Method for pumping dregs through earth pressure balance shield

A technology of earth pressure balance and shield pump, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of reduced construction efficiency, high track requirements, and reduced excavation efficiency, so as to improve excavation work efficiency, reduce safety risks, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

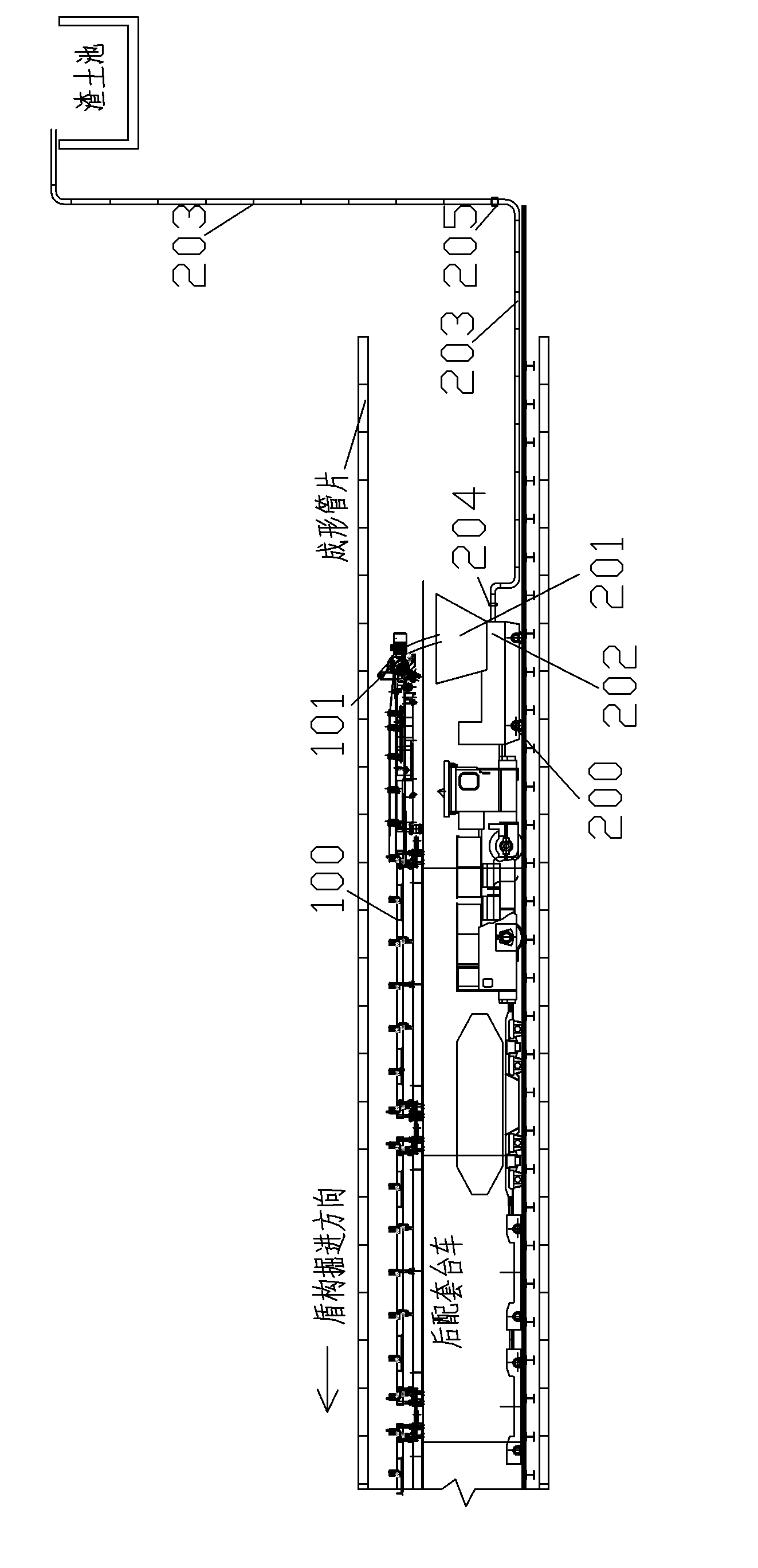

[0022] Realize the system composition of the inventive method as figure 1 As shown, it includes the soil bin (not shown in the figure) supporting the shield machine. The front end of the soil bin is provided with a vibrating screen (used to filter stones). It is an existing structure; The belt conveyer 100, the discharge port 101 of the muck belt conveyer 100 is lowered to the muck pump truck 200, and the dreg pump truck 200 is provided with a pump hopper 201, and the discharge of the pump hopper 201 is connected to the Unicom muck pump 202, The output of the muck pump 202 is connected to a communication pipeline 203, and a water injection ring 204 is connected to the pipeline 203. The water injection ring 204 is a nozzle arranged on the pipeline wall, which can inject high-pressure water into the pipeline to lubricate the muck in the pipeline. A control valve 205 is connected to the pipeline 203 .

[0023] According to the geological conditions, use foam, polymer, bentonite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com