Patents

Literature

37results about How to "With sound and heat insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant fiber reinforced inorganic light composite and preparation method thereof

InactiveCN106747031APrevent shrinkageFast condensationSolid waste managementCeramicwareMagnesium chloride hexahydrateFlexural strength

The invention discloses a plant fiber reinforced inorganic light composite which is mainly prepared from magnesium chloride hexahydrate, magnesium sulfate heptahydrate, light calcined magnesia, water, a water reducer, a reinforcing agent, reinforcing fibers, a foaming agent, an exciting agent, a stabilizer and adjusting admixture. The preparation method comprises steps as follows: magnesium chloride hexahydrate, magnesium sulfate heptahydrate and water are mixed to be made into a saline solution; light calcined magnesia, the water reducer and the reinforcing agent are added to the saline solution, the mixture is stirred at a constant speed, and an inorganic sizing material is obtained; the reinforcing fibers are added to the inorganic sizing material and stirred at a constant speed, the adjusting admixture, the stabilizer and the exciting agent are dropwise added slowly, finally, the foaming agent is added quickly, the mixture is stirred at a high speed, and a foamed inorganic sizing material is obtained; the foamed inorganic sizing material is poured into a die, left to stand for foaming, removed from the die and maintained, and the plant fiber reinforced inorganic light composite is obtained. The composite has the advantages of high pressure resistance, high bending resistance, low density, no formaldehyde, aging resistance, mildew resistance, termite resistance, moisture-proof performance, no deformation, sound and heat insulation, good heat preservation and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

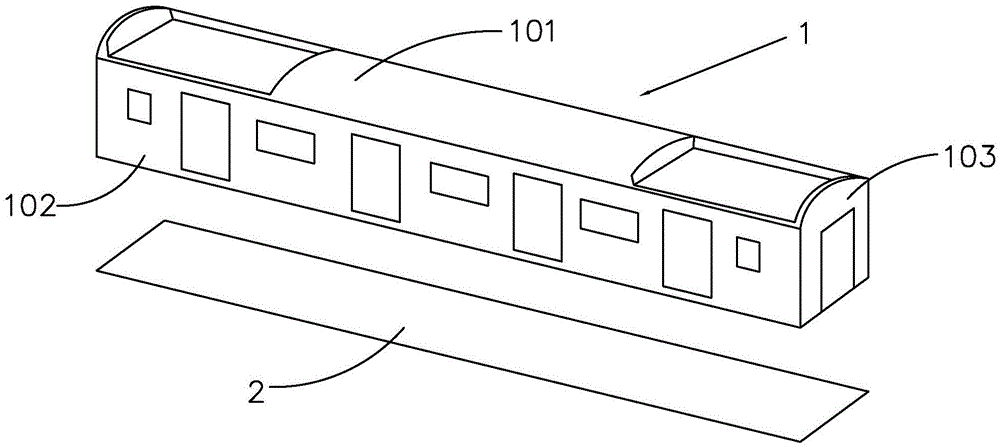

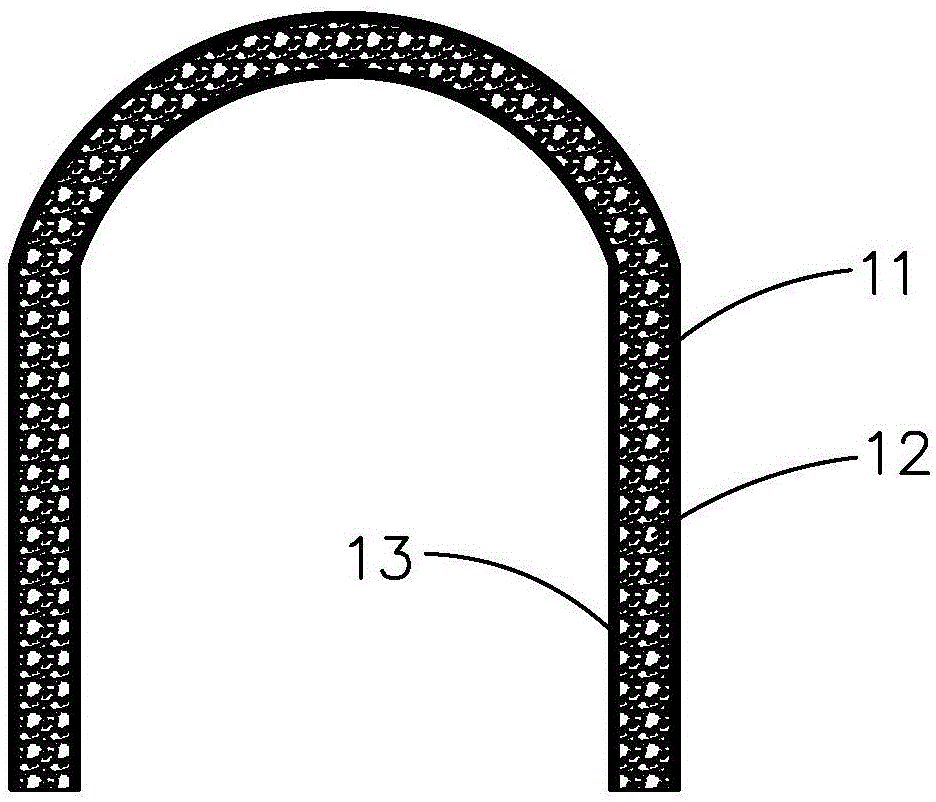

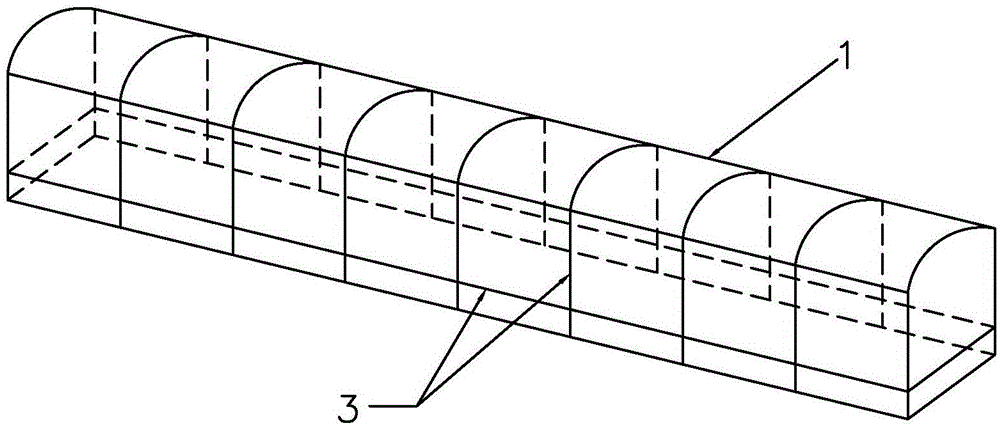

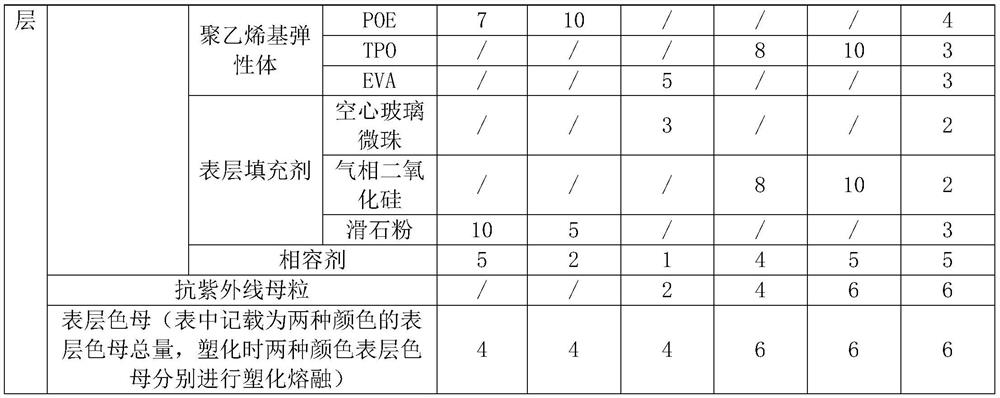

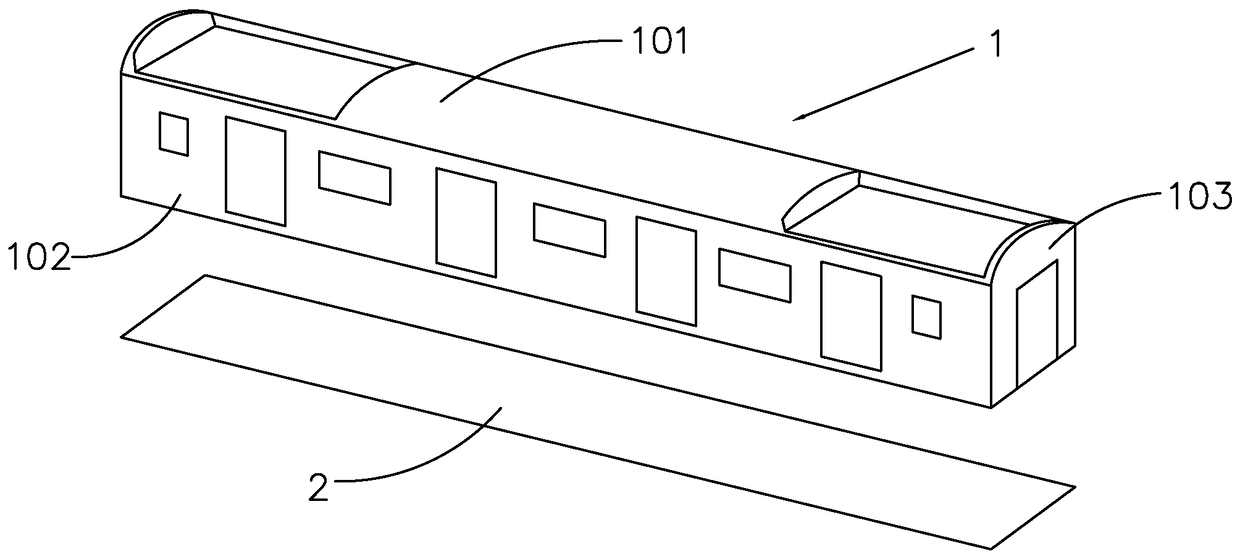

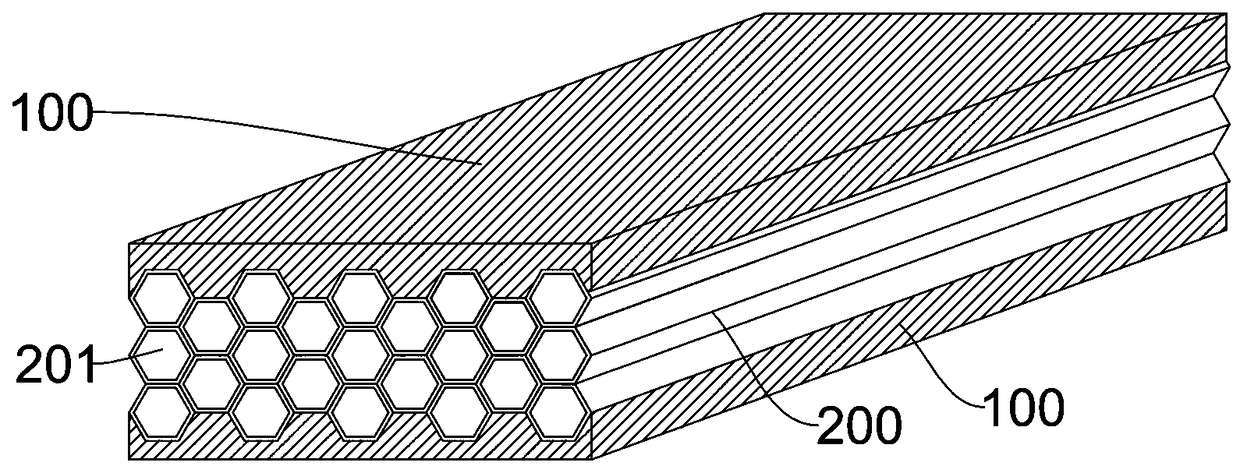

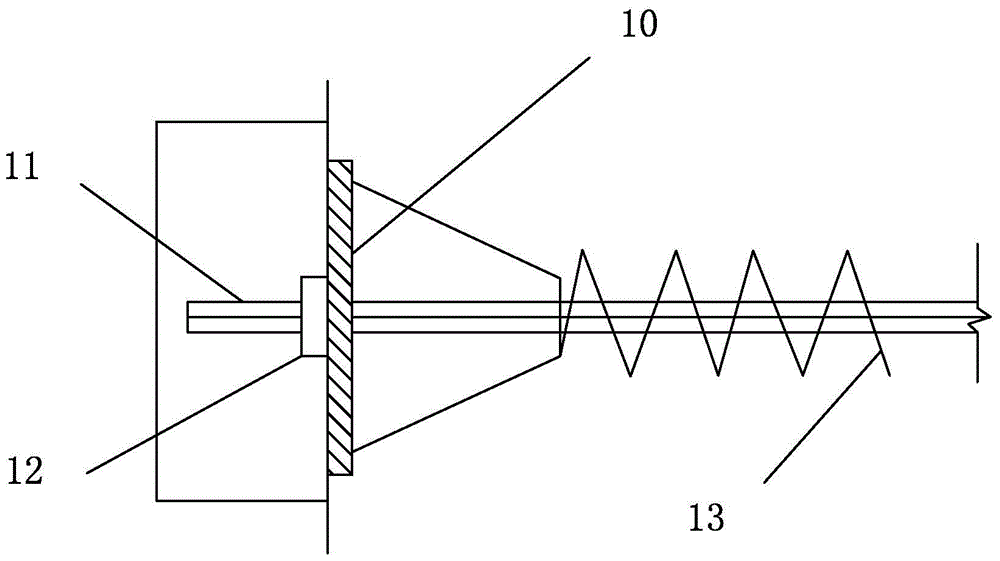

Carbon fiber composite vehicle body and manufacturing method thereof

ActiveCN105128876AWith sound and heat insulationIncreased Strength and RigidityAxle-box lubricationRailway bodiesCarbon fiber compositeMaterials science

The invention discloses a carbon fiber composite vehicle body. The carbon fiber composite vehicle body comprises bodywork and a bottom plate, the bottom plate is connected with the bottom of the bodywork, the bodywork is manufactured through integral forming, the bodywork comprises an outer skin, a sandwich layer and an inner skin which are sequentially arranged from outside to inside, reinforcing ribs are bonded on the inner skin, and the carbon fiber composite vehicle body has the advantages of being high in rigidity and strength, light in mass, soundproof and heat resistant. The carbon fiber composite vehicle body is formed by connecting the bodywork which is manufactured through integral forming with the bottom plate, connecting structures of the vehicle body can be greatly reduced, the rigidity and the strength of the vehicle body are improved, and the safety of the vehicle body is facilitated. The invention further discloses a manufacturing method of the carbon fiber composite vehicle body, the degree of production integration is high, and the method has important meanings on reducing the manufacturing cost and improving the rigidity and the strength of the vehicle body.

