T-shaped connection structure of composite material laminboard

A composite material and connection structure technology, applied in the direction of thin plate connection, connection components, mechanical equipment, etc., can solve problems such as loss, delamination, and insufficient load-bearing capacity, and achieve enhanced load-bearing capacity, clear load-carrying path, and improved structural efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

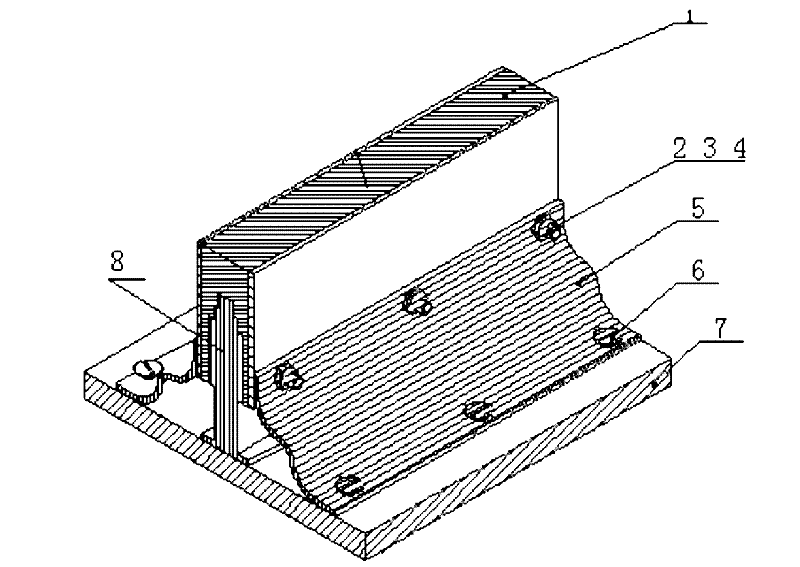

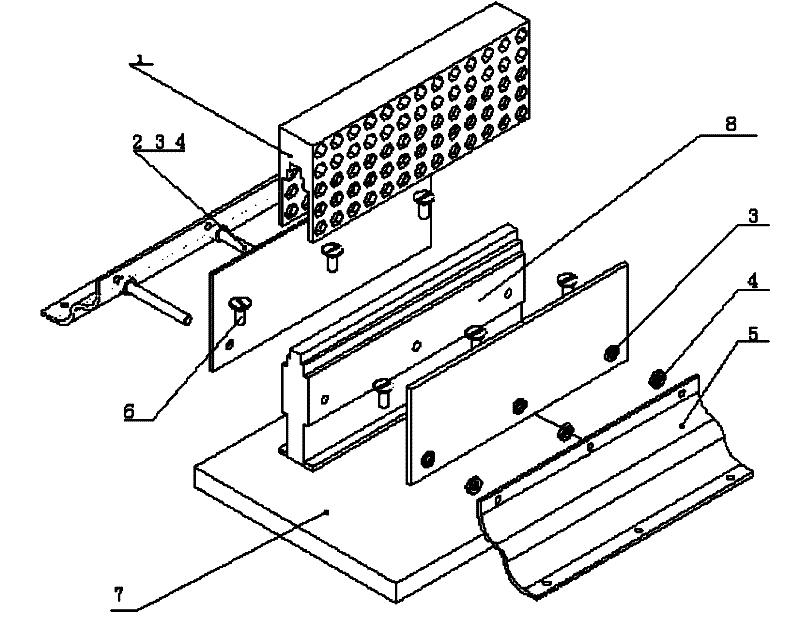

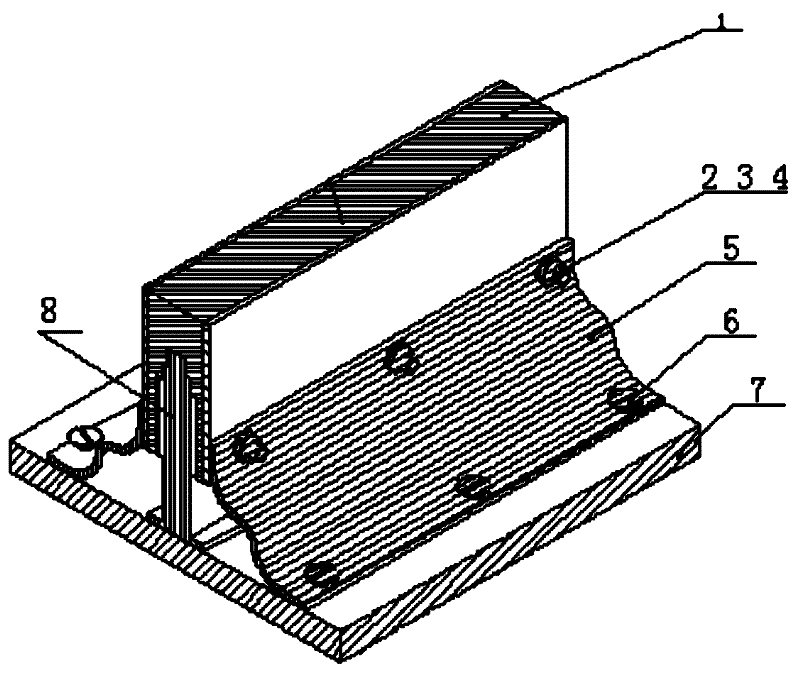

[0017] combine figure 1 and 2 , the present invention mainly includes connecting bottom plate 7, honeycomb sandwich panel 1 and T-shaped reinforcing block 8, the honeycomb sandwich panel has a groove with the same shape as the top of the web of the T-shaped reinforcing block, and the top of the web of the T-shaped reinforcing block Inserted in the groove, the wing rafters of the T-shaped reinforcing block are glued to the connecting bottom plate, and also include two wave-shaped connectors 5, which are located on both sides of the honeycomb sandwich panel. The wave-shaped connectors, T-shaped The reinforcement block and the honeycomb sandwich panel are tightly connected by a bolt connection structure composed of bolts, washers and nuts 2, 3, 4, and the wave connector and the connecting bottom plate are connected by glue and screws 6. The upper end of the web of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com