Patents

Literature

356 results about "Rockdust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rock dust, also known as rock powders, rock minerals, rock flour, soil remineralization, and mineral fines, consists of finely crushed rock, processed by natural or mechanical means, containing minerals and trace elements widely used in organic farming practices.

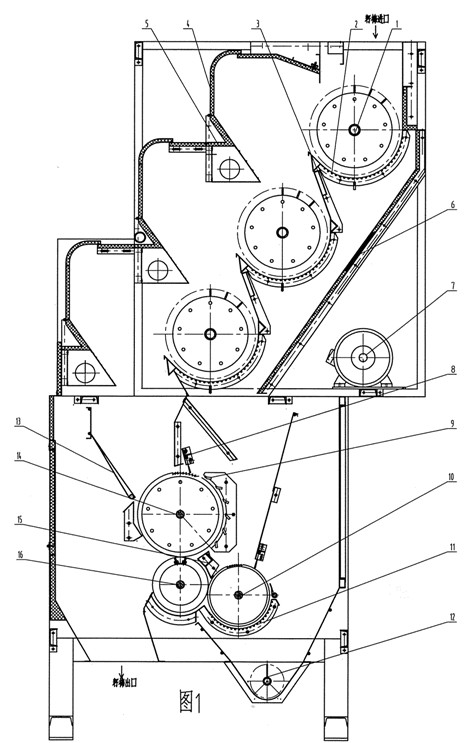

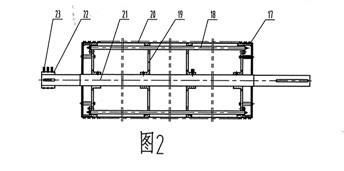

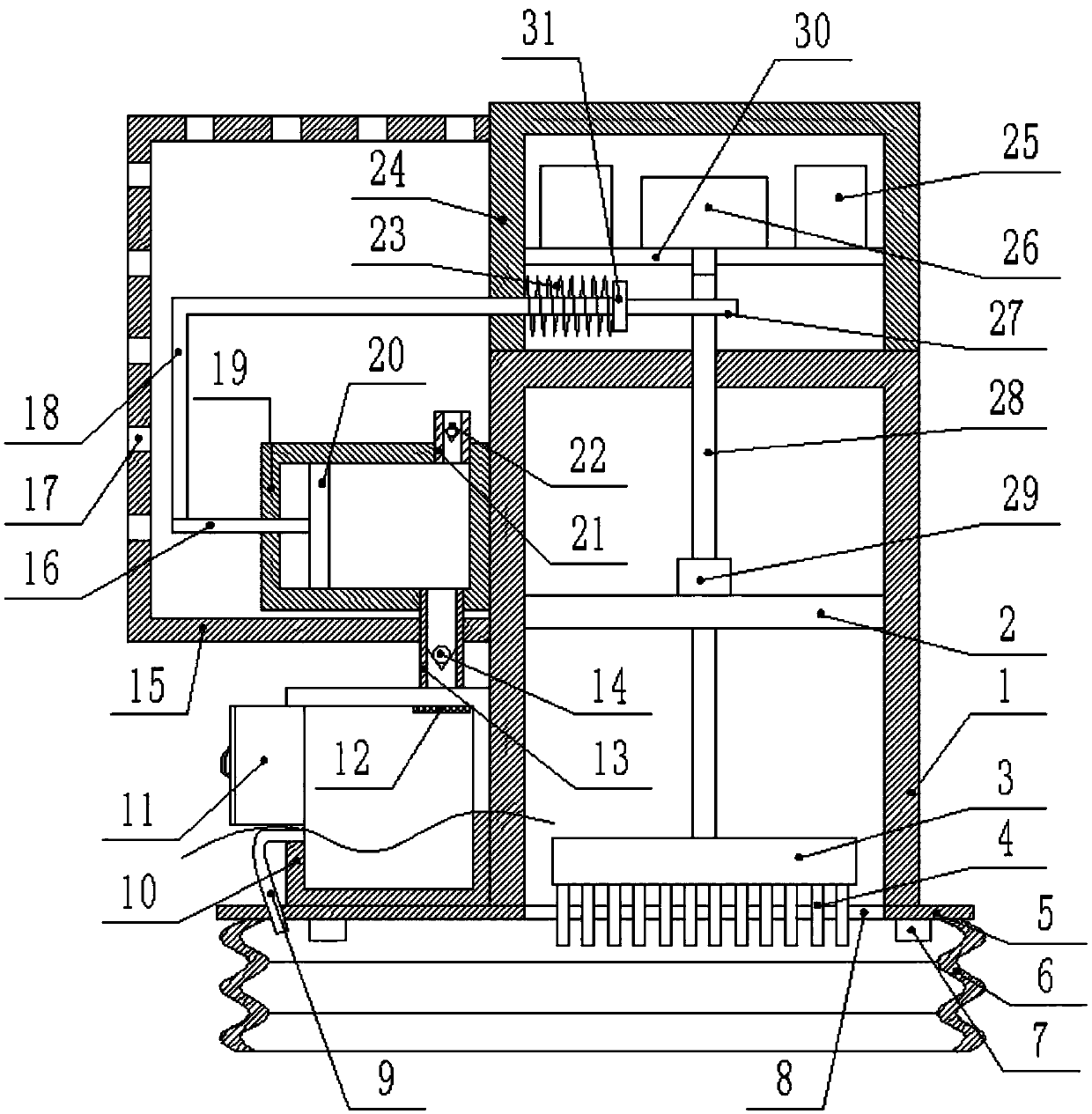

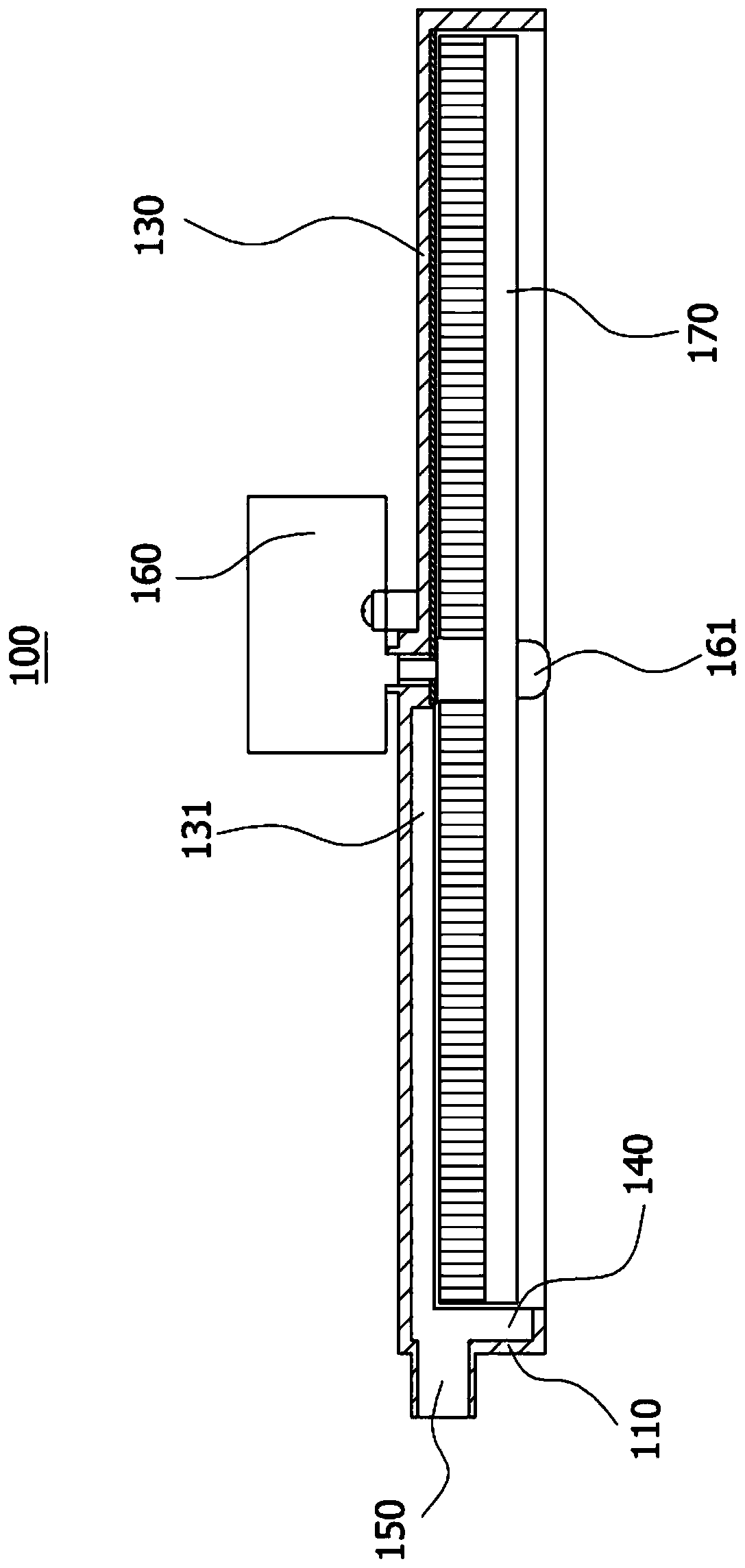

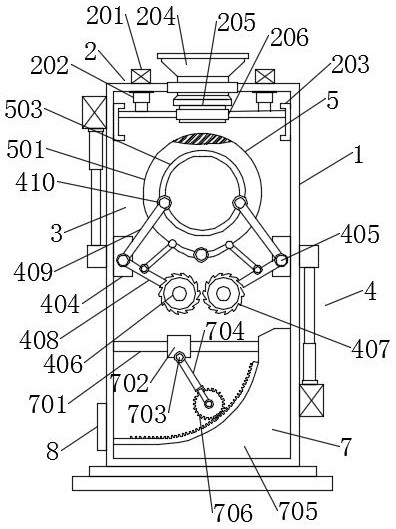

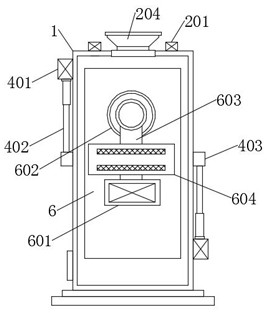

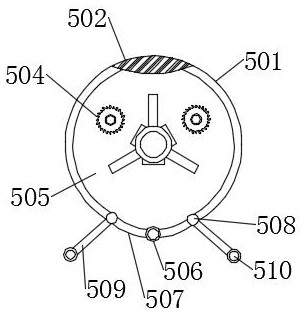

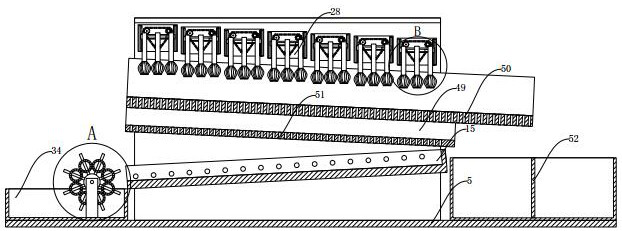

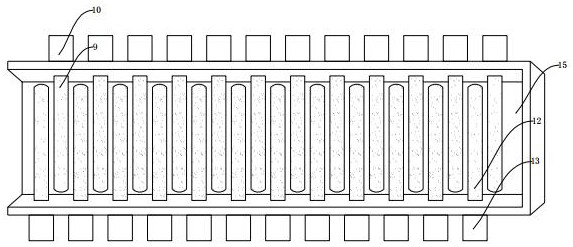

Cleaning machine for purifying and electrically drying seed cotton

ActiveCN102560692AIncrease contact timeDistribute quicklyMechanical treatmentAgricultural engineeringElectric machinery

The invention provides a cleaning machine for purifying and electrically drying seed cotton, comprising a frame with a seed cotton inlet and a seed cotton outlet, and a drying and cleaning device arranged in the frame, wherein the drying and cleaning device is composed of a hot air device and a plurality of groups of electric heating barbed ball rollers; an impurity discharging grid is arranged at the periphery of each group of electric heating barbed ball roller; the adjacent two impurity discharging grids are connected by a baffle; a purifying device for discharging crust or dead cotton is arranged right below the drying and cleaning device in the frame; and the drying and cleaning device and the purifying device are both connected with a driving motor for providing power to the drying and cleaning device and the purifying device. The cleaning machine has functions of cleaning impurities such as a large quantity of crusts and dead cotton, small amount of leaf scraps, dusts, small sand stones and sterile seeds, and drying seed cotton, so that the cleaning machine can be used as a purification type seed cotton cleaning machine normally. According to the machine, the installation process is simplified, the device investment cost is drastically reduced, the installation cost and the production operation cost are reduced, the manual work is reduced, and the installation space is saved, so that the machine is a high-efficient seed cotton cleaning machine.

Owner:JINAN RUNTONG ANJI MACHINERY

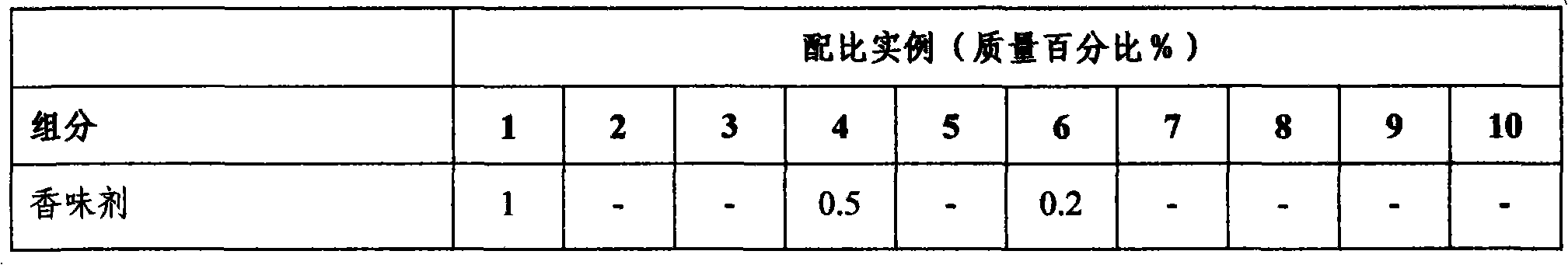

Environment friendly organic cover

The invention provides an environment-friendly organic mat, which consists of wood shavings and accessories. The organic mat can maintain water, reduce the waste of water resource, adsorb dusts of cities, prevent soil loss, inhibit weed breeding, beautify human living environment, and realize cyclic utilization of organic wastes of plants.

Owner:北京华美琪科技有限公司

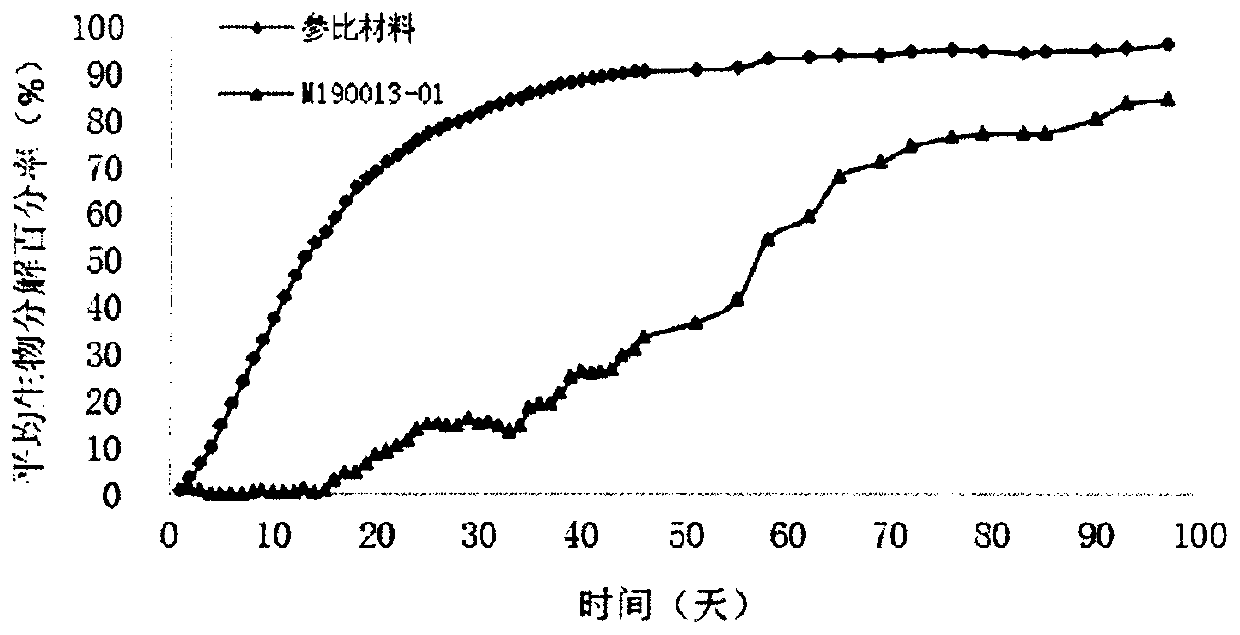

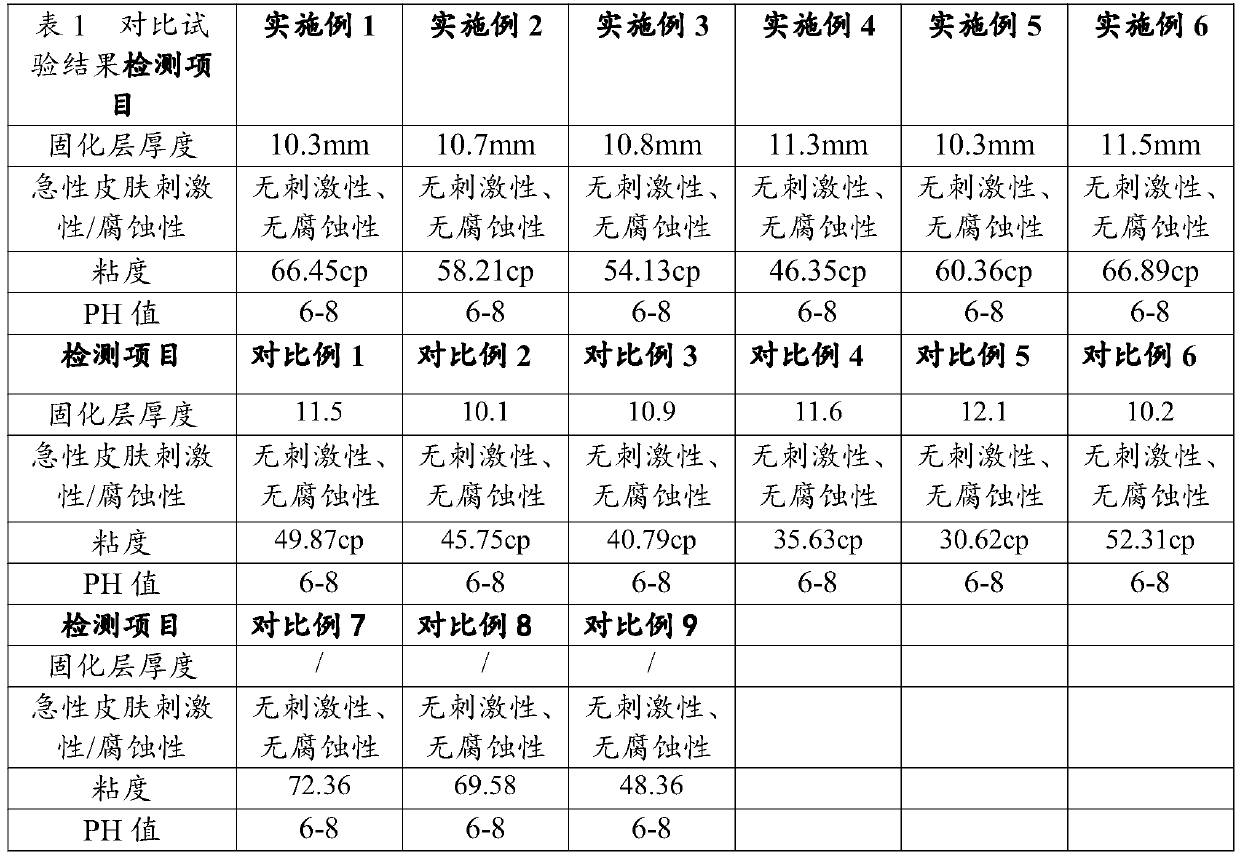

Modified gelatin dust suppressant and preparation method thereof

A modified gelatin dust suppressant and a preparation method thereof relate to a dust suppressant and a preparation method thereof; the dust suppressant comprises the following raw materials by weight percent: 2%-10% of industrial gelatin, 60-99% of water, 2%-10% of inorganic acid, 0-10% of surfactant, 0-10% of crosslinking agent, 0.01%-5% of sodium hydroxide and 0-5% of emulsifier. The preparation method comprises the following steps: adopting inorganic acid to degrade industrial gelatin at 20-80 DEG C for 2-15h, then using sodium hydroxide to neutralize the product and obtaining the finished product. According to different dust compositions and properties in different places, the degraded gelatin is used for wetting and penetrating tests and surfactant is added to increase the wetting and penetrating effect to different dusts. The dust suppressant of the invention is applicable to road surfaces, parks, construction site, scattered stock ground, mineral fields, coal dumps, ports and other operational areas which are easy to generate dust; after being dissolved in water and sprayed out, the dust suppressant can increase the coagulation of dust and inhibit the dispersion and movement of dust particles.

Owner:SHENYANG JIANZHU UNIVERSITY

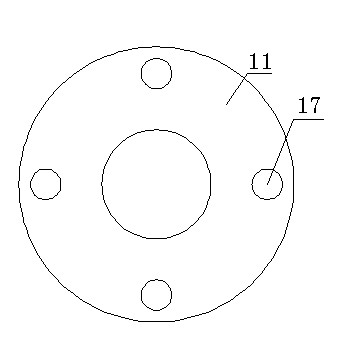

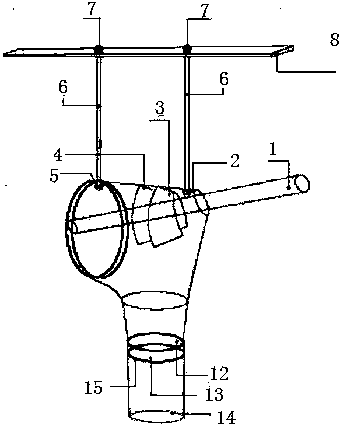

Vortex suction cup

The invention relates to an environment-friendly machine, in particular to a product applied to a road sweeper or other environment-friendly devices. A vortex suction cup comprises air outlet pipes and an air inlet pipe, wherein the air outlet pipes are arranged at the two ends of a dust suction cylinder, and the air inlet pipe is arranged in the middle of the dust suction cylinder. The inner sides of the air outlet pipes at the two ends are provided with two blades respectively, wherein an angle is formed between the two blades. Two air adjusting baffles are arranged below the air inlet pipe in the middle. The bottom surface of the dust suction cylinder is provided with an opening, a soft baffle is arranged in front of the lower portion of the dust suction cylinder. A dust cover is additionally arranged, and in this way, the vortex suction cup is formed. The lower surface of the suction cup and the ground are sealed. The vortex suction cup is characterized in that waste air exhausted from a previous link enters the blades arranged at the two ends inside the dust suction cylinder through air outlets formed in the two ends of the vortex suction cup, swirling air flow is generated inside the dust suction cylinder and blows dust and sundries on the ground towards an air inlet in the middle, the dust and the sundries are sucked up, and therefore secondary pollution to the environment is avoided. According to the vortex suction cup, secondary circulation and recycling are achieved for the exhausted waste air, air pollution is reduced, suction force is increased, the ground is clean, shortcomings of an existing product are overcome, and the environmental protection effect is good.

Owner:王伟

Environment-friendly dust suppressant and preparation method thereof

The invention discloses an environment-friendly dust suppressant and a preparation method thereof. The environment-friendly dust suppressant is prepared from the following raw materials in parts by weight: 8 to 12 parts of modified starch, 10 to 15 parts of carboxymethyl cellulose, 5 parts of xanthan gum, 5 parts of guar gum, 15 to 20 parts of potassium sulfate, 15 to 20 parts of sodium sulfate, 8to 12 parts of magnesium sulfate, 2 to 5 parts of hydroxypropyl methyl cellulose and 0.5 to 1 part of a surfactant. The prepared dust suppressant is wide in raw material source and simple in preparation process, can bond and solidify dust on the surface of bare soil, effectively inhibit the phenomenon of dust raising on the surface of bare soil, is naturally degradable, does not pollute the soil,contains various mineral elements which can be absorbed by the soil, and can increase the fertility and promote the growth of plants.

