Patents

Literature

77results about How to "Reduce structural mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

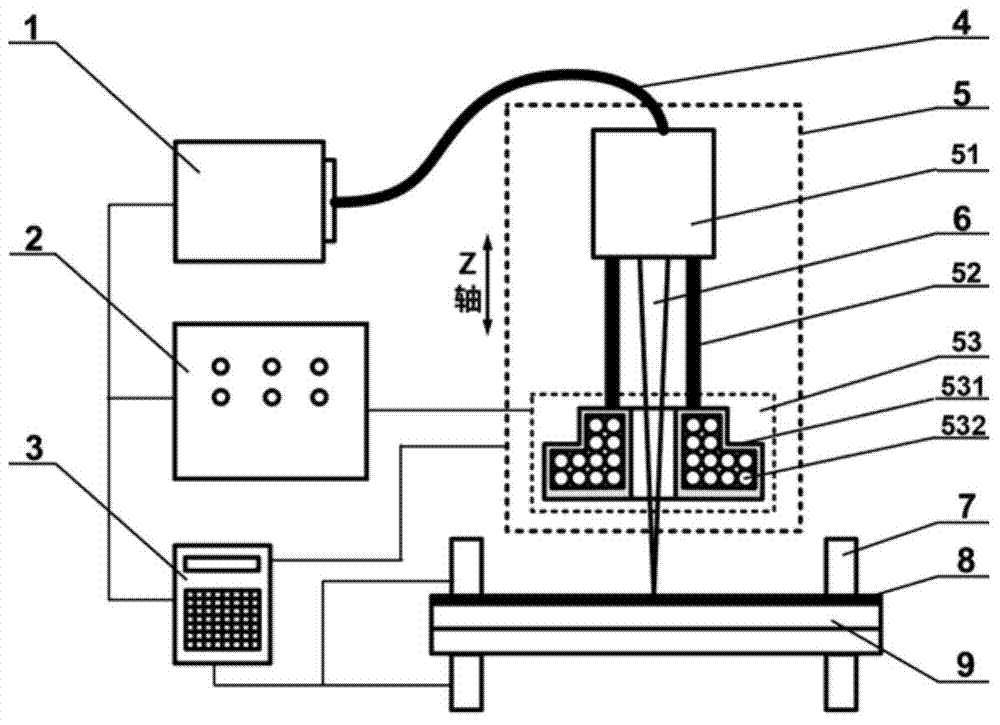

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

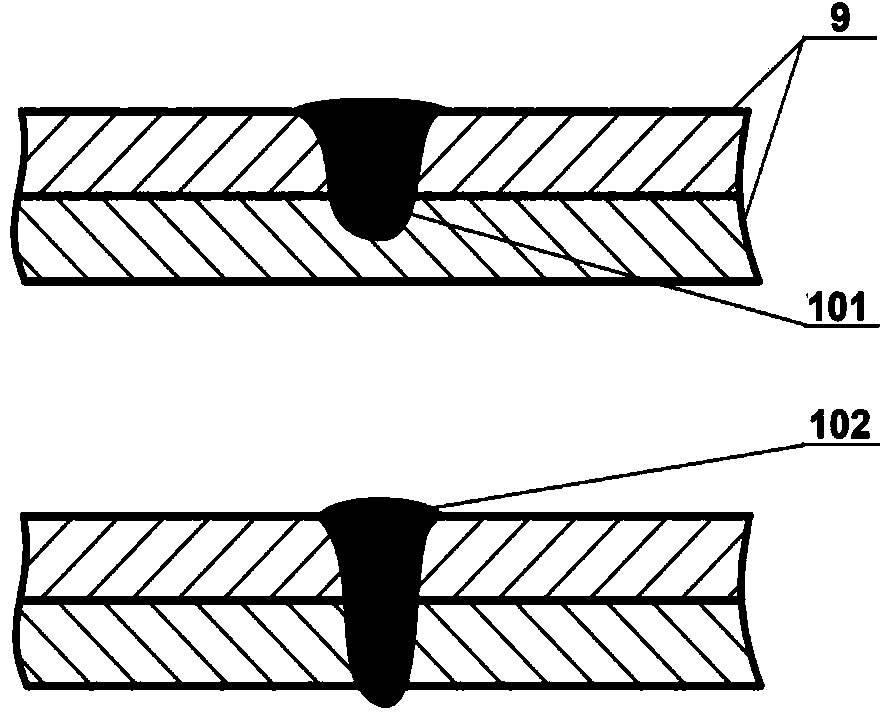

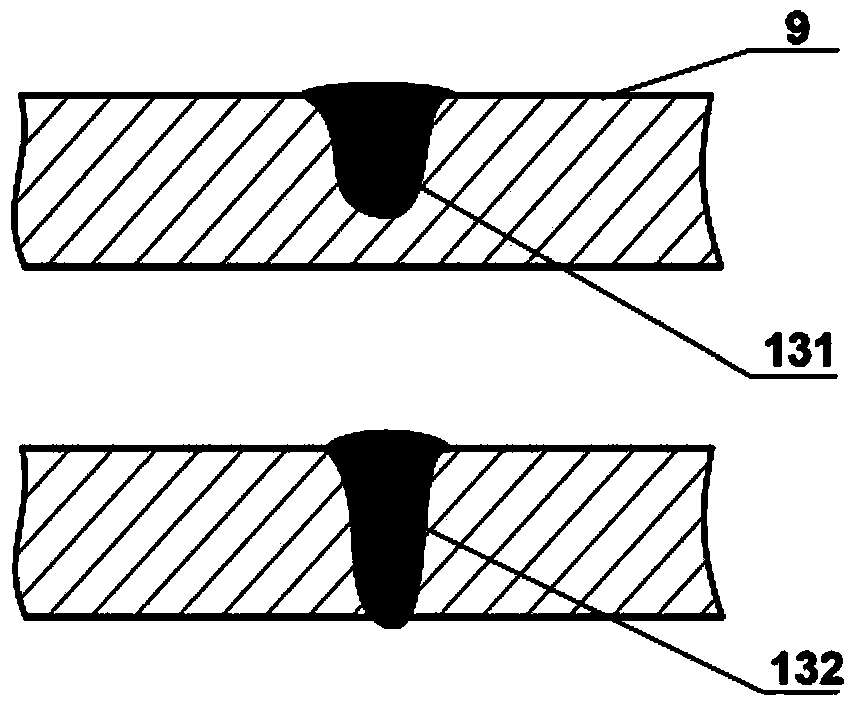

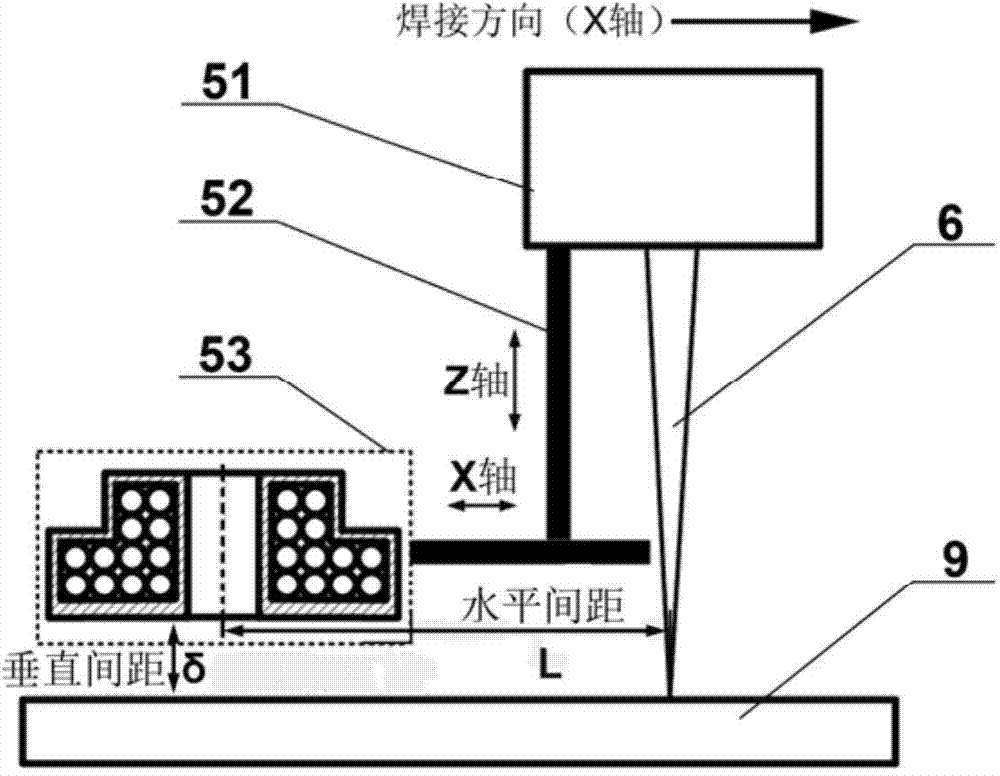

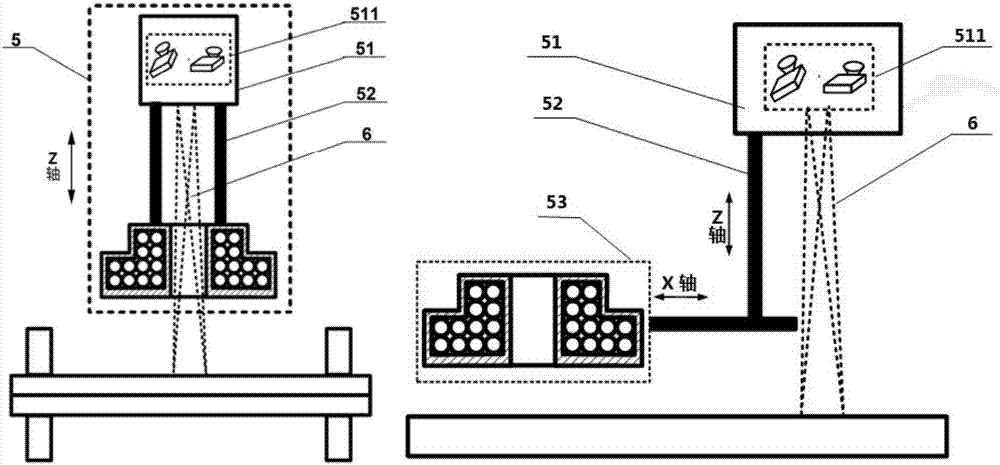

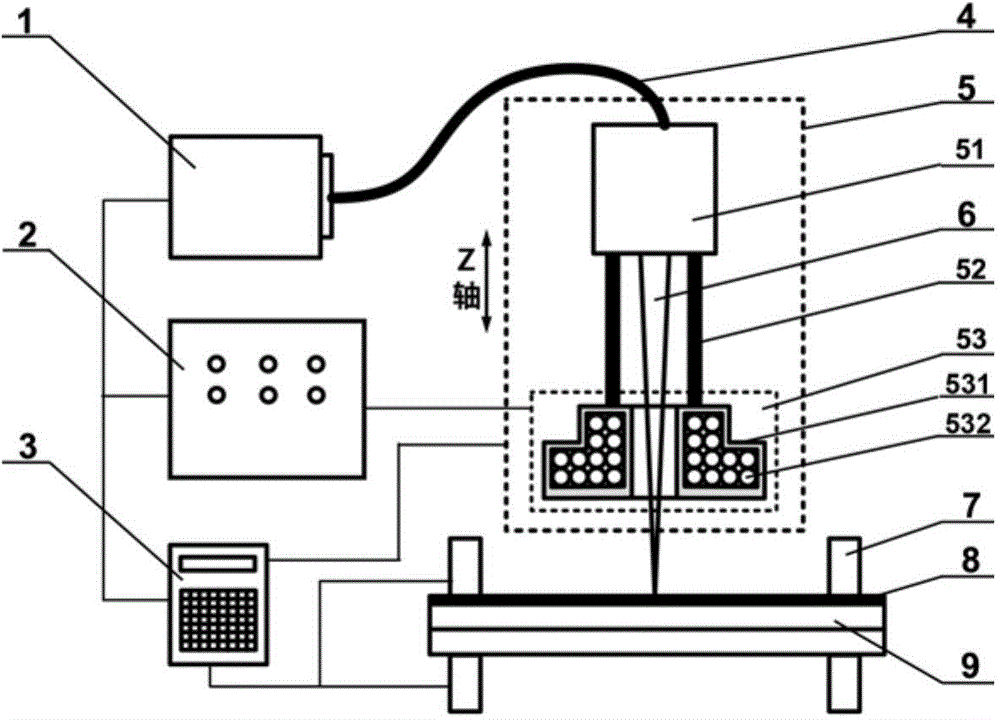

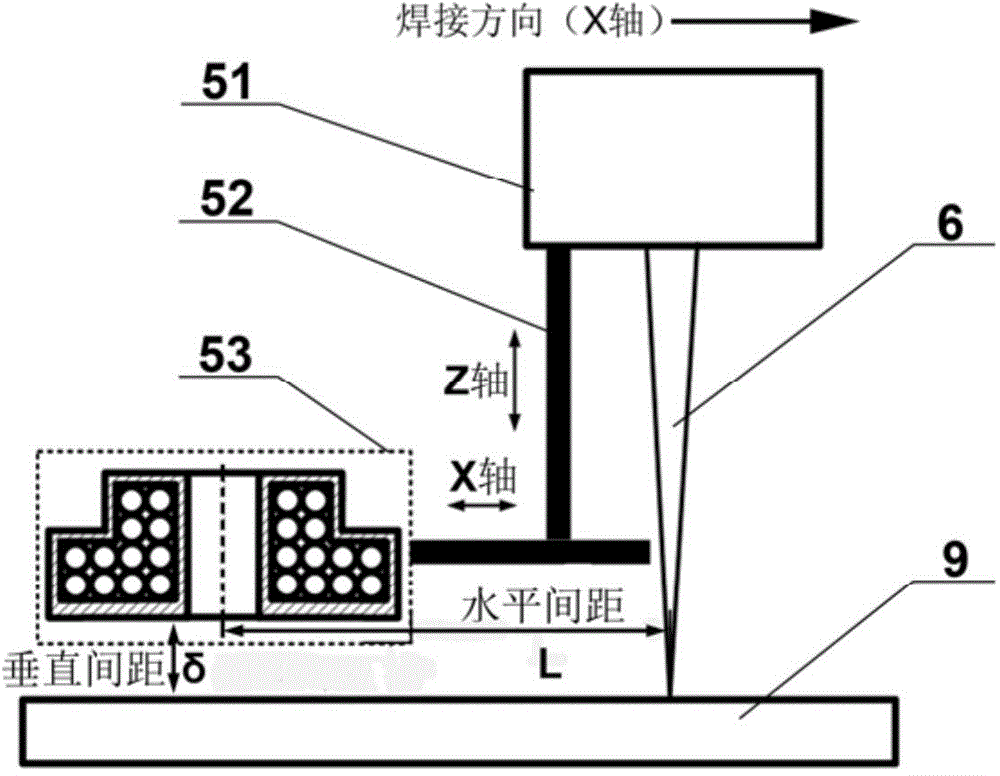

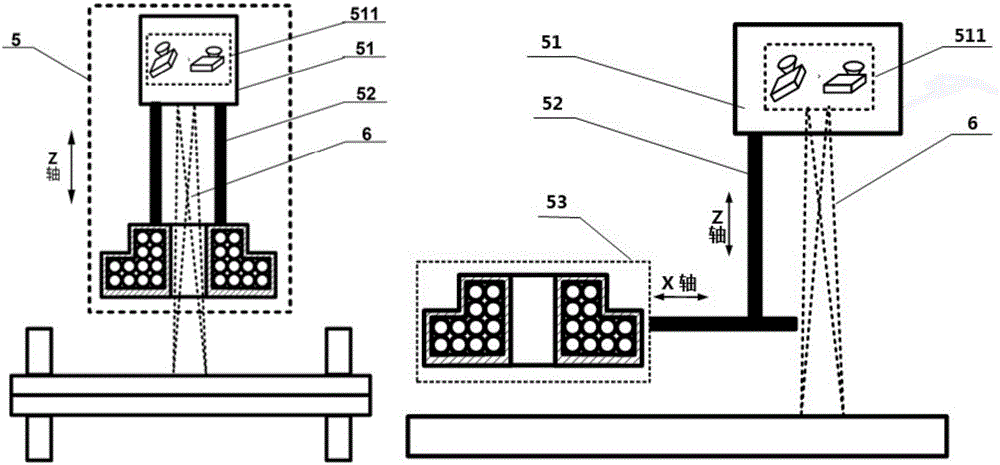

Pulsed high magnetic field auxiliary laser welding method and device

ActiveCN103769746AImprove fatigue strengthSmall structural deformationLaser beam welding apparatusStructural deformationStress concentration

The invention discloses a pulsed high magnetic field auxiliary laser welding method and device. The method and device can be applied to laser spot welding and seam welding. According to the method, in the overall welding process, laser beams are emitted to a workpiece to form a welding connector, a high pulsed magnetic field is exerted to the welding connector which is just solidified and the surrounding area, the pulsed magnetic field generates pressure stress on the surface of the workpiece to enable the connector area to have plastic deformation, residual stress is released to lower the degree of stress concentration and the degree of structural deformation of the welding connector, and the fatigue strength of the welding connector is improved. The device comprises a laser, a pulsed magnetic field generator, a numerical control system, an optical transmission system and a laser pulsed magnetic field composite processing head. The processing head is used for integrating the laser beams and the high pulsed magnetic field, and regulating the perpendicular distance between an electromagnetic conversion device and the surface of the workpiece and the horizontal distance between the electromagnetic conversion device and the laser beams. By means of the pulsed high magnetic field auxiliary laser welding method and device, structural deformation can be lowered, welding quality and processing efficiency are improved, and the processing effect which is superior to that of an existing laser welding process is achieved.

Owner:武汉飞能达激光技术有限公司

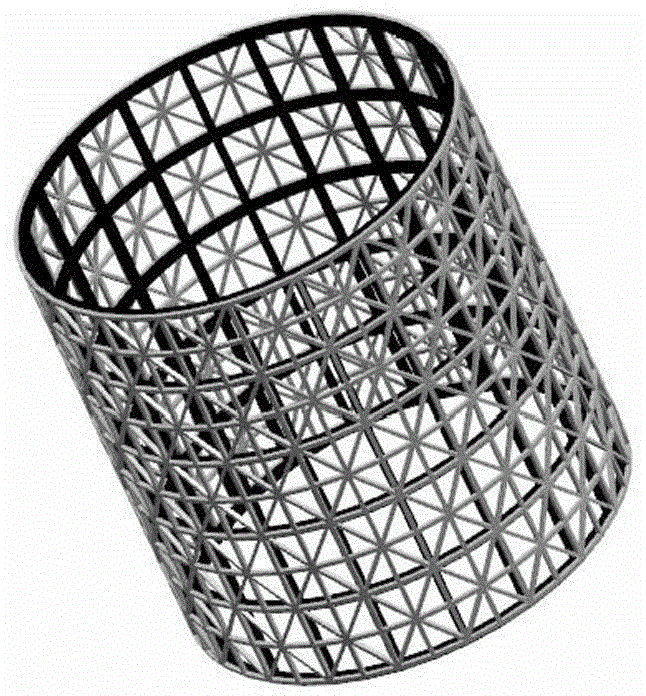

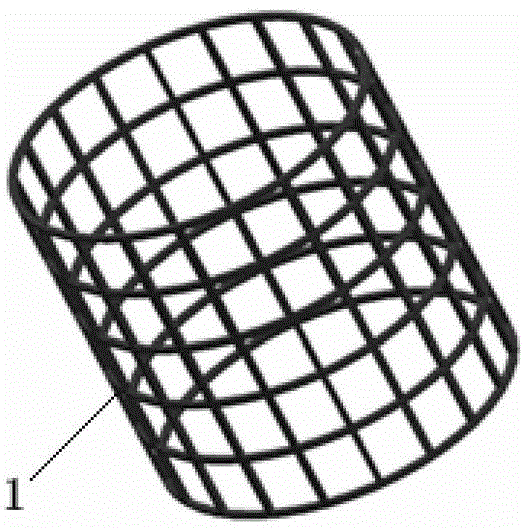

Multilayer grating bearing cylinder and preparation method thereof

ActiveCN104608915AImprove stabilityImproves buckling stabilityFuselage framesWeight reductionGratingEngineering plastic

The invention discloses a multilayer grating bearing cylinder and a preparation method thereof. The multilayer grating bearing cylinder is formed by nesting at least two single-layer grating cylinders, and the densities of the meshes of the adjacent single-layer grating cylinders are different. The preparation method for the multilayer grating bearing cylinder made from a composite material comprises the following steps: producing a wood pattern for casting a soft mode, producing a silicon rubber soft mode, assembling a mould, winding the soft mode in an assistance manner, carrying out vacuum bag moulding, demoulding and carrying out after-treatment, and integrally moulding the multilayer grating bearing cylinder; or preparing the single-layer grating cylinders according to the steps, and then assembling the single-layer grating cylinders into the multilayer grating bearing cylinder. The preparation method for the multilayer grating bearing cylinder made from metal or engineering plastic comprises the following steps: preparing a casting mould for the disassembly components of the single-layer grating cylinders, melting and casting, welding, and then assembling the single-layer grating cylinders into the multilayer grating bearing cylinder; or moulding in one step by a 3D printing technology. The multilayer grating bearing cylinder has the characteristics of good structural stability, light mass, high mechanical properties, difficulty of structural overall buckling instability, simple and practicable preparation method, and low cost.

