Patents

Literature

368results about How to "Protect the working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-embedded self-lubricating texture on surfaces of gear and cam and preparation method thereof

InactiveCN102628544AImprove adaptabilityImprove lubrication and anti-wear performancePortable liftingBase-materialsLaser processingHexagonal boron nitride

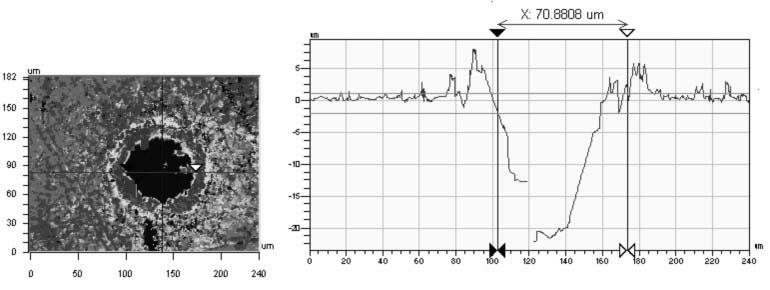

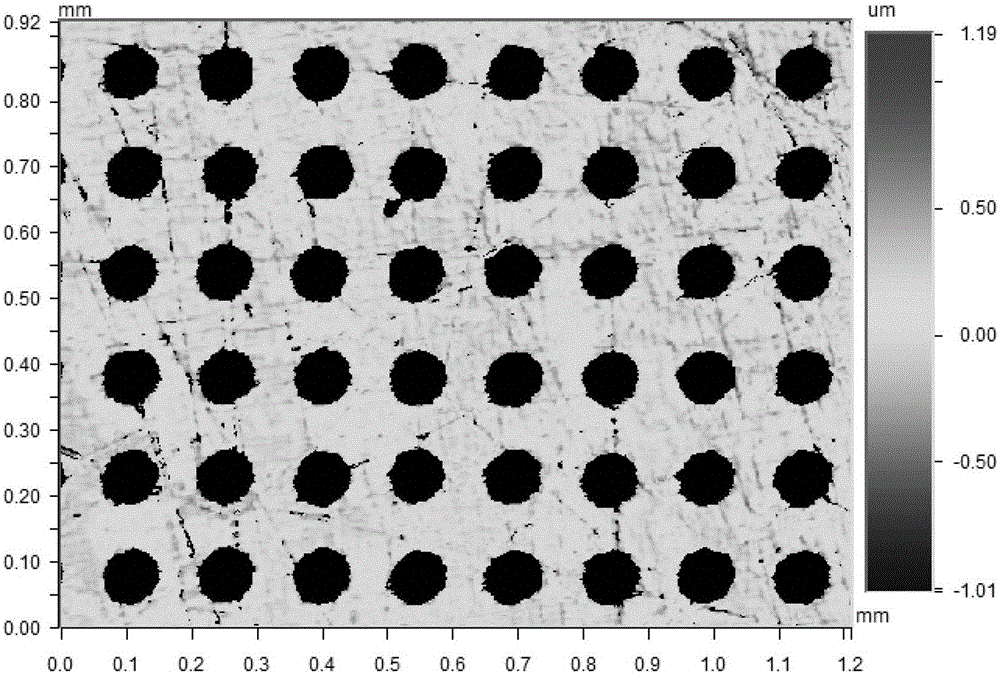

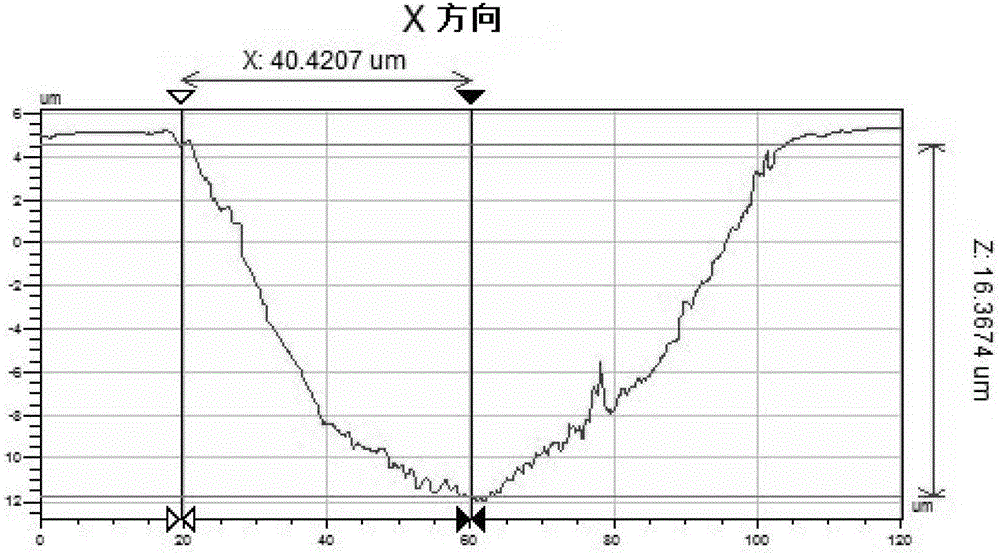

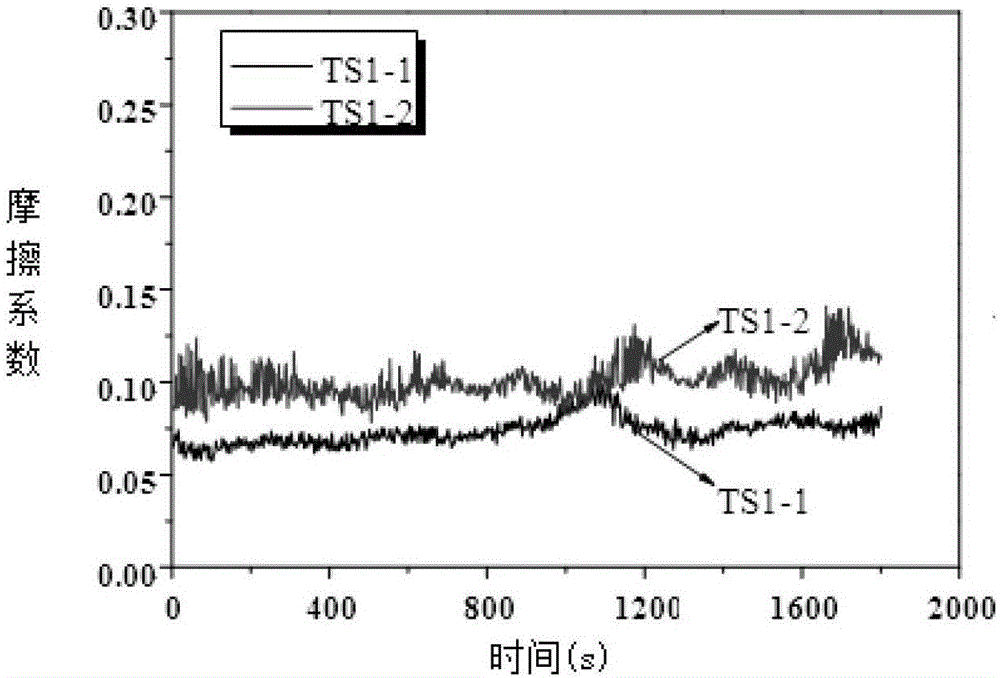

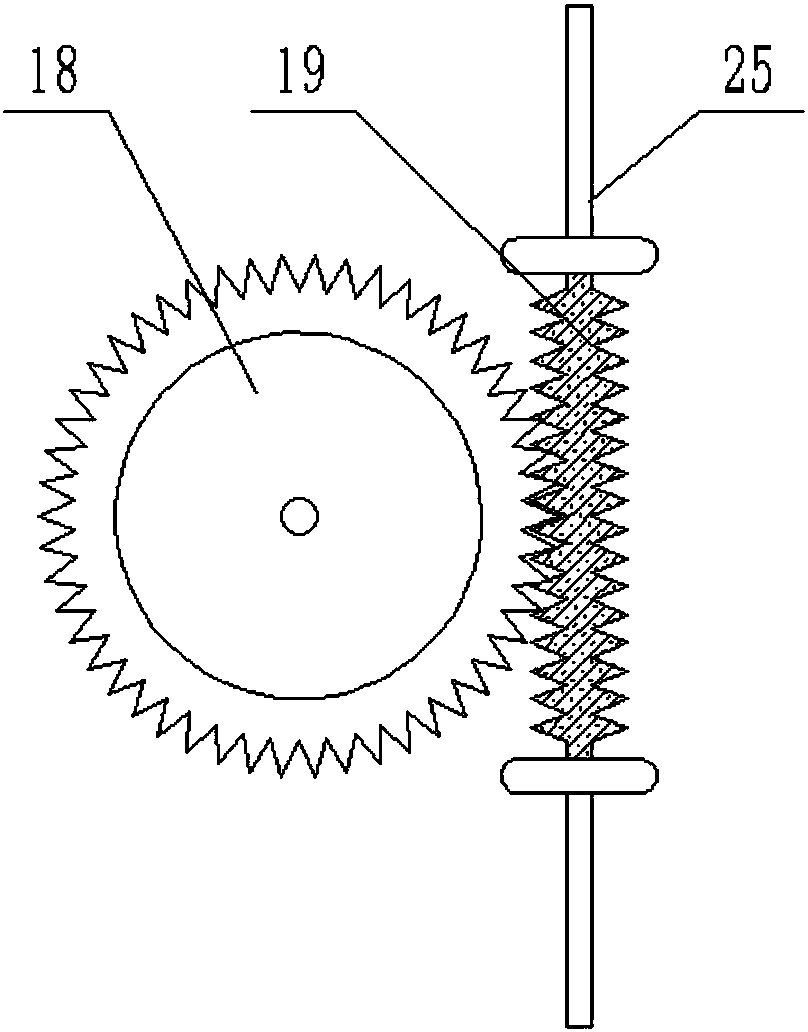

The invention discloses a micro-embedded self-lubricating texture on the surfaces of a gear and a cam and a preparation method thereof. The preparation method comprises the following steps of: performing micro texture processing on the surfaces of the gear and the cam by an Nd: YAG laser processing technology; and embedding a solid lubricant into the micro texture on the surfaces of the gear and the cam by a molding bonding technology of a self-lubricating composite material. The self-lubricating composite material comprises the following formula components in percentage by mass: 15 to 85 percent of polyimide (PI), 0 to 85 percent of polytetrafluoroethylene (PTFE), 10 to 40 percent of MoS2, 0 to 15 percent of WS2, 0 to 16 percent of graphite fluoride, 5 to 15 percent of graphite, 0 to 12 percent of PbO, 0 to 6 percent of antimony trioxide, 0 to 10 percent of CaF2 or BaF2, 0 to 15 percent of hexagonal boron nitride, 0 to 15 percent of nano lubricant and 0 to 5 percent of additive. According to the micro-embedded self-lubricating texture, the self-lubricating texture is subjected to micro embedding on the surfaces of the gear and the cam to ensure that the solid lubricant on the friction surface is stably supplied and uniformly coated, so that the lubrication and anti-wear properties of friction pairs such as the gear and the cam under complicated and harsh operating conditions are improved.

Owner:JIANGSU UNIV

Solid lubrication treatment method for friction pair laser micro-texture surface

InactiveCN105782243AImprove carrying capacityOptimize the spraying processShaftsBearing componentsPre treatmentHigh pressure

The invention provides a solid lubrication treatment method for a friction pair laser micro-texture surface. The method comprises the steps that a micro-pit shape is machined on the surface of a friction pair through the laser surface texturing technology; all components in a self-lubrication composite are evenly mixed and dried to be used later; the surface micro-pit in a pre-treated die is filled with the self-lubrication composite through a die hot-press curing filling method; pressure maintaining hot-press curing filling is conducted through a hot press; then, the filled friction pair is heated for 20 min at the temperature of 250 DEG C and then protected by 99.9% of N2 to be heated for 30 min at the temperature ranging from 370 DEG C to 385 DEG C, insulating sintering is conducted for 0.5 h-1.0 h, and sintering forming is conducted after cooling; and solid lubrication can be finished after surface posttreatment. According to the method, the high-temperature sliding friction performance of the self-lubrication surface of a micro-texture can be improved, a good lubricating effect can be achieved under the conditions such as the high temperature and the high pressure, the bearing capability of a nanometer composite solid lubricating agent is effectively improved, and the nanometer composite solid lubricating agent can be applied under some complex and strict work conditions.

Owner:JIANGSU UNIV

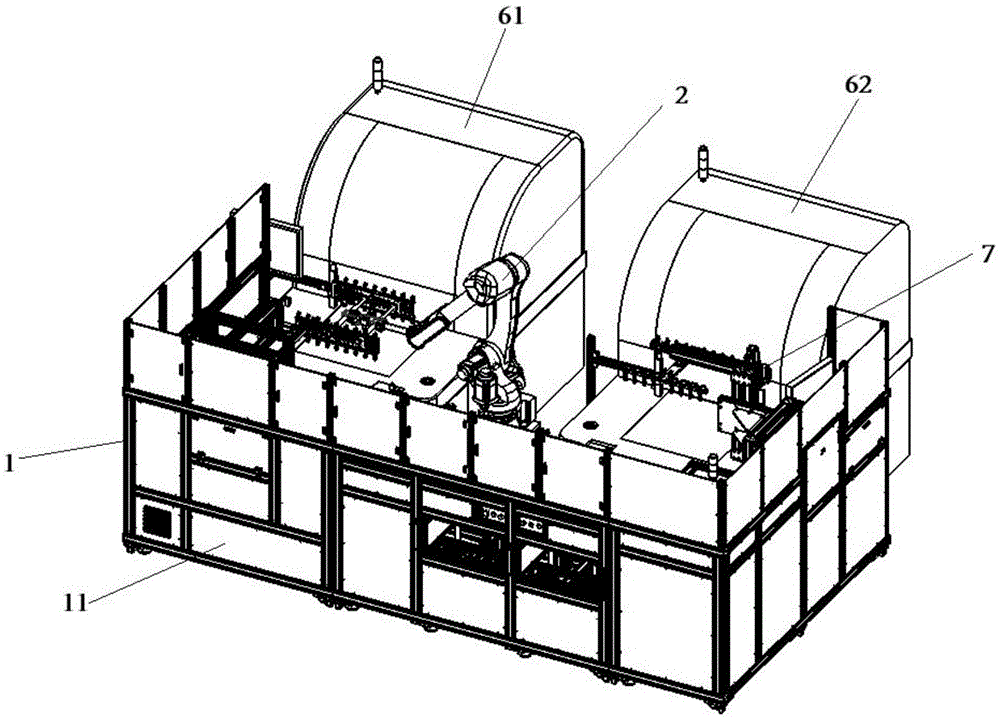

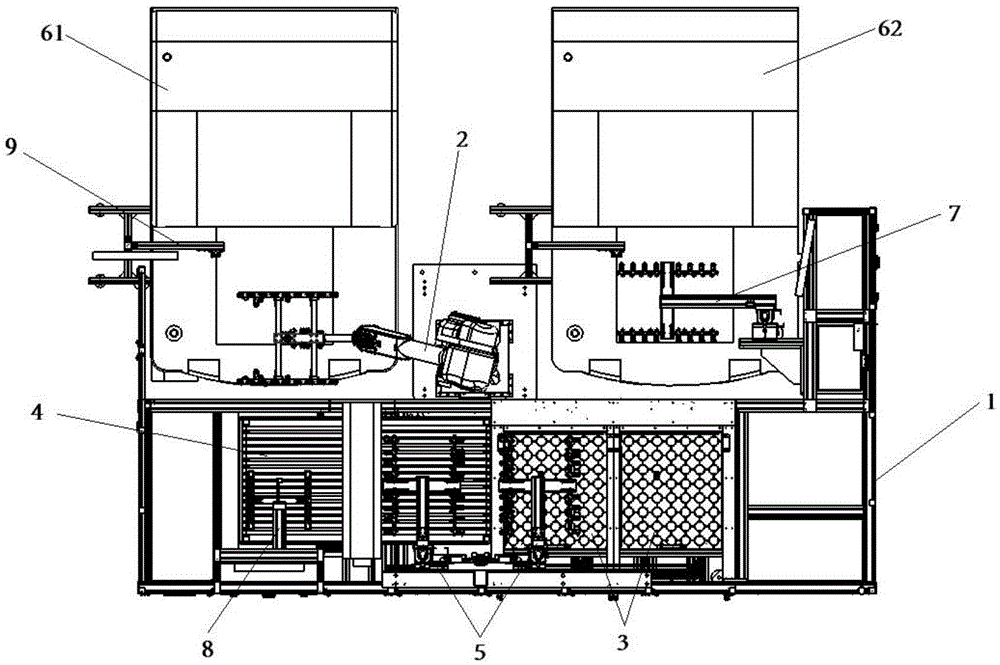

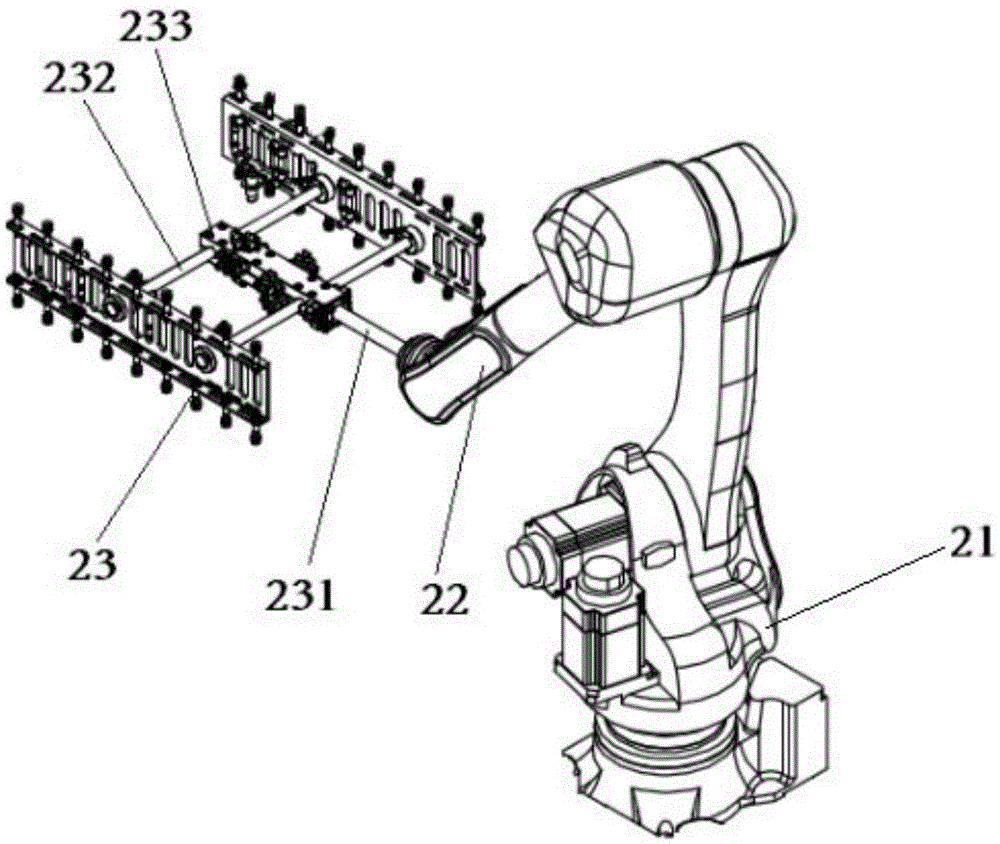

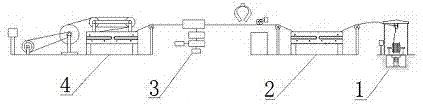

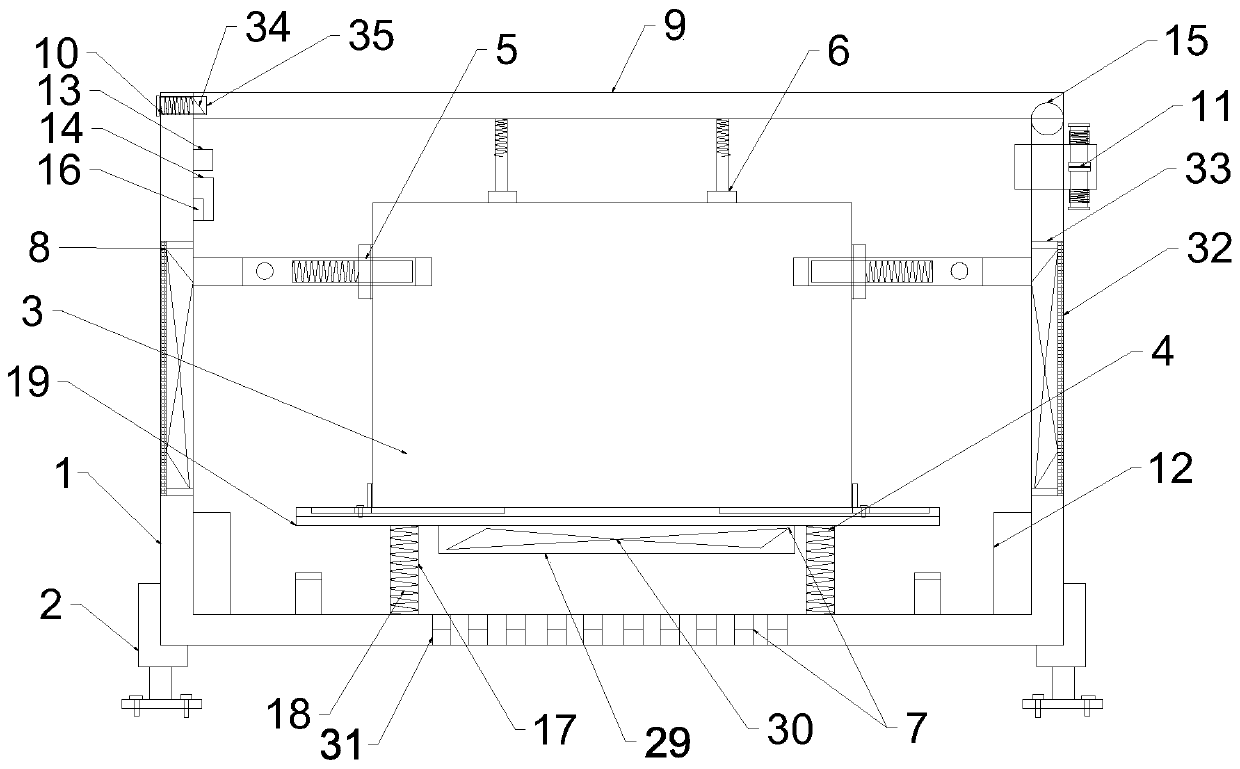

Automatic plate feeding and discharging system for double-faced AOI (Automated Optical Inspection) of circuit board and technological process of automatic plate feeding and discharging system

The invention discloses an automatic plate feeding and discharging system for double-faced AOI (Automated Optical Inspection) of a circuit board. The automatic plate feeding and discharging system comprises a robot device, a feeding and discharging device, a double-faced dust sticking machine, a transferring device, an AOI machine, a butt joint device and a general control system for controlling the equipment to work, wherein the robot device is provided with robot mechanical arms; the double-faced dust sticking machine is located beside the feeding and discharging device; the transferring device is arranged above the feeding and discharging device and the double-faced dust sticking machine; the AOI machine comprises a face A detection and a face B detection machine; detection openings of the face A detection and the face B detection machine are opposite to the feeding and discharging device and the double-faced dust sticking machine; the robot device is located between the face A detection and the face B detection machine; and the butt joint device is located on one side of the face B detection machine and can be in up-down butt joint with the robot mechanical arms. The butt joint device can be in up-down butt joint with the robot mechanical arms so that time consumed by a plate overturning procedure is saved, and furthermore, a whole production process has relatively rapid efficiency; and the structure is compact so that the occupied area of equipment is reduced.

