Patents

Literature

1585results about How to "Not easy to fade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Darkening and coloring finishing agent of dyed cotton fabrics and preparation method thereof

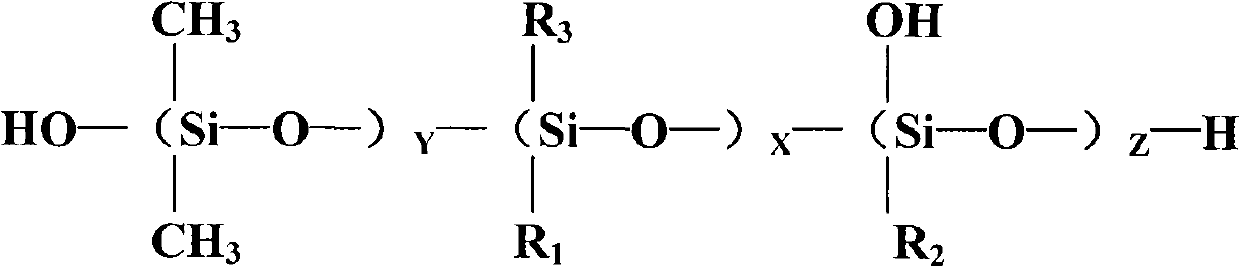

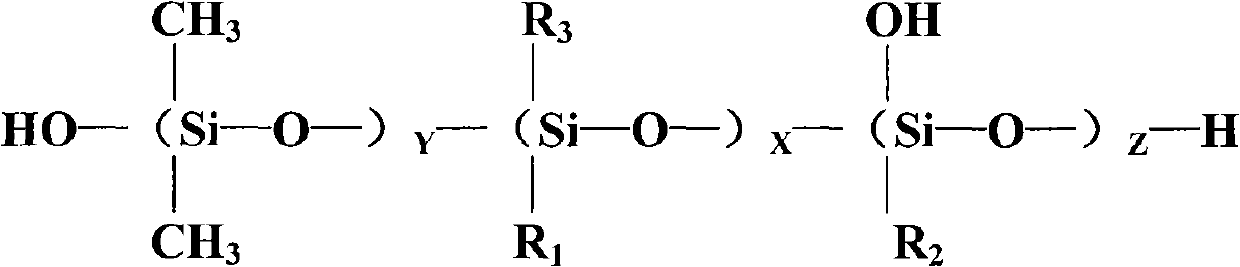

The invention relates to a darkening and coloring finishing agent of dyed cotton fabrics and a preparation method thereof. The darkening and coloring finishing agent of the dyed cotton fabrics is prepared by mixing an organic polysiloxane emulsion and methyl hydrogen-contained silicone oil shown in structural formulas in a ratio of 100 to 5-10, wherein R1=-CH2CH2CH2NH2 and / or -CH2CH2CH2NHCH2CH2NH2 and / or -CH2CH2CH2NHCH2CH2NHCH2CH2NH2, R3=-OH and / or -CH3, X=4-6000, Y=1-100 and Z=1-100. The invention has favorable darkening and coloring effects on the dyed cotton fabrics; and the treated dyed cotton fabrics have soft and smooth hand feeling and good washability without remaining substances harmful to human bodies.

Owner:江苏卓特知识产权服务有限公司

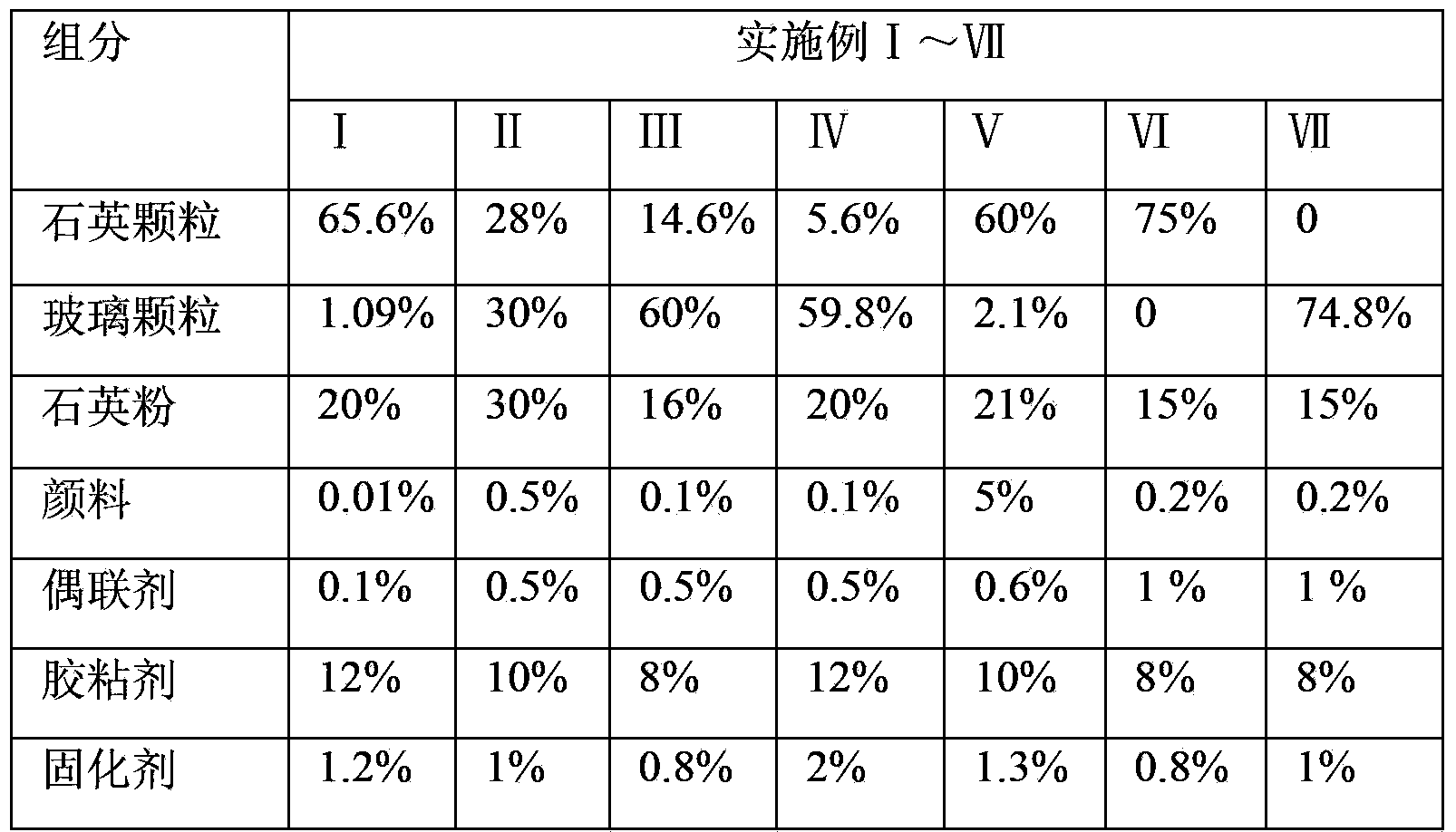

High-impact toughness man-made quartzite slab and preparation method thereof

The invention provides a high-impact toughness man-made quartzite slab and a preparation method thereof. The man-made quartzite slab comprises the following components in percentage by weight: 58-75 percent of particle raw materials, 15-33 percent of quartz powder, 0.01-10 percent of paint, 0.1-1 percent of coupling agent, 8-12 percent of adhesive and 0.8-2 percent of curing agent, wherein the particle raw materials are quartz particles, glass particles, or a mixture of the two. The man-made quartzite slab provided by the invention has the characteristics of low probability of cracking and deformation, and the like.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

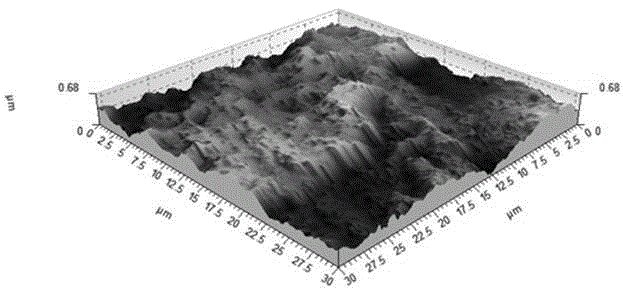

Treatment method of black hard microarc oxidation ceramic membrane on surface of magnesium alloy

InactiveCN102021631AUniform colorImproved color stabilityAnodisationElectrolysisPlasma electrolytic oxidation

The invention belongs to the treatment technology of a black hard ceramic membrane on the surface of magnesium alloy, in particular relating to a treatment method of a black hard microarc oxidation ceramic membrane on the surface of magnesium alloy. The invention mainly solves the technical problems that the colour of a ceramic membrane treated by magnesium alloy microarc oxidation is white or grey white mostly and the deep colour and even black ceramic membranes can not be obtained in the prior art. The method provided by the invention comprises the steps that sodium phosphate, sodium fluoride, sodium hydroxide, sodium molybdate, potassium carbonate, sodium tungstate, copper sulphate and potassium dichromate are added into water and prepared into an alkaline electrolytic solution, and the solution is stirred for later use; and then magnesium alloy and a stainless steel plate are immersed into the alkaline electrolytic solution, the magnesium alloy is taken as an anode, the stainless steel plate is taken as a cathode, and microarc oxidation treatment is carried out until a compact black hard ceramic membrane grows in situ on the surface of the magnesium alloy.