Owner:NAT UNIV OF DEFENSE TECH

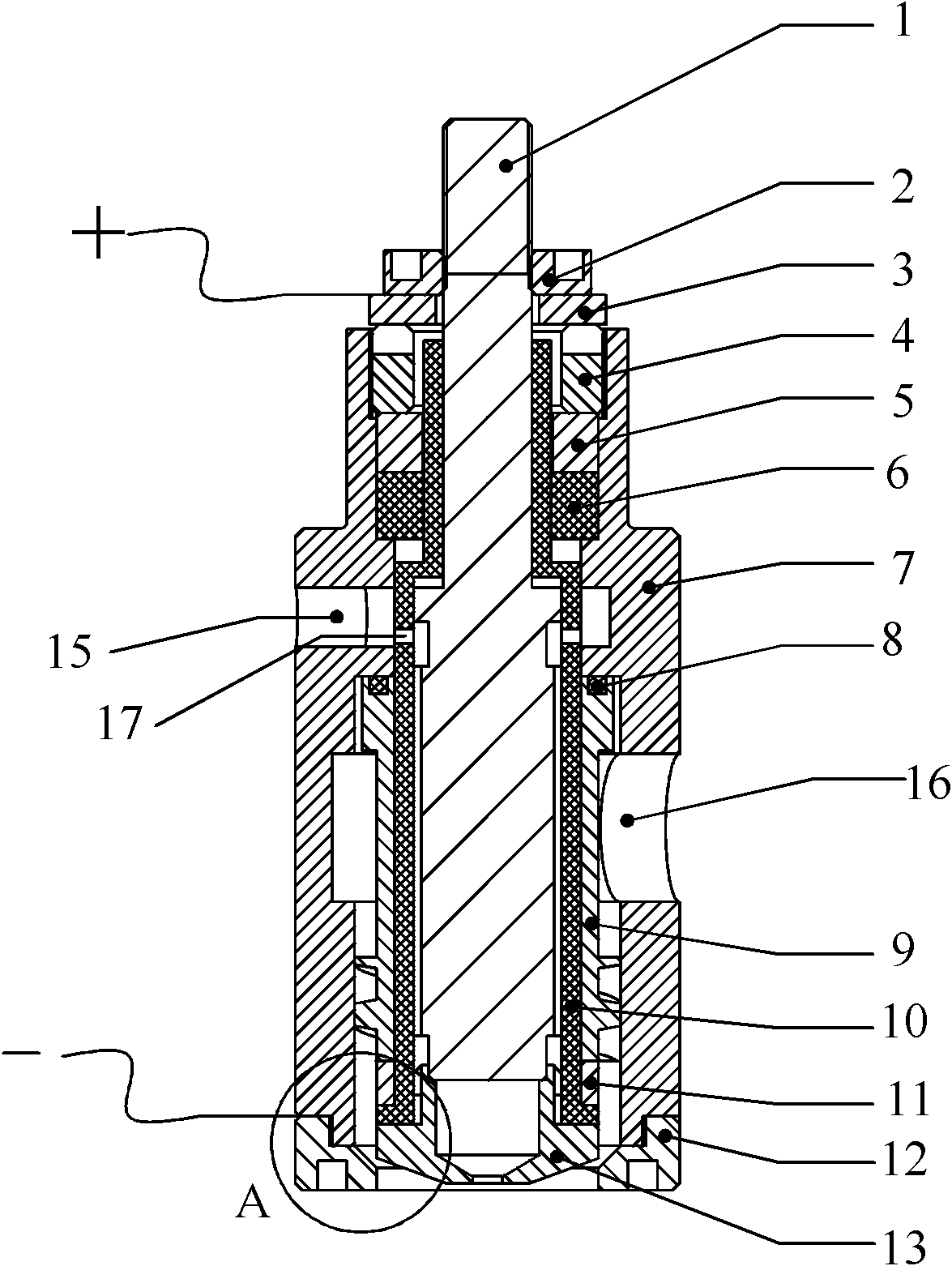

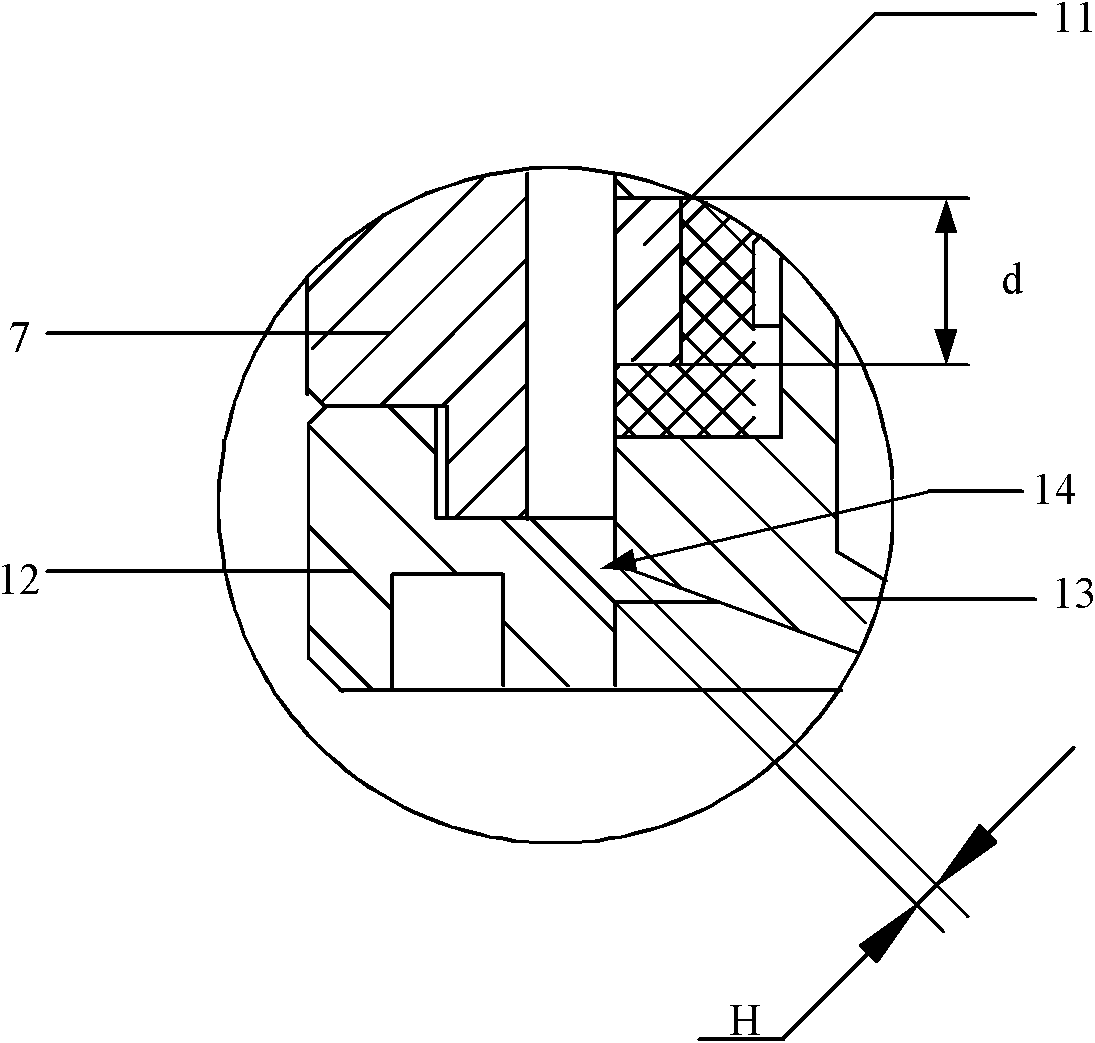

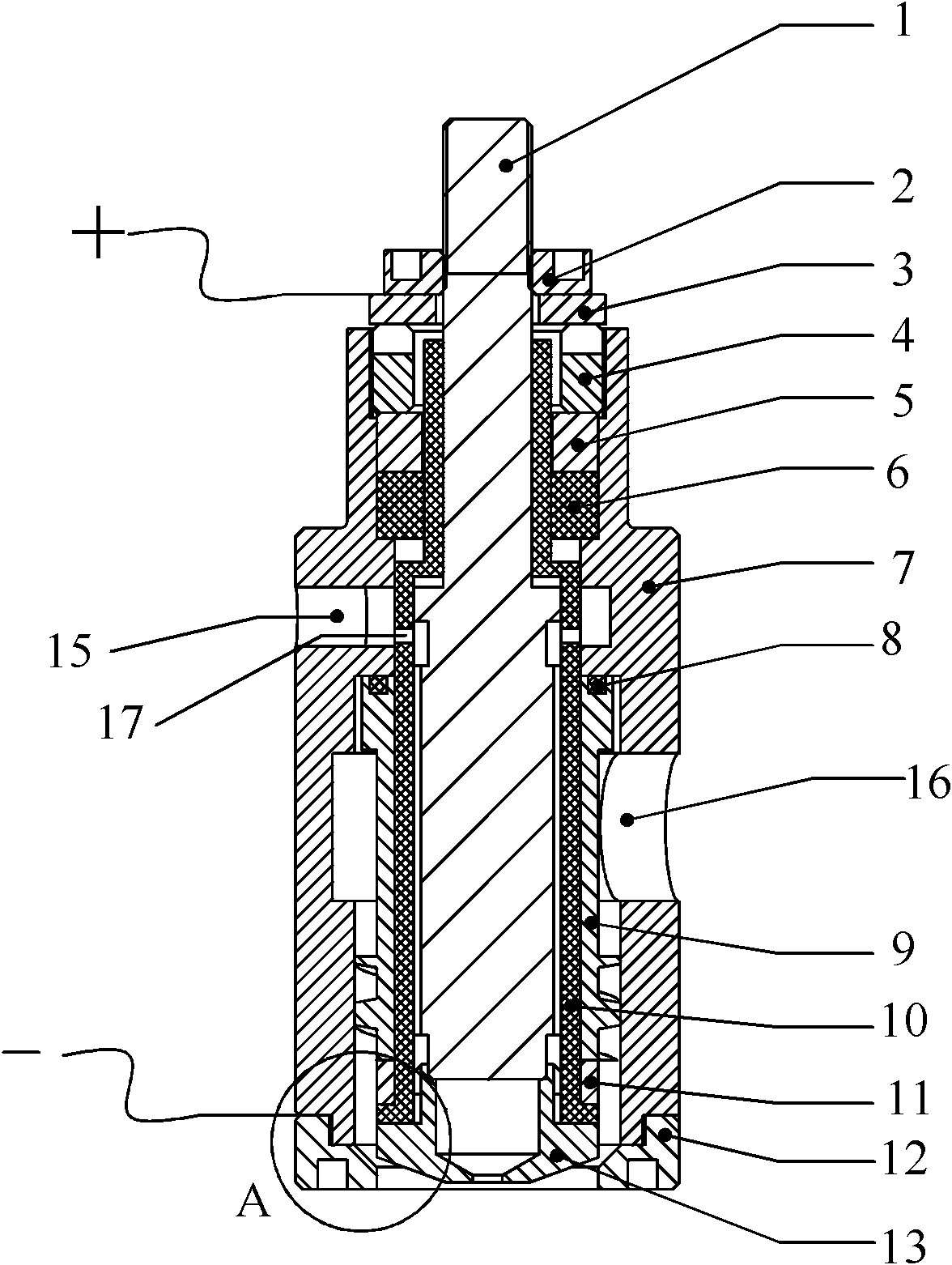

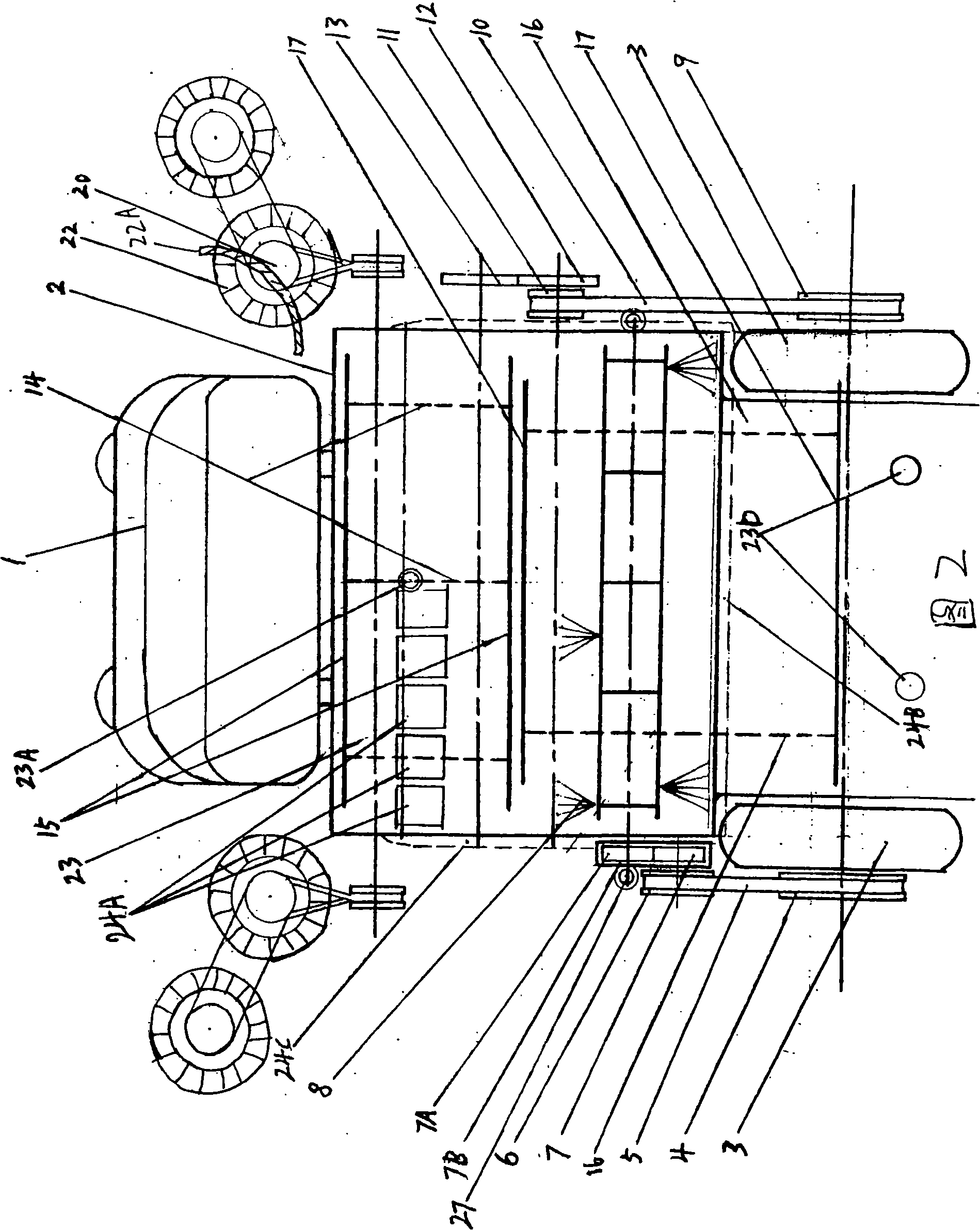

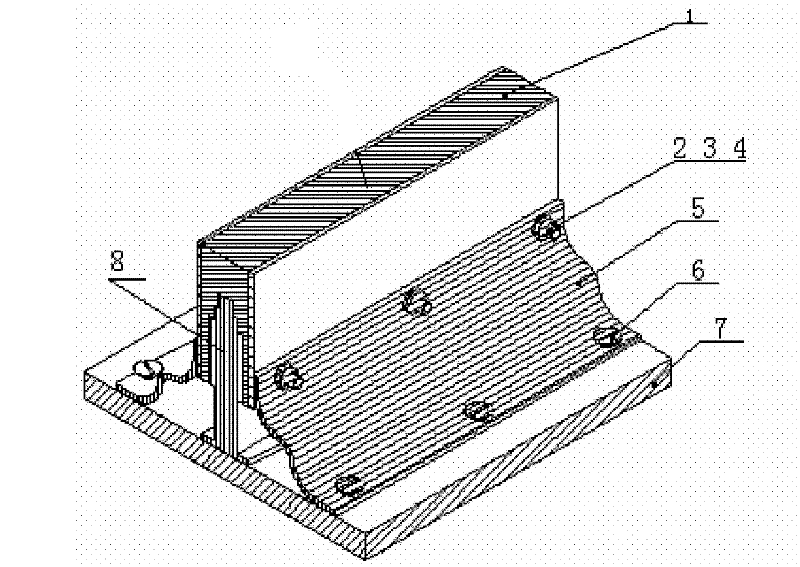

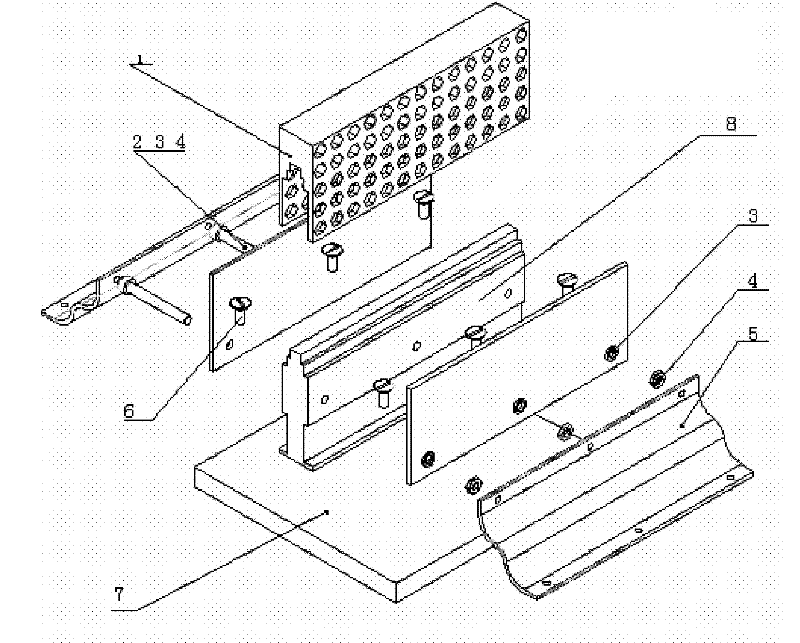

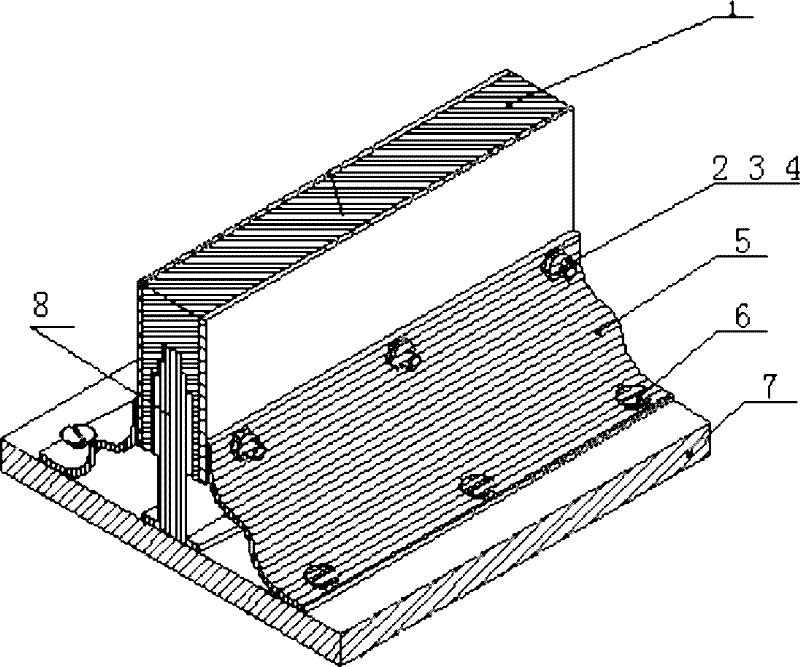

Head injector of low-thrust engine for electric discharge and ignition by utilizing nozzle clearance

InactiveCN102052197AReduce structural weightLarge discharge areaRocket engine plantsElectric dischargeMiniaturization

The invention discloses a head injector of a low-thrust engine for electric discharge and ignition by utilizing nozzle clearance. The head injector provided by the invention comprises a high voltage positive electrode copper rod, a positive electrode wiring nut, a positive electrode insulating spacer, a seal locking nut, a seal extruding ring, a sealing pad, a casing, a sealing ring, an oxidizingagent swirler, a positive electrode insulating sleeve, an electric discharge circumferential seam adjusting block, an oxidizer nozzle outlet end cover and a fuel centrifugal nozzle. The size miniaturization of the head injector of the low-thrust engine can be realized, and because the electric discharge area of the nozzle ring seam is large and the interval can be adjusted, the spark plug single-point electric discharge fault caused by pollution can be avoided effectively.

Owner:BEIHANG UNIV

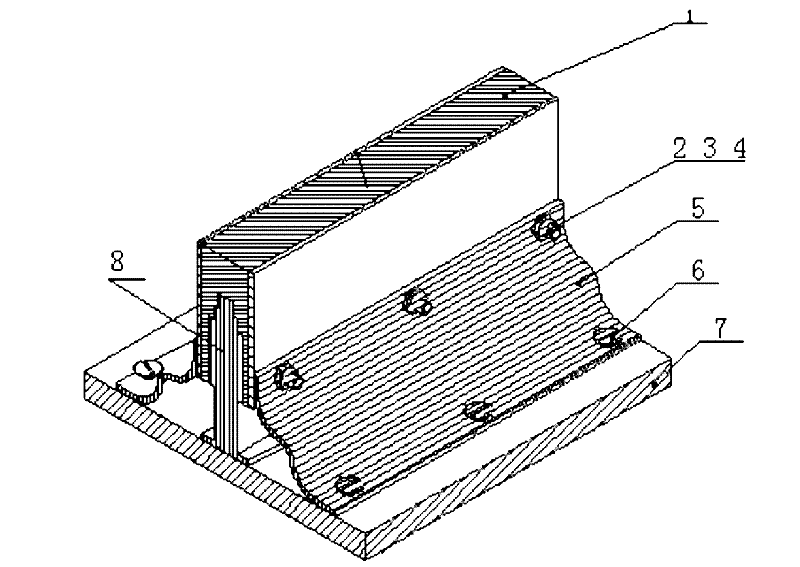

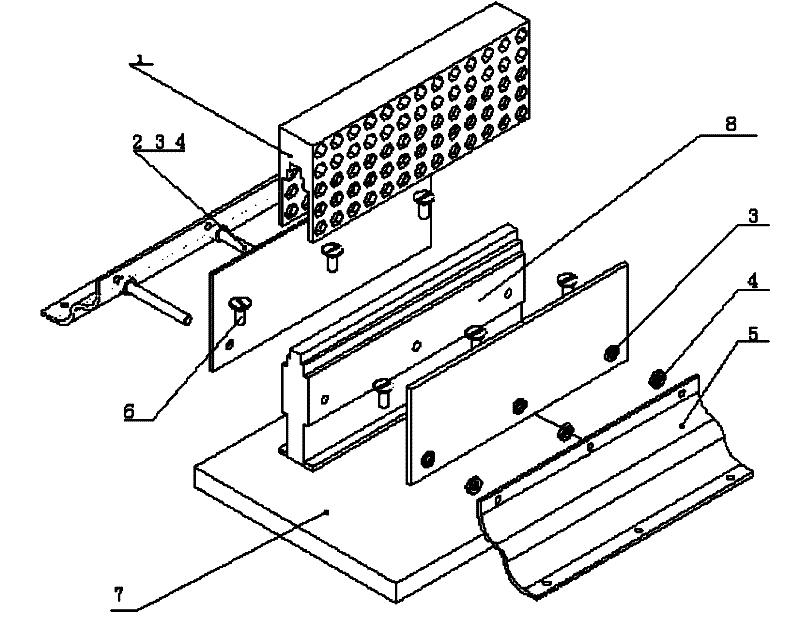

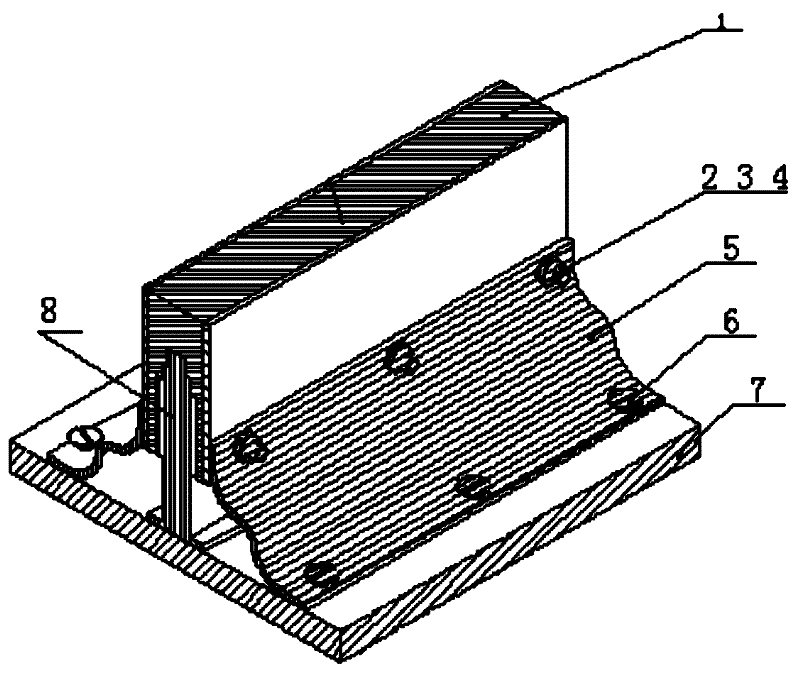

T-shaped connection structure of composite material laminboard

The invention provides a T-shaped connection structure of a composite material laminboard, comprising a connecting bottom plate, a honeycomb laminboard and a T-shaped reinforcing block, wherein the honeycomb laminboard is provided with a groove the shape of which is same with the shape of the upper end of a web of the T-shaped reinforcing block; the upper end of the web of the T-shaped reinforcing block is inserted into the groove; and a wing rafter of the T-shaped reinforcing block is in glue joint with the connecting bottom plate. The T-shaped connection structure also comprises two waveform connecting pieces, wherein the two waveform connecting pieces are positioned on two sides of the honeycomb laminboard; the waveform connecting pieces, the T-shaped reinforcing block and the honeycomb laminboard are fastened and connected by bolts; and the waveform connecting pieces and the connecting bottom pate are connected by glue and bolts in a mixing mode. The T-shaped connection structure has the advantages that the flexural rigidity is high; a bigger space is formed between the two waveform plates to bring convenience for overlaying a number of pipelines and subsequently maintaining; stress concentration on a joint can be effectively alleviated; the structural efficiency is improved; the bearing capability is enhanced, and the like. The T-shaped connection structure disclosed by the invention is suitable for mechanical connection between the composite material laminboard in a large-sized structure and other structures.