Owner:SOUTHWEST JIAOTONG UNIV

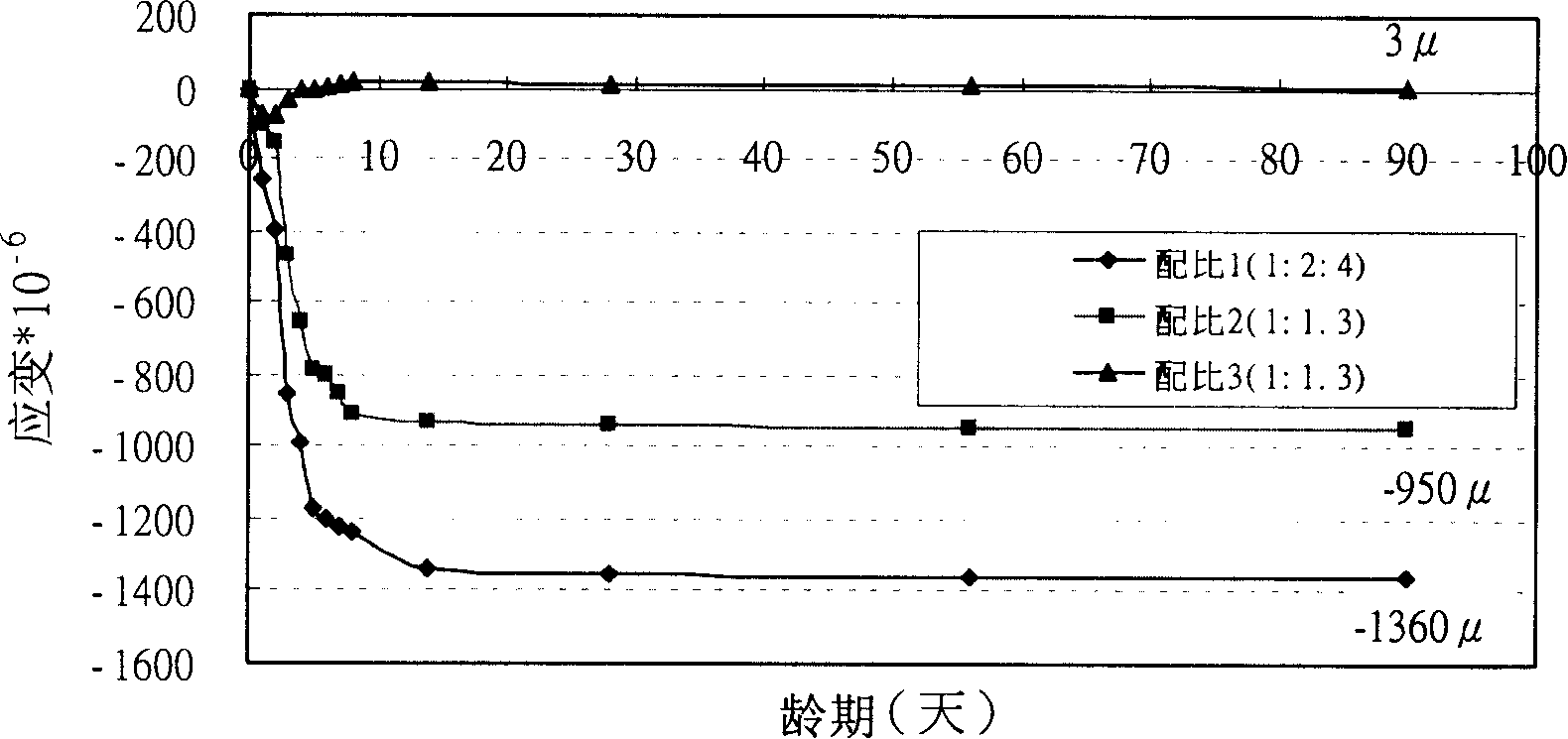

Dry stirring light compartment wall grouting material

ActiveCN101164754AEasy to pumpUniform textureMixing operation control apparatusCement mixing apparatusCelluloseEther

The present invention provides a dry-stirred light partition wall grouting material. It is made up by adding water into the mixture containing aggregate and powder body and stirring them, in which the usage of aggregate is 3-1500kgw / cu.m; in the powder body at least cement is contained, the usage of powder body is 150-1600kgw / cu.m; and the water-solid ratio of said dry-stirred light partition wall grouting material is 0.05-1.0, unit weight is 200-2500kgw / cu.m. Said powder body also can contain pumping aid, said pumping aid is selected from cellulose material, starch ether material or water-soluble polymer, its usage is 0.001%-3.0% of powder body weight.

Owner:RUENTEX MATERIALS CO LTD

A kind of environment-friendly and energy-saving paper-faced wall panel and its manufacturing method

InactiveCN102294858ASimple preparation processHigh speedSynthetic resin layered productsDomestic articlesEnvironmental resistanceEngineering

The invention relates to an environmentally-friendly and energy-saving paper wall board and a manufacturing method thereof. The environmentally-friendly and energy-saving paper wall board is characterized in that a board core is arranged between two composite surface layers composed of coveing papers and non-woven fabrics, the board core is prepared from the following raw materials in parts by weight: 20-50 parts of crop straw, 15-40 parts of light burned magnesium, 3-9 parts of white latex, 10-30 parts of expanded poly styrol powder and 11-33 parts of water, and the thickness of the board core is 60-300mm. Compared with the prior art, the invention has the beneficial effects that: 1) primary compression moulding is adopted, no heating or drying is required; 2) the product has the advantages of environmental friendliness, energy conservation, light weight, high compression strength, low cost and the like; 3) the crop straw and the expanded poly styrol powder are all abandoned resources, thus the effects of environmental protection and energy conservation are achieved; and 4) the environmentally-friendly and energy-saving paper wall board provided by the invention is applicable to multiple civil buildings and can be well matched and connected with various frame structures, steel structures and heterotype structures.

Owner:乔刚

Environment-friendly integrated building lightweight assembly type composite wall material and production technology thereof

The invention discloses an environment-friendly integrated building lightweight assembly type composite wall material. The composite wall material is composed of the following compositions: magnesium oxide, a magnesium sulfate solution, fly ash, sediment, a straw material, a modifier and a foaming agent. The invention also discloses a production technology of the environment-friendly integrated building lightweight assembly type composite wall material. The technology comprises adding clear water into the foaming agent for dilution, so as to prepare a foaming liquid and enabling the foaming liquid to foam and form foams; firstly adding the modifier into the magnesium sulfate solution, stirring uniformly in a machine, then adding magnesium oxide into the stirrer, fully hydrating, and then successively adding fly ash, sediment and the straw material; then adding air; starting a material pump and injecting the material slurry into a molding die, and performing core pulling and demolding; and transporting by a crane after demolding, and then performing maintenance processing. According to the technical scheme, the raw materials magnesium oxide and magnesium sulfate are employed for producing the magnesium oxysulfate wall, the raw materials magnesium oxide, magnesium sulfate, fly ash, sediment and the straw material belong to waste-utilizing environment-friendly products, and the prepared wall material possesses the advantages of light weight, high strength, resistance to shock, resistance to wind, warm keeping, sound insulation, heat insulation and first-grade fire protection.

Owner:南通市朗极新型建材有限公司

Method for preparing desulfurization gypsum beta-powder

The invention discloses a preparation method for desulfurized gypsum Beta powder, and the steps are as follows: A. base material preparation: screening and warehousing the desulfurized gypsum of a power station with the fineness being 40 to 60 Mum, piling upwards by a piling shed and airing, and dehydrating some adhesive water (less than or equal to 10 percent). B. feeding the desulfurized gypsum which is aired and dehydrated off some adhesive water into an airflow rotational flow dynamic flash burning furnace in uniform motion, the inletting temperature when feeding materials is 400 to 500 DEG C, calcining (for 1 to 6 seconds), the discharge is controlled at temperature of 160 to 220 DEG C, then homogenizing and aging, thus preparing the desulfurized gypsum Beta powder by packaging. The method of the invention has the advantages of simple and easy execution, convenient operation and being suitable for mass production, and aims at comprehensively processing and applying smoke gas desulfurized gypsum in the industrial waste of the power station to lead the smoke gas desulfurized gypsum to replace natural dihydrate gypsum for becoming another gypsum building material and material used for ceramic die, thus solving the problems of resource shortage of high quality natural dihydrate gypsum and comprehensive processing hysteresis of the smoke gas desulfurized gypsum of the power station, changing waste into valuables and accelerating the development of cyclic economy.

Owner:黄梅龙源石膏有限公司

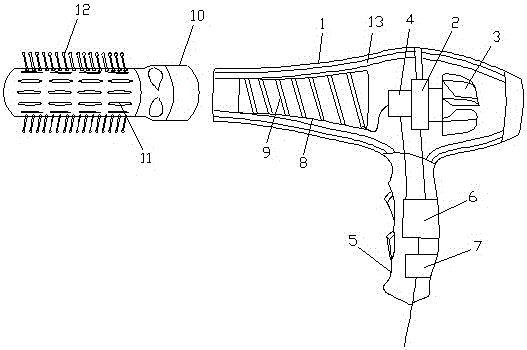

Intelligent electric hair drier

The invention discloses an intelligent electric hair drier. The intelligent electric hair drier comprises a shell, a motor, blades, and a transformer, wherein the motor and the transformer are mounted in the shell; the blades are mounted at one end of the motor; a handle is mounted at the bottom of the shell; a PLC controller and a WIFI module are mounted in the handle; the motor and the transformer are electrically connected with the PLC controller separately; a metal sleeve is also mounted in the shell; spiral electric heating wires are mounted in the metal sleeve; the electric heating wires are electrically connected with the transformer; an air barrel is mounted at the front end of the shell; ventilating holes and combing teeth are mounted outside the air barrel; and a soundproof cotton layer is arranged on the inner side of the shell. The intelligent electric hair drier has the sound insulation and thermal insulation functions, can comb hairs and dry hair rapidly, and has a networking function.

