Under-actuated picking tail end executing device and method

An end-effector, under-actuated technology, applied in picking machines, agricultural machinery and implements, applications, etc., can solve the problems of long distance from the manipulator, difficult to grasp the grasping force, poor reliability of pneumatic transmission, etc. Overall structure size and weight, avoid goaf or fruit damage, improve the effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

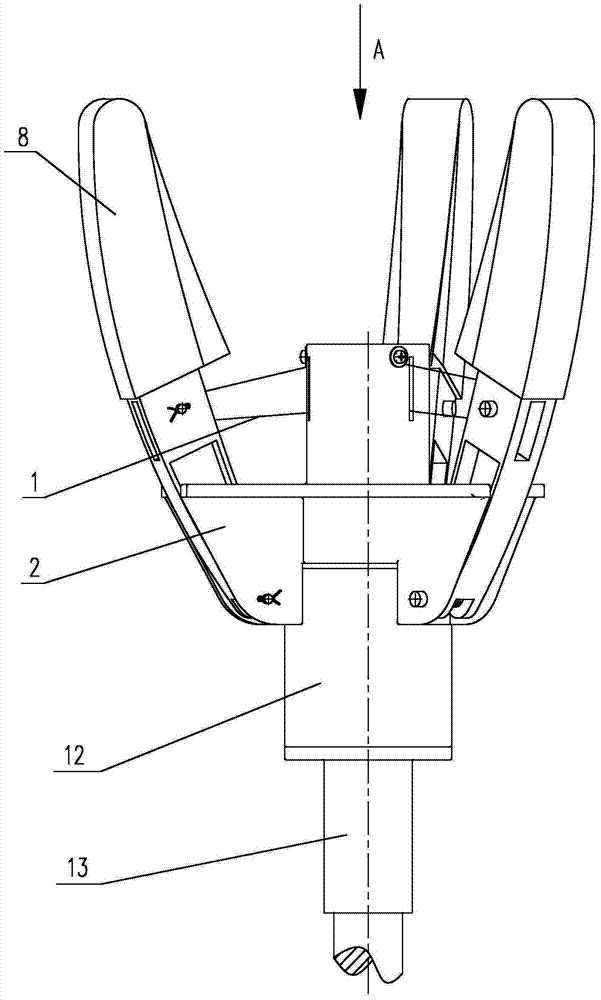

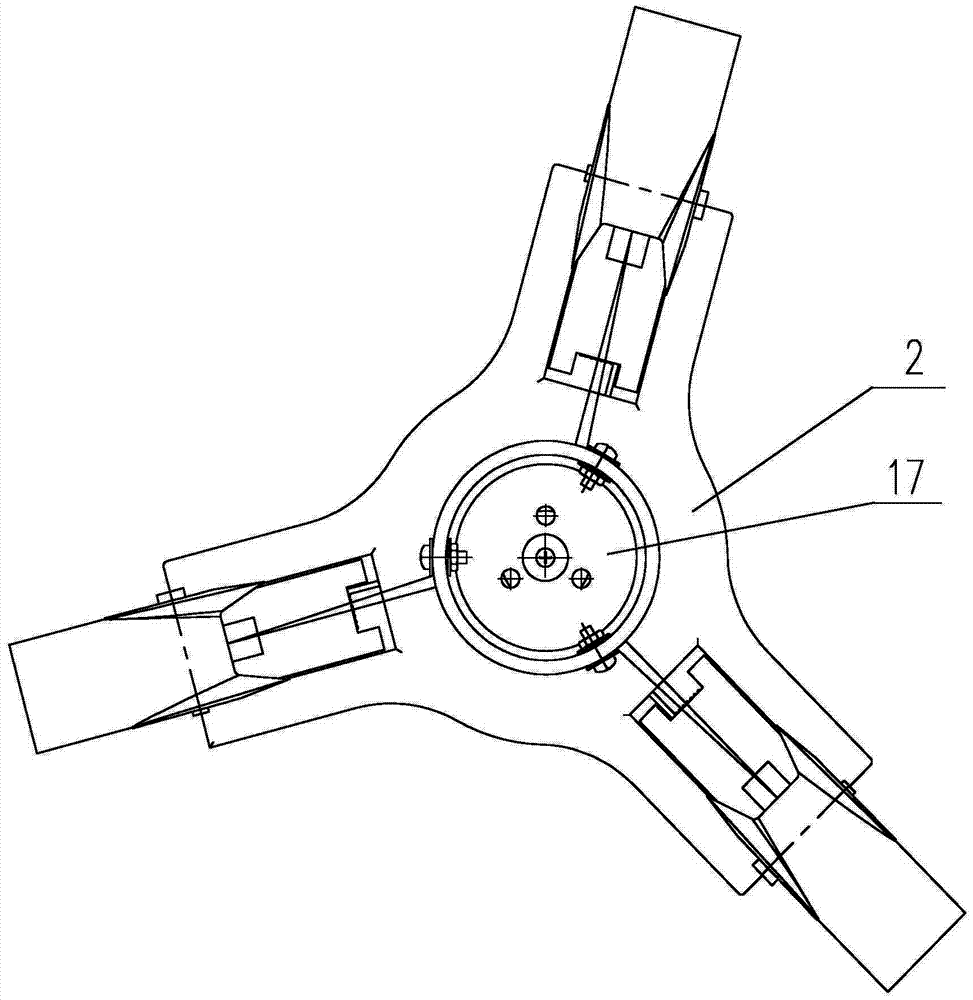

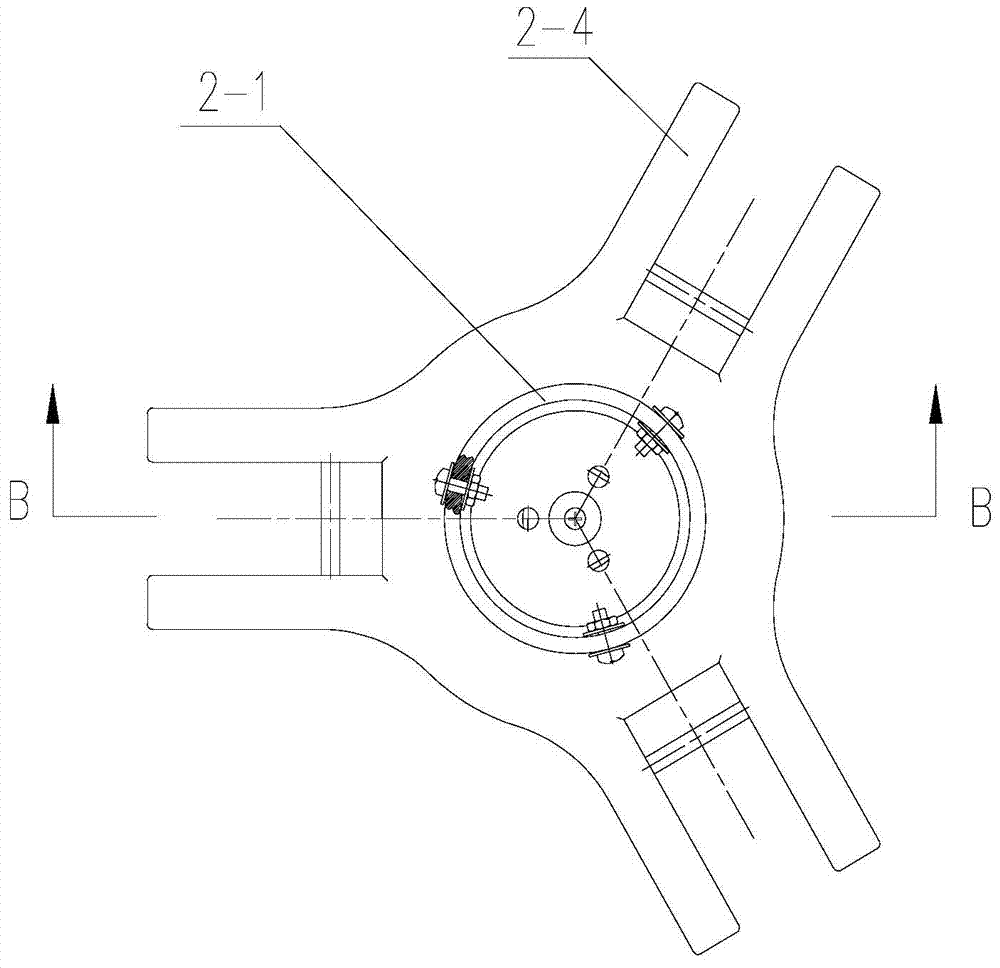

[0037] In this embodiment, an underactuated picking end effector, such as figure 1 or figure 2 As shown, it includes a hand actuator, a drive mechanism and a support assembly, and the hand actuator is connected to the drive mechanism through the support assembly; the hand actuator is a three-claw structure, including three claws, three hinge assemblies, Three sections of wire rope 1, a palm 2 and a pressure block 3 (see Figure 4 ), the three claws are evenly distributed on the peripheral edge of the palm, the bottom of each claw is installed on the palm through the corresponding hinge assembly, the pulley is set in the middle of each claw, each pulley is connected with the palm through a wire rope, and the bottom of the palm is connected to the driving mechanism through a pressure block connect. Wherein, the hand actuator is used to clamp and twist the spherical fruit, the driving mechanism is used to provide power for the hand actuator, and the support assembly is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com