Owner:GUANGZHOU TAILI ELECTRICAL & MECHANICAL EQUIP CO LTD

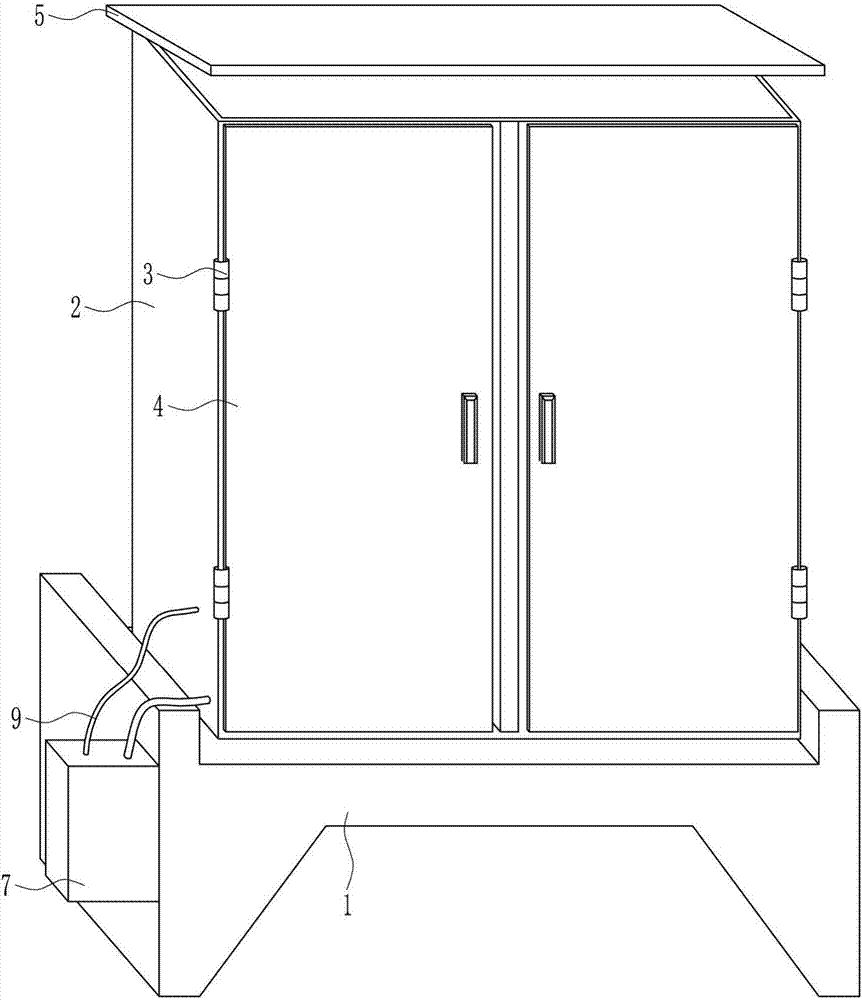

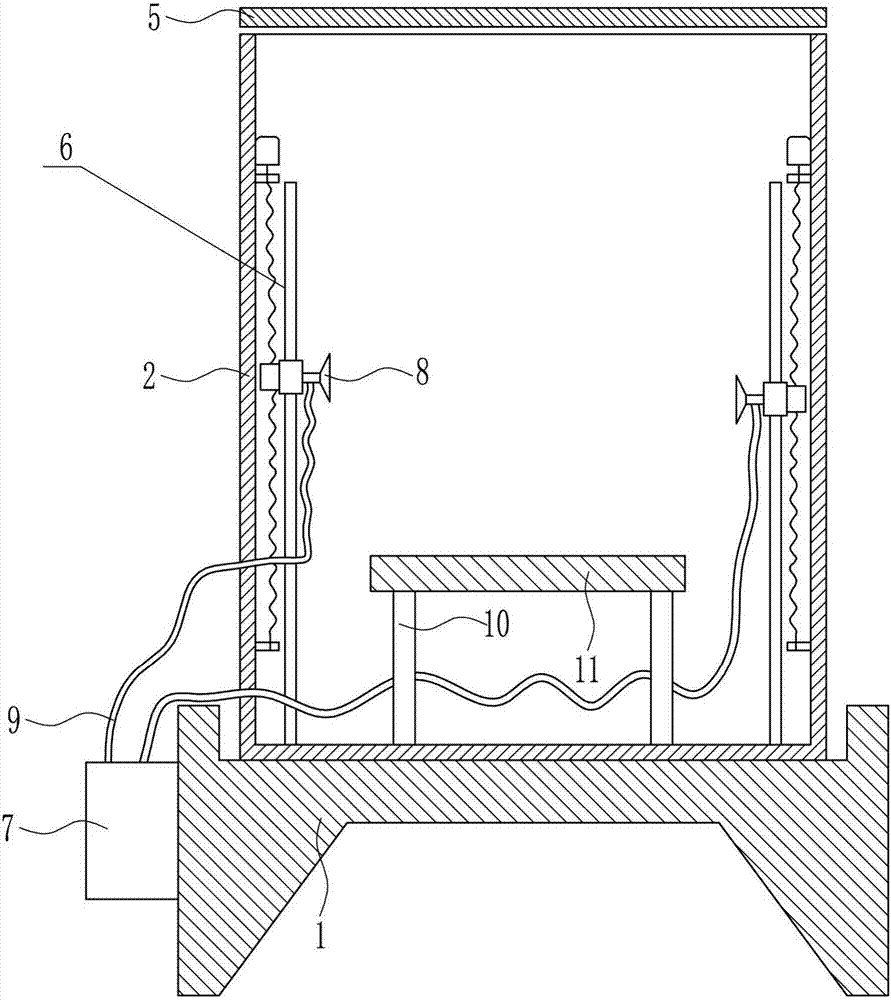

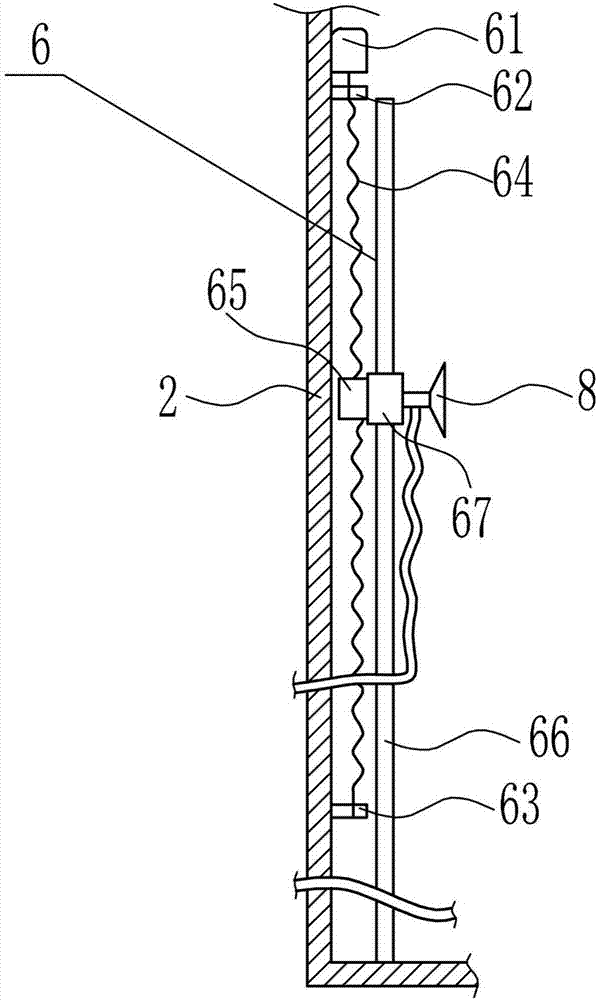

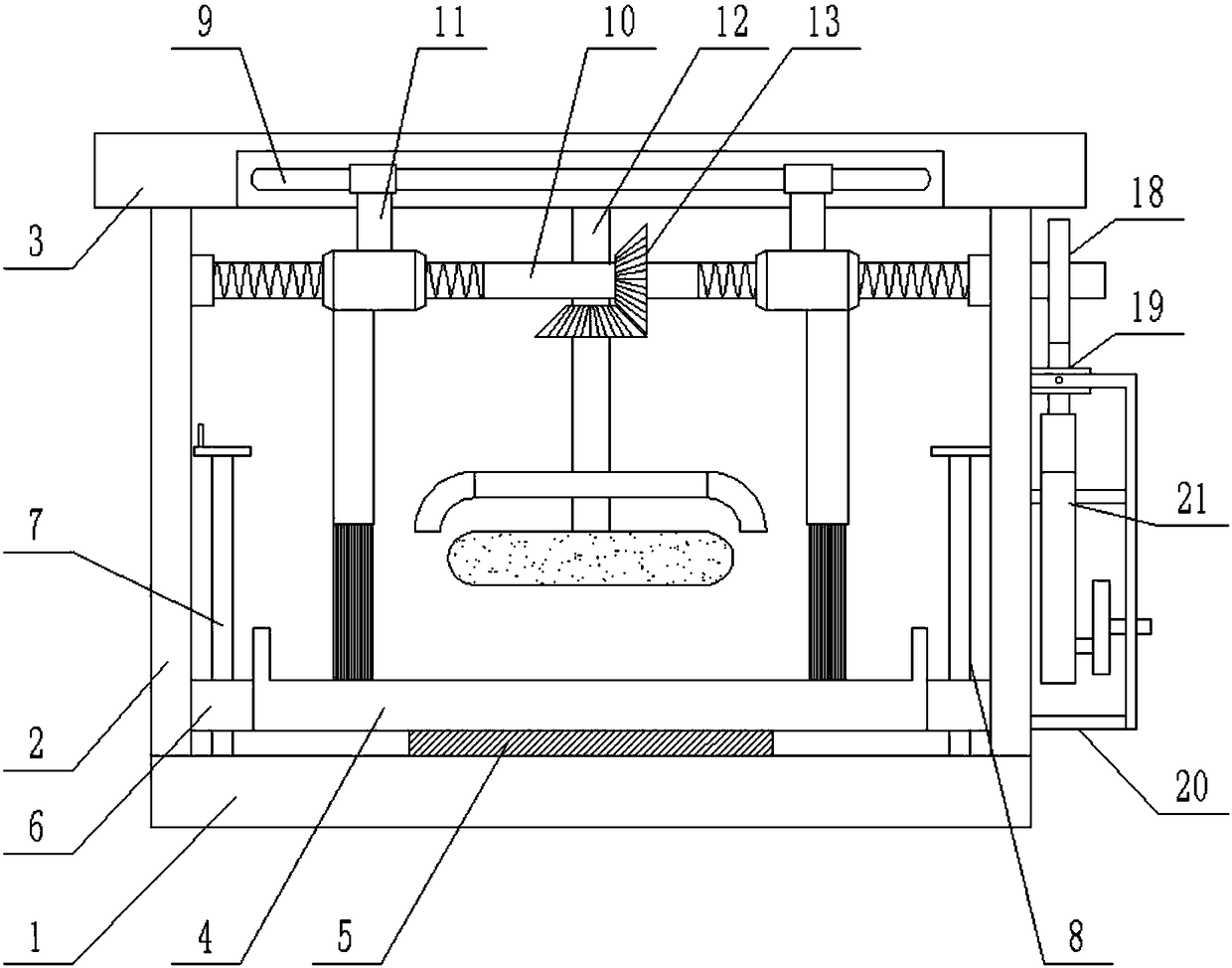

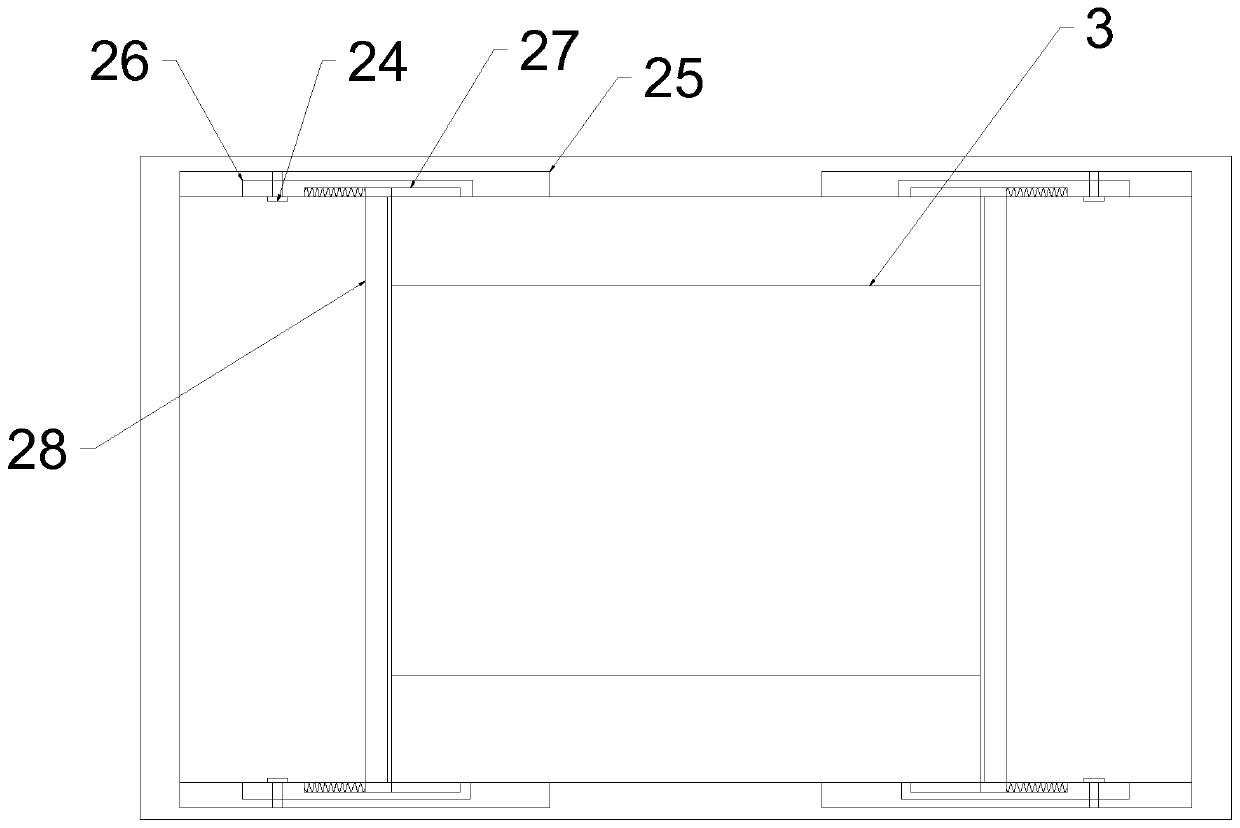

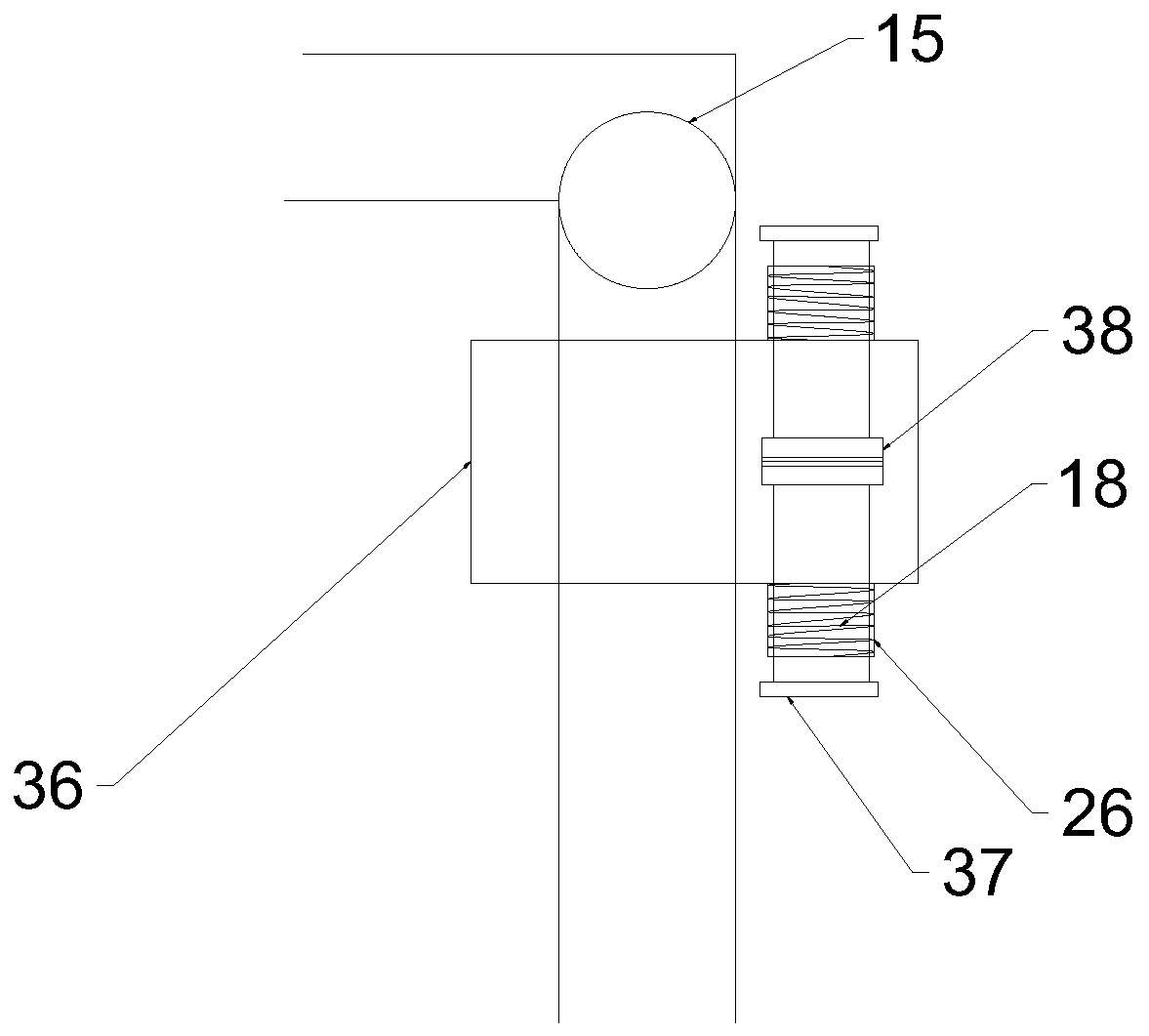

Efficient dust removal equipment for computer host box

InactiveCN106964604AProtect the working environmentIncrease coefficient of frictionDirt cleaningDigital processing power distributionEngineeringBolt connection

The invention relates to dust removal equipment for a computer host box, in particular to efficient dust removal equipment for a computer host box. The efficient dust removal equipment for the computer host box aims at achieving the technical effects that the labor intensity is low, time and labor are saved, working efficiency is high, and environment can be protected. In order to achieve the technical effects, the efficient dust removal equipment for the computer host box comprises a base, a box body, hinges, box doors, a top plate, an up-down movement device, an air pump and the like. The top of the base is connected with the box body in a bolted connection mode. The left side and the right side of the front side of the box body are symmetrically provided with the hinges through screws. The box doors are symmetrically arranged on the left side and the right side of the front side of the box body. A left side gas spray head and a right side gas spray head are adopted for continuously moving up and down, a knock block is adopted for slightly knocking the host box, and the two ways are cooperated, so that efficient dust removal work is carried out on the host box, and dust flies out of the top of the box body.

Owner:湖州浩森科技股份有限公司

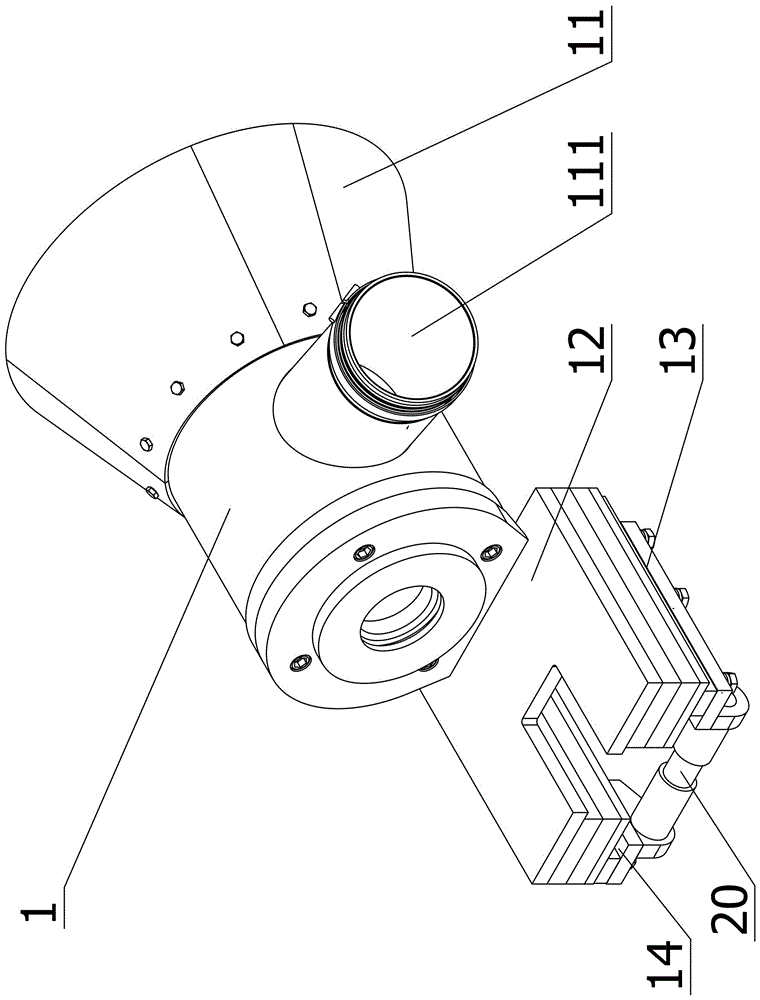

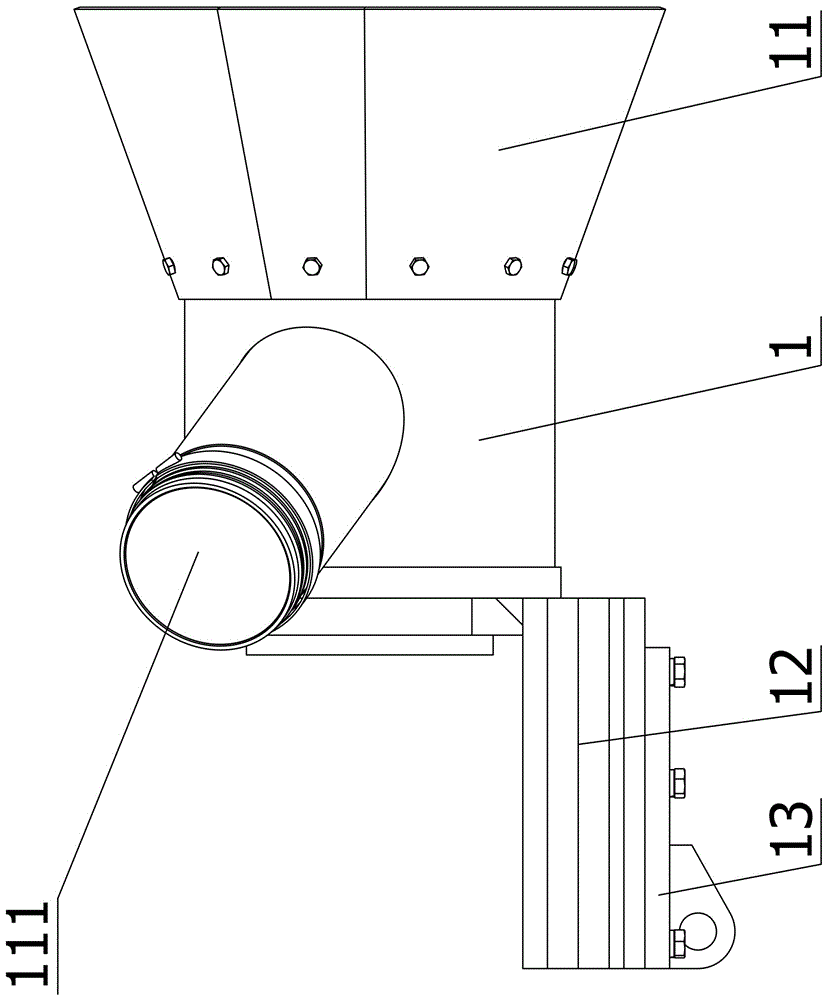

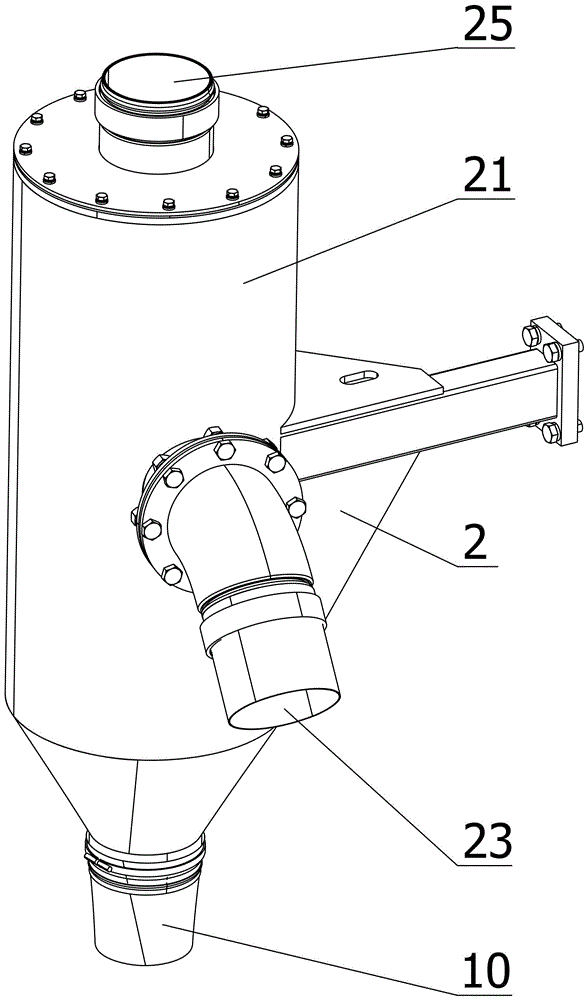

Two-stage dry dust cleaning device and down-hole drilling machine including same

The invention provides a two-stage dry dust cleaning device and a down-hole drilling machine including the same. The two-stage dry dust cleaning device comprises a dust catching part, a first stage dust cleaning part and a second stage dust cleaning part. The dust catching part, the first stage dust cleaning part and the second stage dust cleaning part are connected with flow guiding pipes sequentially; and a centrifugal exhaust fan with an air outlet is installed on the second stage dust cleaning part. According to the down-hole drilling machine provided with the two-stage dry dust cleaning device, rock dust generated from drilling operation is sequentially sucked into the dust catching part, the first stage dust cleaning part and the second stage dust cleaning part from the drilling positions through the sucking power of the centrifugal exhaust fan, and the rock dust is collected into the first stage dust cleaning part and the second stage dust cleaning part according the sizes of the dust particles; and tilting baffles are arranged on air flow paths in the first stage dust cleaning part and the second stage dust cleaning part, and a filtering element capable of adsorbing the light dust is arranged in the second stage dust cleaning part, so that dust sucking effect is improved, working environment and human health are protected, damage to the centrifugal exhaust fan is reduced, and using quality of the down-hole drilling machine is ensured.