Owner:CHENGDU DUOMAO CULTURE COMM CO LTD

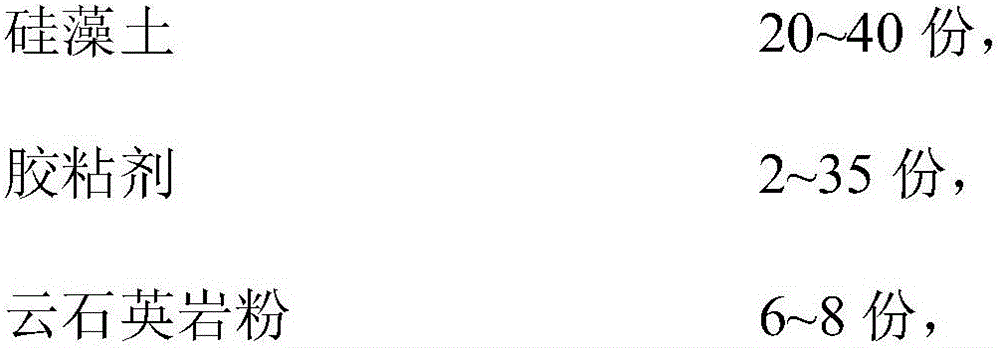

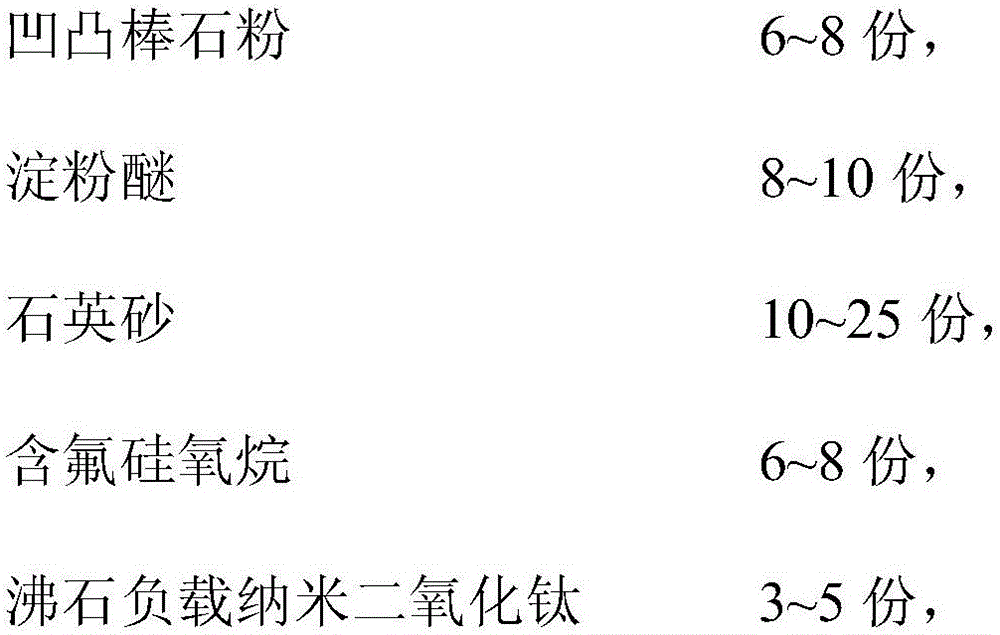

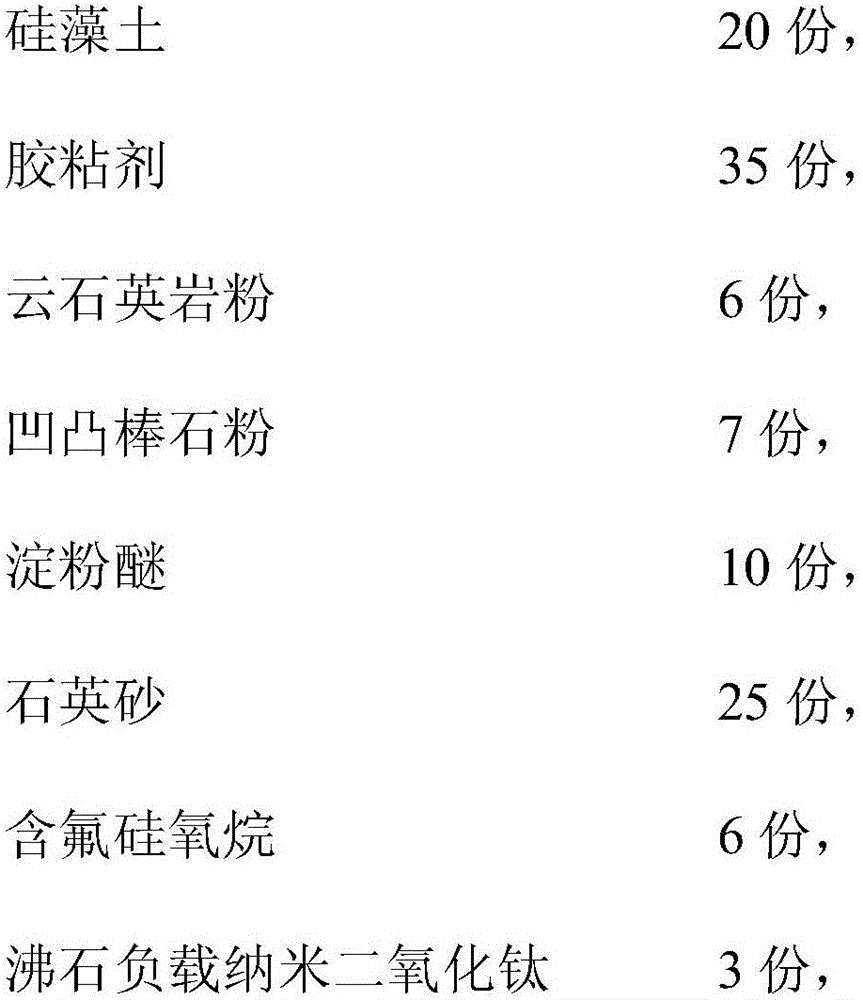

Environment-friendly diatom ooze decorative wall material

InactiveCN106007559AImprove adsorption capacityWith sound and heat insulationHazardous substanceAntibacterial activity

The invention relates to the field of coatings, and discloses an environment-friendly diatom ooze decorative wall material. The environment-friendly diatom ooze decorative wall material is prepared from components in parts by weight as follows: 20-40 parts of diatomite, 2-35 parts of an adhesive, 6-8 parts of marble quartzite powder, 6-8 parts of attapulgite powder, 8-10 parts of starch ether, 10-25 parts of quartz sand, 6-8 parts of fluorine-containing siloxane and 3-5 parts of zeolite-loaded nanometer titania. The energy-saving and environment-friendly diatom ooze decorative wall material contains no harmful substances and has the advantages of good cohesiveness, high formaldehyde removal efficiency, high antibacterial activity and deodorization performance and excellent self-cleaning and purification durability, and the performance index meets requirements specified in the JC / T2177-2013 standard.

Owner:HANGZHOU MAKEDOLLAR ENVIRONMENTAL PROTECTION NEW MATERIAL

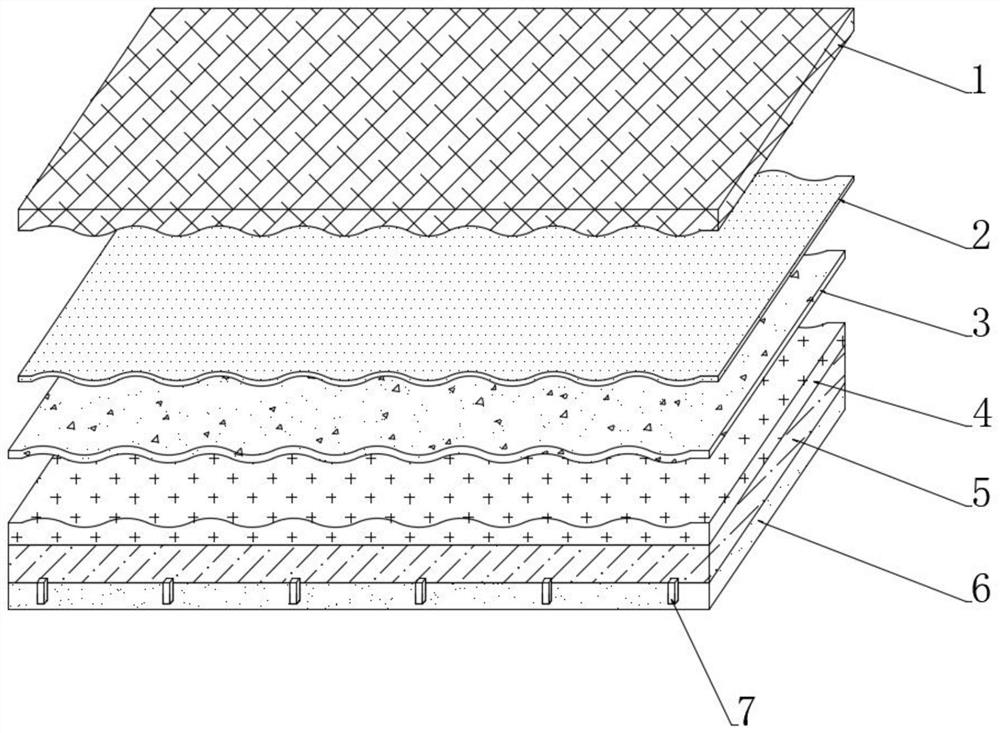

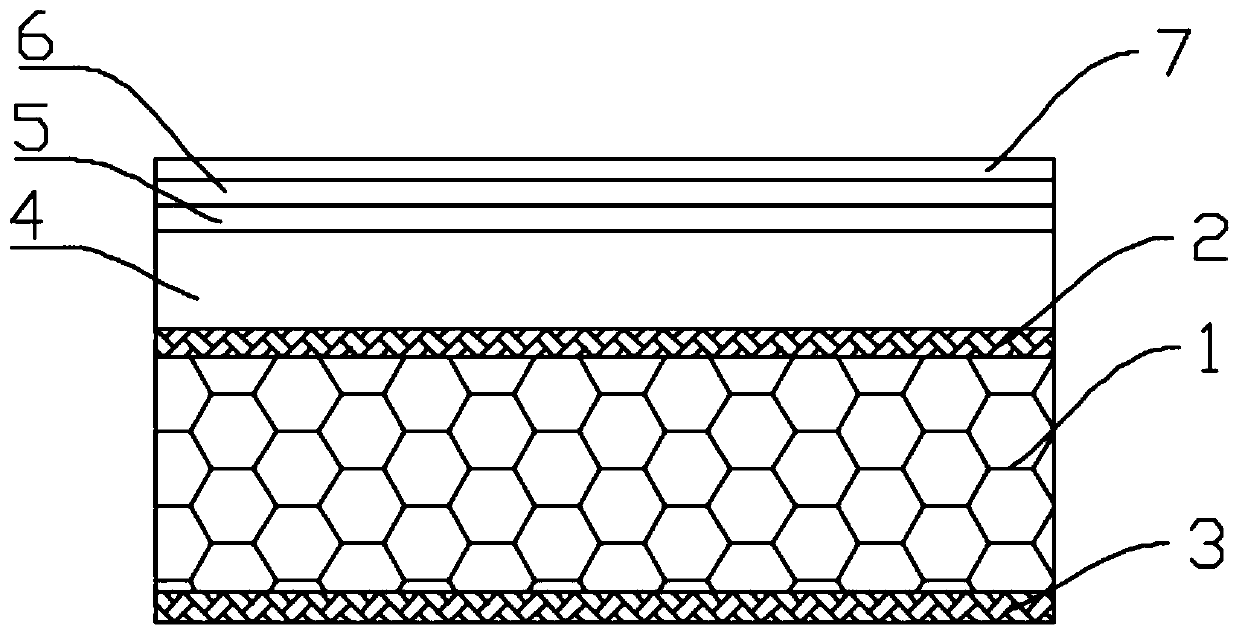

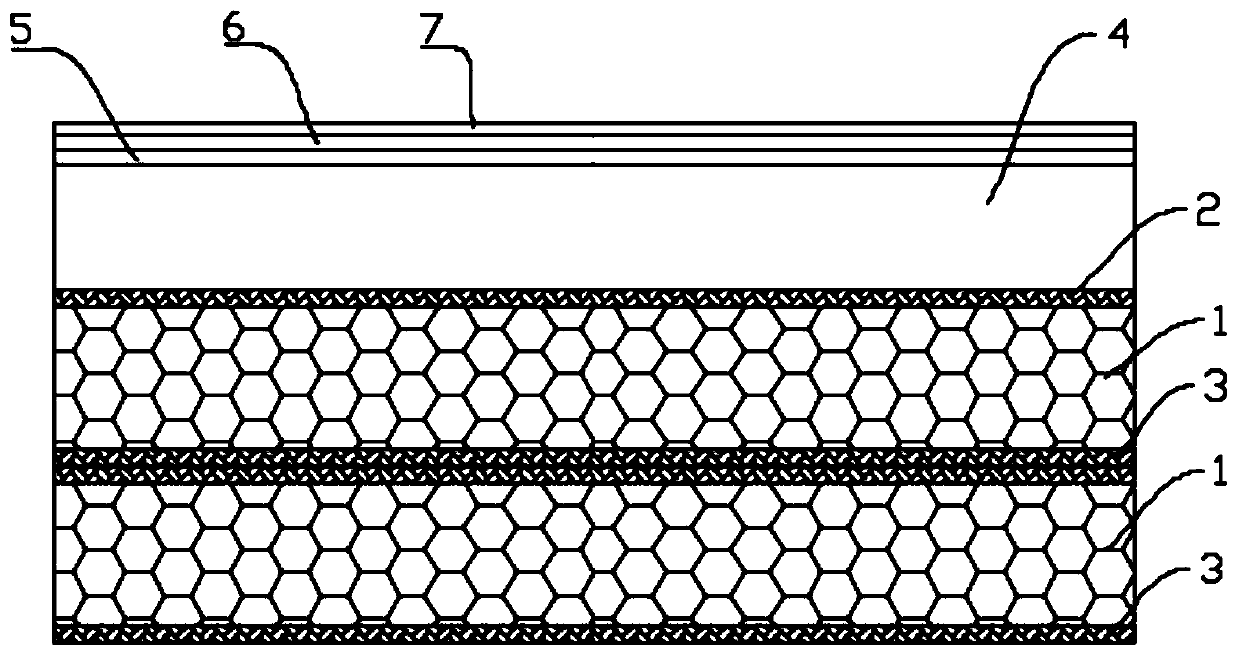

Multi-layer composite building insulation board and preparation method thereof

InactiveCN112389049AImprove insulation performanceHigh mechanical strengthCovering/liningsLamination ancillary operationsScreedArchitectural engineering

The invention discloses a multi-layer composite building insulation board and a preparation method thereof, and belongs to the technical field of insulation boards, the outer layer of the insulation board is provided with a polymer mortar layer, an extruded sheet layer and an outer decorative sheet layer which are in grouting embedded connection, and the bottom end part of the polymer mortar layerextends into the extruded sheet layer and the outer decorative sheet layer; reinforcing steel bar reinforcing pieces are arranged in the upper grouting cavity and the lower grouting cavity to be matched with multiple glass microsphere bags, so that on one hand, the properties of heat insulation, sound insulation, corrosion prevention and the like of the outer layer of the insulation board are effectively enhanced, and on the other hand, the mechanical strength of connection between every two of the polymer mortar layer, the extruded sheet layer and the outer decorative sheet layer is effectively improved; the phenomenon that the outer layer of the heat preservation plate is prone to falling off in the long-term use process is effectively avoided to a certain extent, meanwhile, the inner base plate layer aerogel layer is arranged on the inner side of the heat preservation plate, the aerogel layer is made of a porous and disordered low-density aerogel material of a nano-scale continuousnetwork structure, and the heat insulation effect of the heat preservation plate can be better enhanced.

