System and method for producing rubber powder at normal temperature through waste tires

A technology for waste tires and rubber powder is applied in the system field of producing rubber powder by using waste tires at room temperature, which can solve the problems of easy fire, poor rubber powder quality, dust scattering, etc. The effect of suppressing the spread of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: A system for producing rubber powder at room temperature using waste tires.

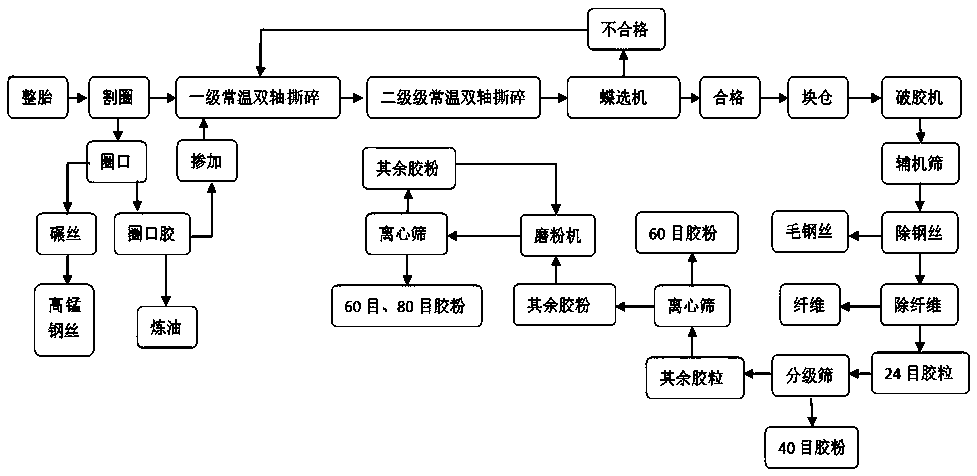

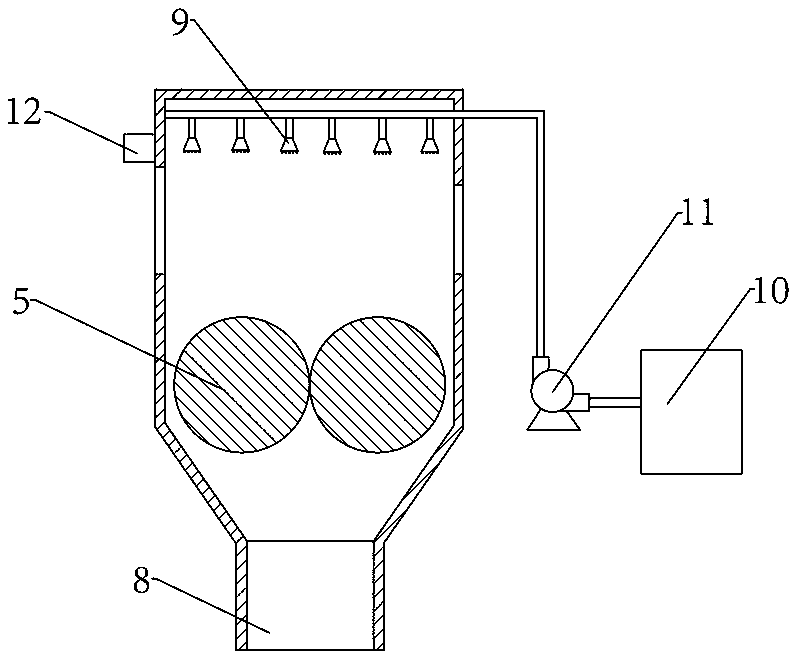

[0042] The present invention mainly consists of a ring cutting machine, a shredder, a butterfly separator 38, a rubber breaker and its auxiliary machines, a magnetic separator, a fiber separator, a rubber powder silo, a rubber powder classification device, a centrifugal sieve and a pulverizer, etc. Partial composition.

[0043] The bead cutting machine is used to cut off the bead on both sides of the tire, and process the bead separately to prevent the poor quality bead glue from being mixed into the tire rubber powder. in the plane.

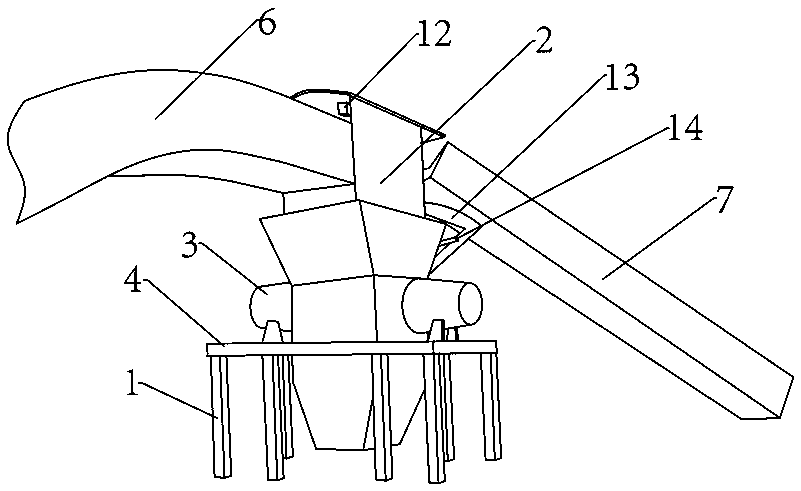

[0044] The shredder is used to tear the tire with the bead cut off into rubber blocks of about 5cm×8cm for rubber breaking, such as figure 2 with image 3 As shown, the shredder includes a frame 1, a shredding bin 2, a driving mechanism 3, a hydraulic pressure plate mechanism and a spray control device.

[0045] The shredding bin 2 is used as a p...

Embodiment 2

[0063] Embodiment 2: the method for producing rubber powder at room temperature by using waste tires.

[0064] The method of utilizing waste tires of the present invention to produce rubber powder at normal temperature comprises the following steps:

[0065] 1) Set up a system for producing rubber powder using waste tires at room temperature as described in Example 1. In the initial state, the pressing plate 13 of the shredder is outside the shredding bin 2 .

[0066] 2) Put the tire into the bead cutting machine, move the cutter, and cut off the bead on both sides of the tire. After the bead is collected, it can be sold directly, or it can be processed to produce bead steel wire, bead glue, and bead steel wire. It can be sold directly, the ring mouth glue can be reused, and the glue can be broken and ground into powder.

[0067] 3) The tire with the bead cut off is sent to the tire conveying track 6, and after being weighed on the tire conveying track 6, it enters the shredd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com