Connecting structure of swinging arm and front axle and mining dump truck

A mining dump truck and connection structure technology, which is applied to vehicle parts, cantilevers mounted on pivots, suspensions, etc., can solve the problems affecting the overall layout of the front axle and the increase in the connection structure between the swing arm and the front axle , to achieve the effect of small structure size, improved stress condition and enhanced bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

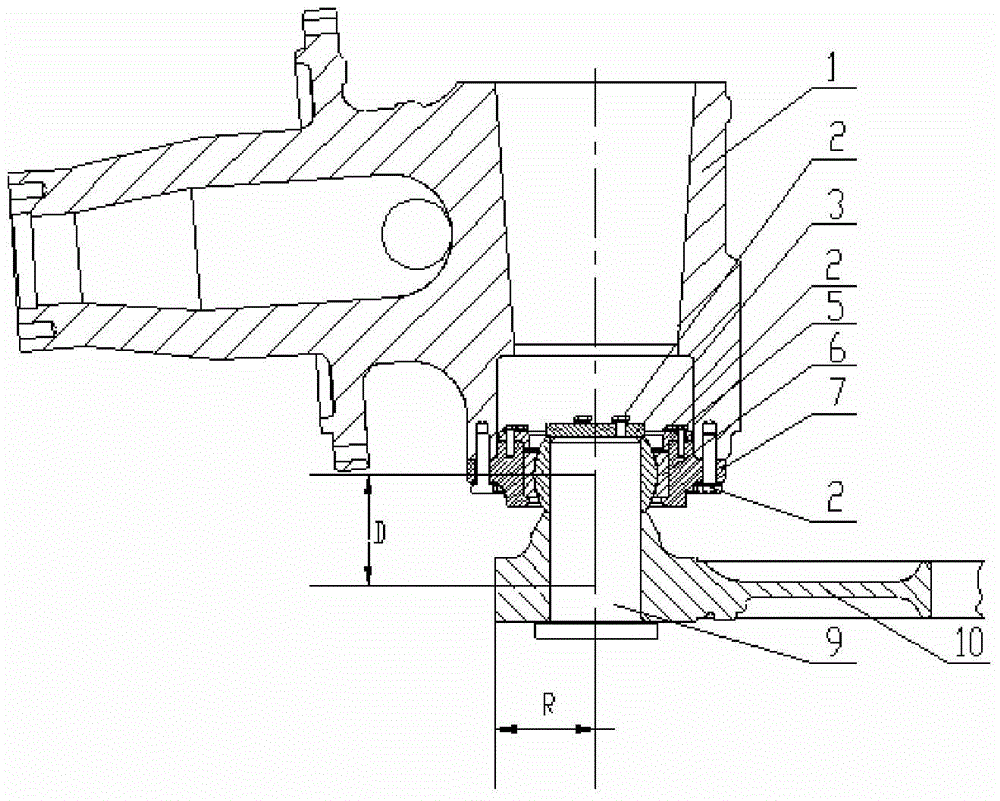

[0021] please join figure 1 As shown, a connection structure between a swing arm and a front axle of the present invention includes a front axle 1, a front axle flange 7, a joint bearing 6, a pin baffle 3 and an A-arm 10, and is characterized in that the joint bearing 6 is installed in the front axle flange 7, the outer ring of the joint bearing 6 is provided with a bearing baffle 5, the A-shaped arm 10 and the joint bearing 6 are connected as a whole through a pin 9, and the middle part of the pin baffle 3 is passed through a bolt 2 It is connected with the small end of the pin shaft 9, and the big end of the pin shaft 9 is attached to the outside of the A-arm 10. The large circle part of the bearing baffle 3 is connected with the upper end of the front axle flange 7 through the bolt 2, and the front axle flange The middle part of 7 is connected with front axle 1 by bolt 2.

[0022] On the basis of the above, the present invention also has the following implementation modes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com