Owner:陈钲仁

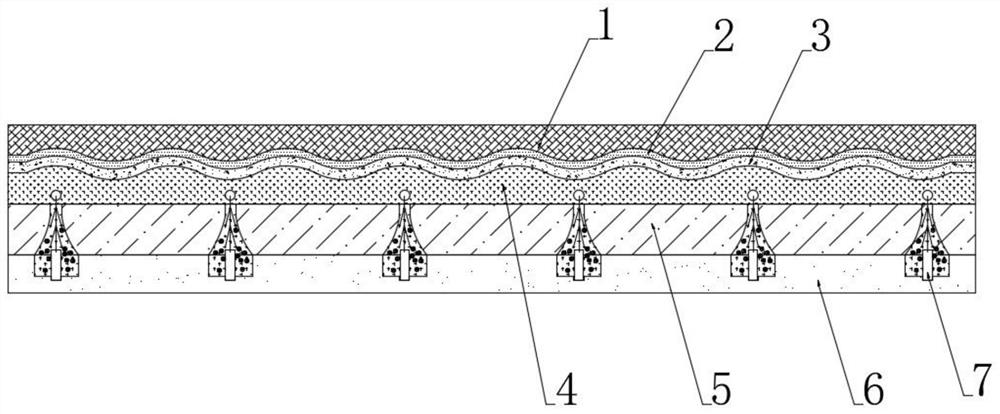

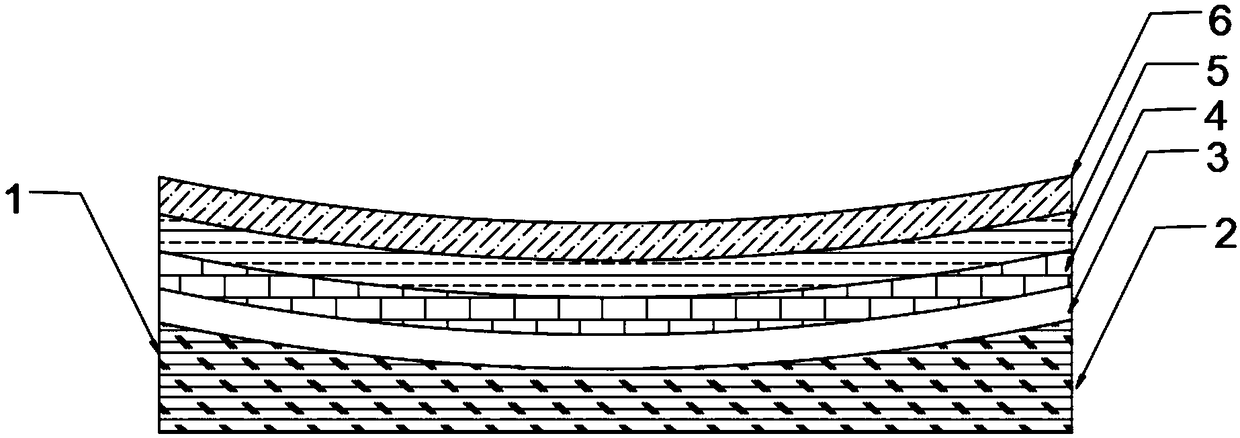

Concave curved-roof-surface waterproof structure and construction technology thereof

InactiveCN108979017AImprove performanceGood weather resistanceBuild-up roofsRoof covering insulationsEngineeringSteel frame

The invention relates to the technical field of building designing, in particular to a concave curved-roof-surface waterproof structure and a construction technology thereof. The concave curved-roof-surface waterproof structure comprises a waterproof structure body, a concrete layer is arranged at the bottom of the waterproof structure body, a waterproof layer is connected to the top face of the concrete layer, a heat preservation layer is arranged on the top face of the waterproof layer, a rigid waterproof layer is arranged on the top face of the heat preservation layer, and a house decorating layer is connected to the top face of the rigid waterproof layer. The construction technology of the waterproof structure body includes the following steps that steel is rolled, a steel frame is placed, concrete is poured, the top face of the concrete is poured into a concave curved structure after fine building, the waterproof layer is laid, the heat preservation layer is sprayed, concrete is poured, and the decorating layer is laid. According to the concave curved-roof-surface waterproof structure and the construction technology thereof, the waterproof layer is directly arranged on the concrete structure layer, construction is simple, the construction procedure is simple, and the waterproof effect of the curved roof surface is good.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

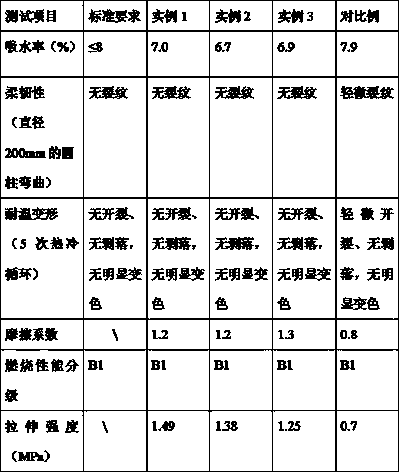

Method for preparing flexible veneer sheet from modified mineral powder

The invention belongs to the field of construction materials and specifically relates to a method for preparing a flexible veneer sheet from modified mineral powder. The method provided by the invention comprises the following steps: pulverizing and calcining minerals such as colored sand and quartz stone, and then spraying substances such as castor oil on the surface of the mineral powder to obtain a modifier; performing aging and rolling to obtain the modified mineral powder; and taking the modified mineral powder, redispersible latex powder and a fireproof emulsion as main raw materials toprepare the flexible veneer sheet. After the mineral powder is modified, the friction resistance and the fluidity of the mineral powder are improved, and the compatibility between the mineral powder and the emulsion as well as the redispersible latex powder also can be improved; and after the modified mineral powder is added into the flexible veneer sheet, the rupture strength and the friction resistance of the flexible veneer sheet can be improved, so that the method provided by the invention has wide application prospects.

Owner:重庆市璧山区鸿丰汽车配件制造有限公司

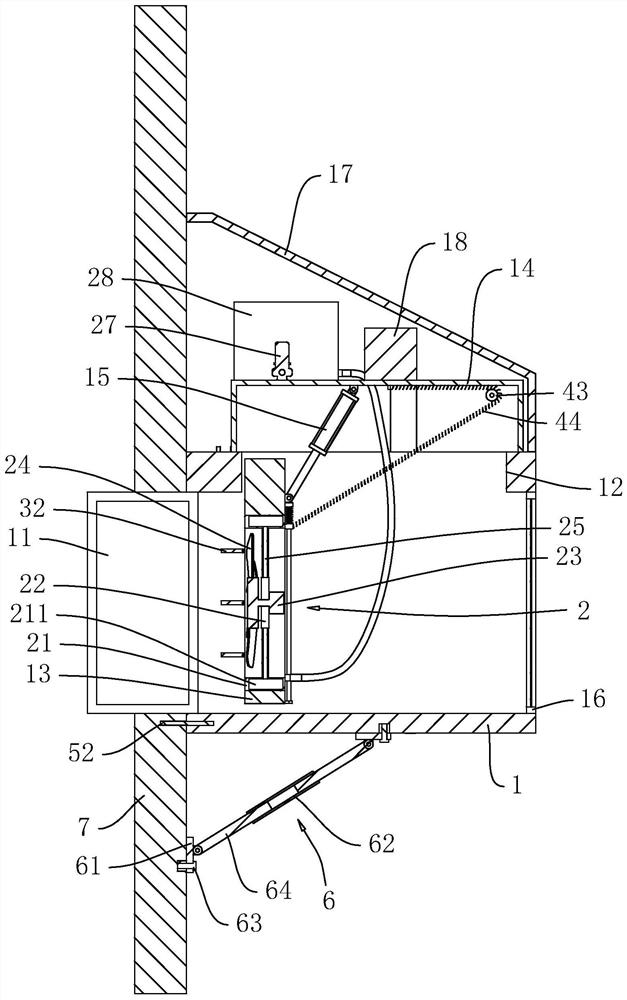

Ventilation energy-saving system of green building

ActiveCN112432266AReduce dependenceReduce the use effectLighting and heating apparatusFree-cooling systemsStructural engineeringMechanical engineering

The invention relates to a ventilation energy-saving system of a green building. The ventilation energy-saving system is applied to the technical field of building ventilation, and comprises a prefabricated frame fixed on a building wall body, an aluminum alloy window is arranged at the end, close to the indoor space, in the prefabricated frame, a through groove is formed in the inner top wall ofthe prefabricated frame, a frame is hinged to the position, in the through groove, of the prefabricated frame, and a fan is arranged in the frame; and a bearing seat is arranged on the prefabricated frame, a servo cylinder is hinged to the bottom face of the bearing seat, and driving rods of the servo cylinder are hinged to the frame. The ventilation energy-saving system has the effect of reducingresource waste caused to the building wall body.

Owner:南京金海设计工程有限公司

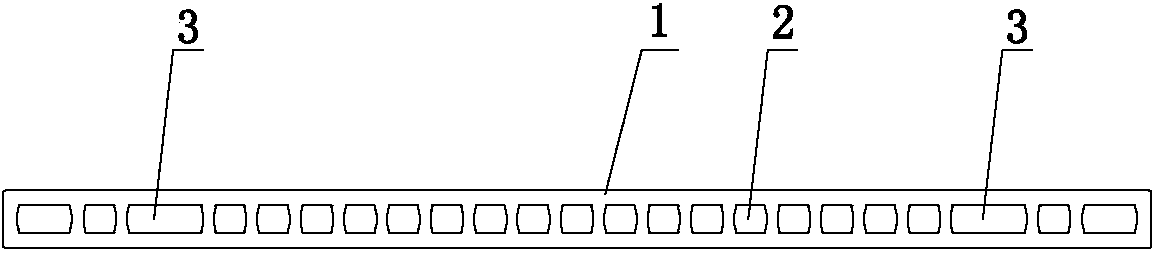

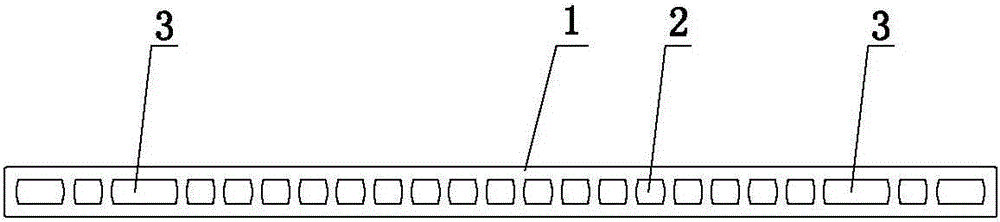

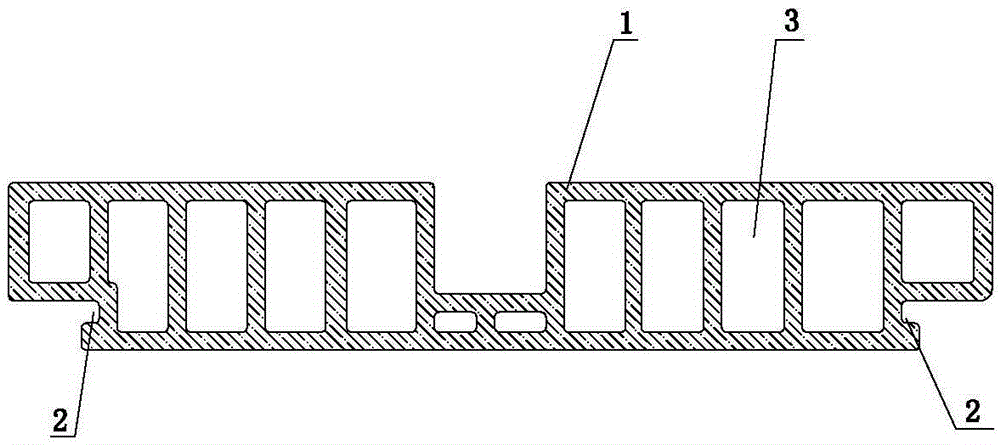

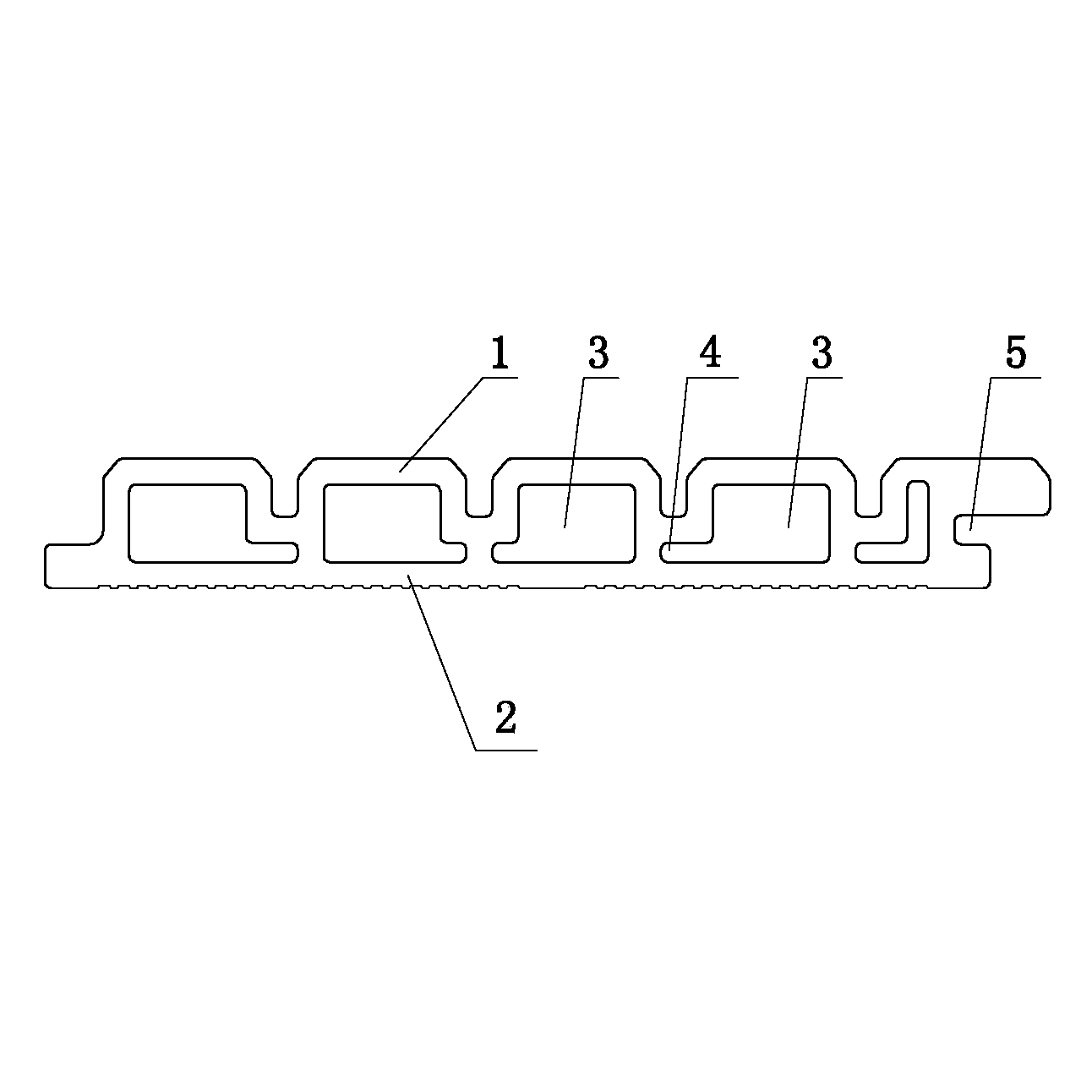

Flat type ceramic decorating plate

The invention discloses a flat type ceramic decorating plate which is characterized by comprising a ceramic plate body (1). A plurality of abreast through holes (2) are formed in one lateral wall of the ceramic plate body (1), the through holes (2) are formed in flat plate sides along two sides of the ceramic plate body (1), the flat plate sides are straight sides, and other two sides are arc sides. The flat type ceramic decorating plate is simple in structure, practical, attractive and elegant in appearance, suitable for indoor and outdoor decoration and wide in use range and has the advantages of being resistant to sound and heat, water-proof and breathable.

