Patents

Literature

50results about "Grass drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weeding machine facilitating weed storage for agricultural production

PendingCN108901315AStir wellAvoid damageGrass dryingDrying solid materials without heatEngineeringWeed

The invention belongs to the technical field of a weeding machine, in particular to a weeding machine facilitating weed storage for agricultural production. Against the problems that a device lacks aweed collecting device, there is no link for fertilization after weeding, and the device is complicated in structure, the operation is relatively tedious, and solar energy is not made good use of, thefollowing scheme is provided, the weeding machine includes a base, anti-vibration pads are fixed on the outer wall of four corners at the bottom of the base through bolts, universal wheels are fixedon the outer walls of the bottoms of the four anti-vibration pads through bolts, a mounting frame is welded to the outer wall of the top of the base, an electric push rod is fixed on the inner wall ofthe top of the mounting frame through a bolt, a mounting plate is fixed at one end of an electric push rod extension rod through a screw, and two fixed plates are welded to the outer wall of the bottom of the mounting plate. The weeding machine can fuse a pesticide and water in a water tank, an insecticidal effect after weeding is achieved well, rotating knives can be driven to move up and down,and thus weeds of different heights can be cut.

Owner:兰州集智信息技术有限公司

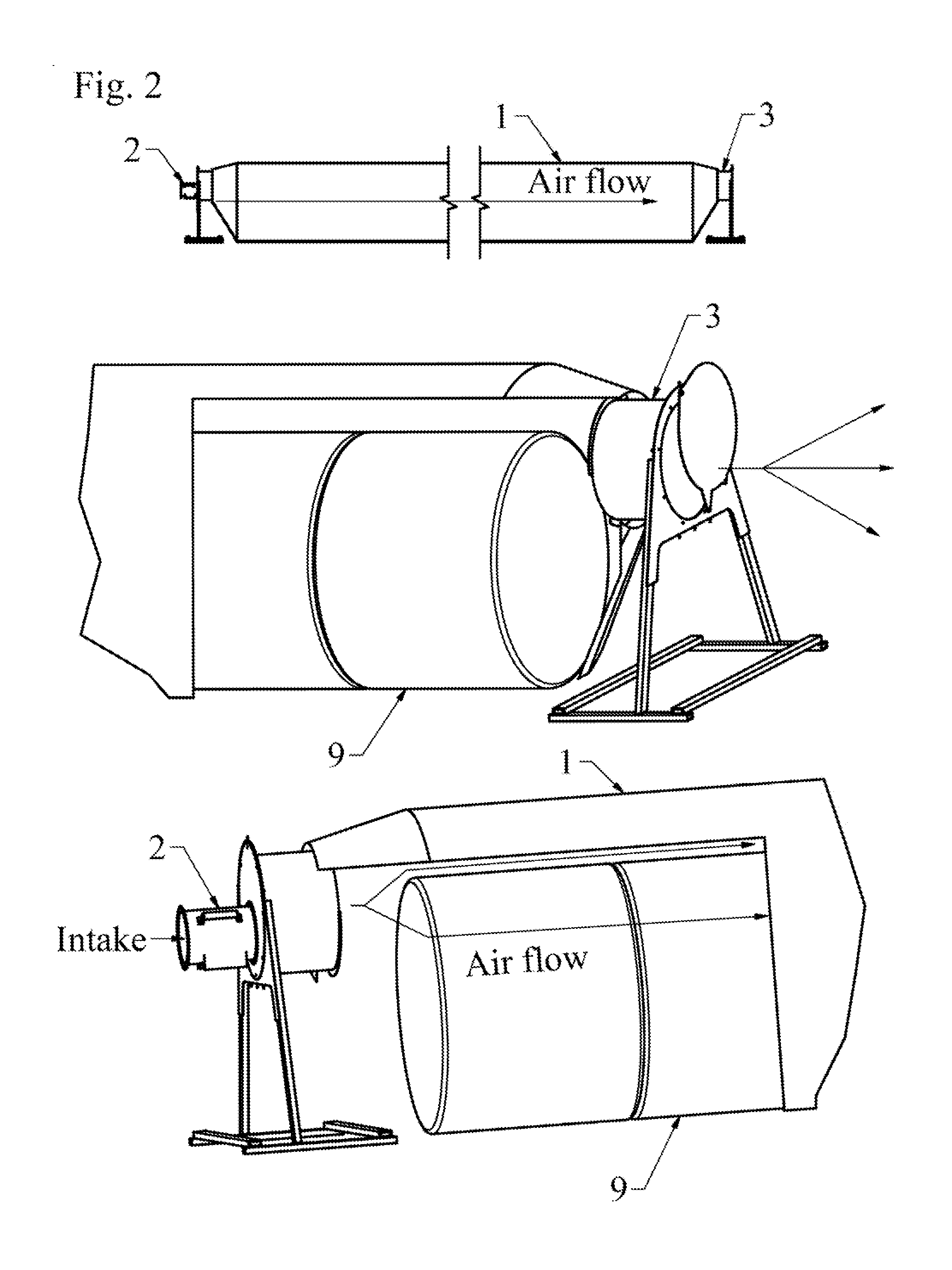

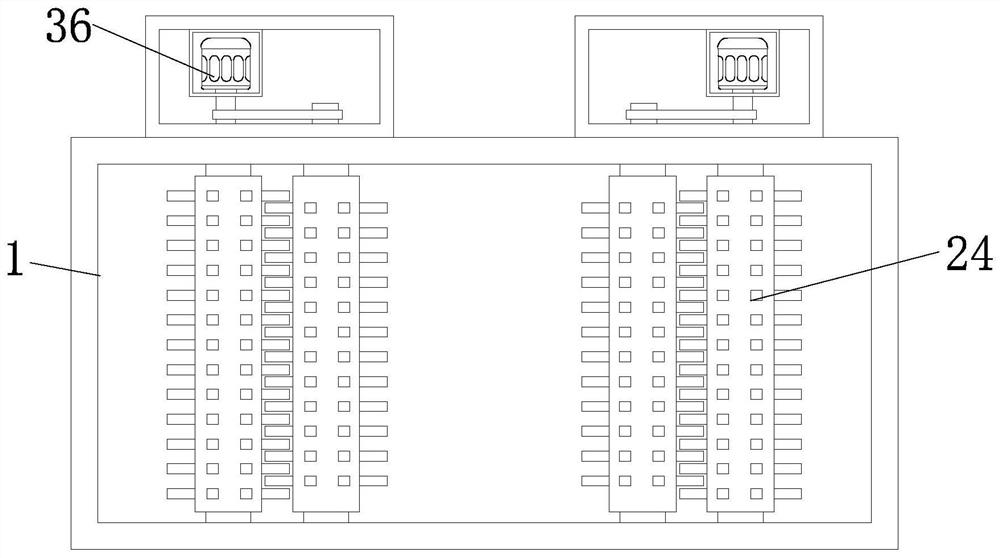

Hay Storage System

InactiveUS20140007451A1Maximize curingUndesired heat buildupDrying using combination processesAgriculture tools and machinesFiberEngineering

A device and method for storing, curing, drying hay and other fibrous plant materials which includes a flexible water impermeable bag, as injection means at one end and an adjustable vent at the opposite end, and preferably spacer means between stacks of baled materials. The bales are progressively loaded at one end as the bag is unrolled and extended progressively laterally for additional bales. After loading, the gas injection and vent means are connected at ends of the bag and are adjusted to generate a back pressure within the bag to partially inflate it. The flowrate of gas or air is adjusted to maintain the temperature within the bales within an optimal range, preferably between ambient temperature and 120 degrees Fahrenheit enabling beneficial curing until sufficient moisture has been removed to prevent mold growth.

Owner:BROWN JR OWEN JACKSON

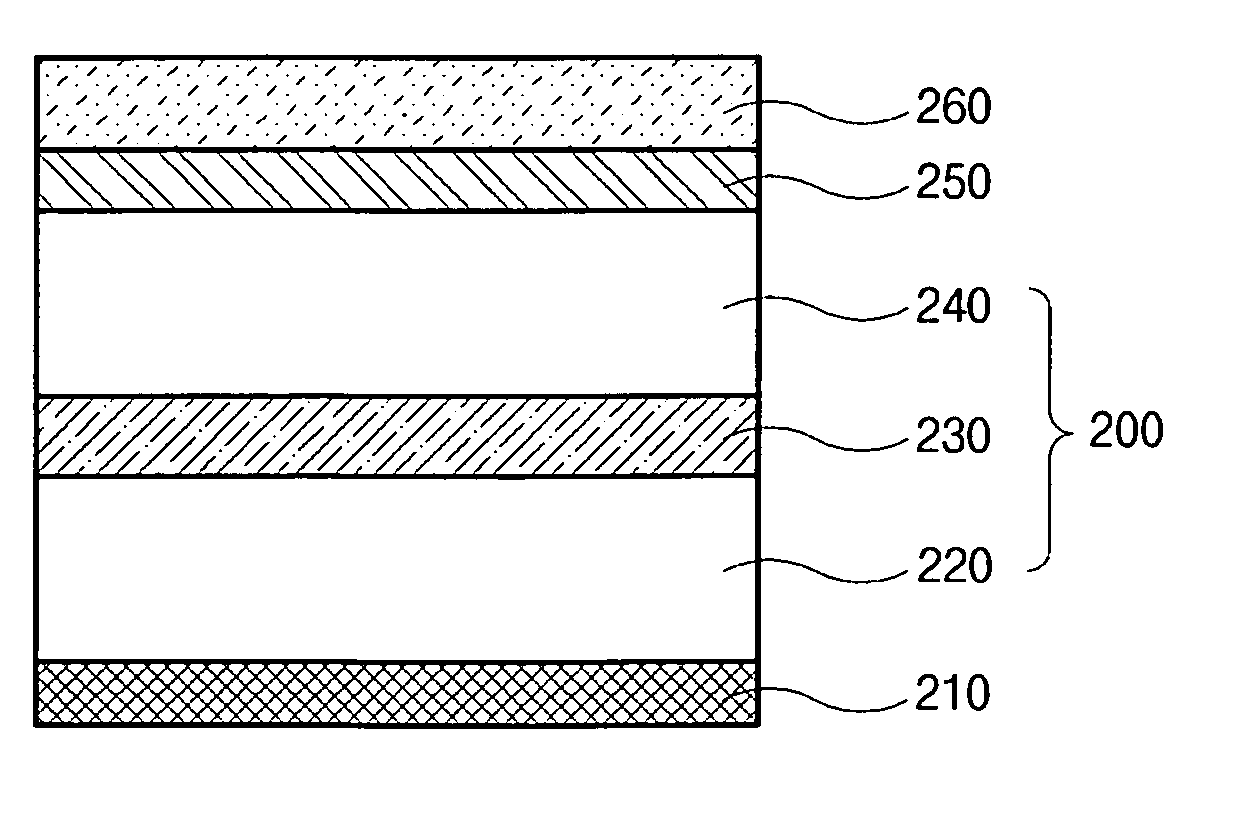

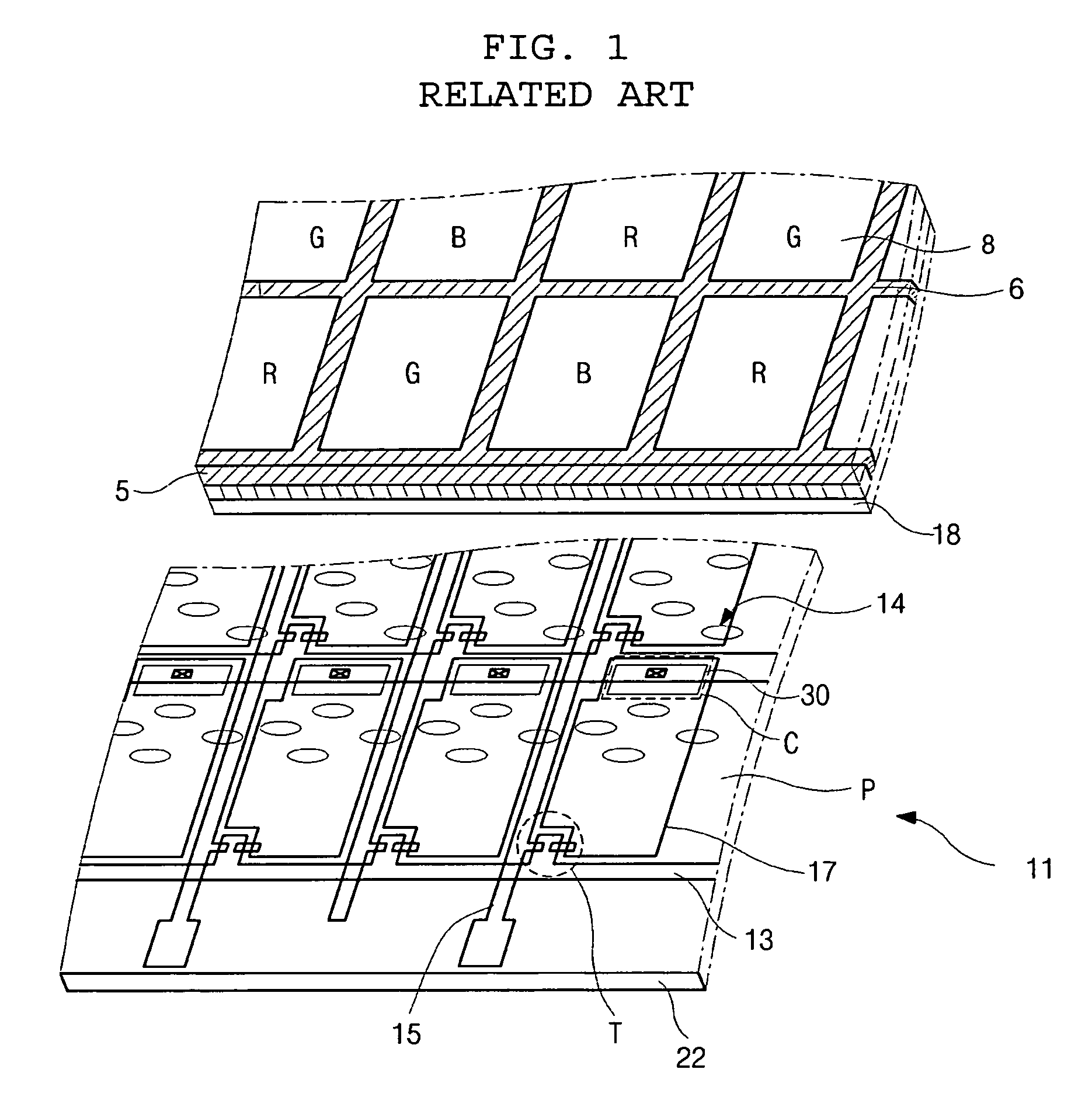

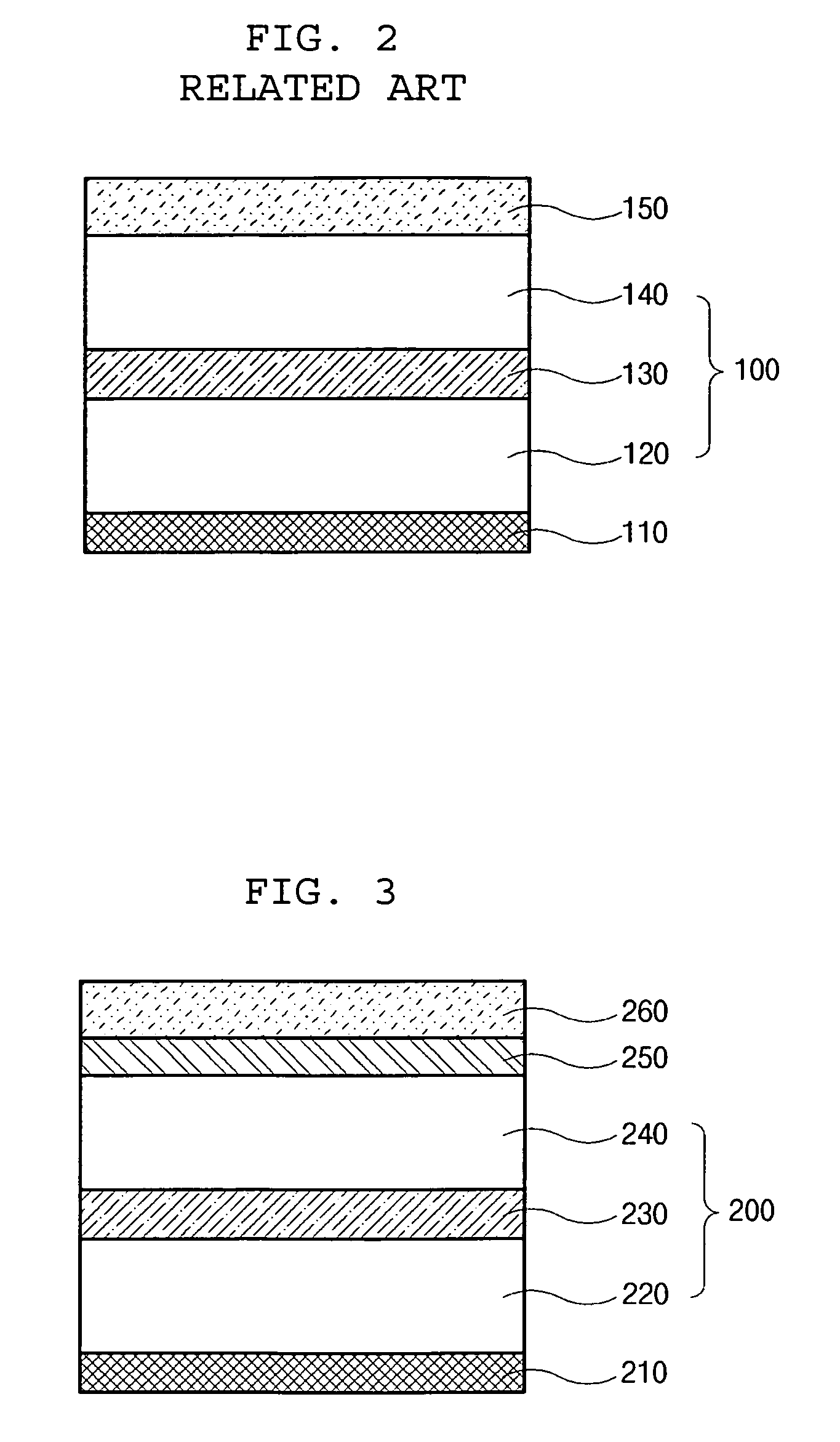

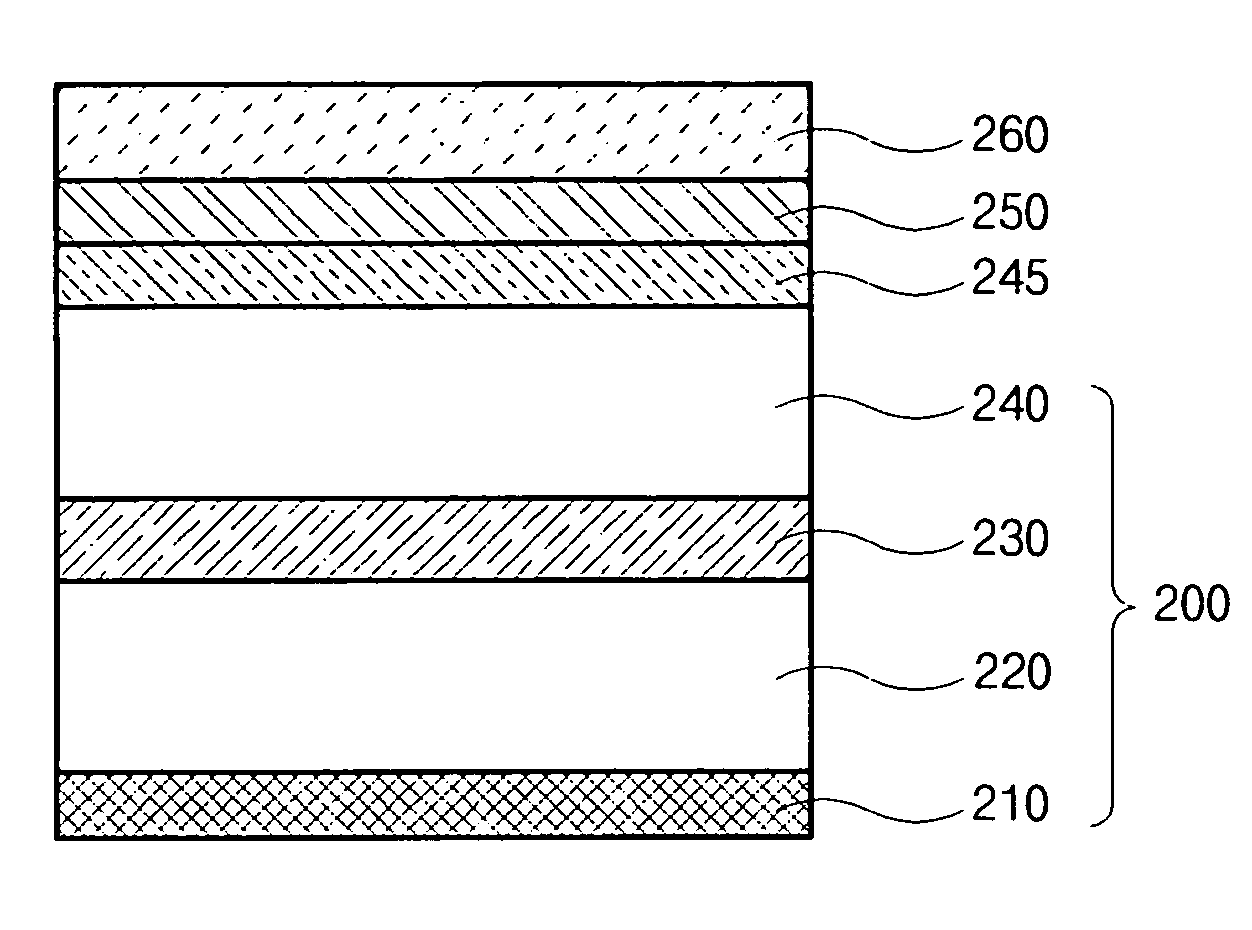

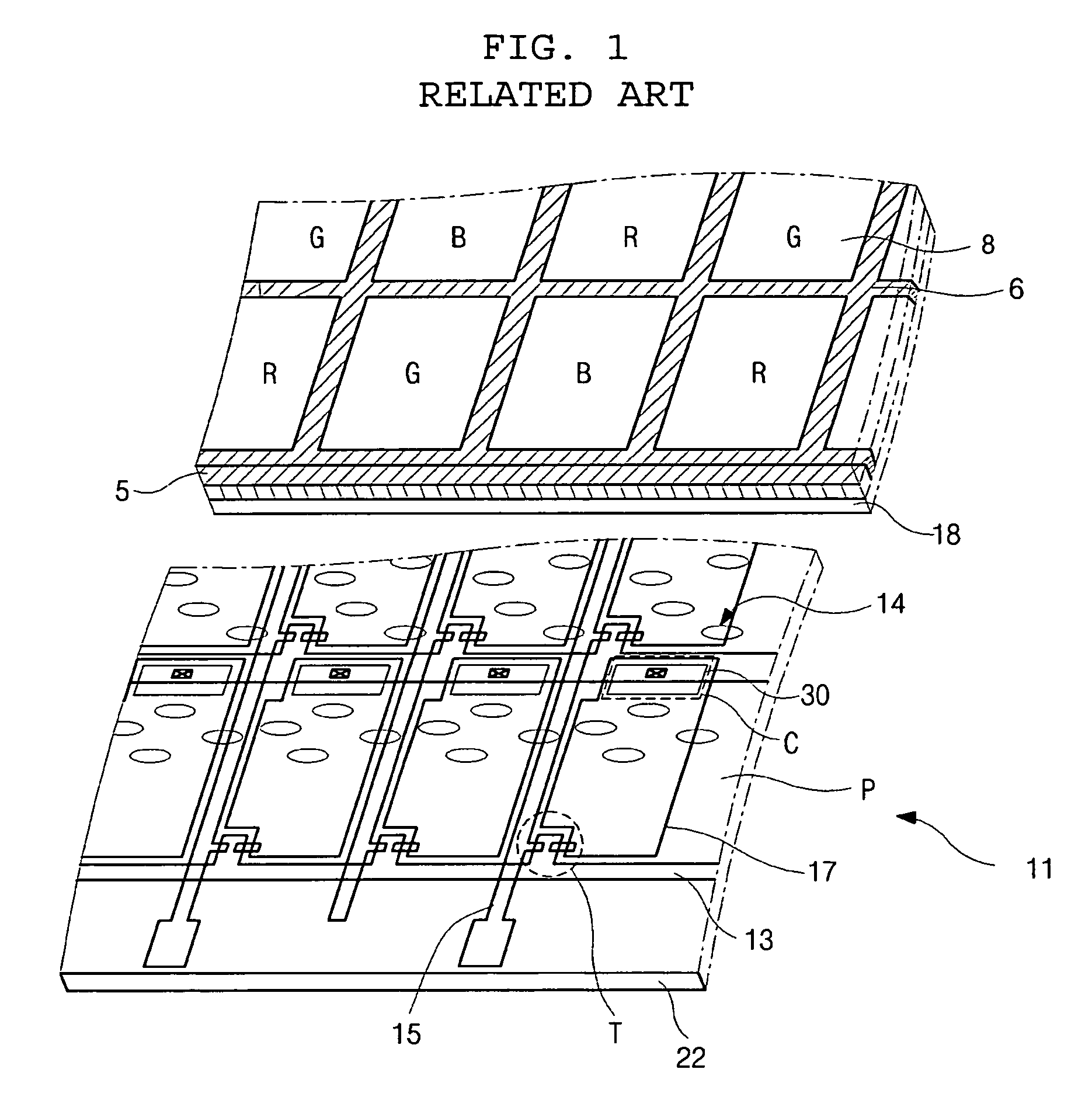

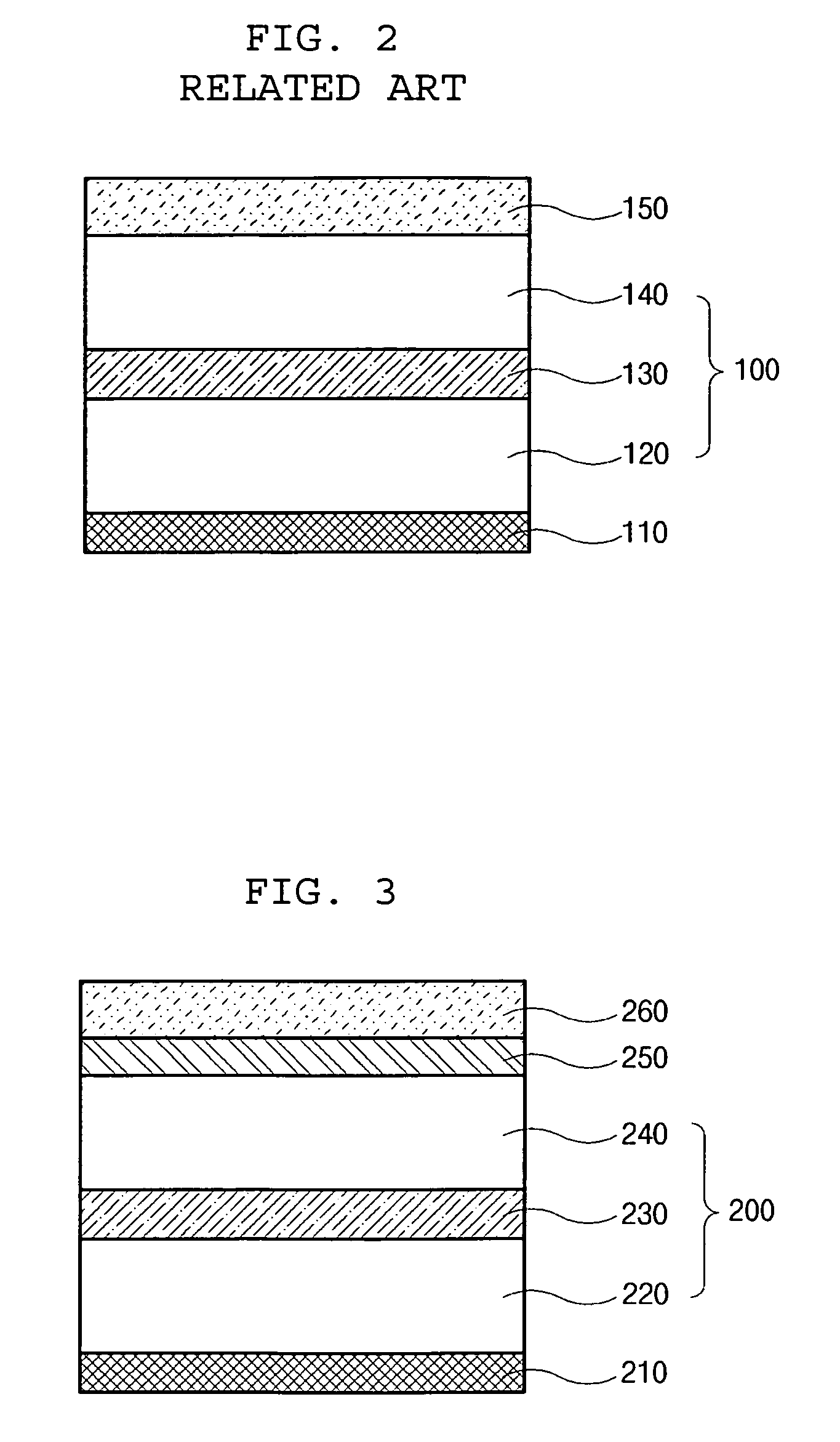

Liquid crystal display device

ActiveUS20050253982A1Improve display qualityGrass dryingDrying gas arrangementsLiquid-crystal displayEngineering

A liquid crystal display device includes first and second substrates facing each other and having a pixel region; a liquid crystal layer between the first and second substrates; a first polarizer on an outer surface of the second substrate; and a friction reducing layer on an outer surface of the first polarizer.

