wall of the metal shell, the situation that more impurities block the filter paper, consequently dirty oil enters an engine, and abrasion of the engine is increased is prevented, and therefore the service life of the engine is prolonged, and meanwhile the replacing frequency of the filter is reduced.

Owner:南京润屹电子科技有限公司

Reinforced wear-resistant PE gas pipe and preparation method thereof

ActiveCN112694656AImprove wear resistanceImprove the ability to resist external pressureSynthetic resin layered productsTubular articlesGraphiteGraphene

The invention discloses a reinforced wear-resistant PE gas pipe and a preparation method thereof. The reinforced wear-resistant PE gas pipe comprises an inner layer, a core layer and an outer layer, the inner layer is prepared from, by weight, 90-94 parts of polyethylene resin and 4-7 parts of graphene functional master batch, and the core layer is prepared from, by weight, 100-120 parts of polyethylene graft resin, and the outer layer is prepared from the following raw materials by weight: 90-95 parts of block copolymer polypropylene and 3-6 parts of graphene functional master batch; the reinforced wear-resistant PE gas pipe is prepared through the following steps of: adding the raw materials of the inner layer, the core layer and the outer layer into a three-layer co-extrusion die, conducting co-extrusion outer layer treatment, and carrying out compounding and extrusion forming at the temperature of 190-220DEG C, thus obtaining the reinforced wear-resistant PE gas pipe; the preparation method of the reinforced wear-resistant graphene functional master batch comprises the following steps of: A1, weighing of raw materials; B1, pretreatment of graphene; C1, internal mixing; and D1, granulation.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

