Method for preparing bias photon and method for preparing polarized light slice

A technology of photons and solutions, applied in the field of polarizers and polarizers, can solve the problems of accelerated bath evaporation, iodine easy to seep out, and large roller tension, etc., to reduce the temperature of the extended bath, not easy to fade, and easy to switch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

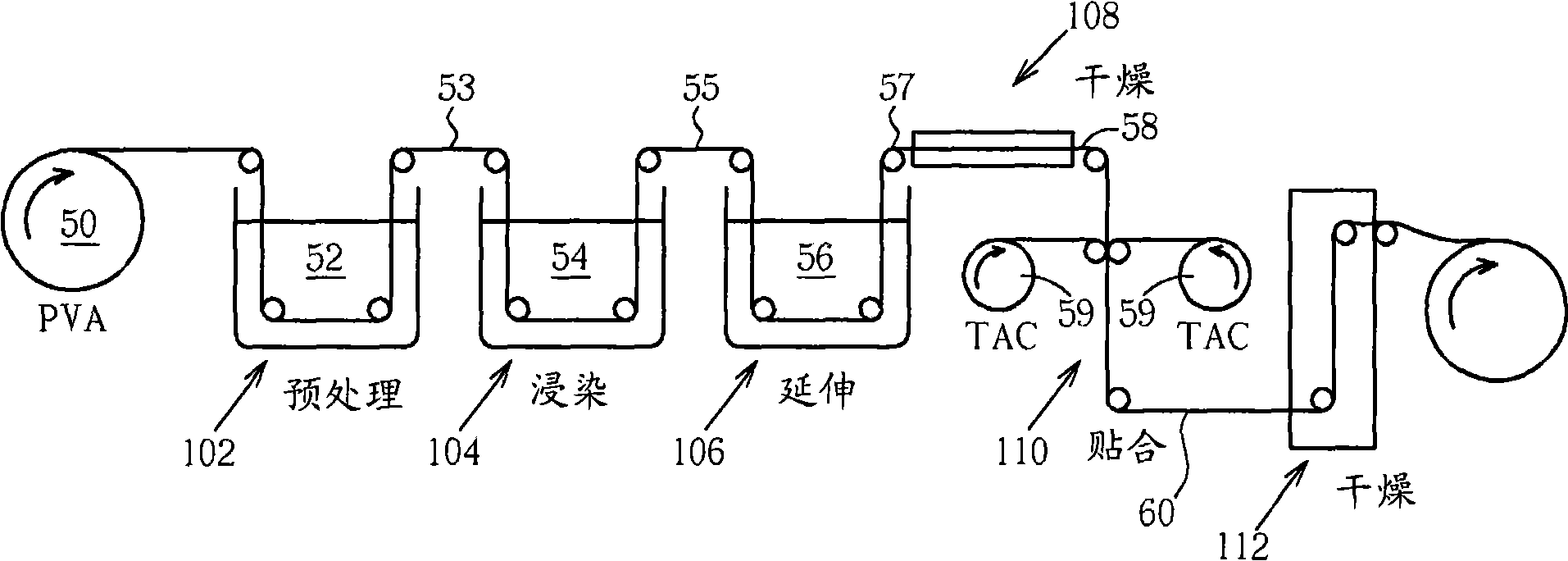

[0056] Please refer to Figure 4 As shown in the schematic diagram of tank configuration in the prior art, the unstretched PVA film 50 with a width of 650 mm and a thickness of 75 μm is transported by rollers, and is first swelled in pure water at 28° C. in the tank 68, and then used as a pretreatment Pretreatment is carried out in an aqueous solution at about 30° C. in the tank 70 of the tank. The aqueous solution in tank 70 contains 2.25% by weight of adipic acid and 0.3% by weight of aluminum sulfate hydrates (Al 2 (SO 4 ) 3 16~18H 2 O). After this pretreatment, dip in the iodine solution (containing iodine concentration of 0.033% by weight, boric acid concentration of 0.95% by weight, and potassium iodide concentration of 0.6 to 0.8% by weight) in the tank 72 at 30°C. The impregnated PVA film was stretched in a stretching tank 74 with a bath temperature of 51° C., and the stretching liquid contained 3.35% by weight of boric acid and 3.01% by weight of potassium iodide...

Embodiment 2

[0058] The production of polarizers was carried out as described in Example 1, but the bath temperature of bath 70 was adjusted to 35°C, and the bath temperature of the elongation bath was lowered to 46.5°C. Measure the elongation ratio, width (mm), film thickness (μm), transmittance (Ys, %), polarization degree (V, %), and hue b value of the obtained polarized photons, and the results are as follows Figure 5 shown in the table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com