Owner:杭州意来客电器设备有限公司

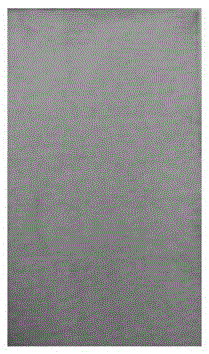

Preparation method of red photonic crystal structured colored glaze

The invention discloses a preparation method of red photonic crystal structured colored glaze, which belongs to the technical field of ceramic glaze preparation. The preparation method comprises the following steps: 1) preparing anhydrous ethanol, ammonia water, water and ethyl orthosilicate in percentage by volume, and after the anhydrous ethanol, the ammonia water and the water are fully and uniformly mixed firstly, adding the ethyl orthosilicate into the obtained mixture, and stirring to have reaction to obtain SiO2 microsphere suspension liquid; 2) centrifuging the SiO2 microsphere suspension liquid, taking precipitates, and washing and drying the precipitates so as to obtain monodisperse SiO2 microspheres; 3) adding the monodisperse SiO2 microspheres into the anhydrous ethanol, carrying out ultrasonic dispersion so as to obtain a SiO2 microsphere emulsion; and 4) putting a ceramic substrate vertically into the SiO2 microsphere emulsion, carrying out vacuum drying until the anhydrous ethanol in the SiO2 microsphere emulsion is completely volatilized, and finally preparing a red photonic crystal structured colored glaze on the surface of the ceramic substrate. Because no pigment or coloring oxide is introduced, the method has the advantages of energy saving and environmental protection, has a broad application prospect, and can be applied to the preparation of red glaze for artistic ceramics, antique ceramics, floor and wall tiles and other ceramics.

Owner:SHAANXI UNIV OF SCI & TECH

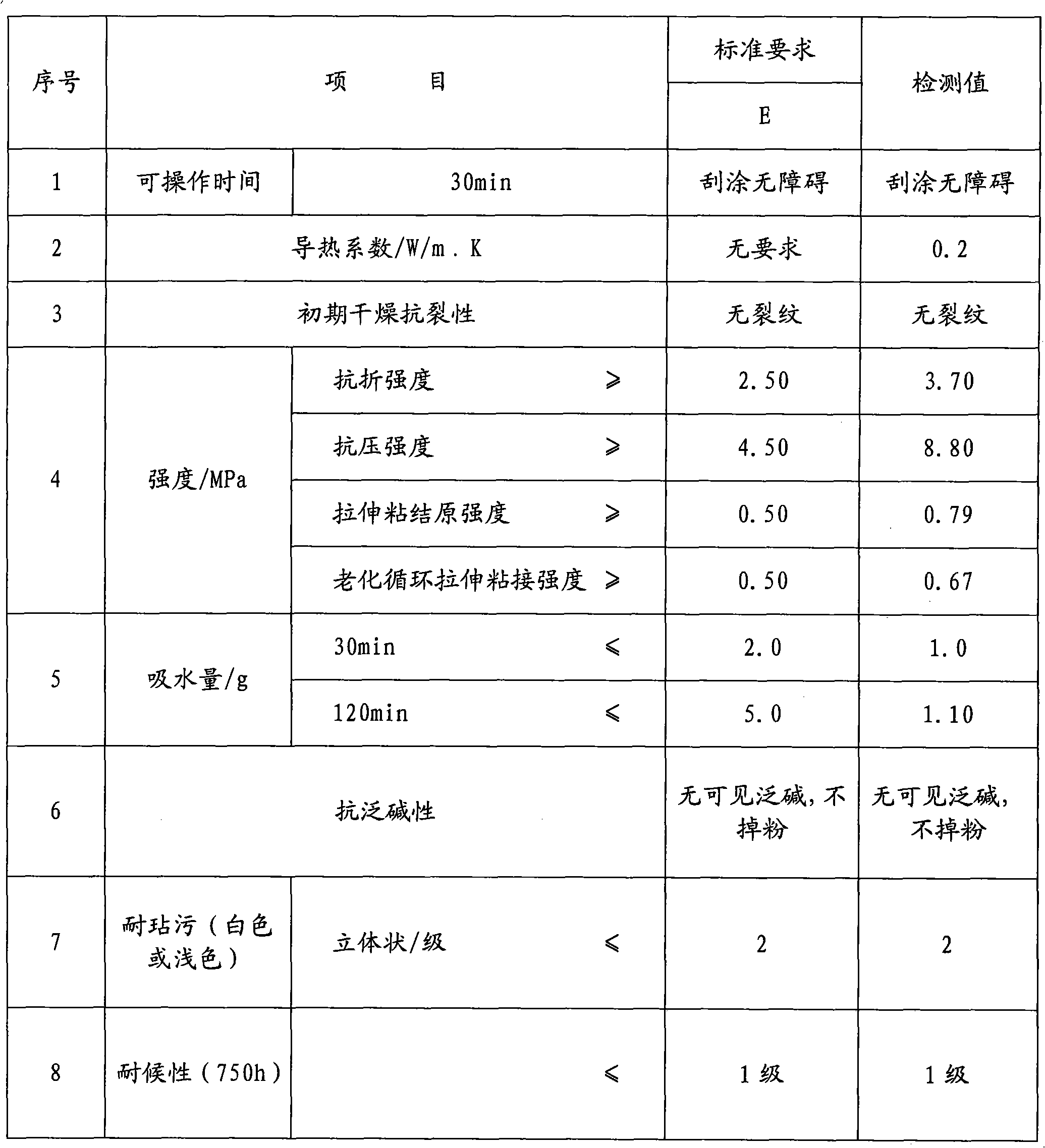

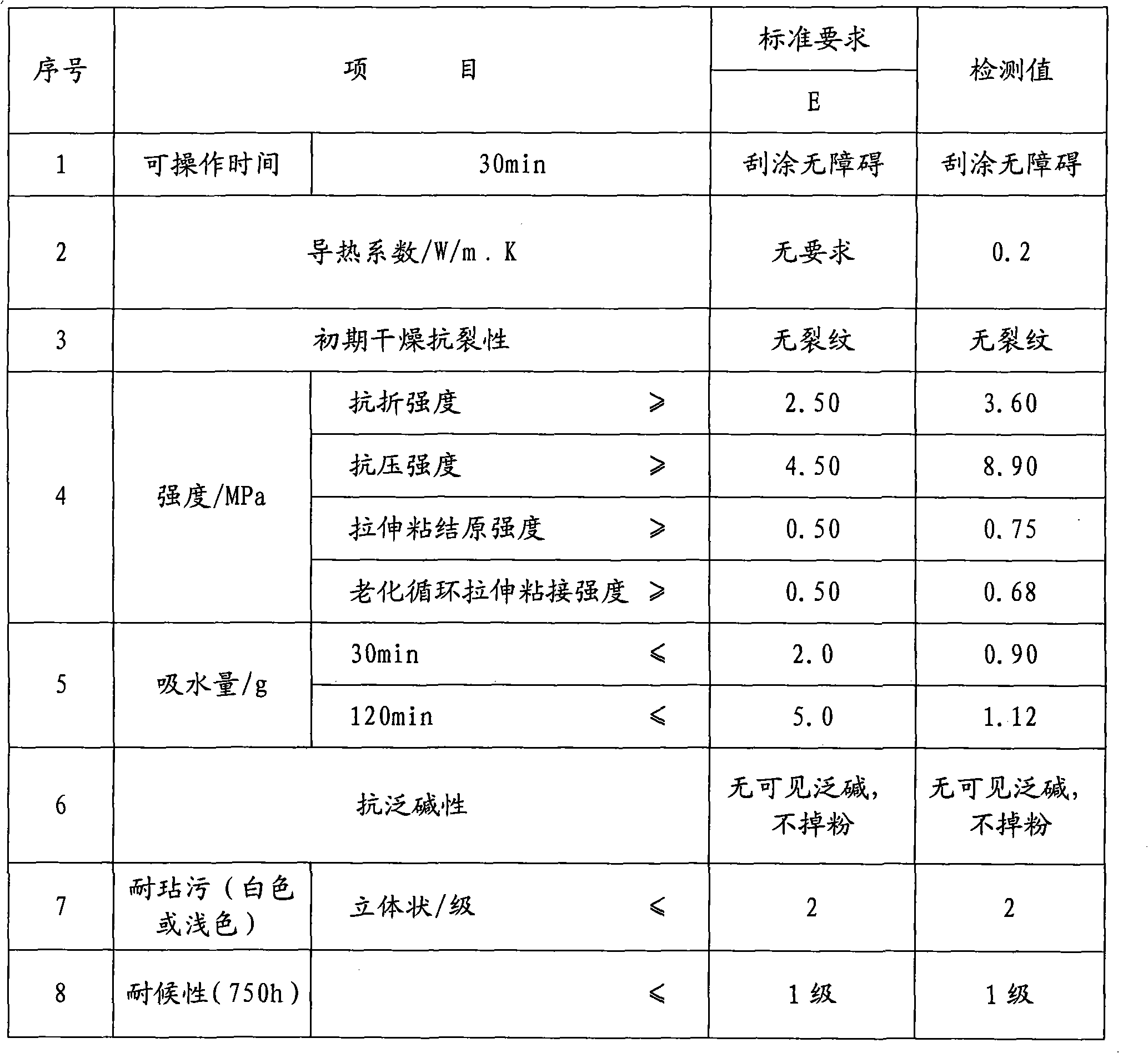

Inorganic thermal insulation and decoration mortar and preparation method thereof

The invention relates to an inorganic thermal insulation and decoration mortar, which is characterized by comprising the following components in parts by weight: 180-220 parts of cement, 40-60 parts of flyash, 560-600 parts of sand, 50-70 parts of heavy calcium carbonate powder, 70-100 parts of inorganic lightweight aggregate, 3-9 parts of bentonite, 4-8 parts of wood fiber, 2-7 parts of moisture repellent, 2-5 parts of saltpetering inhibitor, 0.5-4 parts of cellulose ether, 6-15 parts of rubber powder and 1-30 parts of pigment. The preparation method is implemented as follows: evenly mixing the cement, flyash, sand, heavy calcium carbonate powder, bentonite, wood fiber, moisture repellent, saltpetering inhibitor, cellulose ether, rubber powder and pigment, adding the inorganic lightweight aggregate, and carrying out mechanical mixing uniformity to obtain the product in the invention. The mortar in the invention has the advantages of thermal insulation, strong hydrophobicity, fire resistance, environment protection, no pollution, same duration with buildings and the like.

Owner:奥捷科技股份有限公司

Natural plant hair dye

InactiveCN1923164AStrong penetrating powerAchieve the effect of dyed black hairCosmetic preparationsHair cosmeticsCelluloseSide effect

The invention relates to a hair dye, especially a natural plant hair dye. Wherein, it is formed by mixed A and B solutions; A agent is formed by agent and metal chelant, while the agent can be guar gum, polyquaternary ammonium salt or glycol cellulose, and the chelant can be soluble ferric salt or ferrous salt; B agent contains pomegranate bark extractive and glycol cellulose; while it also can contain logwood extractive as color agent. The invention has short dye time, uniform dye and washing resistance, nearly without side effects.

