Patents

Literature

80results about How to "Reduce connection structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

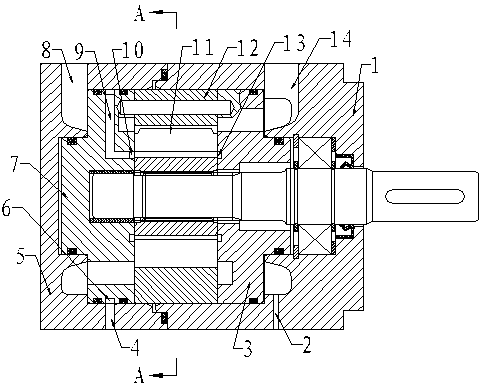

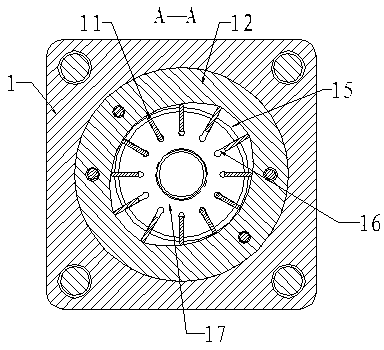

Hydraulic control mechanism for vanes

ActiveCN102840134AReduce work energy consumptionReduce feverRotary piston pumpsRotary piston liquid enginesEngineeringEnergy consumption

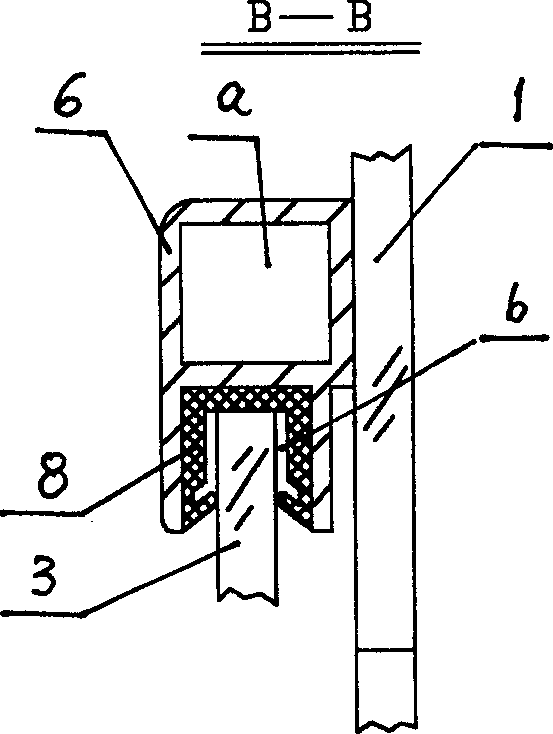

The invention discloses a hydraulic control mechanism for vanes. The hydraulic control mechanism for the vanes solves the problem that vanes can still extend to the outside of a rotor when the existing common vane pump does not work, so that the energy consumption of the vane pump is large. The vane pump structurally comprises a shell, a stator and a rotor, wherein the rotor is arranged in the stator in a rotatable mode, a plurality of vane grooves are radially arranged in the rotor, the vane grooves are internally provided with the vanes in a sliding way, and the vanes can partially extend out of the radial outside of the rotor, or retract into the rotor. A cavity is formed between the rotor and the stator, and is provided with a fluid suction zone, a fluid compression zone and a vane retraction zone, the shell is internally provided with a chamber communicated with the cavity, and the chamber is communicated with the outside through a fluid inlet and a fluid outlet. When the rotor is required to idle, pressure fluid is introduced into the chamber so as to enable the vanes to stably retract into the rotor.

Owner:胡阳

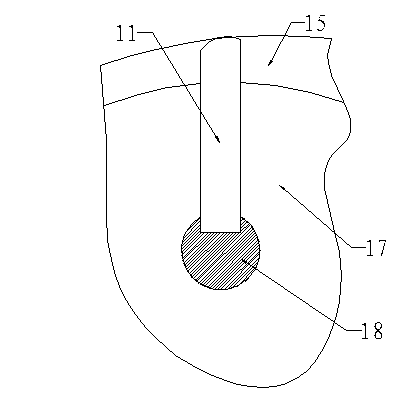

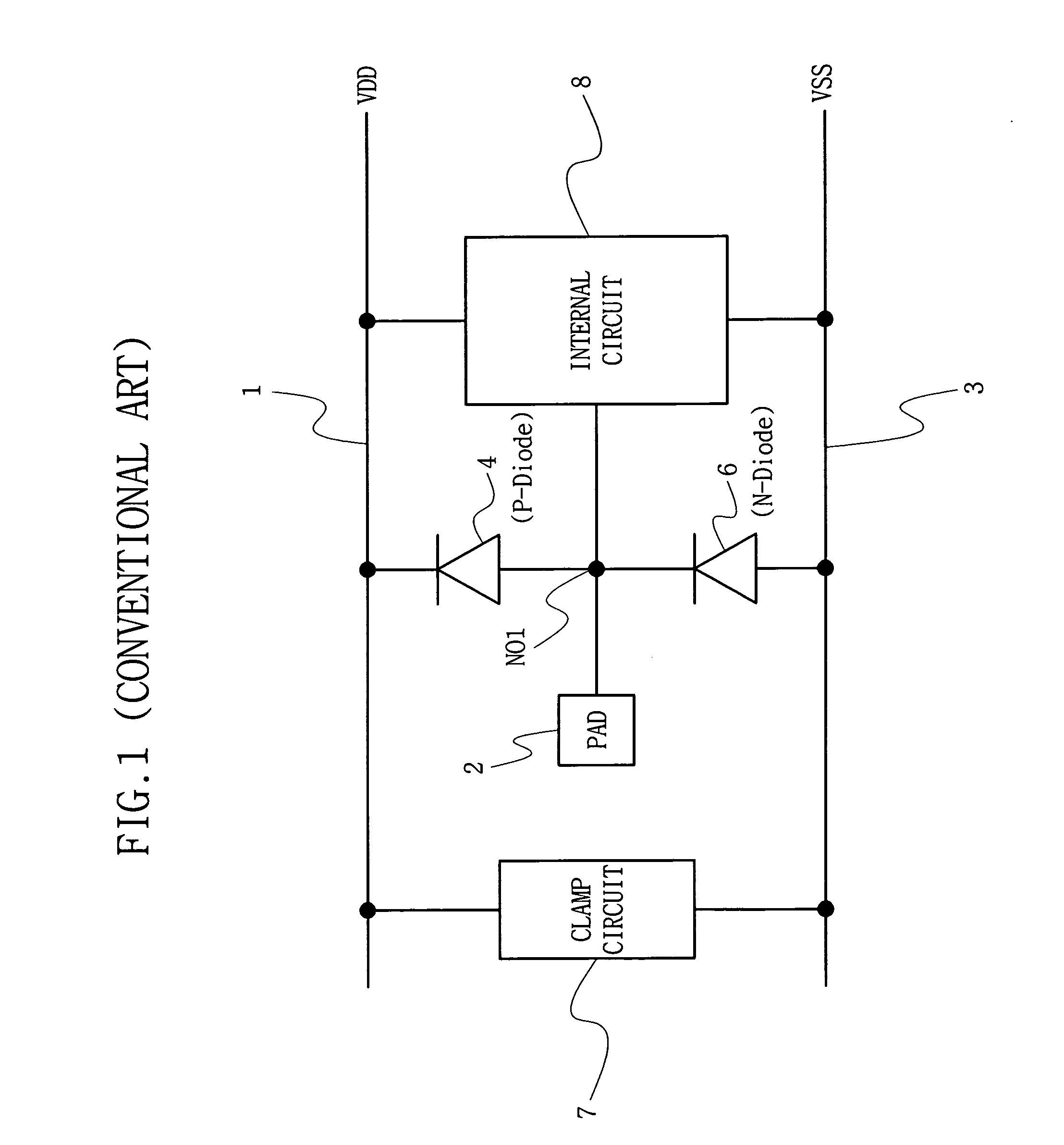

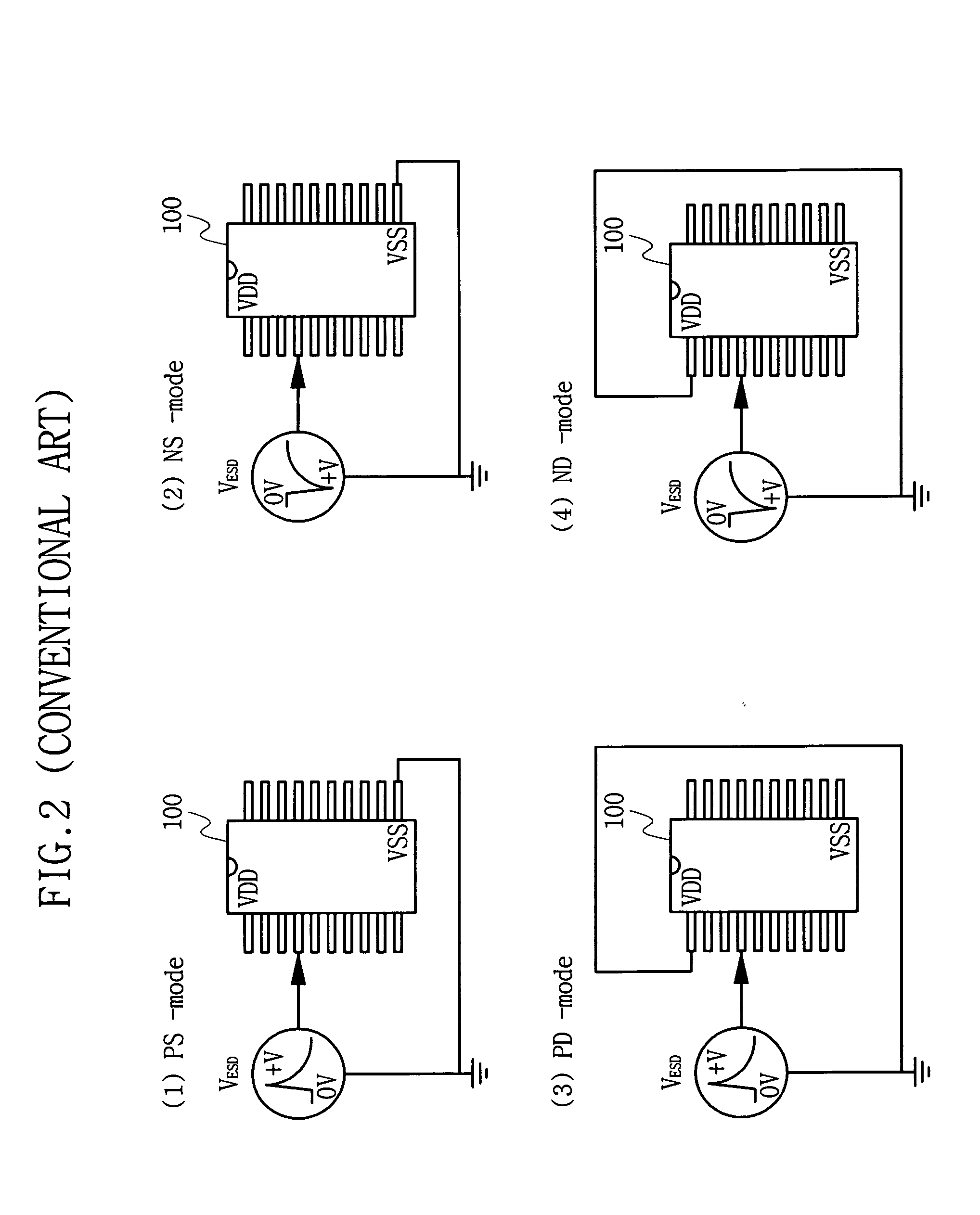

Semiconductor device having function of improved electrostatic discharge protection

ActiveUS20070215948A1Improve protectionImprove stress resistanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device includes a diode region having a plurality of protection diodes and a pad region overlapped with an upper part of the diode region. The pad region having a pad installed corresponding to an external connection terminal. The semiconductor device further includes a contact plug unit which connects at least one of a plurality of active regions constituting the diode region and the pad within the diode region.

Owner:SAMSUNG ELECTRONICS CO LTD

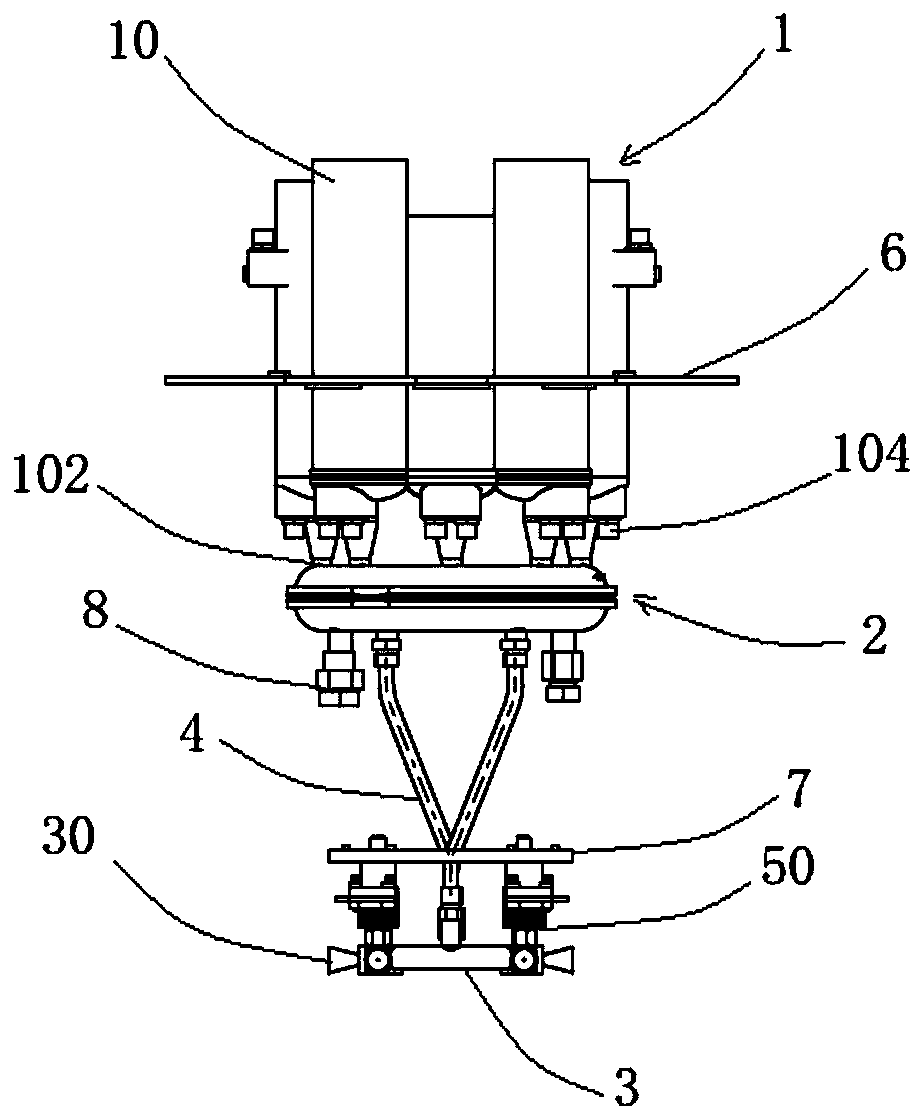

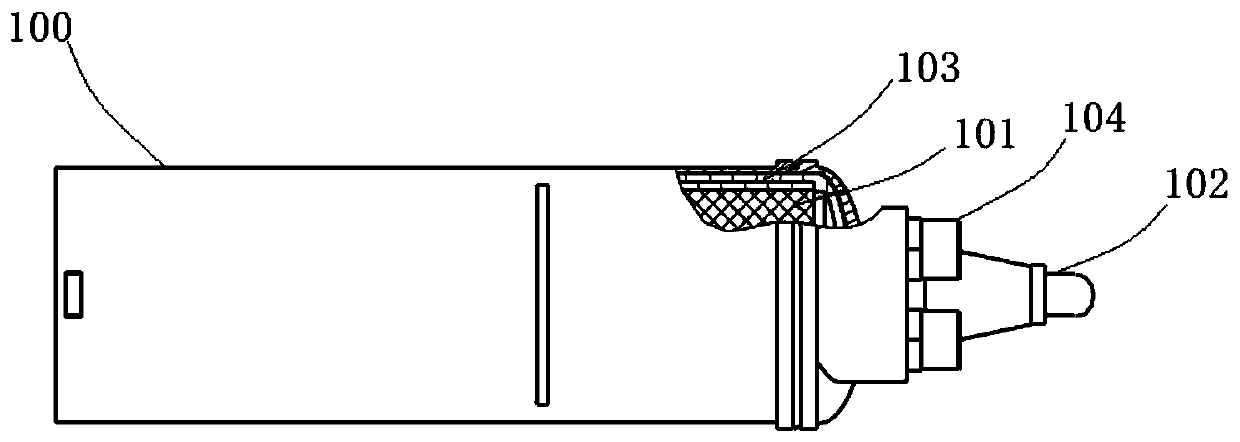

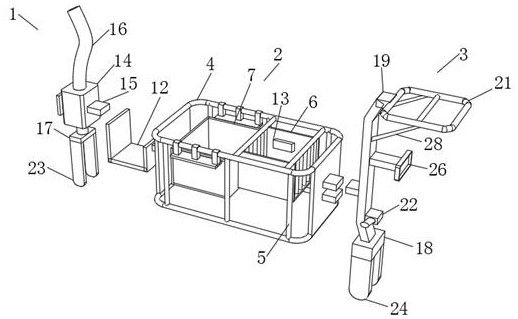

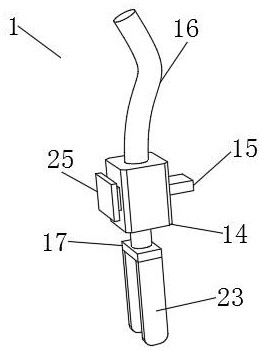

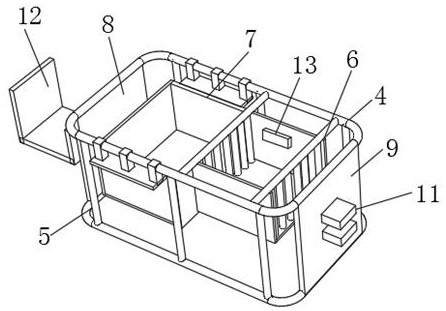

Solid attitude control power system based on energy management and control

InactiveCN109707536AOmit designSave spaceCosmonautic propulsion system apparatusRocket engine plantsSolenoid valveGas cylinder

The invention discloses a solid attitude control power system based on energy management and control, and relates to the technical field of solid attitude control power systems. The solid attitude control power system comprises a burner group, a gas collection filter assembly, a thruster and a solenoid valve assembly, wherein the burner group includes at least one burner; the gas collection filterassembly is arranged below the burner and communicates with the burner; the thruster is arranged below the gas collection filter assembly and communicates with the gas collection filter assembly through a connecting pipe; each side face of the thruster includes at least one nozzle; the solenoid valve assembly is arranged on the thruster; the solenoid valve assembly includes a plurality of solenoid valves; and each solenoid valve is used for controlling a nozzle. The solid attitude control power system based on energy management and control structurally has no need of a gas storage cylinder, so that the overall system is light in weight, small in space and simple in structure.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