Owner:LG DISPLAY CO LTD

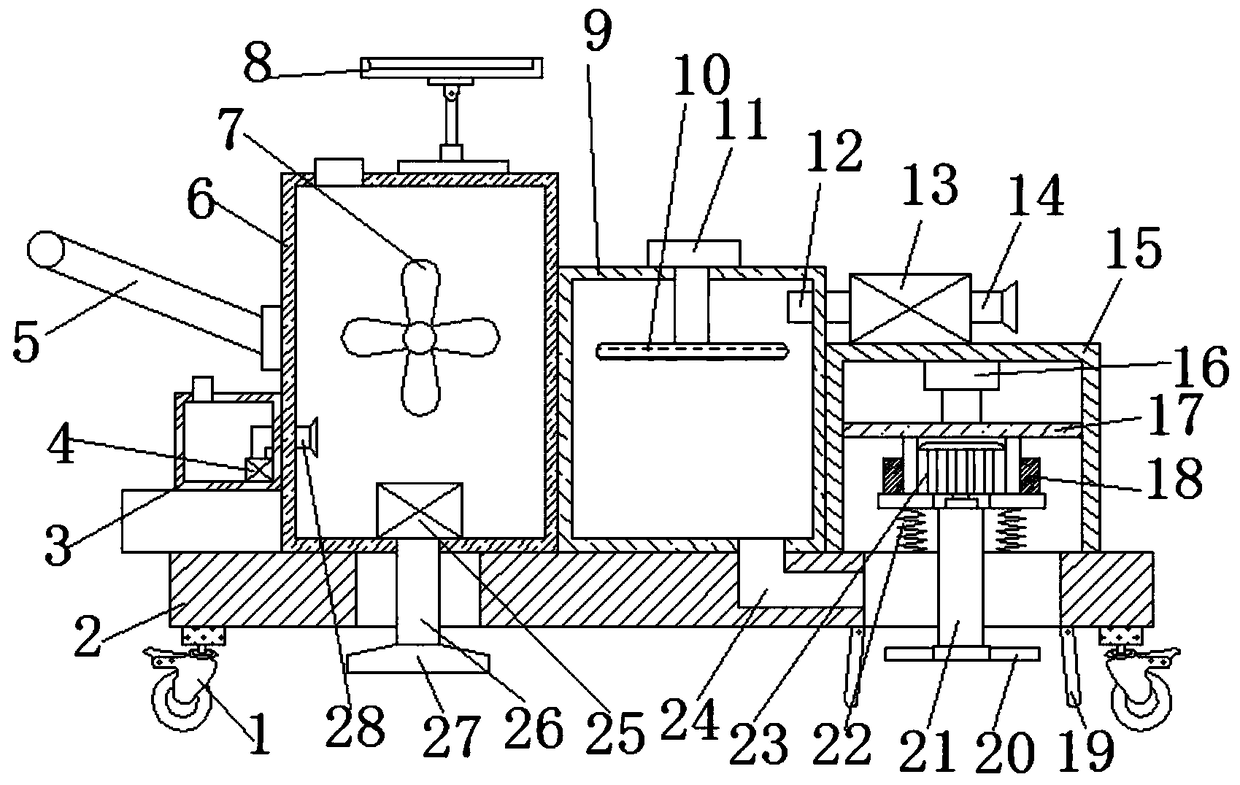

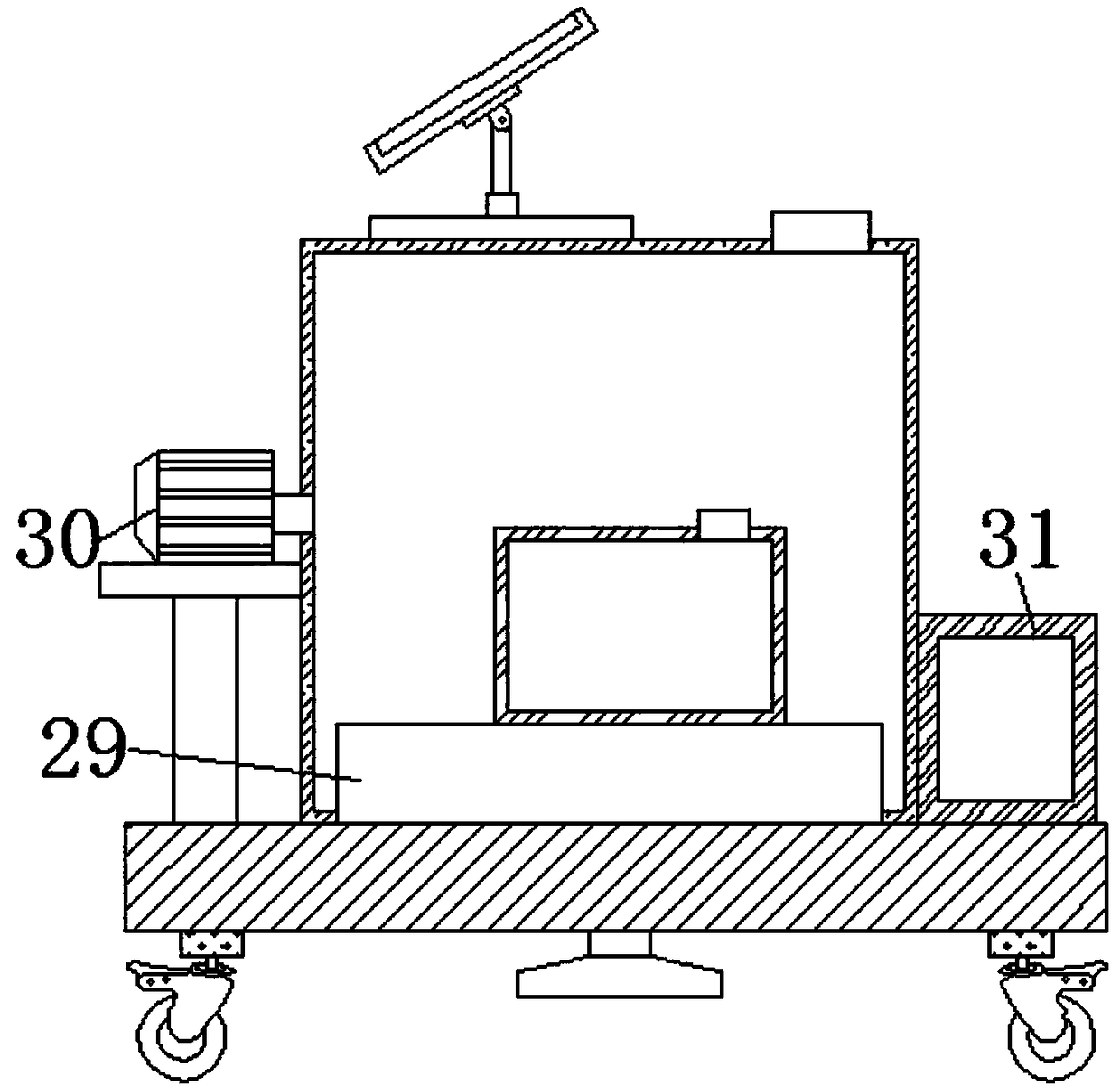

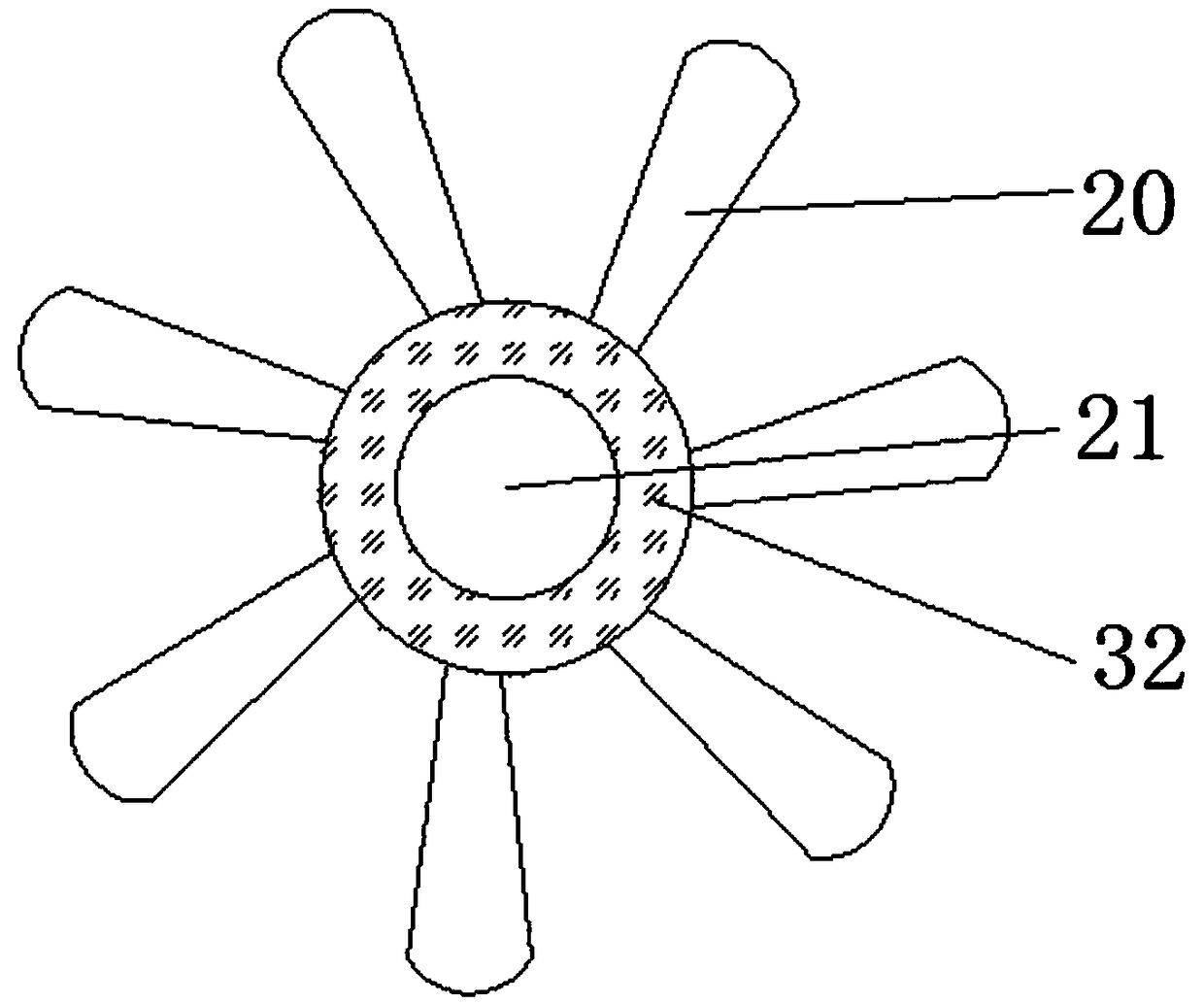

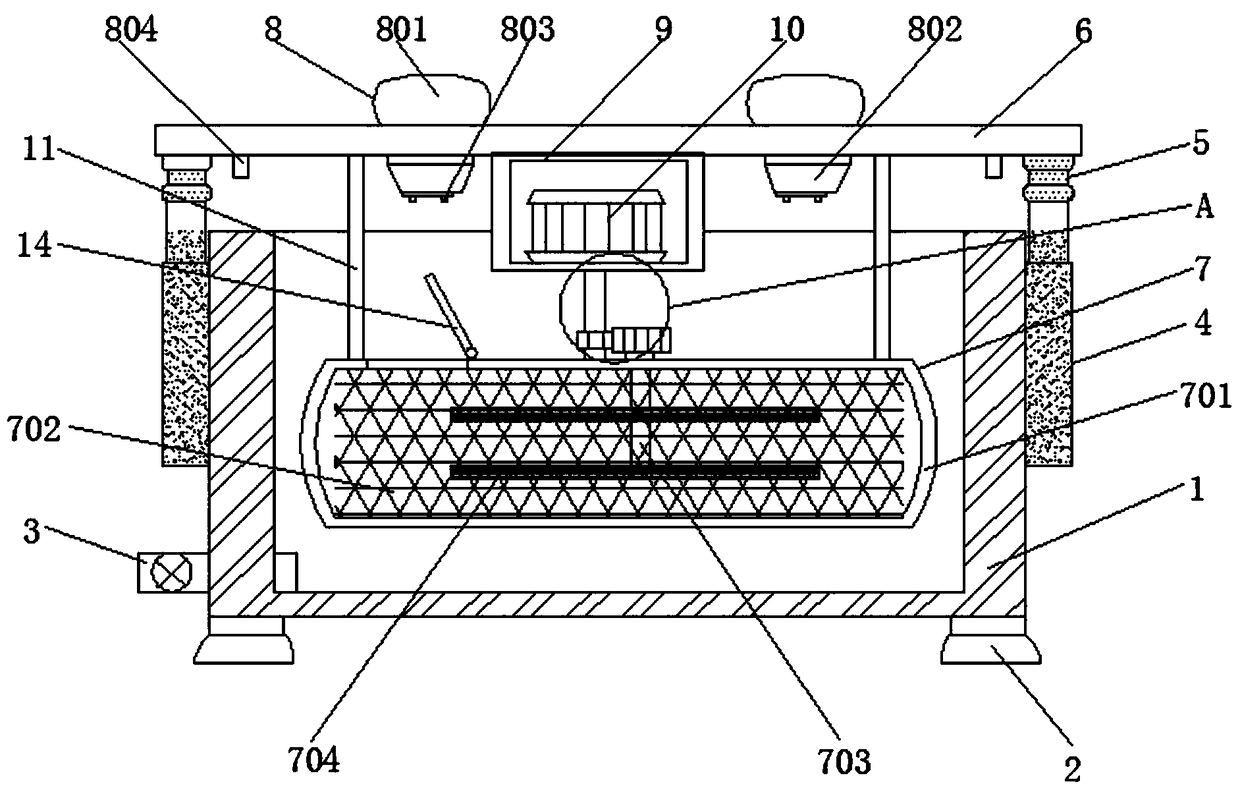

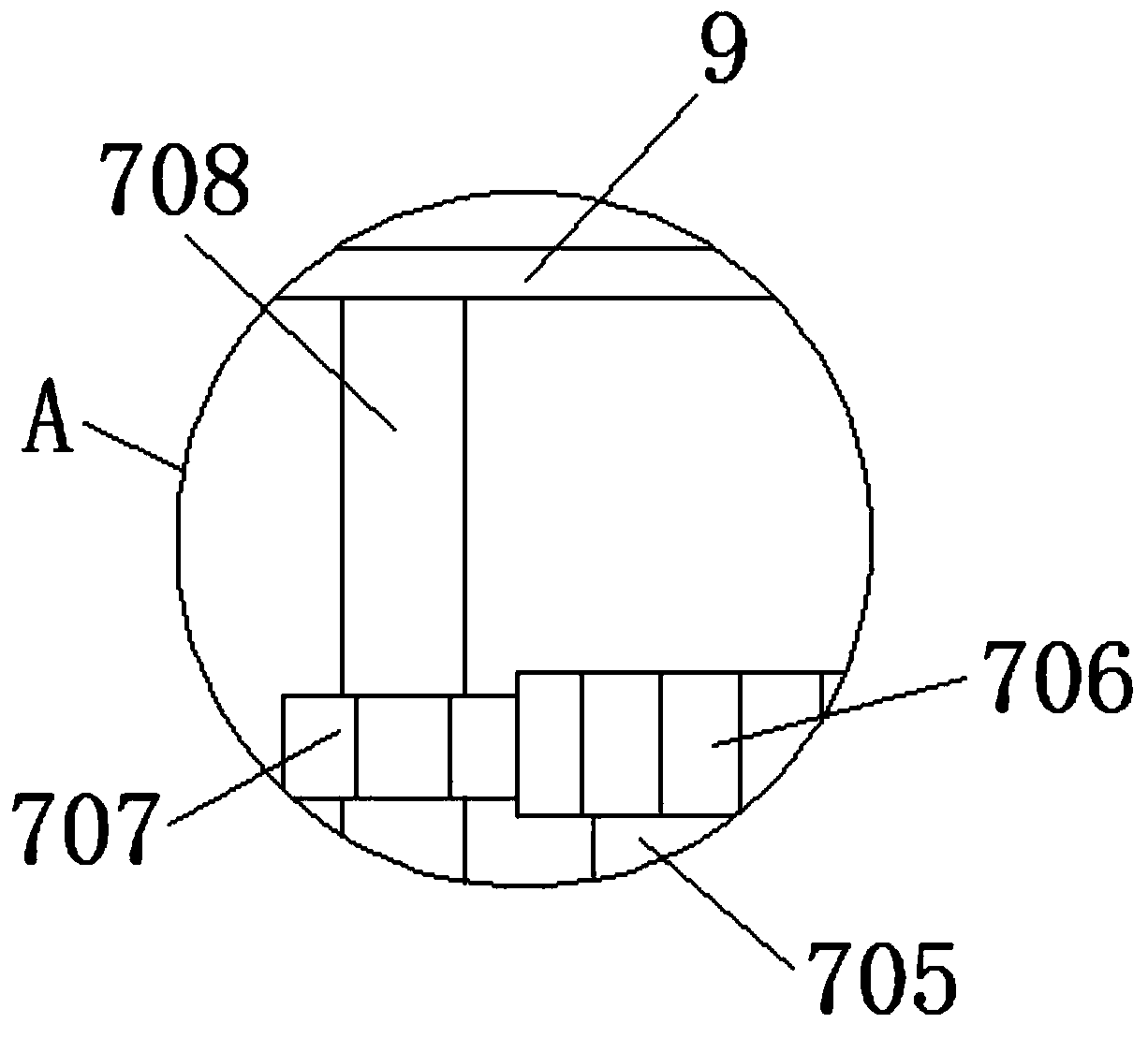

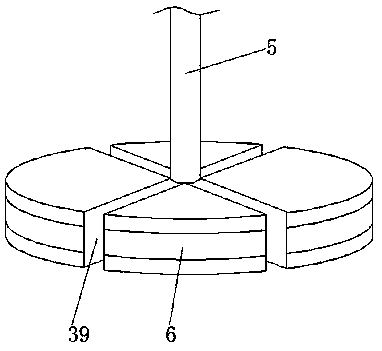

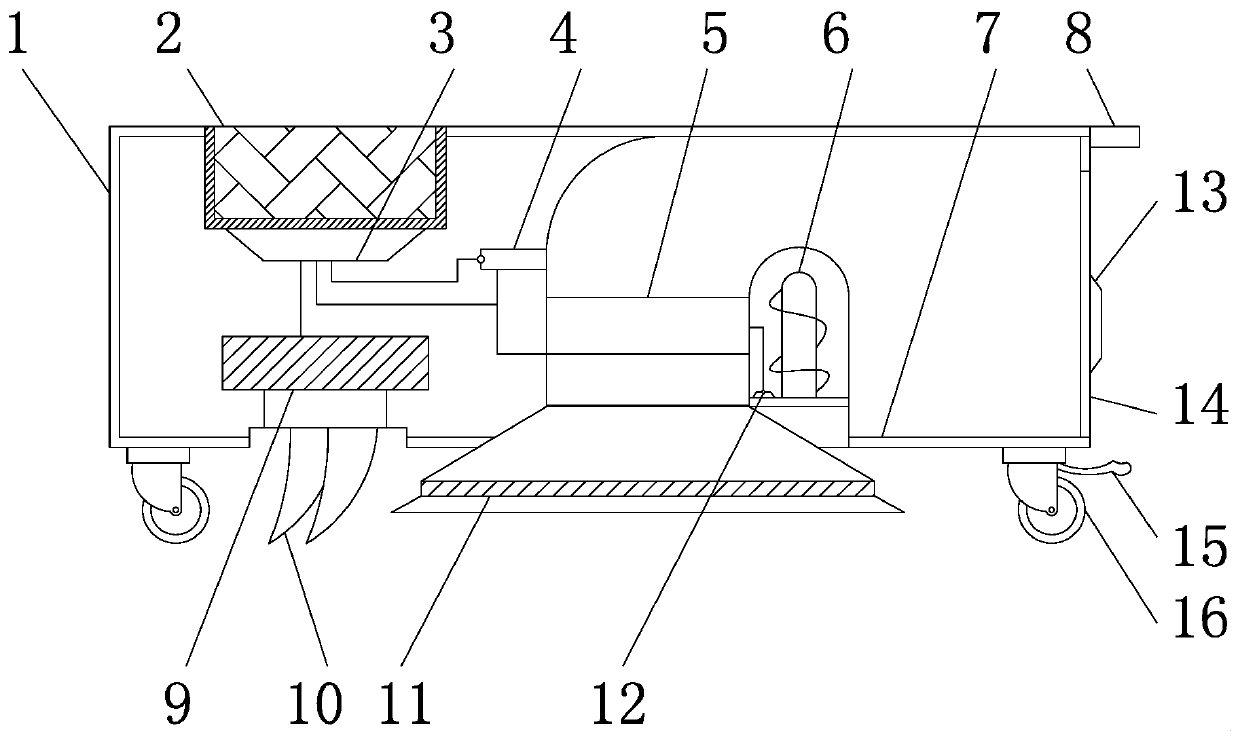

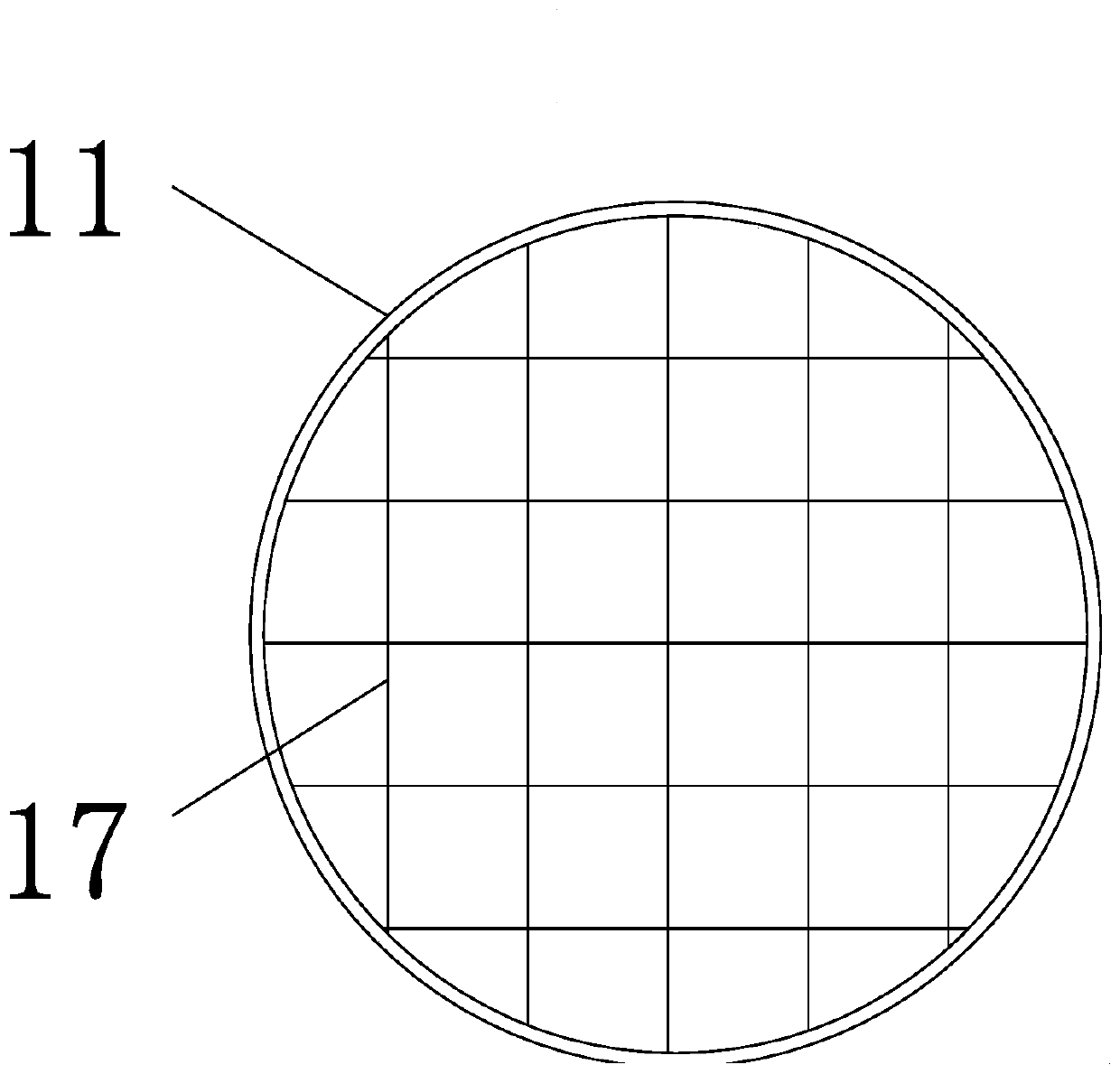

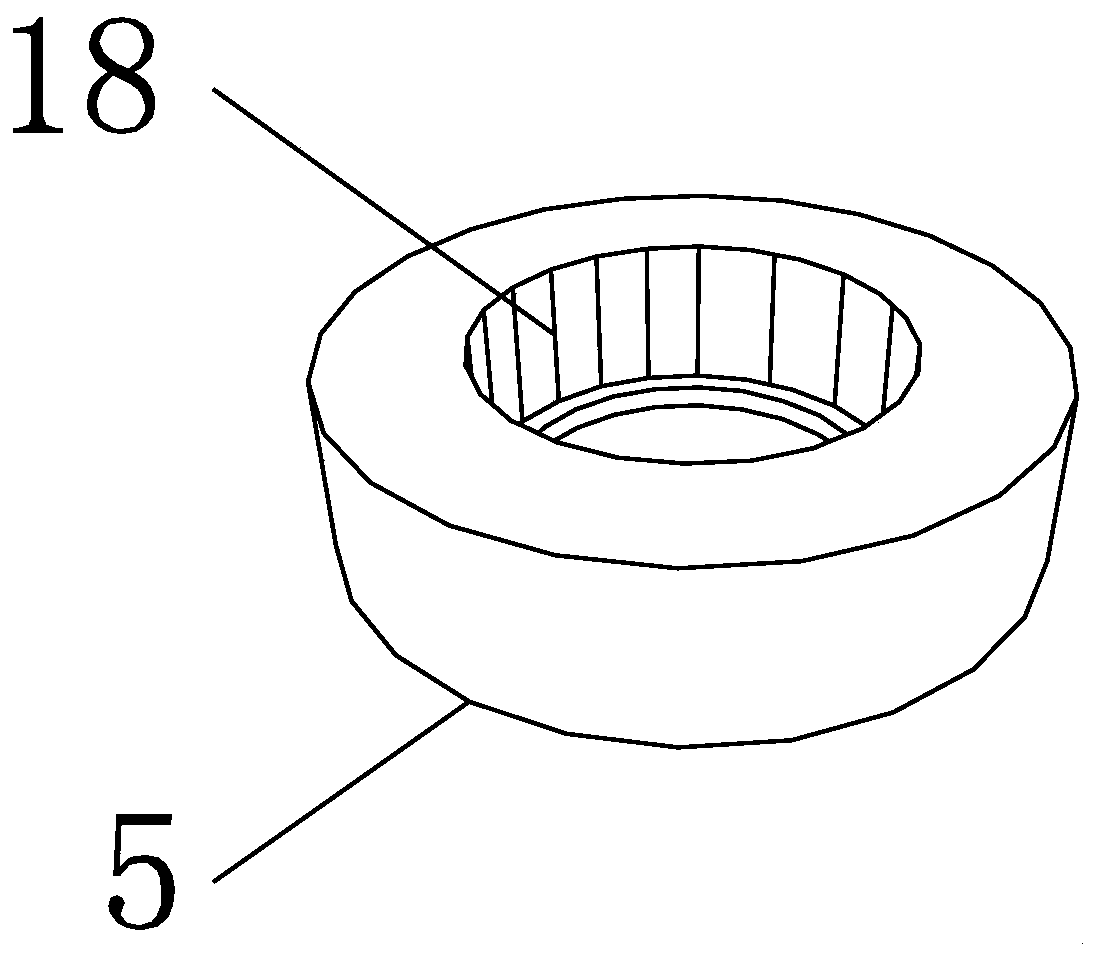

Forage cleaning and drying device for livestock breeding

InactiveCN108568421AAchieve cleaningHelp break upGrass dryingDrying solid materials without heatAnimal ForagingLivestock breeding

The invention provides a forage cleaning and drying device for livestock breeding, relating to the agricultural machinery field. The forage cleaning and drying device comprises a flushing topless tank, wherein a fixing suction disc is adhered to the bottom of the flushing topless tank, an electric telescopic rod is welded to the side wall of the flushing topless tank, the top of the electric telescopic rod is welded with the bottom of an up-down flushing mechanism, the top of the up-down flushing mechanism is welded with the bottom of a sealing cover, and a top tank is welded to the bottom ofthe sealing cover. According to the forage cleaning and drying device, the up-down flushing mechanism is matched with a peripheral flushing mechanism, forages put in a cover net are stirred and cleaned, an upper flushing manner is combined with a lower flushing manner, and a manual forage cleaning manner is simulated, so that the cleaning efficiency of the forages is relatively good; and the forages are driven to rotate by virtue of the rotary cover net and are spin-dried through a centrifugal force, and meanwhile, hot air produced by an electric heating pipe is blown to the forages through afan so as to heat and dry the forages, so that the cleaning and drying efficiencies of the forages are effectively improved.