Owner:广东孔山重工机械有限公司

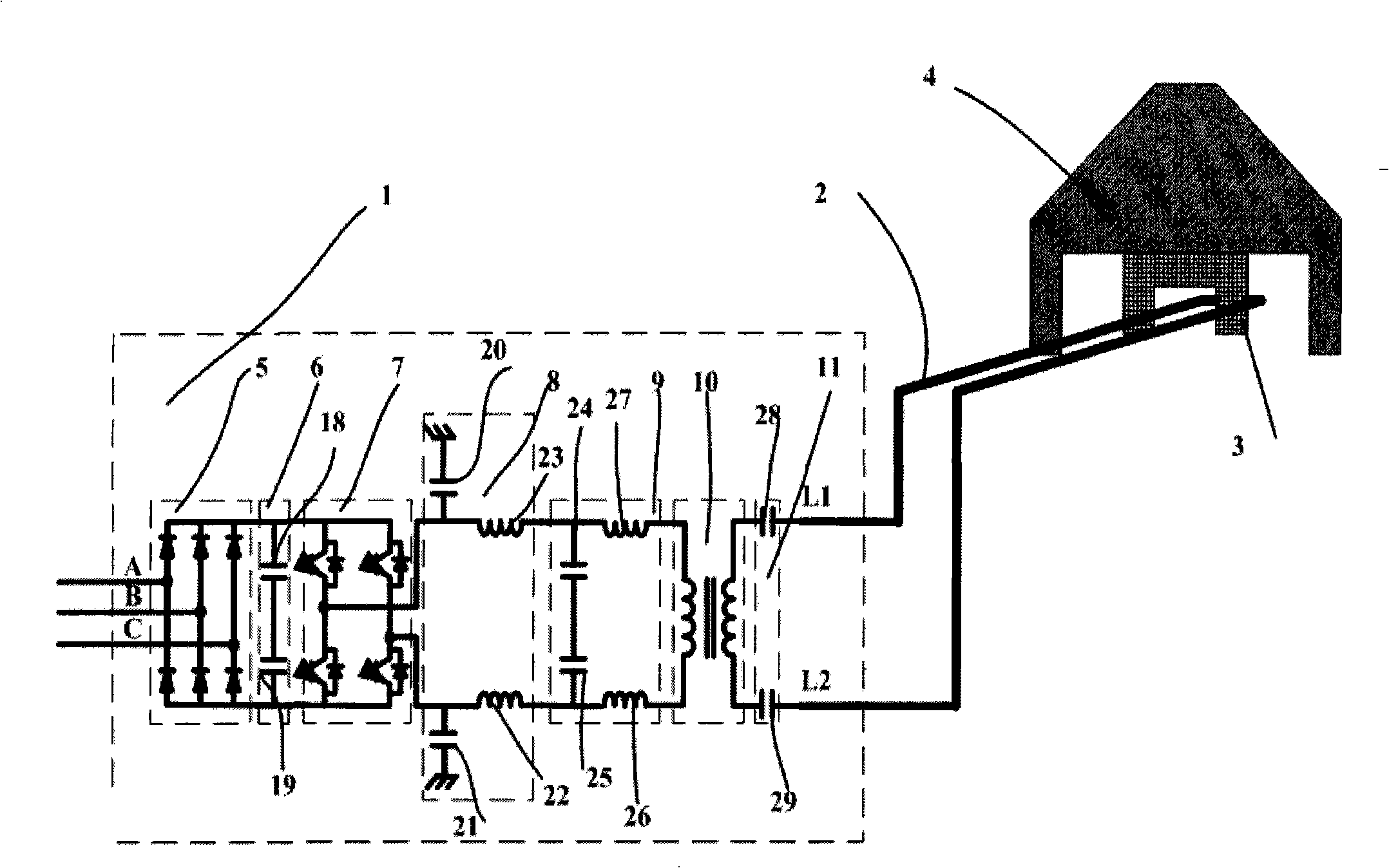

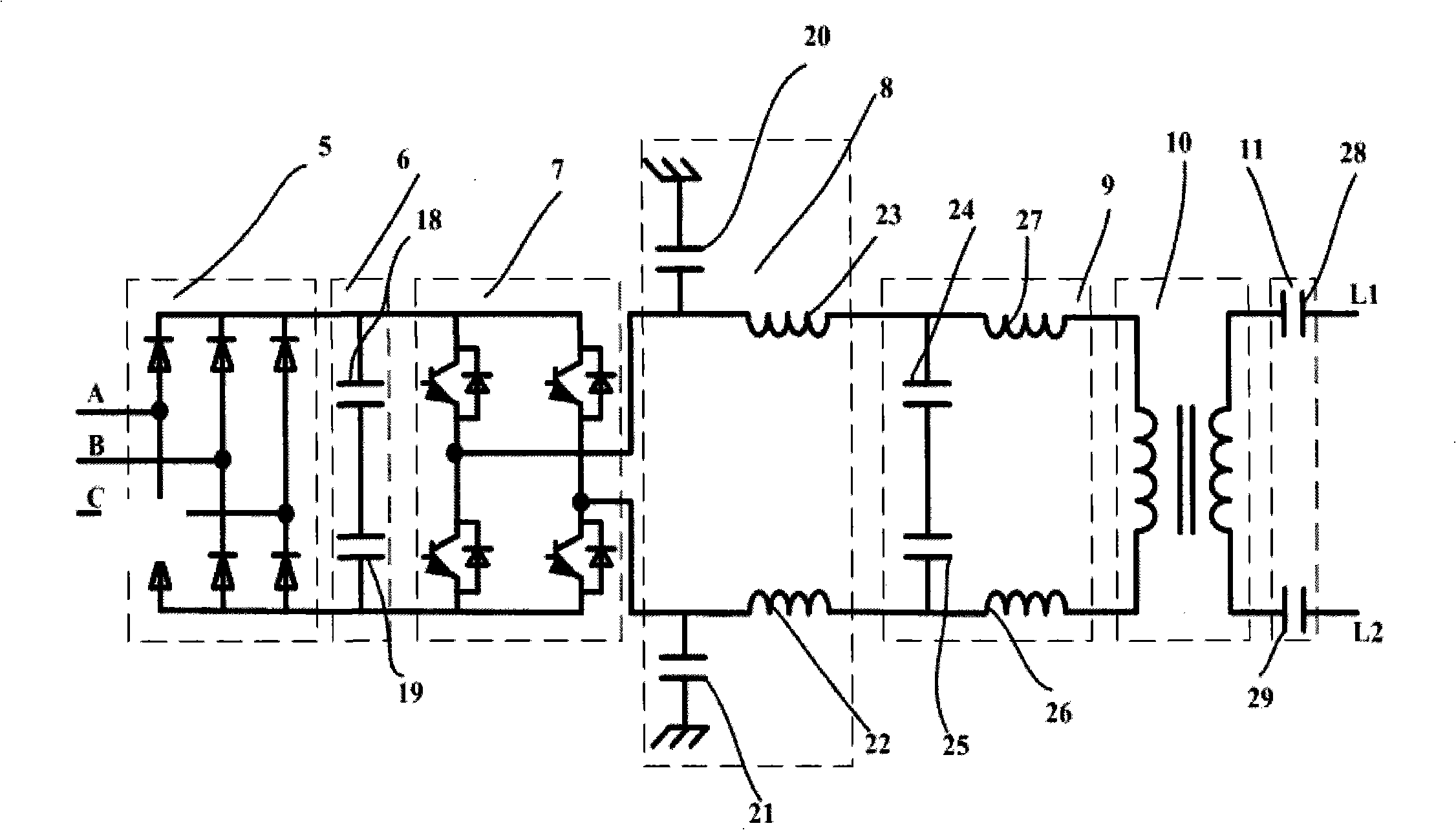

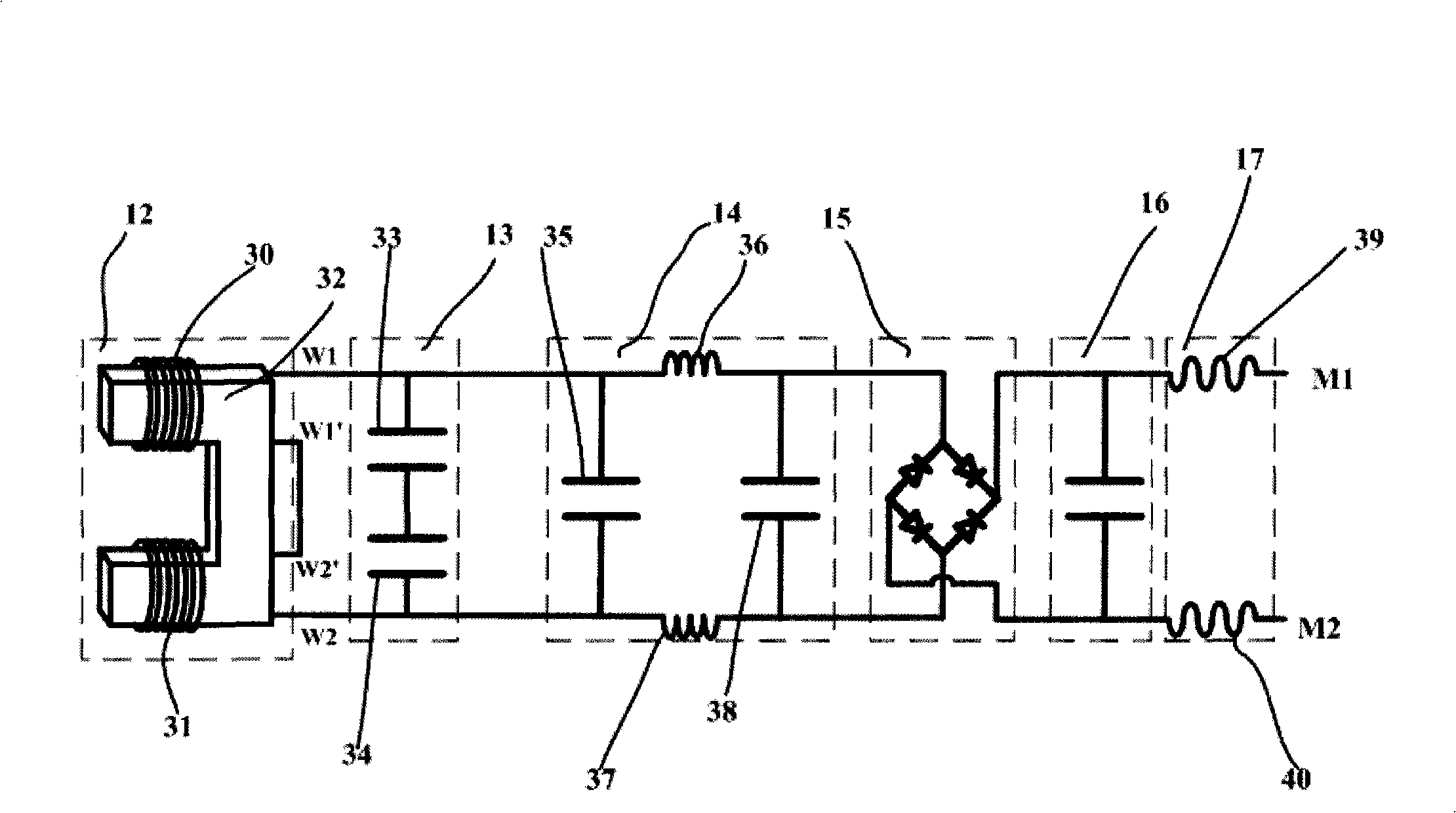

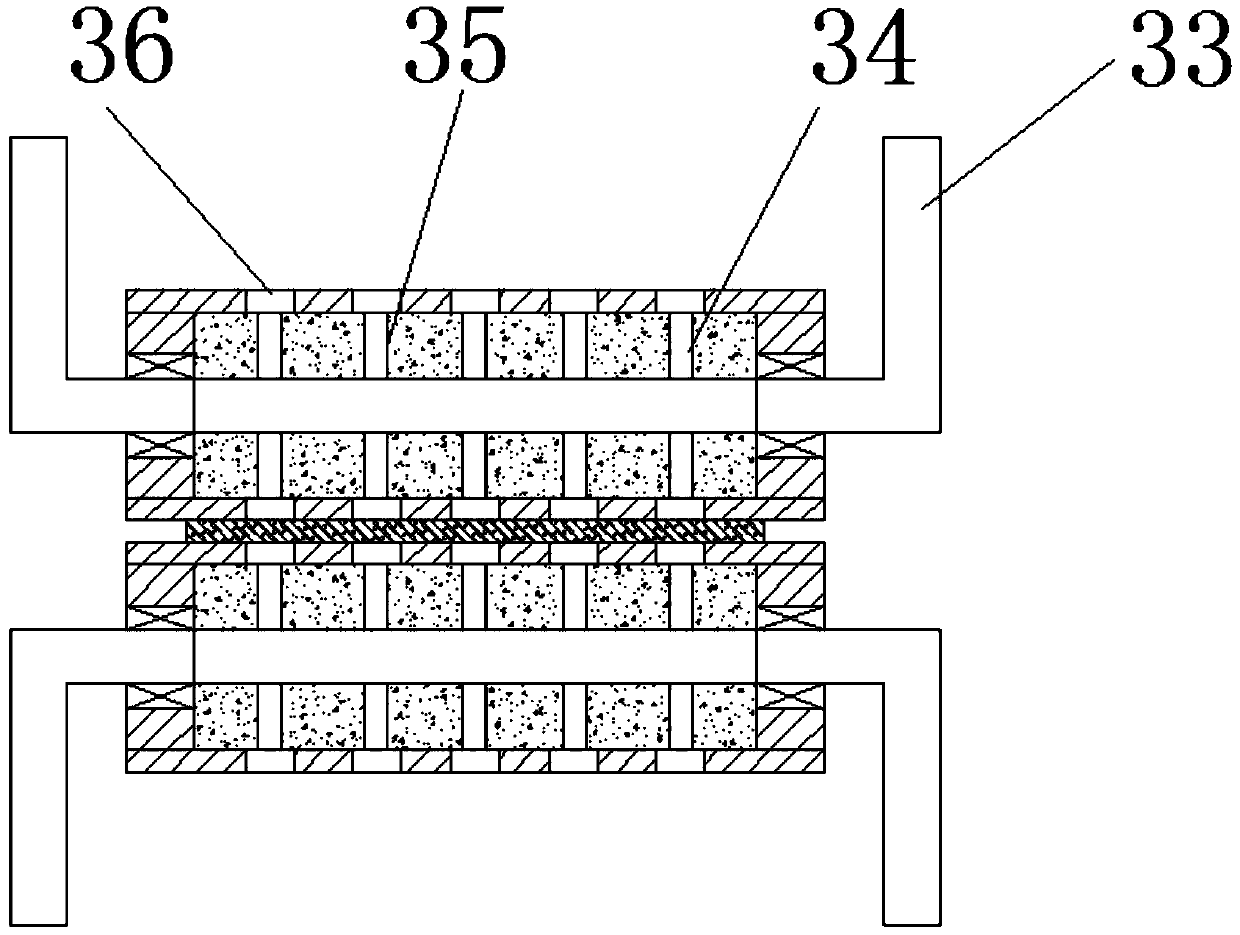

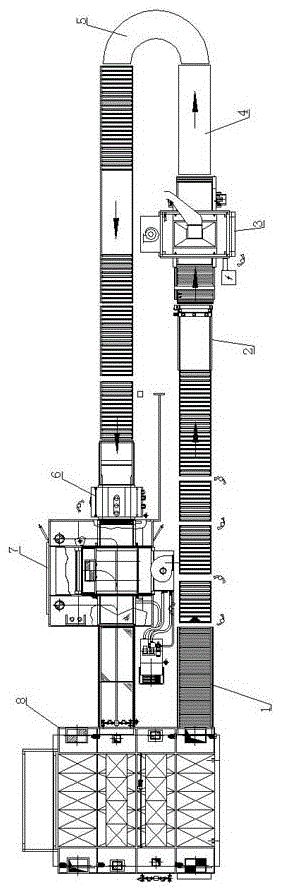

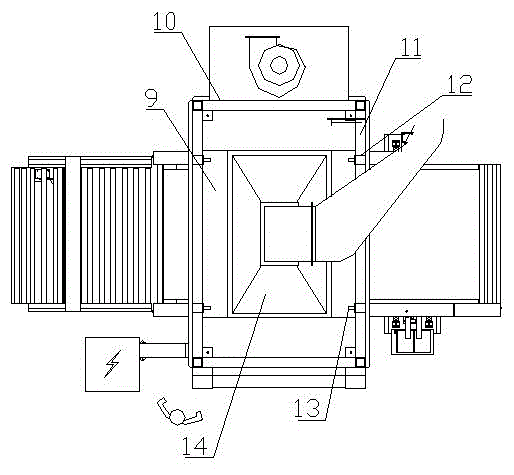

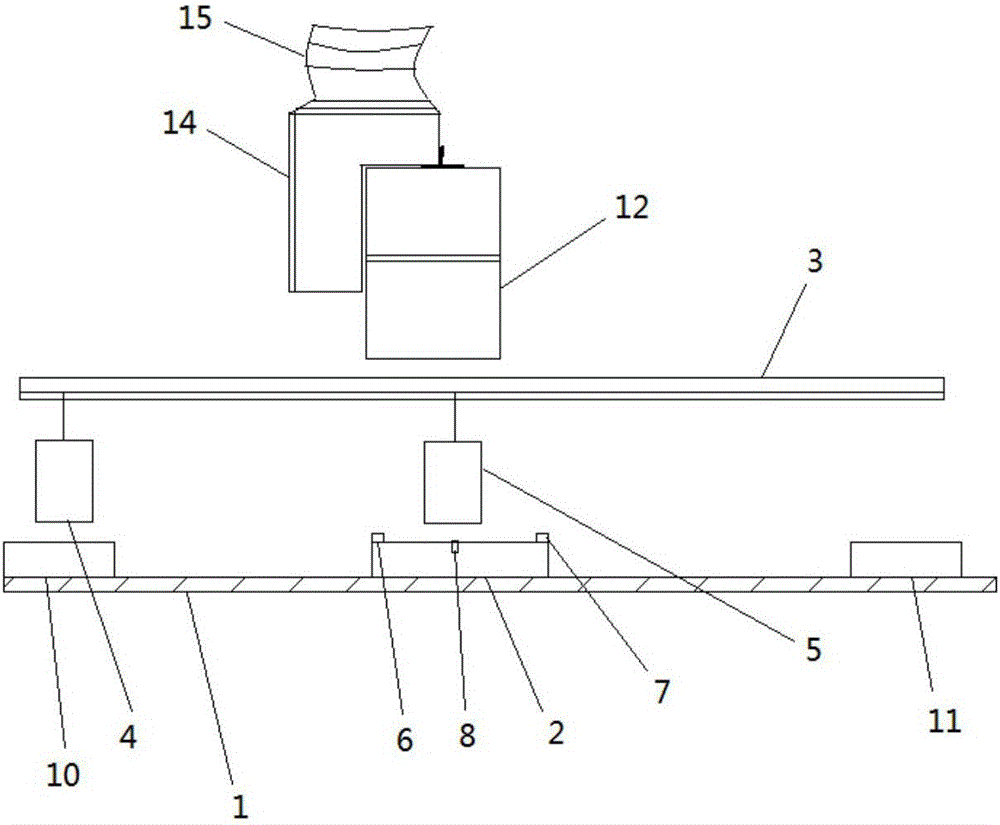

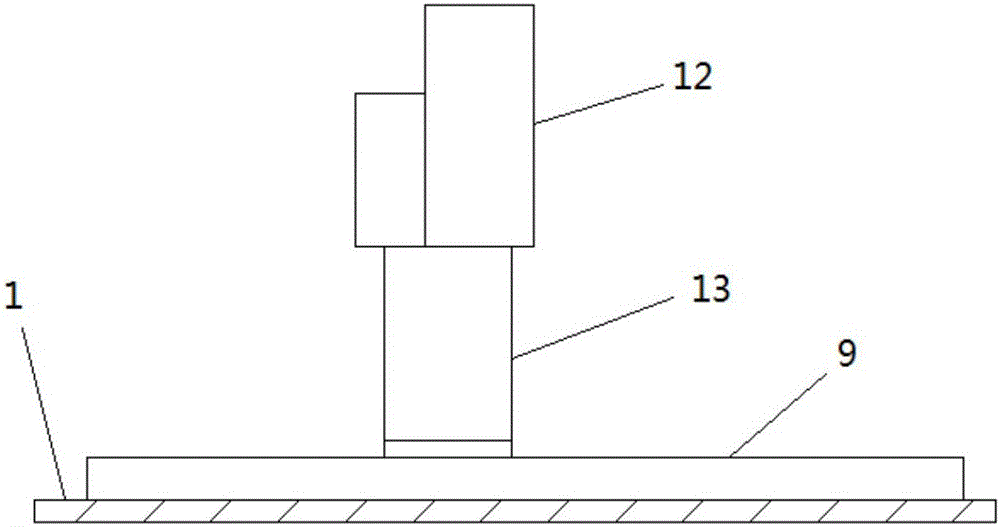

Non-contact power supply of automatic carriage

InactiveCN101404421AReduce weightExpand the working areaElectromagnetic wave systemTransformersElectricityCurrent limiting

A non contact power supply unit of a self-propelled trolley belongs to a power supply unit of a self-propelled trolley. The unit comprises a power transformation cabinet (1), a primary side cable (2) and an electricity picking up part (3).The power transformation cabinet (1) comprises a rectifier module (5), a filtering module (6), a high frequency inversion module (7), a frequency selection module (8), a resonant transformation module (9), an isolating module (10) and a compensation module (11); the electricity picking up part (3) includes an induction power-receiving module (12), a resonance capacitor bank (13), a resonance compensation module (14), a rectifier module (15), a filtering module (16) and a current limiting protection module (17).The power supply unit has the advantages of safe and reliable running, high reliability, and low cost and is suitable for the power supply of the self-propelled trolley in the field of automation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

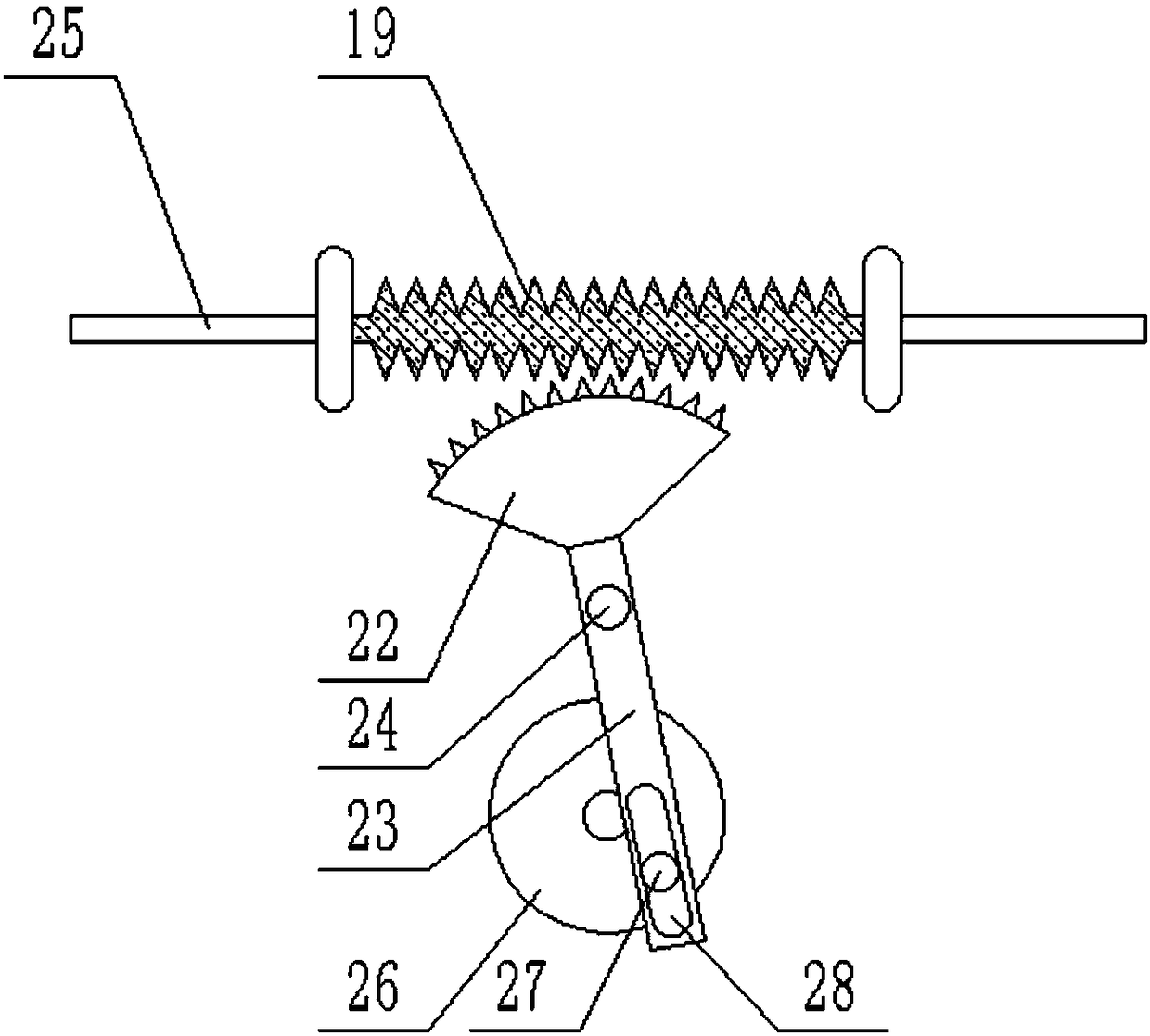

Environment-friendly machine part polishing device based on swinging power

InactiveCN108127520APrevent escapeSimple structureGrinding machinesGrinding/polishing safety devicesDiffusionMechanical components

The invention discloses an environment-friendly machine part polishing device based on swinging power. The polishing device comprises a device body; the device body is provided with a base, a cross beam is arranged above the base, a workpiece groove is formed above the base, and a fixing shaft is arranged in the cross beam; the device body is provided with a driving shaft, connecting pieces are arranged on the driving shaft, connecting rods are arranged at the bottoms of the connecting pieces, and brushes are arranged at the bottoms of the connecting rods; the device body is provided with a fixing frame, and a power assembly is arranged on the inner side of the fixing frame. The polishing device is simple in structure; power is provided for the device body through a gear assembly, reciprocating rotation of a polishing structure of the device body is achieved, and then polishing is conducted; besides, the reciprocating movement drives a cleaning mechanism to clean the surface of a workpiece uninterruptedly, the cleaning effect is good, debris diffusion caused by an existing air-blowing cleaning method is avoided, the working environment is protected, and the polishing device is goodin environmental friendliness and high in practicability.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