Owner:SHANGHAI BAIMAO +1

Hematoxylin eosin staining solution and preparation method thereof

ActiveCN103725040ALong validity periodEfficient removalPreparing sample for investigationOrganic dyesHematoxylin stainAlcohol

The invention provides a hematoxylin eosin staining solution, comprising a hematoxylin staining solution and an eosin staining solution, wherein the hematoxylin staining solution comprises hematoxylin, an alumium salt, an oxidizing agent, benzalkonium chloride, an alcohol, a weak acid and water; the eosin staining solution comprises eosin, Biebrich scarlet, flame red B, water and ethanol. The invention also provides a preparation method of the hematoxylin eosin staining solution, and a dyeing method thereof. When the hematoxylin eosin staining solution provided by the invention is used for dyeing slices, the effects of clear background, distinct gradation, good dyeing effect, easy slice reading, not easy fading and convenience for long-term storage can be achieved.

Owner:无锡市江原实业技贸有限公司

Ultrafine fiber with high color fastness and manufacturing method thereof

InactiveCN101445973AAvoid wastingEliminate heavy pollutionFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterSpinning

The invention relates to ultrafine fiber with high color fastness and a manufacturing method thereof. The method comprises the steps of adding 3-40% coloring agent into a polymer powder to make into colored stock particles; adding the colored stock particles into spinning polymer polyester and / or polyamide in a ratio of 0.2-15%, and mixing; melt extruding the spinning polymer with a conjugate spinning machine, and coiling to obtain colored POY composite fiber; stretching and false-twist texturing to obtain colored fiber with high color fastness; and splitting with a basic hydrolysis method to obtain colored ultrafine fiber with high color fastness. The colored ultrafine fiber with high color fastness has excellent handfeel and color fastness to washing and light, and contains mass-colored dyeing components, so as to dispense with dyeing after being made into a textile. The colored ultrafine fiber has the advantages of simple process, low cost, low pollution, small product color difference, good color fastness, low fading liability, wide color spectra, and vivid and bright color.

Owner:段宏伟

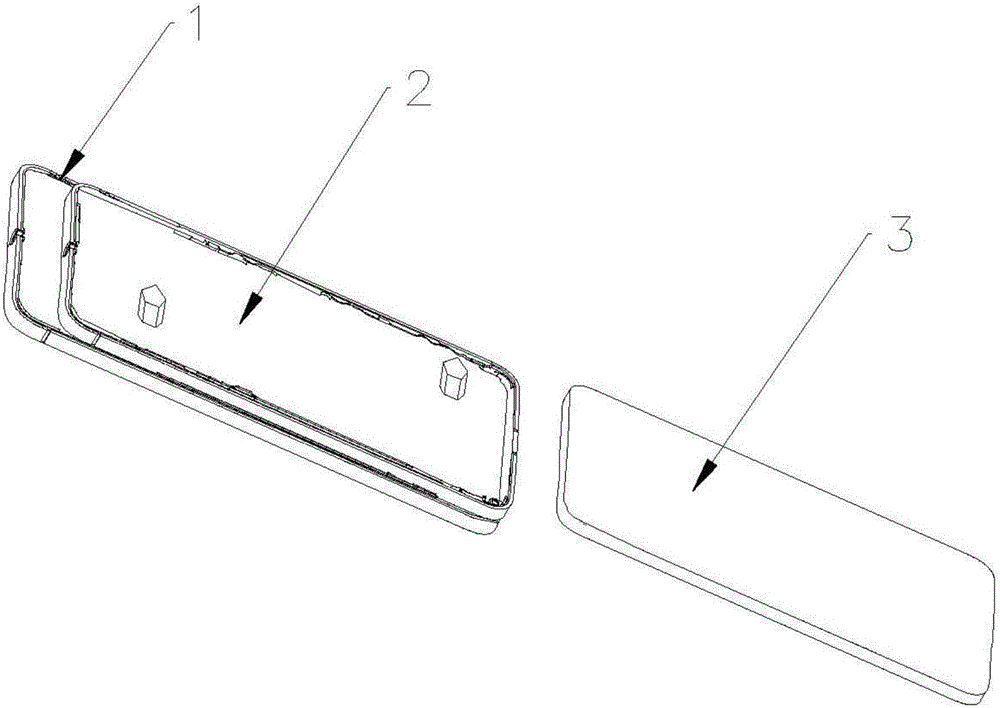

Surface treatment method for highlight edge of aluminum alloy mobile phone shell

ActiveCN106400083ANot easy to fadeImprove yieldSurface reaction electrolytic coatingInksSand blastingPrinting ink

The invention belongs to the technical field of aluminum alloy surface treatment, and particularly relates to a surface treatment method for the highlight edge of an aluminum alloy mobile phone shell. The surface treatment method comprises the following steps of machining of the counter and an inner cavity of the aluminum alloy mobile phone shell, CNC highlight treatment carried out on a frame after surface polishing, surface alkaline washing, surface sand blasting and first-time anodic oxidation, oil removal and cleaning, spraying of printing ink after shielding of the mobile phone shell, printing ink baking, ultraviolet exposure treatment, developing treatment, baking, UV radiation for curing printing ink, second-time anodic oxidation treatment, printing ink removal and third-time anodic oxidation treatment. After the highlight edge of the aluminum alloy mobile phone shell is subjected to three times of anodic oxidation treatment, the portion, close to a display screen, of a longitudinal frame of the mobile phone shell has the same color as the display screen, a frame-free visual sense is formed, the straightness of a color junction edge in second-time anodic oxidation and third-time anodic oxidation is ensured by the adoption of a three-dimensional exposure mode, the production yield reaches up to 90% or above, the cost is low, and production efficiency is high.

Owner:淮北暴风工业设计有限公司

Heat-preserving decorative mortar and preparation method thereof

The invention relates to heat-preserving decorative mortar which comprises the following components in parts by weight: 180-220 parts of cement, 30-70 parts of fly ash, 560-600 parts of sand, 70-100 parts of heavy calcium carbonate, 30-60 parts of heat-preserving aggregate, 3-9 parts of bentonite, 4-8 parts of wood fiber, 2-7 parts of water repellent, 2-5 parts of alkalization inhibitor, 0.5-4 parts of cellulose ether, 6-15 parts of rubber powder and 1-30 parts of pigment. A preparation method thereof comprises the following steps of: firstly uniformly mixing the cement, the fly ash, the sand, the heavy calcium carbonate, the bentonite, the wood fiber, the water repellent, the alkalization inhibitor, the cellulose ether, the rubber powder and the pigment, subsequently adding the heat-preserving aggregate, and then mechanically and uniformly mixing to prepare the heat-preserving decorative mortar. The invention has the advantages of heat preservation, heat insulation, strong hydrophobic property, environmental protection, no pollution, and the like.

Owner:奥捷科技股份有限公司

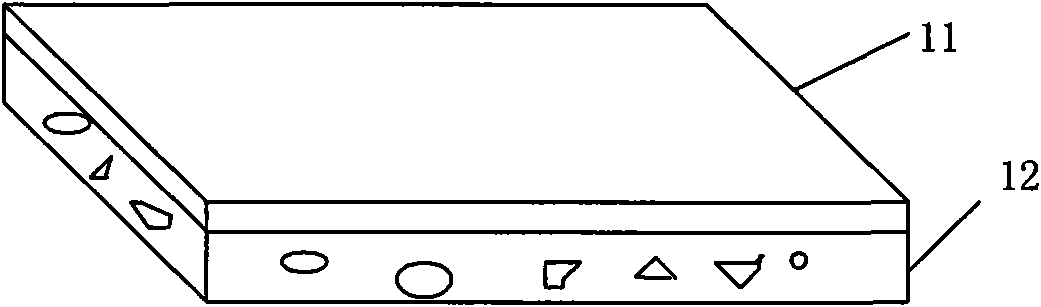

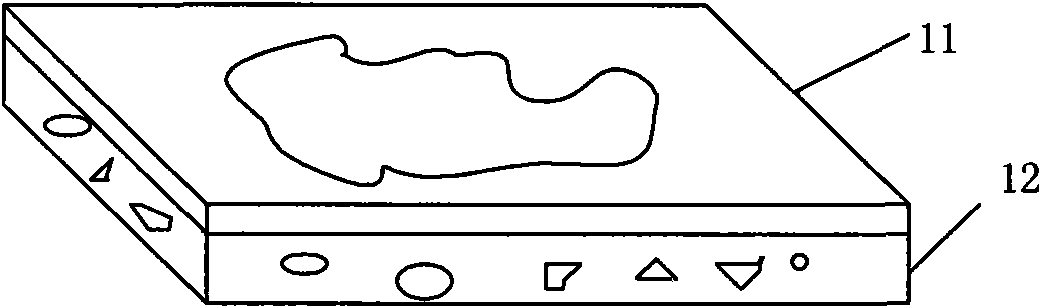

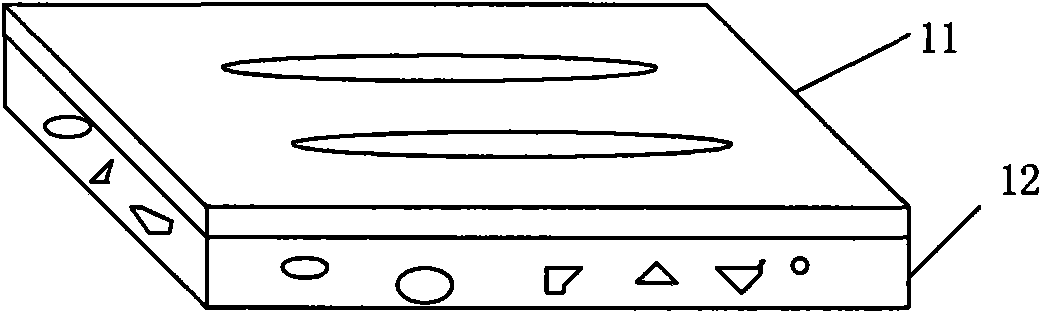

Artificial panel

InactiveCN101644099AHigh hardnessLight textureCovering/liningsSolid waste managementBonding processHardness

The invention provides a multi-layer artificial panel, which at least comprises an outer layer and an inner layer, wherein the outer layer is a color layer made of a building material comprising colorpaste; the inner layer is made of a building material comprising solid waste; the inner layer and the outer layer are all formed by dies after the materials are stirred; the outer layer of the panelshows the color displayed by the color paste; and the inner layer and the outer layer are coupled together through a bonding process. The artificial panel has different colors, beautiful and obvious colors, difficult fading, and simple and convenient manufacturing process; simultaneously, the waste materials are used to achieve the aim of environmental protection; and the panel has high hardness and light mass, and is easily mounted and piled on wall surfaces and in other places.