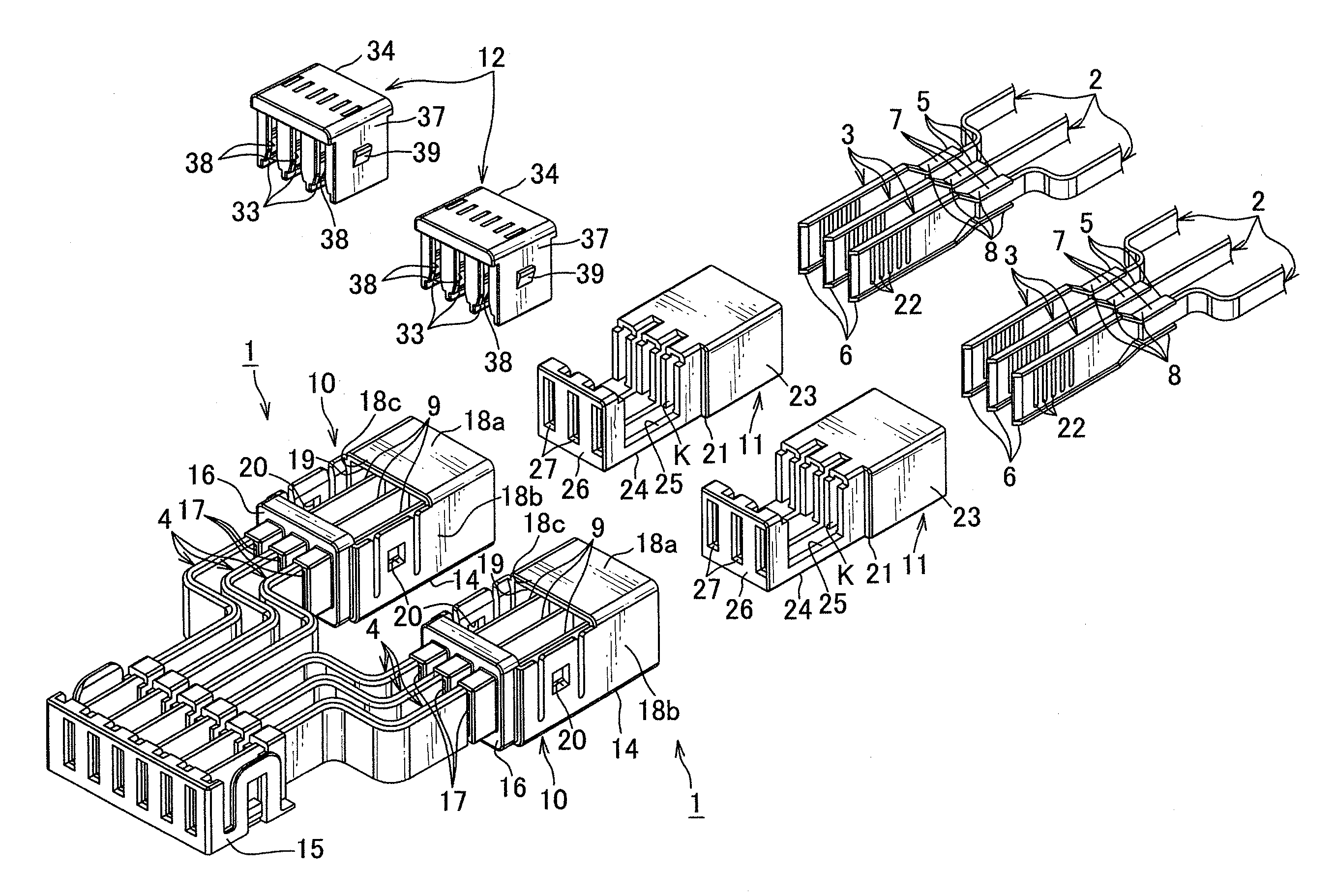

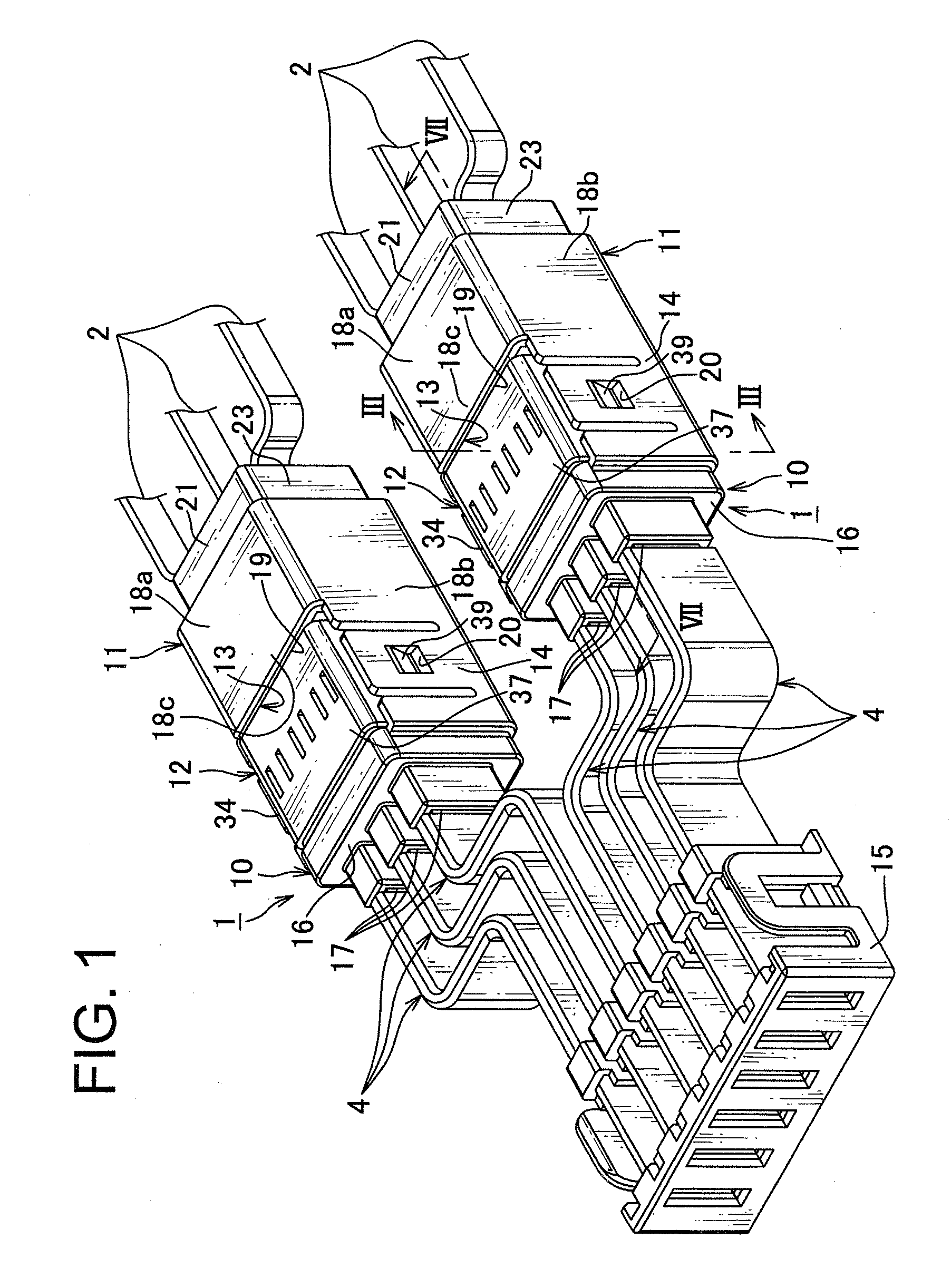

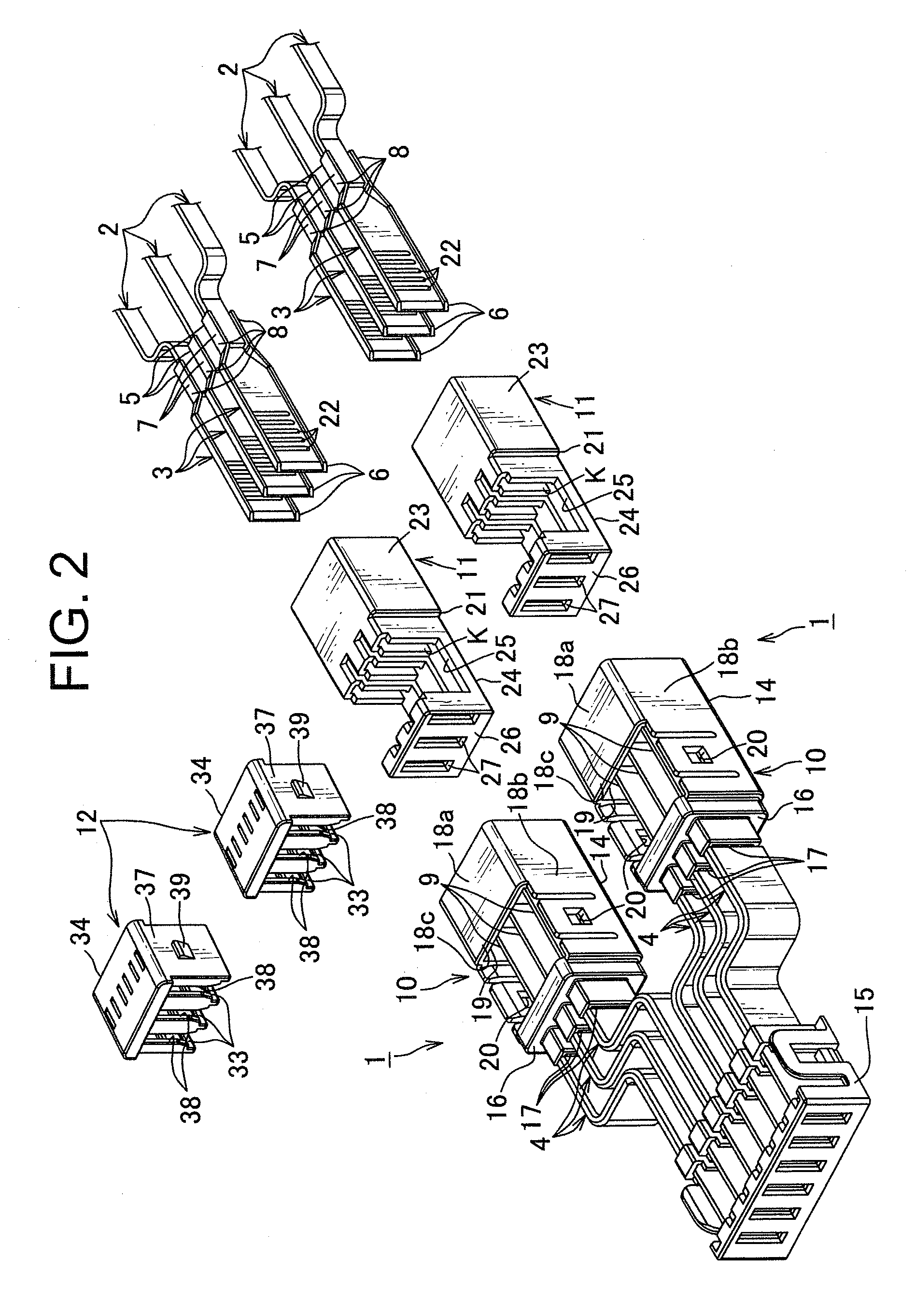

Terminal connection structure

ActiveUS8684759B2Firmly connectedReduce widthEngagement/disengagement of coupling partsVehicle connectorsComputer terminalThin walled

A terminal connection structure which is downsized and easily connects terminal fixtures together without producing variation in electric resistance therebetween. The terminal connection structure connects a bus bar connected to an inverter and a second terminal fixture connected to a motor coil. The terminal connection structure includes a first housing receiving a thin-walled portion of the bus bar, a second housing receiving an electric-contact portion of the second terminal fixture and having an insert portion, a clip terminal arranged to make the thin-walled portion closely contact with the electric-contact portion, and a permitting / restricting portion, which permits the clip terminal to be attached to one of the first housing and the second housing when the insert portion is at a predetermined position and restricts the clip terminal from being attached to one of the first housing and the second housing when the insert portion is not at the predetermined position.

Owner:YAZAKI CORP

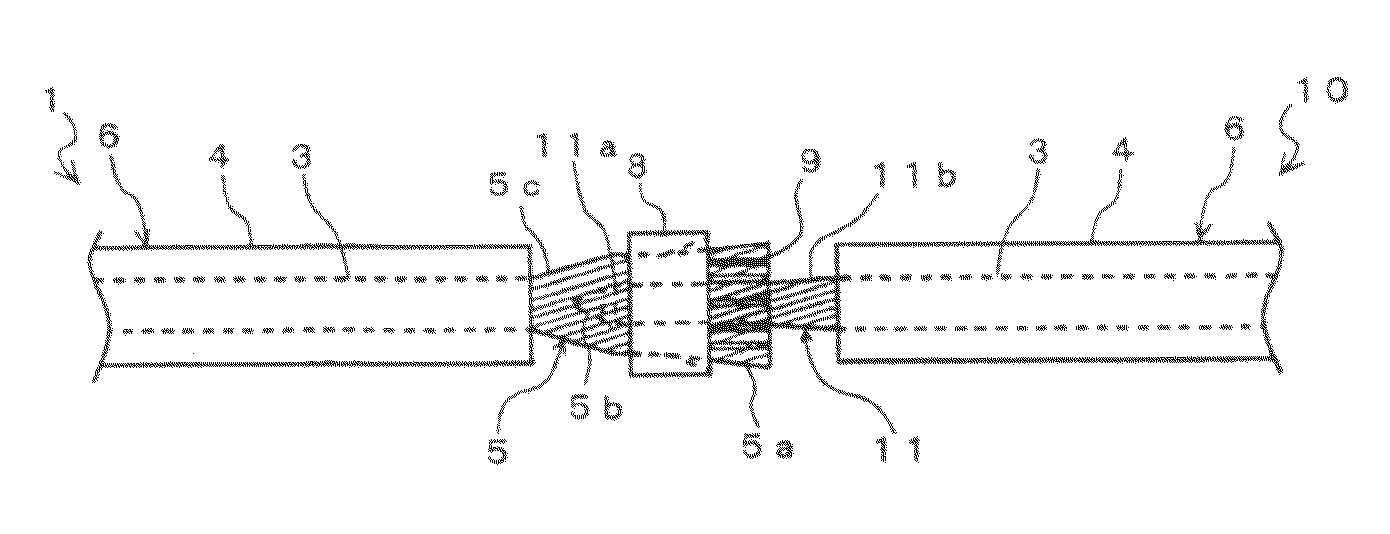

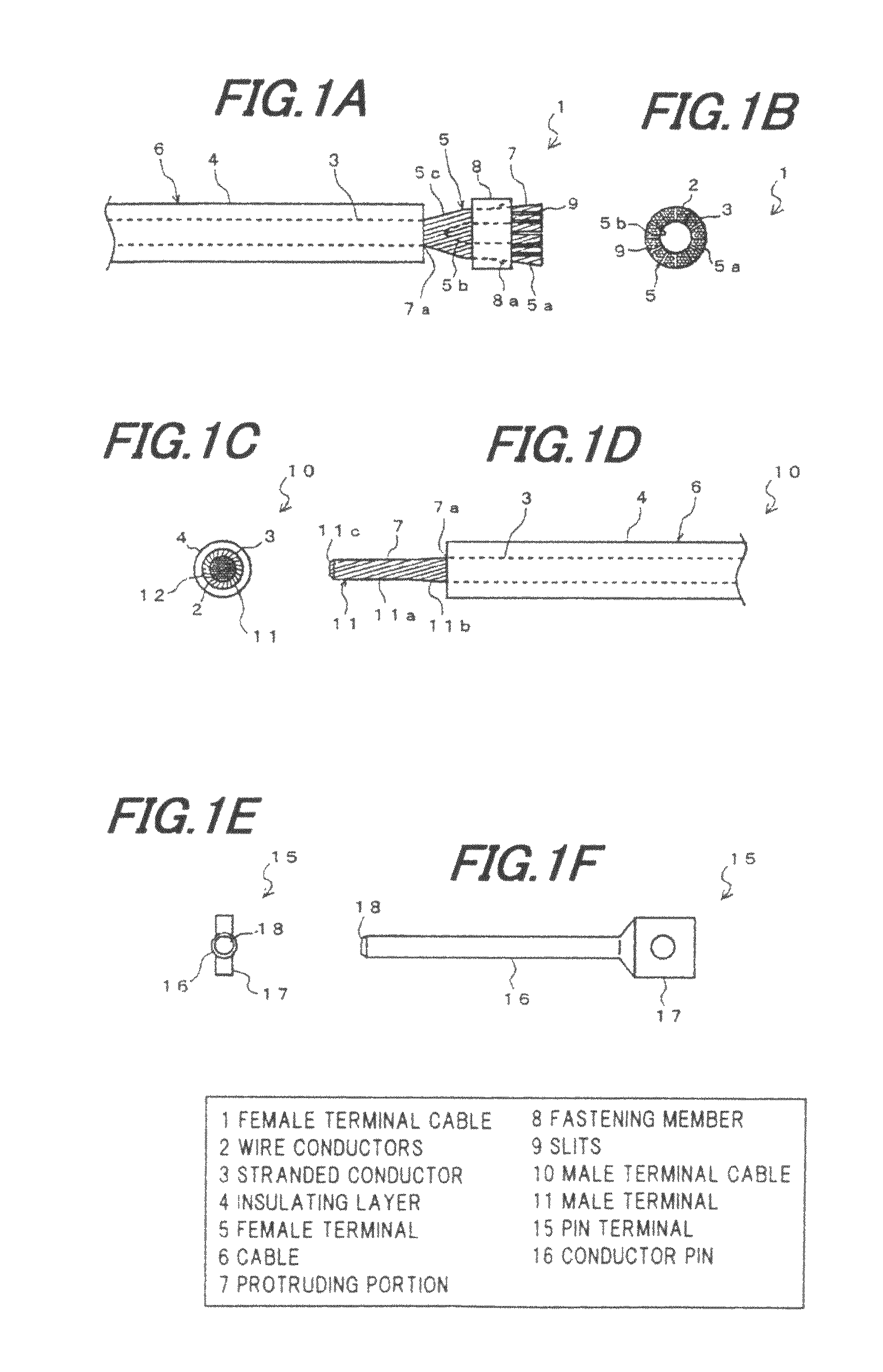

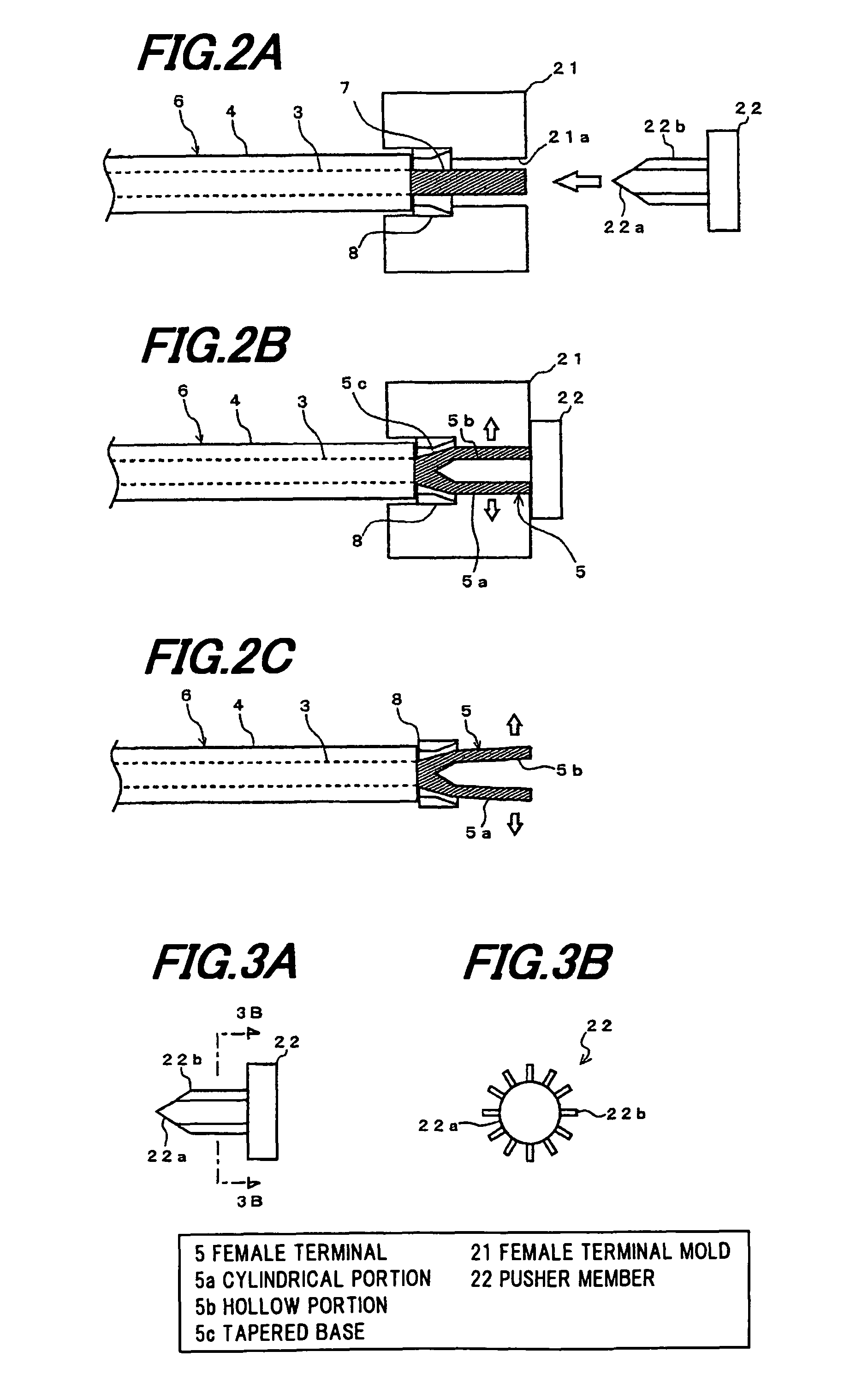

Conductor connection structure

InactiveUS8137125B2Inhibit wearSmall sizeEngagement/disengagement of coupling partsLine/current collector detailsElectrical conductor

Owner:HITACHI CABLE

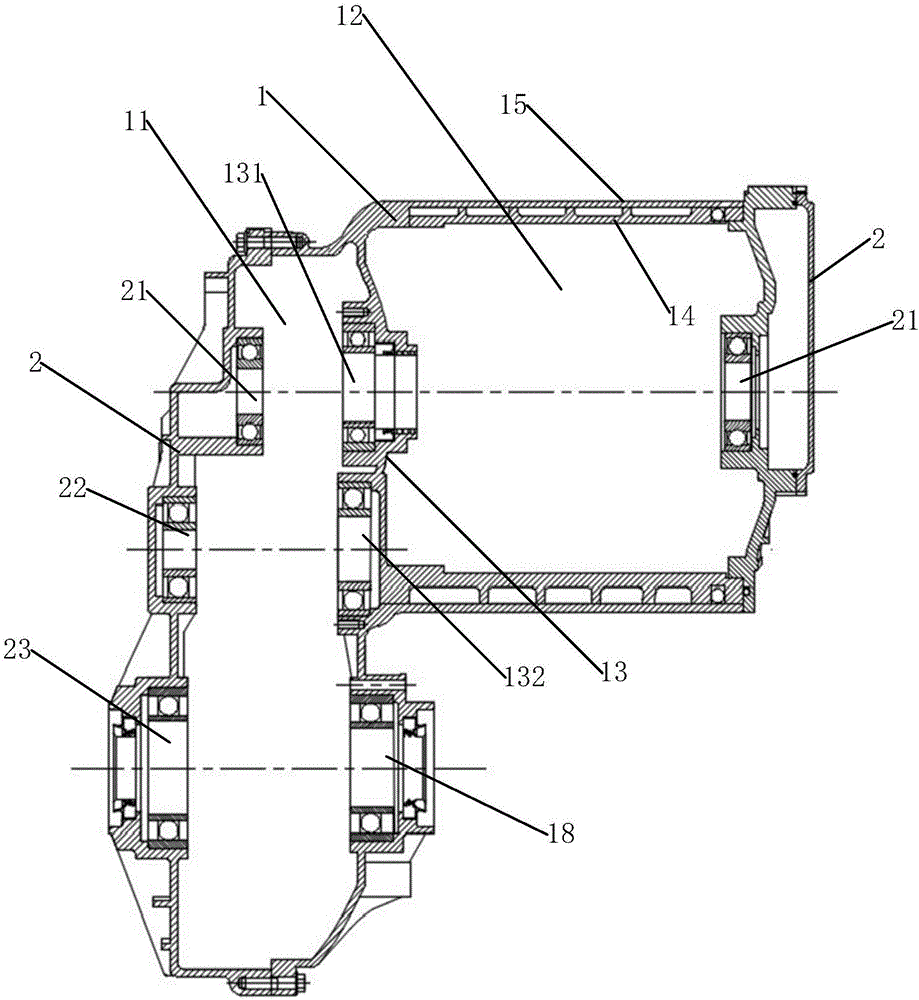

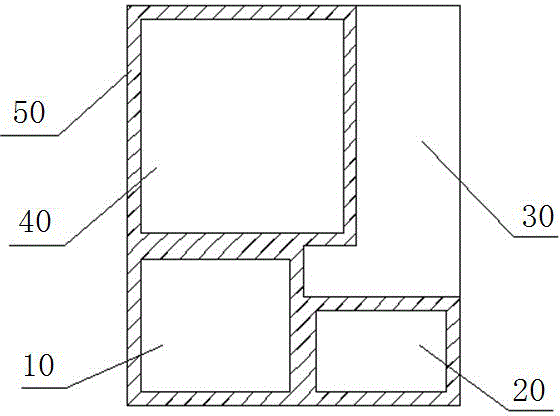

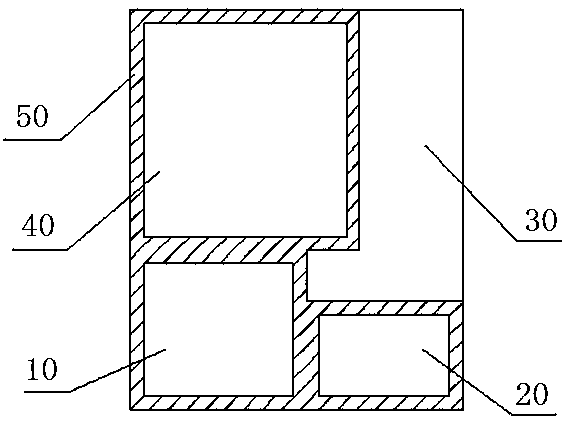

Power assembly housing and automobile

ActiveCN106515405AReduce connection structureStrengthen the connection structureElectric propulsion mountingPropulsion coolingReducerEngineering

The invention provides a power assembly housing and an automobile. The power assembly housing comprises an integrated housing, a speed reducer end cover and a motor end cover, wherein the integrated housing comprises a first mounting space and a second mounting space, the first mounting space and the second mounting space are separated by a connecting structure, and a first positioning hole is formed in the connecting structure; the speed reducer end cover is fixedly connected with a first end of the integrated housing, and a second positioning hole is formed in the speed reducer end cover; and the motor end cover is fixedly connected with a second end of the integrated housing, and a third positioning hole is formed in the motor end cover. By integrating original two housings into the integrated housing, an original spline transition connection structure between a motor and a speed reducer is reduced, and further the problems that the positioning accuracy is low due to spline gaps and the NVH performance of the complete vehicle is low are solved; and a connection structure of a spigot is reduced, so that the positioning accuracy during the assembling of power assemblies is increased.

Owner:BEIJING ELECTRIC VEHICLE

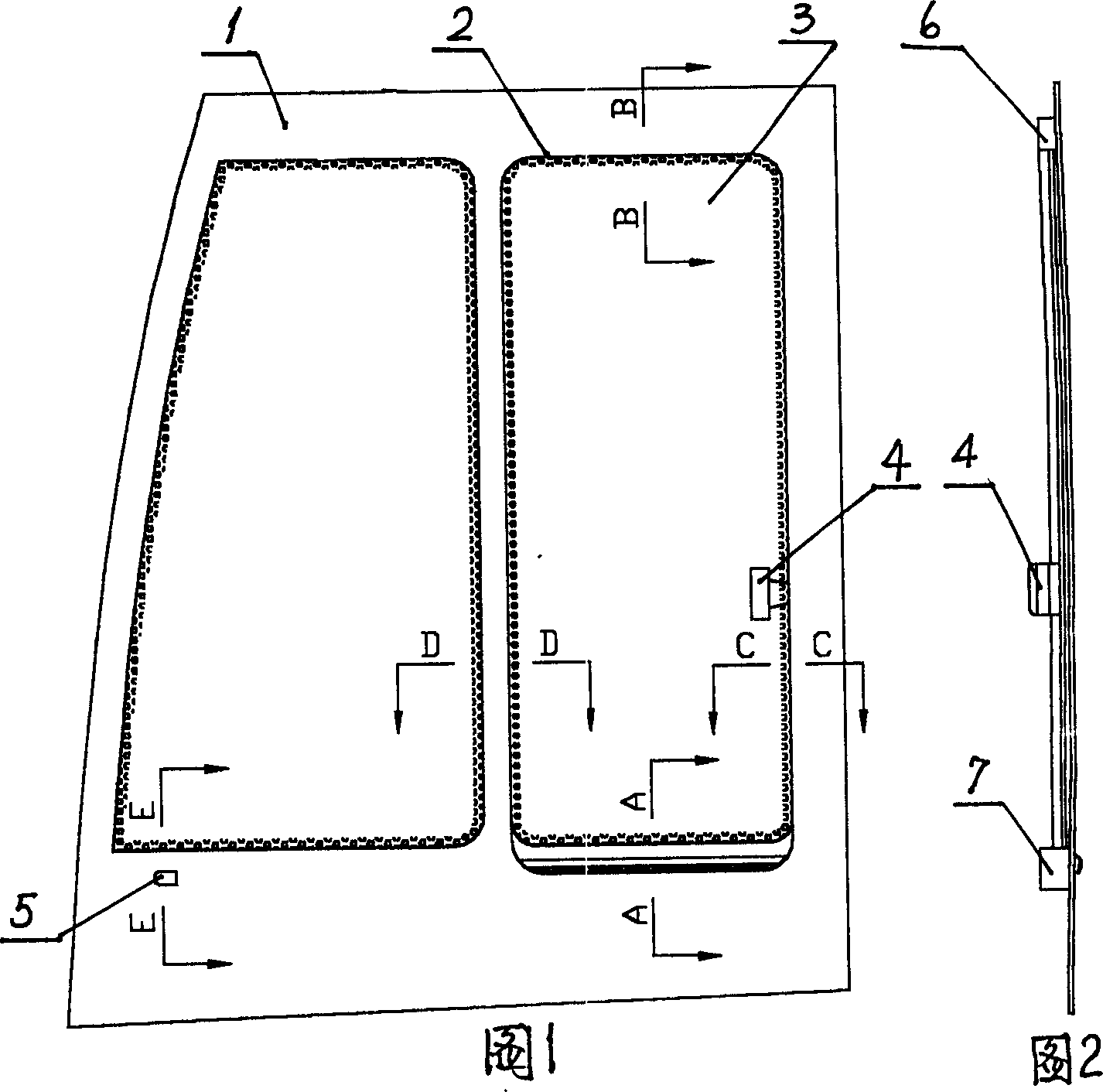

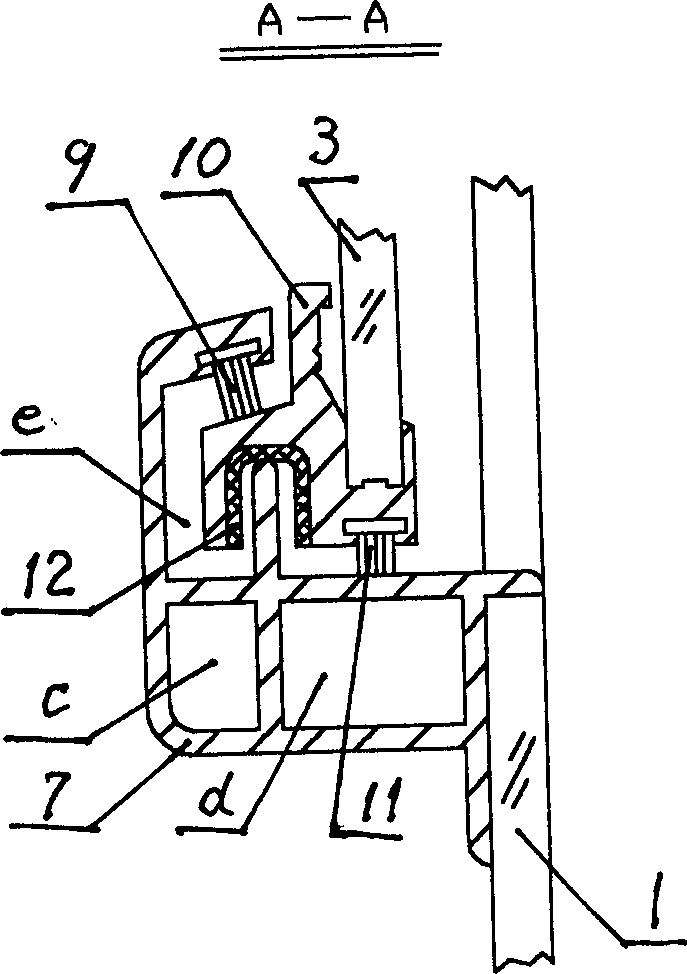

Adhesion type push pull safety glass window for automobile and its manufacturing technology

InactiveCN1590145AIt has the function of preventing rainwater leakageCompact structureWindowsWindscreensManufacturing technologyCutting glass

A high-safety push-pull glass window for car is composed of the fixed glass stuck on the window frame and with a window opening parallel two guide tracks stuck respectively above and under said window opening, and a movable glass sliding along said guide track for exposing or shielding said window opening. Its manufacture technology includes cutting glass, grinding, drilling hole, printing, stengthening, machining aluminium sections, and assembling by sticking with strong adhesive 504AB.

