High solid content acrylic polyurethane paint

A technology of acrylic polyurethane, high solid content, applied in the direction of polyester paint, coating, etc., can solve the problems of paint toxin processing, incompleteness, product quality decline, etc., and achieve the effect of not easy to fade, long life and good polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

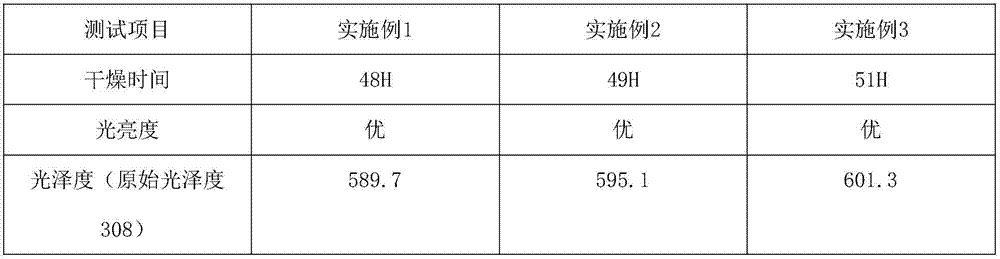

Embodiment 1

[0022] A high-solid acrylic polyurethane paint is characterized in that: it is made of the following materials by weight,

[0023] 35 parts of polyester resin, 20 parts of high solid acrylic polyurethane, 17 parts of absolute ethanol, 7 parts of coupling agent, 7 parts of isopropanol, 3 parts of additives, 4 parts of cyclohexanone, 3 parts of n-butanol, powder 10 parts of solid pigment, 5 parts of xylene, 5 parts of defoamer;

[0024] Including the following preparation steps,

[0025] ⅠPut the polyester resin and absolute ethanol into the batching kettle, stir and mix;

[0026] ⅡPump isopropanol, cyclohexanone and n-butanol into the high-level tank, open the discharge valve and add to the batching kettle;

[0027] Ⅲ Add the measured high-solid acrylic polyurethane and coupling agent and stir evenly;

[0028] Ⅳ Add the powdered pigment, adjust and stir for 30 minutes, pump it into the sand mill and grind it tightly until the fineness is qualified;

[0029] Ⅴ Add xylene and...

Embodiment 2

[0034] A high-solid acrylic polyurethane paint is characterized in that: it is made of the following materials by weight,

[0035] 40 parts of polyester resin, 25 parts of high solid acrylic polyurethane, 23 parts of absolute ethanol, 11 parts of coupling agent, 11 parts of isopropanol, 6 parts of additives, 8 parts of cyclohexanone, 7 parts of n-butanol, powder 15 parts of solid pigment, 10 parts of xylene, 10 parts of defoamer;

[0036] Including the following preparation steps,

[0037] ⅠPut the polyester resin and absolute ethanol into the batching kettle, stir and mix;

[0038] ⅡPump isopropanol, cyclohexanone and n-butanol into the high-level tank, open the discharge valve and add to the batching kettle;

[0039] Ⅲ Add the measured high-solid acrylic polyurethane and coupling agent and stir evenly;

[0040] Ⅳ Add the powdered pigment, adjust and stir for 30 minutes, pump it into the sand mill and grind it tightly until the fineness is qualified;

[0041] Ⅴ Add xylene...

Embodiment 3

[0046] A high-solid acrylic polyurethane paint is characterized in that: it is made of the following materials by weight,

[0047] 38 parts of polyester resin, 22 parts of high solid acrylic polyurethane, 20 parts of absolute ethanol, 8 parts of coupling agent, 9 parts of isopropanol, 5 parts of additives, 5 parts of cyclohexanone, 5 parts of n-butanol, powder 13 parts of solid pigment, 8 parts of xylene, 7 parts of defoamer;

[0048] Including the following preparation steps,

[0049] ⅠPut the polyester resin and absolute ethanol into the batching kettle, stir and mix;

[0050] ⅡPump isopropanol, cyclohexanone and n-butanol into the high-level tank, open the discharge valve and add to the batching kettle;

[0051] Ⅲ Add the measured high-solid acrylic polyurethane and coupling agent and stir evenly;

[0052] Ⅳ Add the powdered pigment, adjust and stir for 30 minutes, pump it into the sand mill and grind it tightly until the fineness is qualified;

[0053] Ⅴ Add xylene and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com