Owner:HARBIN ENG UNIV

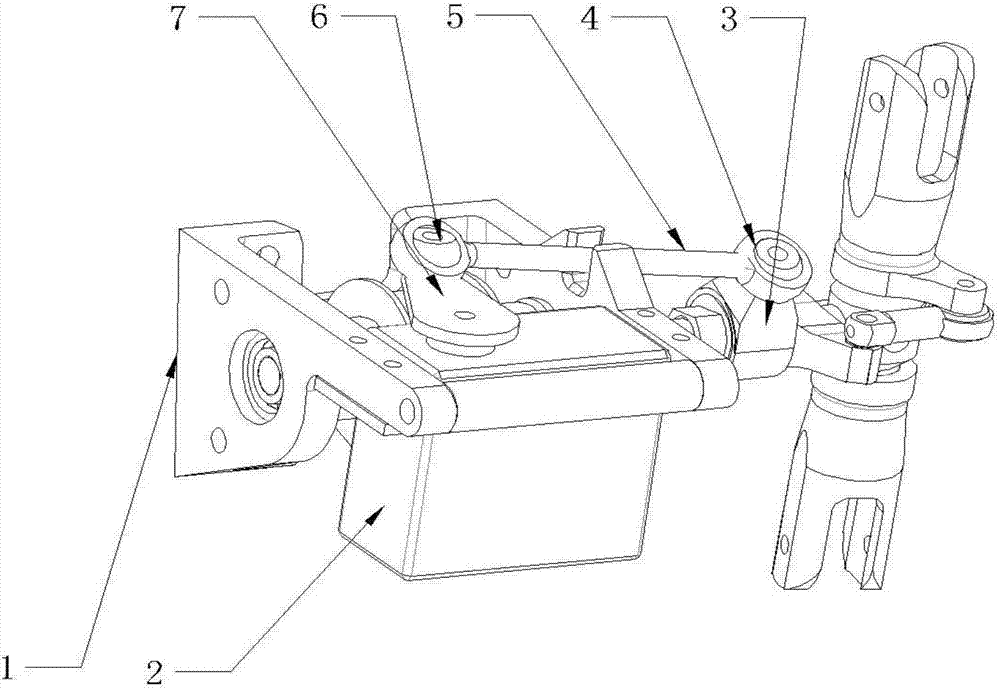

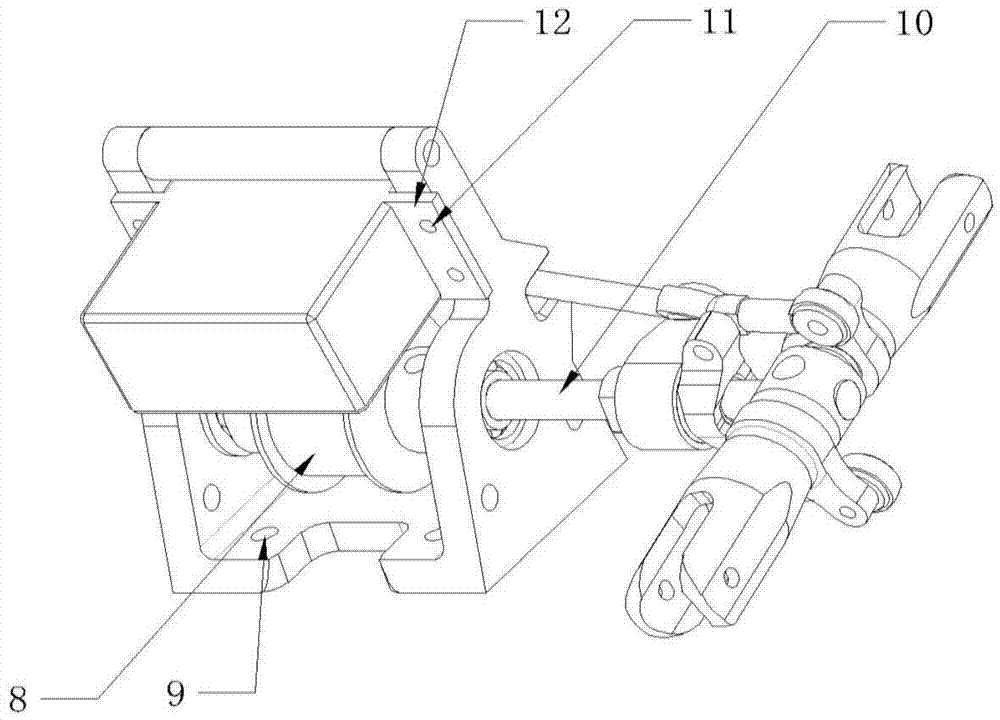

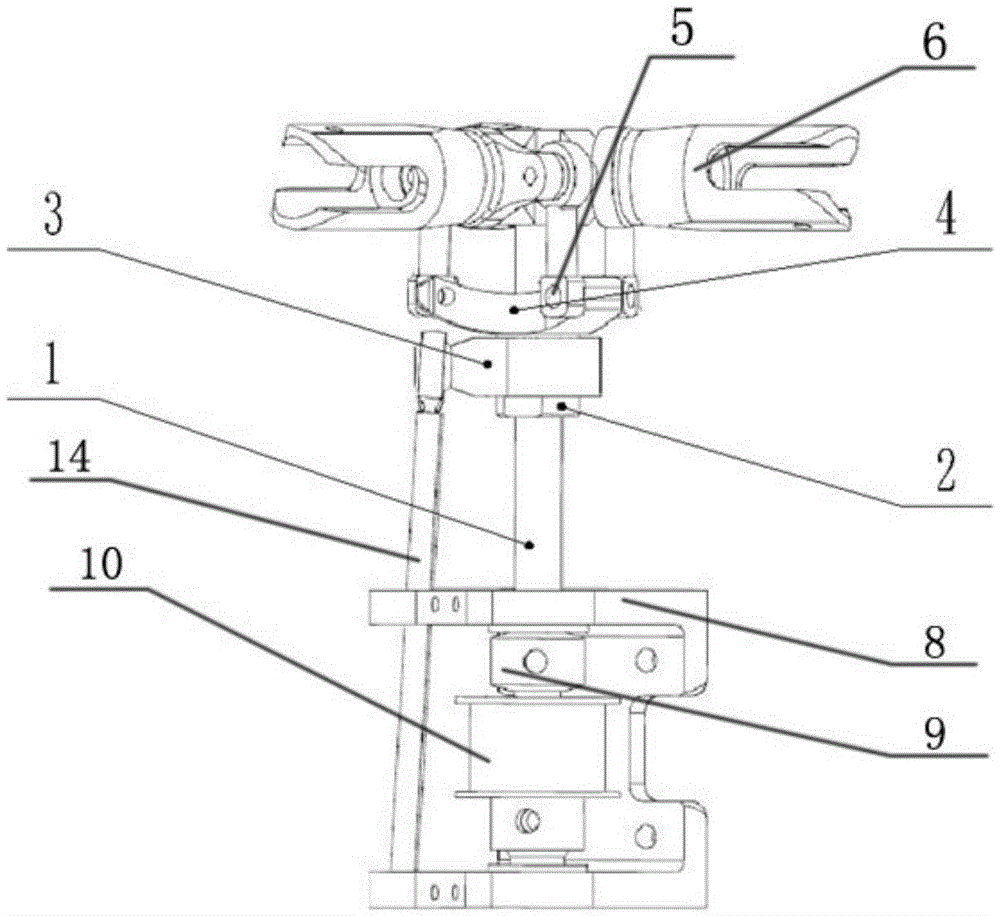

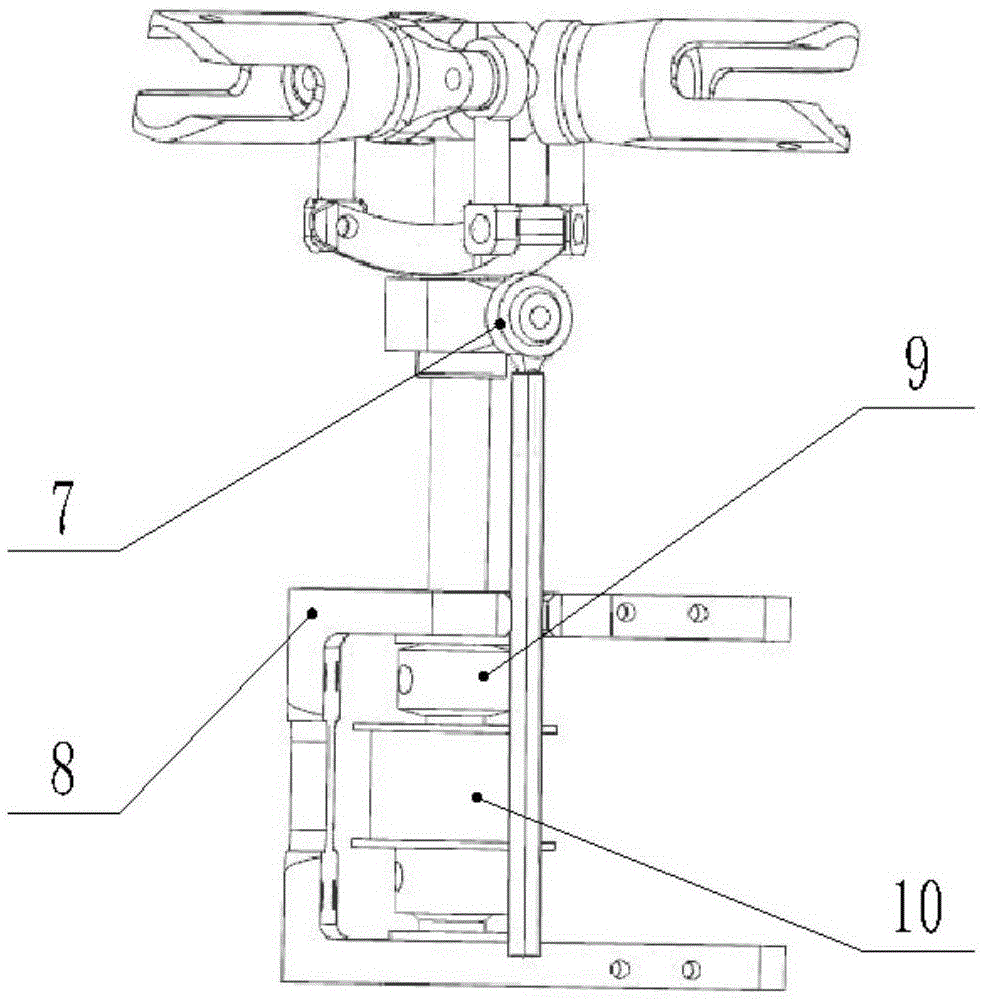

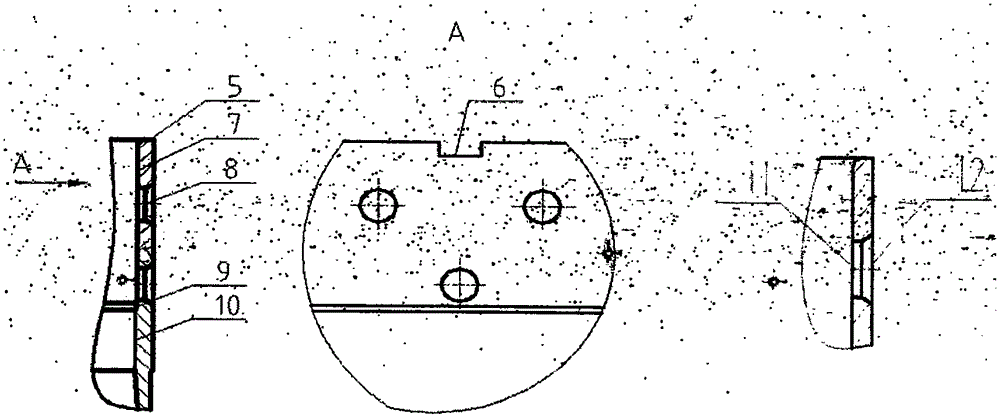

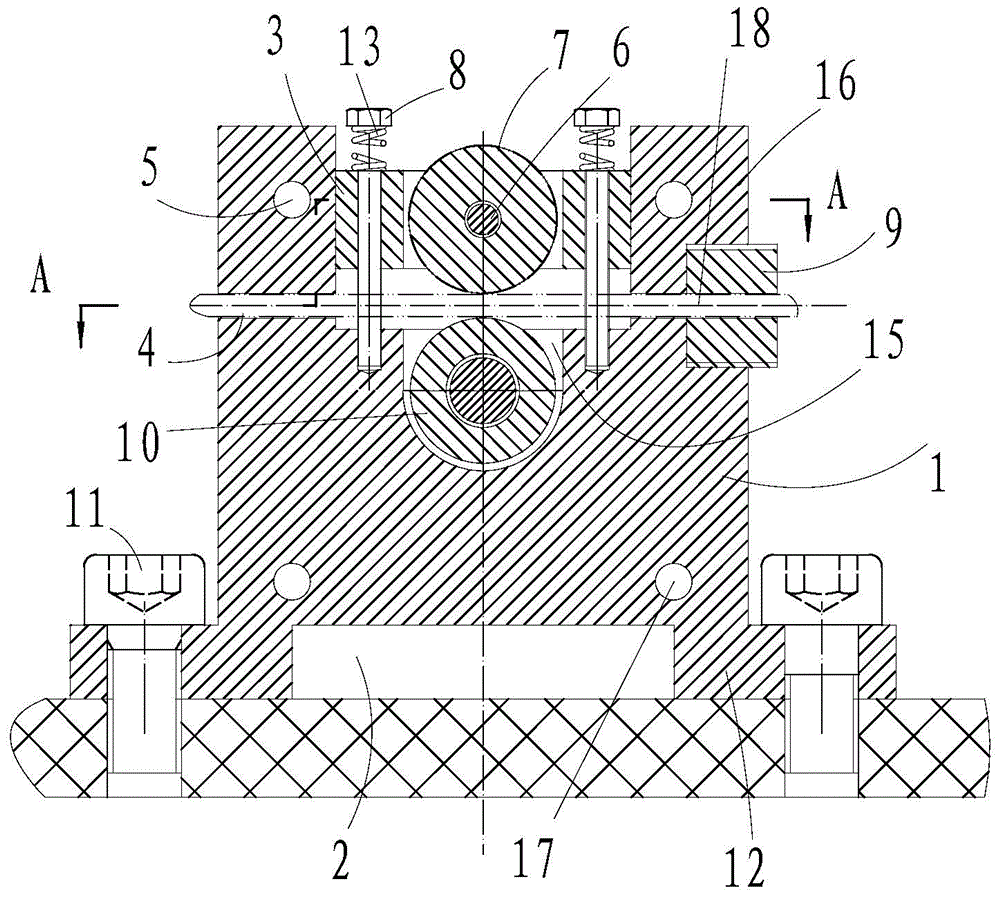

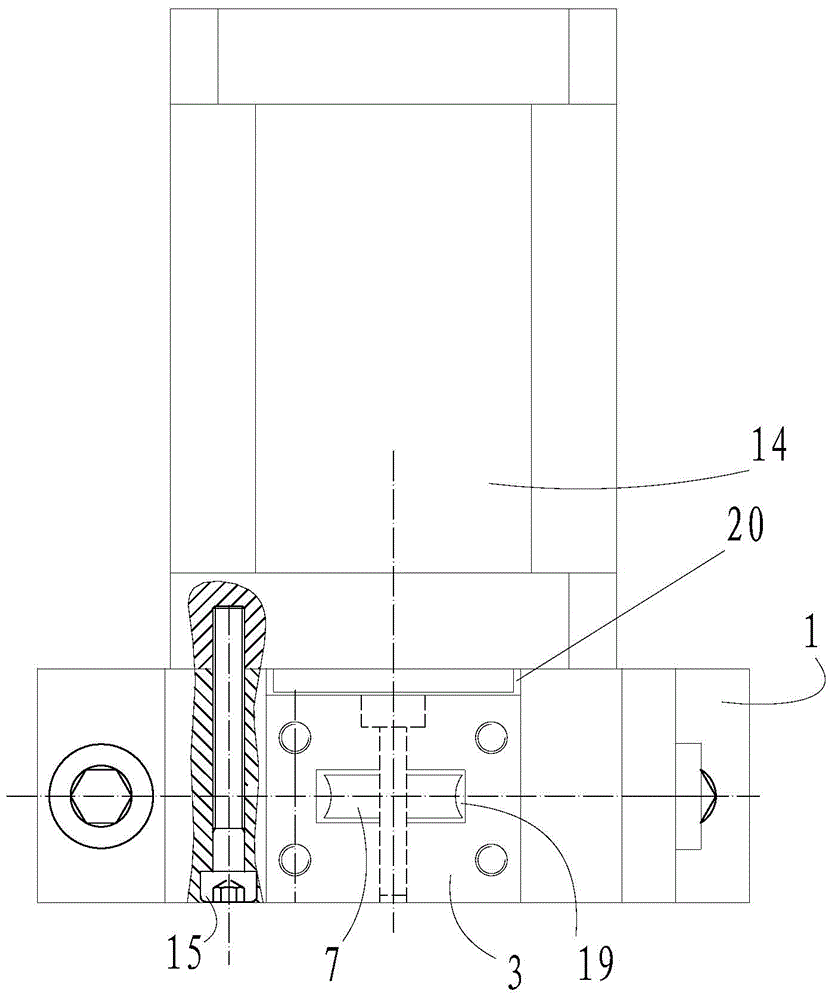

Tail rotor pitch structure of unmanned helicopter

ActiveCN104843183ASimple drivePart Displacement Constraint SimplificationRotocraftTail rotorRocker arm

The invention relates to a tail rotor pitch structure of an unmanned helicopter, which is composed of a bearing pedestal, a steering engine, a variable-pitch slide block, an universal drive shaft head A, a variable-pitch pull bar, an universal drive shaft head B, a pitman arm, a belt wheel, a threaded hole, a transmission shaft, a fixing threaded hole, a steering engine auricle and a tail rotor rocking arm. The bearing pedestal and a tail boom are connected through a screw, the transmission shaft and the belt wheel are fixedly connected, the power input of the transmission shaft can be realized by belt driving formed by the belt and the belt wheel; the steering engine auricle and the bearing pedestal are connected by a screw, the steering engine and the pitman arm are connected through a pitman arm screw, the pitman arm and the end part of the variable-pitch pull bar through the universal drive shaft head B; the variable-pitch slide block and a tail rotor transmission shaft are connected through the bearing, one end of the variable-pitch pull bar and the variable-pitch slide block are connected by the universal drive shaft head A, so that connection of the steering engine and the variable-pitch slide block is realized; and the variable-pitch slide block and the tail rotor rocking arm employs circumferential rotatable connection. According to the invention, a structure design of the tail rotor with high accident rate can be optimized, structural quality is mitigated, connection reliability is enhanced, and the tail rotor pitch structure is an optimization scheme of tail rotor transmission.

Owner:TIANXUN INNOVATION BEIJING TECH CO LTD

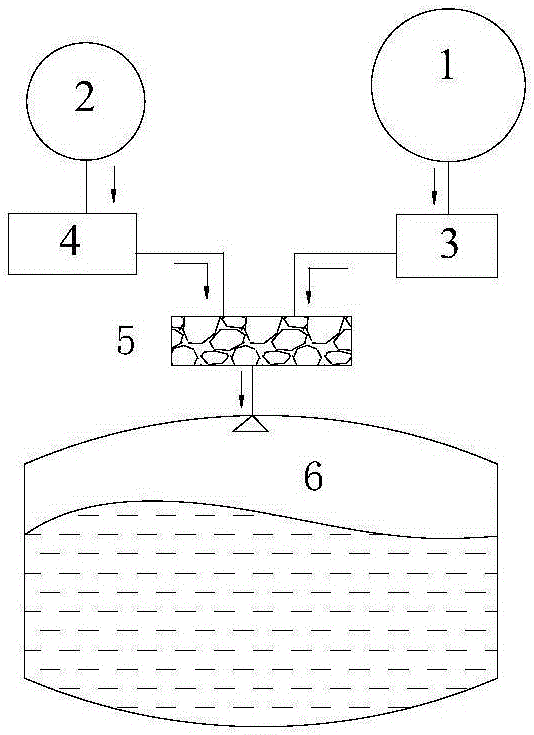

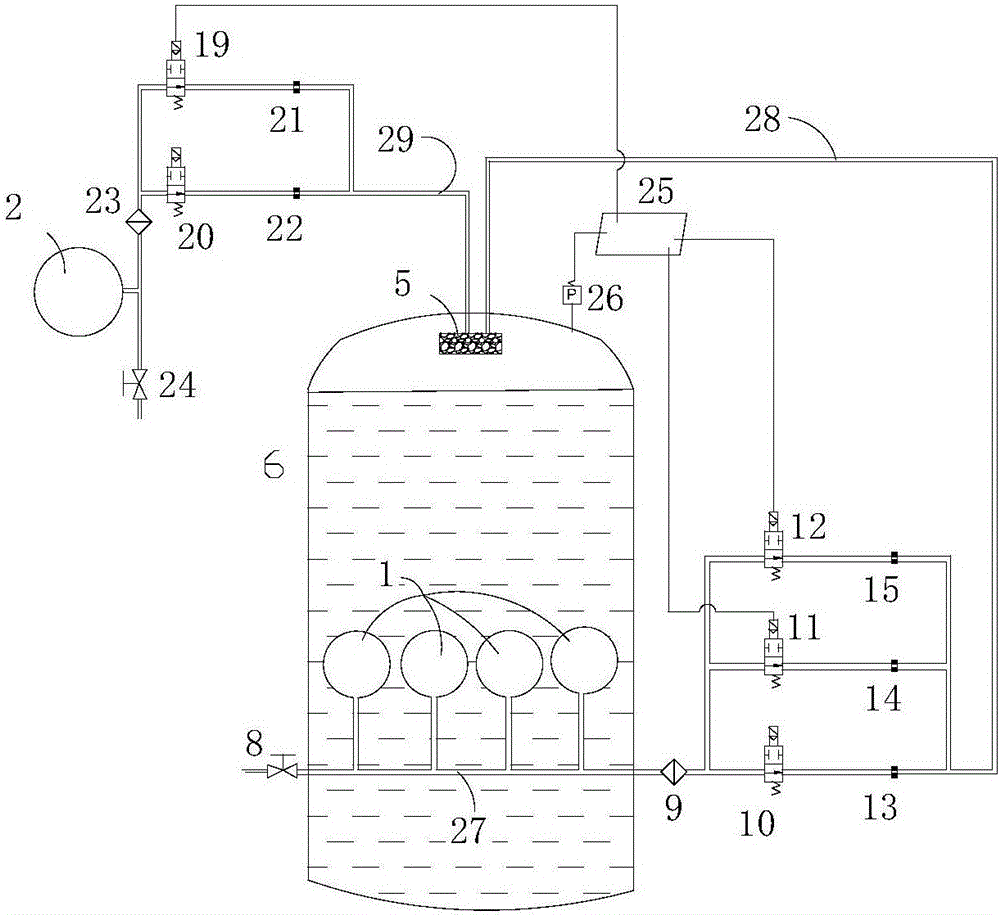

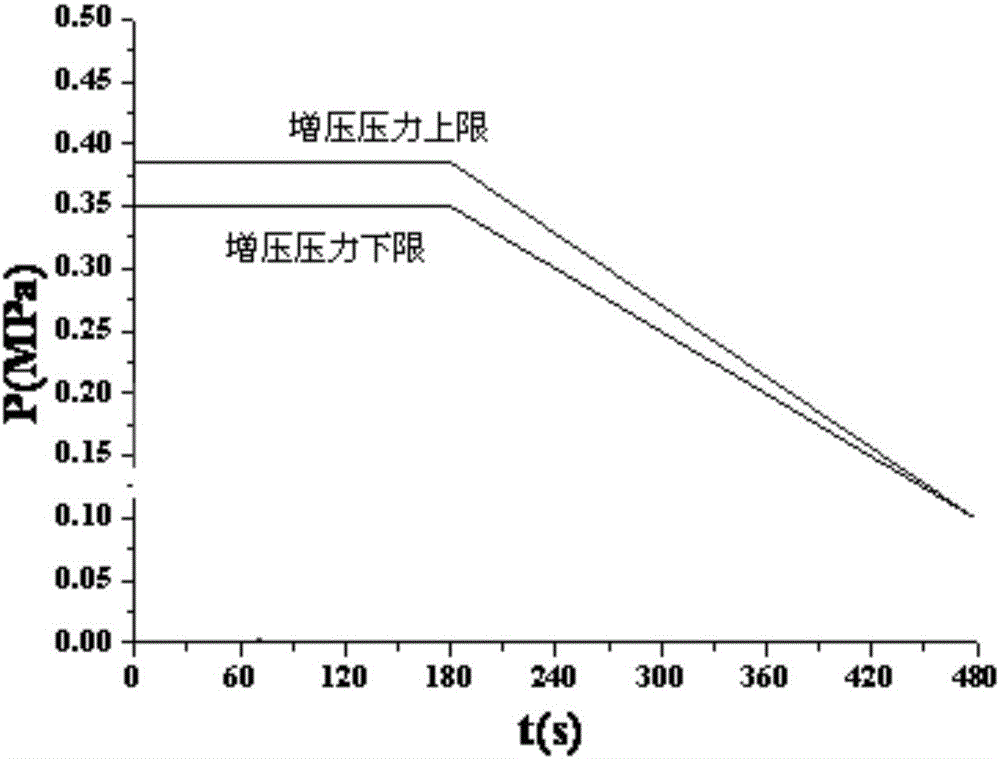

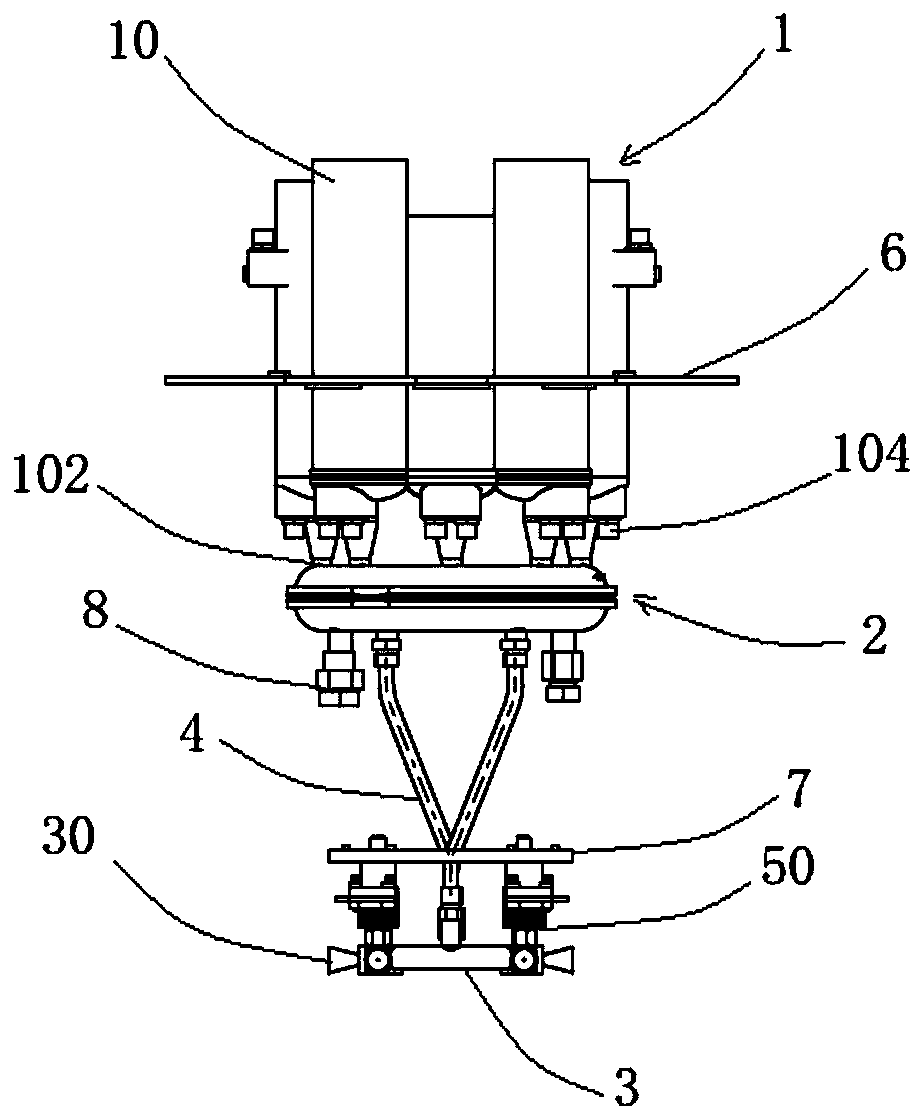

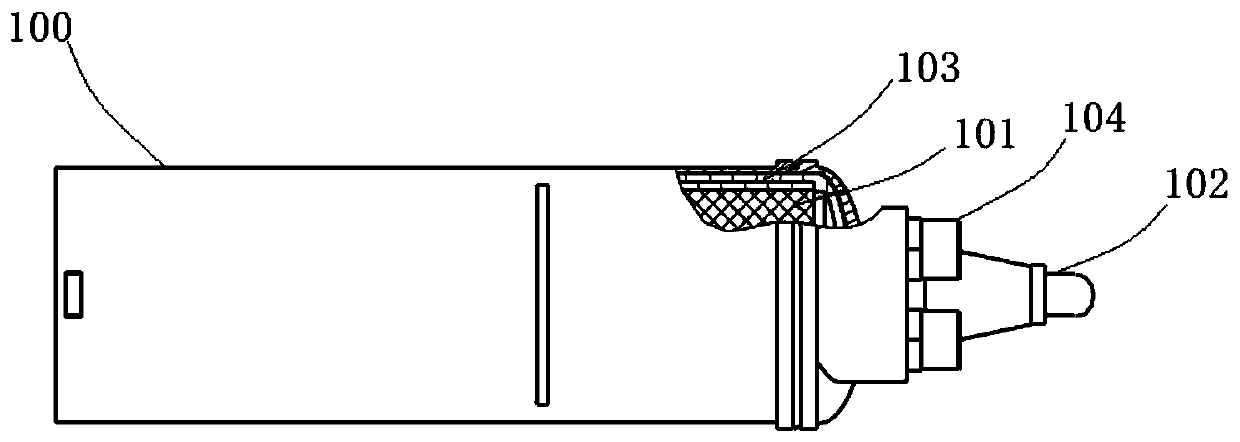

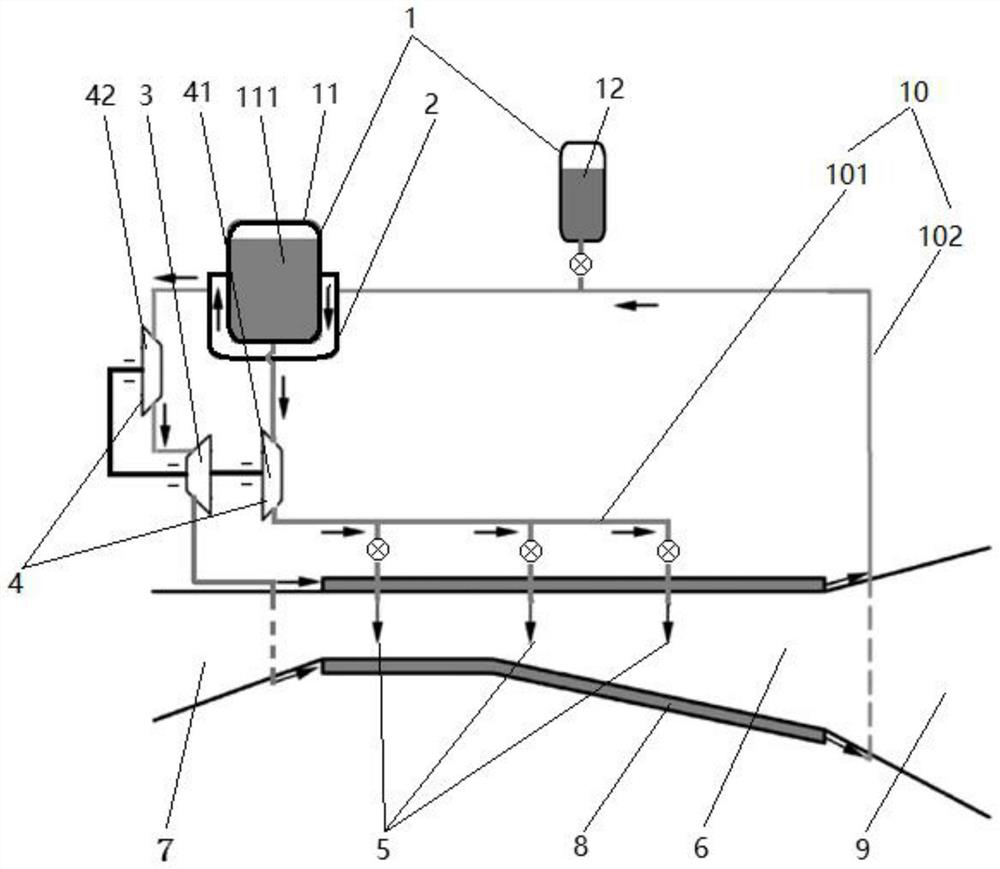

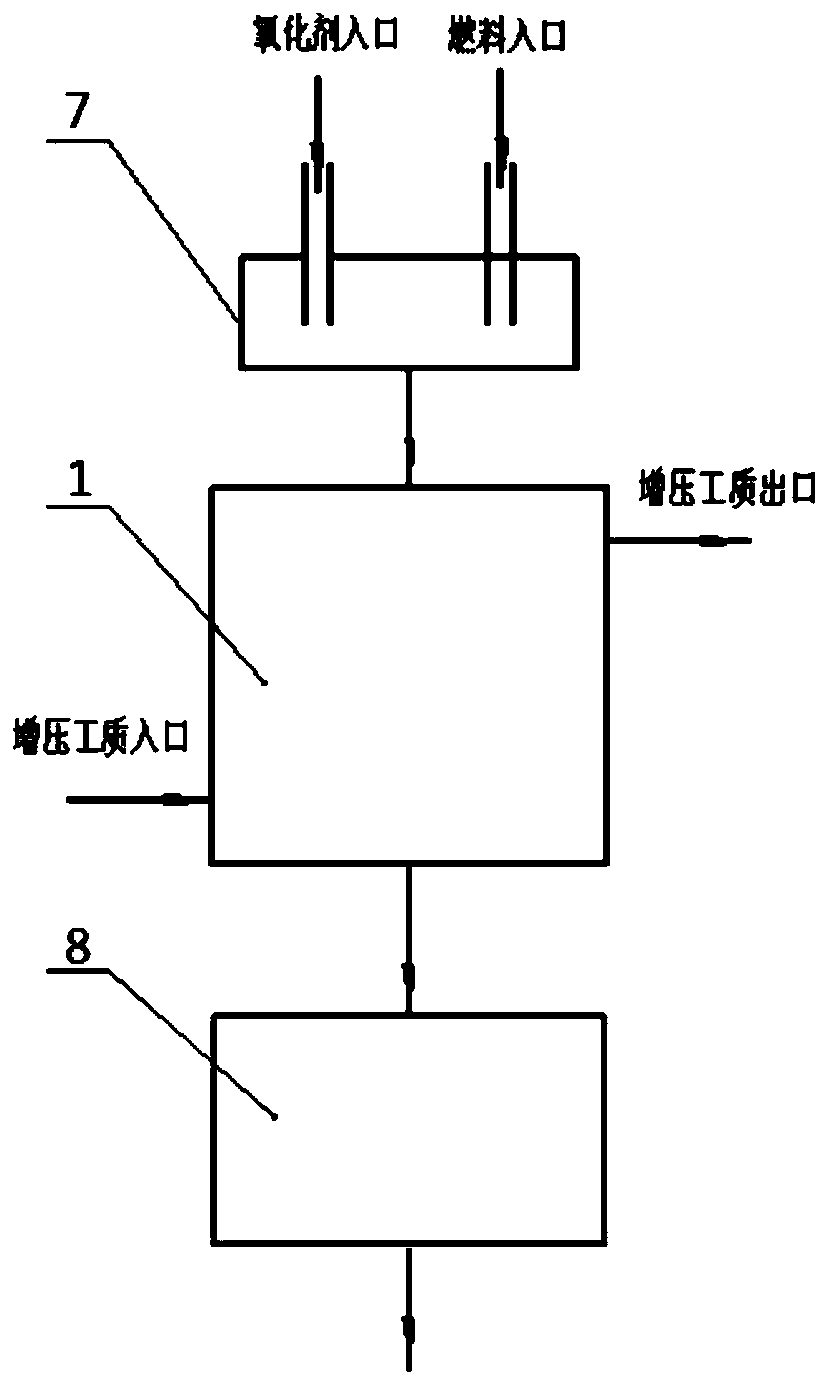

Trimix pressurization system applied to liquid rocket

ActiveCN106194500ACompact structureHigh degree of independenceRocket engine plantsHydrogenOxygen tank

