Patents

Literature

31results about How to "Drying helps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color smoking treatment technology for wood modification face layer

ActiveCN105729597ADrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSmoking treatment

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

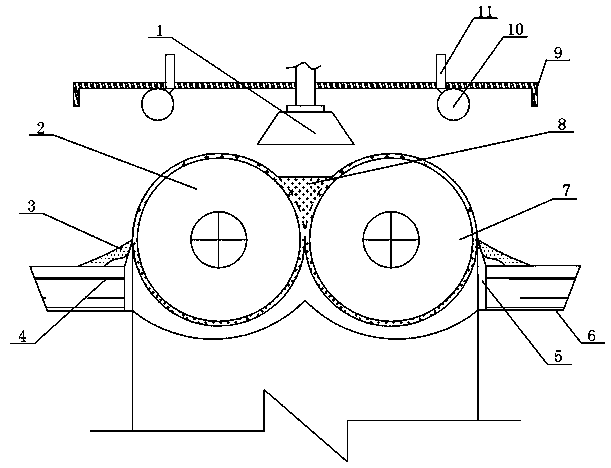

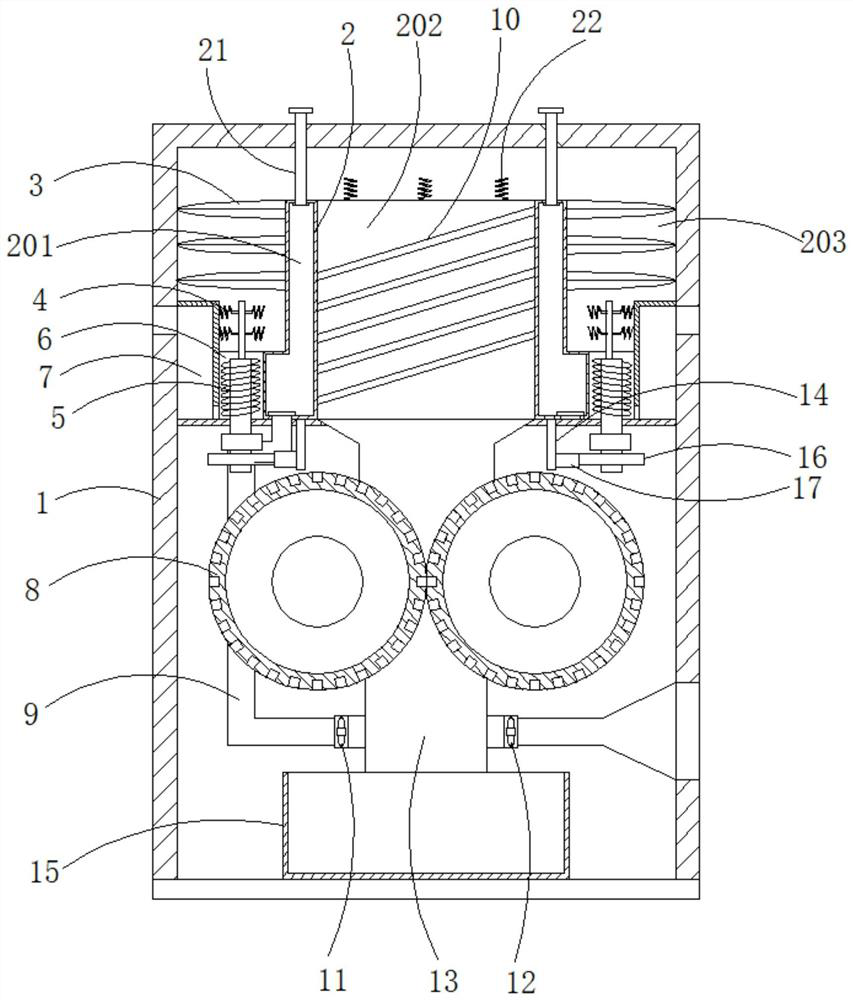

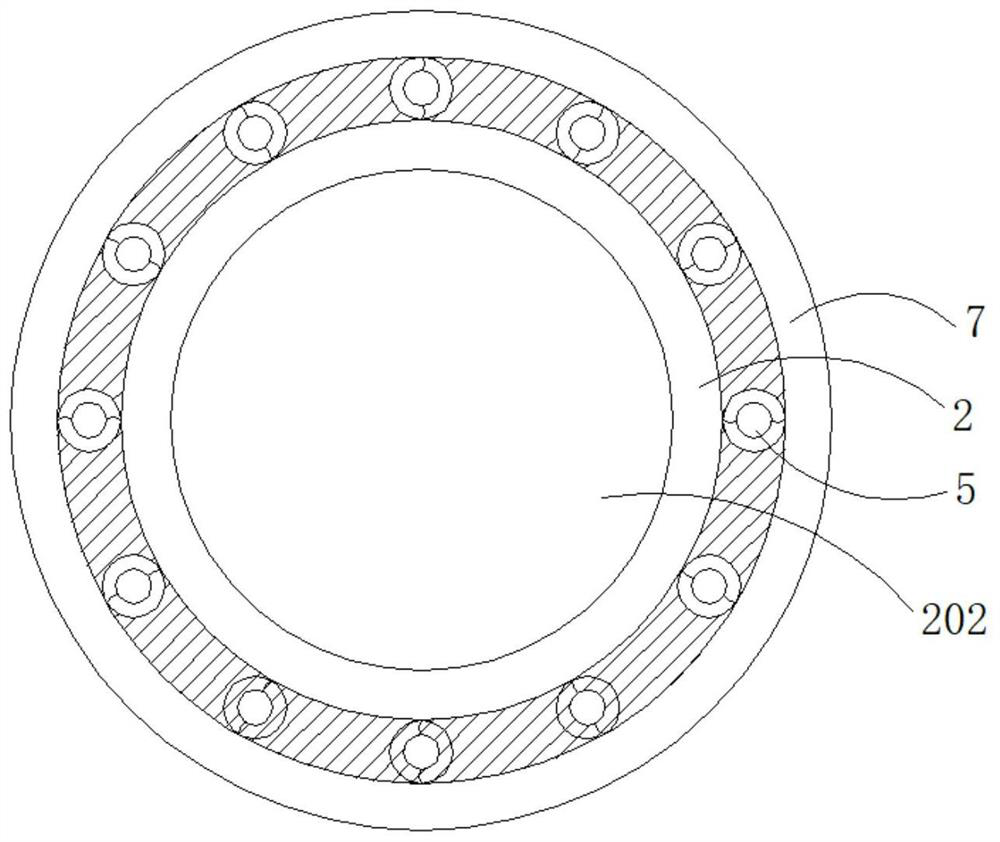

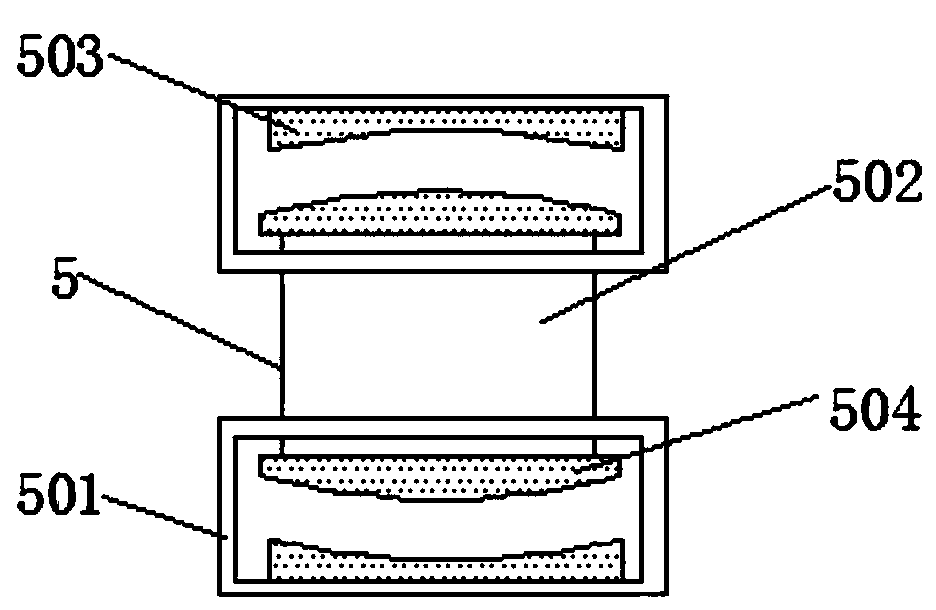

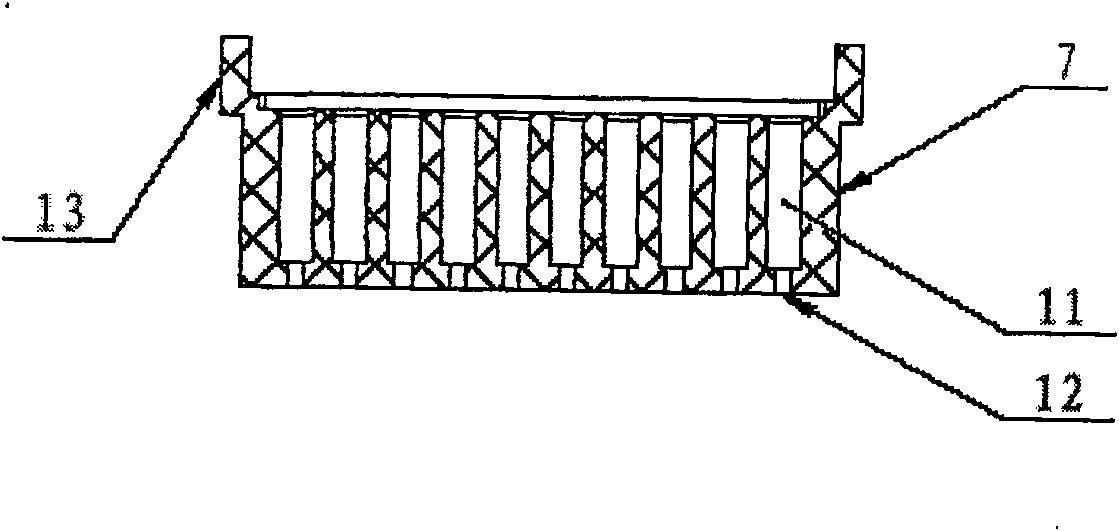

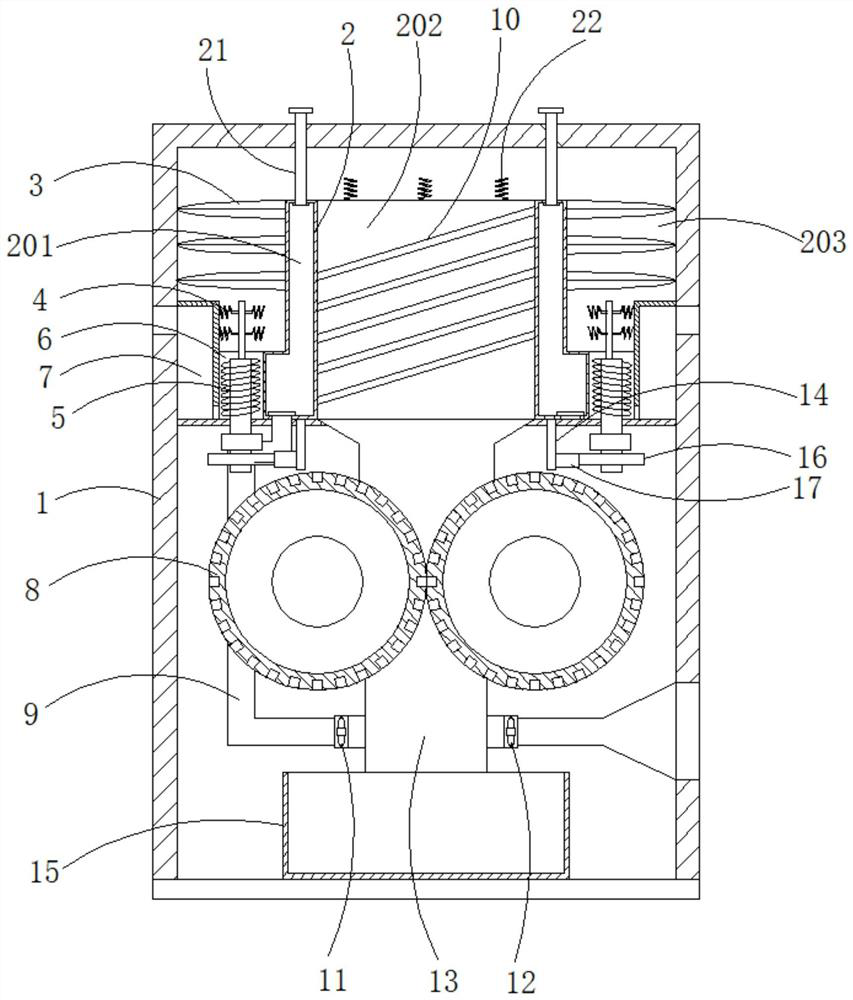

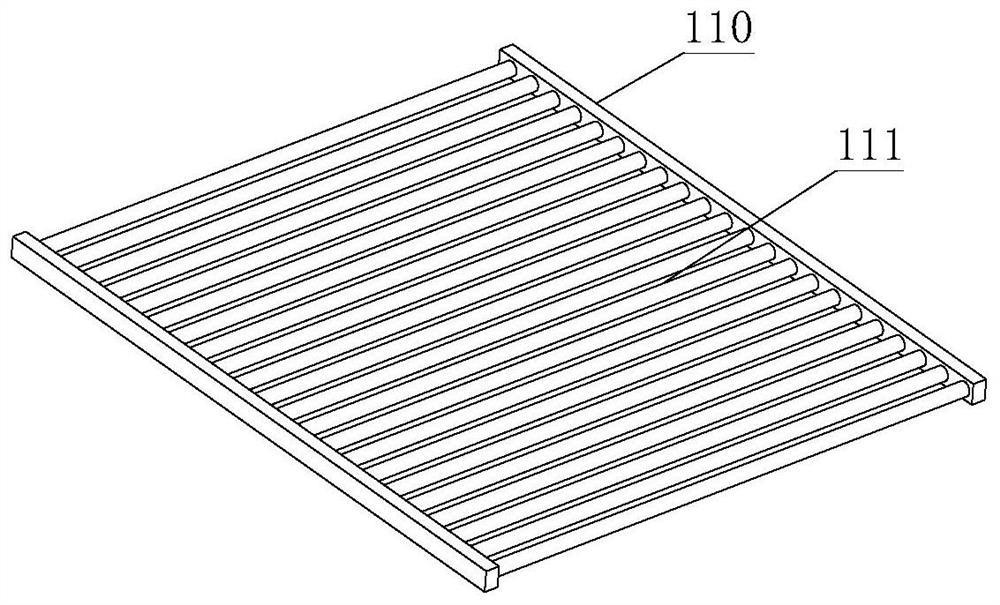

Double-roller dryer

InactiveCN104315829AImprove cooling effectKeep dryDrying solid materialsDrying machinesClassical mechanicsEngineering

The invention relates to the technical field of dryers, in particular to a double-roller dryer. The double-roller dryer comprises a first roller and a second roller, wherein the first roller and the second roller are arranged in parallel and are opposite in rotation direction, a material spraying device is arranged above the first roller and the second roller, a gap smaller than 5 cm is reserved between the first roller and the second roller, and the material spraying device is aligned to the gap. A material bin is arranged on the side opposite to the gap between the first roller and the second roller, a scraping plate is arranged on the material bin, the other end of the scraping plate is in circular contact with the periphery of the first roller and the periphery of the second roller, guide grooves are formed in the positions in contact with the first roller and the second roller, of the scraping plate, and the other end of each guide groove is connected with the inside of the material bin. By means of the technical scheme, the double-roller dryer enables materials to be dried easily and facilitates material discharge.