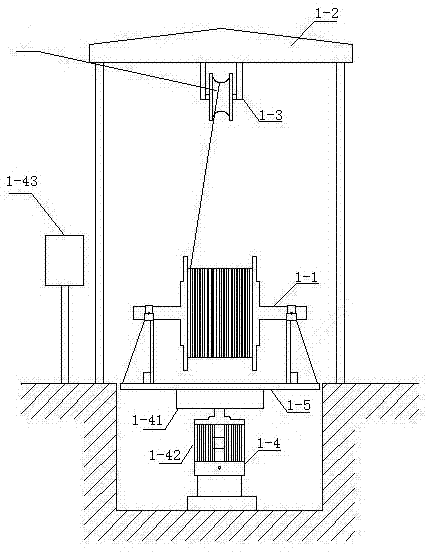

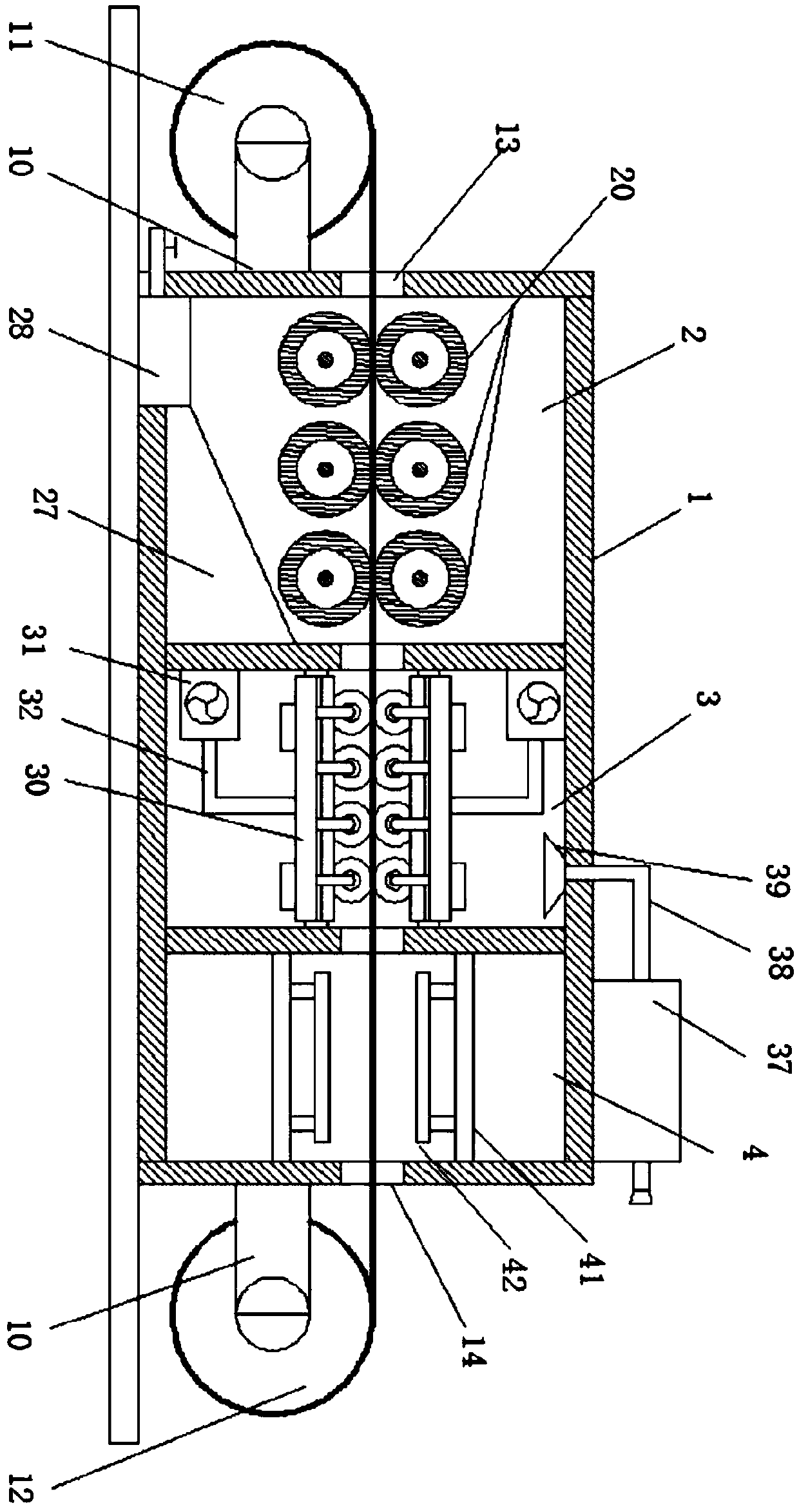

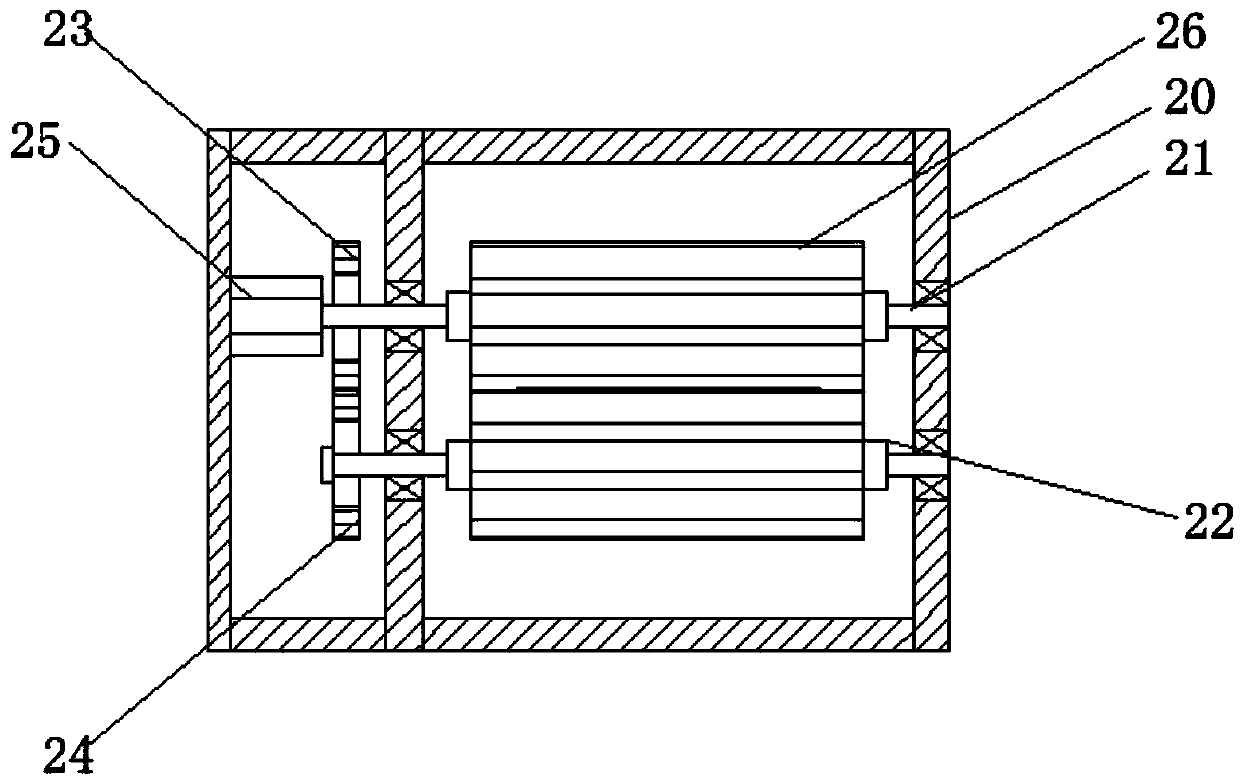

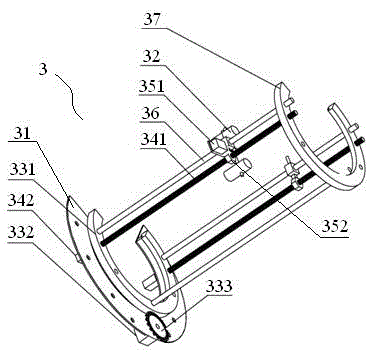

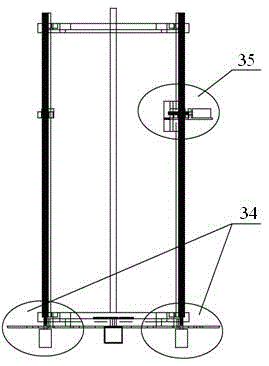

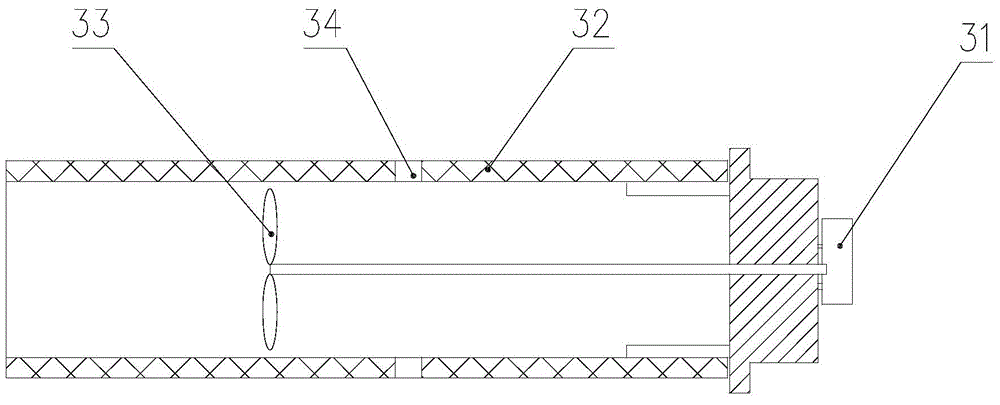

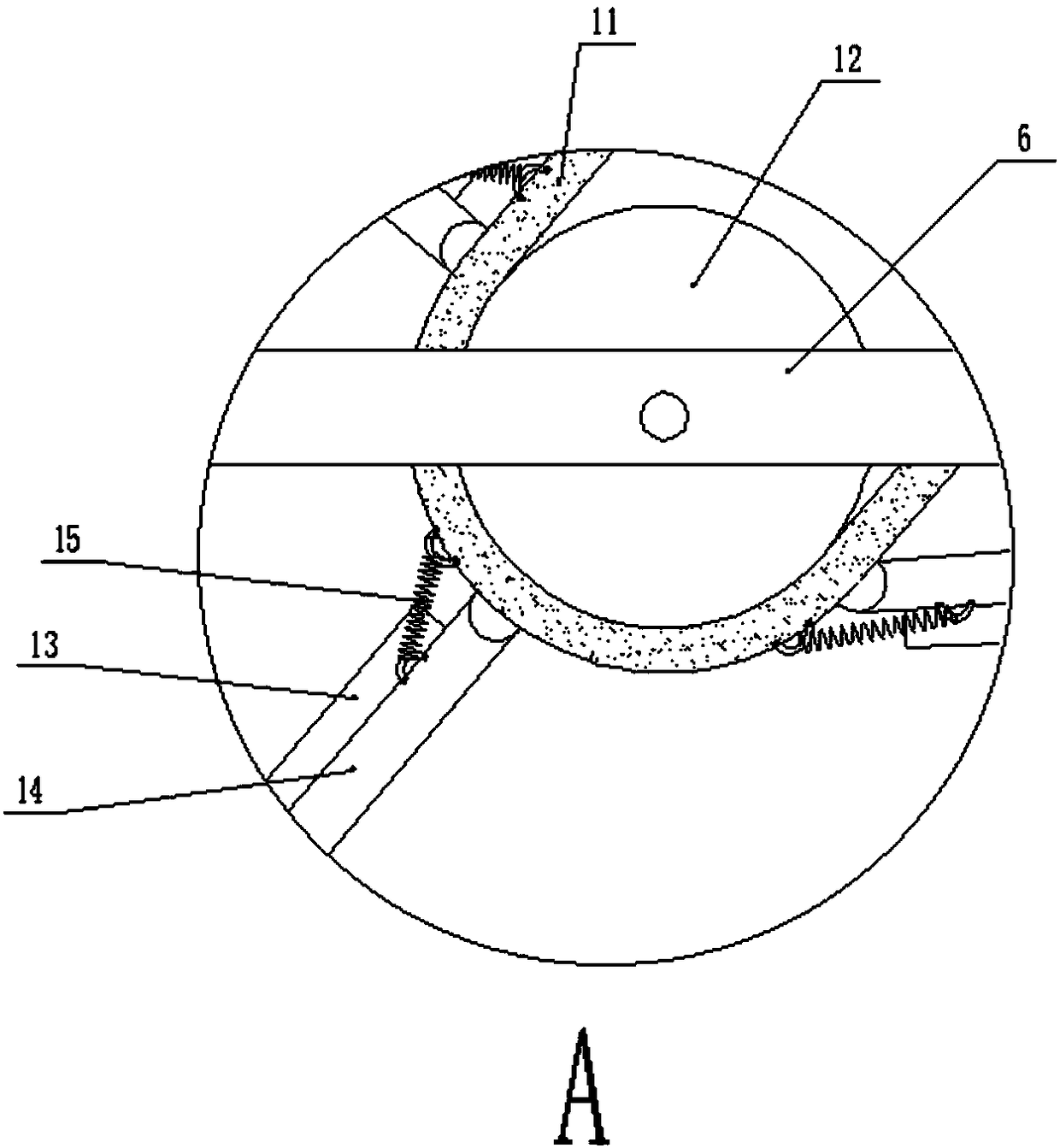

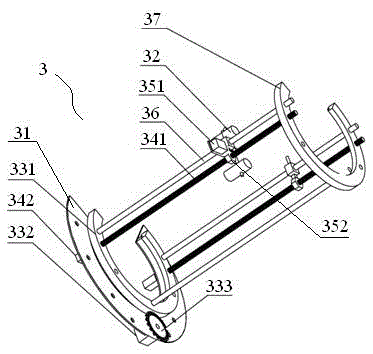

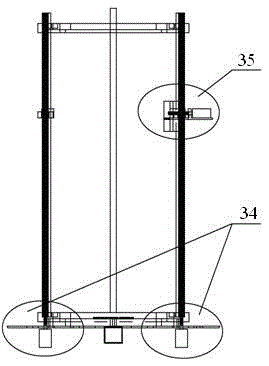

Steel wire rope cleaning/detection/maintenance apparatus

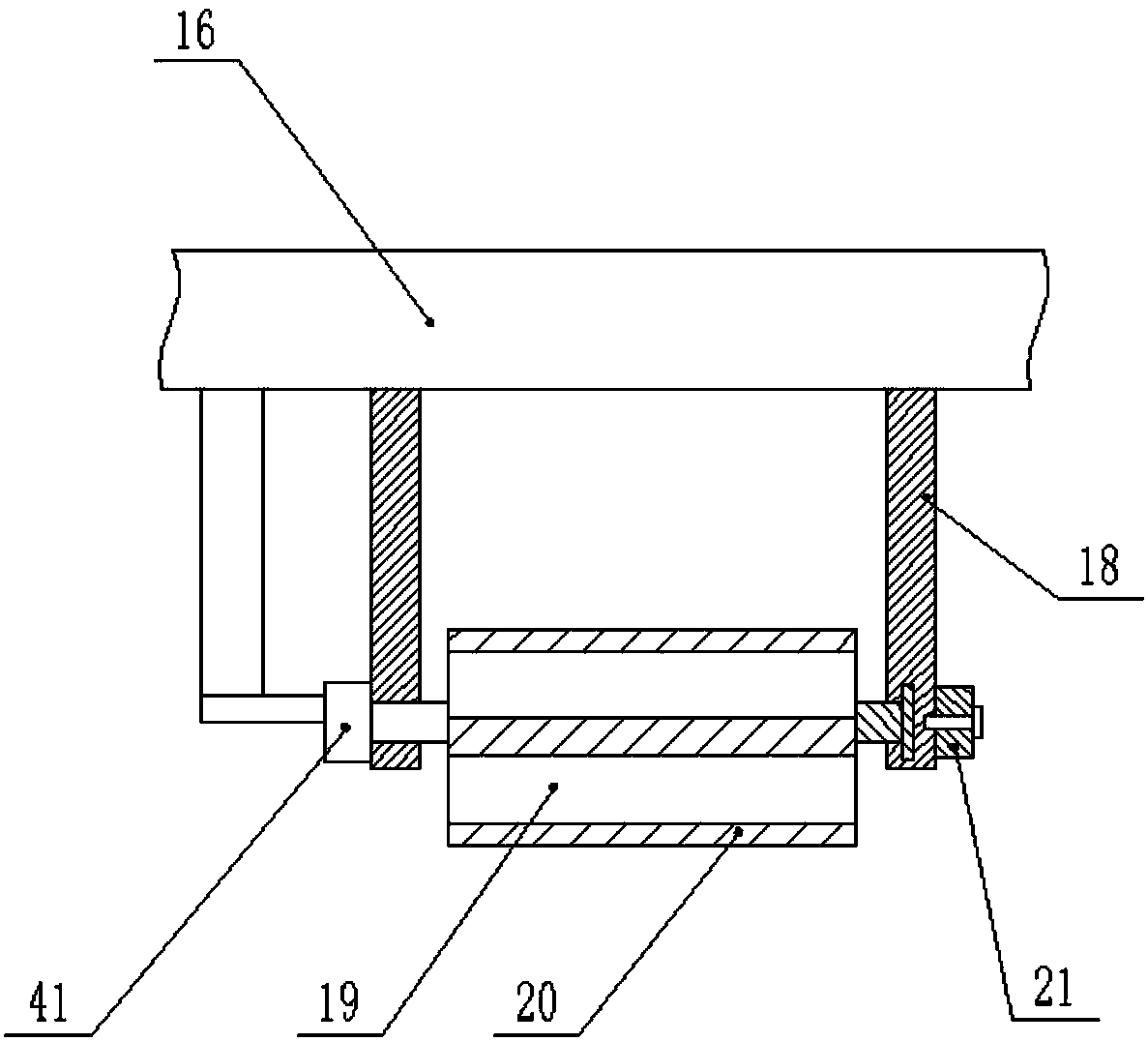

ActiveCN105436021AEliminate torqueUniform adhesionLiquid surface applicatorsFilament handlingEngineeringCost savings

The invention discloses a steel wire rope cleaning / detection / maintenance apparatus and belongs to the field of steel wire rope detection. The steel wire rope cleaning / detection / maintenance apparatus comprises a torsion release unit for releasing the torsion of a steel wire rope, a cleaning unit for cleaning the steel wire rope, a detection unit for performing nondestructive testing on the steel wire rope and an oil immersion unit for immersing the steel wire rope in oil for maintenance, and all the units are arranged in order; the steel wire rope cleaning / detection / maintenance apparatus is capable of completing such operations as torsion release, cleaning descaling, nondestructive testing and oil immersion maintenance on the steel wire rope at one stop in a mechanical operation manner; the torsion of the steel wire rope is released through the torsion release unit; the cleaning unit functions in completing the oil removal and descaling operations on the steel wire rope; the detection unit functions in detection in a moving state of the steel wire rope; the oil immersion unit functions in completing the oil immersion operation on the steel wire rope in an oil tank, and meanwhile, squeezing out superfluous oil for recovery; in short, the steel wire rope cleaning / detection / maintenance apparatus has the advantages of environmental protection, cost saving, reduction of the working labor intensity and improvement of the working efficiency.

Owner:STATE GRID CORP OF CHINA +2

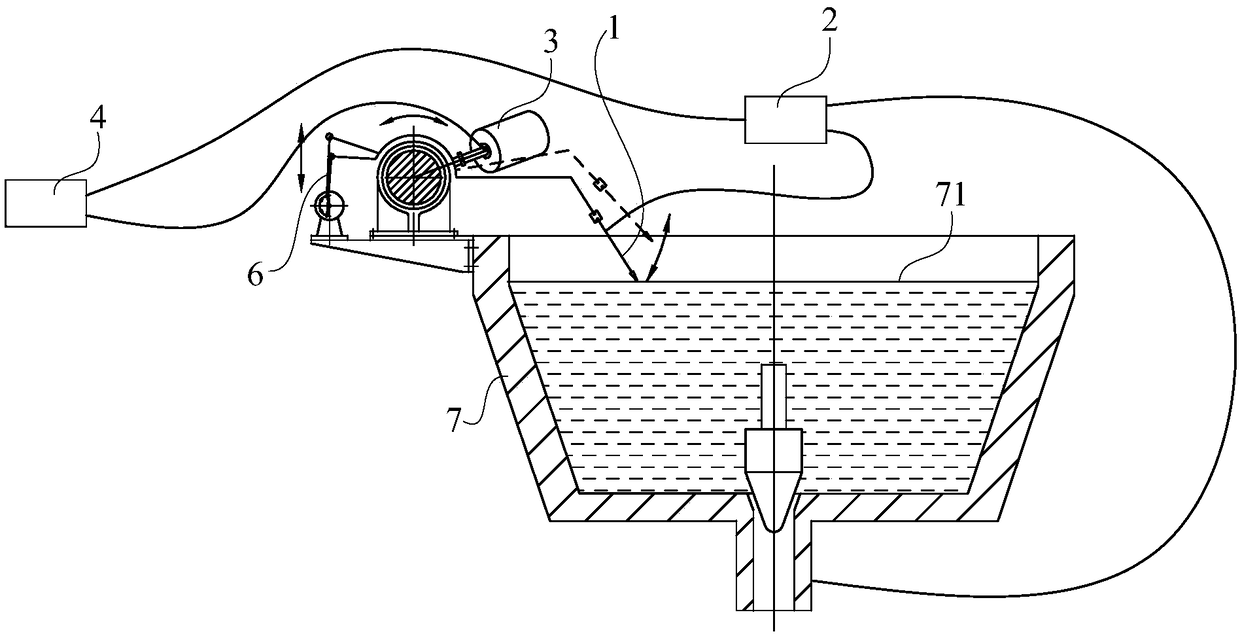

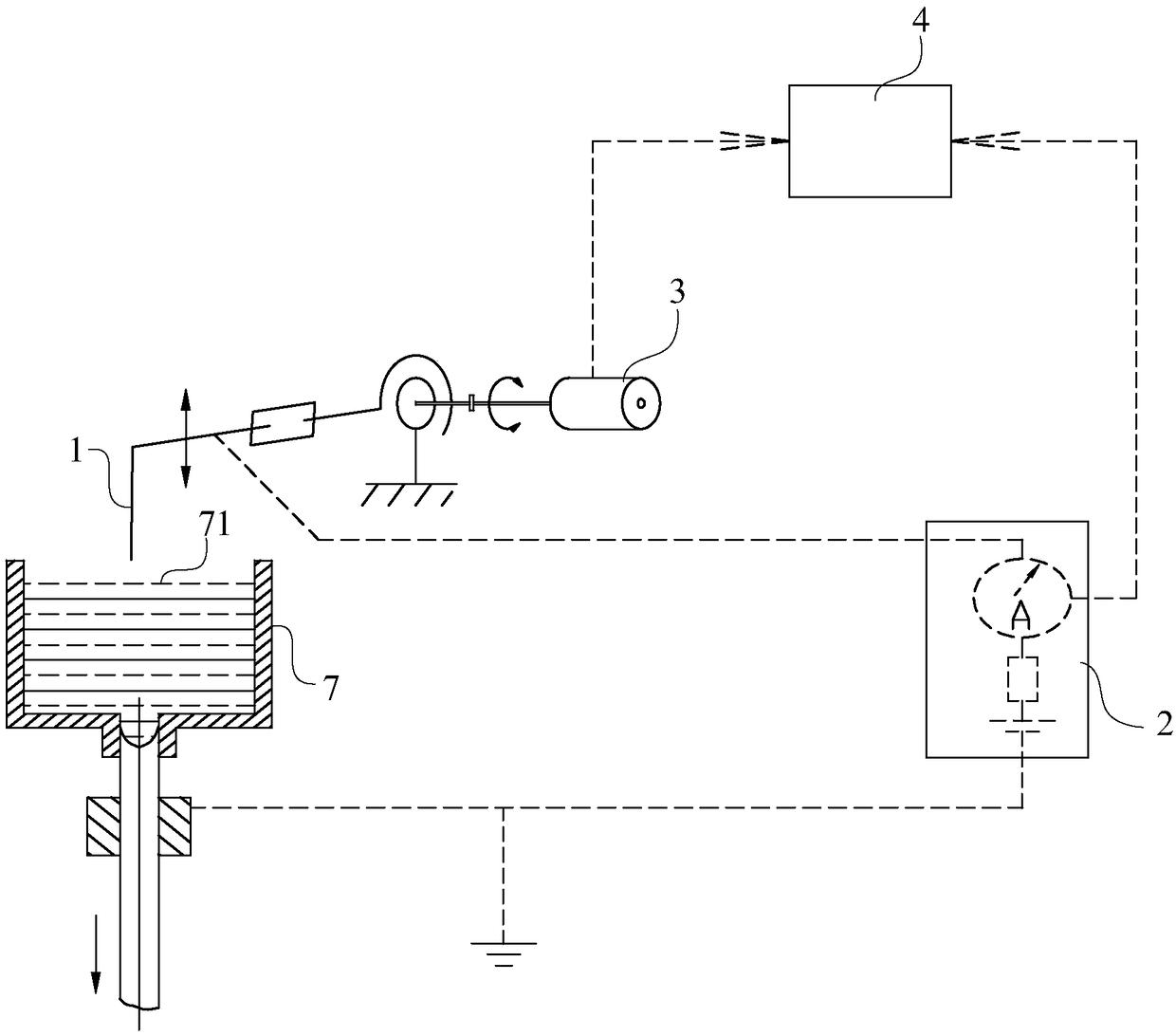

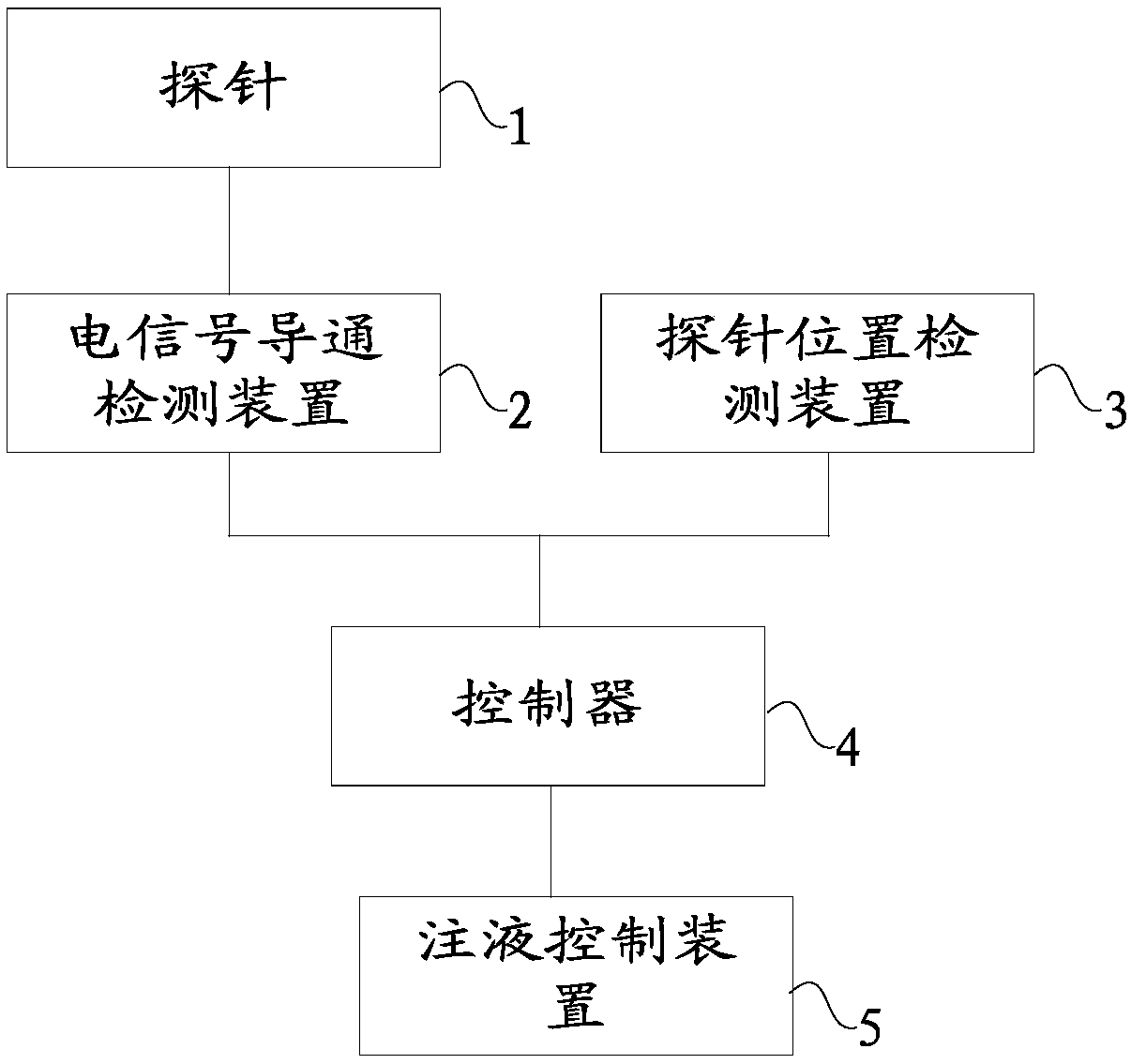

Liquid level detection device and liquid level detection method

PendingCN109238398AQuality improvementAccurate acquisitionLevel controlLevel indicators by physical variable measurementElectricityReciprocating motion

The invention discloses a liquid level detection device and a liquid level detection method. The liquid level detection method comprises the following steps that: through a probe movement mechanism, driving a probe to carry out reciprocating motion relative to the liquid level of metal liquid in the liquid storage containing chamber of continuous casting equipment; through a probe position detection device, detecting the displacement information of the probe in real time, and sending the displacement information of the probe to a controller; and at a moment when the probe is in contact with the liquid level of the metal liquid in the liquid storage containing chamber, forming a loop by an electric signal conduction detection device, the probe and the continuous casting equipment, detectingloop conduction information by the electric signal conduction detection device, sending the loop conduction information to the controller, and judging the liquid level height of the metal liquid in the liquid storage containing chamber of the continuous casting equipment according to the loop conduction information and the displacement information of the probe. By use of the liquid level detection method, the liquid level of the metal liquid can be effectively detected so as to guarantee that vertical continuous casting equipment can successfully cast high-quality metal blanks.

