A kind of granular hollow building material and its preparation method

A kind of building material and granular technology, which is applied in the field of building basic materials, can solve the problems of uneven surface of ceramsite bricks, complicated manufacturing process, high production cost, etc., and achieve the effect of smooth wall surface, simple manufacturing process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

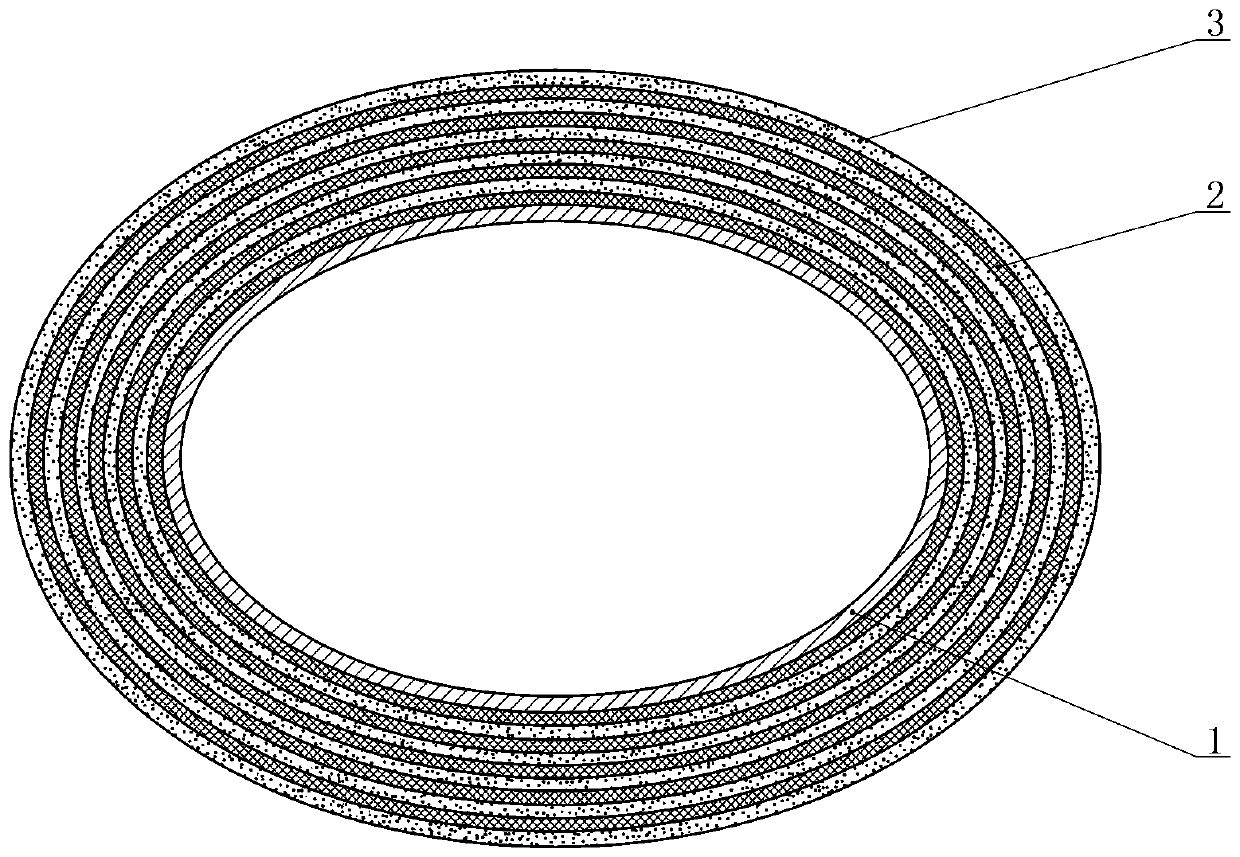

[0038] from figure 1 It can be seen that the building material particles of the present invention consist of an inner shell and an outer shell to form a hollow hard shell structure; an ellipse or a circle is naturally formed during the production process, and the shell structure includes a base layer 1 composed of a mixture of quicklime powder and gypsum powder, Reinforcing layer 2 formed by interlacing glass fibers, and solidified layer 3 composed of cement, stone powder, quicklime powder and gypsum powder;

[0039] The inner shell is composed of a single-layer base layer 1;

[0040] The shell is alternately arranged with reinforcing layers 2 and cured layers 3, covering the outside of the base layer 1; the inner surface layer of the shell is the reinforced layer 2, and the outer layer is the cured layer 3; 5 to 9 floors, which can be set according to the strength requirements of end products (wall panels, blocks, etc.);

[0041] The thicknesses of the base layer, the reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com