Owner:QINGDAO UNIV OF SCI & TECH +1

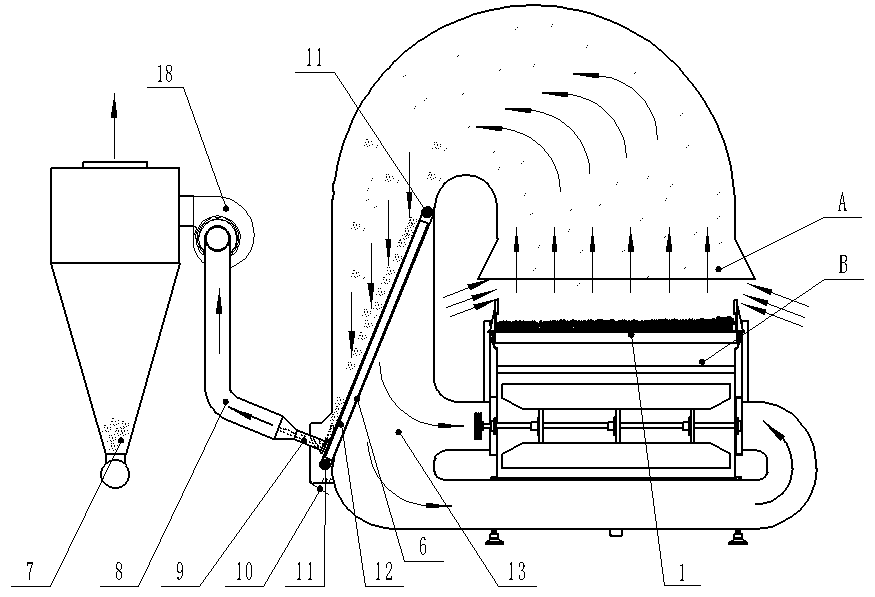

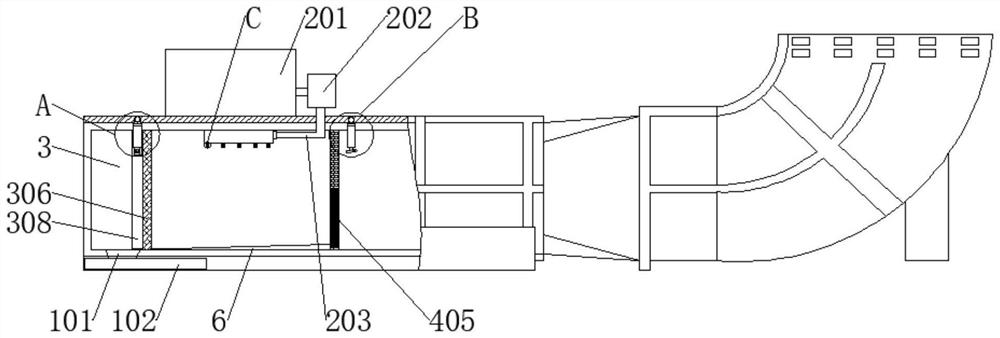

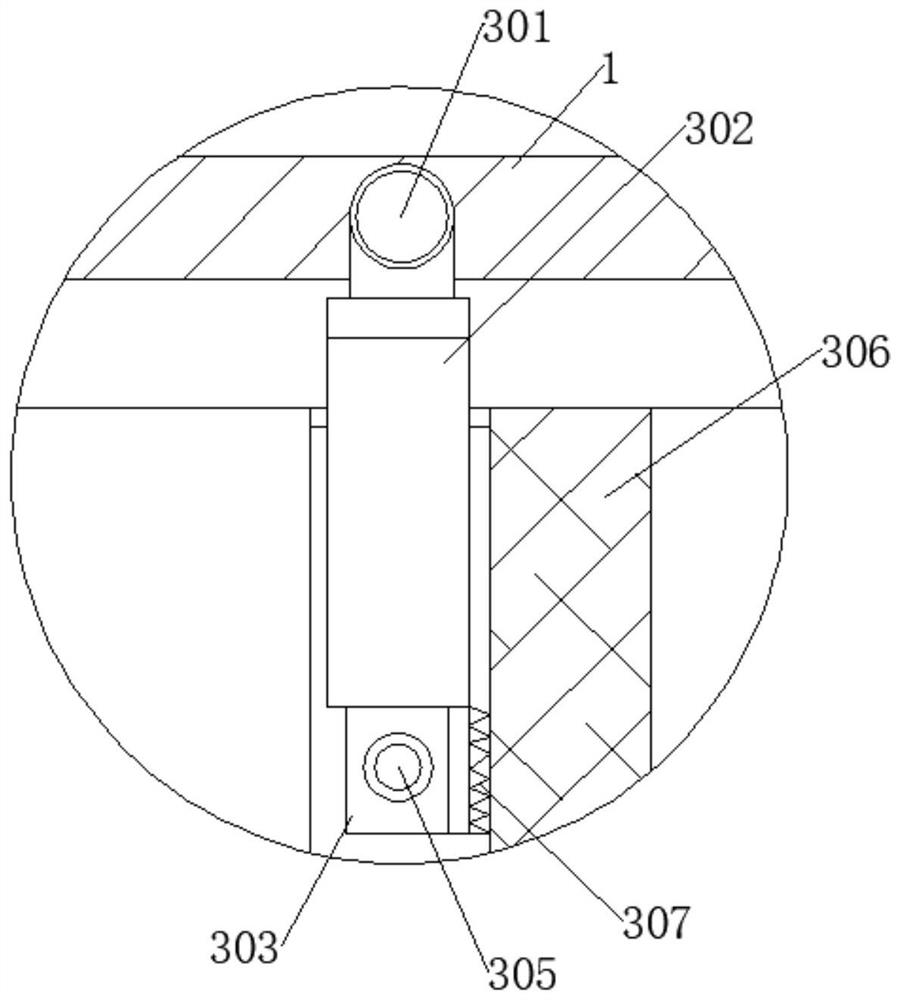

Energy-saving circular distributary negative pressure cleaning method

InactiveCN107890998AAvoid direct row toReduce energy consumptionSievingGas current separationSuspended particlesParticulates

The invention relates to the technical field of grain cleaning mechanical equipment, in particular to an energy-saving environment-friendly method for treatment processes such as impurity (including dust, grass shells) removal on grains by means of circular air flows. The method solves the problem that floating dust and light impurities fly in a cleaning process of existing grain cleaning equipment. By adopting an air flow circular blowing method, an air flow entrained with floating dust and impurities through a vibrating screen is led into an air inlet of a primary fan through a circular pipeline, a filter device is arranged in the circular pipeline, and distributary dust removal is performed through negative pressure, so that the air pressure at the air inlet of the circular pipeline iskept in a negative pressure state, and the air flow entrained with floating dust fully enters the circular pipeline and is not directly discharged to the atmosphere. By means of kinetic energy of theair flow, circulation is achieved, the total energy consumption of equipment is reduced, the air flow blown by the fan is more uniform, and the grain cleaning efficiency is improved. External cyclonedust collecting equipment is very small in power, so that dust and suspended particles in a production process are prevented from being directly discharged to the atmosphere.

Owner:张存生 +1

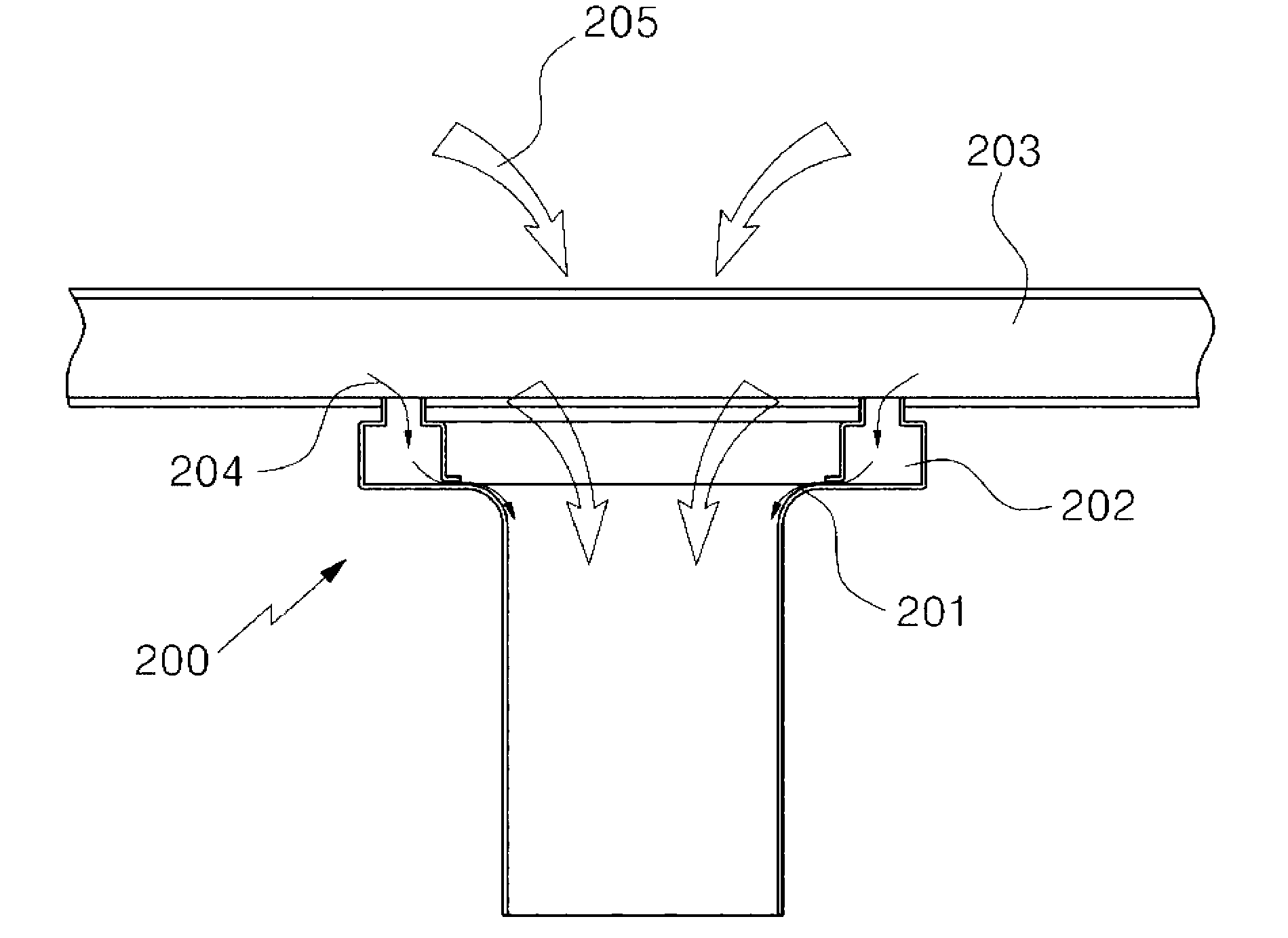

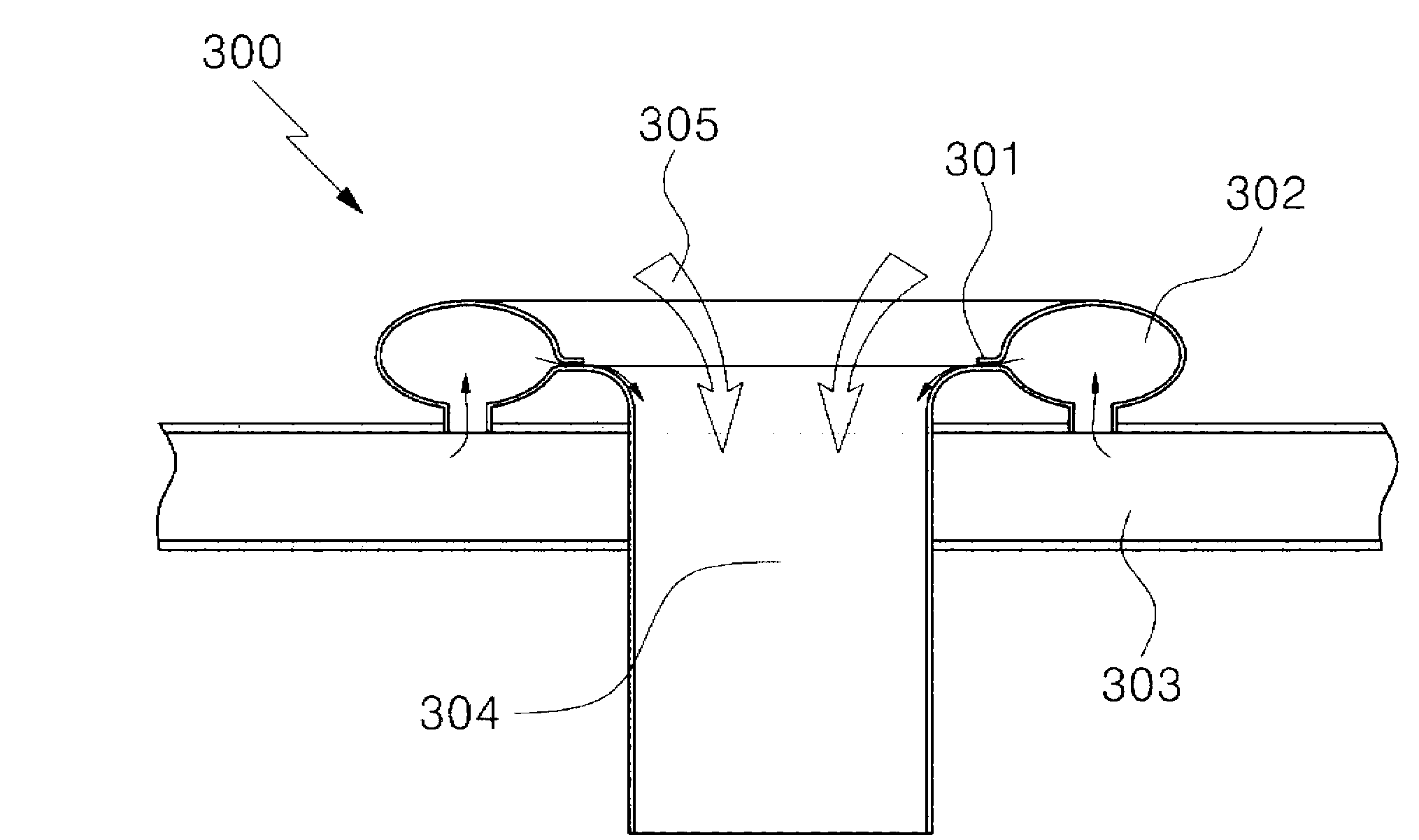

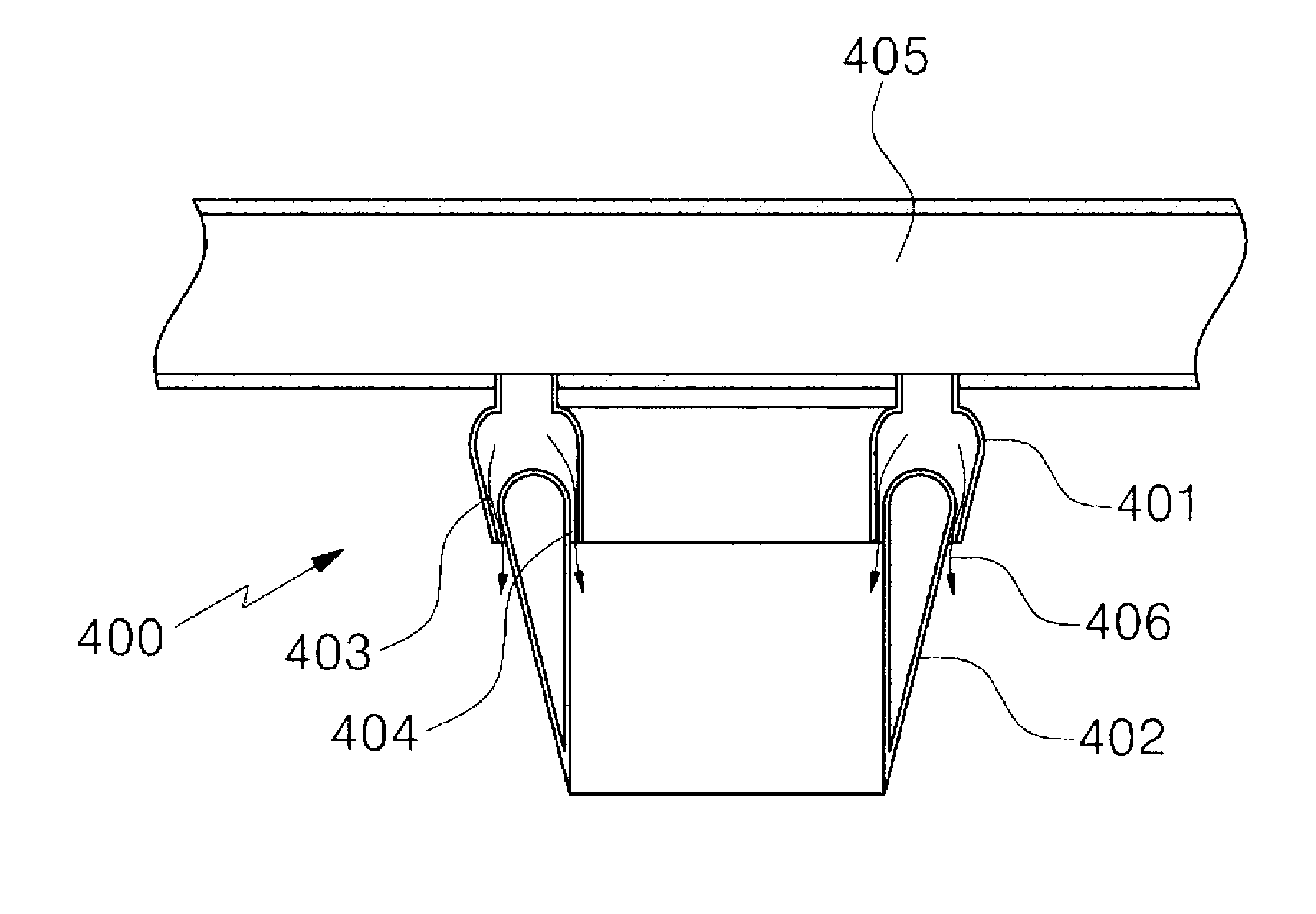

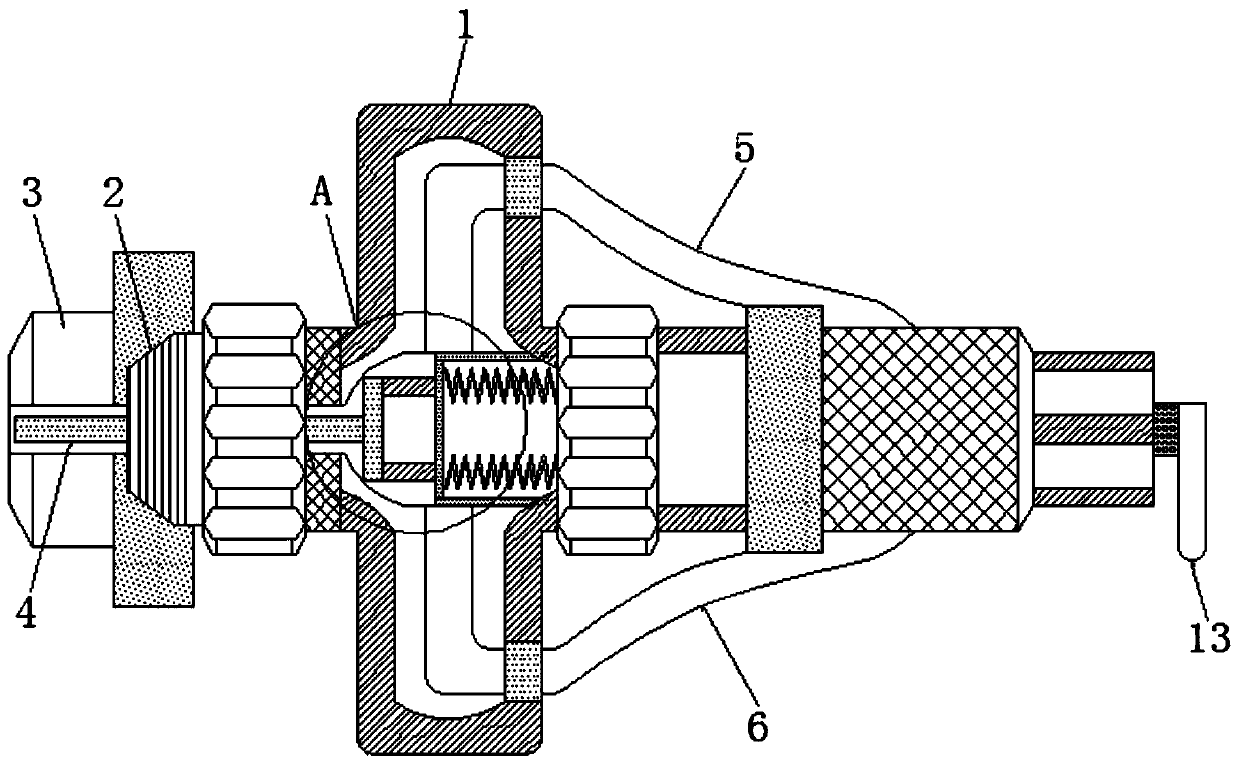

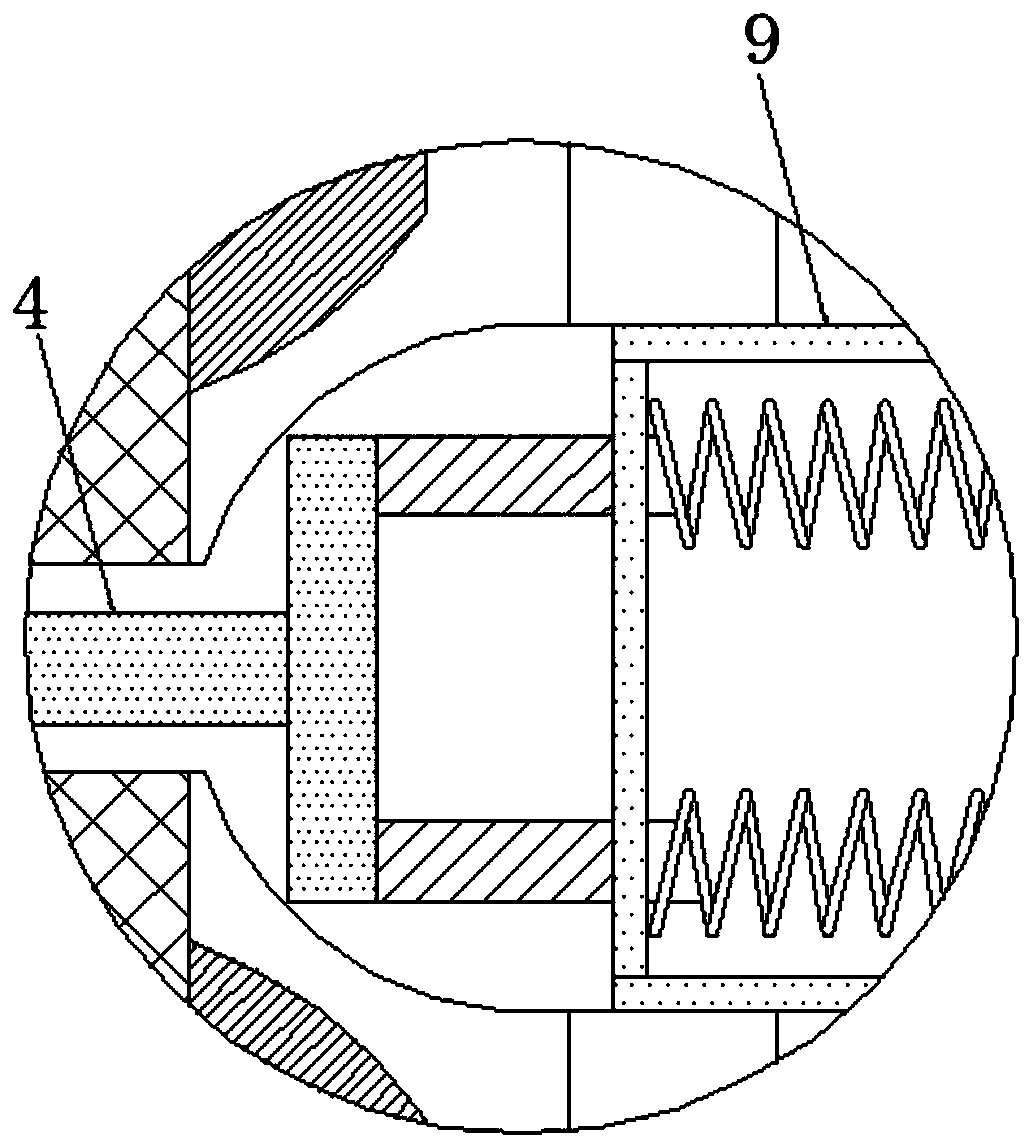

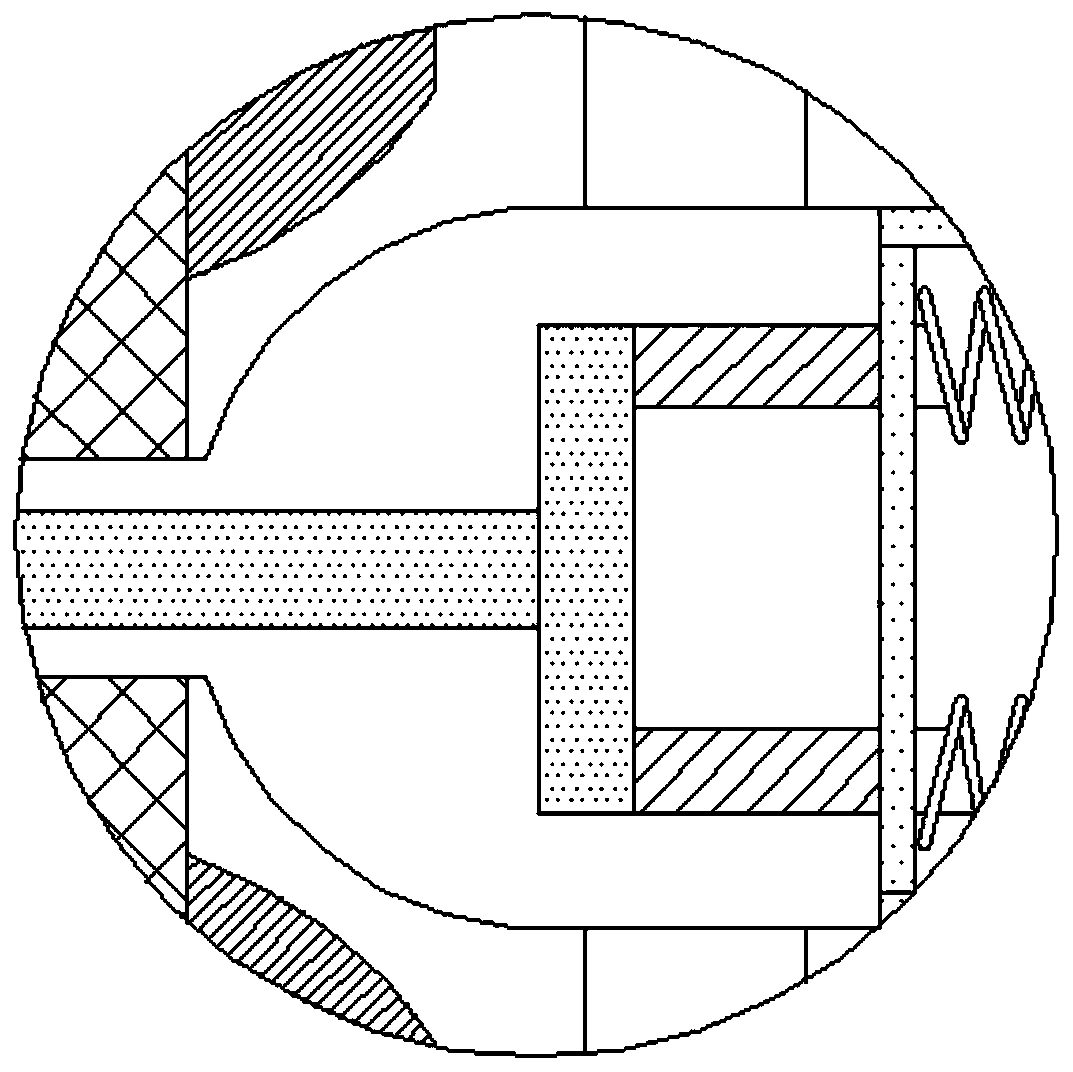

Pulse air injection nozzle with dual columnar slits and bag filter dust removal system using same

