Automatic dust removal method and device of charging pile

A technology of automatic dust removal and charging piles, applied in charging stations, electric vehicles, separation methods, etc., can solve maintenance troubles, enter the interior of the housing, affect heat dissipation, etc., to reduce maintenance costs, prolong service life, and save manpower Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

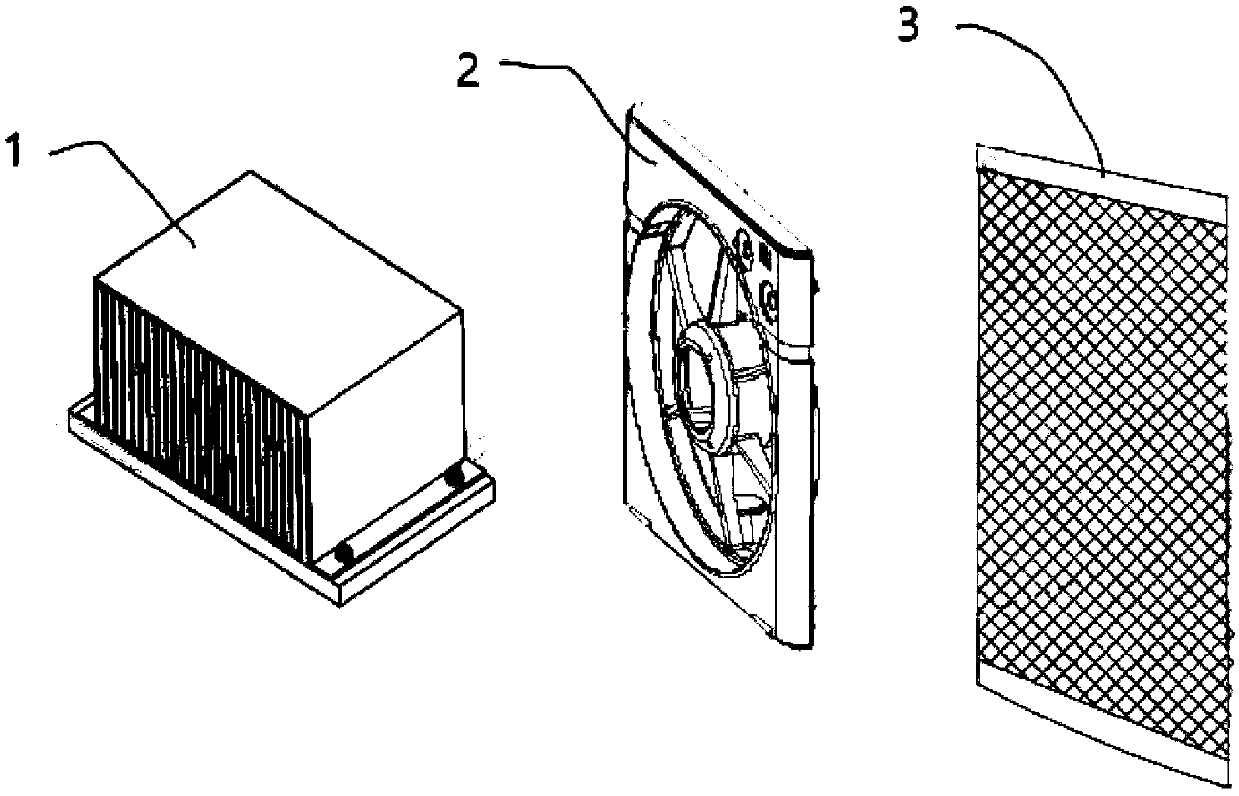

[0051] A charging pile device, such as image 3 As shown, it includes a radiator 1, a heat dissipation fan 2 and a dust filter 3, and also includes a controller, a first collection unit, a second collection unit and a wind pressure detection tube; the first collection unit is arranged outside the charging pile housing, For real-time collection of ambient temperature and ambient humidity; the second collection unit is arranged on the radiator 1 for real-time collection of radiator temperature; the cooling fan 2 is arranged on the radiator 1 and the dust filter 3 Between them, it is used to dissipate the heat of the radiator 1 and remove the accumulated dust on the dust filter 3; pile dust, the dust removal filter screen 3 is provided with a vibration motor, and the vibration motor is connected to the power supply through the coil of the relay; The pressure on both sides respectively represents the external environment pressure value of the charging pile and the inner pressure ...