Owner:陶令

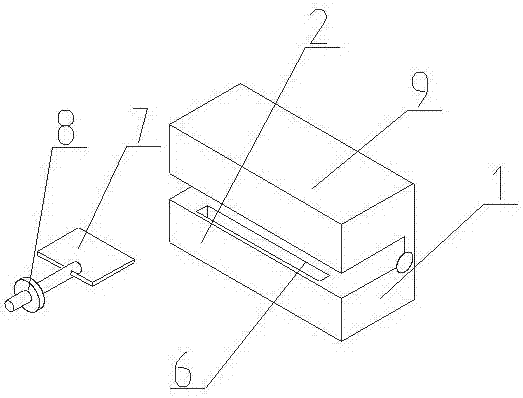

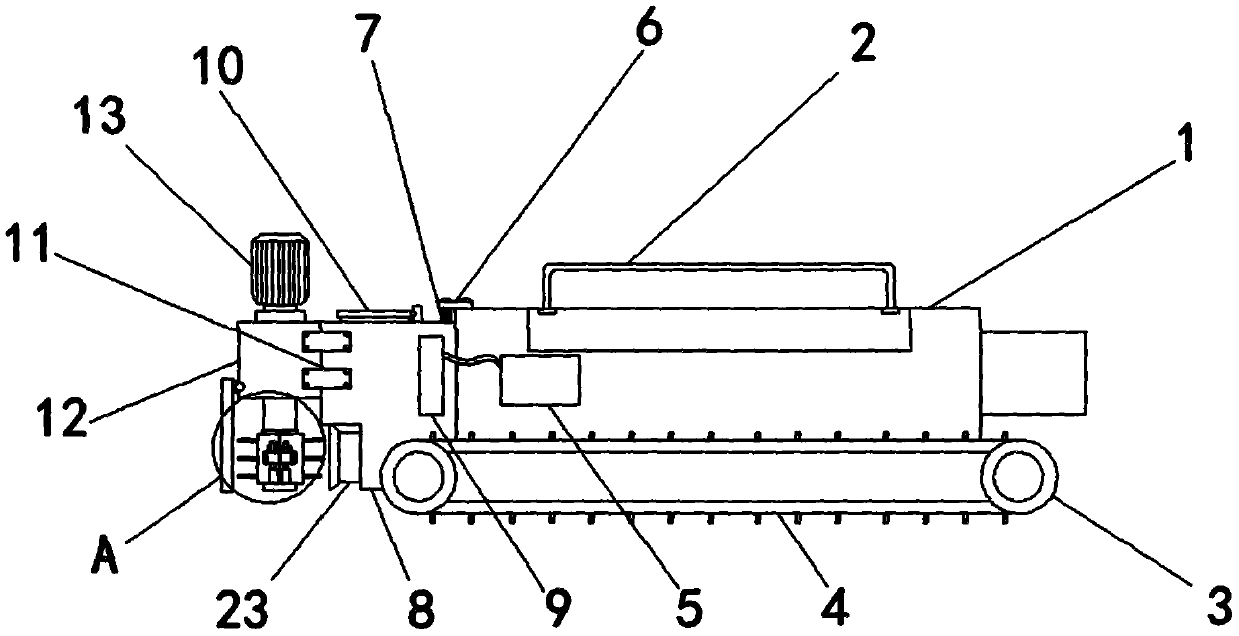

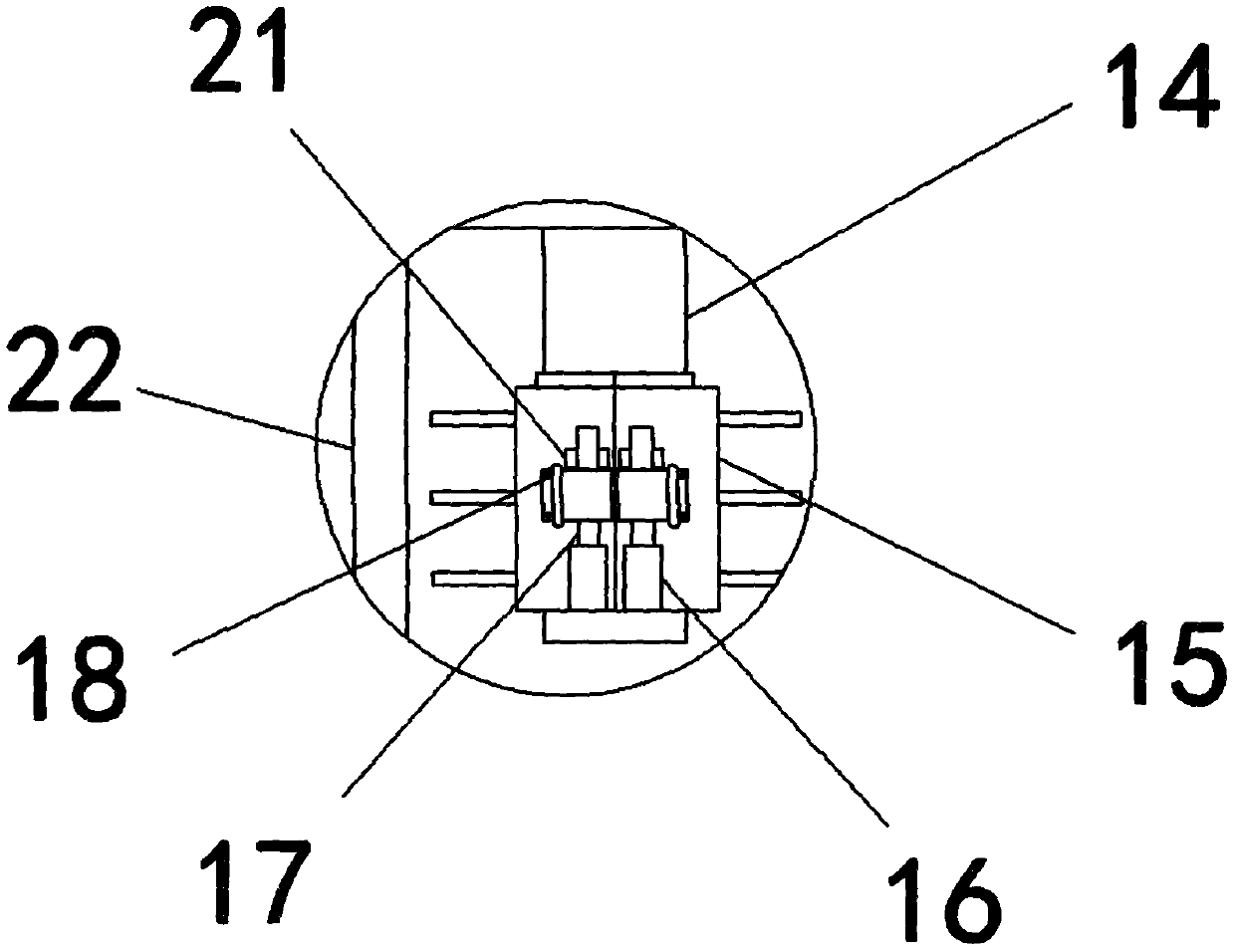

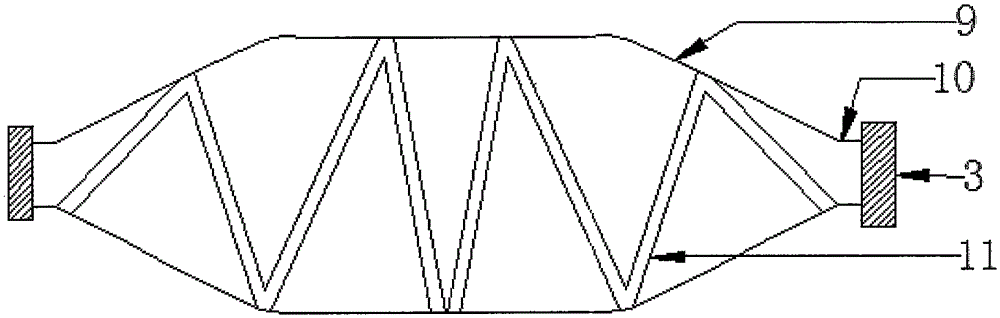

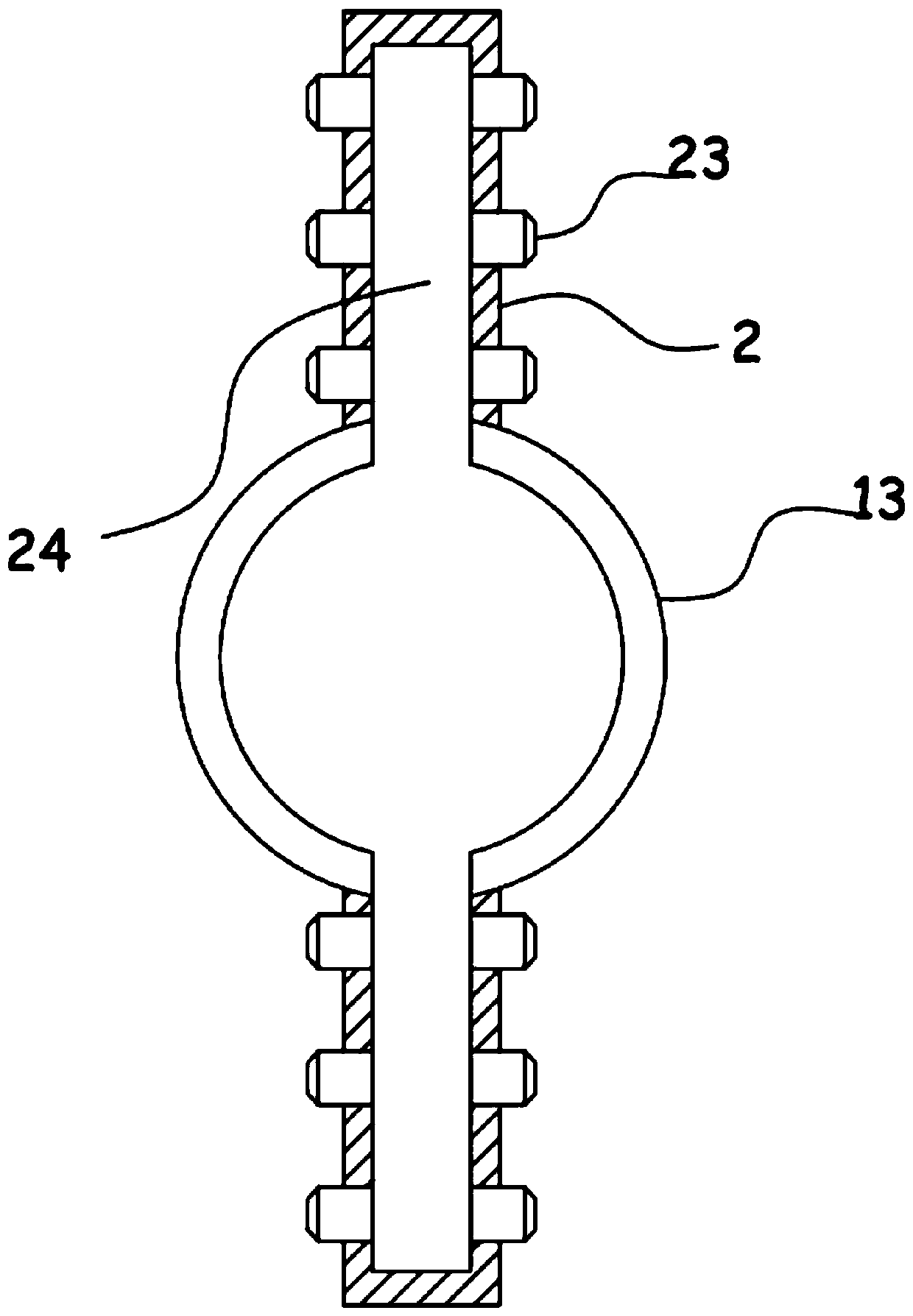

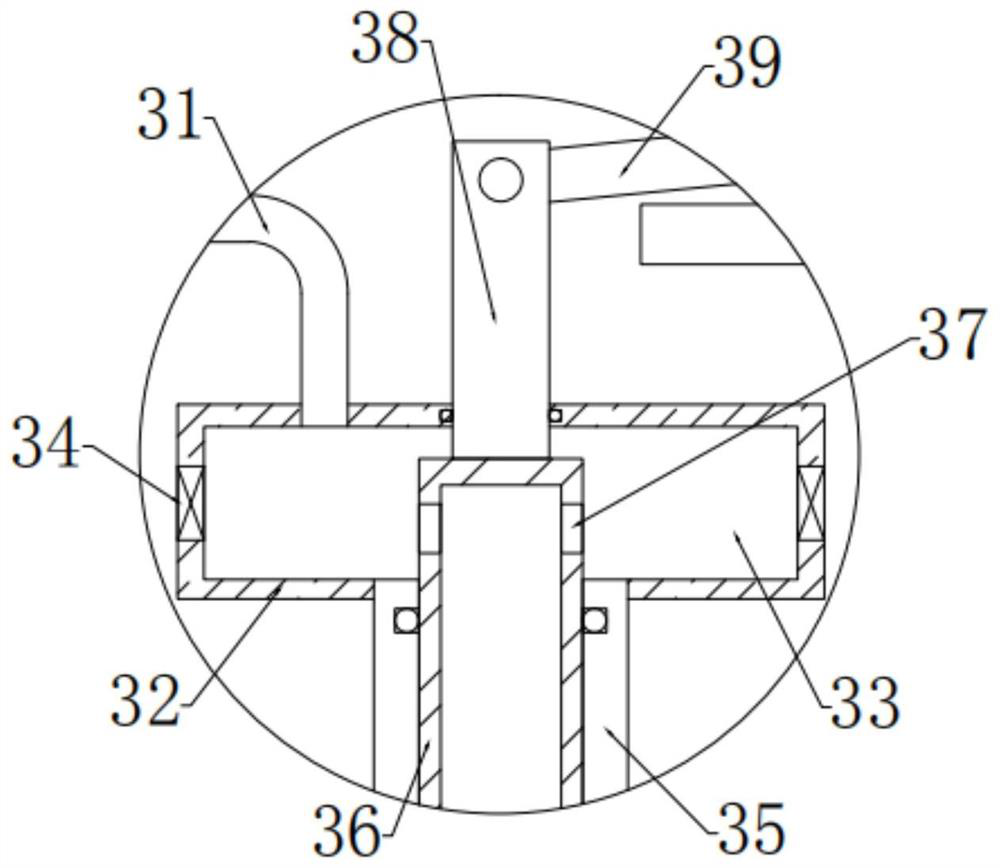

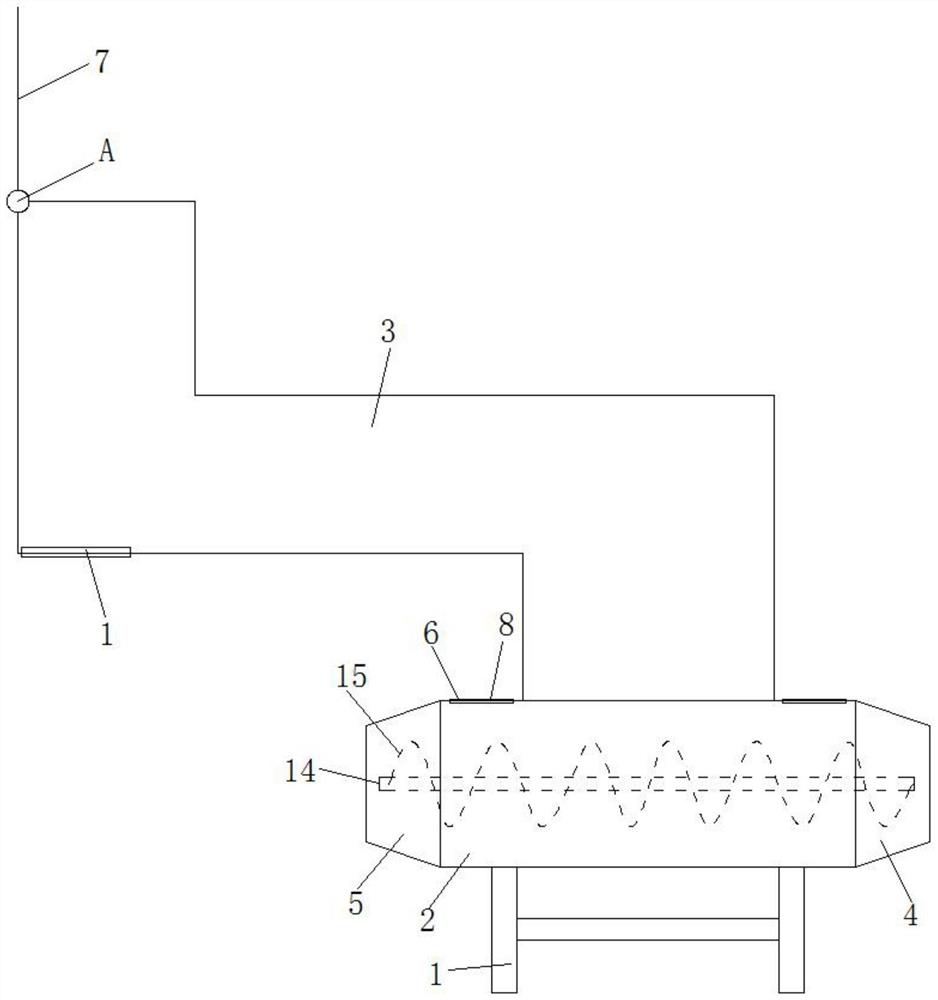

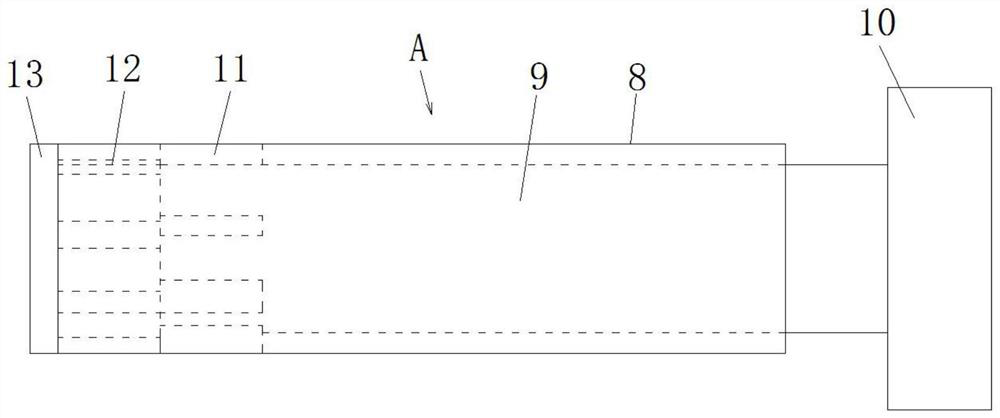

Forage grass drying device

ActiveCN107388803AEasy to cleanReduce energy consumptionGrass dryingDrying gas arrangementsComing outEnergy consumption

The invention discloses a forage grass drying device. The forage grass drying device comprises an air heater (1), a drying cylinder (2) of a cylindrical structure and first supporting frames (3), and is characterized by further comprising a belt conveying device (13) and a cooling cylinder (14), wherein forage grass comes out from the drying cylinder (2), then passes through the belt conveying device (13) and enters the cooling cylinder (14) to be cooled. Compared with the prior art, the forage grass drying device has the advantages that original drying cylinder rotation is changed into rotating shaft rotation so that the energy consumption can be reduced, in addition, the dried forage grass can be directly bundled after being cooled so as to complete the processing so that the cooling time can be shortened, the operation can be convenient, a scraper is arranged so that the inner wall of the drying cylinder and the inner wall of the cooling cylinder can be cleaned conveniently, the structure is simple, and the use effect is good.

Owner:XUZHOU YUANHE ANIMAL HUSBANDRY CO LTD

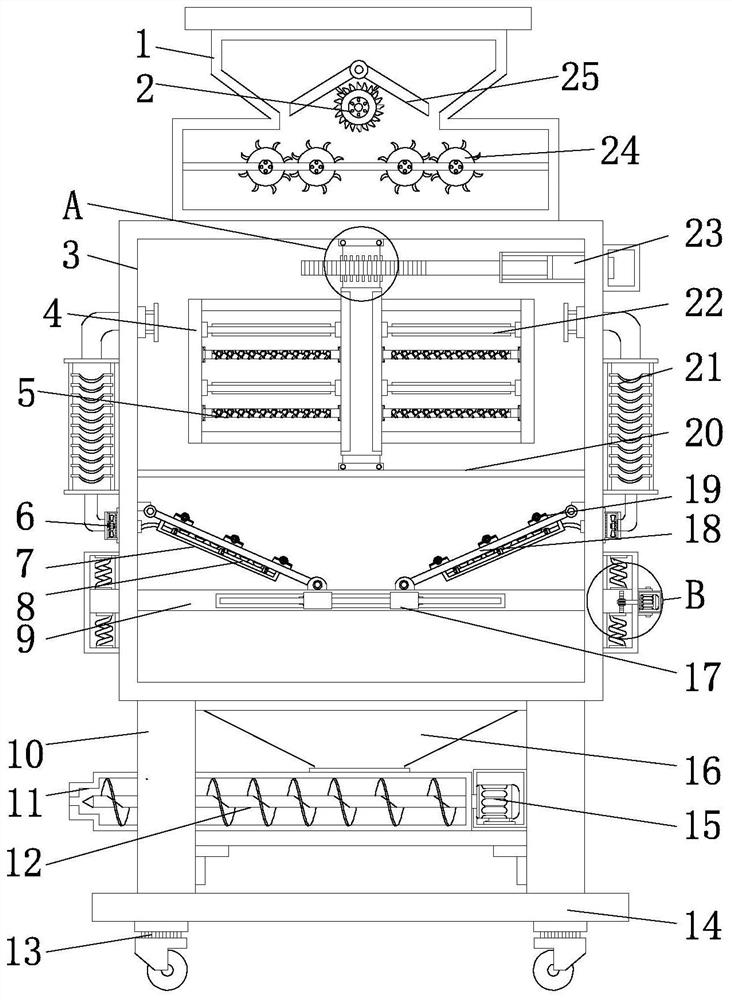

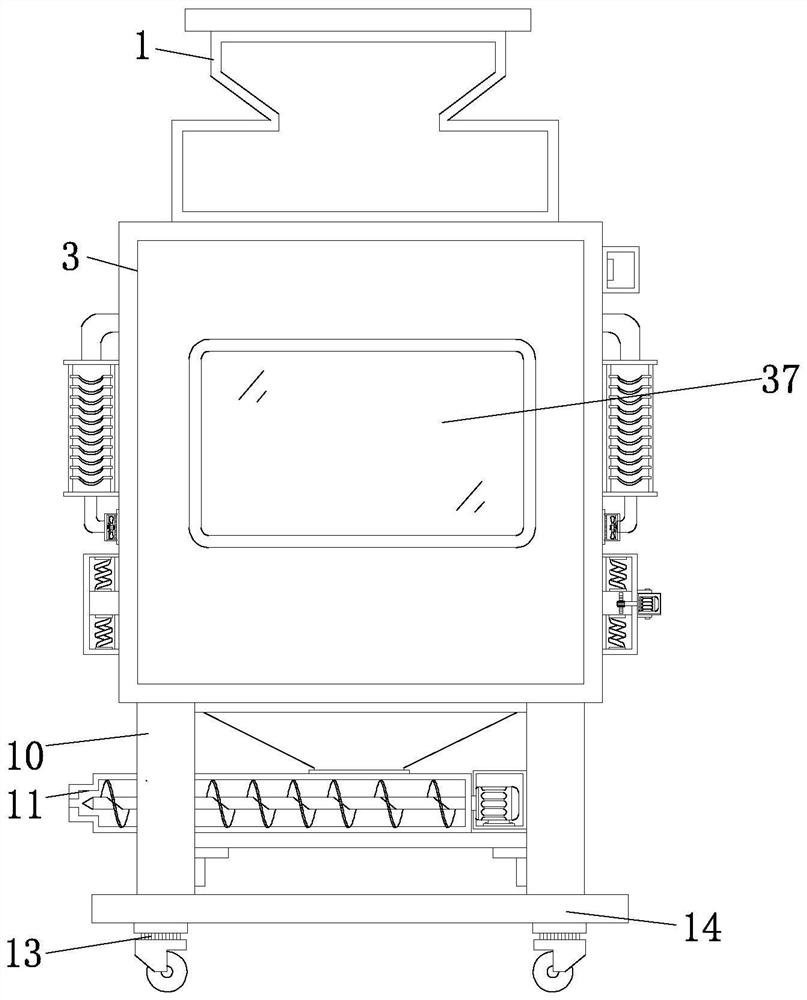

Forage drying device for livestock industry

InactiveCN111631026AFully dryMaximize utilizationGrass dryingDrying gas arrangementsAgricultural scienceDraft animals

The invention discloses a forage drying device for the livestock industry. The forage drying device for the livestock industry comprises a feeding box, a body, a base and a bottom plate. The base is arranged at the top end of the bottom plate, and a spiral conveying groove is transversely formed in the base. The body is arranged at the top end of the base, and a discharging hopper is arranged at the bottom end of the body. The bottom end of the discharging hopper communicates with the interior of the spiral conveying groove. Second mounting grooves are separately formed in the lower ends of the two sides of the body. A first mounting groove is formed in the bottom end of each first material baffle, and an air inlet pipe is arranged in each first mounting groove. One end of each air inlet pipe extends to the outer side of the body through a guide pipe and is provided with an air suction fan. The feeding box is arranged at the top end of the body, and crushing rollers are symmetrically arranged at the bottom end of the inside of the feeding box. According to the forage drying device, through arrangement of the air suction fans and moisture absorbers and cooperation of the effect of second heating pipes, forage on the bottom can be sufficiently dried, and maximum utilization of energy is achieved while the drying quality is improved.