Owner:江苏富陶科陶瓷有限公司

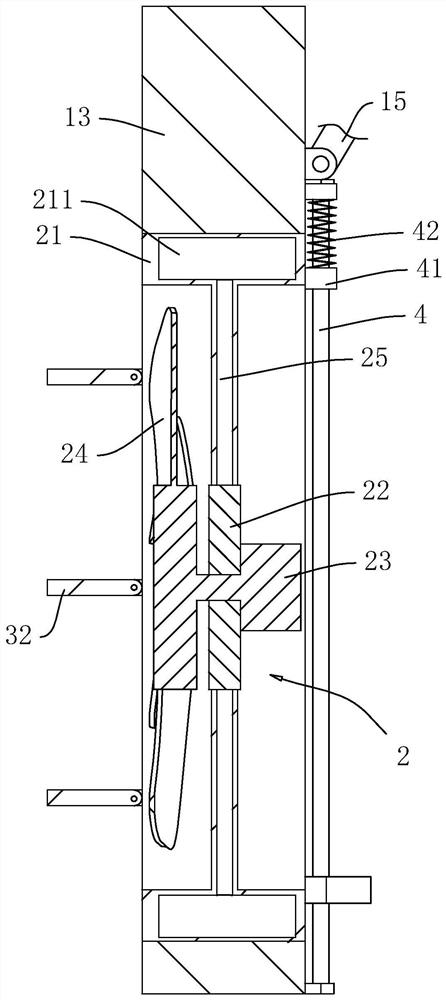

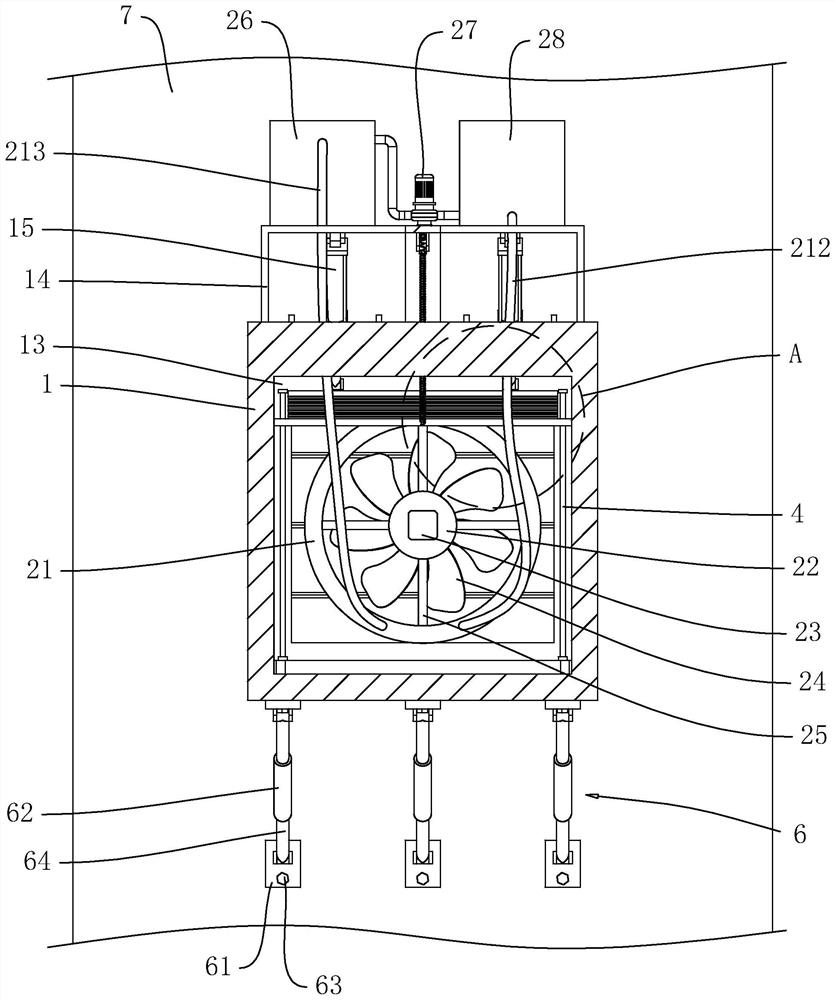

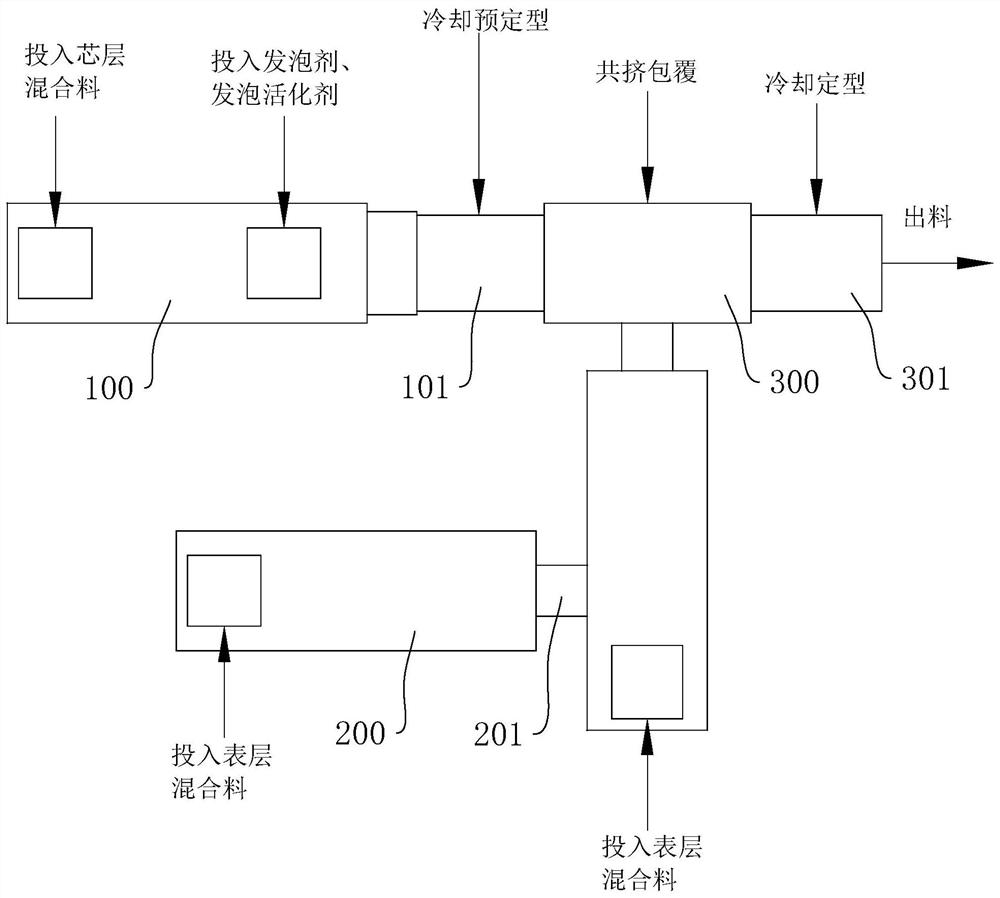

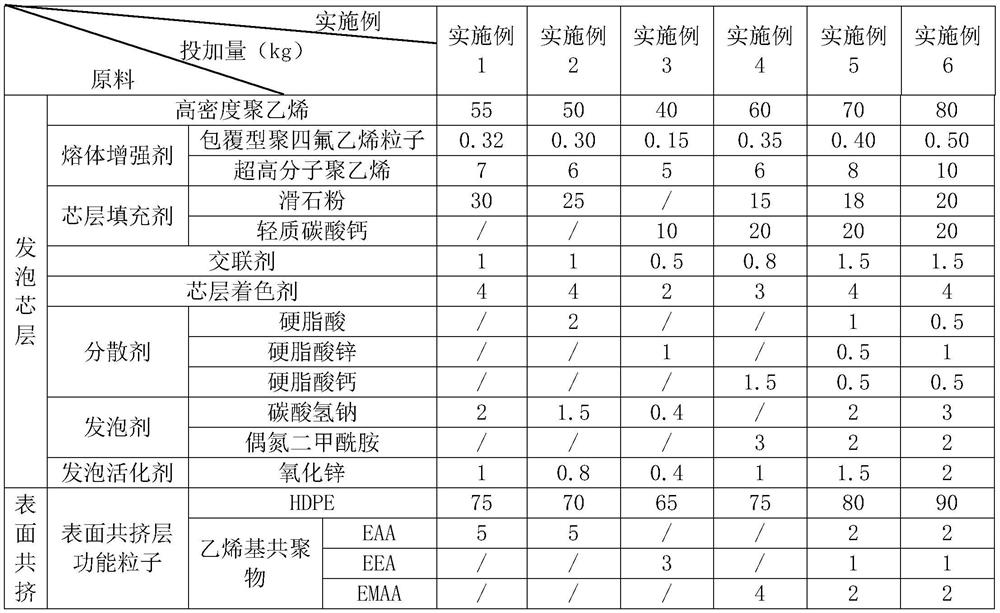

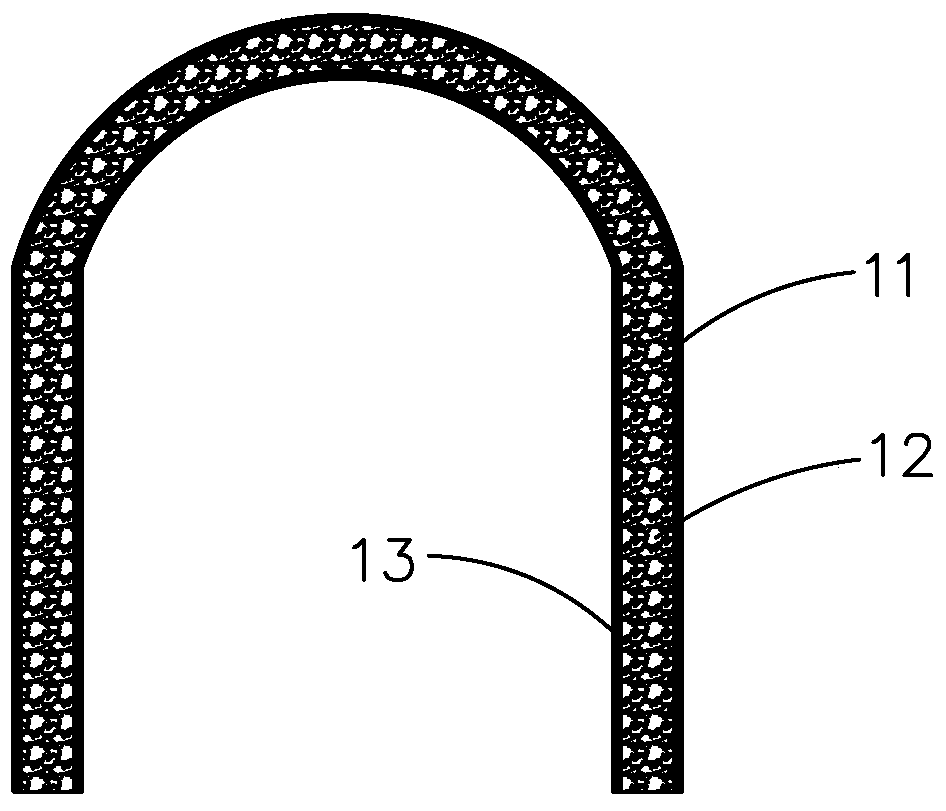

Wood-grain-like HDPE co-extrusion foam board and preparation method thereof

PendingCN114043696AWith energy-saving insulationWith sound and heat insulationFlat articlesElastomerPolymer science

The invention relates to a wood-grain-like HDPE co-extrusion foam board and a preparation process thereof, and belongs to the field of foam boards. The wood-grain-like HDPE co-extrusion foam board comprises a foaming core layer and a surface co-extrusion layer, wherein the foaming core layer is prepared from the following raw materials: high-density polyethylene, a melt reinforcing agent, a core layer filling agent, a foaming agent, a foaming activating agent and a cross-linking agent; and the surface co-extrusion layer is prepared from the following raw materials: HDPE, a vinyl copolymer, a polyvinyl elastomer, a surface filler and surface color master batches with two colors. The preparation method comprises the following steps of: preparing materials; melting, foaming, cooling and pre-shaping a core layer mixture to obtain a foamed core layer; mixing and extruding two molten surface co-extrusion materials with different colors, and coating the surface of a foaming core layer base body to form a wood-grain-like surface co-extrusion layer; and cooling and shaping the wood-grain-like surface co-extrusion layer. The wood-grain-like HDPE co-extrusion foam board is good in heat preservation and sound insulation effect, has better wear resistance and surface hardness compared with a traditional foam board, is more economical in manufacturing cost and has a wider application value.