Owner:陈协民

Anti-static shoes

InactiveCN106820405AExquisite designGood practicalityElectrical testingFootwearProduction lineElectrical conductor

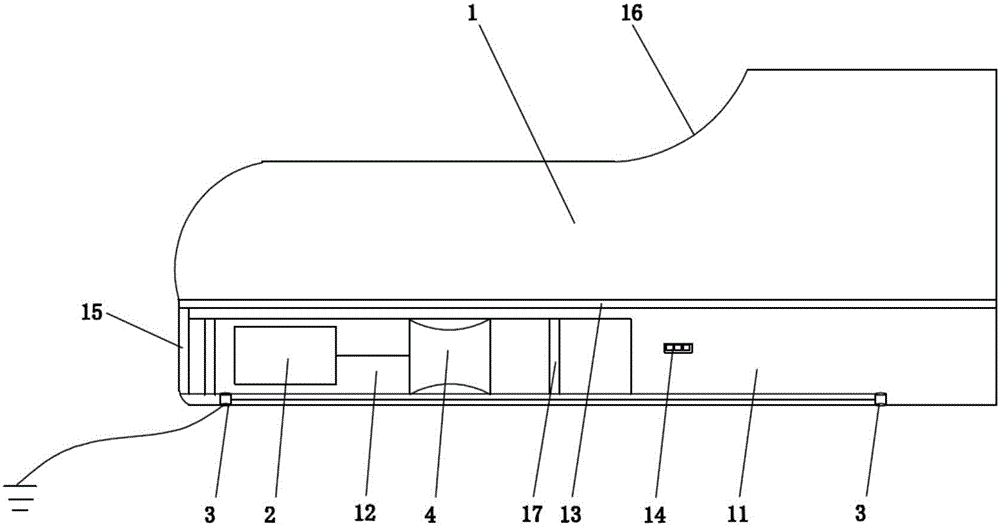

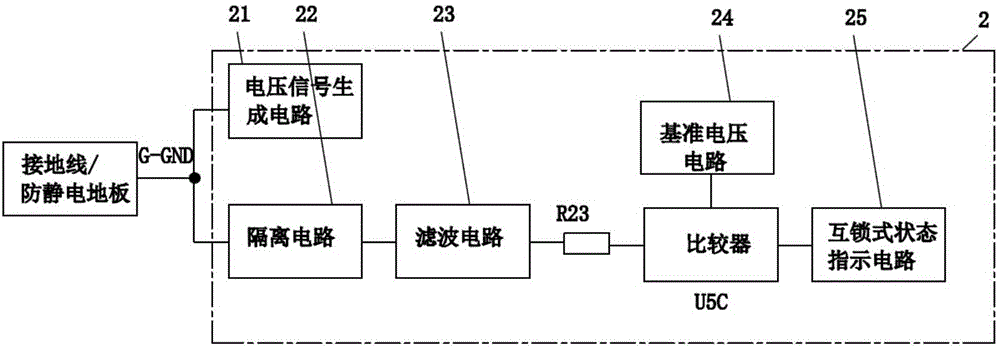

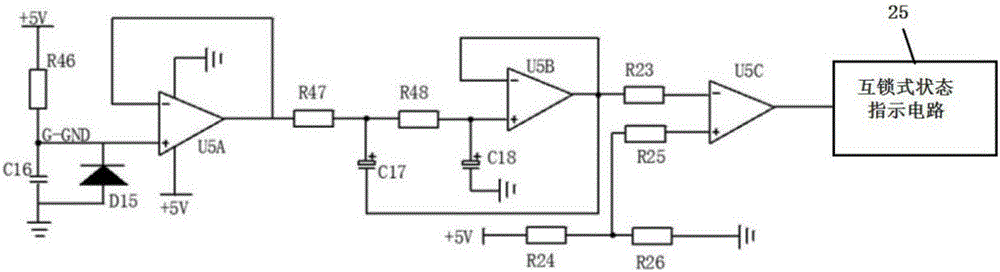

The invention discloses a pair of anti-static shoes. Each anti-static shoe comprise a shoe body made of an anti-static conductor material, wherein an accommodating cavity is formed in the sole part of the shoe body, a ground state monitoring circuit comprising a power supply is arranged in the accommodating cavity, the ground state monitoring circuit is connected with at least one ground button arranged at the sole part, and the at least one ground button is connected with a static discharge common ground point. The anti-static shoes are elaborate in design, the accommodating cavity is formed in the sole part of each shoe, each ground state monitoring circuit is provided with the power supply, so that mounting of the ground state monitoring circuits to the anti-static shoes becomes possible, a monitor is not needed to be additionally arranged to monitor ground state of an ankle band or a wrist band, and working position space is not occupied; meanwhile, the monitor is not needed to be dismounted or mounted when a production line changes, all that is needed is to connect the ground buttons on the anti-static shoes to the static discharge common ground points to realize static discharge and ground state detection, the application is more flexible and variable, and practicability and applicability are better.

Owner:SUZHOU TA&A ULTRA CLEAN TECH

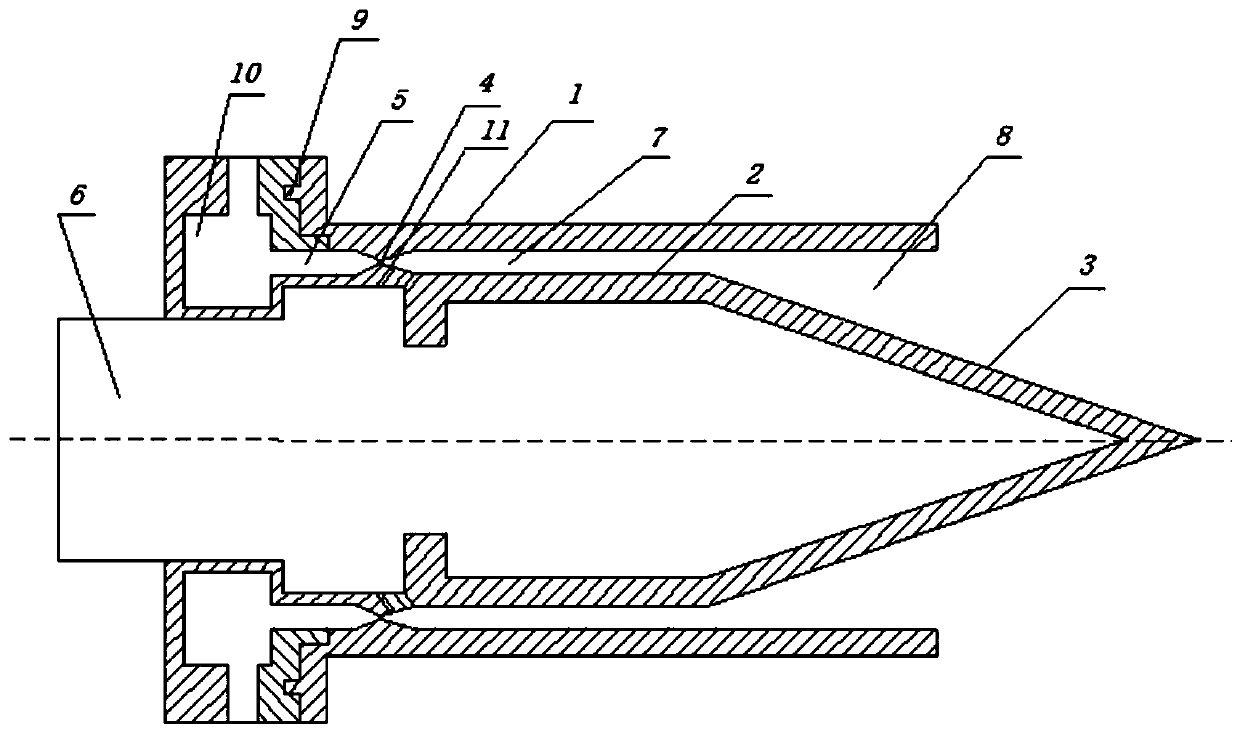

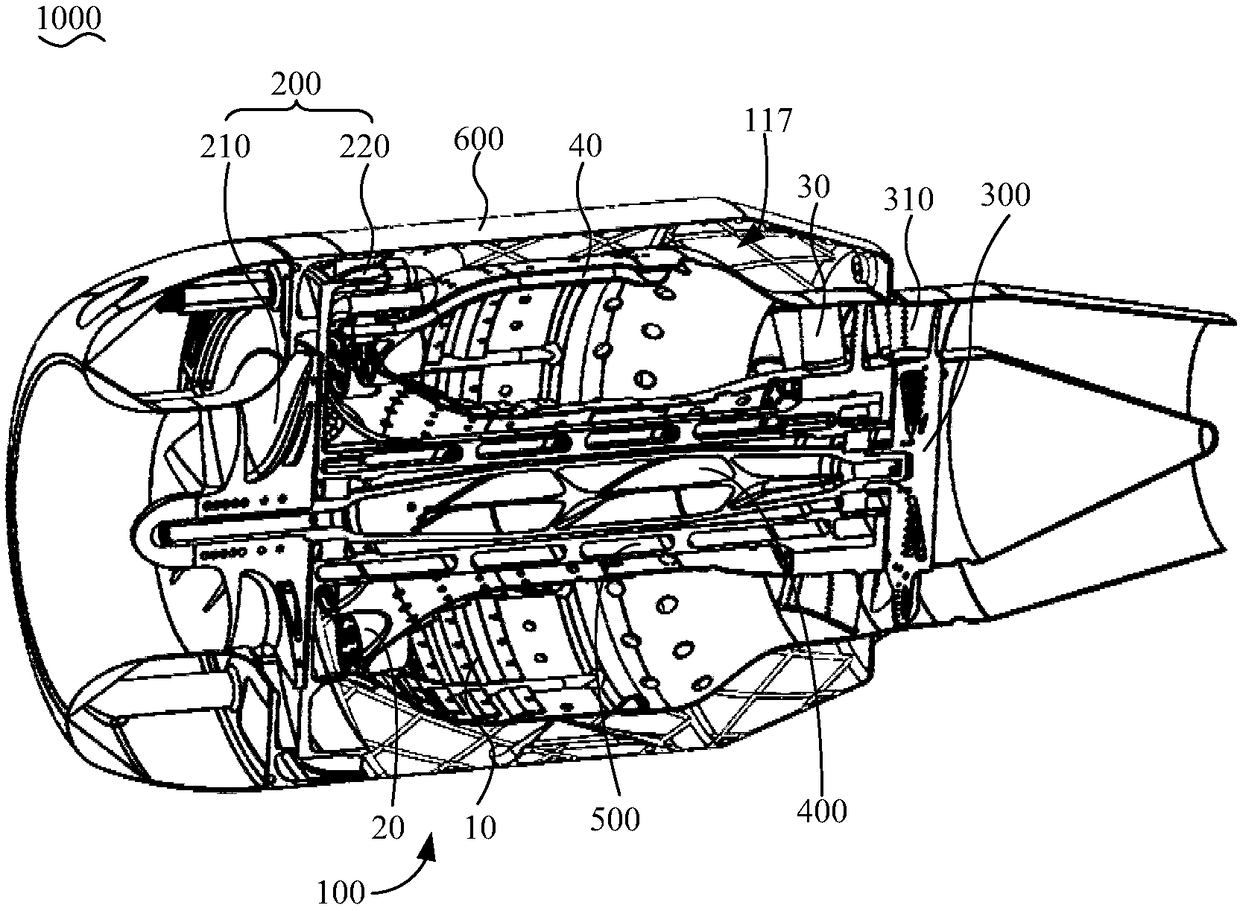

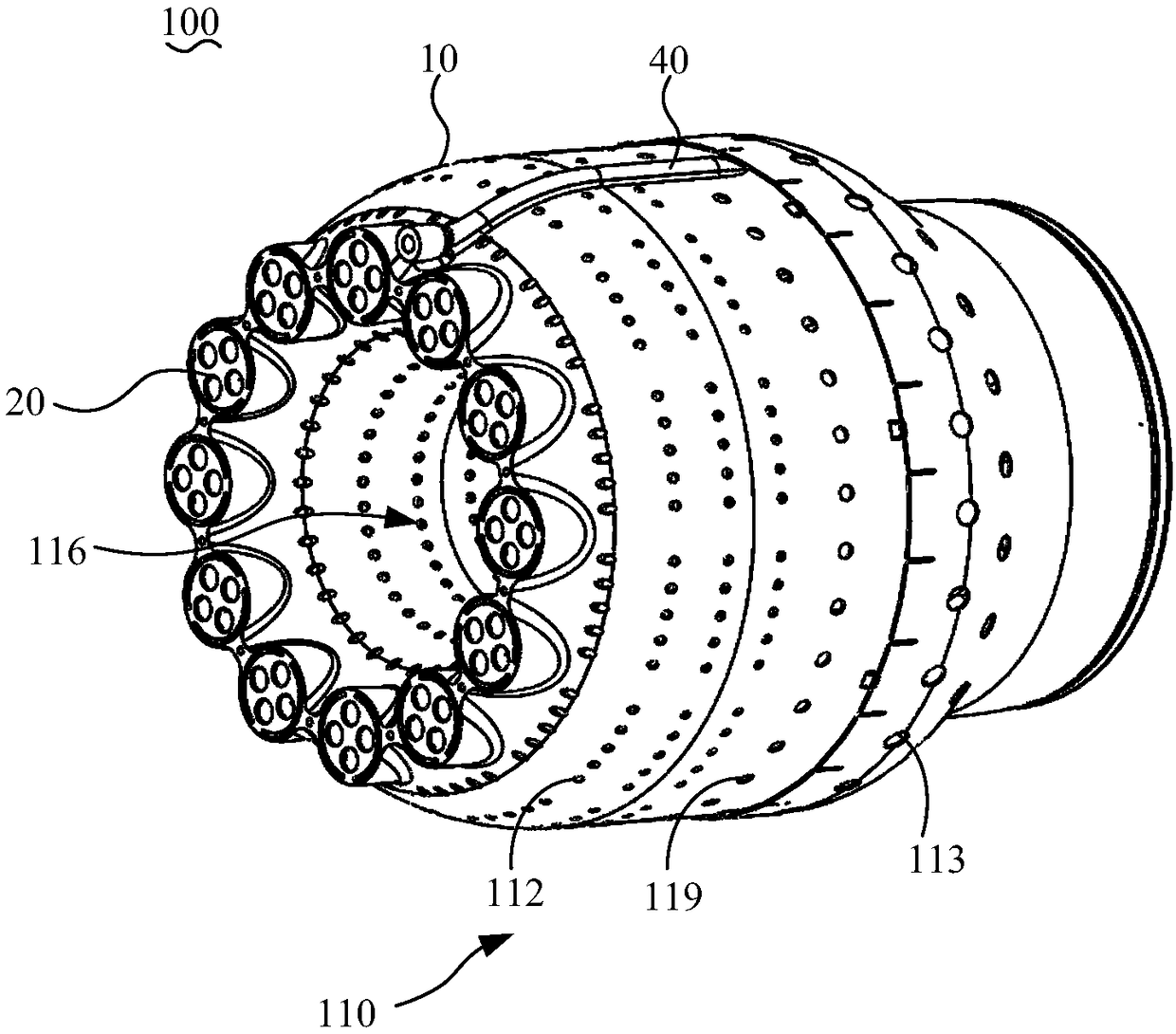

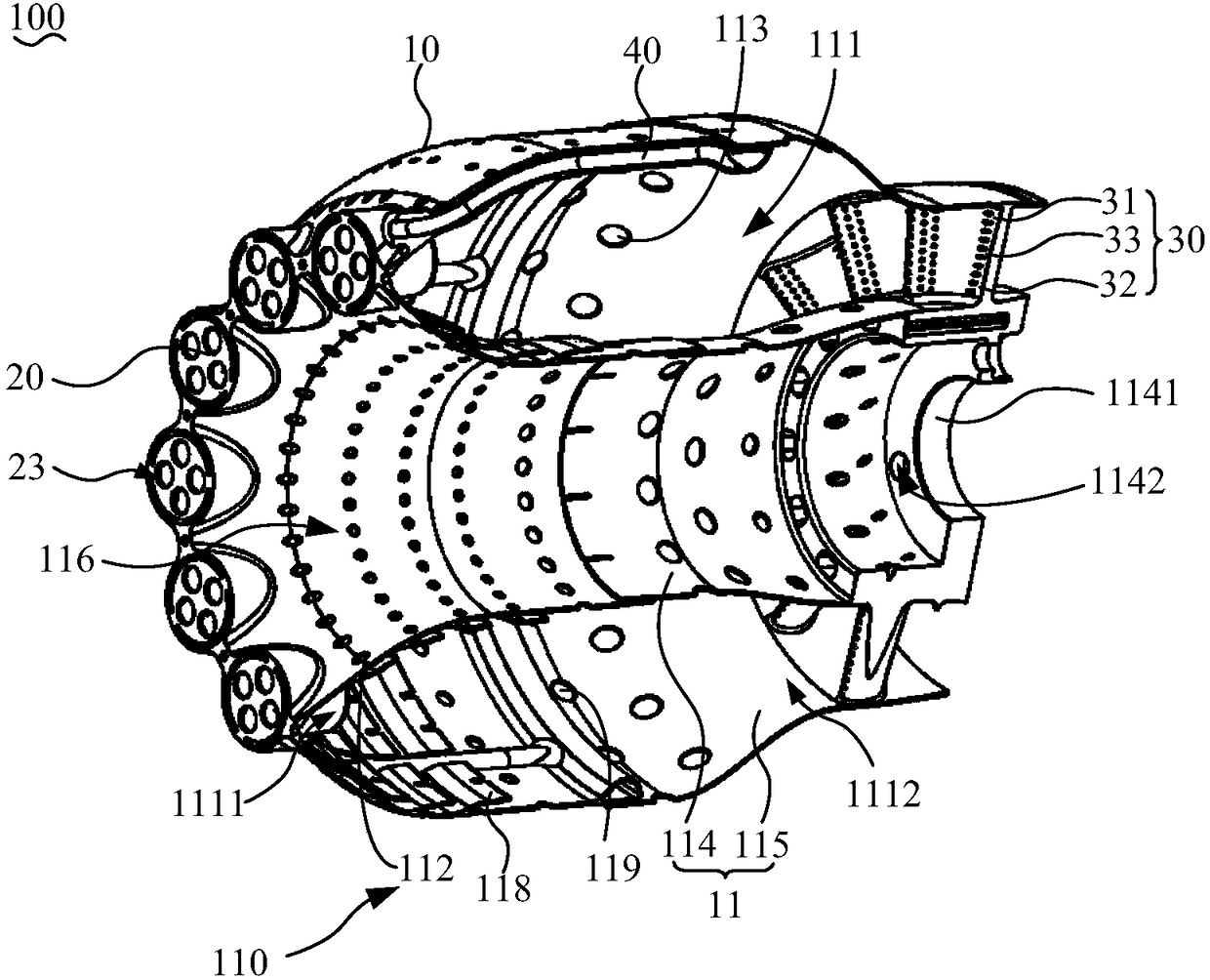

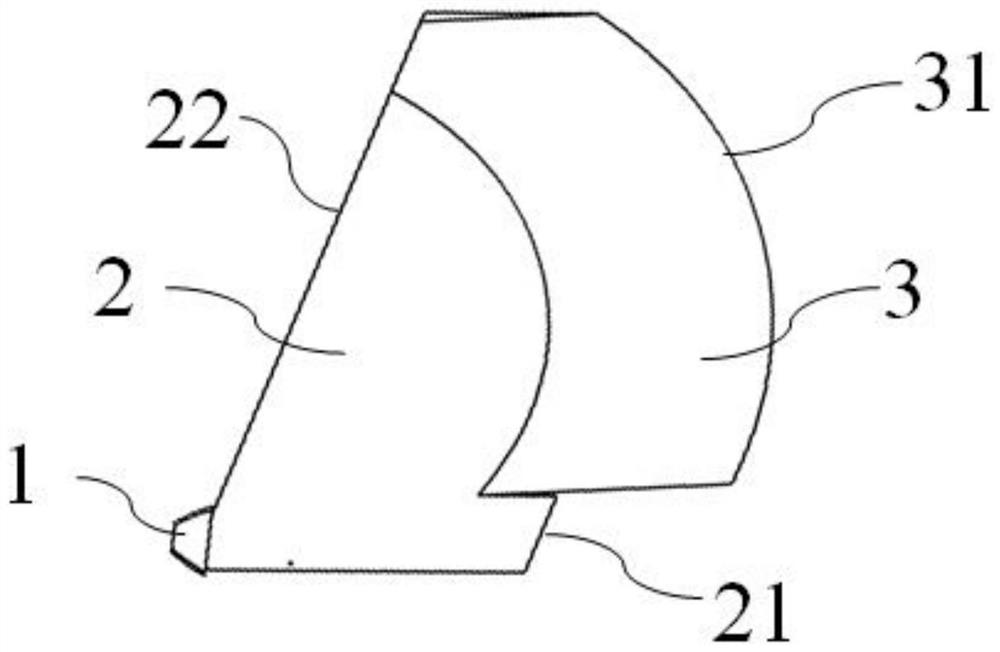

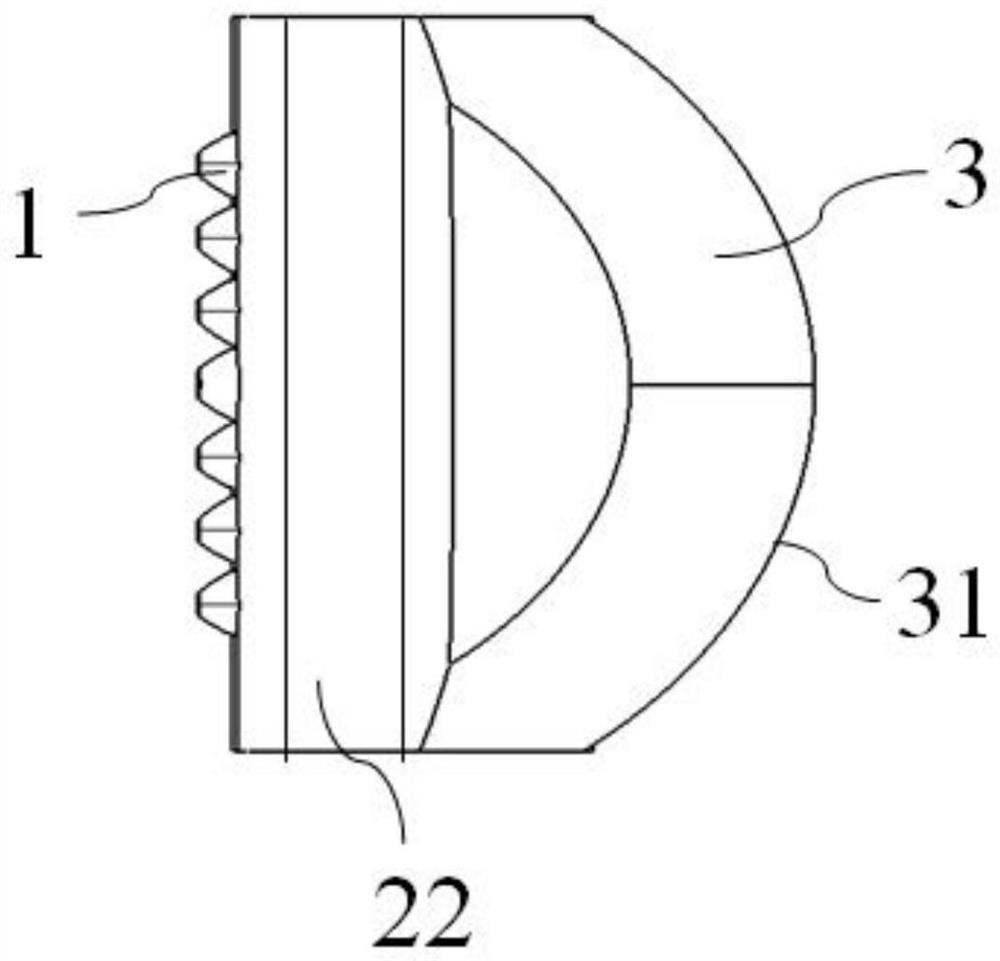

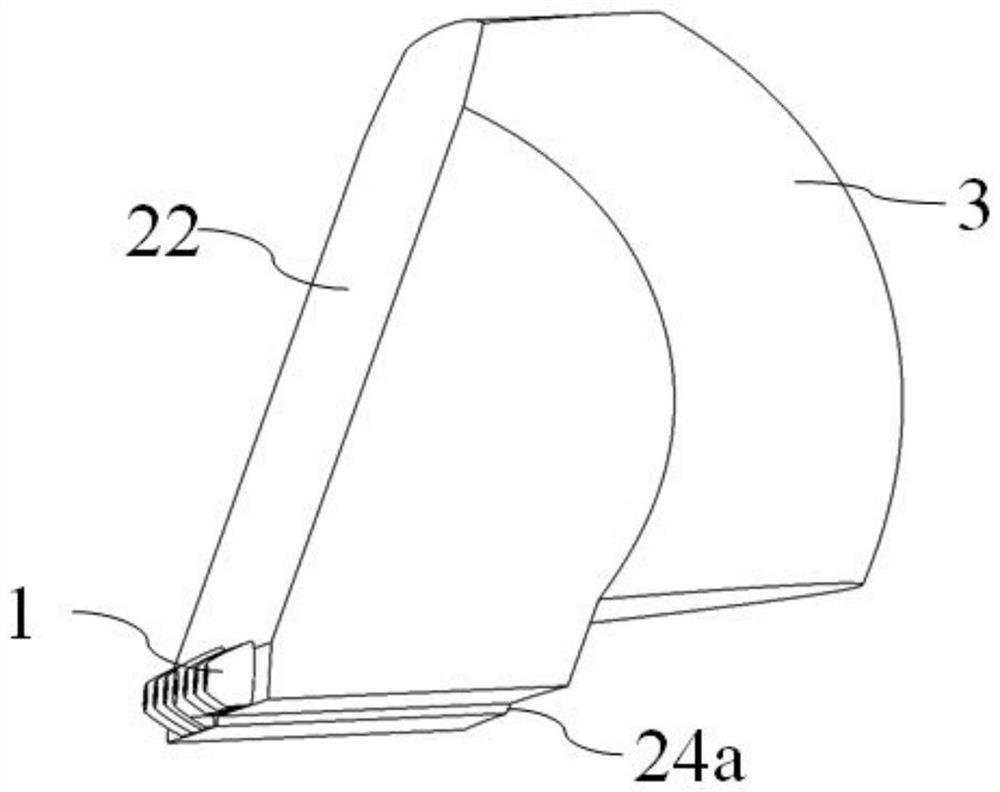

Continuous rotation detonation rocket engine manufactured by additive manufacturing and additive manufacturing method thereof

PendingCN111140399AReduced support structureReduce connection structureAdditive manufacturing apparatusIncreasing energy efficiencyCombustion chamberManufacturing technology

The invention relates to the technical field of aerospace equipment, in particular to a continuous rotation detonation rocket engine manufactured by additive design and manufacturing. The continuous rotation detonation rocket engine comprises an inner cylinder 2 of a rocket engine, a fuel injection unit 4, an oxidant annular cavity 5 and an oxidant gas collection chamber 10, wherein the fuel injection unit 4, the oxidant annular cavity 5 and the oxidant gas collection chamber 10 are connected with the inner cylinder 2 of the rocket engine; the inner cylinder 2, the fuel injection unit 4, the oxidant annular cavity 5 and the oxidant gas collection chamber 10 are integrated into an integral piece by additive manufacturing technology; and the space between a rocket engine casing 1 and the integral piece is a combustion chamber 7, and the rocket engine casing 1 and the integral piece are connected through positioning pins 9. The invention further relates to an additive manufacturing methodfor manufacturing the continuous rotation detonation rocket engine. The continuous rotation detonation rocket engine is integrally manufactured through the additive manufacturing technology, supportand connection structures between various components are reduced, machining is facilitated, and weight reduction and the reduction of the cost and difficulty of machining and maintenance are facilitated.