Owner:俞国锋

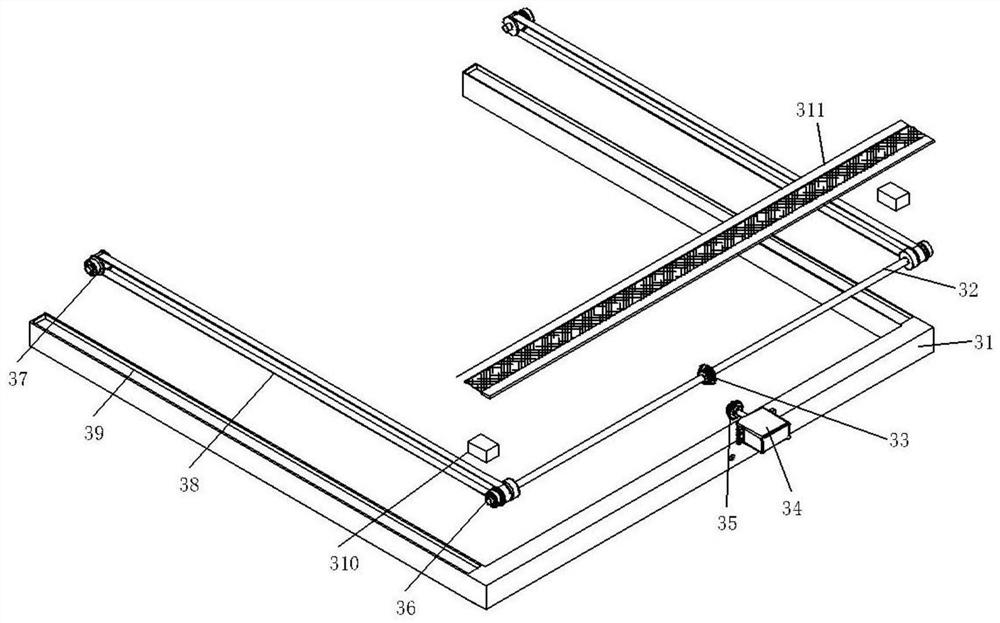

Automatic forage turning and drying device

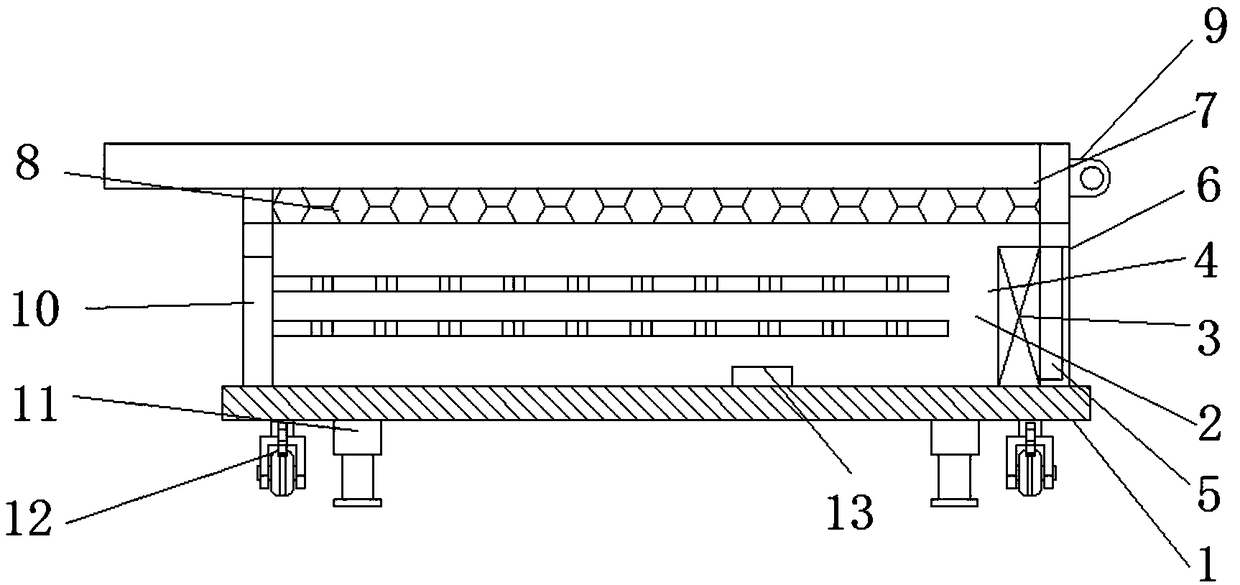

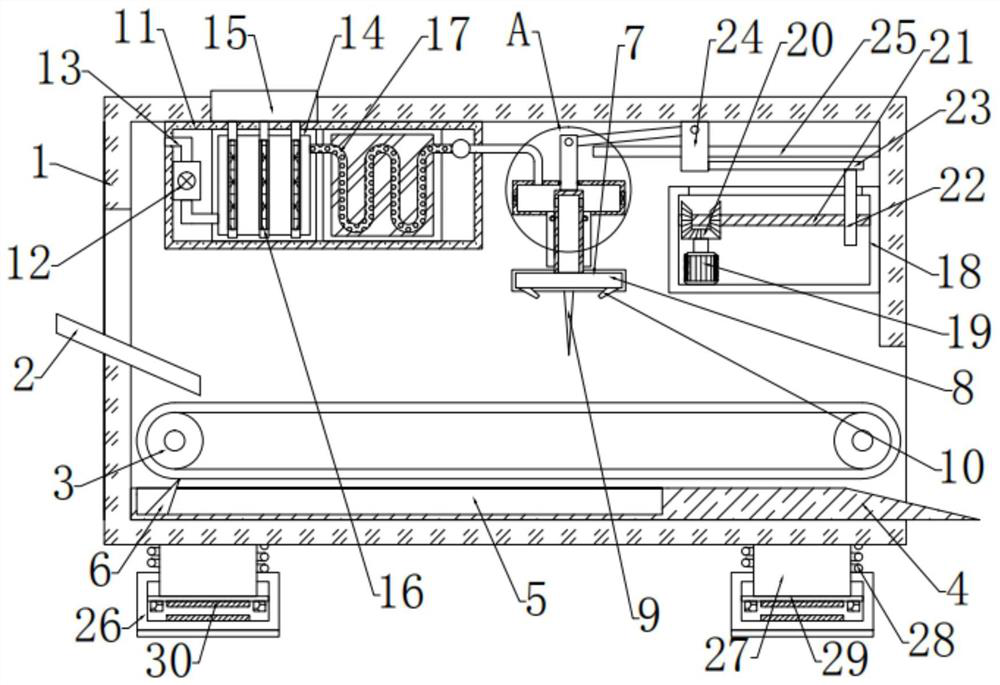

InactiveCN107144112AEasy to moveReasonable structural designGrass dryingDrying machines with progressive movementsEngineeringWindshield

The invention discloses an automatic turning and drying device for forage, which includes a base, a furnace chamber is arranged on the base, a heating module is arranged in the furnace chamber, and a groove is arranged on the surface of one end of the furnace chamber. The furnace cavity is provided with a chain group, the other end surface of the furnace cavity is provided with a groove, and the chain group is arranged at the lower end of the groove, and the furnace cavity is provided with a drying rack. The drying frame is provided with a gear connected to the chain group, the furnace cavity is provided with a windshield, and a fan is provided on one side of the windshield; the device has reasonable structure design, simple operation, safety and reliability, and realizes Multiple groups of drying racks can be dried at the same time, which greatly reduces the cost and achieves the convenience of moving the rolling drying furnace.

Owner:合肥源行农业科技有限公司

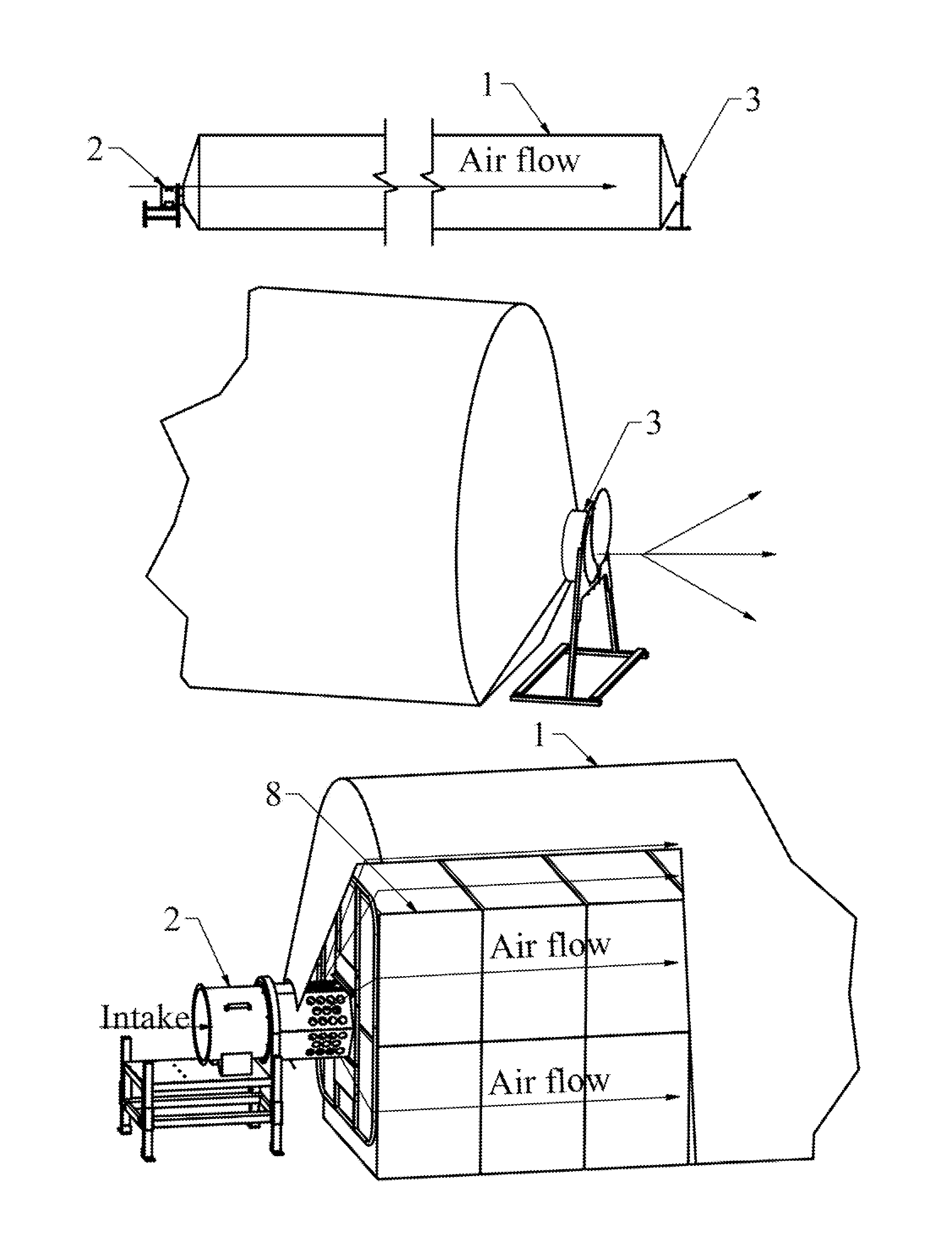

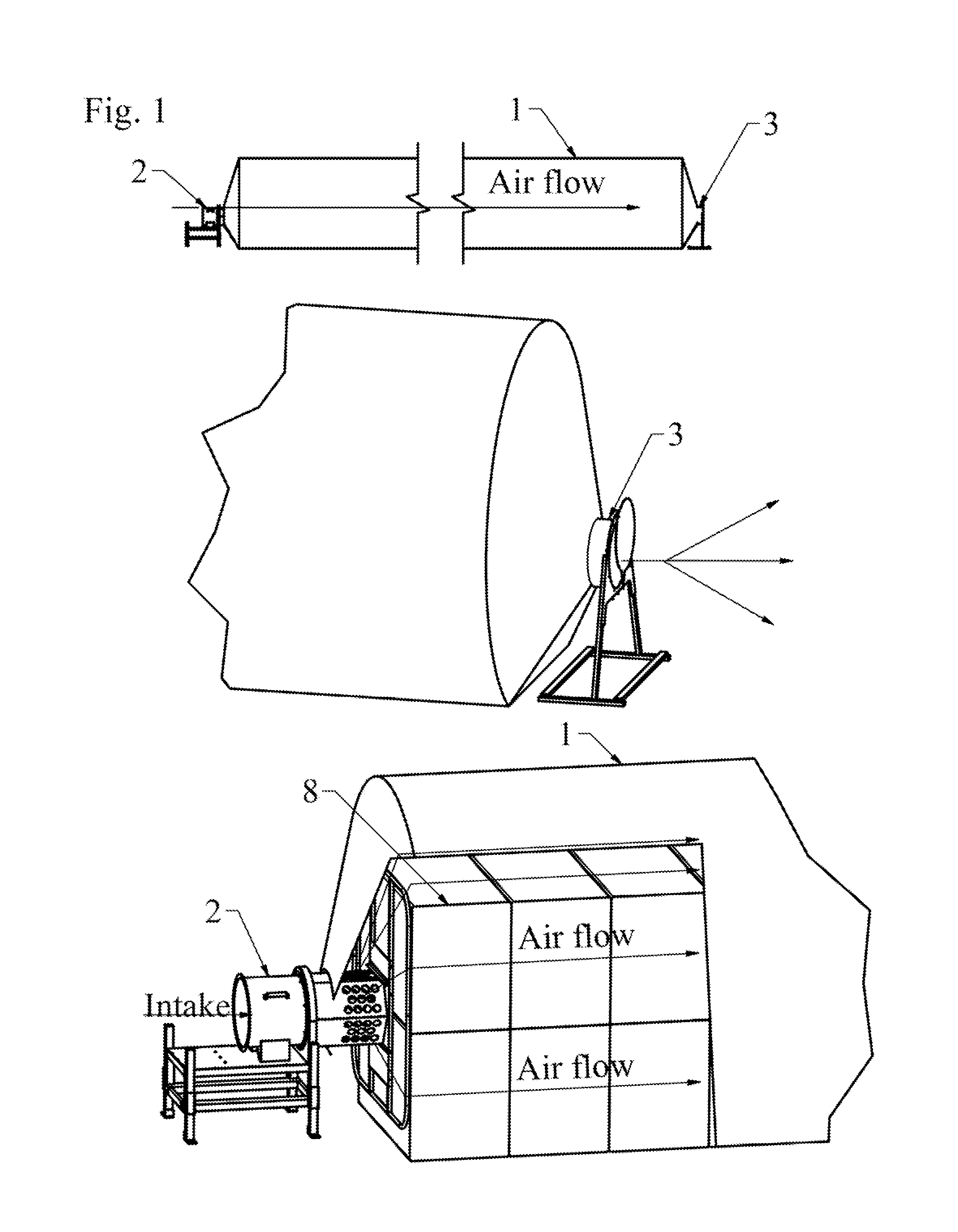

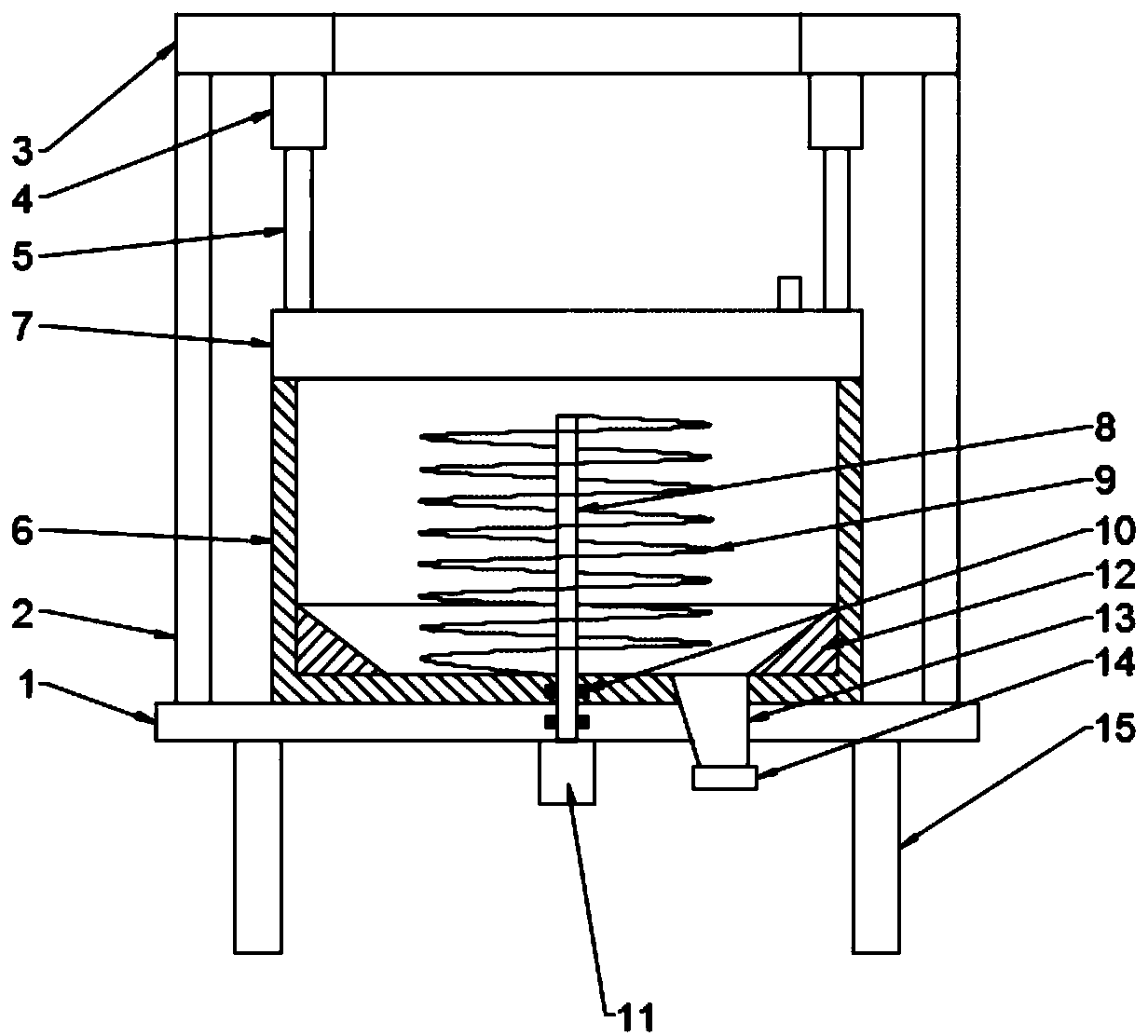

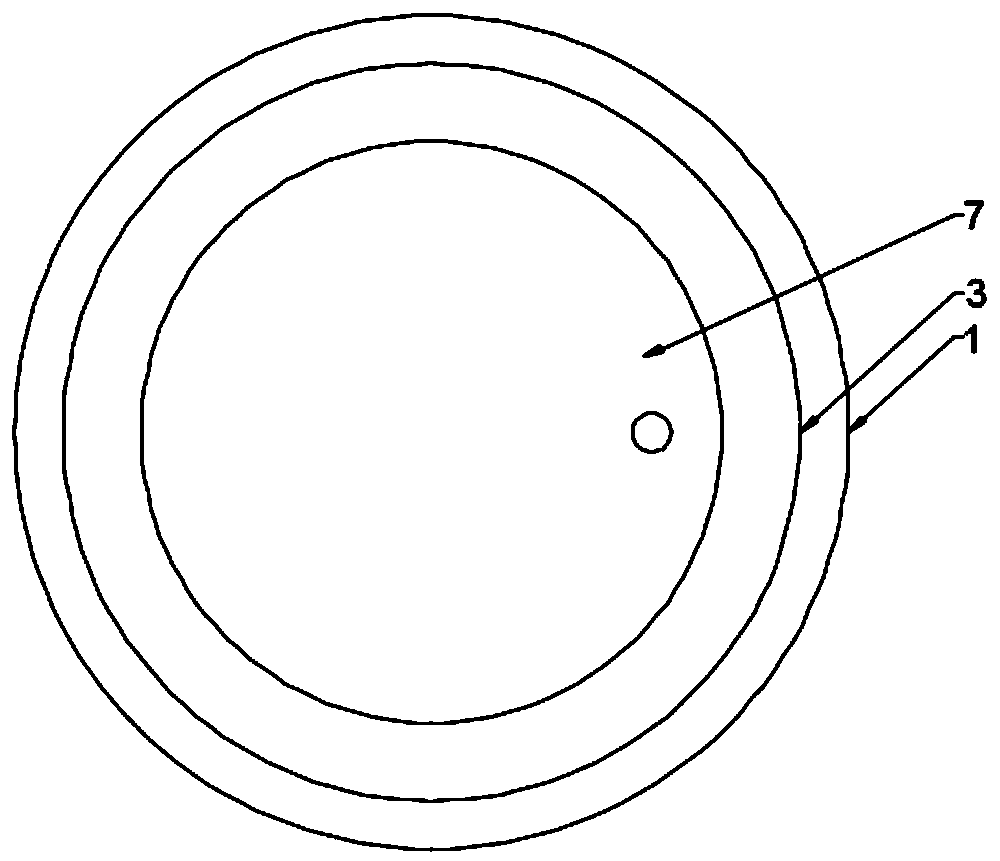

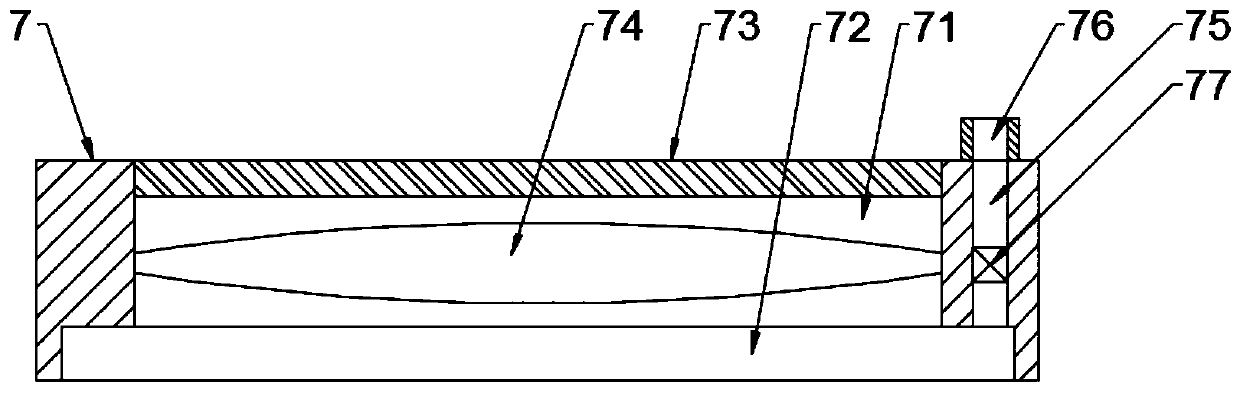

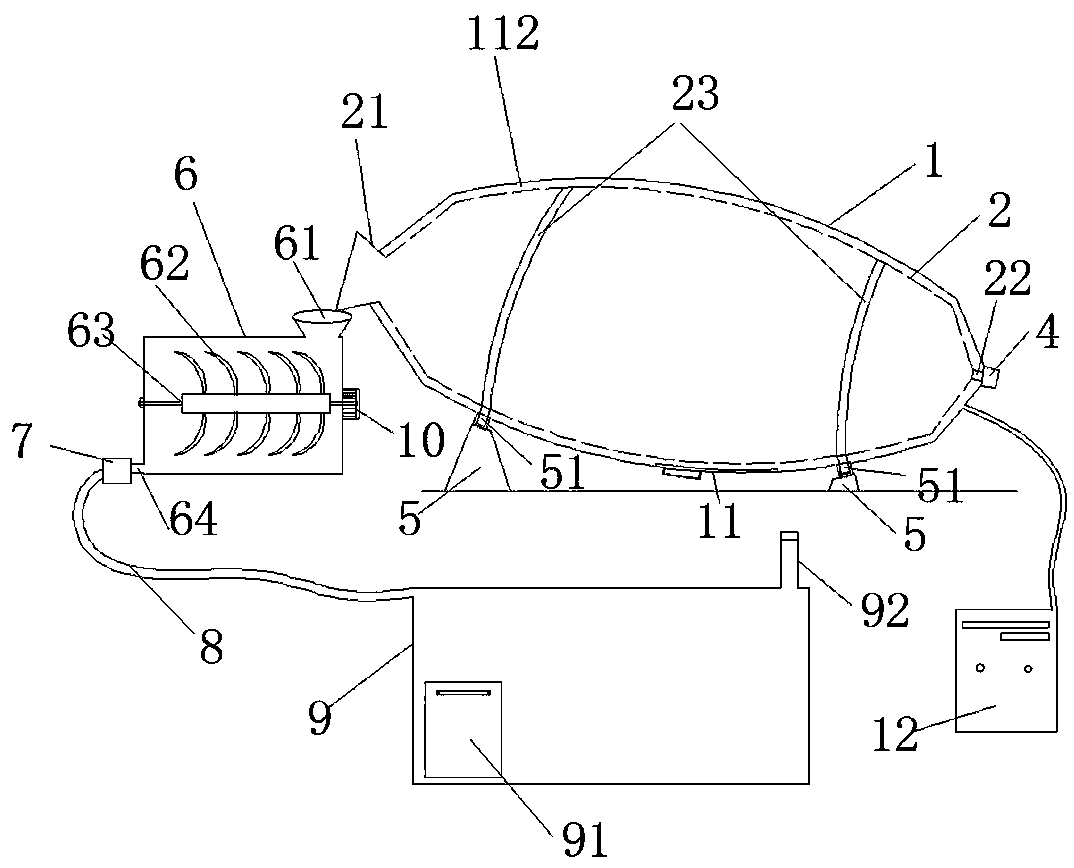

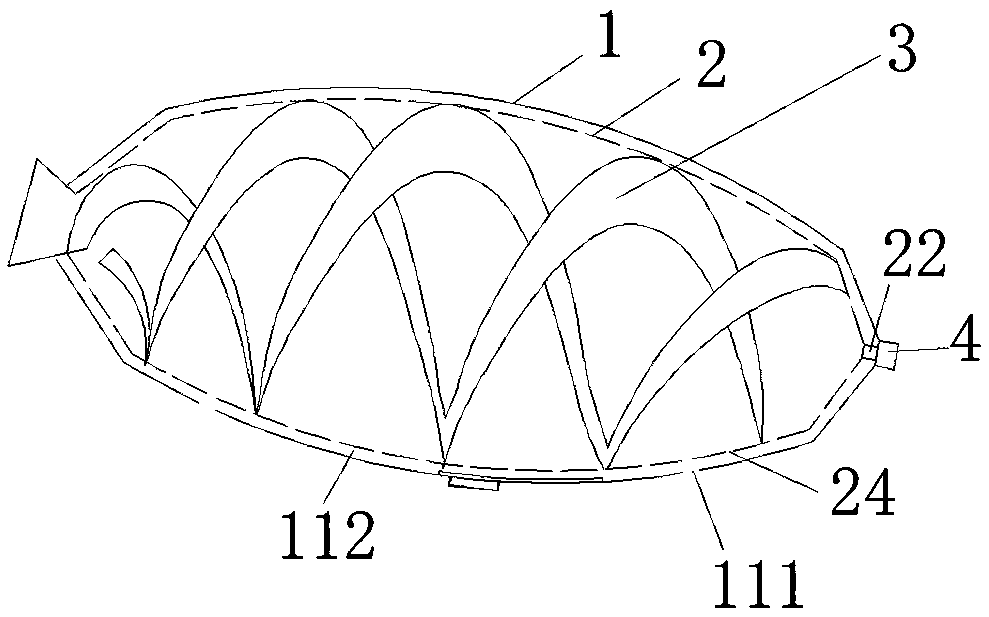

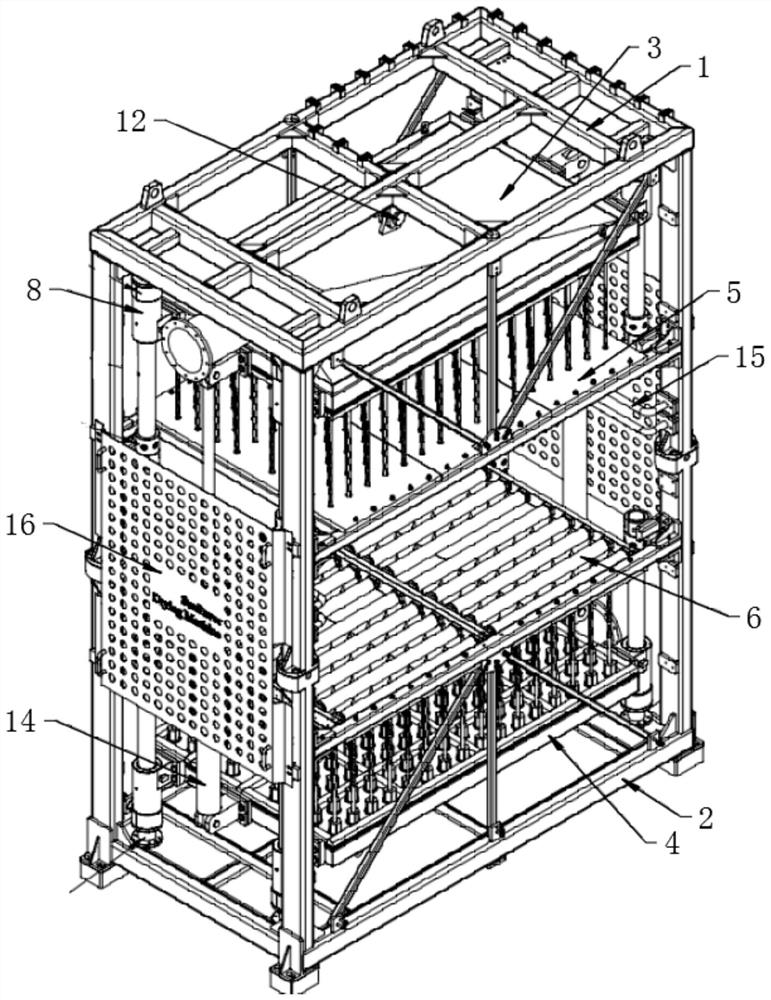

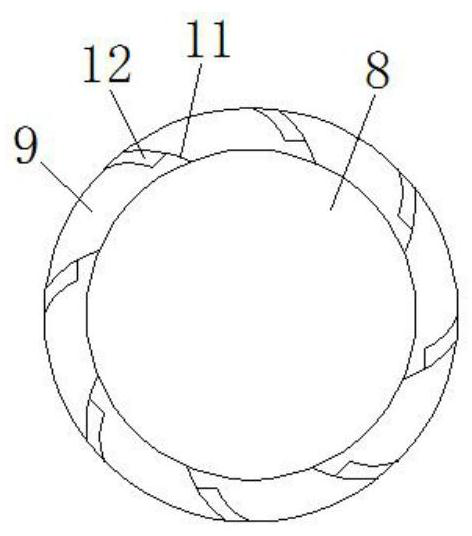

Herbage bale drying system

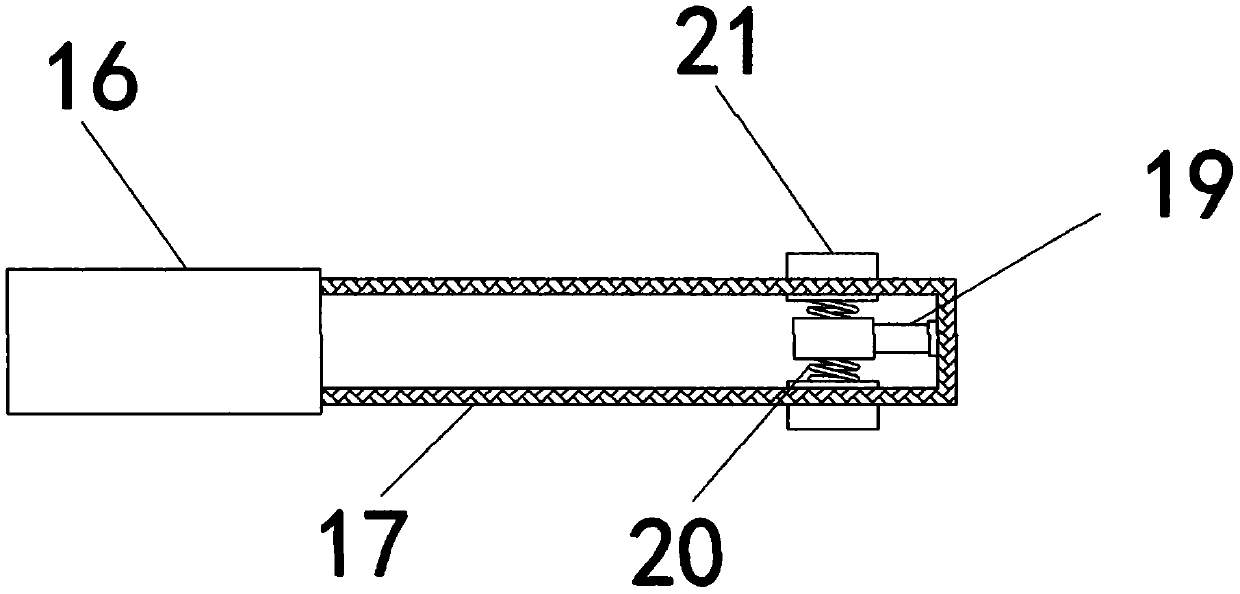

ActiveCN113639535ASolve drying problemsPrevent mildewAgriculture tools and machinesGrass dryingThermodynamicsProcess engineering

The invention belongs to the technical field of herbage machinery, particularly relates to a bale drying system, and aims to solve the problems that herbage bales are difficult to dry and a herbage bale drying system is not intelligent in the prior art. According to the herbage bale drying system, air supply needles can be inserted into the herbage bales, high-pressure hot air is blown into the herbage bales through an air supply device, drying is carried out on the herbage bales, and therefore the herbage bale drying problem is solved, the herbage bales can be dried to be below the storage safety moisture by utilizing the system, and mildewing is avoided. According to the system, automatic control is adopted, the temperature and humidity in the herbage bales are collected through the Internet of Things, the drying time and the drying temperature are intelligently analyzed and adjusted, filling, feeding, drying, cooling and unloading are automatically achieved, in addition, the herbage bales can be dehumidified again during cooling, and a guide mechanism is arranged, so that an upper hollow air needle assembly and a lower hollow air needle assembly rise and fall stably, and the drying efficiency and the system safety are guaranteed.