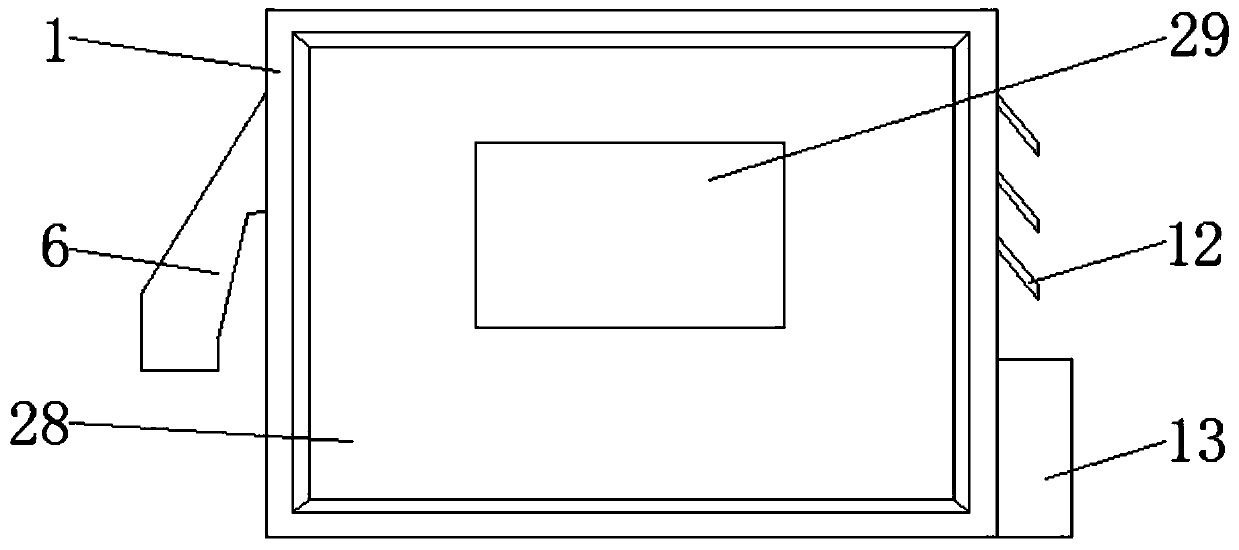

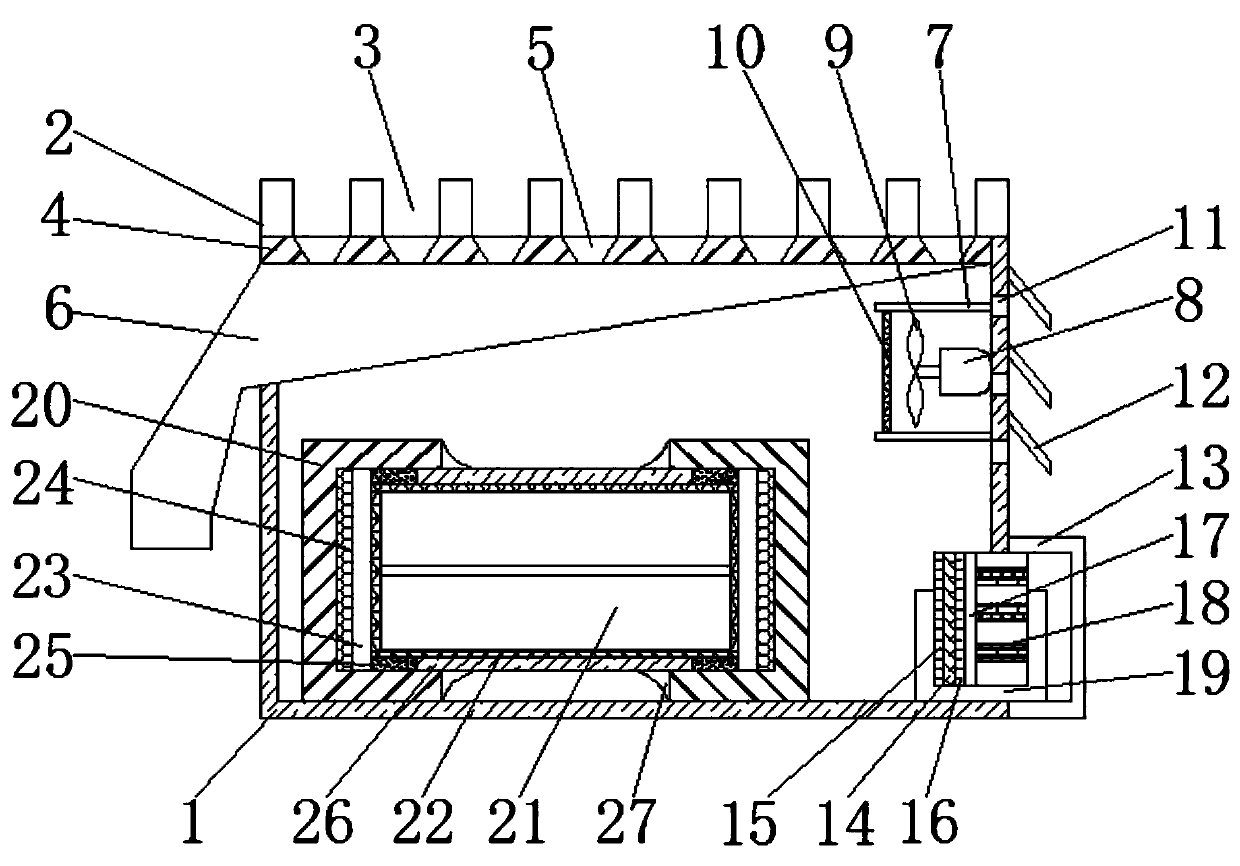

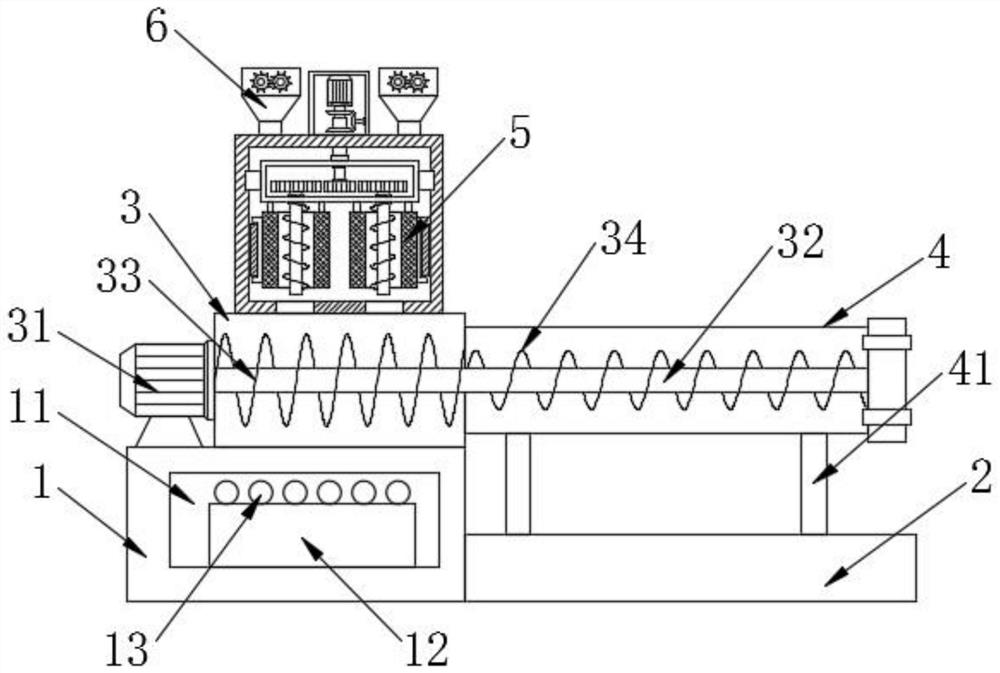

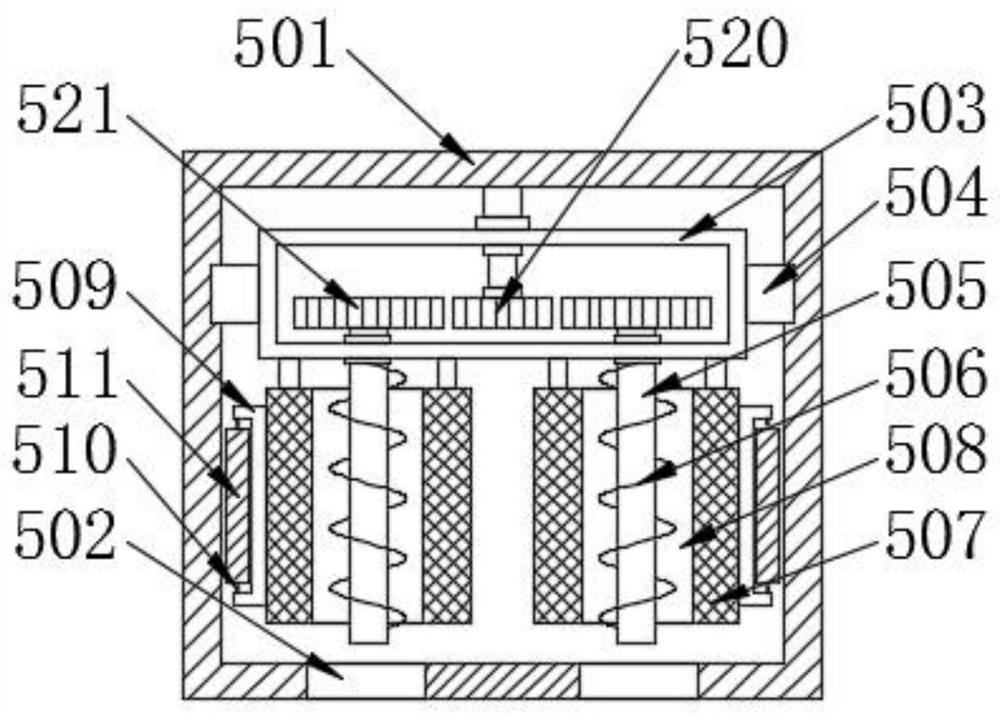

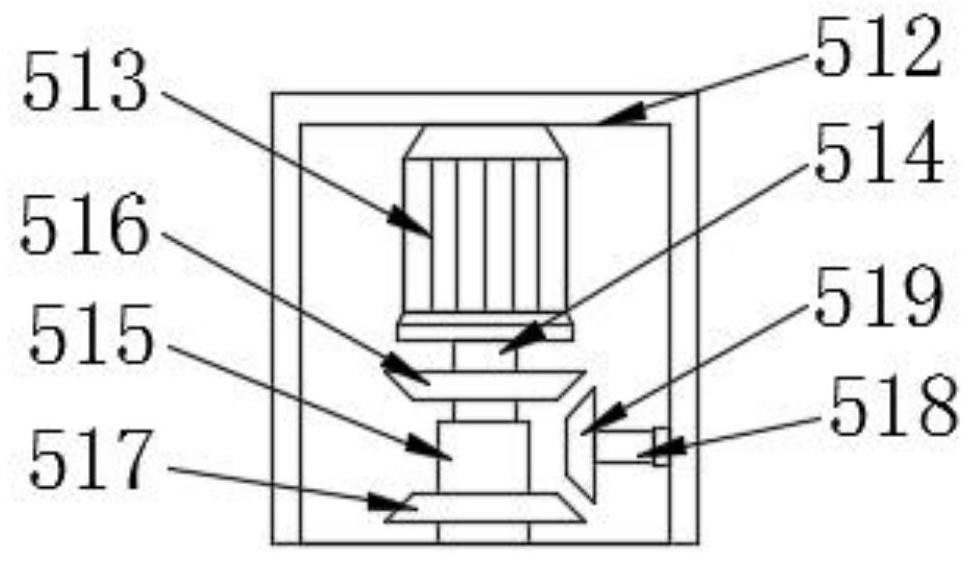

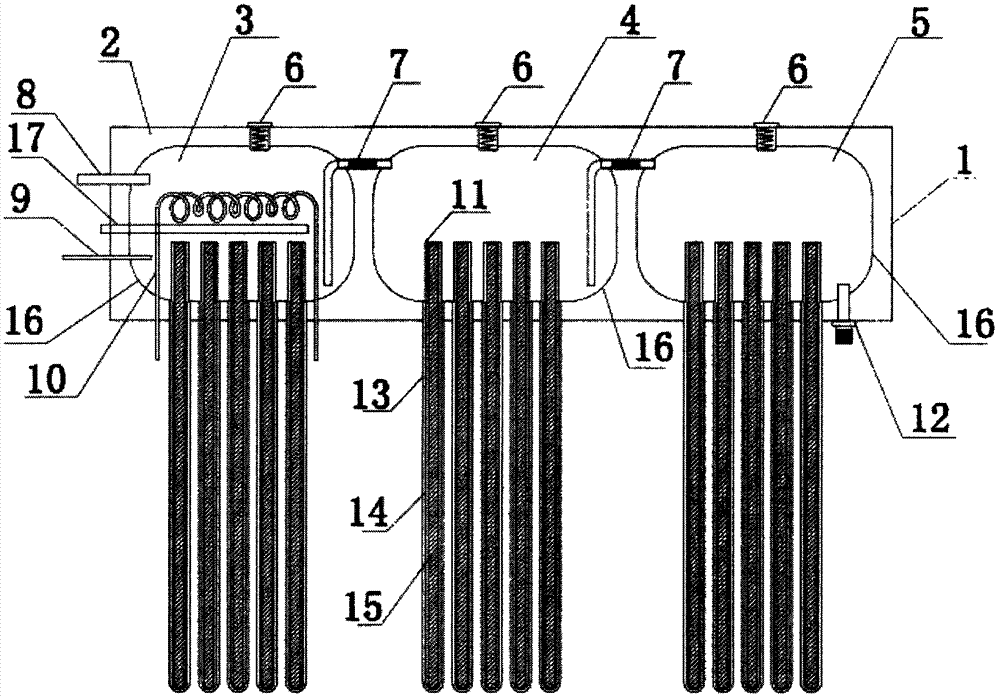

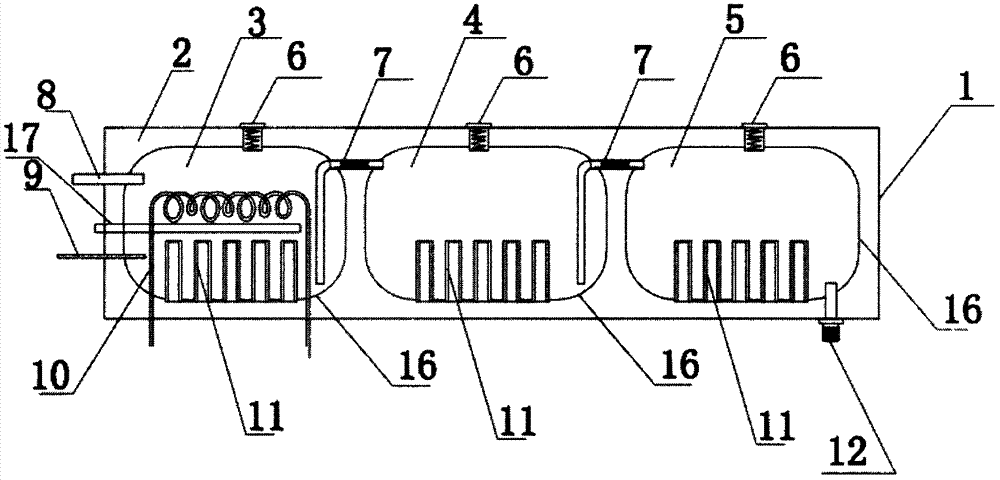

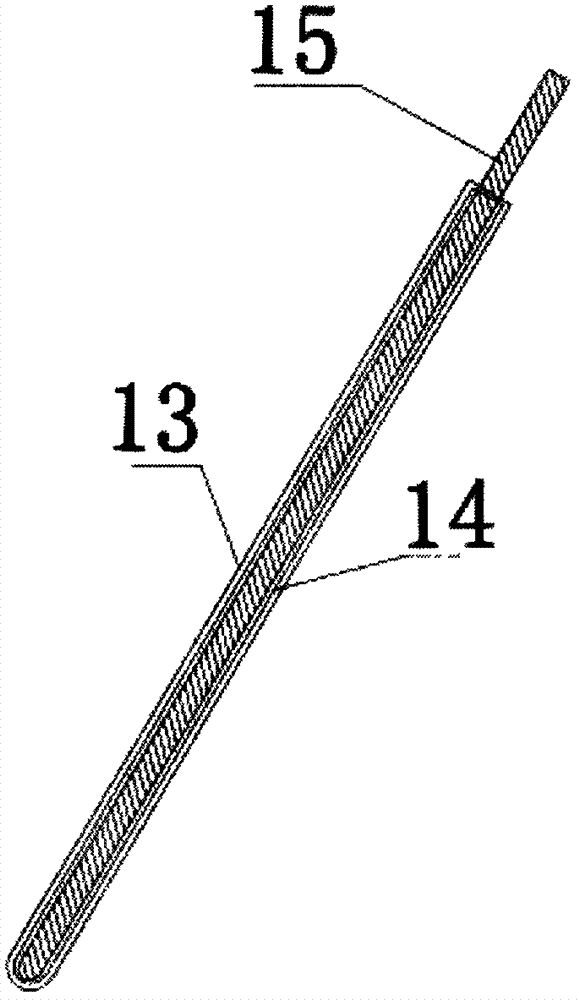

Multi-energy pressure-bearing type vacuum pipe solar water heater

PendingCN107289638APressure-resistantSolar heating energySolar heat devicesFailure rateWater resources

The invention belongs to the field of solar water heaters and provides a multi-energy pressure-bearing type vacuum pipe solar water heater for solving the problem that an existing solar water heater is poor in pressure-bearing effect, heat collecting effect and heat preservation effect. The multi-energy pressure-bearing type vacuum pipe solar water heater comprises a water tank shell and vacuum heat collecting pipes and further comprises pressure-bearing liners. A heat preservation layer is arranged between the water tank shell and the pressure-bearing liners. At least one water tank is arranged in the water tank shell. A pressure-releasing valve is arranged on the top of each water tank. Heating blind pipes are arranged at the bottoms of the water tanks correspondingly, and the heating blind pipes and the pressure-bearing liners are formed integrally. The heating blind pipes and the vacuum heat collecting pipes are arranged in a matched mode. Heat collecting pieces are arranged in the vacuum heat collecting pipes. Superconducting pipes are installed in the heat collecting pieces. The tops of the superconducting pipes make close contact with the heating blind pipes. The multi-energy pressure-bearing type vacuum pipe solar water heater has the advantages of good pressure-bearing effect, heat collecting effect and heat preservation effect, water can be automatically added, the failure rate is greatly decreased, and water resources are saved.

