Automobile axle housing, automobile axle housing forming die and automobile axle housing forming method

A technology for forming molds and axle housings, which is applied to axles, wheels, vehicle parts, etc., can solve the problems of low fatigue life at welds, high welding quality requirements, and low material utilization, and achieves easy implementation, environmental protection of the working environment, and The effect of improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

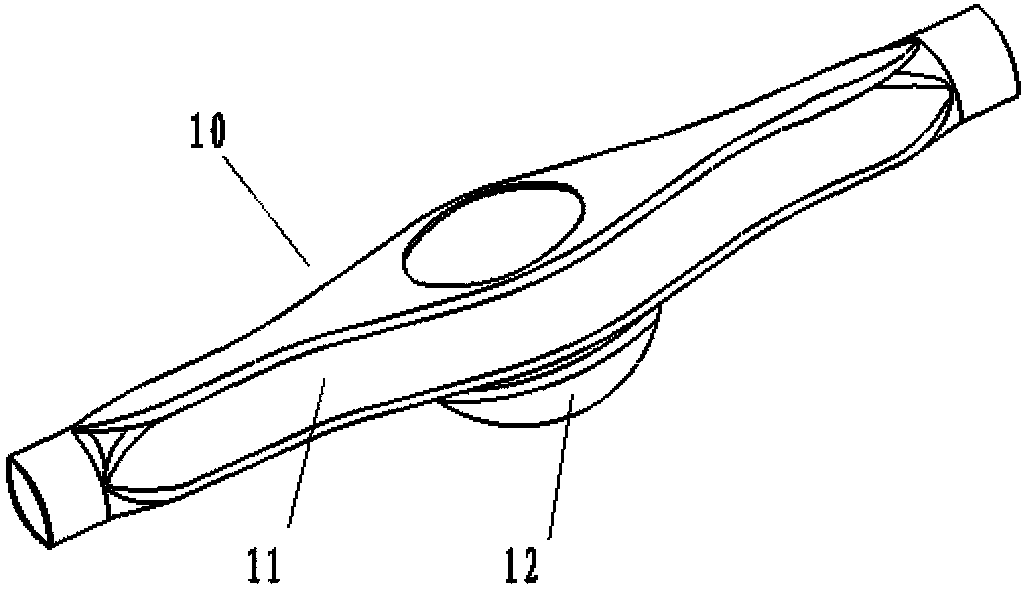

[0038] figure 1 It is a structural schematic diagram of the automobile axle housing body in the embodiment of the present invention. Such as figure 1 As shown, the automobile axle housing 10 of this embodiment is composed of a main body, and the main body is composed of a hollow portion 11 and a raised portion 12 . The hollow part 11 extends along its length direction to form two ends, and is symmetrical about the center line formed by the two ends, and the part between the two ends has a first part connecting the two ends and parallel to each other. side and second side.

[0039] A through hole is provided in the middle of the first side, which is used when the axle housing accommodates the rear axle differential and speed reducer of the automobile. The protruding portion 12 is located on the second side surface corresponding to the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com