ActiveCN102811790AEfficient guidanceImprove cleaning efficiencyDispersed particle filtrationTransportation and packagingAtmospheric pressureInjection air

The present invention relates to a pulse air injection nozzle with dual columnar slits and a bag filter dust removal system using the same, in which the dust removal effect of a dust collector filter can be remarkably improved by introducing massive peripheral air with a small amount of compressed air, and more specifically, to a pulse air injection nozzle with dual columnar slits and a bag filter dust removal system using the same, wherein: internal horizontal columnar slits are formed inside in the upper part of an injection nozzle having an overall cylindrical shape,each of external vertical columnar slits is formed on the outer boundary of the injection nozzle,air currents injected from the internal horizontal columnar slits rapidly flow in a vertical downward direction along a curved surface whereby air pressure inside a cylinder is reduced to allow peripheral air in the upper part of the nozzle to flow into the inside of the nozzle quickly,and air currents injected from the external vertical columnar slits rapidly flow along a curved surface formed toward the inside of the cylindrical nozzle whereby air pressure around the outer side of the nozzle is reduced to allow the peripheral air to be enticed along the outer side of the nozzle, thereby increasing a flow of the overall pulse air introduced into the inside of the dust collector filter. Consequently, the invention is capable of highly improving the dust removal efficiency for removing dust attached to a surface of the dust collector filter.

Owner:KOREA INST OF ENERGY RES

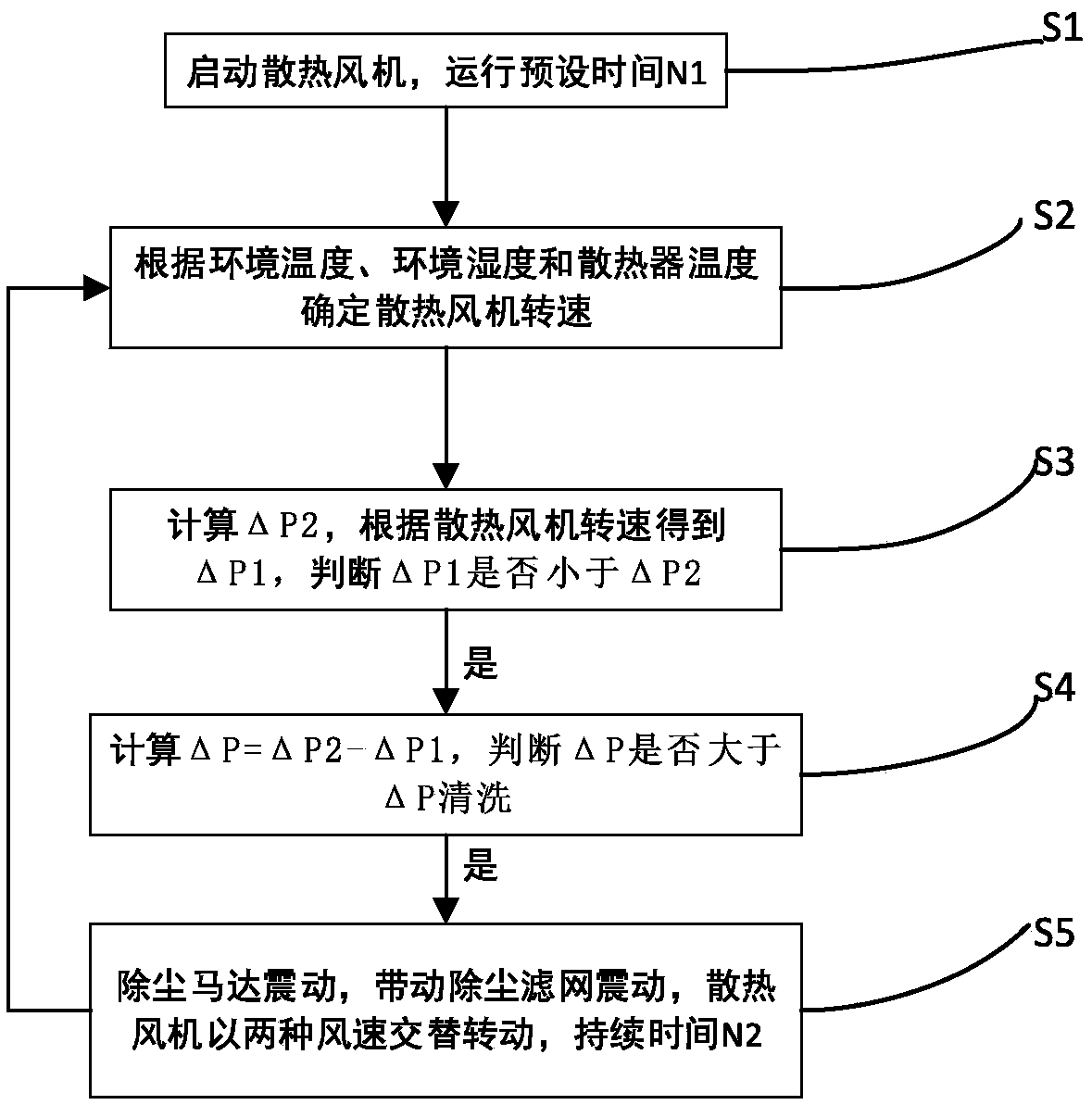

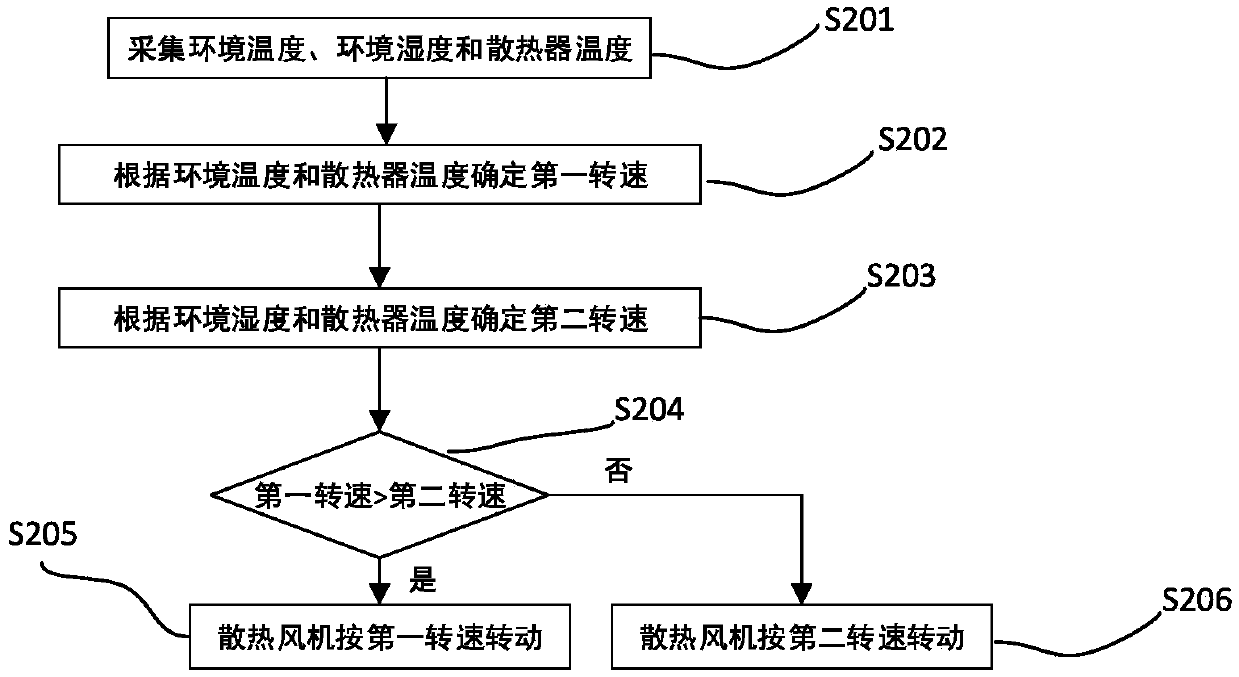

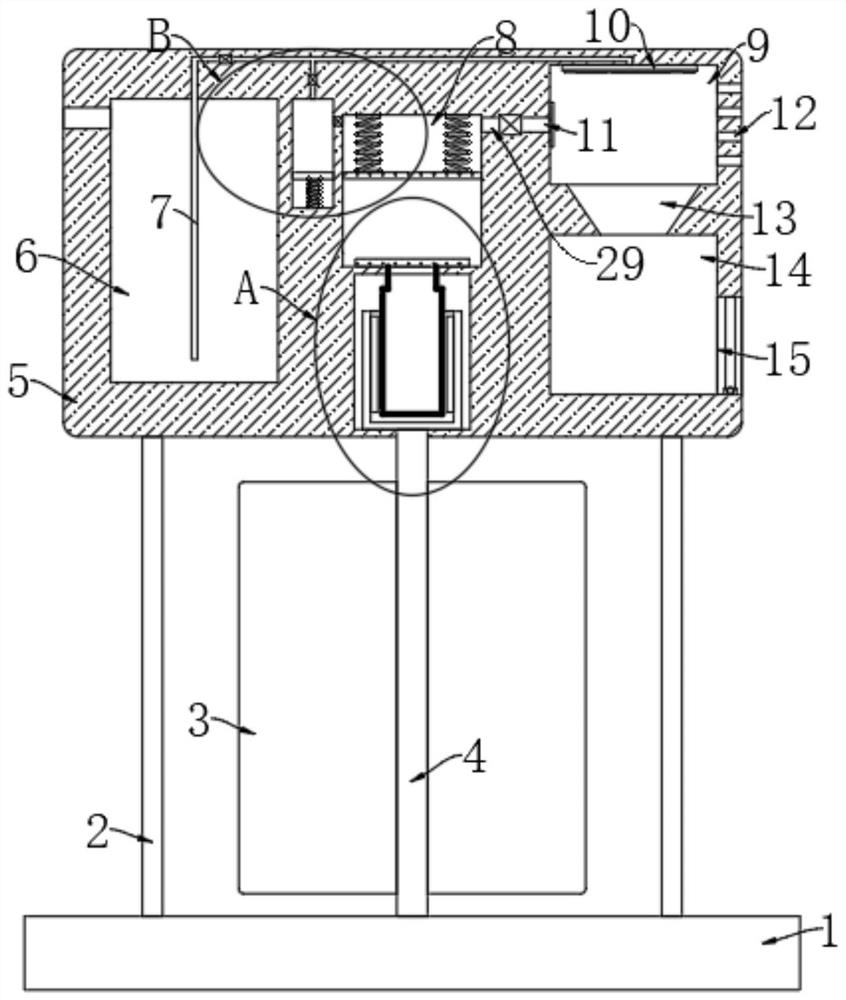

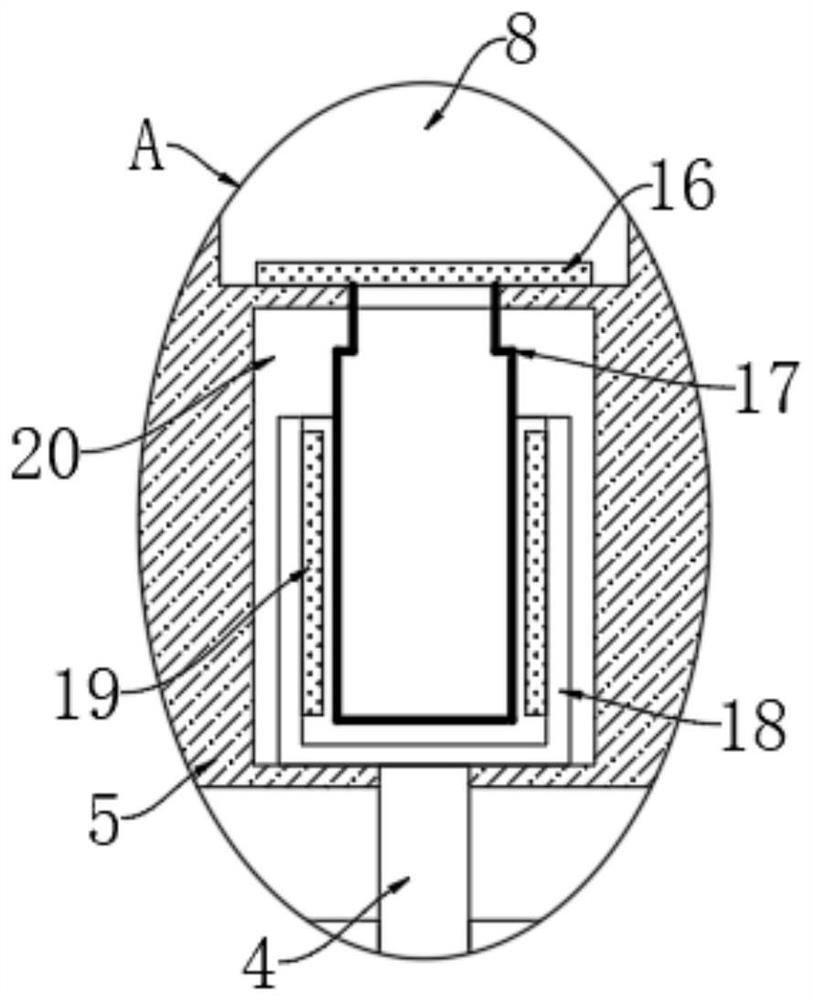

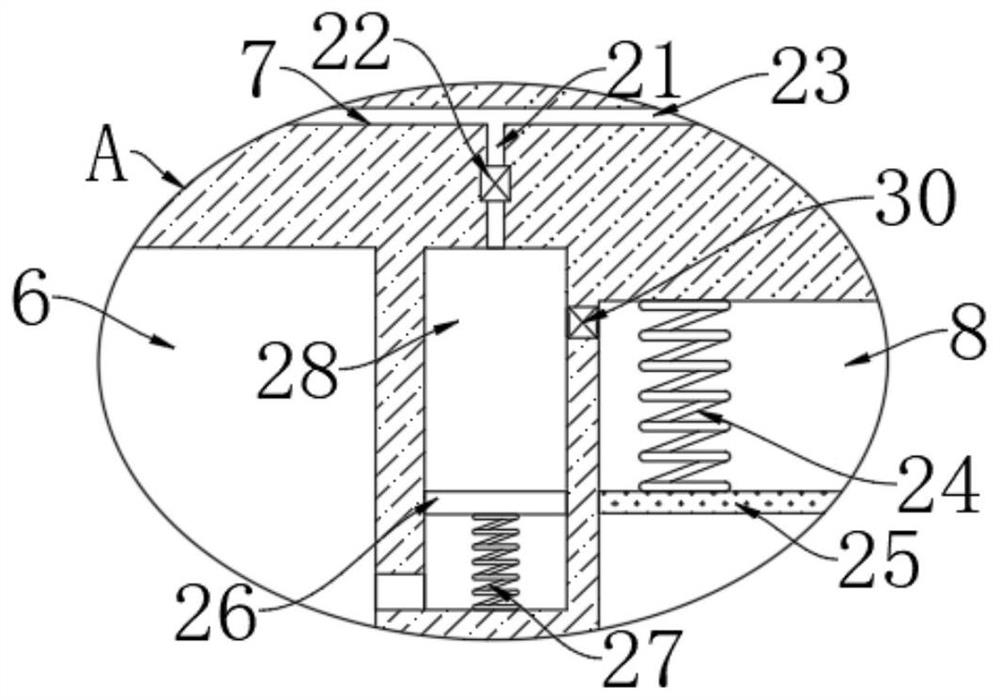

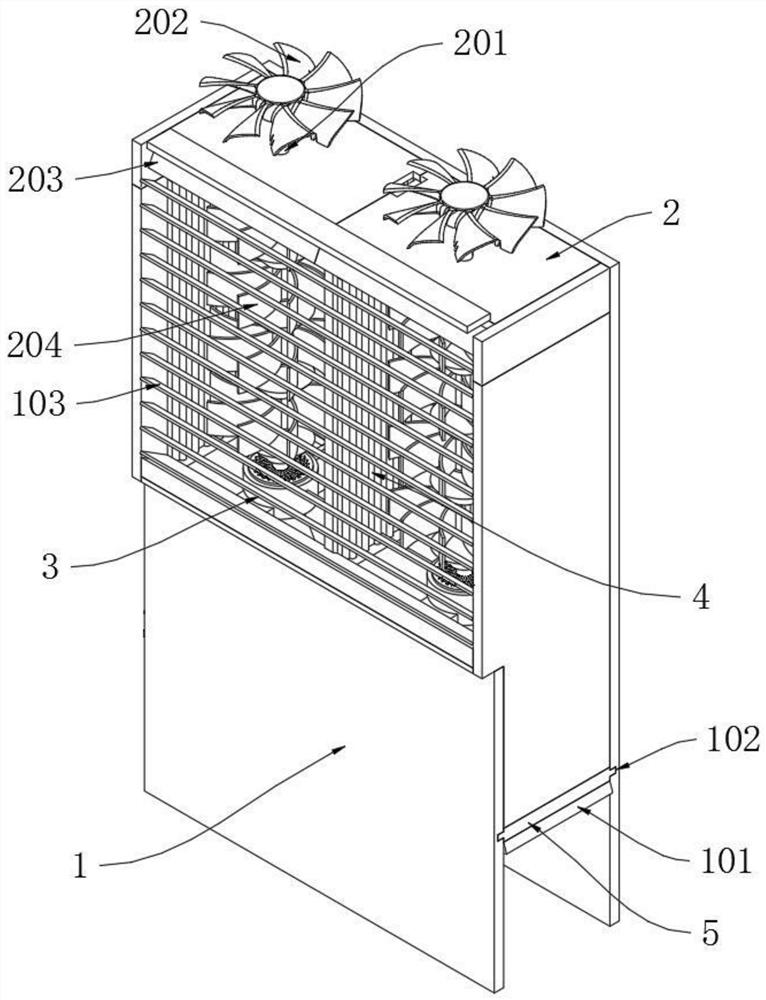

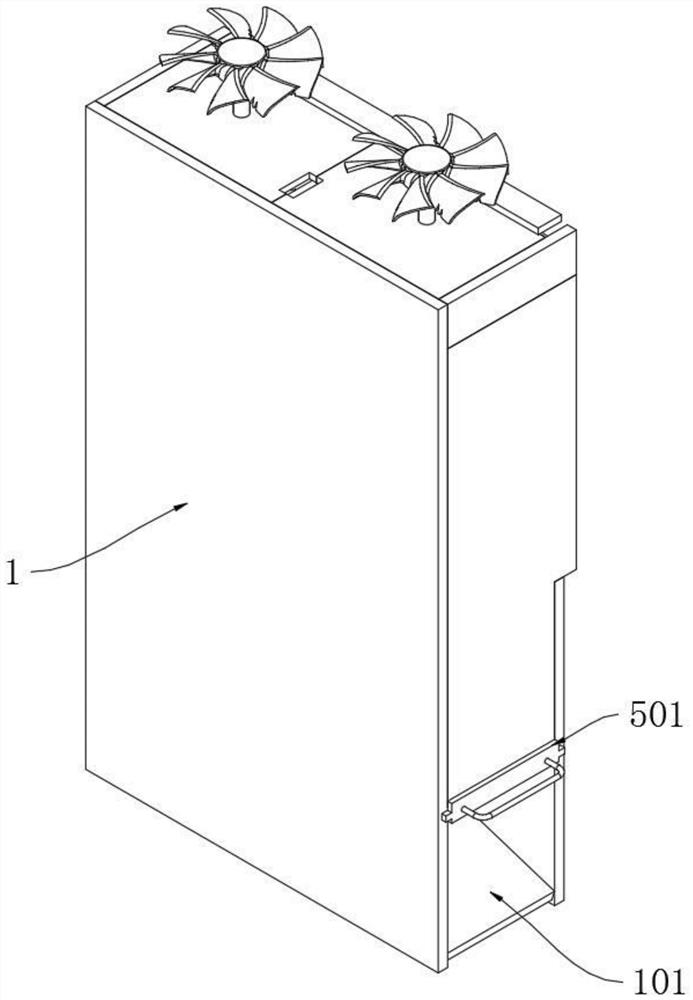

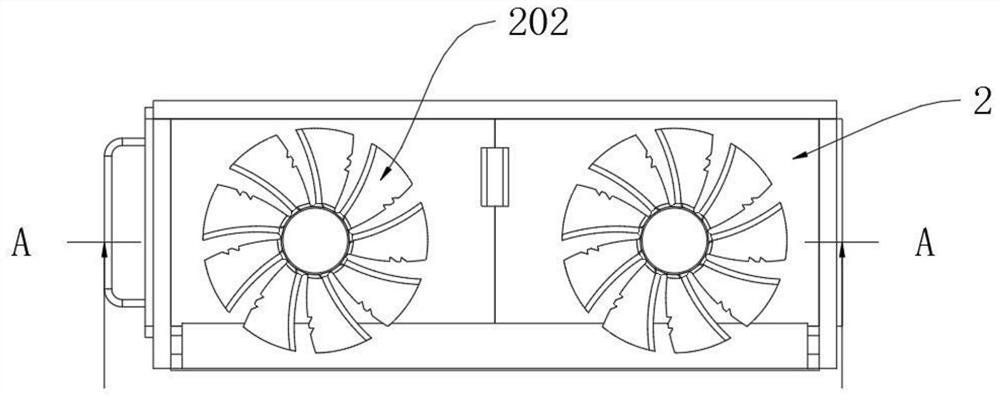

Automatic dust removal method and device of charging pile

ActiveCN110774921AExtended service lifePurifying airCharging stationsDispersed particle filtrationThermodynamicsAmbient humidity

The invention relates to an automatic dust removal method of a charging pile. Each time the charging pile is charged, the rotating speed of a heat dissipation fan is determined according to the ambient temperature and the ambient humidity of the charging pile and the temperature of a radiator, a preset pressure difference absolute value of the two sides of a dust removal filter screen is obtainedaccording to the rotating speed of the heat dissipation fan, the preset pressure difference absolute value is compared with an actual pressure difference absolute value to judge whether dust removal is needed, and if dust removal is needed, a vibration motor is started to vibrate the dust removal filter screen, dust on the dust removal filter screen falls down, the heat dissipation fan alternatelyruns at two speeds to enable the dust removal filter screen to have different tensions, the tension of the dust removal filter screen is instantly changed when the rotating speed is switched, dust attached to the dust removal filter screen can be shaken off, meanwhile, due to the rotation of the heat dissipation fan, air is blown to the outside of a charging pile shell, the dust attached to the dust removal filter screen is effectively removed, the dust removal filter screen of the charging pile is automatically kept clean, and air in the charging pile is purified. The service life of the charging pile is prolonged, and manpower and material resources are saved.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

Municipal automatic dust removal equipment based on electromagnetic effect

PendingCN111687164AAvoid secondary pollutionGuaranteed ventilation effectDispersed particle filtrationTransportation and packagingWater storageDust control

The invention discloses municipal automatic dust removal equipment based on an electromagnetic effect. The municipal automatic dust removal equipment comprises a base and an alternating power generation mechanism, wherein the base is arranged on the two sides of a road, the upper end of the base is fixedly connected with a plurality of connection rods, and the upper ends of the multiple connectionrods are jointly and fixedly connected with a shell; a rotary shaft is arranged between the shell and the base, and the two ends of the rotary shaft are rotationally connected with the upper end of the base and the lower end of the shell correspondingly; the interior of the shell is provided with a water storage chamber, a vertical cavity, a gas cavity and a dust processing chamber from left to right in sequence; the lower portion of the gas cavity is provided with a power generation cavity, and the lower portion of the dust processing chamber is provided with a waste water cavity; and the alternating power generation mechanism comprises a plurality of vertical fan blades arranged in the circumferential direction of the rotary shaft. According to the dust removal equipment, through wind force generated by vehicles coming and going, a dust falling mechanism is driven to operate, dust outside the dust falling mechanism is sucked into the equipment, meanwhile, the interior of the dust falling equipment is washed intermittently, and use is quite convenient.

