Anti-collision cleaning mechanism for reaction cup

A technology of cleaning mechanism and reaction cup, applied in the direction of analyzing materials, instruments, etc., can solve the problems such as the bending of the elution needle and the inability of the anti-collision photoelectric sensor to fully reflect the contact situation, so as to avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

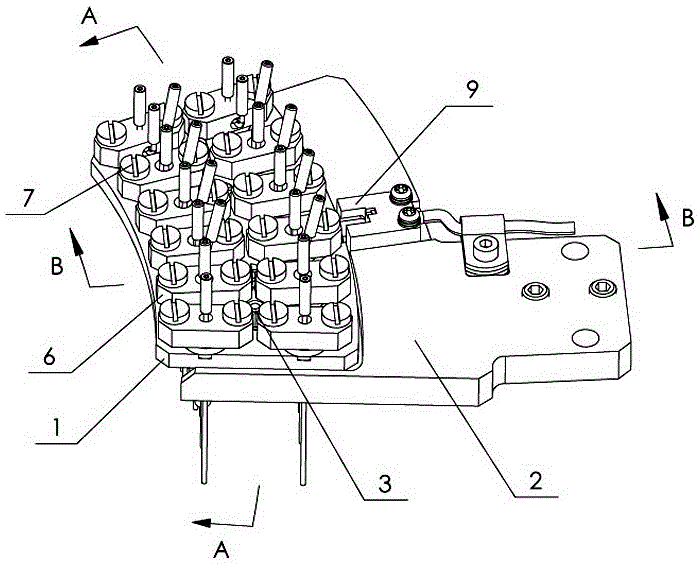

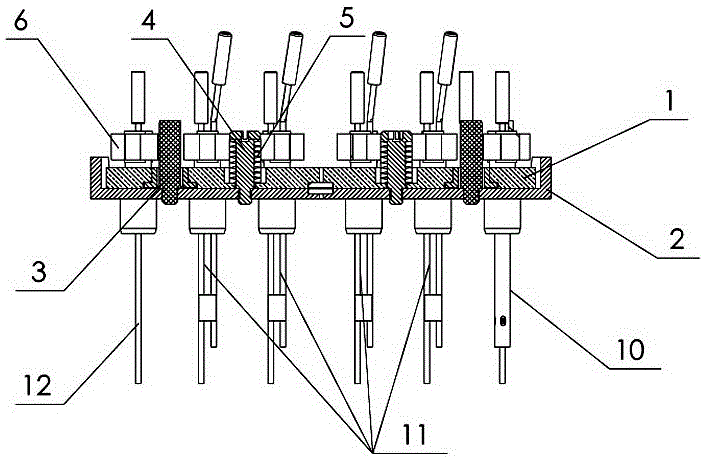

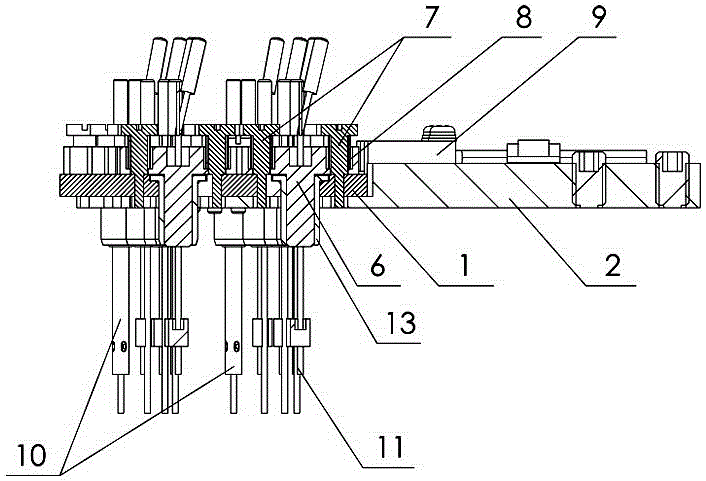

[0031] Such as Figure 1-4 As shown, the anti-collision cleaning mechanism for cuvettes of the present invention includes an elution arm with an anti-collision sensor and an elution unit vertically arranged on the elution arm, and the elution unit includes a needle holder , a needle guide seat and an elution needle, the elution arm includes a floating plate 1 and a fixed plate 2 stacked up and down. Such as figure 2 As shown, the floating plate 1 is set on the guide column 3 provided on the fixed plate 2 and the first limit cover bolt 4, and the lower end of the first elastic member 5 sleeved on the first limit cover bolt 4 is connected with the floating plate 1 The upper surface is in contact. The above-mentioned first elastic member 5 generally selects a compression spring. Such as image 3 , 4 As shown, the eluting needle is fixed in the integrated needle fixing seat 6 and the needle guide seat, and the second limit cap bolts 7 symmetrically arranged on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com