Owner:NINGBO HELONG NEW MATERIAL

A carbon fiber composite car body and its manufacturing method

ActiveCN105128876BWith sound and heat insulationIncreased strength and rigidityAxle-box lubricationRailway bodiesManufacturing cost reductionUltimate tensile strength

Owner:SOUTHWEST JIAOTONG UNIV

Flat type ceramic decorative board

Owner:江苏富陶科陶瓷有限公司

Preparation method of desulphurization gypsum beta powder

The invention relates to a preparation method of desulphurization gypsum beta powder. The method comprises the following steps: (1) preparing basic materials: selecting and warehousing desulphurization gypsum; (2) calcining, scattering, drying and rolling to remove the crystallization water through a one-step secondary temperature increasing method by adopting an airflow rotational-flow dynamic flash roasting furnace to form semi-water desulphurization gypsum powder, and homogenizing, aging and packaging the desulphurization gypsum powder to obtain the desulphurization gypsum beta powder. The method is easy, convenient to operate and applicable to the mass production. The preparation method is used for comprehensively processing and utilizing the industrial waste residue-smoke desulphurization gypsum of a power plant and utilizing the desulphurization gypsum to substitute the natural dihydrate gypsum to become a gypsum building material and a material for ceramic mold, so that the problems that the dehydrate gypsum resource is in shortage and the smoke desulphurization gypsum comprehensive treatment of the power plant is lagging can be solved, the waste can be converted into treasures, and the cycling economic development can be promoted.

Owner:邱伟

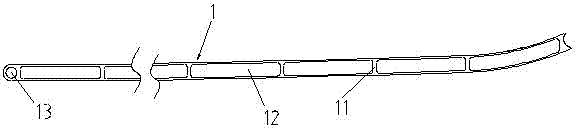

Fiber cavity door plate

InactiveCN104295199AWith sound and heat insulationAdvanced production technologyDoor leavesThermal insulationEngineering

The invention relates to a fiber cavity door plate. The cavity door plate is formed by two wood plate bodies and wood frames on two sides of the wood plate bodies, vertical reinforcing ribs are arranged in the middle of the cavity door plate at a certain interval, a die is arranged between every two adjacent reinforcing ribs, two sides of the reinforcing ribs and the dies are covered with fiber layers, the outer surfaces of the fiber layers are attached to the wood plates, and the periphery of the cavity door plate is sealed with wood strips. The fiber cavity door plate is advanced in production process, attractive in model, solid, durable, low in price and not prone to deforming and has soundproof and thermal-insulation functions.

Owner:王笑天

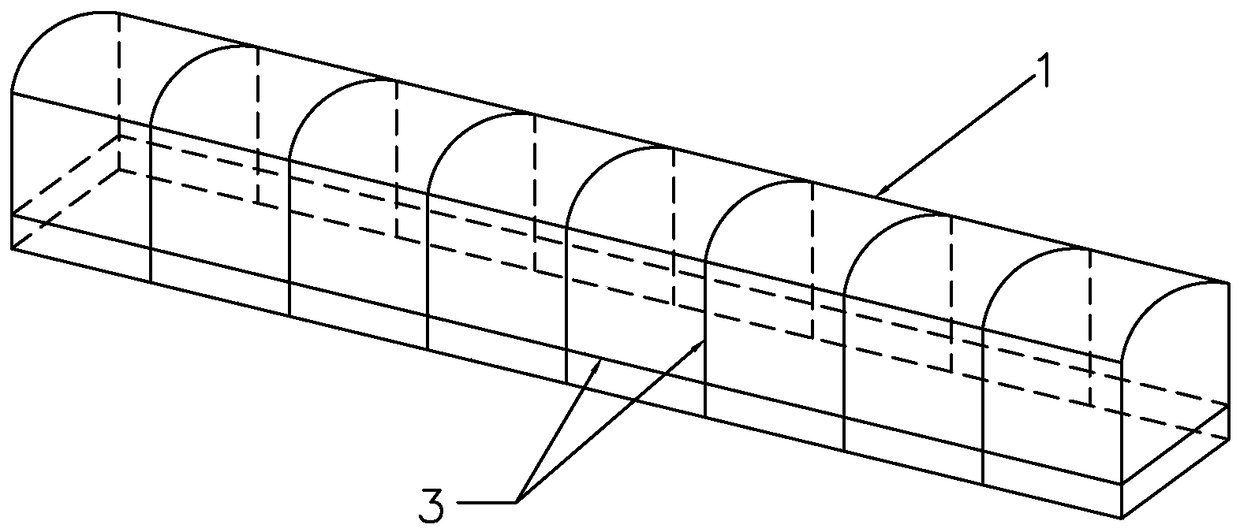

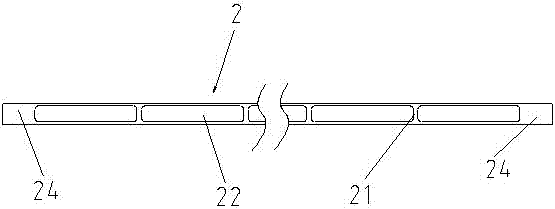

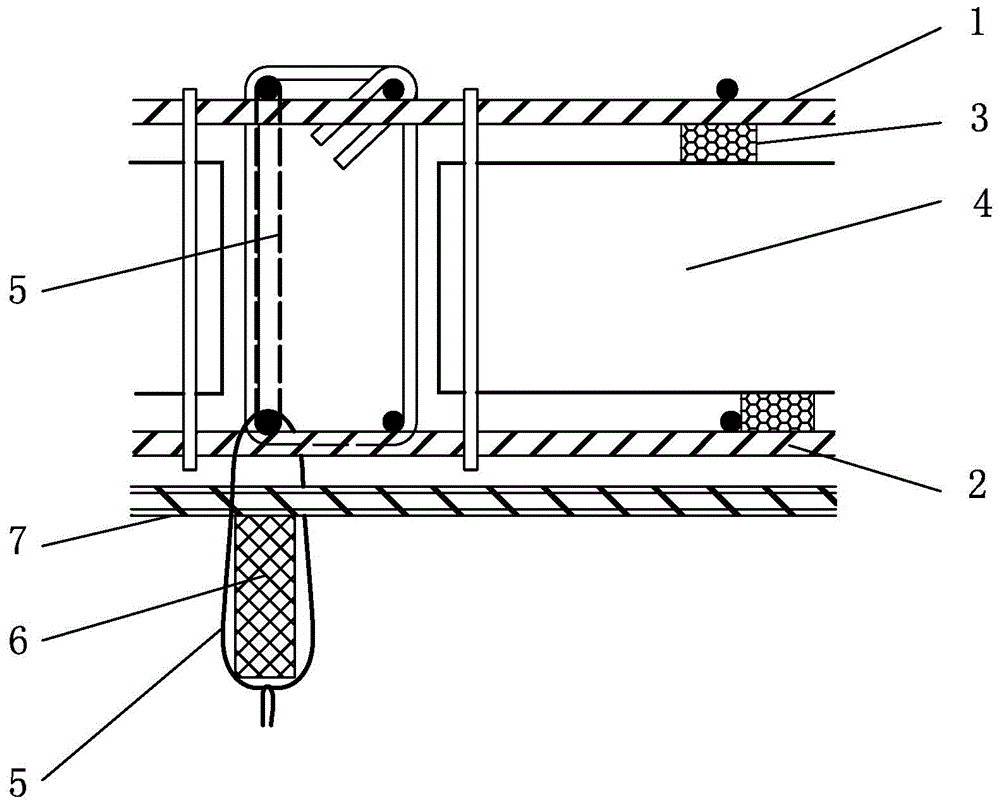

Ceramic connecting part for glass curtain wall

The invention discloses a ceramic connecting part for a glass curtain wall. The ceramic connecting part for the glass curtain wall is characterized by comprising an integrally-formed ceramic connecting part body (1), glass curtain wall installing clamp grooves (2) are arranged at two ends of the back side of the ceramic connecting part body (1), and multiple side-by-side through holes (3) are formed in the ceramic connecting part body (1). The ceramic connecting part for the glass curtain wall is simple and practical in structure and attractive and elegant in appearance and is combined with the glass curtain wall outside a building in use to form a stereo structure, and the integrated structure is natural and attractive. In addition, the ceramic connecting part for the glass curtain wall has the advantages of insulating noise and heat, preventing water penetration and being light in weight and the like.

Owner:江苏富陶科陶瓷有限公司

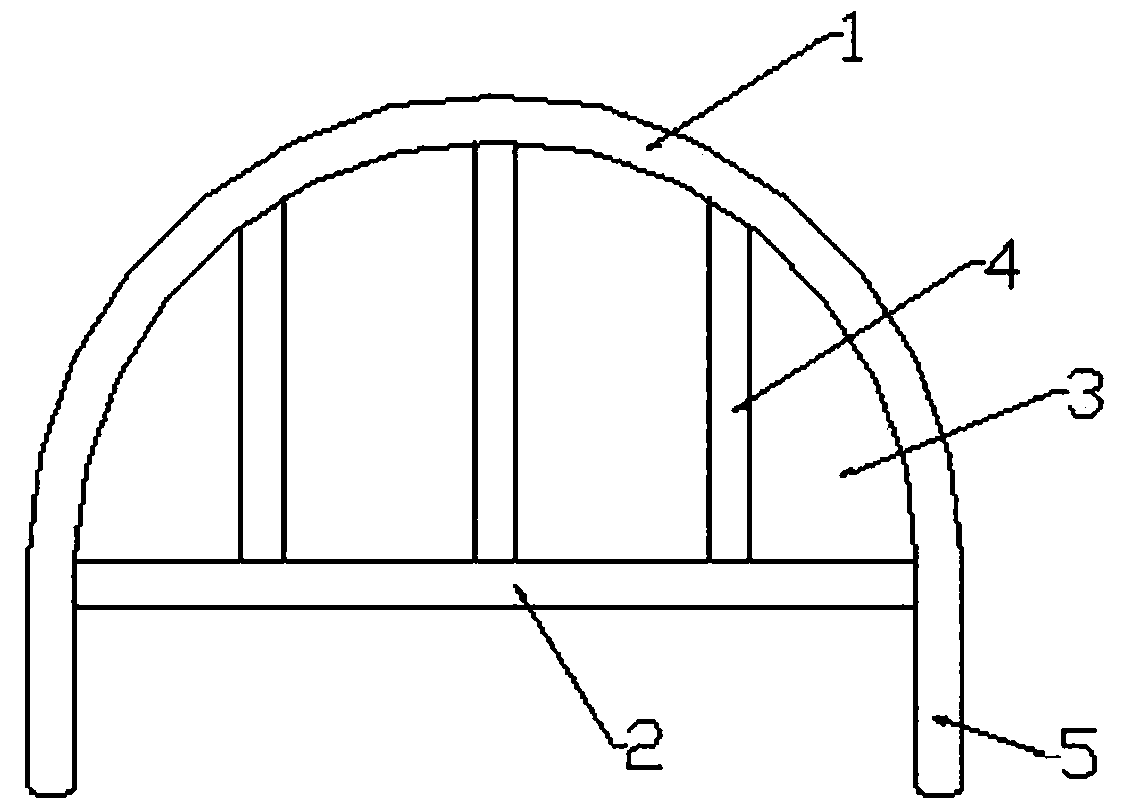

Decorative arc-shaped ceramic tile

The invention relates to a decorative material, in particular to a decorative arc-shaped ceramic tile. The decorative arc-shaped ceramic tile comprises a ceramic arc plate and a ceramic back plate, the two side edges of the ceramic back plate are connected with the two straight edges of the ceramic arc plate to form an arc-shaped cavity with the sealed cross section, reinforcing ribs are mounted in the arc-shaped cavity, and the two side edges of the reinforcing ribs are connected to the inner arc face of the ceramic arc plate and the inner wall of the ceramic back plate correspondingly; and the two straight edges of the ceramic arc plate are further connected with clamping edges correspondingly. The provided decorative arc-shaped ceramic tile is simple and practical in structure, attractive and elegant in appearance, suitable for indoor and outdoor decoration, for example, the decorative arc-shaped ceramic tile is suitable for places such as external walls with the large radian and cylindrical structures, and wide in application, and in addition, further has the advantages of sound and heat insulation, water penetrating proofing, low weight and the like.

Owner:济宁市福傲商贸有限公司

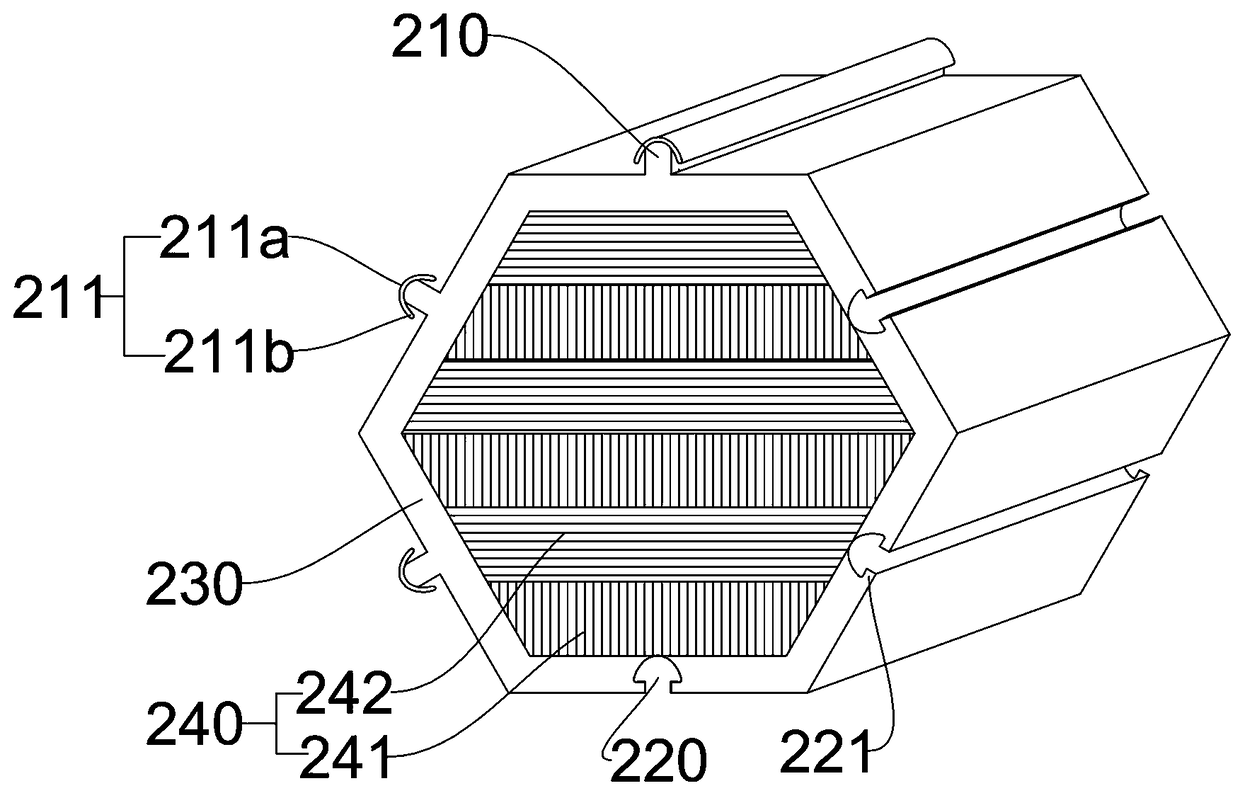

High strength wood plastic composite plate capable of reducing noise

PendingCN108643445AImprove structural strengthReduce weightBuilding componentsBuilding materialEngineering

The invention relates to the technical field of building materials, in particular to a high strength wood plastic composite plate capable of reducing noise. The high strength wood plastic composite plate capable of reducing noise comprises at least two wood plastic base plates and a plate core, wherein the plate core is arranged between the wood plastic base plates. The plate core is composed of aplurality of structure blocks with regular hexagon cross profiles, which are connected through concave-convex structures. The concave-convex structures comprise inserting portions arranged on the non- regular hexagon lateral sides of the structure blocks, and each structure block comprises three inserting portions and three groove portions, wherein the lateral sides of the inserting portions andthe groove portions are opposite. Through the design of structure blocks, the high strength wood plastic composite plate has high structure strength, strong impact resistance and excellent noise reducing effect.

