A carbon fiber composite car body and its manufacturing method

A composite material and carbon fiber technology, applied in the field of rail transit, can solve the problem of no general method for manufacturing composite material car body, and achieve the effect of high degree of production integration, good for safety, and improvement of stiffness and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

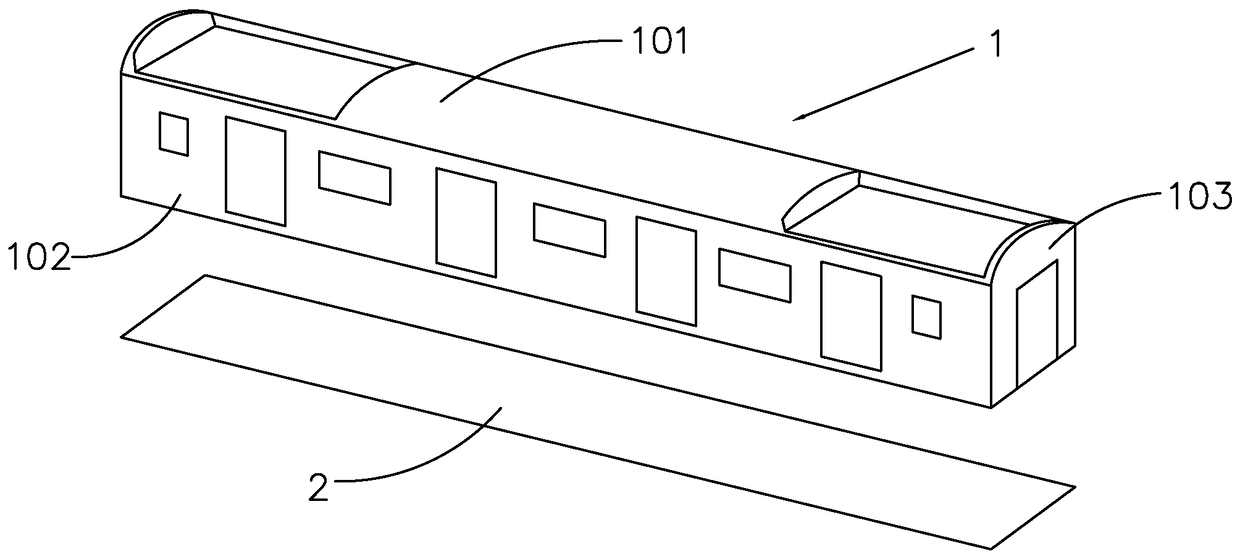

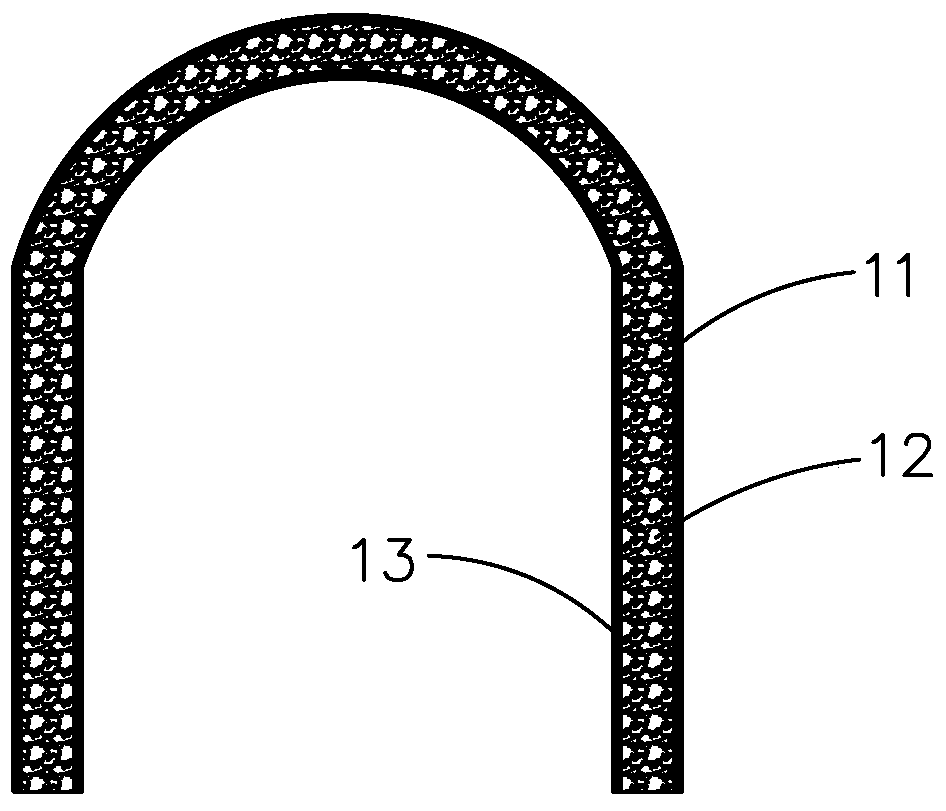

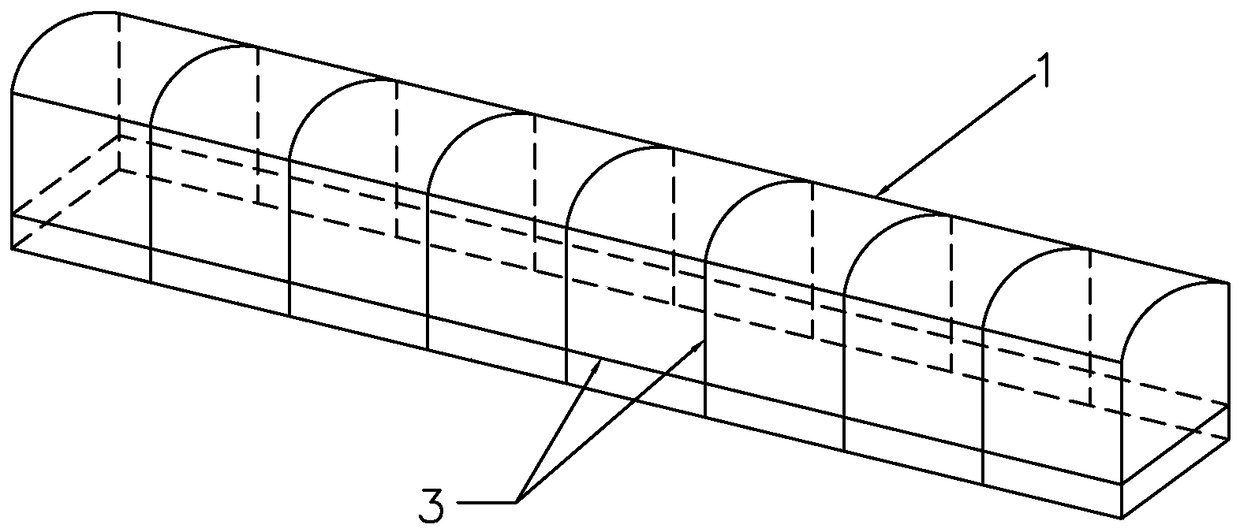

[0029] Such as Figure 1 to Figure 4 As shown, a carbon fiber composite vehicle body of the present invention includes a vehicle body 1 and a bottom plate 2, and the bottom plate 2 is fixedly connected to the bottom of the vehicle body 1 through rivets. Both the vehicle body 1 and the bottom plate 2 are integrally formed. The outer skin 11, the sandwich layer 12 and the inner skin 13 are sequentially arranged from the outside to the inside. The inner skin 13 is bonded with a reinforcing rib 3, and the reinforcing rib 3 includes a U-shaped part and a A rectangular part consistent with the longitudinal section shape of the vehicle body 1, the two parts of the ribs 3 intersect at the lower part of the body 1; Vertical; the outer skin 11, inner skin 13, bottom plate 2 and ribs 3 are all made of carbon fiber prepreg; the sandwich layer 12 is honeycomb or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com