Multi-layer composite building insulation board and preparation method thereof

A building insulation and multi-layer composite technology, which is applied in the direction of construction, building structure, chemical instruments and methods, etc., can solve the problems of reducing the compressive and tensile strength of insulation boards, falling off, and difficulty in ensuring insulation boards, etc., to achieve enhanced heat insulation effect, enhanced heat insulation, and improved mechanical fixation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

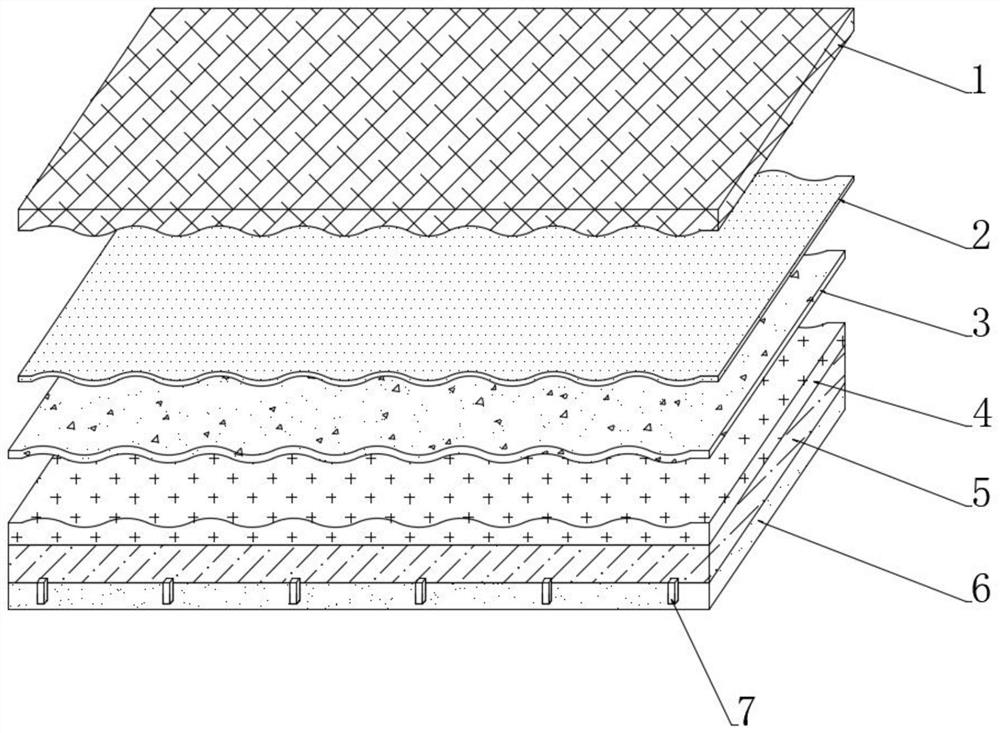

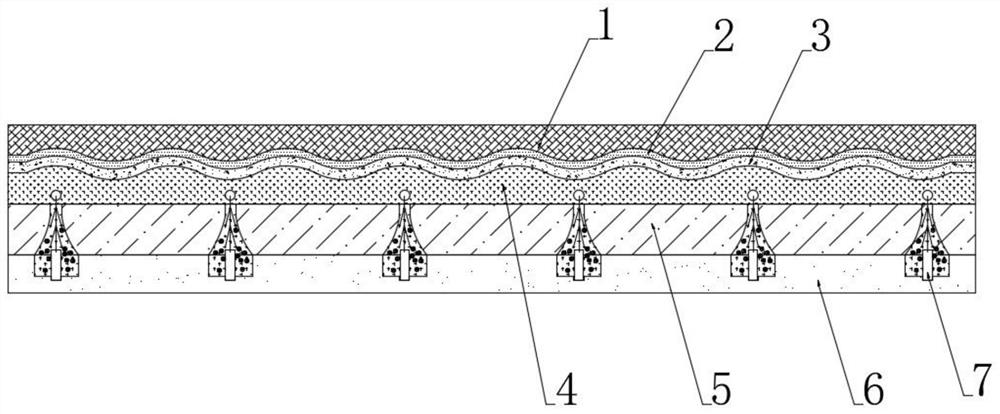

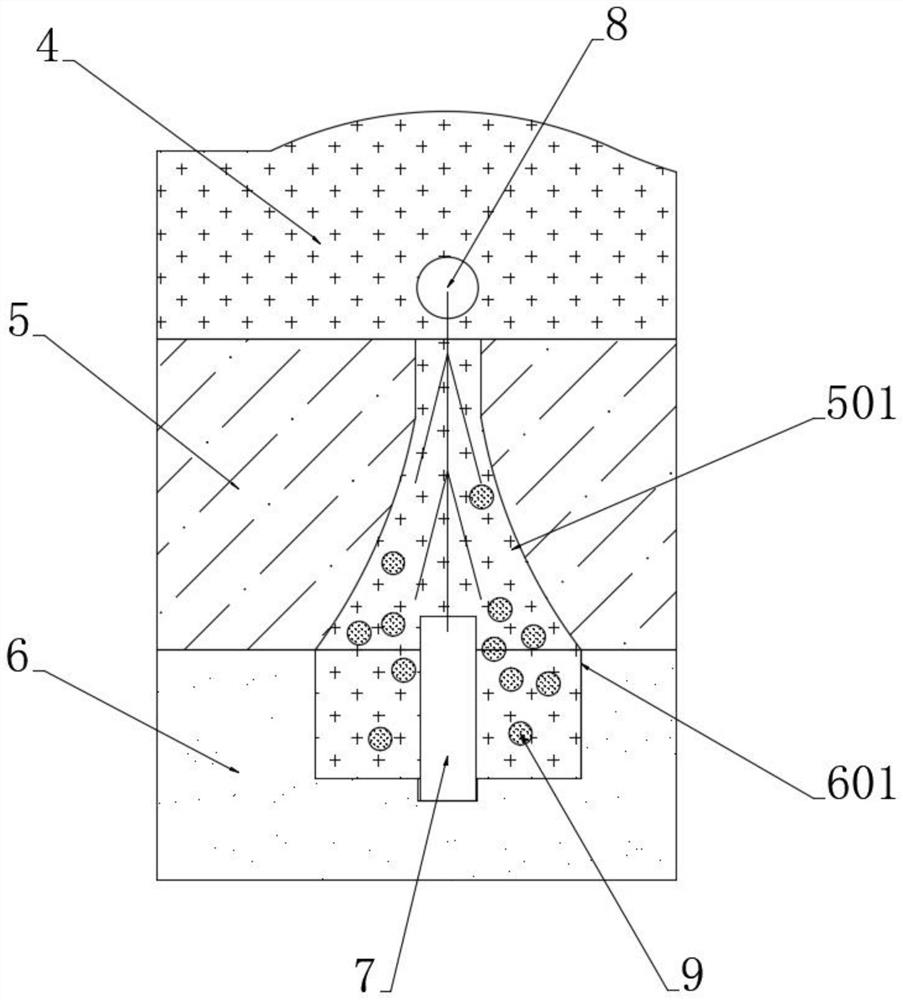

[0042] see Figure 1-2 , a multi-layer composite building insulation board, comprising an inner substrate layer 1, a foam board layer 3, a polymer mortar layer 4, an extruded board layer 5 and an exterior decorative board layer 6 distributed sequentially from the inside to the outside, and the inner substrate layer 1 An airgel layer 2 is arranged between the foam board layer 3, and the upper and lower end surfaces of the airgel layer 2 and the foam board layer 3, as well as the lower end surface of the inner substrate layer 1, are all arranged as wavy curved surfaces that match each other, and the foam board layer 3 The upper and lower end surfaces of the airgel are attached with glass fiber mesh cloth, which is set as a wavy surface. On the one hand, the joint surface of the two-phase junction is enlarged, and the airgel layer 2 is porous, disordered, and has a nanoscale continuous network structure. The low-density airgel material increases the laying area of the airgel la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com