The invention relates to a trimix pressurization system applied to a liquid rocket. The trimix pressurization system comprises a helium and hydrogen bottle (1), an oxygen bottle (2), a flow control unit and a catalytic bed (5), wherein mixed helium and hydrogen are stored in the helium and hydrogen bottle (1) in advance; oxygen is stored in the oxygen bottle (2); flow of gas output in the two bottles is controlled through the flow control unit; a mixed gas of output helium, hydrogen and oxygen is subjected to catalytic reaction through the catalytic bed (5); oxygen and hydrogen react to generate water vapor and release hat; and helium, water vapor and oxygen remaining after reaction are heated and enter a storage tank to pressurize the storage tank.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

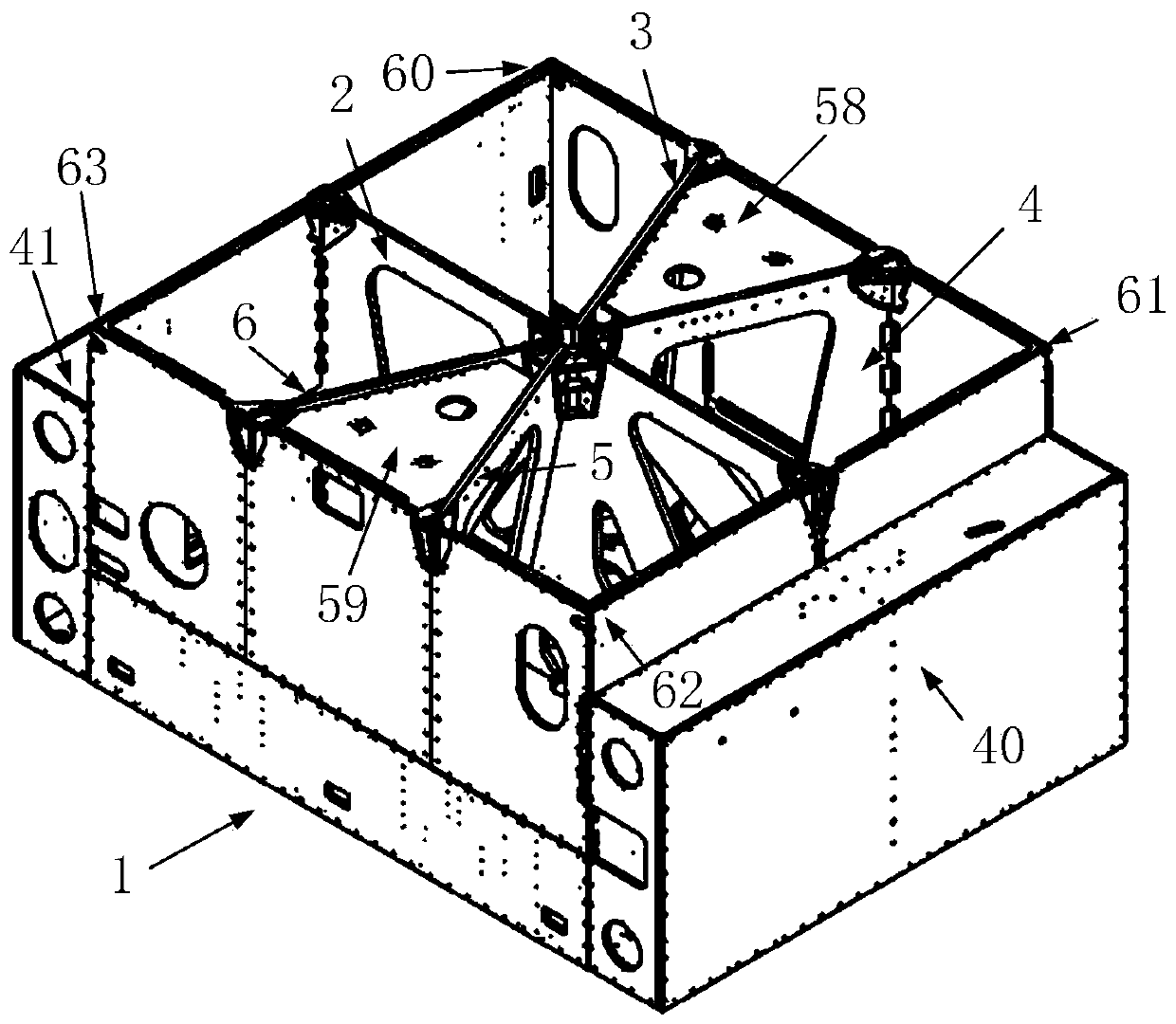

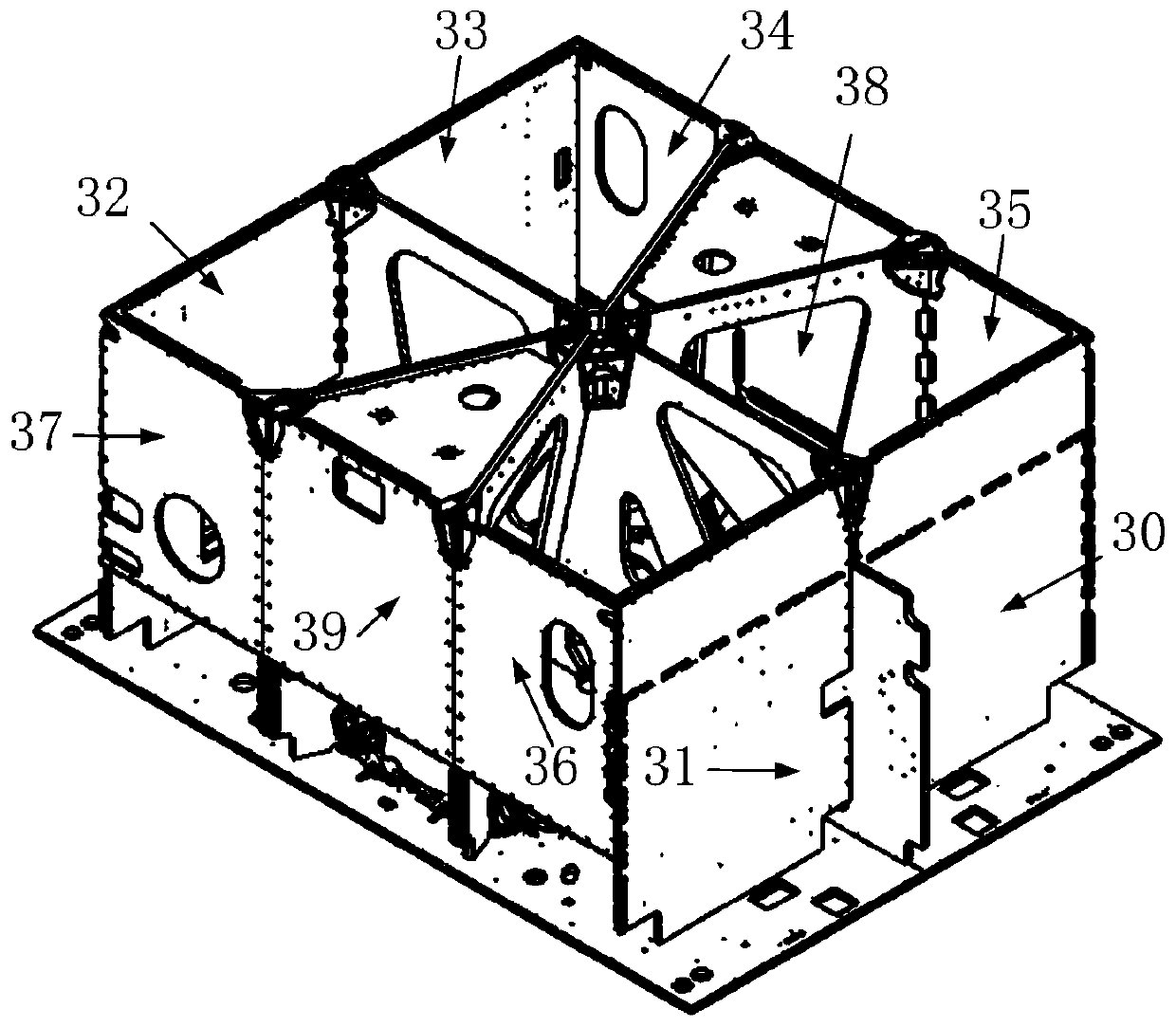

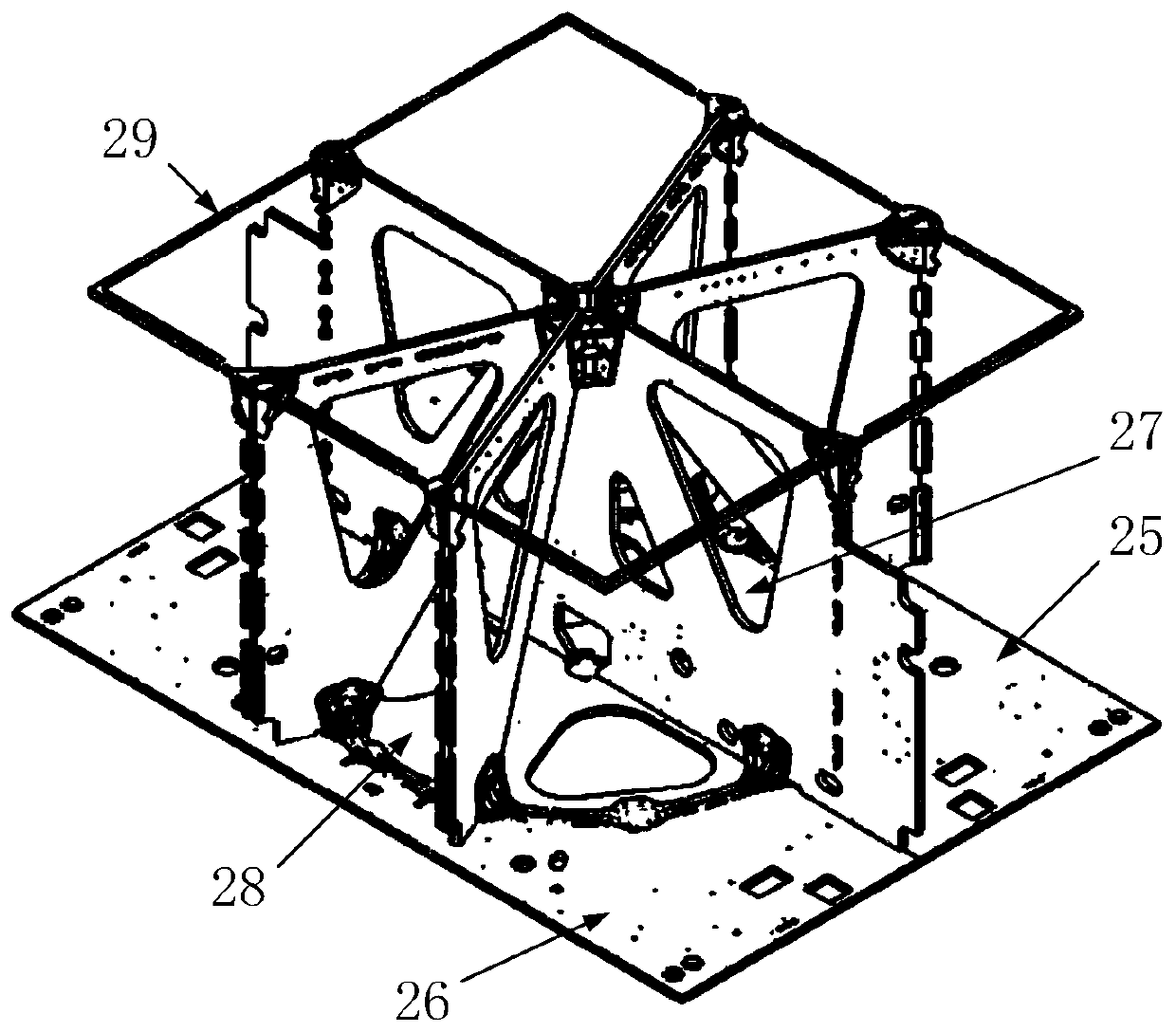

Satellite propulsion service cabin structure

InactiveCN110697087ALow center of massLighten the connection burdenCosmonautic vehiclesCosmonautic propulsion system apparatusComposite constructionGas cylinder

The invention provides a satellite propulsion service cabin structure which is suitable for a satellite structure family system with large bearing and multi-load adaptive capacity requirements. According to the cabin structure, a main force bearing structure is composed of a satellite-rocket butt joint ring and beam-slab composite structural slabs, the beam-slab composite structural slabs form three sets of W-shaped plane truss units, and in a top view, the three sets of planes intersect at the central axis and are distributed in a star shape. According to the cabin structure, the four large spaces divided by the star-shaped truss are used for installing the storage tank, the lower portion of the storage tank is directly connected with the butt joint ring, the upper portion of the storagetank is connected with the truss joint through the pull rod, and the structural weight is greatly reduced through the storage tank connecting mode. The two smaller spaces of the invention allow to beused to mount gas cylinders. By means of the structure, the large bearing capacity of the propelling service cabin is ensured.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Solid attitude control power system based on energy management and control

InactiveCN109707536AOmit designSave spaceCosmonautic propulsion system apparatusRocket engine plantsSolenoid valveGas cylinder

The invention discloses a solid attitude control power system based on energy management and control, and relates to the technical field of solid attitude control power systems. The solid attitude control power system comprises a burner group, a gas collection filter assembly, a thruster and a solenoid valve assembly, wherein the burner group includes at least one burner; the gas collection filterassembly is arranged below the burner and communicates with the burner; the thruster is arranged below the gas collection filter assembly and communicates with the gas collection filter assembly through a connecting pipe; each side face of the thruster includes at least one nozzle; the solenoid valve assembly is arranged on the thruster; the solenoid valve assembly includes a plurality of solenoid valves; and each solenoid valve is used for controlling a nozzle. The solid attitude control power system based on energy management and control structurally has no need of a gas storage cylinder, so that the overall system is light in weight, small in space and simple in structure.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

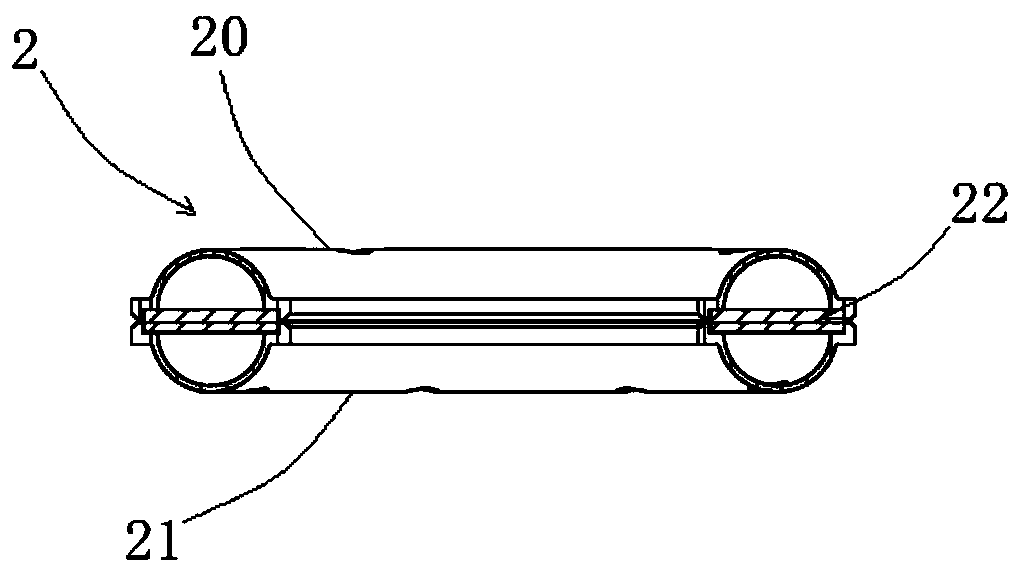

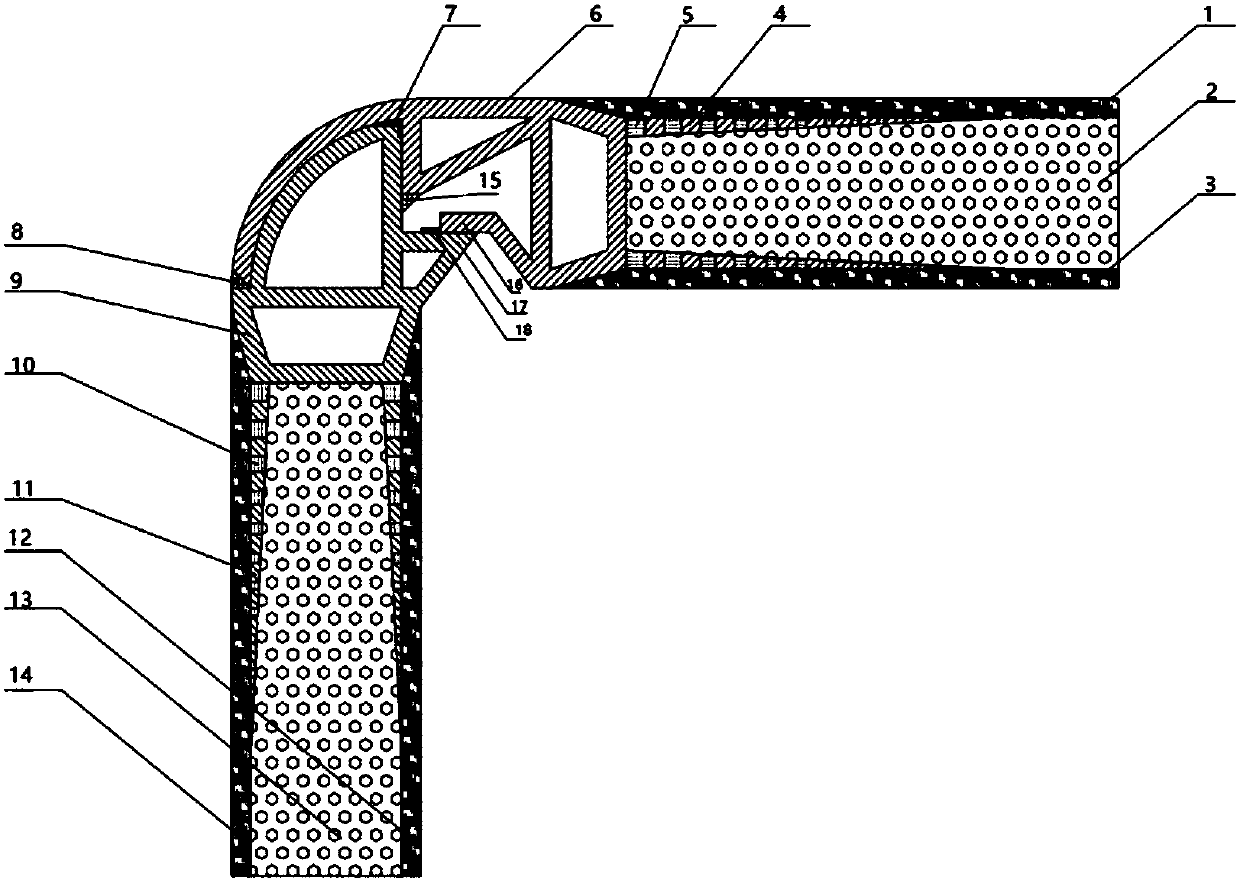

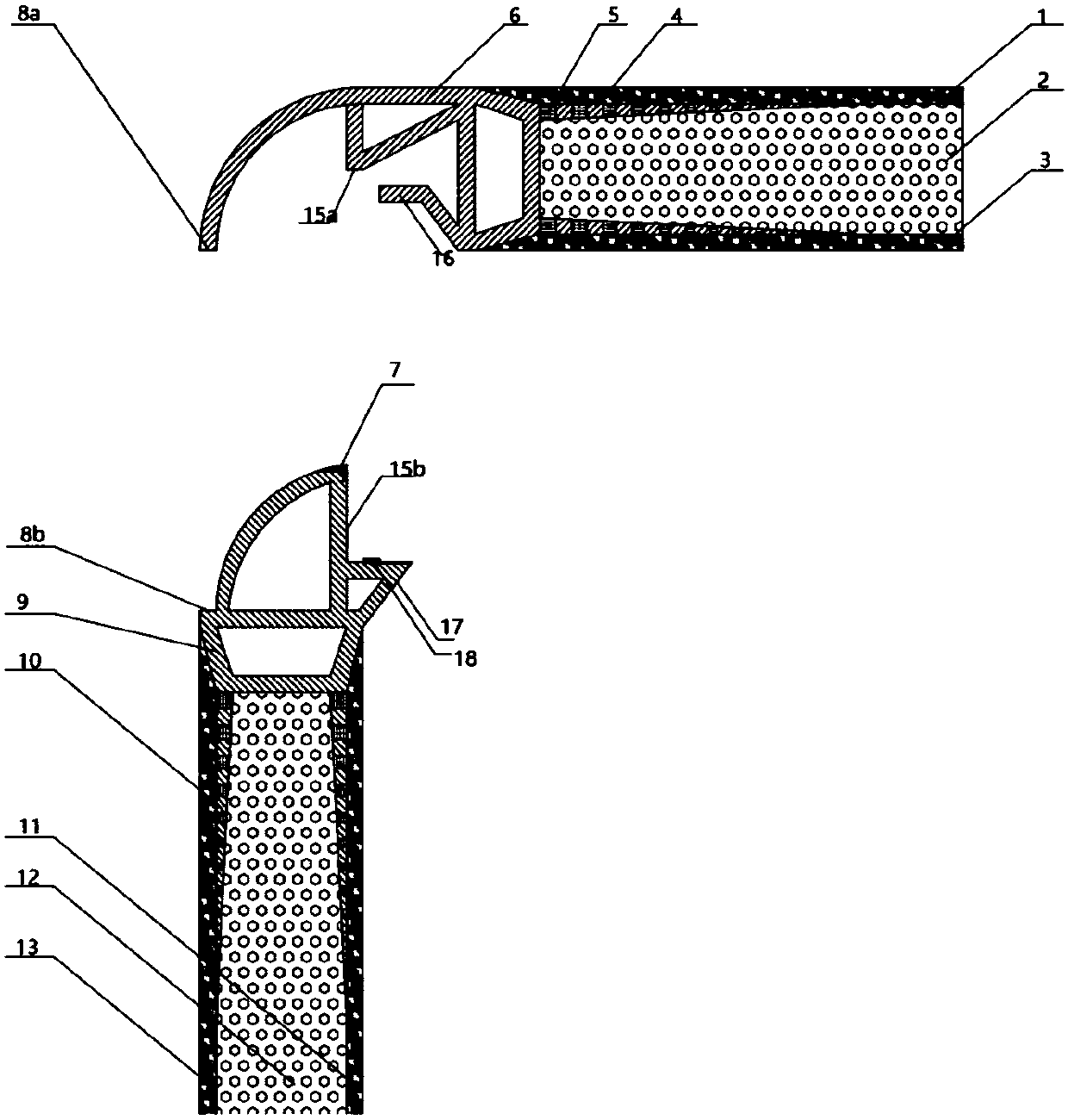

Connecting and sealing device

ActiveCN105888881AReduce structural massGuaranteed reliabilityRocket engine plantsEngineeringRocket engine nozzle

The invention discloses a connecting and sealing device comprising a shell and a spraying pipe connected with the shell. An assembling groove is formed in the inner wall of the shell; the spraying pipe is provided with an assembling step matched with the assembling groove; a clamping groove is further formed in the shell and is internally provided with a snap ring matched with the clamping groove; and part of the snap ring is installed in the clamping groove, and part of the snap ring is tightly clamped to the spraying pipe. The device is complete in function and convenient to operate and has high universality. At present, the device has been applied to many products, many experiments are successfully completed, a good effect is achieved, the assembling problem of a spraying pipe of a small-diameter solid rocket engine can be solved, and the purposes of reducing the structural mass and improving the assembling efficiency are achieved.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

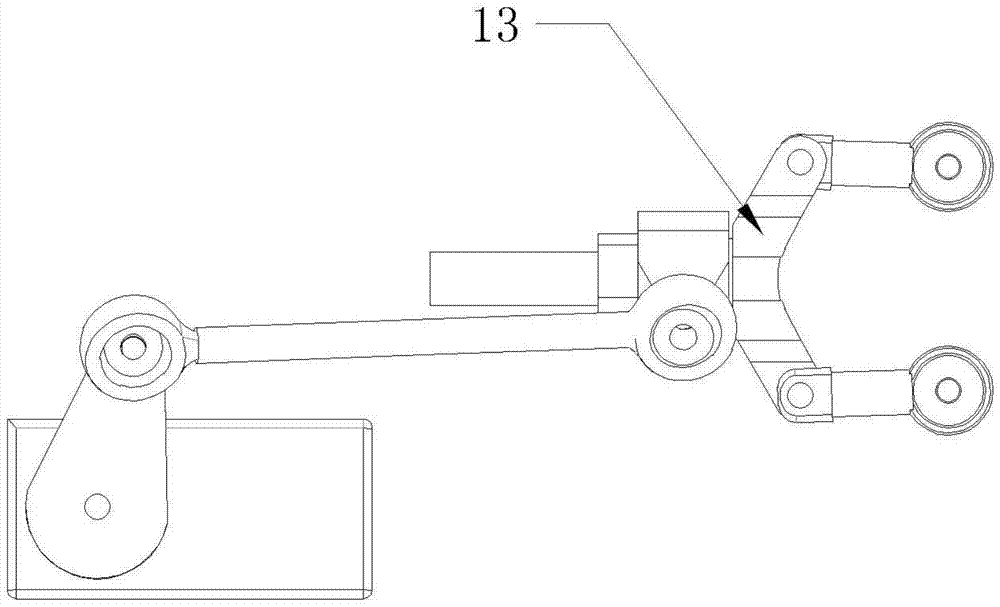

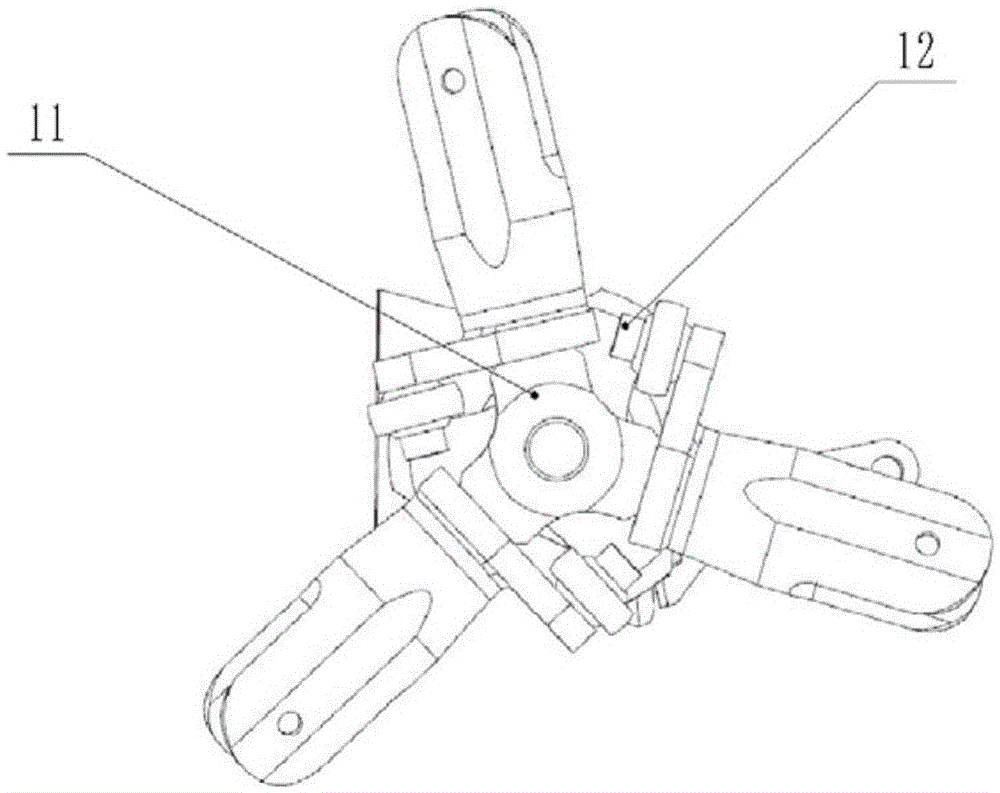

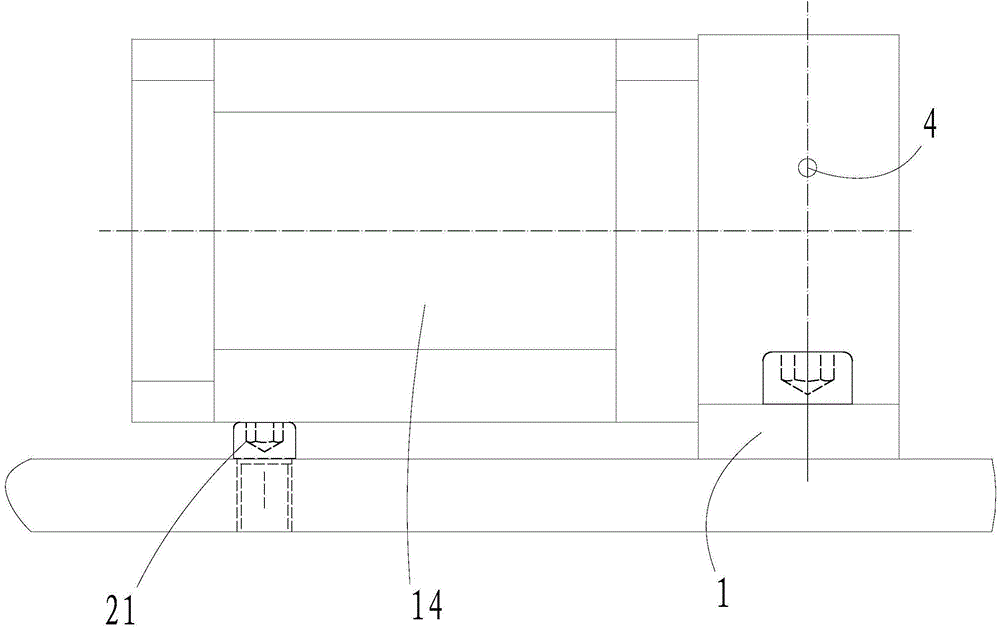

Three-rotor-wing tail rotor hub of unmanned helicopter

The invention discloses a three-rotor-wing tail rotor hub of an unmanned helicopter. The three-rotor-wing tail rotor hub comprises a tail shaft, a tail shaft seat, a tail shaft sleeve, a sliding sleeve, a crab claw, a crab claw connecting rod, rotor clamps, a bulb connecting rod, a tail shaft belt wheel, a tail rotor middle joint and a variable-pitch connecting rod. The tail shaft is assembled and fixed to the tail shaft seat through a flange bearing, the tail shaft belt wheel is arranged in the tail shaft seat, the tail rotor middle joint is fixed to the top end of the tail shaft, the tail rotor clamps are assembled on branches of the tail rotor middle joint, the crab claw connecting rod is fixed to rocker arms of the tail rotor clamps and connected with the crab claw, the crab claw is fixed to the tail shaft sleeve and the sliding sleeve in a matched mode, and the tail shaft sleeve and the sliding sleeve are fixedly assembled through two bearings. A steering engine rocker arm controls the variable-pitch connecting rod and drives the bulb connecting rod to move so as to drive the sliding sleeve, and finally a variable pitch of the tail rotor is achieved.