Embodiment 2

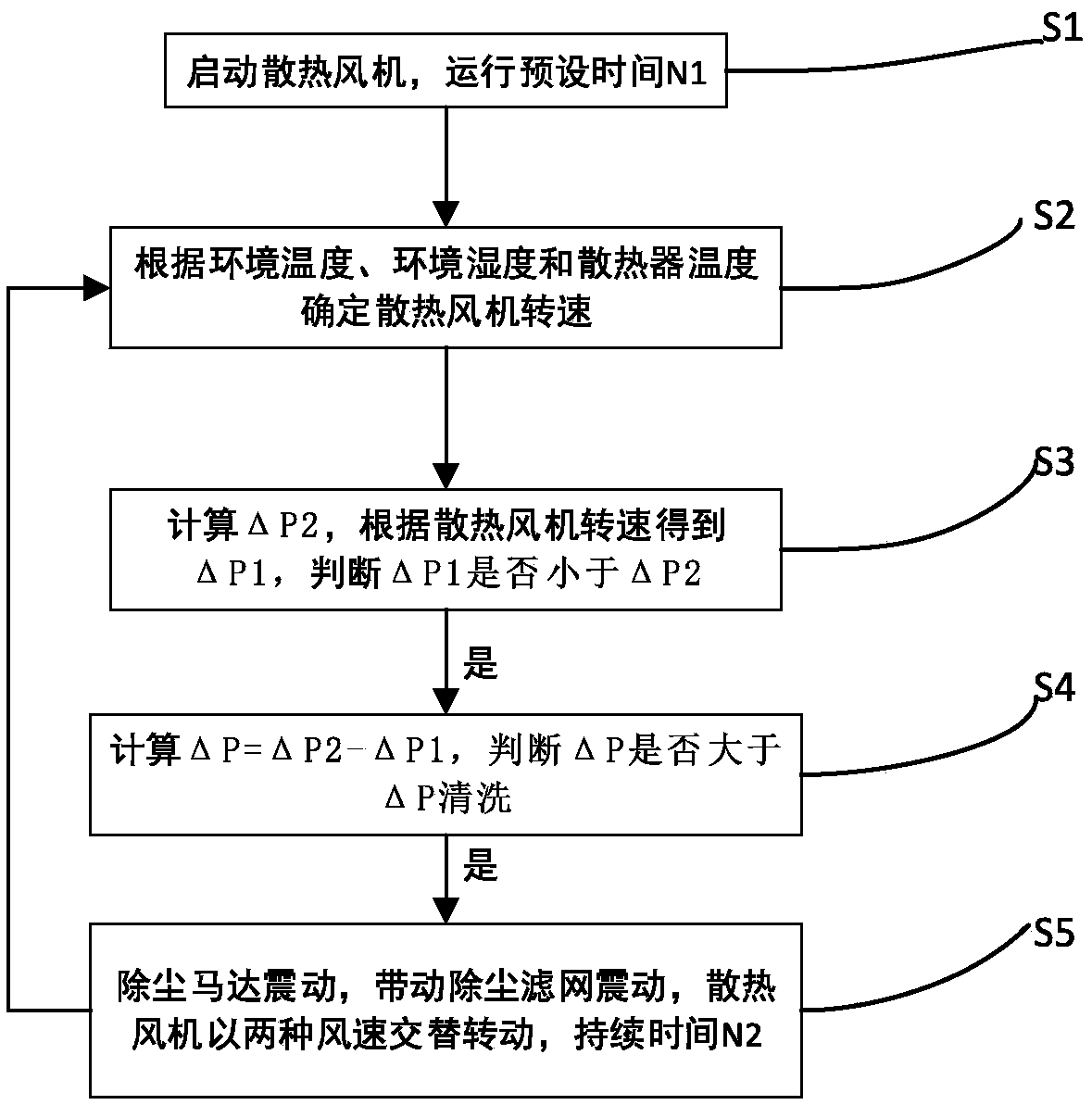

[0053] In order to realize the automatic dust removal method for the charging pile with the above dust removal device, as attached Figure 1-2 As shown, the automatic dust removal method of the charging pile includes the following steps:

[0054] S1, start charging, start the cooling fan, run the preset time N1, and enter S2;

[0055] Specifically, after the cooling fan 2 runs for a period of time, the operation of the charging pile enters a stable state, the temperature of the current radiator 1 is relatively stable, and the collected data is more reliable. In general, N1 can be 2 minutes to 5 minutes.

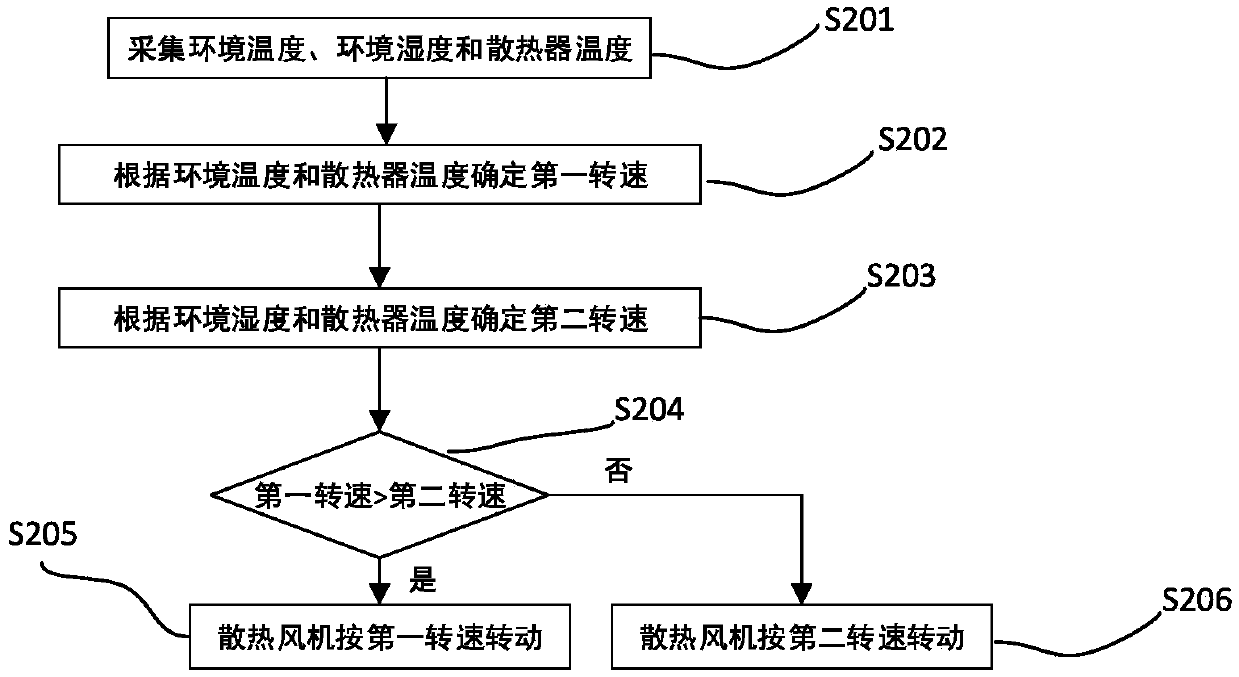

[0056] S201, real-time collection of ambient temperature, ambient humidity and radiator temperature;

[0057] Specifically, the first collection unit is set on the charging pile casing to collect the ambient temperature and humidity in real time. The ambient temperature and humidity have a certain influence on the heat dissipation rate. When the ambient temperature and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com