Owner:杨年生

Sweeping device for underground lamp

InactiveCN111215418AAvoid flying aroundAvoid flyingDirt cleaningFlexible article cleaningElectric machineGas passing

The invention discloses a sweeping device for an underground lamp. The sweeping device comprises a cylinder, wherein a first fixing plate is fixedly connected to the interior of the cylinder, a secondcover body is fixedly connected to the top face of the cylinder, a second fixing plate is fixedly connected to the interior of the second cover body, and a motor is fixedly connected to the top faceof the second fixing plate. When the sweeping device is in use, through running of the motor, the output end drives a rotary shaft to rotate, then a hairbrush is utilized for sweeping dust on the underground lamp, and the first fixing plate can prevent the dust generated during sweeping from flying upward; and in the rotary process of the rotary shaft, a cam is driven to intermittently beat a stopdog under the effect of a spring, then a slide block is driven to slide in a box body, and the dust generated through sweeping is sucked into a dust settling box through a dust inlet pipe, and is stopped by a filtering net to be effectively settled in the dust settling box. In the meanwhile, gas is sucked into the box body through a first one-way valve, and then discharged through a second one-way valve, and then the settled dust is cleaned within a certain time through a door.

Owner:黎桃玲

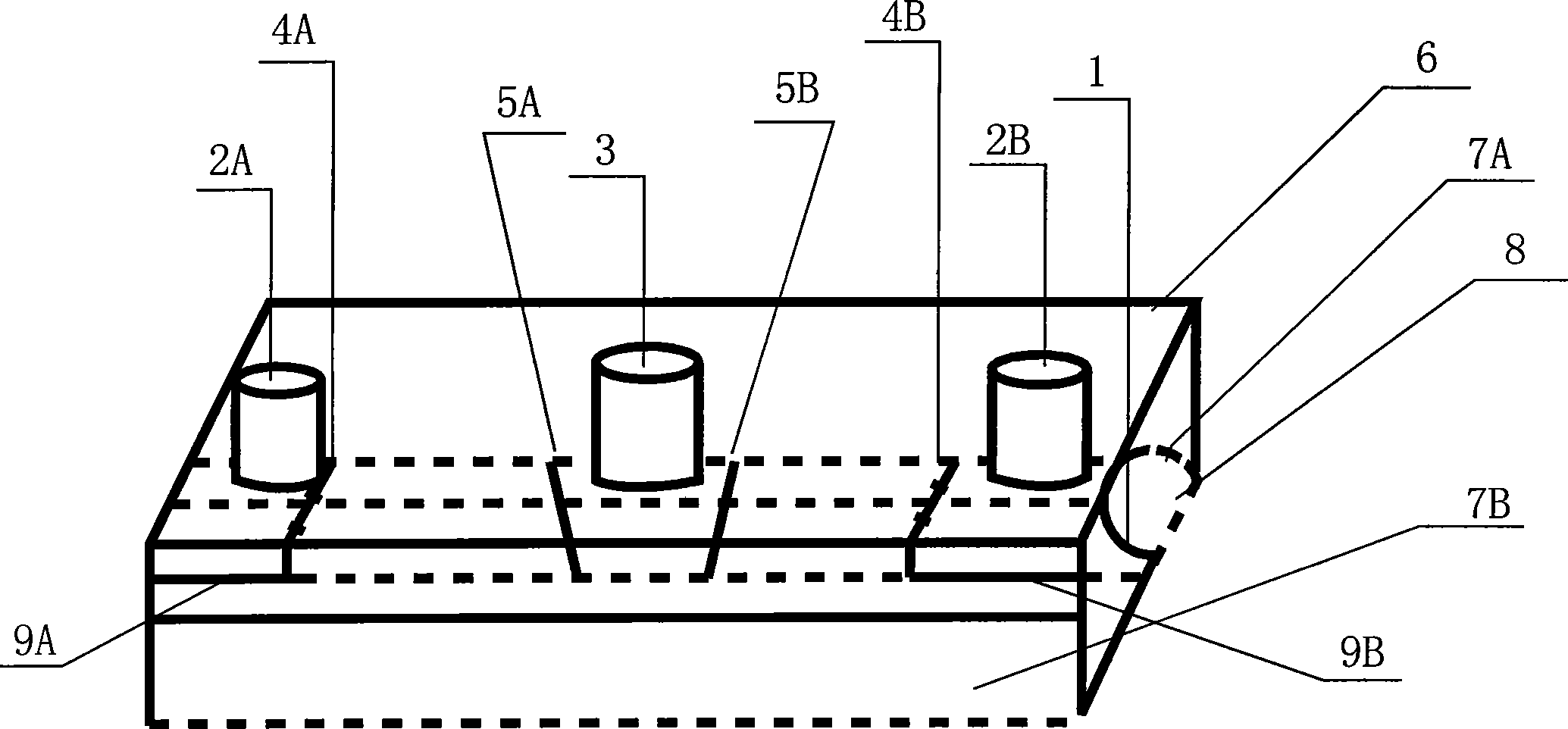

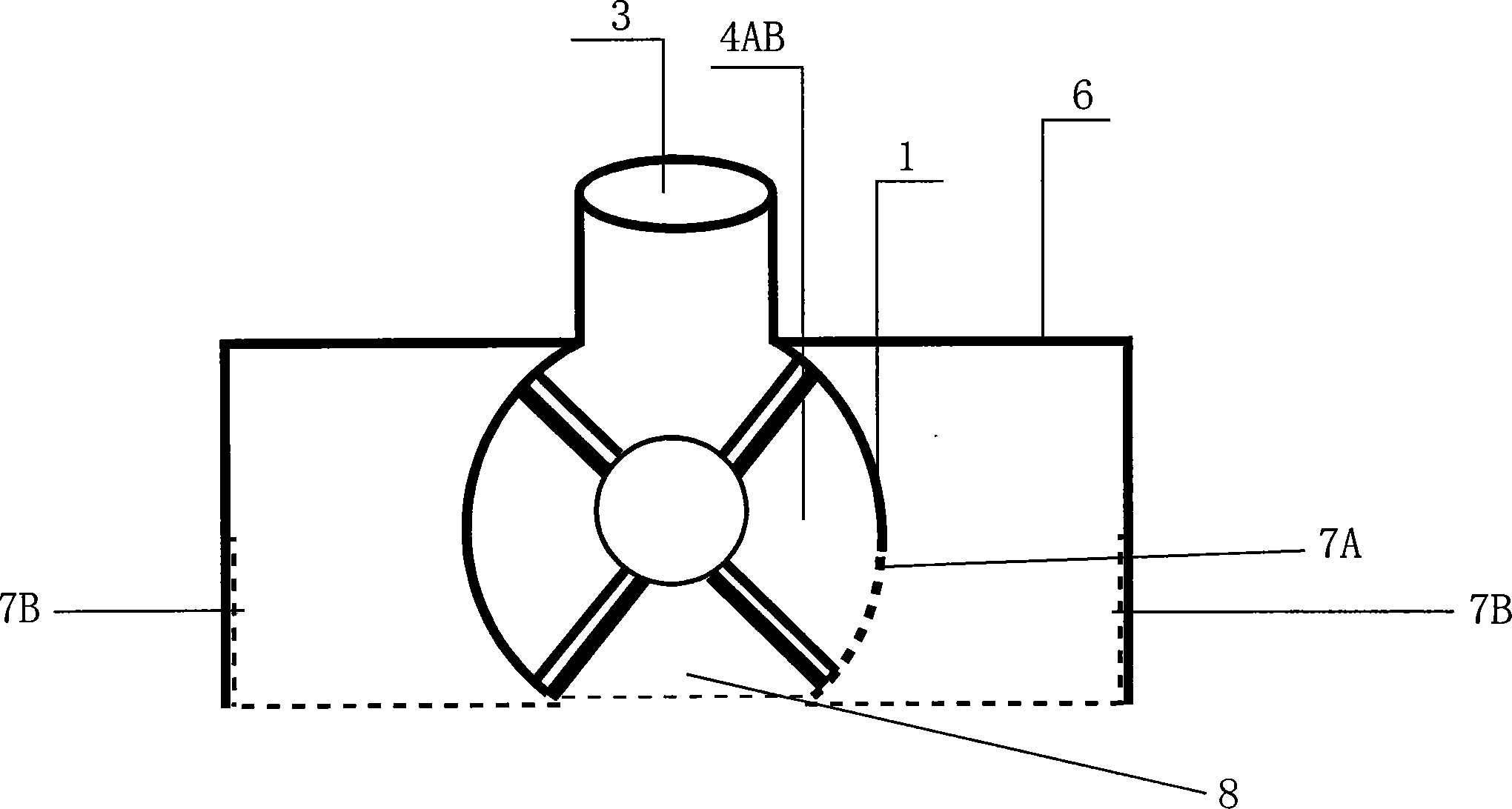

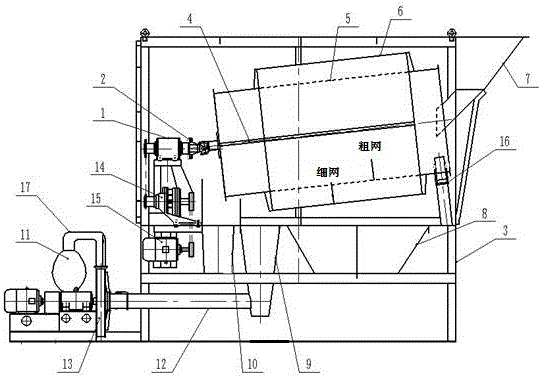

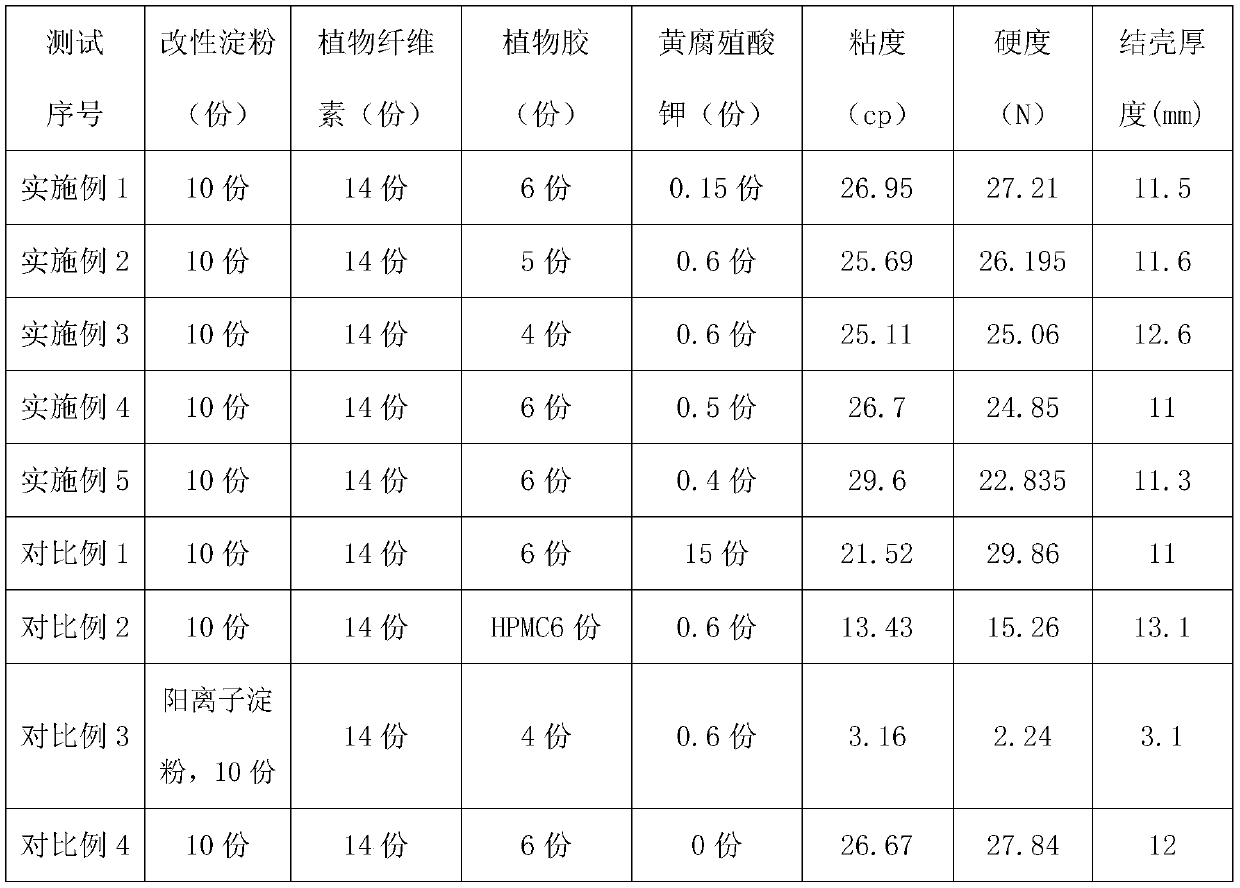

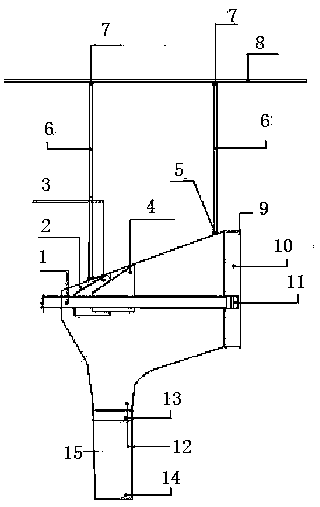

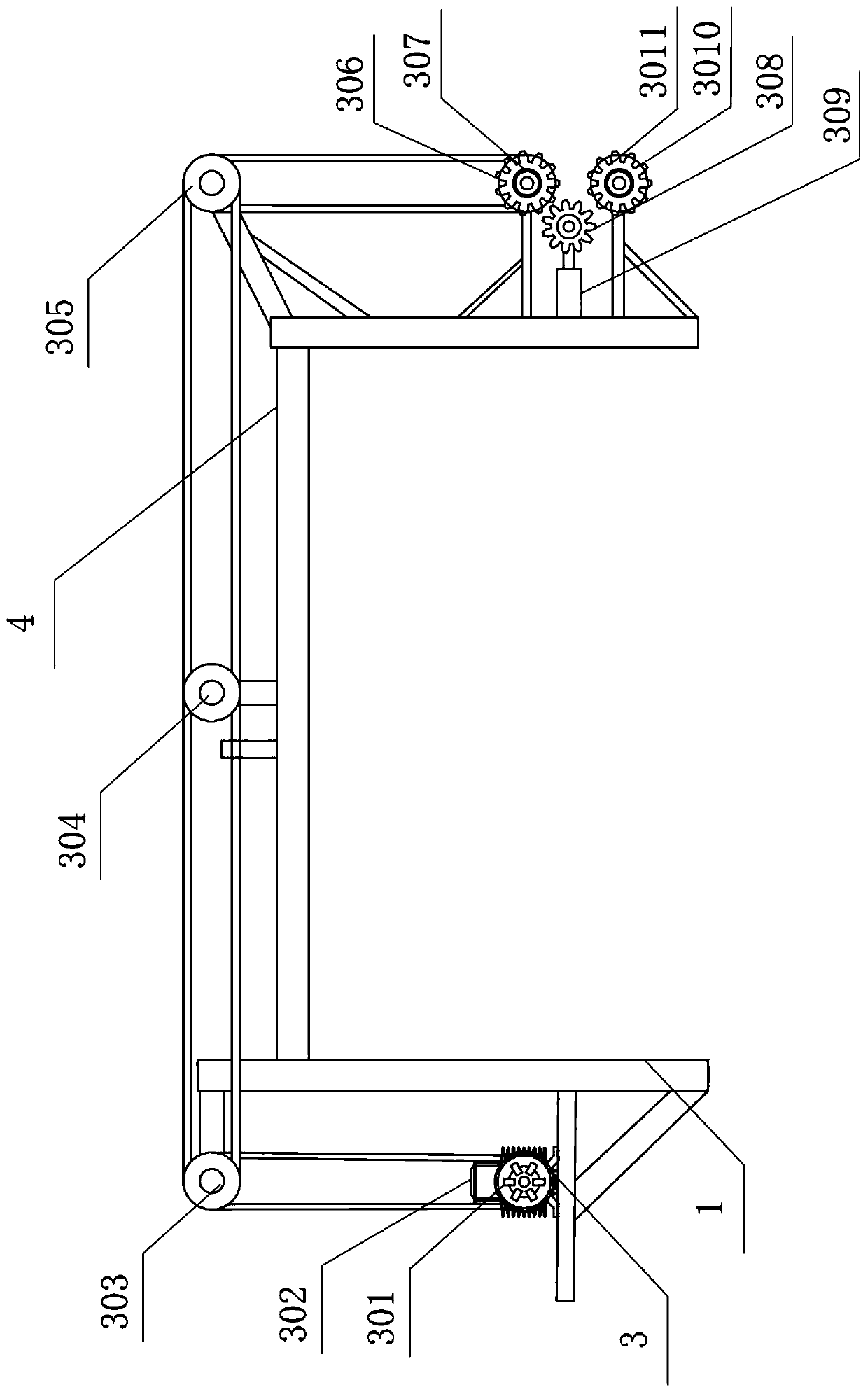

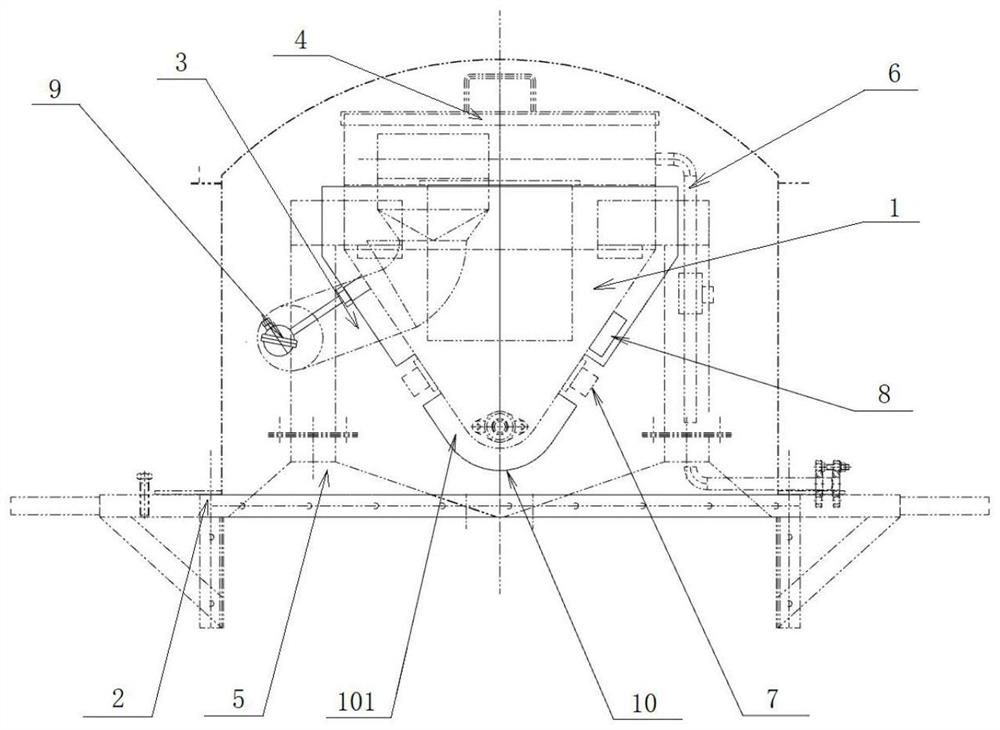

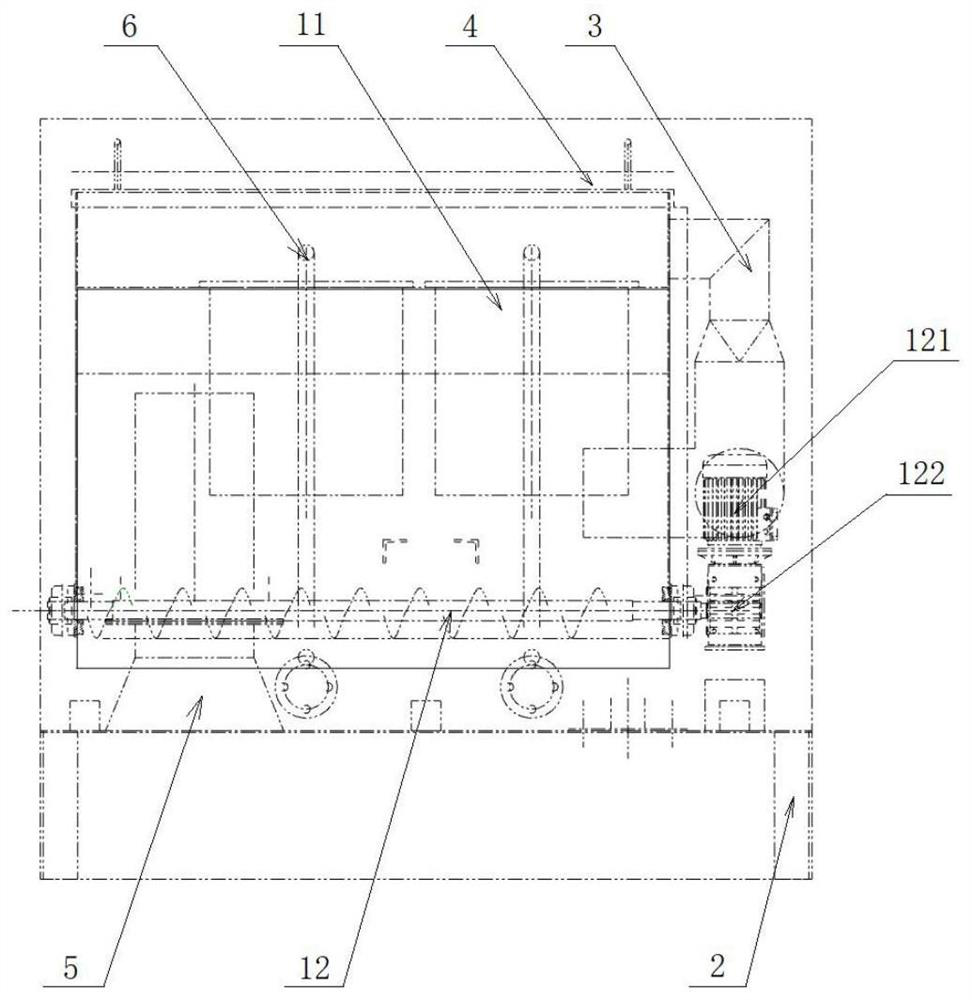

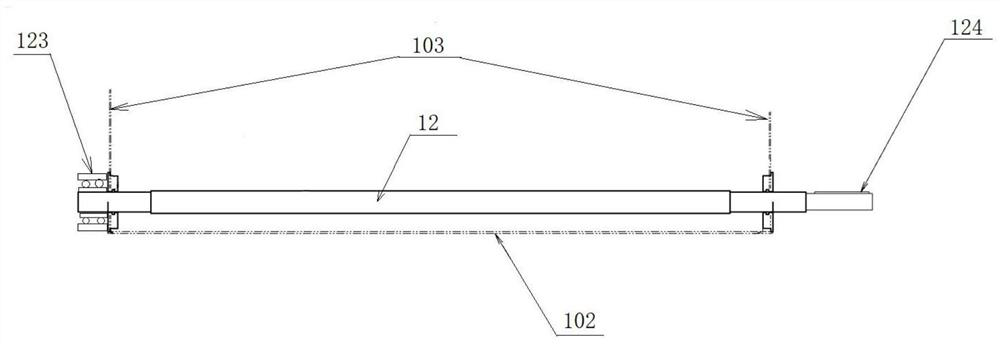

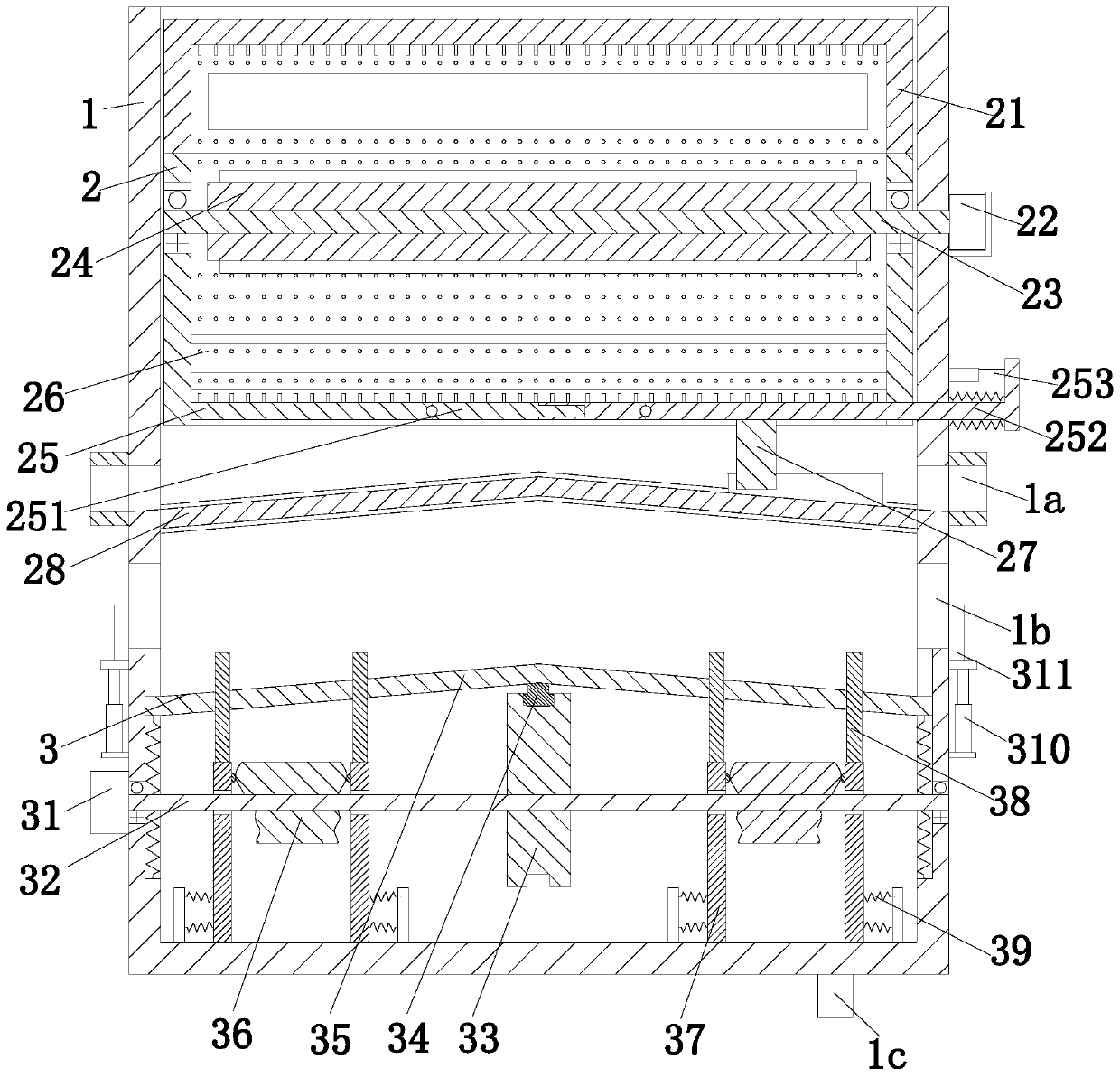

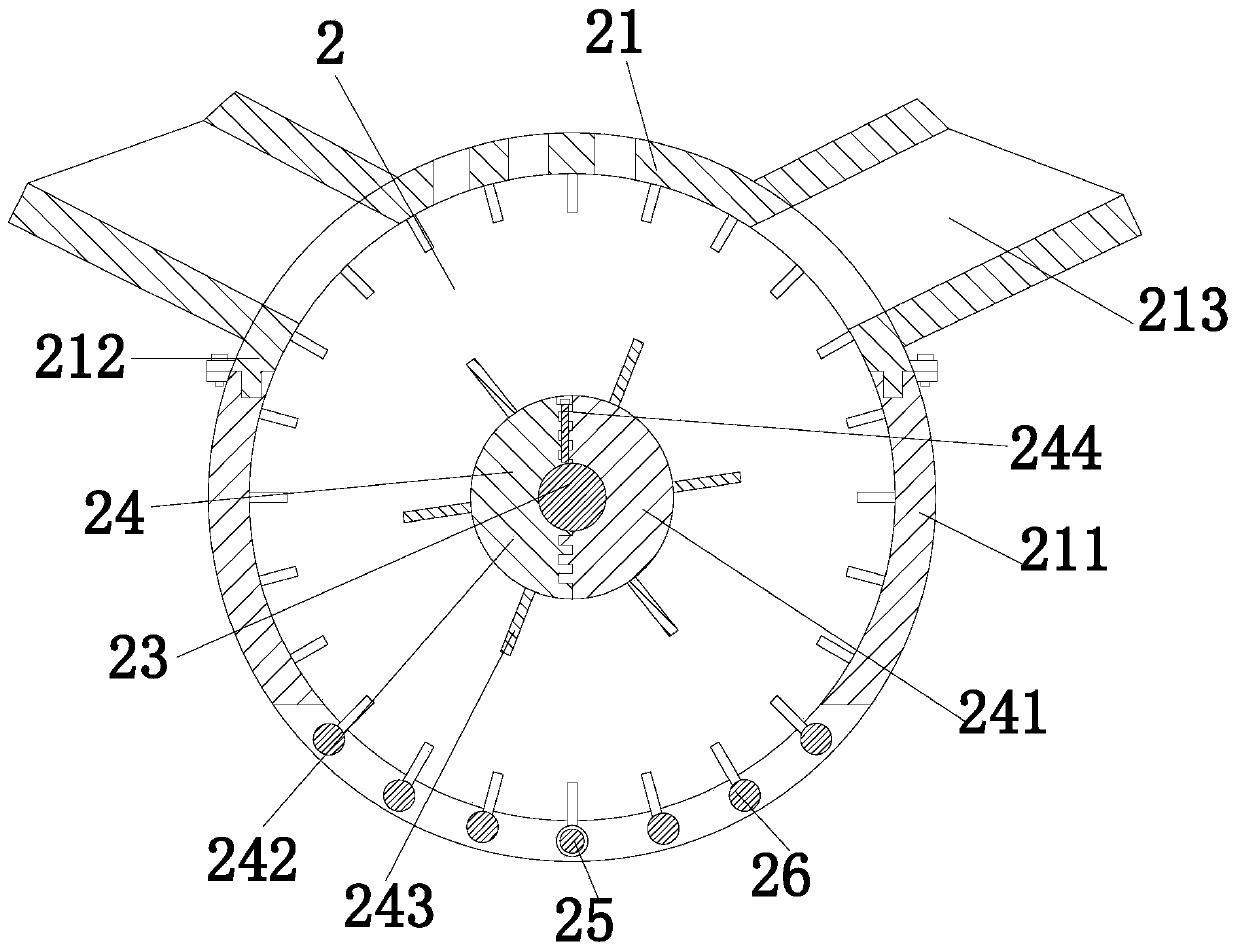

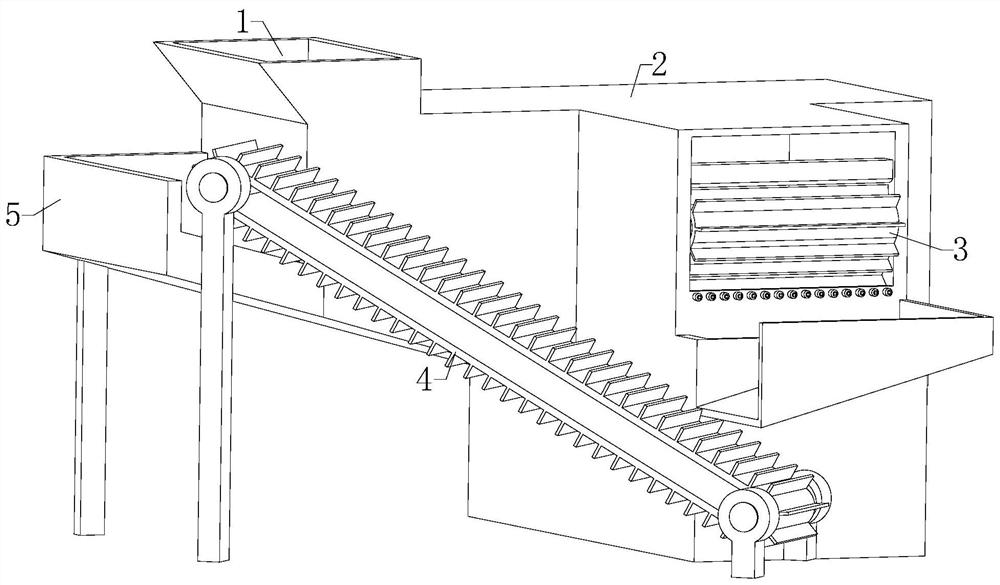

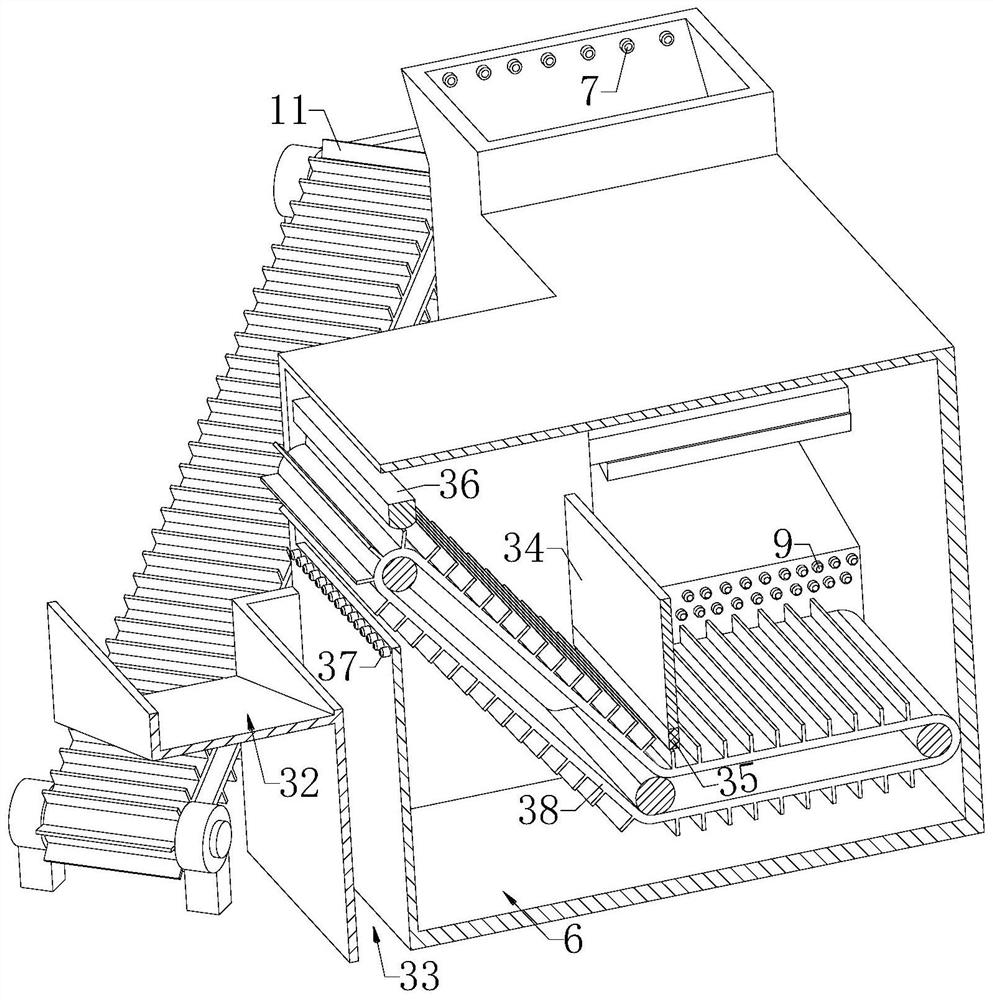

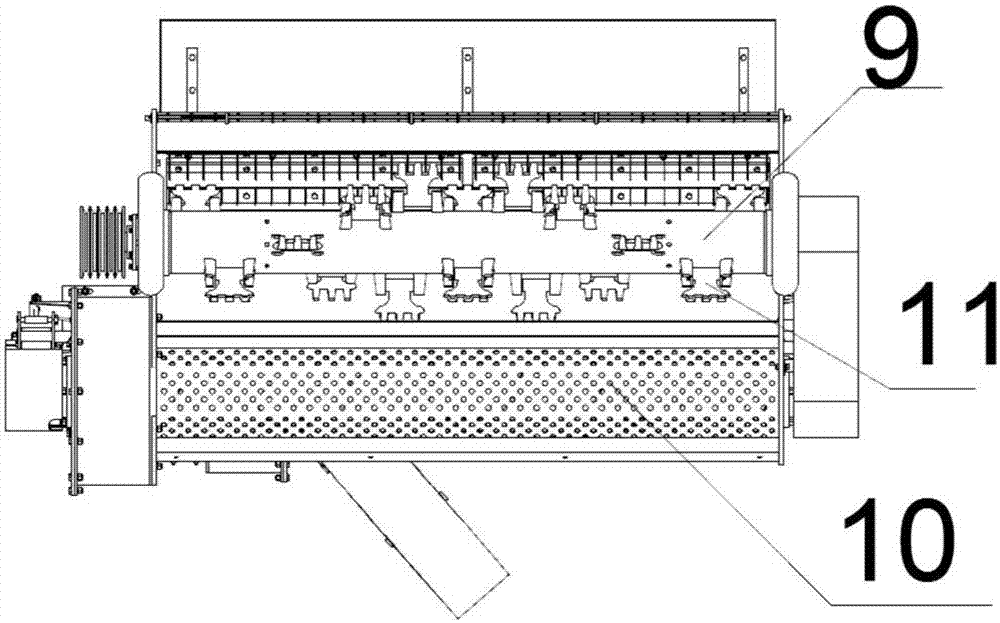

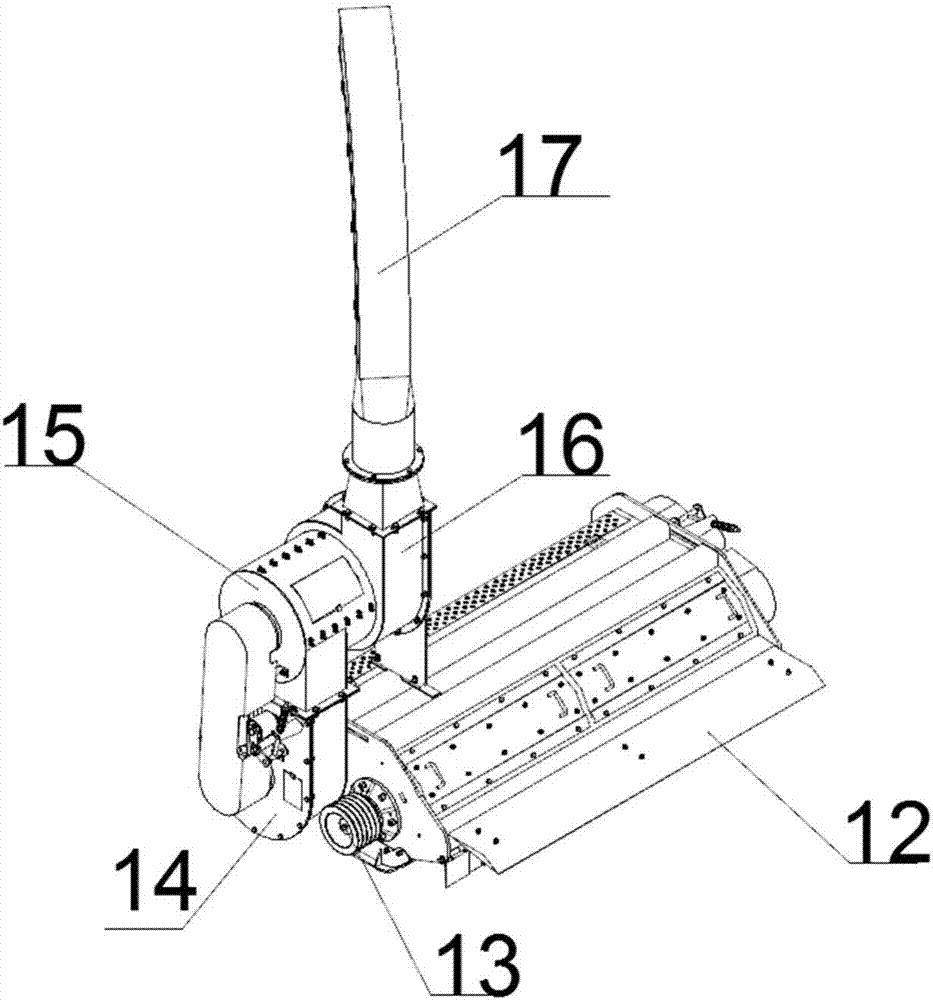

Compound impurity removing and sorting machine for crop seeds

PendingCN107520128AHigh impurity removal rateReduce energy consumptionSievingGas current separationAgricultural engineeringRockdust

The invention provides a compound impurity removing and sorting machine for crop seeds. Impurities such as leaves, bran hulls, dust and stones in the crop seeds can be removed. The compound impurity removing and sorting machine comprises a rack, a feeding hopper, discharging outlets, a filtering device and a dust removing device; the filtering device comprises a motor, a rotation shaft and drum screens, the motor is installed on the rack, the drum screens comprise a thick-net drum screen installed on the rack and a thin-net drum screen installed on the thick-net drum screen in a sleeving manner, the output end of the motor is connected with one end of the rotation shaft through a speed reducer, a pillow block bearing and a universal coupler, and one end of the rotation shaft is connected to the thick-net drum screen; and the discharging outlets comprise a coarse impurity discharging outlet, a clean grain discharging outlet and a fine impurity discharging outlet, wherein the coarse impurity discharging outlet is located at the end, far away from the feeding hopper, of the lower portion of the thick-net drum screen, the fine impurity discharging outlet is located under the thin-net drum screen, and the clean grain discharging outlet is located at the end, far away from the feeding hopper, of the lower portion of the thin-net drum screen and connected with the dust removing device.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Dust removing device for filter of automobile