Owner:CHONGQING TENGHAN IND & TRADE

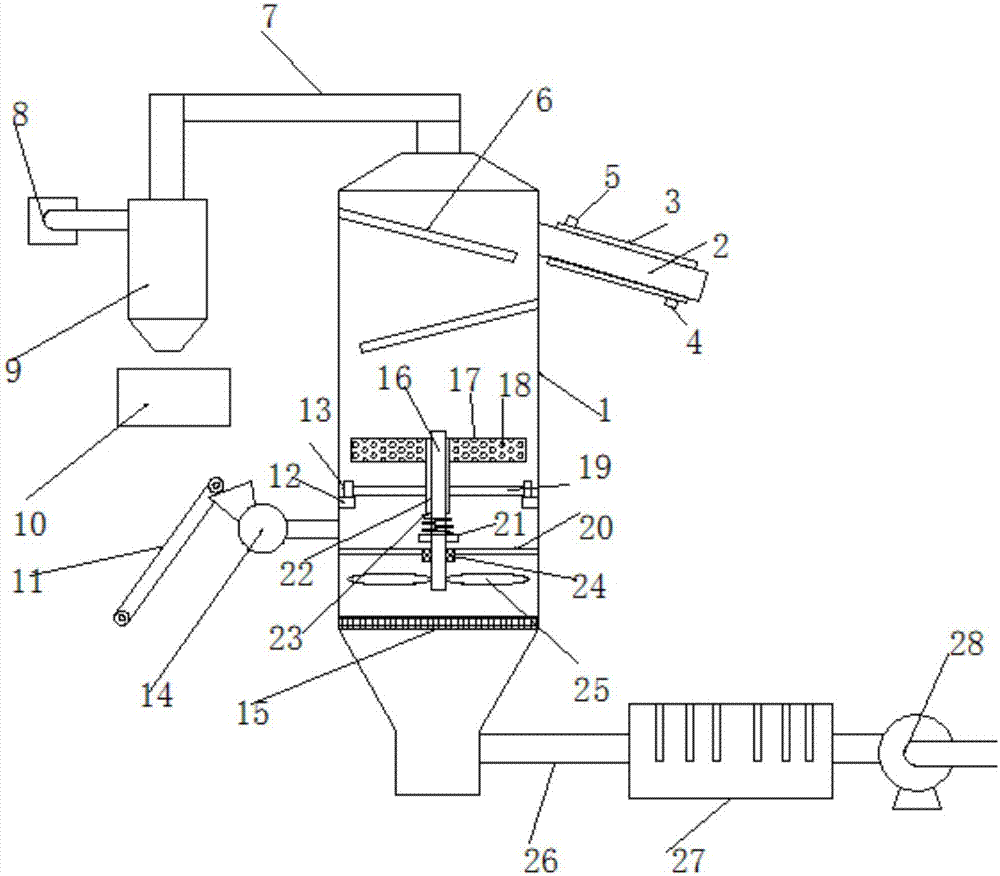

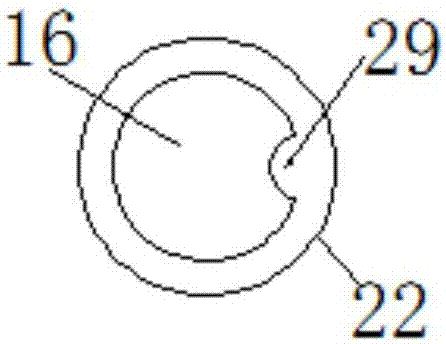

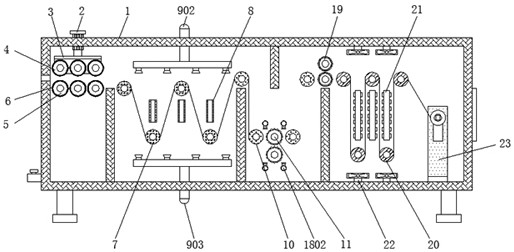

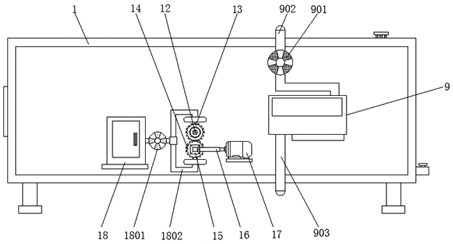

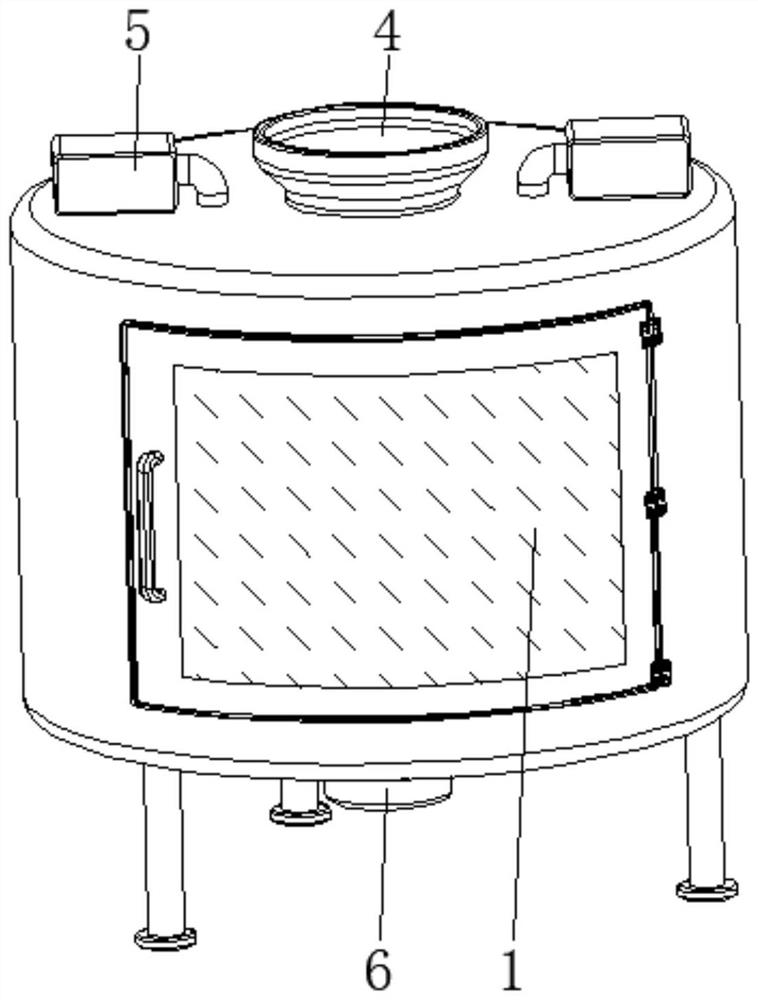

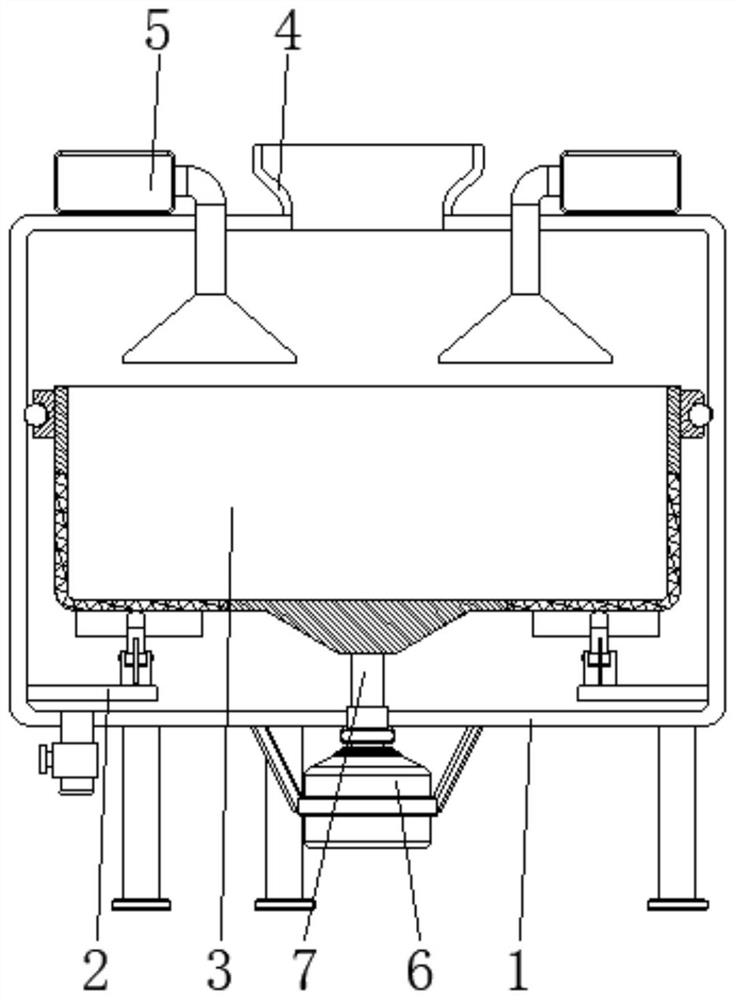

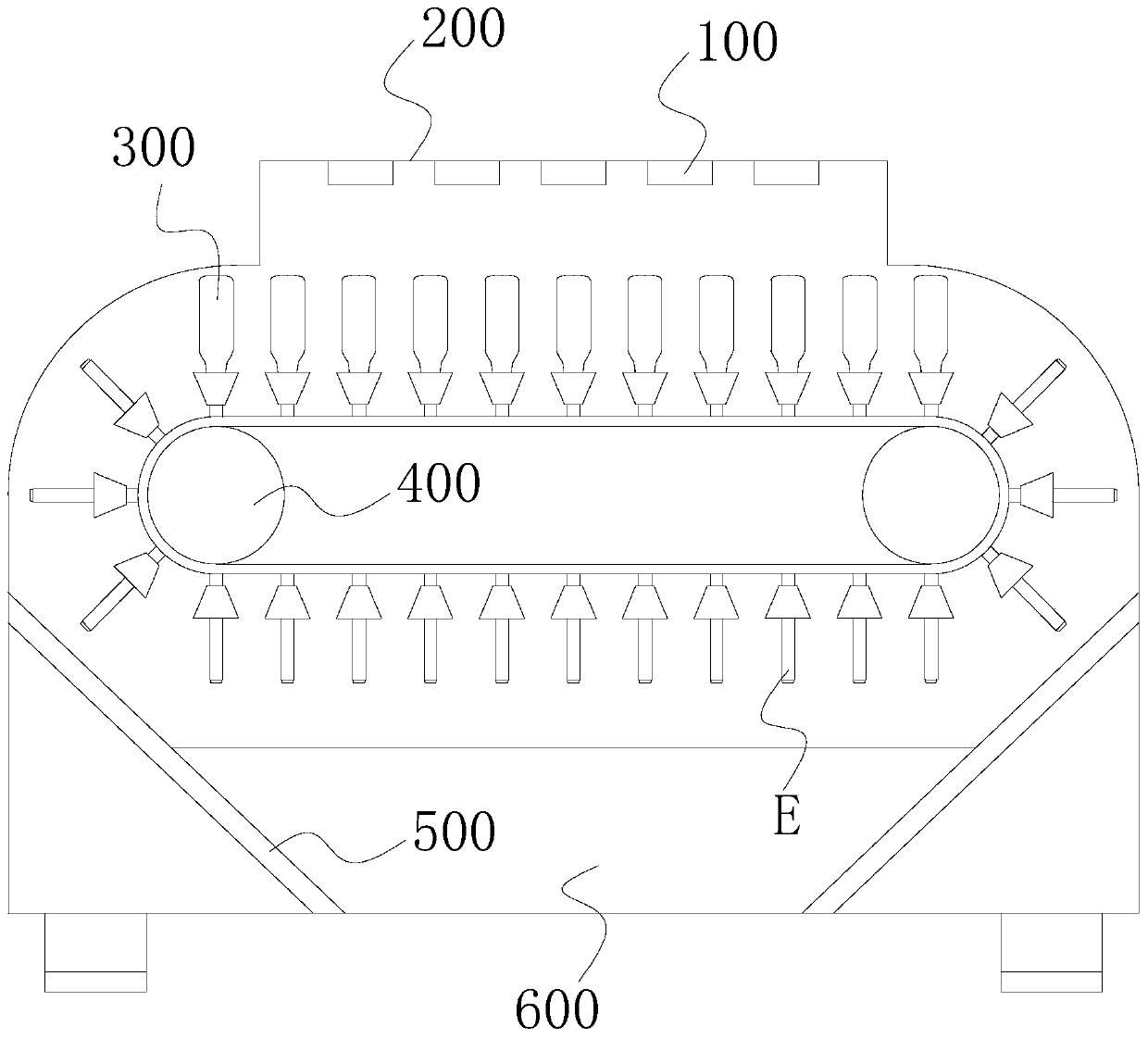

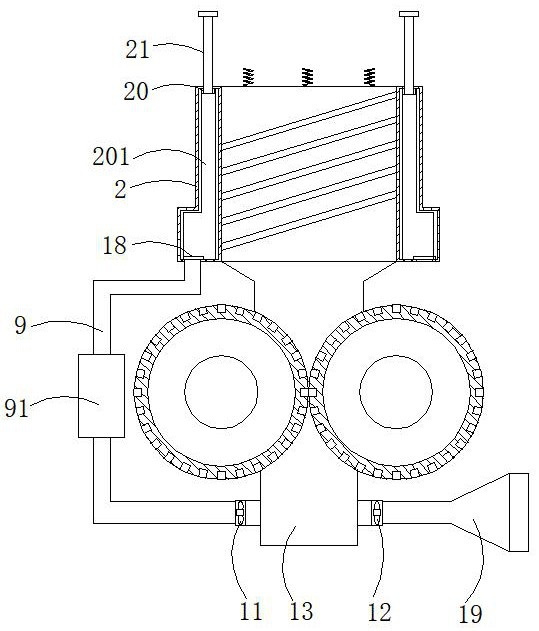

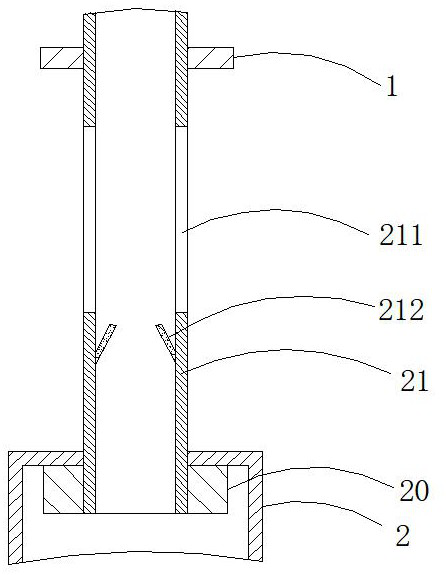

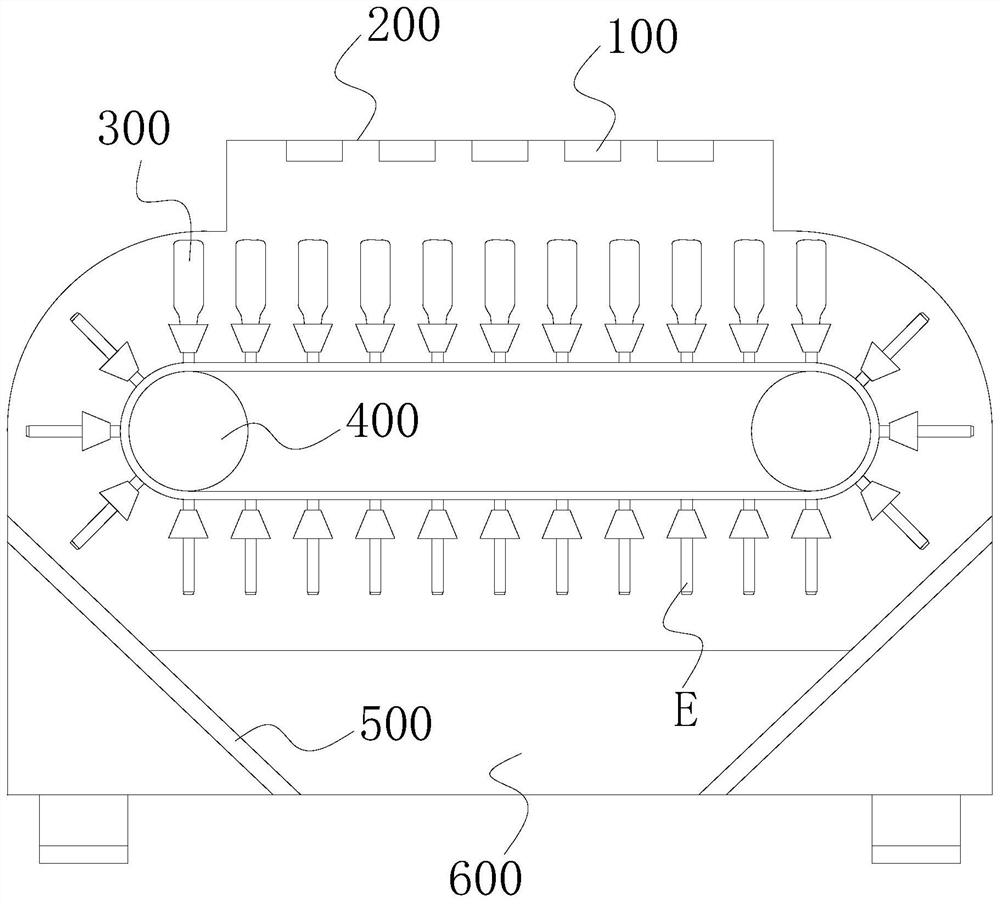

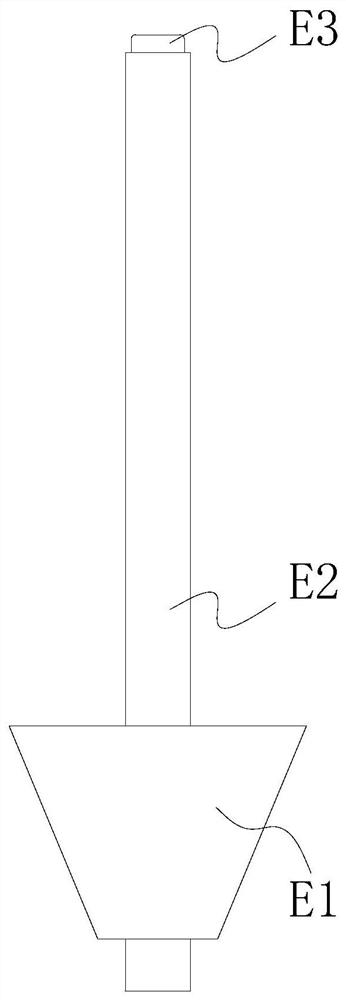

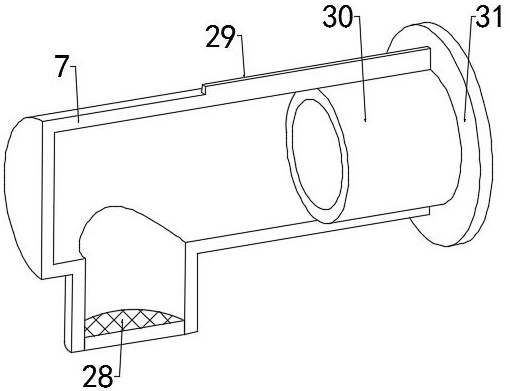

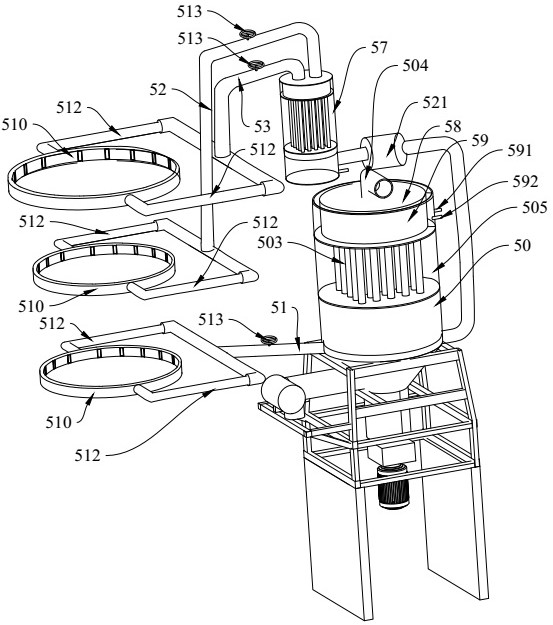

Fluidized bed drying device used for traditional Chinese medicine production and achieving crushing through air flow driving

InactiveCN107576150ADrying helpsHelp break upDrying solid materials with heatGrain treatmentsFluidized bed dryingEngineering

The invention discloses a fluidized bed drying device used for traditional Chinese medicine production and achieving crushing through air flow driving. An air inlet of the lower right end of a fluidized bed is connected with the air outlet end of a heating box through an air inlet pipe. The air inlet end of the heating box is connected with the air outlet end of an air blower. A discharging pipe is arranged on the right upper side of the fluidized bed, and a heat exchange water tank is arranged on the outer side of the discharging pipe. An air outlet at the upper end of the fluidized bed is connected with a cyclone separator through an air outlet pipe, and the air outlet end of the cyclone separator is connected with an exhaust fan. A feeding pipe is arranged on the lower left side of thefluidized bed, and a feeding mechanism is arranged on the left side of the feeding pipe and is a circulating conveyor belt. An air distributing plate is arranged at a lower end opening of the fluidized bed, and air outlets facilitating air outlet are evenly distributed in the air distributing plate. Distributing frames are arranged at an upper end opening of the fluidized bed in a staggered mode.The structure is simple and reasonable, the discharging temperature is decreased, the drying effect on materials is improved, and practicability is high.