Owner:TSINGHUA UNIV

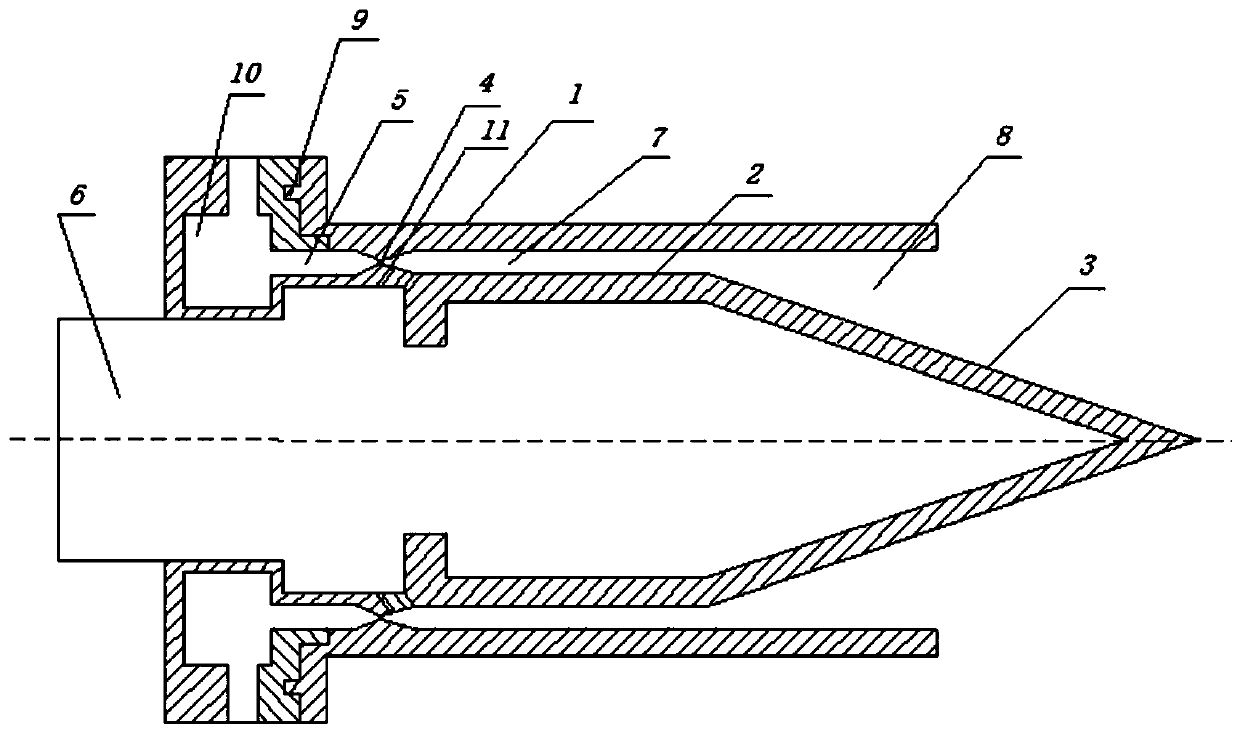

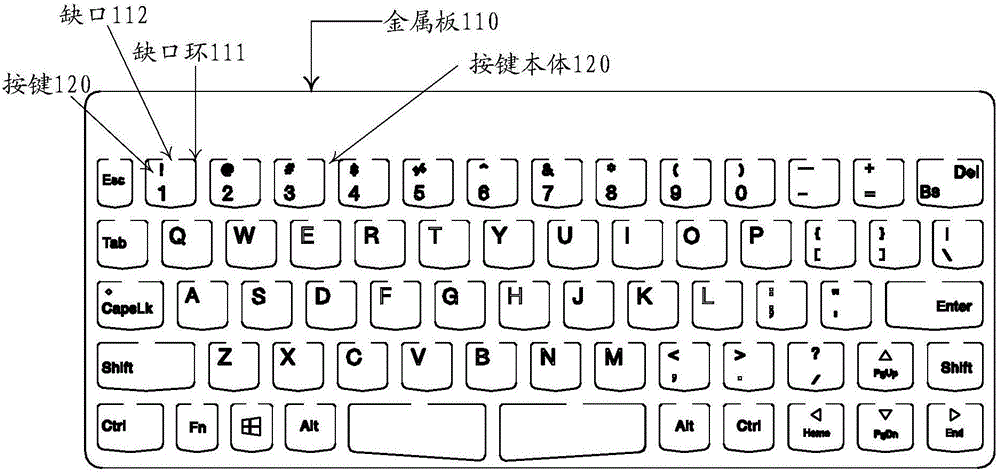

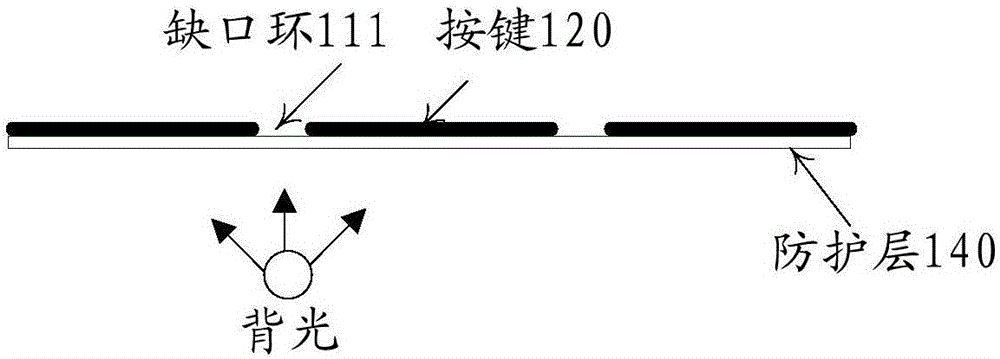

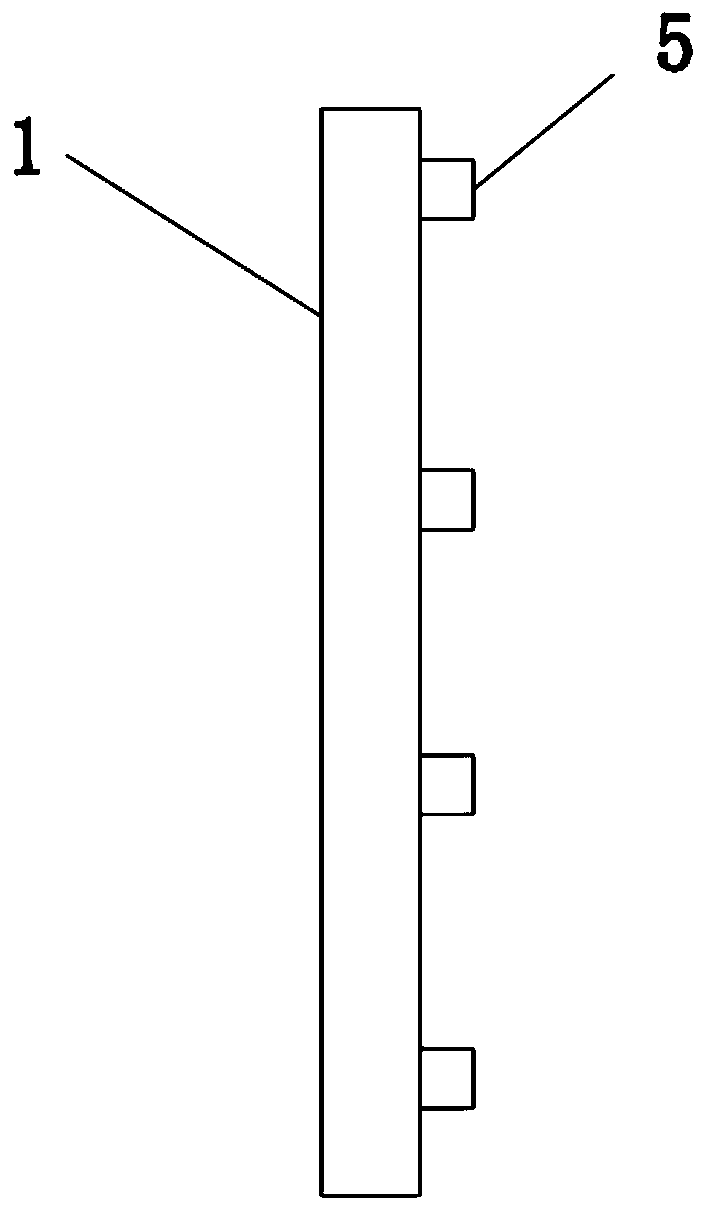

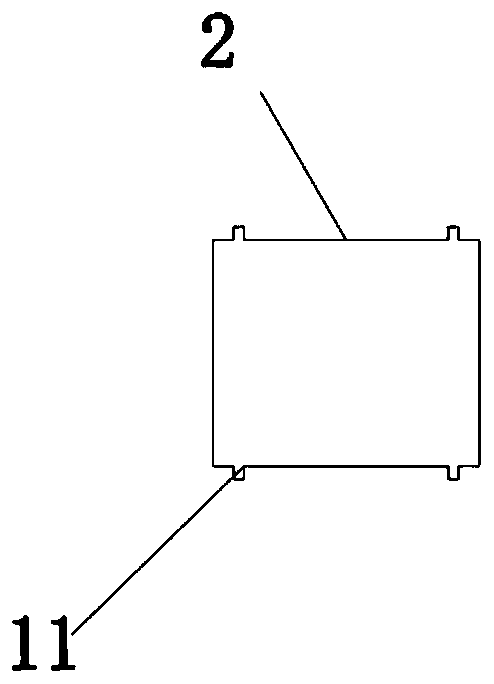

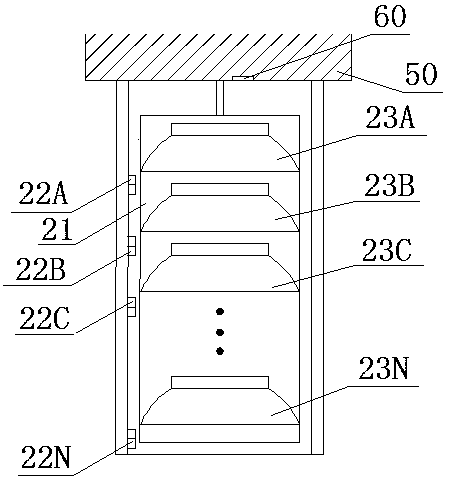

Key structure and electronic equipment

InactiveCN106229190AAvoid bad usageReduce connection structureElectric switchesEngineeringCantilever

The embodiment of the invention discloses a key structure and electronic equipment. The key structure comprises a metal plate; N notch rings are arranged on the metal plate, and N is an integer no less than 1; the notch ring is formed by a gap not closed completely; the unclosed place of the notch ring is the notch; the metal plate inside the notch ring forms a key; the metal plate out of the notch ring forms a key body; and the metal plate located at the notch is a cantilever connecting the key and the key body.

Owner:LENOVO (BEIJING) LTD

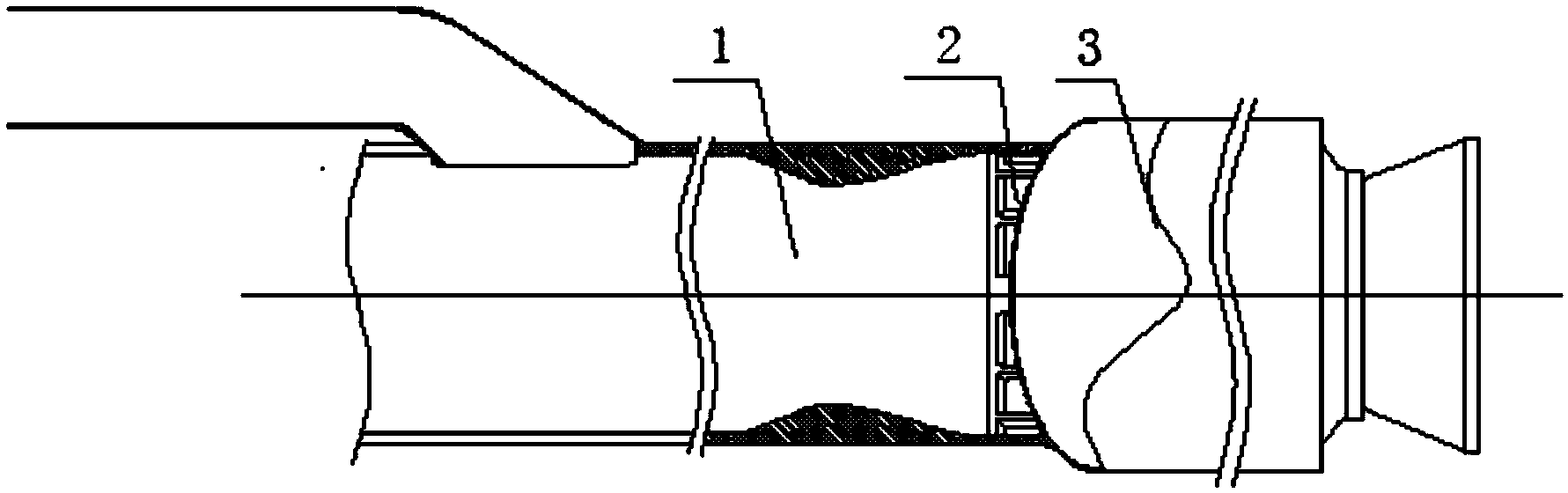

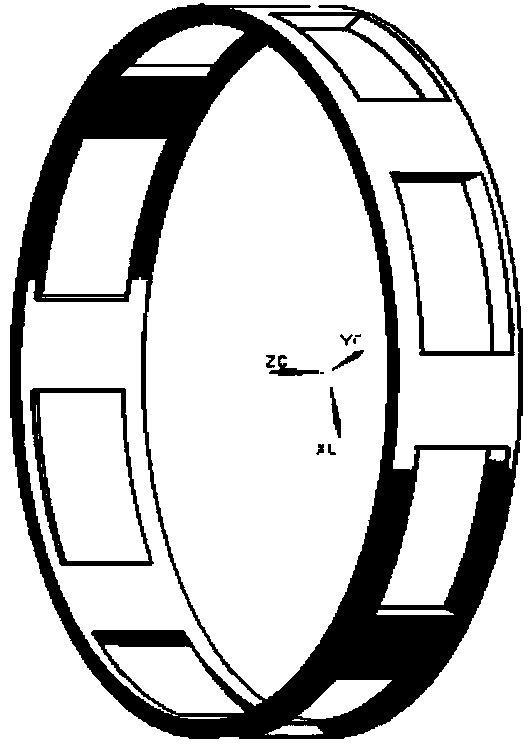

Air bleeder for ramjet

The invention belongs to the technical field of engines and particularly relate to an air bleeder for a ramjet. The air bleeder is of an annular structure. An air discharge port is formed in the outer circumferential surface of the air bleeder. The diameter of the outer circle of the air bleeder is equal to the diameter of the outer circle of the ramjet. The rear end of the air bleeder is fixedly connected with a booster. The front end of the air bleeder is connected with the tail portion of the ramjet. The air bleeder is simple in structural design and easy to obtain; through the structural design of the air bleeder, the pressure of a channel in the ramjet is effectively lowered in the operation process of the booster, so that the structure load is relieved, and the weight of the ramjet is reduced; the air bleeder and the booster structure can be formed in an integrated mode, so that a connecting structure is omitted, and the reliability is improved; in addition, after the operation process of the booster is ended, the air bleeder is separated from the booster, and therefore the extra weight of the ramjet is not increased.

Owner:BEIJING POWER MACHINERY INST

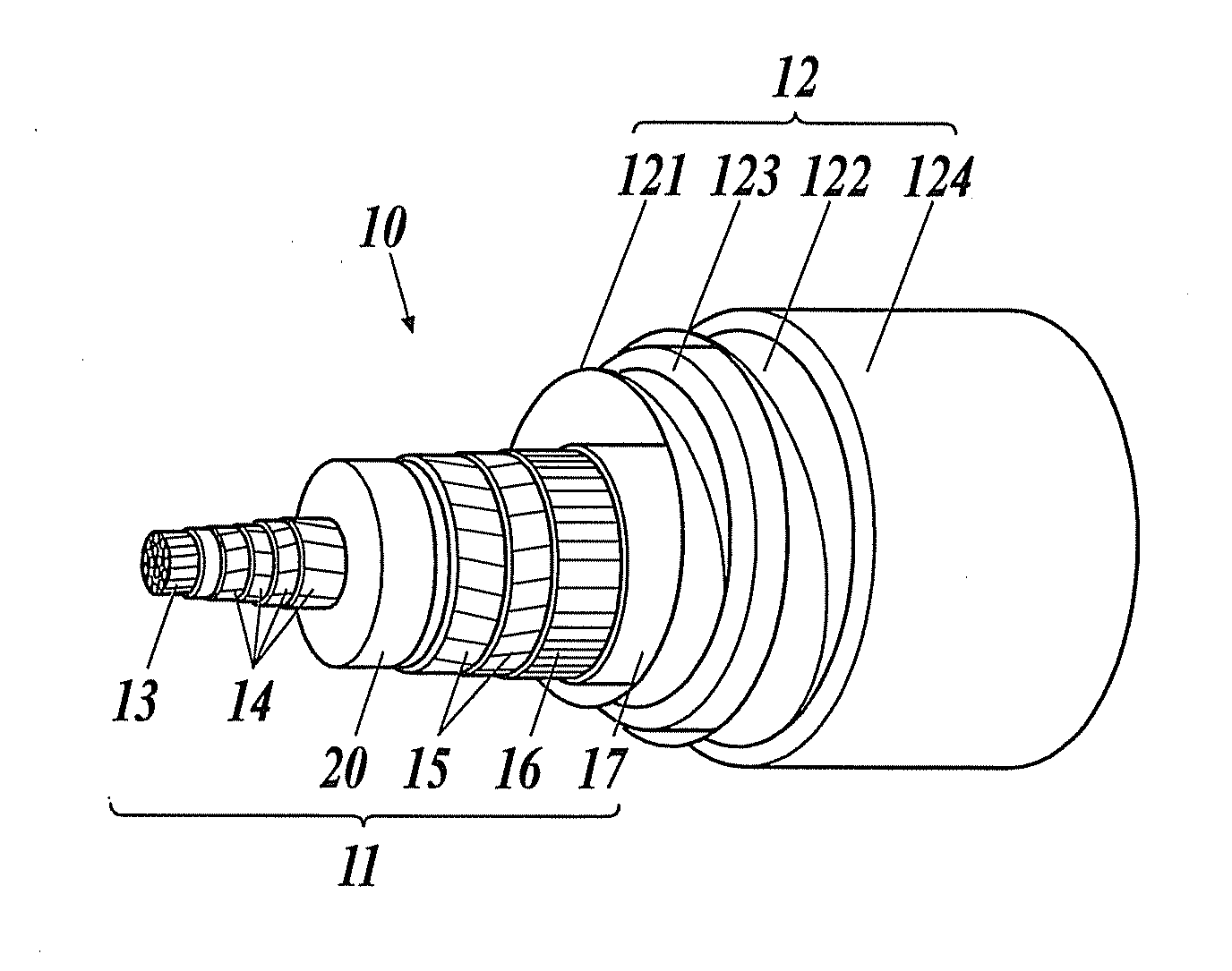

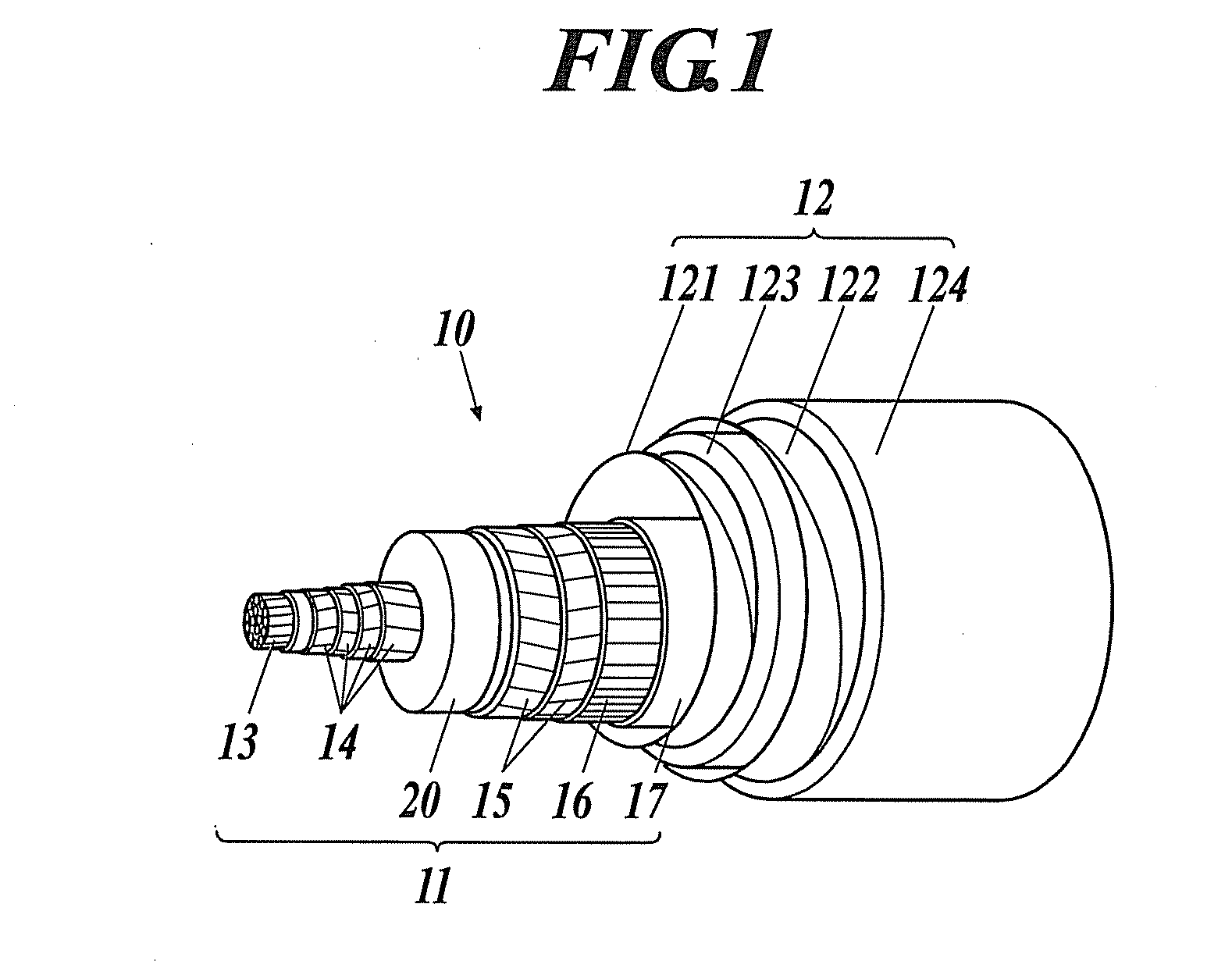

Engine, combustion assembly of engine and integrated designing and manufacturing method for combustion assembly

ActiveCN108592086ASimple structureReduced support structureContinuous combustion chamberCombustion chamberManufacturing technology

The invention discloses an engine, a combustion assembly of the engine and an integrated designing and manufacturing method for the combustion assembly. The combustion assembly comprises a flame tubeand nozzles; the flame tube comprises a main body; a combustion chamber is formed in the main body; through holes are formed in the main body and enable the combustion chamber to communicate with theoutside of the flame tube; the combustion chamber comprises a head part and a tail part which back onto each other; gas enters the flame tube from the head part and the through holes and flows out ofthe flame tube from the tail part; the nozzles are arranged on the head part; and the nozzles and the flame tube are integrally manufactured through an additive manufacturing technology. According tothe engine, the combustion assembly of the engine and the integrated designing and manufacturing method for the combustion assembly, the combustion assembly of the engine is integrally designed and manufactured by utilizing the additive manufacturing technology, the flame tube and the nozzles are fused into a whole, the structure of the combustion assembly can be simplified, supporting and connecting structures among components of the combustion assembly can be reduced, machining can be facilitated, weight reduction can be facilitated, the reliability can be improved, and the machining and maintenance cost can be lowered.