A dust removing device for a filter of an automobile comprises an upper cover, a shell and a dust removing mechanism. The upper cover and the shell are fastened together, the dust removing mechanism is used for blowing off dust on the filter, a dust removing plate and a fixing plate which are provided with central holes are horizontally arranged in the shell, a supporting barrel used for supporting the filter is arranged between the center hole of the dust removing plate and the center hole of the fixing plate, and is a hollow barrel, dust removing holes are circumferentially arranged on the dust removing plate, and each dust removing hole is communicated with a dust sucking opening on one side of the shell by a dust removing guide tube. The dust removing device is simple in structure, anoperator can clean the filter in an environment without smoke dust, cleaned dust is treated together, environmental pollution is reduced, and the operation environment is improved.

Owner:赵长营

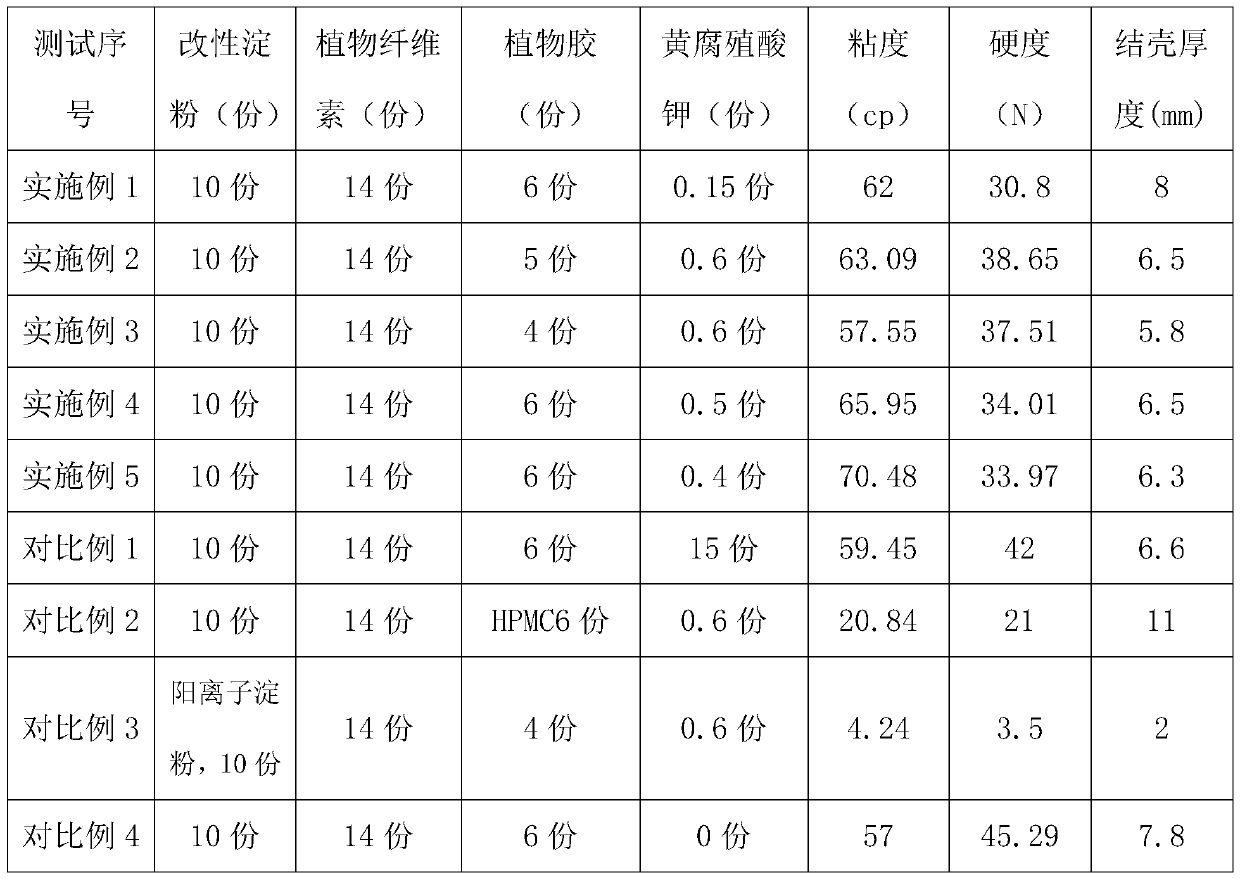

Soil improvement-type environment-friendly dust suppressant

ActiveCN111073599APromote root growthLow costOther chemical processesOrganic fertilisersCelluloseNatural organic matter

The invention relates to a soil improvement-type environment-friendly dust suppressant, which is prepared from the following components in parts by weight: 10 to 15 parts of cellulose, 10 to 15 partsof modified starch, 0.4 to 1 part of potassium fulvic acid and 3 to 6 parts of vegetable gum. According to the environment-friendly dust suppressant, dust on the surface of bare soil is bonded and solidified, flying dust on the surface of bare soil is effectively inhibited; the components of the dust suppressant are all natural plant products, nutrition can be provided for later plant growth afternatural degradation, potassium fulvate in the dust suppressant is rich in natural organic matter, various mineral elements and a large amount of nitrogen, phosphorus, potassium and other elements needed by plant rooting and growth, and plant growth and bare soil vegetation coverage can be jointly promoted in the later stage of artificial dust suppression.

Owner:QINGDAO UNIV OF SCI & TECH +1

Caragana intermedia natural-color semi-chemical mechanical pulping process

InactiveCN104711885ASimple processEasy to operatePulping with inorganic basesFibrous raw materialsCaragana intermediaRockdust

The invention discloses a Caragana intermedia natural-color semi-chemical mechanical pulping process which comprises the following steps: 1) cutting Caragana intermedia into material fragments, and conveying to a claw filter to remove heavy impurities such as soil dust; 2) conveying the qualified Caragana intermedia to a boiler for softening after dust and impurities are removed; 3) conveying the boiled Caragana intermedia to a press master, performing high-pressure steeping devillication by using a double-screw thread rolling machine, and pulping in a high-concentration pulping machine so as to obtain crude pulp; 4) performing high-speed latency on the grinded crude pulp by using a hydrapulper, removing residues, finishing, screening, concentrating, conveying to a pulp chest, and conveying to a papermaking workshop. Aiming at the characteristics of Caragana intermedia, the Caragana intermedia natural-color semi-chemical mechanical pulping process disclosed by the invention is simple in process, easy to operate, relatively friendly to the environment when being compared with the prior art, the obtained slurry is high in performance and low in cost, and the process does not need large and complex equipment.