Owner:HUNAN HUIXUN ENTERPRISE MANAGEMENT CO LTD

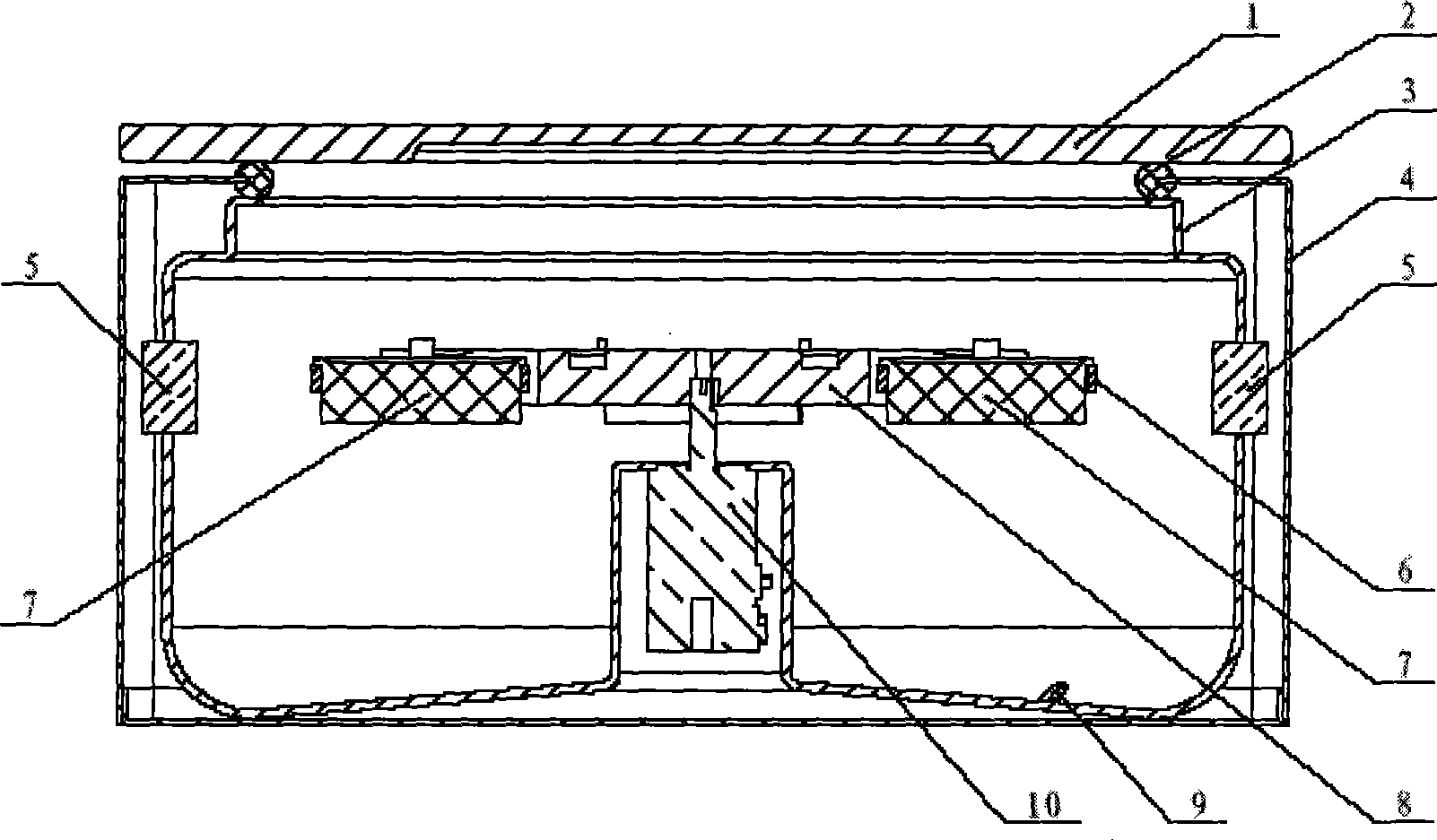

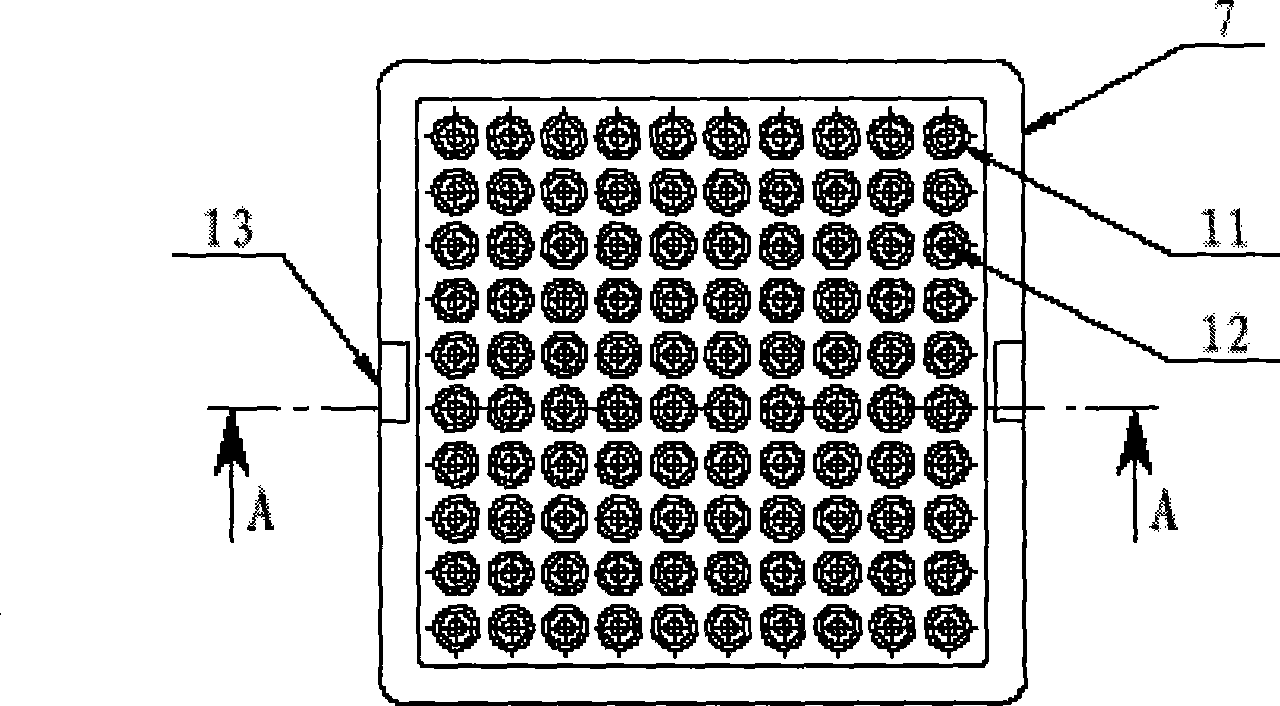

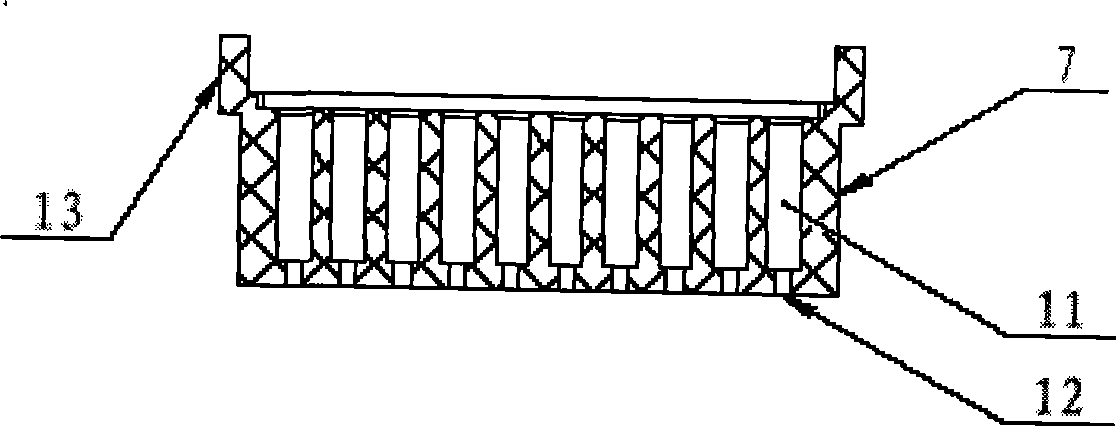

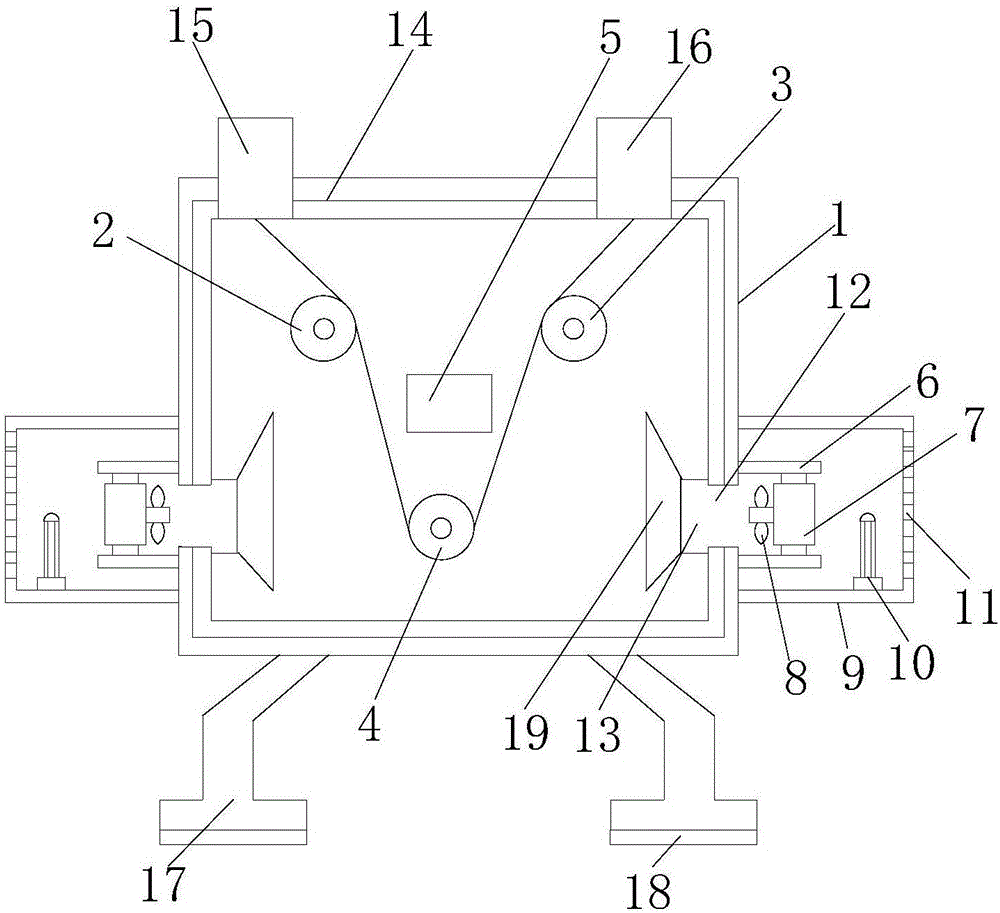

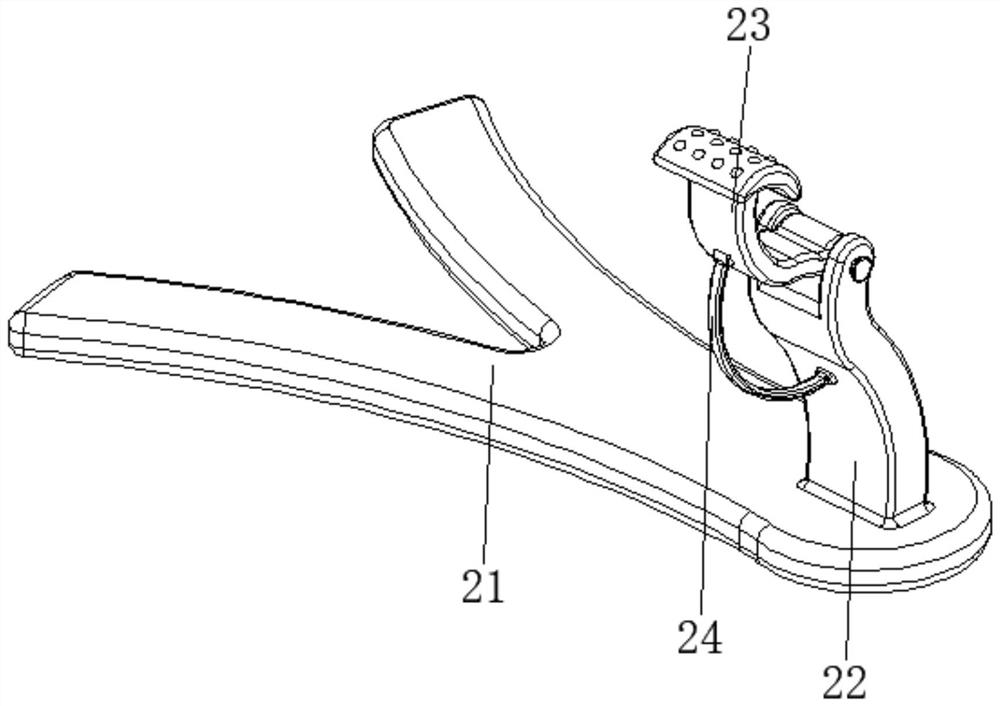

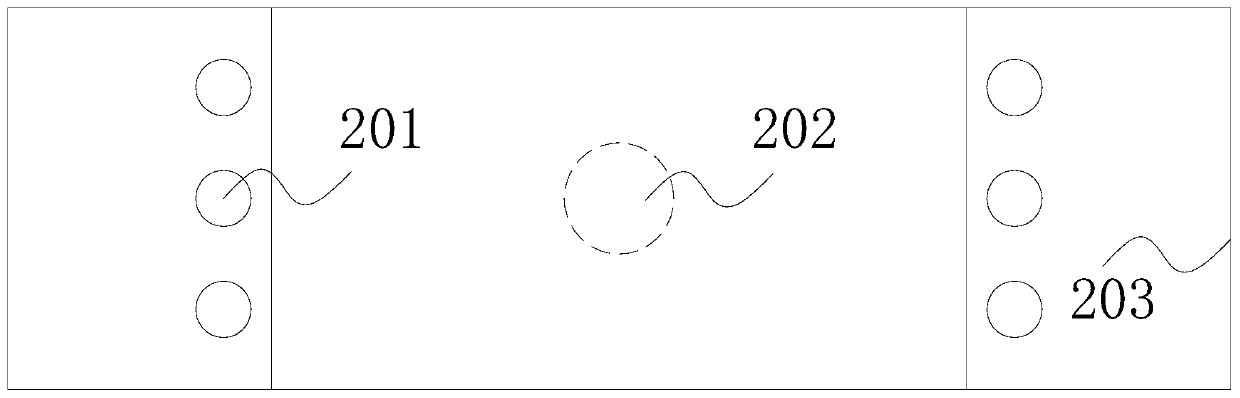

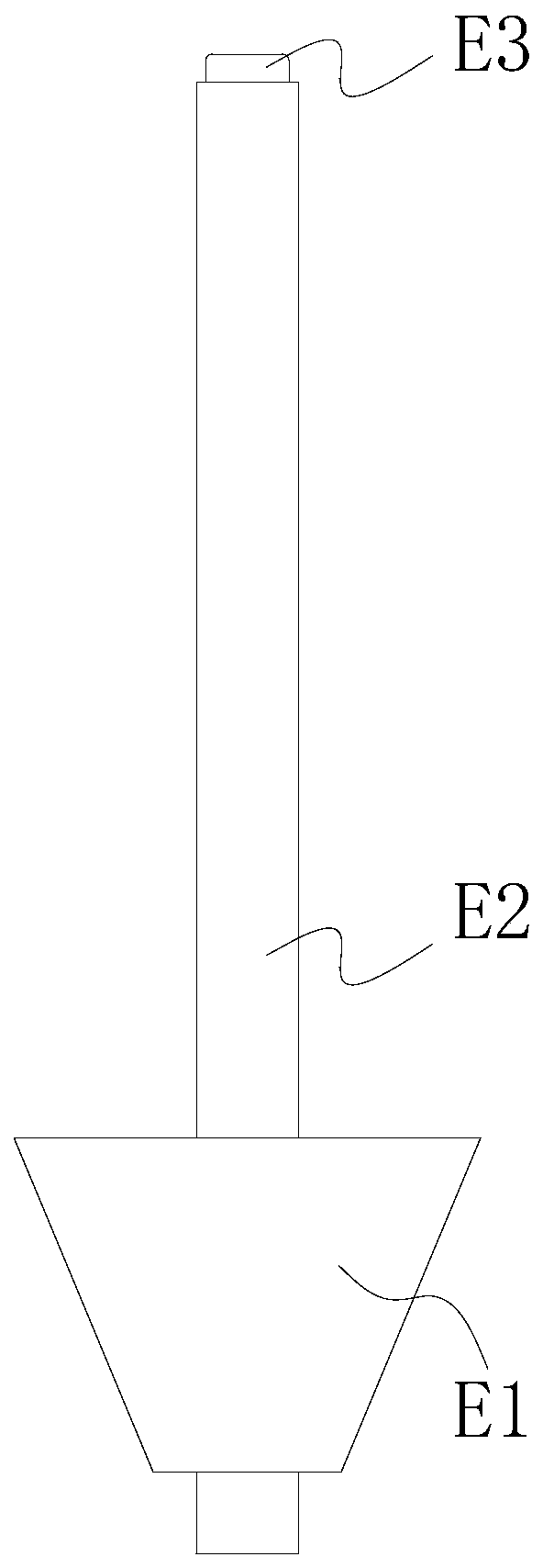

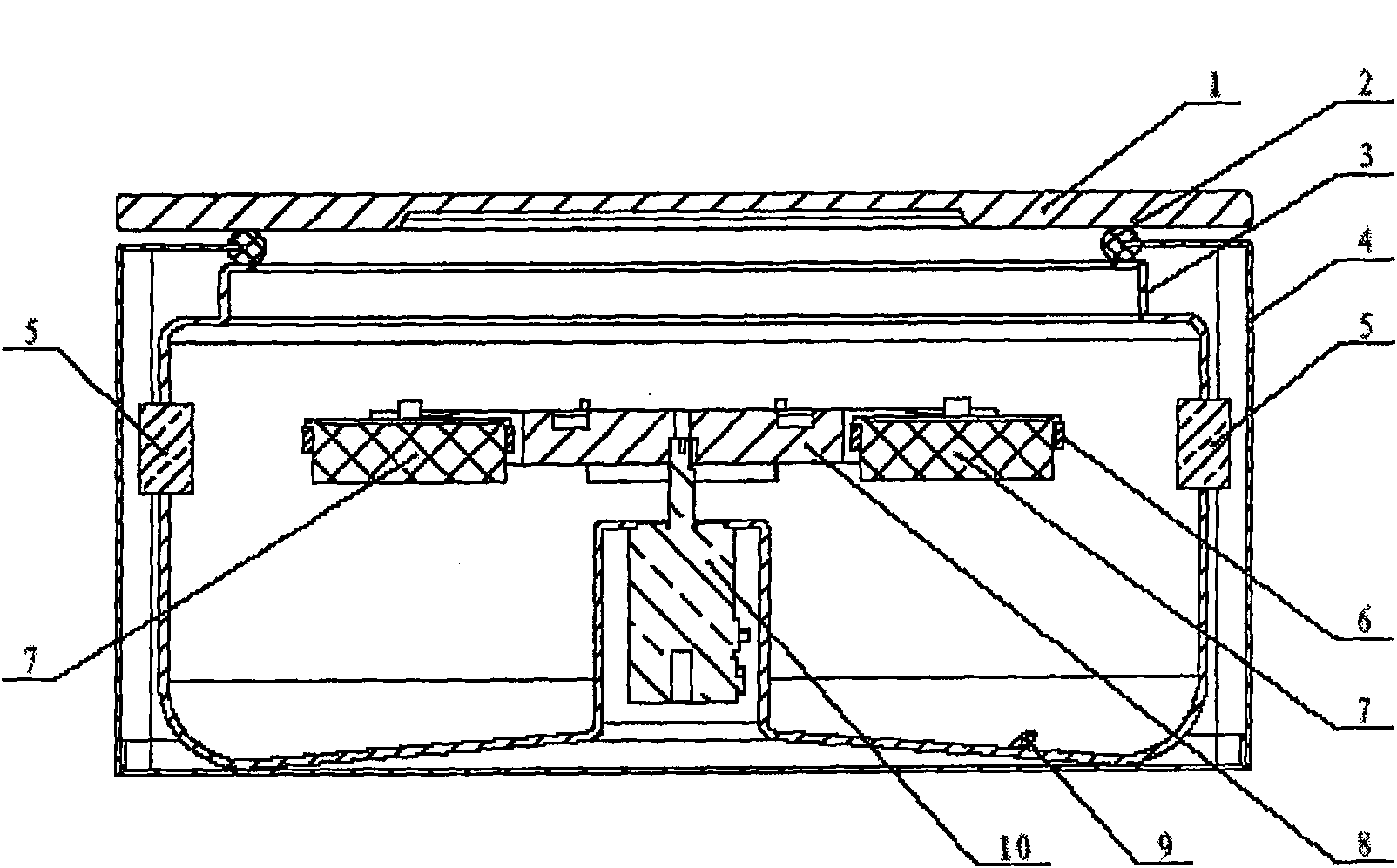

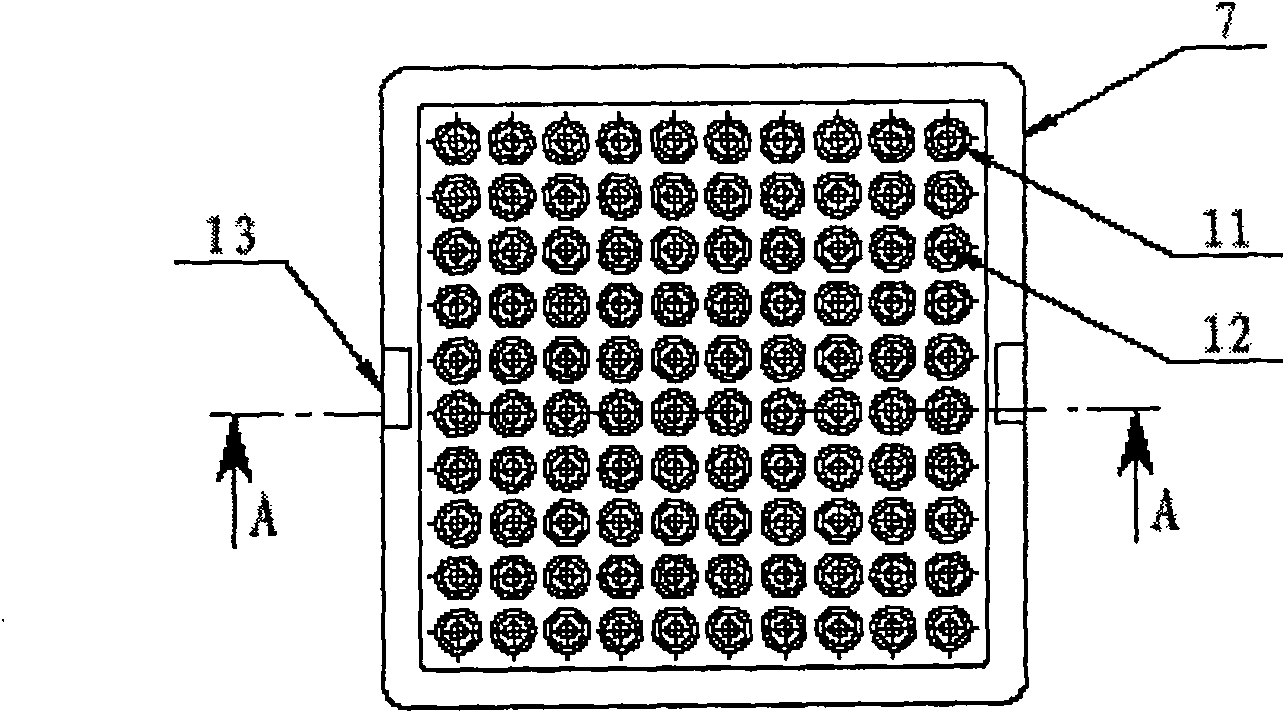

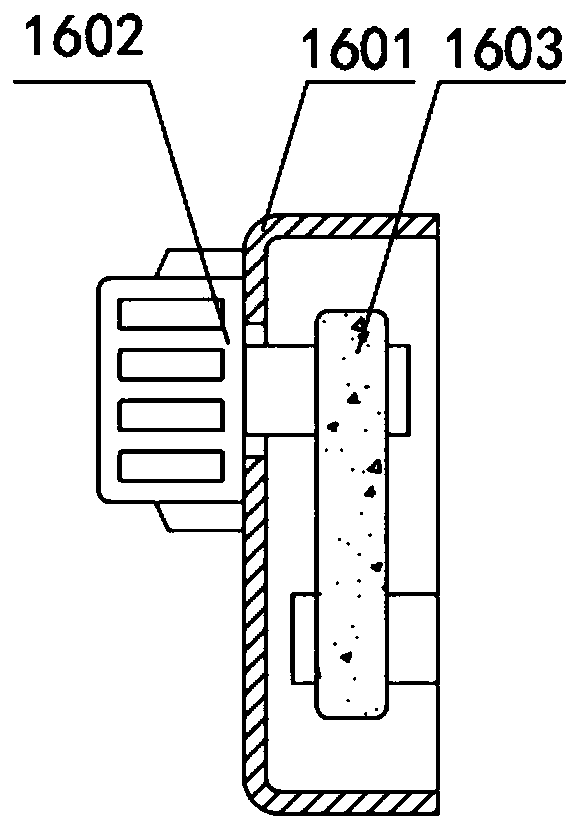

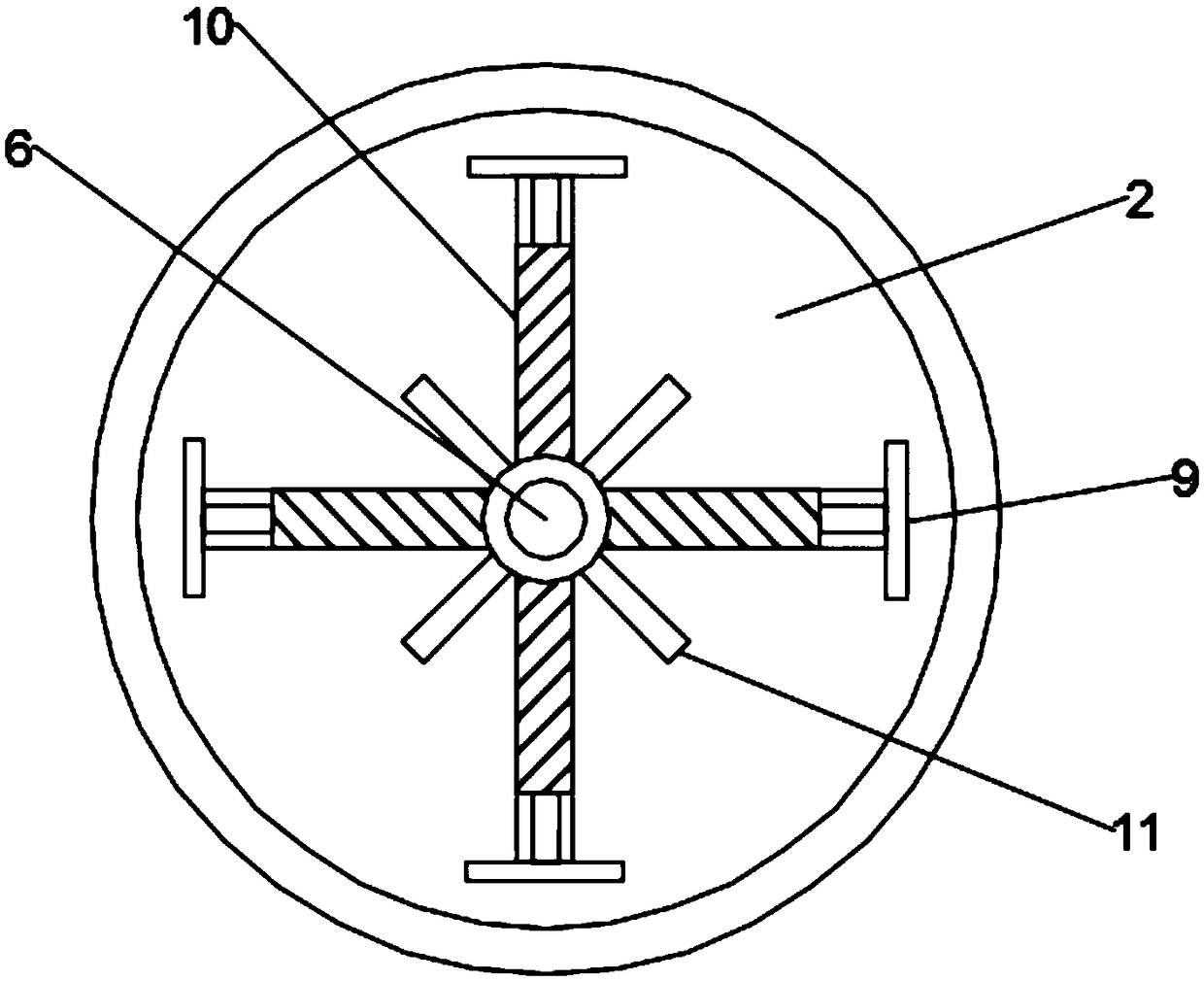

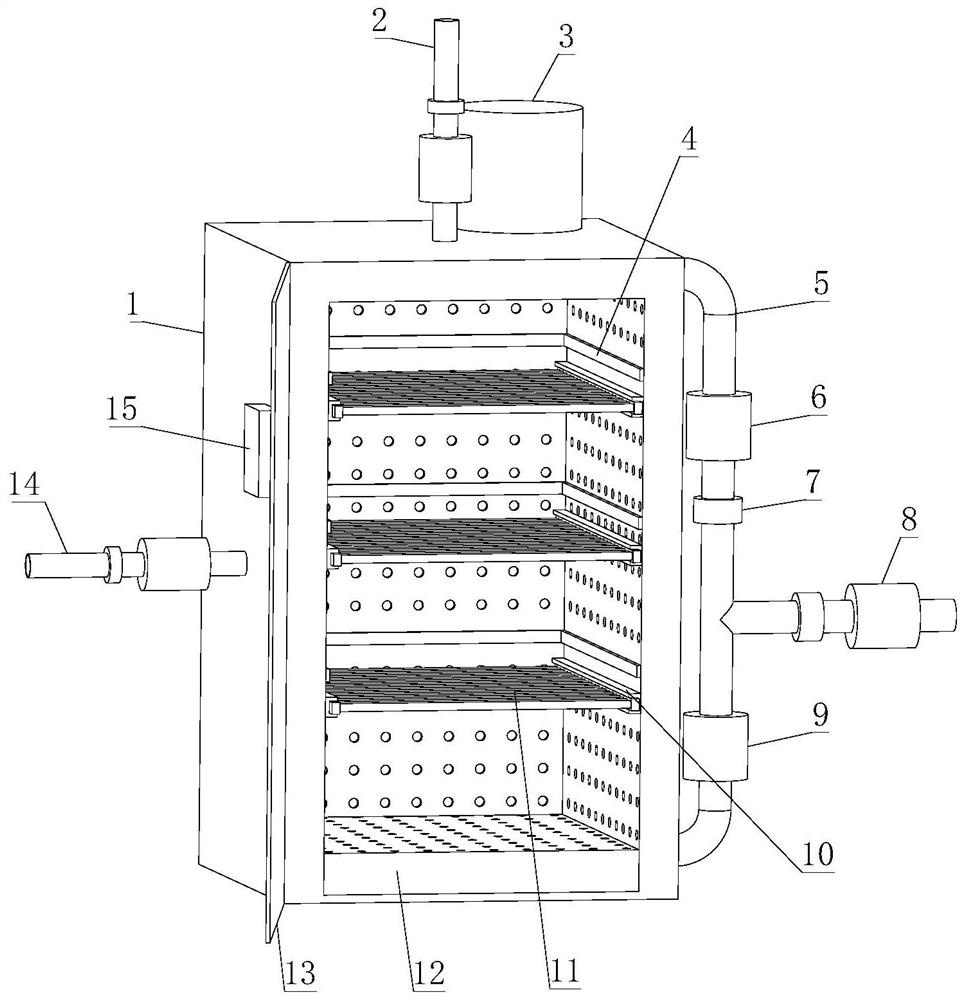

Method and tool for drying hard substrate biological chips

ActiveCN101435655AKeep dryAchieve dryingDrying machines with non-progressive movementsTemperature controlEngineering

The invention discloses a method for drying a hard-substrate biological chip and a drying tool thereof. The method comprises the following technical proposal: (1) the chip drying tool is started; temperature is set between 22 and 37 DEG C and is balanced for 8 to 15 minutes; (2) the hard-substrate biological chip is put to a mould of the drying tool; the centrifugal rotational speed is between 2,000 and 5,000 rmp; and the hard-substrate biological chip is subjected to centrifugal rotation for 5 to 40 minutes. The chip drying tool used in the method for drying the hard-substrate biological chip comprises a shell, an inner liner and a top cover; a motor is arranged between the shell and the inner liner; a rotating shaft of the motor runs through the liner wall of the inner liner, and extends into a chamber of the inner liner; the rotating shaft of the motor is connected with a rotary arm; two ends of the rotary arm are connected with a mould bracket respectively; a mould is arranged on each mould bracket; the mould is provided with densely distributed macropores; and the macropores run through the bottom of the mould through small pylomes running through the bottom. The periphery of the inner liner is provided with a temperature control module. Through the chip drying tool and the matched mould, the drying method utilizes centrifugal force to firstly fully throw closed liquid remained on the surface of the chip off the chip and fully evaporate less moisture remained on the surface of the chip under the centrifugal vacuum environment in order that the chip achieves the drying effect.