Owner:峰特(浙江)新材料有限公司

Connection structure for superconducting cables

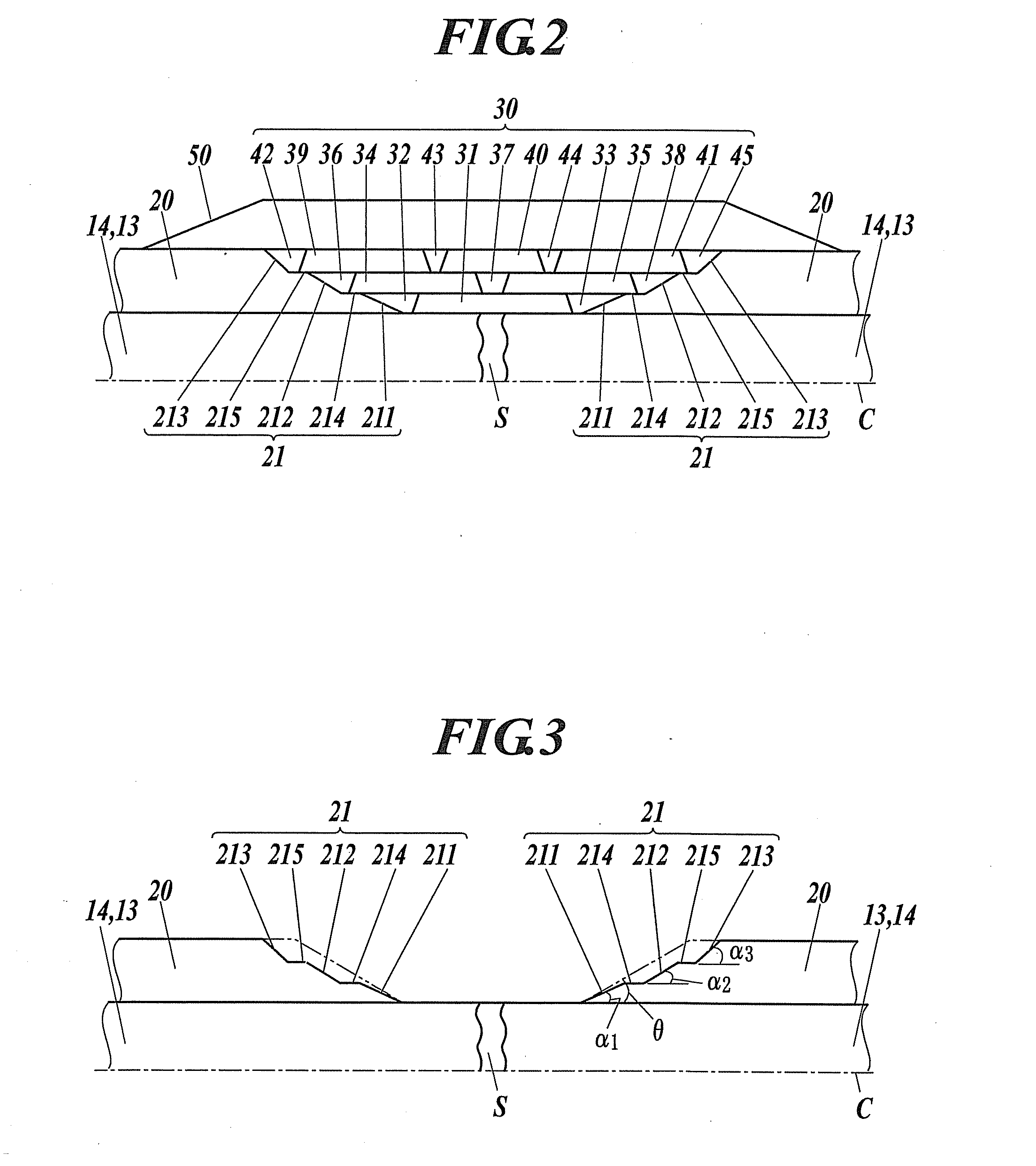

ActiveUS20150031546A1Reduce componentsShorten the lengthSuperconductors/hyperconductorsInsulated cablesElectrical conductorThermal insulation

A connection structure for superconducting cables includes: superconducting cables that are connected to each other and include cable cores containing formers and superconducting conductor layers, and each cable core is housed in a thermal insulation tube with a cooling medium, wherein the cable cores include electric insulating layers obtained by winding insulating sheets around the superconducting conductor layers, the electric insulating layers on both sides of a conductor connecting part, in which the formers and the superconducting conductor layers are connected to each other, include taper shape portions each having a diameter reducing towards the conductor connecting part, each taper shape portion is formed so as to have an inclination angle changing in a stepwise fashion by a plurality of tapered portions among which a tapered portion nearer the conductor connecting part has smaller inclination angle, and a reinforcing insulating layer is provided between the taper shape portions.

Owner:FURUKAWA ELECTRIC CO LTD

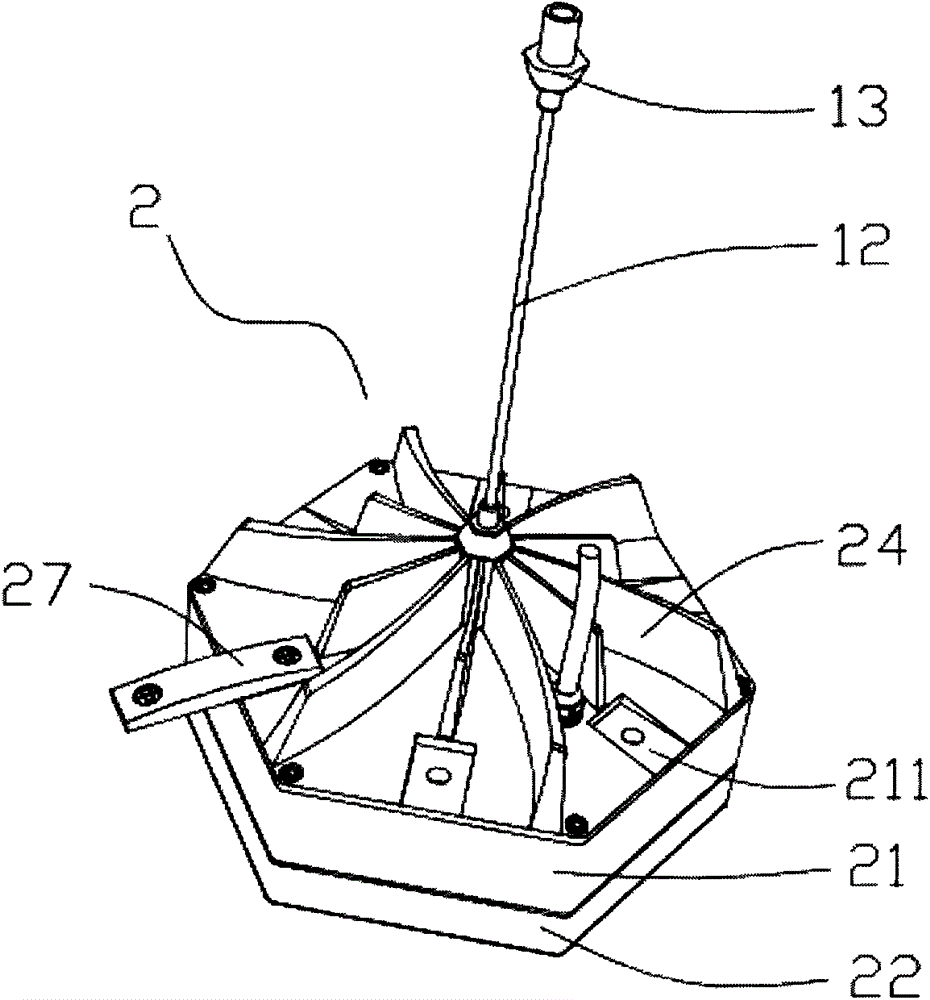

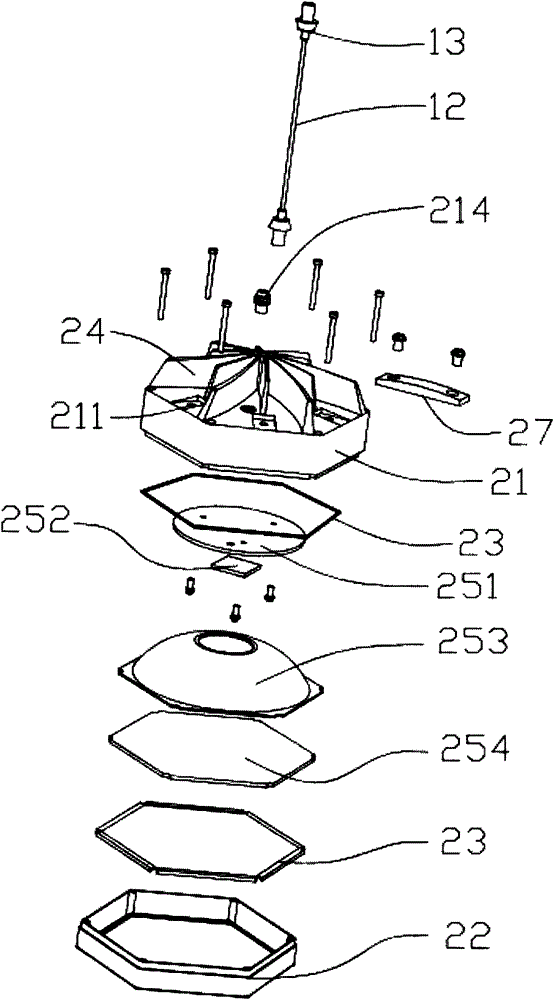

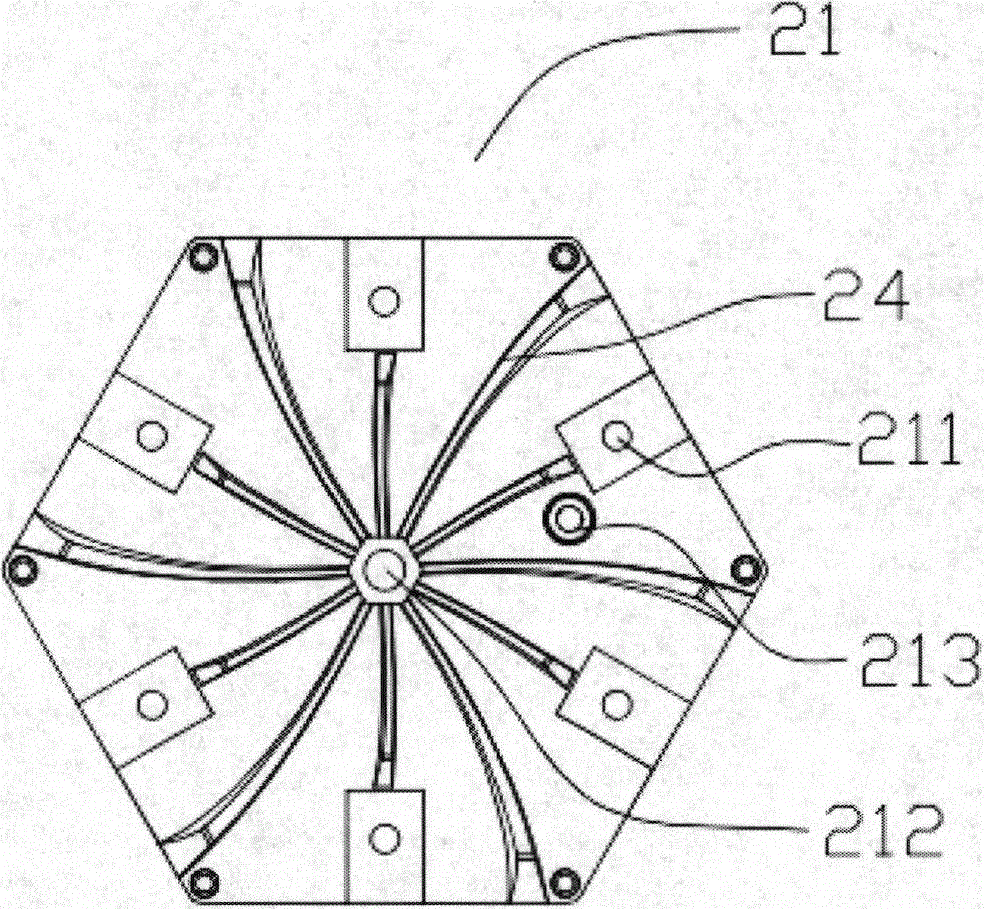

LED module assembly of lamp and mining lamp with module assembly

InactiveCN105202502ALow costIncrease ascent speedLighting applicationsPoint-like light sourceEffect lightEngineering

The invention discloses an LED module assembly of a lamp. The LED module assembly comprises an upper module cover and a lower module cover which form a lighting lamp cavity, and an LED light source arranged in the lighting lamp cavity. Multiple cooling fins are arranged on the upper module cover and arranged around the center axis of the upper cover in a vortex mode. The invention further discloses the mining lamp with the LED module assembly. The mining lamp comprises a lamp support which is used for being connected with and fixing the LED module assembly and is of a flexible structure or a rigid structure. Through the effective improvement in the cooling structure of the LED module assembly, heated airflow ascends to meet the cooling airflow motion Coriolis theorem, the flow speed of heat is increased, and meanwhile the cooling area is increased; the combined high-power lamp has better cooling performance, the working efficiency of LEDs is effectively improved, and the service life of the lamp is prolonged; meanwhile, it is possible to form the large-area lighting lamp through the LED module assembly.

Owner:雷格工业设计(杭州)有限公司

Electric motorcycle frame assembly with modular design

InactiveCN111976878AIncrease productivityReduce manufacturing stepsCycle batteriesVehiclesVehicle frameElectrical battery

The invention provides an electric motorcycle frame assembly with modular design. The electric motorcycle frame assembly comprises a first component module, a second component module and a third component module, and two girder frames are arranged symmetrically, wherein a battery stacking mechanism and a storage mechanism are fixedly connected at the position, located on the top, between the girder frames; a first fixing plate and a second fixing plate are fixedly connected with both sides between the two girder frames separately, and one side of the first fixing plate is fixedly connected with two first connecting pieces; one side of the second fixing plate is fixedly connected with two second connecting pieces, and a pedal frame is welded between the two first connecting pieces; and thefirst component module is fixedly connected with one side of the pedal frame, and the third component module is fixedly connected with the two second connecting pieces. According to the scheme of theelectric motorcycle frame assembly, the modular motorcycle frame assembly is simple in structure and light in motorcycle body, and facilitates users to ride; meanwhile, battery packs are stacked in the battery stacking mechanism, and heat dissipation of the battery packs can be achieved in the using process through a plurality of fixing rods properly.

Owner:何鹏程

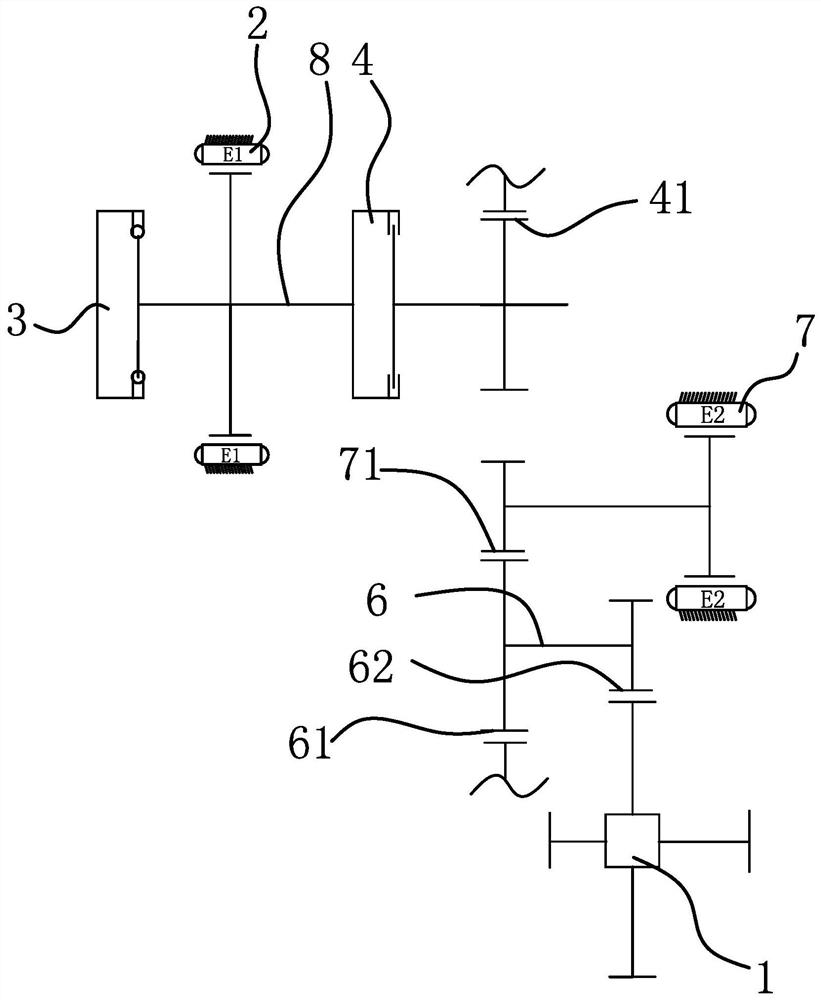

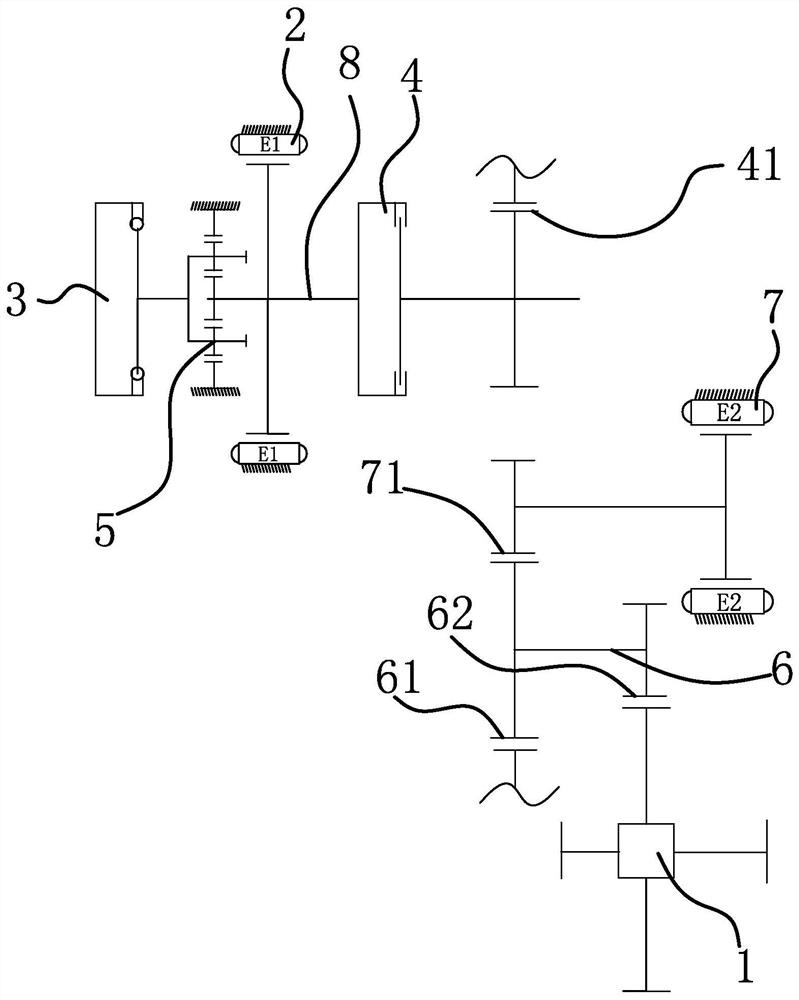

DMT dual-motor hybrid transmission

InactiveCN113085535AReduce axial layout spaceReduce connection structureGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectric machineryDrive motor

The invention provides a DMT dual-motor hybrid transmission, and belongs to the technical field of hybrid power. With the DMT dual-motor hybrid transmission adopted, the problem that an existing hybrid power system is high in energy consumption is solved. The transmission comprises a differential mechanism assembly, a generator, a driving motor, an input shaft and a flywheel which is connected with an engine crankshaft, the input shaft is in transmission connection with the differential mechanism assembly through a clutch, the input shaft is in transmission connection with the flywheel, the driving motor is in transmission connection with the differential mechanism assembly, the generator is located between the flywheel and the clutch. the input shaft penetrates into the generator and is connected with a rotor of the generator, and the input shaft and the flywheel are coaxially arranged. The transmission is simple in transmission structure, and the power generation efficiency of the generator is high, so that energy consumption is reduced, the axial arrangement space of the transmission is reduced, and the difficulty of the mounting process of parts in the transmission is reduced.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

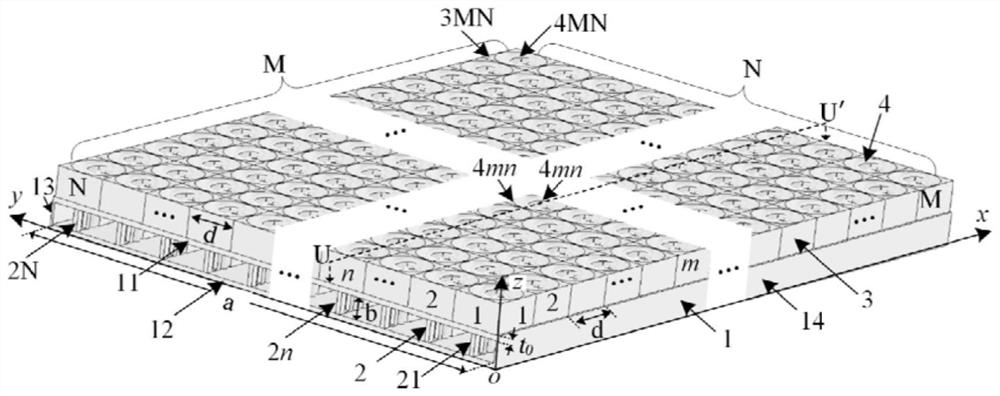

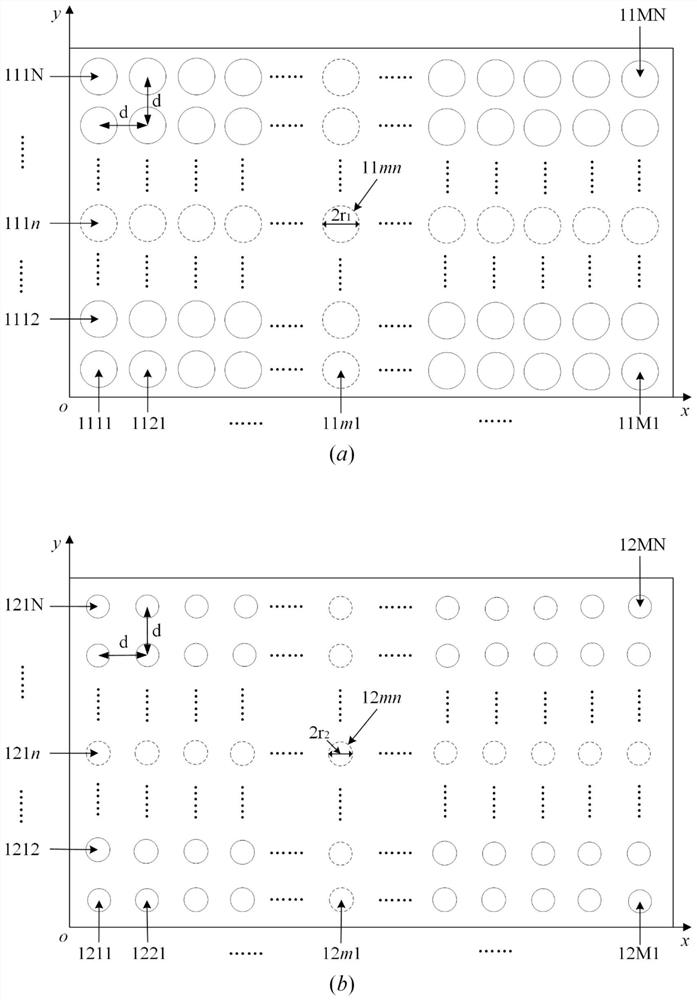

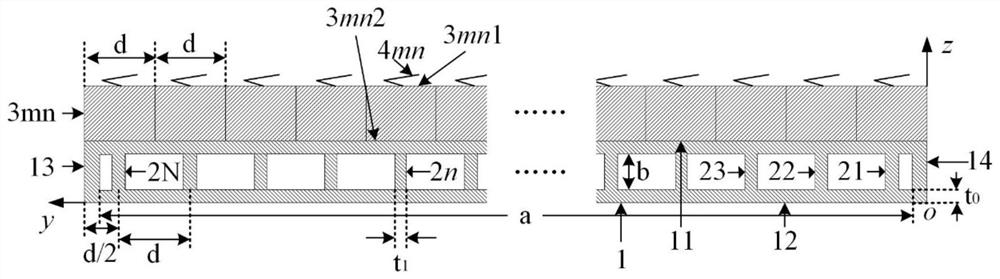

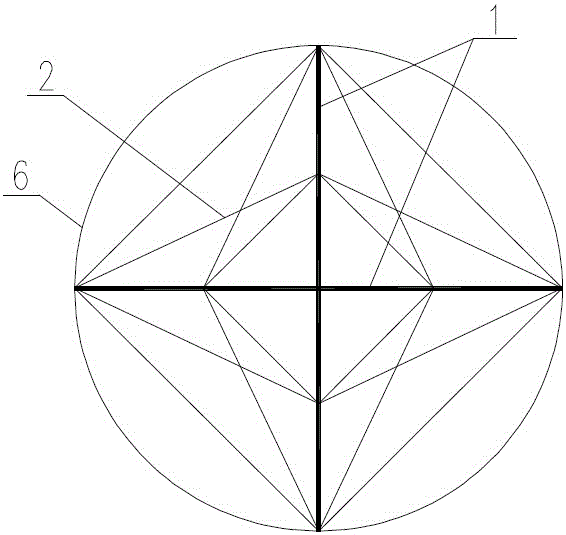

Flat waveguide feed two-dimensional beam scanning antenna

ActiveCN112615156AReduce section heightReduce connection structureParticular array feeding systemsIndividually energised antenna arraysEngineeringBeam scanning

The invention discloses a flat waveguide feed two-dimensional beam scanning antenna; the antenna is composed of a flat waveguide, N baffles, M*N outer cavities and M*N short spiral antennas; the baffle is a long rectangular plate; the outer cavity is a cuboid of which the center is provided with a radius-variable circular channel; the N baffles are inserted into the flat waveguide in the direction parallel to the x axis, so N+1 rectangular channels are formed in the flat waveguide, and the width of the N-1 rectangular channels in the middle is d; the M*N outer cavities are tightly arranged in a manner that square grids with the side length of d are parallel to the xoy plane, and the lower surfaces of the outer cavities are attached to the upper surface of the flat waveguide; and the M*N short helical antennas respectively pass through the M*N outer cavity circular channels and sequentially pass through the upper waveguide wall of the flat waveguide, the baffle plate and the lower waveguide wall of the flat waveguide. According to the method, defects of high profile, narrow working bandwidth, low power capacity and non-uniform microwave transmission of the existing spiral array antenna are overcome, the spiral antenna can be controlled to rotate in rows and columns, and two-dimensional scanning of wave beams is realized.