Owner:TIANXUN INNOVATION BEIJING TECH CO LTD

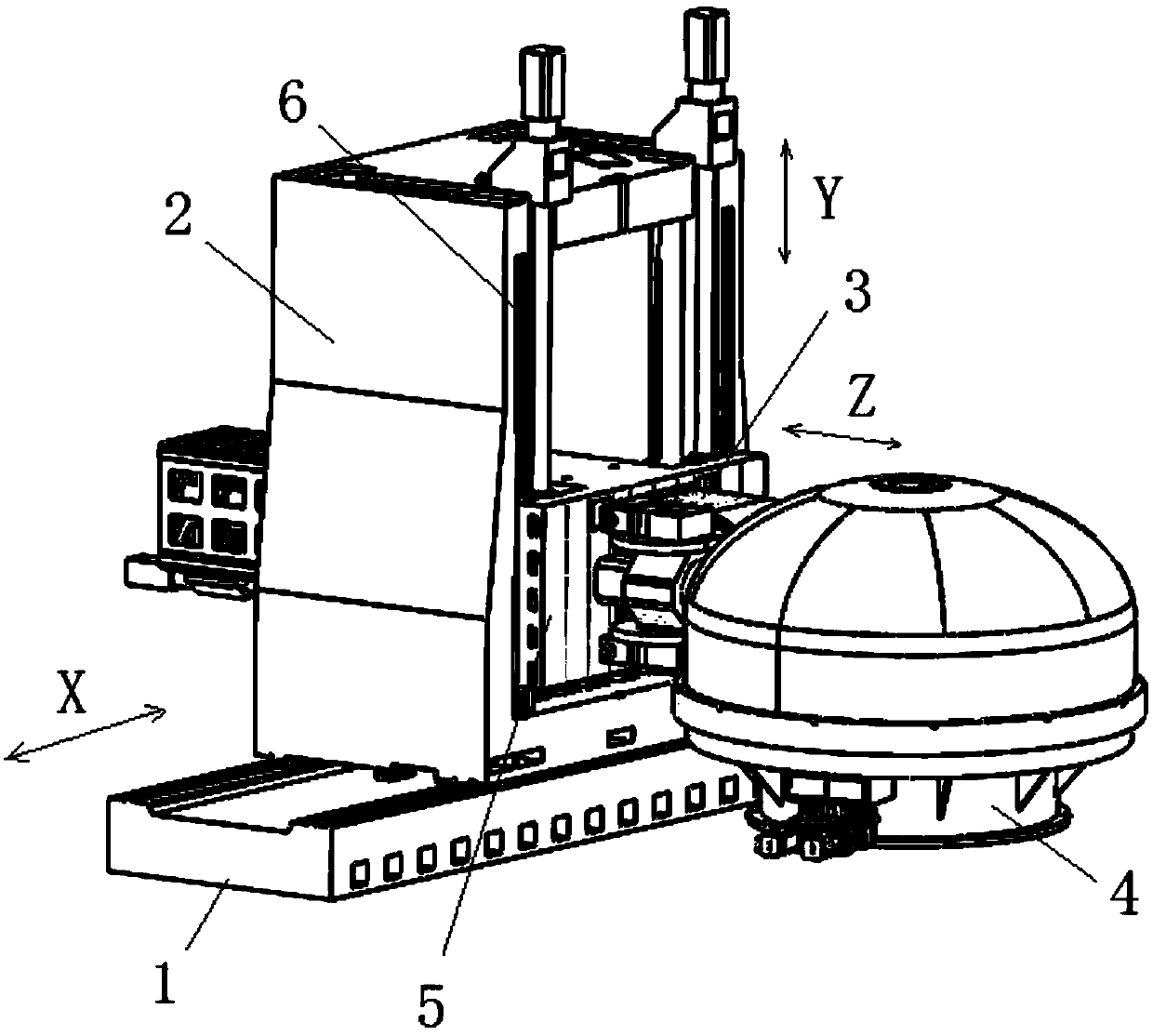

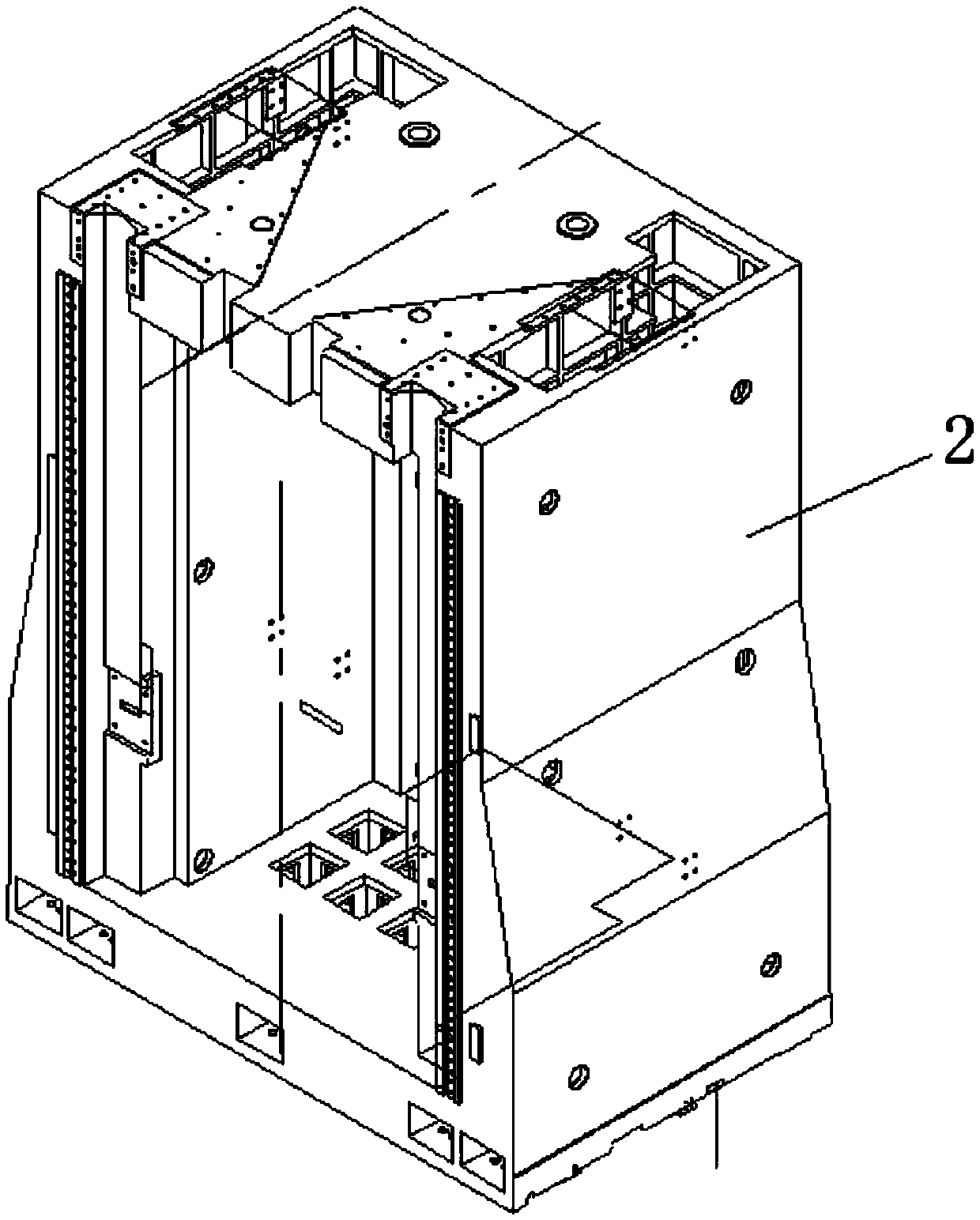

Topological optimization design method for stand column structure of friction stir welding robot

ActiveCN110580361AShorten the time of iterative calculationExcellent comprehensive dynamic performanceInternal combustion piston enginesSpecial data processing applicationsColumn modelColumn structure

The invention relates to the field of structural analysis of friction stir welding robots, in particular to a topological optimization design method for a stand column structure of a friction stir welding robot, which comprises the following steps of: 1, dynamically optimizing the stand column structure; 2, optimizing the load and boundary conditions of the stand column structure; 3, realizing topological optimization analysis of the stand column structures: firstly, carrying out three-dimensional modeling, carrying out mesh generation on a stand column model after modeling, then applying loadvalues under different working conditions to the model, carrying out topological optimization respectively, carrying out weighted optimization analysis on the stand column structures after topological optimization, and obtaining a final optimization result; and 4, reasonably configuring the stand column structure according to the obtained topological optimization analysis result of the stand column structure. According to the method, optimization design is carried out on the stand column structure firstly, then a new round of topological optimization correction design is carried out on the stand column structure again according to the optimized structure, and therefore the light-weight stand column structure with the excellent comprehensive dynamic performance is obtained.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

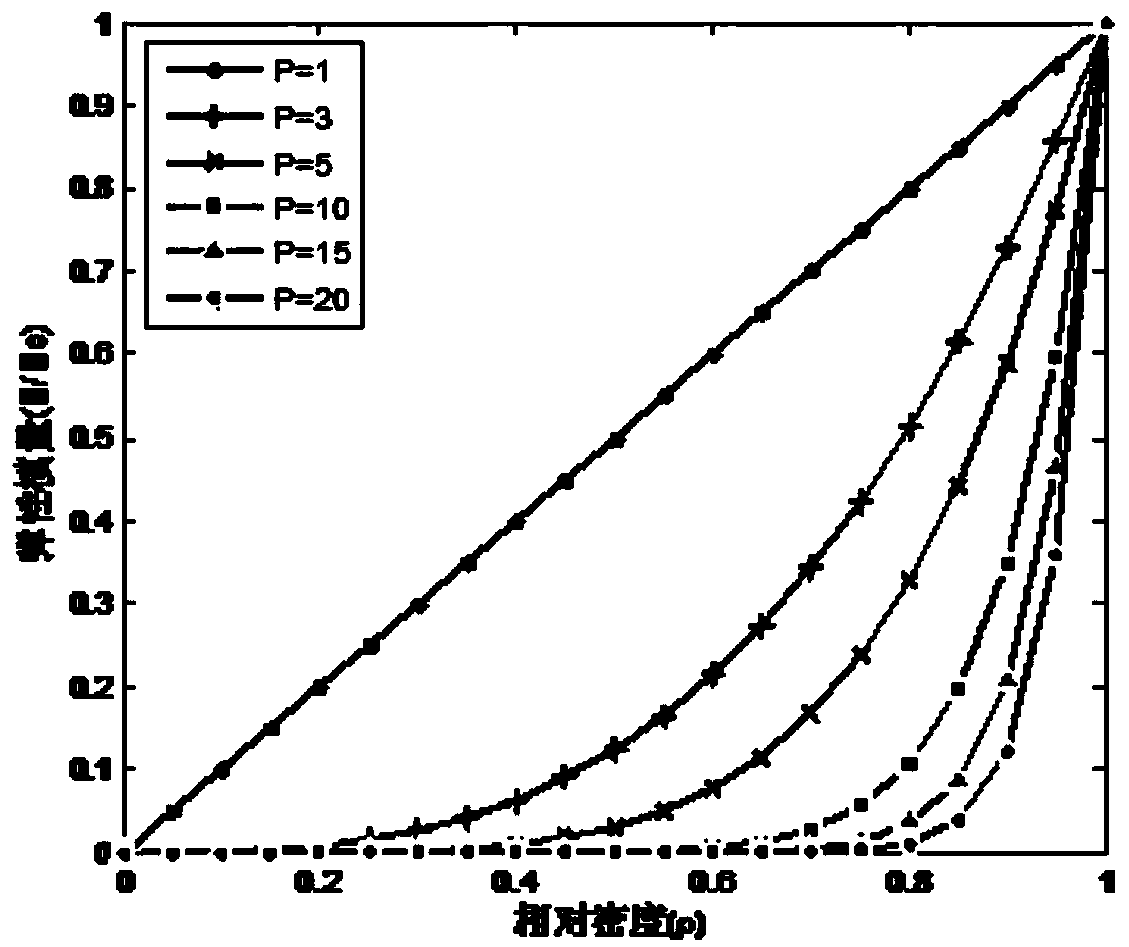

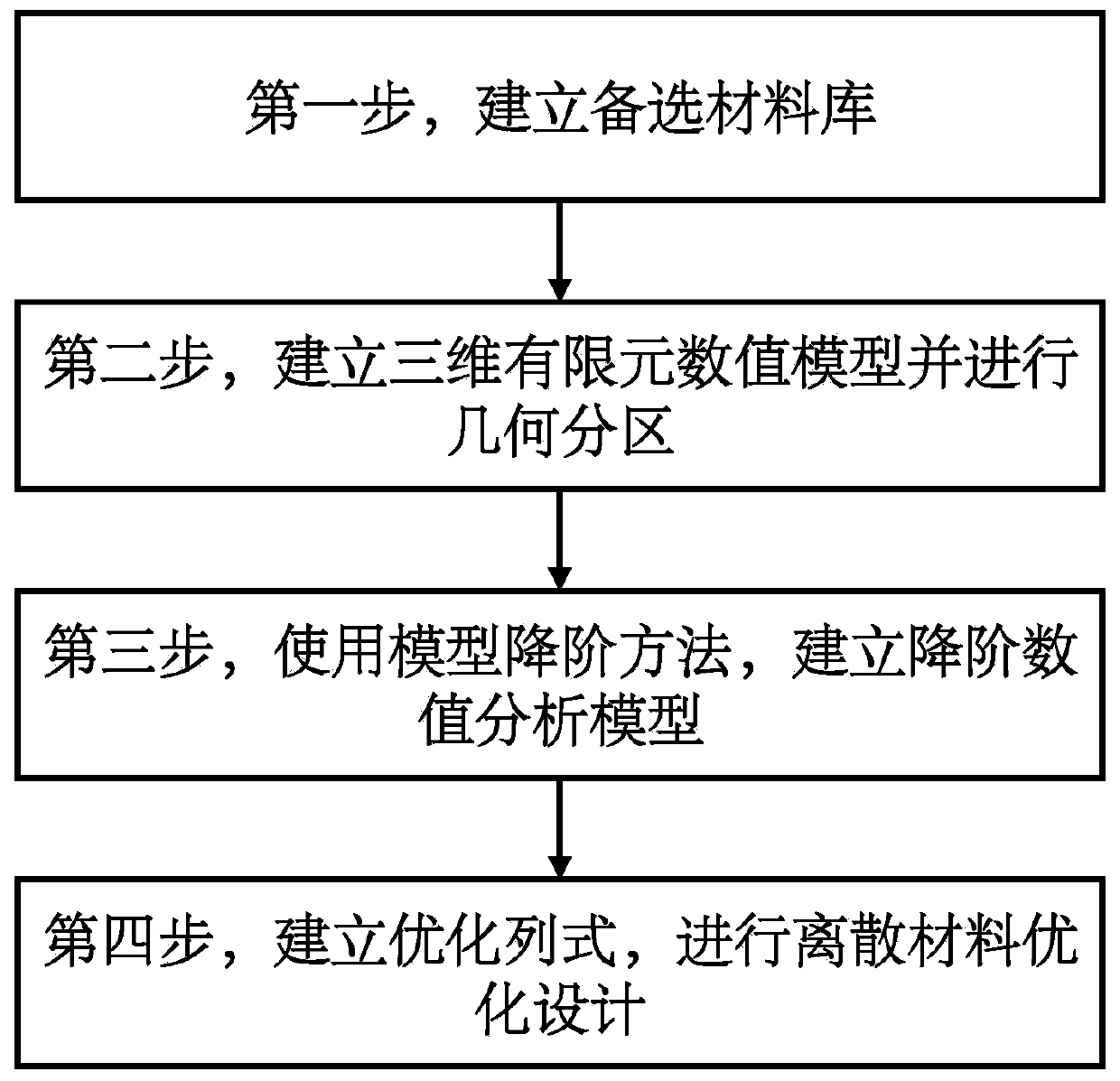

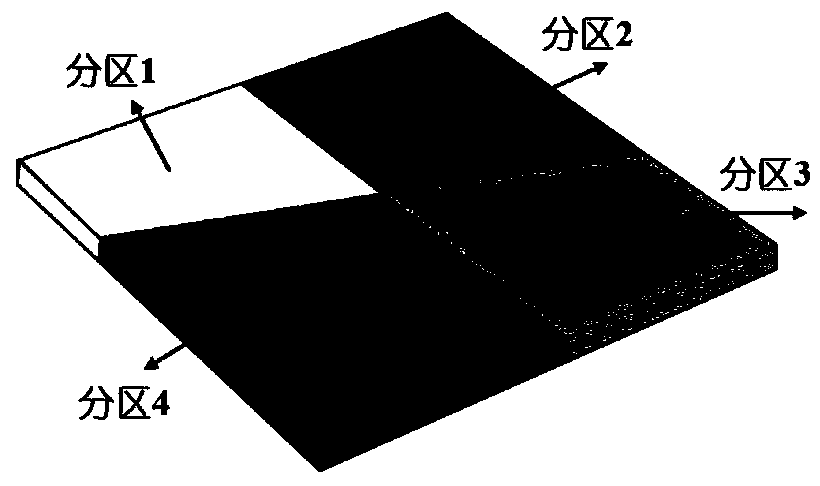

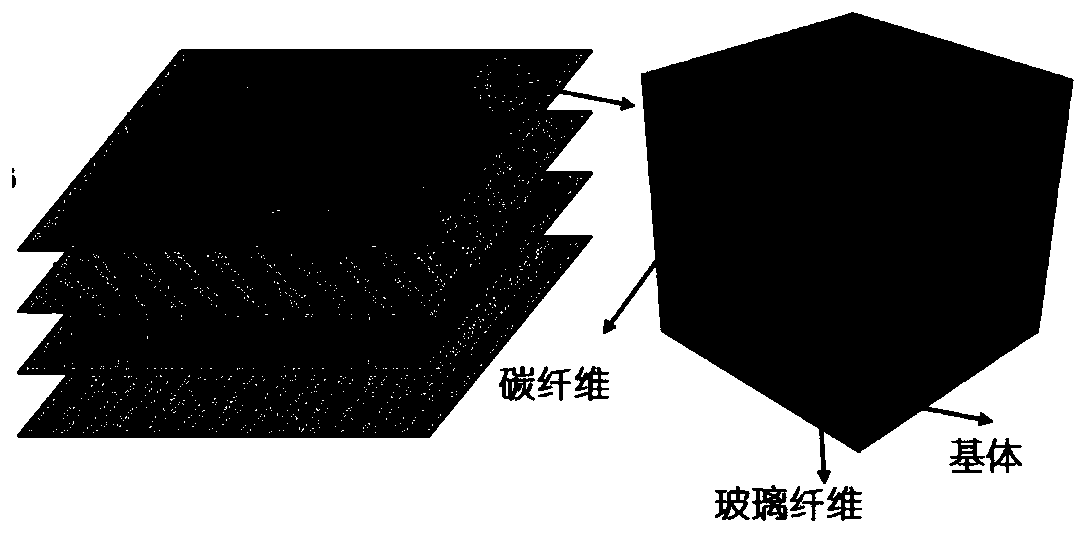

Rapid collaborative optimization method for hybrid fiber composite material plate shell structure

ActiveCN110083900ALow costNovel layout configurationDesign optimisation/simulationSpecial data processing applicationsIntegrated designNumerical models

The invention relates to a rapid collaborative optimization method for a hybrid fiber composite material plate shell structure, which belongs to the technical field of composite material structure optimization design, and comprises the following steps of: 1) establishing an alternative material library; 2) establishing a three-dimensional finite element numerical model and performing geometric partitioning; 3) establishing a reduced-order numerical analysis model by using a model reduced-order method; and 4) establishing an optimized column, and carrying out discrete material optimization design. A continuous interpolation function is adopted to represent a discrete material in a material library, numerical calculation is carried out by adopting a reduced-order model to obtain a target anda constraint response according to geometric partitions, an optimization target and a constraint distribution design variable of a model, discrete material optimization design is carried out, multi-variable collaborative optimization is realized, and an optimal design configuration is obtained. Integrated design of the hybrid fiber composite material structure can be achieved, collaborative optimization design of multi-level variables such as the structure topology, the fiber content, the fiber angle and the laying sequence is achieved, the structural function requirement is met, meanwhile, the structural mass is reduced, and the material cost is reduced.

Owner:DALIAN UNIV OF TECH

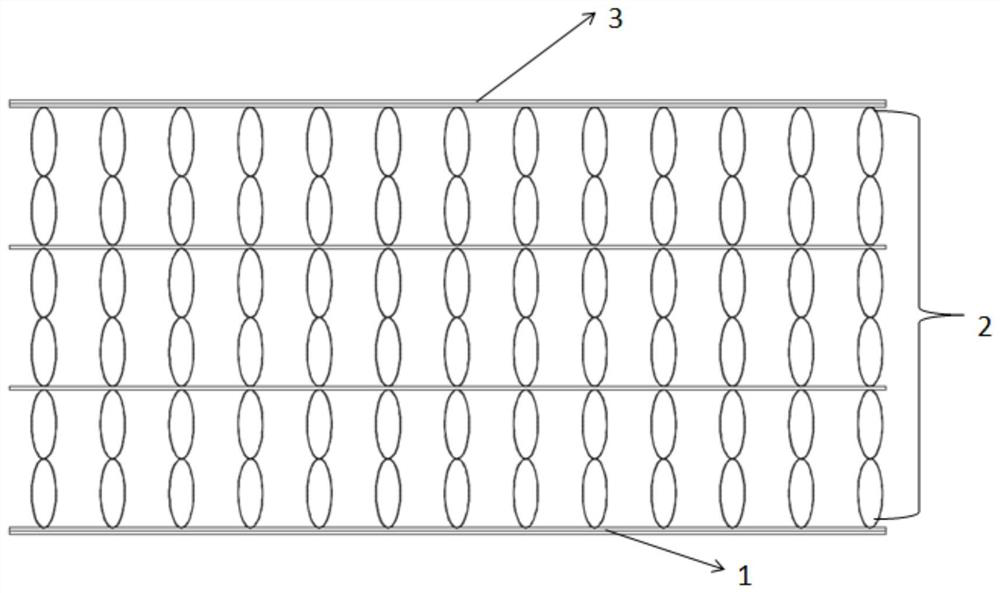

Wave-absorbing composite material and preparation method thereof

PendingCN113524820AGood overall performanceCompatible mechanical propertiesLamination ancillary operationsMagnetic/electric field screeningElectric propertiesFiber

The invention discloses a wave-absorbing composite material and a preparation method thereof. The wave-absorbing composite material comprises a wave-transparent layer, a reflecting layer and a wave-absorbing layer arranged between the wave-transparent layer and the reflecting layer, wherein the wave-absorbing layer comprises multiple layers of wave-absorbing hollow fabric composite materials which are sequentially stacked, and each layer of wave-absorbing hollow fabric composite material comprises a hollow fabric and a resin which is filled on the fiber surface of the hollow fabric and is dispersed with a wave-absorbing agent. According to the invention, a wave-absorbing agent is dissolved in a resin, and the wave-absorbing resin is added to the fibers of a hollow fabric, so that the wave-absorbing agent of the prepared multi-layer wave-absorbing hollow fabric composite material is uniformly dispersed, the wave-absorbing composite material is excellent in overall performance, does not have interfacial properties, and has excellent properties of light weight, high strength, layering resistance and impact resistance, and different wave-absorbing paving layer structures can be designed according to the requirements of the electrical property and the mechanical property so as to achieve the compatibility of the electrical property and the mechanical property and meet the feasibility of a forming process.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

L-shaped composite material laminboard connecting structure with flexible metal connector

ActiveCN107901518AGood bending resistanceReduce manufacturing stepsLayered productsFastening meansLaminated compositesMetal

The invention provides an L-shaped composite material laminboard connecting structure with a flexible metal connector. The structure comprises foamed laminated composite material plates and metal connecting parts, wherein pre-buried metal plate parts of the metal connecting parts are embedded between laminated foams and composite material plates; composite material laminboards and the metal connecting parts are cured together by using an integral molding technique. Due to adoption of adjustable flexible connectors, the assembling stress is effectively reduced, and flexible assembling is achieved; the pre-buried metal plate parts are designed as a forked tail structure, so that the concentrated stress at the connecting parts of the metal plates and the composite material plates is effectively reduced; the connecting parts are of circular arc-shaped design, so that the bending strength is improved; due to a co-curing technique, composite material openings and the like are avoided, and the integrity of the composite material plates is ensured; a relatively large space is reserved in the metal connecting parts, so that convenience can be brought to pipeline laying and later maintenance. The structure is applicable to mechanical connection of composites material laminboards and other structures of large-size structures.