Owner:江苏三联生物工程股份有限公司

Textile cloth drying device capable of conducting fast drying

InactiveCN106322957AImprove drying effectDrying helpsDrying gas arrangementsDrying chambers/containersElectric machineryEngineering

The invention discloses a textile cloth drying device capable of conducting fast drying. The textile cloth drying device comprises a box body. A first roller shaft, a second roller shaft, a third roller shaft and a heating plate are arranged in the box body. Fixing rods are fixedly connected to the left side and the right side of the box body. Motors are fixedly installed on the fixing rods. The output ends of the motors are fixedly connected with blades. The two sides of the box body are fixedly connected with heating boxes. The fixing rods are located in the heating boxes. Heating bars are fixedly installed at the bottoms of the inner walls of the heating boxes. According to the textile cloth drying device capable of conducting fast drying, cloth moves in the box body through the first roller shaft, the third roller shaft and the second roller shaft, the area for the cloth to make contact with heat and wind becomes larger, drying is facilitated, primary drying can be conducted on the cloth through the heating plate, the motors are used for driving the blades to blow hot wind into the box body, the wind is evenly blown to the cloth, the cloth can be effectively blown dry, and the drying effect is greatly improved.

Owner:新昌县城关宾立机械厂

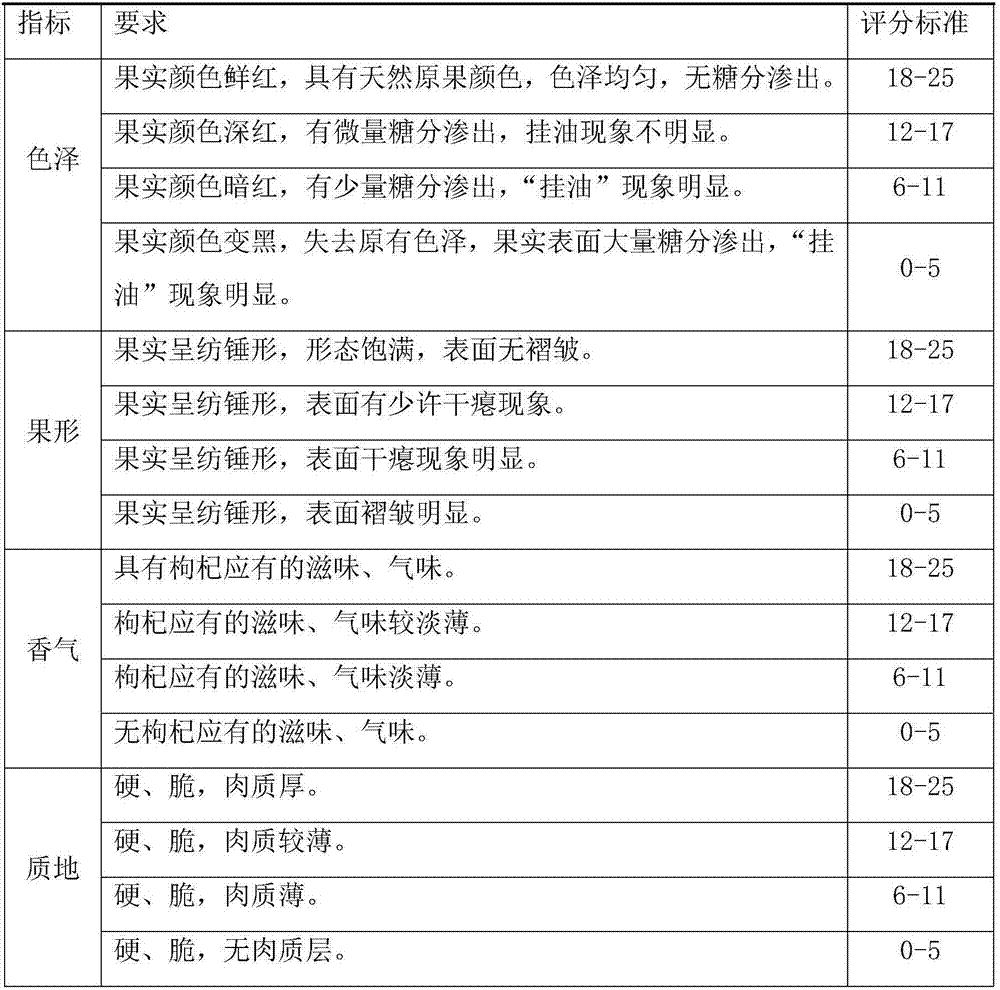

Microwave vacuum drying method of Chinese wolfberry fruits

InactiveCN107361125ASolve uneven heatingInhibitory activityFruits/vegetable preservation by irradiation/electric treatmentFood dryingBiotechnologyProcess engineering

The invention relates to the technical field of food processing, in particular to a microwave vacuum drying method of Chinese wolfberry fruits. The microwave vacuum drying method of the Chinese wolfberry fruits comprises the following steps of performing sorting, performing automatic sorting, removing peach stems, performing sterilization and enzyme deactivation treatment on fresh Chinese wolfberry fruits with high-pressure water mist under a high pressure pulse electric field, performing microwave vacuum predrying, performing microwave vacuum drying and performing nitrogen-filled packaging. Segmented-type microwave vacuum drying is particularly adopted and combined with timely disk inversion, so that the drying time of the Chinese wolfberry fruits is effectively shortened, the dried Chinese wolfberry fruits are bright red in color, plump in shape, crisp in mouth feel, easy to chew, safe and hygienic.

Owner:NINGXIA UNIVERSITY

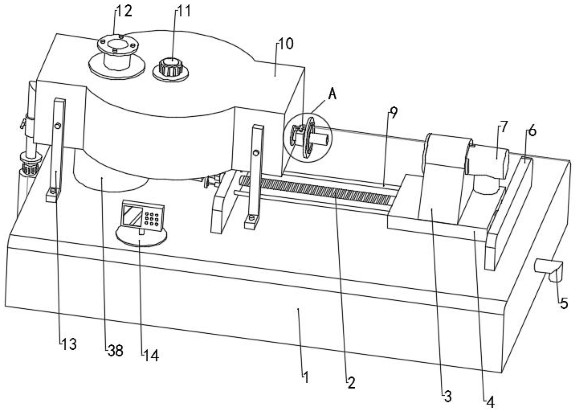

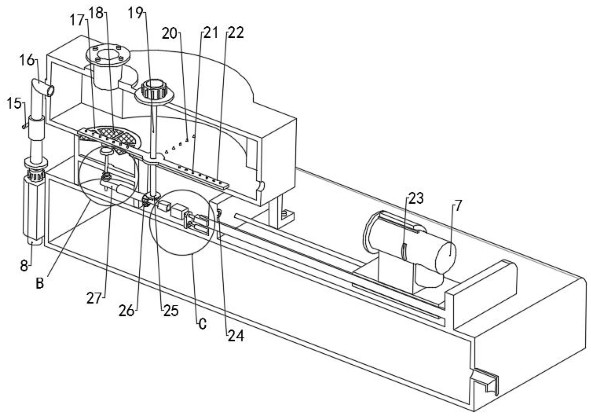

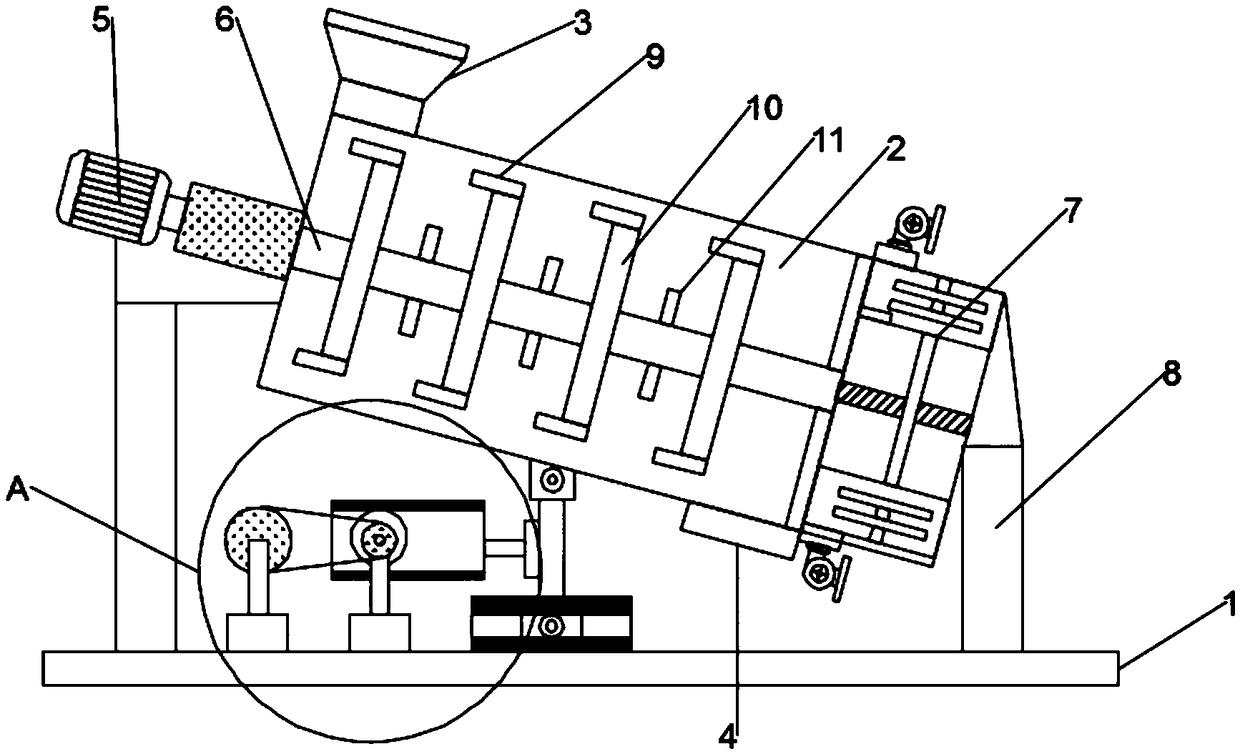

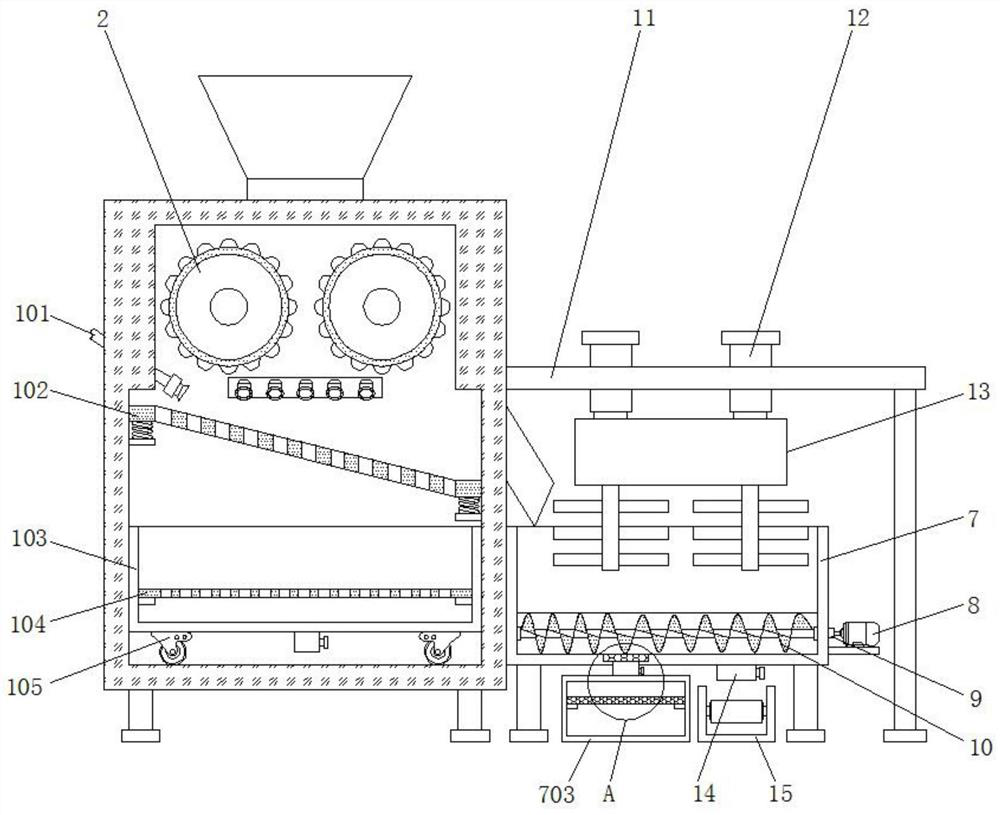

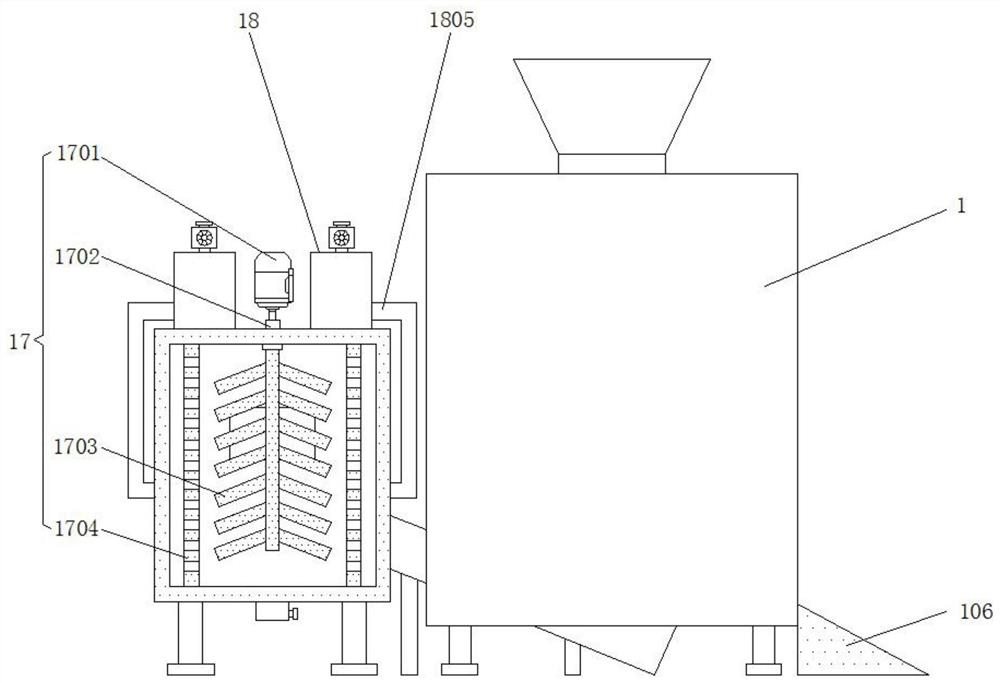

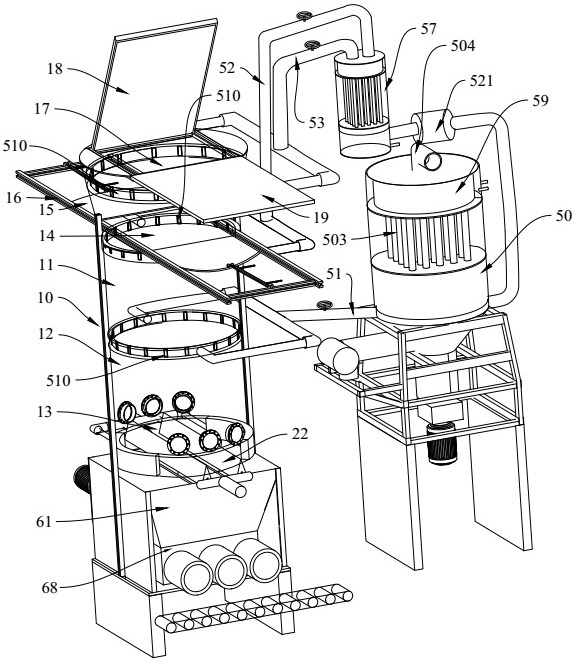

Self-drying biomass particle granulating device

ActiveCN112237886ACompact structureRealize energy sharingDomestic cooling apparatusDrying gas arrangementsThermodynamicsProcess engineering

The invention discloses a self-drying biomass particle granulating device which comprises a box body; a hollow cylindrical rotating seat and a feeding cavity are arranged on the upper portion of a partition plate of the box body, feeding blades are arranged on the inner wall of the rotating seat, lifting blades are arranged on the outer wall of the rotating seat, and a lifting screw rod and a stirring rod are arranged between the cylindrical rotating seat and the feeding cavity. The biomass particle granulation device is used for granulation of biomass particles and drying of biomass materials, multiple procedures such as secondary stirring, drying, feeding and cooling in biomass particle processing can be completed, the drainage performance of the materials can be improved, the drying effect is better, energy sharing of multiple functions is achieved in the process, and the existing equipment can be replaced in actual production of biomass particles, and the equipment cost is saved.

Owner:桃江县新辉生物质颗粒有限公司

Production equipment for drying treatment of textiles

PendingCN111764078AAvoid flatteningAvoid wrinklesMechanical cleaningPressure cleaningEngineeringIndustrial engineering

The invention discloses production equipment for drying treatment of textiles. The production equipment comprises an equipment body, a clearing roll and an ironing roll. A hydraulic telescopic rod isarranged on the equipment body, and the lower end of the hydraulic telescopic rod penetrates through the upper surface of the equipment body to be connected with a supporting frame. The inner side wall of the supporting frame is rotationally connected with first pressing rolls, and protection bushes are arranged on the outer side faces of the first pressing rolls and the outer side faces of secondpressing rolls. Meanwhile, the second pressing rolls are rotationally connected to the inner side wall of the equipment body, the inner side wall of the equipment body is rotationally connected withfirst guide rolls, and the first guide rolls are arranged on the right sides of the second pressing rolls. Heating elements are arranged in the equipment body, and the heating elements are arranged between the first guide rolls. According to the production equipment for drying treatment of the textiles, placed cloth is flattened through the first pressing rolls and the second pressing rolls, and the phenomenon that when subsequent textile cloth is dried, wrinkles are generated is avoided; and meanwhile too much water in the textile cloth can be extruded out under the action of the first pressing rolls and the second pressing rolls, and subsequent drying is benefited.