Owner:NAT UNIV OF DEFENSE TECH

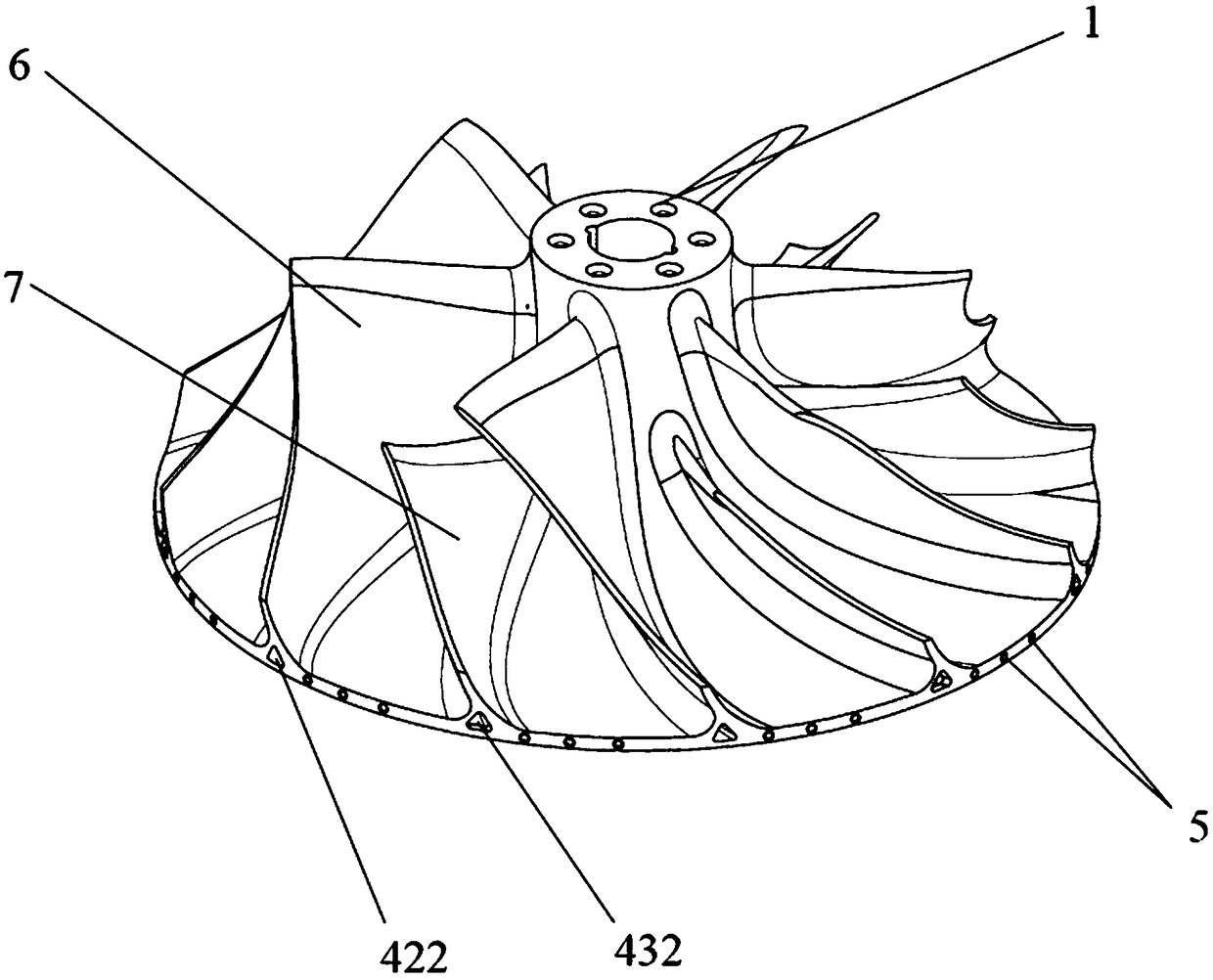

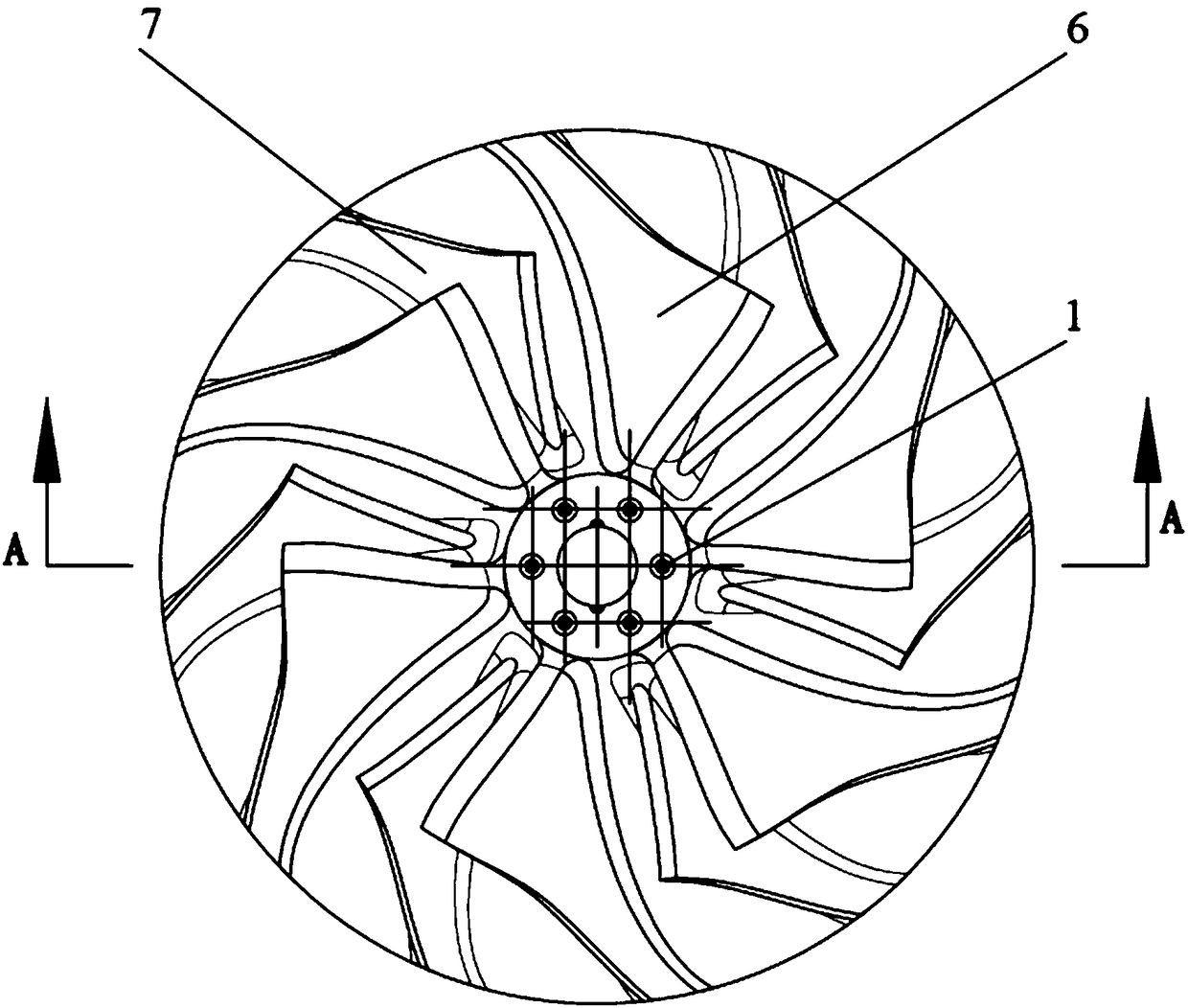

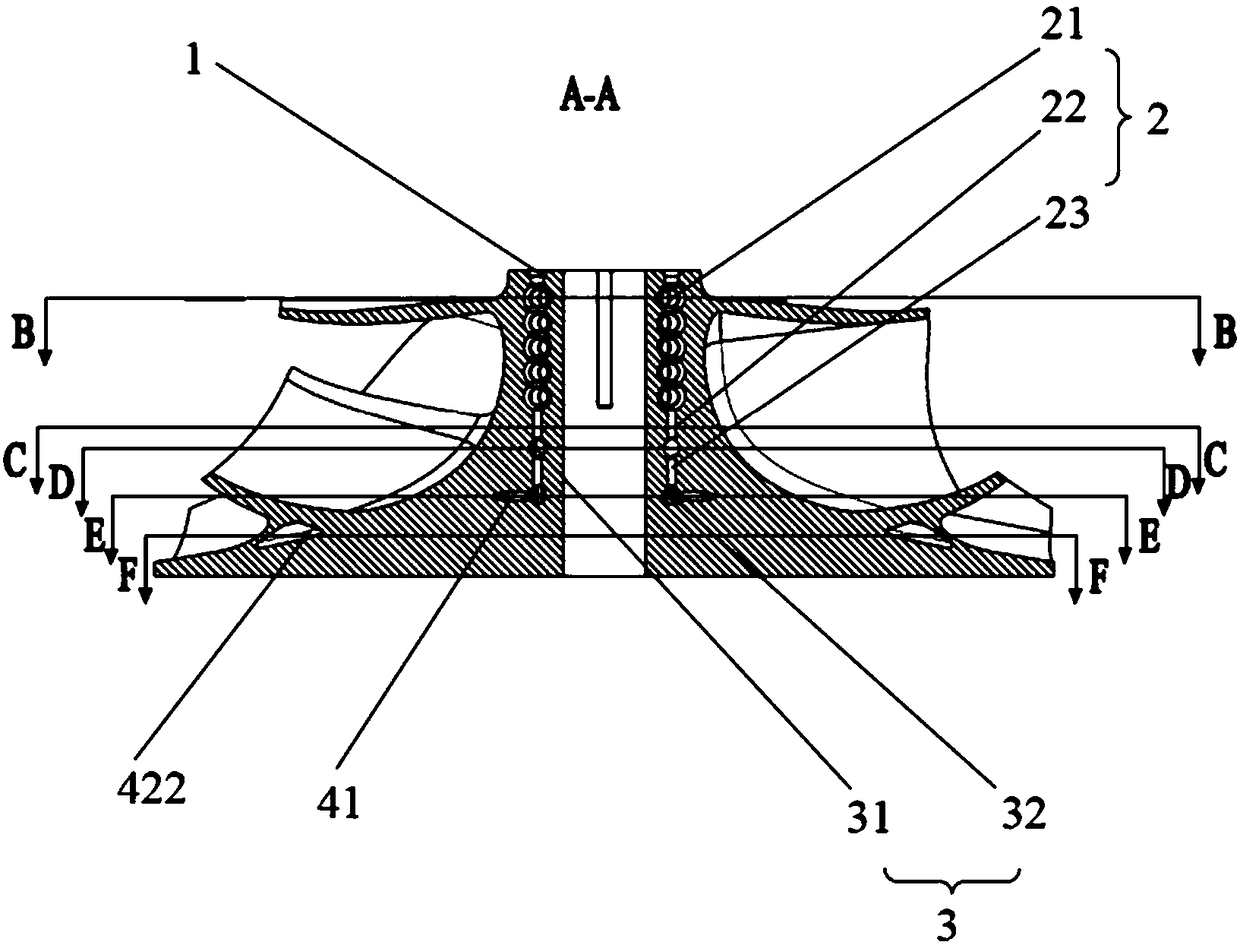

Wheel disc and air compressor comprising same

ActiveCN108412806ASimplify the production processEasy to processPump componentsPumpsAir compressorProduction cycle

The invention belongs to the technical field of aero-engine manufacturing, and discloses a wheel disc and an air compressor comprising the same. The wheel disc comprises a wheel disc body; a pluralityof main vanes and a plurality of sub vanes are arranged on the wheel disc body; the wheel disc body is of an integral structure; the wheel disc body is of a hollow structure; the hollow structure comprises a communication ring component which is arranged along the periphery of the wheel disc body, a main pipeline component which is arranged in the axial direction of the wheel disc body and a subpipeline component which is arranged in the radial direction of the wheel disc body; a plurality of first powder discharging holes are formed in the top end surface of the wheel disc body; a pluralityof second powder discharging holes are formed in the bottom outer side of the wheel disc; and the first powder discharging holes, the main pipeline component, the communication ring component, the sub pipeline component and the second powder discharging holes communicate with one another. The invention further provides the air compressor comprising the wheel disc. The wheel disc body is of the integrated structure, so that production procedures are simplified, and a production cycle is shortened.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

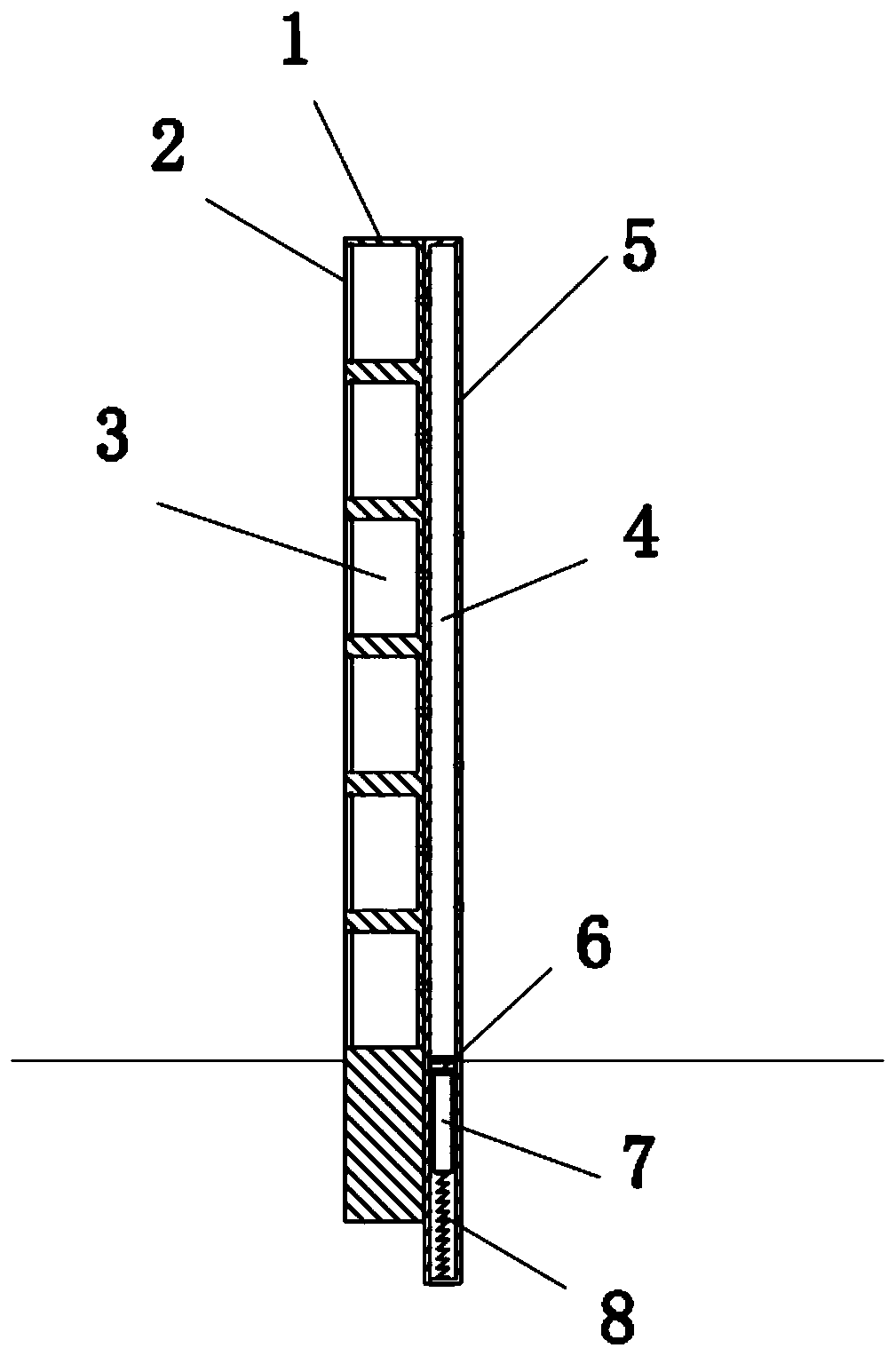

Light building wall

The invention discloses a light building wall. The light building wall comprises a wall framework which is integrally formed, more than one stand column is perpendicularly arranged on the inner side surface of the wall framework, the wall framework and the stand columns are inserted into soil, the bottoms of the stand columns extend out of the lower end surface of the wall framework, the position,right opposite to each stand column, of the wall framework is provided with more than one independent hollow cavity from top to bottom, a wallboard is movably arranged in each hollow cavity and sealsthe open end of the outer side of the whole hollow cavity, the position, right opposite to the corresponding stand column, of the bottom surface of each hollow cavity is provided with a first throughhole, the stand columns right opposite to the first through holes are provided with second through holes, the first through holes are communicated with the second through holes, and each stand columnis internally provided with a sealing channel. The light building wall is suitable for construction sites, a light wall structure is adopted, the wind-resistant performance can be guaranteed, in addition, the impact failure of a construction site base material or a construction vehicle to a wall body can be well avoided, and the use is safer.

Owner:东阳市君泰建筑工程有限公司

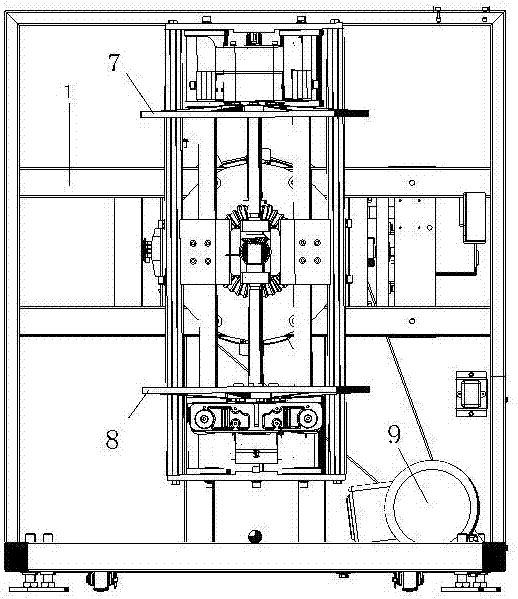

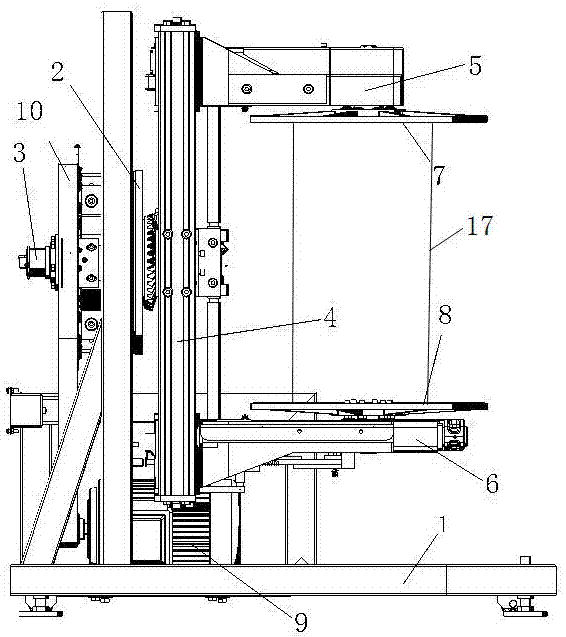

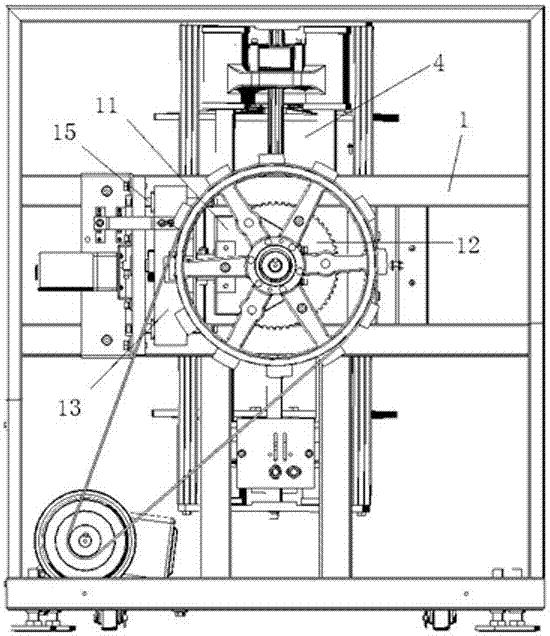

Transmission mechanism applicable to double-rotation coating mixing machine

ActiveCN107376769AReduce connection structureLow failure rateRotating receptacle mixersTransportation and packagingDouble rotationCoating

The invention relates to a transmission mechanism applicable to a double-rotation coating mixing machine. The transmission mechanism comprises a rotary main shaft, a compression main shaft, a guide rail frame, an upper support arm, a lower support arm, an upper pressure disc and a lower pressure disc, wherein the rotary main shaft is mounted on the stander, the compression main shaft penetrates into the rotary main shaft, the guide rail frame is fixed at the front end of the rotary main shaft, the upper support arm and the lower support arm are arranged eon the guide rail frame and can move up and down in different opposite directions along the guide rail frame, and the upper pressure disc and the lower pressure disc are respectively mounted on the upper support arm and the lower support arm and can rotate; and the rotary main shaft can be used for driving the whole guide rail frame to rotate along the axis of the rotary main shaft and simultaneously driving the upper pressure disc to rotate around the axis through a driving system. The transmission mechanism applicable to the double-rotation coating mixing machine is simple and reasonable in structure and is arranged on the double-rotation coating mixing machine, and by virtue of the action of a driving disc locking device, two independent works including the independent rotation of the compression main shaft and the synchronous rotation of the compression main shaft and the rotary main shaft are independently finished through the driving of a motor.