Owner:XIAN METALWK HYDRAUMATIC MACHINERY

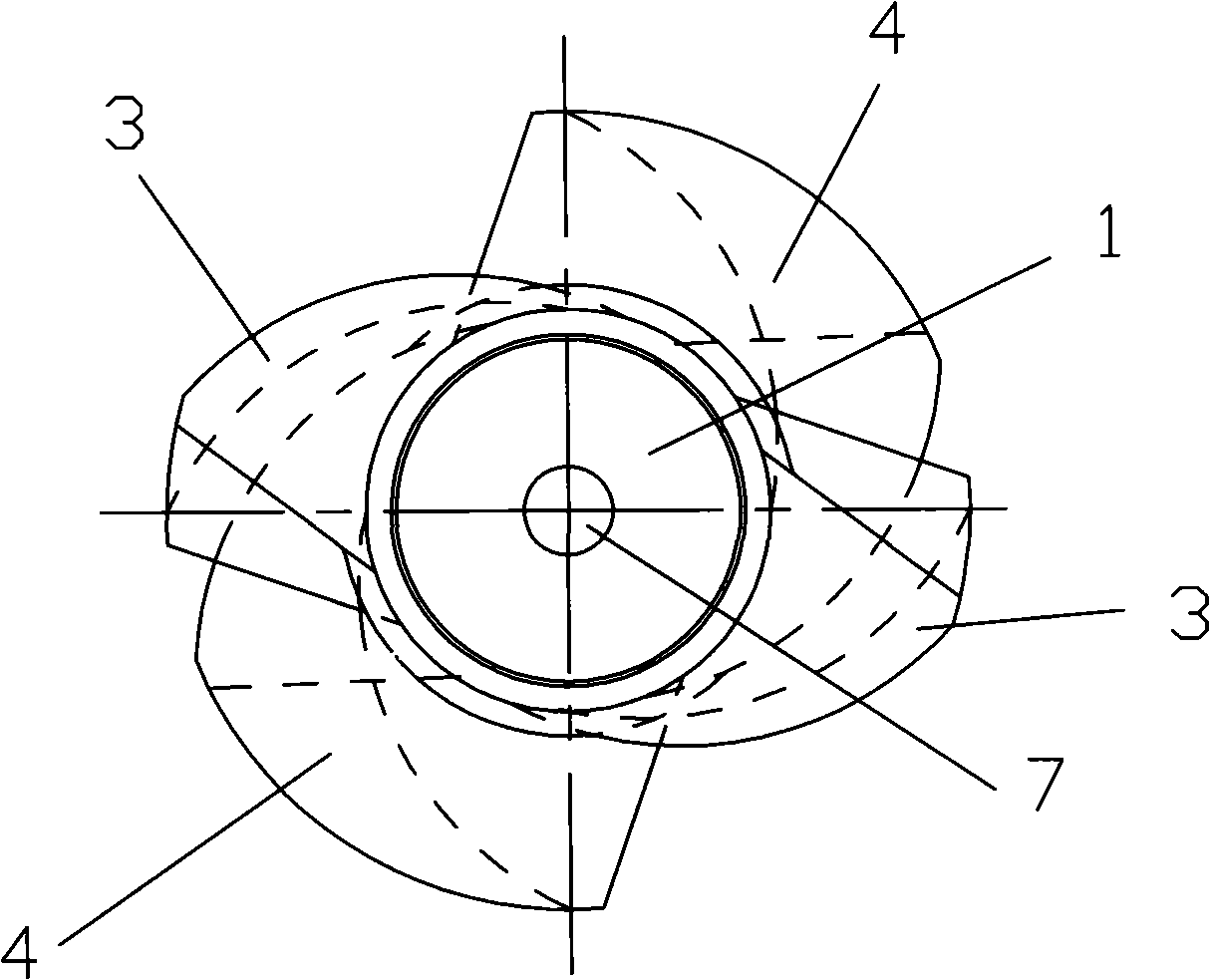

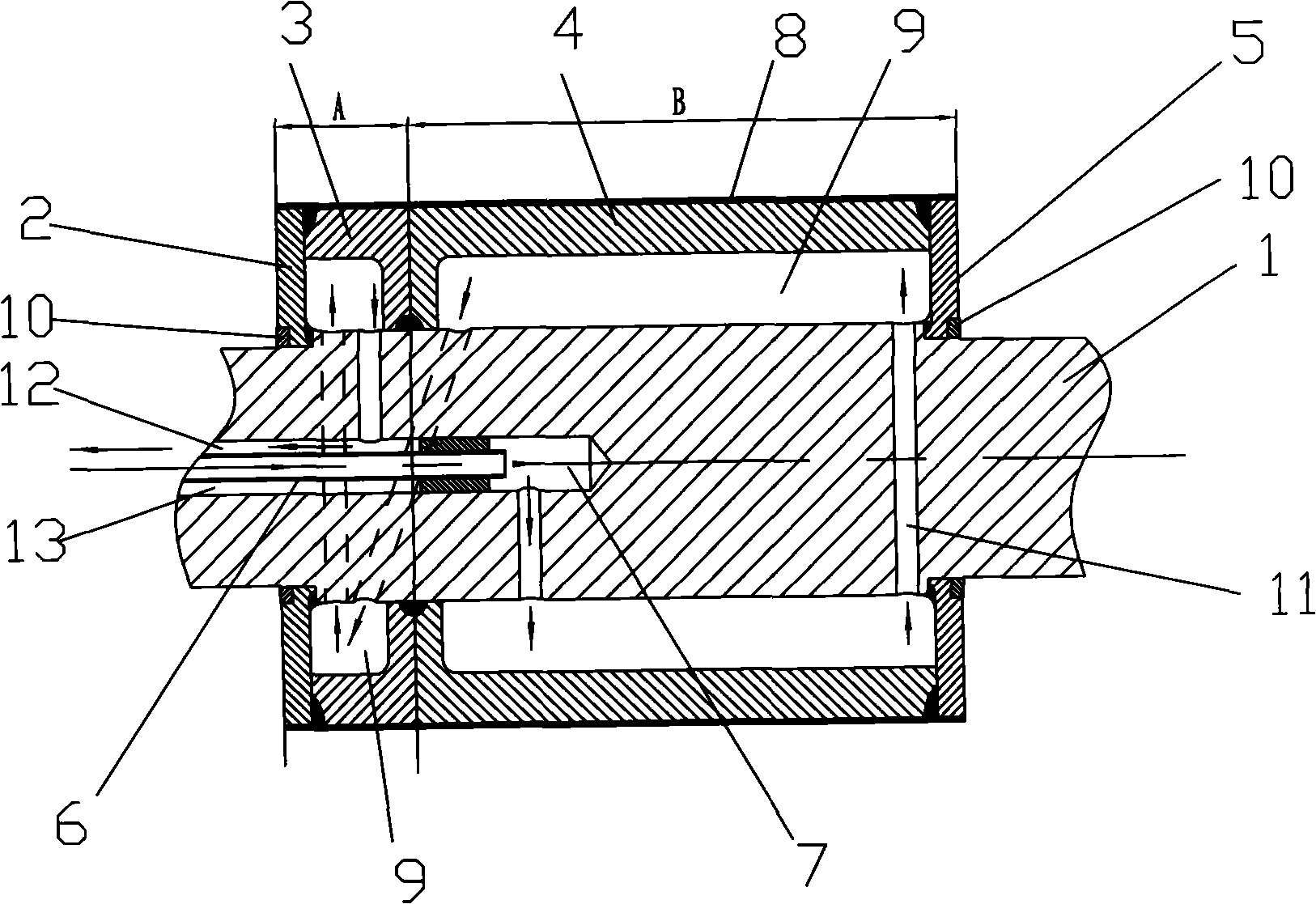

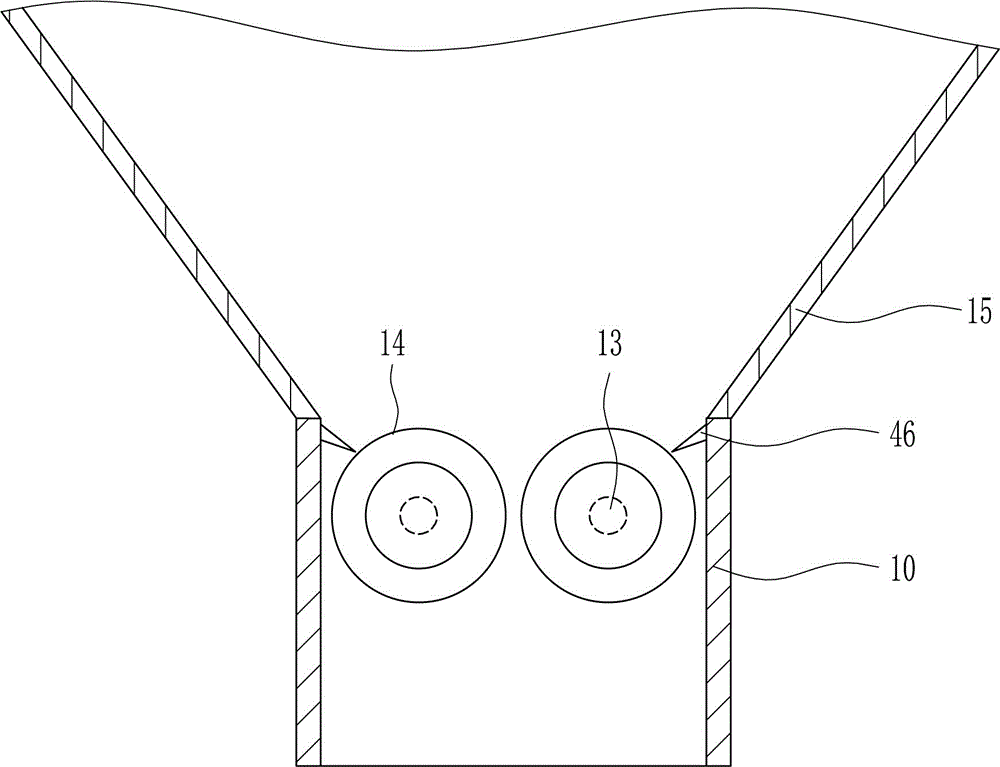

Technique for producing regenerative rubber by using kneading machinery chemical method and interrelated device thereof

InactiveCN101259739APrevents carbonization or scorchingThe equipment is easy to operatePlastic recyclingEngineeringRubber material

The invention relates to a technique for producing regenerated rubber by utilizing a milling mechanical and chemical method, wherein wasted sulfured rubber is firstly prepared into rubber powder; the rubber material is cast into a milling machine banburying room after being blended with chemical additives; a four-wing synchronous rotor of the milling machine is used for doing work on the rubber material, thereby the rubber material is heated and desulfurized; the rubber material is cooled and prepared into the finished product of the regenerated rubber by compressing and refining. The rotor comprises a rotor shaft and a left end sheet and a right end sheet on the shaft; a dextrorotatory screw wing body and a levorotary screw wing body are arranged on the rotor shaft between the left and the right end sheets; the two wing body are distributed uniformly and intersected along the circumference of the rotor shaft with an interval of 90 degrees; the cooling equipment is a spiral conveyor, wherein one end of a machine barrel is an inlet, and the other end is an outlet; a spiral mandrel connected with a power device is arranged in the machine barrel; a spiral lamina is welded on the mandrel; revolving joints are connected on two ends of the mandrel; the machine barrel is a jacketed structure; an inner cavity of a jacket and an inner bore of the mandrel are communicated with a watering and cooling device through the revolving joints and a rubber tube. The technique has the advantages of a safety and reliability, non pollution, energy saving, and low production cost.

Owner:DALIAN GENERAL RUBBER MACHINERY

Cutting device for building fireproof plates

InactiveCN107433630APrevent escapeProtect healthUsing liquid separation agentMetal working apparatusWorking environmentEngineering

The invention discloses a cutting device for building fireproof plates. The cutting device comprises a working table and a dust sucking fan; an adjusting box is fixedly arranged at one side edge of the upper surface of the working table; the adjusting box is internally provided with an adjusting rod parallel to the side edge, where the adjusting rod is located, of the working table; a cutting through groove is formed in the position, away from the adjusting box, of the working table; and a cutting motor is fixedly arranged on the lower surface of the working table. A cutting disc is fixedly arranged on an output shaft of the cutting motor; a lower dust collecting cover is fixedly arranged on the position, on the lower portion of the cutting through groove, of the working table; a vertical frame of an L-shaped structure is fixedly arranged on the adjusting box; a vertical column is fixedly arranged at the end of a horizontal arm of the vertical frame; and a lifting screw rod perpendicular to the working table is fixedly arranged in the vertical column. The lifting screw rod is provided with a pressing rod in a threaded connection mode, and an upper dust collecting cover is fixedly arranged at the lower end of the pressing rod. The cutting device for the building fireproof plates is simple in structure, the cutting size can be accurately and conveniently adjusted through the adjusting rod, dust is collected through the wet method to avoid dust dispersing, and the human health and working environment are protected.

Owner:HUIZHOU JINHENG IND MOLD DESIGN PARTNERSHIP ENTERPRISE GENERAL PARTNERSHIP

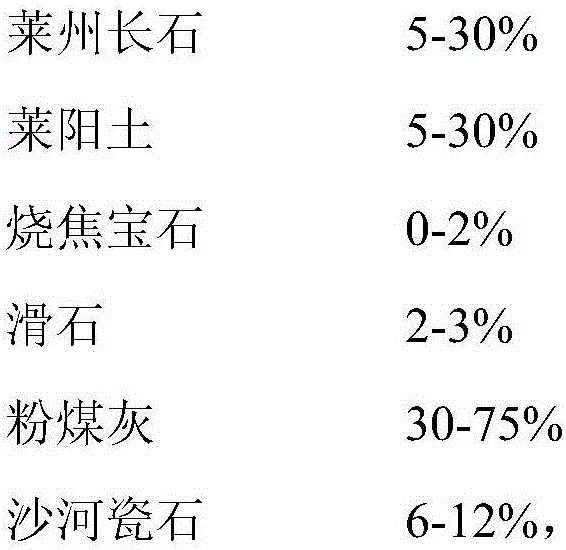

Anti-static antimicrobial ceramic tile prepared from coal ash and preparation method of anti-static antimicrobial ceramic tile

InactiveCN105837169AImprove performanceImprove the decorative effectCeramic materials productionClaywaresBrickHuman health

The invention belongs to the technical field of ceramic materials and particularly relates to an anti-static antimicrobial ceramic tile prepared from coal ash and a preparation method of the anti-static antimicrobial ceramic tile. The anti-static antimicrobial ceramic tile comprises a blank body and a glaze layer, wherein the blank body is prepared from the following raw materials: Laizhou feldspar, Laiyang soil, scorched gems, talc, coal ash, Shahe porcelain stone and composite conductive powder, wherein the composite conductive powder consists of iron oxide and anti-static materials; and the glaze layer is prepared from the following raw materials: potash feldspar, soda feldspar, dolomite, burnt talc, alumina, quartz, clinker, kaolin, anti-static materials and an antibacterial agent for ceramic glaze. The anti-static antimicrobial ceramic tile prepared from coal ash has the excellent performance of ceramic floor tiles and is strong in decoration and durable. Furthermore, the anti-static antimicrobial ceramic tile further has the functions of resisting static electricity and inhibiting and killing bacteria, is capable of eliminating static electricity and has the effects of promoting human health and protecting living and working environments.

Owner:山东电盾科技股份有限公司

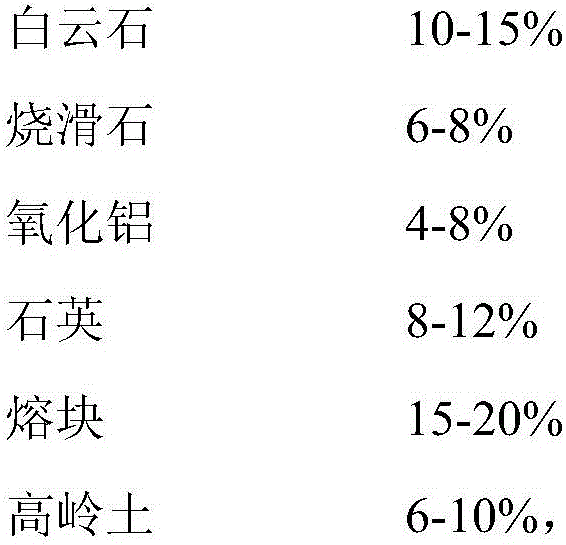

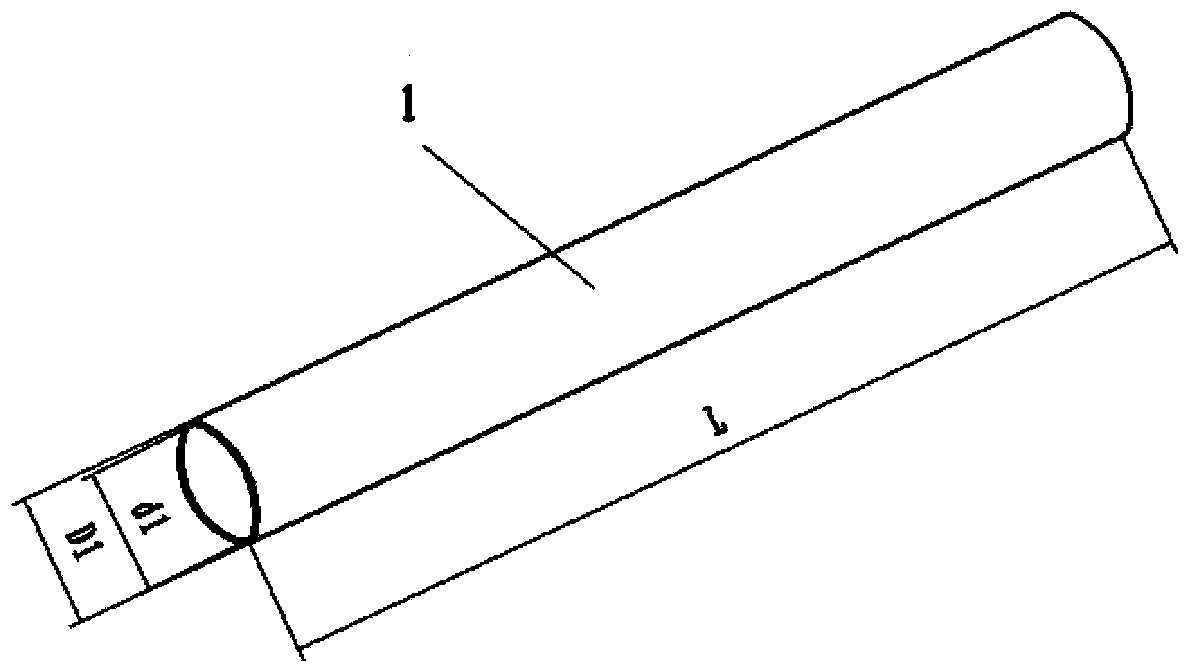

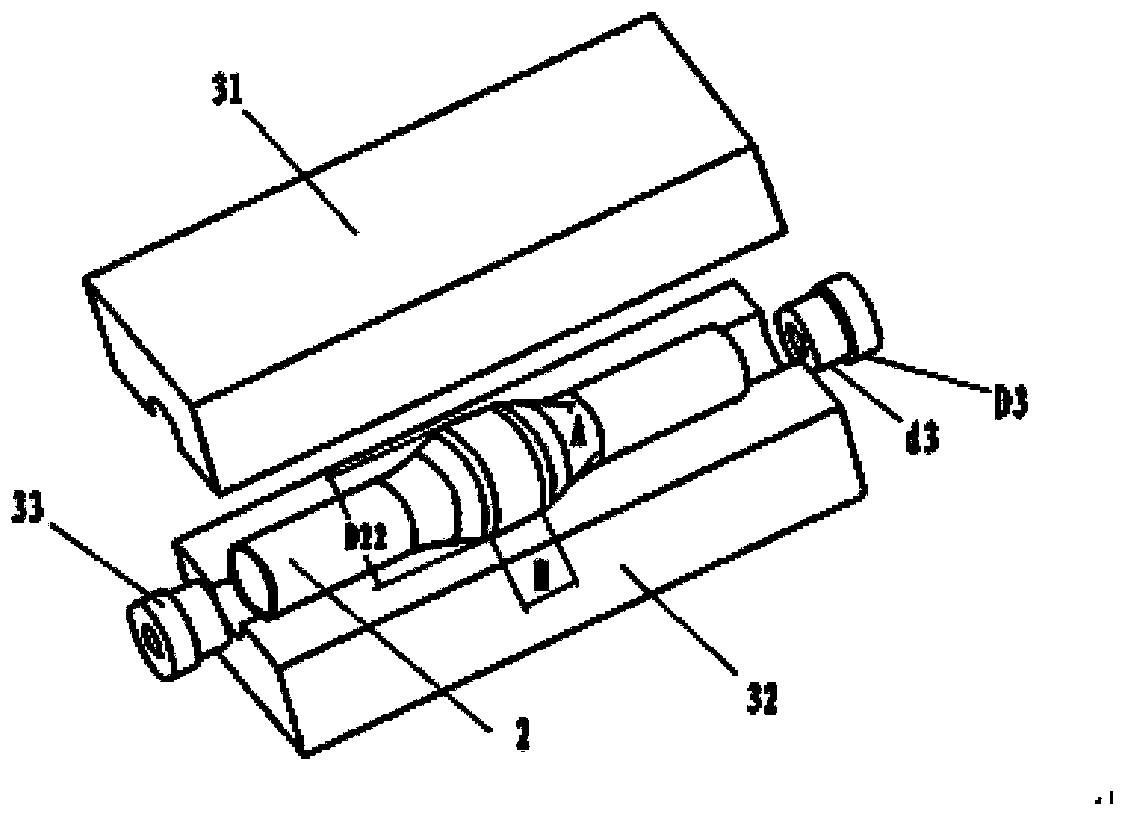

Automobile axle housing, automobile axle housing forming die and automobile axle housing forming method

ActiveCN103568724AIncreased Strength and RigidityShort production processAxle unitsWeld seamSteel tube

The invention discloses an automobile axle housing, an automobile axle housing forming die and an automobile axle housing forming method. The automobile axle housing forming method includes subjecting a round steel pipe to secondary internal high pressure to form a middle portion, performing forward extruding diameter shortening on two ends, performing compression forming on the middle portion, and cutting and processing an upper-side middle through hole. The automobile axle housing of a novel structure is formed by the method and the die. The automobile axle housing has a body of a hollow structure, the body extends along the length direction of the same to form two end portions, is symmetrical according to a central line formed by the two end portions, and gradually shrinks from the middle to the two end portions, a portion positioned between the two end portions has two side faces which are both connected with the two end portions and parallel to each other to serve as a first side face and a second side face, the through hole is formed in the middle of the first side face, a protrusion portion protruding towards a direction away from the body is arranged at a position, corresponding to the through hole, of the second side face, and the two end portions and the portion positioned between the same are integrally formed to be the body which is free of a welding seam.

Owner:SHANGHAI YONGTAI AUTOMOBILE PARTS CO LTD

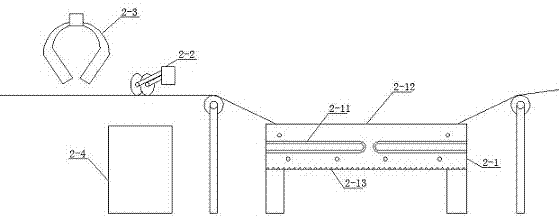

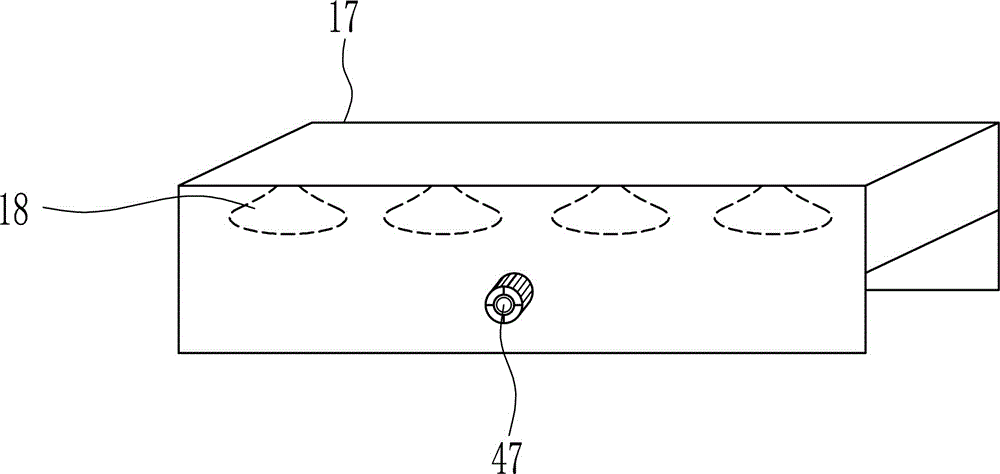

Rapid drying and disinfecting device for textile dyeing

PendingCN108677431AGuaranteed flatnessProtect the working environmentLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsTrach tubeProcess engineering

The invention discloses a rapid drying and disinfecting device for textile dyeing. The rapid drying and disinfecting device comprises a case, wherein an extrusion chamber, a drying chamber and a disinfecting chamber are formed in the case; the drying chamber is located on the rear side of the extrusion chamber and communicated with the extrusion chamber; two gas delivery boxes are mounted in an inner cavity of the drying chamber; a plurality of drying rollers are mounted on the gas delivery boxes; the gas delivery boxes are mounted in a mirroring manner with a central axis of the drying chamber as a standard; gas delivery pumps are mounted at the upper and lower parts of the drying chamber and gas delivery pipes are mounted at gas delivery ends of the gas delivery pumps; gas inlet holes are formed in the gas delivery boxes and connected with the gas delivery pipes; each drying roller is of an internal hollow structure; a plurality of secondary gas delivery pipes are mounted on the leftand right sides of the gas delivery boxes and connected with the corresponding drying rollers. According to the rapid drying and disinfecting device, smoothness of distribution is guaranteed during dewatering, and the effective sterilization and disinfection effects can be realized according to the principle of high temperature.