Owner:XINJIANG GUOLIYUAN INVESTMENT

Dust prevention device special for earthen archaeological site drilling machine

The invention discloses a dust prevention device special for an earthen archaeological site drilling machine. The dust prevention device is a special-shaped barrel and is fixed by locking a locating support, it is guaranteed that a drill rod operates normally in the barrel in the drilling process, a plurality of dust prevention baffles are arranged in the barrel, the drilling deslagging speed is effectively reduced, dust is effectively prevented from flowing out through a dust prevention closing-in flexible device, rotary flow is formed in the dust prevention device, the speed of large and small drilling deslagging particles is comprehensively reduced through blocking of multiple times, and the large and small drilling deslagging particles flow out of a deslagging opening in a centralized mode. The work environment of a drilling operation platform is improved, the pollution of drilling deslagging on the environment is relieved or eliminated, and the security measures in the implementation process are enhanced. The high-quality drilling technology of a construction field is improved, and the positive effect is achieved in the earthen archaeological site protection and reinforcement project practice.

Owner:DUNHUANG ACAD +1

Ceramic product recycling device

ActiveCN111014092AImprove ornamental valueImprove recycling efficiencyCleaning using toolsCleaning using liquidsRockdustProcess engineering

The invention relates to the technical field of ceramic tile recycling, in particular to a ceramic product recycling device. The technical problem to be solved is to provide the ceramic product recycling device. The ceramic product recycling device comprises a suspension type telescopic clamping mechanism and a second water spraying head, and the middle of the left side in a supporting frame is connected with the suspension type telescopic clamping mechanism. Tiles are intermittently conveyed to the position below an arc-shaped scraper and an arc-shaped protection plate through an intermittentconveying mechanism, a suspension type telescopic scraping mechanism can move up and down and drive the arc-shaped scraper to scrape away moss on the surfaces of the tiles, the moss and soil are washed away in cooperation with a first water spraying head, and the tiles are clamped by the suspension type telescopic clamping mechanism; and dust on the concave surfaces of the tiles is washed away through cooperation of the second water spraying head, the ornamental value of the tiles is improved, the recycling efficiency is improved, and the recycling value is increased.

Owner:杭州翔毅科技有限公司

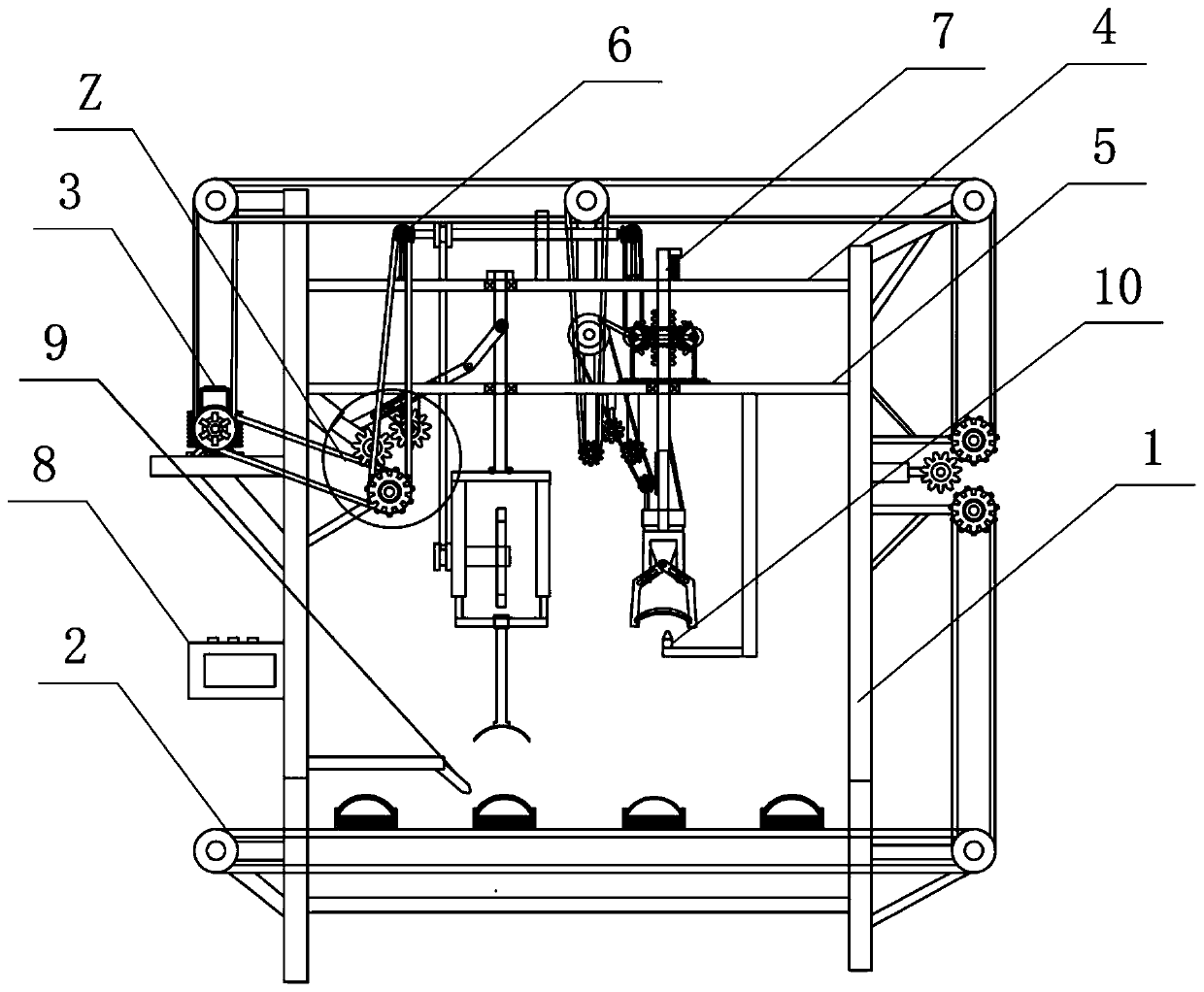

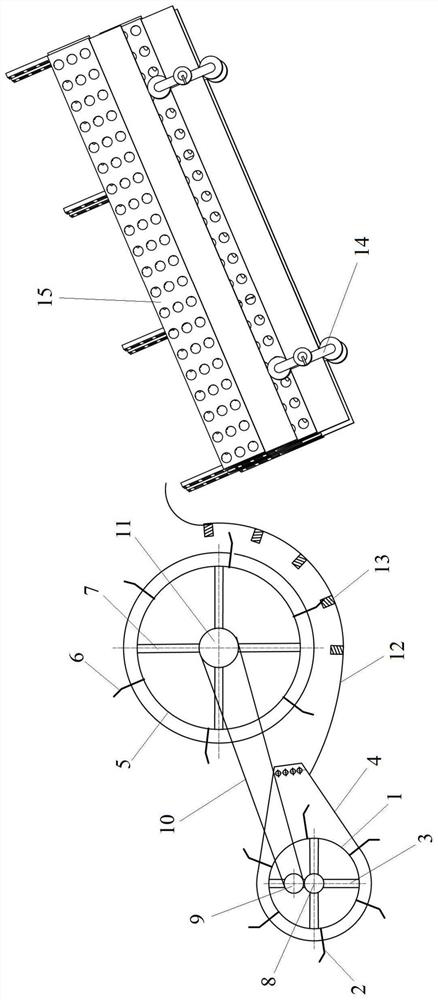

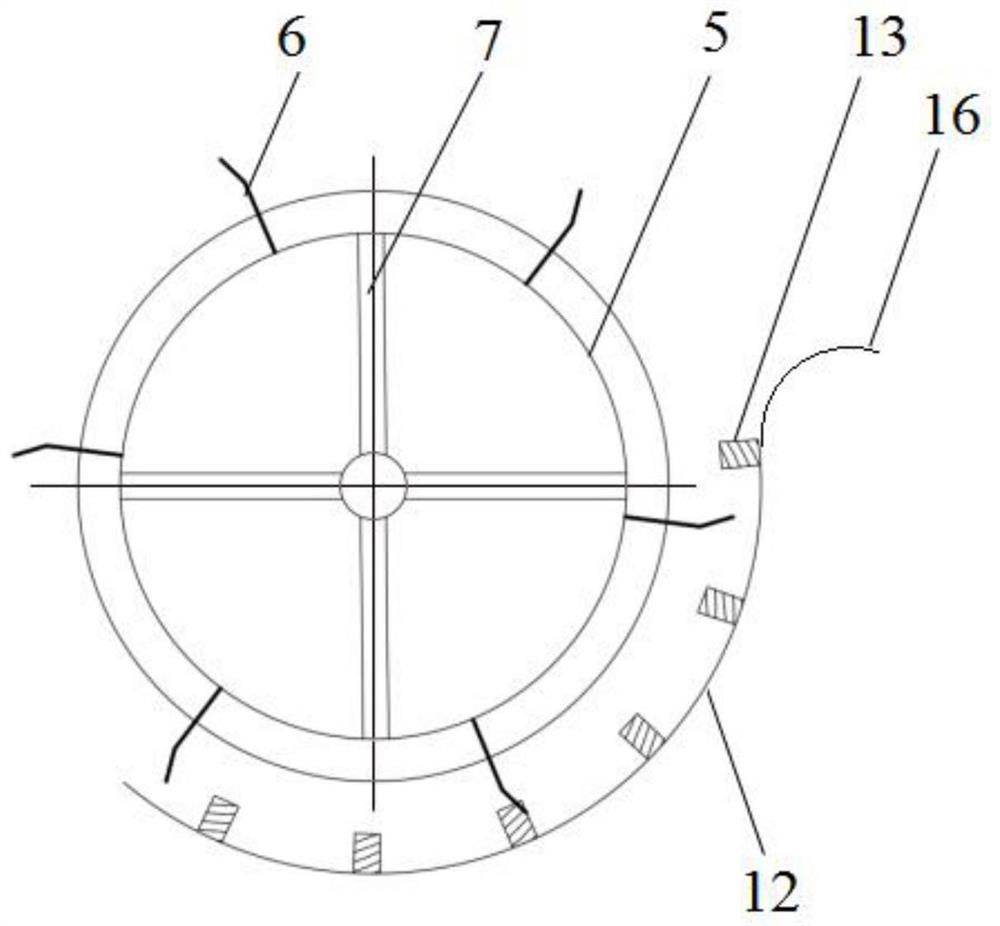

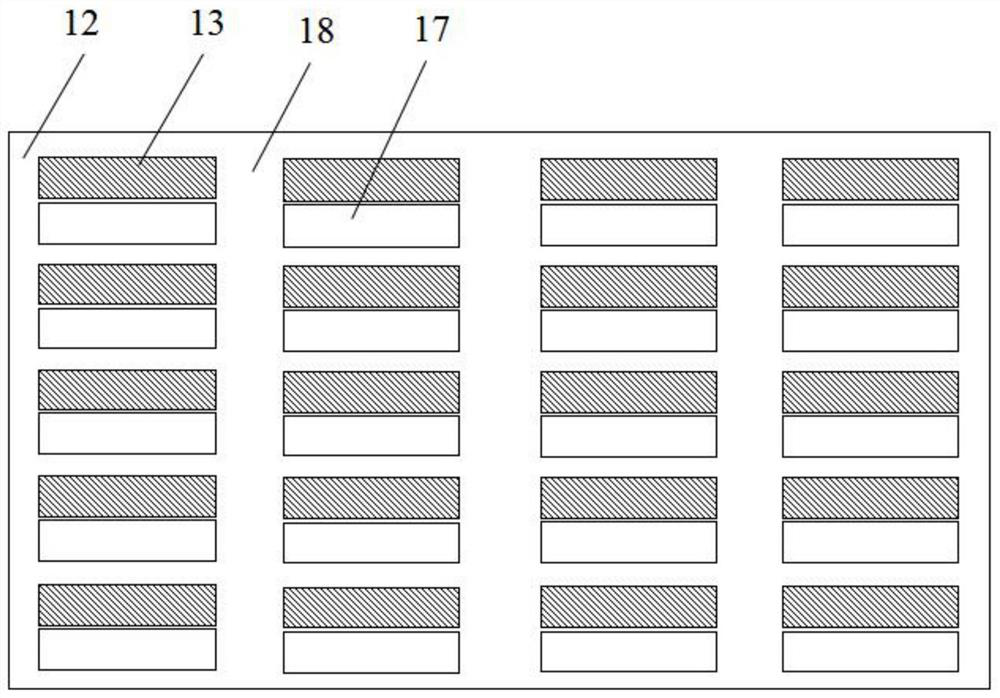

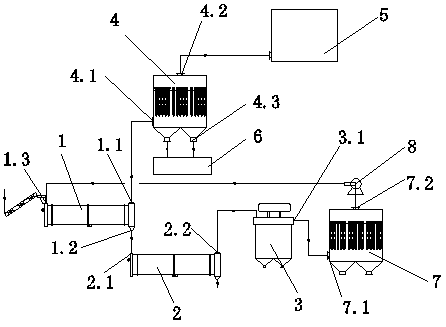

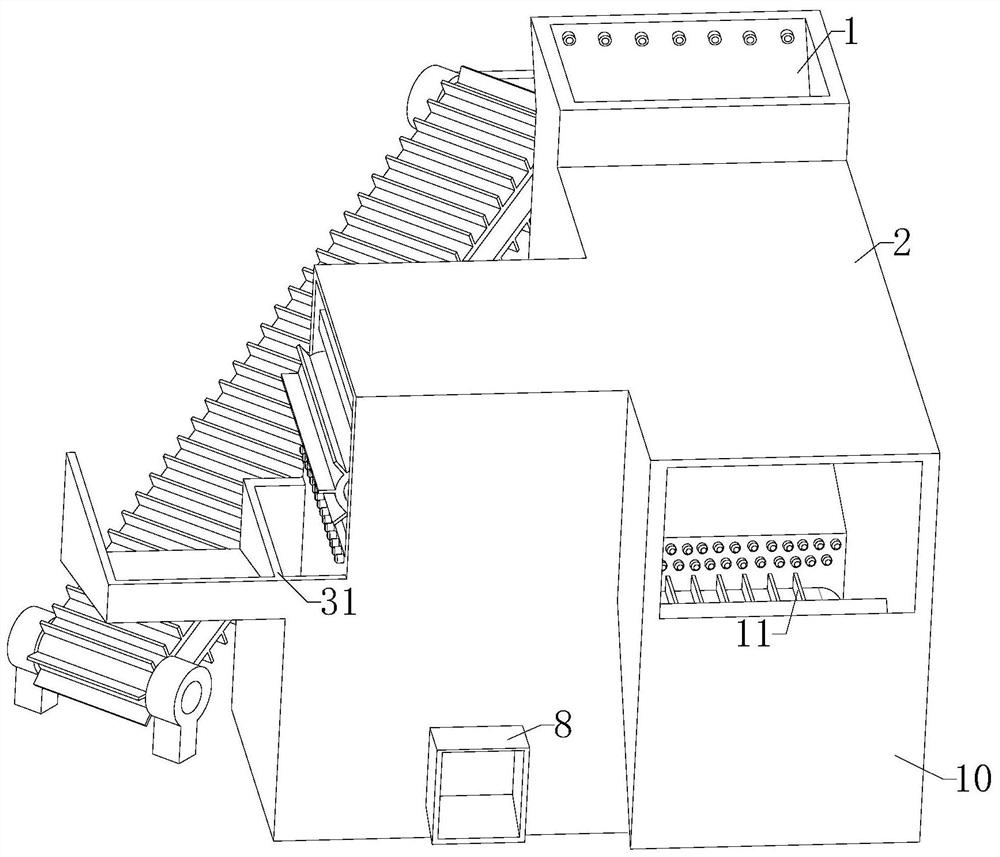

Straw picking and soil removing device for bale burning

PendingCN111642244ARealize secondary soil removalAvoid affecting combustion efficiencySievingGas current separationAgricultural engineeringRockdust

The invention discloses a straw picking and soil removing device for bale burning, and relates to the technical field of agricultural machinery. The straw picking and soil removing device comprises apicking device, a supporting and conveying device, a transmission device, a beating soil removing device and a vibrating soil screening device, wherein the picking device, the beating soil removing device and the vibrating soil screening device are arranged from front to back sequentially; the transmission device is used for being connected with the picking device and the beating soil removing device, and the picking device comprises a first roller and a plurality of picking elastic teeth arranged on the first roller; the supporting and conveying device covers the picking device; the beating soil removing device comprises a soil remover, a second roller and a plurality of beating elastic teeth installed on the second roller; and the vibrating soil screening device comprises a rotating assembly and a plurality of vibrating screens, the rotating assembly is rotatably installed on a rack, and the plurality of vibrating screens are all installed on the rotating assembly. The device can remove dust inside straw bales and dust adhered to the surface of straw, has better soil remove effect and prevents influence on combustion efficiency of the straw bales.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Air water atomization blockage preventing sprayer for preventing blockage based on pressure intensity changes

The invention relates to the technical field of gardens, and discloses an air water atomization blockage preventing sprayer for preventing blockage based on pressure intensity changes. A shell is included. An inner nozzle is arranged on the left side of the shell. The inner nozzle is used for atomization, the outer side of the inner nozzle is movably connected with an outer nozzle, and through cooperative usage of the inner nozzle and the outer nozzle, detachment is convenient. Outer nozzles different in hole diameter can be rotated according to different situations, and the usage range is enlarged. Through the arrangement of a blockage block, when the device does not need to be used, the inner nozzle can be blocked, and blockage caused by falling of ash or dust into the inner nozzle is avoided. Through cooperative usage of an air inlet pipe and a water inlet pipe, on one hand, the blockage block is automatically opened, and on the other hand, the situation that after closing, water spots are still left in the nozzles, the temperature is low, and icing is caused is avoided. Through cooperative usage of a first baffle and a second baffle, opening and closing of the water inlet pipeand the air inlet pipe are controlled, and operation is more intelligent.

Owner:日照金慧科技信息咨询有限公司

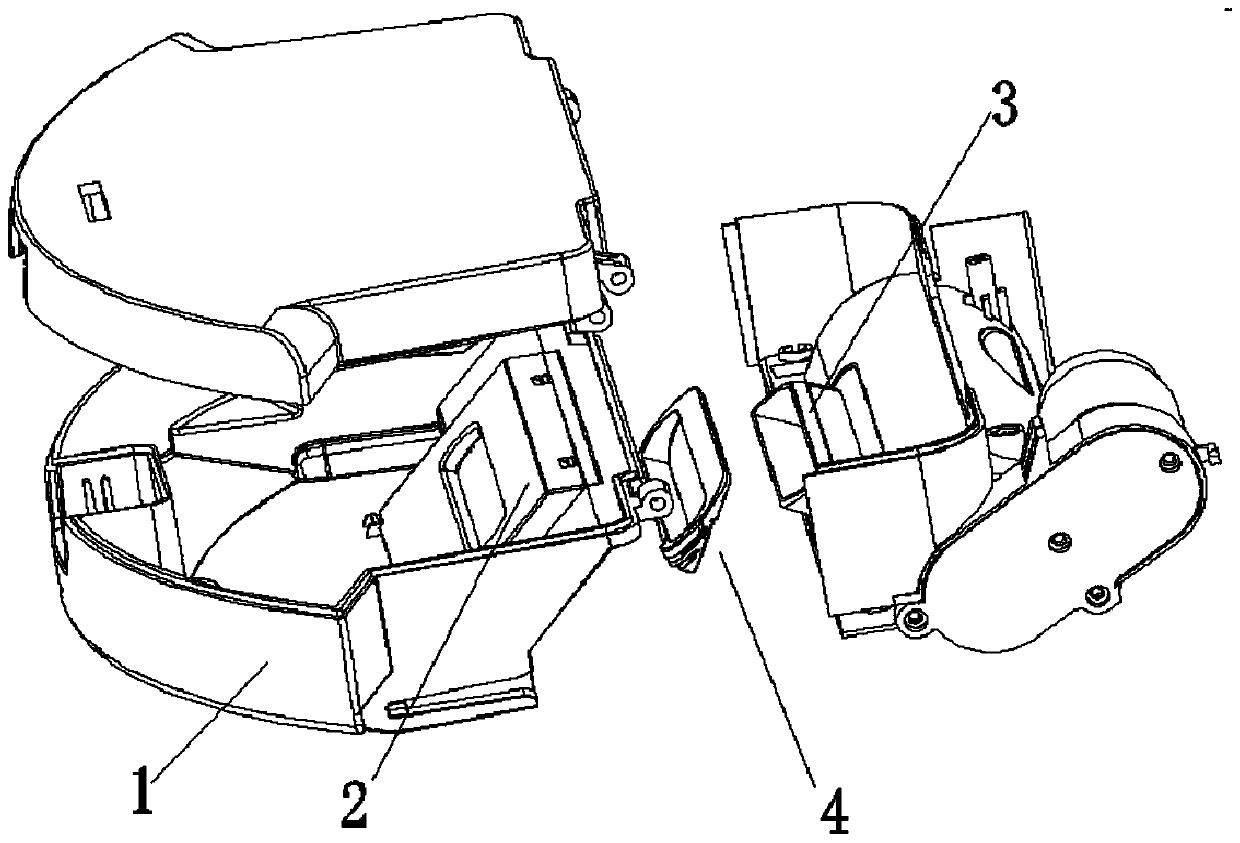

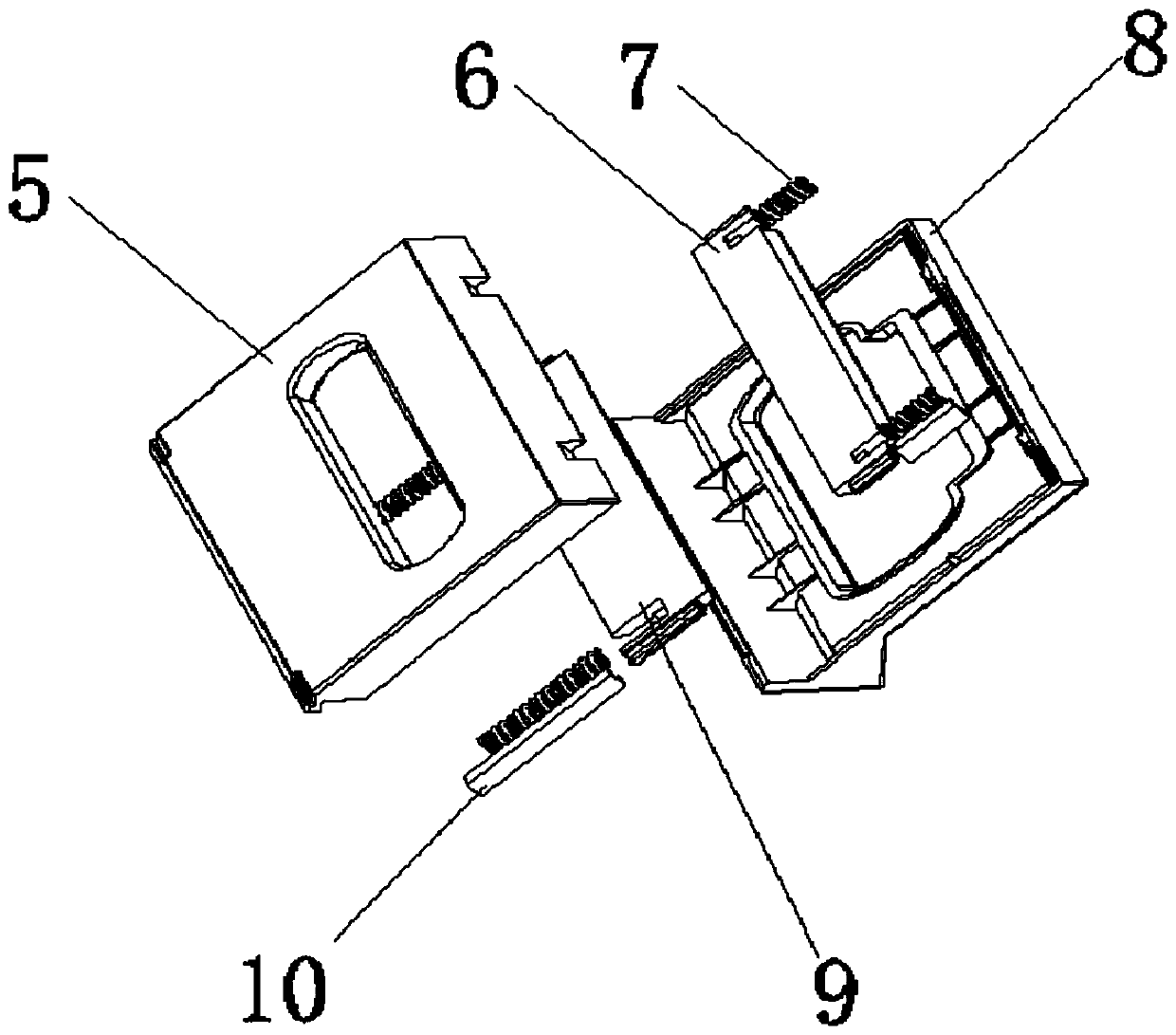

Dust falling prevention mechanism for dust collection box of sweeper

PendingCN111358376ASolve the problem of secondary dropAvoid clogging the dental boxCarpet cleanersFloor cleanersThermodynamicsRockdust

The embodiment of the invention discloses a dust falling prevention mechanism for a dust collection box of a sweeper. The mechanism comprises a dust box movably connected into a sweeper body and an air rolling cylinder installed in the sweeper body. A dust inlet is formed in one end, close to the air rolling cylinder, of the dust box; a blocking mechanism used for sealing the dust inlet is installed at the position, corresponding to the dust inlet, of the inner wall of the dust box. The air rolling cylidner is provided with a gear box. The cross section of the gearbox box is of a right trapezoid structure, and the gearbox box is used for pushing away the blocking mechanism and being inserted into the dust inlet to guide dust into the dust box; according to the invention, the blocking mechanism with an automatic closing effect is additionally arranged in the dust box; therefore, the problem of secondary falling of dust caused by untight sealing when the dust collection box is pulled outis solved, that is, when the dust collection box is not used in daily life or the sweeper is pulled out, the upper and lower blocking pieces can be pushed by the spring to block the dust collection port, and the upper and lower blocking pieces are not easily influenced even if the dust collection box is vibrated or shaken, so that dust in the box falls out.