Owner:ZHENGZHOU SANHUA TECH & IND

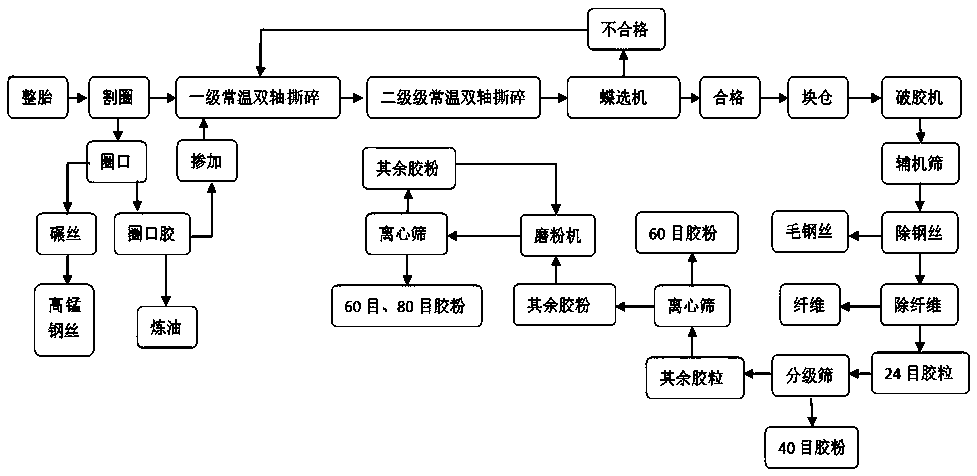

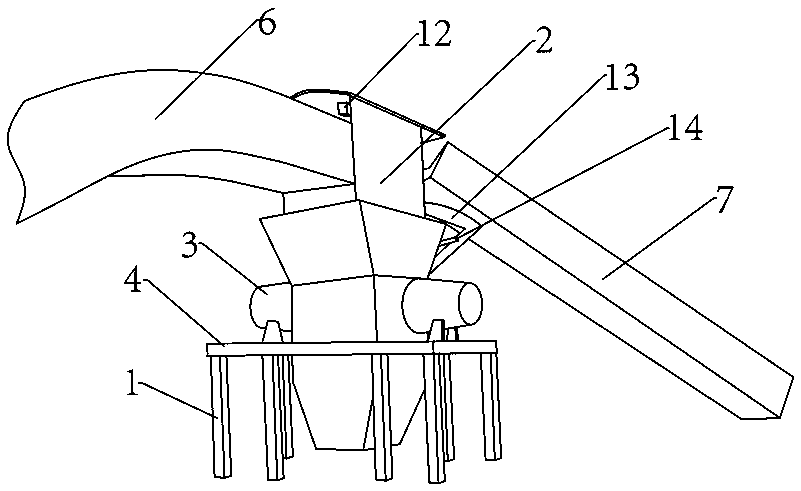

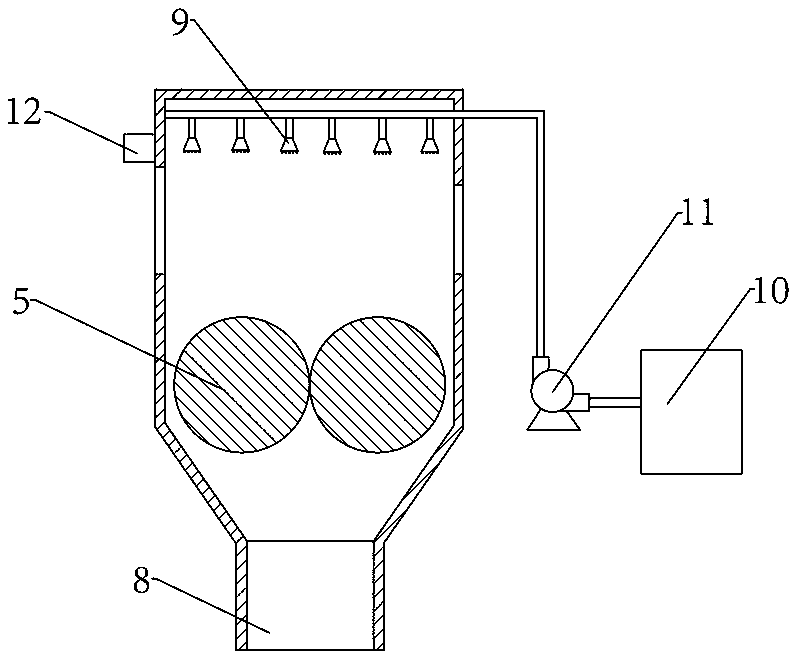

System and method for producing rubber powder at normal temperature through waste tires

InactiveCN107813444AIngenious designHigh degree of automationUsing liquid separation agentPlastic recyclingMagnetic separatorEngineering

The invention relates to a system and method for producing rubber powder at normal temperature through waste tires. The system comprises a ring cutting machine, a shredder, a butterfly separator, a plurality of rubber crushers and auxiliary machines thereof, a magnetic separator, a fiber separator, a rubber powder bin and a rubber powder grading device. Through the system and method for producingthe rubber powder at the normal temperature through the waste tires, the problems that in the process for producing rubber powder through waste tires, energy consumption is high, dust pollution is serious, and many accidents occur are solved completely, automatic operation of whole crushing, intermediate crushing of crushed rubber and fine powder grinding is achieved, energy conservation and environment protection are achieved, manpower quantity and labor intensity are lowered substantially, and quality of the obtained rubber powder is good.

Owner:河北增利橡胶科技有限公司

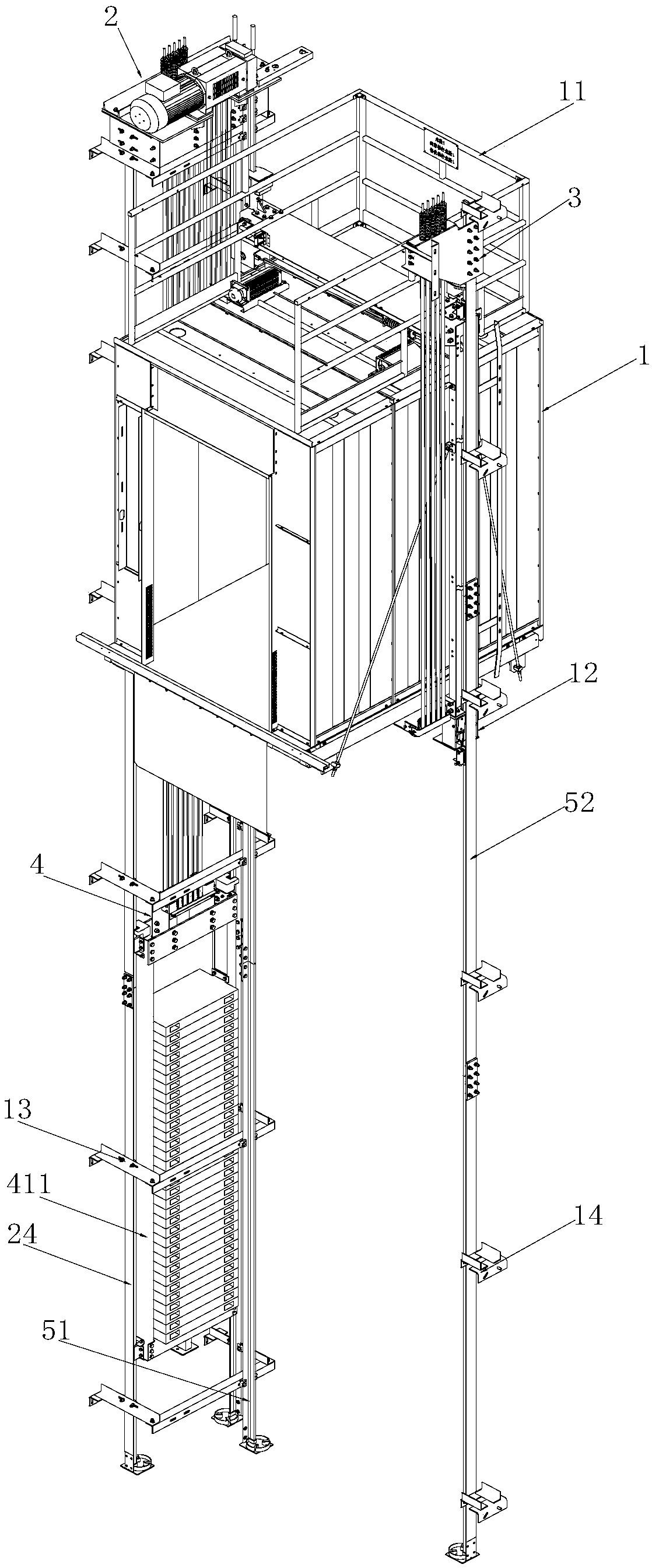

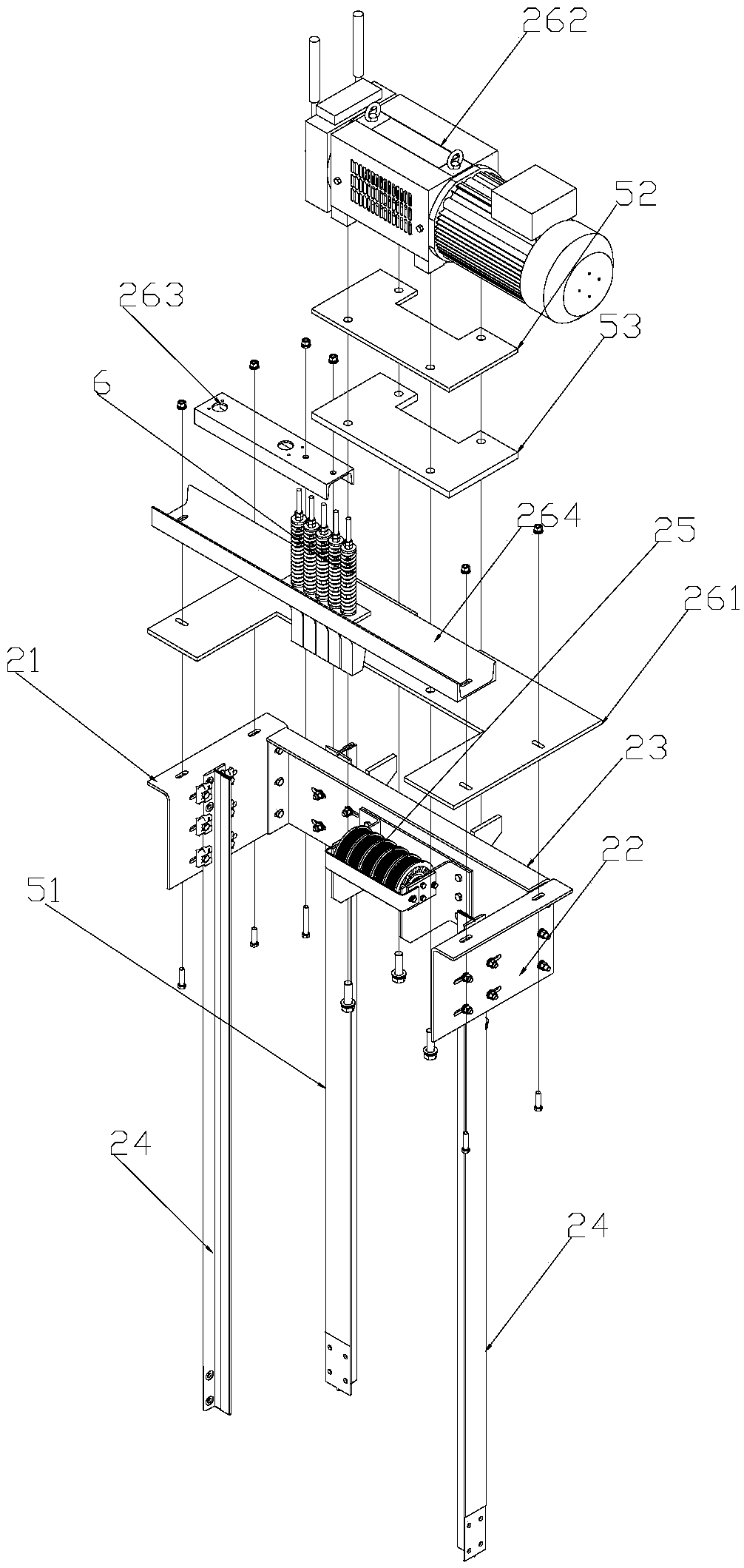

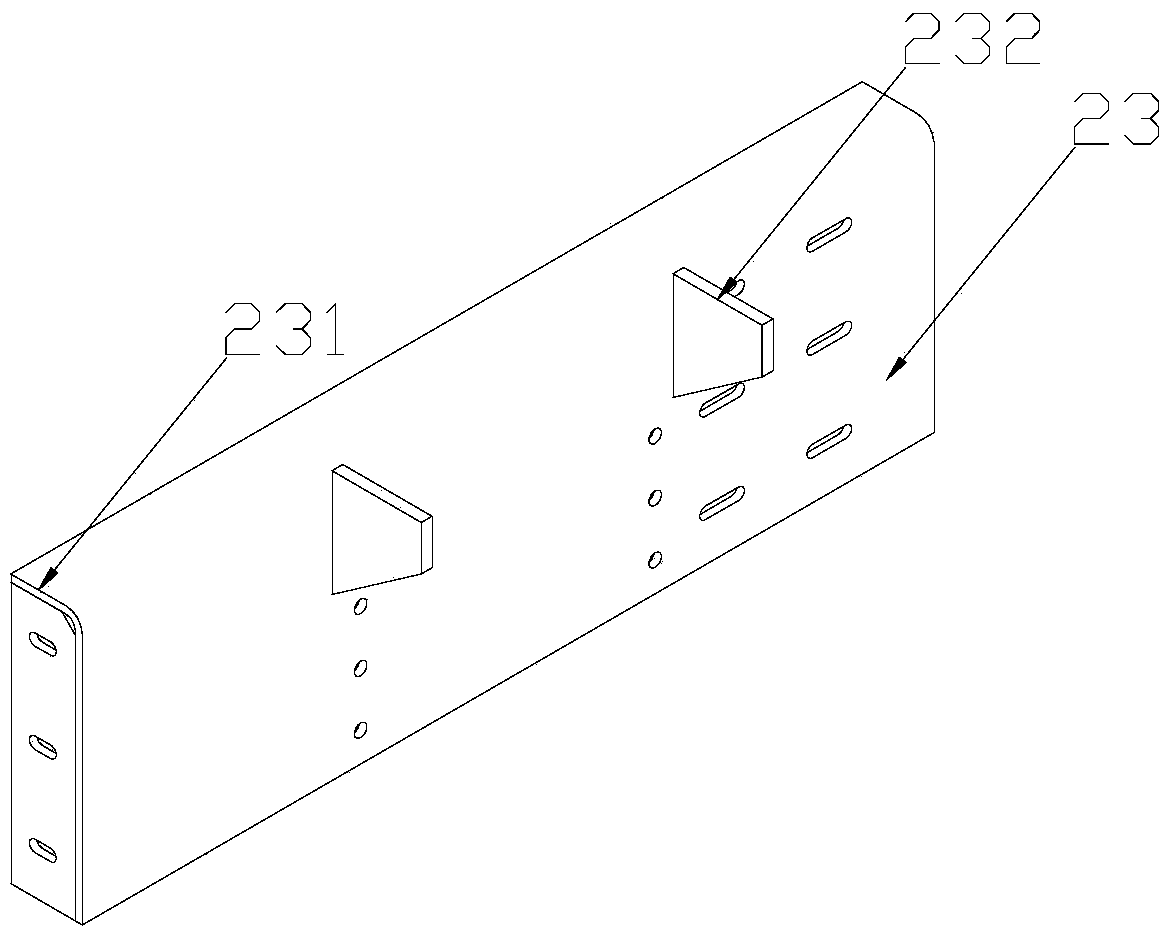

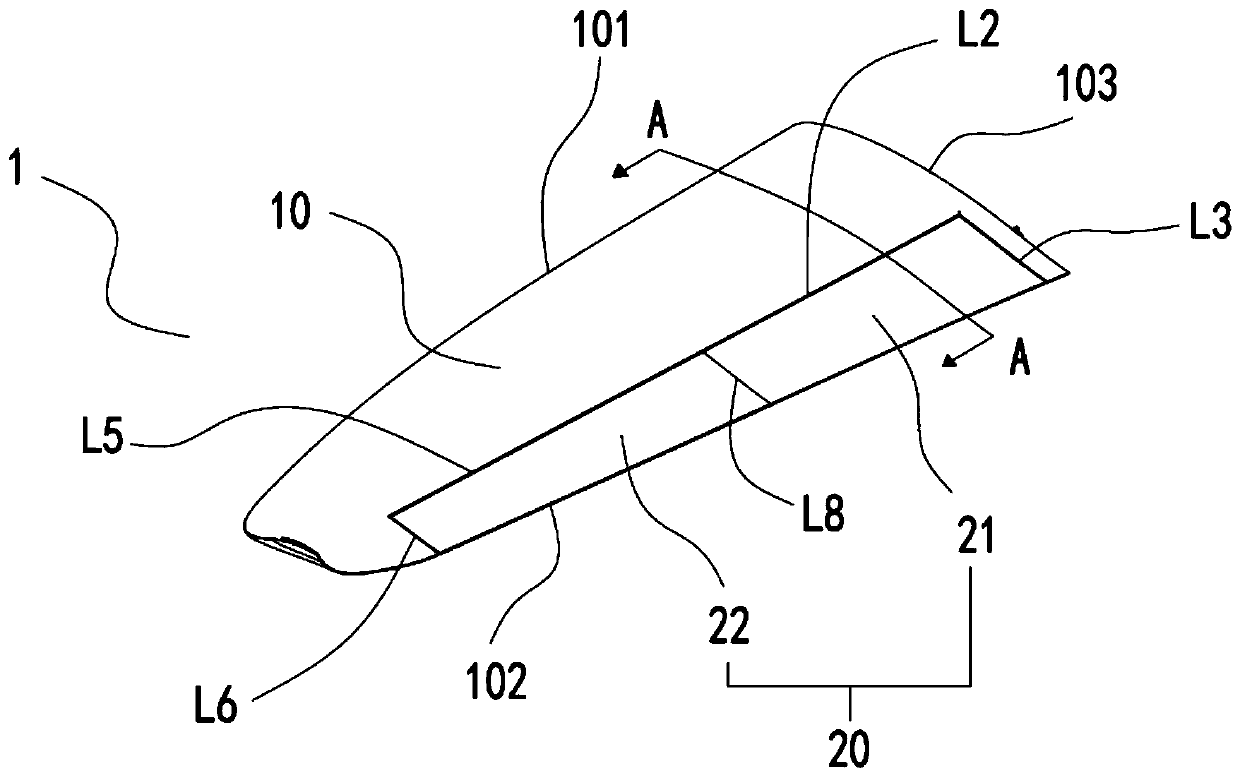

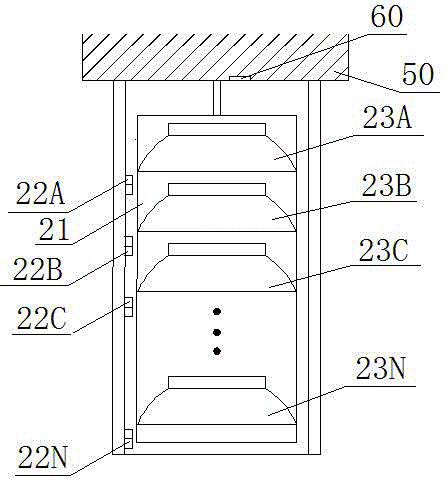

Steel belt elevator

InactiveCN108946398ALow building well requirementsLower requirementBuilding liftsStructural relationArchitectural engineering

The invention belongs to the technical field of elevator equipment, and particularly relates to a steel belt elevator. The elevator comprises an elevator car, a bearing device, a rope head device anda counterweight device, wherein the bearing device, the rope head device and the counterweight device are used in cooperation with the elevator car, a safety fence opened on a car door side is arranged on the top of the elevator car, the bearing device used for bearing the weight of the elevator car and the rope device for fixing an elevator transmission steel belt are arranged on the two sides ofa mounting hoistway of the elevator car, the elevator car is provided with a safety clamp used in cooperation with a speed limiter and a guide rail, and the counterweight device for balancing the weight of the car is arranged below the bearing device. The bearing device, the rope head device and the counterweight device does not need to generate structural relation, except for transmission, withother external parts, the connecting structure is reduced, meanwhile, the use stability is improved, mounting is convenient, the requirement for the elevator building shaft is low, the elevator can bewidely applied to steel belt elevator products, and the considerable economic value is generated.

Owner:佛山菱王科技有限公司

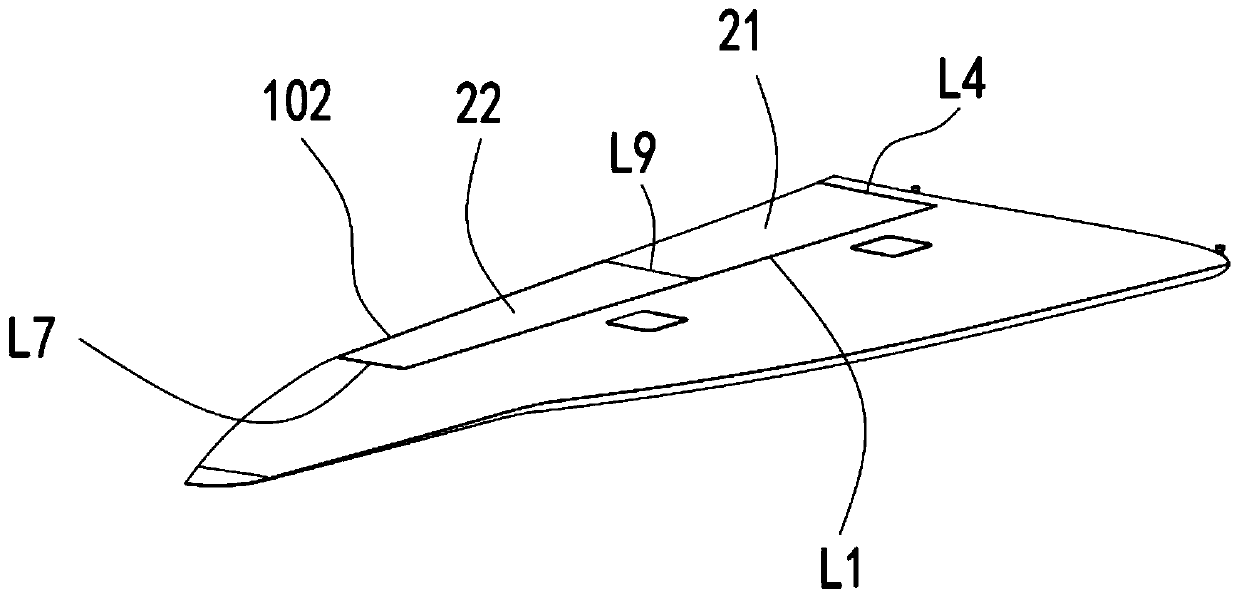

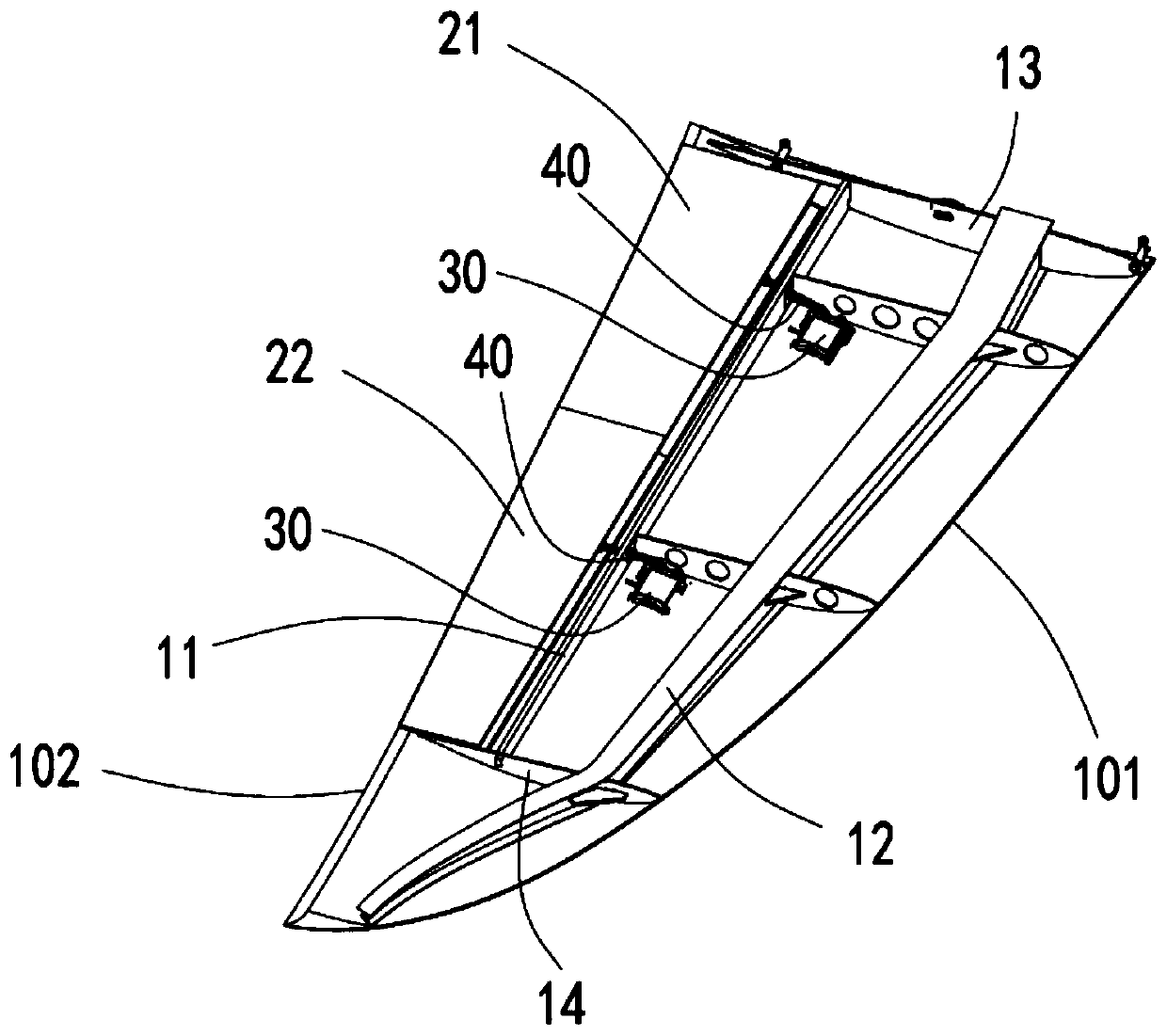

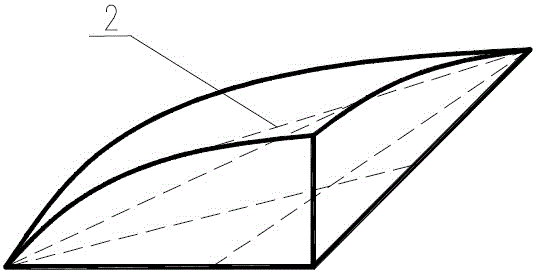

Wing and manufacturing method of wing

PendingCN109850122ASave the step of installing on the wing bodyReduce connection structureAircraft assemblySandwich constructionsAerospace engineering

Owner:丰翼科技(深圳)有限公司

Dish-washing method, dish-washing device and dish washer

ActiveCN104905747AReduce connection structureReduce manufacturing costTableware washing/rinsing machine detailsManufacturing cost reductionWater flow

The invention provides a dish-washing method, a dish-washing device and a dish washer.The dish-washing method is characterized in that sprayers are arranged at fixed positions; a rotary frame is arranged for framing pieces of tableware to be cleaned; water flow sprayed out of each sprayer is flushed to a corresponding piece of tableware; and impact of water flow drives bowls or plates and the rotary frame to rotate so that the effect of manual dish-washing is achieved in a reasonable manner. Compared with the prior art, the dish-washing method, the dish-washing device and the dish washer have following beneficial effects: with no rotary or movable spray arms required, no power device and energy are provided for rotation or movement of spray arms; only by pressurizing water flow, power devices are saved and connection structures among power devices, the spray arms and tableware are saved as well; and the dish washer is simplified in structure, reasonable in construction, high in cleaning speed and fine in effect and helps to decrease manufacture cost and energy consumption.