Owner:呼伦贝尔菁华草业科技发展有限公司

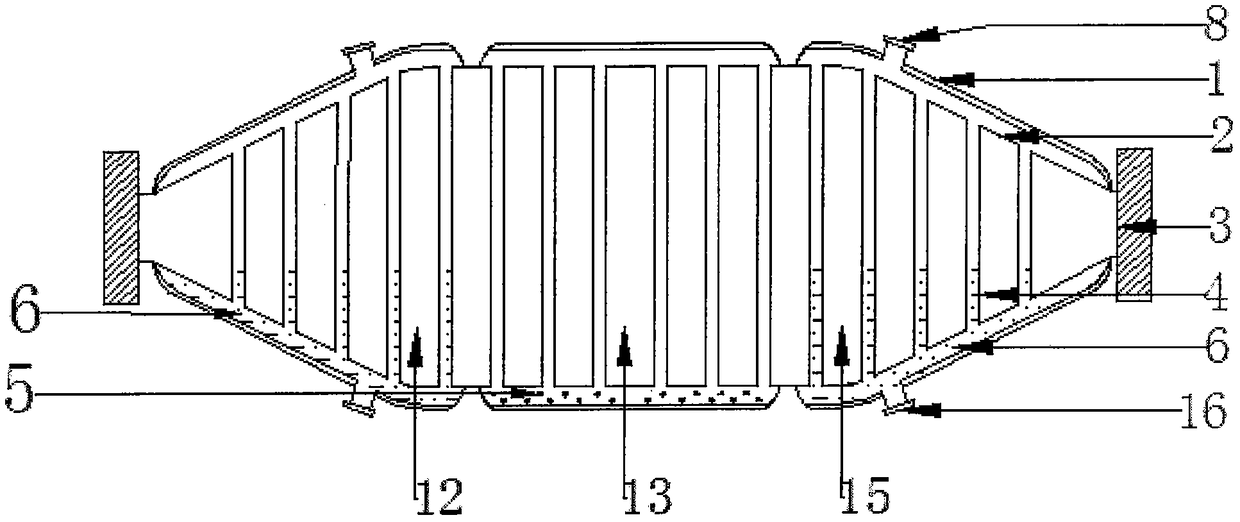

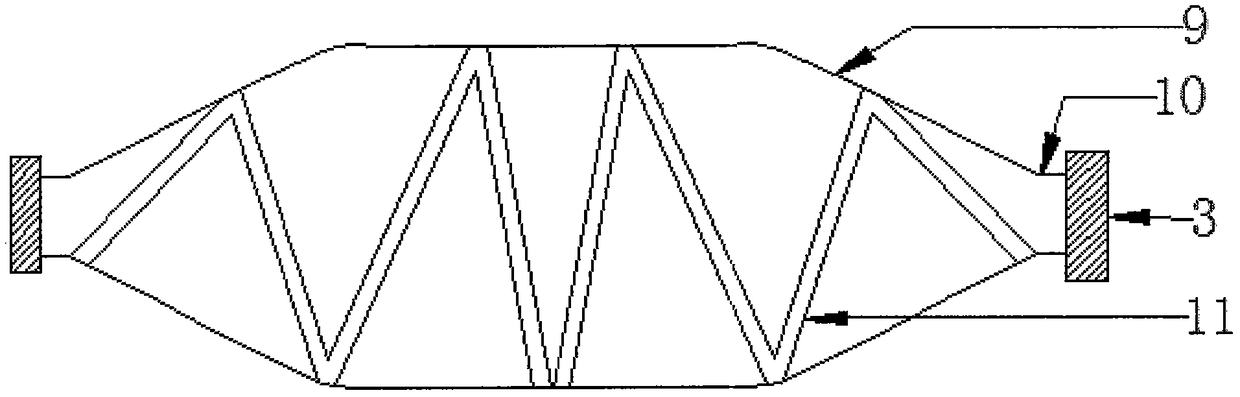

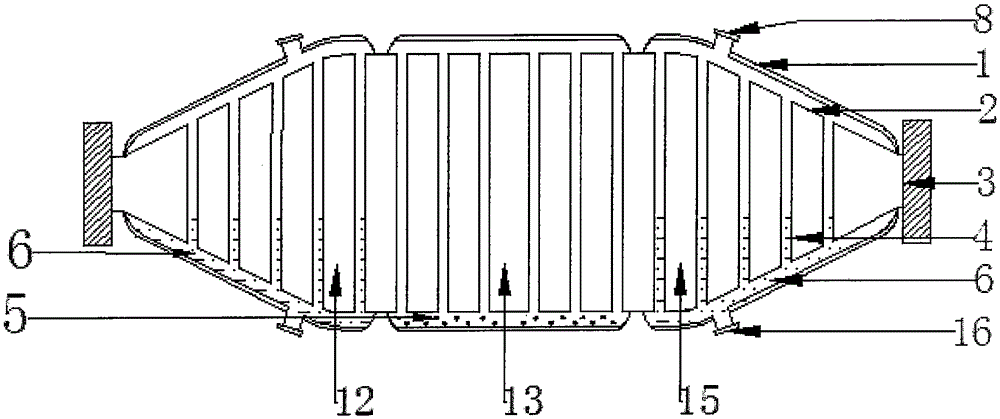

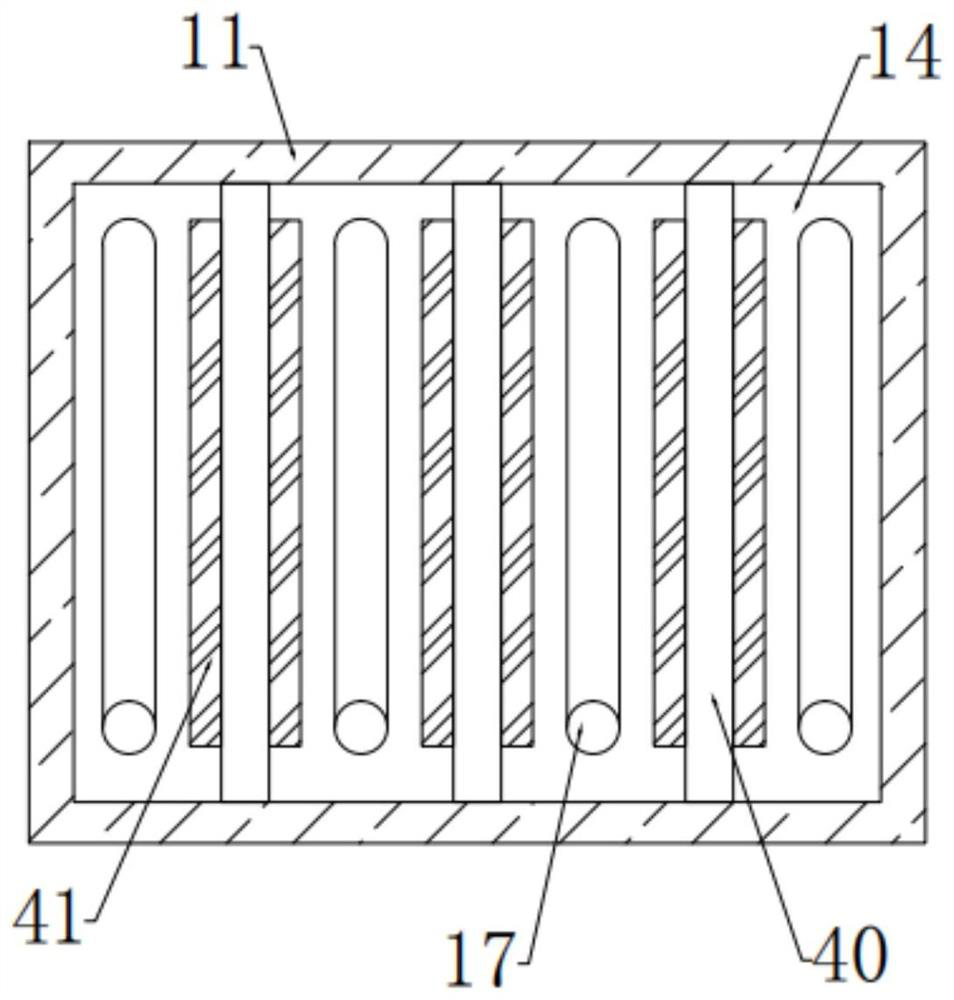

Heat pipe drying chamber that can utilize waste heat

ActiveCN105423739BImprove heat conduction and heat exchange speedAchieve dryingGranular material dryingGrass dryingThermal energyVertical tube

The invention discloses a thermo-tube drying storehouse capable of utilizing afterheat. The thermo-tube drying storehouse consists of shells, an inner storehouse, a discharging device, a heat conducting medium and a heat conducting working medium, wherein the three shells are respectively mounted over a preheating section, a drying section and a cooling section of the inner storehouse; the inner storehouse consists of a storehouse body, a cooling vertical tube and a helical blade; an inner chamber between the shells and the inner storehouse is filled with the heat conducting medium and the heat conducting working medium; the heat conducting working medium and the heat conducting medium are used for conducting heat and radiating heat by the storehouse body and the cooling vertical tube of the inner storehouse; the heat conduction speed and heat exchange speed of heat energy are increased; materials can be dried rapidly; the cooling vertical tube and the helical blade of the inner storehouse have the function of stirring the materials; wet materials are hard to cake during a drying process; the drying quality of the materials is improved; the materials can be cooled during the drying process; the heat energy released during cooling of the materials can be effectively used for preheating the materials, so energy-saving drying of the materials is realized.

Owner:宁波华泰盛富聚合材料有限公司

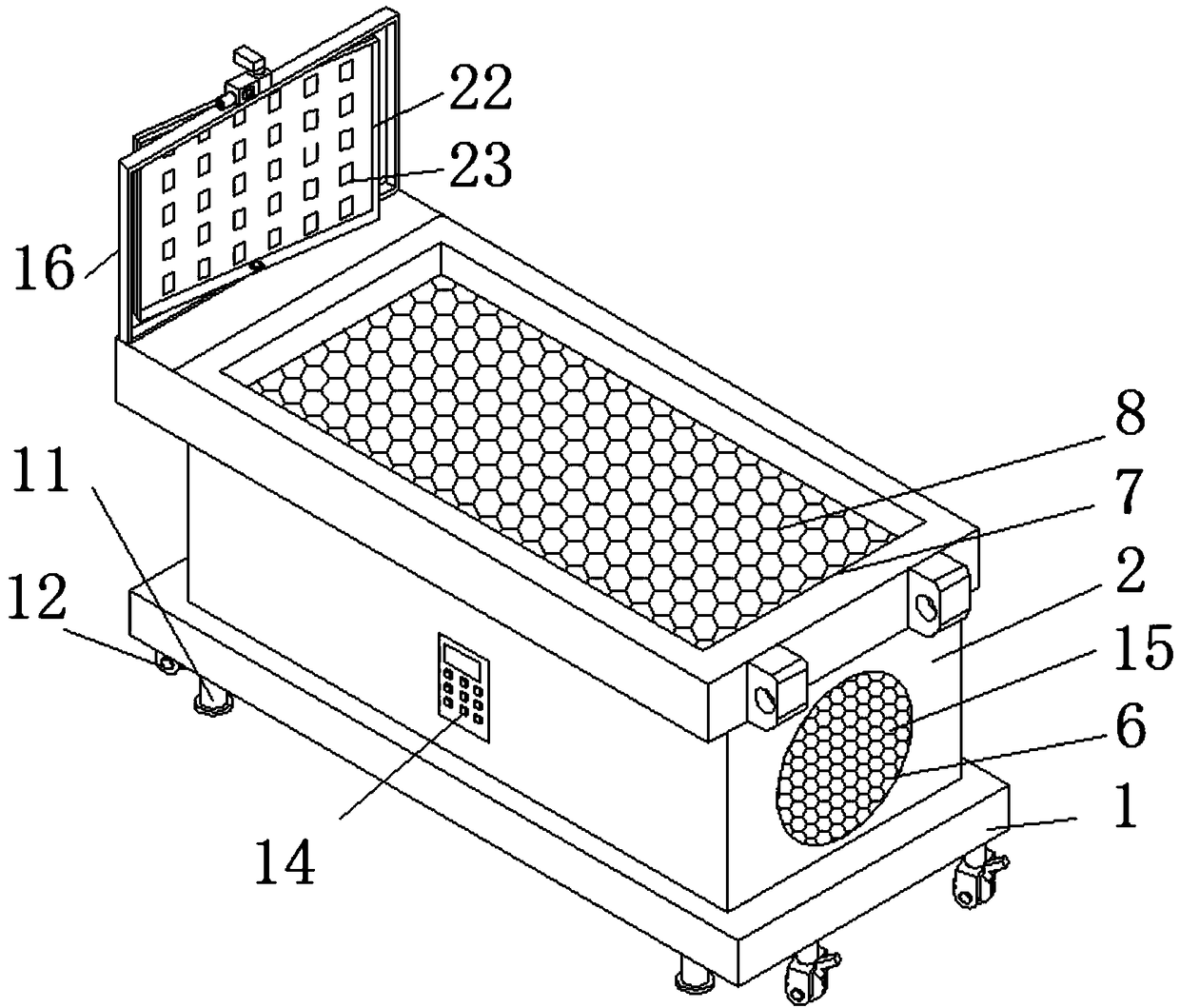

Grass material dehydrator utilizing solar energy to dehydrate directly

InactiveCN110192661ADirect useRealize cyclic tumblingDrying solid materials with heatFeeding-stuffEngineeringIrradiation

The invention discloses a grass material dehydrator utilizing solar energy to dehydrate directly, wherein the grass material dehydrator includes a bottom plate, a box body and a box cover. The top endof the bottom plate is provided with a box body and a number of stand columns. The top ends of the stand columns are fixedly connected with a cross beam plate. The bottom end of the cross beam plateis evenly provided with a plurality of electric telescopic devices. An opening of the top end of the box body is provided with the box cover, an inner cavity of the box body is provided with a stirring shaft, the external circle surface of the stirring shaft is provided with a packing auger in a sleeved manner, and one side of the bottom wall of the box body is connected with a discharge pipe in acut-through manner; the bottom end of the box cover is provided with a sealing cavity matched with the box body, the top wall of the inner cavity of the sealing cavity is connected with an irradiation hole in a cut-through manner, and the irradiation hole is internally provided with a protective plate and a convex lens. Solar energy is directly utilized for illuminating via the convex lens and cooperates with the box body to transpire moisture in a grass material in a sealed environment, so that heat energy of the solar energy can be directly and fully utilized without pollution. By arrangement of the packing auger cooperating with a guide plate, the grass material in the box body can be rolled circularly, the grass material is uniformly heated and the dehydrating effect of the grass material is ensured.

Owner:苏州朝霞生物科技有限公司

Liquid crystal display device

ActiveUS7532273B2Improve display qualityGrass dryingDrying gas arrangementsLiquid-crystal displayEngineering

Owner:LG DISPLAY CO LTD

Intelligent recognition self-propelled paddy field weeding robot

InactiveCN111296050AFacilitate unified collection and processingIncrease the use of spaceGrass dryingMowersAgricultural scienceAgricultural engineering

The invention relates to the technical field of weeding, and discloses an intelligent recognition self-propelled paddy field weeding robot. The intelligent recognition self-propelled paddy field weeding robot comprises a machine body, wherein a lifting handle is fixedly installed at the top of the machine body; moving wheels are fixedly installed at the bottom of the machine body; and a crawler belt is fixedly connected to the exteriors of the moving wheels. According to the intelligent recognition self-propelled paddy field weeding robot, an exhaust fan is arranged on the right sides of bladeshells, cut weeds can enter a weed collecting box through the exhaust fan, and meanwhile, a heating plate is fixedly installed on the front face of the weed collecting box to treat water in the weedsaccording to the characteristics of a paddy field environment, the actual use space of a box body is promoted for facilitating unified collection and treatment of the weeds, a protective shell is arranged on the left side of a motor shell, personnel are prevented from accidentally making contact with and colliding with the blades to be injured, meanwhile, the blade shells are of a spliced type and are installed and limited through the limiting rods, the robot is convenient in disassembly and easy in maintenance, and the crawler belt adapts to paddy field terrains to prevent the device from rollover.

Owner:JINHUA VOCATIONAL TECH COLLEGE

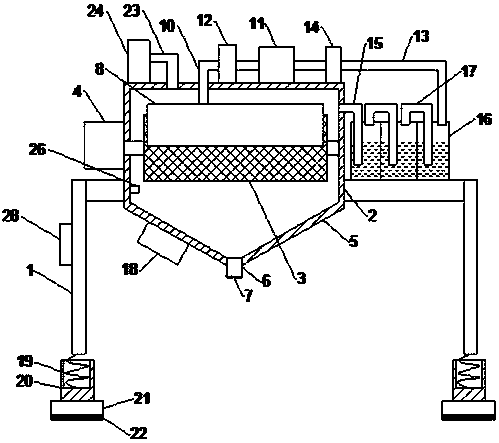

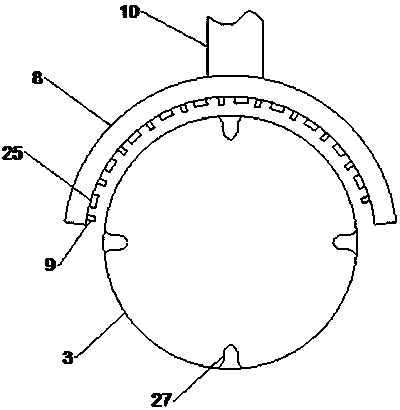

Green grass drying machine

ActiveCN107860185AGood removal effectImprove drying efficiencyDrying solid materials with heatGrass dryingSpray nozzleRockdust

The invention relates to a green grass drying machine which comprises a support. A drying barrel is arranged on the support, a net-shaped stirring barrel is arranged in the drying barrel and is connected with a motor through a rotating shaft, an ash collecting hopper is arranged at the bottom of the drying barrel, a hollow arc air bellow is arranged at the upper portion of the stirring barrel in asurrounding manner, the inner surface of the air bellow is provided with a plurality of air spraying nozzles communicated with an inner cavity of the air bellow, an air blower is connected to the airbellow through an air inlet pipe, a heating device is arranged on the air inlet pipe, an air inlet of the air blower is connected with a connecting pipe, a gas-water separating device is arranged onthe connecting pipe, and the connecting pipe is communicated with the drying barrel through a dust removal device and an air outlet pipe; and the dust removal device comprises a plurality of water tanks, the end of the connecting pipe is arranged at the top of the interior of the water tank at the right end, one end of the air outlet pipe is connected with the drying barrel, the other end of the air outlet pipe is arranged at the bottom of the interior of the water tank at the left end, and the adjacent water tanks are connected through 7-shaped guide pipes. The green grass drying machine hasthe beneficial effects that the drying efficiency is high, the effect is good, dust on green grass can be well removed, and the heat using efficiency is high.

Owner:GANSU AGRI UNIV

Mobile tracking type solar pasture drying device

The invention discloses a mobile tracking type solar pasture drying device. The mobile tracking type solar pasture drying device comprises a bottom plate; a pasture drying box is welded to the top ofthe bottom plate; the top of the pasture drying box is fixedly provided with a groove; a first screen plate is welded in the bottom end of the groove; a protruding part of one end of the groove extends to the left side of the top of the pasture drying box; an air blower and a heating device are started by a DSP controller to operate, so that the air blower heats and dries air around the heating device, the bottom of pasture is subjected to drying treatment through the dried air, through driving of a motor, a worm is driven by a speed reducer to rotate and drives a turbine to rotate, the turbine drives a rotating shaft to rotate, thus, the rotating shaft is driven to rotate, and a movable plate is further driven to rotate; and the DSP controller is used for controlling a photoelectric sensor for treating and tracking sunlight and receiving output signals of the photoelectric sensor and is driven by the motor, and the mobile tracking type solar pasture drying device has the functions ofphotovoltaic power generation and automatic intelligent sunlight tracking.

Owner:HUIZHOU WULING KANGTAI HEALTH TECH CO LTD

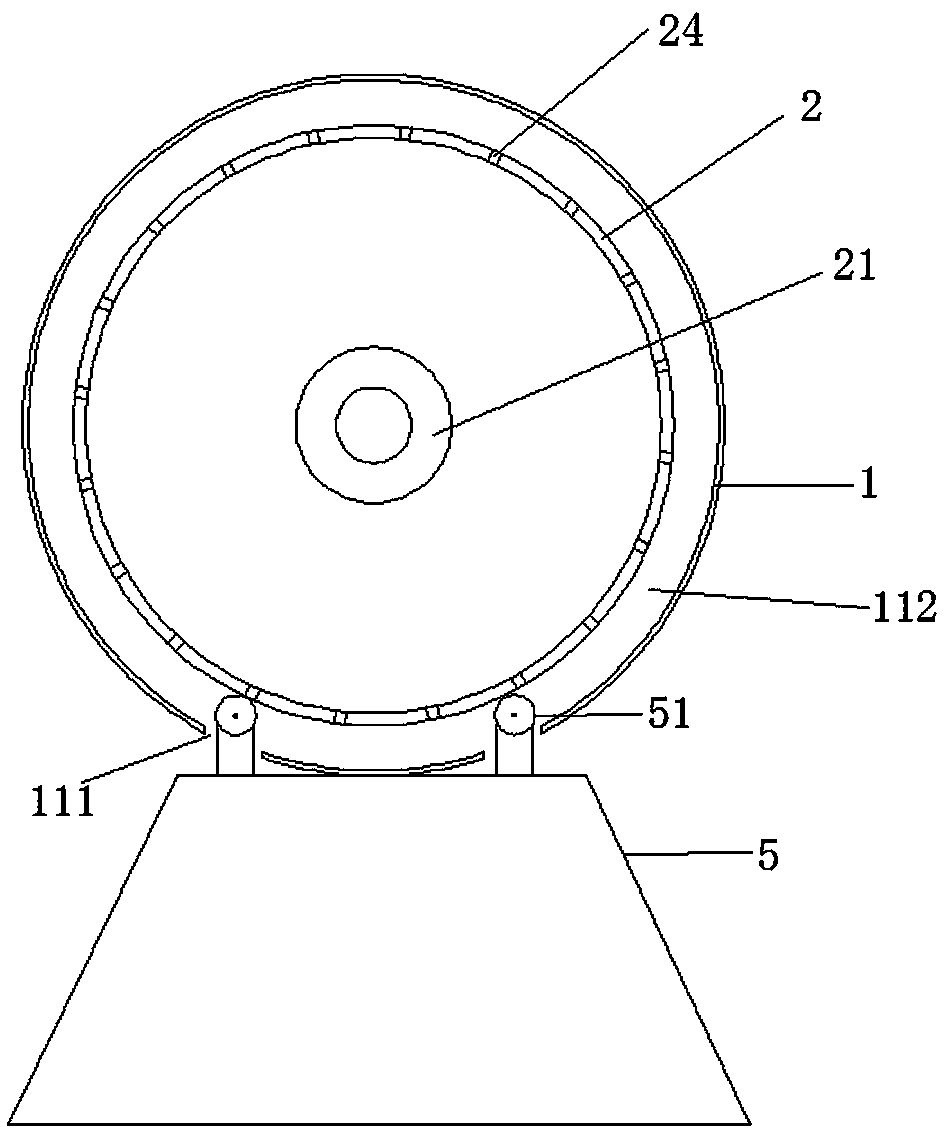

Herbage crusher

InactiveCN109417917AEasy to storeSimple and fast operationSievingFeeding-stuffSpiral bladeElectric machine

The invention relates to a herbage crusher, comprising an outer cylinder, an inner drum, a rotating electric machine for driving the inner drum to roll in forward and reverse directions, a plurality of supporting rollers, a fixing support for fixing the supporting rollers and the rotating electric machine, an air heater, a crushing chamber, an air blower, a cutting motor, a material conveying pipeand a storage chamber; the inner drum is in a shape of a rugby, one end of the inner drum is provided with a drum mouth, and the other end of the inner drum is closed and has an outer wall fixedly provided with a flange; the flange is fixedly connected with a rotary shaft of the rotating electric machine; the inner drum is slanted on the supporting rollers, and the end, provided with the drum mouth, of the inner drum is disposed upward; the outer wall of the circumferential surface of the inner drum is provided with a plurality of annular rolling ways for cooperative use with the supporting rollers; a plurality of holes having a diameter of two to five millimeters are uniformly arranged in the inner drums; and the interior of the inner drum is provided with two continuous but non-intersecting spiral blades, and two ends of each of the spiral blades are respectively disposed at both ends of the inner drum.

Owner:闽清县金沙大龙湾生态养殖场有限公司

Thermo-tube drying storehouse capable of utilizing afterheat

ActiveCN105423739AImprove heat conduction and heat exchange speedAchieve dryingGranular material dryingGrass dryingVertical tubeThermal energy

The invention discloses a thermo-tube drying storehouse capable of utilizing afterheat. The thermo-tube drying storehouse consists of shells, an inner storehouse, a discharging device, a heat conducting medium and a heat conducting working medium, wherein the three shells are respectively mounted over a preheating section, a drying section and a cooling section of the inner storehouse; the inner storehouse consists of a storehouse body, a cooling vertical tube and a helical blade; an inner chamber between the shells and the inner storehouse is filled with the heat conducting medium and the heat conducting working medium; the heat conducting working medium and the heat conducting medium are used for conducting heat and radiating heat by the storehouse body and the cooling vertical tube of the inner storehouse; the heat conduction speed and heat exchange speed of heat energy are increased; materials can be dried rapidly; the cooling vertical tube and the helical blade of the inner storehouse have the function of stirring the materials; wet materials are hard to cake during a drying process; the drying quality of the materials is improved; the materials can be cooled during the drying process; the heat energy released during cooling of the materials can be effectively used for preheating the materials, so energy-saving drying of the materials is realized.