Owner:HARBIN ENG UNIV

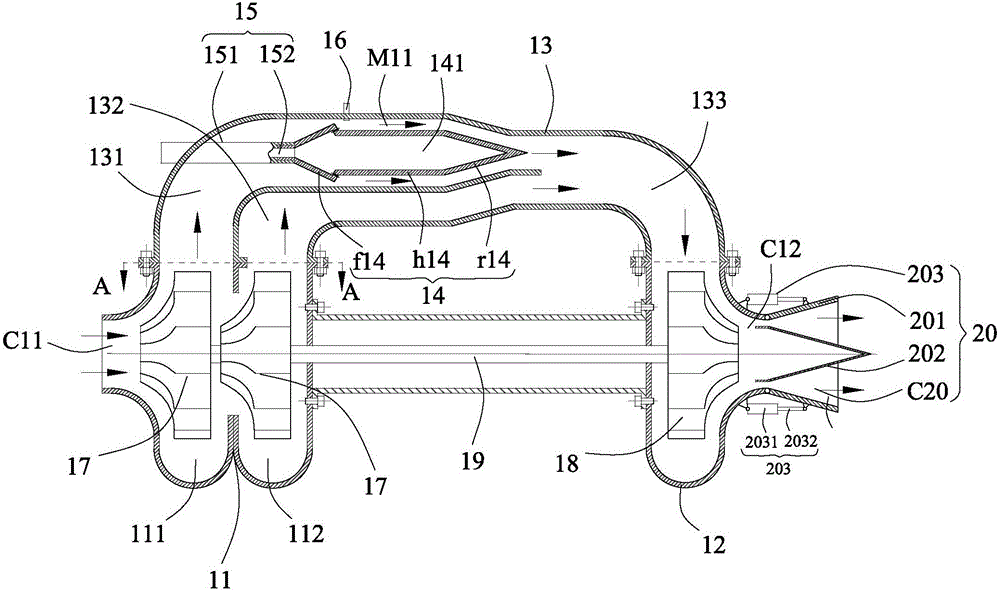

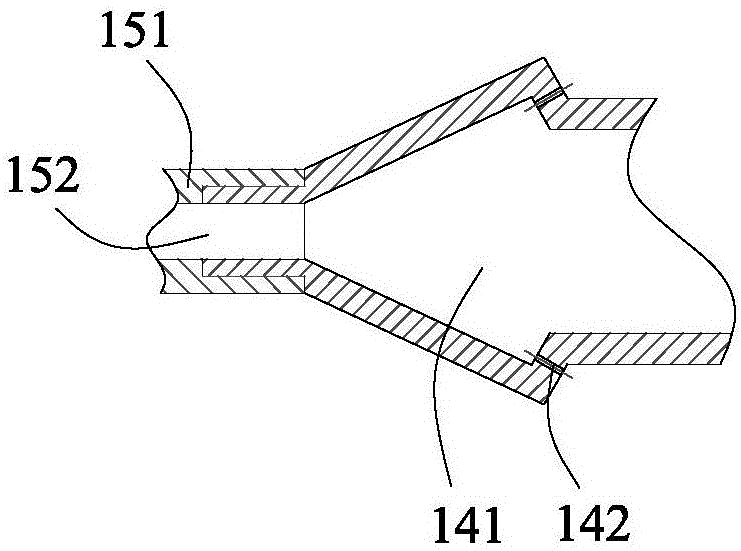

Turbine engine

ActiveCN106762220AReduce structural massCompact structureTurbine/propulsion fuel flow conduitsGas turbine plantsCombustion chamberDetonation

The invention provides a turbine engine. The turbine engine comprises a first housing, a second housing, a third housing, a central body, an oil passage assembly, an igniter, a compressor, a turbo machine and a spindle. The first housing has an air inlet. The third housing is fixedly connected to the first housing and the second housing and communicates with the first housing and the second housing. The central body is arranged in the third housing. The outer wall surface of the central body and the inner wall surface of the third housing form a rotary detonation combustion chamber. The oil passage assembly communicates to the rotary detonation combustion chamber in a controllable manner. The igniter is used for igniting combustion gas which is formed by fuel and air entering the rotary detonation combustion chamber such that combustion gas rotates and combusts in a detonation manner. The compressor is used for compressing air entering the first housing through an air inlet. The turbo machine performs rotary motion under the drive of gas in the second housing. The spindle is used for connecting with the compressor and the turbo machine such that the turbo machine drives the compressor to perform motion. The turbine engine has following beneficial effects: the turbine engine is compact in structure and high in combustion efficiency; oil consumption rate of the engine is reduced; and the thrust-weight ratio and the overall performance of the engine are improved.

Owner:清航空天(浙江)科技有限公司

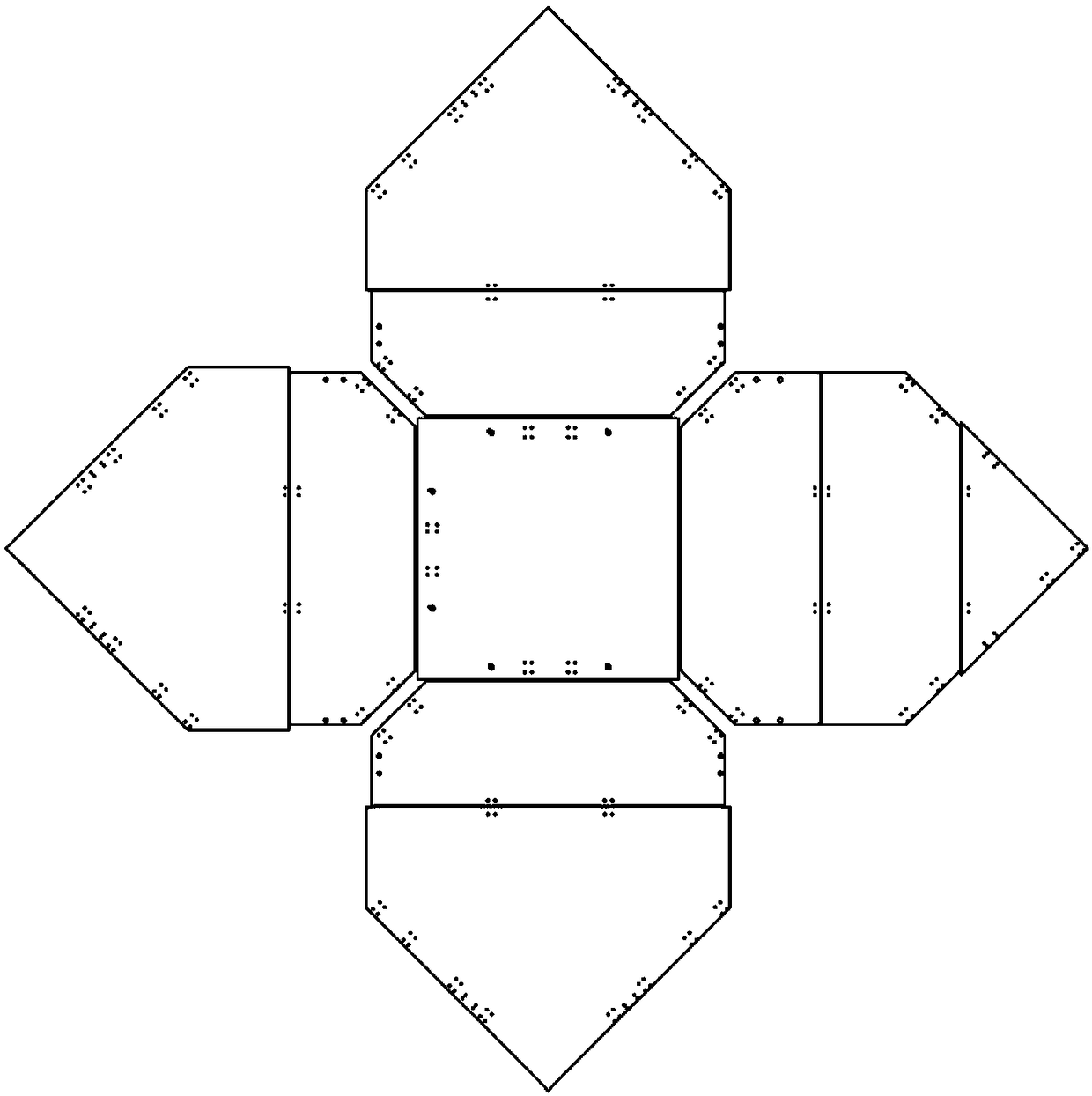

Composite-material core-level cover plate for rocket, and preparation method thereof

The invention discloses a composite-material core-level cover plate for a rocket, and a preparation method thereof. The cover plate comprises nine detachable units, wherein each detachable unit is a composite-material interlayer structure containing an inner framework; and one is a central quadrilateral unit and the other eight detachable units are divided into four groups, the two detachable units in each group are connected together through a hinge, the four sides of the central quadrilateral unit are lapped and fixed to one turned edge of the four groups of detachable units separately, theother sides of the four groups of detachable units are placed on a launching platform installation frame and fixed, and the whole outer edge outline is determined by an installation connector space where the cover plate is located. The invention puts forward for the first time that a light-weight foam interlayer structure containing the inner framework is applied to the core-level cover plate forthe rocket. The composite-material core-level cover plate has the advantages of being convenient to transport, simple to install, rapid to detach, and the like; and the disclosed preparation method has the advantages of ensuring the good forming quality of products, realizing integrated forming, and achieving low cost.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

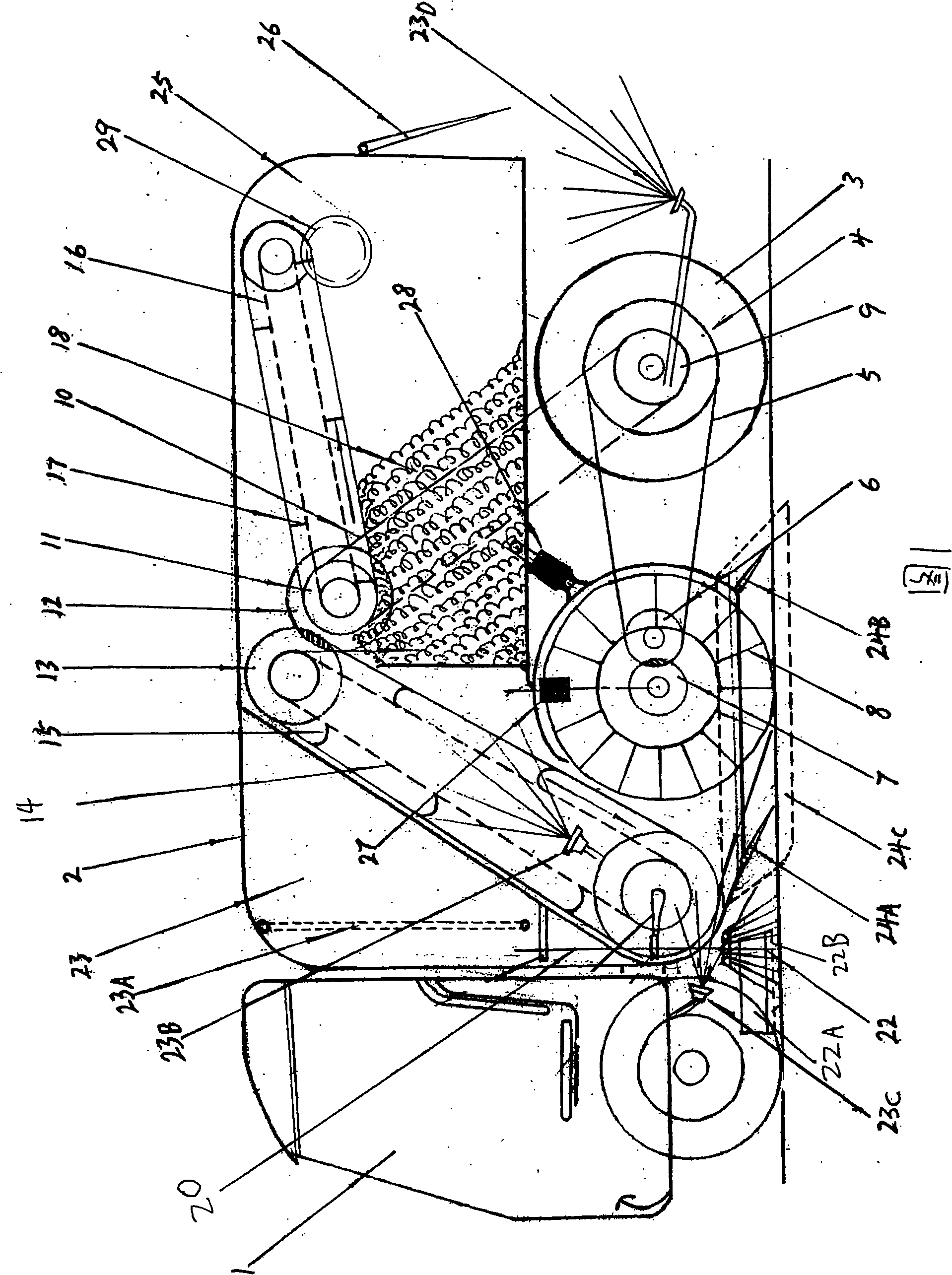

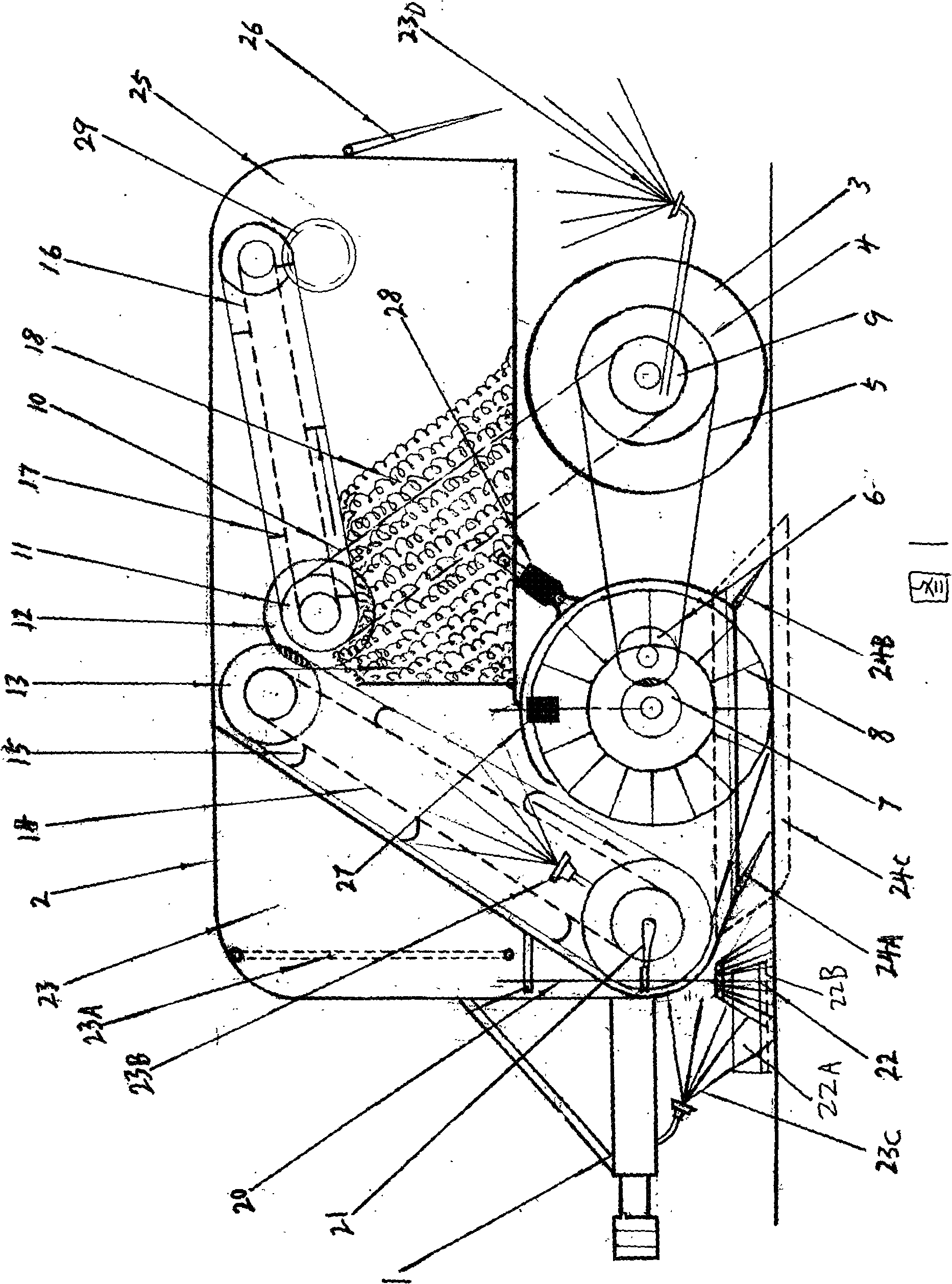

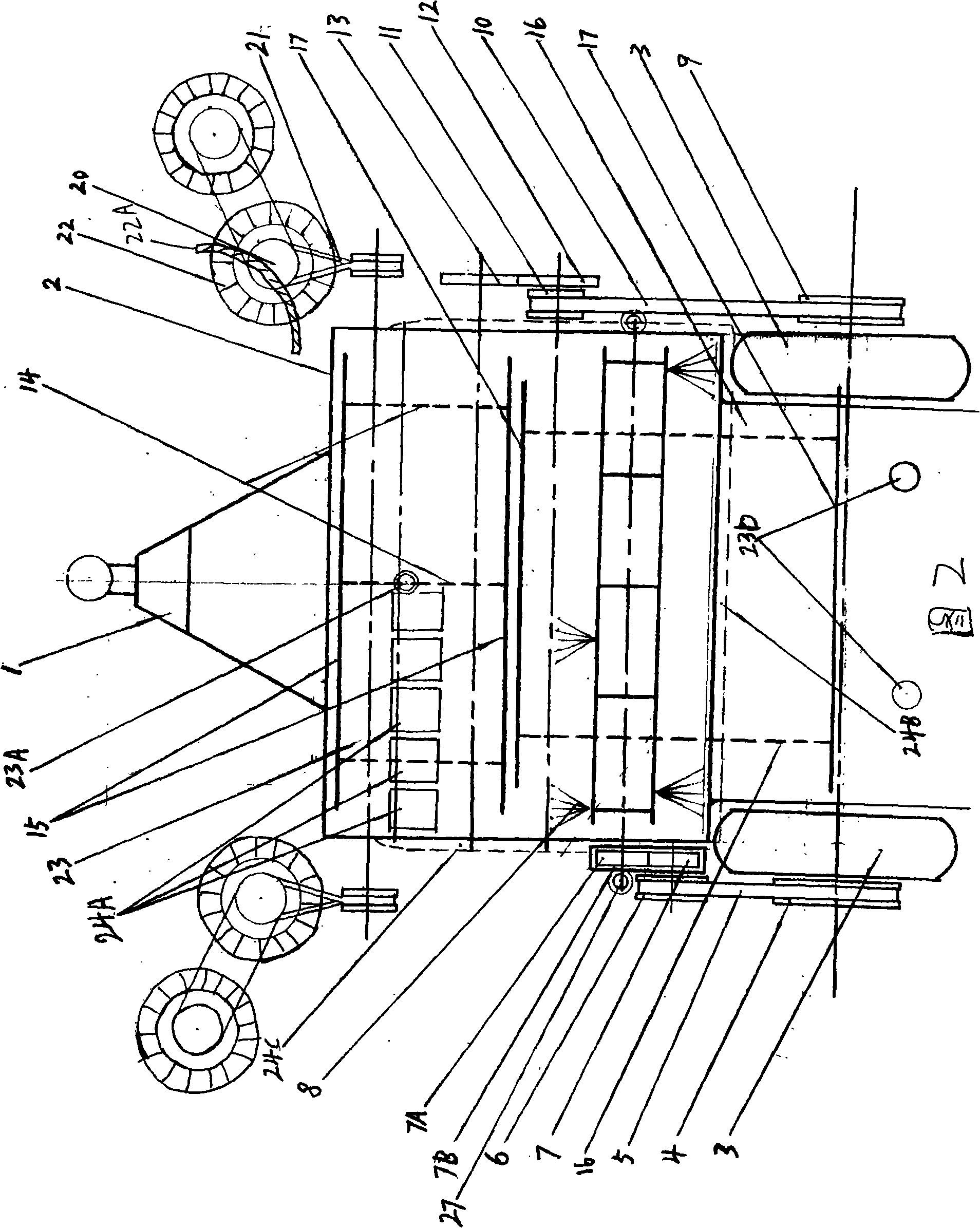

Self-propelled totally-enclosed environment-protecting and energy-conserving sweeper

The invention relates to a self-propelled totally-enclosed environmental-friendly energy saving sweeping vehicle, comprising a vehicle head and a vehicle frame which are combined into a whole, as well as a brush roller and a dustbin which are arranged on the vehicle frame, wherein two sides of the vehicle head and the vehicle frame are respectively provided with a moving wheel; the brush roller driven by the moving wheels of the vehicle head is transversely arranged on the vehicle frame; a large number of floor sweeping brushes are arranged on the brush roller; the dustbin is arranged on the rear upper part of the frame through a rotating shaft and a hydraulic self-unloading mechanism; a garbage conveying chain is arranged between an inlet of the dustbin and the front of the sweeping brush roller; two ends of the garbage conveying chain are respectively arranged on the vehicle frame through sprocket wheels. The invention has the advantages that: the sweeper is thorough in sweeping, high in efficiency, free from raising dust, light in load, low in energy consumption, convenient to use, totally enclosed in the whole process of floor sweeping operation, capable of sweeping and collecting a variety of lightweight and hard garbage effectively and good in garbage collecting effect, which solves the problem that the prior sweeper is not thorough to sweep garbage and does not collect garbage so as to cause secondary pollution and raising dust pollution.

Owner:袁东明

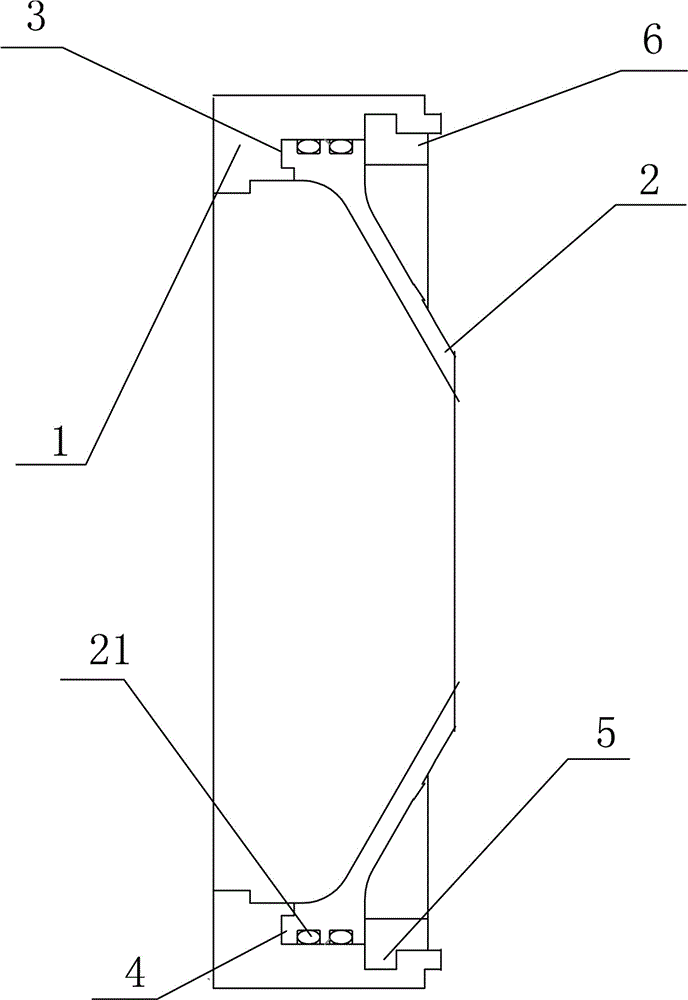

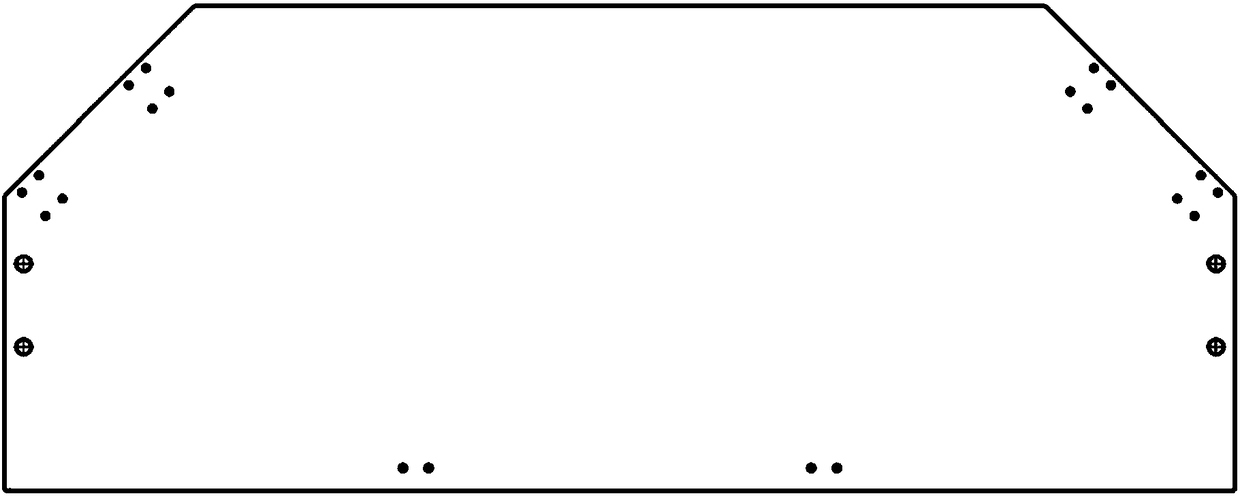

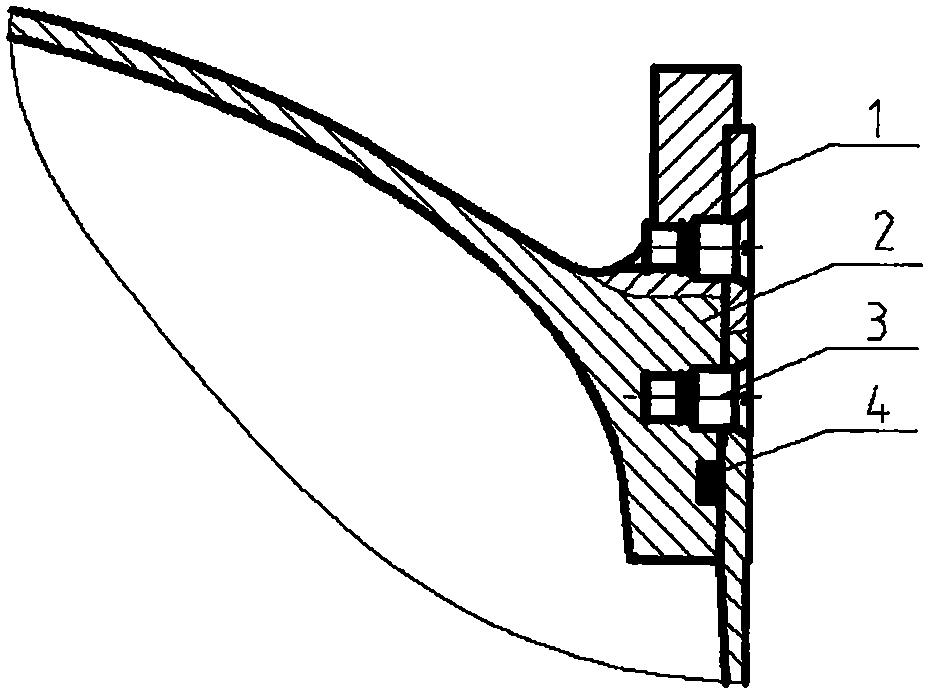

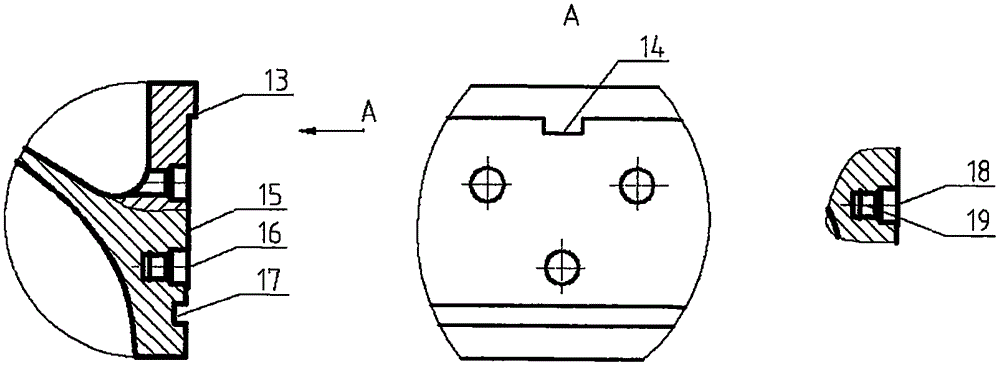

Pin connection structure for metal shell of solid rocket engine

InactiveCN105626311AReduce axial sizeReduce structural massRocket engine plantsStructural reliabilityMass ratio

The invention relates to a pin connection structure for a metal shell of a solid rocket engine. The pin connection structure comprises shell connectors, a top cover, pins and a sealing ring. Each shell connector is provided with an axial locating face, a circumferential locating groove, a shell connector connection face, pin holes, a transition face and a sealing face. The top cover is provided with an axial locating boss, a circumferential locating boss, a top cover connection face, top cover pin holes and a sealing groove. Each pin is composed of a pin cap, a polished rod and a screw. The sealing ring is installed in the sealing groove in the top cover. According to the pin connection structure, assembly and disassembly are simple, and the structural reliability is high. The opening radial dimension of the front shell connector and the rear shell connector can be effectively increased, the structural mass of the shell of the solid rocket engine can be decreased, the structural mass of the top cover is decreased, the axial dimension of the engine is shortened, and the mass ratio of the solid rocket engine to a missile is effectively increased.

