Texture multicolor coating and preparation method thereof

A technology of colorful paint and texture, applied in the direction of multi-color effect paint, coating, etc., can solve the problem of color fading, and achieve the effect of strong adhesion, safe production, non-toxic, and not easy to fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

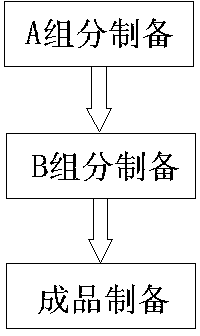

Method used

Image

Examples

Embodiment 1

[0042] 1: Prepare the raw materials in component A and the raw materials in component B according to the following formula; among them:

[0043] A component formula (each raw material in the formula is based on mass percentage)

[0044] Pure acrylic polymer 30%

[0045] Hydroxyethyl cellulose 0.5%

[0046] Titanium dioxide 5%

[0048] Snow White Color Sand 20%

[0049] Organobentonite 5%

[0050] Lithium Magnesium Silicate 3%

[0051] Polycarboxylate sodium salt 0.3%

[0052] Water 26.2%

[0053] B component formula (each raw material in the formula is based on mass percentage)

[0054] Silicone acrylic emulsion 60%

[0055] Dispersant 0.5%

[0056] Alkali swelling associative thickener 0.2%

[0057] Alcohol ester 12%

[0058] Water 27.3%

[0059] 2: Preparation of component A: Pour 26.2% water into the dispersing kettle of the disperser first, add 0.5% hydroxyethyl cellulose under the condition of the speed of the disperser at 300r / min~800r / min, and disperse for 10mi...

Embodiment 2

[0063] 1: Prepare the raw materials in component A and the raw materials in component B according to the following formula; among them:

[0064] A component formula (each raw material in the formula is based on mass percentage)

[0065] Pure acrylic polymer 15%

[0066] Silicone modified acrylic polymer 15%

[0067] Hydroxyethyl cellulose 0.5%

[0068] Titanium dioxide 5%

[0069] Kaolin 10%

[0070] White marble colored sand 20%

[0071] Magnesium aluminum silicate 5%

[0072] Lithium Magnesium Silicate 3%

[0073] Polyoxyethylene octylphenol ether 0.3%

[0074] Water 26.2%

[0075] B component formula (each raw material in the formula is based on mass percentage)

[0076] Silicone acrylic emulsion 30%

[0077] Fluorocarbon emulsion 30%

[0078] Dispersant 0.5%

[0079] Alkali swelling associative thickener 0.2%

[0080] Tripropylene glycol monobutyl ether 15%

[0081] Water 24.3%

[0082] 2: Preparation of component A: Pour 26.2% water into the dispersing kettle of the disperser first, add 0.5% hyd...

Embodiment 3

[0086] 1: Prepare the raw materials in component A and the raw materials in component B according to the following formula; among them:

[0087] A component formula (each raw material in the formula is based on mass percentage)

[0088] Styrene modified acrylic polymer 10%

[0089] Silicone modified acrylic polymer 15%

[0090] Hydroxyethyl cellulose 0.5%

[0091] Hydroxymethylcellulose 0.3%

[0093] Talc 5%

[0094] Kaolin 5%

[0095] White marble colored sand 30%

[0096] Magnesium aluminum silicate 5%

[0097] Lithium Magnesium Silicate 3%

[0098] Alkylphenol ethoxylate 0.3%

[0099] Water 20.9%

[0100] B component formula (each raw material in the formula is based on mass percentage)

[0101] Silicone acrylic emulsion 10%

[0102] Fluorocarbon emulsion 60%

[0103] Dispersant 0.8%

[0104] Polyurethane associative thickener 0.5%

[0105] Ethylene glycol 10%

[0106] Alcohol ester twelve 7%

[0107] Water 11.7%

[0108] The following manufacturing method is the same as in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com