Owner:ZHEJIANG NEW INSIGHT MATERIAL TECH CO LTD

Polyurethane composite floor and manufacturing process thereof

PendingCN111550003AWith sound and heat insulationImprove mechanical propertiesCovering/liningsSynthetic resin layered productsFiberWeather resistance

The invention relates to the technical field of composite structures, and discloses a polyurethane composite floor and a manufacturing process thereof. The polyurethane composite floor comprises a foaming layer and a decorative layer arranged on the foaming layer, the foaming layer comprises a middle core material, continuous woven fiber layers are arranged on the upper portion and the lower portion of the middle core material correspondingly, wherein the continuous woven fiber layer located on the upper portion of the middle core material is an upper continuous woven fiber layer, the continuous woven fiber layer located on the lower portion of the middle core material is a lower continuous woven fiber layer, a plurality of filling gaps are formed in the middle core material, and rigid polyurethane foams are loaded in the filling gaps. According to the polyurethane composite floor and the manufacturing process thereof, the polyurethane composite floor has the advantages of being low incost, high in weather resistance and wide in adaptability, a mold is adopted for integral forming, mutual catalytic curing is carried out through chemical internal energy of reaction of products, production energy consumption is greatly reduced, meanwhile, glue bonding is avoided, the polyurethane composite floor is more environmentally friendly and durable, and the processing procedures are simple.

Owner:龙钟江

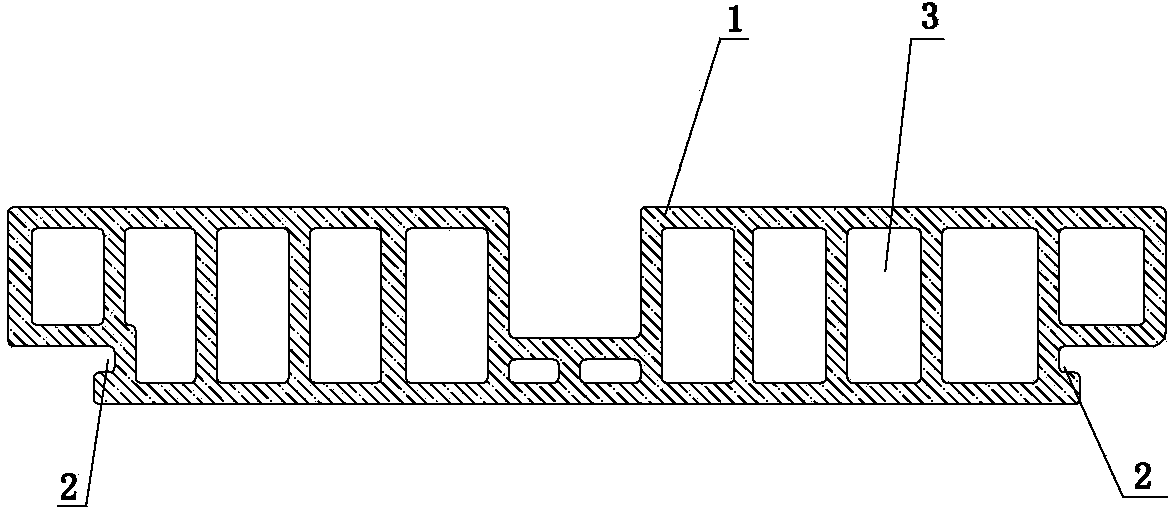

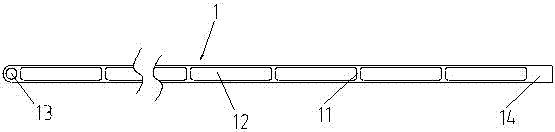

Material plate used for manufacturing door plate

InactiveCN108005543AUse less materialReinforced impact-resistant structureFireproof doorsNoise insulation doors/windowsEngineeringMechanical engineering

The invention relates to a material plate used for manufacturing a door plate. A first plate body is formed by integral extrusion, and a hinging hole can be directly used as a door mounting hole. In the actual using process, the material plate can be formed adaptively only through further door frame adaption cutting or widening of the material plate, the manufacturing technique of the material plate is simple, and the complicated assembling processes in subsequent door plate manufacturing are avoided; the first plate body is provided with a first cavity, and a plurality of first supporting reinforcing bar parts are arranged parallelly at intervals to divide the first cavity into a plurality of first through holes formed in a mode of being spaced in the left-right direction; through the first through holes, the quantity of using materials of the door plate is decreased, and the weight and cost are reduced; the first supporting reinforcing bar parts are supported on the upper side and the lower side of the first cavity correspondingly, accordingly, an anti-impact structure of the material plate is reinforced, and the anti-impact performance of the front face of the door plate can beensured while the cavity is formed; and meanwhile, the material plate is formed integrally and provided with the multiple first through holes, and thus the door plate has good sound insulation and heat insulation performance.

Owner:佛山市南霏精密铝配件制造有限公司

Ceramic connectors for glass curtain walls

The invention discloses a ceramic connecting part for a glass curtain wall. The ceramic connecting part for the glass curtain wall is characterized by comprising an integrally-formed ceramic connecting part body (1), glass curtain wall installing clamp grooves (2) are arranged at two ends of the back side of the ceramic connecting part body (1), and multiple side-by-side through holes (3) are formed in the ceramic connecting part body (1). The ceramic connecting part for the glass curtain wall is simple and practical in structure and attractive and elegant in appearance and is combined with the glass curtain wall outside a building in use to form a stereo structure, and the integrated structure is natural and attractive. In addition, the ceramic connecting part for the glass curtain wall has the advantages of insulating noise and heat, preventing water penetration and being light in weight and the like.

Owner:江苏富陶科陶瓷有限公司

Dry stirring light compartment wall grouting material

ActiveCN101164754BEasy to pumpUniform textureMixing operation control apparatusCement mixing apparatusCelluloseEther

Owner:RUENTEX MATERIALS CO LTD

Stripe type ceramic decorative plate

The invention discloses a stripe type ceramic decorative plate. The stripe type ceramic decorative plate is characterized by comprising ceramic decorative surface plates (1) and ceramic back plates (2) which are integrally formed. Between the ceramic decorative surface plates (1) and the ceramic back plates (2) are provided with a plurality of hanging holes (3), and the ceramic decorative surface plates (1) and the ceramic back plates (2) are arranged in a mutually staggered mode to enable both sides of the decorative plate to form a staggered step shape. The stripe type ceramic decorative plate is simple and practical in structure, attractive and elegant in appearance and applicable to both indoor and outdoor decoration and can be mounted horizontally as well as vertically, thereby being wide in application range. Besides, the stripe type ceramic decorative plate has the advantages of sound insulation, heat insulation, water impermeability and breathability.

Owner:江苏富陶科陶瓷有限公司

Environmentally-friendly and energy-saving paper wall board and manufacturing method thereof

InactiveCN102294858BSimple preparation processHigh speedSynthetic resin layered productsDomestic articlesEngineeringCompressive strength

The invention relates to an environmentally-friendly and energy-saving paper wall board and a manufacturing method thereof. The environmentally-friendly and energy-saving paper wall board is characterized in that a board core is arranged between two composite surface layers composed of coveing papers and non-woven fabrics, the board core is prepared from the following raw materials in parts by weight: 20-50 parts of crop straw, 15-40 parts of light burned magnesium, 3-9 parts of white latex, 10-30 parts of expanded poly styrol powder and 11-33 parts of water, and the thickness of the board core is 60-300mm. Compared with the prior art, the invention has the beneficial effects that: 1) primary compression moulding is adopted, no heating or drying is required; 2) the product has the advantages of environmental friendliness, energy conservation, light weight, high compression strength, low cost and the like; 3) the crop straw and the expanded poly styrol powder are all abandoned resources, thus the effects of environmental protection and energy conservation are achieved; and 4) the environmentally-friendly and energy-saving paper wall board provided by the invention is applicable to multiple civil buildings and can be well matched and connected with various frame structures, steel structures and heterotype structures.

Owner:乔刚

Environmentally friendly integrated building lightweight prefabricated composite wall material and its production process

The invention discloses an environment-friendly integrated building lightweight assembly type composite wall material. The composite wall material is composed of the following compositions: magnesium oxide, a magnesium sulfate solution, fly ash, sediment, a straw material, a modifier and a foaming agent. The invention also discloses a production technology of the environment-friendly integrated building lightweight assembly type composite wall material. The technology comprises adding clear water into the foaming agent for dilution, so as to prepare a foaming liquid and enabling the foaming liquid to foam and form foams; firstly adding the modifier into the magnesium sulfate solution, stirring uniformly in a machine, then adding magnesium oxide into the stirrer, fully hydrating, and then successively adding fly ash, sediment and the straw material; then adding air; starting a material pump and injecting the material slurry into a molding die, and performing core pulling and demolding; and transporting by a crane after demolding, and then performing maintenance processing. According to the technical scheme, the raw materials magnesium oxide and magnesium sulfate are employed for producing the magnesium oxysulfate wall, the raw materials magnesium oxide, magnesium sulfate, fly ash, sediment and the straw material belong to waste-utilizing environment-friendly products, and the prepared wall material possesses the advantages of light weight, high strength, resistance to shock, resistance to wind, warm keeping, sound insulation, heat insulation and first-grade fire protection.