Owner:范沈江

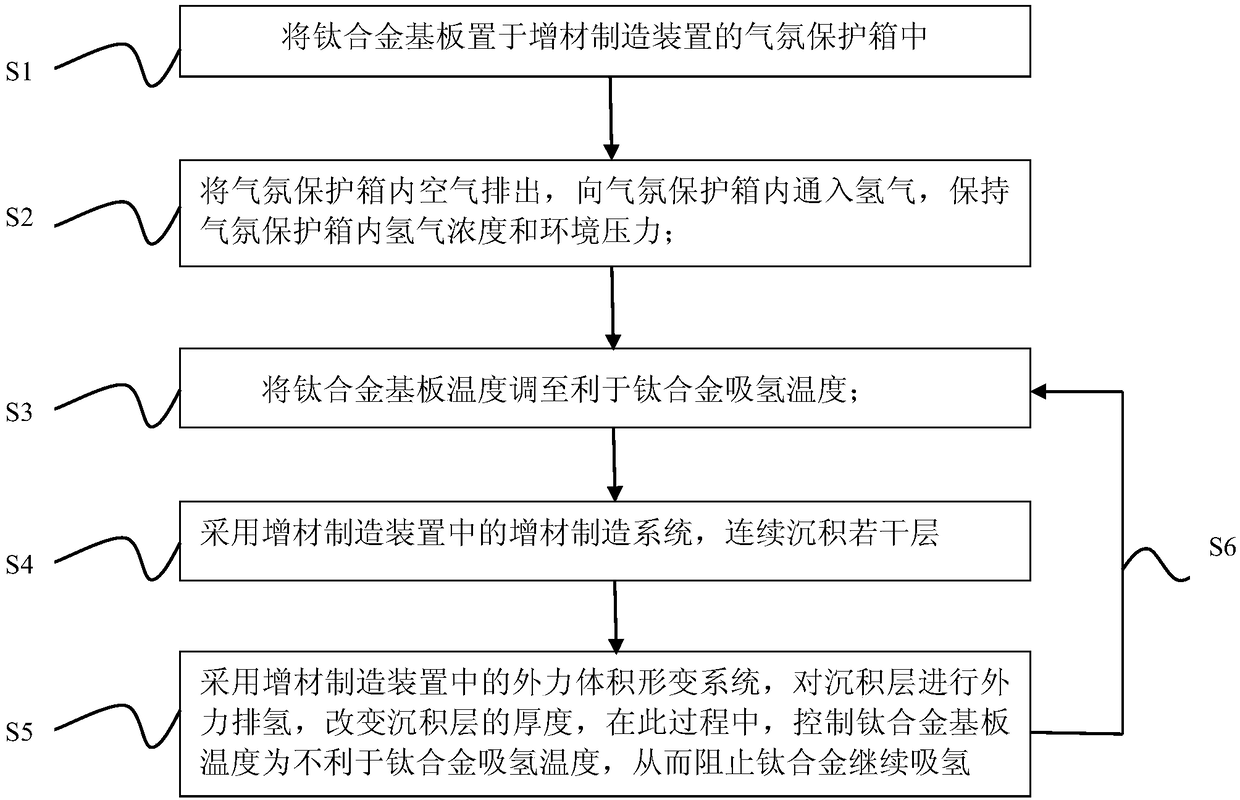

Method for refining additive manufactured titanium alloy grains

ActiveCN109128172AAirtightPressure resistantAdditive manufacturing apparatusIncreasing energy efficiencyHydrogen concentrationTemperature control

The invention relates to a method for refining additive manufactured titanium alloy grains, belonging to the field of v. The method comprises the following steps of: placing a titanium alloy substratein an atmosphere protection box of an additive manufacturing device; controlling the hydrogen concentration and environmental pressure in the atmosphere protection box to be favorable to hydrogen absorption of titanium alloy; adjusting the temperature of the titanium alloy substrate to be favorable for hydrogen absorption temperature of the titanium alloy; adopting an additive manufacturing system in the additive manufacturing device, after several layers are continuously deposited, introducing an external force volume deformation system to discharge hydrogen from the deposited layer by an external force, and controlling the temperature of the titanium alloy substrate to be unfavorable to hydrogen absorption temperature of the titanium alloy, and repeating the temperature control and deposition until a predetermined deposition form is obtained. The method is based on the hydrogen absorption principle of titanium alloy and exerts an external force to prevent the formation of columnar grain of titanium alloy and achieve the purpose of grain refinement. The method has the characteristics of further grain refinement, high efficiency and convenient realization.