Owner:中国航天科工集团第六研究院四十一所

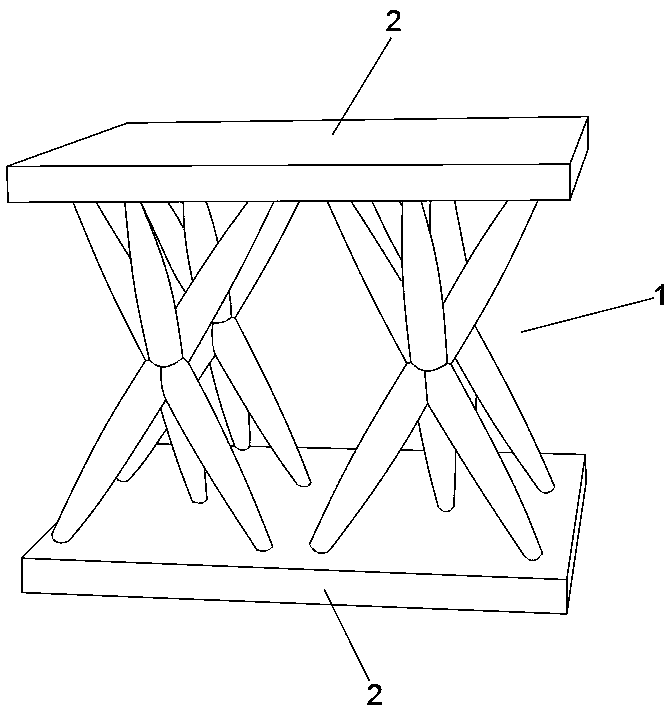

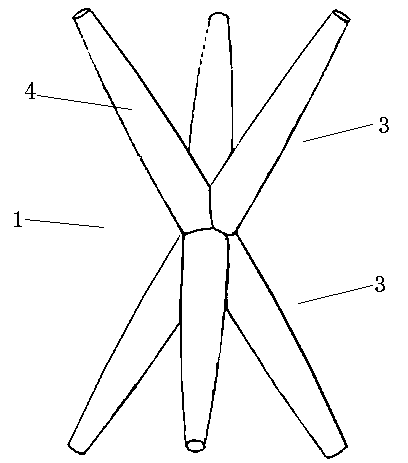

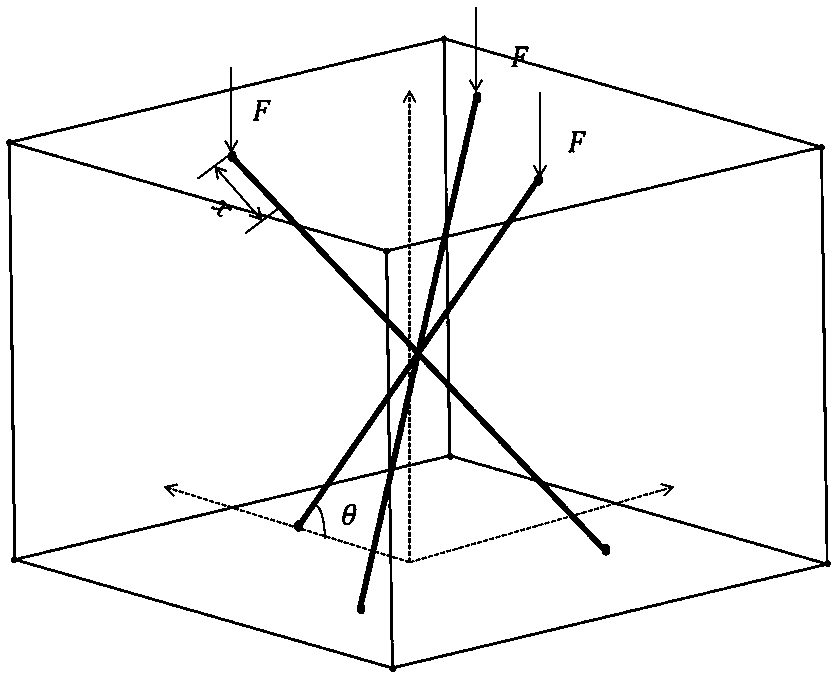

Improved kagome micro-truss lattice sandwich structure and calculation method thereof

ActiveCN110043786AIncrease stiffnessHigh strengthGeometric CADSheets/panelsStress conditionsUnit mass

The invention discloses an improved kagome micro-truss lattice sandwich structure and a calculation method thereof. The improved kagome micro-truss lattice sandwich structure comprises a plurality ofspatial micro-truss lattice units and two metal panels, wherein the two metal panels are arranged in parallel up and down, the spatial micro-truss lattice units are periodically arranged between the two metal panels, and the top surface and the bottom surface are correspondingly connected with the two metal panels; each spatial micro-truss lattice unit comprises two subunits, the two subunits aresymmetrically distributed in a center symmetry mode, each subunit comprises three variable-cross-section rods, one end with the large diameter of the six variable-cross-section rods serves as a starting end to be fixedly connected to the same node, and the other end with the small diameter is a tail end. Aiming at the design that a common micro-truss lattice sandwich structure type kagome unit isimproved, the rod diameter is matched with stress, and the numerical value is determined by the stress condition; and the improved structure and the original structure have higher specific rigidity and specific strength under the condition that the quality is the same, and the bearing capacity per unit quality is stronger.

Owner:NANJING UNIV OF SCI & TECH

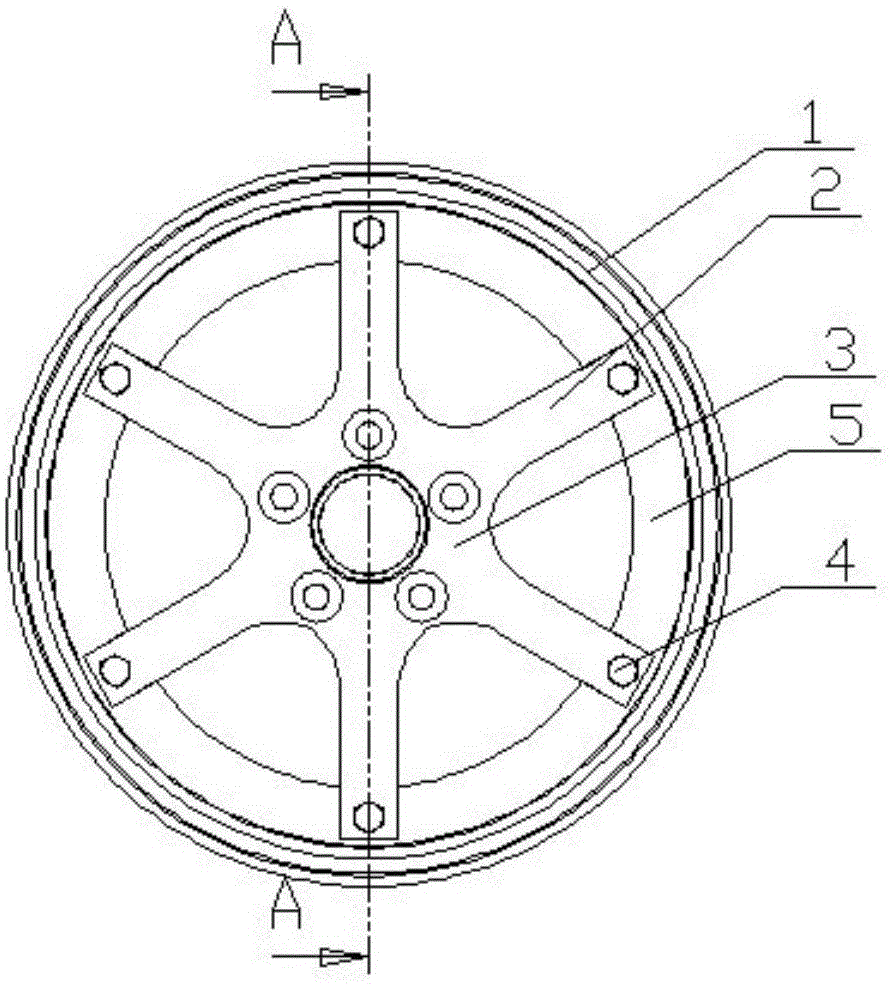

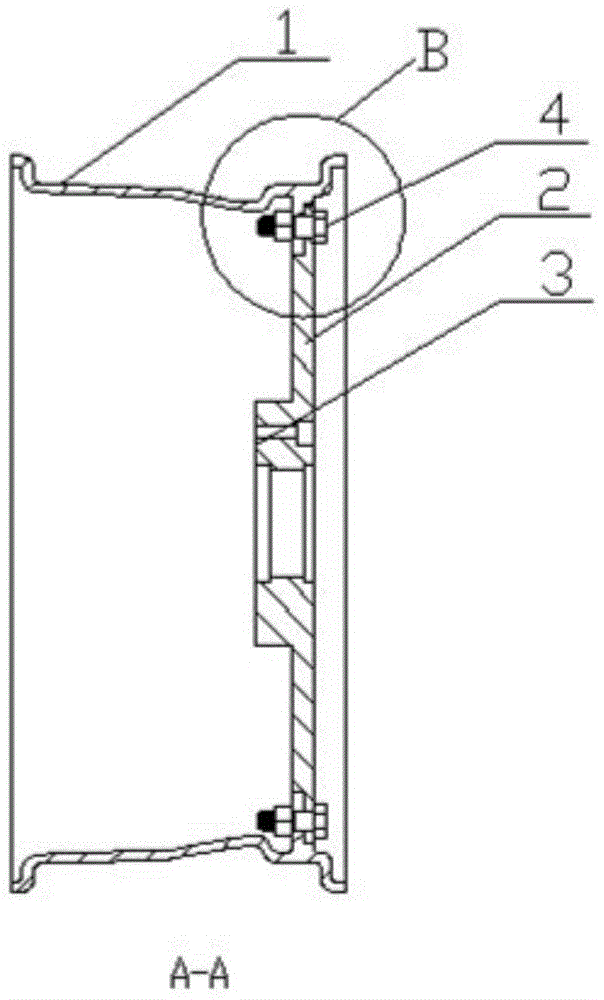

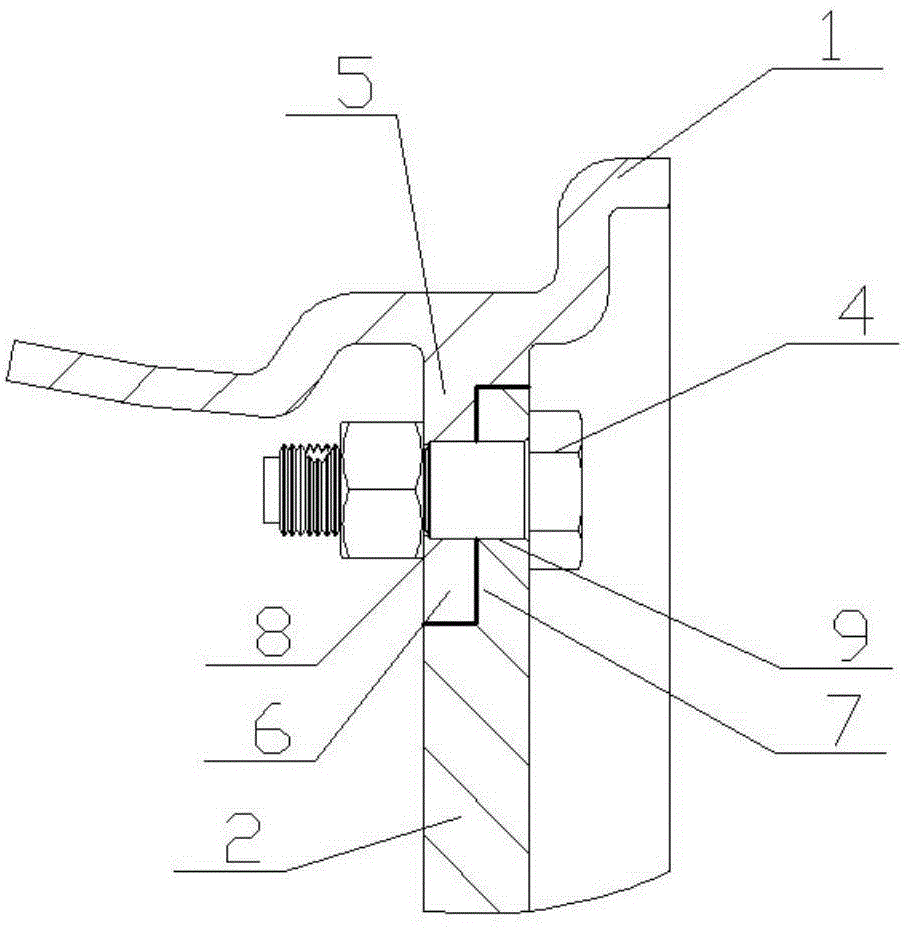

Lightweight magnesium-aluminum alloy assembled wheel

ActiveCN103950350ALarge damping capacityImprove shock absorptionRimsSpoked wheelsUltimate tensile strengthBolt connection

The invention discloses a lightweight magnesium-aluminum alloy assembled wheel and relates to a wheel structure. According to the lightweight magnesium-aluminum alloy assembled wheel, the problems that the maintenance cost is high and the waste is generated due to the fact that the existing structure of the wheel is a rim and spoke integrated structure and the whole wheel is required to be changed if the wheel is damaged are solved. The lightweight magnesium-aluminum alloy assembled wheel comprises a rim, a spoke and a hub, wherein an annular boss is arranged on the inner side of the rim; positioning grooves and mounting holes are uniformly distributed in the annular boss along the circumferential direction and are used for being connected with the spoke; the hub and the spoke are integrated; a radial positioning spigot and a mounting hole are distributed in the outer edge of the spoke. According to the lightweight magnesium-aluminum alloy assembled wheel, the spoke made of a magnesium alloy is protected by a tire, and the exposed area of the rim on the outer side of the wheel is small, so that the possibility of scratch is reduced and the defect that the magnesium alloy is poor in corrosion resistance is overcome; the spoke is made of an aluminum alloy, and thus high strength is obtained; the rim and the spoke form an assembled structure and are connected by bolts, so that the rim and the spoke can be respectively changed after being damaged; the convenience in maintenance is realized, the scrappage of the whole wheel is avoided, the manufacturing process is greatly simplified, the die cost is reduced and the manufacturing efficiency is increased.

Owner:JILIN UNIV

Trail-behind totally-enclosed self-discharging, environment-protecting and energy-conserving sweeper

The invention relates to a traction-type totally-enclosed self-unloading environmental-friendly energy saving sweeper, comprising a traction frame, moving wheel, a brush roller and a dustbin which are arranged on a frame, wherein the traction frame is arranged at the front end of the frame; the moving wheel are power wheels; the sweeper comprises two moving wheels positioned on two sides of the frame; the brush roller driven by the moving wheel is transversely arranged on the frame; a large number of floor sweeping brushes are arranged on the brush roller; the dustbin is arranged on the rear upper part of the frame through a rotating shaft and a hydraulic self-unloading mechanism; a garbage conveying chain is arranged between an inlet of the dustbin and the front of the brush roller. The invention has the advantages that: the sweeper is thorough in sweeping, high in efficiency, little in raising dust, light in load, convenient to use, totally enclosed in the whole process of floor sweeping operation, capable of sweeping and collecting a variety of lightweight and hard garbage effectively and good in garbage collecting effect, which solves the problem that the prior sweeper is not thorough to sweep garbage and does not collect garbage so as to cause secondary pollution and raising dust pollution.

Owner:袁东明

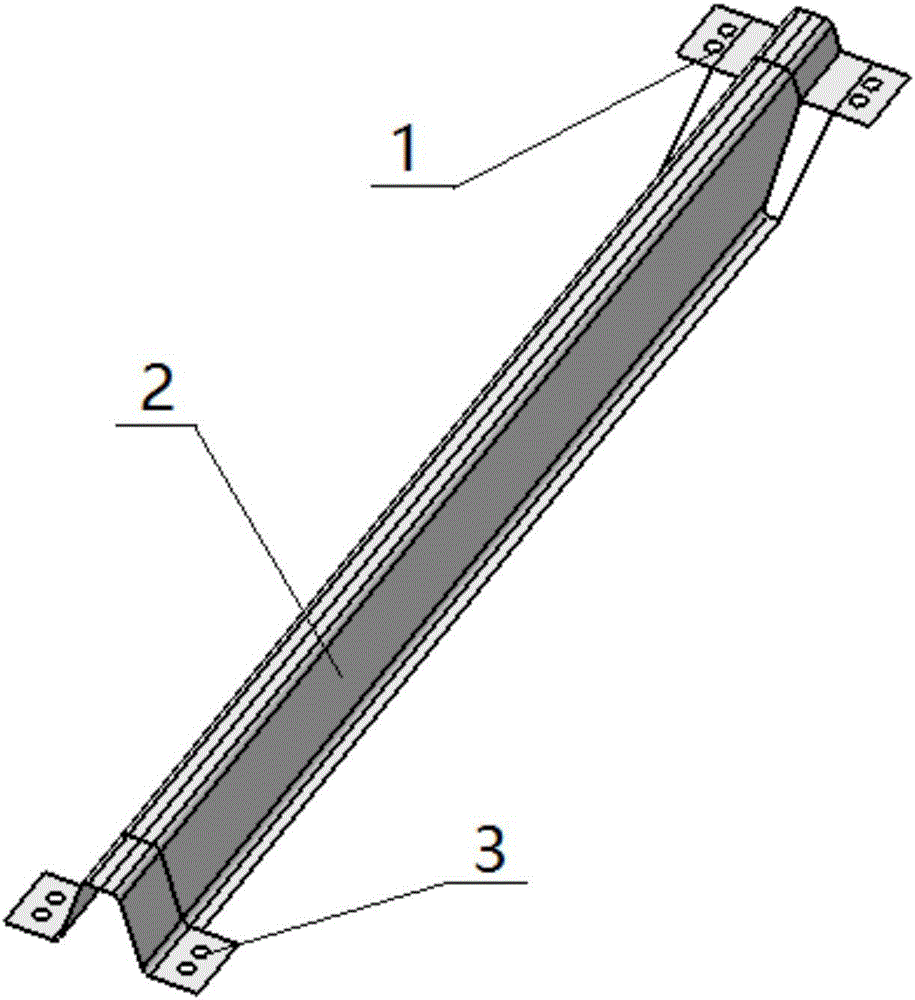

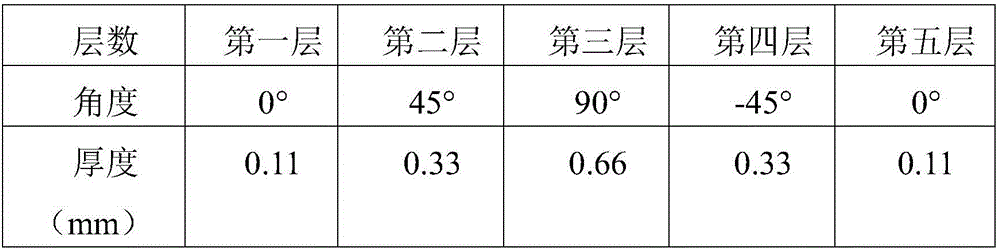

Carbon fiber reinforced composite vehicle door anti-collision beam

PendingCN106696654AImprove side impact safetyRealize lightweight structureBumpersDoorsVariable thicknessThermal expansion

The invention provides a carbon fiber reinforced composite vehicle door anti-collision beam, which relates to the technical field of vehicle engineering and solves problems of the existing vehicle door anti-collision beam of limited layout form, high mold cost, large weight and so on. The carbon fiber reinforced composite vehicle door anti-collision beam comprises an anti-collision beam, a front fixed bracket and a rear fixed bracket, wherein the front fixed bracket is connected with the front end of the anti-collision beam, and the rear fixed bracket is connected with the rear end of the anti-collision beam. The cross section of the anti-collision beam is trapezoidal; the open side of the anti-collision beam is opposite to a vehicle door inner panel; the whole anti-collision beam adopts a variable-thickness and variable-angle carbon fiber reinforced composite layer; and the front fixed bracket and the rear fixed bracket are formed by extruding aluminum alloys or stamping steel sheets so that the materials of the front fixed bracket and the rear fixed bracket are as same as that of the vehicle door inner panel. As the anti-collision beam is connected with the vehicle door inner panel by using the front fixed bracket and the rear fixed bracket, the joint strength of the carbon fiber reinforced composite vehicle door anti-collision beam is prevented from being damaged due to directly drilling holes in the carbon fiber reinforced composite vehicle door anti-collision beam; meanwhile, electrochemical corrosion and thermal expansion difference generated by different materials during connecting the fixed brackets with the vehicle door inner panel by using bolts are effectively avoided. The carbon fiber reinforced composite vehicle door anti-collision beam has the advantages of simple structure, easy molding and manufacturing, low mold cost and easy popularization and use.

Owner:JILIN UNIV

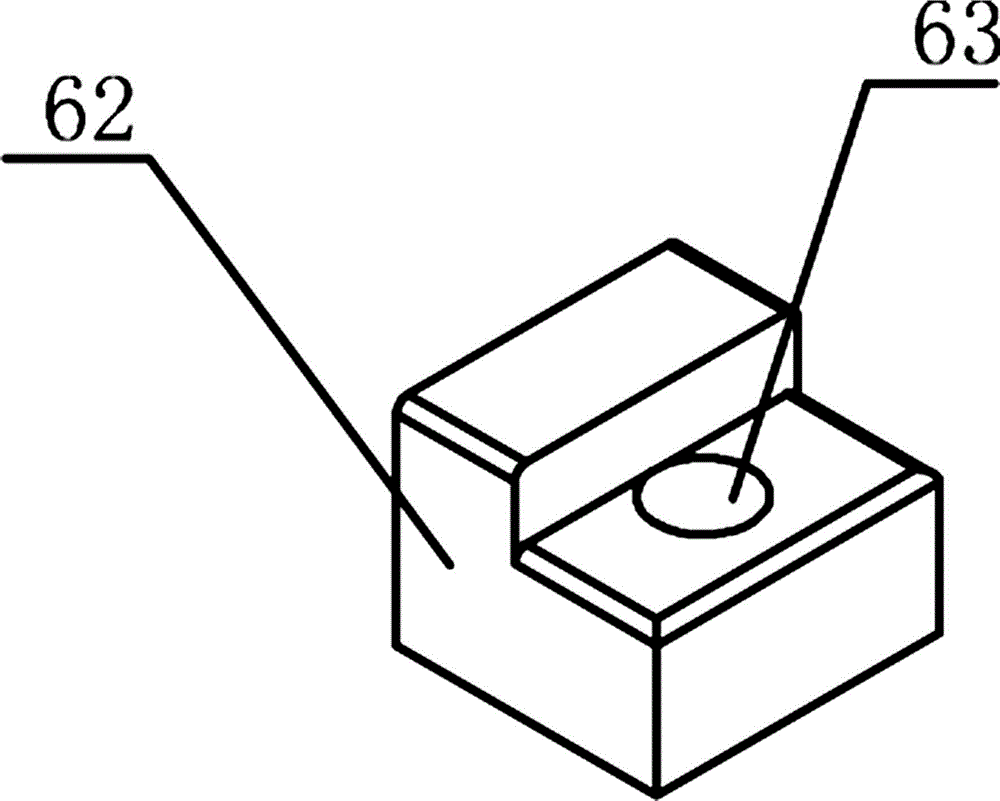

Material feeding mechanism for 3D printer

InactiveCN104608390ACompact structureLight in massAdditive manufacturing apparatusFeed driveEngineering

Owner:UNIV OF JINAN

Solid fuel ramjet engine

ActiveCN113803190AIncrease in sizeImprove heat transfer performanceEfficient propulsion technologiesRam jet enginesRamjetCombustion chamber

The invention relates to a solid fuel ramjet engine. The solid fuel ramjet engine comprises a storage tank, the storage tank comprises a fuel storage tank and a coolant storage tank, the fuel storage tank is filled with solid fuel, and the coolant storage tank is filled with coolant. The ramjet engine further comprises a heat exchanger, a turbine, a fuel pump, a coolant pump, an injector, a combustion chamber, a cooling channel and a pipeline. The solid fuel comprises normal-temperature blocky solid metal or normal-temperature solid nonmetal energetic materials. The solid fuel ramjet engine has the advantages that metal blocks and the solid nonmetal energetic materials are directly used as the fuel of the ramjet engine, no anti-settling agent needs to be added, the fuel wire drawing phenomenon in the injection process is reduced, the combustion efficiency is improved, the net thrust of the ramjet engine is improved, the flame stability is higher, the energy density of the fuel is improved, when the blocky solid fuel reaches the self ignition temperature, the blocky solid fuel can directly participate in combustion after making contact with air, the structural mass of a combustion chamber is reduced, and the waste heat utilization rate is further increased.

Owner:宁波天擎航天科技有限公司

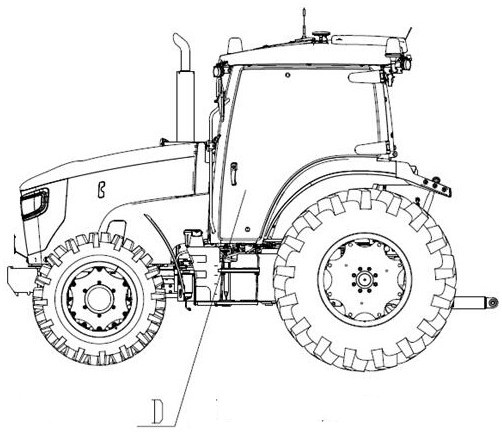

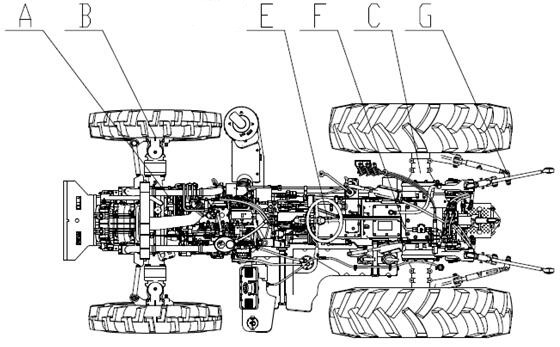

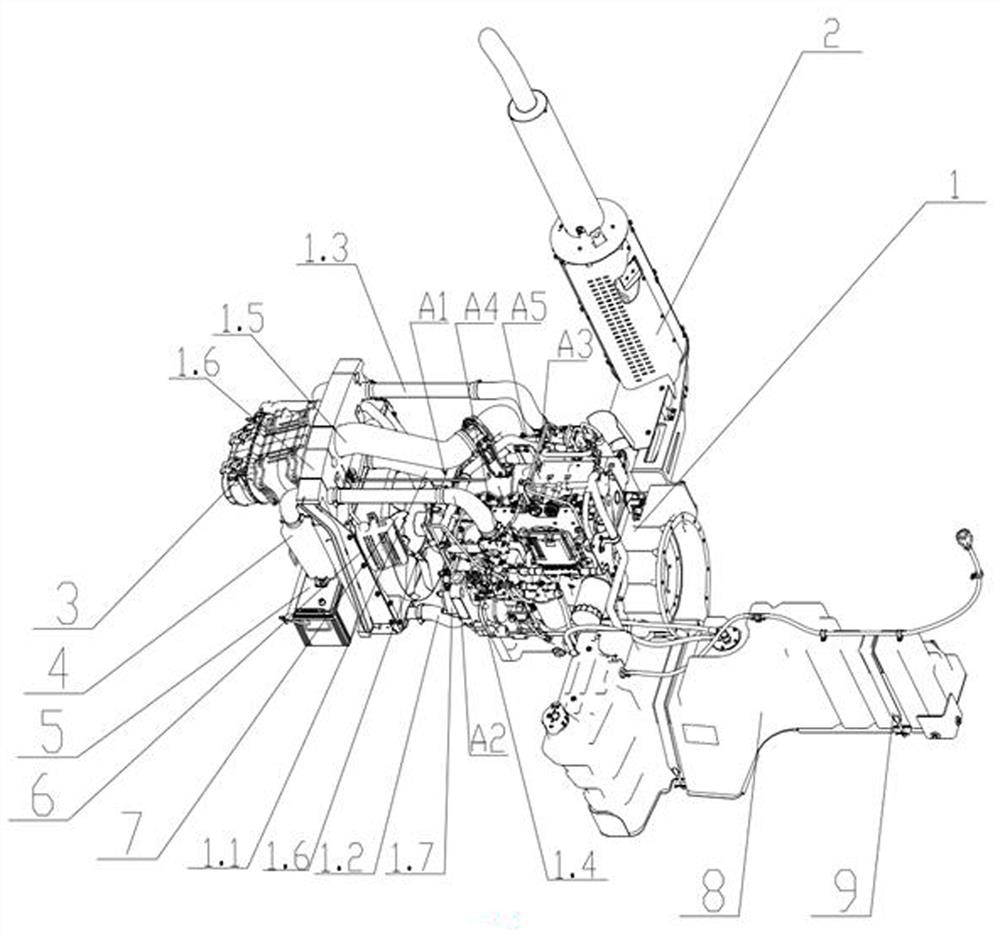

Paddy field wheeled tractor

PendingCN112297813AImprove passabilityImprove adaptabilityHydrostatic brakesTractorsAgricultural scienceSteering angle

The invention relates to a paddy field wheeled tractor which comprises a power system assembly, a walking system assembly, a transmission system assembly, a covering part assembly, a steering system assembly, a hydraulic system assembly and a rear working device. The transmission system assembly serves as the basis of the whole tractor. The power system assembly, the walking system assembly, the covering part assembly, the steering system assembly, the hydraulic system assembly and the rear working device are directly or indirectly connected with the transmission system assembly. By optimizingthe structural layout, the front wheel steering angle is increased, the turning radius of the whole machine is reduced, the ground clearance of the whole machine is increased, and the mass of the whole machine is reduced, so that the tractor has good trafficability in a paddy field, and the requirements of the national IV emission standard are met.