Owner:彭竞原

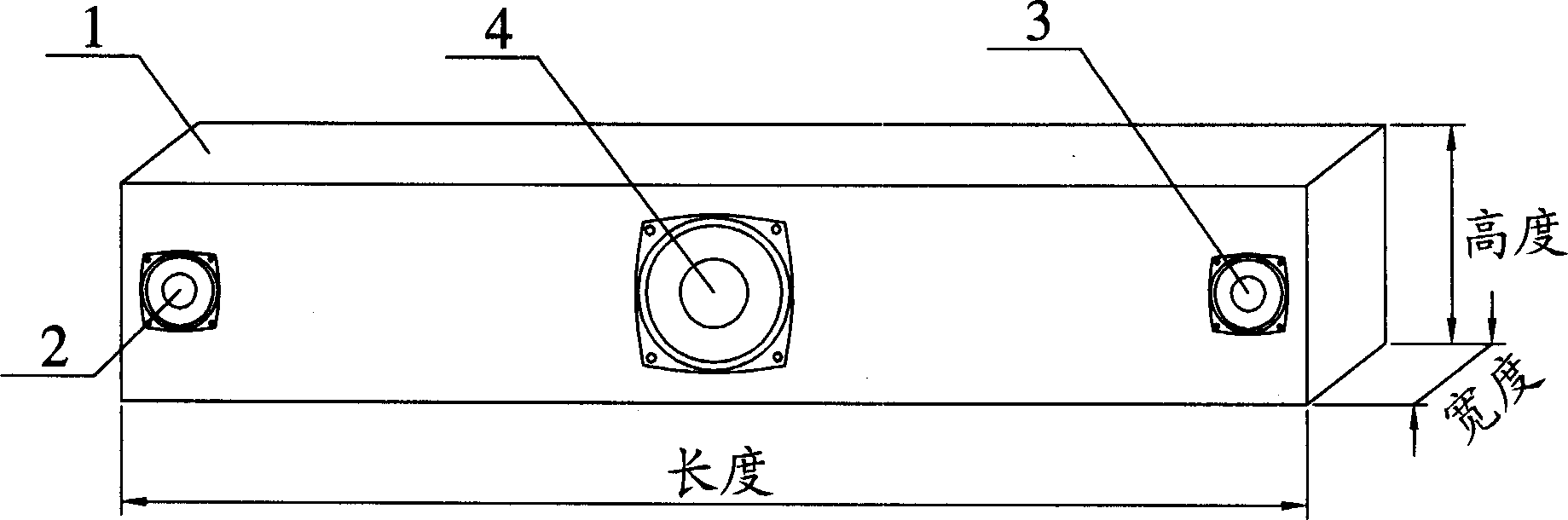

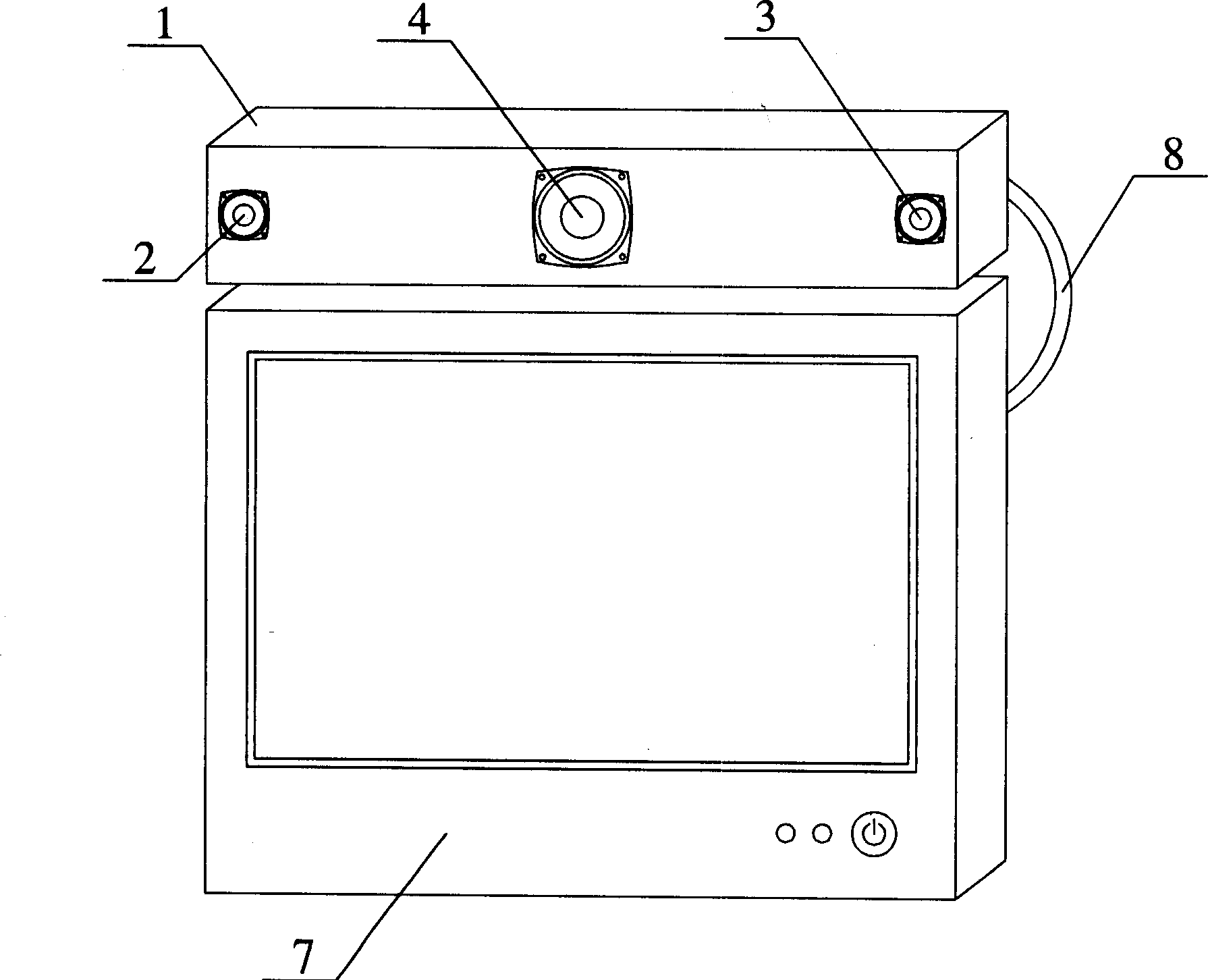

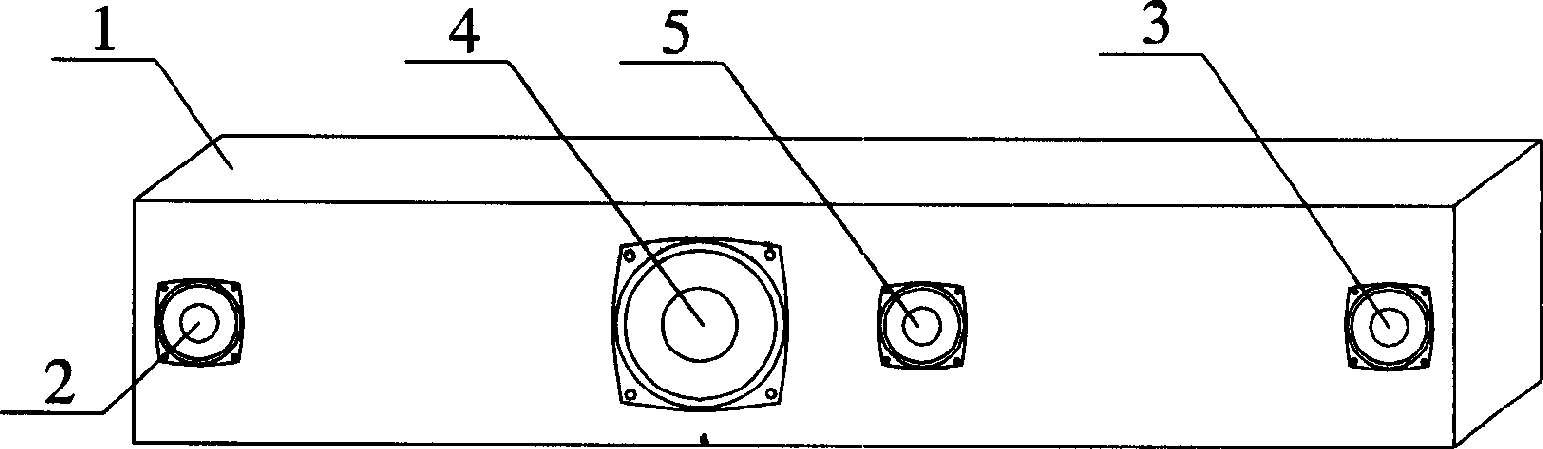

Transverse integrative sound box for flat television

InactiveCN1770924AHighlight substantiveSignificant progressFrequency/directions obtaining arrangementsLoudspeaker spatial/constructional arrangementsEngineeringAudiovisual device

This invention relates to one stereo visual device and one with beautiful outlook and without redundant wires, which comprises Stereo body, left loudspeaker, right loudspeaker, low loudspeaker and control circuit in the main chamber, wherein, the loudspeaker is distributed level; the said stereo body is in long bar shape with proportion of length to width between three to sixty; the low loudspeaker is located between the stereo box; the left and right loudspeaker are located on both sides of low loudspeaker near the two ends of main body connected through control circuit board. Besides TV, it can also be connected to other stereo device like DVD, CD, recorder, MP3 or game machine.

Owner:梁荣锵

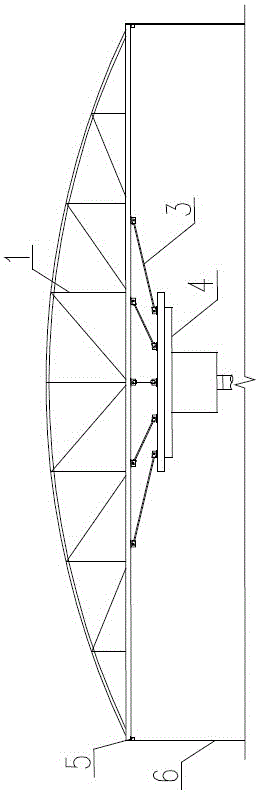

A heat storage tank water distribution tray connection structure

ActiveCN104807353BReduce connection structureSimple structureHeat storage plantsWater storage tankEngineering

The invention relates to a thermal storage tank water distribution plate connecting structure which is simple in structure, reasonable in design and fine in stability and economical efficiency. The thermal storage tank water distribution plate connecting structure is characterized by comprising a thermal storage tank water distribution plate, at least two truss structures, truss reinforcement components, at least three water distribution plate suspension structures and at least four truss support connecting structures, the truss structures are used for sharing the weight of the thermal storage tank water distribution plate, the truss reinforcement components are used for reinforcing stability of the truss structures, the water distribution plate suspension structures are used for transferring the weight of the thermal storage tank water distribution plate, the truss support connecting structures are used for fixing the truss structures to the upper inner wall of a thermal storage tank, each truss structure comprises an upper chord member, a lower chord member, a plurality of vertical rods and a plurality of diagonal web members, two ends of each diagonal web member are fixed onto the corresponding upper chord member and the corresponding lower chord member, water distribution plate lifting lugs are fixed onto a top plate of the thermal storage tank water distribution plate, the truss support connecting structures are fixed onto the upper inner wall of the thermal storage tank, and two ends of each truss structure are fixed onto the corresponding truss support connecting structure. The thermal storage tank water distribution plate connecting structure is fine in stability and economical efficiency.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Vehicle lamp optical element, vehicle lamp module and vehicle

PendingCN112781001AHigh degree of integrationLow costVehicle headlampsOptical signallingEngineeringOptics

Owner:HASCO VISION TECHNOLOGY CO LTD

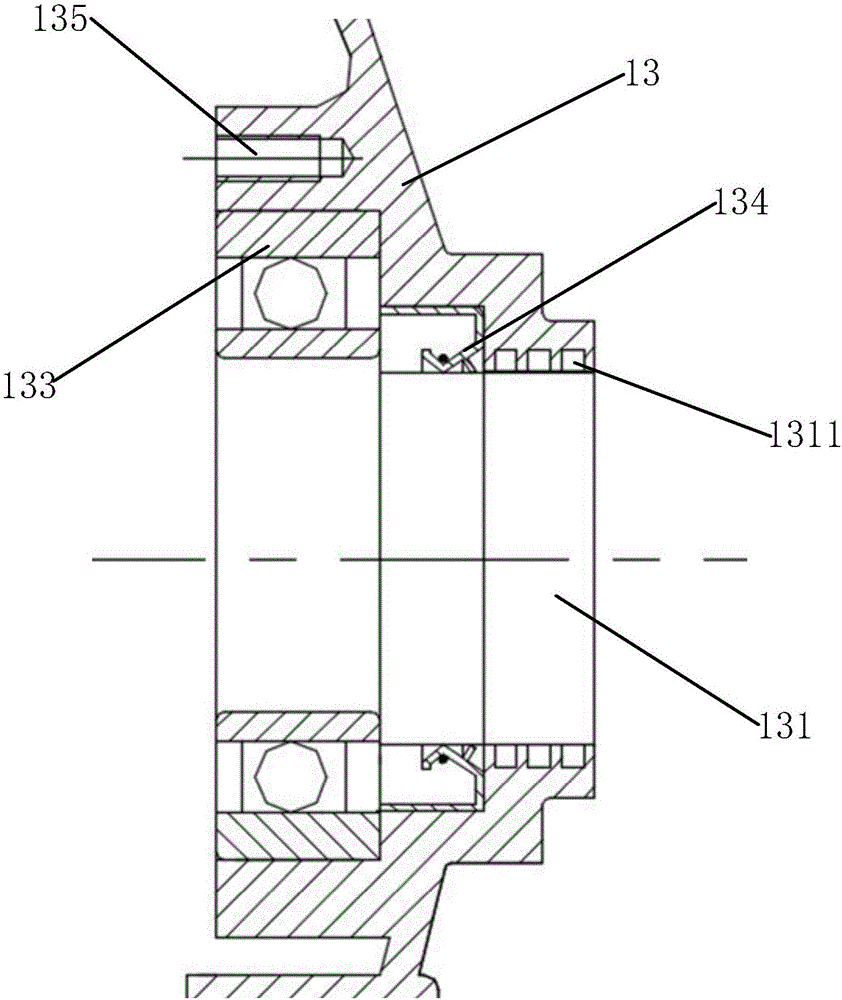

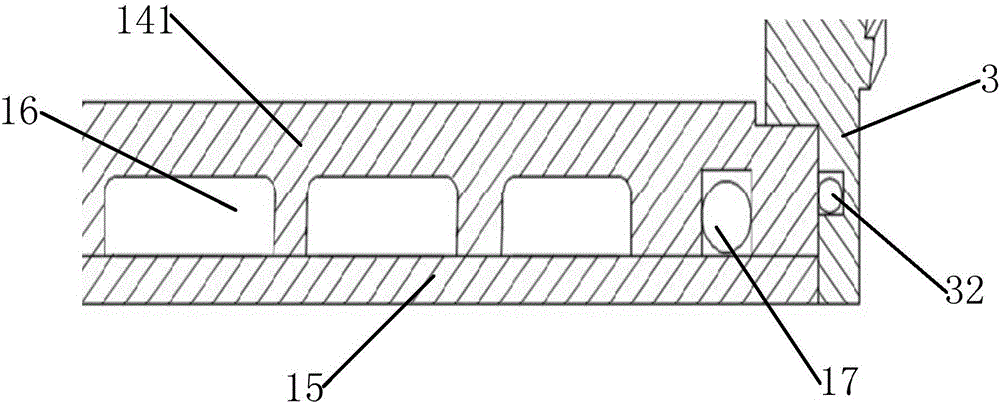

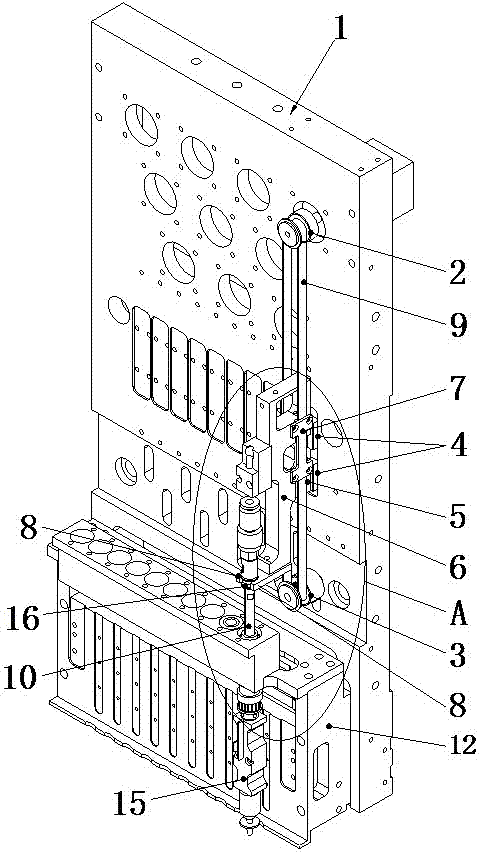

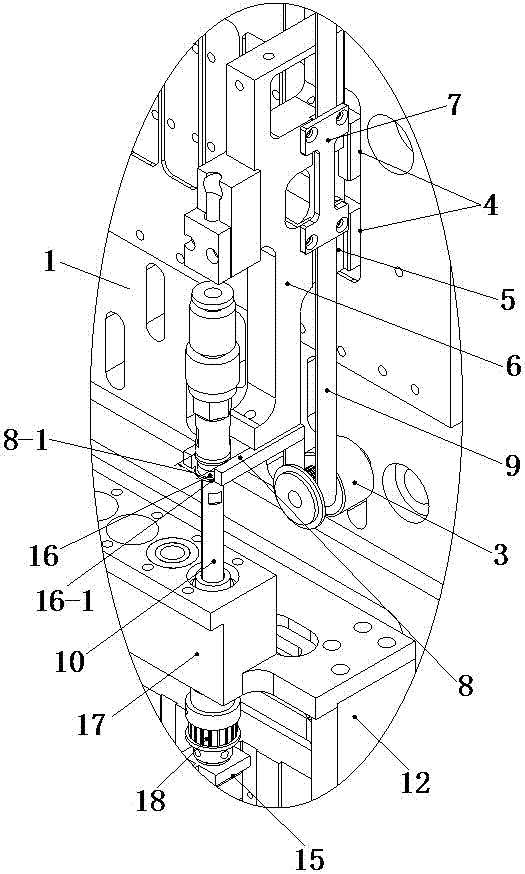

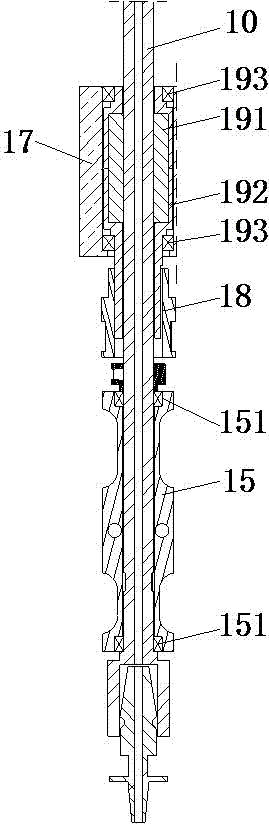

Z-axis driving connection mechanism of nozzle rod of SMT system

ActiveCN107517584AGuaranteed accuracyGuaranteed stabilityElectrical componentsSurface mountingFixed frame

The invention relates to the technical field of SMT (surface mount technology) systems, in particular to a Z-axis driving connection mechanism of a nozzle rod of an SMT system. The Z-axis driving connection mechanism comprises a press-down linkage plate, the surface of a surface mount head fixing base plate is fixedly connected with the press-down linkage plate through a guide mechanism, one end of a nozzle rod press plate is fixedly arranged at the bottom end of the press-down linkage plate, the nozzle rod press plate is connected with the nozzle rod through a bearing component consisting of flange bearings, and a nozzle rod sleeve is connected to the outer circumferential wall of the nozzle rod through a rod sleeve bearing. One end of a slidable fixed frame is fixedly arranged on the surface of the surface mount head fixing base plate while the other end thereof is connected with the nozzle rod through a slide mechanism body, and the nozzle rod sleeve is capable of sliding on the slide mechanism body along the length direction of the nozzle rod. The Z-axis driving connection mechanism has the advantages that miniaturization of the SMT system is facilitated, mounting is facilitated to reduce production cost of a surface mount head, and surface mount precision is guaranteed enduringly.

Owner:浙江华企正邦自动化科技有限公司

Dishwashing method, dishwashing device and dishwasher

ActiveCN104905747BReduce connection structureReduce manufacturing costTableware washing/rinsing machine detailsManufacturing cost reductionWater flow

Owner:彭竞原

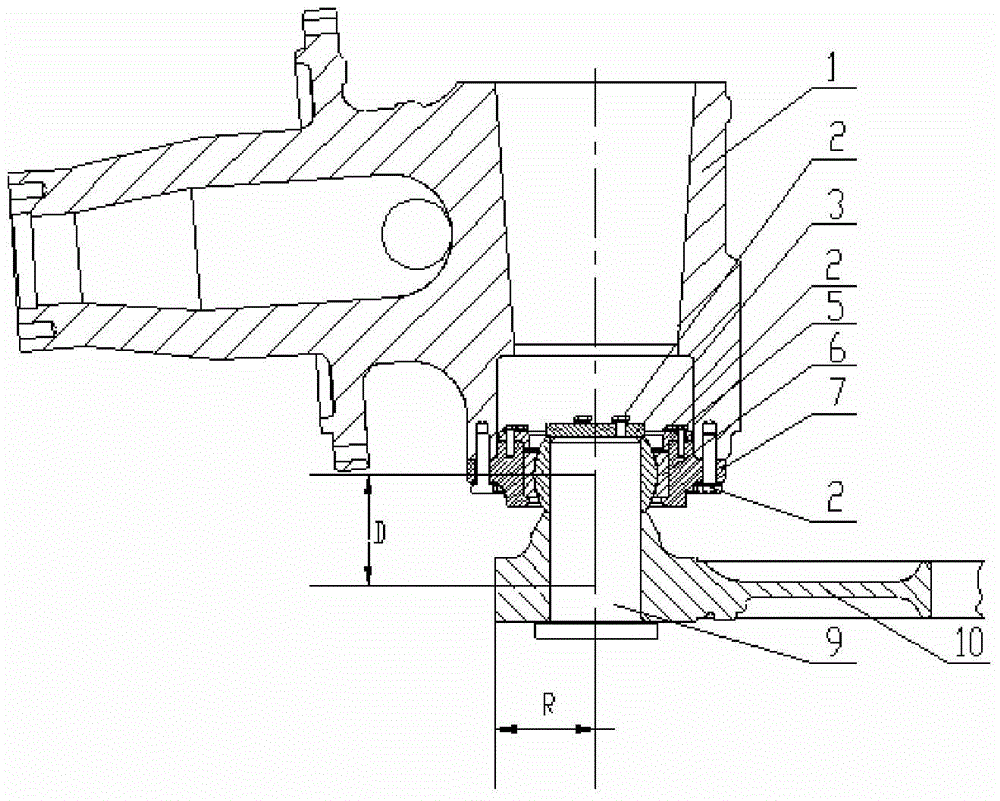

Connecting structure of swinging arm and front axle and mining dump truck

The invention discloses a connecting structure of a swinging arm and a front axle. The connecting structure comprises the front axle, a front axle flange plate, a knuckle bearing, a pin shaft baffle and an A-shaped arm, wherein the knuckle bearing is installed inside the front axle flange plate, the bearing baffle is arranged on the outer circle of the knuckle bearing, the A-shaped arm and the knuckle bearing are connected into a whole through a pin shaft, the middle of the pin shaft baffle is connected with the small end of the pin shaft through a bolt, the exterior of the pin shaft baffle is attached to the upper portion of the inner circle of the knuckle bearing, the large end of the pin shaft is attached to the outer portion of the A-shaped arm, the large circle portion of the bearing baffle is connected with the upper end of the front axle flange plate through a bolt, and the middle of the front axle flange plate is connected with the front axle through a bolt. According to the connecting structure of the swinging arm and the front axle, due to the fact that the knuckle bearing is installed on the front axle flange plate, the connecting structure of the swinging arm and the front axle becomes smaller, the structural size of the A-shaped arm is smaller, the connecting structure is simple, compact and practical, and the arrangement space in a front axle system is reduced; the length of a moment arm, connected with the front axle, of the A-shaped arm is reduced, the bearing capacity is greatly enhanced, and the stress situation is greatly improved.

Owner:SANY HEAVY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com