Owner:湖州市千金金耀制丝有限公司

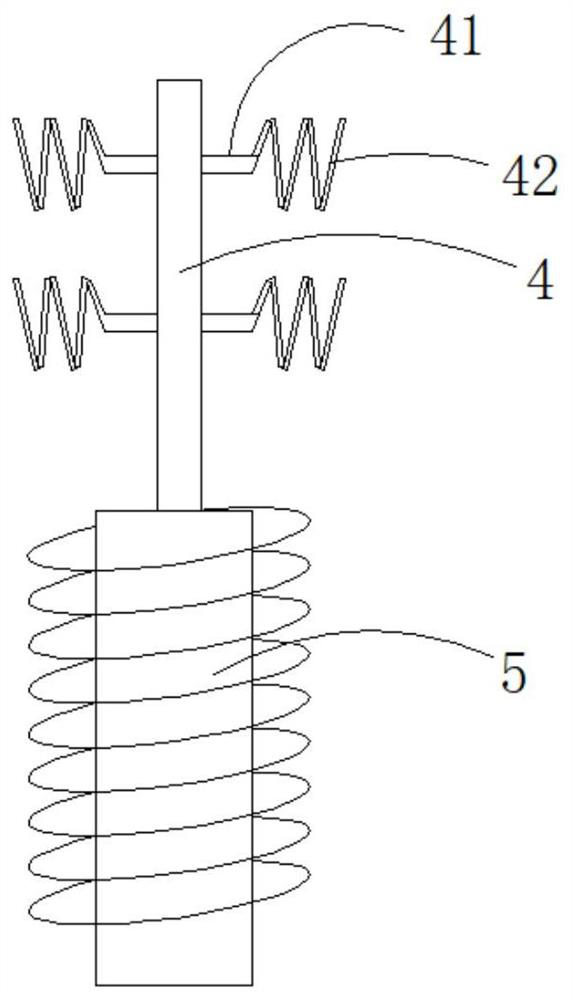

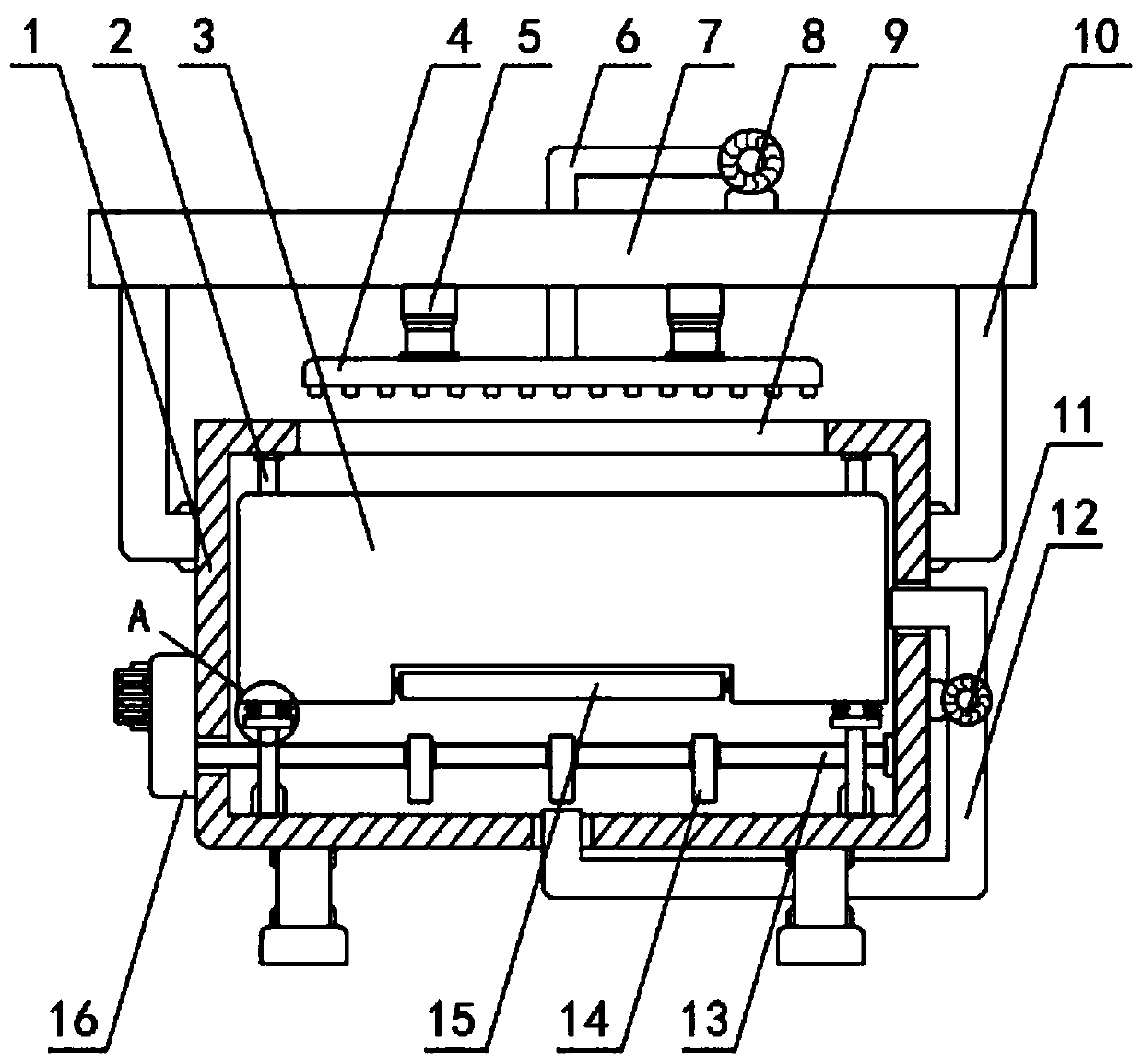

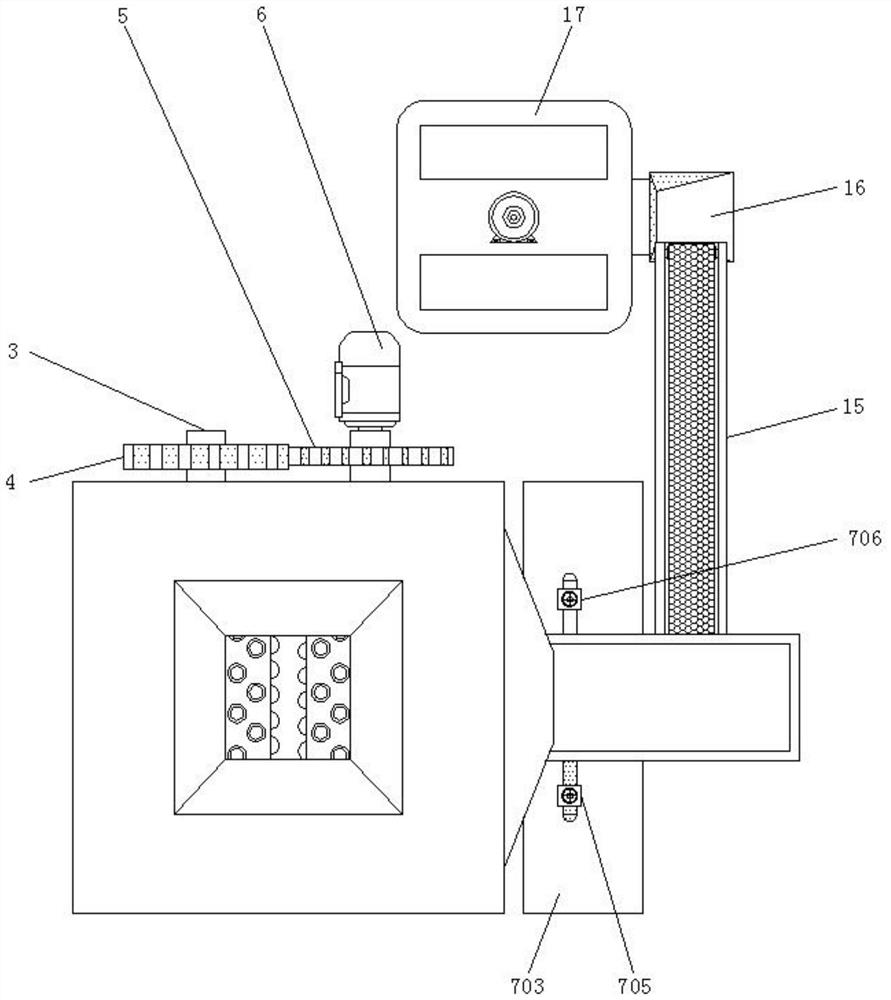

Electronic component processing equipment and method

ActiveCN114322465AFacilitate water removalAdaptableDrying solid materials without heatDrying gas arrangementsMaterial storageElectronic component

The electronic component processing equipment comprises a machine body, a knocking device and a material storage device, the knocking device is arranged on the inner wall of the machine body and close to the bottom, the material storage device is arranged in the machine body and close to the knocking device, and a curved surface supporting column is fixed to the end, away from the inner wall of the machine body, of the top of a base. The striking device is arranged at the top of the curved-surface supporting column, the arc-shaped elastic piece is arranged between the two sides, corresponding to the surface of the curved-surface supporting column, of the surface of the striking device, the bottom end of the supporting and jacking piece is hinged to the top of the curved-surface supporting column, and the arc-surface striking head is fixed to the top end of the supporting and jacking piece. According to the electronic component processing equipment and method, the rapid drying effect is achieved, sheet parts are not prone to adhesion and accumulation, rapid and thorough drying can be conducted, follow-up use is facilitated, safety and reliability are achieved, and the working efficiency and the use performance are improved.

Owner:淮安市宝鼎科技有限公司

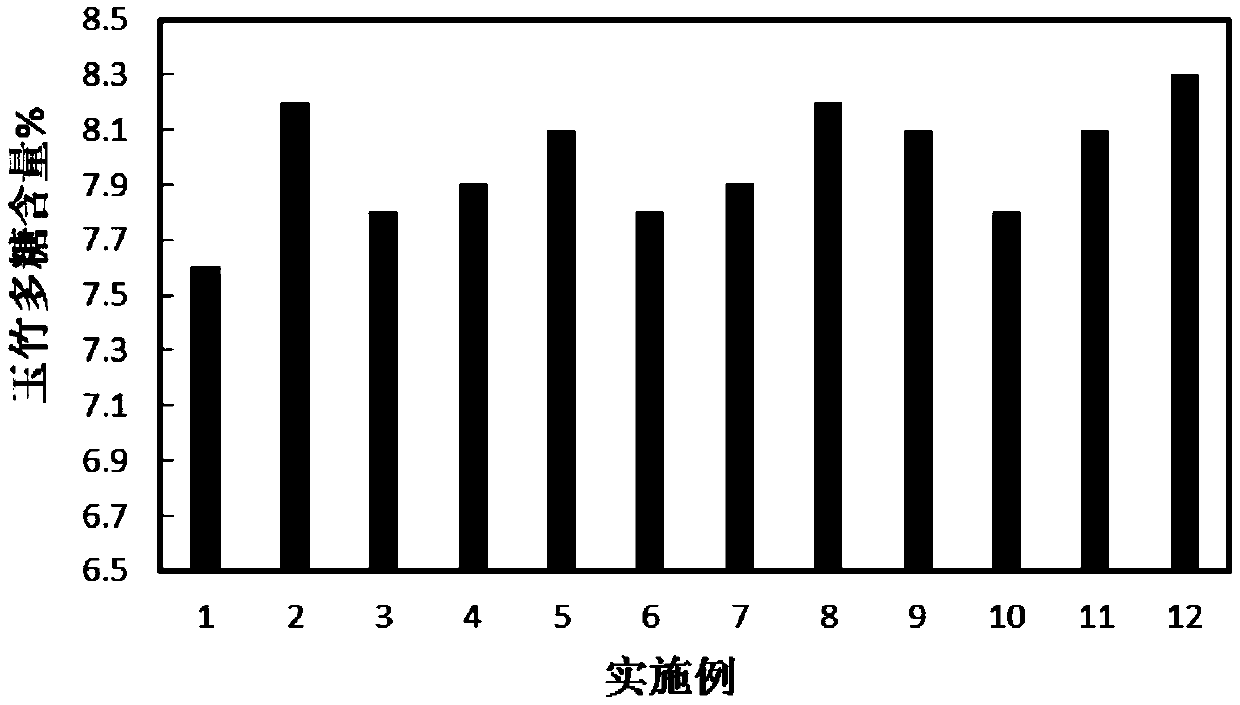

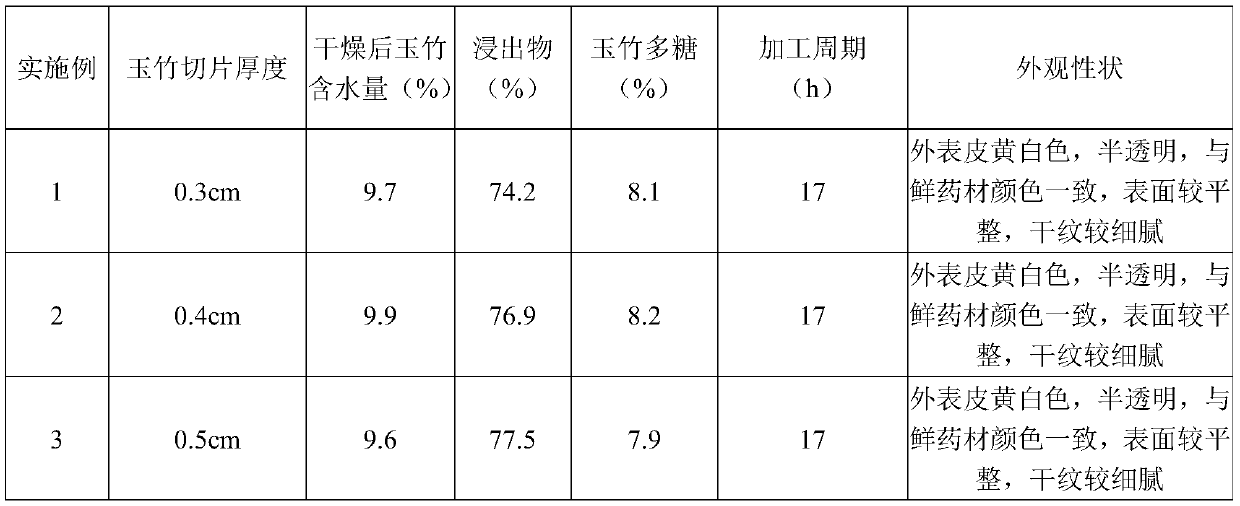

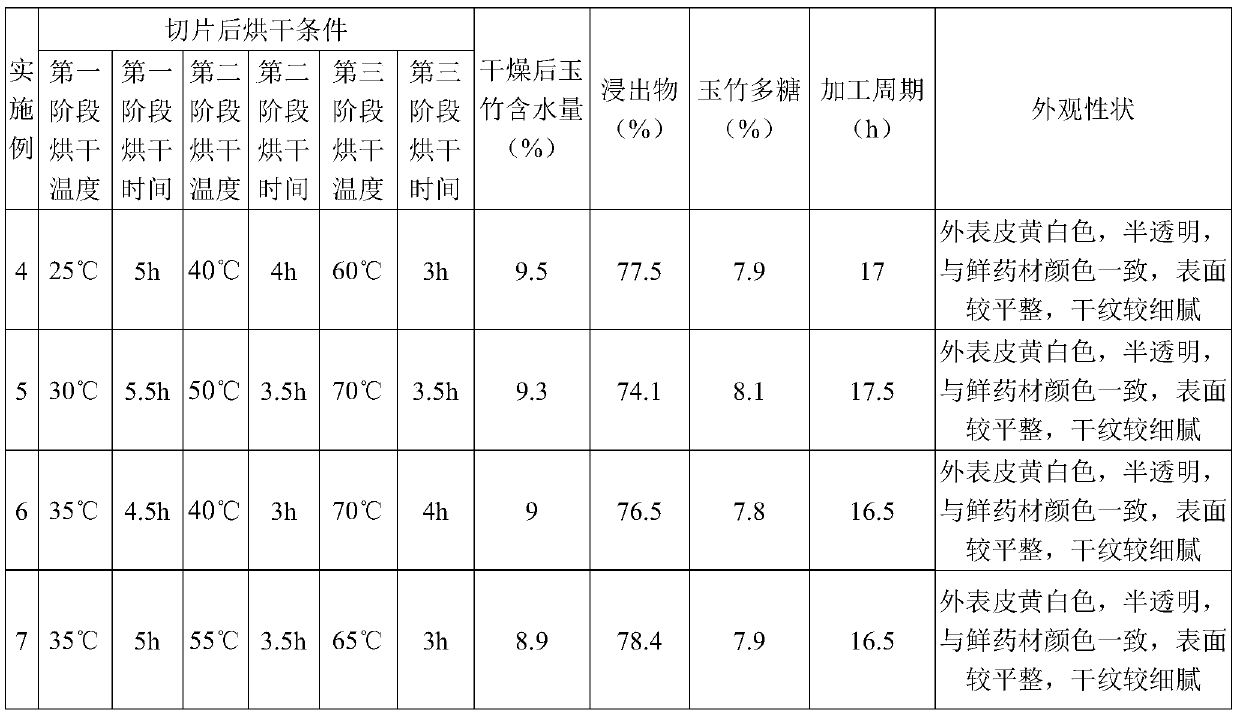

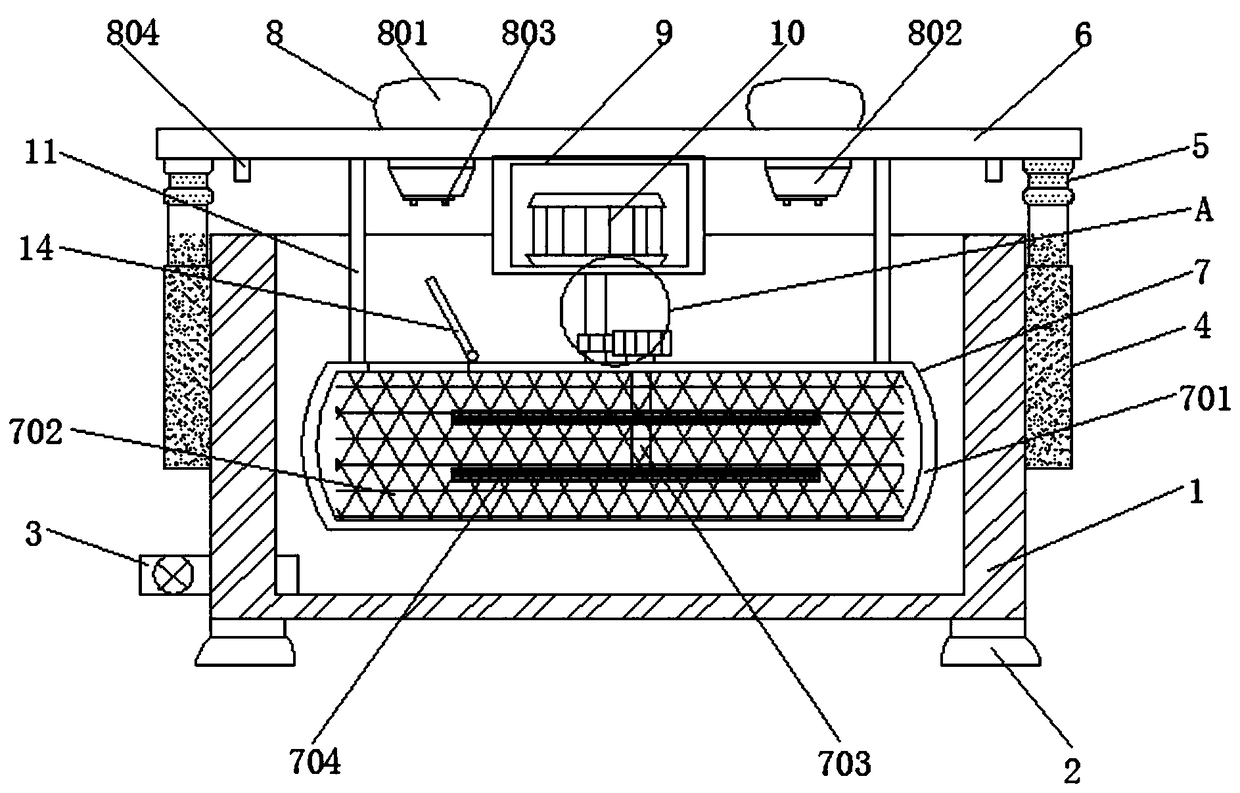

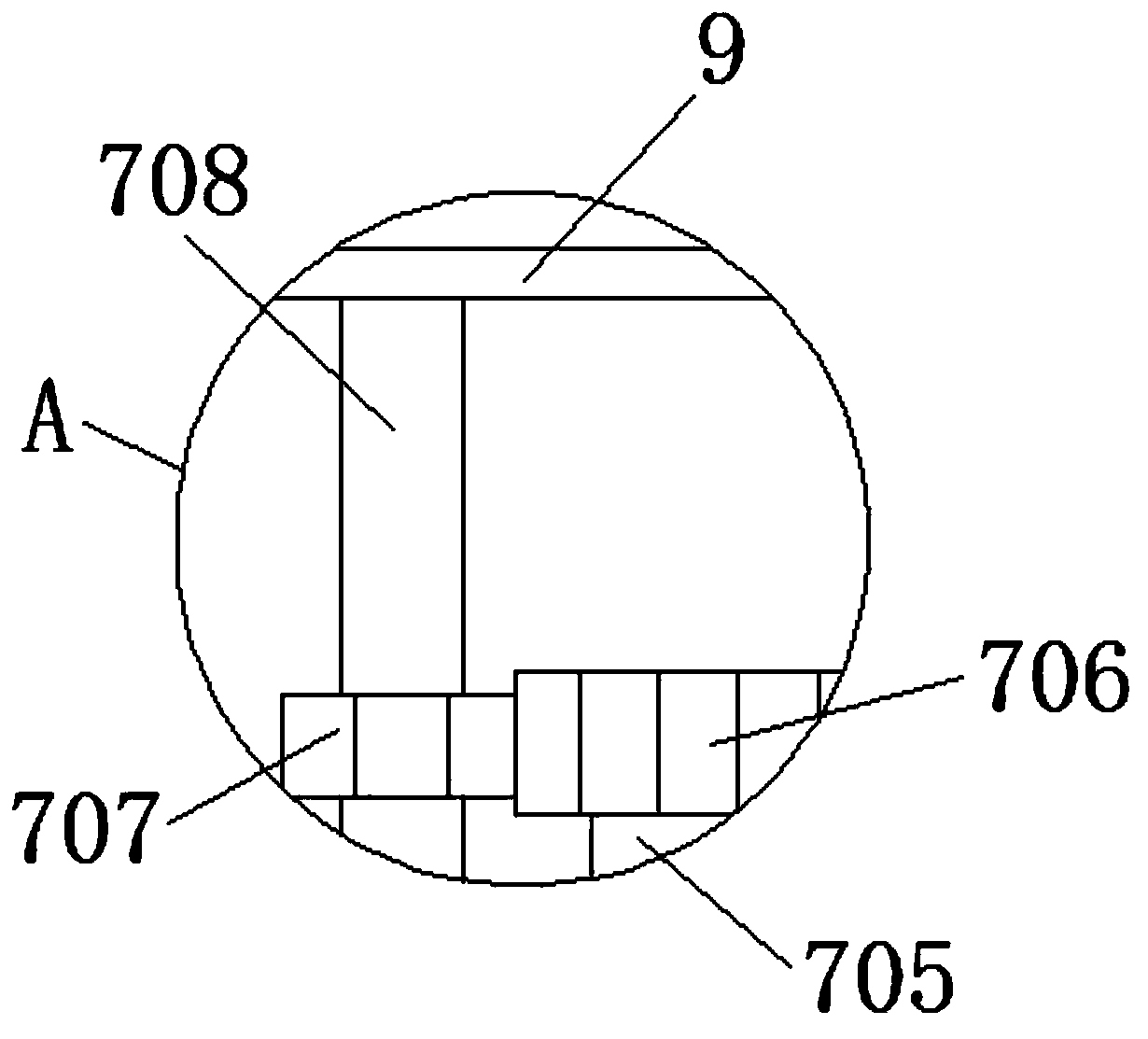

Processing technology for fresh-cut radix polygonati officinalis medicinal slices ready for decoction

InactiveCN110237181AShorten the production cycleEasy to operatePlant ingredientsPolygonum odoratumCool storage

The invention belongs to the technical field of processing of traditional Chinese medicines, and particularly relates to a processing technology for fresh-cut radix polygonati officinalis medicinal slices ready for decoction. The processing technology comprises the steps of (1) grading, wherein dug fresh radix polygonati officinalis is graded into a large-size grade, a medium-size grade and a small-size grade according to the rhizome size; (2) thorough washing, wherein the fresh radix polygonati officinalis of the same grade is placed in a medicinal material washing machine, and after silt is removed thoroughly, the fresh radix polygonati officinalis is poured out; (3) cleaning processing, wherein a fibrous root removing machine is adopted, fibrous roots of the radix polygonati officinalis are removed, and after the fibrous roots are thoroughly removed, the radix polygonati officinalis is washed thoroughly; (4), cutting into slices and drying, wherein the radix polygonati officinalis is cut into the slices, and the slices are poured in a baking pan, flat spread uniformly and conveyed into a nitrogen charging dryer for stage-type heating drying; (5) screening and packaging, wherein dried radix polygonati officinalis pieces are screened and stored in a ventilated and dried cool storage. The thoroughly washed radix polygonati officinalis is directly cut, a wetting process is saved, and the loss of effective components is reduced; the nitrogen charging dryer is adopted for drying treatment to avoid the oxidation stain phenomenon of the radix polygonati officinalis, and the drying time is shortened; a stage-type heating method is adopted for drying, it is avoided that the radix polygonati officinalis pieces warp, so that the radix polygonati officinalis pieces are more attractive, and the quality of the radix polygonati officinalis pieces is ensured.

Owner:九信(武汉)中药研究院有限公司

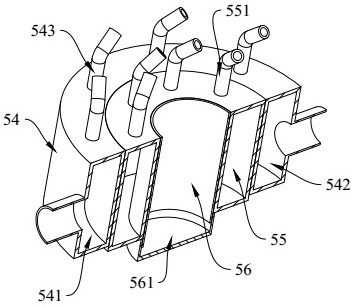

Fodder cleaning and drying device for livestock breeding

InactiveCN108636916AImprove cleaning efficiencyEnhanced flushingGrass dryingDrying solid materials without heatElectric heatingEngineering

The invention provides a fodder cleaning and drying device for livestock breeding, and relates to the field of agricultural machinery. The fodder cleaning and drying device for livestock breeding comprises a flushing topless box; a fixed sucker is bonded at the bottom of the flushing topless box; an electric extension rod is welded on the side wall of the flushing topless box; the top of the electric extension rod is welded with the bottom of an up-down flushing mechanism; the top of the up-down flushing mechanism is welded with the bottom of a sealing cover; and a top box is welded at the bottom of the sealing cover. In the fodder cleaning and drying device for livestock breeding, the up-down flushing mechanism is provided for cooperating with a peripheral flushing mechanism to stir and clean fodders in a cover net; upper and lower flushing modes are combined to simulate a manual fodder cleaning mode, so that the fodder cleaning efficiency is better; during drying, the cover net is rotated to drive rotation of fodders; centrifugal force is used for spin-drying of the fodders; and meanwhile, a fan blows hot air, generated by an electric heating tube, to the fodders to heat and drythe fodders, so that the cleaning and drying efficiency of the fodders is effectively improved.