Owner:陈璐

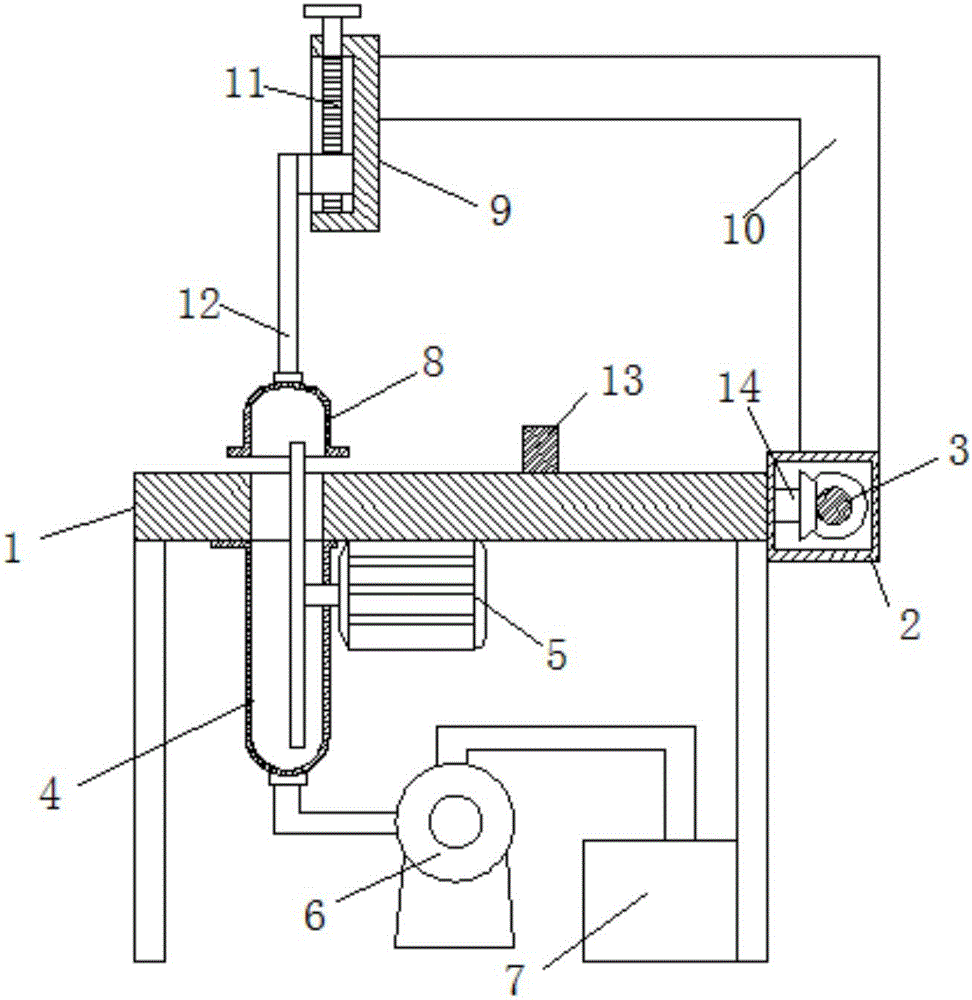

Rare earth dehydrating and drying device for recovering rare earth waste

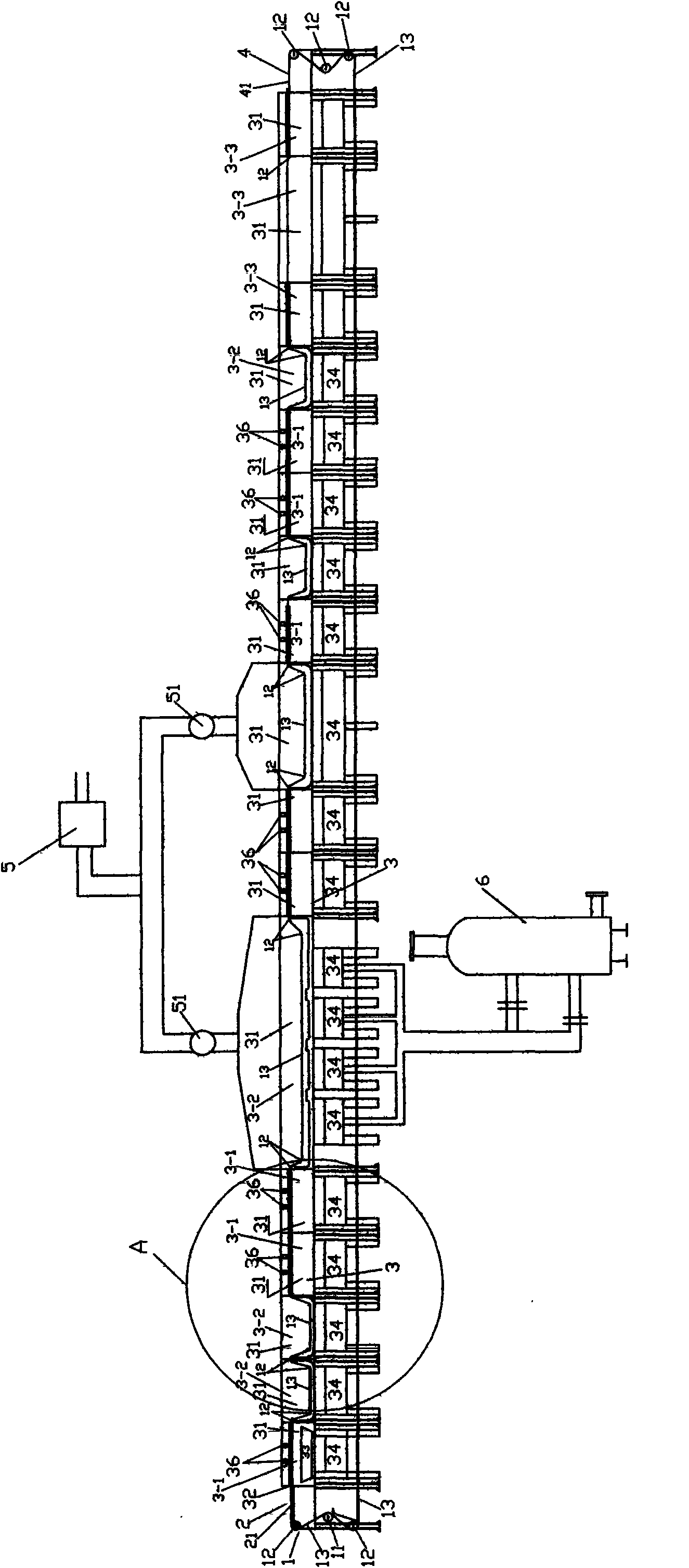

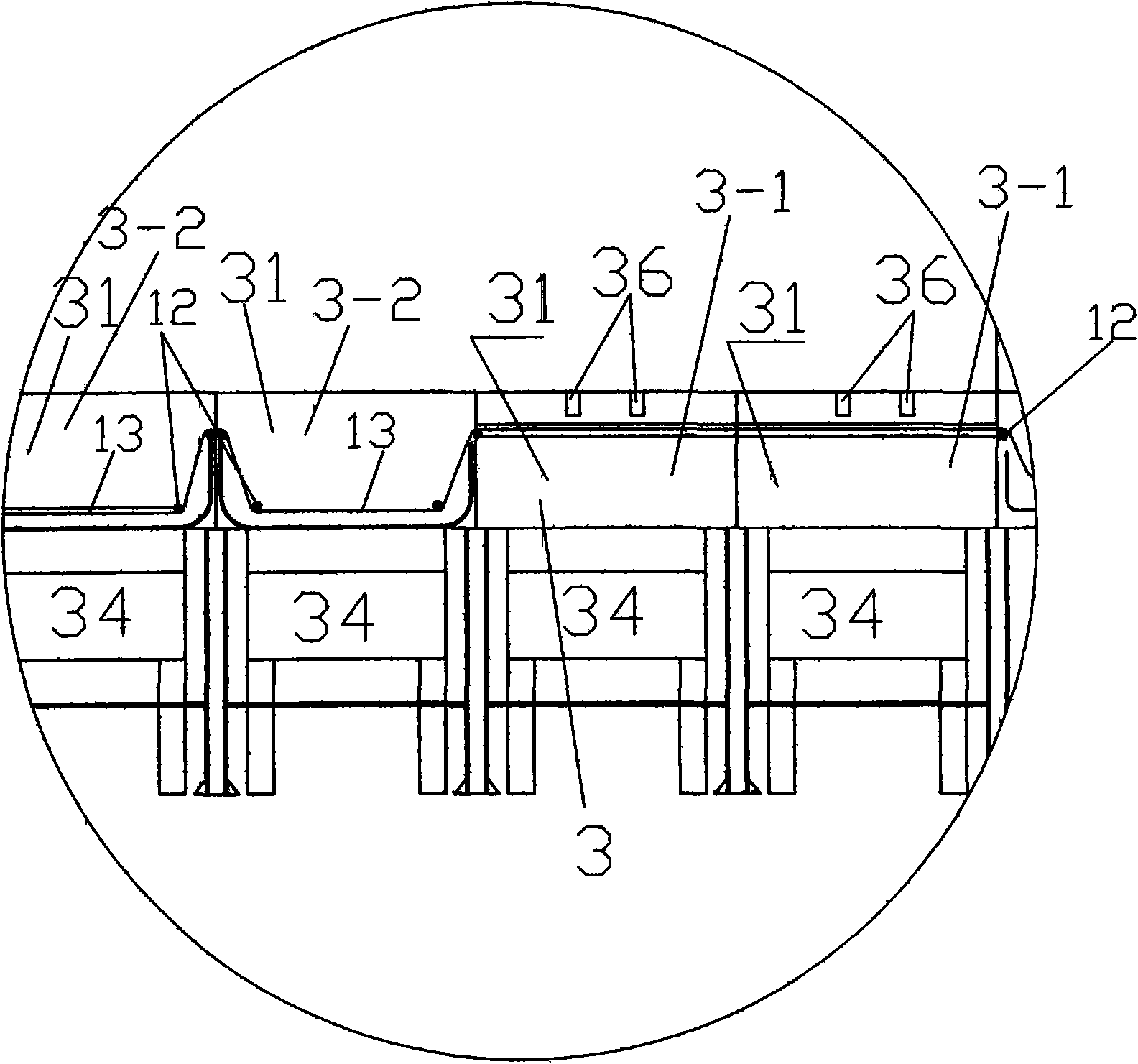

ActiveCN106546084AProtect the working environmentNot easy to agglomerateDrying gas arrangementsDrying machines with progressive movementsScrapChain type

The invention relates to a rare earth dehydrating and drying device, and particularly relates to a rare earth dehydrating and drying device for recovering rare earth waste. The invention aims at providing a rare earth dehydrating and drying device for recovering the rare earth waste, which is good in dehydrating and drying effects and high in work efficiency, is capable of saving labor power and is simple to operate. In order to achieve the aim, the invention provides the rare earth dehydrating and drying device for recovering the rare earth waste. The rare earth dehydrating and drying device comprises a frame, a first mounting plate, a first motor, a first belt pulley, a chain type conveying belt, a driving roller, a second belt pulley, a flat belt, a driven roller, a first box body and the like, wherein the left end of the top of the frame is provided with the driving roller. By using the rare earth dehydrating and drying device for recovering the rare earth waste, the effects of being good in the dehydrating and drying effects, low in labor intensity, high in work efficiency and short in waiting time, being capable of saving the labor power and being simple to operate are achieved.

Owner:靖江德方科技服务有限公司

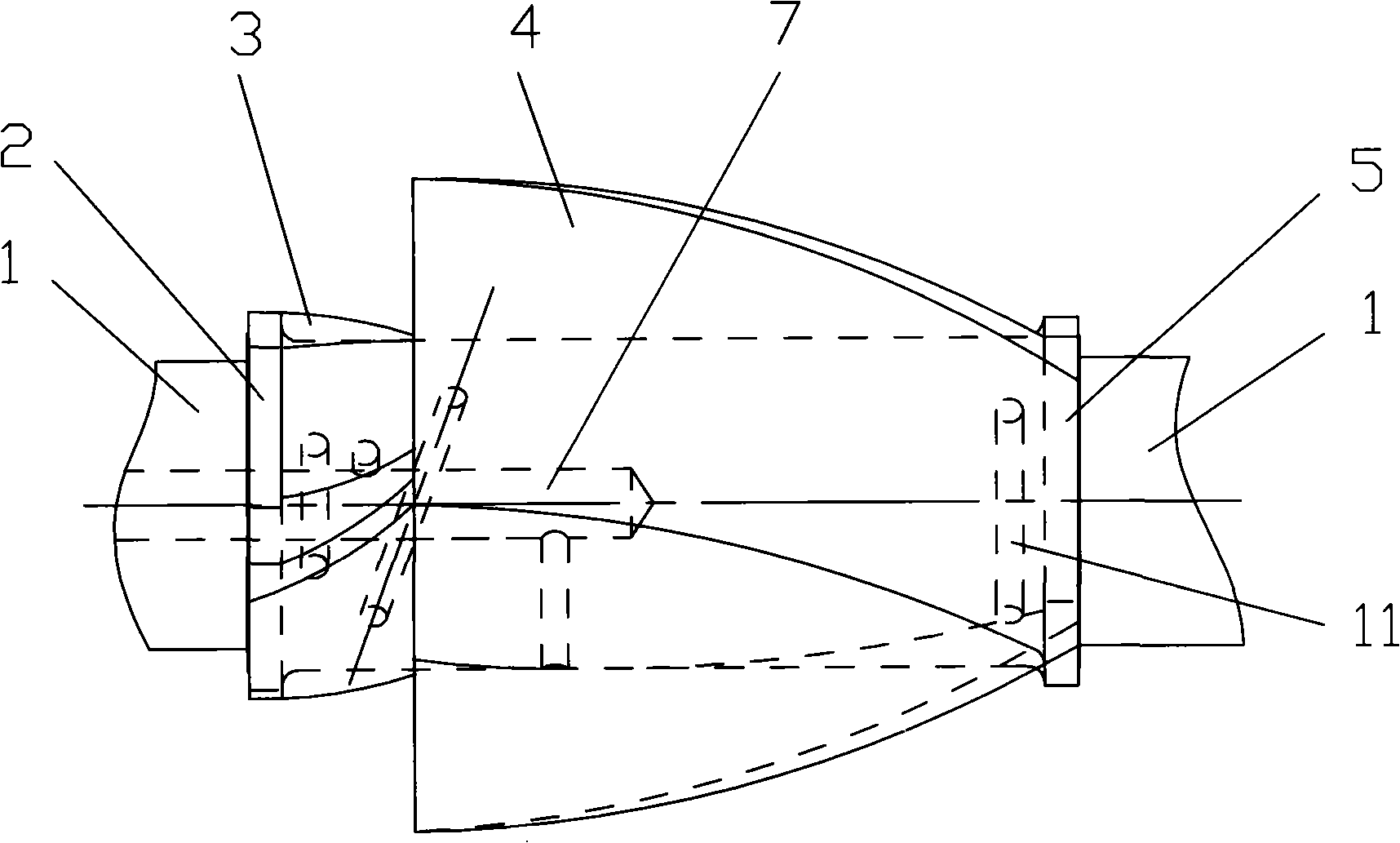

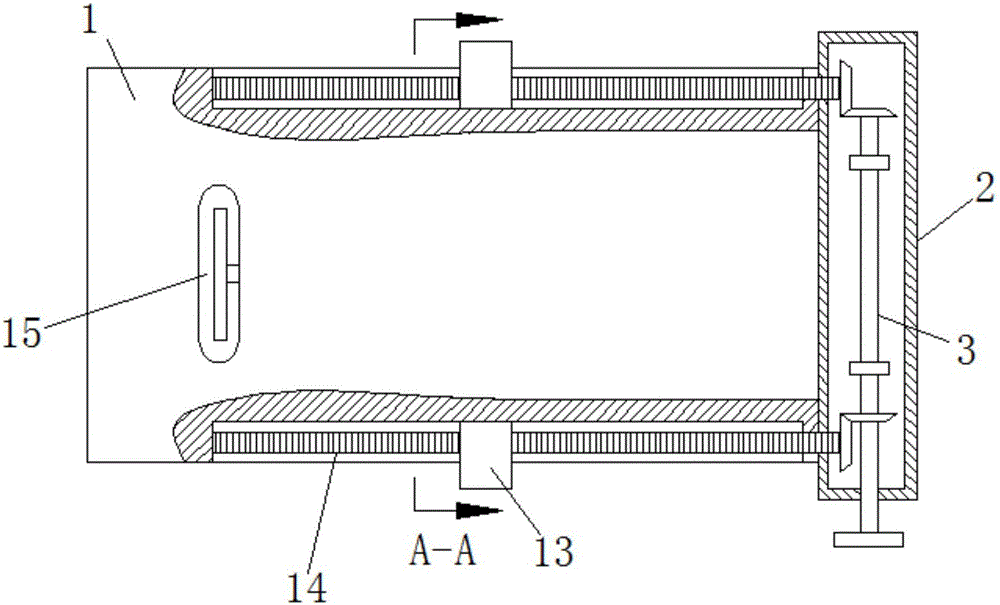

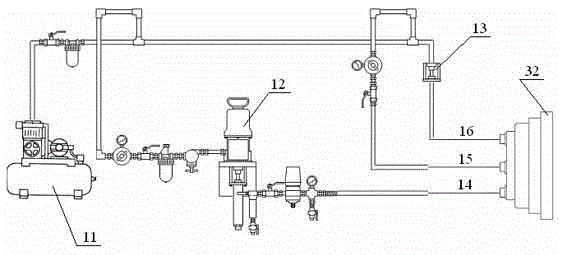

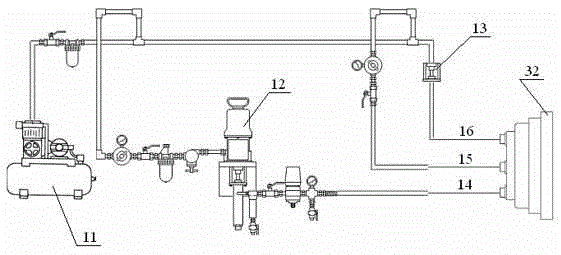

RTV coating spraying equipment for supporting column insulator of transformer substation

ActiveCN105537038AQuality improvementUniform thicknessLiquid surface applicatorsLiquid spraying apparatusPressure systemTransformer

The invention discloses RTV coating spraying equipment for a supporting column insulator of a transformer substation. The RTV coating spraying equipment comprises a spraying pressure system and a spraying device with a spray gun, wherein the spraying pressure system comprises an air compressor, a material storage tank, a spraying pump and a controller; the air compressor is communicated with the spray gun through an air supply pipeline; the material storage tank is communicated with the spray gun through a coating pipeline; the spraying pump is arranged in the coating pipeline; the controller is connected to each controlled end of the spraying device through a control circuit; and the controller is further respectively connected to the air compressor and the spraying pump. The RTV coating spraying equipment can enable the RTV coating on the surface of the insulator to be uniform and consistent, so that the service life of the insulator is prolonged.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

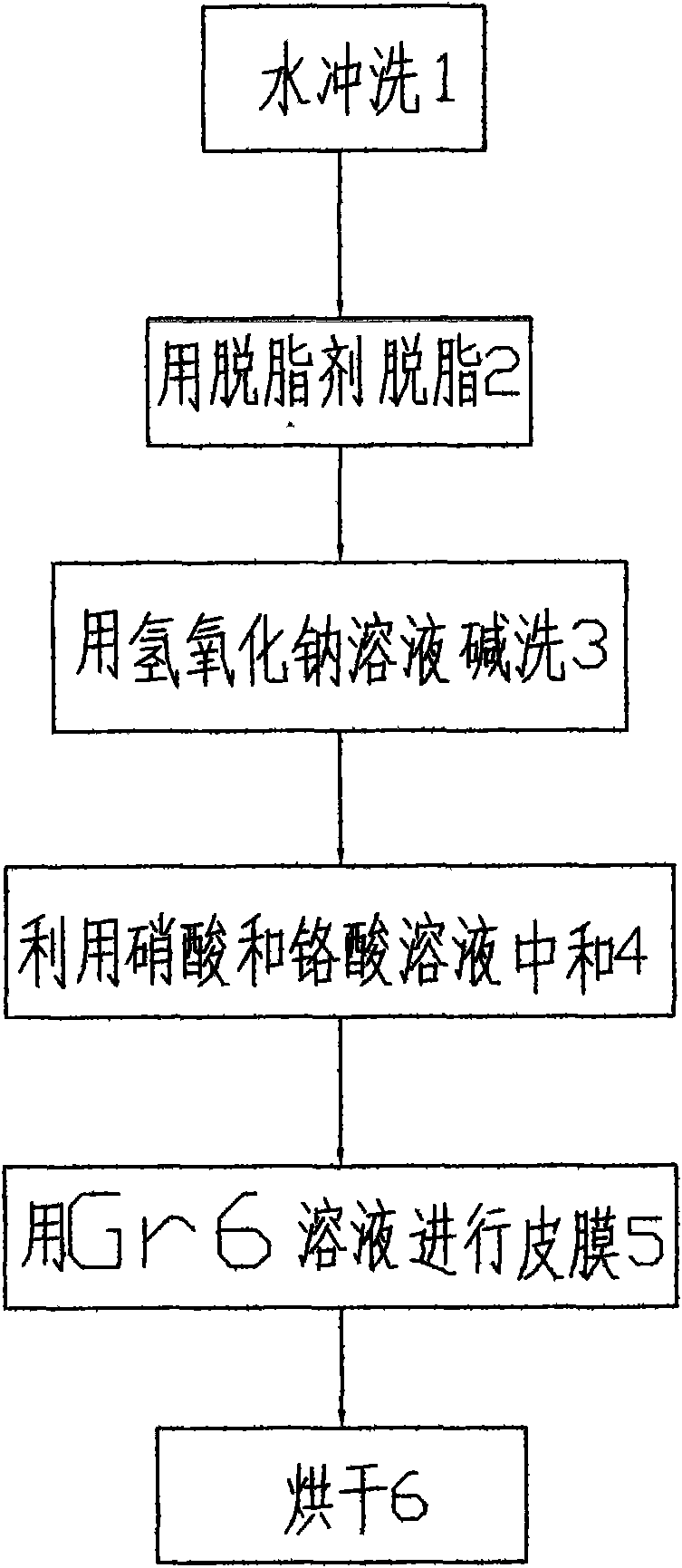

Method and device for cleaning aluminum alloy radiating fin

InactiveCN101775608ATo achieve the purpose of automatic operationImprove cleaning efficiencyTectorial membraneSlag

The invention relates to a method and a device for cleaning mechanical parts after processing, in particular to a method and a device for cleaning aluminum alloy radiating fins. The steps of the method are that: 1. water is used to flush the aluminum alloy radiating fins to remove dirt and aluminum slag; 2. degreasing agent is used of remove greasy dirt and impurities on the surface of the aluminum alloy radiating fins; 3. sodium hydroxide solution is used to wash the aluminum alloy radiating fins to remove burr on the degreased aluminum alloy radiating fins; 4. nitric acid solution and chromic acid solution are used to neutralize alkali compound left on the surface of the alkali-washed aluminum alloy radiating fins to remove the alkali compound; 5. surfacing agent (Gr5) is used to treat the surface of the aluminum alloy radiating fins to form a protective film covering the surface of the aluminum alloy radiating fins; and 6. the aluminum alloy radiating fins are dried. The invention additionally discloses a device for realizing the method. The invention has the advantages that the cleaning efficiency is improved, the labor is saved and the clearing cost is greatly reduced.

Owner:邓伟明

Mould release agent for precision forging forming and preparation method of mould release agent

The invention relates to a mould release agent for precision forging forming. The mould release agent comprises the following ingredients in percentage by weight: 8 to 12 percent of silica gel, 35 to 45 percent of aluminum hydroxide, 18 to 22 percent of talc powder, 8 to 12 percent of hibiscus leaf extraction liquid, 2.5 to 3.5 percent of dispersing agents, 2.5 to 3.5 percent of defoaming agents, 3 to 4 percent of stabilizing agents and the balance of water. The mould release agent provided by the invention is applicable to precision forging moulds made of aluminum, copper, steel and iron and the like, a preparation method is simple, the silica gel in the mould release agent has the effect of bonding all ingredients and simultaneously takes neutralization reaction with the aluminum hydroxide, the talc powder and the hibiscus leaf extraction liquid respectively have the effects of lubricating the inner surface of a mould, and have the effects of smoothening the surface of a product, and the hibiscus leaf extraction liquid has the cleaning and lubricating effects. The mould release agent provided by the invention is used on the precision forging mould, is suitable for being used for smoothening the surface of the product, and meets the precision forging requirements, meanwhile, the mould release agent does not contain aquadag, aquadag dust cannot be generated in the use process, the work environment is protected, and the influence cannot be caused on the human body respiration.

Owner:葛秀林

Special integrated production device for furniture parts

ActiveCN105057150AReduce transfer stepsSuitable for mechanized productionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

A special integrated production device for furniture parts comprises a machine frame and a feeding rack arranged on the machine frame. One end of the feeding rack is a feeding end, the other end of the feeding rack is a discharging end, and a first automatic dust removal device, a embellishing device, a drying device, a paint spraying device and an airing bin are arranged on the feeding rack sequentially from the feeding end to the discharging end at intervals. The embellishing device and the paint spraying device each comprises a paint spraying chamber with a paint spraying platform and two groups of spraying guns arranged in the paint spraying chamber, wherein each group comprises two spraying guns, a conveying belt is laid horizontally on the paint spraying platform, a transverse sliding rail is arranged above a feeding end and a discharging end of the conveying belt, and a movable seat is installed on the transverse sliding rail. The two spraying guns in each group are installed on the same movable seat and are arranged in the mode of inclining downwards towards the two outer sides of the corresponding paint spraying platform. The transverse sliding rails and the movable seats are arranged, uniform paint spraying on the furniture parts is realized through transverse and reciprocating swinging of the spraying guns. The special integrated production device is suitable for embellishing and paint spraying of various furniture parts, and improves the production and quality.