Owner:许春雷

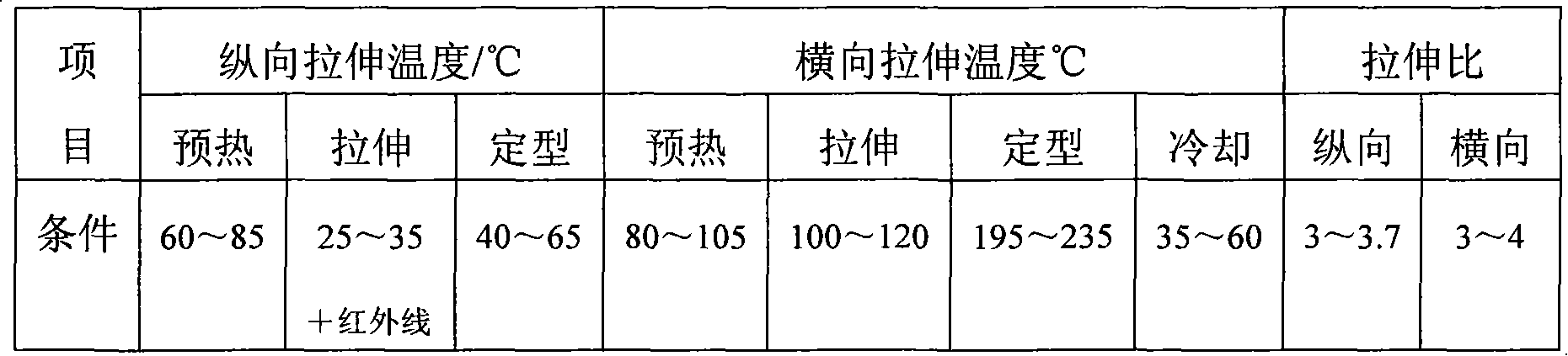

Full-dull colorful insulation polyester film and production technology thereof

The invention relates to a full-dull colorful insulation polyester membrane, which is prepared by matt film polyester chips, color master batches, and master batches containing silicon oxide, while the three materials are mass rationed as 20-30 accounts of matt film polyester chip, 2-6 accounts of color master batches, and 2-6 accounts of the master batches containing silicon oxide. The invention has the advantages that 1, the product is hard to lose color and be polluted in the insulation applications as electron, wire and electric fields, the membrane is easily to be sliced, with high electric strength and good insulation, 2, the membrane has flat and smooth surface, 3, the invention can prepare insulation polyester membranes with different colors.

Owner:TIANJIN SHIQI TECH DEV

Coating with characteristics of ceramic color and quartz sand texture, preparation method and application thereof

The present invention discloses a coating with characteristics of a ceramic color and quartz sand texture, a preparation method and an application thereof, wherein the coating is prepared from the following components, by weight, 18-25% of an acrylate emulsion, 60-70% of color quartz sand and marble sand, 0.5-2% of a film forming additive, 0.1-1% of a thickener, 0.01-0.1% of a wetting agent, 0.05-0.3% of a dispersing agent, 0.5-2% of an additive, and the balance of deionized water. The coating of the present invention does not provide harm for human body and environment, and belongs to a green environment protection product. According to the present invention, based on the traditional texture coating, a high quality aqueous pure acrylic resin is adopted as a base material, and color quartz sand and marble sand are adopted to replace color paste to carry out color adjustment, such that the resulting coating film has characteristics of good flexibility, good bond strength, high hardness, ceramic-like color, nature, simplicity, and good color retention.

Owner:CHINA PAINT MFG CO SHENZHEN

Method for dyeing and finishing polyester and nylon composite filament corduroy

InactiveCN102605584ADamage intensityHigh strengthSolvent-treatmentFibre typesDisperse dyeNylon material

The invention discloses a method for dyeing and finishing polyester and nylon composite filament corduroy, which comprises the following processes: checking a gray fabric; sewing the gray fabric; pre-shrinking in full width; splitting; pre-shaping; dyeing; soft finishing shaping; and packaging an end product, wherein a full width water washing machine is used for performing the process of pre-shrinking in full width; the process of splitting is performed according to a thermal treatment method and an alkali treatment method; during the process of pre-shaping, the temperature is 195 DEG C-200 DEG C and an assembly line turning speed is 30m / min-35m / min; dye liquor in the process of dyeing is aqueous solution of disperse dye or mixed aqueous solution of disperse dye and acidic dye; and the process of the soft finishing shaping is as follows: the corduroy passes through a material chute containing 10-15g / l softening agent aqueous solution, and then the corduroy is dried and shaped at high temperature, wherein the drying temperature is 165 DEG C-175 DEG C, the assembly line turning speed is 30m / min-35m / min and the softening agent is an organic silicon softening agent. The end product prepared according to the method provided by the invention has the advantages of high strength, full and mild velvet feeling, excellent shape-keeping property, convenience in washing and finishing, uniform dyeing effect, and capability of obtaining specific gigging effects such as frostwork or polyester peach skin, and the like.

Owner:杭州天宇印染有限公司

Vegetable fiber tableware and preparation method thereof

The invention provides a vegetable fiber tableware and a preparation method of the tableware. The method comprises the following steps: mixing raw materials uniformly, hot pressing and molding to obtain vegetable fiber shell, wherein the raw materials comprise bamboo fiber powder, corn starch, urea formaldehyde resin and rice husk with weight ratio of (4-6):(0.5-2): 2-4):1; polishing the surface of the vegetable fiber shell; spraying or soaking water soluble paint to the surface of the polished vegetable fiber shell, and then drying to finally obtain the vegetable fiber tableware. In the method, bamboo fiber powder, corn starch, urea formaldehyde resin and rice husk are used as raw materials, a shell is formed firstly by hot pressing, then a layer of water soluble paint protection film is coated at the surface of the shell, finally the tableware is obtained. The vegetable fiber tableware prepared by the method is coated with the water soluble paint protection film at the surface, the external water and other solvent are hard to permeate into the vegetable fiber shell under the protection of the water soluble paint film. In this way, the waterproof property and the fading resistance of the tableware are improved.

Owner:宁波鑫宸大自然竹纤维科技有限公司

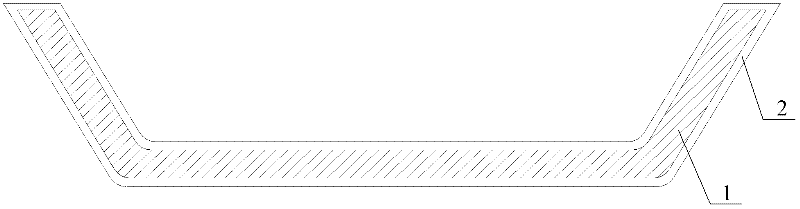

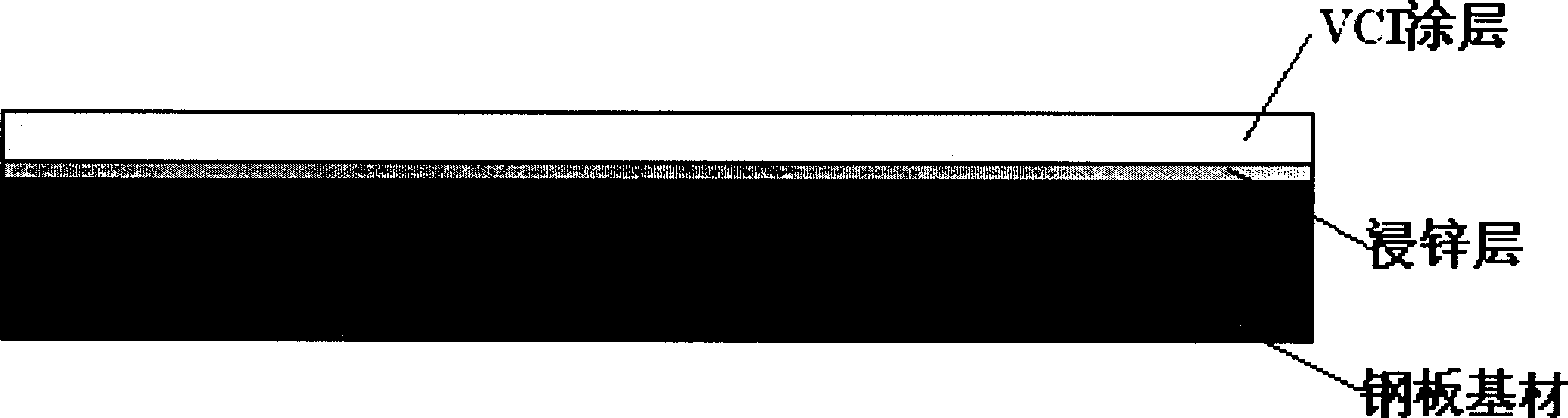

VCI-containing flake zinc and aluminum protective coating on galvanizing surface and preparation method thereof

ActiveCN101397412AImprove efficiencyImprove shielding effectAnti-corrosive paintsCoating systemPre treatment

A squama aluminum-zinc protective coating used for the surface of zincing plates and containing VCI (Vapor corrosion inhibitor) is used for the pretreatment technology of the zincing plates. Besides, the invention also provides a VCI squama aluminum-zinc protective coating system on a zincing surface and prepared by the coating.