Owner:宁波华泰盛富聚合材料有限公司

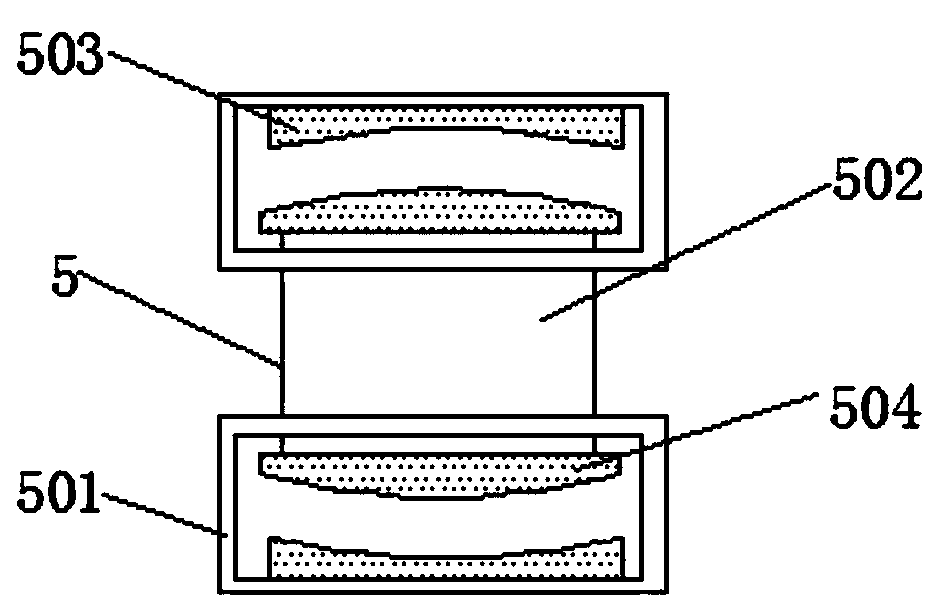

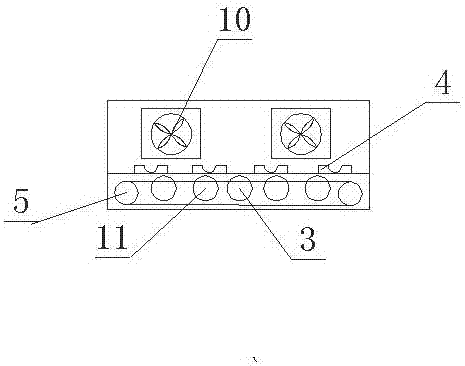

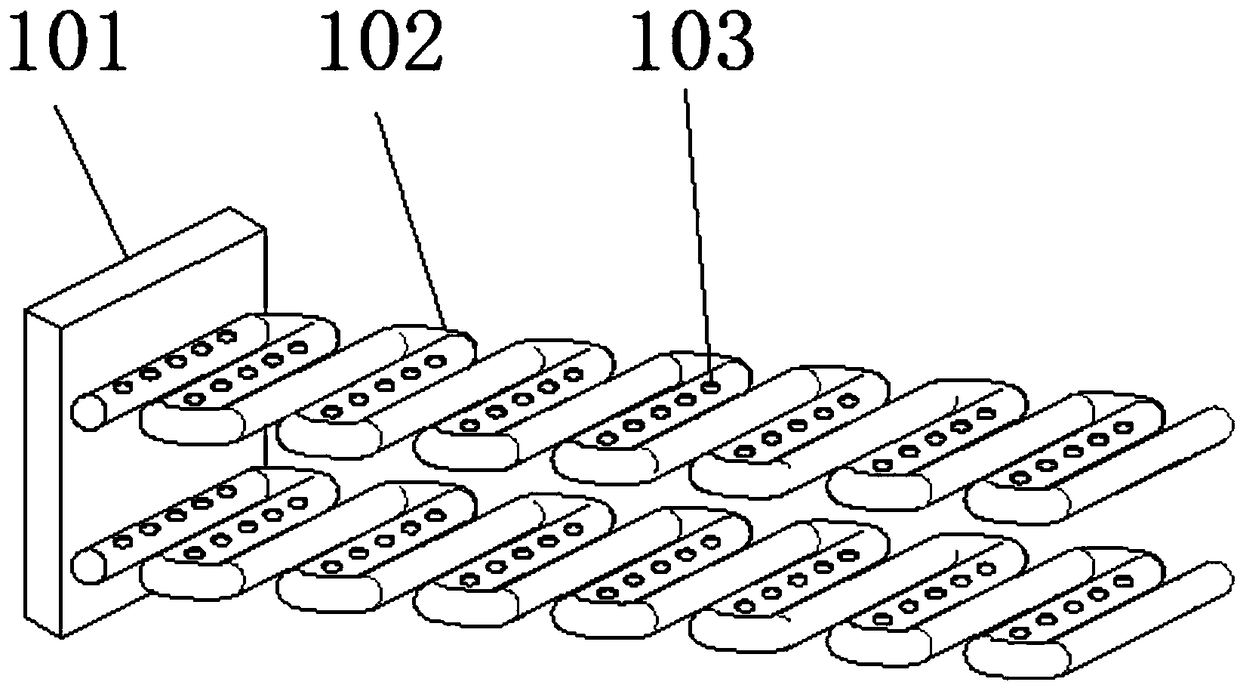

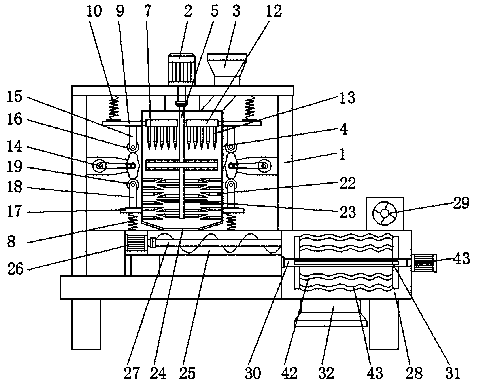

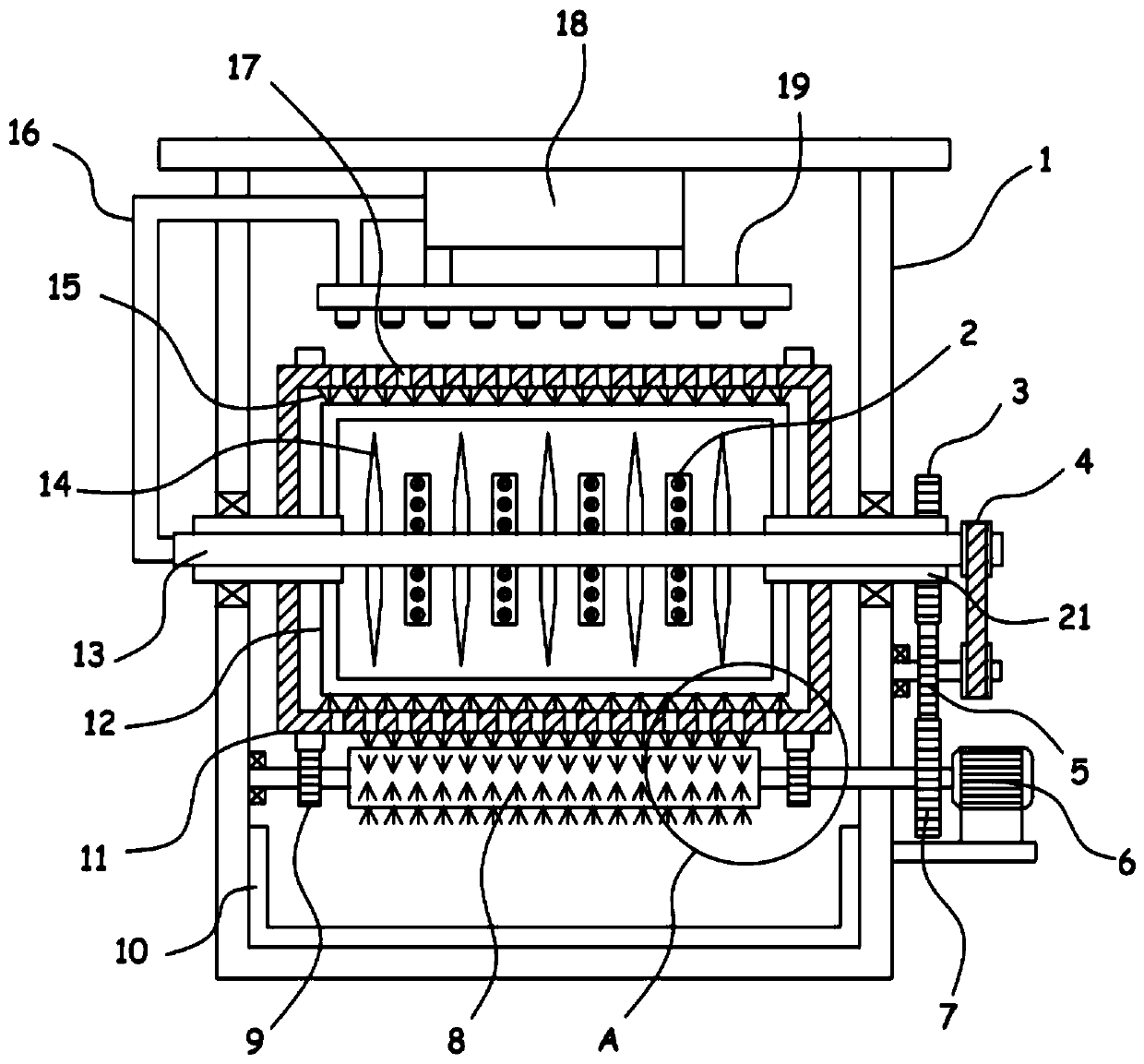

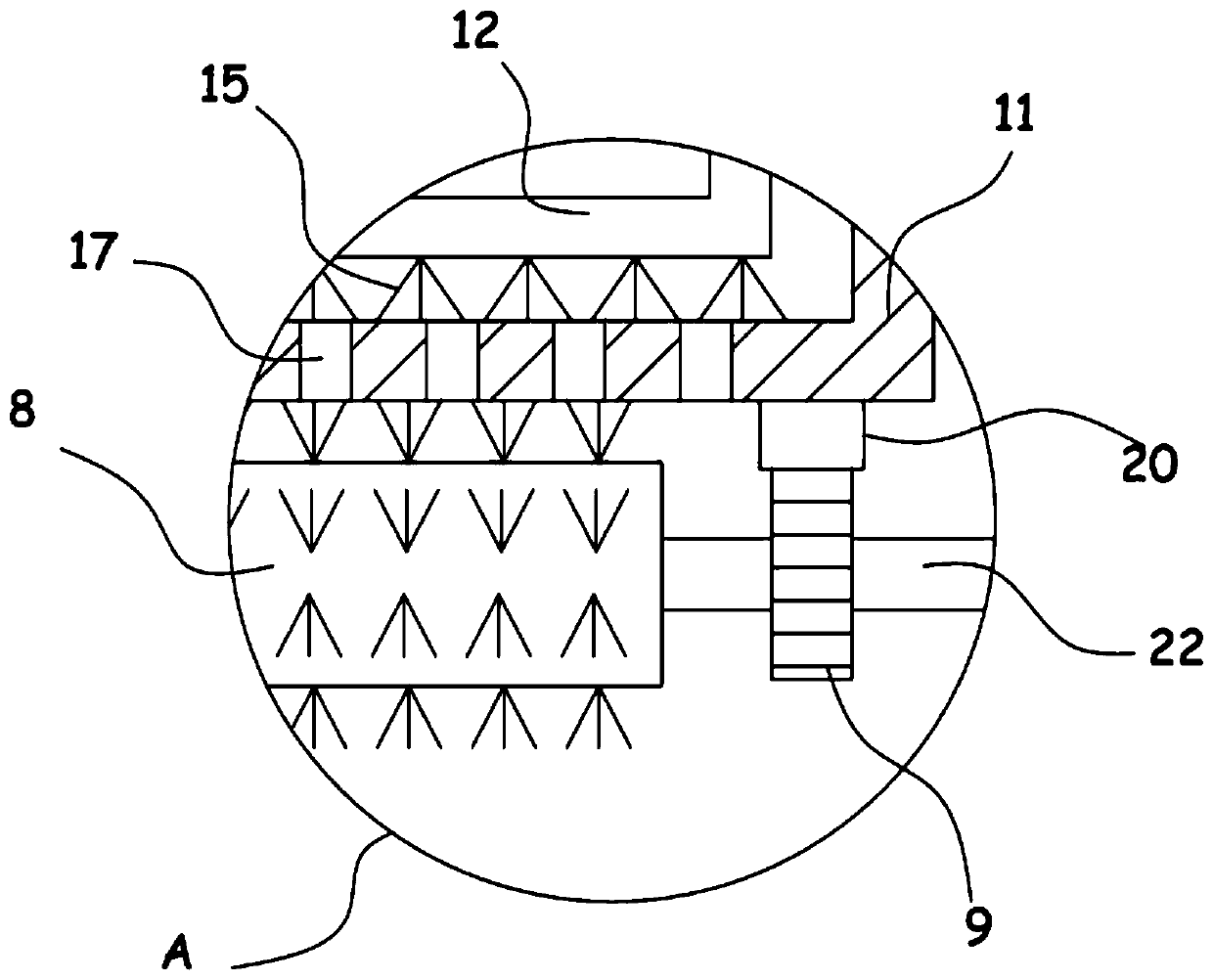

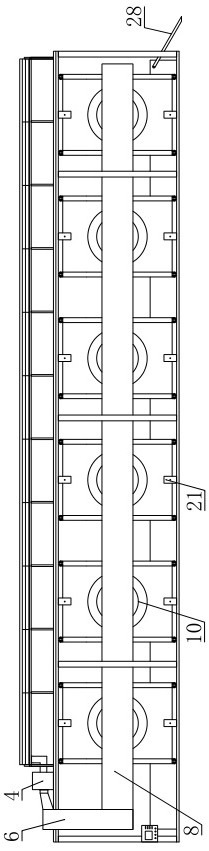

Modularized multifunctional dryer

PendingCN114413606AImprove drying efficiencyReduce excess spaceGrass dryingDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention belongs to the technical field of dryers, and particularly relates to a modularized multifunctional dryer which comprises a dryer body, a feeding device and a discharging device, the dryer body is formed by assembling a plurality of groups of functional modules which are connected in series, and each functional module comprises an upper frame and a lower frame which are fixedly connected together; an upper air outlet mechanism and a lower air outlet mechanism are installed in the upper frame and the lower frame in a sliding mode respectively, and the upper air outlet mechanism and the lower air outlet mechanism are distributed in a mirror image mode. The modular multifunctional drying machine is high in production efficiency and suitable for drying treatment of agricultural and pasture products, the functional modules in the modular multifunctional drying machine comprise a plurality of station drying units and cooling units, continuous drying of forage grass such as alfalfa and grassland grass is achieved, continuous and rapid drying of grains can also be achieved, and the production efficiency is improved. The loss caused by weather influence is reduced, and the daily processing capacity of the dryer is improved, so that the production efficiency is improved.

Owner:厦门奔晨机械科技有限公司

Efficient shredding device for pasture in animal husbandry

InactiveCN109964663AAchieve preliminary cuttingRealize secondary cuttingGrass dryingDrying gas arrangementsCouplingEngineering

The invention discloses an efficient shredding device for pasture in animal husbandry. The efficient shredding device comprises a rack. A first motor is arranged on the top of the rack, a feed port isformed in one side of the first motor, a cutting box body is arranged on the inner side of the rack, an output shaft of the first motor is connected with a rotary rod through a coupler, the middle ofthe rotary rod is sleeved with a pasture chopping plate, a first cutting assembly is arranged above the pasture chopping plate, drive mechanisms are symmetrically arranged on the two sides of the cutting box body, an upper supporting rod is fixed to the bottom of a movable plate, sliding blocks are arranged below the drive mechanisms, lower supporting rods are arranged on the tops of the slidingblocks, sliding grooves are symmetrically formed in the lower portions of the outer walls of the two sides of the cutting box body, and the sliding grooves are matched with the sliding blocks. A second cutting assembly is arranged on the portion, below the pasture chopping plate, of the inner side of the cutting box body, a feeding barrel is arranged below the cutting box body, and the end of thefeeding barrel is communicated with a drying barrel. Use is convenient and rapid, and the pasture can be efficiently and completely cut through the first cutting assembly and the second cutting assembly.

Owner:黄小卡

Forage processing and refining device for livestock breeding

InactiveCN110383990AImprove crushing efficiencyAvoid stickingGrass dryingHollow article cleaningLivestock breedingEngineering

The invention discloses a forage processing and refining device for livestock breeding, and relates to the technical field of the livestock breeding. The device comprises a fixed bracket, wherein a rotating drum is in transmission connection on the fixed bracket through a driving mechanism, a plurality of discharging holes are uniformly formed in the side wall of the rotating drum, a cleaning mechanism for cleaning the discharging holes is fixed on a rotating sleeve, and a drying mechanism for drying forage is arranged above the rotating drum. A transmission mechanism drives a hollow pipe andthe rotating sleeve to rotate synchronously reversely, rotating plates, crushing blades and a rotating bracket rotate in opposite directions, so that forage in the rotating drum is rapidly crushed inthe sufficient rotating process, the forage crushing efficiency is greatly improved, the drying mechanism can dry the forage, meanwhile, a brush plate rotationally cleans the inner wall of the rotating drum, forage sticking is avoided, and rapid turning and efficient crushing are realized.