Owner:LIANYUNGANG MOBO HOUSEHOLD

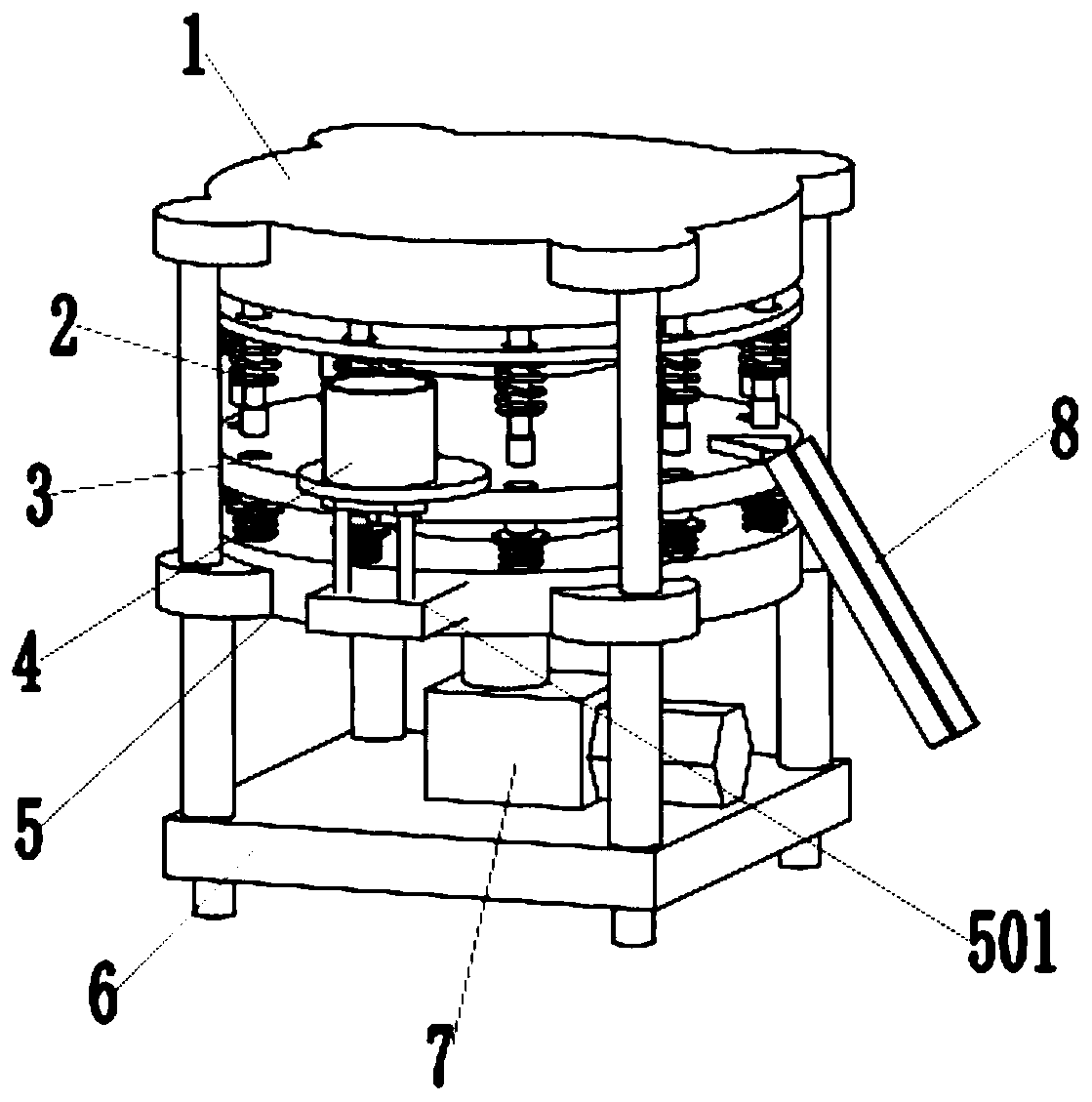

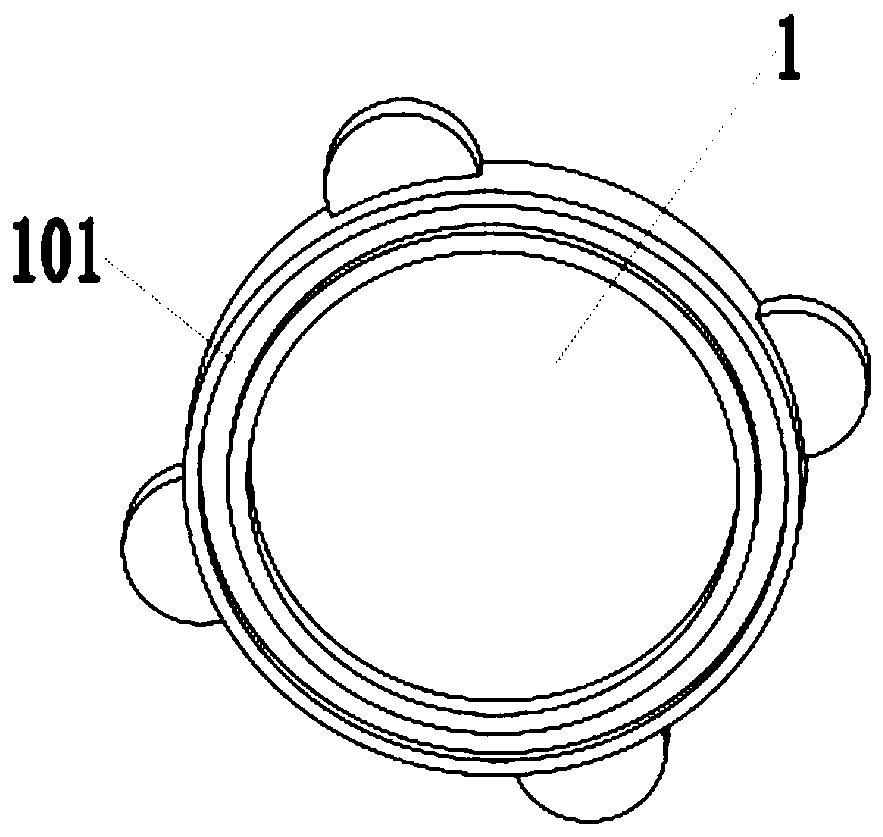

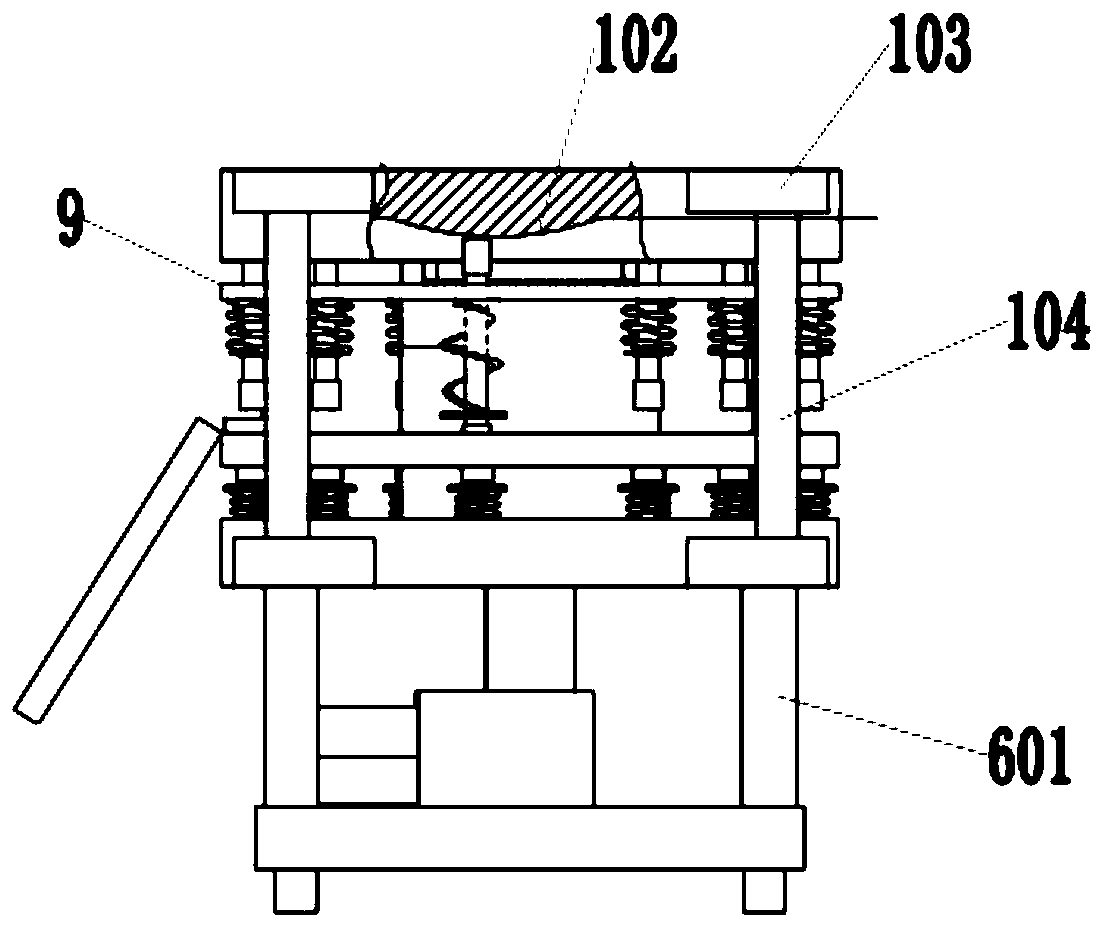

Tablet press for producing tablets

The invention discloses a tablet press for producing tablets. The tablet press comprises a pressure disc, the die punching rods, a die pressing rod, a feeder, a tray, a base and a motor. The upper endof the base is connected with the tray, the upper end of the tray is connected with the pressure disc, and a pressing mold disc is arranged between the pressing disc and the tray; the motor is arranged at the upper end of the base and is connected with the die pressing disc through a rotating shaft, an upper rotating disc is arranged between the pressing die disc and the pressing disc and is connected with the rotating shaft, and a lower rotating disc is arranged between the pressing die disc and the tray and is connected with the rotating shaft; the punching die rods are arranged on the upper side and the lower side of the pressing die disc; the punching die rods are arranged at the two sides of the pressing die disc, the punching die rod arranged above the pressing die disc penetrates through the upper rotating disc to be connected with the pressing disc in a sliding manner, and the punching die rod arranged below the pressing die disc penetrates through the lower rotating disc to be connected with the tray in the rotating manner; a pressing die hole is formed on the pressing die disc, the feeder matched with the pressing die hole is arranged at one side of the tray, and a discharging sliding way is arranged at one side of the pressing die disc.

Owner:SHANDONG KANGFUSEN BIOTECH CO LTD

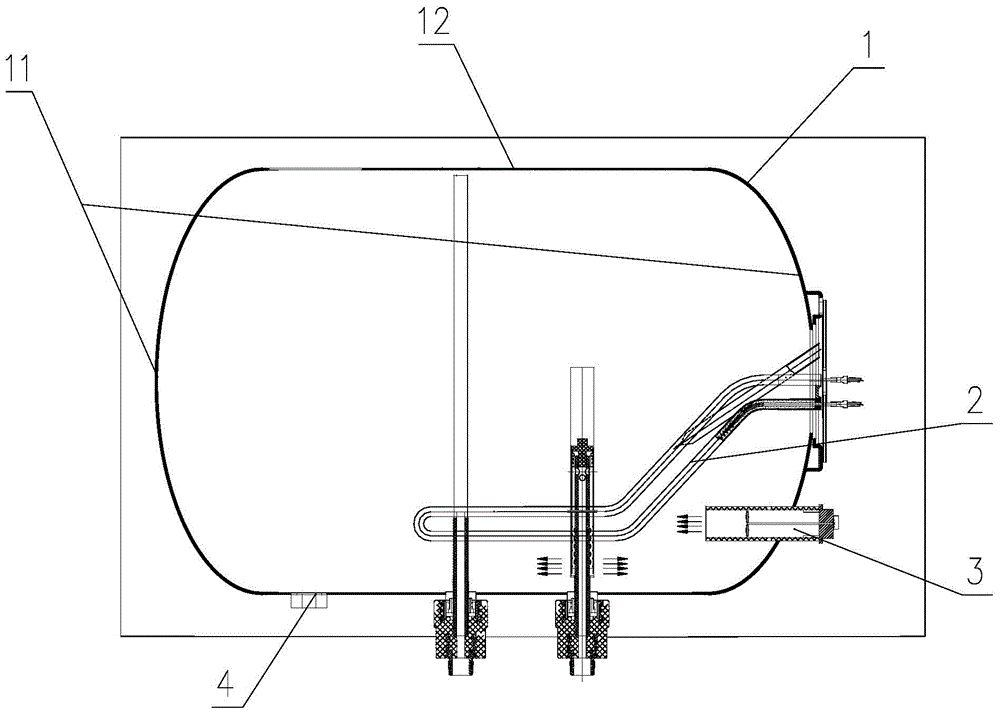

Heater body scaling delaying method and water heater

The invention discloses a heater body scaling delaying method and a water heater and aims to solve the problem that the heater body surface of an existing water heater is prone to scaling. The method includes producing disturbance to drive the water scale to move in the flow of the region where the heater body located, and avoiding the scale accumulation on the heater body surface. The water heater comprises a controller, a cylinder and a heater body installed in the cylinder; at least one flow drive device is arranged in the cylinder adjacent to the heater body; the water heater controls the at least one flow drive device to produce continuous or intermittent disturbance to drive the scales of the flow to move in the flow of the region where the heater body located through the controller, and the scale is prevented from accumulating on the heater body surface. The water heater is capable of delaying heater body scaling and saving energy and is simple and reliable in structure.

Owner:HAIER GRP CORP +1

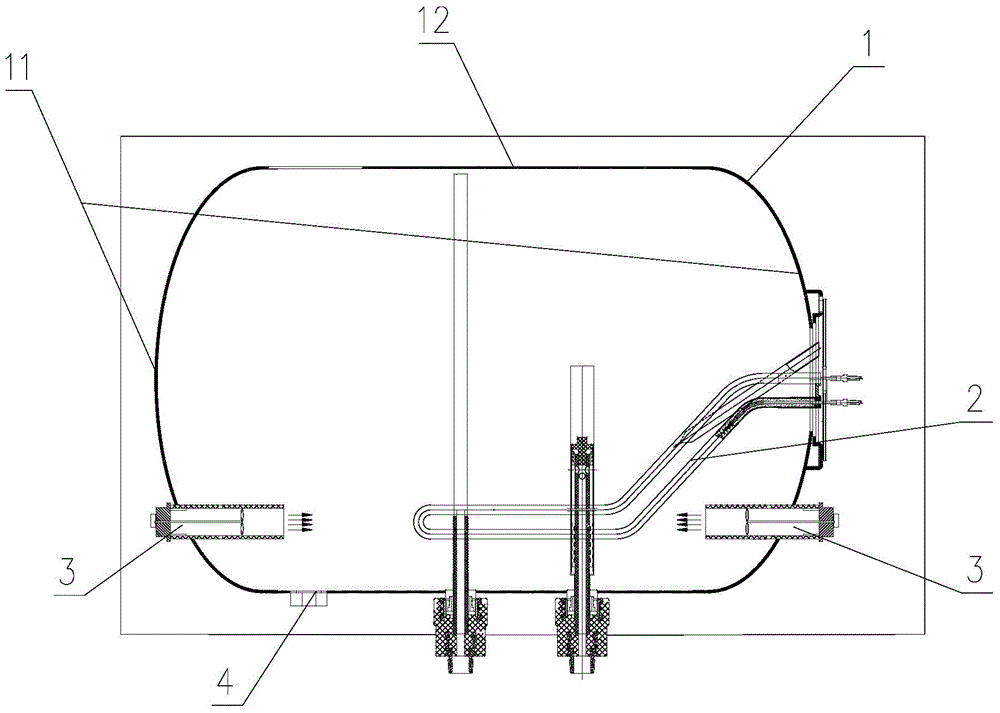

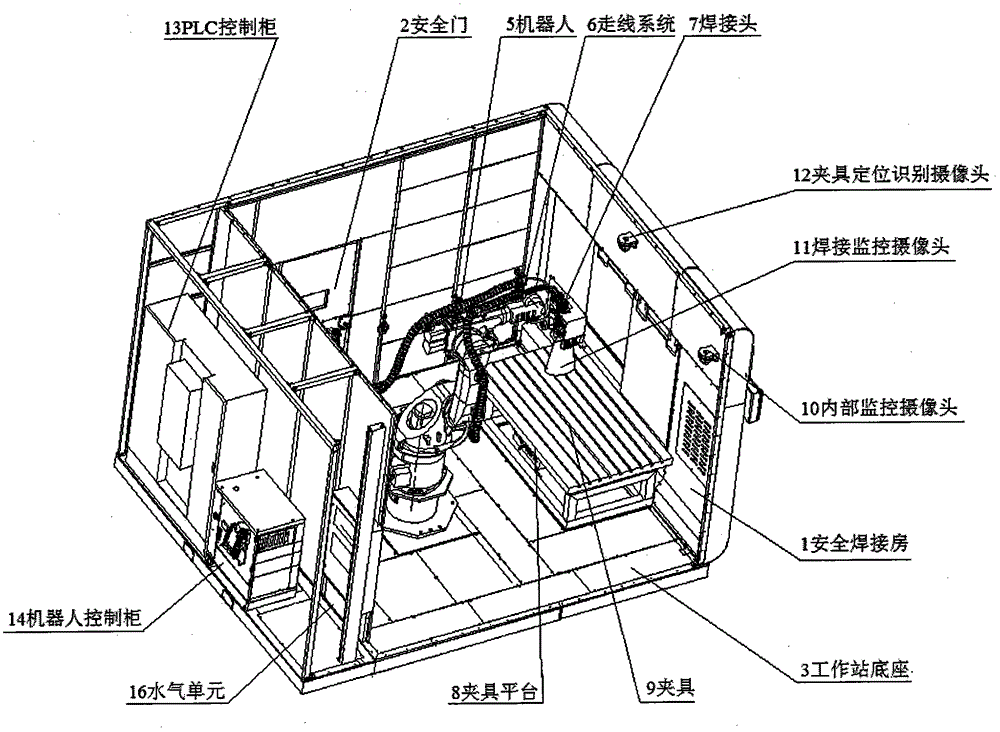

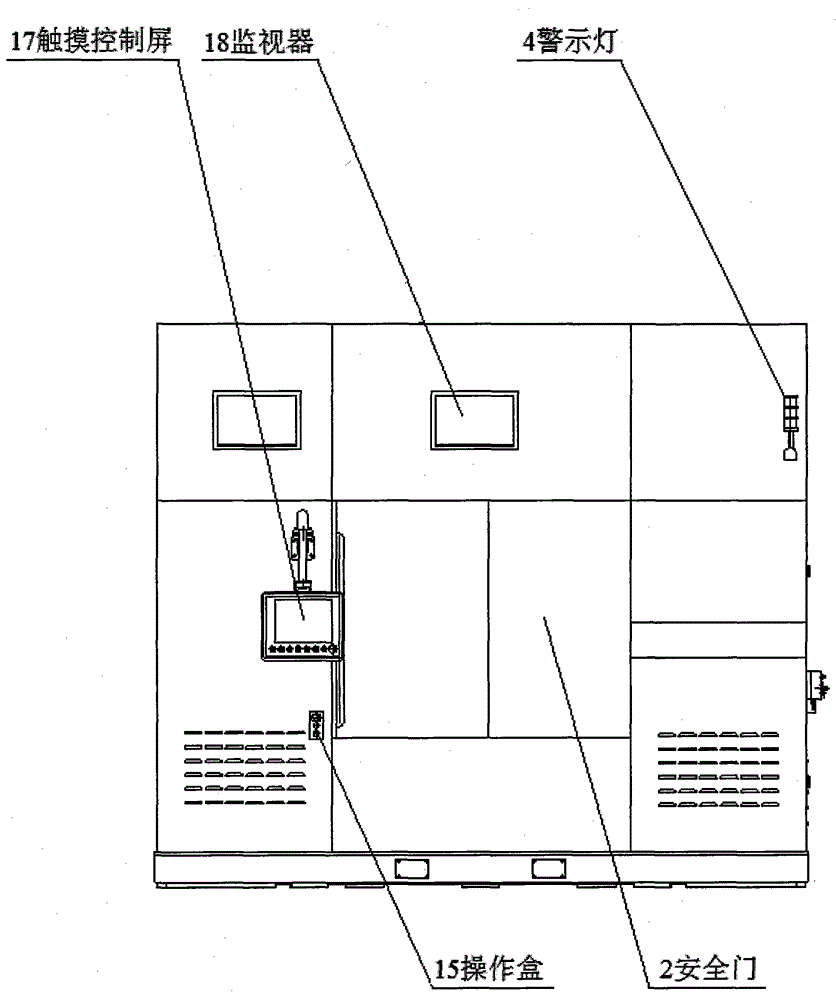

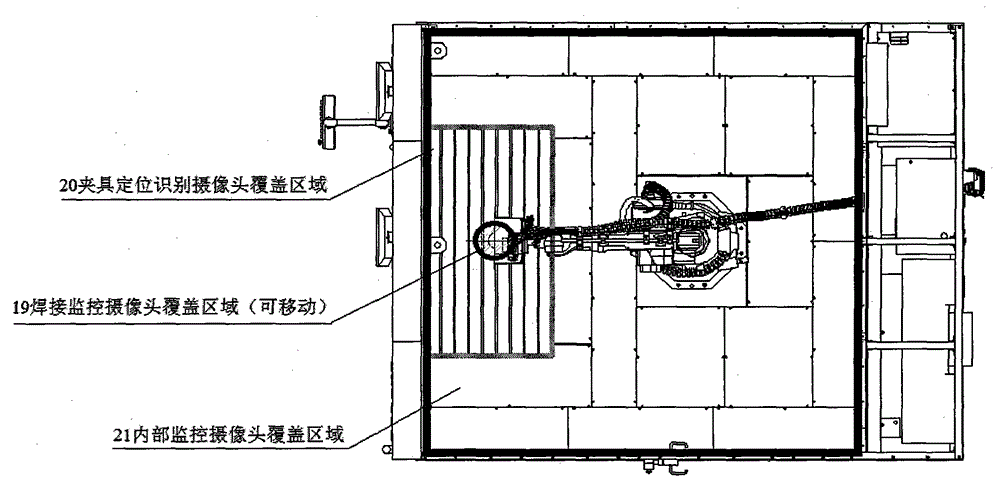

Robot welding monitoring system

InactiveCN104625510AAvoid harmImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectricityControl system

A robot welding monitoring system is composed of a monitoring system, a welding system, a security system and a control system which are electrically connected. An internal monitoring camera 10 is used for observing the working state of equipment in a welding room, and a welding monitoring camera 11 can observe the working environment of a welding head 7 and the condition of a weld pool. A clamp positioning and recognizing camera 12 has a recognition function and can judge whether a workpiece is installed in place according to the position change of the workpiece. The welding system, the monitoring system, the control system and the security system are integrated to form the robot laser welding monitoring system. The four systems can be organically combined into a whole to form a monitoring network without any dead corner, the condition in the welding safety room can be monitored in real time, the welding efficiency and welding effect of a whole work station are improved, and laser injuries are avoided due to the fact that people do not make direct contact with laser during demonstration and debugging.

Owner:国融新兴投资有限公司

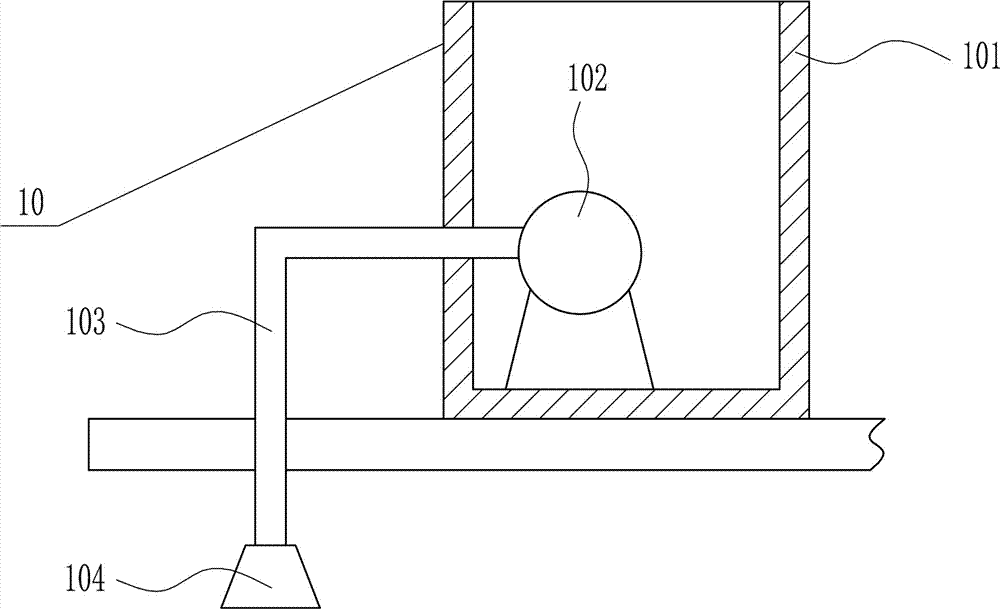

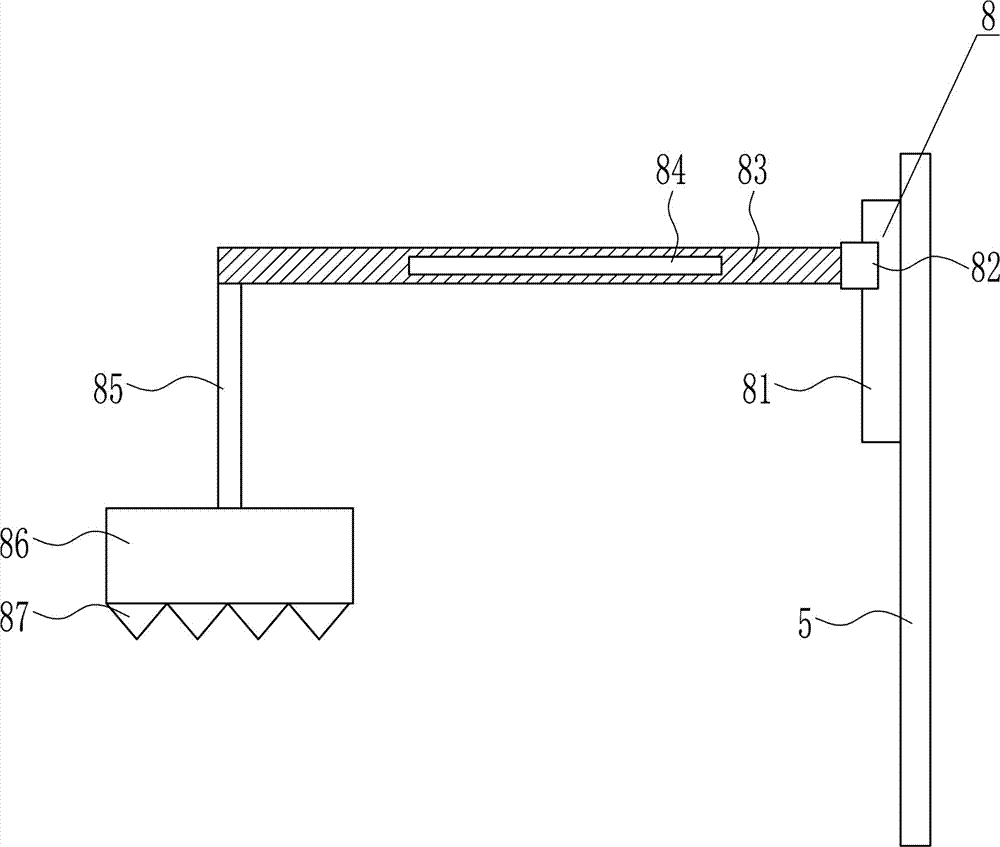

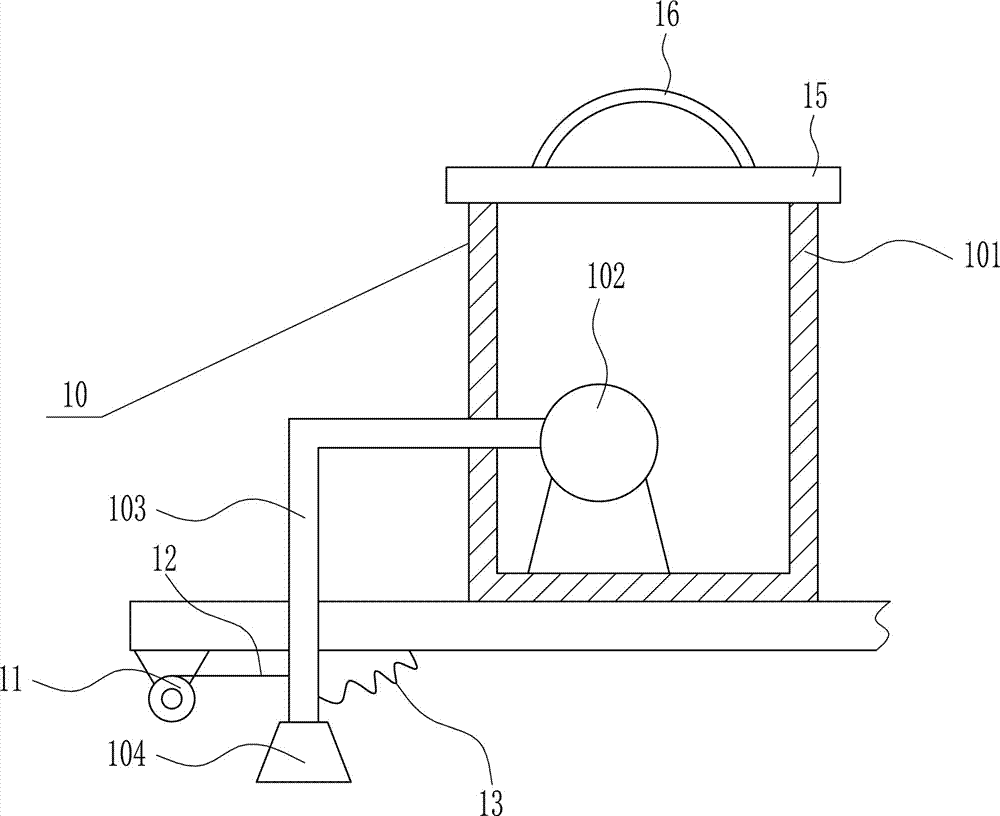

Cement block recovery processing equipment for highway construction

ActiveCN107469907AAvoid flyingImprove crushing effectUsing liquid separation agentCement productionEngineeringWorking environment

The invention belongs to the technical field of highway construction and particularly relates to cement block recovery processing equipment for highway construction. The technical effect that the cement block recovery processing equipment for highway construction is capable of saving time and effort, good in breaking effect and capable of preventing dust flying in the breaking process and protecting the working environment is achieved. In order to achieve the technical effect, the provided cement block recovery processing equipment for highway construction comprises a bottom plate, a first sliding rail, a first sliding block, a breaking frame, a support and the like. The first sliding rail is horizontally mounted at the top of the bottom plate in a bolt connection mode, and the support is vertically mounted at the top of the bottom plate in a bolt connection mode. The first sliding rail is located on the left side of the first sliding rail. The first sliding block is slidably arranged on the first sliding rial. The breaking frame is mounted at the top of the first sliding block in a bolt connection mode. The effect that the cement block recovery processing equipment for highway construction is capable of saving time and effort, good in breaking effect and capable of preventing dust flying in the breaking process and protecting the working environment is achieved.