Owner:陶令

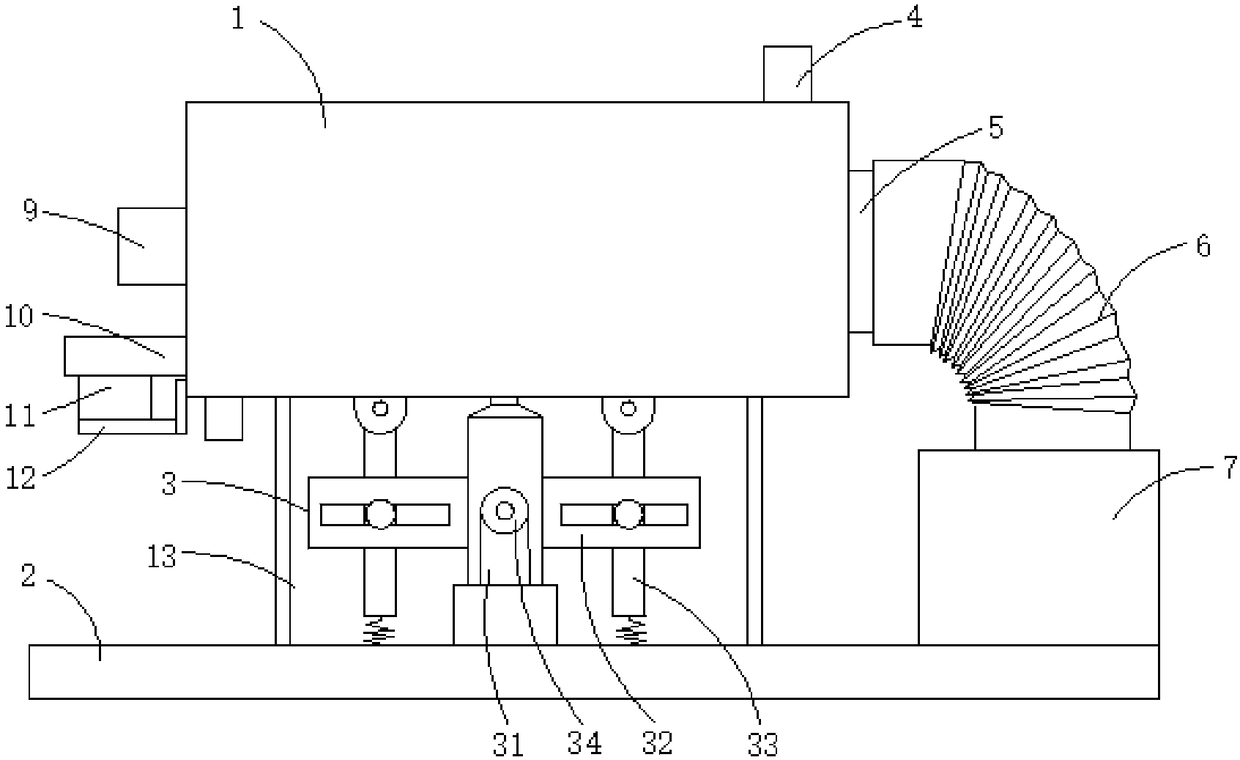

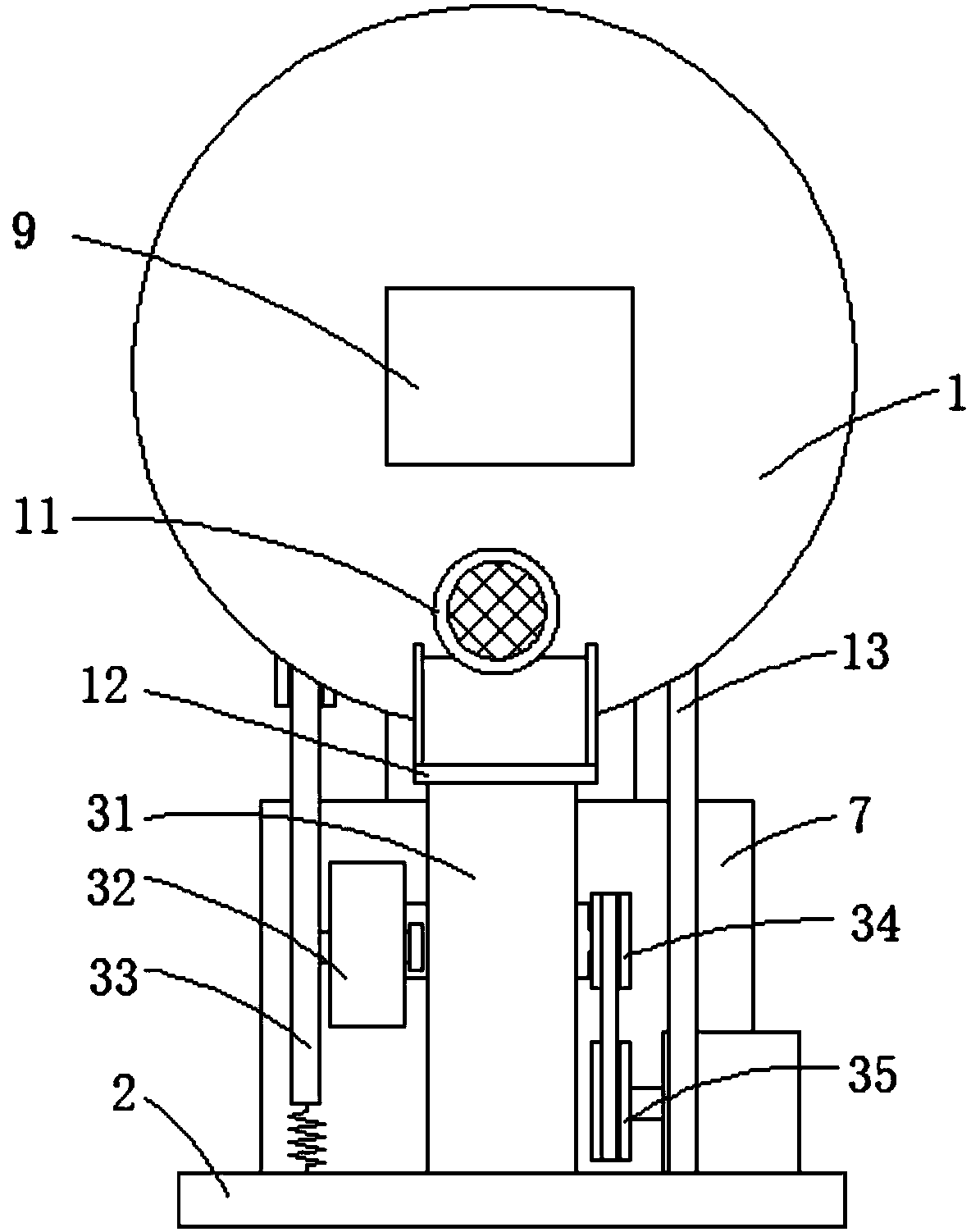

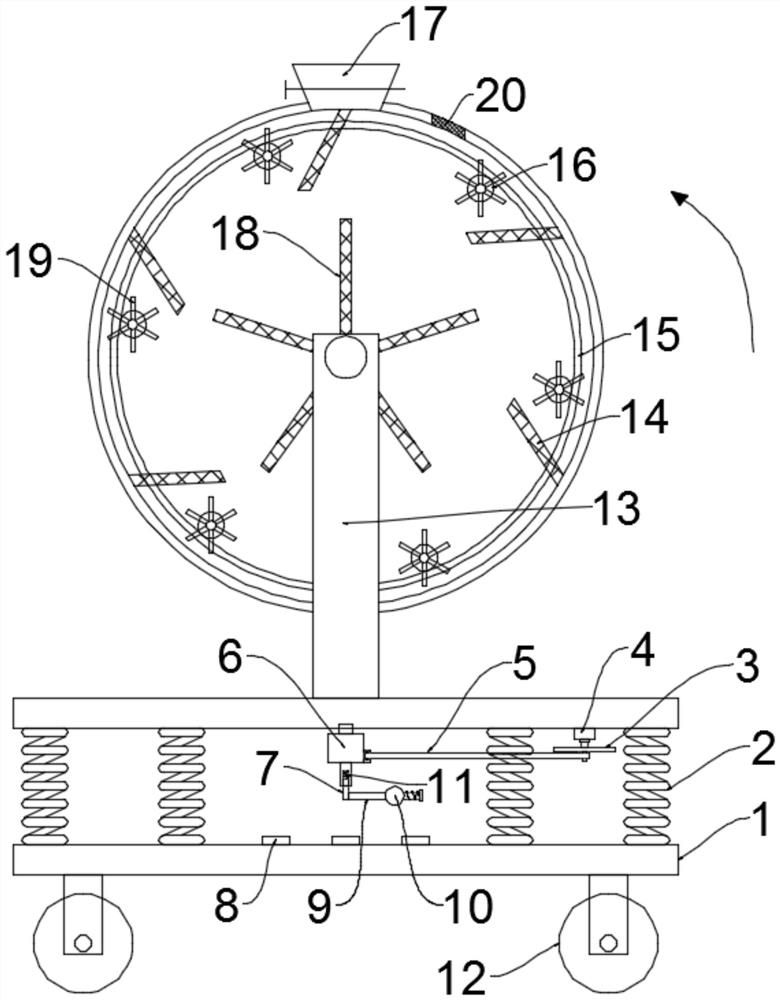

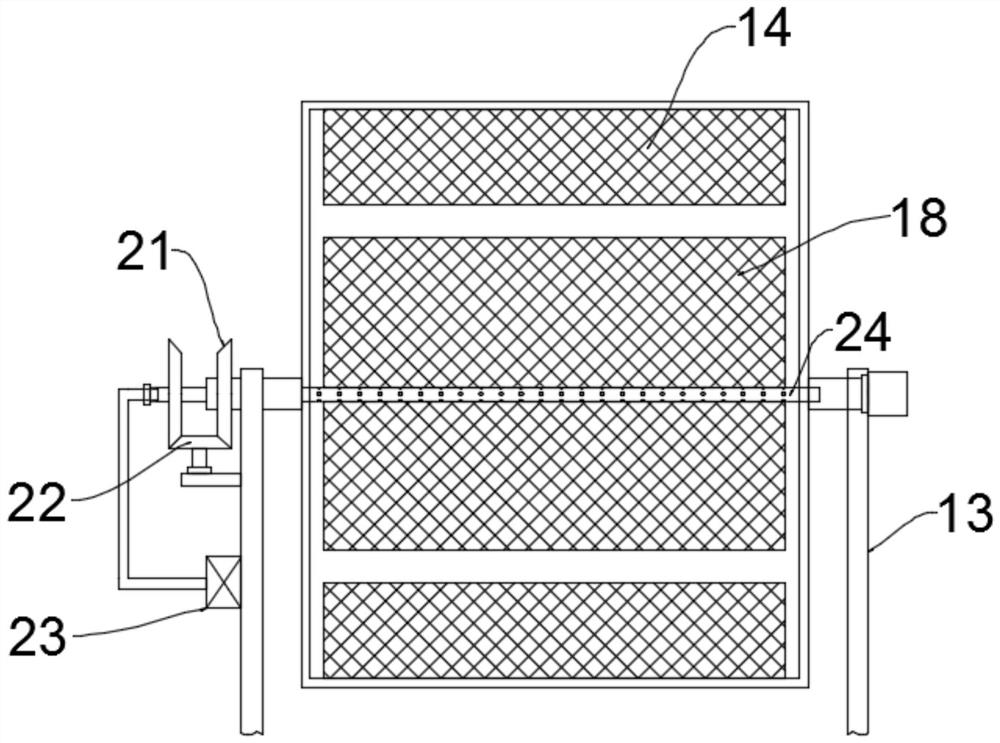

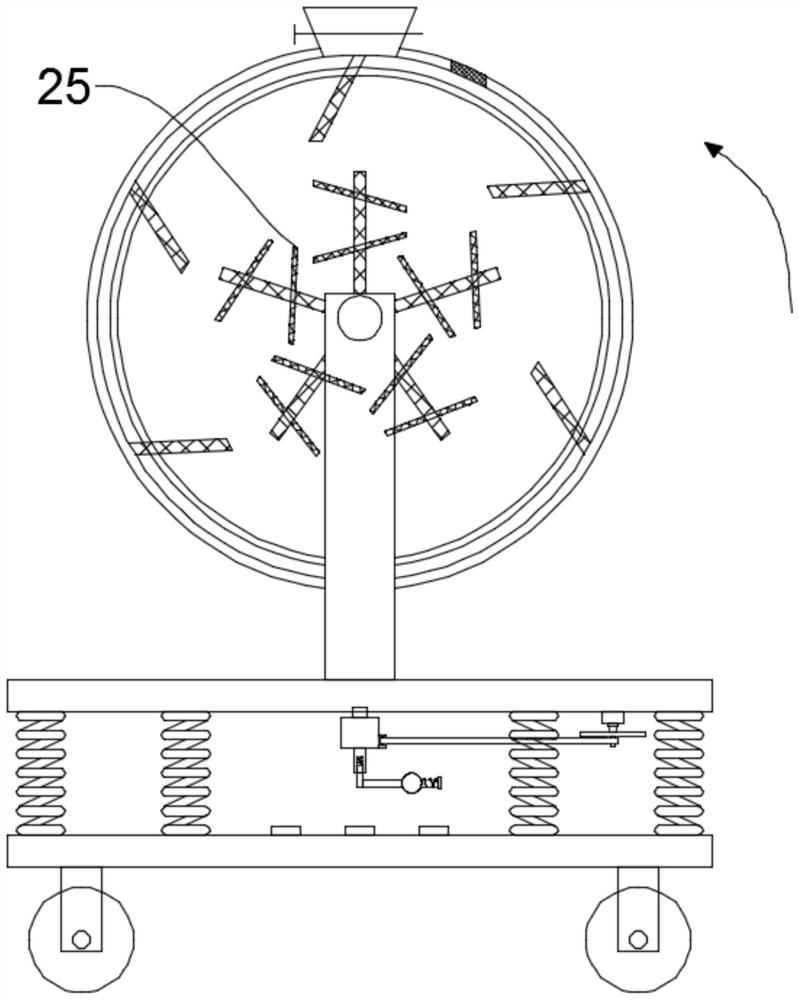

Quick drying granulator for organic fertilizer

PendingCN110732291ADry fastKeep dryDrying gas arrangementsGranulation in stationary drums/troughsAgricultural engineeringOrganic manure

The invention relates to a quick drying granulator for an organic fertilizer. The quick drying granulator comprises a fixed seat, wherein a granulating device is mounted on the upper portion of the fixed seat, the granulating device comprises a fixing frame and a material storage box, an extrusion pipe is arranged on the upper portion of the fixing frame, a flow guide cover is arranged on the upper portion of the extrusion pipe, and the interior of the flow guide cover is communicated to the interior of the extrusion pipe. According to the invention, by combining the granulating device and thewind power and heat power interactive drying device, the granulating device can prepare the organic fertilizer into the granules, and the wind power and heat power interactive drying device can combine the heat of the heating plate and the wind power generated by the fan to accelerate the drying of the high-humidity organic fertilizer particles produced by the granulating device under the combined action of high temperature and airflow in the rolling down process through the flow guide pipe, so that the wet organic fertilizer particles are prevented from being dried and hardened together so as to improve the quality of the organic fertilizer.

Owner:CHANGCHUN AGRI MACHINERY

Drying assembly line for glass wine bottle recycling

ActiveCN111006489APlay a buffer roleDrying helpsDrying gas arrangementsDrying machines with progressive movementsWine bottleWater flow

The invention discloses a drying assembly line for glass wine bottle recycling. The drying assembly line structurally comprises an air blower, a drying machine body, a glass wine bottle, a chain plateconveyor, an inclined plate and a water collecting tank; the chain plate conveyor is arranged in the drying machine body; and the air blower is arranged on the chain plate conveyor. According to therecycled glass wine bottle drying assembly line, the glass wine bottle can be inversely inserted into a placing rod; since the glass wine bottle is inversely arranged, water on the inner wall of the bottle can slide down more easily, and therefore, the drying of the glass wine bottle is facilitated; an upper inflator and a lower inflator in the placing rod are used for inflating discontinuously; gas can be obliquely blown to the inner wall of the glass wine bottle, so that the water on the inner wall of the glass wine bottle can be guided out quickly, and therefore, the drying efficiency of the glass wine bottle can be further improved; a water receiving hopper can receive the water flowing out of the bottle, so that the water can be effectively prevented from dropping on the chain plate conveyor, and the chain plate conveyor can be prevented from being damaged; and the water in the hopper can be poured out along with the change of the conveyor and is prevented from being left in the hopper.

Owner:吴楚元 +1

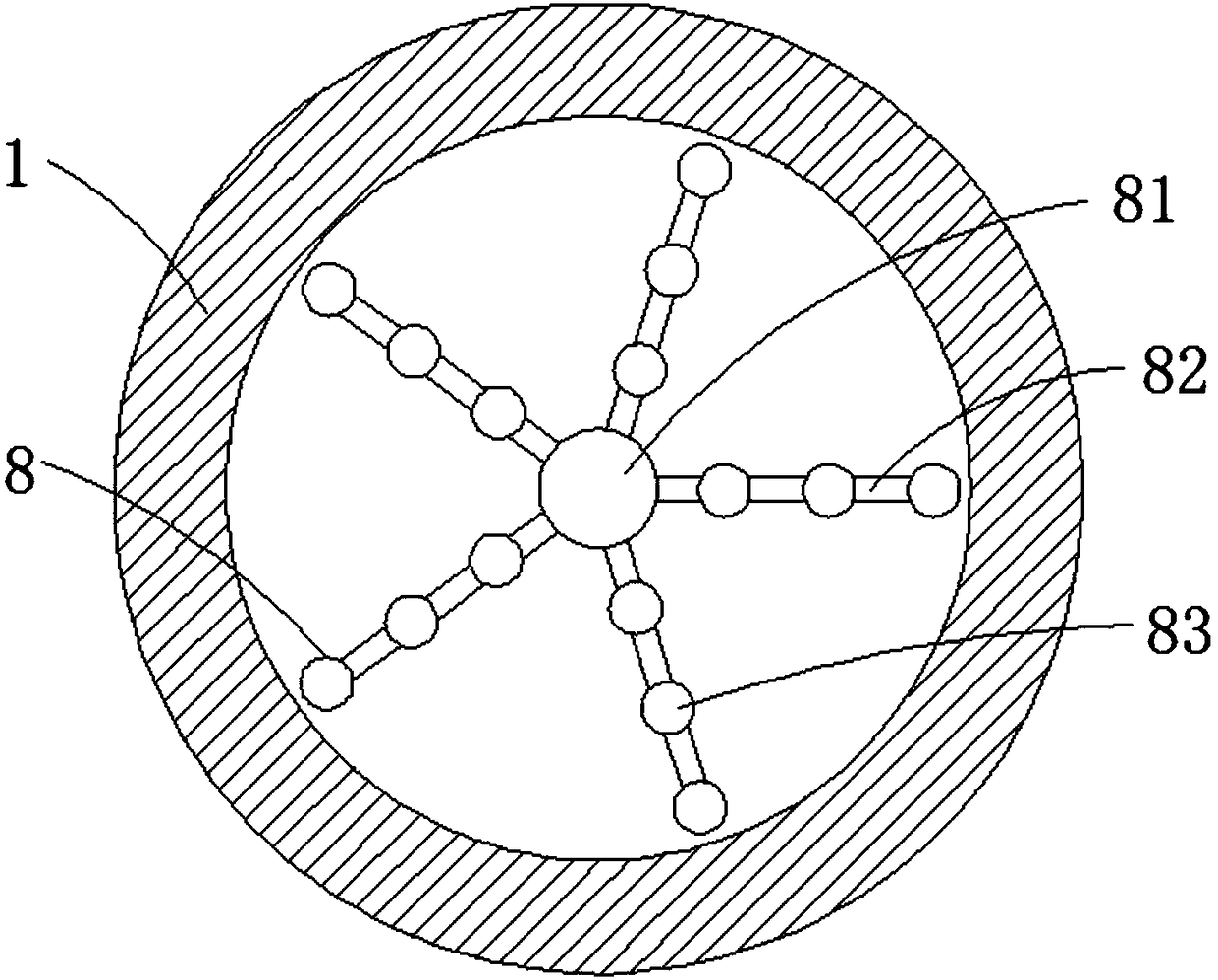

Drying device for fluororesin particle production

InactiveCN108534492AImprove drying efficiencyFacilitate mobilityGranular material dryingDrying gas arrangementsAir heaterEngineering

The invention discloses a drying device for fluororesin particle production. The drying device for fluororesin particle production comprises a drying barrel; a base is arranged on the lower side of the drying barrel, and a swinging device is connected between the drying barrel and the base; a feeding port is formed in the top of the end, away from the swinging device, of the drying barrel, and anair inlet is formed in the end, close to the feeding port, of the drying barrel; the end, away from the drying barrel, of the air inlet is connected with a corrugated pipe; the end, away from the airinlet, of the corrugated pipe is connected with an air heater; a stirring device is arranged in the drying barrel, and comprises a stirring rotating shaft, stirring rods and stirring balls; the stirring rotating shaft is rotationally connected in the drying barrel; the uniformly distributed stirring rods are arranged on the outer side of the stirring rotating shaft; each stirring rod is provided with the corresponding stirring balls at equal intervals; and a stirring motor is installed at the end, away from the air inlet, of the drying barrel through a screw. According to the drying device forfluororesin particle production, fluororesin particles are dried through hot air, in the drying process, the stirring device and the swinging device are used for increasing flowing of the fluororesinparticles, and the drying efficiency is improved.

Owner:湖州和轩翥新材料科技有限公司

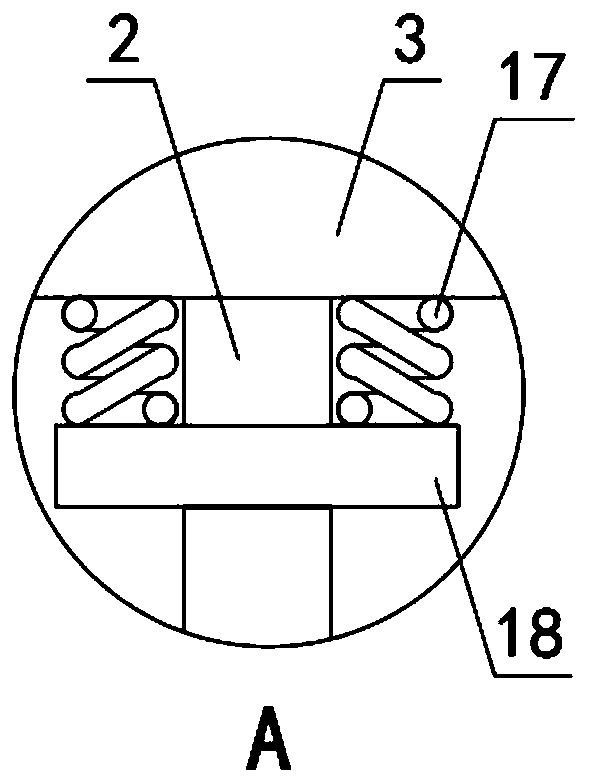

A processing device for processing Coptidis rhizome decoction pieces and processing technology based on the device

ActiveCN112902610BWide range of changesEnhance the shake effectInorganic non-active ingredientsDrying gas arrangementsVibration amplitudeStructural engineering

The invention discloses a processing device for processing Coptis chinensis pieces, which comprises a bottom plate, a mounting plate and a drying unit. The dry cylinder, the first net plate, the second net plate and the hollow rotating shaft, the vibration assembly is connected between the installation plate and the bottom plate, and the vibration assembly includes a first spring, a first motor, a horizontal slide bar and a rotating ball , equipped with a shaking component, vibrating in the circumferential direction, so that the flaky coptis to be dried can fully move, and the shaking amplitude changes, which improves the shaking effect and is helpful for drying; it is equipped with a drying unit, which circulates repeatedly to make the flaky coptis The continuous movement helps the hot air to fully and evenly contact the flaky coptis, reduces the accumulation of the flaky coptis, and improves the drying efficiency. The invention also discloses a processing process based on the processing device, which can well remove Pesticide residues, more green and safe.