Owner:FIRST TRACTOR

A pulsed strong magnetic field assisted laser welding method and equipment

ActiveCN103769746BImprove fatigue strengthSmall structural deformationLaser beam welding apparatusStructural deformationStress concentration

The invention discloses a pulsed high magnetic field auxiliary laser welding method and device. The method and device can be applied to laser spot welding and seam welding. According to the method, in the overall welding process, laser beams are emitted to a workpiece to form a welding connector, a high pulsed magnetic field is exerted to the welding connector which is just solidified and the surrounding area, the pulsed magnetic field generates pressure stress on the surface of the workpiece to enable the connector area to have plastic deformation, residual stress is released to lower the degree of stress concentration and the degree of structural deformation of the welding connector, and the fatigue strength of the welding connector is improved. The device comprises a laser, a pulsed magnetic field generator, a numerical control system, an optical transmission system and a laser pulsed magnetic field composite processing head. The processing head is used for integrating the laser beams and the high pulsed magnetic field, and regulating the perpendicular distance between an electromagnetic conversion device and the surface of the workpiece and the horizontal distance between the electromagnetic conversion device and the laser beams. By means of the pulsed high magnetic field auxiliary laser welding method and device, structural deformation can be lowered, welding quality and processing efficiency are improved, and the processing effect which is superior to that of an existing laser welding process is achieved.

Owner:武汉飞能达激光技术有限公司

Rocket engine heat exchanger and aerospace craft

InactiveCN110700966AReduce structural massImprove push-to-mass ratio performanceEngine componentsRocket engine plantsCombustion chamberFlight vehicle

The invention discloses a rocket engine heat exchanger and an aerospace craft. A rocket engine comprises a combustion chamber body with a combustion cavity. An outer-layer structure is arranged on theouter wall of the combustion chamber body, and a heat exchange space allowing a pressurizing working medium and the combustion cavity to be in heat exchange is formed between the outer-layer structure and the combustion chamber body. An inlet structure and an outlet structure communicating with the heat exchange space to enable the pressurizing working medium to come in and go out is further included. As the heat exchange space allowing the pressurizing working medium and the combustion cavity to be in heat exchange is formed between the outer-layer structure arranged on the outer wall of thecombustion chamber body and the combustion chamber body, a heat exchanger device specially designed for a rocket accumulator pressurizing system on the engine is omitted, the structural mass of the engine is reduced, and therefore the thrust-mass ratio performance of the engine is improved. The parts of the engine are simplified, and the structural reliability of the heat exchanger is improved.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

T-shaped connection structure of composite material laminboard

The invention provides a T-shaped connection structure of a composite material laminboard, comprising a connecting bottom plate, a honeycomb laminboard and a T-shaped reinforcing block, wherein the honeycomb laminboard is provided with a groove the shape of which is same with the shape of the upper end of a web of the T-shaped reinforcing block; the upper end of the web of the T-shaped reinforcing block is inserted into the groove; and a wing rafter of the T-shaped reinforcing block is in glue joint with the connecting bottom plate. The T-shaped connection structure also comprises two waveform connecting pieces, wherein the two waveform connecting pieces are positioned on two sides of the honeycomb laminboard; the waveform connecting pieces, the T-shaped reinforcing block and the honeycomb laminboard are fastened and connected by bolts; and the waveform connecting pieces and the connecting bottom pate are connected by glue and bolts in a mixing mode. The T-shaped connection structure has the advantages that the flexural rigidity is high; a bigger space is formed between the two waveform plates to bring convenience for overlaying a number of pipelines and subsequently maintaining; stress concentration on a joint can be effectively alleviated; the structural efficiency is improved; the bearing capability is enhanced, and the like. The T-shaped connection structure disclosed by the invention is suitable for mechanical connection between the composite material laminboard in a large-sized structure and other structures.

Owner:HARBIN ENG UNIV

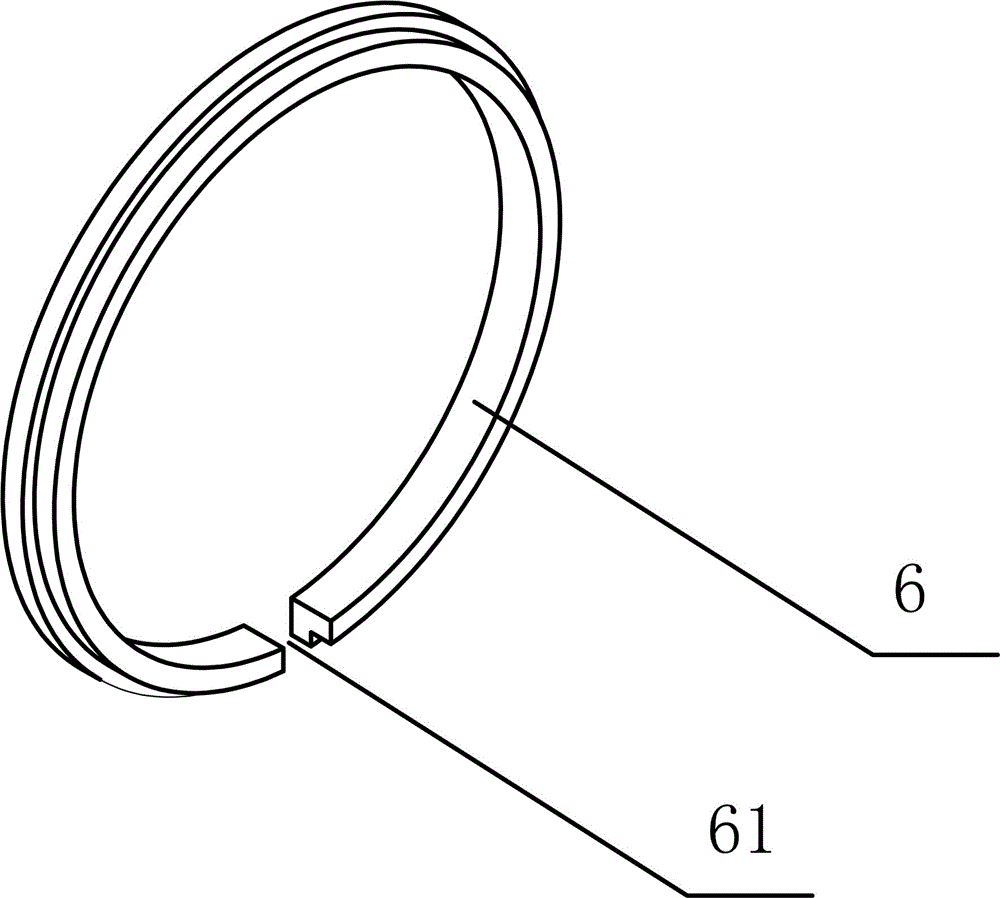

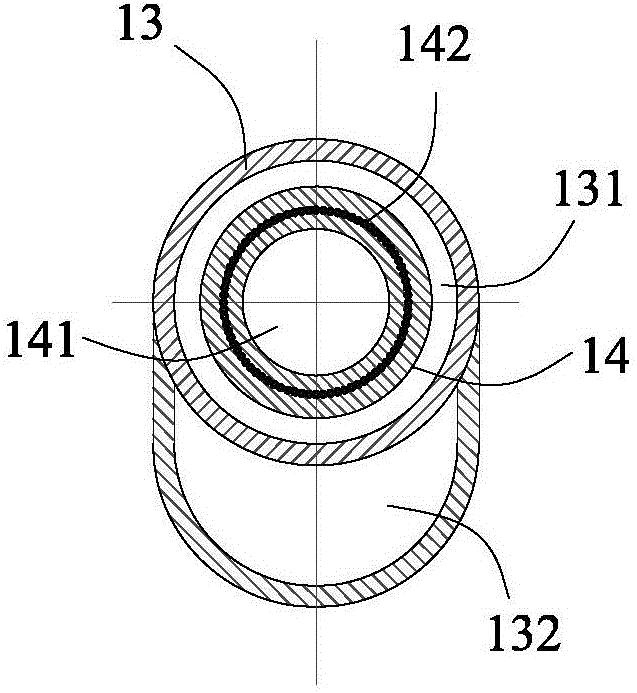

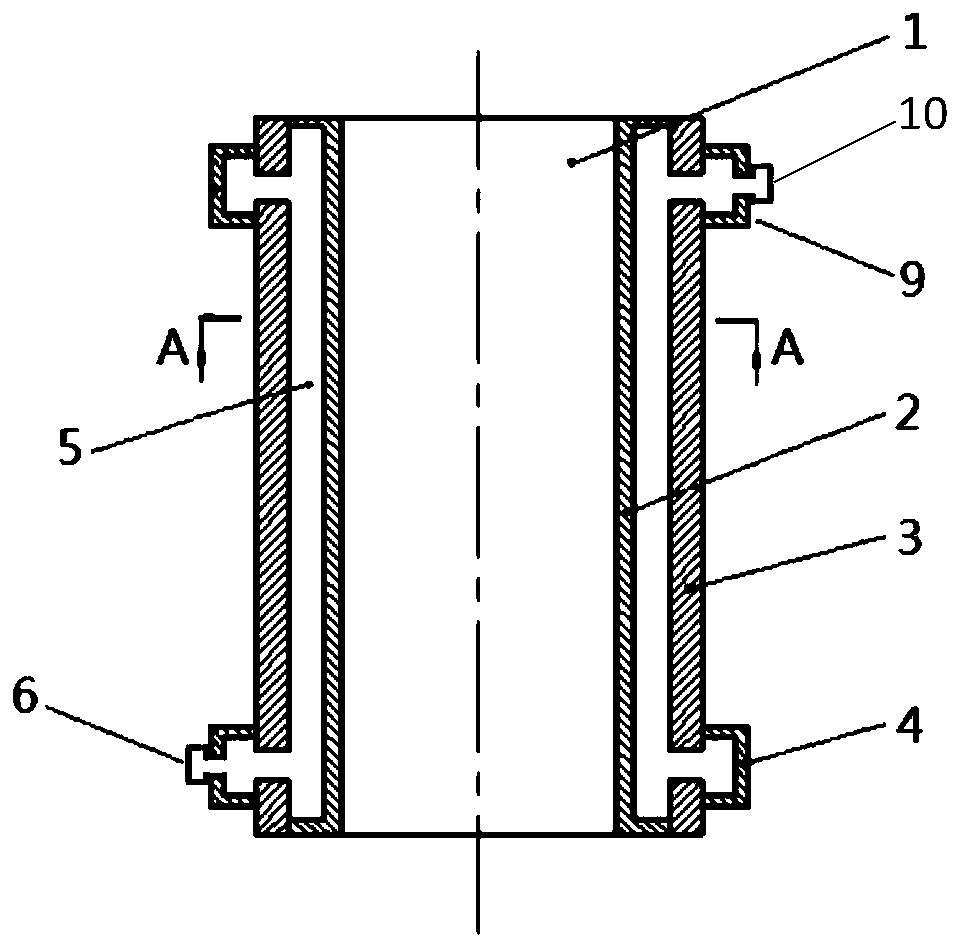

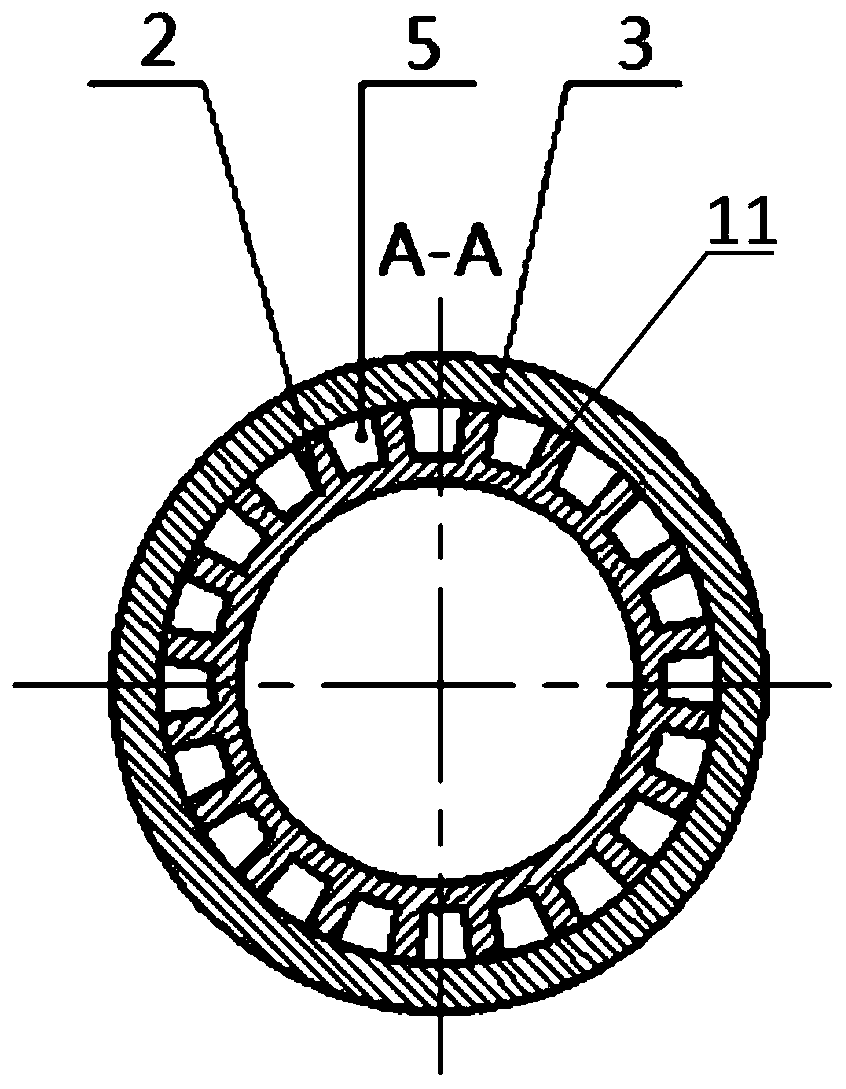

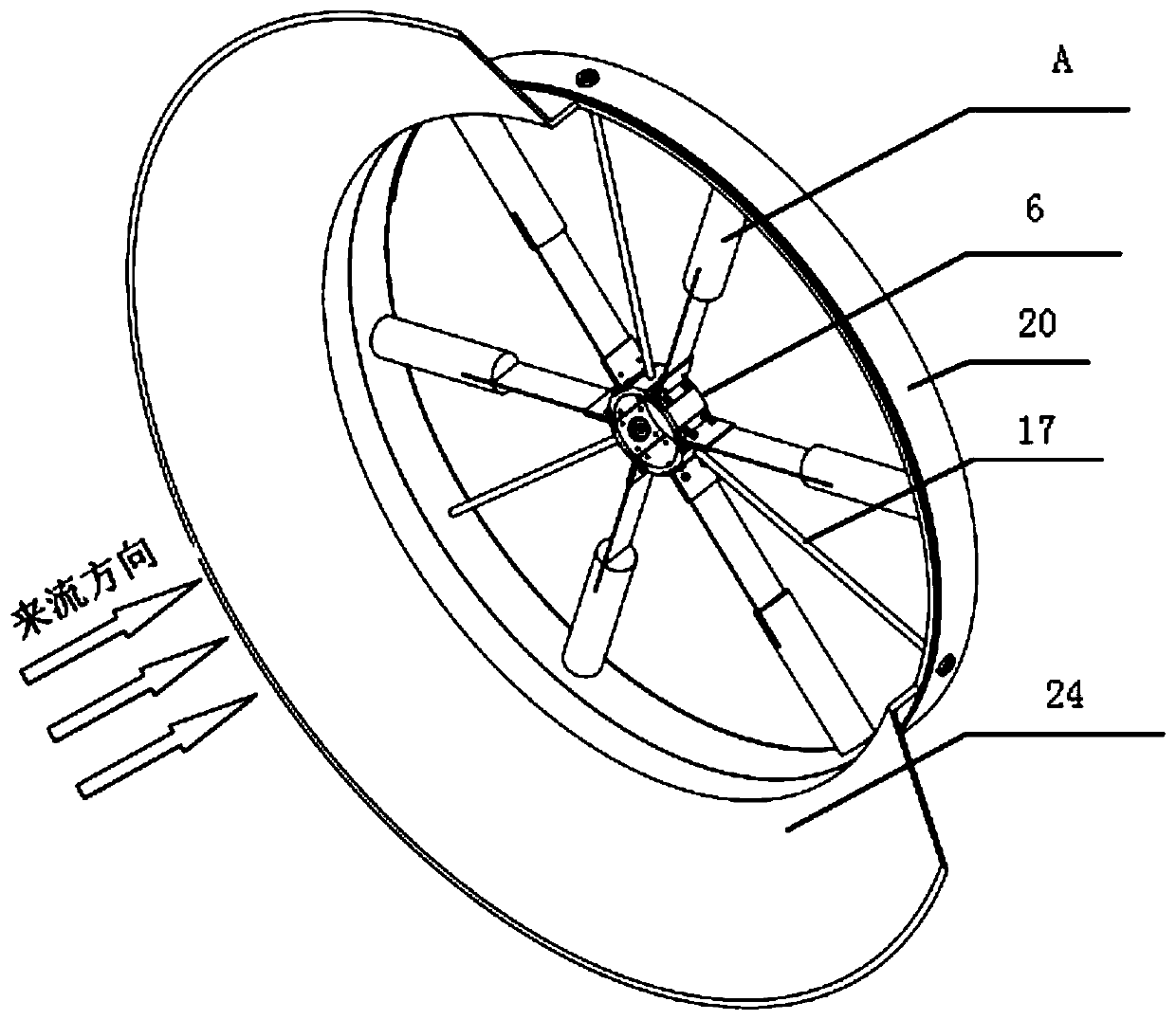

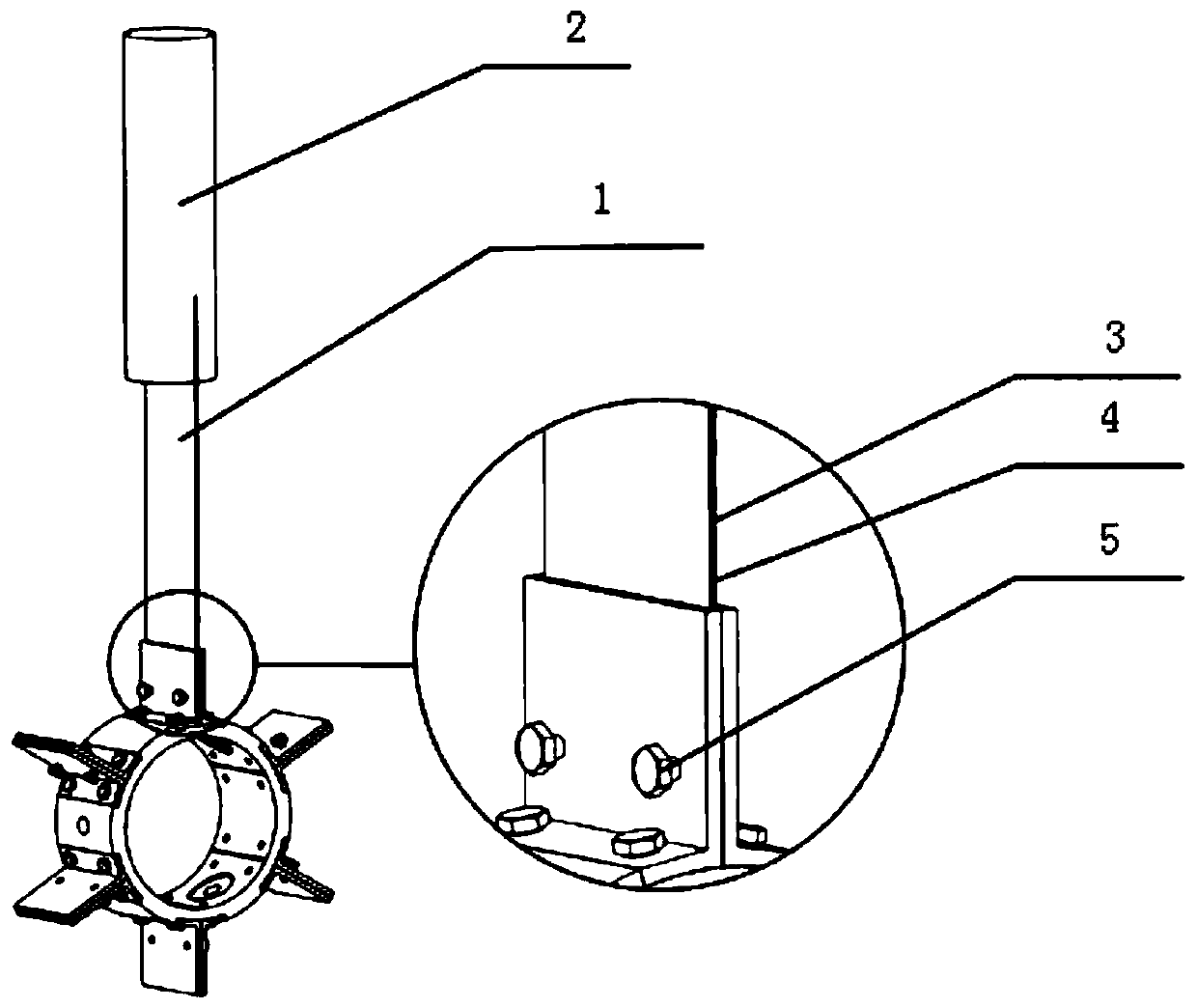

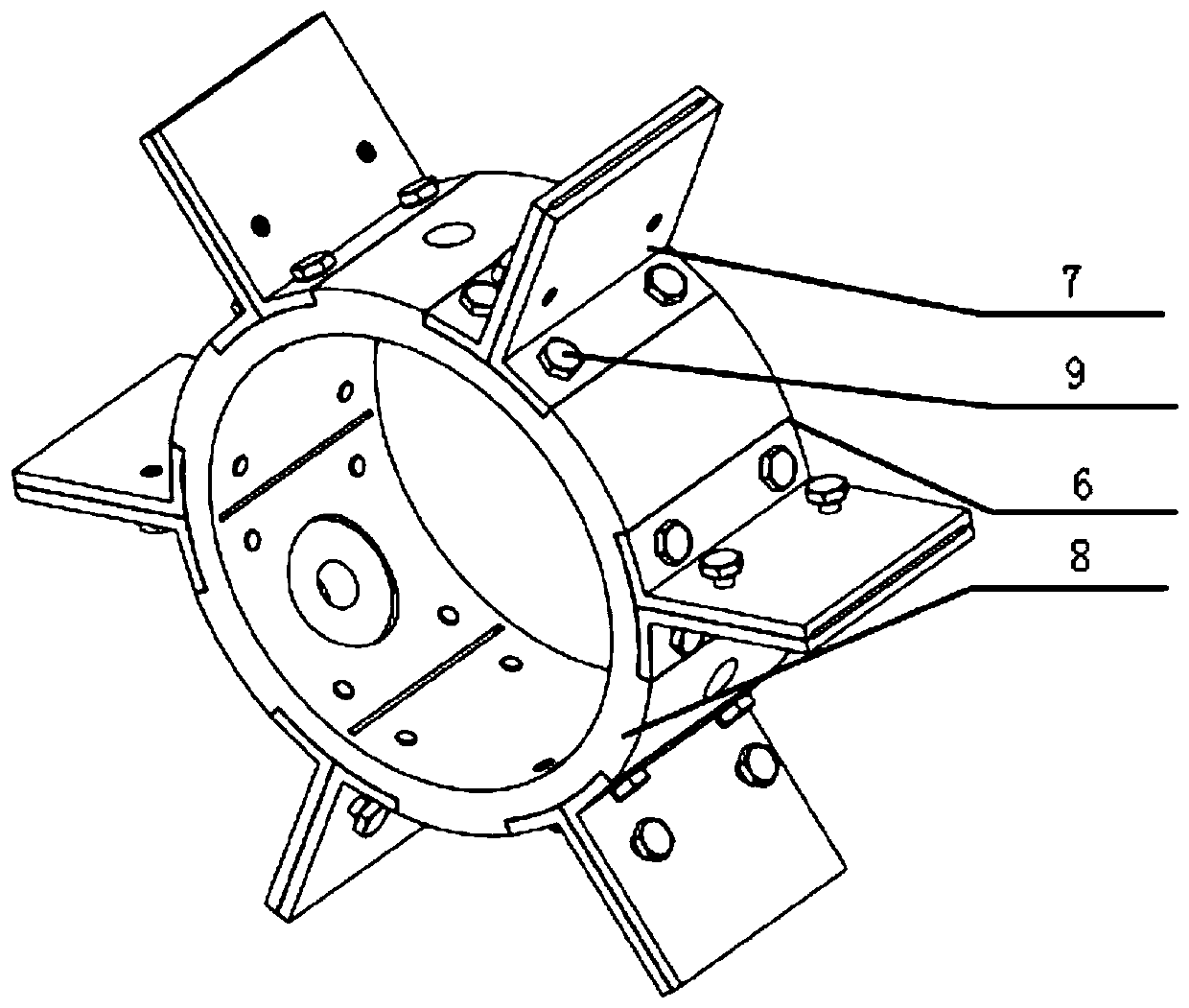

Modular directional flow pipeline type piezoelectric energy harvester arranged in a circumferential array

ActiveCN110380645AReduce distractionsReduces interference while reducing overall structural massPiezoelectric/electrostriction/magnetostriction machinesCurrent limitingPiezoelectric actuators

The invention relates to a modular directional flow pipeline type piezoelectric energy harvester arranged in a circumferential array, which belongs to the technical field of water flow and air flow induced vibration energy harvesting and solves the problems that energy harvesters in the existing flow-induced energy harvesting are mostly fixed, the mutual coupling relation is difficult to adjust and that the application limitation is large. The piezoelectric energy harvester comprises a flow-gathering and speed-accelerating coil and at least one piezoelectric module, the piezoelectric modules are connected in series when there are two or more piezoelectric modules, each piezoelectric module includes a plurality of piezoelectric vibrators, a central support, a current-limiting outer ring andconnecting screws; the central support and the current-limiting outer ring are coaxially arranged inside and outside and are connected through a plurality of connecting screws, and the plurality of piezoelectric vibrators are arranged in a circumferential array between the central support and the current-limiting outer ring; the flow-gathering and speed-accelerating ring is coaxially arranged onthe outer end face of the current-limiting outer ring on the incoming side; and a plurality of long holes are formed in the central support along the circumferential direction of the central support.The piezoelectric energy harvester can be widely applied to energy collection in the fields of stream pipelines, distillation pipelines, tap water pipelines, exhaust pipelines and the like.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com