Owner:海南骏达交通规划勘察设计有限公司

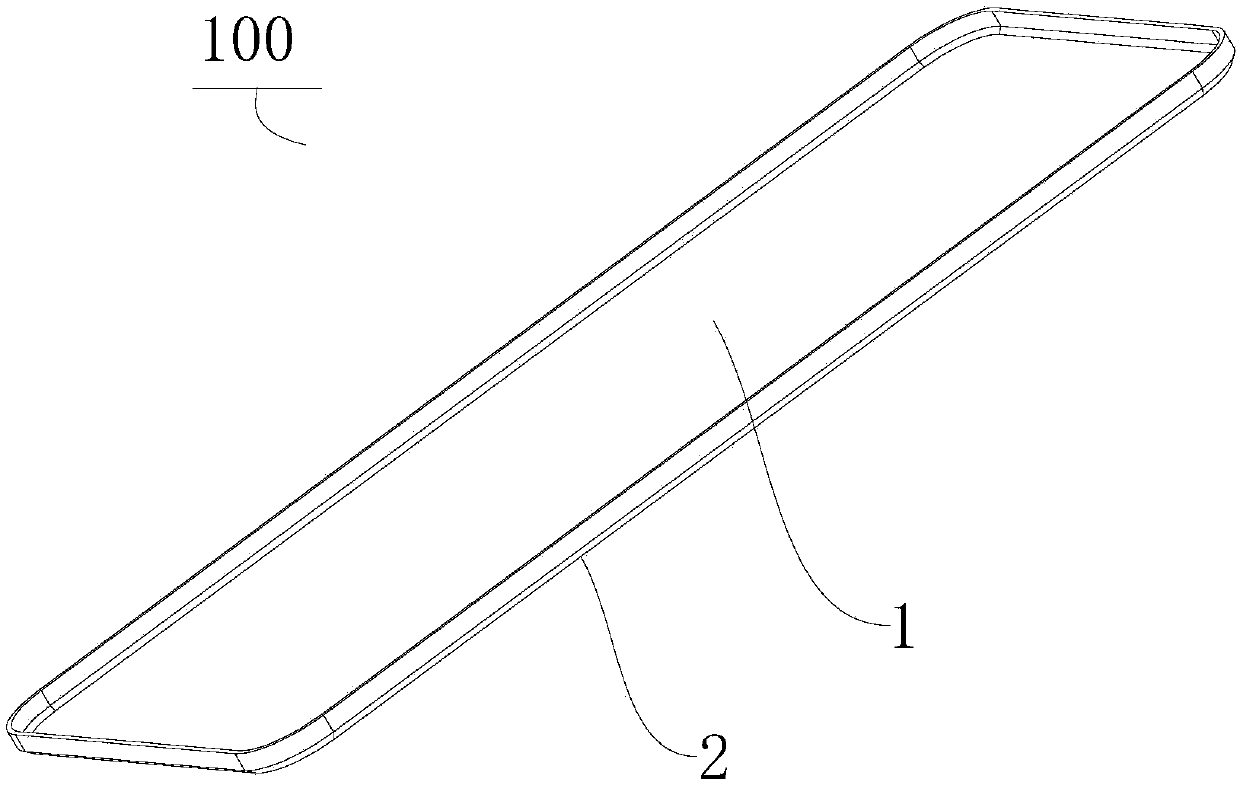

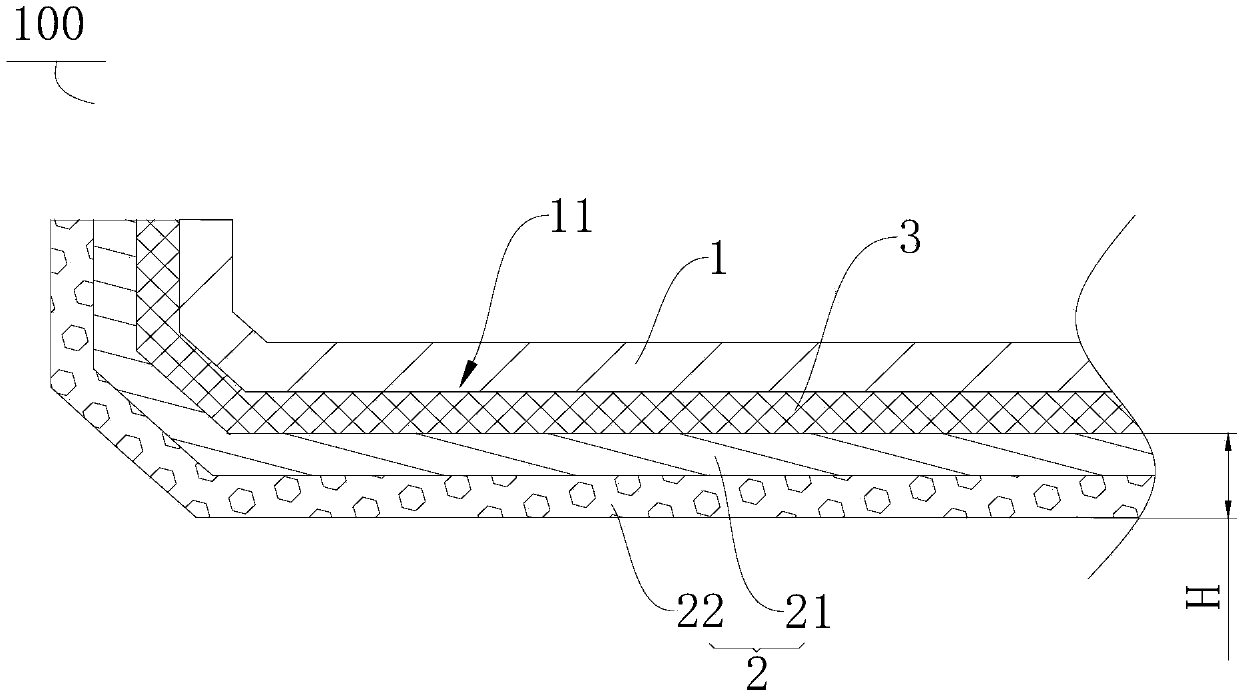

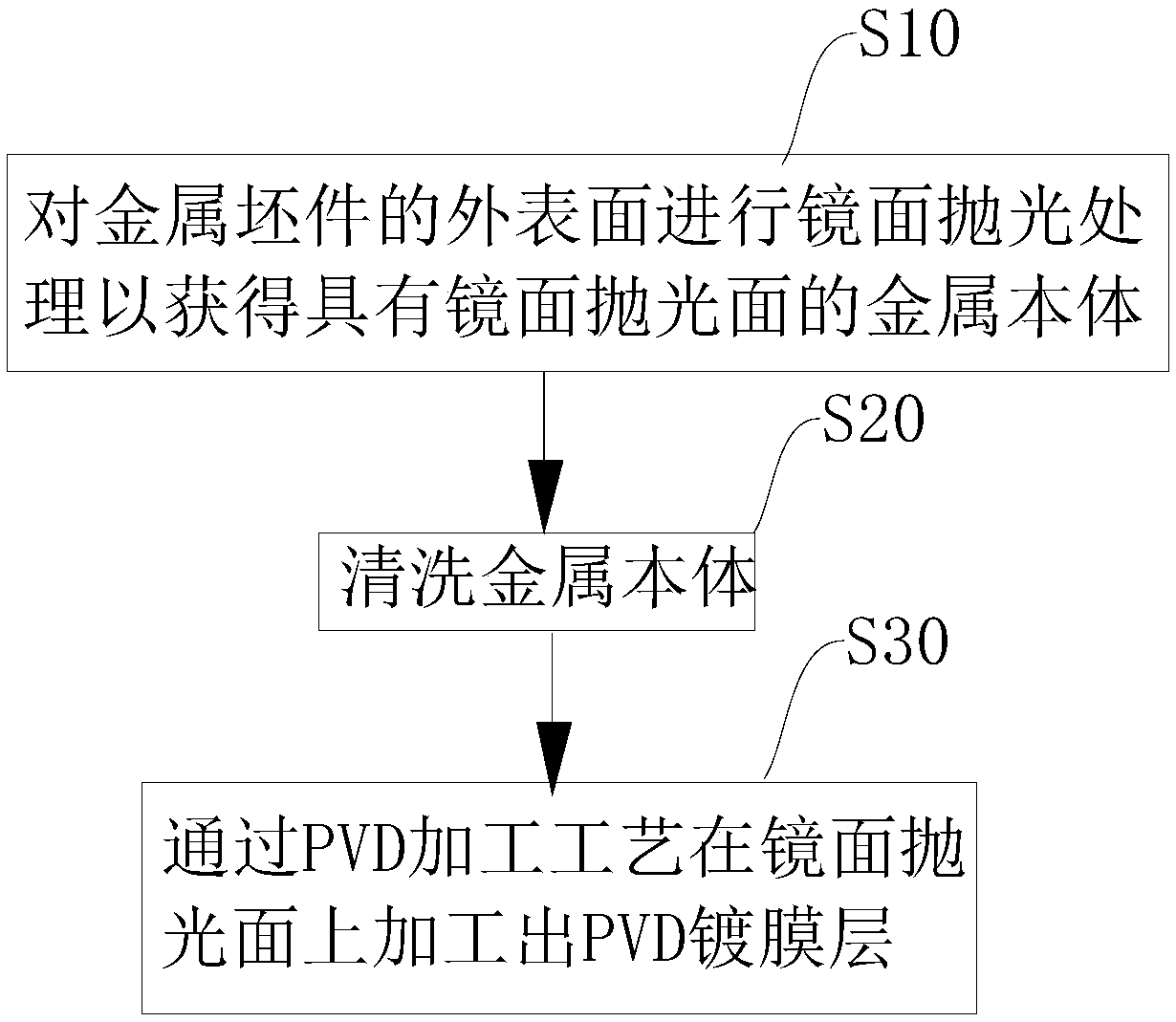

Terminal, terminal shell, and shell processing method

InactiveCN107587108AImprove processing yieldGood uniformityVacuum evaporation coatingSputtering coatingNanotechnologyYield rate

The invention discloses a terminal, terminal shell, and shell processing method. The shell comprises a metal body, the outer surface of which is a mirror polished surface, and a PVD plated film layer,which is arranged on the mirror polished surface through PVD processing technology through plating. According to the terminal shell, the PVD plated film layer is arranged on the mirror polished surface of the metal body through plating. The PVD plated film layer is relatively small in thickness and good in uniformity. Therefore, the shell provides a high light metal effect, and the processing yield rate and appearance aesthetic property of the shell are improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Battery box of new energy automobile

InactiveCN110233217AImprove installation efficiencyProtect the working environmentSecondary cellsCell component detailsNew energyAlternative fuel vehicle

The invention discloses a battery box of a new energy automobile. The battery box comprises a box body, supporting legs, a battery, a supporting device, limiting devices, a compressing device, a firstheat dissipation device, second heat dissipation devices, a cover plate, a fixing device, a wire device, containing boxes, a temperature sensor and a controller, wherein the supporting device is arranged at the bottom end of the box body; the first heat dissipation device is arranged at the bottom of the supporting device; the limiting devices are arranged on the front side wall and the rear sidewall of the box body; the cover plate is mounted on the box body through a rotating shaft; the cover plate is fixed on the box body through the fixing device; the compressing device is arranged on the cover plate; the battery is fixed in the box body through the supporting device, the limiting devices and the compressing device; the second heat dissipation devices are arranged on the four side walls of the box body; the wire device is arranged on one side of the box body; and the containing boxes are arranged on the two sides of the bottom end of the box body. The battery box is convenient for battery mounting, can adapt to batteries of different sizes, and can provide buffer damping and heat dissipation protection functions, so that the service life of the battery is prolonged.

Owner:合肥蓝色梦想信息科技有限公司

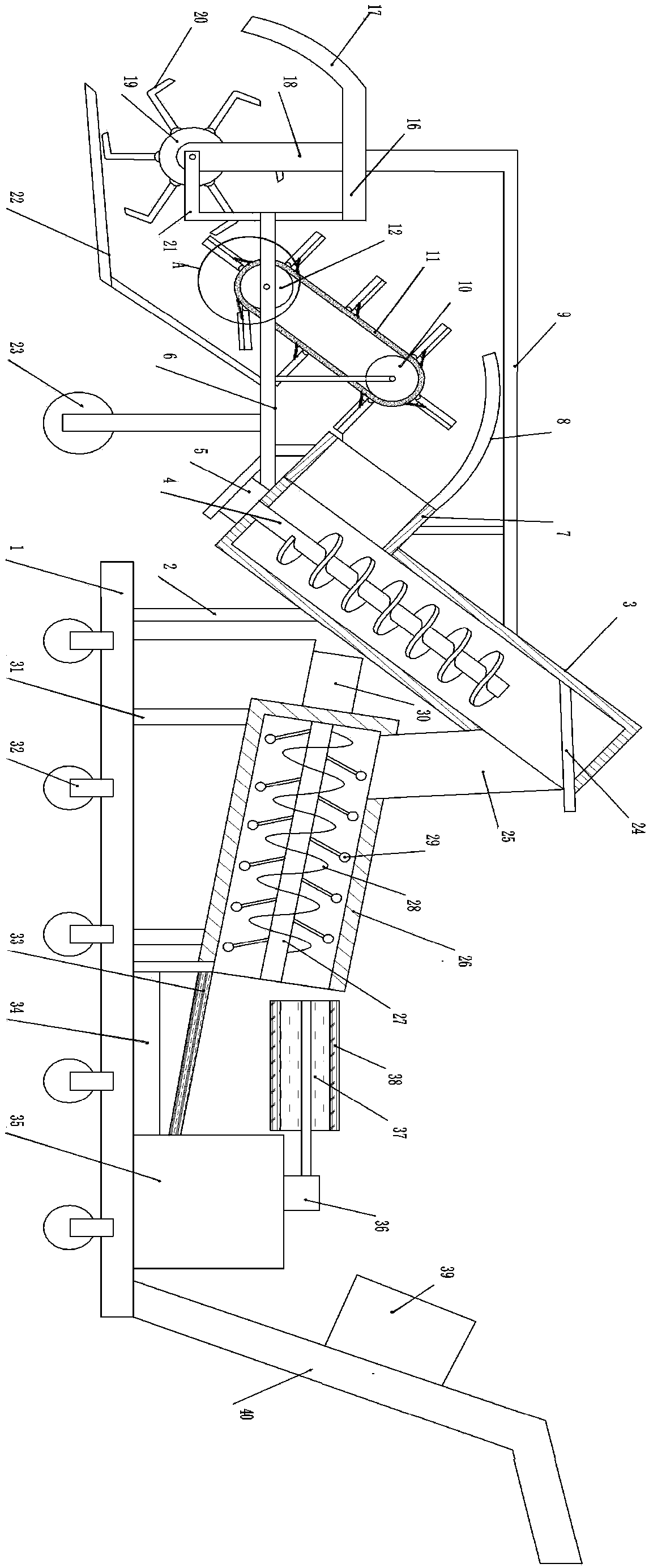

Construction waste sorting device

InactiveCN108187818AEasy to collectImprove delivery efficiencyMagnetic separationGrain treatmentsArchitectural engineeringElectric machinery

The invention discloses a construction waste sorting device. The construction waste sorting device comprises a bottom plate. A fixing supporting rod is fixedly arranged at the top end of the bottom plate. A conveying barrel is obliquely and fixedly arranged at the top end of the fixing supporting rod. A conveying screw rod is arranged in the conveying barrel. A connecting shaft of the conveying screw rod penetrates out of the lowest end of the conveying barrel and is fixedly connected with the output end of a motor A. The motor A is fixedly connected with a positioning transverse rod through aconnecting rod. The construction waste sorting device is reasonable in structure design, convenient and flexible to move, capable of collecting construction waste conveniently, and high in conveyingefficiency, saves time and labor, realizes sorting of the construction waste, does not cause dust pollution in the sorting process, effectively protects the work environment of sorting of the construction waste, guarantees the physical and psychological health of workers, and is high in sorting efficiency. Besides, through a continuously rotary electromagnet, waste iron in the construction waste can be attracted. Through a vibration sieve, dust in the construction waste can be filtered out continuously, and direct recycling of the treated construction waste is effectively guaranteed.

Owner:张志通

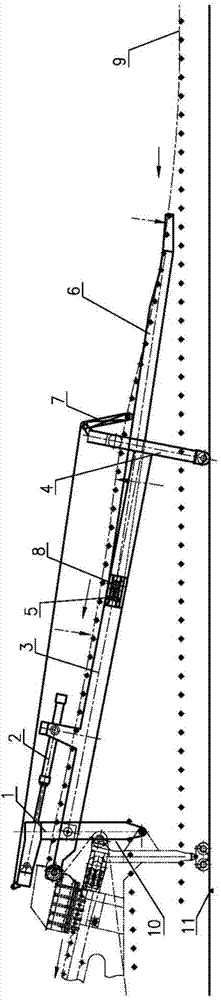

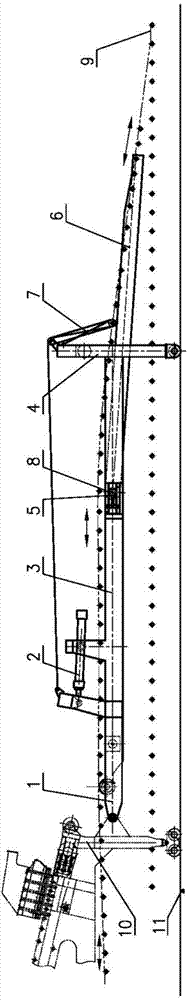

Two-stage lifting two-tail vehicle with two swinging ends for material piling and taking machine

ActiveCN103662859ASolve the problem of shutdown cleanupSimple structureLoading/unloadingEconomic benefitsMaterial scattering

The invention relates to a two-stage lifting two-tail vehicle with two swinging ends for a material piling and taking machine. A front-stage swing tail vehicle beam, namely a T-shaped swing tail vehicle beam 3, is driven by a hydraulic oil cylinder 2 to swing up and down, a rear-stage swing tail vehicle beam, namely a straight-line swing tail vehicle beam 6, swings along with the T-shaped swing tail vehicle beam 3 through a pulley system 7 at the same time, and two-stage swing action is realized by sharing one set of drive, so that material piling, material taking and straight through conditions are synchronously switched. The two-stage lifting two-tail vehicle has the technical and economic benefits that relative heights and angles of a tail vehicle belt conveyor and a ground surface belt conveyor are adjustable, so that an original tail vehicle and a ground surface angle are divided into two parts; the edge tensions of transition sections of the tail vehicle are balanced through the design of the belt conveyor that a concave arc section, a convex arc section and a concave arc section are connected, the distance and angle between the rear end of the tail vehicle and a ground surface belt are adjustable, and the problem of stop cleaning caused by belt flying, material scattering and the like in the transition sections of the ground surface and the tail vehicle is solved. The structure is simple, and the two-stage swing action is realized by utilizing one set of drive, so that material piling, material taking, straight through and straight taking conditions are synchronously switched. Meanwhile, the two-stage lifting two-tail vehicle is beneficial for environmental protection.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

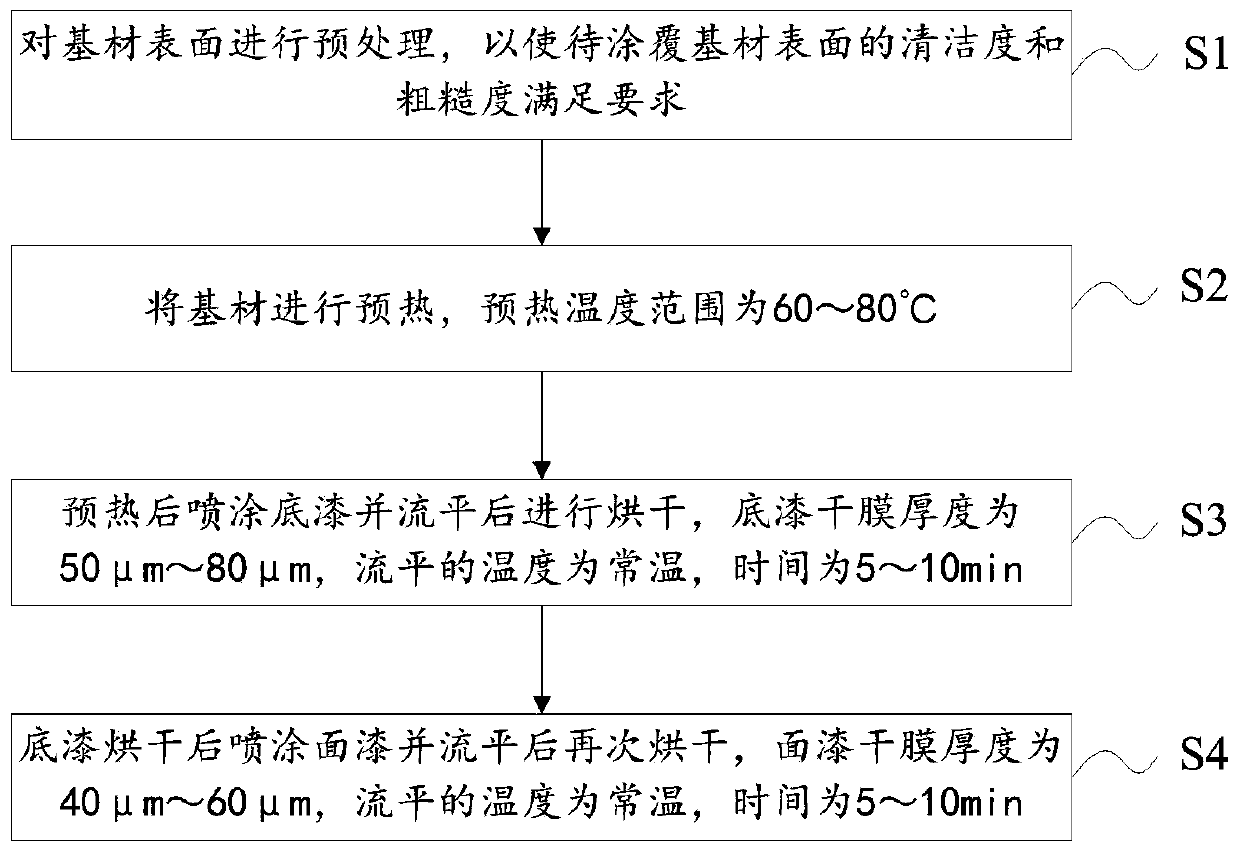

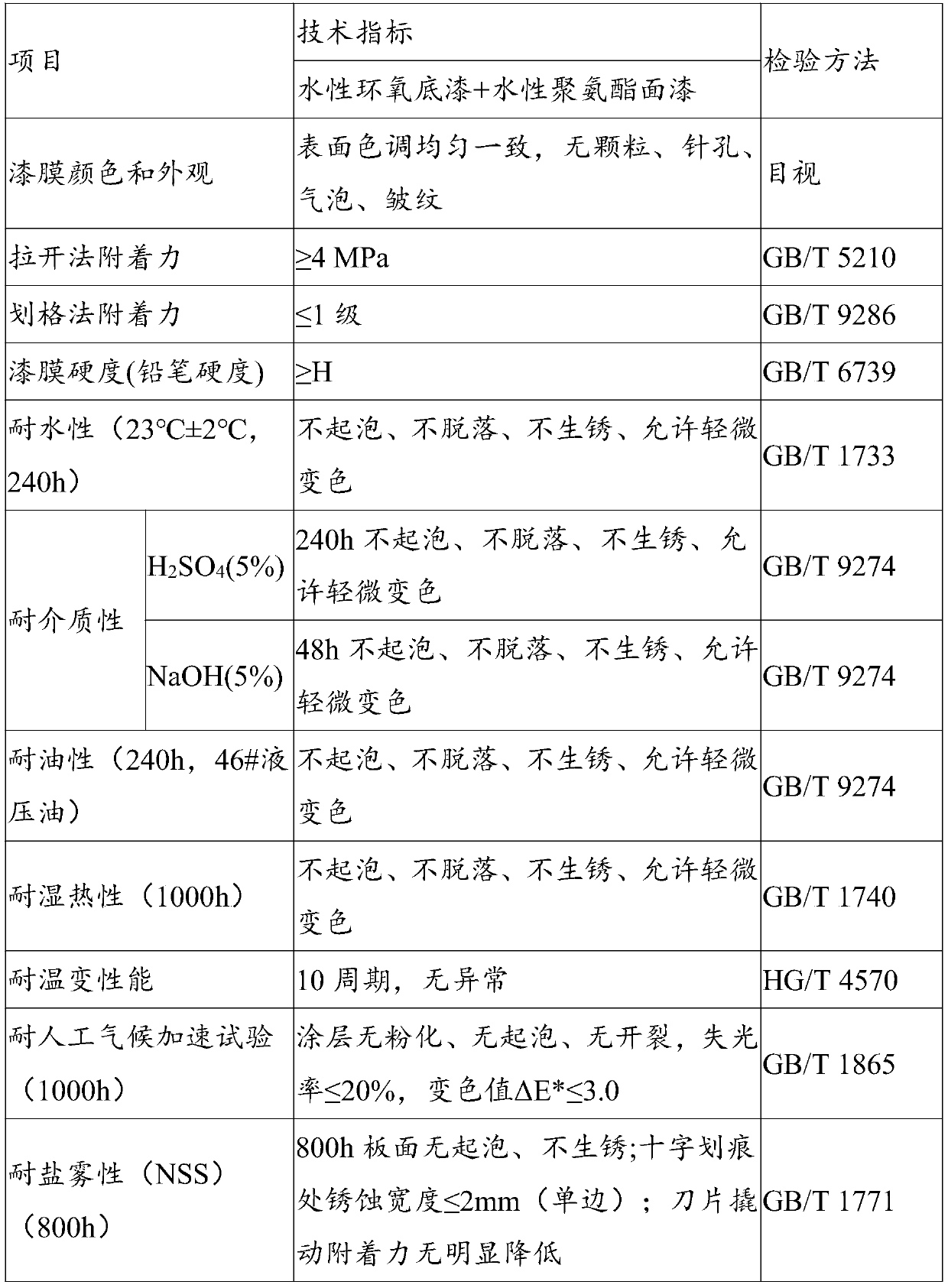

Coating technology of water-based coating for thick steel plate

InactiveCN111250375AEmission reductionReduce pollutionPretreated surfacesCoatingsWeather resistanceThick plate

The invention discloses a coating technology of a water-based coating. The technology comprises the steps that first, the surface of a base material is pre-processed; then, the base material is pre-heated, wherein the pre-heating temperature range is 60-80 DEG C; primer is sprayed after pre-heating is performed, and levelling and drying are performed, wherein the thickness of a dry film of the primer is 50-80 microns, the levelling temperature is the normal temperature, and the levelling time is 5-10 minutes; and after the primer is dried, finish paint is sprayed, and levelling and drying arepreformed again, wherein the thickness of a dry film of the finish paint is 40-60 microns, the levelling temperature is the normal temperature, and the levelling time is 5-10 minutes. By adopting thecoating technology of the water-based coating, by setting reasonable technical parameters, a thick steel plate structure is coated with the water-based coating, the technology is simple and easy to implement, the demand for the construction condition and energy consumption are low, the construction time is shortened, the production efficiency is improved, the product does not have the obvious defect of a paint film, the demand for the oil paint performance of the product such as wear resistance and weather resistance is met, and the cost is effectively lowered for enterprises.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Laser engraving machine

The invention aims to provide a laser engraving machine which is high in code printing efficiency, good in quality and wide in application range. The laser engraving machine comprises a machine frame, a laser engraving unit and a feeding unit, wherein the laser engraving unit is arranged on the machine frame, and the feeding unit right faces the laser engraving unit. The laser engraving unit comprises a laser device and a scanning camera which horizontally move along the machine frame. The feeding unit comprises a feeding belt which right faces the laser device and the scanning camera. The feeding belt is driven by a transmission mechanism on the machine frame. According to the laser engraving machine, using of wastage materials is avoided, and the using cost is greatly reduced; and the code printing quality is high, and compared with label printing or pasting, the phenomena of defacing, scraping, disengagement and the like are avoided.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

RTV coating spraying technology for transformer substation post insulator

ActiveCN105529122AQuality improvementUniform thicknessInsulatorsWorking environmentWorking temperature

The invention discloses a RTV coating spraying technology for a transformer substation post insulator. The technology specifically includes the following steps of A, preparing spraying solution; B, cleaning the surface of the insulator, and covering parts not to be sprayed; C, regulating the working temperature of a spraying device to be more than minus twenty degrees, and regulating the humidity of a working environment to be within the range of 20%-80%; D, using the spraying device for spraying; and E, examining the coating and eliminating defects. According to the RTV coating spraying technology, the thickness of the RTV coating on the surface of the insulator can be uniform, and thereby the service life of the insulator is prolonged.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com