Dry stirring light compartment wall grouting material

A technology for partition walls and grouting materials, applied in cement mixing devices, clay preparation devices, mixing operation control devices, etc., can solve problems such as uneven quality, poor construction efficiency, and difficult pumping, and achieve uniform texture, Good volume stability and easy pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

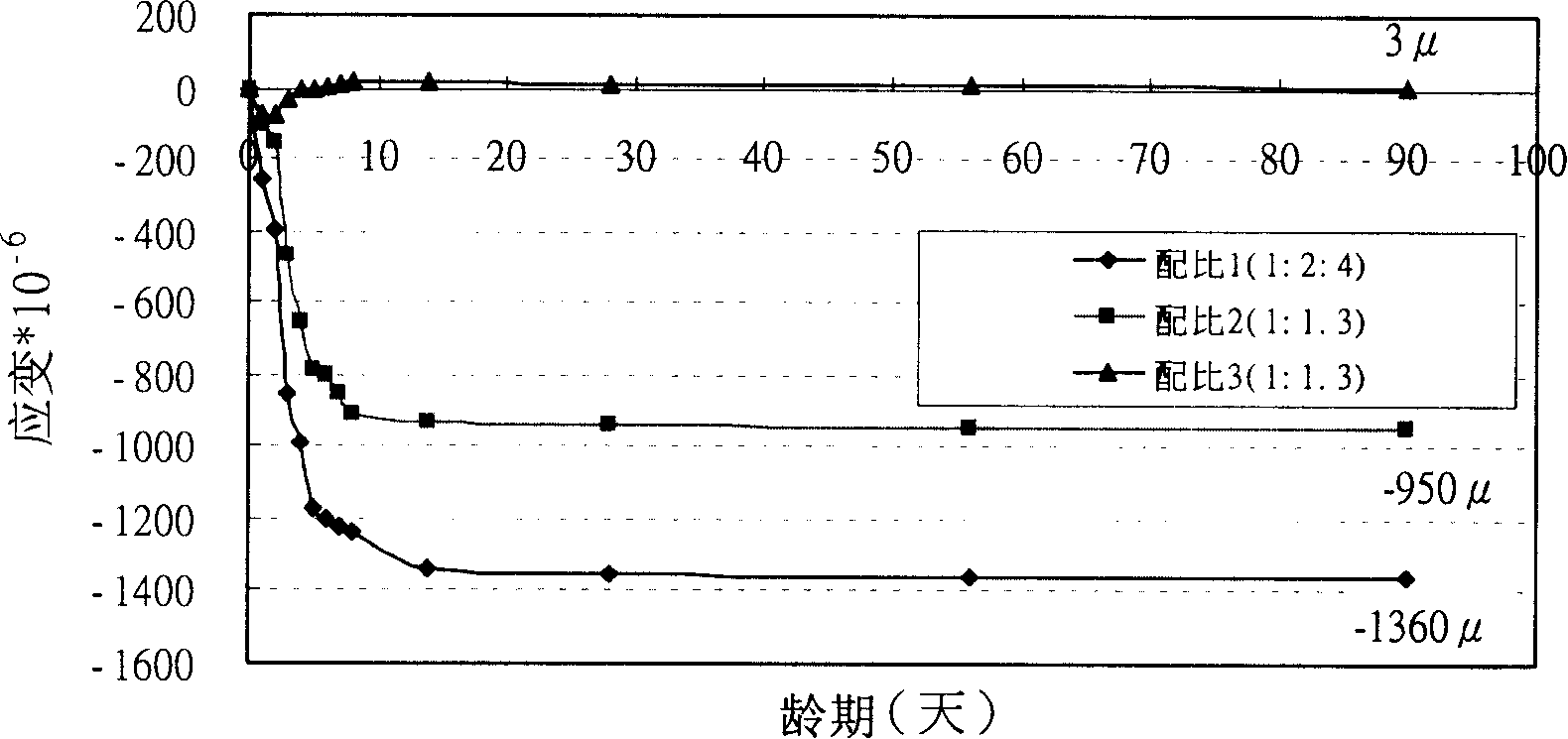

[0016] The present invention provides an easily pumpable grout such as figure 2 As shown, it has the characteristics of uniform texture, light weight, sound insulation and heat insulation, fire safety, durable corrosion resistance, and good volume stability. The grouting material of the present invention is used as a dry-mix light partition wall grouting material, preferably for indoor compartments such as residences and offices, and can also be used for indoor compartments including factory buildings and storage buildings.

[0017] The dry-mix light partition wall grouting material of the present invention preferably mainly includes granular materials and powder in its ingredients. Granules are selected from fine aggregate (sand), artificial lightweight aggregate (sintered fly ash lightweight aggregate; artificial sintered clay; foamed furnace stone; expanded shale, clay, schist, etc.), natural lightweight aggregate (Vermiculite; Pumice; Diatomite; Pearl stone, etc.), expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com