Owner:天津中航百慕新材料技术有限公司

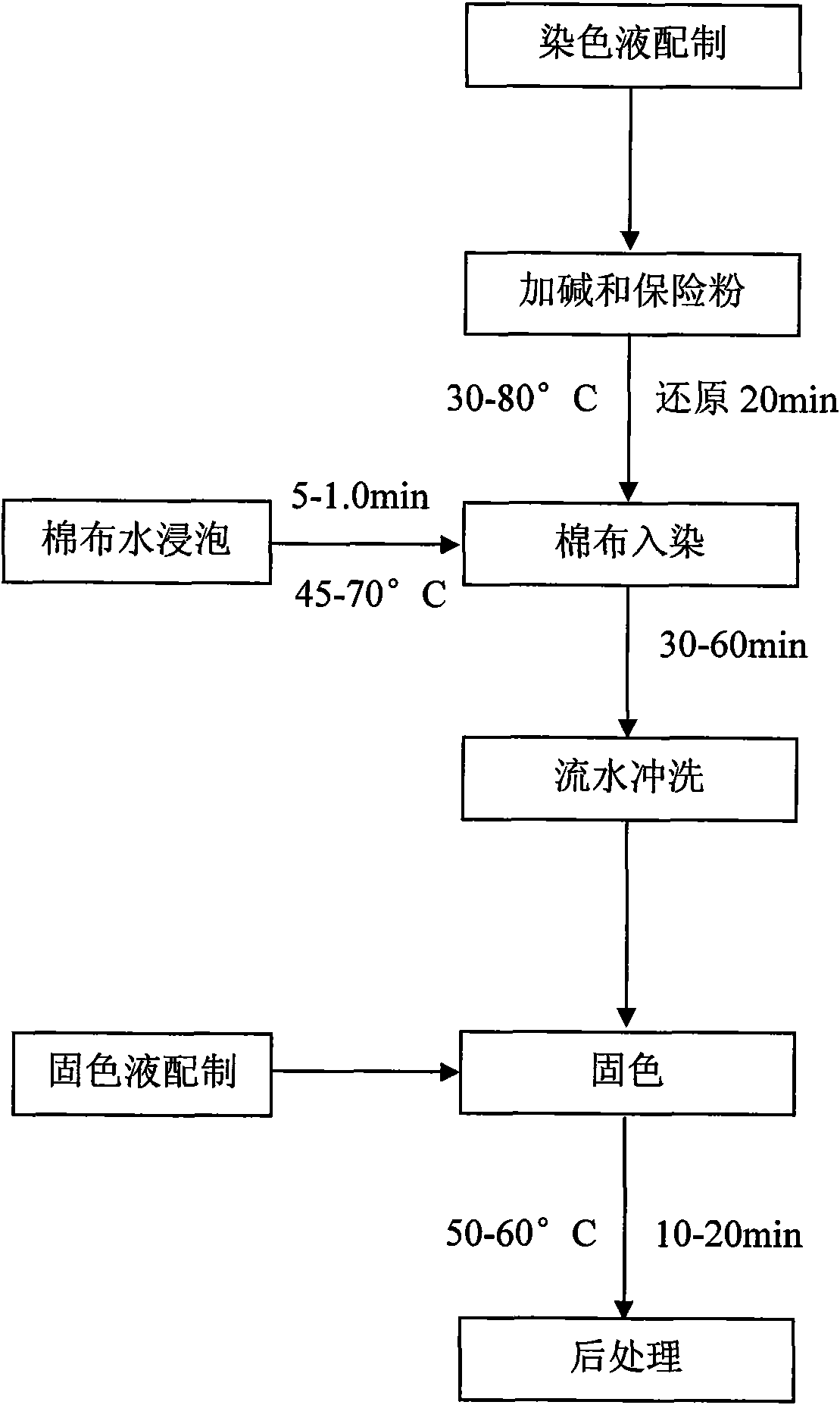

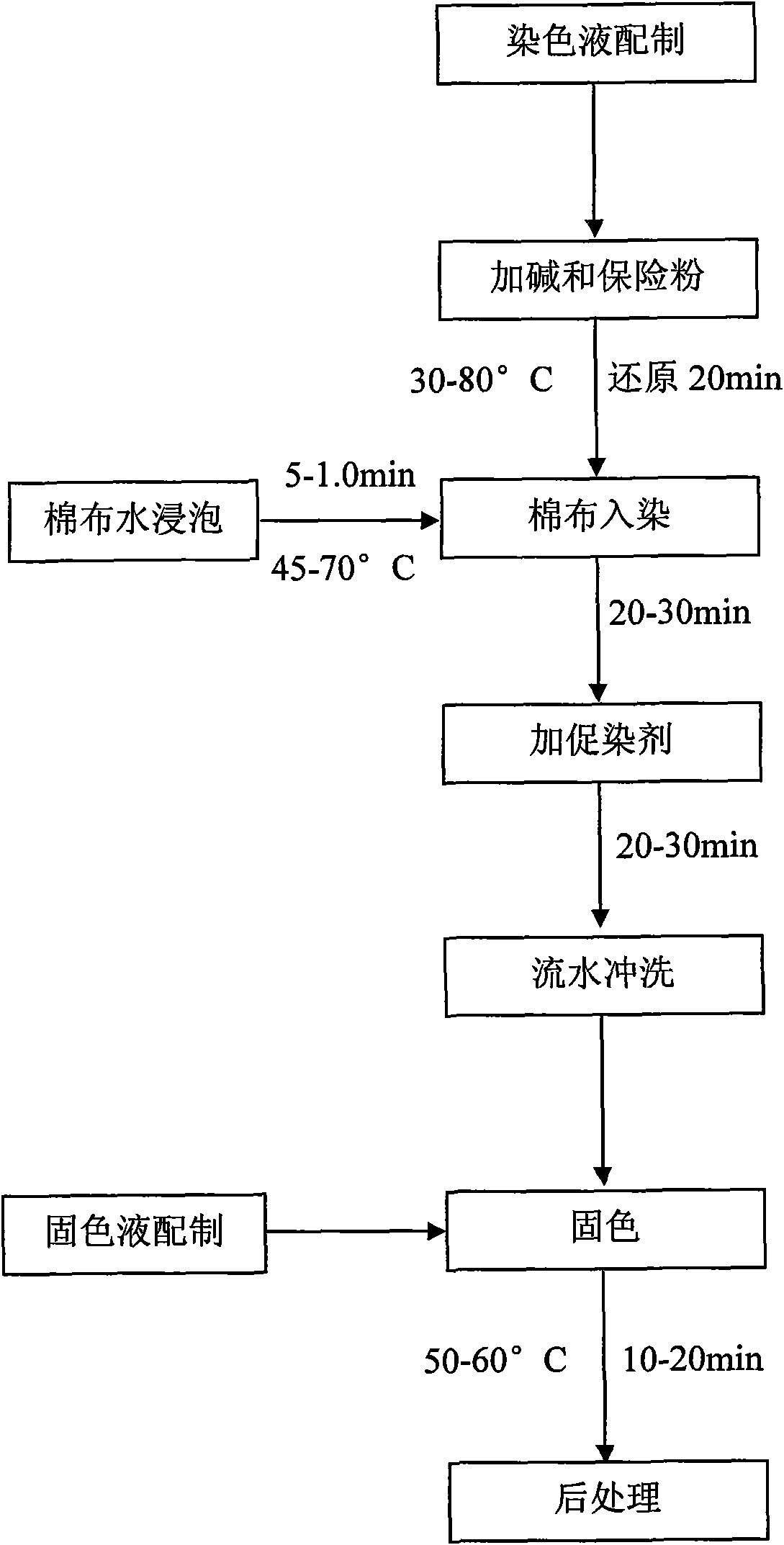

Preparation method of salvia miltiorrhiza bunge vegetable dye and method for dyeing cotton fabrics using salvia miltiorrhiza bunge vegetable dye

InactiveCN101570646AHigh priceNot easy to change colorNatural dyesDyeing processSalvia miltiorrhizaMacroporous resin

The invention discloses a preparation method of a natural salvia miltiorrhiza bunge vegetable dye. Salvia miltiorrhiza bunge is used as a raw material of a natural vegetable dye to prepare the naturalsalvia miltiorrhiza bunge vegetable dye. The invention also provides a method for dyeing cotton fabrics using the natural salvia miltiorrhiza bunge vegetable dye. The natural salvia miltiorrhiza bunge vegetable dye can be prepared by one of such methods as solvent extraction method, solvent extraction, macroporous resin method, column chromatography, supercritical counter-current extraction and the like or arbitrary combination of multiple methods. The prepared natural salvia miltiorrhiza bunge vegetable dye is red fat-soluble dye. The method for dyeing cotton fabrics adopts vat dyeing. The dyed cotton fabrics are red, uniform, soft and natural in colors and high in color fastness, and are not easy to fade and change color. The natural salvia miltiorrhiza bunge vegetable dye has the advantages of innocuity and no pollution, etc, and has certain medical health care function. Besides, the dyeing method of the invention is simple and can be greatly applied to health care underwear, household textile products and the like.

Owner:FUJIAN QINGYUAN TECH

Surface spray dyeing method for aluminum or aluminum-alloy product

ActiveCN102407702ANot easy to fadeNot easy to fall offOther printing apparatusPre treatmentMaterials science

The invention discloses a surface spray dyeing method for an aluminum or aluminum-alloy product, the aluminum or aluminum-alloy product and spray dyeing ink. The surface spray dyeing method comprises the following steps of: 1) pre-treating, namely polishing the aluminum or aluminum-alloy product, removing oil and performing chemical polishing; 2) performing anode oxidation, namely performing anode oxidation treatment on the pretreated aluminum or aluminum-alloy product to form a porous oxidation film on the surface; 3) performing surface spray dyeing, namely spraying the spray dyeing ink ontothe surface of the aluminum or aluminum-alloy product obtained through anode oxidation by using planar printing equipment and / or three-dimensional (3D) spraying equipment to form color and / or patterns; 4) cleaning, namely cleaning the spray dyeing ink which remains outside holes of the oxidation film on the aluminum or aluminum-alloy product obtained through surface spray dyeing; and 5) sealing ahole, namely performing hole sealing of the cleaned aluminum or aluminum-alloy product. By the surface spray dyeing method, colored and vivid patterns can be produced on the surface of the aluminum or aluminum-alloy product, a coating cannot be formed on the surface, and the aluminum or aluminum-alloy is difficult to fade after long-term use.