Owner:南通市朗极新型建材有限公司

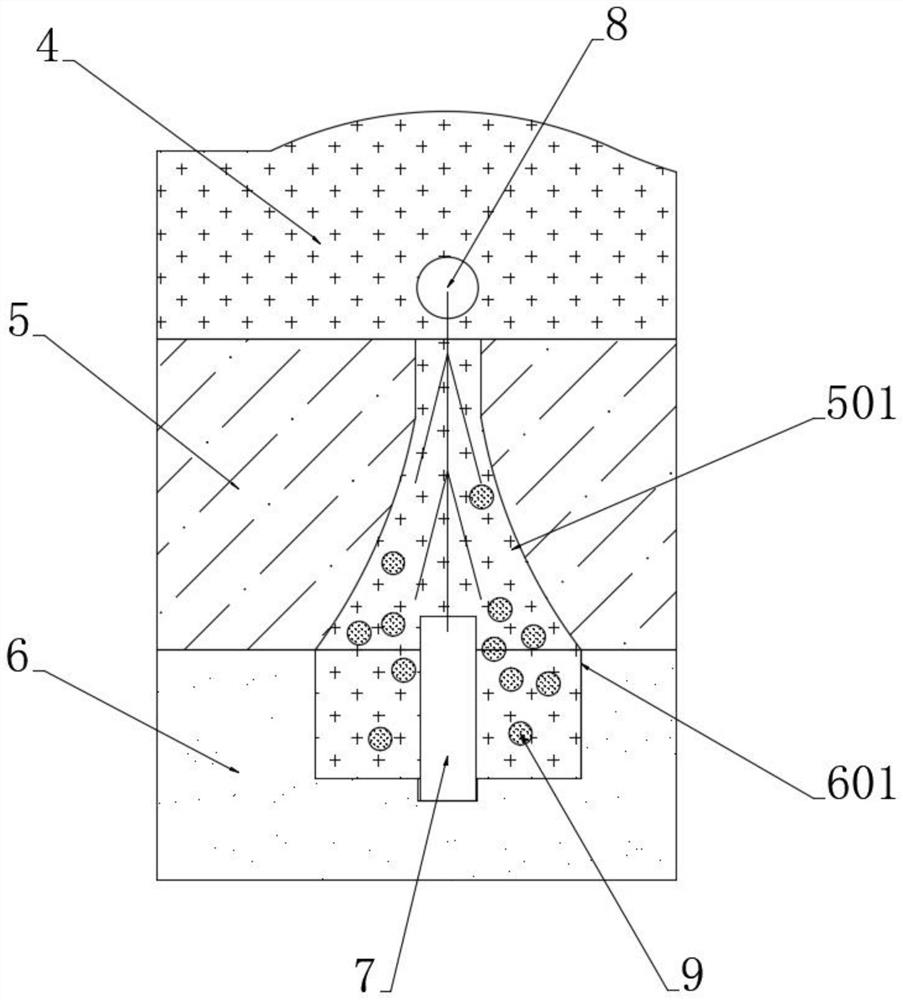

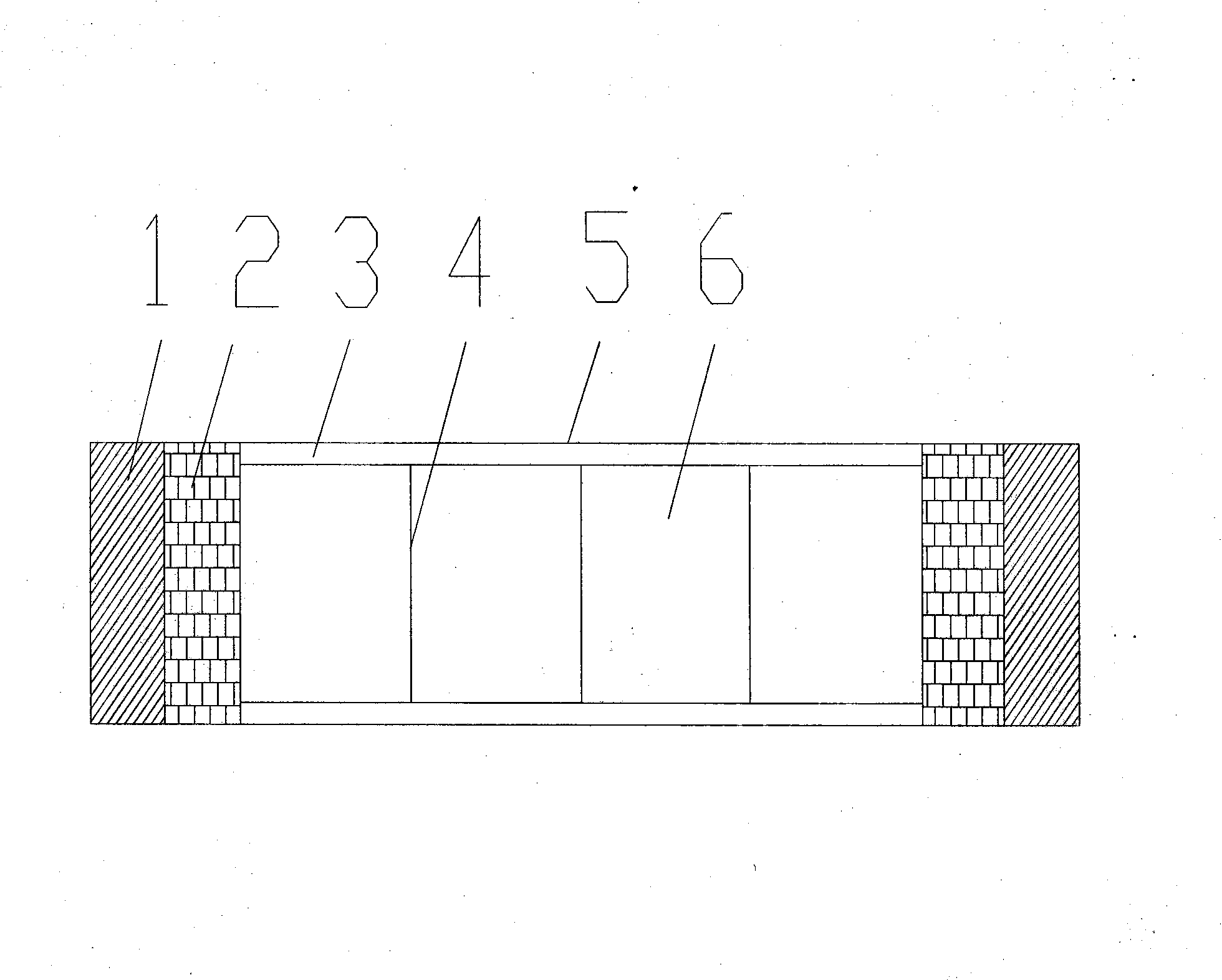

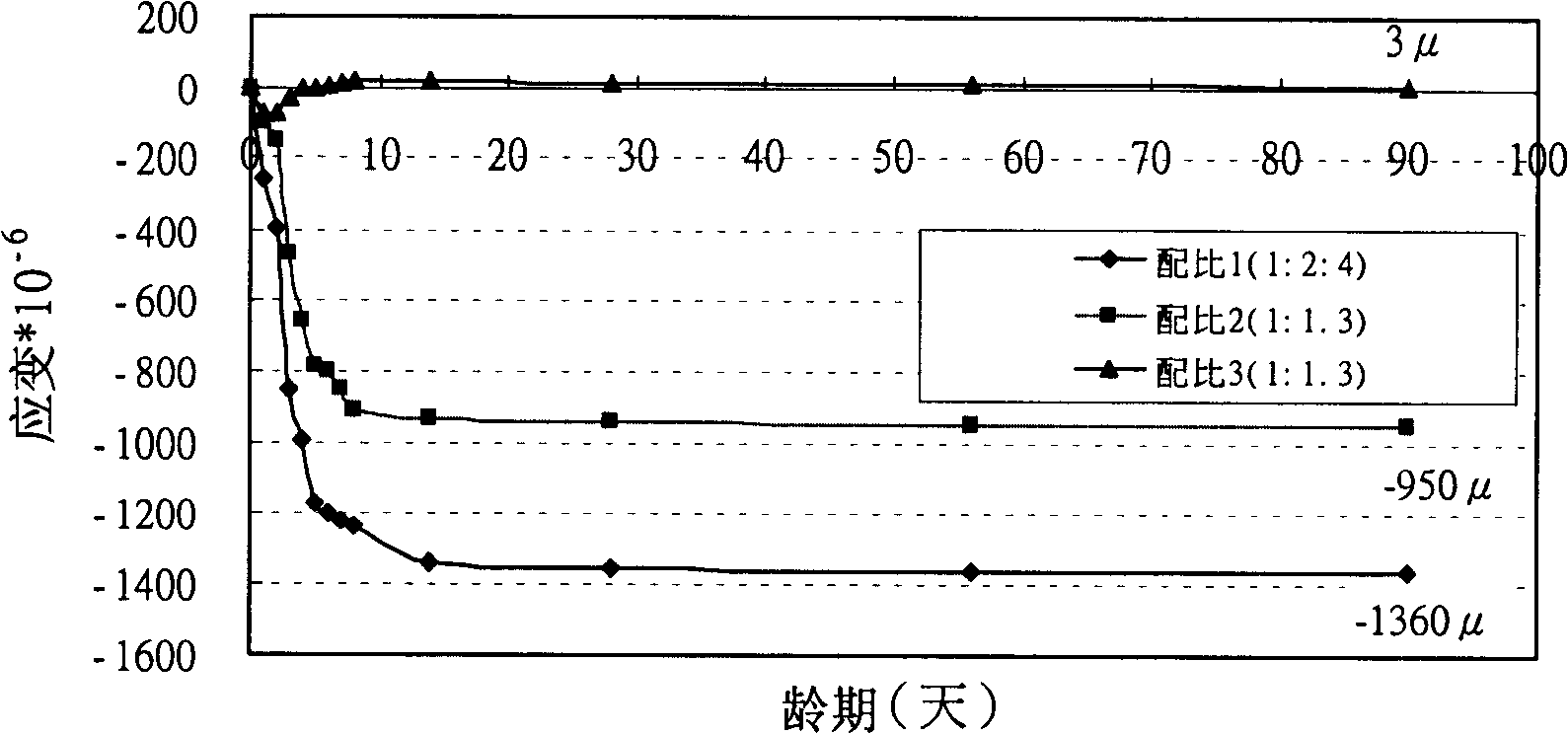

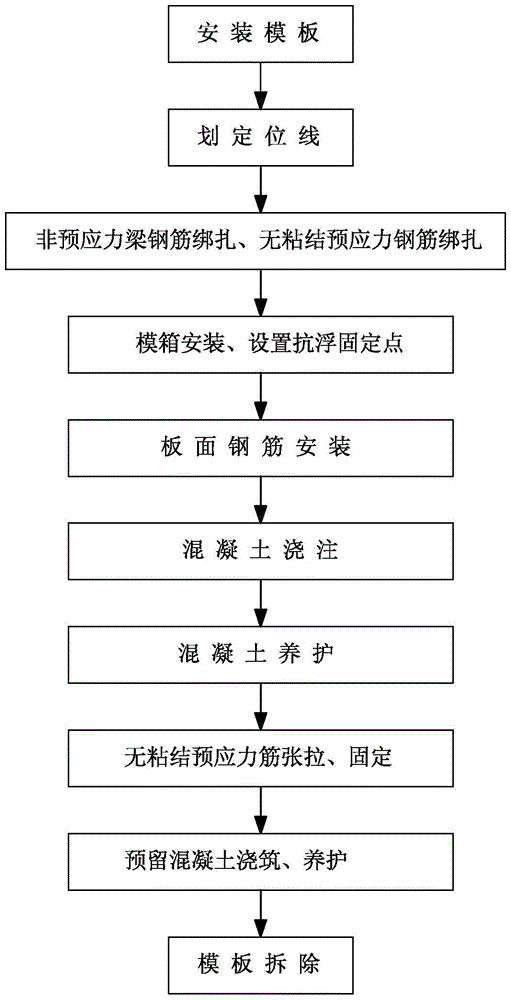

Construction method of box-type cast-in-place concrete hollow floor

The invention belongs to the technical field of building construction, and relates to a construction method of a box-type cast-in-place concrete hollow floor. Wire harness installation; (4) box formwork installation, setting anti-floating fixed points; (5) panel reinforcement installation; (6) concrete pouring; (7) concrete curing; (8) unbonded prestressed strand tensioning, (9) reserved concrete pouring; (10) maintenance and formwork removal; the advantage is: the present invention adopts unbonded prestressed tendons, which can effectively improve the structural mechanical performance of the building, and solve the problem that the building structure is under normal conditions. It is difficult to control the cracks and deflection in the use state to prevent the leakage of the floor.

Owner:ZHEJIANG ZILI CONSTR GRP

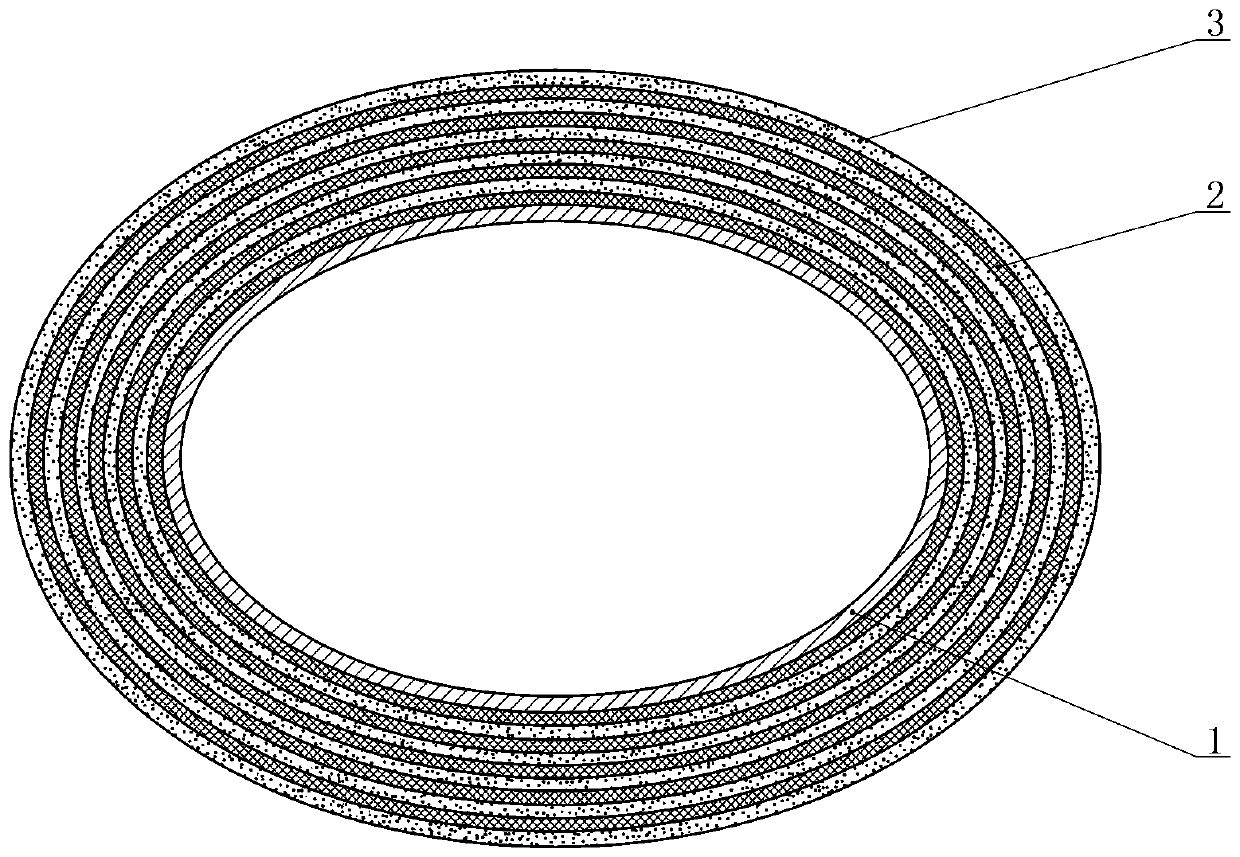

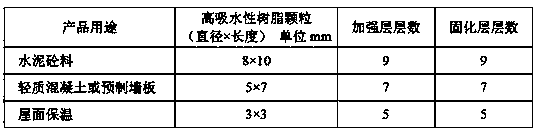

A kind of granular hollow building material and its preparation method

The invention relates to the technical field of building base materials, in particular to a granular hollow building material and a preparation method thereof. At present, wall blocks applied in later secondary structural construction in building industry mostly are building materials such as ceramsite bricks and aerated concrete blocks, and the light building materials have respective defects. According to the hollow building material, a hollow hard shell is composed of an inner shell body and an outer shell body; the inner shell body is composed of a single base layer; the outer shell body is formed by alternatively arranging a reinforcing layer and a solidification layer and wraps the exterior of the base layer; the inner surface layer of the outer shell body is the reinforcing layer, and the outer surface layer of the outer shell body is the solidification layer. Through the characteristics of super absorbent resin, the base layer inner shell body is made and alternatively coated with the reinforcing layer and the solidification layer. The hollow building material has the advantages of being small in weight, capable of insulating sound and thermal and resisting dampness and fire and the like, the preparation technology is simple, the production cost is low, high-temperature calcination is not needed in the preparing and producing process, and energy conversation and environment protection are achieved.

Owner:张振华 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com