Owner:SHENYANG AEROSPACE UNIVERSITY

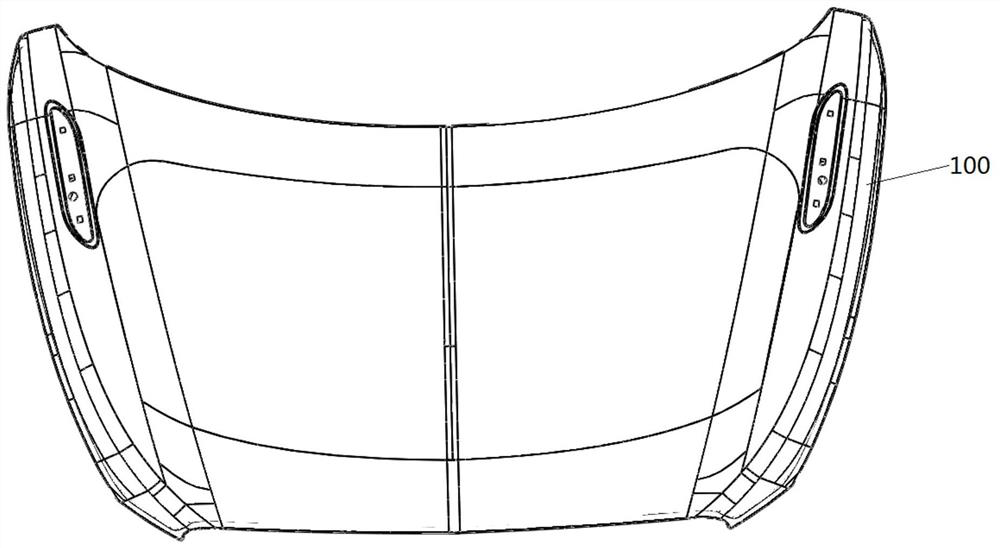

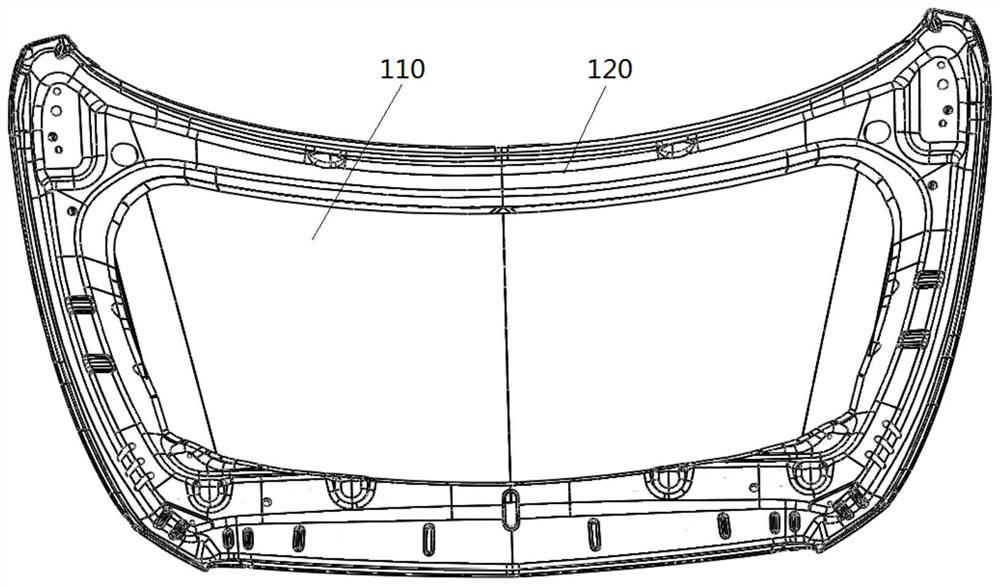

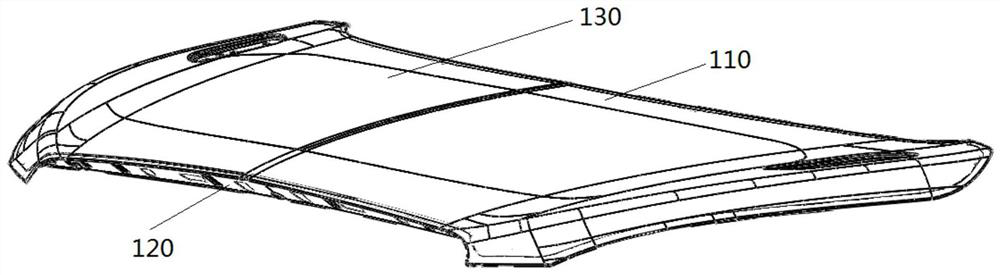

Novel engine hood with inward-sunken outer plate

ActiveCN113184056AGood structural vibration characteristicsAchieve lightweight designPedestrian/occupant safety arrangementSuperstructure subunitsEngineeringStructural engineering

The invention discloses a novel engine hood with an inward-sunken outer plate, and the engine hood comprises an inner plate which is of a frame structure; an outer plate which comprises a plate body, an extending part and a sunken part, wherein the extension parts are arranged at the two ends of the plate body in a bent mode, the extension parts are connected with the inner plate, and the sunken part is arranged in a head impact area on the plate body; and a filling layer, wherein one side of the filling layer is matched with the concave part, and the other side of the filling layer and the plate body form the same plane. The engine hood has the characteristics of reducing collision damage and improving the light weight of the engine hood.

Owner:JILIN UNIV

Building construction multi-purpose foundation pile

InactiveCN109339034AAvoid corrosionReduce shockProtective foundationBulkheads/pilesHoopingHorizontal force

The invention discloses a building construction multi-purpose foundation pile. The building construction multi-purpose foundation pile comprises a device body, the device body is composed of a foundation pile base, a steel bar net cage arranged at the top of the foundation pile base and a cushion cap, wherein the steel bar net cage is arranged inside the foundation pile base and the cushion cap inan embedded manner correspondingly and is composed of longitudinal bars and hooping bars arranged on one sides of the longitudinal bars, and the longitudinal bars are arranged to be perpendicular tothe hooping bars and welded to the hooping bars. According to the building construction multi-purpose foundation pile, on the basis of traditional building construction foundation piles, the outer surface of a steel pipe is provided with an epoxy resin layer, corrosion caused by underground moisture and other underground elements on the foundation pile can be prevented, and the epoxy resin layer further has pressure resistance, the steel pipe and a cast-in-place concrete layer can be assisted to fix buildings, at the same time, by means of the manner that one side of the steel bar net cage isprovided with shock absorption steel plates, the horizontal force bearing area can be increased, and impact of earthquake on a foundation pile body is lightened.