Owner:HUNAN JUSHEN ELECTRONICS CO LTD

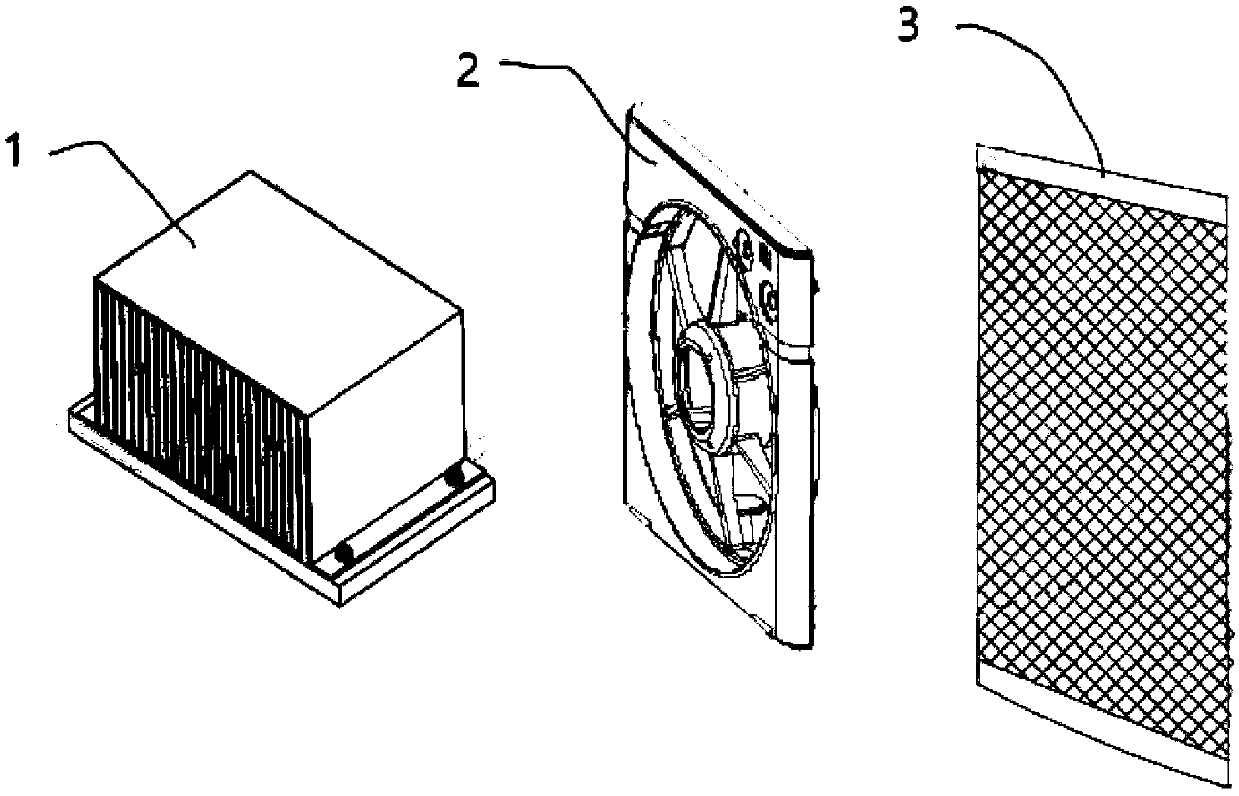

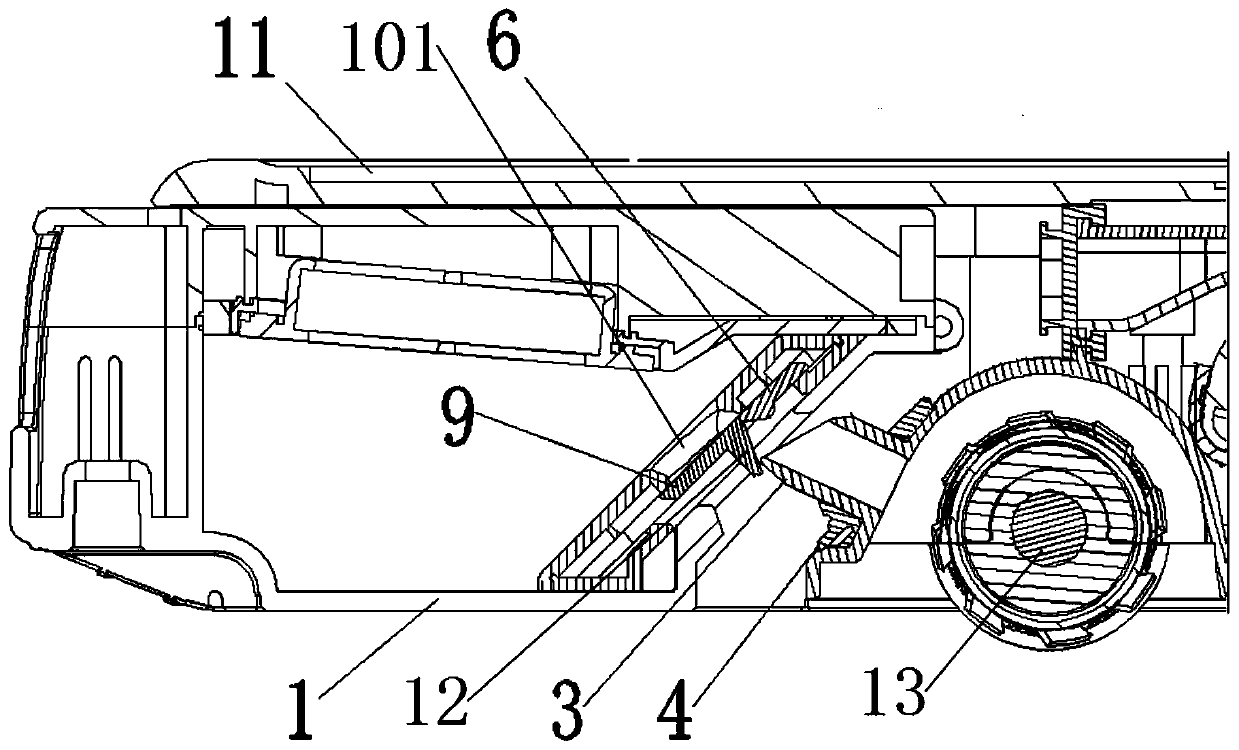

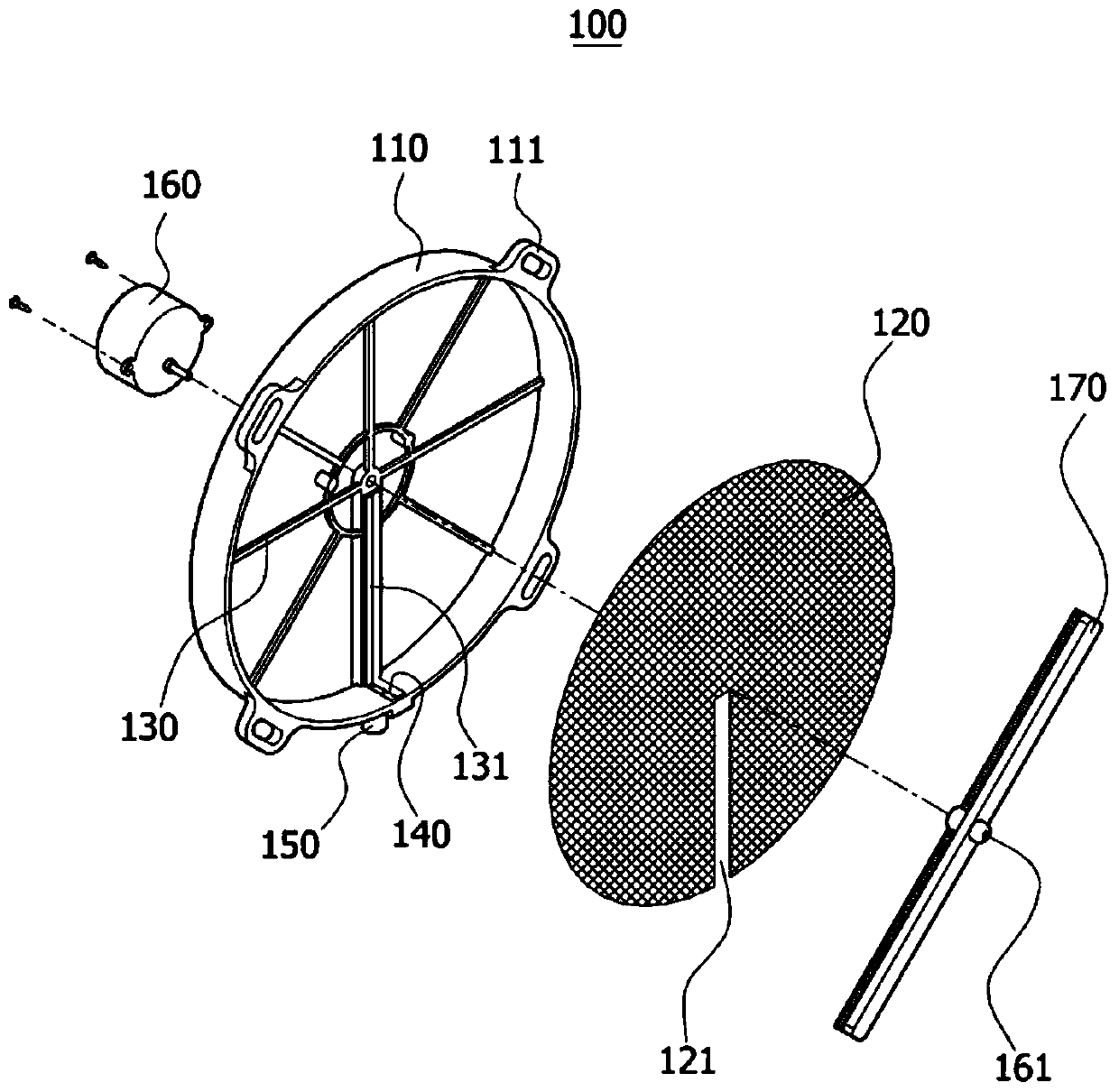

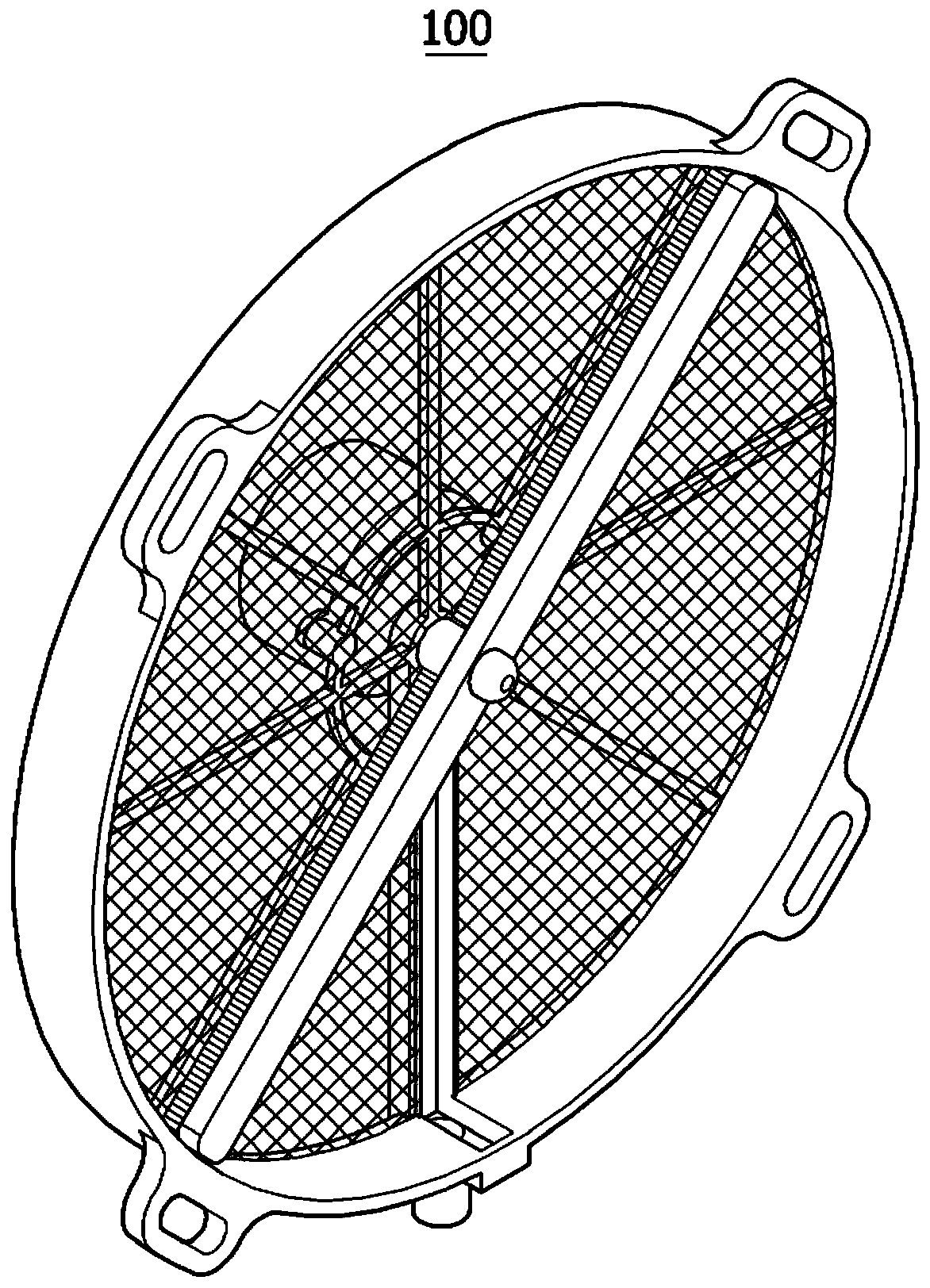

Filter structure capable of removing dust

InactiveCN111602008AWon't rotateEfficient removalMechanical apparatusDispersed particle filtrationRockdustEnvironmental engineering

The objective of the present invention to provide a filter structure capable of removing dust, comprising: a circular rim part; a frame, extending from the rim part, for installing a motor; a dust collection net attached to the frame; a brush which is in close contact with the dust collection net and is rotated by means of the motor; an opening, formed at a lower end of the rim part, for discharging dust; an open part formed at one side of the dust collection net; and a concave groove part having an outside coupled to the open part and in one-side communication with the opening at the rim part. The present invention has the effect that a dust removing means of the brush can be continuously shaken off by the concave groove part formed on one side of the dust collection net, such that the dust can be efficiently removed without the brush dragging around and rotating the dust. Particularly, the dust introduced into an air conditioner is blocked from an outdoor air inlet in advance to prevent the dust from entering an air conditioner case, thereby preventing dust collecting efficiency from being deteriorated.

Owner:森德利株式会社

Multifunctional dust removal equipment

PendingCN111888839ARealize concentrated adsorptionProtect the working environmentConveyorsDispersed particle filtrationRockdustEngineering

The invention discloses multifunctional dust removal equipment which mainly solves the problem that existing dust collection equipment cannot recycle flying dust. The multifunctional dust removal equipment comprises a containing device, wherein the interior of the containing device is a space capable of containing materials; an air draft device which is connected with the containing device, and isused for extracting air in the containing device and sucking flying dust into the containing device; a dust filtering device which is arranged in the containing device, is used for collecting flyingdust and can adsorb the flying dust into a pile in a centralized mode, and is provided with a collecting part, wherein the collecting part is arranged on the periphery of the dust filtering device andused for preventing the flying dust from penetrating through the collecting part; and a blowing device which is connected with the containing device, and is used for blowing air into the dust filtering device to blow down flying dust adsorbed on the dust filtering device. The multifunctional dust removal equipment has the advantages that flying dust is recycled and treated into dust, and the dustis recycled.

Owner:ZHANGJIAGANG HUASHEN INDAL RUBBER PRODS

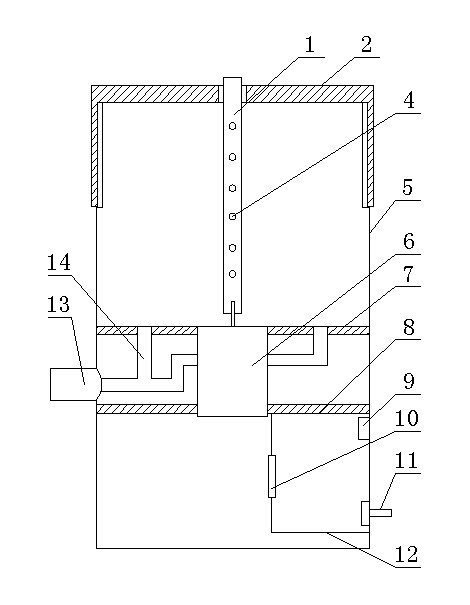

In-hole wave velocity test sampling equipment and sampling method for rock and soil exploration

PendingCN114354756AExtended service lifeEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesSeismologySoil scienceRockdust

The invention discloses in-hole wave velocity test sampling equipment for rock-soil exploration and a sampling method, and relates to the field of rock-soil exploration, the sampling equipment comprises a drilling detection device, an impact sampling device, a protection device and a dust removal device, the drilling detection device is connected with the impact sampling device, the drilling detection device is connected with the protection device, and the protection device is connected with the dust removal device. A detector holds the grab handle with a hand to keep the impact sampling device vertical, the impact sampling device generates impact to enable the drill bit to continuously punch downwards and make detection preparation, after a hole is punched to a proper depth, the drilling detection device stretches out the probe, the probe pierces into rock soil, detection is started, and the probe transmits detection data into the detection instrument through the connecting line. The impact sampling device can sample different layers in rock soil, the protection device can protect a detection instrument to prevent collision, and the dust removal device can remove dust around the detection instrument to keep the instrument clean. The process is simple, and operation is convenient and fast.

Owner:中化学华晋工程有限公司

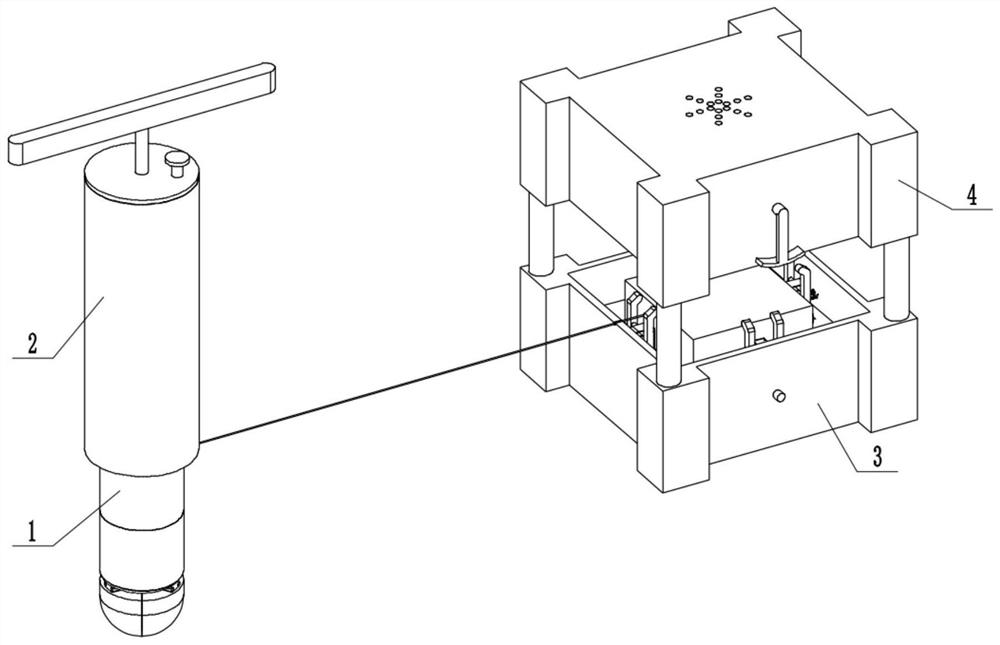

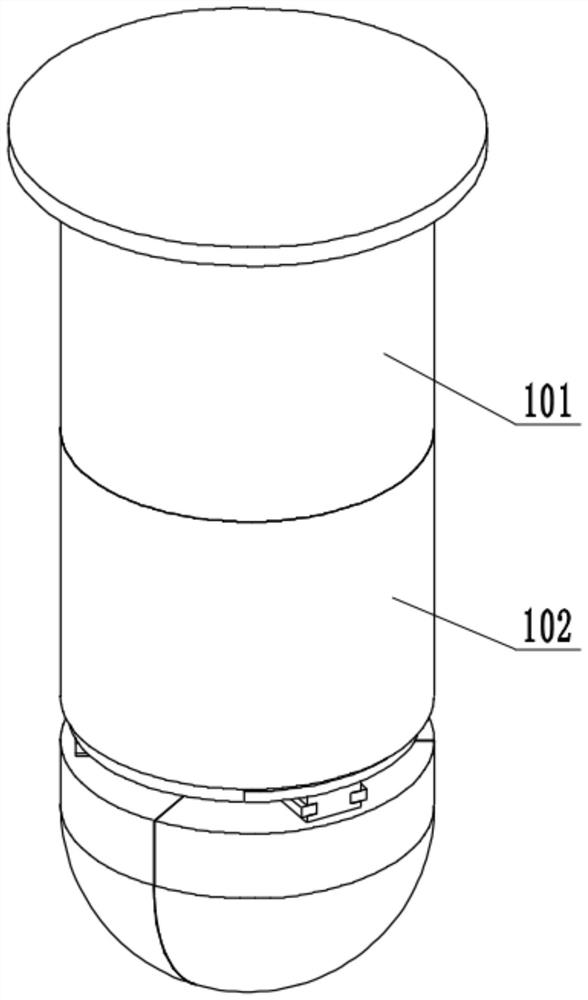

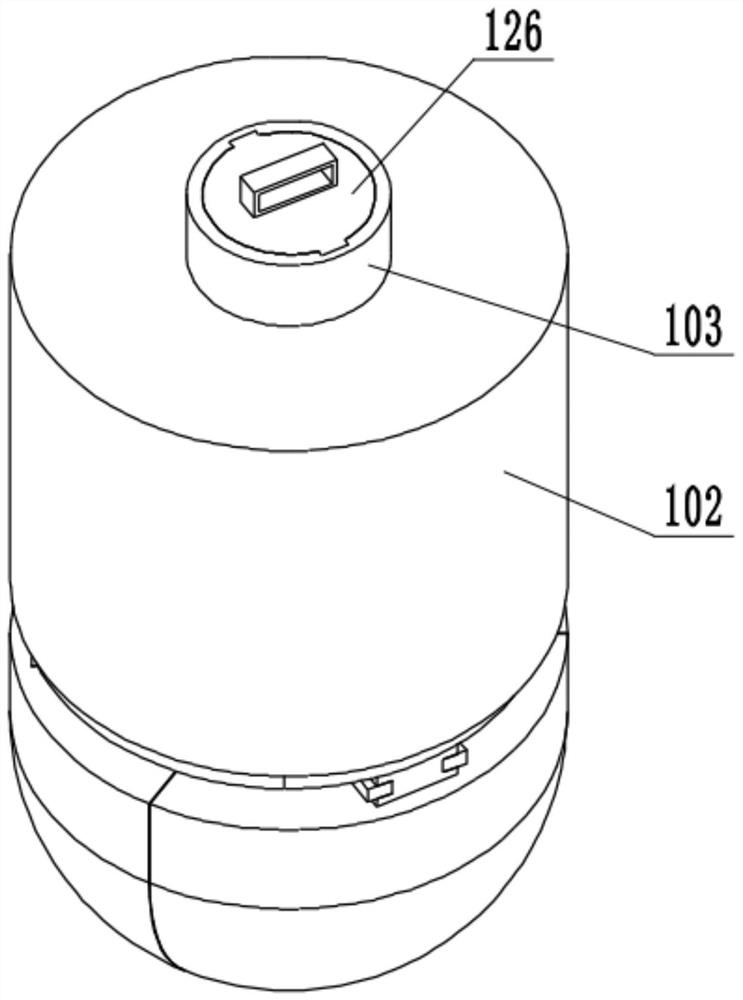

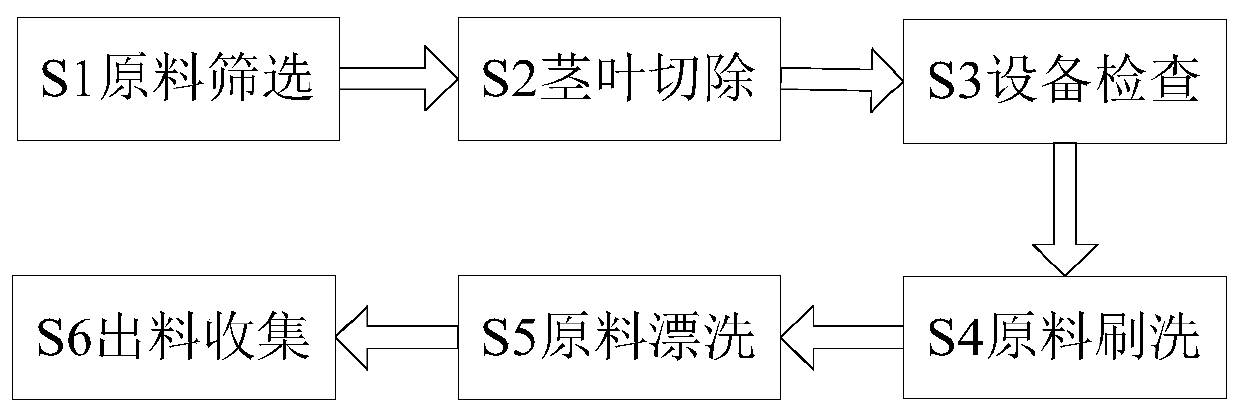

Plant essential oil raw material pretreatment process

InactiveCN111171952AClean enoughIncrease the areaEssential-oils/perfumesFatty-oils/fats productionRockdustProcess engineering

The invention relates to a plant essential oil raw material pretreatment process. Automatic cleaning equipment is used, the automatic cleaning equipment comprises a work box, a brushing device and a rinsing device, and when the automatic cleaning equipment is used for pretreating citrus plant essential oil raw materials, the specific technological process is as follows: raw material screening, stem and leaf cutting, equipment inspection, raw material brushing, raw material rinsing and discharged material collection. According to the process, the citrus plant essential oil raw material is cleaned by adopting a mode of brushing and rinsing in sequence; the raw materials can be fully cleaned, raw material full cleaning is ensured, dirt such as silt and dust remaining in round holes in the surfaces of orange raw materials can be effectively removed, the raw materials can be pushed to reciprocate in the rinsing process, the rinsing area of the raw materials is increased, the rinsing thoroughness is guaranteed, the brushed raw materials can fall into the rinsing device without being transported by transfer equipment, and the working time is saved.