Owner:祥兴泰五金制品(江门)有限公司

Textile dye

The invention relates to a textile dye. The textile dye is made of the following raw materials in parts by weight: 6-11 parts of polyvinyl alcohol, 3-6 parts of methylcellulose, 7-9 parts of polydimethylsiloxane diquaternary ammonium salt, 2-8 parts of polymethylcyclotetrasiloxane, 4-6 parts of dimethicone, 4-9 parts of alkyl glycoside, 1-5 parts of edetic acid, 2-5 parts of citronellyl nitrile, 1-2.5 parts of malic acid, 3.5-6 parts of sodium dihydrogen phosphate, 2-6 parts of alcohol, 4.3-6 parts of diphenylmethane and 4-11 parts of sodium sulphamidate. The textile dye has the beneficial effects that the textile dye provided by the invention has very good adhesive force, very good dyeing can be realized under high temperature, the color is not easily faded and the dyeing is uniform.

Owner:QINGDAO DONGCHANGRUI TEXTILE

Ink-absorbing quick-drying painting canvas

ActiveCN103741481AImprove antioxidant capacityNot easy to fadeFibre treatmentChemistryEconomic shortage

The invention discloses an ink-absorbing quick-drying painting canvas. The preparation method of the canvas comprises the following steps: (1) painting gel resin on the surface of fabric, drying in an oven with a temperature of 100 to 120 DEG C so as to obtain a gel resin layer; (2) painting prime paint on the gel resin layer, drying in an oven with a temperature of 90 to 100 DEG C so as to obtain a prime paint layer; (3) painting surface paint on the prime paint layer, drying in an oven with a temperature of 70 to 85 DEG C so as to obtain a surface paint layer, wherein during this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute; (4) painting ink-absorbing quick-drying paint on the surface paint layer, drying in an oven with a temperature of 70 to 85 DEG C, wherein in this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute. The ink-absorbing quick-drying painting canvas preserves the unique wash-painting effect of raw Xuan paper, overcomes the inherent shortages of raw Xuan paper, thus enlarges the application range and increases the collection value of wash paintings.

Owner:沭阳凤凰画材有限公司

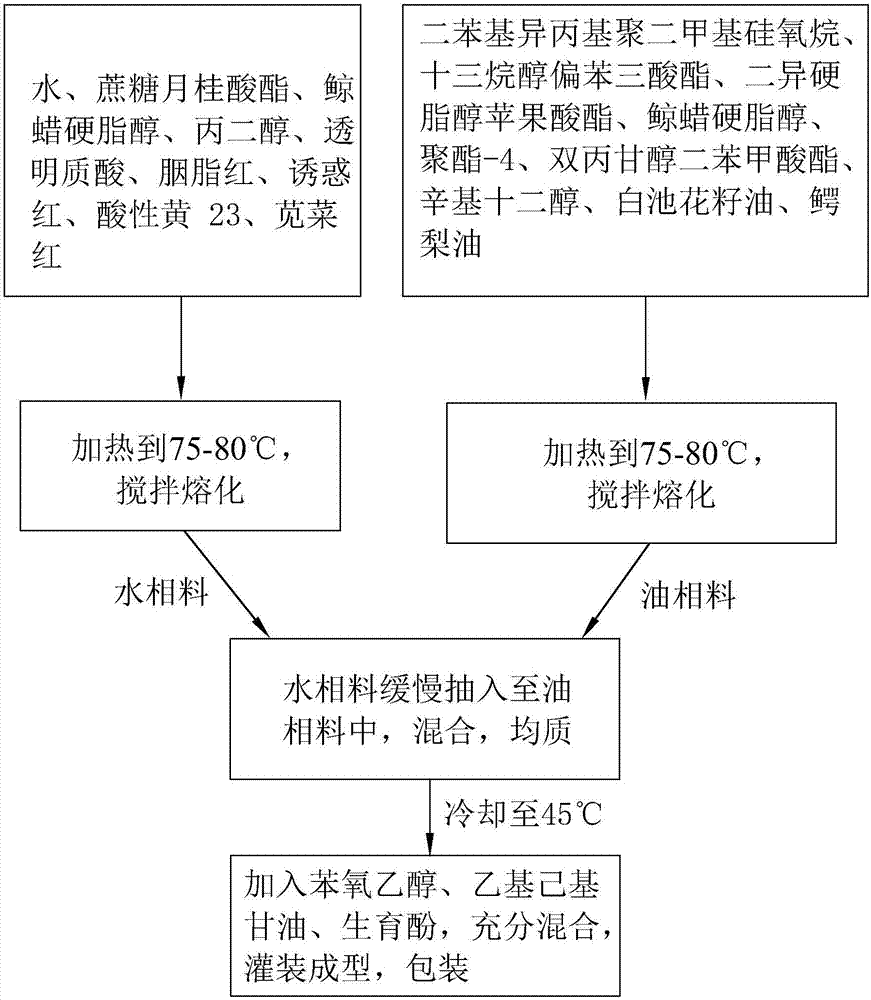

Cup sticking prevention lip gloss with maintenance function

InactiveCN107184432AEvenly dispersedFully moisturizedCosmetic preparationsMake-upPolyesterMeadowfoam seed oil

The invention discloses cup sticking prevention lip gloss with a maintenance function. The lip gloss comprises, by weight, 1-40 parts of water, 2-6 parts of cetostearyl alcohol, 10-20 parts of meadowfoam seed oil, 10-20 parts of avocado oil, 1-3 parts of sucrose laurate, 2-10 parts of propylene glycol, 0.5-2 parts of hyaluronic acid, 0.5-1 part of phenoxyethanol, 0.1-0.5 part of ethylhexylglycerin, 0.1-1 part of tocopherol, 16-60 parts of emollient, 6-35 parts of emulsifying agents and 0.1-0.5 part of coloring agents. The emollient comprises at least two of diphenyl isopropyl polydimethyl siloxane, tridecyl trimellitate, diisostearyl malate and dipropylene glycol dibenzoate; the emulsifying agents comprise at least one of polyester-4 and octyldodecanol; the coloring agents comprise at least three of carmine, allura red, acid yellow 23 and amaranth. The lip gloss has the maintenance functions of preserving moisture, moisturizing skin and the like and does not easily fade.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

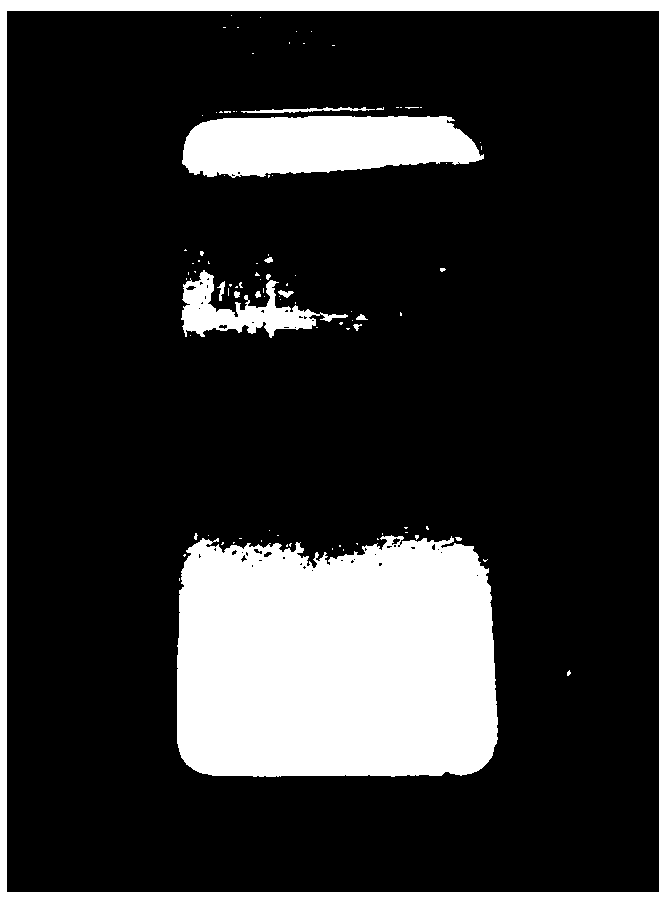

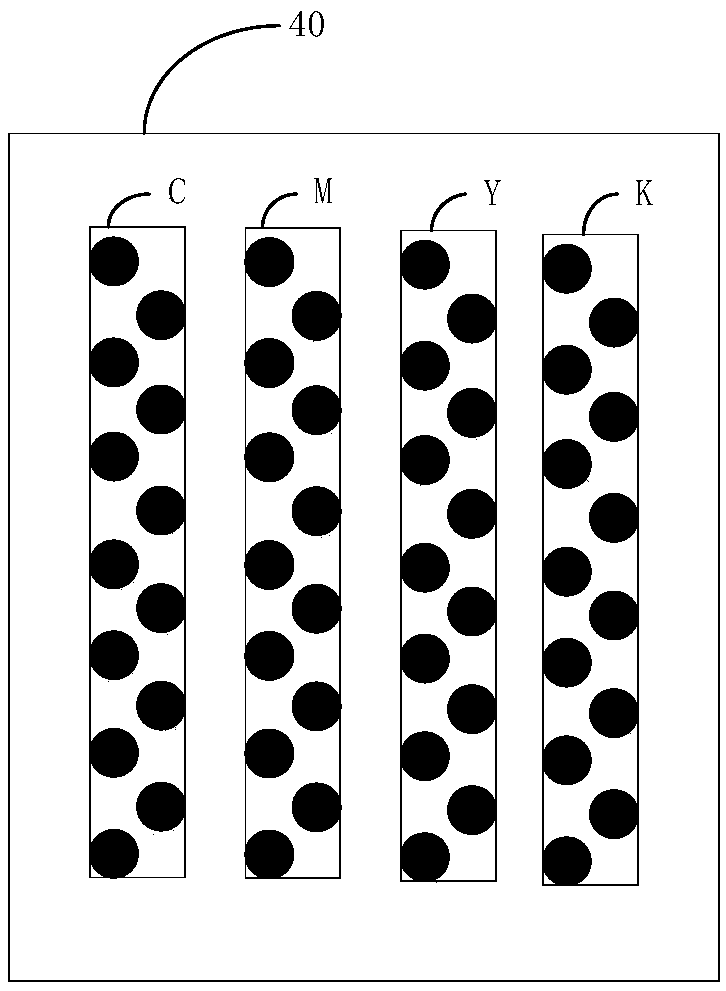

Printing ink curing method, printing ink curing device, printing ink curing equipment, printing control system and storage medium

ActiveCN108891132AThere will be no yin and yangColor saturationOther printing apparatusPrinting after-treatmentControl signalControl system

The invention discloses a printing ink curing method, a printing ink curing device, printing ink curing equipment, a printing control system and a storage medium. The method includes the steps of determining power change laws of a first light source by acquiring the number of times of printing covering a designated printing medium area, determining power changes laws of a second light source according to the relative positional relationship at the same time, and acquiring a first control signal and a second control signal for controlling the first light source and the second light source according to the power change laws of the first light source and the second light source; controlling the first light source to perform light curing on printing ink for pattern forming according to the first control signal after the printing ink is formed on a printed pattern, and controlling the second light source to perform light curing on transparent printing ink printed on the printing ink for pattern forming. The method has the advantages that printing ink in different colors on a printing medium can be cured timely and thoroughly, the surfaces of printed products are flat and do not have two-tone colors, the whole products have more smooth surfaces, the colors are more saturated, and images are more delicate and free from discoloration and scratching.