Owner:李玉清

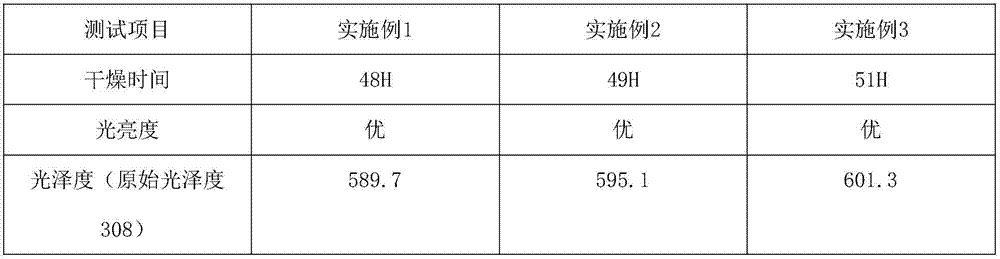

High solid content acrylic polyurethane paint

Relating to the technical field of paint processing and manufacturing, the invention provides a high solid content acrylic polyurethane paint. The high solid content acrylic polyurethane paint is characterized in that it is prepared from the following raw materials by weight: 35-40 parts of polyester resin, 20-25 parts of high solid content acrylic polyurethane, 17-23 parts of anhydrous ethanol, 7-11 parts of a coupling agent, 7-11 parts of isopropyl alcohol, 3-6 parts of an assistant, 4-8 parts of cyclohexanone, 3-7 parts of n-butanol, 10-15 parts of powdered pigment, 5-10 parts of xylene, and 5-10 parts of a defoaming agent. The method adopted by the invention is reasonable, convenient for operation and harmless to the human body.

Owner:安徽江锐新材料有限公司

A preparation method of a headless fiber-reinforced resin-based composite material combustion chamber shell for rockets

ActiveCN110978558BIncrease burst pressureImprove insulation performanceDomestic articlesCoatingsYarnCombustion chamber

A method for preparing a headless fiber-reinforced resin-based composite material combustion chamber casing for rockets, and the invention relates to the field of polymer-based composite material preparation methods. The invention aims to solve the technical problems of poor heat insulation, low blasting strength and heavy quality in the combustion chamber shell prepared by the existing method. Methods: 1. Milling the metal ring to obtain a metal hanging wire ring; 2. Assembling the assembly; 3. Dipping the fiber yarn in glue, and then winding it on the surface of the assembly; 4. Heating and solidifying, and releasing the core-pulling mold after natural cooling. The lining layer of the invention has good performance, and can meet the airtightness and ablation resistance performance of the combustion process of the powder column in the combustion chamber. The structural layer formed by winding meets the requirements for pressure resistance and rigidity of the shell. The fiber yarn is dropped between the wire hanging tables of the metal wire hanging ring according to the law, so as to improve the connection strength between the composite material and the metal and the bursting pressure of the casing. The invention is used for preparing the shell of the combustion chamber of the headless fiber-reinforced resin-based composite material of the rocket.

