Environment-friendly machine part polishing device based on swinging power

An environmental-friendly technology for mechanical parts, which is applied in the field of environmental-friendly mechanical parts grinding devices, can solve problems such as flying debris, poor environmental protection, and impact on the working environment, and achieve good cleaning effects, good environmental protection, and the effect of protecting the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

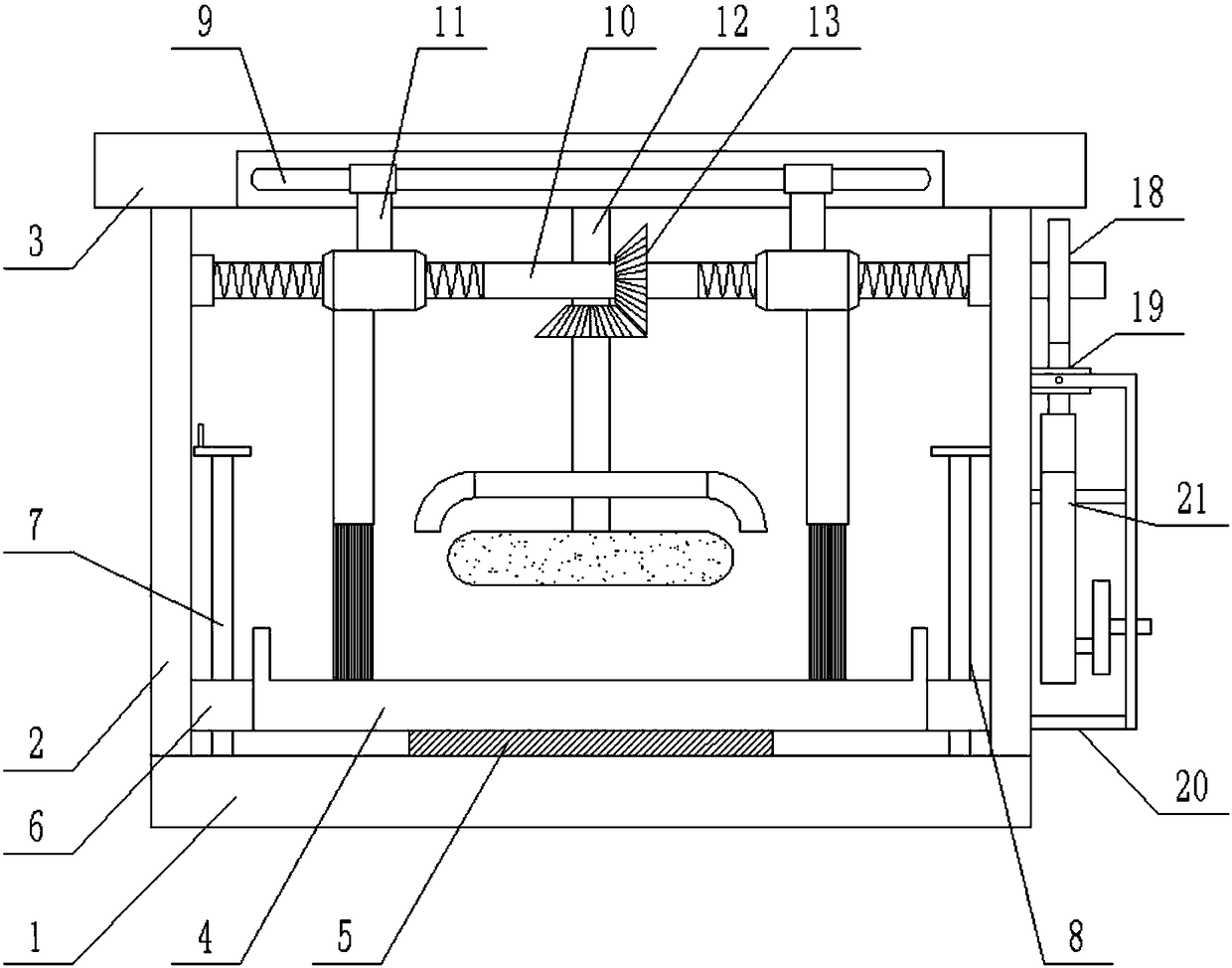

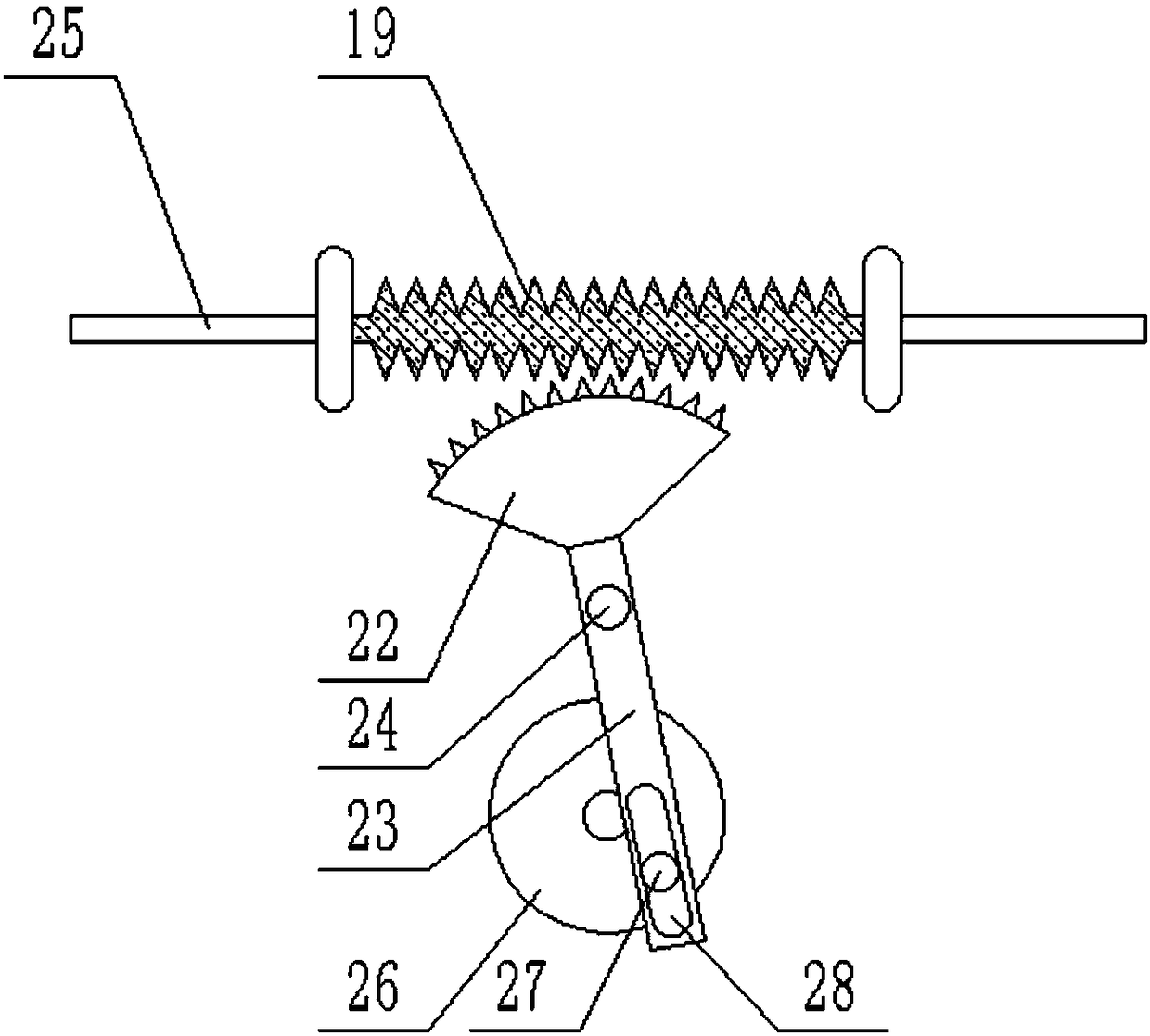

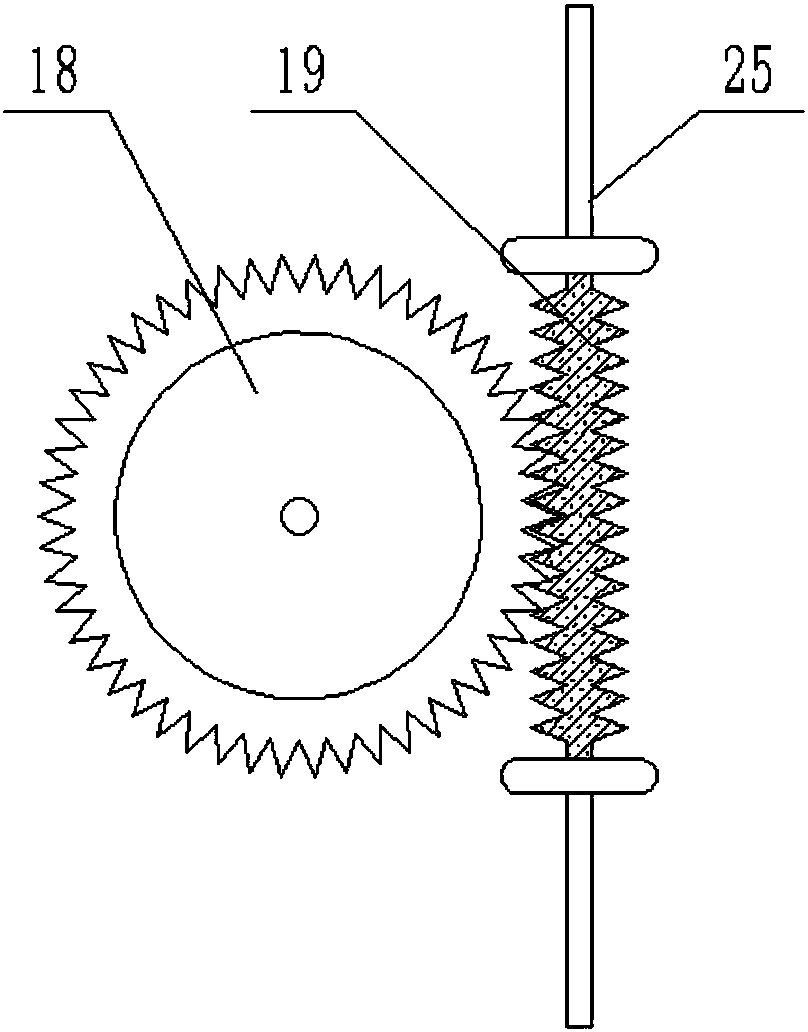

[0022] see Figure 1-3 , an environment-friendly grinding device for mechanical parts based on swing power, comprising a device body, the device body is provided with a base 1, a crossbeam 3 is arranged above the base 1, and the crossbeam 3 and the base 1 are supported by The function of the frame 2 is fixed welding connection, the workpiece groove 4 is set above the base 1, and the bottom of the workpiece groove 4 is provided with a protective pad 5, and the protective pad 5 and the end surface of the base 1 are fixedly connected by glue , the left and right ends of the workpiece groove 4 are provided with sliders 6, which are welded and connected between the slider 6 and the workpiece groove 4, and the slider 6 on the left side is provided with a threaded rod 7, and the threaded rod 7 is connected to the slider 6 are connected through a screw ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com