Owner:东莞市图创智能制造有限公司

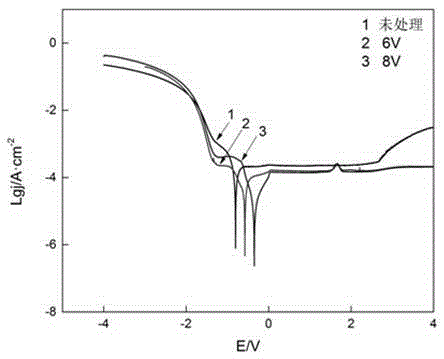

Titanium and titanium alloy surface anodic oxidation coloring method

InactiveCN105239133ASimplify the anodizing processIncreased self-corrosion potentialSurface reaction electrolytic coatingElectrolysisTitanium

The invention discloses a titanium and titanium alloy surface anodic oxidation coloring method and belongs to the technical field of metal surface treatment. The method includes the following steps that a cleaned commercial pure titanium sample is put in a solution with a proportion of HF: HNO3: H2O for electrolytic polishing; the cleaned and dried sample is put in a mixed solution of concentrated sulfuric acid and methanesulfonic acid for anodic oxidation treatment; and the sample obtained after being subjected to the anodic oxidation treatment is rapidly cleaned through ethyl alcohol and deionized water and then dried under the vacuum condition so that the colored sample can be obtained. Anodic oxide films in different colors are obtained through control over anodic oxidation voltage and treatment time, and the anodic oxide films are bright and uniform in color and luster and good in corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

Fabric coloring agent

The invention discloses a fabric coloring agent. The fabric coloring agent is prepared from the following constituents in parts by weight: 2-3 parts of sodium pyrophosphate, 1-2 parts of dibutyl phthalate, 4-5 parts of calcium sulphate, 6-7 parts of magnesium sulfate, 1-2 parts of aluminium oxide powder, 3-4 parts of iron blue, 4-5 parts of dinitrosopentatetramine, 4-5 parts of dimethyl formamide, 5-6 parts of diethylaminoethyl methacrylate, 3-4 parts of tert-butyl peroxybenzoate, 8-9 parts of an initiator, 8-9 parts of hexamethoxymethylmelamine, 8-9 parts of water, and 1-2 parts of glycerol. The fabric coloring agent disclosed by the invention is easy to color and low in possibility of color fading.

Owner:江苏金牛华尔车服饰有限公司

Color smoking treatment technology for wood modification face layer

ActiveCN105729597ADrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSmoking treatment

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

Printing ink and phone press key coating method using the same

The invention provides a sort of ink which consists of main material, stuffing, pigment, wax, thinner, and curing agent; the overall weight of the ink is set as a standard; the content of the main material is 30-70 weight percent; the content of the stuffing is 10-40 weight percent; the content of the pigment is 5-25 weight percent; the content of the wax is 1-10 weight percent; the content of the thinner is 5-15 weight percent; the content of the curing agent is 5-15 weight percent. The invention also provides a method for coating a cell-phone keypad, which consists of the steps of: understratum spraying on the surface of the cell-phone keypad, surface spraying on the surface of the cell-phone keypad after the understratum spraying, printing on the surface of the cell-phone keypad after the surface spraying; the ink used in the printing is supplied by the invention. The ink supplied by the invention can not be easy to fade or wear; meanwhile, with the coating method of the ink, the yield rate of the product can be greatly improved.

Owner:BYD CO LTD

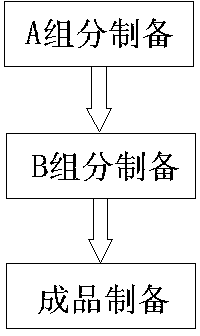

Texture multicolor coating and preparation method thereof

The invention discloses a texture multicolor coating. The texture multicolor coating is prepared by mixing and modulating an A component, a B component and proper color paste, wherein the mass ratio of the A component to the B component is 1:3-3:1; the A component is prepared from the raw materials in percentage by weight: 10-60 percent of polymer, 5-50 percent of powder, 0.3-8 percent of cellulose, 5-50 percent of sand fly, 0.1-30 percent of gel, 0.1-10 percent of surfactant and 10-60 percent of water; the B component is prepared from the raw materials in percentage by weight: 10-80 percent of polymer, 0.1-5 percent of dispersant, 0.1-5 percent of thickener, 1-15 percent of film forming additive and 5-70 percent of water. A preparation method of the texture multicolor coating comprises the steps: A component preparation, B component preparation and finished product preparation. The texture multicolor coating is simple in the manufacturing process, is low in the cost, can have the self coarse texture of rocks when presenting rock patterns after spray forming and drying, has high fidelity effect of natural granites, is good in the color retention, is difficult in color fading and is decorative coating in the building industry.

Owner:宁波新安涂料有限公司

Stable dye for spinning

The invention discloses a stable dye for spinning. The stable dye is prepared from the following raw materials in parts by weight: 6-11 parts of soap powder, 4-10 parts of sodium aliphatate, 3-10 parts of ethyl alcohol, 4-8 parts of sodium alginate, 6-12 parts of ammonium ethoxylated alkyl sulfate, 4-7 parts of alcohol alkoxylate, 6-9 parts of sodium ethoxylated alkyl sulfate, 2-6 parts of organic solvent, 1-4 parts of antifoaming agent, 15-22 parts of organic dyeing raw materials, 1-4 parts of pentanediol, 4-9 parts of tannic acid, 6-10 parts of 5-diaminophenyl ethanol sulfate, 2-6 parts of crylic acid, 7-9 parts of butyl acrylate and 1-4 parts of protein amino acids. The stable dye has the beneficial effects that the dye for spinning disclosed by the invention is stable in performance and can dye cloth materials well, colors are unlikely to fade, and regular work can also be achieved under high temperature.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