Owner:XINJIANG AGRI UNIV

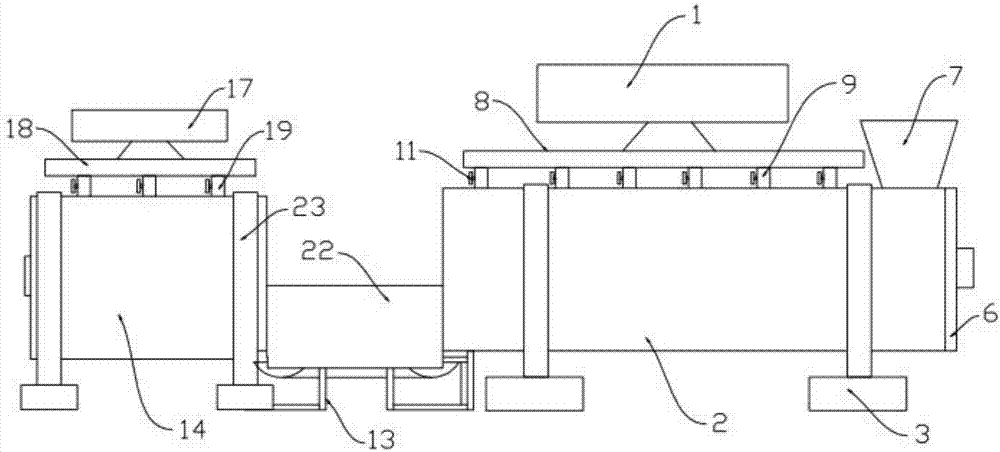

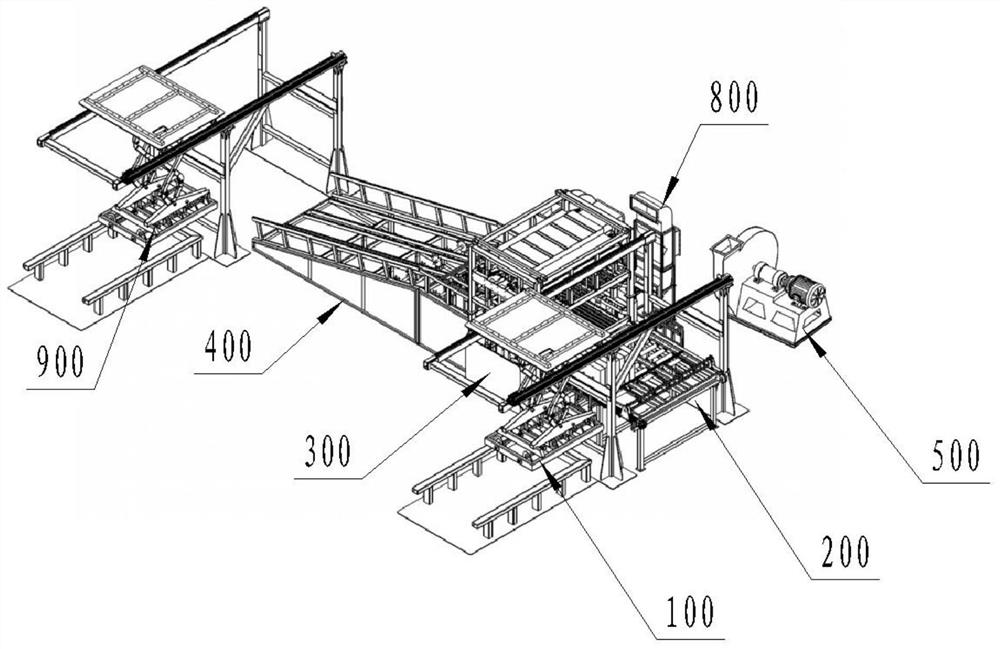

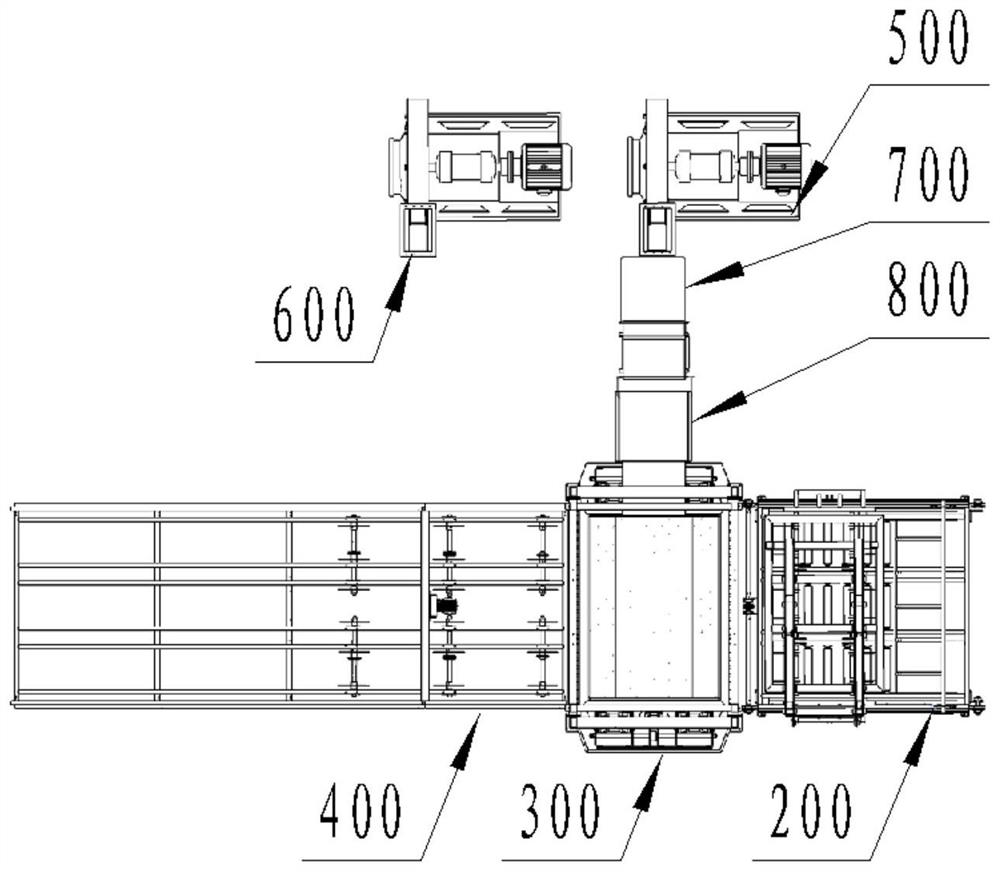

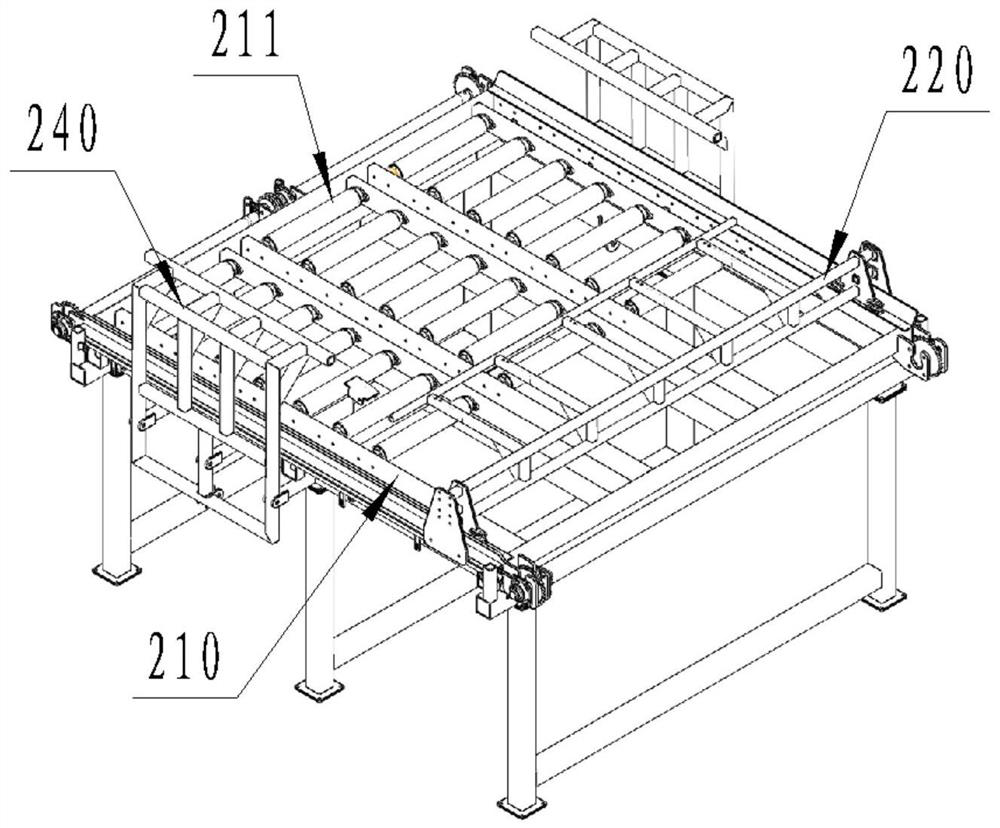

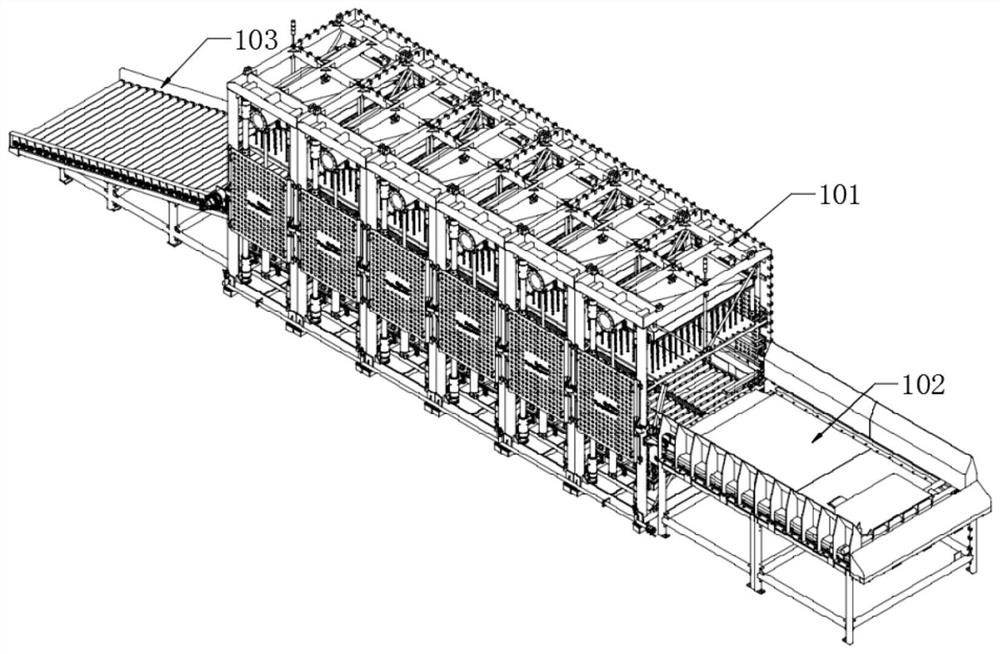

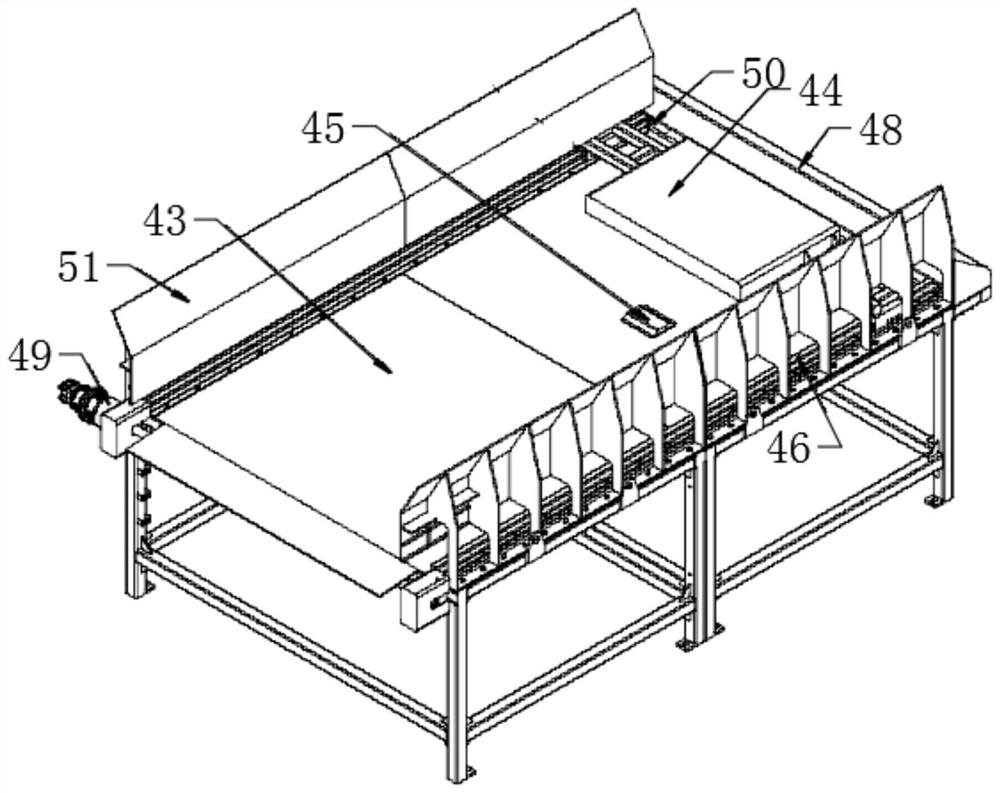

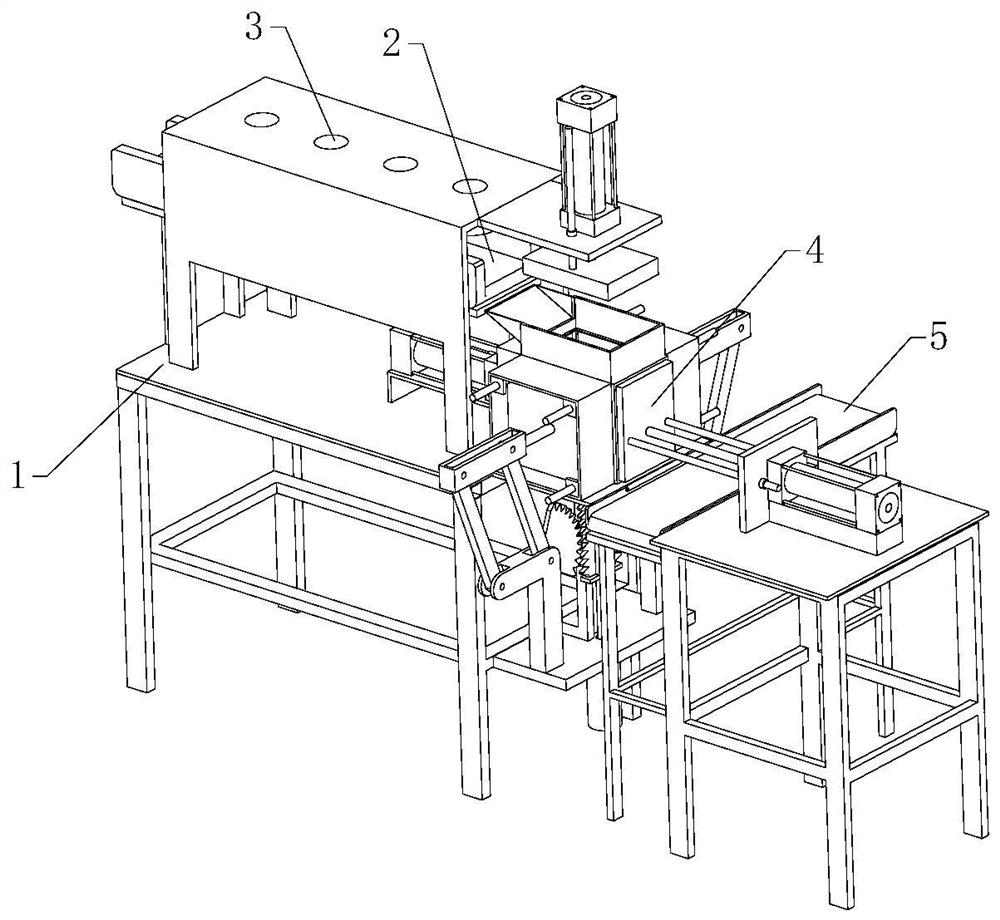

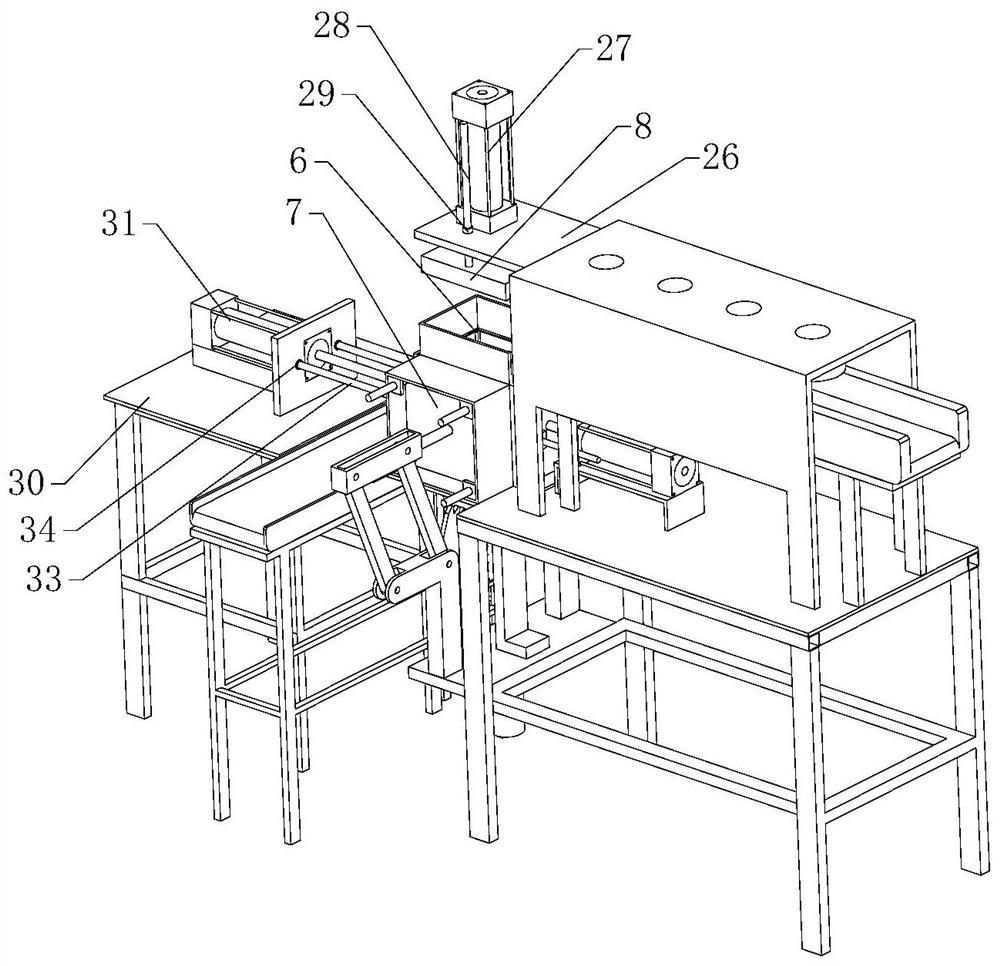

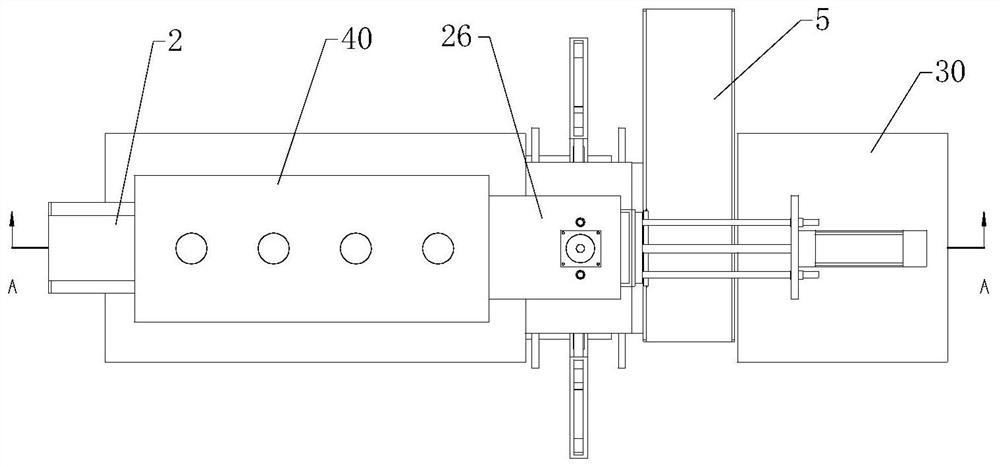

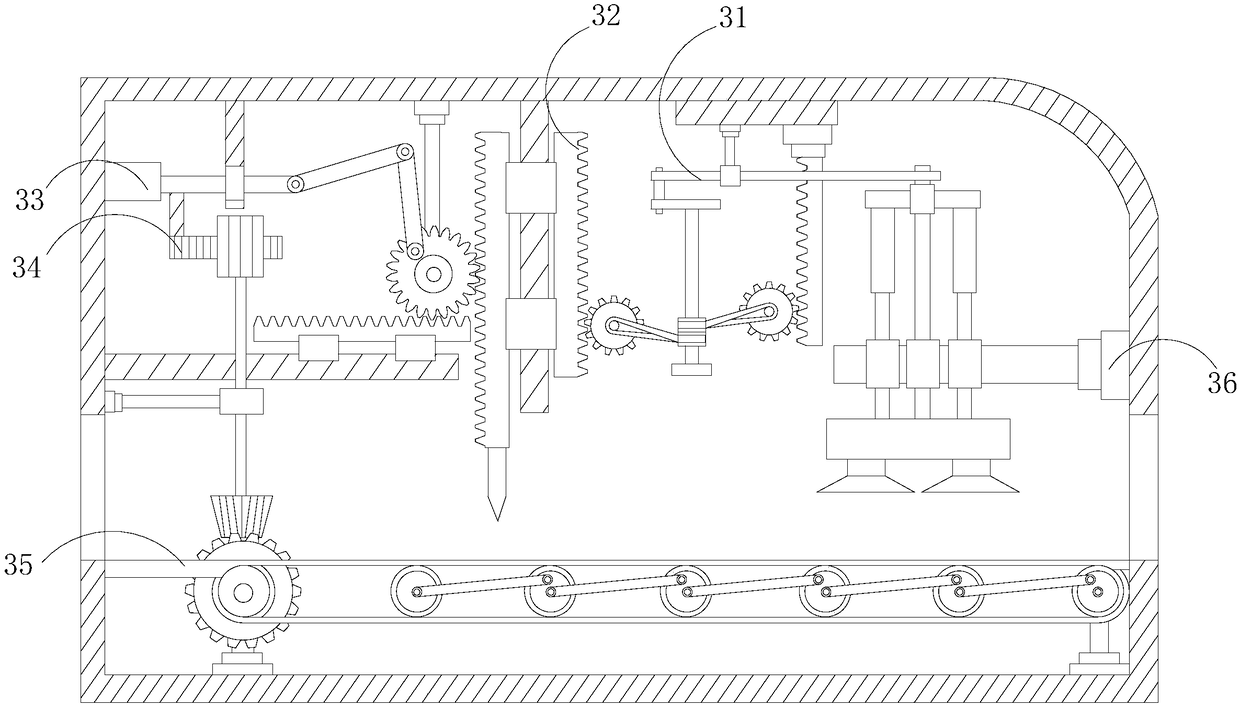

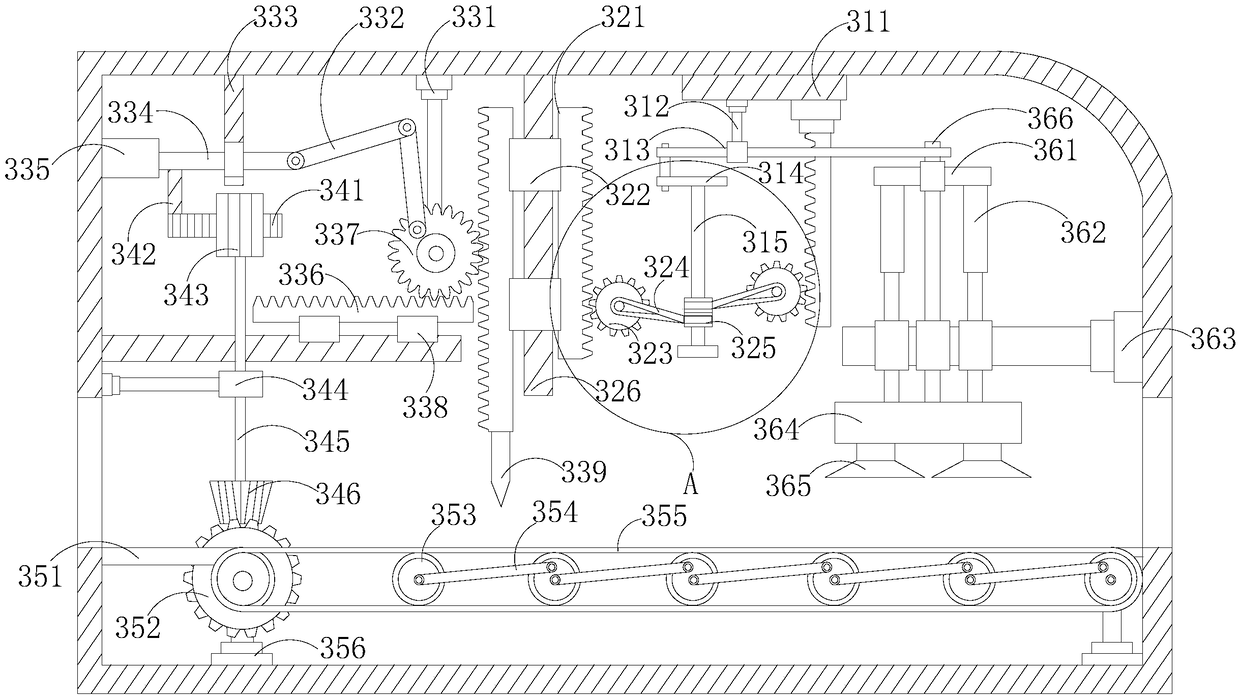

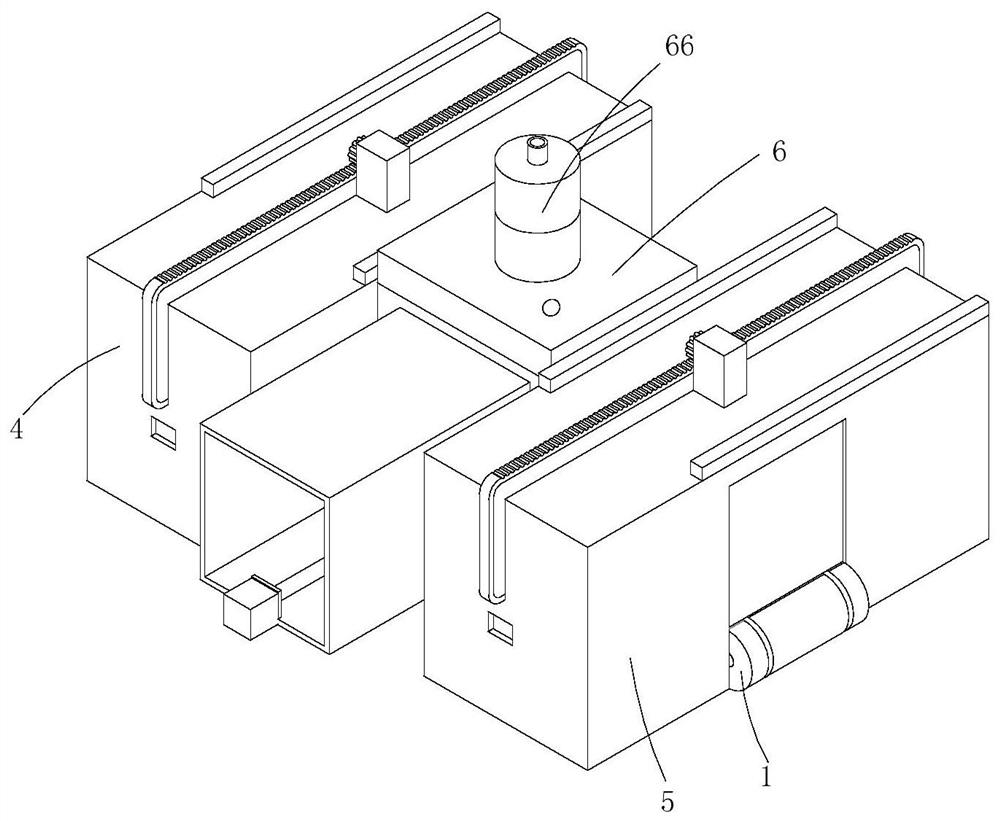

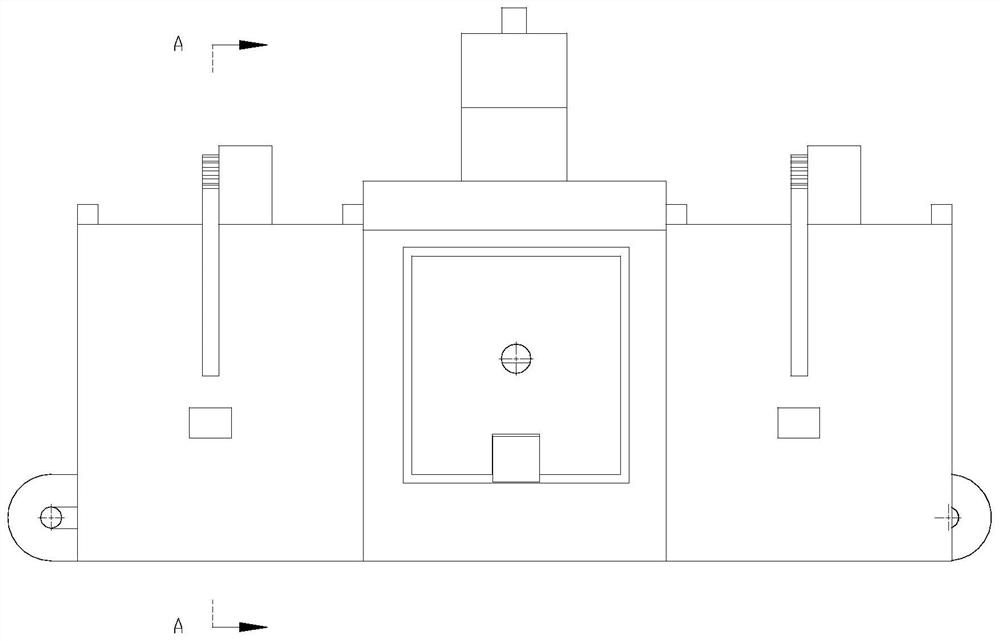

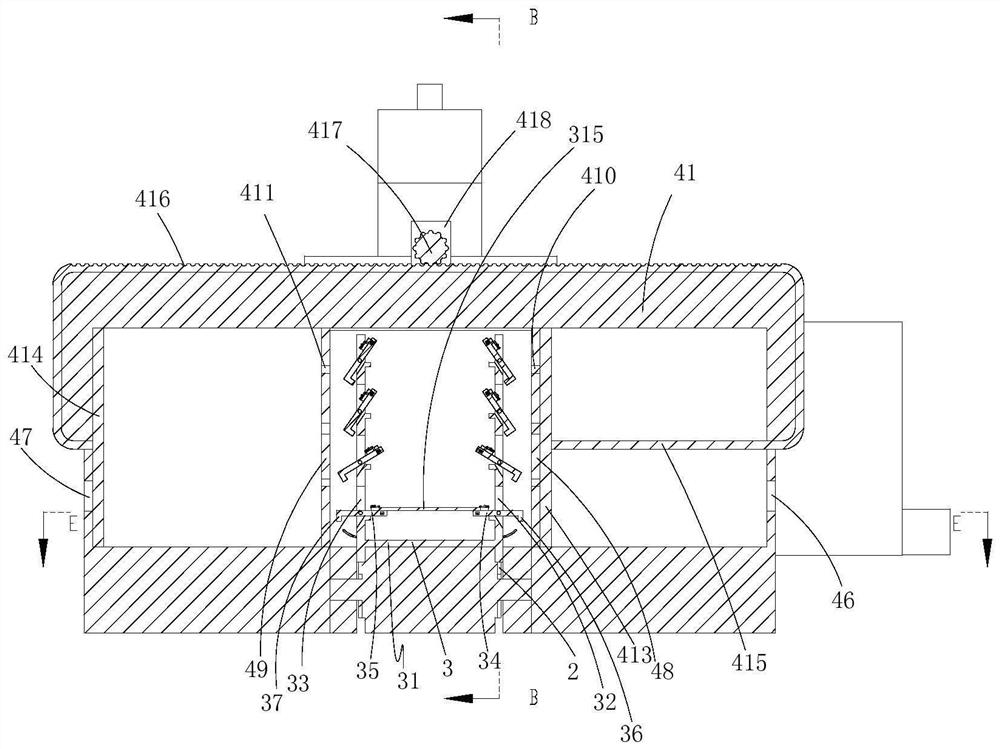

Efficient forage grass drying and bundling equipment

InactiveCN112314191AAutomatic and efficient dryingImprove drying and bundling efficiencyGrass dryingBalingAgricultural scienceAgricultural engineering

The invention relates to the technical field of forage grass bundling processing, in particular to efficient forage grass drying and bundling equipment. The efficient forage grass drying and bundlingequipment comprises a rack, a feeding conveyor, a drying mechanism, a bundling mechanism and a discharging conveyor. The bundling mechanism comprises a bundling bin arranged at the end, close to the discharging conveyor, of the rack, two side pressing plates which are symmetrically arranged at the two sides of the bundling bin and can move towards or away from the interior of the bundling bin, a lower pressing plate which is arranged over the bundling bin and can ascend and descend towards the interior of the bundling bin, a discharging baffle which is arranged on the side close to the discharging conveyor and can horizontally move in the direction, away from the bundling bin, of the discharging conveyor, and a discharging push plate which is arranged on the side away from the dischargingbaffle and can move towards the discharging conveyor along the interior of the bundling bin. By means of the efficient forage grass drying and bundling equipment, forage grass can be automatically andefficiently dried, the dried forage grass is automatically bundled and discharged, and the forage grass drying and bundling efficiency is improved.

Owner:HULUNBUIR UNIV

Feed for breeding guinea pigs and production method thereof

InactiveCN106359865AHigh energyHigh in proteinDrying solid materials with heatGrass dryingFood additiveAnimal science

The invention belongs to the technical field of feeds and particularly discloses a feed for breeding guinea pigs and a production method thereof. The feed is prepared from, in certain weight part ratio, a green feed, a concentrated feed, and a feed additive through the steps of cleaning and selecting the raw materials, drying, crushing and sieving the raw materials, and performing mixing granulation. The green feed is composed of, in certain weight part ratio, Timothy grass, rye grass, alfalfa, and stalk and leaves of corn; the concentrated feed is composed of, in certain weight part ratio, soybean powder, peanut powder and fishmeal; and the feed additive is composed of, in certain weight part ratio, artemisia argyi, corydalis bungeana, eucommia ulmoides, semen cuscutae, donkey-hide gelatin, compound vitamins and compound microelements. The feed is prepared from green and safe raw materials, has comprehensive nutrients and disease resistant elements, is not liable to deteriorate and mildew, can effectively improve reproduction capability and growth and development speed of the guinea pigs and can improve optimization of individual of the guinea pigs.

Owner:广西河池市明达特种养殖专业合作社

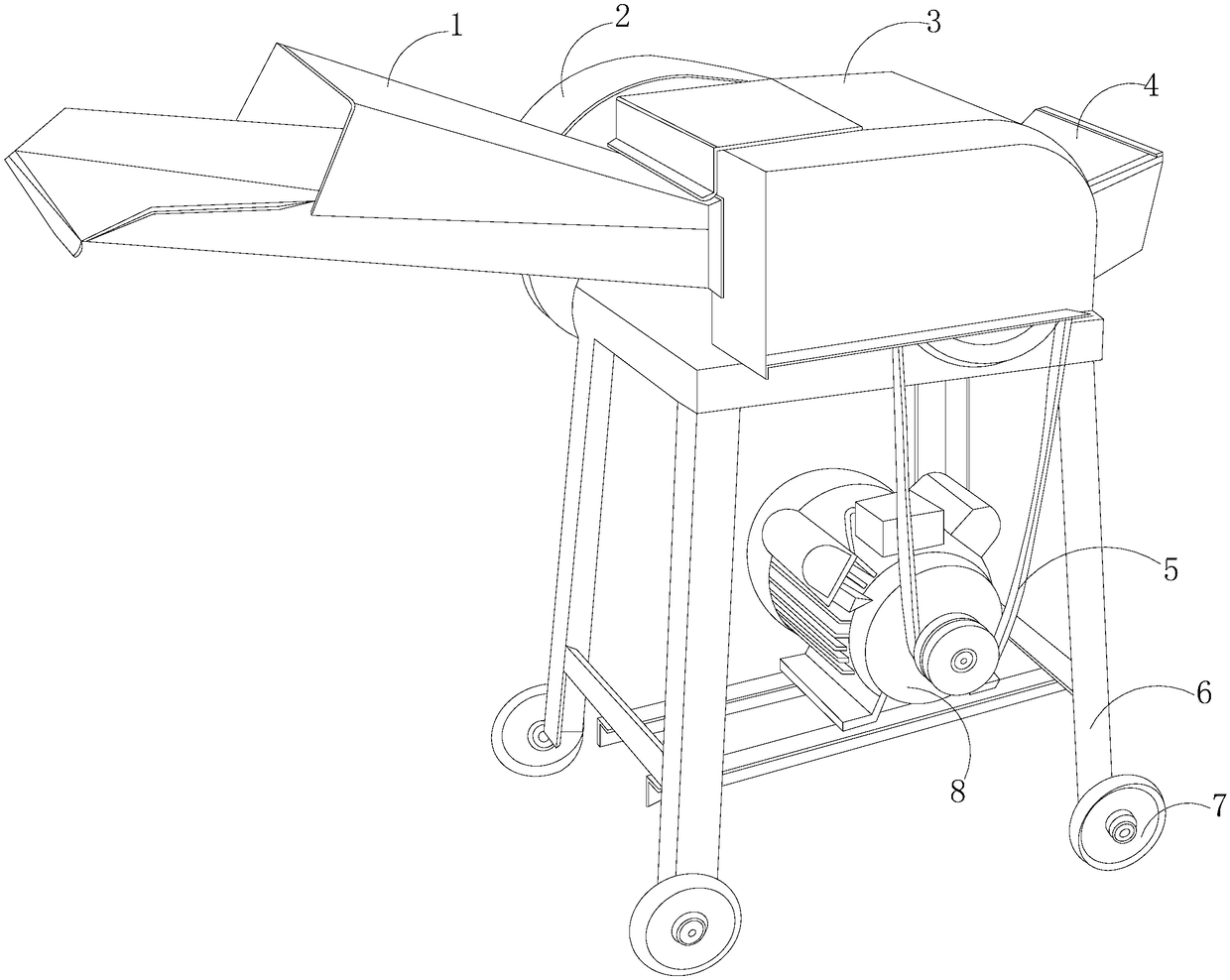

Livestock forage cutting device

InactiveCN108990568AKeep colorRetain nutrientsGrass dryingDrying gas arrangementsEconomic benefitsEngineering

The invention discloses a livestock forage cutting device structurally comprising a feeding hole, a belt wheel guard, a cutting box, a discharging hole, a belt, support frames, sliding wheels and a motor; the feeding hole is welded and fixed in the left side of the cutting box and is intercommunication with the inside of the cutting box; the surface of the obverse side of the belt wheel guard clings to and is fixedly arranged at the back of the cutting box; the discharging hole is welded and fixed in the right side of the cutting box and is in communication with the inside of the cutting box;the cutting box is horizontally fixed on the tops of the support frames; the belt is buckled and mounted on a central part of the obverse side of the motor and is connected to the inside of the cutting box in a driving way; the sliding wheels are mounted and fixed at the bottoms of the support frames; and the motor is horizontally fixed between the support frames. The inside of the livestock forage cutting device disclosed by the invention is provided with a drying device, so that the color and mouthfeel of fresh grass are retained, the fresh grass is high in nutrient content and good in taste, not only is the appetite of livestock enhanced, but also the economic benefit is increased, and the cut forage can be stored for a longer time.

Owner:谢跃连

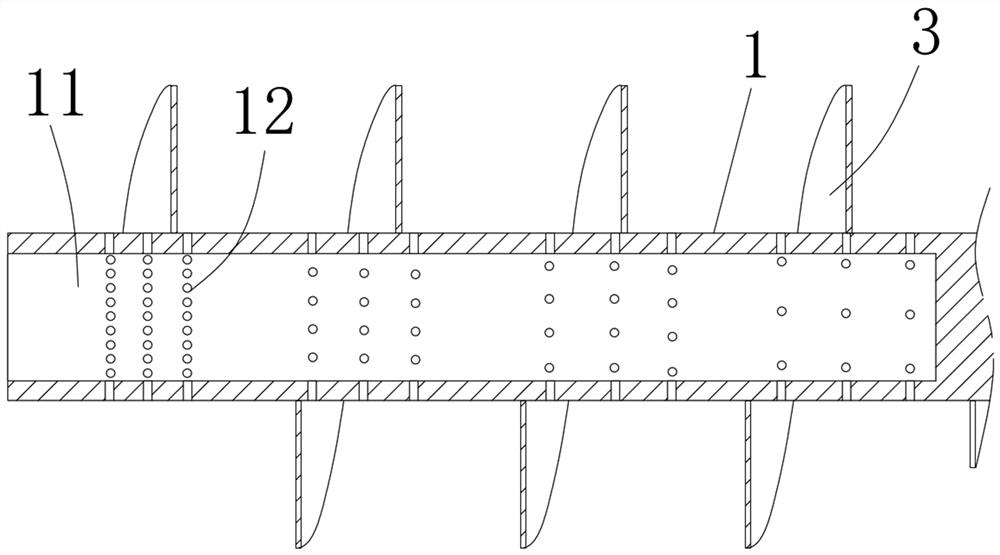

Semi-dry stored grass airing device for modern agriculture

InactiveCN112240686AIncrease the turning areaDry evenlyGrass dryingDrying chambers/containersAgricultural scienceThunderstorm

The invention discloses a semi-dry stored grass airing device for modern agriculture. The device comprises a box body, a lifting mechanism, a shielding mechanism, an electric hydraulic rod, a turningmechanism and a controller; the lifting mechanism is arranged in an inner cavity of the box body; the shielding mechanism is mounted at the top end of the lifting mechanism; the electric hydraulic rodis arranged in the center of the top end of the rear side of the box body in the up-down direction; the turning mechanism is arranged at the top end of the electric hydraulic rod in the left-right direction; and the controller is arranged on the front side of the top end of the box body and electrically connected with the electric hydraulic rod. According to the semi-dry stored grass airing device for modern agriculture, aired fresh grass can be shielded in thunderstorm weather, workers do not need to transfer the grass into a room, time and labor are saved, the grass can be automatically turned over up and down in the airing process to guarantee uniform airing, the workers do not need to manually and frequently turn over the aired grass, operation is simple, and labor waste is avoided.