Owner:广东汇群中药饮片股份有限公司 +1

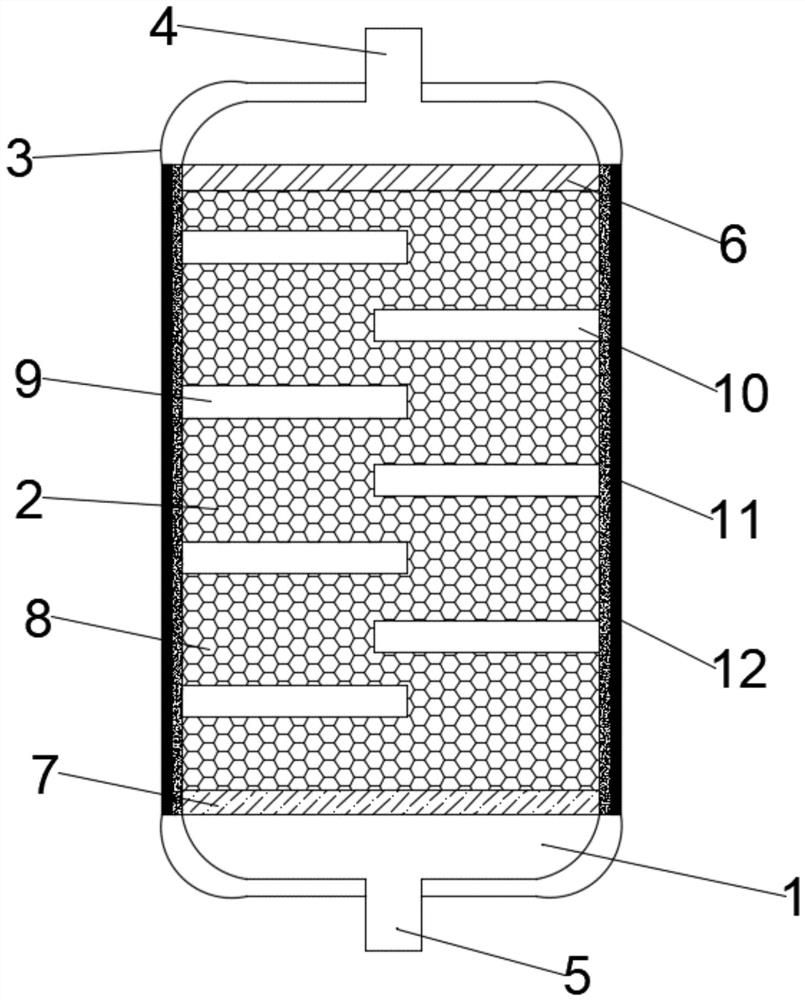

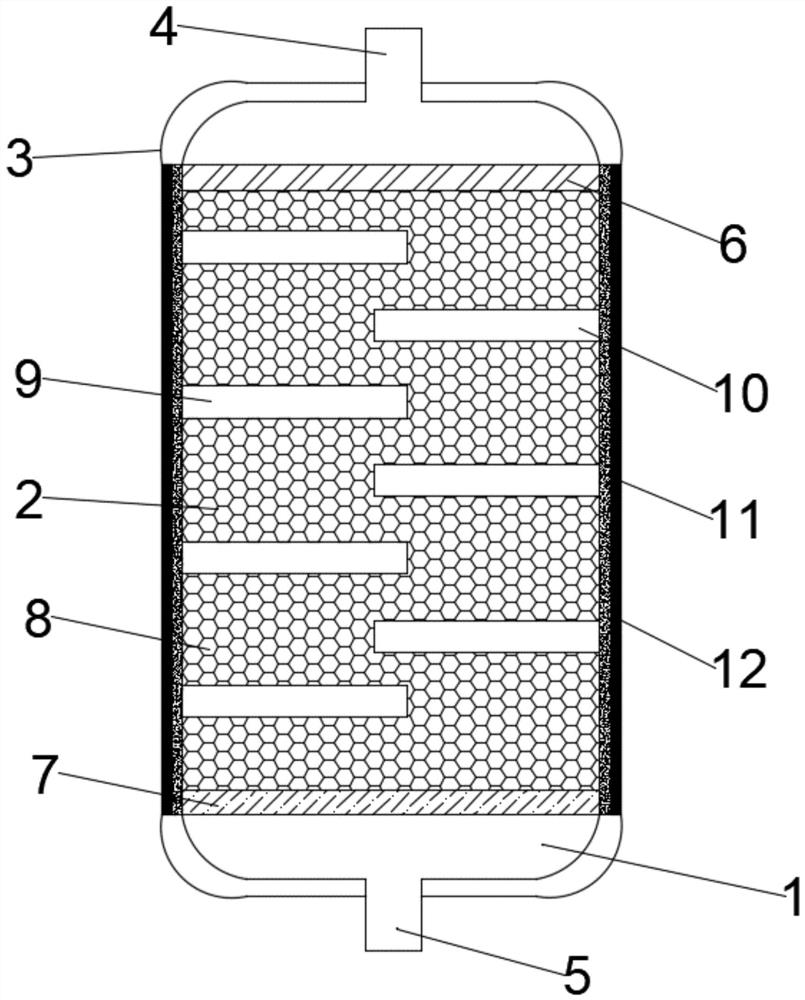

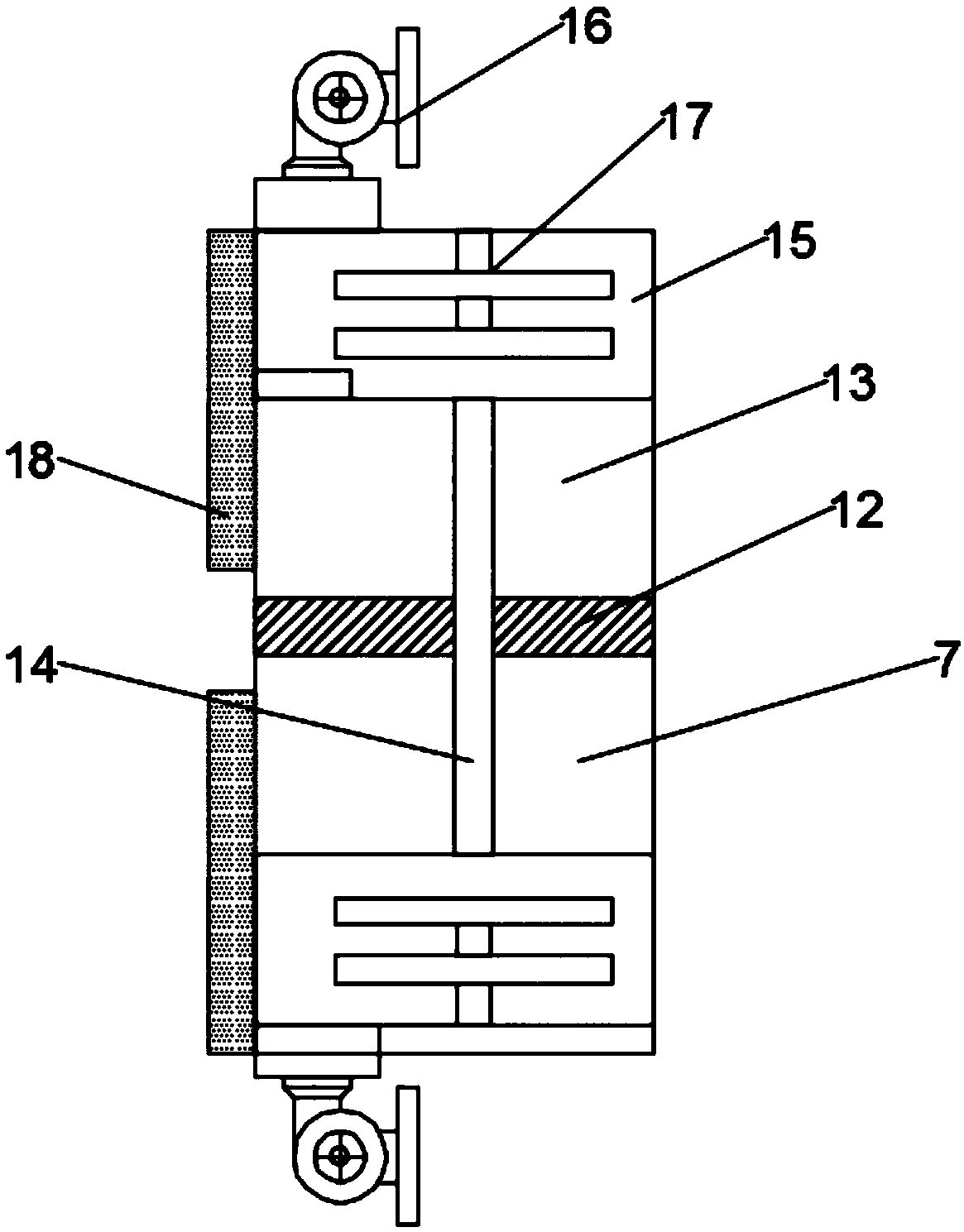

A high-efficiency continuous medicine drying device

ActiveCN113405326BDrying helpsKeep dryDrying solid materials without heatDrying machines with local agitationInsulation layerDesiccant

The invention relates to a high-efficiency and continuous medicine drying device, which comprises a drying device body, the drying device body includes a device cavity and a device shell arranged on the surface of the device cavity, a discharge port is arranged at the upper port of the device cavity, and the device The lower port of the cavity is provided with a feed port, the inside of the device cavity is provided with a deflector on the side close to the discharge port, and the side of the device cavity close to the feed port is provided with a diffuser, a deflector and A desiccant is filled between the diffuser plates. The present invention prepares a kind of medicine drying equipment, which can have a good drying effect on gas or volatile medicines, and overcomes the relatively high risk, low dehydration efficiency and poor dehydration effect existing in the drying of gas medicines. Defects. The diffuser plate, deflector plate and desiccant provided in the present invention all contribute to the drying of the gas, and the purpose of the heating layer and the thermal insulation layer is to provide a suitable drying environment for the drying device.

Owner:北京市永康药业有限公司

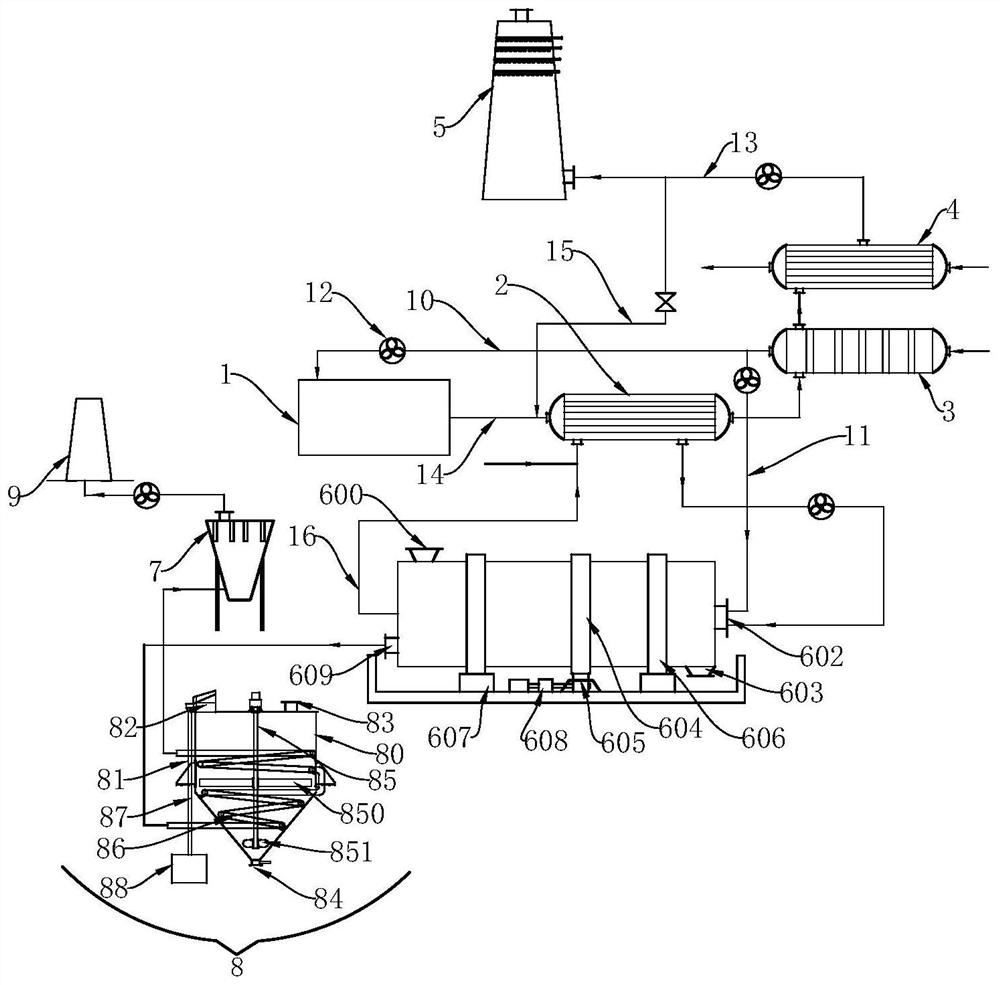

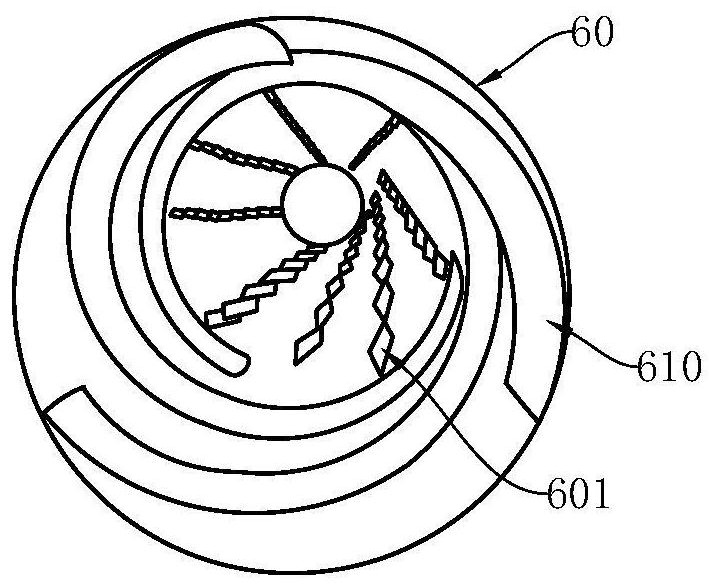

Comprehensive waste heat utilization device in zero-water sodium metasilicate production process

PendingCN113670061AEasy to transportAvoid destructionEmission preventionDrying gas arrangementsSodium metasilicateDust control

The invention relates to the technical field of inorganic silicide production, in particular to a comprehensive waste heat utilization device in the zero-water sodium metasilicate production process, the comprehensive waste heat utilization device comprises a hot blast stove, a flue gas outlet of the hot blast stove is communicated with a heating medium inlet of a first heat exchanger, and a heating medium outlet of the first heat exchanger is communicated with a heating medium inlet of a second heat exchanger; a heating medium outlet of the second heat exchanger is communicated with a heating medium inlet of a third heat exchanger; a heating medium outlet of the third heat exchanger is communicated with a desulfurization tower; and a preheated air outlet of the first heat exchanger is communicated with an air inlet of a dryer, an air outlet of the dryer is communicated with a bag-type dust collector, an exhaust outlet of the bag-type dust collector is communicated with a pulping tank, and an exhaust outlet of the pulping tank is communicated with a dedusting chimney. By the adoption of the whole comprehensive waste heat utilization device, heat of high-temperature flue gas and heat of hot air extracted in the drying process of the dryer are recycled, and resource waste is avoided.

Owner:山东龙港硅业科技有限公司

Hard matrix biochip drying tool

ActiveCN100582625CPerformance is not affectedAccelerate evaporationDrying machines with non-progressive movementsTemperature controlEngineering

The invention discloses a method for drying a hard-substrate biological chip and a drying tool thereof. The method comprises the following technical proposal: (1) the chip drying tool is started; temperature is set between 22 and 37 DEG C and is balanced for 8 to 15 minutes; (2) the hard-substrate biological chip is put to a mould of the drying tool; the centrifugal rotational speed is between 2,000 and 5,000 rmp; and the hard-substrate biological chip is subjected to centrifugal rotation for 5 to 40 minutes. The chip drying tool used in the method for drying the hard-substrate biological chip comprises a shell, an inner liner and a top cover; a motor is arranged between the shell and the inner liner; a rotating shaft of the motor runs through the liner wall of the inner liner, and extends into a chamber of the inner liner; the rotating shaft of the motor is connected with a rotary arm; two ends of the rotary arm are connected with a mould bracket respectively; a mould is arranged on each mould bracket; the mould is provided with densely distributed macropores; and the macropores run through the bottom of the mould through small pylomes running through the bottom. The periphery of the inner liner is provided with a temperature control module. Through the chip drying tool and the matched mould, the drying method utilizes centrifugal force to firstly fully throw closed liquid remained on the surface of the chip off the chip and fully evaporate less moisture remained on the surface of the chip under the centrifugal vacuum environment in order that the chip achieves the drying effect.

Owner:江苏三联生物工程股份有限公司

Self-drying biomass granulation device

ActiveCN112237886BCompact structureRealize energy sharingDomestic cooling apparatusDrying gas arrangementsThermodynamicsEngineering

The invention discloses a self-drying type biomass particle granulation device, which comprises a box body, a hollow cylindrical rotating seat and a feeding chamber are arranged on the upper part of the partition plate of the box body, and a feeding blade is arranged on the inner wall of the rotating seat , the outer wall of the rotating seat is provided with lifting blades, and the screw rod and the stirring rod are lifted between the cylindrical rotating seat and the feeding chamber. The biomass particle granulating device in the present invention is used for granulating and producing Material drying can complete multiple processes such as secondary stirring, drying, feeding and cooling in the processing of biomass particles, which can improve the drainage performance of materials, and the drying effect is better. In this process, energy sharing of multiple functions can be realized. Replace existing equipment in the actual production of biomass pellets, saving equipment costs.

Owner:桃江县新辉生物质颗粒有限公司

A recycling and reuse glass wine bottle drying line

ActiveCN111006489BPlay a buffer roleDrying helpsDrying gas arrangementsDrying machines with progressive movementsWine bottleWater flow

Owner:王晓霞

Efficient and continuous medicine drying device

ActiveCN113405326ADrying helpsSolve the dangerDrying solid materials without heatDrying machines with local agitationPhysicsDrying Agents

The invention relates to an efficient and continuous medicine drying device. The efficient and continuous medicine drying device comprises a drying device body, wherein the drying device body comprises a device cavity and a device shell arranged on the surface of the device cavity; a discharging opening is formed in the upper end opening position of the device cavity, and a feeding opening is formed in the lower end opening position of the device cavity; and a flow guide plate is arranged on the side, close to the discharging opening, inside the device cavity, a flow dispersing plate is arranged on the side, close to the feeding opening, inside the device cavity, and the space between the flow guide plate and the flow dispersing plate is filled with a drying agent. According to the medicine drying equipment, the equipment can have a good drying effect on gas or volatile medicine, and the defects that in the prior art, gas medicine drying is large in danger, low in dehydration efficiency and poor in dehydration effect are overcome; and according to the efficient and continuous medicine drying device, the flow dispersing plate, the flow guide plate and the drying agent are arranged, so that gas drying is facilitated, and a heating layer and a heat preservation layer aim at providing a suitable dry environment for the drying device.

Owner:北京市永康药业有限公司

Waste liquid treatment device used after steel slag treatment

PendingCN114288727ADrying helpsAvoid accumulationDispersed particle filtrationStationary filtering element filtersSlagElectric machine

The invention discloses a waste liquid treatment device used after steel slag treatment. The waste liquid treatment device comprises a water tank, a water outlet pipe installed on the water tank and a filter box body fixed to the water tank through a support. According to the device, an electric push rod drives a moving plate to move, after a connecting cover is in butt joint with a second rectangular block, a screw rod rotates in the process that a motor drives a first transmission shaft to rotate, the screw rod is used for butt joint of a flange and a connecting disc, hot air flow generated by a heat pump enters the interior of a filtering box through an air outlet pipe, and fine particles can be dried; under the action of a rotating arm and a touch piece, accumulation of fine particles on a first filter screen can be avoided, drying of the fine particles is facilitated, along with increase of airflow, the dried fine particles enter a collecting shell through a connecting pipe, and under the action of a second filter screen, the fine particles are collected in the collecting shell, so that the collecting effect is improved. Compared with a wastewater treatment device in the prior art, fine particles can be collected in time, so that subsequent wastewater treatment is facilitated.

Owner:郑友能

A color and luster smoke treatment process for wood modification surface

ActiveCN105729597BDrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSurface layer

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

Tea drying equipment and process

InactiveCN110583811AImprove utilization efficiencyAvoid accumulationPre-extraction tea treatmentEngineeringCam

The invention discloses tea drying equipment comprising a drying box, a hot air blower, a drying rack and an opening. The drying box is internally provided with a placing frame, and a placing net is fixed to the inner surface wall of the placing frame; sliding rods are slidably embedded at the four corners of the placing frame; a rotating shaft in the horizontal direction is arranged between the placing frame and the inner surface wall of the bottom of the drying box, and the rotating shaft is sleeved with a cam; and the cam is connected with the placing frame through a spring elastically. Inthe tea drying equipment, the rotating shaft in the horizontal direction is arranged between the placing frame and the drying box, and the rotating shaft is sleeved with the cam; through arrangement of a motor and a belt, the cam can be driven by the rotating shaft to rotate, and through arrangement of the cam and the spring, the placing frame can be vibrated slightly in the vertical direction; tea can be prevented from being stacked in the placing frame effectively, and the interior and exterior of the tea can be effectively prevented from being heated unevenly; and the tea drying equipment benefits drying of the tea.