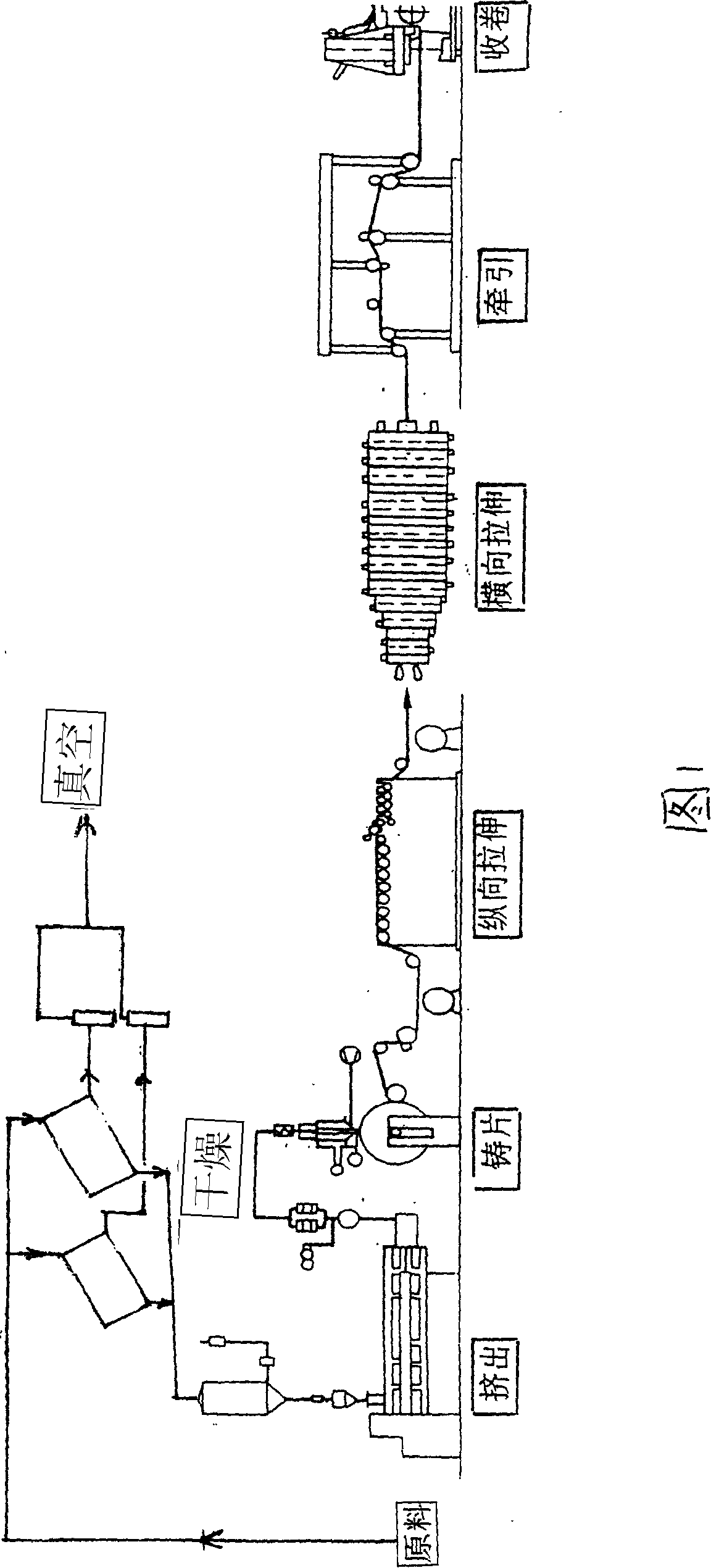

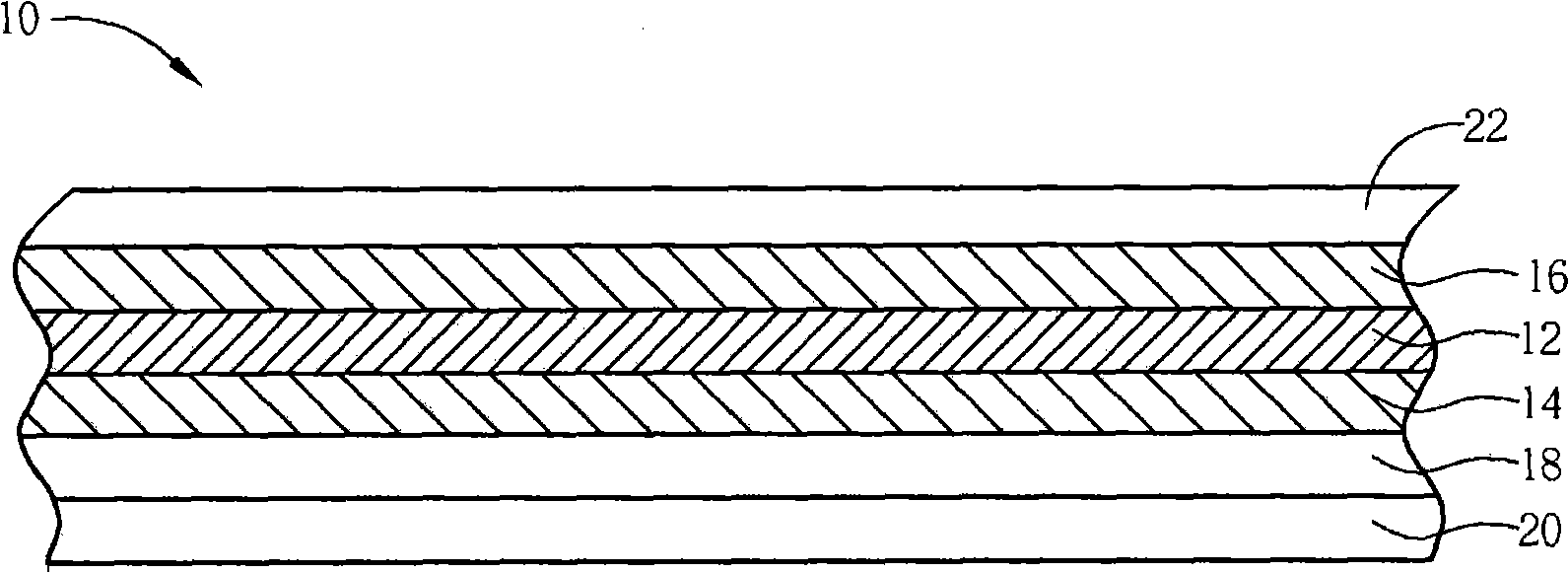

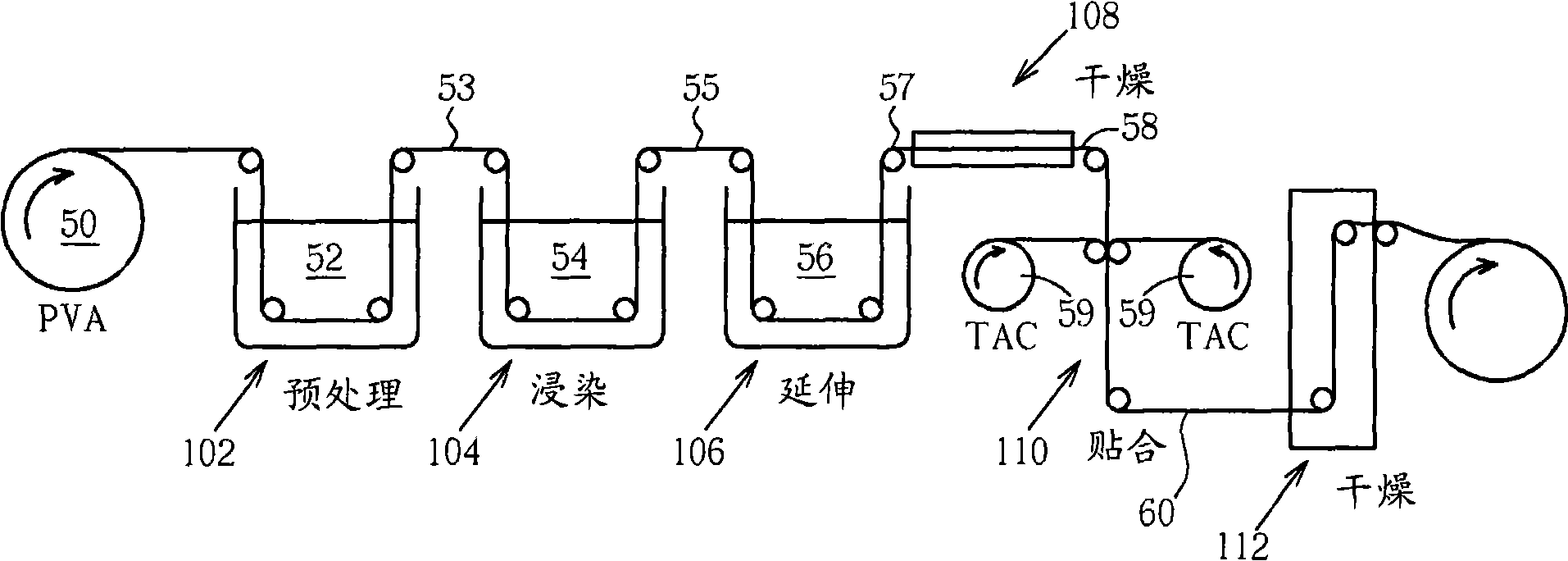

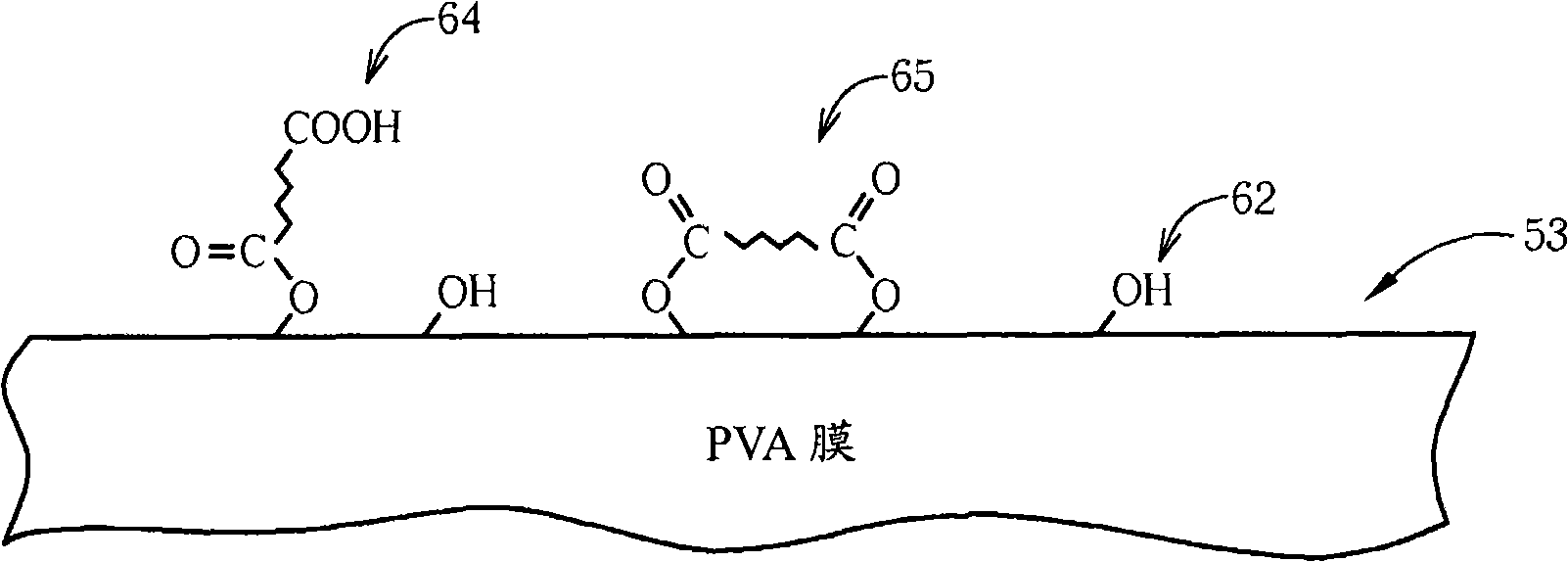

Method for preparing bias photon and method for preparing polarized light slice

InactiveCN101281267ANot easy to fadeEasy to switchPolarising elementsNon-linear opticsSurface reactionPolyvinyl alcohol

The invention discloses a method for preparing polarizing photon and polarizing sheet. The method for preparing polarizing photon includes providing a polyvinyl alcohol PVA film; soaking the PVA film in a first solution in order to execute preprocess, wherein the first solution includes at least a carboxyl acid or derivative thereof with at least two carboxyl, and at least a catalyzer catalyzing the reaction between the carboxyl acid and the PVA film surface; soaking the PVA film after preprocess in the dyeing solution to execute a tray dyeing process; soaking the PVA film after the tray dyeing process in a second solution, and meanwhile extending the PVA film, wherein the second solution includes a boric acid; and drying the PVA film after the extension process to form polarizing photon.

Owner:DAXON TECH INC

Silk screen printing ink

The invention relates to silk screen printing ink which comprises the following materials in parts by weight: 90-190 parts of a main body material and 15-25 parts of a curing agent. The silk screen printing ink provided by the invention can effectively enhance the adhesion property of the ink by adding an appropriate ratio of the curing agent into the ink. The silk screen printing ink is colorful and bright in color, stable in adhesion property, good in abrasion resistance and color fading resistance after being completely dried, and is not easy to be subjected to yellowing, discoloring and fading under radiation of intensive sunshine.

Owner:SUZHOU ANJIE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com