Owner:沈水松

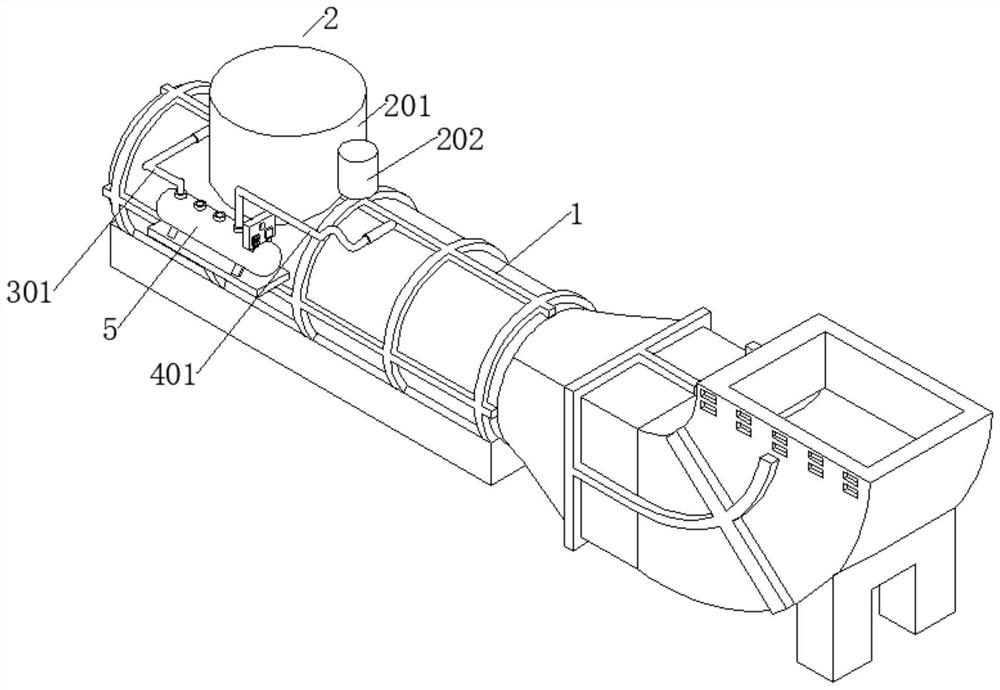

Fly ash multi-stage recycling treatment device and process

PendingCN111521000ANothing producedReduce energy consumptionChloride preparationRotary drum furnacesDust controlRockdust

The invention discloses a fly ash multi-stage recycling treatment device. The fly ash multi-stage recycling treatment device comprises a first-section rotary kiln, a second-section rotary kiln, a crystallization device, a first high-temperature dust remover and a waste gas treatment device, wherein the tail parts of the first-section rotary kiln and the second-section rotary kiln are provided withan exhaust port and a discharge port correspondingly; the exhaust port of the first-section rotary kiln communicates with an air inlet of the first high-temperature dust remover; the exhaust port ofthe first high-temperature dust remover communicates with the waste gas treatment device; a dust discharge port of the first high-temperature dust remover communicates with a collecting device; the discharge port of the first-section rotary kiln communicates with a feeding port of the second-section rotary kiln; and the exhaust port of the second-section rotary kiln communicates with the crystallization device. The invention further provides a fly ash multi-stage recycling treatment process. According to the fly ash multi-stage recycling treatment device and process, chlorine salt and a smallamount of heavy metal are separated from light fly ash through a two-stage combustion process, the chlorine salt and the small amount of heavy metal can also be used as industrial salt after being treated by a subsequent process in the later period, the separated light fly ash is subjected to dust removal through the high-temperature dust remover, then dust is collected and used for producing light bricks, and secondary pollutants are basically not generated.

Owner:JIANGSU JINNIU ENVIRONMENTAL ENG EQUIP

High-efficiency ventilation device for coal mining

InactiveCN112196604AAvoid damageReduce cloggingCombination devicesMining devicesToxic gasWater storage tank

The invention discloses a high-efficiency ventilation device for coal mining. The high-efficiency ventilation device comprises a ventilation pipeline, wherein an air pump is arranged on one side of the ventilation pipeline; an atomization dust-settling mechanism is arranged in the ventilation pipeline and comprises a water storage tank; one side of the water storage tank is connected with a waterpump; one end of the water pump is connected with a water supply pipeline; one end, which is positioned in the ventilation pipeline, of the water supply pipeline is connected with a water flow pressurizer; a plurality of atomizers are arranged at the bottom of the water flow pressurizer; connecting shafts are arranged in the atomizers; connecting pieces are arranged in the connecting shafts; and springs are arranged on the outer sides of the connecting pieces in a sleeving manner. According to the high-efficiency ventilation device disclosed by the invention, a filtering mechanism and an atomization dust removal mechanism are arranged on the conventional coal mining ventilation device, so that damage of dust, impurities and toxic gases in the mine to the device is reduced, the problem thatthe ventilation pipeline of the device is blocked due to dust accumulation is solved, damage of fine particulate matters entering the device to the ventilation device is reduced, the ventilation efficiency is improved, and air in the mine is circulated.

Owner:HEILONGJIANG UNIV OF TECH

Coal gangue material sorting device based on terahertz recognition

InactiveCN113941432AReduce workloadImprove efficiencyCleaning using toolsSortingCoal waterThermodynamics

The invention relates to the technical field of coal gangue sorting, in particular to a coal gangue material sorting device based on terahertz recognition. The coal gangue material sorting device comprises a feeding port, a sorting water tank, a recognition mechanism, a washing mechanism, water outlet holes and a coal storage bin. The feeding port is formed in one end of the sorting water tank. The bottom of the feeding port is connected with the washing mechanism. A row of water outlet holes are formed in one side of the top of the feeding port. The coal storage bin is arranged at the other end of the sorting water tank. A coal and water mixing bin is arranged at the end, close to the coal storage bin, in the sorting water tank. One side of the sorting water tank is connected with the recognition mechanism. According to the coal gangue material sorting device, gangue with coal is conveyed and screened out through the recognition mechanism, then through usage of the washing mechanism and a washing push plate, a rotating plate reciprocates to sufficiently extrude and wash the gangue, coal waste is reduced, the tedious steps of manual operation are avoided, the workload of operators is relieved, repeated operation is conducted in cooperation with the washing mechanism, and coal and dust attached to the surface of the gangue can be cleaned away.

Owner:ANHUI UNIV OF SCI & TECH

Road dust collecting device for municipal engineering

InactiveCN112517588AAvoid stickingAvoid backmixing and effluxDirt cleaningVapor flow controlEnvironmental resource managementDust control

The invention provides a road dust collection device for municipal engineering, and relates to the technical field of dust collection. The road dust collection device for municipal engineering aims tosolve the problems that most of existing dust collection devices adopt an active collection mode and have one defect, namely, collection is performed after dust is generated, the environment is damaged, pollution is generated, kinetic energy equipment is needed, and the dust is hard to collect and treat in real time. The road dust collection device for municipal engineering comprises a collectingbox; a vertical dust collection mechanism is fixedly mounted in the middle of the upper end of the collection box; an electrostatic generator is fixedly mounted in the position where the lower end ofthe dust collection mechanism is rotationally connected with the bottom of an inner cavity of the collecting box. According to the road dust collection device for municipal engineering, due to the fact that four driven dust collection paddles which are evenly arranged at intervals are fixedly mounted on the part, located in the collecting box, of a dust collection shaft, dust in the collecting box can be further adsorbed, so that backmixing and discharging in the absorption process are avoided; and when rotation is stopped, static electricity is gradually eliminated, so that the dust can freely fall off.

Owner:杨明玉

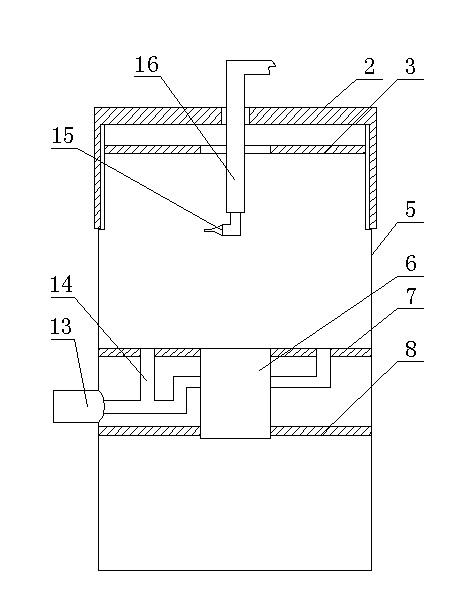

Landscaping waste treatment device

ActiveCN113695367AIncrease granularityReasonable designSolid waste disposalRotary stirring mixersGreen wasteRockdust

The invention relates to the landscaping industry, in particular to a landscaping waste treatment device. The landscaping waste treatment device comprises a shell, a material guide device, a purification device and a dust falling device; the material guide device is arranged on the outer portion of the shell and is used for directional guide-in connection of external materials; the purification device is arranged on the outer portion of the material guide device and is used for oscillating and separating soil of waste; the dust falling device is connected with the purification device; the purification device comprises at least two groups of adjusting devices, and the adjusting devices are arranged on the outer portion of the shell; and the dust falling device is connected with the adjusting devices and used for crushing and separating the soil. By means of the device, the inner adjusting devices cooperate with the dust falling device, dust entrained on the outer portion of greening waste is separated, then directional collection is achieved through a dust removing device arranged on the outer portion, meanwhile, the device is further provided with multiple sets of crushing equipment, the refining degree of the greening waste is further improved, and follow-up collection and treatment are facilitated.

Owner:邳州市铁富九龙公共服务有限公司

Soil screening type passive action environment-friendly ore lossless screening machine

ActiveCN113634497AAchieve inhibitionReduce difficultySievingGas current separationMining engineeringRockdust

The invention discloses a soil screening type passive action environment-friendly ore lossless screening machine. The machine comprises a quick replacement type self-adsorption dust suppression conveying mechanism, a lossless soil screening separation mechanism, a passive action type dust suppression collecting mechanism, a vibration screening mechanism, a mounting base, an ore containing shell, a primary screening frame and a screening rear side support. The invention belongs to the field of ore screening equipment, and particularly relates to the soil screening type passive action environment-friendly ore lossless screening machine. Aiming at the contradictory characteristics that soil attached to ore needs to be separated and the ore cannot be damaged during ore screening, the screening machine overcomes the technical prejudice that a sensor can be adopted to detect the position where the soil is attached to the ore and screen the soil, meanwhile, the ore screening difficulty is reduced, a claw-shaped elastic distribution strip is used as an intermediate substance, so that the contradictory technical problems that the soil attached to the ore needs to be separated and the ore cannot be damaged in the prior art are solved.

Owner:徐州东坤耐磨材料有限公司

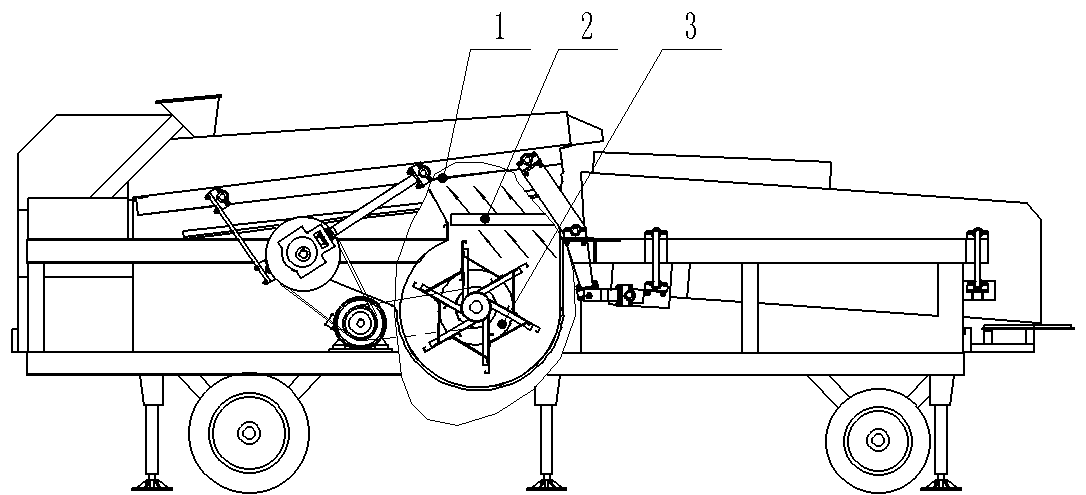

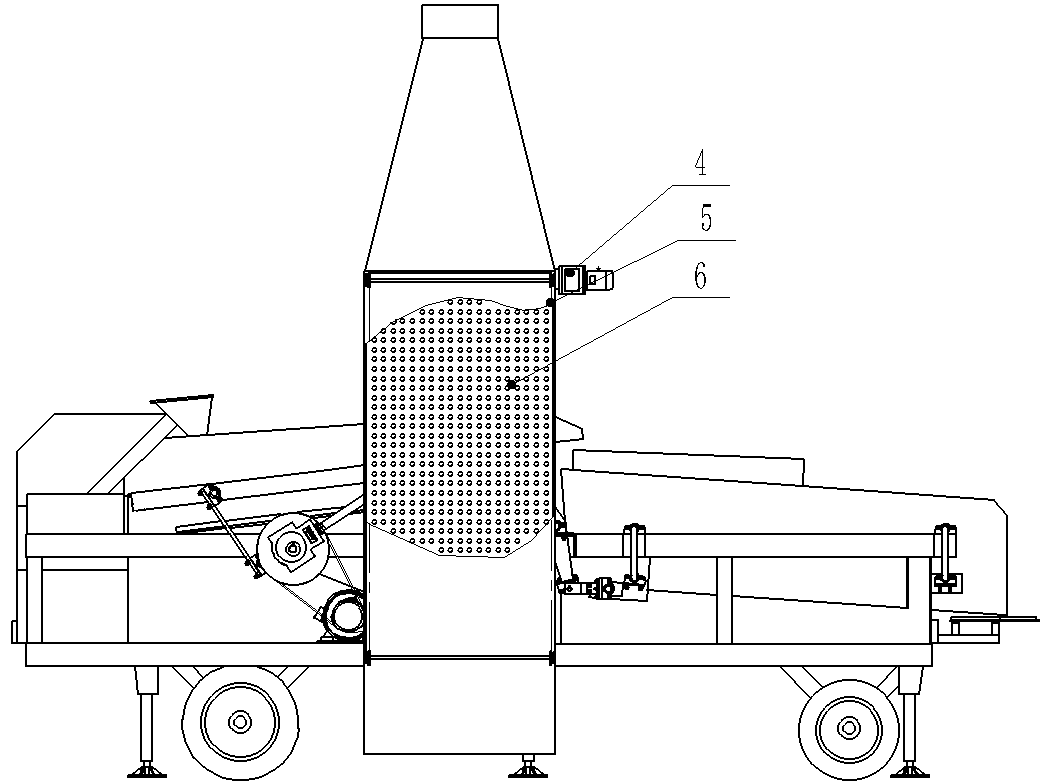

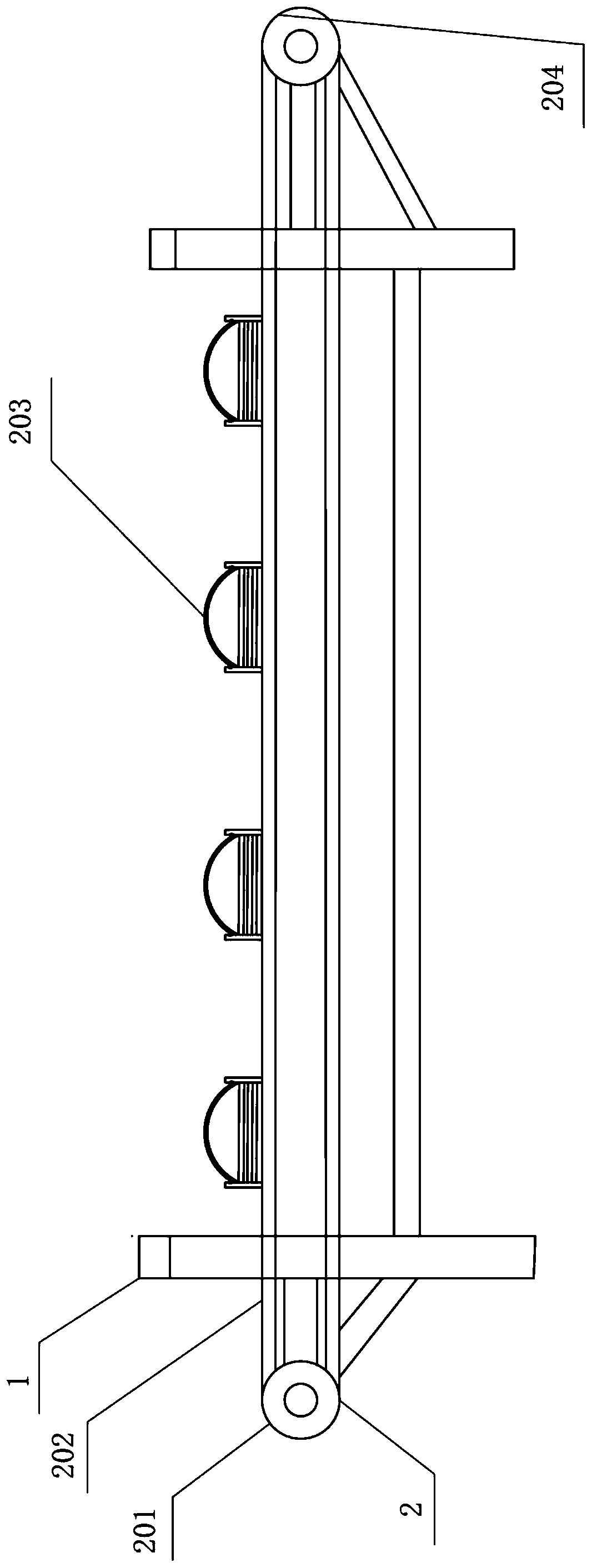

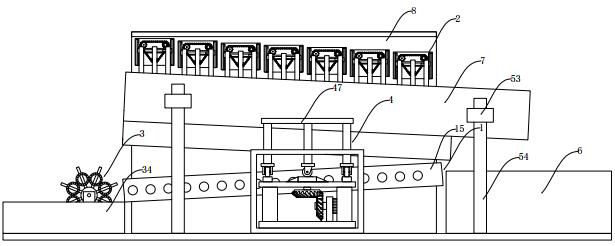

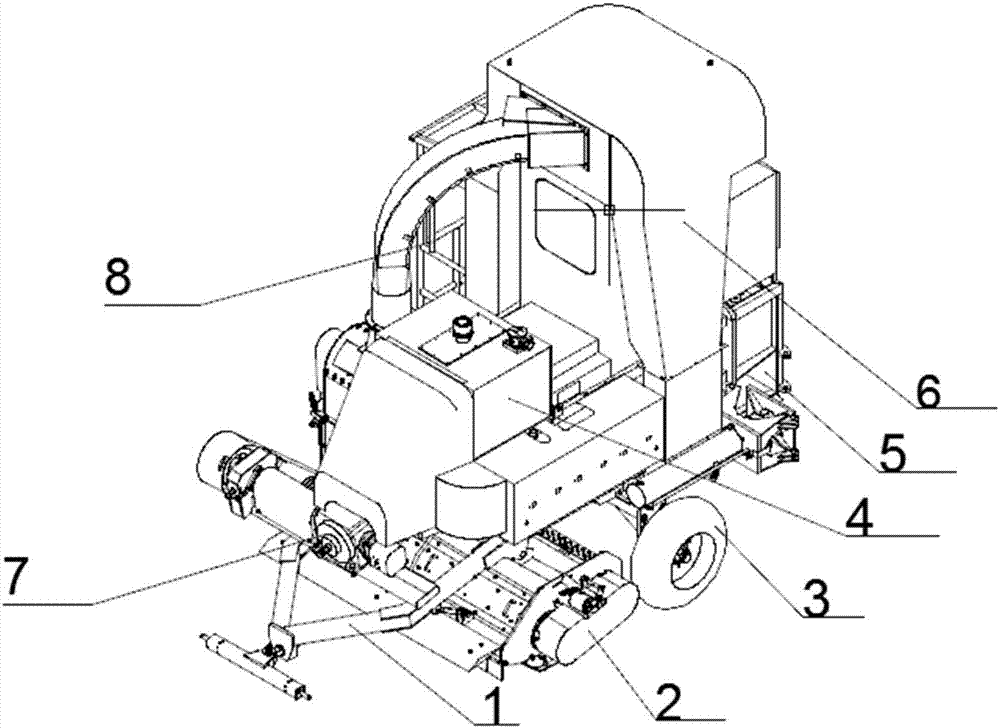

Multipurpose straw gleaning bundling machine

InactiveCN106973646AShorten blowing distanceReduce consumptionLoadersAgricultural scienceAgricultural engineering

The invention discloses a multipurpose straw gleaning bundling machine and belongs to the technical field of straw bundling machines. The machine solves the problems that the multipurpose requirements cannot be met by the existing straw gleaning bundling machines, and the machine provides a straw smashing bundling machine which is capable of meeting different smashing degrees and removing the soil cleanly; according to the machine, the volume of a secondary smashing mechanism is reduced, the secondary smashing mechanism is arranged on one side of a twisted dragon exit, so that the structure is more compact, the distance of draught fan blowing is shortened, the power consumption of a draught fan is reduced, accordingly, more torque power can be driven to the secondary smashing mechanism, and the secondary smashing efficiency is improved; the detachable design is adopted by the secondary smashing mechanism, overall disassembly and face-lifting are convenient, a closed type material collecting box is adopted, the dust and the smashed straw can be separated, the phenomenon of flying dust is avoided, and the work environment of the manipulators is improved. A closed shell is removed so that the soil content can be lowered, and accordingly multipurpose requirements for the straw can be met.

Owner:吉林天朗新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com