Owner:HUITONG RUICHUN TEA IND CO LTD

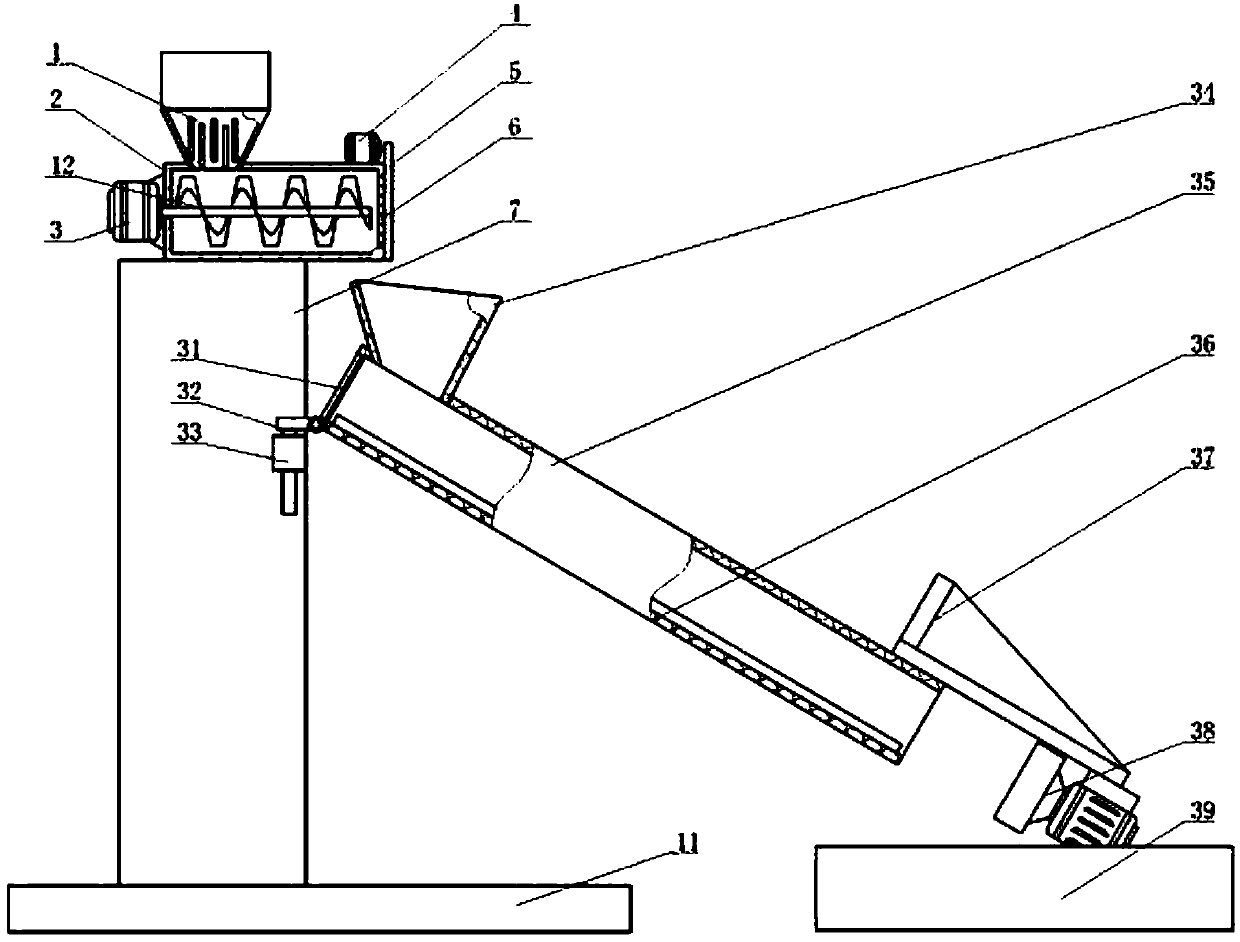

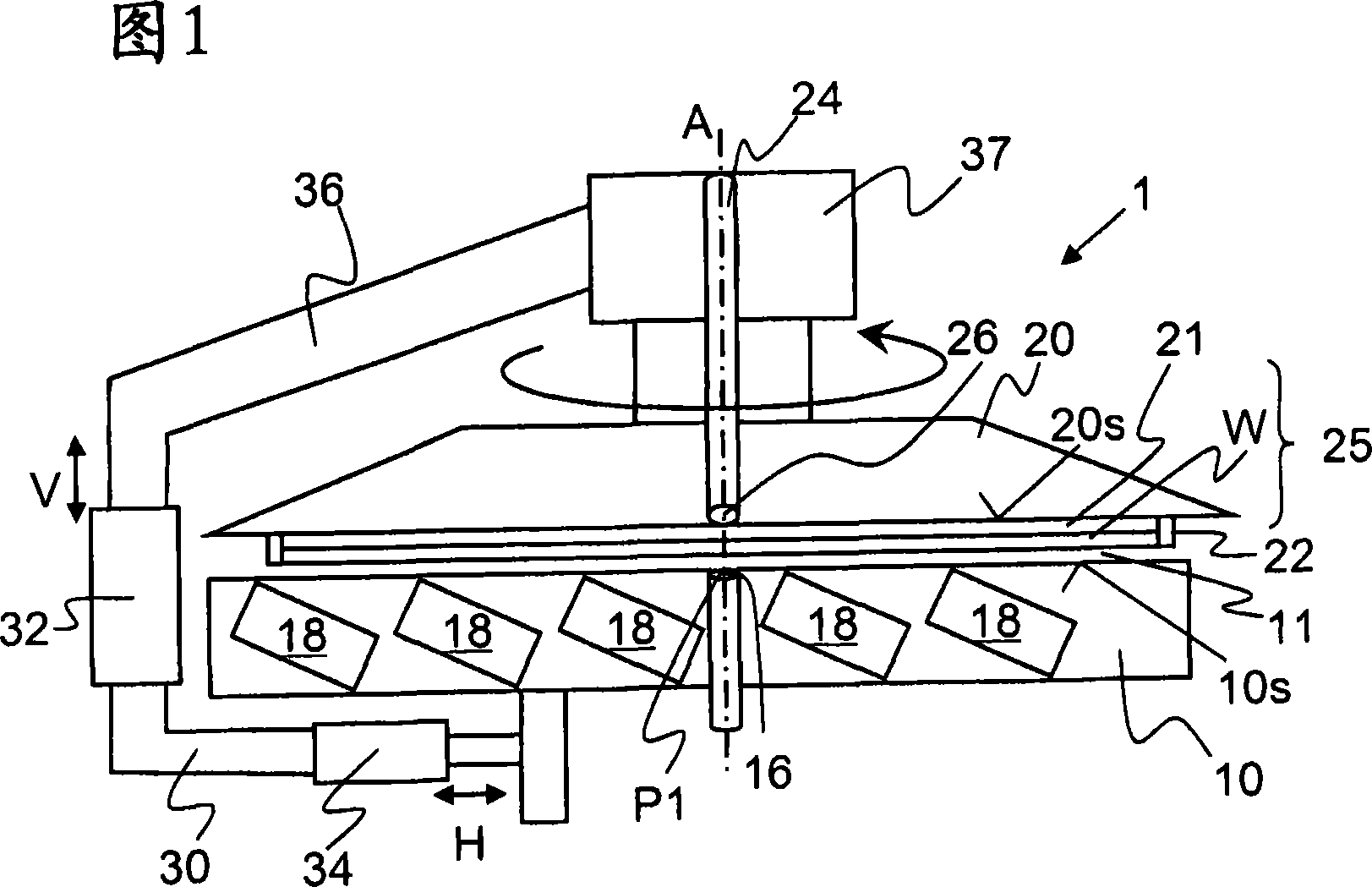

Efficient agricultural grain processing equipment

InactiveCN108645158AQuick drying processGood drying effectSeed preservation by dryingDrying machines with non-progressive movementsAgricultural engineering

The invention discloses efficient agricultural grain processing equipment which comprises a base, a drying cavity and a working motor, wherein supporting racks are fixedly welded to two sides of the base, and the drying cavity is obliquely formed between the supporting racks; the right side of the drying cavity is fixedly connected to a heating device; the working motor is mounted on the left sideof the drying cavity, the output end of the working motor is fixedly connected to one end of a first rotating shaft, the other end of the rotating shaft extends into the inner cavity of the drying cavity, first stirring blades and second stirring blades are mounted in the drying cavity, the four first stirring blades are fixedly connected to the first rotating shaft, and the second stirring blades are arranged among the first stirring blades. The efficient agricultural grain processing equipment disclosed by the invention can dry gains quickly, is good in drying effect, and prevents waste ofthe grains as the grains go bad as a result of moist.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

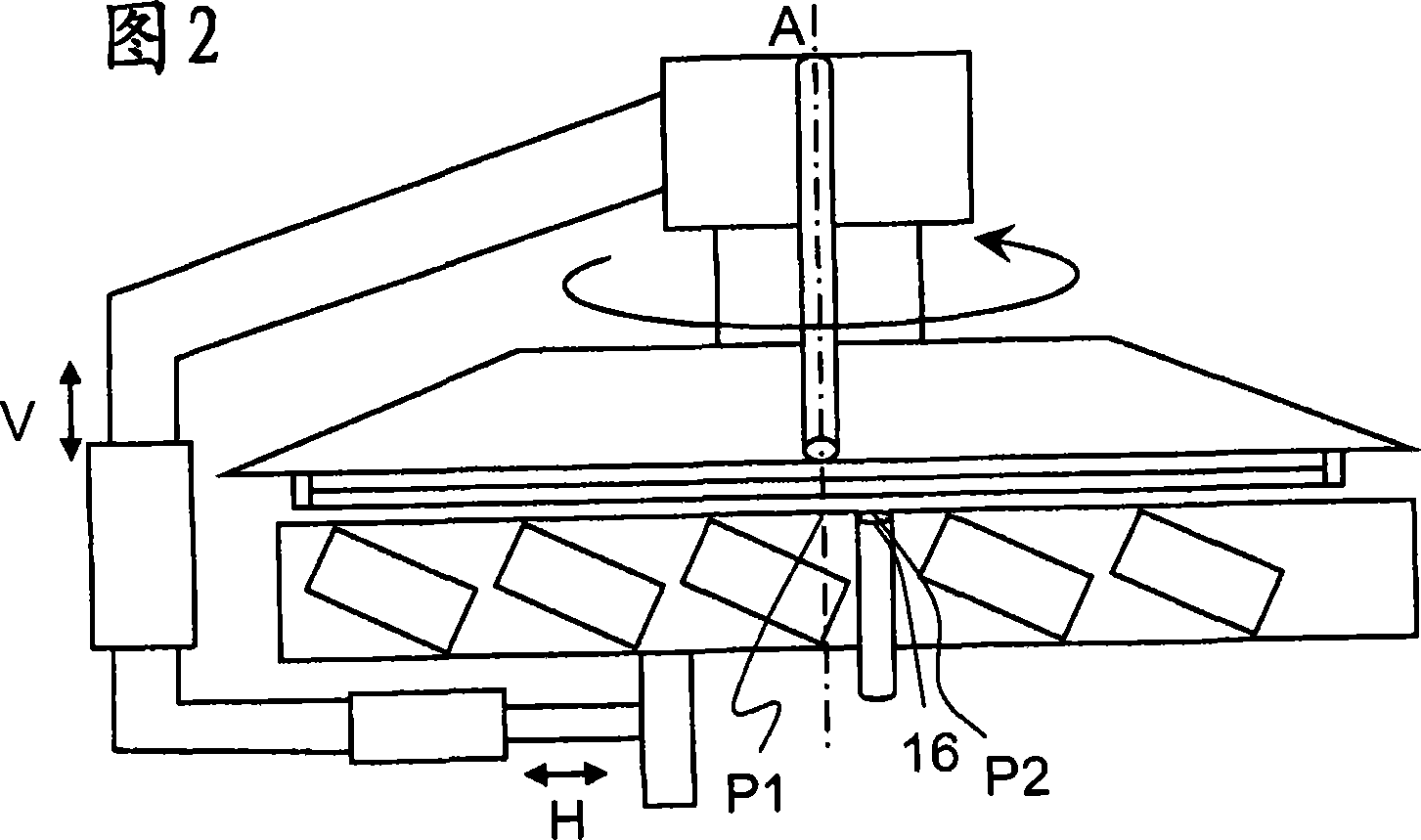

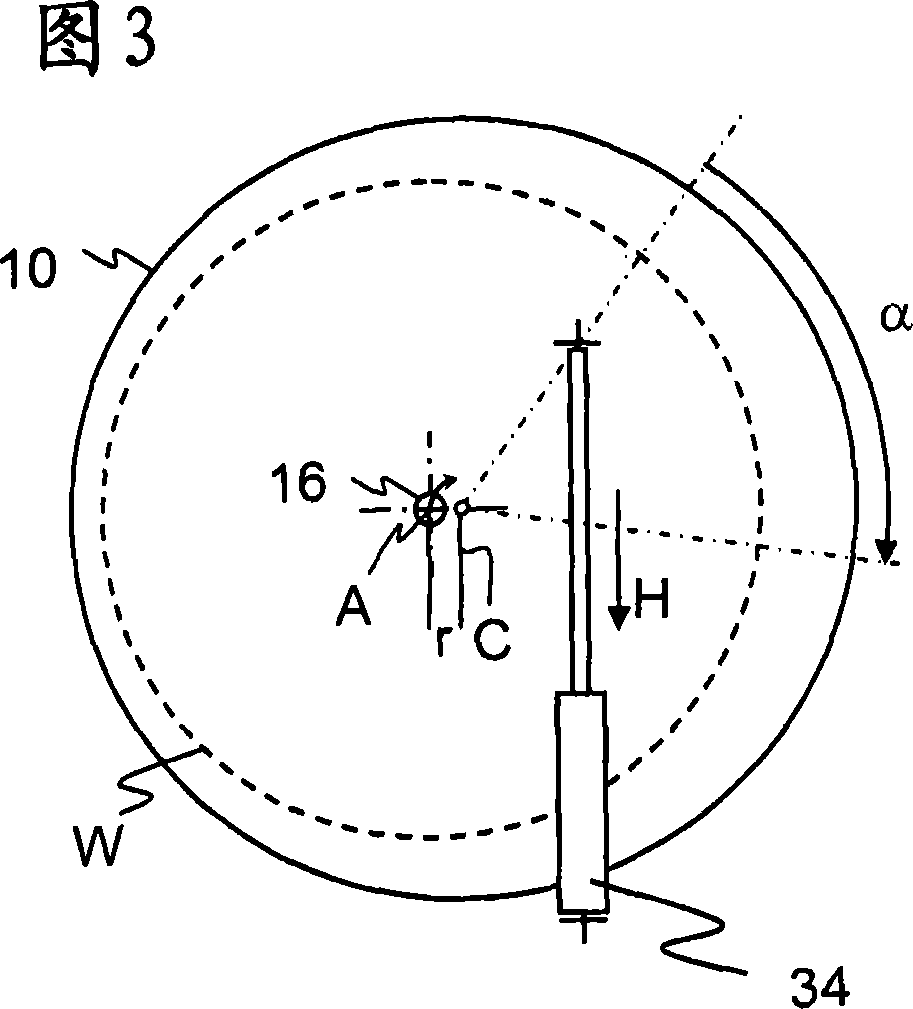

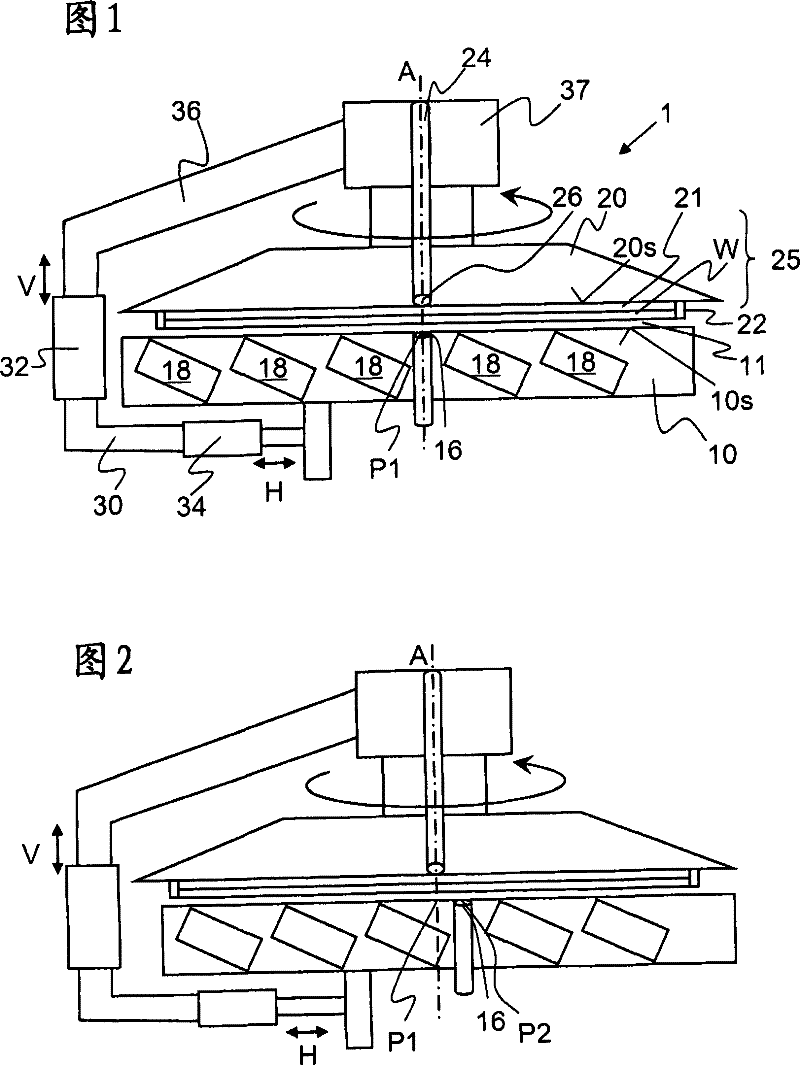

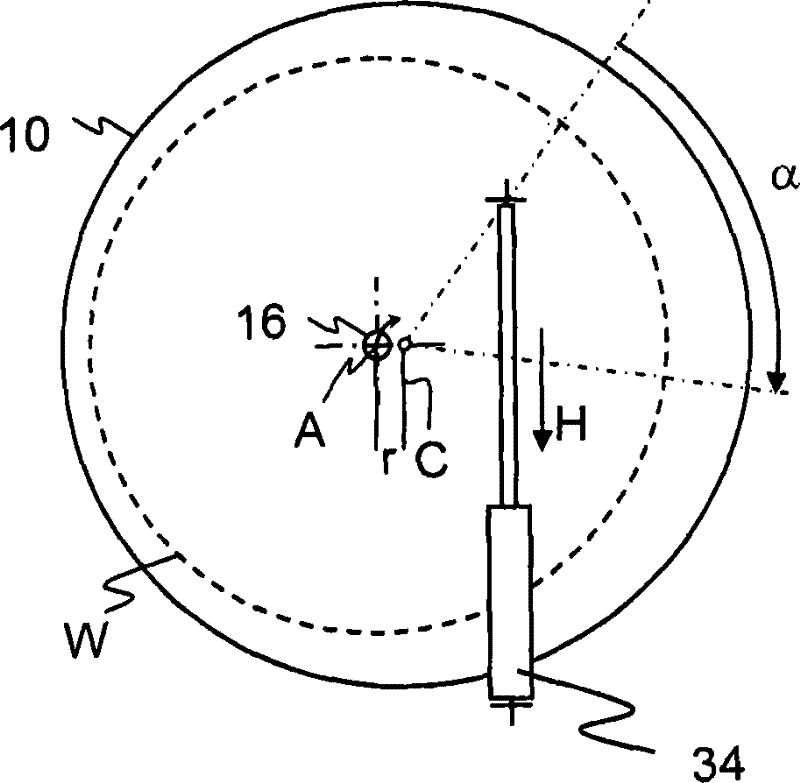

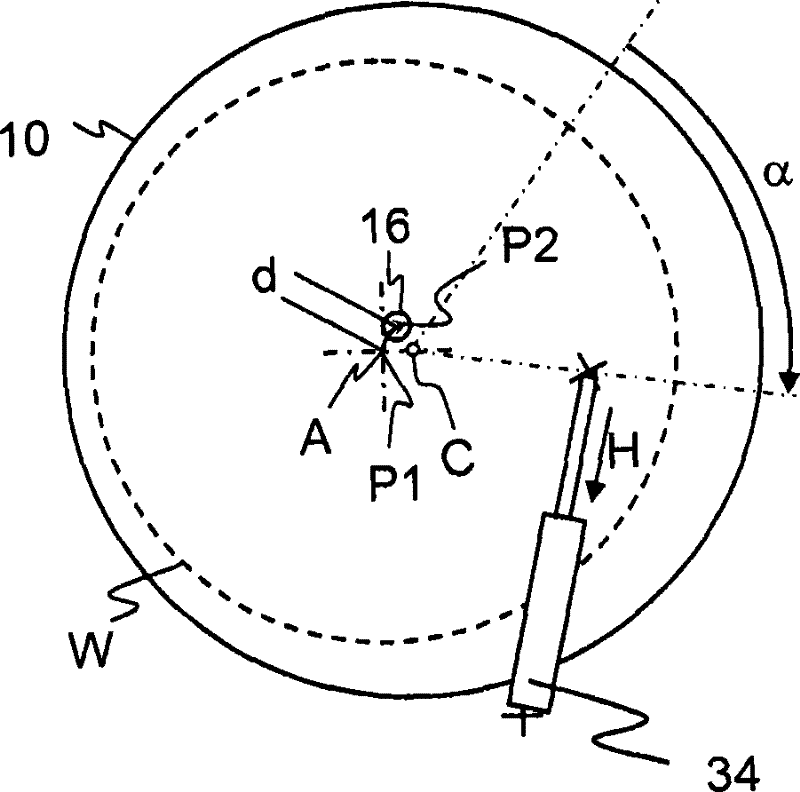

Apparatus method for wet treatment of wafers

InactiveCN101065828ADrying helpsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:LAM RES AG

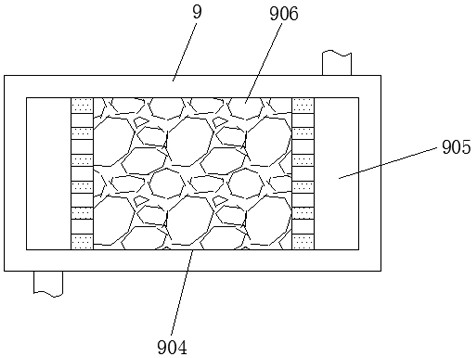

A device for improving the active performance of aggregates for recycled concrete processing

ActiveCN112225479BHigh activityImprove performanceSolid waste managementProcess engineeringSupport plane

The invention discloses a device for improving the active performance of aggregates used in recycled concrete processing, which comprises a pretreatment box, a modified treatment box and a support frame. It runs through the pretreatment box, and the first rotating shaft is engaged with the first gear and the second gear. The first gear is arranged on the first rotating shaft on the left side, and the second rotating shaft is arranged on the first rotating shaft on the right side. gear, the second stirring rod is rotatably connected to the top end of the after-treatment box, and the inner wall of the after-treatment box is provided with a partition, the after-treatment box is arranged behind the modified treatment box, and the treatment box is provided with a drying mechanism. In this device for improving the active performance of aggregates used in recycled concrete processing, part of the waste concrete after screening falls into the modification treatment box as recycled aggregates, which can improve the performance of the aggregates through the reaction of glacial acetic acid and cement hydrate in the recycled aggregates. The role of the surface of recycled aggregate particles, thereby improving the performance of recycled aggregates.

Owner:QINGDAO AGRI UNIV

Apparatus method for wet treatment of wafers

InactiveCN101065828BDrying helpsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:LAM RES AG

Garbage pyrolysis gasification furnace

PendingCN114383136AGuaranteed clean emissionsStable combustionIncinerator apparatusThermodynamicsCombustion chamber

According to the garbage pyrolysis gasification furnace, a first smoke pipe, a second smoke pipe and a third smoke pipe are arranged at the upper end of a garbage pyrolysis chamber, the upper end of a garbage drying chamber and the upper end of a garbage storage chamber correspondingly and communicate with a smoke combustion chamber of a smoke combustion device, so that regulation and control over garbage combustion, garbage pyrolysis and garbage drying are more accurate; the flue gas with different temperatures, different oxygen contents and different water contents can be respectively led out for combustion treatment, the flue gas combustion is stable, clean and efficient, toxic and harmful gases such as dioxin are basically burnt out, and the flue gas is effectively ensured to reach the standard and be discharged cleanly; and garbage combustion, pyrolysis and drying in a garbage combustion chamber, a garbage pyrolysis chamber, a garbage drying chamber and a garbage storage chamber of the garbage pyrolysis gasification furnace can be adjusted and controlled.

Owner:中环国投生态科技股份有限公司 +1

Device for prolonging storage life of camellia fruits

PendingCN112167329AIncrease the gapNormal up and down circulationFruit and vegetables preservationGaseous food ingredientsCold airCamellia oleifera

The invention discloses a device for prolonging the storage life of camellia oleifera fruits, and belongs to the technical field of camellia oleifera storage. The device comprises a box body, a desiccation assembly and a controller, the box body is provided with a cold air injection assembly which communicates with an adjusting cavity and a carbon dioxide injection assembly, one end of the desiccation assembly communicates with the upper portion of the adjusting cavity, the other end of the desiccation assembly is connected with an air distribution box, the controller is arranged on the box body and electrically connected with a temperature sensor, a humidity sensor and a carbon dioxide sensor, a spraying assembly is arranged on a portion, on the upper side of a supporting frame, in a storage cavity, a sterilizing assembly is arranged at the top of the box body and is connected with the spraying assembly through a pipeline, and a drying assembly is arranged on the desiccation assembly.The temperature, the humidity, the carbon dioxide concentration and the oxygen concentration in the box body can be effectively controlled, and a mould bactericide can be sprayed regularly to inhibitand kill moulds on the camellia oleifera fruits, so that the storage life of the camellia oleifera fruits is greatly prolonged.

Owner:贵州石阡佛顶山野生油茶油业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com