Ground wind power generation station of manufacturing wind power support frame by using bamboo winding composite pressure pipe columns

A composite pressure tube and wind turbine technology, applied in the installation/support of wind turbine configuration, wind energy power generation, wind turbine and other directions, can solve the problems of decomposition, heavy weight, difficulty in handling metal materials, etc., to achieve long service life, increase Economic income, the effect of expanding new uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

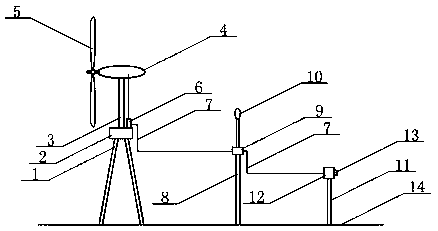

Embodiment 1

[0021] Use the bamboo material in the southern mountainous area to manufacture bamboo winding composite pressure pipe columns, and build ground wind power stations that use bamboo winding composite pressure pipe columns to manufacture wind power support frames in mountainous areas or rural areas where power supply is inconvenient. Install a bamboo winding composite pressure platform on the top surface of the bamboo winding composite pressure pipe column A, install a bamboo winding composite pressure column on the top of the bamboo winding composite pressure platform, and install a horizontal axis wind generator on the top surface of the bamboo winding composite pressure column , the blades are installed at the front end of the horizontal axis wind generator, the wind blows the blades to rotate, and the current generated by the wind generator is input through the conductive wire to the micro inverter installed on the right side of the bamboo winding composite pressure column and ...

Embodiment 2

[0023]Use the bamboo material in the southern mountainous area to manufacture bamboo winding composite pressure pipe columns, and build ground wind power stations that use bamboo winding composite pressure pipe columns to manufacture wind power support frames in mountainous areas or rural areas where power supply is inconvenient. Install a bamboo winding composite pressure platform on the top surface of the bamboo winding composite pressure pipe column A, install a bamboo winding composite pressure column on the top of the bamboo winding composite pressure platform, and install a vertical axis wind generator on the top surface of the bamboo winding composite pressure column , the blades are installed at the front end of the vertical axis wind turbine, the wind blows the blades to rotate, and the current generated by the wind generator is input through the conductive wire to the micro inverter installed on the right side of the bamboo winding composite pressure column and on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com