Owner:HARBIN FRP INST

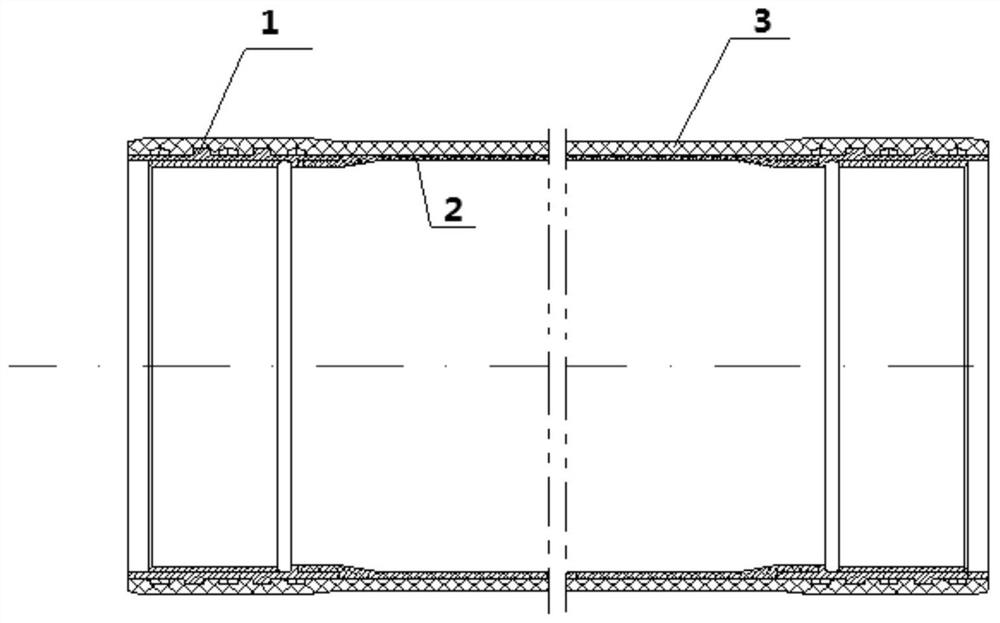

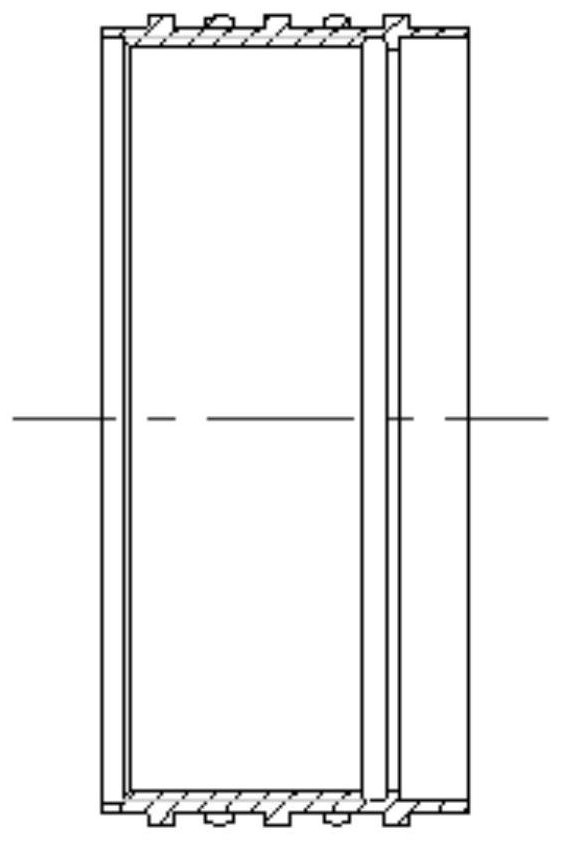

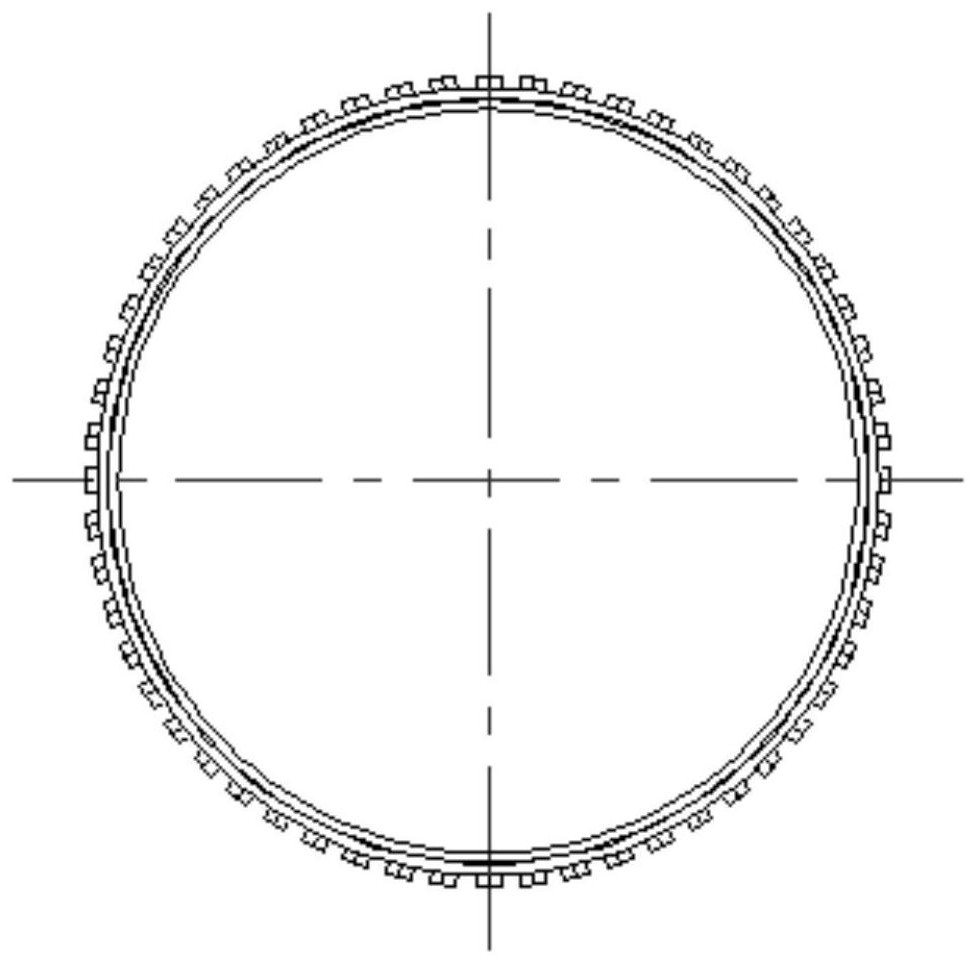

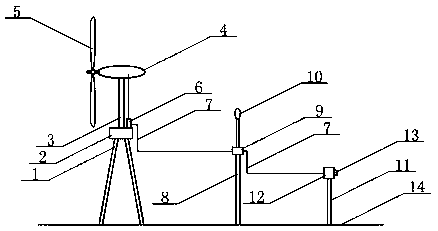

Ground wind power generation station of manufacturing wind power support frame by using bamboo winding composite pressure pipe columns

InactiveCN108869183APressure resistantAnti-deformationFinal product manufactureWind motor supports/mountsWind drivenNew energy

The invention relates to a ground wind power generation station of manufacturing a wind power support frame by using bamboo winding composite pressure pipe columns, and belongs to the technical fieldof new energy application. A bamboo material is used for manufacturing bamboo winding composite pressure pipe columns, and a bamboo winding composite pressure platform is arranged on the top faces ofthe four bamboo winding composite pressure pipe columns A 1, a bamboo winding composite pressure stand column is installed on the upper face of the bamboo winding composite pressure platform, a wind driven generator is installed on the top face of the bamboo winding composite pressure stand column, and blades are installed at the front end of the wind driven generator; wind power blows the bladesto rotate, the current generated by the wind driven generator is driven to be input into a micro inverter through a conducting wire, the current output from the micro inverter is input into a transformer on the top faces of a bamboo winding composite pressure pipe column B 8 through the conducting wire, and the current output from the transformer is input into a charging pile on a bamboo winding composite pressure pipe column C 11 through the conducting wire; the current output from the wind driven generator is used for charging an electric appliance by passing through the conducting wire, themicro inverter, the transformer, the charging pile and a charging port.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com