Owner:薛刚

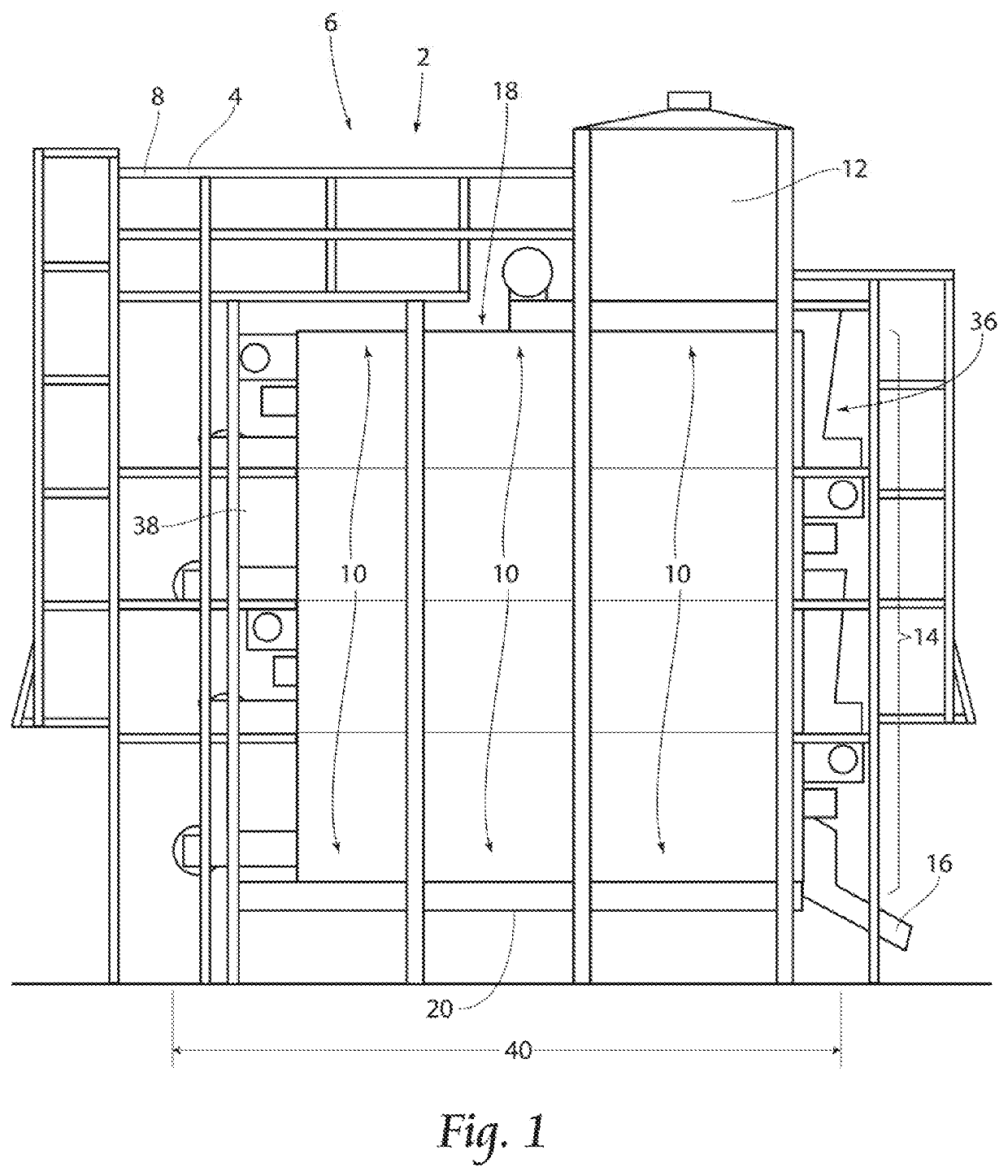

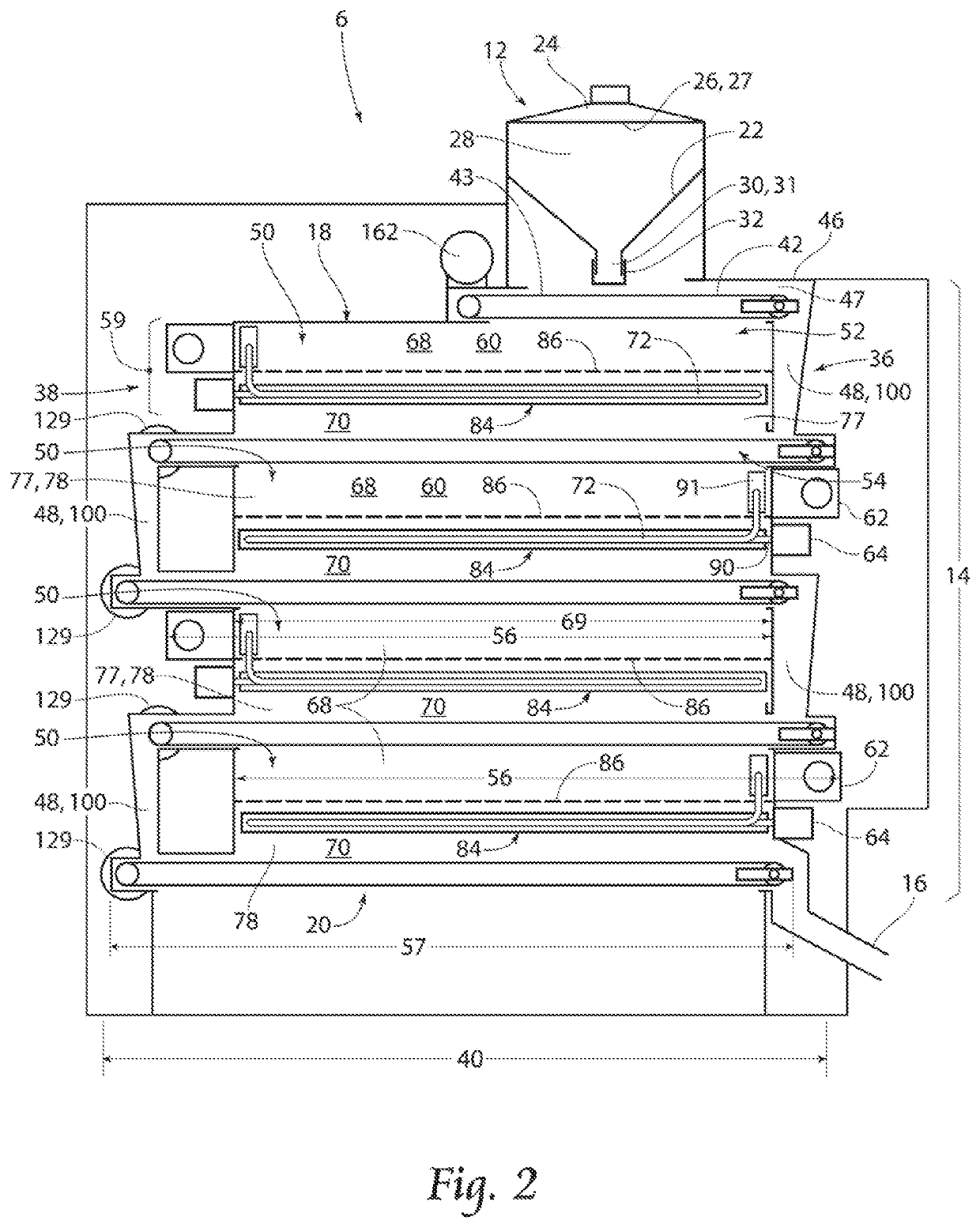

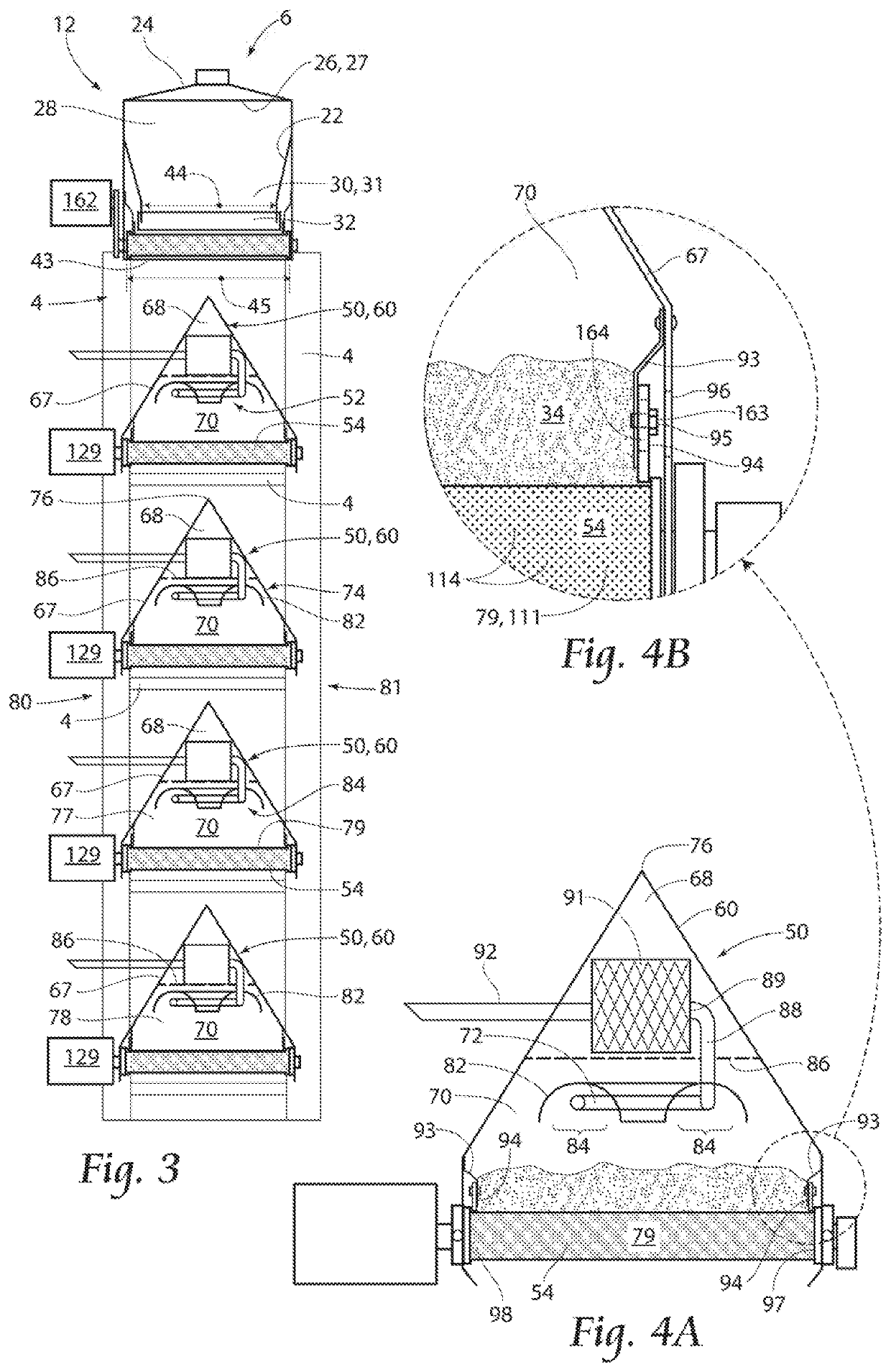

Radiant conveyor drying system and method

ActiveUS11435141B2Encouraging movement of radiant heatPromote sportsDrying solid materials with heatGrass dryingThermodynamicsProcess engineering

A system according to the present invention provides a radiant conveyor drying system and method of operation. The radiant conveyor drying system generally comprises an input assembly, a drying assembly and an exit assembly mechanically fixed to one another. The drying assembly comprising at least one drying unit in communication with one another to provide for passage of product between the respective drying units and the input assembly and the exit assembly. The drying unit comprising a conveyor belt and a drying unit heating assembly. The drying unit heating assembly comprising a plenum and a heating chamber. The drying unit further comprising a burning unit in communication with the heating chamber to provide for radiant heat to contact the product traveling on the conveyor through the drying unit. The drying unit further comprising a blower fan in communication with the plenum to provide for convective air advancing from the plenum, over and through the radiant heat, to the product. Wherein the radiant heat is disbursed throughout the product. A first embodiment of the invention controlling hear generated by the burning unit of each respective drying unit. A second embodiment of the invention controlling heat generated by the burning unit and rate of the conveyor of each respective drying unit. A method of operation of the radiant conveyor drying system is described.

Owner:WOOD WILLIAM J

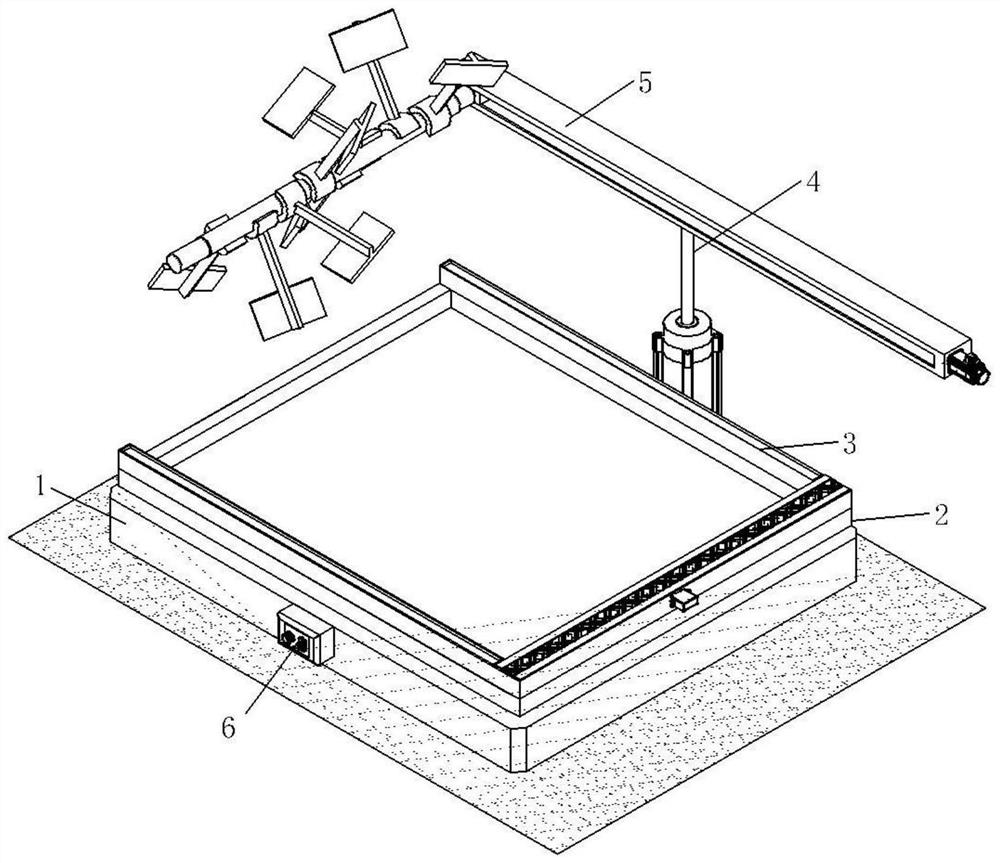

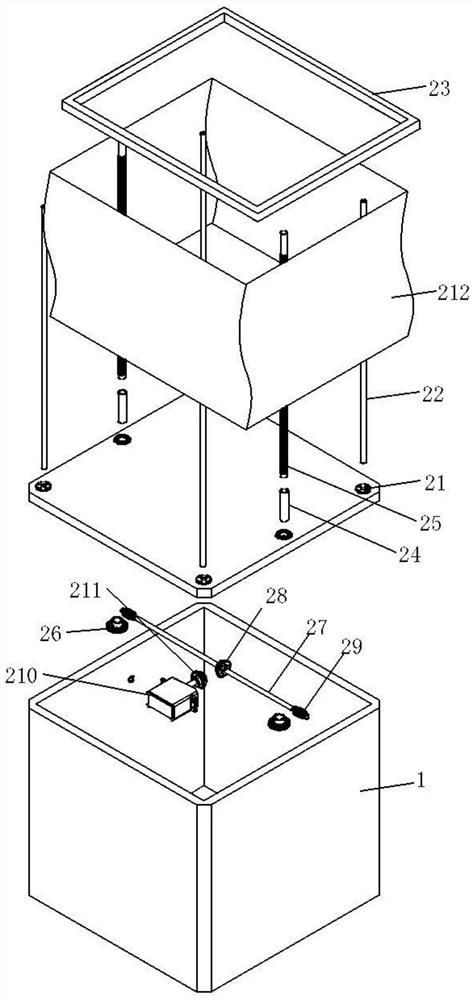

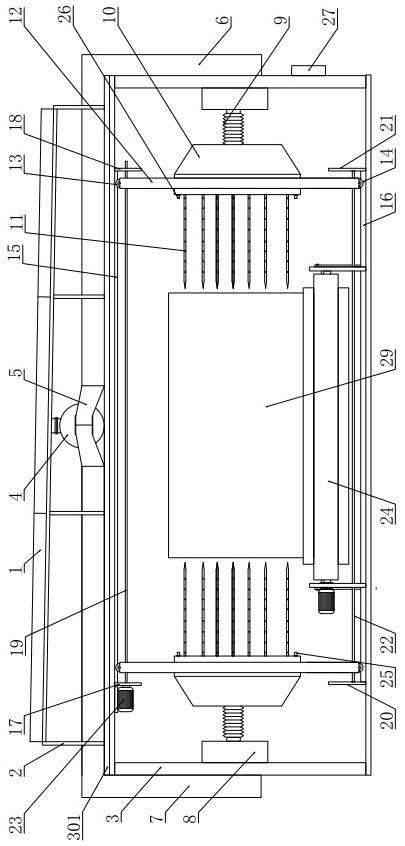

Full-automatic processing system for medicinal herbs

InactiveCN113091415AImprove drying efficiencyImprove drying effectGrass dryingDrying gas arrangementsMedicinal herbsEngineering

The invention discloses a full-automatic processing system for medicinal herbs. The full-automatic processing system comprises a machine body, a conveying belt arranged on the machine body, a containing frame arranged on the conveying belt, a feeding device arranged on the machine body and located at one end of the conveying belt, a discharging device arranged on the machine body and located at the other end of the conveying belt, a heating device arranged on the machine body and located between the feeding device and the discharging device, and a plurality of arc-shaped grooves formed in the conveying belt.

Owner:TONGREN UNIV

Forage cutting device for livestock processing in animal husbandry

PendingCN113892353ARealize automatic cuttingContinuous automatic cuttingDispersed particle filtrationGrass dryingAgricultural scienceCrop livestock

The invention relates to the technical field of animal husbandry processing, in particular to a forage cutting device for livestock processing in animal husbandry. The forage cutting device comprises a shell, a conveyor belt, a circulating cutting mechanism and a driving mechanism, wherein the conveyor belt is connected with the shell; the circulating cutting mechanism is arranged on the outer side of the conveying belt and connected with the shell; the driving mechanism is connected with the shell and used for driving the circulating cutting mechanism to achieve repeated cutting of the forage located on the conveying belt; the circulating cutting mechanism comprises a supporting and connecting assembly, a cutting assembly and an air conveying assembly, and the supporting and connecting assembly is connected with the shell; the cutting assembly is in sliding connection with the supporting and connecting assembly; and the air conveying assembly is connected with the shell. According to the forage cutting device, the driving mechanism and the circulating cutting mechanism are arranged, so that forage can be continuously and automatically cut, forage residues attached to the surface of the device can be automatically cleaned, and the forage cutting efficiency is greatly improved.

Owner:林晓锐

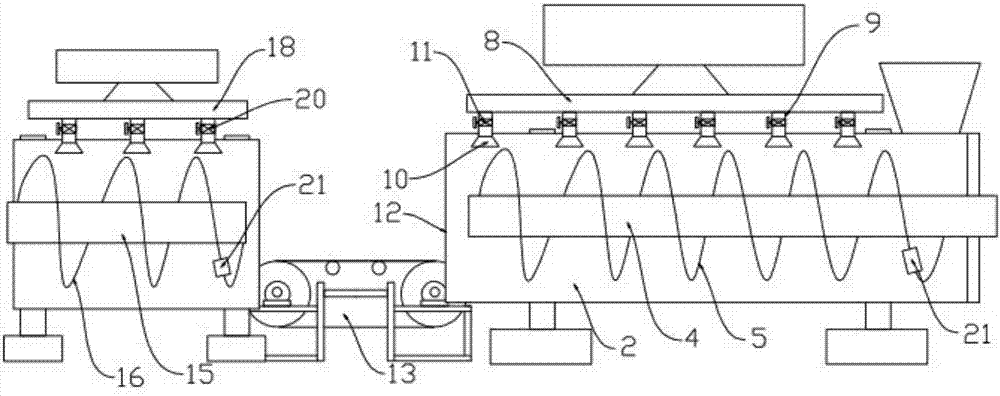

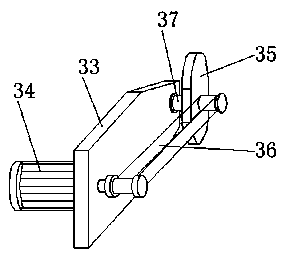

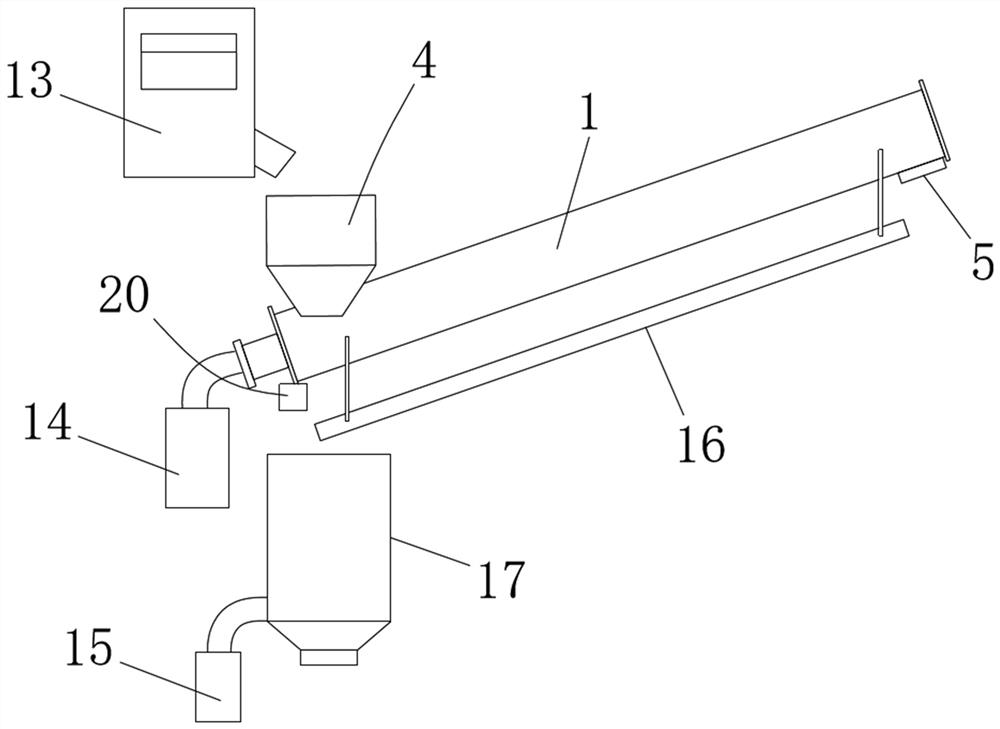

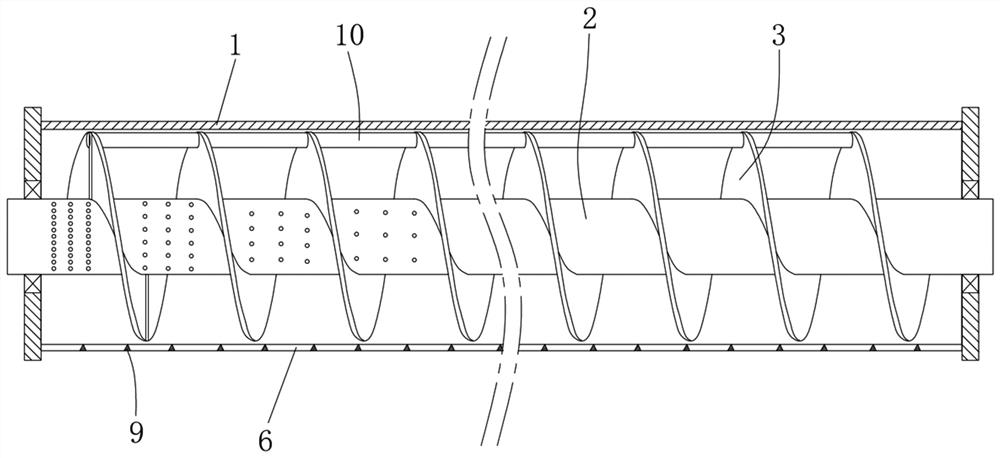

Grass Grading Drying System

ActiveCN111108925BProportionally largeConvenient drying workGrass dryingHarvestersAnimal scienceCrop livestock

The present invention relates to the technical field of animal husbandry, in particular to a pasture grading and drying system, which includes a grading conveying device, the grading conveying device includes an auger, and the auger includes a cylinder, a rotating shaft arranged in the cylinder, and a rotating shaft arranged on the rotating shaft. The helical blade on the upper side of the cylinder is provided with a strip-shaped gap along the direction of the generatrix of the cylinder. The pasture grading conveying device also includes a pasture cutting device and a first hot air device. The first hot air device is used to move toward the The blowing hole on the rotating shaft blows hot air, and a material receiving trough whose length matches the long strip-shaped notch is also arranged under the long strip-shaped notch of the cylinder. A drying device is also arranged under one end. The drying system of this application realizes the distinction between leaves and stalks of forage grass, avoids the risk of mildew in forage grass storage caused by uneven drying, and reduces the waste of forage grass and the occurrence of young animals eating stalks in the current feeding work. Adverse conditions such as indigestion.

Owner:黑龙江省农业科学院畜牧兽医分院

Energy-saving forage grass drying device

InactiveCN112556321AEasy to drySave energyDrying solid materials with heatGrass dryingMirror reflectionAgricultural engineering

The invention discloses an energy-saving forage grass drying device. The energy-saving forage grass drying device is characterized by comprising a support, a charging barrel and a mirror reflection pipe, the charging barrel is arranged above the support, a feeding port is formed in one side of the charging barrel, a discharging port is formed in the other side, corresponding to the feeding port, of the charging barrel, a steam exhaust port is formed in the upper portion of the charging barrel, one end of the mirror reflection pipe is arranged in the middle of the upper portion of the chargingbarrel, and the other end of the mirror reflection pipe extends upwards to form a reflecting plate for adjusting the angle at the end part of the mirror reflection pipe. According to the forage grassdrying device, the temperature in the charging barrel is kept at 60 DEG C or above by utilizing the solar energy concentration heat production principle, forage grass can be rapidly dried, electricityand coal consumption is not needed, and energy is saved.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION INST OF ANIMAL HUSBANDRY

Weeding machine storage device

InactiveCN110800459AConvenient mobile weedingSave energyGrass dryingMowersElectric machineryControl theory

The invention discloses a weeding machine storage device which comprises a body, a storage battery groove, a weed removal cutter and a spacer net. The storage battery groove is formed in the upper left end of the body, a form of the storage battery groove is a groove form, an adapter is mounted at the low end of the storage battery groove, a transmission line is connected on the adapter, a first motor is arranged at the right end of the adapter and connected with the adapter through the transmission line each other, an air-blowing machine is mounted on the right side of the first motor, an airsuction port is formed in the lower end of the air-blowing machine, a heating pipe is mounted on the left side of the air-blowing machine, and a connecting seat is mounted on the left lower portion of the heating pipe. The storage device has the advantages that the storage battery groove is formed in the body, a fully charged battery can be placed into the storage battery groove in a connected manner, so that power is supplied for a wire on the adapter, wheels are mounted at the bottom of the body, a weeding machine conveniently moves and removes weed in the weeding process, strength of a user is saved, and the weeding machine is convenient to operate.

Owner:泰州卡尔特机械制造有限公司

Solar air heat collection pasture drying equipment

PendingCN114739127AImprove drying efficiencyDry evenlySolar heating energyMeasurement devicesThermodynamicsEngineering

The invention discloses solar air heat collection pasture drying equipment, and belongs to the field of pasture drying equipment. The equipment comprises a drying frame and a solar air heat collector array, a top plate is arranged at the top of the drying frame, a supporting frame and a draught fan are arranged on the top plate, a chain scraper conveyor and a needling type drying mechanism are arranged in the drying frame, the solar air heat collector array is installed on the supporting frame, and an air outlet of the solar air heat collector array is connected with an air inlet of the draught fan. The multiple needling type drying mechanisms are symmetrically arranged on the outer sides of the left side and the right side of the chain scraper conveyor, and each pair of symmetrically-arranged needling type drying mechanisms can synchronously move in the reverse direction. Energy-saving and environment-friendly solar energy is used as pasture bundle drying energy, and pasture bundles are subjected to batch drying treatment; and the multiple sets of needling type drying mechanisms capable of synchronously moving in the reverse direction are adopted for conducting left-right mutual needling type drying on the pasture bundles, the pasture bundles are dried more evenly, and the efficiency of manually drying the pasture bundles is improved.

Owner:中科咨信(甘肃)科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com